Page 1

X20 Sprayer Reference Manual

Part Number A2677

Rev. 1.5

© Copyright Topcon Precision Agriculture

March, 2008

All contents in this manual are copyrighted by Topcon. All rights

reserved. The information contained herein may not be used, accessed,

copied, stored, displayed, sold, modied, published or distributed, or

otherwise reproduced without express written consent from Topcon.

Page 2

Page 3

X20 Sprayer Reference Manual

Table of Contents

Preface............................................................................ 1-1

Terms and Conditions.................................................................. 1-1

Manual Conventions ................................................................... 1-6

Chapter 2

Introduction .................................................................... 2-1

Chapter 3

Using This Manual ......................................................... 3-1

First Time Users .................................................................................. 3-1

Operators Who Are Upgrading Their Software .................................. 3-1

Chapter 4

Before Installing or Servicing Your Spray ECU .......... 4-1

Testing Procedure ................................................................................ 4-2

Testing Procedure For Installations With No Existing Switchbox

(switches on existing controller) ................................................. 4-2

Testing Procedure For Installations With Existing Switchbox

(including Joystick Control) ........................................................ 4-3

Chapter 5

Installing the Spray ECU (all models) .......................... 5-1

Installing the Spray ECU 30S ............................................................. 5-2

Installing the Spray ECU 30S Topcon Precision Agriculture Sprayer

Kits ..................................................................................................... 5-4

Installing the Tractor Harness ..................................................... 5-5

Tractor Harness Extras ........................................................... 5-5

Two 37-Pin Connectors...................................................... 5-5

Connector 3 ........................................................................ 5-6

3-Pin Weather Pack Connector/Ground Speed .................. 5-6

A2677 Rev 1.5

i

Page 4

X20 Sprayer Reference Manual

Installing the Sprayer Harness ................................................... 5-8

Sprayer Harness Connectors .............................................. 5-8

Connecting to a Speed Sensor ..................................................5-11

Installing the Shaft/Speed Sensor Kit to an Un-Driven Wheel

for Ground Speed ..............................................................5-11

Installing the Shaft/Speed Sensor Kit to a Tailshaft ........ 5-15

Using an Existing Radar Speed Sensor for Ground

Speed ............................................................................... 5-16

Connecting to a Flow Meter .................................................... 5-17

Connecting to the Regulator Valve .......................................... 5-18

Pressure Sensor Installation and Connection ........................... 5-19

Installing the Valve Harness ..................................................... 5-20

Single Line Install ............................................................... 5-22

Dual Line Install ................................................................. 5-22

Connecting to the Dump Valve........................................... 5-23

Different Valve Types ............................................................... 5-25

Plumbing for Diaphragm Pumps for Topcon Precision Agriculture

Sprayer Kits .............................................................................. 5-26

Plumbing for Centrical Pumps for Topcon Precision Agriculture

Sprayer Kits .............................................................................. 5-27

Installing the Spray ECU 30S Kits to an Existing Topcon Precision

Agriculture Controller ....................................................................... 5-28

Before Removing the Existing Controller ................................. 5-28

Removing the Existing Controller ............................................. 5-28

Installing the Spray ECU 30S Kits ............................................ 5-28

Connecting the Spray ECU to the Battery ........................................ 5-31

Chapter 6

Getting Started ............................................................... 6-1

Warnings ............................................................................................. 6-1

Starting the X20 Console .................................................................... 6-2

Using Spray Controller Only ....................................................... 6-3

Using Spray Controller and Guidance ........................................ 6-3

About Spray Rate Controller Window ................................................ 6-4

ii

www.topconpa.com

Page 5

X20 Sprayer Reference Manual

Registering the Sprayer Software ................................................ 6-5

Overview of the Sprayer Working Screen Functions .......................... 6-6

Chapter 7

Conguration Setup ...................................................... 7-1

Audio Volume ..................................................................................... 7-2

Setting the Audio Volume............................................................ 7-2

Conguration ...................................................................................... 7-2

