Page 1

INSTRUCTION MANUAL

COMPUTERIZED TONOMETER

CT

-

80

Page 2

INTRODUCTION

Thank you for purchasing the TOPCON Computerized Tonometer CT-80.

(To get the best use from the instrument, please carefully

read these instructions and keep this Instruction Manual in a

convenient location for future reference.)

This instrument features the following:

• An exact, non-contact intraocular pressure measurement that

can be done by air ejection.

• An alignment bar that enables easy operation.

This text outlines the Computerized Tonometer CT-80 and describes basic operations, troubleshooting, checking, maintenance

and cleaning.

To encourage the safe, efficient use of this instrument and prevent

danger to the operator and others, we suggest you carefully read

the “Displays for Safe Use” and the “Safety Cautions”.

Again, please keep this Instruction Manual in a convenient location

for future reference.

Precautions

•

This machine is a precision instrument; install it in a place set to the following conditions: temperature (10∼60°C), humidity (30∼85%) and atmospheric pressure (70∼106KPa). Avoid direct exposure to sunlight.

To ensure smooth operation, install the instrument on a level place free of

•

vibrations. Also, do not place any objects on the instrument.

Before using the instrument, connect all cables correctly.

•

Use the specified source voltage.

•

When not in use, turn the power off and put the measuring window cap and

•

dust cover on.

To ensure a correct reading, do not soil the measuring window with finger

•

prints, dust, etc. Also, do not touch the measuring nozzle except when

cleaning.

1

Page 3

DISPLAY FOR SAFE USE

In order to encourage the safe use of the product and prevent any danger to the operator and

others or damage to properties, important warnings are placed on the product and inserted in the

instruction manual.

We suggest that everyone understand the meaning of the following displays and icons before

reading the “Safety Cautions” and text.

DISPLAY

WARNING

CAUTION

• Injury refers to cuts, bruises, sprains, fractures, burn, electric shock, etc.

• Physical damage refers to extensive damage to buildings or equipment and furniture.

Ignoring or disregarding this display may lead to

death or serious injury.

Ignoring or disregarding this display may lead to

personal injury or physical damage.

MEANING

ICONS MEANING

This icon indicates Hazard Alerting (Warning).

Prohibition.

Specific content is expressed with words or an icon either inserted in the icon itself or located next to the icon.

2

This indicates Prohibition.

Specific content is expressed with words or an icon either inserted in the icon itself or located next to the icon.

This indicates Mandatory Action.

Specific content is expressed with words or an icon either inserted in the icon itself or located next to the icon.

Page 4

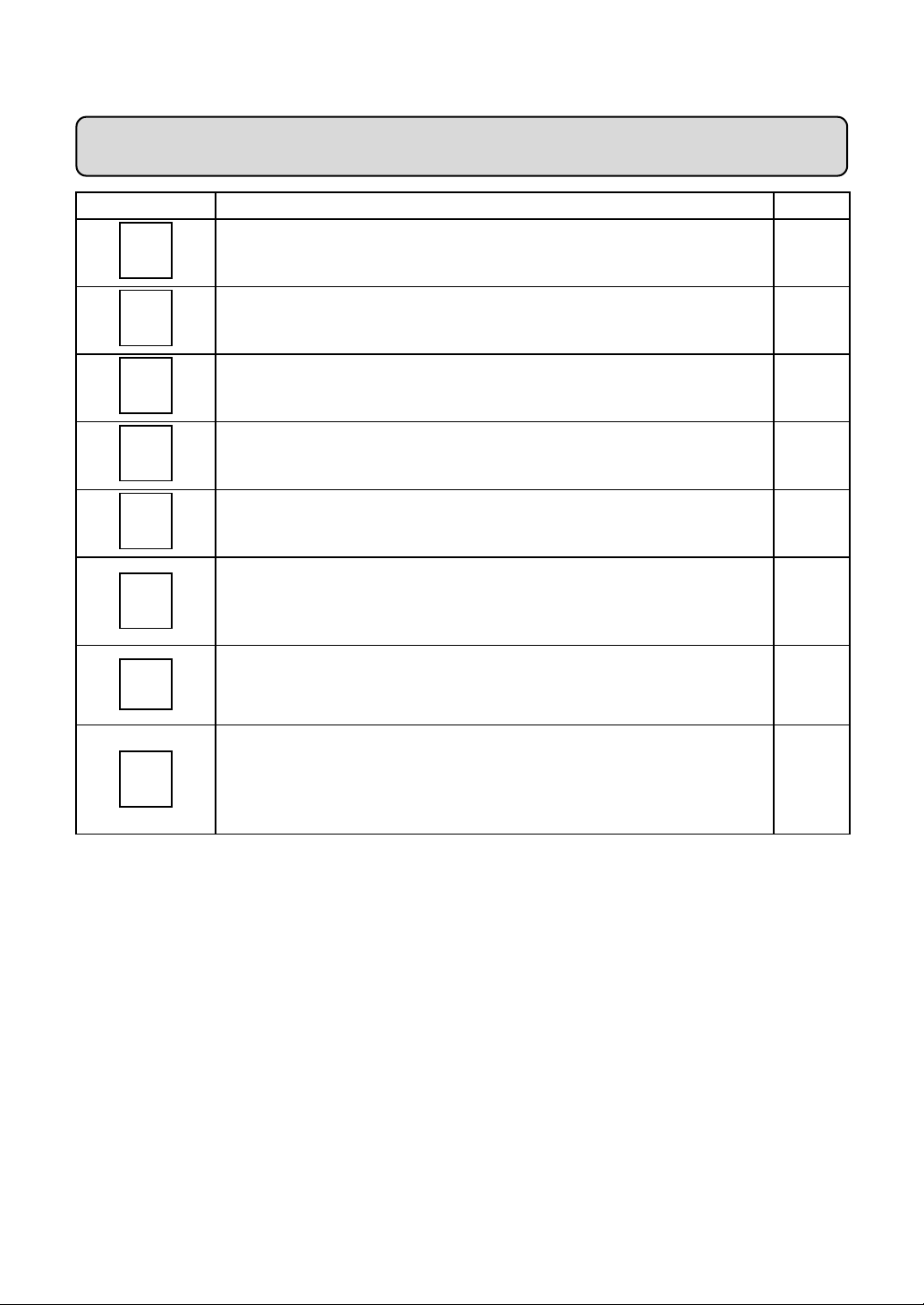

SAFETY CAUTIONS

WARNING

Icons Prevention item Page

To avoid electrical shock, do not open the instrument.

Refer all servicing to qualified personnel.

To avoid electric shocks, do not remove the covers from the bottom

and top surfaces, TV monitor, measuring unit, etc.

To prevent shock hazard, do not allow water or other foreign matter

to enter into the instrument.

To avoid fire and electric shocks in case of tumbling, do not place a

cup or vessel containing water/fluid on the instrument.

To avoid electric shocks, do not insert objects or metals through the

vent holes or gaps or contain them inside the machine body.

To avoid electrical shock and fire, unplug the power cable before

removing the fuse cover. Additionally, be sure to replace the fuse

cover before plugging in the power cable.

Use only the attached fuses. Using other fuses may cause a fire.

Should any anomaly, such as smoke, occur, immediately switch

OFF the power source and unplug the power cable.

Continued use ignoring the condition may cause fire. Contact your

dealer for repair.

45

45

—

—

—

55

55

—

3

Page 5

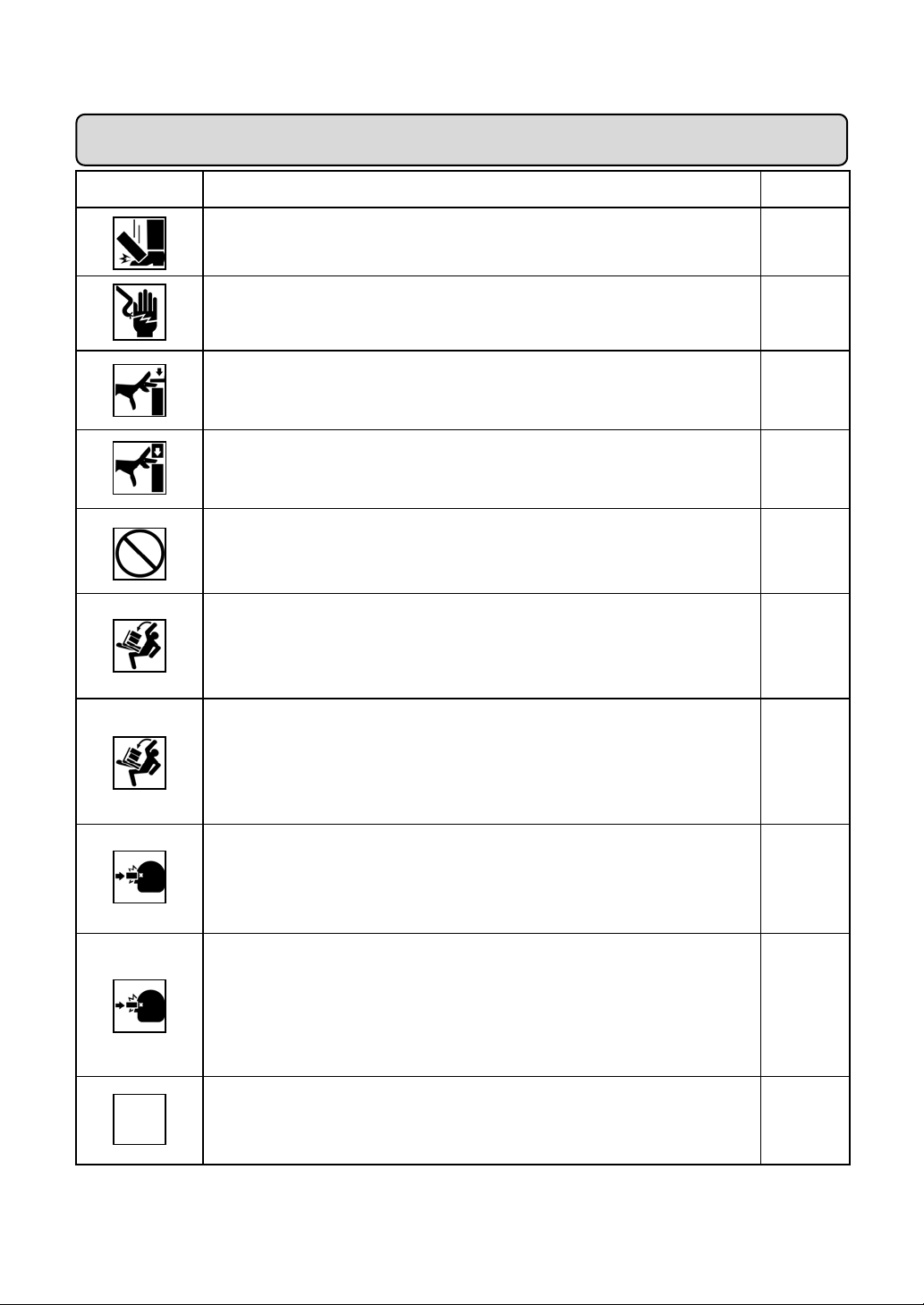

SAFETY CAUTIONS

CAUTION

Icon Prevention item Page

To avoid potential injury, hold the instrument in the proper position.

To avoid electrical shock, do not handle the power plug with wet

fingers.

Never insert your fingers under the measuring head.

∗ Inform the patient of this, too.

Careless insertion of fingers may cause injury by pinching.

Never insert your fingers under the measuring head.

∗ Inform the patient of this, too.

Careless insertion of fingers may cause injury by pinching.

Do not use or apply any spray-typed cleaner near the instrument.

If a drop of cleaner remains inside the measuring nozzle, the patient’s eye may be injured during measurement.

Before carrying the instrument, be sure to affix it firmly by turning

the fixing screw at the base.

If the instrument is moved with the screw loosened, it may result in

damage to the instrument.

When moving the instrument, be sure to hold it at the bottom surface with two people. Carrying by one person may cause back injury or injury by falling parts. Also, holding areas other than the bottom surface may cause pinching fingers between parts and injury

by falling parts as well as damage to the instrument.

13

14

30

34

56

13

13

4

Before measuring, set the safety stopper. If the safety stopper is

not set, it may cause injury to the eye that comes in contact with the

measuring window glass. Set the safety stopper separately for the

right and left eyes.

When setting the safety stopper, do it from the instrument side

(safety stopper knob side).

Setting from another position does not easily allow you to check the

positions of the measuring window glass and the patient’s eye and

may cause injury to the eye that comes in contact with the measuring window glass.

To clean the measuring window glass and the window glass inside

the measuring nozzle, use ethanol. Using other chemicals may

cause damage to the patient's eye during measurement.

31

31

52

53

Page 6

USAGE AND MAINTENANCE

PURPOSE

This tonometer “CT-80” is a precision electrical device for medical use that must be

used under the instruction of a doctor.

