Page 1

INSTRUCTION

MANUAL

COMPUTERIZED LENSMETER

CL

-

100

Page 2

INTRODUCTION

Thank you for purchasing the TOPCON

Computerized Lensmeter CL-100.

This Instruction Manual covers an overview of the TOPCON

Computerized Lensmeter CL-100’s basic operations,

troubleshooting, maintenance and cleaning.

To get the best usage from the instrument, please read the “Safety indications”

and “Safety precautions”.

Keep this Manual within reach for future reference.

Precautions

• This is a precision instrument. It is expected that the instrument is used

under normal room temperature and humidity condition.

• Install the instrument on a level, stabilized desk. Do not exposed to direct

sunlight.

• Instrument must be kept clean at all times. Turn off and cover the instrument

when it is not in use.

• For accurate measurements, make sure there is no dust or oil on the lens to

be tested or on any portion in which the lens comes into contact with.

• Topcon is not responsible for any unauthorized disassembling and

remodeling of the instrument.

• If the equipment is used in a manner other than that specified by the

manufacturer, the warranty provided for the equipment may be impaired.

1

Page 3

DISPLAY FOR SAFE USE

In order to encourage the safe use of this product, important warnings are put on the product and

written in the instruction manual.

We suggest that everyone understands the meaning of the following displays and icons before

reading the “Safety Cautions” and text.

DISPLAY

CAUTION

• Personal

injury refers to hurt, burn, electric shock, etc.

• Property damage refers to extensive damage to building or equipment and furniture.

Ignoring this display may lead to personal

injury or property damage.

MEANING

ICONS MEANING

This icon indicates a Hazard Warning.

Specific content is expressed with words or an icon either

inserted in the icon itself or located close to the icon

SAFETY CAUTIONS

CAUTION

Icons Prevention item Page

To prevent electrical shock, turn off the power switch and

disconnect power cord before replacing fuses.

Replace fuses with the same rating and type.

2

23

Page 4

USAGE AND MAINTENANCE

Usage:

The lensmeter is an electric equipment and the usage must be based on the

Instruction Manual.

USER MAINTENANCE:

To maintain the safety and performance of the equipment, never attempt to do the

maintenance of parts specified herein, which should be taken care of by our servicemen.

The maintenance items that can be covered by users are the following; for details, follow

the instructions.

Operating the fuse:

The fuse is replaceable.

For details, see page 23 of this manual.

ESCAPE CLAUSE

• TOPCON shall not take any responsibility for damages due to fire, earthquake,

actions by third person, or the negligence and missuse by the user and used under

unusual conditions.

• TOPCON shall not take any responsibility for damage derived from the inability to

use this equipment, such as a loss of business profit and suspension of business.

• TOPCON shall not take any responsibility for damage caused by operations other

than those described in this Instruction Manual.

WARNING INDICATIONS AND POSITIONS

To insure safety, warning labels are provided.

Use the equipment correctly by following the warning instructions. If any of the following

labels are missing, please contact us at the address stated on the back cover.

3

Page 5

CONTENT

INTRODUCTION

DISPLAY FOR SAFE USE

SAFETY PRECAUTIONS

USAGE AND MAINTENANCE

ESCAPE CLAUSE

WARNING INDICATIONS AND

POSITIONS

COMPONENTS

COMPONENT NAMES

ACCESSORIES

TV MONITOR

1

2

AXIS MARKING

PRINTING THE ADDITIONAL

TEXTBOX (WITH - PRINTER TYPE)

19

21

2

SETTING A SEQUENCE NO.

22

3

ABBE COMPENSATION

3

FUNCTION

LENS PROTECTION PAD

22

22

3

MAINTENANCE

MAINTENANCE

23

5

BEFORE REQUESTING

5

SERVICE

CAUTION MESSAGES

25

MONITOR SCREEN

MENU SCREEN

MENU LIST

USING THE INSTRUMENT

PREPARATION

SETTING THE PAPER

(WITH - PRINTER TYPE)

MEASURING

4

10

10

11

6

8

9

CHECK ITEMS

SPECIFICATIONS

SPECIFICATIONS

WITH - PRINTER TYPE

OPTIONAL ACCESSORIES

25

26

26

26

USING THE INSTRUMENT

AS A SYSTEM

ON - LINE SYSTEM

27

Page 6

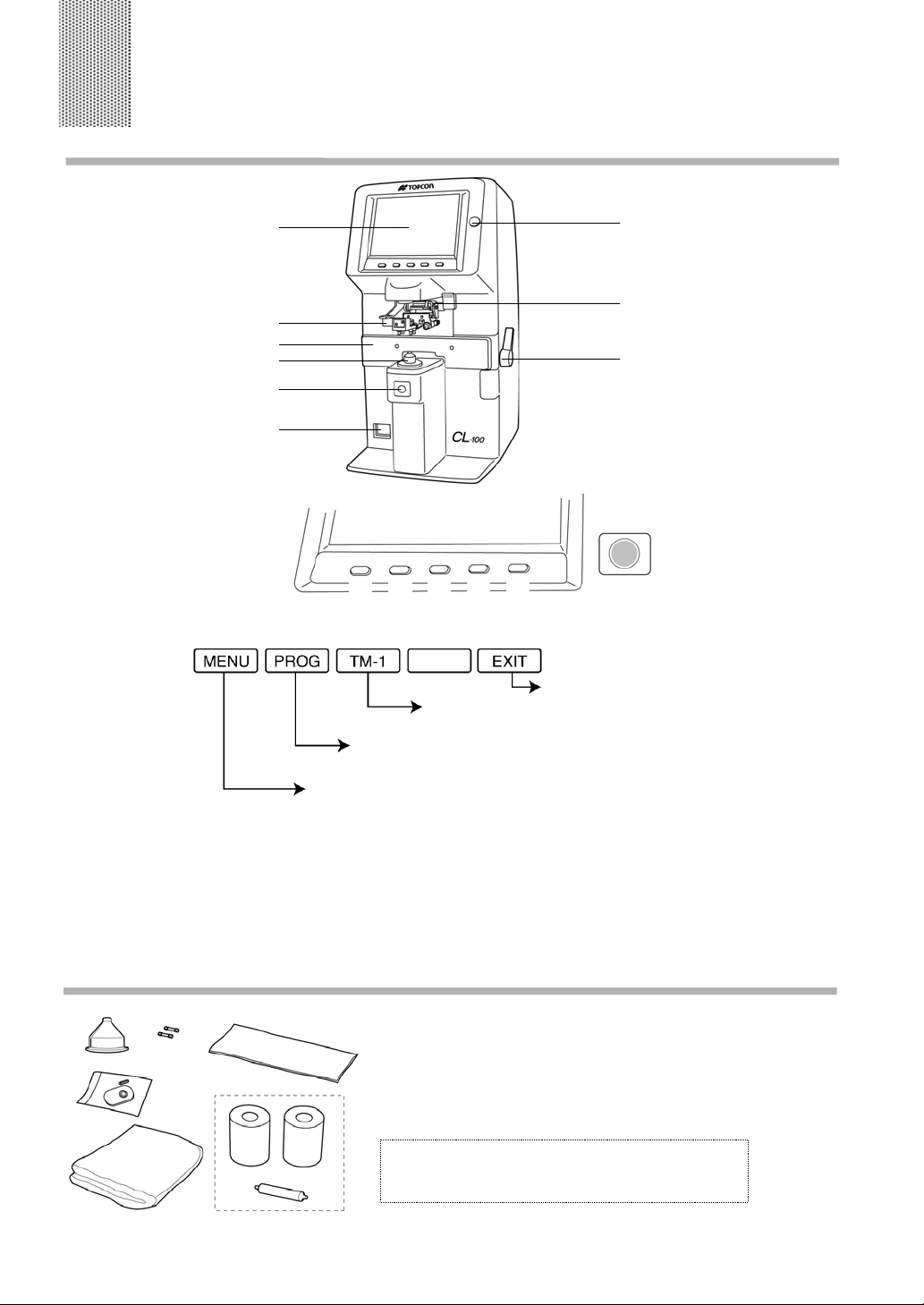

COMPONENTS

COMPONENT NAMES

TV Monitor

Lens retainer

Lens table

Lens support

MEMORY button

Power supply

(3)

(2)(1)

(5)(4)

BRIGHT control dial

Axis marker lever

Lens table lever

(6)

(1) Mode buttons Pressed to change the mode, and when pressed;

Returns to the initial state.

Pressed on to connect the spectral transmittance

meter (optional).

if a progressive lens is known, this begins the far vision

power measurement.

brings the Menu screen.

(2) TRANS button Used to change (+) to (−) and vice versa in displayed cylinder

value.

(3) R/L button Used to designate R for right lens or L for left lens.

(4) CLEAR button Used to delete memory data.

(5) PRINT button Press to output RC-232C data.

Press to print out the measurement data. (with printer-type)

(6) MEMORY button ● Used to store the measurement data.

ACCESSORIES

(A)

(E)

(B)

(C)

(D)

(F)

(A) Contact lens support .....................1 set

(B) Lens protection pad.......................1 set

(C) Dust cover .....................................1 pc.

(D) Silicon cloth ...................................1 pc.

(E) Fuse............................................. 2 pcs.

WITH-PRINTER TYPE

(F) Printer paper ................................ 2 rolls

(G) Printer paper shaft ........................1 pc.