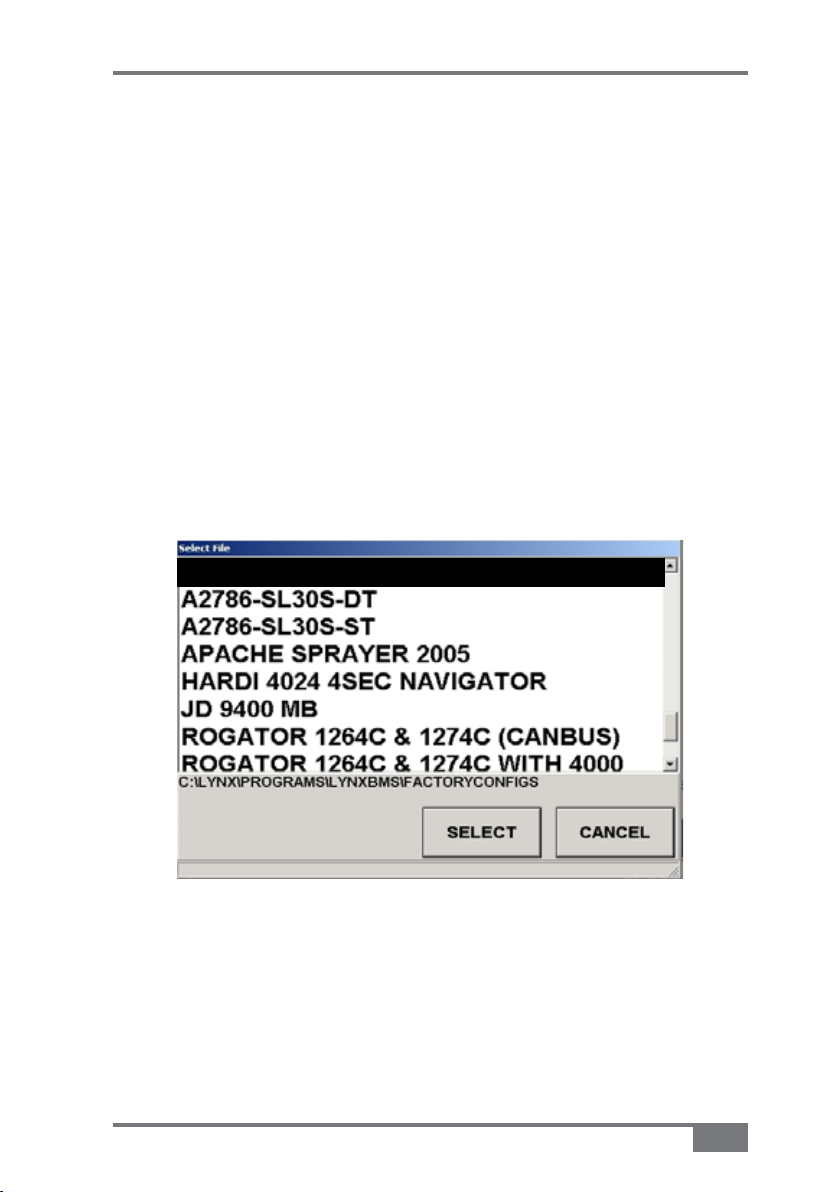

Change Current Conguration .................................................... 7-2

Load Conguration ..................................................................... 7-2

Selecting a Factory Conguration File .................................. 7-3

Setup ................................................................................................... 7-6

Quick Setup Guide ...................................................................... 7-6

Chapter 8

Conguration ................................................................. 8-1

GPS ..................................................................................................... 8-1

Automatic Section Control (ASC) .............................................. 8-1

Variable Rate Control (VRC)/Logging Mode ............................. 8-2

(VRC)/Logging Synchronization ................................................ 8-2

On Time ....................................................................................... 8-3

Off Time ...................................................................................... 8-4

Coverage Map Offset .................................................................. 8-4

Show Virtual Road If Moving ..................................................... 8-4

ASC Master Button ..................................................................... 8-4

VRC Master Button ..................................................................... 8-5

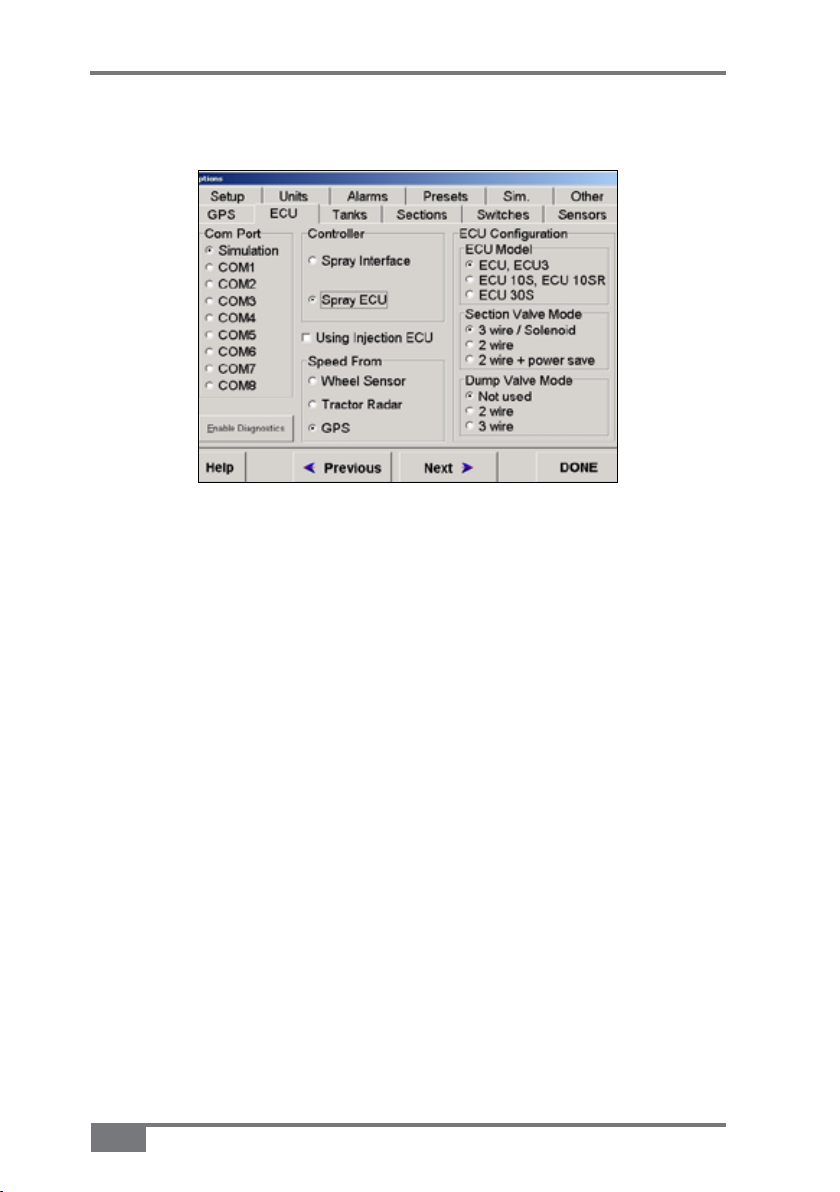

Electronic Control Unit (ECU) ........................................................... 8-6