USER MAINTENANCE

To maintain the safety and performance of the equipment, never attempt to do maintenance on your own. Ask our serviceman for repair except for the items specified here

which can be maintained by the user. For details, follow the instructions.

Fuse replacement

The primary fuses for the main body may be replaced by a non-trained service technician. For details, refer to “Replacing the Fuse” on page 55.

Cleaning of measuring window

Cleaning of the measuring window glass is possible. For details, refer to the instructions in “Cleaning the Measuring Window Glass” on page 52.

Cleaning of window inside the nozzle

Cleaning of the window inside the nozzle is possible by following the instruction in

“Cleaning the Window Glass inside the Nozzle” on page 53.

ESCAPE CLAUSE

• TOPCON shall not take any responsibility for damage due to fire, earthquakes, actions

by a third party or other accidents, or the negligence and misuse of the user and use under unusual conditions.

• TOPCON shall not take any responsibility for damage derived from the inability to use

this equipment, such as a loss of business profit and suspension of business.

• TOPCON shall not take any responsibility for damage caused by operations other than

those described in this Instruction Manual.

• Diagnoses shall be made on the responsibility of pertaining doctors and TOPCON shall

not take any responsibility for the results of such diagnoses.

5

Page 7

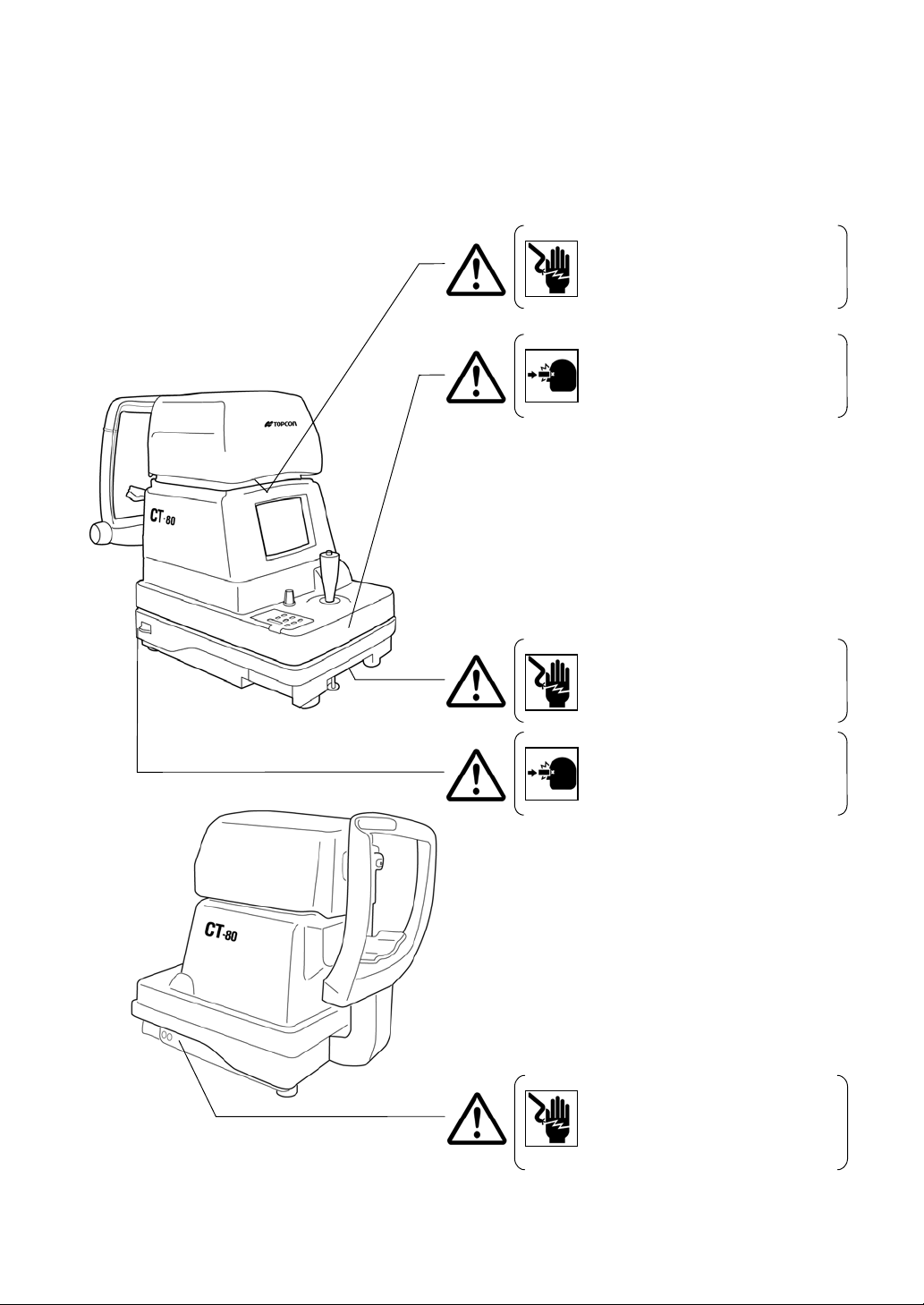

WARNING INDICATIONS AND POSITIONS

To ensure the safe usage of this equipment, precaution indications are provided.

Abide by the following warning instructions. If any of the following labels are missing,

please contact us at the address printed on the back cover of this manual.

• To avoid electrical shock, do not open

the instrument. Refer all servicing to

qualified personnel.

CAUTION

WARNING

• To avoid potential injury during operation, do not touch the patient’s

eyes or nose with the instrument.

WARNING

• To avoid electrical shock, do not open

the instrument. Refer all servicing to

qualified personnel.

CAUTION

• To avoid potential injury, insure that

the safety stopper knob is engaged

prior to use.

6

• Electrical shock may cause burns or

WARNING

possible fire. Turn the main power

OFF and UNPLUG the power cord

before replacing the fuses. Replace

only with fuses of the correct rating.

Page 8

CONTENT

Introduction

Display for Safe Use

Safety Cautions

Usage and Maintenance

Escape Clause

Warning Indications and Positions

NAMES OF COMPONENTS

Main Body Components

Control Panel Components

Monitor Screen Components

Contents of Printer Output

Standard Accessories

PREPARATIONS

How to Install the Instrument

10

11

12

13

1

2

3

5

5

6

INDIVIDUAL OPERATIONS

How to Print Out Measurement Values

How to Correct Measurement Values

Input/Output via RS-232C

BEFORE REQUESTING SERV-

ICE

Checking Operations

42

43

44

45

REFERENCE

8

Optional Accessories

46

9

Specifications & Performance

RS-232C Communication Specifications

MAINTENANCE AND CHECKING

Accuracy Maintenance

Special Notes on Cleaning

46

47

52

56

How to Connect the Power Cable

How to Connect External I/O Terminals

Initial Settings

How to Set Printer Paper

How to Reset from Power Save Status

BASIC OPERATIONS

Preparations Before Measurement

Measurement Under Auto Mode

Measurement Under Manual Mode

How to Delete Measurement Values

14

14

15

23

28

29

33

38

41

7

Page 9

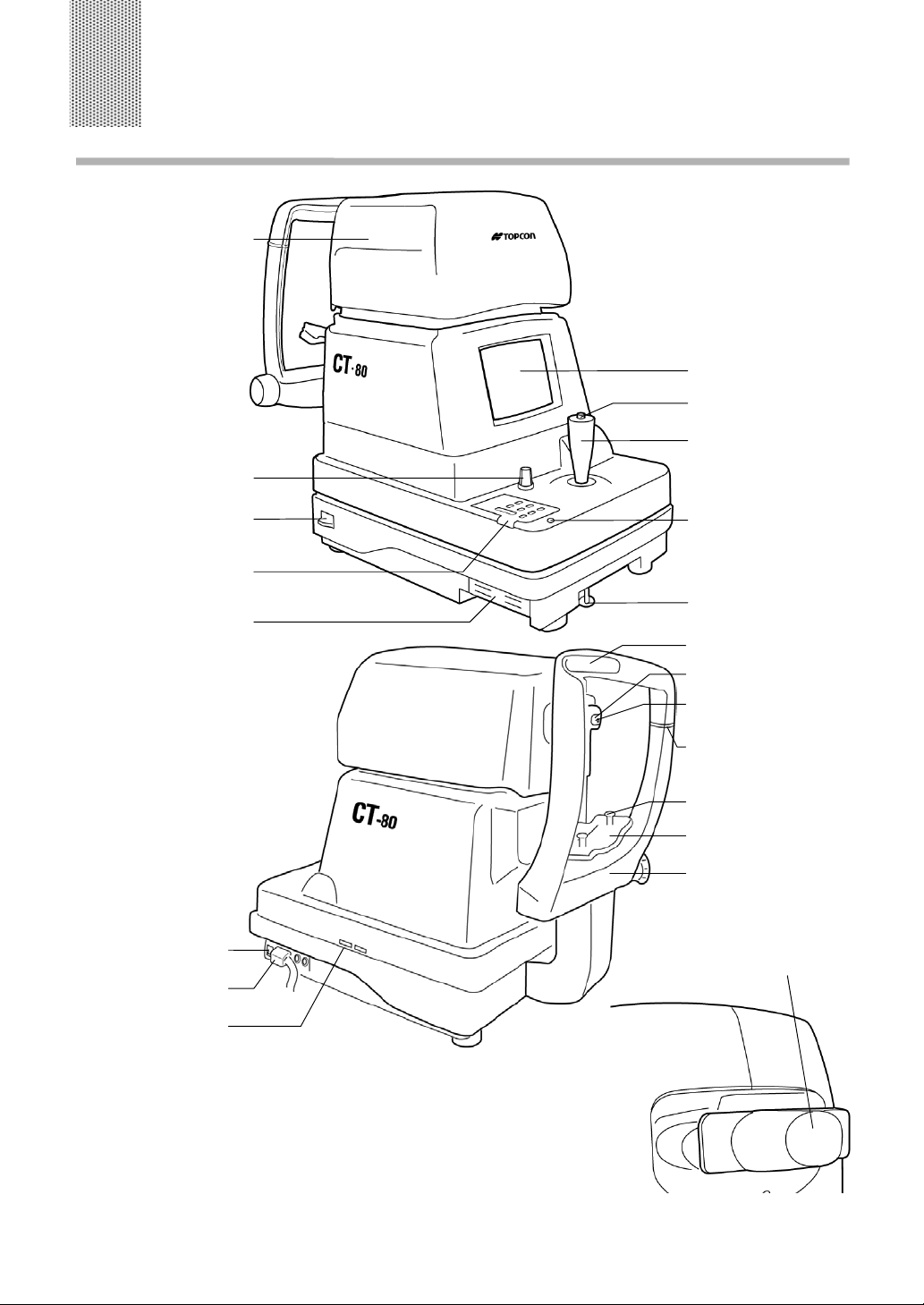

COMPONENTS

MAIN BODY COMPONENTS

Measuring head

Clamping knob

TV Monitor

Measuring switch

Control lever

Safety stopper knob

Control panel

External I/O terminal

Power switch

Power cable

Adjusting knob

Power lamp

Fixing knob (used to

stop movements

during removal)