(G)

5

COMPONENTS

Page 7

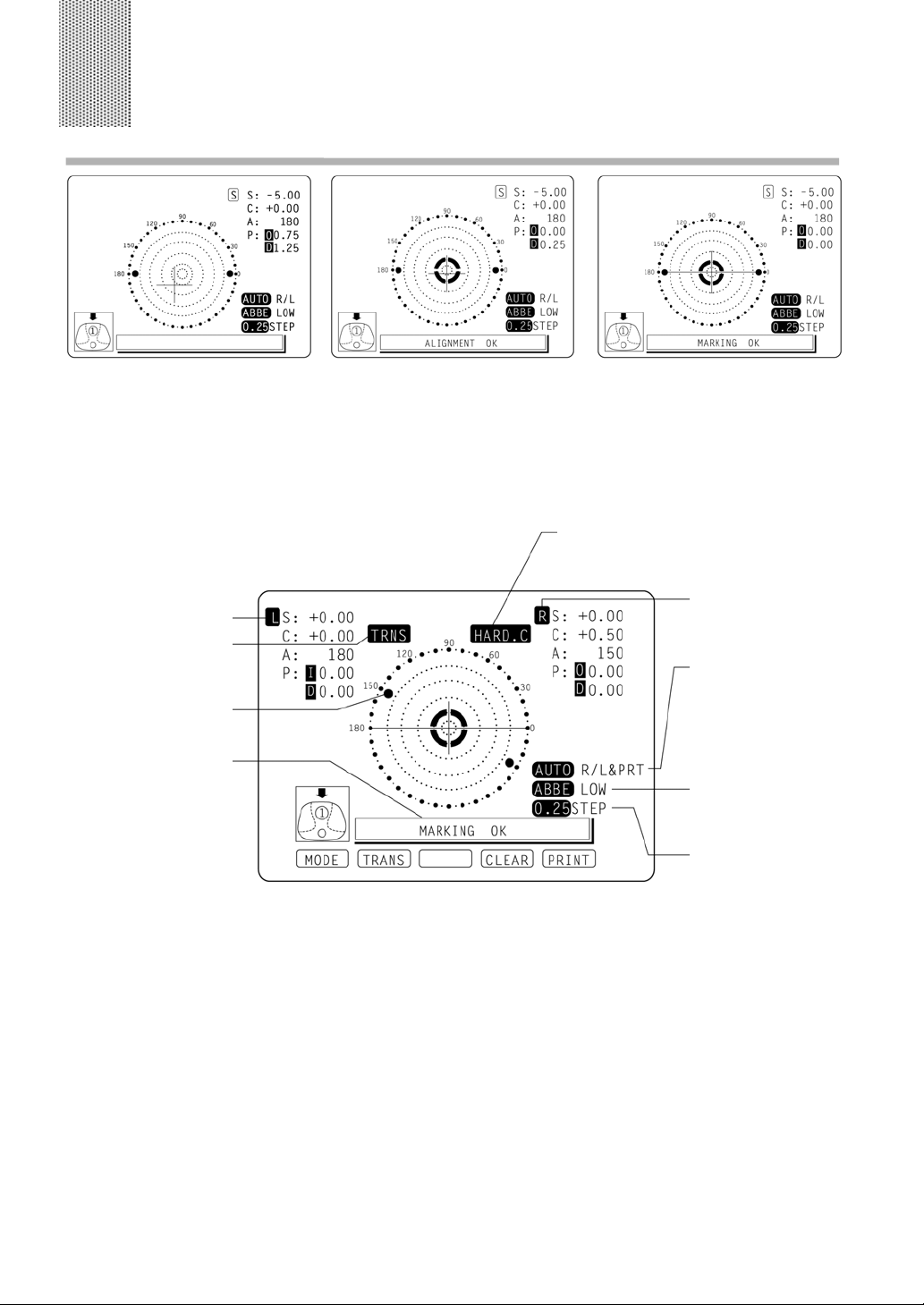

TV MONITOR

MONITOR SCREEN

Optical center’s off.

[OFF CENTER] is displayed

when the optical center is off

by 4∆ or more.

Left-eye lens

Transpose

Axial angle (every 5°)

OFF CENTER

ERROR

ALIGNMENT OK

MARKING OK

[ALIGNMENT OK] appears

when the lens is ready for

measurement.

Place + in center [MARKING

OK] appears, and the lateral

line will extend, getting the

instrument ready for marking.

HARD.C (HARD CONTACT)

SOFT.C (SOFT CONTACT)

PAD (LENS PROTECTION PAD)

Right-eye lens

(Inversion indicates a

storage status.)

AUTO R/L on status

(auto memory and auto R/L

switching)

When AUTO is displayed

inversion, R/L is automemory

off.

AUTO PRINT waiting status

When a high-refraction

lens diopter is

compensated

Step

6

TV MONITOR

Page 8

Enlargement:

When MENU/DISPLAY/HORIZONTAL LARGE is selected, the SCA display is

horizontally enlarged to make it easier to see.

When MENU/DISPLAY/VERTICAL LARGE is selected, the SCA display is vertically

enlarged to make it easier to see. The graphic moves to the opposite side.

Screen print display: (when enlaraged )

For framed lenses, of which both R and L are memorized, pressing the PRINT button

enlarges the SCA of both eyes. To return to the original state, press the EXIT button.

7

TV MONITOR

Page 9

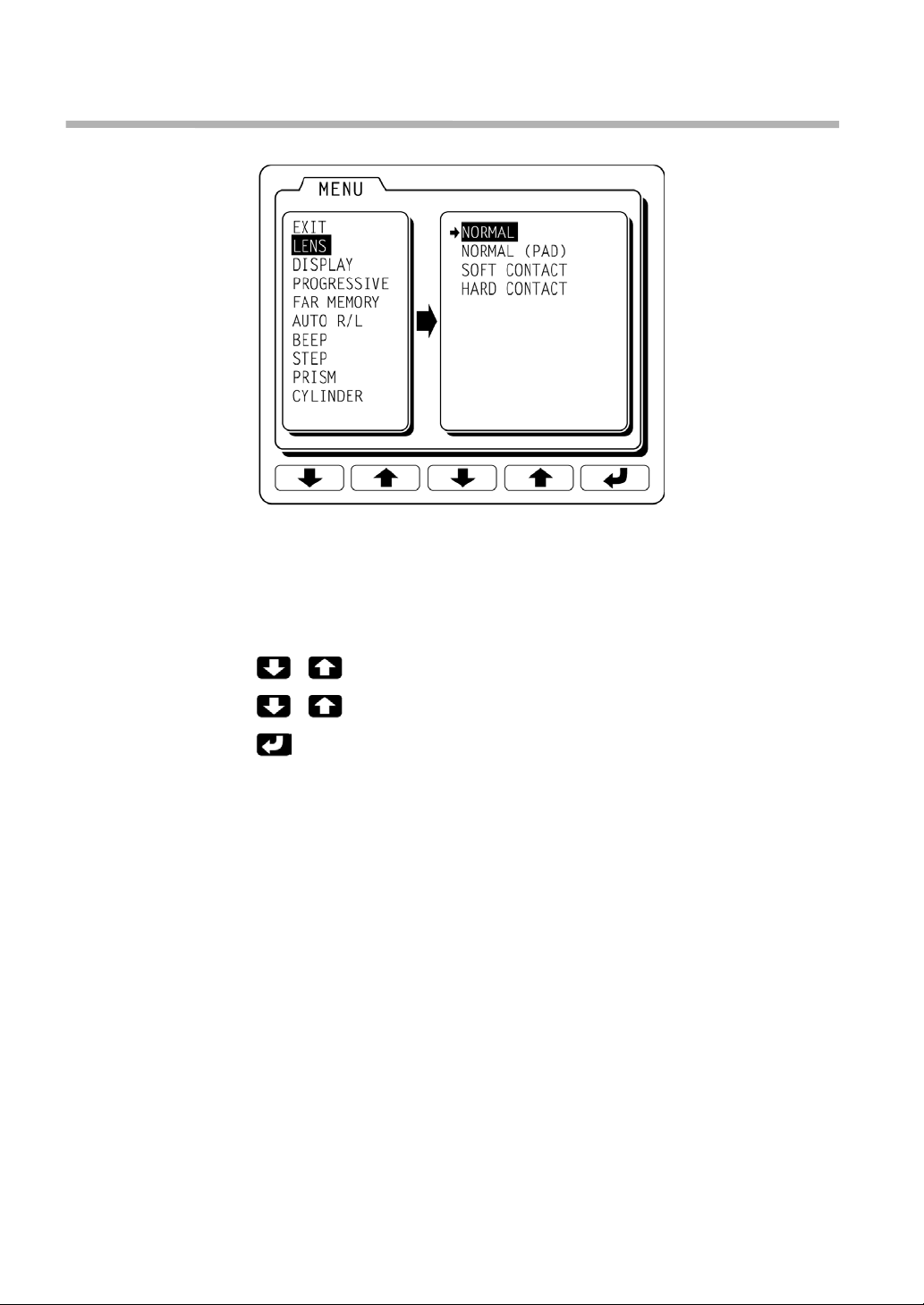

MENU SCREEN

To display the “MENU” screen, press the “MODE”

button then the “MENU” button.

Icons will appear at the bottom of the screen.

Refer to the buttons at the bottom of the screen to

scroll through the Menu.

Selects a menu.

Selects the contents of each menu.

Changes the setting, and return to

the measurement screen.

8

TV MONITOR

Page 10

MENU LIST

EXIT Returns to the initial state without changing settings.

LENS NORMAL Measures a normal lens.

NORMAL (PAD) Measures a normal lens wearing a lens protection seal.

SOFT CONTACT Measures a soft contact lens.

HARD CONTACT Measures a hard contact lens.

DISPLAY HORIZONTAL LARGE Horizontally enlarges the SCA display.

VERTICAL LARGE Vertically enlarges the SCA display.

NORMAL Normal display

PROGRESSIVE OFF Auto progressive judgment mode OFF.

AUTO Auto progressive judgment mode ON.

PROGRESSIVE ONLY Always begins the far vision power measurement of a

progressive lens.

REVERSE Measures the diopter power with the concave side up.

FAR MEMORY ON Auto memory of far vision power measurement.

OFF Manual memory of far vision power measurement.

AUTO R/L ON-R/L Measurement of framed lens: Auto R/L switching and auto

memory.

ON-S/R/L Measurement of single lens/framed lens: Auto R/L switching

and auto memory

OFF Auto memory OFF

BEEP ON Buzzer sounds when a measured value is stored and a

button is pushed.

OFF Buzzer OFF

STEP 0.25 0.25-step measurement.

0.12 0.12-step measurement.

PRISM NO DISPLAY No prism display.

X-Y Coordinate display

P-B Polar coordinate display

mm mm display

CYLINDER MIX Mixed display

+ Plus-fixed display

- Minus-fixed display

ABBE NORMAL 50-60 Abbe

MID 40-50 Abbe

LOW 30-40 Abbe

AUTO OFF YES Power save ON

NO Power save OFF

RS-232C NEW FORMAT External output (NEW FORMAT)

OLD FORMAT External output (OLD FORMAT)

STD1 External output (STD FORMAT)

TM-1 Pressed on to connect the spectral transmittance meter

(optional).