COM Port .................................................................................... 8-6

Controller .................................................................................... 8-7

Using Injection ECU ................................................................... 8-7

Speed From ................................................................................. 8-8

Spray Interface ....................................................................... 8-8

Spray ECU ............................................................................. 8-9

ECU Conguration (Spray ECU Only) ..................................... 8-10

ECU Model .......................................................................... 8-10

Section Valve Mode ..............................................................8-11

Dump Valve Mode .................................................................... 8-12

A2677 Rev 1.5

iii

Page 6

X20 Sprayer Reference Manual

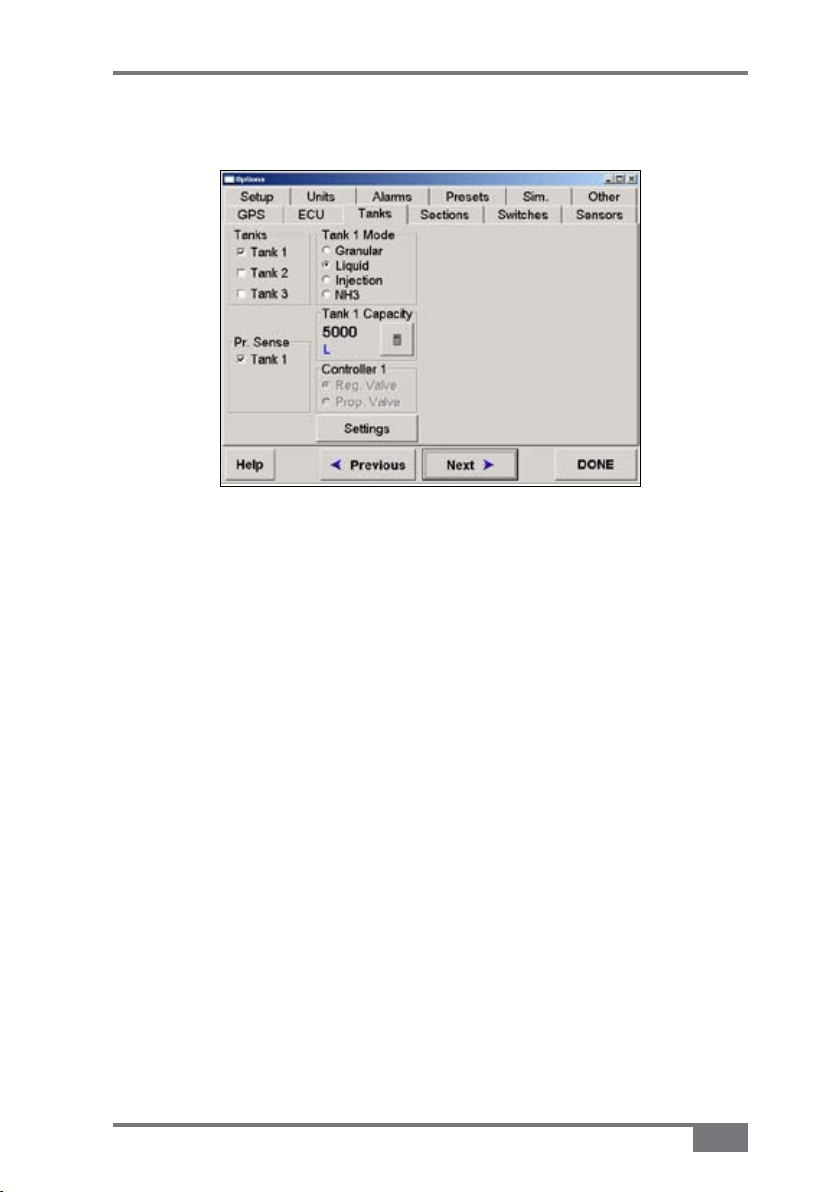

Tanks ................................................................................................. 8-13

Tanks ......................................................................................... 8-13

Tank 1 Mode ............................................................................. 8-14

Controller 1 ............................................................................... 8-14

Pressure (Pr) Sense ................................................................... 8-15

Regulator Valve Settings ........................................................... 8-16

Controller Mode ................................................................. 8-16

Reverse Valve Direction ..................................................... 8-20

Close Valve When Flow Off ............................................... 8-20

Sensitivity ........................................................................... 8-20

Proportional Valve Settings ....................................................... 8-21

Valve Options ..................................................................... 8-21

Min PWM ........................................................................... 8-22

Using High Minimum PWM Range Option ................ 8-22

Max PWM .......................................................................... 8-23

Controller Response ..................................................... 8-24

Sections ............................................................................................. 8-25

Lines .......................................................................................... 8-25

Sections ..................................................................................... 8-26

Setting the Number of Sections When Selecting Dual ....... 8-26

Setting the Number of Sections When Using a Primary

Section Valve to Switch Secondary Line On ...................... 8-27

Widths ....................................................................................... 8-27

Guidance Sections ..................................................................... 8-28

Valves ........................................................................................ 8-28

Nozzles ...................................................................................... 8-28

Total .................................................................................... 8-28