Forehead rest

Measuring window

Measuring nozzle

Height mark

Chinrest pad pin

Chinrest

Chinrest handle

Measuring window cap

8

COMPONENTS

Page 10

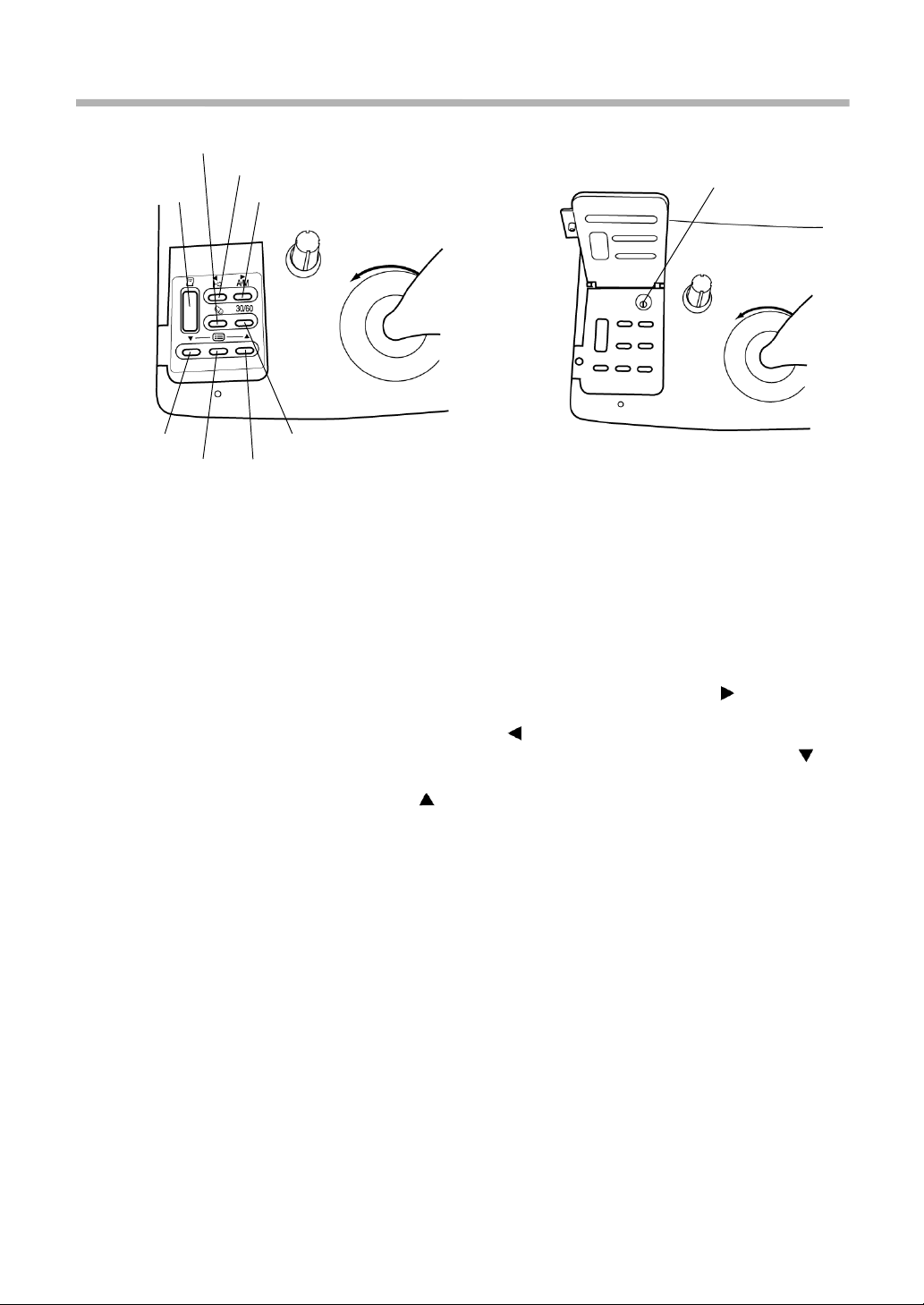

CONTROL PANEL COMPONENTS

Clear switch

Air check switch

Print switch Auto/Manual switch

Down switch Range switch

Menu switch

Print switch ................... Prints out the screen readings. When there is no reading, holding

Range switch ................ Switches the range between 0-30 and 0-60.

Clear switch .................. Deletes all the measurement values from the screen.

Menu switch .................. Displays the Menu screen.

Auto/Manual switch...... Switches the mode between auto and manual. Also, when se-

Air check switch ........... Performs an air check. Also, when selecting menu software, it

Down switch ................. When selecting menu software, it moves the cursor down (

Up switch....................... Range switch. When selecting menu software, it moves the

Up switch

the switch down feeds the paper.

lecting menu software, it moves the cursor right (

moves the cursor left (

cursor up (

).

).

Select switch

).

).

9

COMPONENTS

Page 11

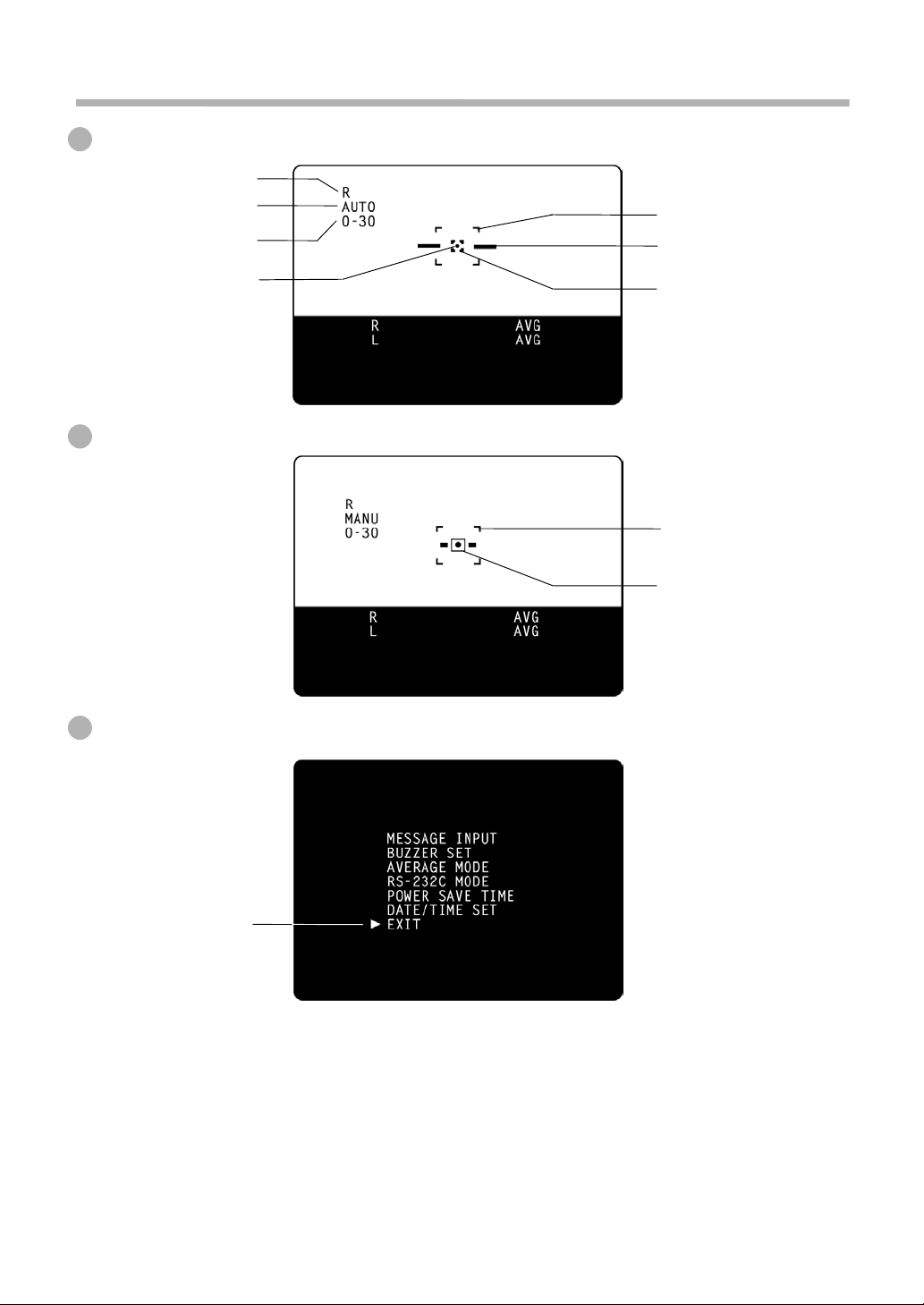

MONITOR SCREEN COMPONENTS

Measurement Screen (Auto mode, alignment)

Target eye

Measurement mode

Measuring range

Outer alignment mark

Alignment bar

Alignment dot

Measurement Screen (Manual mode, alignment OK)

Menu Screen

Inner alignment mark

Outer alignment mark

Inner alignment mark

(alignment OK)

10

COMPONENTS

Cursor

Page 12

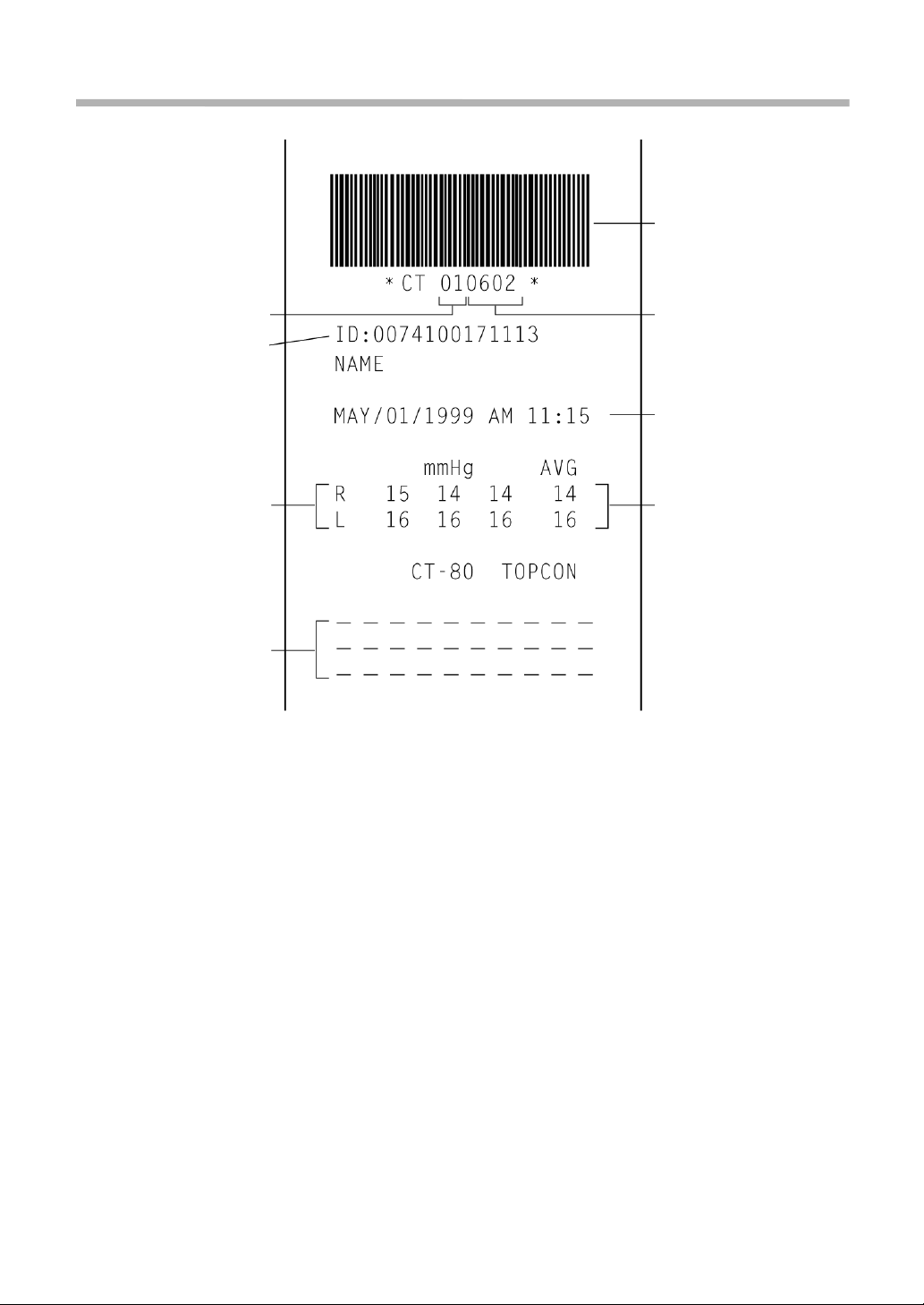

CONTENTS OF PRINTER OUTPUT

Bar code

Equipment No.

ID No.

Measured eye pressure

values

Message column

Work ID No.