SEQ.NO. SET Serial No. print mode

with-printer Type (added to the above)

PRINTER ON Printer output ON

OFF Printer output OFF

AUTO PRINT ON Auto memory output (S: When the lens is removed

R/L: When both lenses are the same class (1st/2nd near

vision power of far vision power)

OFF Manual memory output

NAME SET Shop name print mode

TV MONITOR

9

Page 11

USING THE INSTRUMENT

PREPARATION

Remove the tape from the lens support.

1

Remove the tape from the marking ink cartridge.

2

Connect the power cable to the body.

3

Turn on the power switch ( O → − ).

4

SETTING THE PAPER (WITH-PRINTER TYPE)

Remove the printer cover and slide the paper into the slit until it comes out from the

1

outlet, as illustrated.

Keep the lever at the top position.

2

Take care of the roll direction.

Pass the printer paper shaft through the paper to load the printer with paper.

3

Set the printer cover.

4

Lower the lever to the bottom position.

5

Press

PRINT

button

while

pressing

CLEAR

Lever

• Do not install the instrument in a place which is exposed to direct sunlight, high

temperature and humidity and dust.

• Do not install the instrument at a place exposed to intense light or on a glossy table.

• The instrument may not operate properly or “ERROR” may be displayed.

• Use a power of AC100, 120, 220, 240V/±10% (50/60Hz)

button.

Shaft

10

USING THE INSTRUMENT

Page 12

MEASURING

Checking before measuring

Connect the power plug with a power outlet.

1

Check to see that there is no lens on the lens support.

2

Turn on the power switch, and display will appear on the screen in a few seconds.

3

INITIAL ERROR will appear when power is turned on with a lens on the lens support.

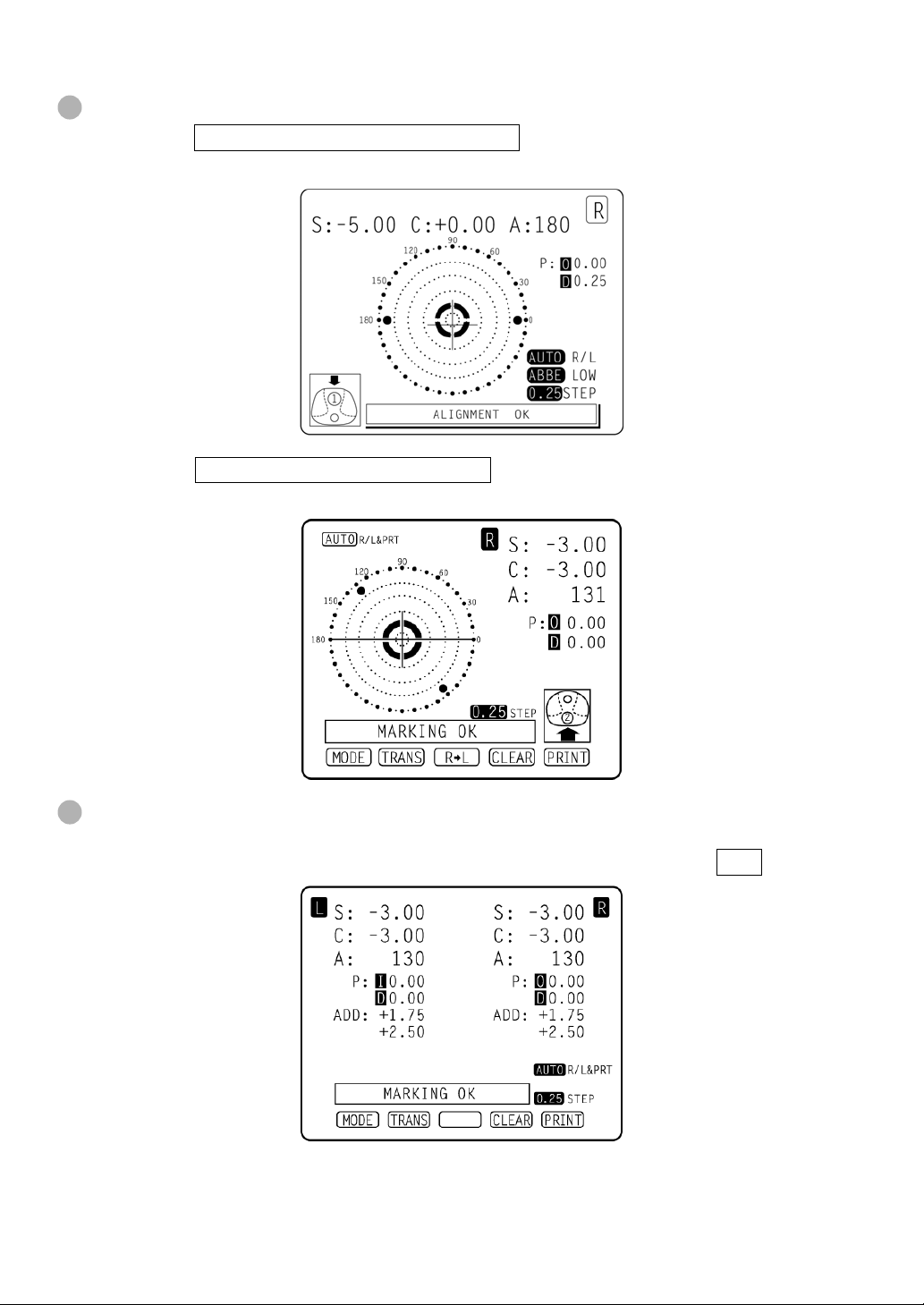

Measuring a single lens

Place the target lens with the concavity downward.

1

Lift and place down the lens retainer to retain the target lens with an accompanying

2

hand.

ALIGNMENT OK will be displayed when the target image center is within the

3

minimum circle (0.5∆ or smaller).

The ALIGNMENT OK mark is displayed when the target image center is reached. In

4

the case of S measurement with AUTO R/L on (AUTO being inverted), “single

lens” is memorized automatically. When BEEP is ON, the buzzer sounds.

(Note) The target may move in a contrary manner immediately after the lens is

placed.

Changing measuring steps

1

Select on the menu screen [0.12] or [0.25].

When prism display is needed

2

Set as follows in the Menu screen:

[NO DISPLAY] ............. No display

[X-Y] ............................. Orthogonal coordinates display

[P-B] ............................. Polar coordinates display

[mm] ............................. Display by mm

11

USING THE INSTRUMENT

Page 13

When diopter transposition is required

3

Press TRANS button, and the astigmatism

symbols will change.

Press the button again, and the original data

will reappear.

When storing

4

Press the MEMORY button ●. S will turn to S .

When R/L designation is required

Press the R/L button.

In the screen, S R L appears in this order.

For example, S R now after pressing is displayed.

When printing

5

Press PRINT button.

Measuring a framed lens

Turn the lens table lever and bring it before you.

1

Gently, place the glass frame against the lens

2

table for measurement.

Alignment

Right and left......... Place the frame against the

Vertically ............... Move the table easily with the

When AUTO R/L is off (neither AUTO R/L nor AUTO R/L is displayed)

•

Press the S R button.

First align the right lens and press the Memory button ●.

Press the R L button.

Align the left lens and press the Memory button ●.

When AUTO R/L ON-/R/L is set (AUTO R/L is displayed):

•

*Measurement of single lens.

At first, align the right lense to display “MARKING OK”. Then the result is

automatically memorized, when the right lense is hold.

Removing the right lens will automatically move to the L measurement.

Align & hold the left lens. The result is automatically memorized.

When AUTO R/L ON-S/R/L is set ( AUTO R/L is displayed):

•

*Measurement of single lens/framed lens

Press the S R button.

At first, align the right lense to display “MARKING OK”. Then the result is

automatically memorized, when the right lense is hold.

Removing the right lens will automatically move to the L measurement.

Align & hold the left lens. The result is automatically memorized.

AUTO R/L: Both auto memory and auto R/L switching

AUTO R/L: Auto R/L switching only

To set AUTO R/L, set PROGRESSIVE/OFF and AUTO R/L/ON-R/L

or AUTO R/L/ON-S/R/L .

S: −1.50 S: −1.00

C: +0.50 C: −0.50

A: 90 A: 180

lens table gently, and move the

frame right and left finely.

lens table lever.

12

USING THE INSTRUMENT

Page 14

Judging a progressive lens

• Judging a progressive lens MENU screen/PROGRESSIVE/AUTO

Judges a single focal lens or a progressive lens, which otherwise is difficult.

Under this mode, a graphic operation procedure is displayed at the bottom left.

Select [PRGRSVE.] [PROGRESSIVE] with MENU button, and a

1

single focal lens will be told from a progressive focal lens, which

is not easy from appearance.

Under this mode, the graphic operation procedure appears at

2

the lower left on the screen.

Measure the lower frame center (position (1)); do not move the

3

frame during measurement.

Measure the upper frame center (position (2)); do not move the

4

frame during measurement.

Graphic

operation

procedure

Pressing the Mode button and then the PROG button will omit the auto progressive

judgment mode.

Or, when MENU screen/PROGRESSIVE/ PROGRESSIVE ONLY is designed, always

the far vision power measurement for progressive lens begins.

• Measuring a progressive lens for far vision power (excluding prism prescription lens)

The initial screen for far vision measurement shows the right

1

figure.

Move the glass frame to match + with

Move the glass frame according to the direction of the arrow.

2

.

13

USING THE INSTRUMENT

Page 15

After measuring the far vision region, the screen automatically switch itself to near

3

vision power measurement. (To facilitate detecting the far vision region, hold the lens

gently and more the lens slowly.)

Press the Memory button ●. Optionally store the result of far vision power measurement.

The screen switches to the near vision power measurement.

When MENU screen/FAR MEMORY/OFF is set, the result of far vision power

measurement is not automatically stored. Press the Memory button ●.

For high-power lenses, sometimes the far vision region cannot be detected so easily. In

this case, do measurement around the position shown in the right figure, and press ADD

button.

Measuring a progressive lens for near vision power

While watching the screen, bring the lens table foremost.

1

The maximum value remains in inversion

10mm approx.

Under the condition illustrated below, a position off the progressive zone is being

2

measured. Move the frame along the arrow.

14

USING THE INSTRUMENT

ADD value

Page 16

Within the progressive zone, press the Memory button at a position where the ADD

3

value is the maximum.