Min. Flow ........................................................................... 8-29

Switches ............................................................................................ 8-30

External Master Switch ............................................................. 8-30

External Auto Switch ................................................................ 8-31

External Section Switch ............................................................ 8-31

Switches (Spray ECU Only) ..................................................... 8-33

Boom Sensing ..................................................................... 8-33

Section Switches ................................................................. 8-34

Switch Mapping ................................................................. 8-34

Custom Section Mapping ................................................... 8-35

iv

www.topconpa.com

Page 7

X20 Sprayer Reference Manual

Use Presets .................................................................. 8-36

Undo ............................................................................ 8-36

OK ............................................................................... 8-36

Cancel .......................................................................... 8-36

Sensors .............................................................................................. 8-37

Pressure ..................................................................................... 8-37

Type ........................................................................................... 8-38

Input Gain .................................................................................. 8-38

Flow ........................................................................................... 8-38

Calibration Factor ............................................................... 8-39

Minimum Flow ................................................................... 8-40

Mico-Track Flow Sensor .................................................... 8-41

Sensors (Spray ECU Only) ....................................................... 8-42

Pressure .............................................................................. 8-42

Calibration Method ..................................................... 8-43

Sensor Specications .................................................. 8-44

Current .................................................................. 8-44

Voltage .................................................................. 8-45

Setup ................................................................................................. 8-46

Wheel Factor ............................................................................. 8-46

Manual Entry ...................................................................... 8-47

Calibrate ............................................................................. 8-47

Distance Check ................................................................... 8-48

Low Speed Options ................................................................... 8-49

Low Speed Shutoffs ........................................................... 8-49

Low Pressure Hold ............................................................. 8-50

Pressure Boost .................................................................... 8-51

Pump Options ............................................................................ 8-52

Enable Speed Smoothing .......................................................... 8-52

Setup (Spray ECU Only) ........................................................... 8-53

Enable Pump Control Button ............................................. 8-53

Holding Pressure ................................................................ 8-54

Units .................................................................................................. 8-55

Quick Set ................................................................................... 8-56

Lock NH3 Calibration Factor at Pulse per 1b ........................... 8-56

Alarms ............................................................................................... 8-57

A2677 Rev 1.5

v

Page 8

X20 Sprayer Reference Manual

Selecting the Alarm ................................................................... 8-58

Alarm Type ............................................................................... 8-58

Audio Alarm .............................................................................. 8-58

Select Tank ................................................................................ 8-59

Setting Alarms ........................................................................... 8-59

Tank Low Alarm % ................................................................... 8-60

Test Tank ................................................................................... 8-60

Defaults ..................................................................................... 8-60

Presets ............................................................................................... 8-62

Change Preset List ..................................................................... 8-62

Backup Preset List ..................................................................... 8-64

Simulation ......................................................................................... 8-65

Other ................................................................................................. 8-66

Language ................................................................................... 8-66

Effects ........................................................................................ 8-66

Chapter 9

Saving the Sprayer Conguration ............................... 9-1

Changing the Sprayer Settings of the Current Conguration ............. 9-3

New File Name ........................................................................... 9-5

Overwrite Existing File ............................................................... 9-5

Chapter 10

Setting Up the Sprayer ................................................ 10-1

Pressure Sensor ................................................................................. 10-1

Alarms ...................................................................................... 10-2

High Pressure....................................................................... 10-2

Low Pressure ....................................................................... 10-2

Calibrating the Pressure Sensor ................................................ 10-3

Correction Factor After a Pressure Calibration is

Unacceptable ....................................................................... 10-4

Manual Entry of Pressure Calibration Factors (Spray ECU

Only) ......................................................................................... 10-4

Flow .................................................................................................. 10-6

Speed ................................................................................................. 10-8

Area/Volume ................................................................................... 10-10

vi

www.topconpa.com

Page 9

X20 Sprayer Reference Manual

Tank Setup ...................................................................................... 10-13

Filling the Tank ....................................................................... 10-15

Flow Meter Setup ............................................................................ 10-17

Calibrating the Flow Meter ..................................................... 10-17

Flow Calibration for Balanced (Hardi) Valves ........................ 10-19

Enable Lockout ............................................................................... 10-21

Disable Lockout .............................................................................. 10-22

Sprayer Switchbox .......................................................................... 10-23

Chapter 11

Start Spraying ...............................................................11-1

Simulate Spraying ..............................................................................11-1

Start Spraying .....................................................................................11-3

Spraying in Manual Mode .........................................................11-4

Spraying in Auto Mode..............................................................11-4

While Spraying ..................................................................................11-5

Guidance and Spray Rate Control ......................................................11-6

Automatic Section Control (ASC) .............................................11-8

Chapter 12

Testing .......................................................................... 12-1

Regulator ........................................................................................... 12-1

Regulator Drive Test Procedure ............................................... 12-2

Switched Power ................................................................................ 12-3

Switched Power Test ................................................................ 12-3

Dump................................................................................................. 12-4

Dump Drive Test ...................................................................... 12-4

Topcon Sensors ................................................................................. 12-5

Sensor Input Test ...................................................................... 12-5

3 Wire Section Valves ....................................................................... 12-7

Section Valve Drive Test .......................................................... 12-7

Switch Master Switch ON ........................................................ 12-7

PWM Regulator Valve ...................................................................... 12-8

Prop Output Test ....................................................................... 12-8