Time/Date display

Average eye pressure

values

11

COMPONENTS

Page 13

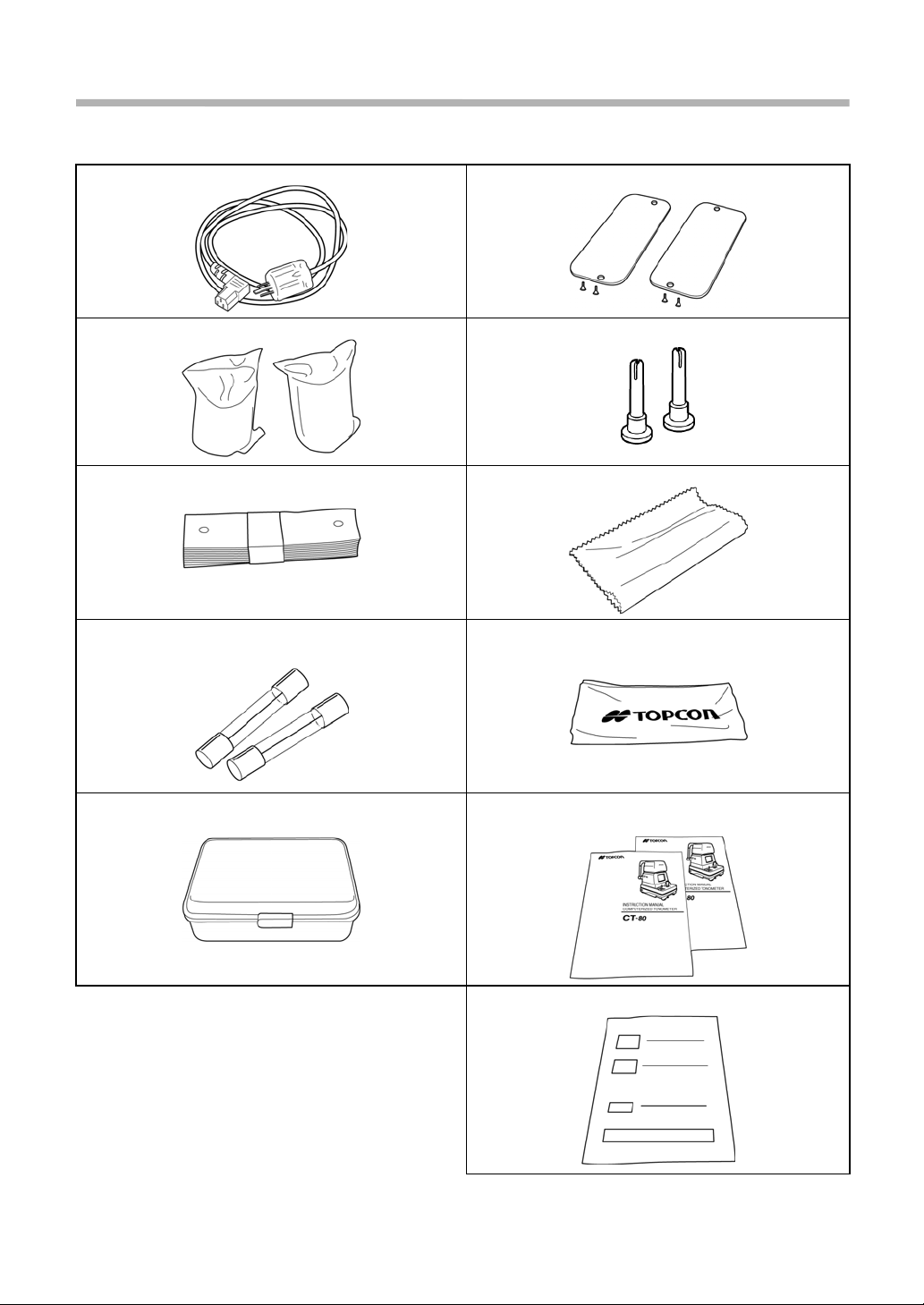

STANDARD ACCESSORIES

The following are the standard accessories. The figures in parentheses are the

quantities. Please check to see that all accessories are contained.

Power cable (1)

Printing paper (2) Chinrest pin (2)

Chinrest pad (1) Silicone cloth (1)

Rail cover (2)

Fuse (2)

* Different by destinations

Cleaning kit (1) Instruction Manual, Unpacking and Assembly

Dust cover (1)

(1 each)

Window glass cleaning procedure (1)

12

COMPONENTS

Page 14

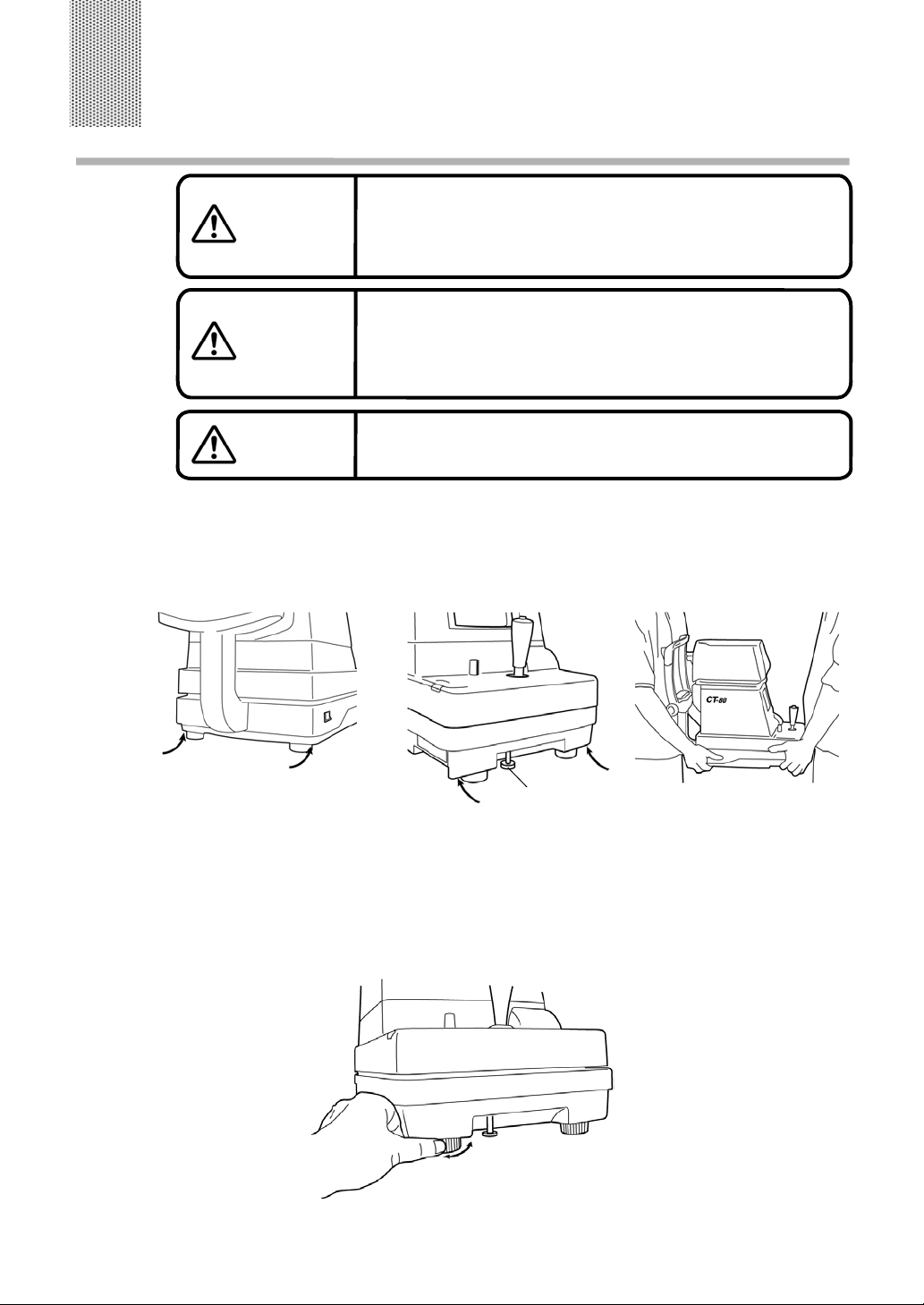

PREPARATIONS

HOW TO INSTALL THE INSTRUMENT

Before carrying the instrument, be sure to affix it firmly by

CAUTION

CAUTION

turning the fixing screw at the base.

If the instrument is moved with the screw loosened, it may

result in damage to the instrument.

When moving the instrument, be sure to hold it at the bottom surface

with two people. Carrying by one person may cause back injury or

injury by falling parts. Also, holding areas other than the bottom surface may cause pinching fingers between parts and injury by falling

parts as well as damage to the instrument.

CAUTION

Fasten the clamping knob.

1

Hold the instrument body firmly at the specified positions and place it on the auto-

2

matic instrument table.

For the automatic instrument table, see “OPTIONAL ACCESSORIES” on page 46.

After installing the instrument, loosen the fixing knob.

3

Now the body components can be moved.

If the machine body is slightly off level, properly turn the adjusters at the four corners

4

for fine adjustment.

Do not unscrew the adjusters more than 1cm.

To avoid potential injury, hold the instrument in the proper

position.

Fixing knob

Holding the instrumentSpecified holding positions

13

PREPARATIONS

Page 15

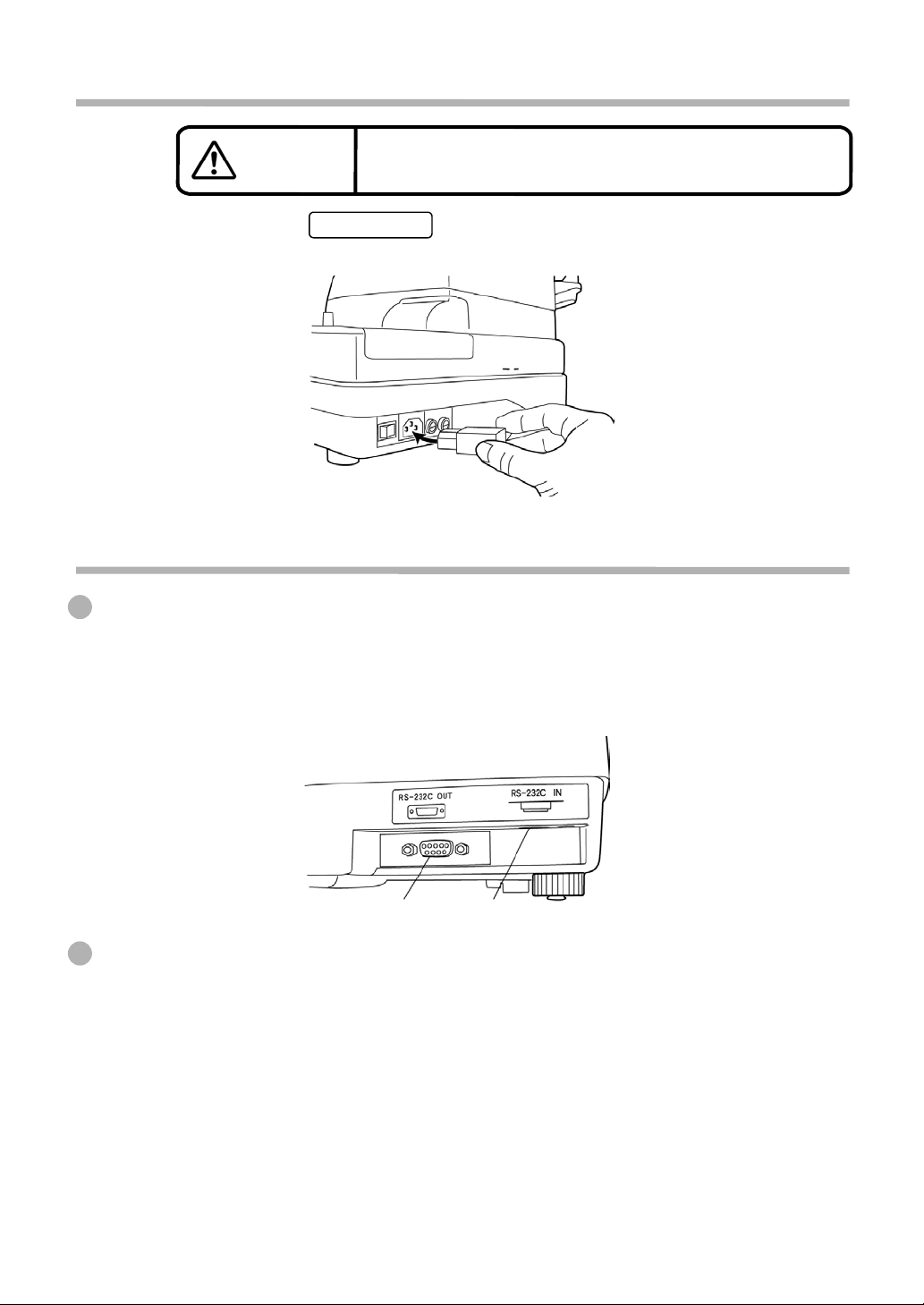

HOW TO CONNECT THE POWER CABLE

CAUTION

Make sure the

1

Attach the power cable to the machine body.

2

Plug the power cable into the 3-pin AC receptacle with grounding.

3

To avoid electrical shock, do not handle the power plug

with wet fingers.

POWER SWITCH

is OFF.