When measuring a lens mounted in a large frame, ADD

power may be higher because some lenses increase in

ADD power at a position lower than the near vision

region. If the lens is measured, accordingly, at a point

lower than the near-vision eye point, ADD power may

be higher. If you want to know the previous

prescription, it is advisable to check the measurement

position with *** mark.

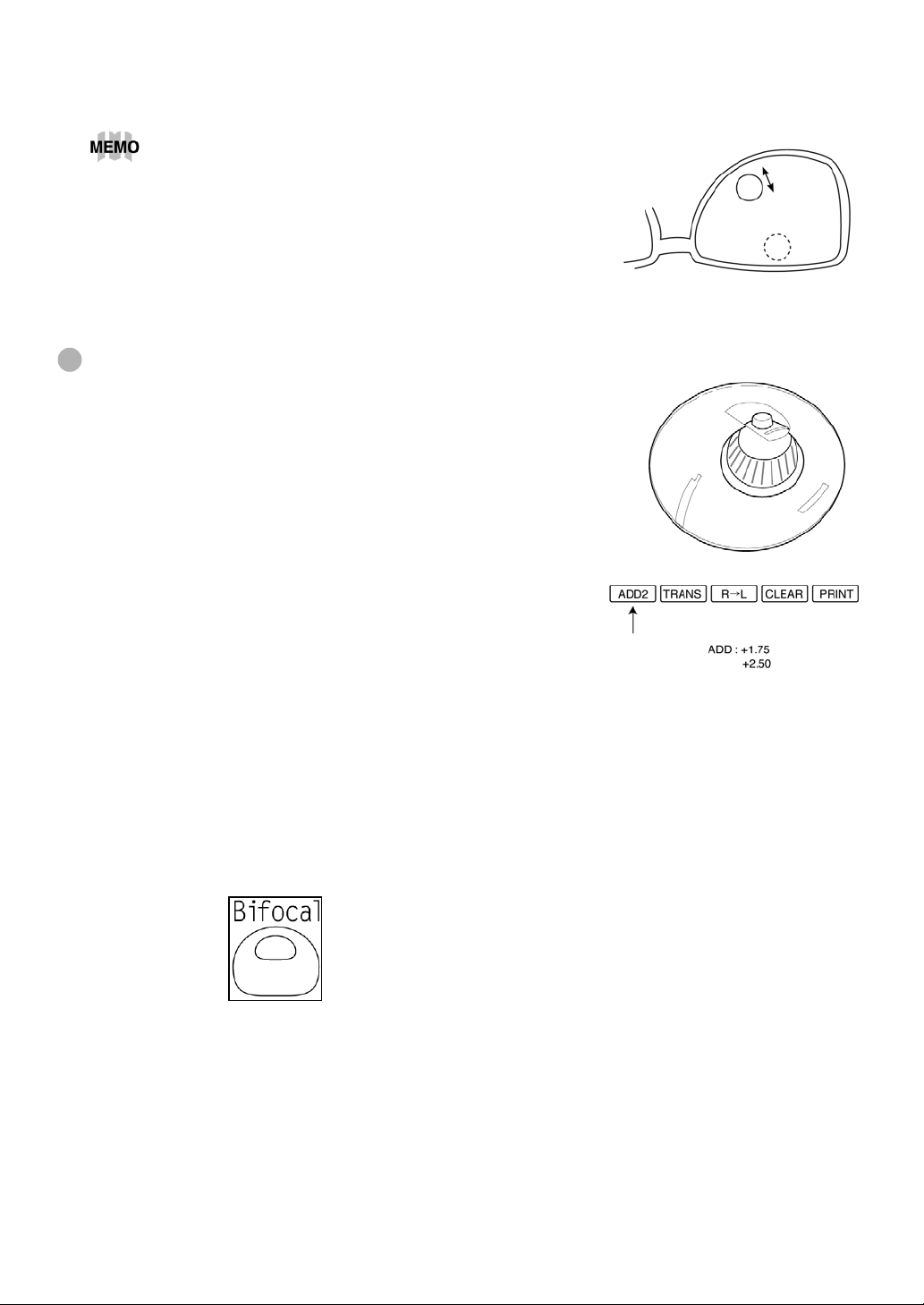

Measuring a bi- and tri-focal lens

When using progressive graphics from the auto

•

progressive judgment mode:

Set the bottom center of screen under the Auto

progressive judgment mode (position (1)) to the near

vision power region (near segment) and measure the

lens at rest. Upon measuring the far vision power

region at rest in like measuring a progressive lens,

the screen automatically switches to the far vision

power measurement.

When measuring the 2nd near vision power of tri-focal lenses, memorizing the 1st

near vision power changes the mode button to the

ADD2 button. Pressing the button starts the 2nd

diopter power measurement.

When marking the optical center of far vision power

•

region:

Align the far vision power region and press the MEMORY button ●.

1

Mark the optical center.

2

Set the screen to the near vision power region (near segment).

3

Press the MEMORY button ● (in this case the MEASUREMENT OK button of near

4

vision power).

The mark shown left is displayed on the screen.

Measure the near vision power and press the MEMORY button ●.

5

15

USING THE INSTRUMENT

Page 17

Measuring an unprocessed progressive lens

As each unprocessed lens has a mark on the measuring point. Do measurement on the

mark position. For measurement, follow the procedure of “Judging a progressive lens,

measuring a progressive lens for far vision power” and “Measuring a progressive lens

for near vision power”.

Far vision region marked

Near vision region marked

The measuring point for the far or near vision region may be narrowed by marks. Take

care that the luminous flux may not be shaded during measurement.

ADD values will flicker when the luminous flux is shaded by marks or off the progressive

zone at the time of measuring the near vision region. An EX lens may not be provided

with accurate measurements when measured in the boundary.

Mode to measure the diopter power of lenses with the concave side up

Set MENU/PROGRESSIVE/REVERSE .

1

Lens position Screen

Set the lens with the concave side down

2

as usual, align the far vision power

region, and press the MEMORY button.

Set the lens with the concave side up,

3

align the far vision power region, and

press the MEMORY button.

Leaving the lens with the concave side

4

up, align the near vision power region

and press the MEMORY button.

16

USING THE INSTRUMENT

Page 18

Measuring a contact lens

• Measuring a hard contact lens

Replace the lens support with the contact lens support.

1

Select [LENS] [HARD CONTACT] from the menu, and HARD.C will be displayed on

2

the screen.

Carefully with a tweezer, place the target contact lens on the plate and fit it as is.

3

Tweezer

17

USING THE INSTRUMENT

Page 19

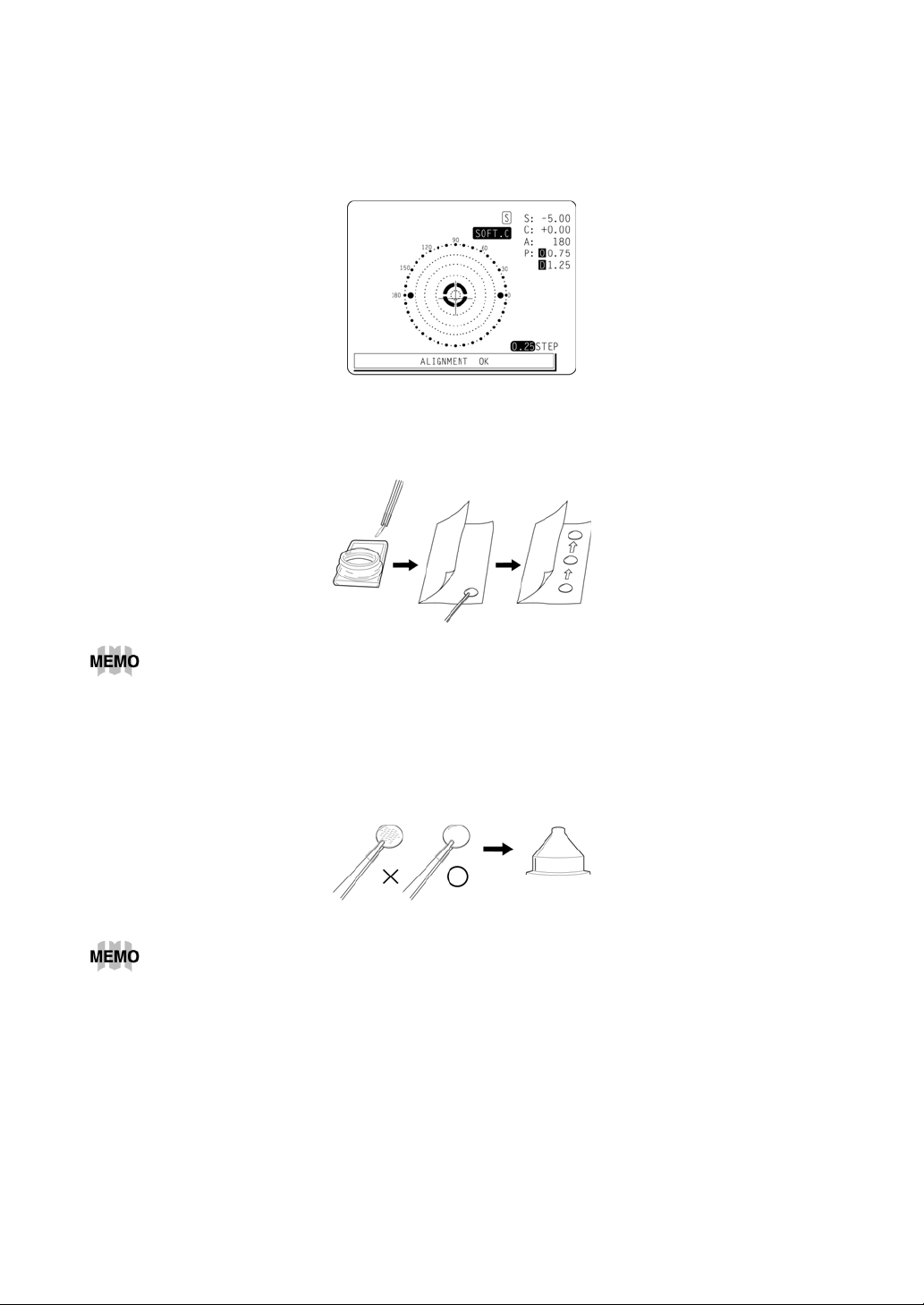

• Measuring a soft contact lens without astigmatism

Use the contact lens support for measuring as measuring a hard contact lens.