A2677 Rev 1.5

vii

Page 10

X20 Sprayer Reference Manual

Chapter 13

Sprayer Components Spare Parts List ...................... 13-1

In Cab ................................................................................................ 13-1

Ground Speed/Shaft Sensor .............................................................. 13-2

Flow Sensors ..................................................................................... 13-2

Pressure ............................................................................................. 13-2

Dump Valve Adaptors (to suit Sprayer Harness) .............................. 13-3

Spares ................................................................................................ 13-3

Chapter 14

Specications .............................................................. 14-1

Console ............................................................................................. 14-1

Ground Speed, Fan Speed and Auxiliary Shaft Sensors ................... 14-2

Flow Sensors ..................................................................................... 14-2

Polmac (Broadacre) .......................................................................... 14-3

Orion (Broadacre) ............................................................................. 14-3

Pressure Transducer .......................................................................... 14-3

Chapter 15

Spray ECU 30S............................................................. 15-1

Console ............................................................................................. 15-1

Setup ................................................................................................. 15-2

Wiring Connection ............................................................................ 15-2

Connector 1 ............................................................................... 15-3

Connector 2 ............................................................................... 15-5

Connector 3 ............................................................................... 15-7

Connector 4 ............................................................................... 15-8

Chapter 16

Hardi 5500 Spray ECU ................................................. 16-1

Console ............................................................................................. 16-1

Connecting ........................................................................................ 16-2

Setup ................................................................................................. 16-2

Wiring Connection ............................................................................ 16-3

Connector 1 ............................................................................... 16-3

viii

www.topconpa.com

Page 11

X20 Sprayer Reference Manual

Connector 4 ............................................................................... 16-6

Connector 5 ............................................................................... 16-7

Chapter 17

Service Bulletins.......................................................... 17-1

Pressure Relief .................................................................................. 17-1

Fitting ........................................................................................ 17-1

Sprayer Software Settings ................................................................. 17-3

Setting the Pressure Relief ................................................................ 17-3

Chapter 18

Troubleshooting .......................................................... 18-1

Communication ................................................................................. 18-1

Speed ................................................................................................. 18-2

Boom Sections .................................................................................. 18-3

Rate and Pressure .............................................................................. 18-6

Control .............................................................................................. 18-9

Volumes ............................................................................................. 18-9

Nozzles ............................................................................................ 18-10

Alarms ............................................................................................. 18-10

Additional Data ................................................................................18-11

Appendix A

Options Window ................................................. Appendix

Index

A2677 Rev 1.5

ix

Page 12

X20 Sprayer Reference Manual

Notes:

x

www.topconpa.com

Page 13

X20 Sprayer Reference Manual

NOTICE

Preface

This manual has been developed to provide you with the information

necessary to operate and maintain this Topcon Precision Agriculture

(TPA) product. Proper service and use is important for the safe and

reliable operation of the product. The sections provided in this manual

include information necessary for the safe and correct operation, care,

and troubleshooting of this product. The benets this product provides

can be greatly inuenced by your knowledge of the products described

in this manual.

NOTICE

Please read these Terms and Conditions carefully.

Terms and Conditions

General

APPLICATION - You accept these Terms and Conditions by

purchasing the product from Topcon Precision Agriculture (TPA)

or from one of TPA’s product dealers.

COPYRIGHT - All information contained in this manual is the

intellectual property of, and copyrighted material of TPA. All

rights are reserved. You may not use, access, copy, store, display,

create derivative works of, sell, modify, publish, distribute, or allow any third parties access to, any graphics, content, information

or data in this manual without TPA’s express written consent and

may only use such information for the care and operation of your

product. The information and data in this manual are a valuable

asset of TPA and are developed by the expenditure of considerable work, time and money, and are the result or original

selection, coordination and arrangement by TPA.

A2677 Rev 1.5

1-1

Page 14

X20 Sprayer Reference Manual

TRADEMARKS – ZYNX, PRO STEER, EAGLE, KEE Technologies, Topcon, Topcon Positioning Systems and Topcon Precision Agriculture are trademarks or registered trademarks of the

Topcon Group of companies. Microsoft and Windows are trademarks or registered trademarks in the United States and/or other

countries of Microsoft Corporation. Product and company names

mentioned herein may be trademarks of their respective owners.

WEBSITE and OTHER STATEMENTS - No statement contained at the website of TPA or any other Topcon Group company

or in any other advertisements or TPA literature or made by an

employee or independent contractor of TPA modies these Terms

and Conditions (Including the software licence, warranty and

limitation of liability).

IMPORTANT: SAFETY - Improper use of the product can lead

to death or injury to persons, damage to property and/or malfunction of the product. The product should only be repaired by

authorized TPA service centres. You should closely review the

safety warnings and directions as to the proper use of the product

in this manual and at all times comply with the same.

Limited Warranty

ELECTRONIC and MECHANICAL COMPONENTS -TPA

warrants that the electronic components manufactured by TPA

shall be free of defects in materials and workmanship for a period

of one year from the original date of shipment to the dealer. TPA

warrants that all valves, hoses, cables and mechanical parts manufactured by TPA shall be free of defects in materials and

workmanship for a period of 12 months from the date of sale.

RETURN and REPAIR - During the respective warranty periods, any of the above items found defective may be shipped to

TPA for repair. TPA will promptly repair the defective item at no

charge, and ship it back to you. You must pay the shipping and

1-2

www.topconpa.com

Page 15

X20 Sprayer Reference Manual

handling charges in respect of the same. Calibration or compo-

nents, labour and travel expenses incurred for in-eld removal

and replacement of components are not covered in this warranty

policy. Damage to components due to negligence, abuse or im-

proper use, maintenance, modication or repair is NOT covered

under this warranty.