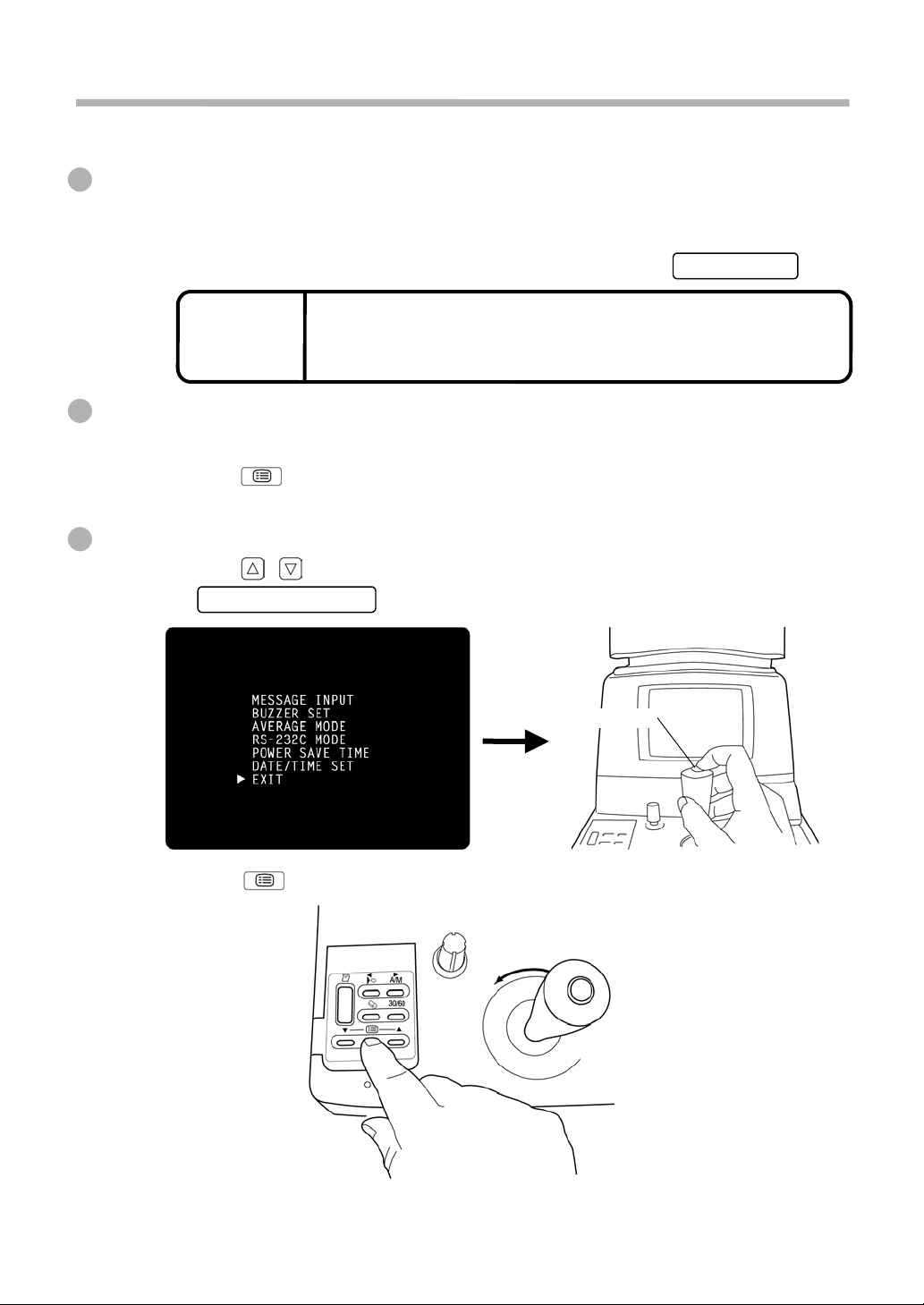

HOW TO CONNECT EXTERNAL I/O TERMINALS

RS-232C OUT

This machine can be connected to another device, including a personal computer via

the RS-232C OUT terminal.

RS-232C IN

Connect the cable to the RS-232C OUT terminal of this machine.

1

Connect the other cable end to another device.

2

This machine can be connected to another device, including a bar code reader via the

RS-232C IN terminal.

Connect the cable to the RS-232C IN terminal of this machine.

1

Connect the other cable end to the external device.

2

Input terminalOutput terminal

14

PREPARATIONS

Page 16

INITIAL SETTINGS

During the initial setting, date, time, operating time of the power save function, RS232C, mode of average value, buzzer and message can be set.

Preparations

Make sure the power cable is connected.

1

For connection, see “HOW TO CONNECT THE POWER CABLE” on page 14.

Check the no-patient condition of the instrument and turn the

2

When the machine is moved from a cold room to a warm room or

•

MEMO

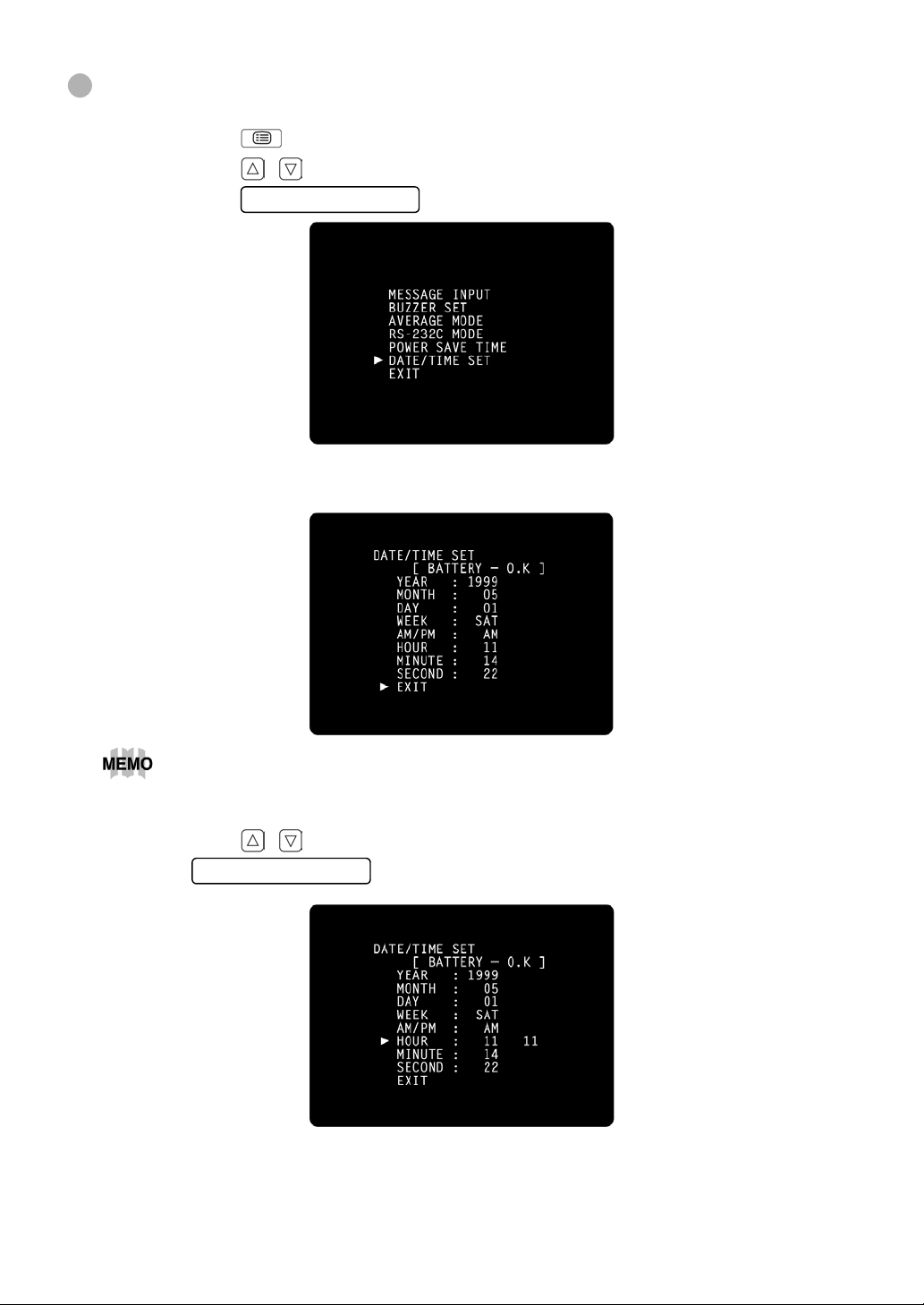

Displaying The Menu Screen

Make sure that the Measurement screen is displayed.

1

Press on the control panel.

2

The Menu screen is displayed.

Returning To The Measurement Screen

Press , on the control panel, move the cursor to “EXIT” and press

1

MEASUREMENT SWITCH

when the room temperature suddenly rises, it may cause dewing inside the machine and disable measurement. In this case, leave the

machine alone for about 30min until it reaches room temperature.

.

POWER SWITCH

ON.

Or, press

Measurement switch

on the control panel. The Measurement screen returns.

15

PREPARATIONS

Page 17

Time/Date Setting

Example of operation: Illustrations show time setting.

Press on the control panel to get the Menu screen.

1

Press , on the control panel, move the cursor to “DATE/TIME SET” and

2

press

The Date/Time setting screen is displayed.

Make sure that the display “BATTERY → O.K.” appears.

3

MEASUREMENT SWITCH

.

If the display is “BATTERY → N.G.”, the built-in clock battery is used up. Contact your

dealer. Additionally, when the battery becomes exhausted, time and date items are

not printed and “DATE” is displayed instead.

Press

4

MEASUREMENT SWITCH

16

PREPARATIONS

on the control panel, move the cursor to “HOUR” and press

,

.

Page 18

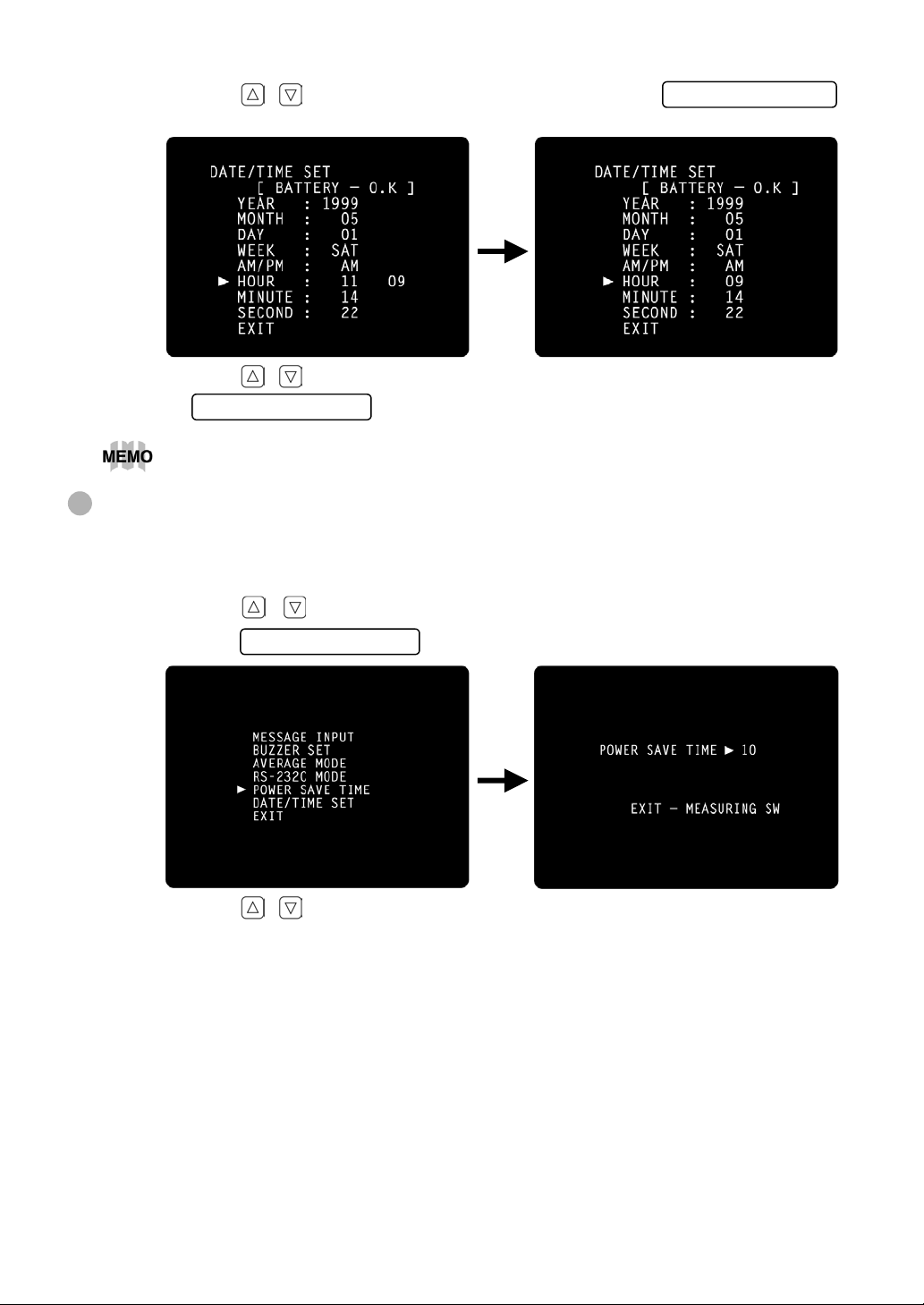

Press

5

The renewed figures are inputted.

of the control panel, renew figures and press

,

MEASUREMENT SWITCH

.