1

Select [LENS][SOFT CONTACT] from the menu, and SOFT CONTACT will appear

2

on the screen.

Pinch the target soft contact lens with special tweezers to swish off moisture from the

3

lens. Put the lens between paper to remove moisture from the surface.

If you observe dews on the soft contact lens surface, measurement will not be possible

because the luminous flux gets out of order.

If there are dews on the surface when the target contact lens is held to the light, put

4

the lens in the special solution again, and repeat the above. If the lens is ready for

measurement, put it on the contact lens holder and tell the shape (with tweezers) for

alignment.

Use the hard contact mode when measuring a soft contact lens with astigmatism.

18

USING THE INSTRUMENT

Page 20

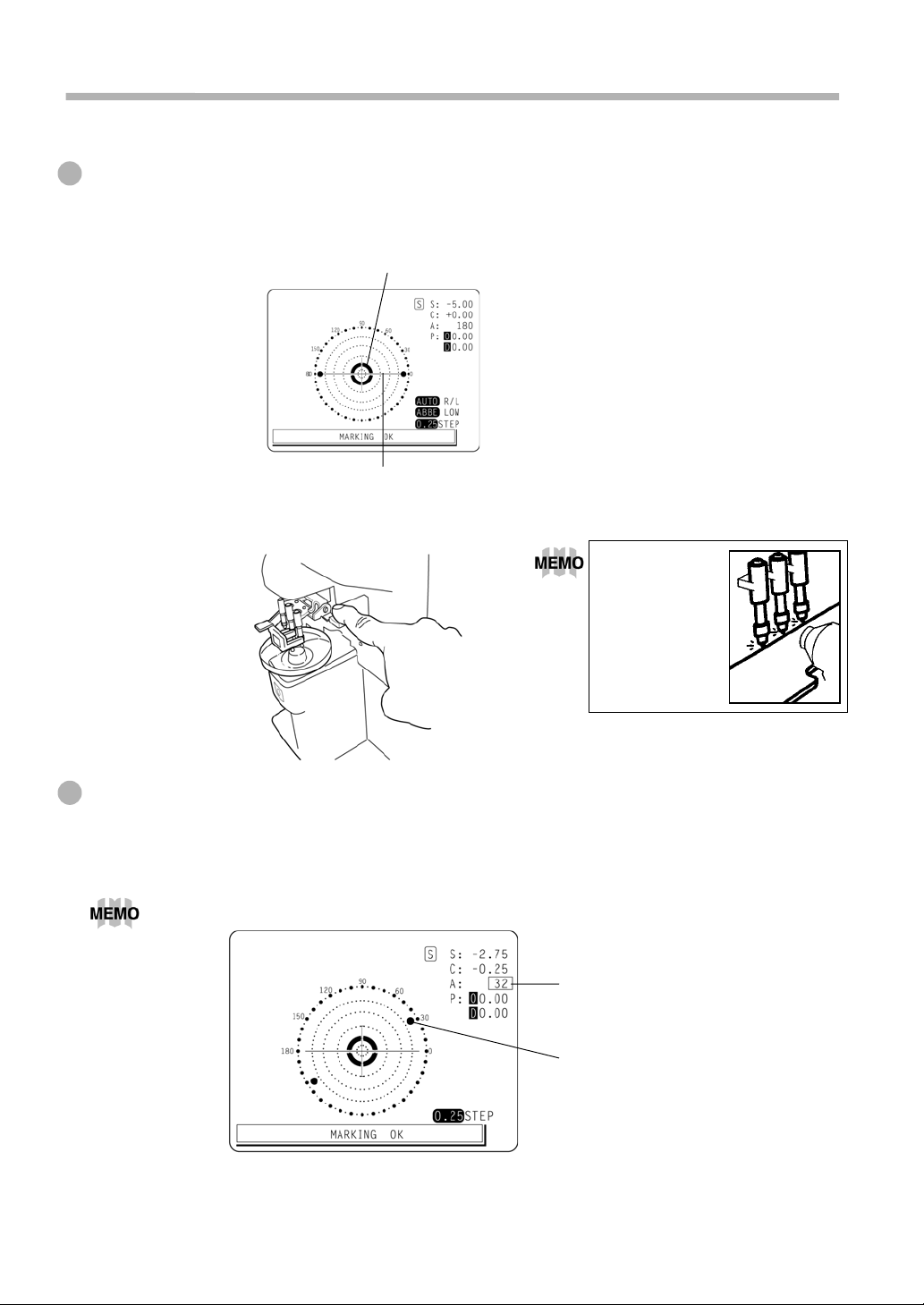

AXIS MARKING (CARTRIDGE SPECIFICATION/STEEL NEEDLE SPECIFICATION)

Using the cartridge, one light touch to the lens can put a clear ink mark.

Marking a lens without astigmatism

Move the target lens until the centering mark coincides with the target image

1

completely, and MARKING OK will appear.

Centering mark

Line extends laterally to the target.

Depress the marking lever to mark the lens.

2

Ensure the ink

cartridges do

not interfere

with the lens

Marking a lens with astigmatism

Axis marking, maintaining the axis as prescribed

1

Align the target image with the center mark, approximating the axis angle mark to the

angle as prescribed.

Do it with AUTO R/L off.

Check here

Axis angle mark (every 5°)

19

USING THE INSTRUMENT

Page 21

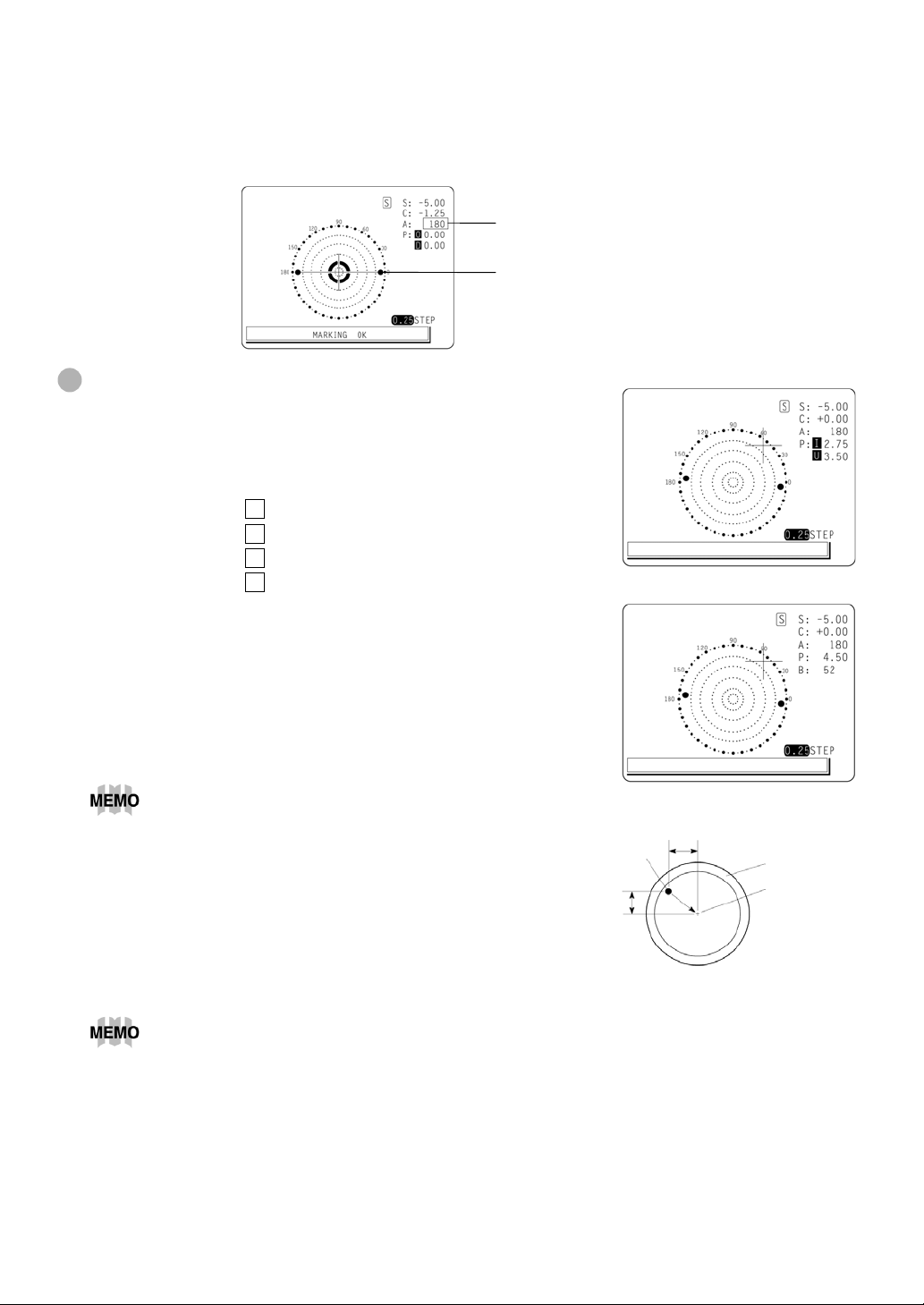

Marking a cylindrical axis

2

Match the center mark with the target image, approximating the axis angle mark to

180 degrees.

Adjust A of the axis angle to 180 degrees.

Marking a lens with prism power

• When the prescription is displayed with X-Y

(orthogonal coordinates):

Select [PRISM][X-Y] from the menu.

Carry out aligning according to the prism value as

prescribed and as displayed on the screen.

I in prism value: Base In

O in prism value: Base Out

U in prism value: Base Up

D in prism value: Base Down

• When the prescription is displayed with P-B (polar

coordinates)

Select [PRISM][P-B] from the menu.

Carry out aligning according to the prism value as

prescribed and as displayed on the screen.

P: Prism value

B: Base orientation

Adjust to 180°.

Axis angle mark (every 5°)

Take care that the polar coordinates are not the same as the value on the angular scale

in the target image.

• When the unit is mm.

Select [PRISM][mm] from the menu.

The ↑ ↓ ← → marks show the optical center

reaches the center of measurement by

moving the target lens in the arrow directions

by the distance as displayed.

→ 3.0mm

↓ 2.0mm

0 will be displayed if the spherical power S is around 0.