WARRANTY DISCLAIMER - Other than for the above warranties or warranties in an appendix or a warranty card accompanying the product, this manual and the product are provided ‘as

is’. There are no other warranties and to the extent allowed by

law TPA excludes all implied terms, conditions and warranties

in respect of the manual and the product (including any implied

warranty or merchantability or tness for any particular use or

purpose).

LIABILITY LIMIT and INDEMNITY - TPA and its dealers,

agents and representatives shall not be liable for technical or editorial errors or omissions contained herein or for special, indirect,

economic, incidental or consequential damages resulting from

the furnishing, performance or use of this material or the product

(including where TPA has been advised of the possibility of such

damage). Such disclaimed damages include but are not limited to

loss of time, loss or destruction of data, loss of prot, savings or

revenue or loss of or damage to the product. In addition, TPA is

not responsible or liable for damages or costs incurred in connection with obtaining substitute products or software, claims by

others, inconvenience, or any other costs.

In any event, TPA’s liability to you or any other person for any

claim, loss or damage (in contract, tort or on any other basis) will

be limited (in TPA’s option) to either (a) the replacement or repair

of the product, or (b) payment of the cost of replacing or repairing the product. You indemnify and hold TPA harmless against

any claim, action, damage, loss, liability or cost (including legal

fees) which TPA incurs arising from (a) your operation, use and/

or maintenance of the product other that in accordance with the

A2677 Rev 1.5

1-3

Page 16

X20 Sprayer Reference Manual

terms set out in this manual, or (b) your negligence or wrongful

act or omission in respect of the product.

Other

These Terms and Conditions may be amended, modied, superseded or cancelled, at any time by TPA. These Terms and Conditions will be governed by, and construed in accordance with:

- the laws of South Australia if the product is sold and supplied

to you in Australia (in which case the courts of South Australia or

the Federal Court of Australia (Adelaide Registry) have exclusive

jurisdiction in respect of any claim or dispute); or

- the laws of the State of California if the product is sold and supplied to you outside of Australia.

All information, illustrations, and applications contained herein

are based on the latest available information at the time of publication. TPA reserves the right to make product changes at any

time without notice.

If any part of these Terms and Conditions would be unenforceable, the provision must be read down to the extent necessary

to avoid that result, and if the provision cannot be read down to

that extent, it must be severed without affecting the validity and

enforceability of the remainder of these Terms and Conditions.

Comments, suggestions, and questions about TPA products are

welcomed. Contact your local TPA representative or a representative at our corporate facility.

Topcon Precision Agriculture

14 Park Way

Mawson Lakes, South Australia 5095.

Phone: +61 8 8203 3300

Fax: +61 8 8203 3399

A2677 Rev 1.5

1-4

Page 17

X20 Sprayer Reference Manual

Service Information

Service assistance can be provided by contacting your local TPA

Authorized Dealer or by calling the Topcon Precision Agriculture

Service Centre.

Phone: +61 8 8203 3300

Fax: +61 8 8203 3399

8.30am to 5pm (Adelaide Local Time), Monday through Friday.

A2677 Rev 1.5

1-5

Page 18

X20 Sprayer Reference Manual

TIP

NOTICE

CAUTION

WARNING

DANGER

Manual Conventions

This Manual uses the following conventions:

File>Exit ~ Click/tap/press the File menu, then click/tap/press Exit.

Enter ~ Click/tap/press the button or key labelled Enter.

Supplementary information that can help you congure,

maintain, or set up a system.

Supplementary information that can have an effect on

system operation, system performance, measurements

& personal safety.

Notication that an action has the potential to

adversely effect system operation, system

performance, data integrity, or personal health.

Notication that an action will result in systems

damage, loss of data, loss of warranty, or personal

injury.

UNDER NO CIRCUMSTANCES SHOULD THIS

ACTION BE PERFORMED.

1-6

www.topconpa.com

Page 19

X20 Sprayer Reference Manual

Introduction

The Spray Electronic Control Unit (ECU) is a new generation Spray

Controller, which is used in conjunction with the Topcon Precision

Agriculture X20 (or X15) console. The X20 console is the graphical

interface of the Spray ECU controller. The Spray ECU replaces the

Spray Rate Interface.

The Spray ECU can control up to 30 section valves (3 wire), and

allows Automatic Section Control (ASC) of the 30 section valves (the

X15 console can control up 15 sections under ASC). The Spray ECU

can control up to 2 liquid tanks directly. If the Spray ECU is used in

conjunction with a Multi-Drive Electronic Control (MDECU) unit, it

can control up to 3 liquid injection tanks.

The Spray ECU can handle Boom Sensing inputs, therefore it can be

connected to existing Remote switches. The Spray ECU also has a

new feature called Section Mapping, which allows one section switch

to control a number of section valves. Therefore the existing Topcon

Precision Agriculture Switchbox or remote switches (usually 6 or 8

switches) can control all 30 section valves, when they are controlled

manually. The X20 Sprayer software sets up the section mapping to

allow the six switches to control the 30 section valves. The ASC still

controls all 30 section valves individually.

The Spray ECU can control Regulator or Proportional type Control

Valves. The Spray ECU can control 3 Wire, 2 Wire (reverse polarity)

or Solenoid type Section Valves.