Press

6

MEASUREMENT SWITCH

Date and other items can also be renewed at the same time.

Setting The Power Save Time

A time for the power save function to achvale can be selected from 10, 20, 30 or 60min.

For shipment, 10min. is set.

Return to the Menu screen.

1

Press

2

press

MEASUREMENT SWITCH

of the control panel, move the cursor to “EXIT” and press

,

on the control panel, move the cursor to “POWER SAVE TIME” and

,

.

. The Power Save Time Setting screen is displayed.

3

Press

on the control panel and change the power save time.

,

17

PREPARATIONS

Page 19

5 ↔ 10 ↔ 20 ↔ 30 ↔ 60

Press

4

RS-232C INPUT/OUTPUT Settings

For shipment, settings are EQUIPMENT (Equipment No.) No.1, FORMAT (communi-

Each time

cation mode) OFF, and SPEED (communication speed) 2400

,

Example: Setting the equipment No.

Return to the Menu screen.

1

Press

2

The RS-232C Mode is displayed.

MEASUREMENT SWITCH

is pressed, the display changes as follows:

of the control panel, move the cursor to “RS-232C MODE” and press

,

MEASUREMENT SWITCH

. The Menu screen is displayed.

.

18

PREPARATIONS

Page 20

Press

3

MEASUREMENT SWITCH

,

on the control panel, move the cursor to “EQUIPMENT” and press

.

Press

4

MEASUREMENT SWITCH

,

on the control panel, change the equipment No. and press

.

The equipment No.(EQUIPMENT) can be selected from 0000 to 0099. Each time

is pressed, the display changes as follows:

OFF ↔ MODE1 ↔ MODE2 ↔ MODE3 ↔ MODE4 ↔

When setting the speed, the display changes from 2400-9600 each time

pressed.

2400 ↔ 9600

“EQUIPMENT” and “WORK ID NO.” can be reset by pressing .

Press

5

MEASUREMENT SWITCH

on the control panel, move the cursor to “EXIT” and press

,

. The Menu screen returns.

PREPARATIONS

,

19

is

,

Page 21

Setting The Average Value Mode

The average value display of the measurement values can be selected from integer and

decimal displays. For shipment, the integer display is set.

Return to the Menu screen.

1

Press

2

press

The Average Value Mode screen is displayed.

MEASUREMENT SWITCH

on the control panel, move the cursor to “AVERAGE MODE” and

,

.

Press

3

20

PREPARATIONS

on the control panel to change the mode.

,

Page 22

15 : The average value is displayed as an integer (by rounding fractions to the

nearest whole number).

15.0 : The average value is displayed up to one decimal (by rounding fractions to the

nearest tenth).

Press

4

Setting The Buzzer

The buzzer can be turned ON/OFF by pressing the switches on the control panel.

Return to the Menu screen.

1

Press

2

MEASUREMENT SWITCH

The Buzzer Setting screen is displayed.

MEASUREMENT SWITCH

on the control panel, move the cursor to “BUZZER SET” and press

,

.

. The Menu screen returns.

3

Press

on the control panel to select ON/OFF.

,

21

PREPARATIONS

Page 23

4

Message Input

You can add a brief message to the printout.

1

Press

The Menu screen returns.

Return to the Menu screen.

MEASUREMENT SWITCH

.

Press

2

press

The Message Input screen is displayed.

MEASUREMENT SWITCH

on the control panel, move the cursor to “MESSAGE INPUT” and

,

.

Input column

Selection column

Press

3

in the selection column for input.

22

PREPARATIONS

, , ,

on the control panel to move the blinking icon to a character

Page 24

■ : A space for 1 character (Use this to delete a character, too.)

STEP : The blinking icon of the input column moves right.

BACK : The blinking icon of the input column moves left.

Press

4

The character selected by the blinking icon is inputted.

Press

5

column to “EXIT” and press

The Menu screen is displayed.

MEASUREMENT SWITCH

, ,

,

HOW TO SET PRINTER PAPER

Auto Setting

.

on the control panel, move the blinking icon in the selection

MEASUREMENT SWITCH

.

Press the printer cover with your thumb, slide it aside and remove.

1

When the right/left end is reached, the blinking icon goes down to the next line.

A message can contain up to 3 lines, 20 characters per line.

Printer cover

PREPARATIONS

23

Page 25

Slide the paper roll onto the paper shaft, paying attention to the direction of unwind-

2

ing, and pull out the top of the paper 7-8cm.

Unwinding direction

Insert the paper straight into the printer

3

along the paper guide.

When the top of the paper stops inside the printer, press to further insert the

4

paper into the printer.

Paper feeding starts when the top of the paper reaches a certain depth inside the

printer.

When the top of the paper comes out 1cm or so from the outlet, release .

5

At this moment, hold the top of the paper firmly so that it is not rolled back.

Turn the paper retainer lever to the illustrated position, and pull out the paper 2-3cm

6

so that it comes out straight from the outlet.

24

PREPARATIONS

Paper retainer lever

Page 26

Return the paper retainer lever back to its original position.

7

Reset the printer cover, holding the top of the paper outside.

8

The paper is not fed unless the paper retainer lever is lowered.

Use the following 58mm wide printer paper:

TF50KS-E2C

Using another paper may cause a printing noise or thin prints.

25

PREPARATIONS

Page 27

Manual Setting

1

2

3

4

Press the printer cover with your thumb, slide it aside and remove.

Slide the paper roll onto the paper shaft, paying attention to the direction of unwinding, and pull out the top of the paper 7∼8cm.

Turn the paper retainer lever in the arrow direction.

Cut the paper on the control lever side at about 2cm.

Paper retainer lever

Control lever

Cut here

26

PREPARATIONS

Page 28

Insert the paper straight into the printer along the paper guide.

5

Further insert the paper and draw out the top of the paper from the outlet.

6

Adjust the paper so that it comes out straight from the outlet, and then lower the pa-

7

per retainer lever.

The paper does not easily pass through the printer unless it is cut on the control lever

side.

27

PREPARATIONS

Page 29

Set the printer cover, holding the top of the paper outside.

8

If the paper is jammed, turn the paper retainer lever to the illustrated position, and

take out the jammed paper from the printer.

HOW TO RESET FROM POWER SAVE STATUS

This machine employs a power save function. If the machine is not used during a set

time, the power save function stops supplying power to the monitor and CCD camera.

Under the power save status, the POWER lamp of the control panel flashes.

Press

1

The Monitor screen is displayed in a few seconds, when the measurements become

available.

After resetting, the measurement mode is AUTO and the measuring range is 0-30.

Also, values measured before power saving are deleted.

MEASUREMENT SWITCH

.

28

PREPARATIONS

Page 30

BASIC OPERATIONS

PREPARATIONS BEFORE MEASUREMENT

Turn ON the Power

Make sure the power cable is connected.

1

For connection, see “HOW TO CONNECT THE POWER CABLE” on page 14.

Make sure the instrument is in the no-patient condition and turn ON the

2

Air Check

POWER SWITCH

The Title screen is displayed, and then the Measurement screen is displayed.

3

This machine is equipped with a function for checking the correct operations measurement system inside the instrument.

Remove the measuring window cap.

1

Press on the control panel.

2

Air is ejected from the measuring nozzle and checking is done automatically.

Make sure “OK” is displayed on the monitor screen. The Menu screen should be

3

displayed a few seconds afterwards.

.

Normal operation screen

29

BASIC OPERATIONS

Page 31

If “NG (+)” or “NG (-)” is displayed, an anomaly has occurred. Turn OFF the

POWER SWITCH

uring nozzle. If there is an object, remove it, and then press the

Press

If no object is there, a problem has occurred. Turn OFF the

the power cable, and call your dealer.

Setting the Patient

, and check whether or not there is any obstacle in front of the meas-

and perform the checking procedure again.

Never insert your fingers under the measuring head.

CAUTION

∗ Inform the patient of this, too.

Careless insertion of fingers may cause injury by pinching.

POWER SWITCH

POWER SWITCH

.

, unplug

Return to the Measurement screen.

1

Ask the patient to sit in front of the instrument.

2

Adjust the automatic instrument table or the chair for height so that the patient can

3

put his or her chin on the chinrest in a comfortable position.

The patient places his or her chin on the chinrest and stops his or her forehead at

4

the forehead rest.

Abnormal operation screen

30

BASIC OPERATIONS

Page 32

Adjust the height of the chinrest, by operating the chinrest handle, so that the tail of

5

the patient's eye becomes level with the height mark of the chinrest post.

Chinrest handle

Setting the Safety Stopper

CAUTION

CAUTION

Height mark

Before measuring, set the safety stopper. If the safety

stopper is not set, it may cause injury to the eye that comes in contact with the measuring window glass. Set the

safety stopper separately for the right and left eyes.

When setting the safety stopper, do it from the instrument

side (safety stopper knob side).

Setting from another position does not easily allow you to

check the positions of the measuring window glass and the

patient's eye and may cause injury to the eye that comes

in contact with the measuring window glass.

Hold the control lever and pull the machine body towards the operator.

1

Turn the control lever and adjust the height of the measuring nozzle to the center of

2

the patient's cornea.

While holding the safety stopper knob in a pressed position, hold the control lever

3

and slowly push out the machine body.

BASIC OPERATIONS

31

Page 33

When the measuring nozzle reaches a position 8∼10mm from the cornea, release

4

the safety stopper knob.

8∼10mm

Holding the control lever, try to slightly

5

push out the machine body to make sure the stopper is working.

If the machine body does not move forward any further, the setting is completed.

32

BASIC OPERATIONS

Page 34

MEASUREMENT UNDER AUTO MODE

Adjust the height of the automatic instrument table so that

•

correct measurement values can be obtained by allowing the

MEMO

Setting the Measurement Mode

The initial status of the measurement mode is AUTO, upon turning the power ON.

Return to the Measurement screen.

1

Press on the control panel and change the measurement mode display to

2

AUTO.

patient to undergo measurements in a comfortable position.

Make the patient relaxed so as to secure correct measure-

•

ment values; make sure the patient does not hold his breath

or remain tense.

Setting the Measuring Range

In this machine, the measuring range can be switched between 0-30 and 0-60.

Normally, the 0-30 range is used, but if the patient's intraocular pressure is high, switch

it to 0-60. The initial status of the measuring range is 0-30, upon turning the power ON.

Return to the Measurement screen.

1

Press on the control panel and make the measuring range display 0-30.

2

33

BASIC OPERATIONS

Page 35

Alignment and Measurement

MEMO

The alignment operation can be performed with the control lever.

Moving the machine body by the control lever

When the machine body needs to be moved slightly back and forth or right and left,

•

move the control lever in each direction.

It is recommended that you do intraocular pressure measurements several times. Since the intraocular pressure varies by

heart beats and tears, often it is not possible to obtain exact

measurement values by measuring only once or twice.

Operating the control lever

(back and forth, right and left)

Never insert your fingers under the measuring head.

CAUTION

To move the measuring head vertically, turn the control lever right for raising and left

•

for lowering.

∗ Inform the patient of this, too.

Careless insertion of fingers may cause injury by pinching.

Operating the control lever

(up and down)

34

BASIC OPERATIONS

Page 36

Hold the control lever and pull the machine body towards the operator.

1

Move the control lever in directions as

2

needed and bring the patient’s eye to the center of the monitor screen.

Tell the patient to gaze at the yellow-green light.

3

Move the machine body toward the patient and focus the target eye. A vague

4

alignment dot becomes seen reflected in the cornea.

Inner alignment mark

Alignment dot

35

BASIC OPERATIONS

Page 37

Move the machine body in directions as needed in order to get the alignment dot

5

within the inner alignment mark on the monitor screen.

Holding the alignment dot within the inner alignment mark, slightly push the machine

6

body toward the patient.

When the machine body approaches the target eye, the alignment bar and “FORWARD” display appear on the monitor screen.

Alignment bar

At this moment, be careful not to catch eyelashes and eyelids within the outer alignment mark so as to ensure correct measurements.

If the instrument is too close to the target eye, with regard to the alignment reference

position, “TOO CLOSE” is displayed on the monitor screen, and if it is too far, “FORWARD” is displayed.

The alignment bar is displayed as a broken line when the instrument is close to the

target eye and as a solid line when it is far. Also, the alignment bar is shortened accordingly as it approaches the alignment reference position.

These factors are displayed only when the alignment dot is near the inner alignment

mark.

36

BASIC OPERATIONS

Page 38

Reference position

After the alignment bar is displayed, push the machine body out a little bit more.

7

When the alignment is adjusted, measurement is done automatically and the measurement value is displayed on the monitor screen.

Too far

When the outer alignment mark is not displayed, measurement is not possible.