20

USING THE INSTRUMENT

Optical center

2mm

3mm

Lense

support

Center of

measurement

Page 22

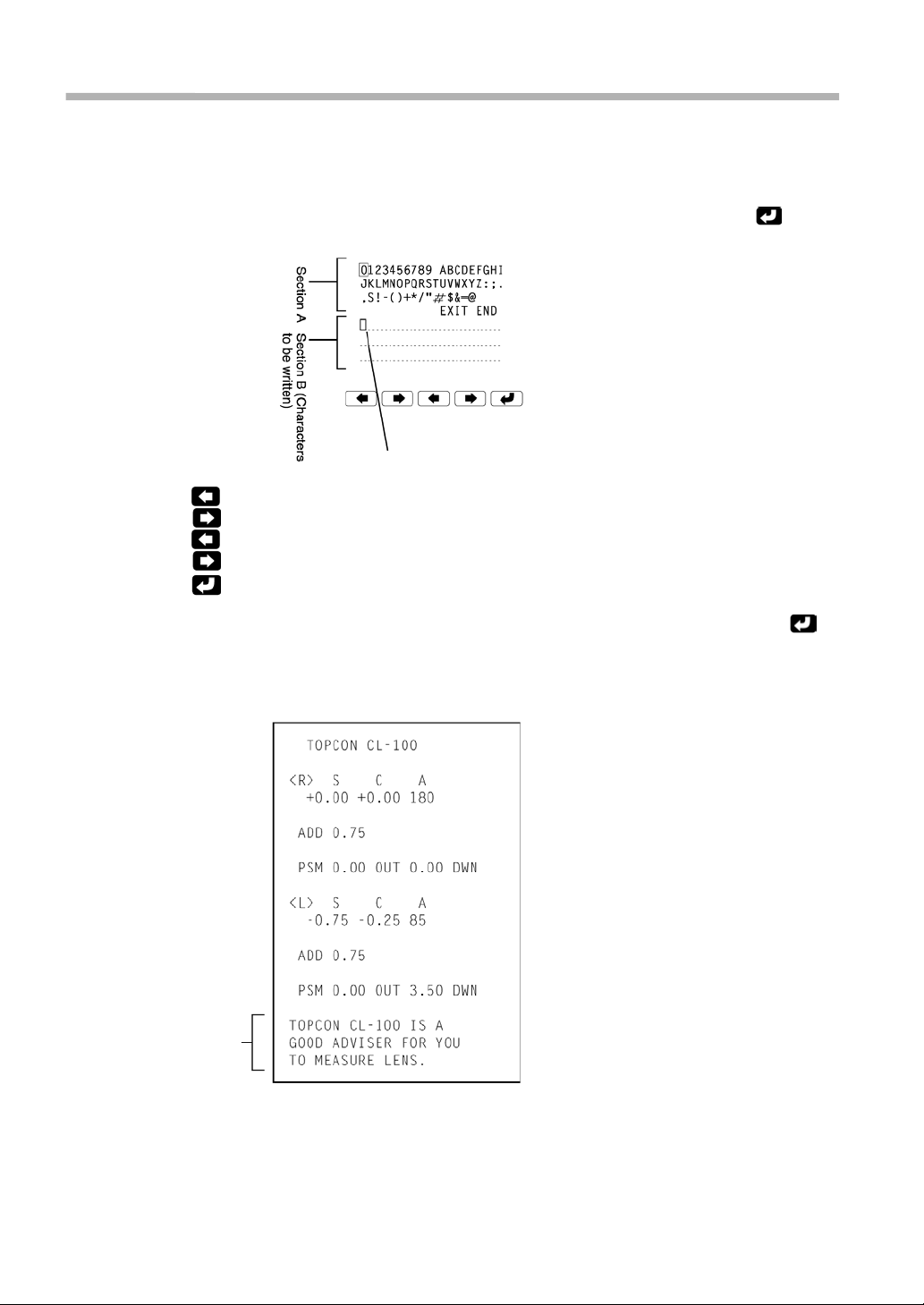

PRINTING THE ADDITIONAL TEXTBOX (WITH-PRINTER TYPE)

On the print out with the measuring data, the user can input his own text, like the name

of shop, address or special message. Available space is three line of 20 characters

each.

Select NAME SET from the menu and press the button below the icon

, and the

world of marking of text will appear (as shown at below).

Cursor 20 character x 3 rows

: Moves to the left the cursor in Section A.

: Moves to the right the cursor in Section A.

: Moves to the left where to write in Section B.

: Moves to the right where to write in Section B.

: Writes the character in Section B.

Upon completing Section B, move the cursor to END of Section A and press

, and

writing may be possible, returning the measurement screen. Once the characters are

written, they will remain even after the instrument power is turned off.

Printout

Printing

the

additional

textbox

21

USING THE INSTRUMENT

Page 23

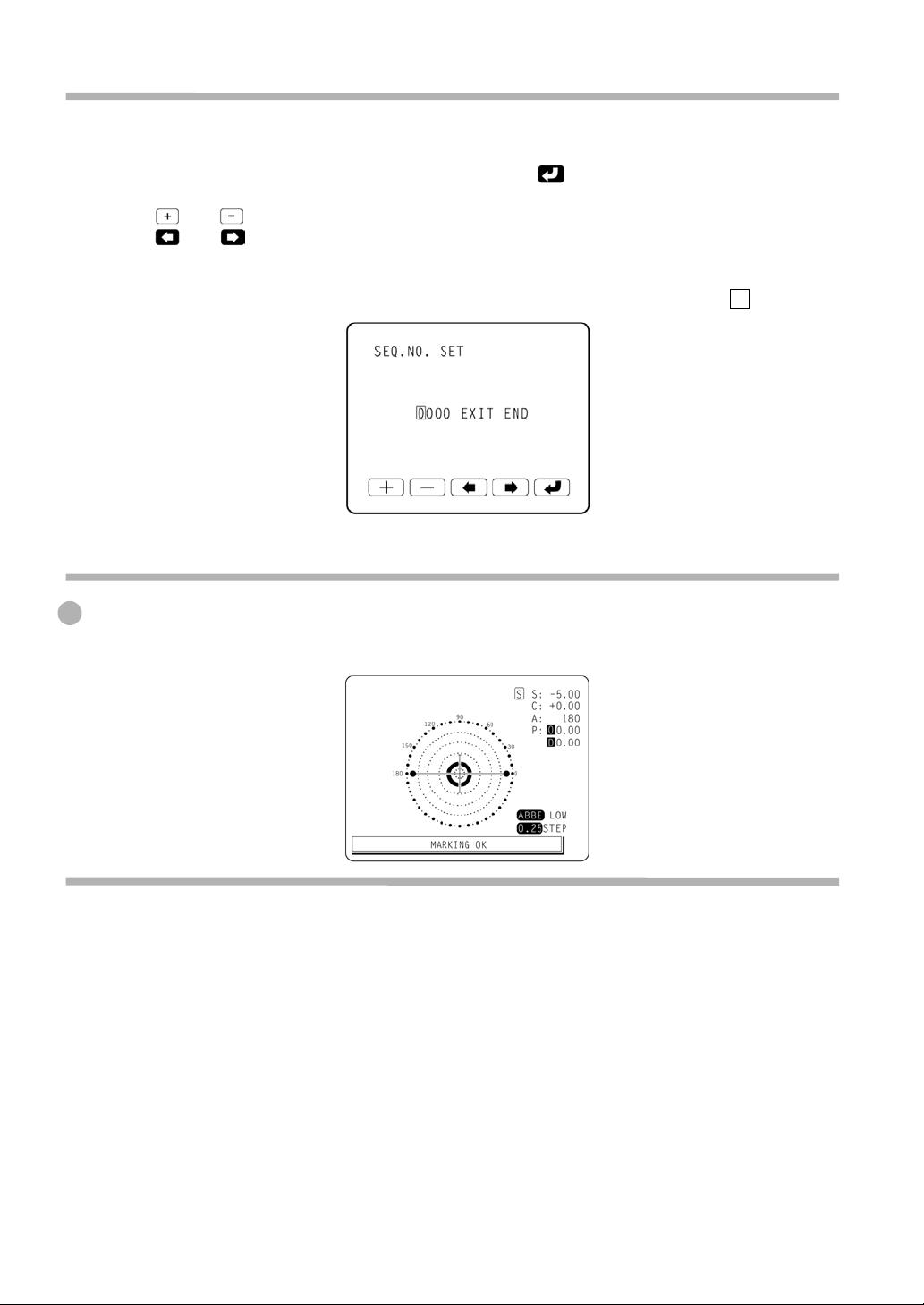

SETTING A SEQUENCE NO.

Setting is carried out when writing a sequence No. on printing paper and transferring the

serial No., using RS232C.

Select SEQ. NO SET from the menu and press

appear.

and are used to change the cursor figure.

and are used to change the cursor position.

Bring the cursor to END and press A to finish setting.

No printing or counting is carried out in case of 0000. Press MEMORY, PRINT. and

CLEAR buttons in this order. and counting will be carried out. (except for S single lens).

ABBE COMPENSATION FUNCTION

, and the screen as shown below will

When the Abbe number of lens is known:

In the menu screen ABBE, select any of the following according to the Abbe number of

target lens:

Normal (50-60)

MID (40-50)

LOW (30-40)

Lens protection PAD

The attached lens protection pad allows a soft contact with the measuring lens.

Fit the lens protection pad according to the instructions.

1

Select [LENS][NORMAL(PAD)], and the measurement result will be automatically

2

compensated.

22

USING THE INSTRUMENT

Page 24

MAINTENANCE

Auto shut-off

The monitor screen will shut off automatically if not in use for about 10 minutes.

1

Press any button, and the instrument will resume.

2

Select MENU screen/AUTO OFF/NO from the menu if it is not desirable.