A2677 Rev 1.5

2-1

Page 20

X20 Sprayer Reference Manual

Notes:

2-2

www.topconpa.com

Page 21

X20 Sprayer Reference Manual

Using This Manual

This manual is written for:

First time users of this Spray ECU •

Operators who are upgrading their existing Sprayer software to •

a later version and their Spray Rate Interface or Spray ECU is

already installed.

First Time Users

First time users of Topcon Precision Agriculture’s Spray ECU must

read all chapters.

Operators Who Are Upgrading Their Software

Operators who are upgrading their existing Topcon Precision

Agriculture Sprayer software must read Chapter 4.

After reading Chapter 4, upgrading operators may then go to

Chapter 7, "Configuration Setup".

A2677 Rev 1.5

3-1

Page 22

X20 Sprayer Reference Manual

Notes:

3-2

www.topconpa.com

Page 23

X20 Sprayer Reference Manual

WARNING

TIP

WARNING

Before Installing or

Servicing Your Spray ECU

You must follow the procedures in this chapter to ensure your safety

while installing or servicing your Spray ECU.

WARNING

Damage will occur if any external power is

applied to the Section Drive Outputs on the

Spray ECU.

TIP

Follow the procedures carefully, to ensure that no

damage is done.

WARNING

Disconnect both the X20 console and Spray

ECU controller from the battery before charging,

jump starting or welding on the vehicle and/or

Sprayer.

A2677 Rev 1.5

4-1

Page 24

X20 Sprayer Reference Manual

WARNING

WARNING

Testing Procedure

WARNING

Before commencing testing procedure

disconnect the existing tractor harness from the

existing controller.

You must complete one of two testing procedures, before upgrading

your software.

Make sure you choose the testing procedure that is applicable to your

product.

Testing Procedure For Installations With No

Existing Switchbox (switches on existing

controller)

On existing tractor harness, turn the ignition on 1.

4-2

Check each Section Drive Output pin for voltage (refer to 2.

manufacturer manual of existing tractor harness for pin

details)

Locate where voltage is supplied, to determine if it can be 3.

removed without limiting existing functionality

WARNING

If it is not possible to remove this voltage, then

you must install a Section Drive Output Protection

Adaptor (A2812 for 37-pin on Connector 1 and

A2813 for 16-pin on Connector 3).

www.topconpa.com

Page 25

X20 Sprayer Reference Manual

WARNING

When no voltage is found, disconnect the vehicle’s battery 4.

before continuing with installation.

Testing Procedure for Installations With Existing

Switchbox (including Joystick Control):

Determine whether it is possible to disconnect the existing 1.

Switchbox without limiting existing functionality, eg: Boom,

Lift, Lower or Fold

WARNING

If it is not possible to remove the existing

Switchbox, without limiting functionality and

voltage is present, then you must install a Section

Drive Output Protection Adaptor (A2812 for 37-pin

on Connector 1 and A2813 for 16-pin on Connector

If it is possible to disconnect the existing Switchbox without 2.

limiting existing functionality disconnect the Switchbox

On existing tractor harness, turn the ignition on 3.

Check each Section Drive Output pin for voltage 4.

(refer to manufacturer manual of existing tractor

harness for pin details)

When no voltage is found, disconnect the vehicle’s 5.

battery before continuing with installation.

A2677 Rev 1.5

4-3

Page 26

X20 Sprayer Reference Manual

WARNING

WARNING

The vehicle battery must be disconnected before

proceeding with any installation or servicing of the

Spray ECU, Tractor, Sprayer or Valve Harnesses.