Measurement can be done when the outer alignment mark is displayed after a few

•

MEMO

After measurement

If measurement is not possible under the Auto mode, use

the Manual mode. Sometimes Auto mode is not available if

the condition of the cornea is unfavorable.

37

BASIC OPERATIONS

Page 39

Display of Measurement Values

Measurement values are displayed on the monitor screen for up to three measurements. From the fourth measurement on, values of earlier measurements are deleted

in order.

Figure only : Correct measurement

Figure in ( ) : Low in reliability

ERR : Incorrect measurement

OVER : Measurement value exceeding the measuring range

If the result is a figure in parentheses or ERR, do the measurement again, making

sure the patient does not blink and eyelashes do not get in the outer alignment mark.

If OVER is displayed, switch the measuring range to 0-60 and do the measurement

again.

MEASUREMENT UNDER MANUAL MODE

Adjust the height of the automatic instrument table so that correct

•

measurement values can be obtained by allowing the patient to un-

MEMO

Setting the Measurement Mode

The initial status of the measurement mode is AUTO, upon turning the power ON.

dergo measurements in a comfortable position.

Make the patient relaxed so as to secure correct measurement val-

•

ues; make sure the patient does not hold his breath or remain tense.

Return to the Measurement screen.

1

Press on the control panel and change the measurement mode display to

2

“MANU”.

Setting the Measuring Range

See page 33.

Alignment and Measurement

The alignment operation is controlled through the control lever.

For details about the adjustment of the machine body using the control lever, see

“Memo” on page 34.

38

BASIC OPERATIONS

Page 40

Hold the control lever and pull the machine body towards the operator.

1

Move the control lever in directions as

2

needed in order to bring the patient’s eye to the center of the monitor screen.

Tell the patient to gaze at the yellow-green light.

3

Move the machine body toward the patient and focus the target eye.

4

A vague alignment dot becomes seen reflected in the cornea.

Move the machine body in directions as needed in order to get the alignment dot

5

within the inner alignment mark on the monitor screen.

Inner alignment mark

Alignment dot

39

BASIC OPERATIONS

Page 41

Holding the alignment dot within the inner alignment mark, slightly push the machine

6

body toward the patient.

When the machine body approaches the target eye, the alignment bar and the

“FORWARD” display appear on the monitor screen.

Alignment bar

At this moment, be careful not to catch eyelashes and eyelids within the outer alignment mark so as to ensure correct measurements.

See descriptions about the alignment bar, “FORWARD” and “TOO CLOSE” on page

36.

Move the machine body back and forth, with the alignment bar as a reference, while

7

holding the alignment dot within the inner alignment mark.

When the alignment is adjusted, the shape of the inner alignment mark changes to a

.

Alignment is not adjusted

After the alignment is adjusted, press

8

Air is ejected for measurement, and the measurement value is displayed.

In Manual mode, measurement is done by pressing

alignment is not adjusted correctly. To ensure high-precision measurements, make

sure the alignment is adjusted correctly.

MEMO

40

BASIC OPERATIONS

Alignment is adjusted

MEASUREMENT SWITCH

MEASUREMENT SWITCH

If the shape of the inner alignment mark does not change to a

•

even after correctly adjusting the alignment, check again to see if

the alignment is adjusted correctly. Sometimes the shape of the

inner alignment mark does not change to a if the condition of

the cornea is unfavorable.

.

even if the

Page 42

DELETING MEASUREMENT VALUES

Press on the control panel.

1

All the measurement values of the right and left eyes are deleted and the instrument

settings return to their status upon turning the power ON.

41

BASIC OPERATIONS

Page 43

INDIVIDUAL OPERATIONS

HOW TO PRINT OUT MEASUREMENT VALUES

To avoid printer problems due to paper jams, do not feed paper

•

if it is torn or creased.

To avoid discoloring, particularly of the recording part, do not

•

store the printer paper in holders made of materials containing

plasticizers (ex., vinyl chloride).

MEMO

This machine can print out measurement values with the built-in printer.

Return to the Measurement screen.

1

Press on the control panel.

2

Measurement values of the monitor screen are printed out.

Upon printing, the measured values are deleted automatically from the screen.

To avoid coloring in the white part and discoloring in the re-

•

cording part, do not use bonds containing solvents. Use water

bonds.

The printer paper is heat sensitive and cannot keep records for

•

long periods of time. Copy the records to other paper for storage.

The ERR display is not printed. Also, printing can not be done when no measurement

values exist. When a red line appears in the printer paper, replace it. For details

about the replacement of paper, see “HOW TO SET PRINTER PAPER” on page 23.

Again, use the 58-mm wide TF50KS-E2C (Japan) paper for the printer.

When “PRINTER HEAD IS UP” is displayed, lower the paper retainer lever and press

again.

42

INDIVIDUAL OPERATIONS

Page 44

Hold the paper and pull it diagonally to cut.

3

To avoid paper jams, cut the paper carefully and evenly.

MEMO

•

HOW TO CORRECT MEASUREMENT VALUES

MEMO

Though the machine is adjusted for displaying optimal measurement values, the values

can be corrected within a -4 ∼ +3mmHg range.

Make sure the power is OFF.

1

Open the control panel lid.

2

Using a screwdriver, turn the “ ” of the select switch.

3

Select switch

Settings: 0: Base setting For shipment, the switch is set here.

1: +1mmHg Base setting + 1mmHg

2: +2mmHg Base setting + 2mmHg

3: +3mmHg Base setting + 3mmHg

F: -1mmHg Base setting - 1mmHg

E: -2mmHg Base setting - 2mmHg

D: -3mmHg Base setting - 3mmHg

C: -4mmHg Base setting - 4mmHg

Turn the

4

The measurement procedure is exactly the same as with the correction.

Never set the select switch for more than eight points to avoid

malfunctions.

POWER SWITCH

ON.

43

INDIVIDUAL OPERATIONS

Page 45

INPUT/OUTPUT VIA RS-232C

Output via RS-232C

This machine can output data via the RS-232C interface to a personal computer or

similar device.

Make sure the RS-232C OUT is connected.

1

For connection, see “HOW TO CONNECT EXTERNAL I/O TERMINALS” on page

14.

Check the settings for data communication.

2

For data communication, see “RS-232C Input/Output Settings” on page 18.

Obtain the measurements.

3

Press on the control panel.

4

“RS-232C DATA OUT” is displayed on the screen and the data output is completed.

Input via RS-232C

This machine can input data from a bar code reader and the like via the RS-232C interface.

Make sure the RS-232C OUT is connected.

1

For connection, see “HOW TO CONNECT EXTERNAL I/O TERMINALS” on page

14.

Check the settings for data communication.

2

For data communication, see “RS-232C Input/Output Settings” on page 18.

Return to the Measurement screen.

3

Input the ID No. from the external device.

4

The inputted “ID No.” is displayed.

44

INDIVIDUAL OPERATIONS

Page 46

BEFORE REQUESTING SERVICE

CHECKING OPERATIONS

Air Check

If a problem is suspected, do an air check.

If the result is “NG (+)” or “NG (-),” call your dealer.

For instructions on how to perform an air check, see “Air Check” on page 29.

Checking Operations

WARNING

To avoid electric shocks, do not open the instrument.

Refer all servicing to qualified personnel.

To avoid electric shocks, do not remove the covers from

WARNING

the bottom and top surfaces, TV monitor, measuring unit,

etc.

If a problem is suspected, perform checks following the Check List shown below. If the

condition is not improved by the suggested remedy or if it is not described in the list, call

your dealer.

CHECK LIST

Problem: Check point: Remedy: Page:

Monitor screen does not work. Power cable is not plugged into

receptacle.

Power cable is not plugged into

machine body.

Power save function is on. Return to normal status. P.28

Fuse is burned. Replace fuse. P.55

Monitor screen display is not

clear.

Auto mode measurement is not

possible.

Measurement values have ( ) or

ERRs are displayed.

Paper comes out unprinted. Printer paper winding is re-

Paper does not come out. Printer paper is used up. Supply printer paper. P.23, 56

Machine body does not move. Clamping knob/fixing knob is

Monitor screen needs to be

readjusted.

Measuring window needs to be

cleaned.

Measuring window needs to be

cleaned.

Window in nozzle needs to be

cleaned.

Condition of patient's eye is

unfavorable.

Manual mode is on. Set Auto mode. P.33

Measuring window is not clear

enough.

versed.

Paper is jammed. Remove jammed paper. P.55

fastened.

Secure plug in power cable.

Plug power cable into machine

body.

Adjust monitor screen.

Clean measuring window.

Clean measuring window.

Clean window in nozzle.

Measure under Manual mode.

Clean window in nozzle.

Set printer paper correctly.

Loosen up clamping knob/fixing

knob.

P.14

P.14

P.54

P.52

P.52

P.53

P.38

P.53

P.23,26

P.8

45

BEFORE REQUESTING SERVICE

Page 47

REFERENCE

OPTIONAL ACCESSORIES

Automatic instrument table AIT-20 and Table Board

Driven by electric power, it can change the height of the instrument as desired so as to

enable the patient to undergo measurement in a comfortable position.

Size...............................586(W) × 520(D)mm

Table height ..................675-865mm (differs by destination)

Table size .....................450(W)x500(D)mm

SPECIFICATIONS & PERFORMANCE

Measuring range

Working distance 11mm

Measurement display Monitor screen (with average value)

Measurement recording Built-in printer (with average value)

Alignment display Monitor screen

Monitor screen 5in.

Power saving Power save system

External I/O terminal RS232C

Power supply AC 100, 120, 220, 230 and 240V; 50/60Hz

Power consumption 80VA

Classification

Operating temperature

Body movement, back & forth 44mm

Body movement, right & left 88mm

Body movement, up & down 28mm

Chinrest adjustment 68mm

Dimensions

Weight 18kg

0∼60mmHg

IEC 601-1 CLASS I TYPE B

10∼40°C

272(W)×505(D)×430∼458(H)mm

∗ For product improvements, specifications and appearance

may be changed without prior notice.

46

REFERENCE

Page 48

RS-232C COMMUNICATION SPECIFICATIONS

Connector Types

Input terminal: DIN 8-pin (TSC0838-01-2051, Hoshiden)

Output terminal: DSUB 9-pin (DE-9S-N, JAE)

I/O Terminal Pin Arrangement

⋅ Output terminal: DSUB 9-pin (Pin Nos.1 and 9 are not used.)

Pin No. Code Description I/O

2 RD (RXD) Data receiving I

3 SD (TXD) Data transmission O

4 ER (DTR) Data terminal ready O

5 SG (GND) Signal ground I/O

6 DR (DSR) Data set ready I

7 RS (RTS) Request transmission O

8 CS (CTS) Transmission ready I

Input terminalOutput terminal

⋅ Input terminal DIN 8-pin (Pin No.1 is not used.)

Pin No. Code Code Description I/O

2 SD (TXD) Data transmission I

3 RD (RXD) Data receiving O

4 RS (RTS) Request transmission O

5 CS (CTS) Transmission ready I

6 DR (DSR) Data set ready I

7 SG (GND) Signal ground I/O

8 ER (DTR) Data terminal ready I

Input terminal

47

REFERENCE

Page 49

Transmission Formula

Mode 1, 2, 3

Synchronization Non-synchronous

Communication speed 2400/9600 bps

Start bit 1 bit

Stop bit 2 bit

Data length 8 bit

Parity None

Operating code ASCI code

Mode 4, STD1 mode

Synchronization Non-synchronous

Communication speed 2400/9600 bps

Start bit 1 bit

Stop bit 1 bit

Data length 8 bit

Parity None

Operating code ASCI code

Contents of Data Transmission

Communication format Mode 1, 3:

Model name, Type No. 10 byte

Time/Date 19 byte

R (right eye) average data 9 byte

L (left eye) average data 9 byte

∗ When the content is data with parentheses only, the average value is sent; when it is

OVER data only, OVER is sent; and when there is no data or ERRs only, a space is

sent.

(Example)

48

REFERENCE

Page 50

Communication format Mode 2:

Model name, Type No. 10 byte

Time/Date 19 byte

Measurement value (right or left eye) average data 9 byte

∗ If ERRs only, transmission is not done.

(Example)

Communication format Mode 4, STD 1:

• Data Transmission

Model name, Type No. 15 byte

Machine No. 2 byte

ROM version 10 byte

ID No. 13 byte

Work ID No. 13 byte

Machine work ID No. 4 byte

Time/Date 20 byte

R (right eye) average data 9 byte

L (left eye) average data 9 byte

(Example)

49

REFERENCE

Page 51

• Data Receiving

Patient ID data 13 byte

(Example)

or

or

Setting RS-232C Communication Conditions

In the Menu screen, move the cursor using the

press

MEASUREMENT SWITCH

. Further, move the cursor to an item to be changed on

the screen shown below, and press

at the bottom of the screen. Change the setting using

setting is registered by pressing

to EXIT and press

MEASUREMENT SWITCH

MEASUREMENT SWITCH

details, see “RS-232C Input/Output Settings” on page 18.