3

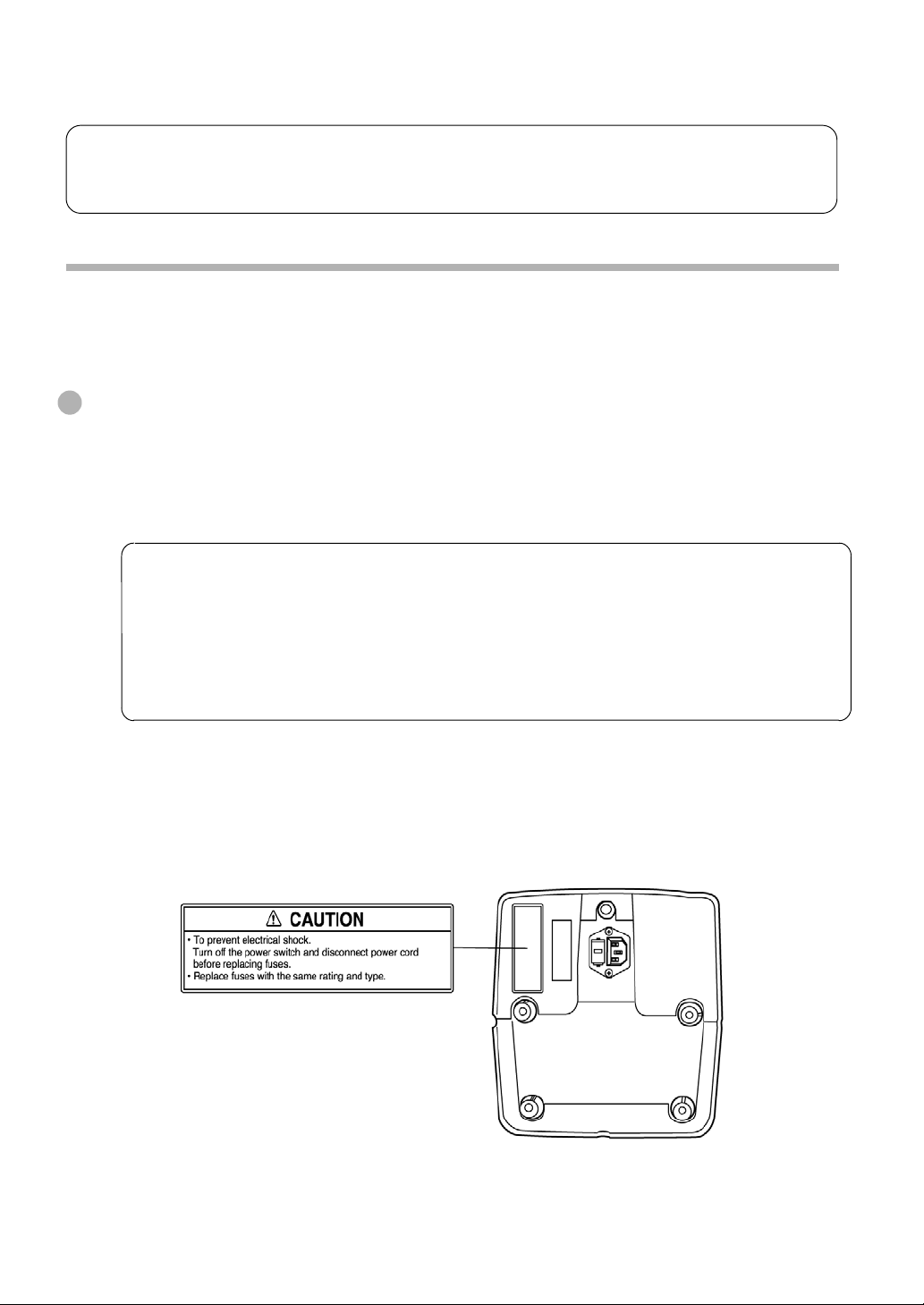

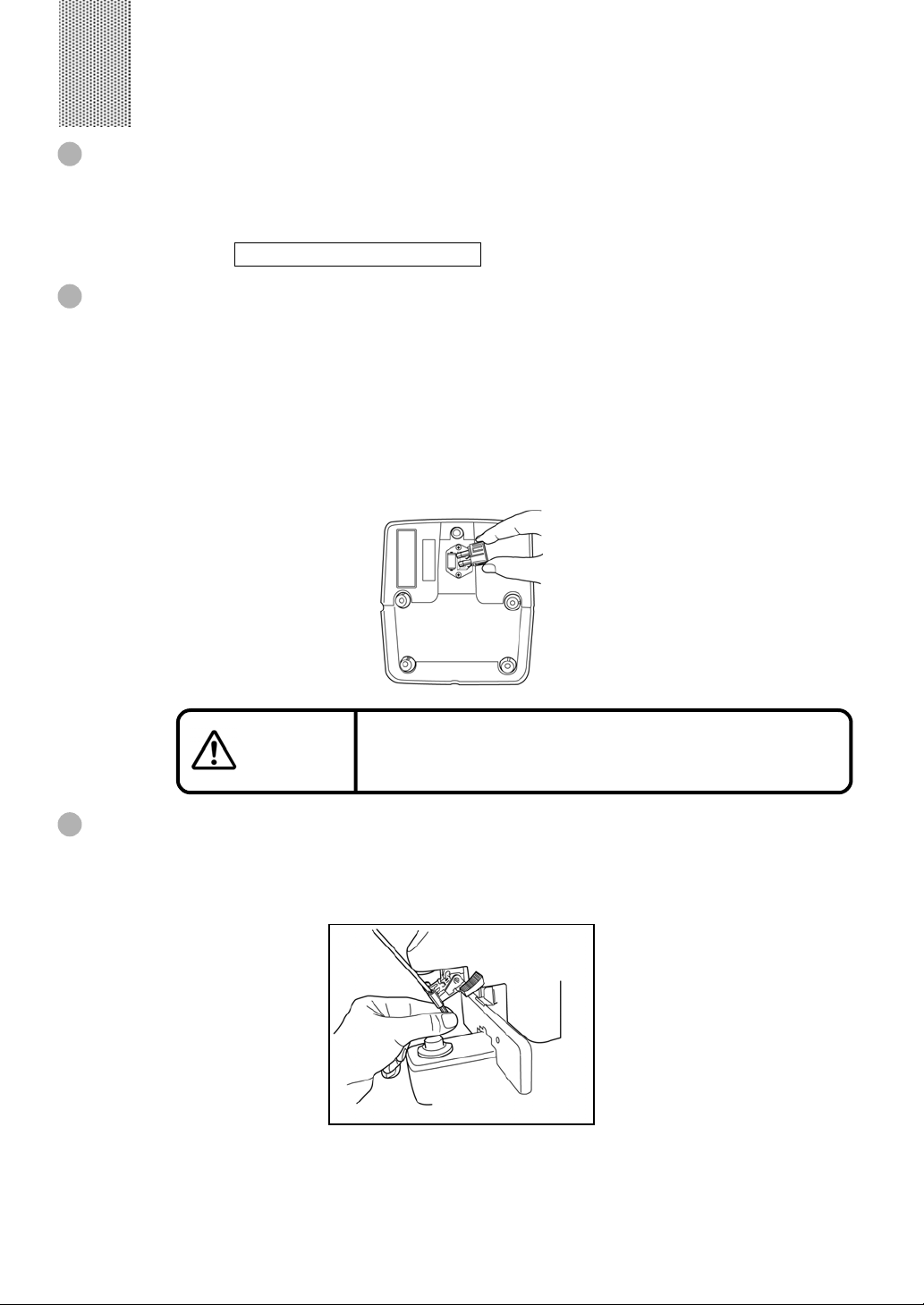

Fuse

(Note) To prevent electrical shock, turn off the power switch and disconnect power cord

before replacing fuses.

The fuse holder is provided at the bottom part of the instrument.

1

Disconnect the power cable.

2

To remove the cover, push the top and bottom pawls simultaneously, using 2 screw

3

drivers.

A 1.6A (250V) glass tube fuse is provided in the holder.

4

To prevent electrical shock, turn off the power switch and

CAUTION

Replacing the marking ink cartridge (the same applies to the optional steel needle)

To replace the marking ink cartridge, remove the top screw does. Pull out the

1

cartridge while applying pressure to it so as the spring not jump out from the inside.

Work the lens holder/stopper under the lowered condition.

disconnect power cord before replacing fuses.

Replace fuses with the same rating and type.

MAINTENANCE

23

Page 25

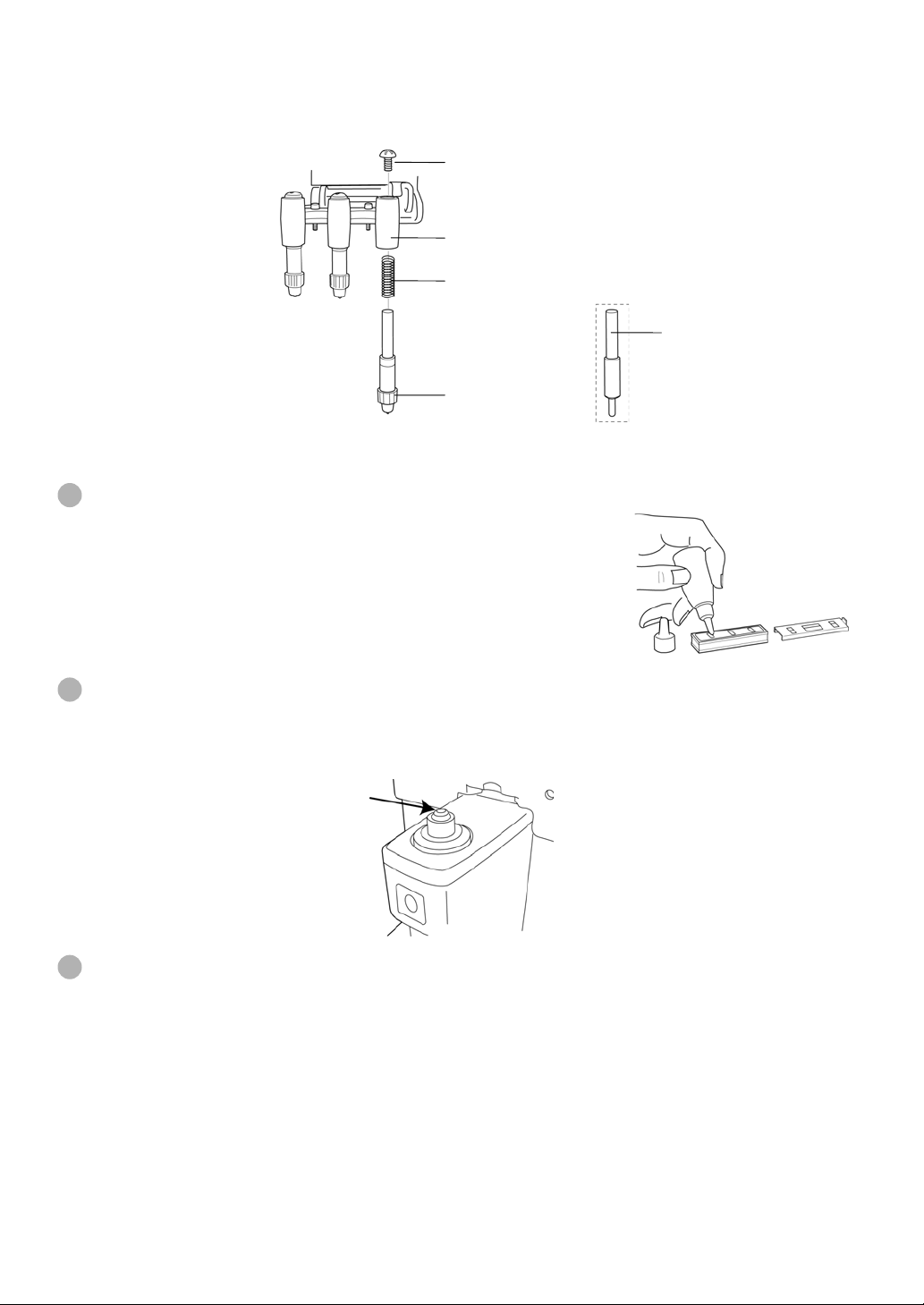

To set the cartridge, insert the spring and keep the cartridge top well above the