, keys on the control panel, and

MEASUREMENT SWITCH

. [SET→∗∗∗∗] is displayed

,

. After changing, the

. After setting, move the cursor

to return to the Menu screen. For further

Items of setting (5 items)

⋅ Machine No. (EQUIPMENT) Set value: 0∼99. (For shipment, “1” is set.)

⋅ Input ID mode (ID MODE) Set value: 1 or 2 (For shipment, “1” is set.)

⋅ Work ID No. Set value: 0∼9999 (For shipment, “0” is set.)

(WORK ID NO.) Desired serial numbers can be attached to measure-

50

REFERENCE

When more then one unit of inspection equipment

is installed in the same hospital, for example, data

can be controlled using these Machine Nos.

1. For inputting patients' ID numbers.

2. For inputting the temporary ID numbers of new

patients.

ment results. The number is automatically added (1

at a time) each time the printing of data communication is performed.

Page 52

⋅ Communication format Format: OFF, MODE 1, MODE 2, MODE 3, MODE 4,

(FORMAT) STD 1 (For shipment, “OFF” is set.)

MODE 1: When

after printing.

MODE 2: Data communication is done every measure-

ment.

MODE 3: When

without printing.

MODE 4: When

without printing.

STD 1: When

after printing.

When Mode 1, 2 or 3 is set, data is transmitted automatically without confirmation

from the receiver side. When STD 1 is set, communication is controlled by RTS-CTS.

Under the RTS-CTS control, if no CS (CTS) signal is returned from the receiver side,

transmission can be canceled by pressing

turned, it is recognized as a communication failure and FAIL is displayed on the

monitor screen.

⋅ Communication speed (SPEED) Baud rate: 2400, 9600 (bps) (For shipment,

2400bps is set.)

is pressed, communication is done

is pressed, communication is done

is pressed, communication is done

is pressed, communication is done

. Also, if no DR (DSR) signal is re-

The Topcon CT-80 complies with the CE marking.

Before connecting a personal computer to the TOPCON

product, make sure that such external equipment is in

compliance with the CE marking.

51

REFERENCE

Page 53

MAINTENANCE AND CHECKING

ACCURACY MAINTENANCE

Cleaning the Measuring Window Glass

To secure auto alignment and correct measurement values, clean the measuring

•

window glass after each day’s work.

Clean the glass when “CLEAN THE MEASURING WINDOW GLASS” is displayed

•

on the monitor screen.

To clean the measuring window glass and the window

CAUTION

MEMO

Prepare the ethanol.

1

Using a blower, remove dust and dirt from the glass surface.

2

Moisten the applicator with ethanol.

3

glass inside the measuring nozzle, use ethanol. Using

other chemicals may cause damage to the patient's eye

during measurement.

Do not use tissues, as they may make the stain more notice-

•

able.

Do not use tweezers or gauze, as these may scratch the lens

•

and glass surfaces.

Wipe the glass surface lightly with the applicator, from the center outward.

4

Use a new applicator and wipe the glass surface in a similar manner; repeat this

5

several times.

To ensure thorough removal of grease from the window glass, be sure to replace the

applicator and use a new one for each of these repeated wiping operations.

Cleaning is completed when grease is thoroughly removed.

6

If stains cannot be removed easily, call your dealer.

When the measuring window glass becomes stained “CLEAN THE MEASURING

WINDOW GLASS” is displayed on the monitor screen.

Wiping the glass surface

52

MAINTENANCE AND CHECKING

Page 54

Cleaning the Window Glass inside the Nozzle

When the window glass inside the nozzle becomes stained, it makes the fixation tar-

•

get unclear, causing errors in auto alignment and measurement values. If the fixation target is unclear or measurement values with parentheses are frequent, clean

the window glass inside the nozzle.

Clean the glass when “CLEAN THE CHAMBER GLASS” is displayed on the monitor

•

screen.

To clean the measuring window glass and the window

CAUTION

MEMO

Prepare the ethanol.

1

Moisten the applicator with ethanol.

2

Insert the applicator into the nozzle, lightly touch the glass surface, and turn the ap-

3

plicator a few times.

glass inside the measuring nozzle, use ethanol. Using

other chemicals may cause damage to the patient's eye

during measurement.

Do not apply unreasonable force to the measuring nozzle

•

while cleaning.

To avoid problems, do not leave the cotton fibers inside.

•

Be sure to use only the attached applicator.

•

Applicator (attached)

Use a new applicator and wipe the glass surface in a similar manner; repeat this a

4

few times .

The used applicator contains grease and it only scatters grease if used again; the light

transmittance is not improved at all. Be sure to replace the applicator and use a new

one for each of these repeated cleaning operations.

Cleaning is completed when the grease is thoroughly removed.

5

If stains cannot be removed easily, call your dealer. Press

confirm normal operation.

When the window glass inside the nozzle becomes stained, it makes the fixation target unclear and “CLEAN THE CHAMBER GLASS” is displayed on the monitor screen.

MAINTENANCE AND CHECKING

for a air check to

53

Page 55

Daily Maintenance

This machine must be kept free of dust; apply the measuring window cap and dust

•

cover when not in use.

When not in use, turn the

•

Ordering Consumable Supplies

When placing an order for consumable supplies, tell your dealer the product name,

•

part code and quantity.

POWER SWITCH

OFF.

Name Code

Chinrest pad 40310 4082

Silicone cloth 31087 2007

Dust cover 42360 9002

Chinrest pad pin 42364 4021

Adjusting the Monitor Screen

Although the machine is adjusted for optimal screen conditions before shipment, a

•

screen readjustment may be required due to vibrations during transportation.

To adjust the contrast and brightness, move the BRIGHT/CONT. knobs after turning

•

them all the way to the right, as viewed from the operator.

Name Code

Applicator 41601 8606

Printer paper 44800 4001

Fuse 125V-3A-M 41801 5012

Fuse 250V-1.5A-M 42364 5313

54

MAINTENANCE AND CHECKING

Page 56

Paper Jam in Printer

MEMO

Remove the printer cover, release the paper retainer lever and remove the jammed

•

paper.

Replacing the Fuse

•

WARNING

If paper is jammed inside the printer, printing is not complete.

Attempts to forcibly use the printer may lead to problems.

To avoid electrical shock and fire, unplug the power cable

before removing the fuse cover. Additionally, be sure to

replace the fuse cover before plugging in the power cable.

WARNING

Make sure the power is OFF and the power cables are unplugged.

1

Press the fuse holder with a screwdriver and turn it counterclockwise.

2

The fuse holder can be taken out.

Use only the attached fuses. Using other fuses may cause

a fire.

Removing the Fuse Holder

55

MAINTENANCE AND CHECKING

Page 57

Replace the fuse with the attached fuse.

3

Replacing the Fuse

Press the fuse holder with a screwdriver and turn it clockwise.

4

The fuse holder is now reset.

Setting the Fuse Holder

SPECIAL NOTES ON CLEANING

Cleaning the Outer Cover

Do not use or apply any spray-typed cleaner near the in-

CAUTION

MEMO

When the outer cover, operation panel and the like become stained, clean them with

•

a dry cloth. If the stain is extreme, a neutral detergent for tableware may be used by

diluting it with tepid water. Soak the cloth in the solution, squeeze it out, and then

use if to wipe off stains.

strument. If a drop of cleaner remains inside the measuring nozzle, the patient’s eye may be injured during measurement.

To avoid discoloring/deterioration of the plastic components, do

not use volatile solvents (benzine, thinner, gasoline, etc.).

56

MAINTENANCE AND CHECKING

Page 58

When calling please give us the following infor-

mation about your unit:

Machine type: CT-80

⋅

Manufacturing No. (Shown on the rating plate on

⋅

the right side of the base.)

Period of Usage (Please give us the date of pur-

⋅

chase).

Description of Problem (as detailed as possible).

⋅

COMPUTERIZED TONOMETER (CT-80)

INSTRUCTION MANUAL

Version of 1999 (9906-100LW0)

Date of issue: 1st, June, 1999

Published by

75-1 Hasunuma-cho, Itabashi-ku, Tokyo, 174-8580 Japan.

© 1999 TOPCON CORPORATION

ALL RIGHTS RESERVED

Page 59

COMPUTERIZED TONOMETER

80

CT

TOPCON AMERICA CORPORATION

CORPORATE OFFICE:37 West Century Road, Paramus, New Jersey 07652, U.S.A. Phone: 201-261-9450 Fax: 201-387-2710 www.topcon.com

TOPCON CANADA INC.

110 Provencher Avenue, Boisbriand, QC J7G 1N1 CANADA Phone: 514-430-7771 Fax: 514-430-6457

TOPCON OMNI SYSTEMS, INC.

Valley Forge Business Center, 2430 Blvd. of the Generals, Norristown, PA 19403, U.S.A Phone: 610-630-9200 Fax: 610-630-6428

TOPCON EUROPE B.V.

(European Representative)

ESSE Baan 11, 2908 LJ Capelle a/d IJssel, THE NETHERLANDS. Phone: 010-4585077 Fax: 010-4585045 www.topconeurope.com

TOPCON DEUTSCHLAND G.m.b.H.

Halskestrasse 7 47877 Willich, GERMANY. Phone: 02154-9290 Fax: 02154-929111

TOPCON ESPAÑA S.A.

HEAD OFFICE:Frederic Mompou 5, 08960, Sant Just Desvern Barcelona, SPAIN Phone: 93-4734057 Fax: 93-4191532

MADRID OFFICE:Avenida Ciudad de Barcelona 81, 1 Planta 28007, Madrid, SPAIN Phone: 91-5524160 Fax: 91-5524161

TOPCON S.A.R.L.

HEAD OFFICE:104/106, Rue Rivay, 92300, Levallois-Perret, FRANCE. Phone: 014106-9494 Fax: 014739-0251

LYON OFFICE:138, Avenue du 8 Mai 1945, 69100 Villeurbanne, FRANCE Phone: 0478688237 Fax: 0478681902

TOPCON SCANDINAVIA A. B.

Industrivägen 4 P.O.Box 2140 43302 Sävedalen SWEDEN Phone: 031-261250 Fax: 031-268607

TOPCON (GREAT BRITAIN) LTD.

Topcon House,Kennet Side,Bone Lane,Newbury,Berkshire RG14 5PX United Kingdom Phone:01635-551120 Fax:01635-551170

TOPCON SINGAPORE PTE.LTD.

Alexandra Distripark Block 4, #05-15, Pasir Panjang Road, Singapore 118491 Phone: 2780222 Fax: 2733540 web.singnet.com.sg/˜topconts

TOPCON INSTRUMENTS (MALAYSIA) SDN. BHD.

Lot 226 Jalan Negara 2, Pusat Bandar Taman Melawati, Taman Melawati 53100 Kuala Lumpur, MALAYSIA. Phone: 03-4079801 Fax: 03-4079796

TOPCON INSTRUMENTS (THAILAND) CO., LTD.

77/162 Sinn Sathorn Tower, 37th Fl.,Krungdhonburi Rd.,Klongtonsai, Klongsarn, Bangkok 10600 Phone: 662-440-1152~7 Fax: 662-440-1158

TOPCON AUSTRALIA PTY.LTD.

408 Victoria Road, Gladesville, NSW 2111, AUSTRALIA Phone: 02-9817-4666 Fax: 02-9817-4654 www.topcon.com.au

TOPCON KOREA CORPORATION

Hyobong Bldg., 1-1306, Seocho-Dong, Seocho-Gu, Seoul, KOREA. Phone: 02-3482-9231 Fax: 02-3481-1928 www.topcon.co.kr

TOPCON OPTICAL (H.K.) LTD.

2/F Meeco Industrial Bldg., No.53-55 Au Pui Wan Street, Fo Tan Road, Shatin, N.T., Hong Kong

Phone: 2690-1328 Fax: 2690-2221 E-mail: sales@topcon.com.hk

TOPCON CORPORATION BEIJING OFFICE

Room No. 962 Poly Plaza Building, 14 Dongzhimen Nandajie Dongcheng District, Beijing, 100027, CHINA Phone: 10-6501-4191~2 Fax: 10-6501-4190

TOPCON CORPORATION BEIRUT OFFICE

P.O.BOX 70-1002 Antelias, BEIRUT-LEBANON Phone: 961-4-523525/523526 Fax: 961-4-521119

TOPCON CORPORATION DUBAI OFFICE

Office No.102 KHALAF RASHD AL NAYLI BLDG., Deira, Dubai, UAE Phone: 971-4-696511 Fax: 971-4-695272

-

TOPCON CORPORATION

75-1 Hasunuma-cho,Itabashi-ku,Tokyo,174-8580 Japan.

Phone:3-3558-2520 Fax:3-3960-4214

Loading...

Loading...