2

marking ink holder, and then fasten the screw.

Supply of ink for the optional steel needle

Replenish ink when poor marking happens.

1

Slide laterally and pull out the inkpot.

2

Slide off cover from the inkpot.

3

Screw

Marking ink holder

Spring

Steel needle

(optional accessory)

Marking ink cartridge

Infiltrate replenish ink into the sponge well.

4

Cleaning cover glasses

If the glass is dirty as indicated by arrows, it will affect measurement accuracy adversely.

If this occurs, clean them with the attached silicon cloth.

Remove the lens support before cleaning the cover glass.

Cleaning the instrument

Wipe cover with silicone or damp cloth, never use cleanser or other chemicals.

1

24

MAINTENANCE

Page 26

BEFORE REQUESTING SERVICE

CAUTION MESSAGES

DIOPTER OVER

PRISM OVER’

ERROR

INITIAL ERROR Request repair service.

PAPER END (with printer-type) Printer paper is out. Load new paper.

PRINTER HEAD UP

(with-printer type)

Check to see that the target lens is in the measurable

scope.

Check to see that the target lens is free from any flaw, dust

or oil.

Clean both glasses and turn power on again.

Check the lens value is not beyond the unit’s measuring

range.

Remove the lens from the lens support, and turn on power

again.

The printer lever is Up. Lower the printer lever.

CHECK ITEMS

The instrument does not get ready for

operation even if the power switch is

turned on.

The monitor screen is not visible well. Adjust the Bright adjustment dial.

S, C values are wrong. Is the lens place with power off?

Marking is poor. Replace the marking ink cartridge. For a lens with

The screen went out all of a sudden. The auto shut-off function is on.

Pushed the Print button but the printer

does not work. (with-printer type)

Re-plug the power cord.

Give a check to the fuse.

Remove the lens and turn on power again.

Is the beam blocked by an unusual flaw, dust, mark,

grease, etc. in the measured lens?

sharp surface curve, use the optional steel needle

marking set.

Press the any button ●, and the instrument will

resume.

Is printer paper set properly?

Not inside out?

25

BEFORE REQUESTING SERVICE

Page 27

SPECIFICATIONS

SPECIFICATIONS

Measurable scope S: 0~±25D C: 0~±10D ADD: 0~+10D (0.12/0.25)

P: 0~10∆ (0.12/0.25) A: 1~180° (1°)

Cylinder mode

Prism mode No display / X-Y (orthogonal coordinates) / P-B (polar coordinates) / mm

Contact lens Hard and soft contact lenses are measurable.

Progressive focal lens Single focal/progressive lens judgment, far vision power detection, ADD

Compensating Compensation of a lens different in Abbe number.

Display screen

Frame Auto R/L function

Menu screen Easy-to-watch screen with icon display

Target lens diameter Ø5 ~ 100mm

Power supply 100/120/220/240V 55VA (Auto shut-off in 10 minutes)

Dimensions, weight

Environment condition : Indoor use Altitude up to 2,000m

MIX/−/+

A contact lens plate and a fine-movement ring provided.

power bar-meter display

LCD 300 × 240 dots S, C, A, P, ADD, ADD R/L display en bloc.

Enlarged SCA display.

( CE marking: only 230V )

215 (W) × 220 (D) × 420 (H) 6.5kg approx.

* Subject to changes in design and/or specifications, without advanced notice.

Pollution degree II Temperature 5~40°C

Maximum relative humidity 80% for temperatures up to 31°C decreasing

linearly to 50% relative humidity at 40°C

WITH-PRINTER TYPE

Printer: Thermal printer, paper width 58mm

OPTIONAL ACCESSORIES

Steel needle marking set (steel needle, supply ink, ink bottle, holder)

Ordering consumable supplies and spares

Product name Part code No. Remark

Spare part 100~120V Fuse (250V, 1.6A)

220~240V Fuse (250V, 1.0A)

Consumables Marking ink cartridge (3 cartridges/set) 4203699500 Standard accessory

Lens protection pad 4203656000 Standard accessory

Steel needle marking set 4203625100 Optional accessory

Supply ink 4203690060 Optional accessory

Printer paper 4480040010 With-printer type

0514111620

0514110130

Standard accessory

Standard accessory

26

SPECIFICATIONS

Page 28

USING THE INSTRUMENT AS A SYSTEM

ON - LINE SYSTEM

The data of computerized lensmeter can be transfered to the instruments through RS232C interface, and also measuring data of the instruments can be transfered to

computerized visiontester.

COMPUTERCVRM/KRCL

27

USING THE INSTRUMENT AS A SYSTEM

Page 29

COMPUTERIZED LENSMETER

CL-100

TOPCON AMERICA CORPORATION

CORPORATE OFFICE:37, West Century Road, Paramus, New Jersey 07652, U.S.A. Phone: 201-261-9450 Fax: 201-387-2710

TOPCON OMNI SYSTEMS, INC.

Valley Forge Business Center, 2430 Blvd. of the Generals, Norristown, PA 19403, U.S.A Phone: 610-630-9200 Fax: 610-630-6428

TOPCON EUROPE B.V.

(European Representative)

Esse Baan 11, 2908 LJ Capelle a/d IJssel, The Netherlands. Phone: 010-4585077 Fax: 010-4585045

TOPCON S.A.R.L.

HEAD OFFICE:104/106, Rue Rivay 92300, Levallois-Perret, France. Phone: 01-41069494 Fax: 01-47390251

LYON OFFICE:138, Avenue du 8 Mai 1945, 69100 Villeurbanne, France Phone: 0478688237 Fax: 0478681902

TOPCON DEUTSCHLAND G.m.b.H.

Halskestr. 7, 47877 Willich, Germany. Phone: 02154-9290 Fax: 02154-929-111 Telex: 8531981 TOPC D

TOPCON ESPAÑA S.A.

HEAD OFFICE:Frederic Mompou 5, 08960 Sant Just Desvern Barcelona, Spain. Phone: 03-4734057 Fax: 03-4733932

MADRID OFFICE:Avenida Ciudad de Barcelona 81, 1 Planta 28007, Madrid, Spain. Phone: 01-552-4160 Fax: 01-552-4161

TOPCON SCANDINAVIA A. B.

Industrivägen 4 P. O. Box 2140 43302 Sävedalen Sweden. Phone: 031-261250 Fax: 031-268607

TOPCON (GREAT BRITAIN) LTD.

Topcon House,Kennet Side,Bone Lane,Newbury,Berkshire RG14 5PX United Kingdom Phone:01635-551120 Fax:01635-551170

TOPCON SINGAPORE PTE. LTD.

Alexandra Distripark Block 4, #05-15, Pasir Panjang Road, Singapore 118491 Phone: 2780222 Fax: 2733540 Telex: 61121 TOPSIN

TOPCON INSTRUMENTS (MALAYSIA) SDN. BHD.

Lot 226 Jalan Negara 2, Pusat Bandar Taman Melawati, Taman Melawati, 53100, Kuala Lumpur, Malaysia. Phone: 03-4079801 Fax: 03-4079796

TOPCON INSTRUMENTS (THAILAND) CO., LTD.

77/162 Sinn Sathorn Tower, 37th Fl.,Krungdhonburi Rd.,Klongtonsai, Klongsarn, Bangkok 10600 Phone: 662-440-1152~7 Fax: 662-440-1158

TOPCON AUSTRALIA PTY. LTD.

408 Victoria Road, Gladesville, NSW 2111, Australia Phone: 02-9817-4666 Fax: 02-9817-4654

TOPCON KOREA CORPORATION

Hyobong Bldg., 1-1306, Seocho-Dong, Seocho-Gu, Seoul, Korea. Phone: 02-557-9231~2 Fax: 02-556-1928 Telex: K23231 EXT2264

TOPCON OPTICAL (H.K.) LIMITED

2-4/F Meeco Industrial Bldg, No. 53-55 Au Pui Wan Street, Fo Tan Road,Shatin, N.T., Hong Kong Phone: 26901328 Fax: 26910264

TOPCON CORPORATION BEIJING OFFICE

Room No. 962 Poly Plaza Building, 14 Dongzhimen Nandajie Dongcheng District, Beijing, 100027, China Phone: 10-6501-4191~2 Fax: 10-6501-4190

TOPCON CORPORATION BEIRUT OFFICE

P. O. BOX 70-1002 Antelias, BEIRUT-LEBANON. Phone: 961-1-521119 Fax: 961-1-521119

TOPCON CORPORATION DUBAI OFFICE

Office No.102, KHALAF RASHD AL NAYLI BLDG., Deira, Dubai, UAE Phone: 971-4-696511 Fax: 971-4-695272

TOPCON CORPORATION

75-1 Hasunuma-cho,Itabashi-ku,Tokyo,174-8580 Japan

Phone:3-3558-2520 Fax:3-3960-4214

Loading...

Loading...