4-4

www.topconpa.com

Page 27

X20 Sprayer Reference Manual

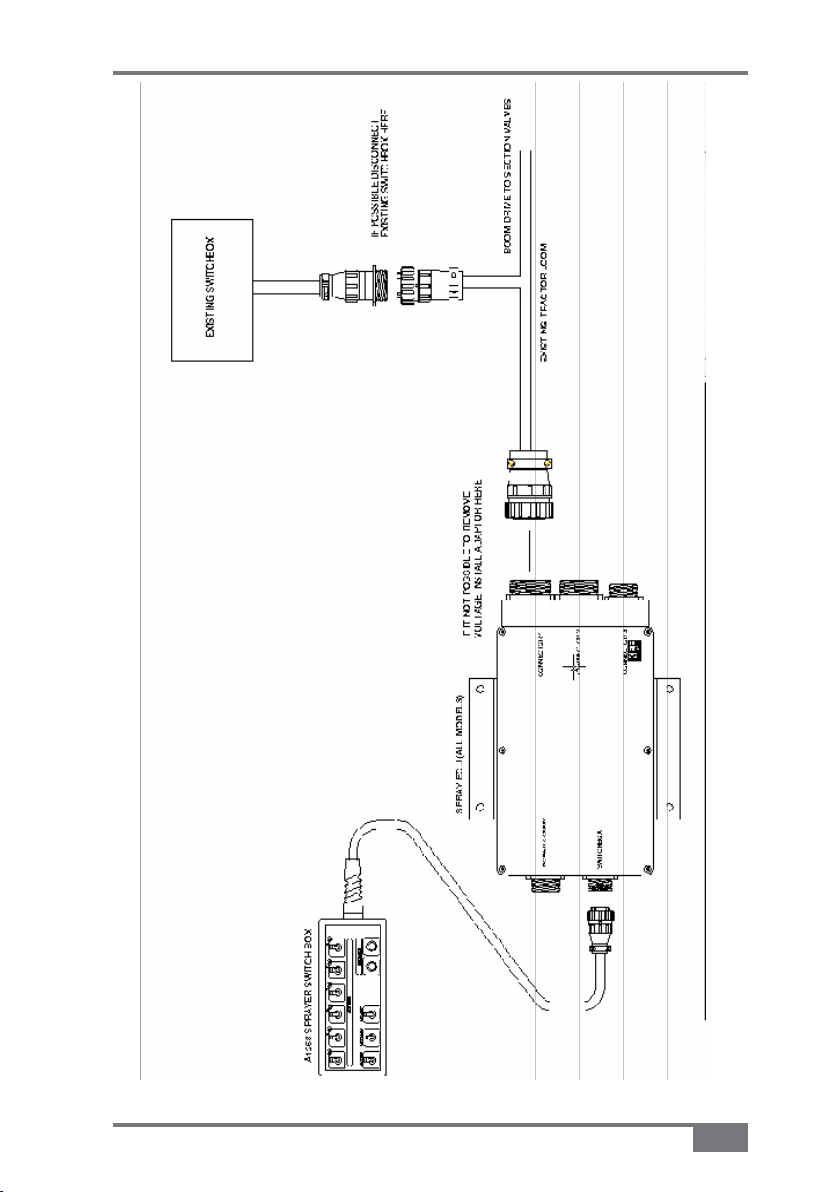

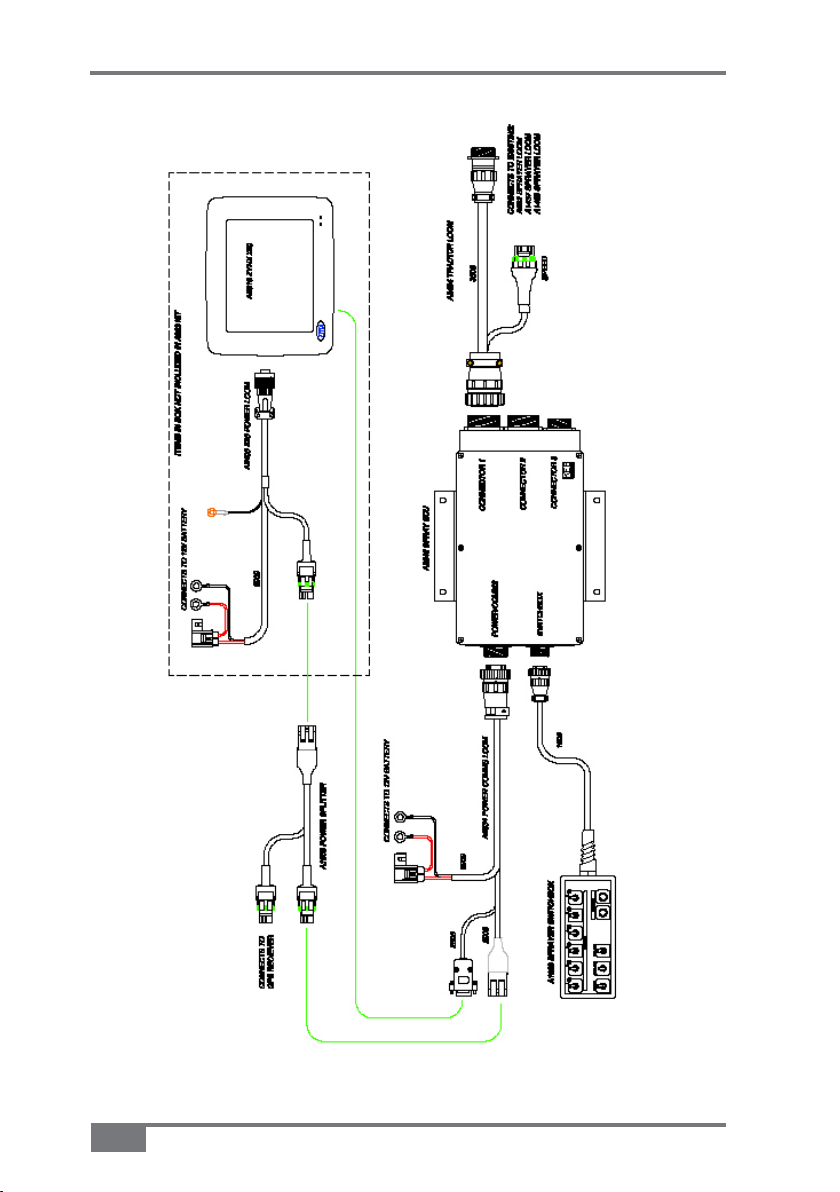

Figure 4-1. Connecting the Spray ECU to Existing Installations

A2677 Rev 1.5

4-5

Page 28

X20 Sprayer Reference Manual

Notes:

4-6

www.topconpa.com

Page 29

X20 Sprayer Reference Manual

WARNING

TIP

WARNING

Installing the Spray ECU

(all models)

This chapter is for first time operators of the Sprayer software. If you

are an operator who is installing upgrades to your existing software

(Spray Rate Interface or Spray ECU is already installed) please ensure

you have read Chapter 4, and then continue to Chapter 7.

WARNING

Damage will occur if any external power is

applied to the Section Drive Outputs on the

Sprayer ECU.

TIP

Follow the following procedures carefully, to ensure

that no damage is done.

WARNING

Disconnect both the X20 console and Spray ECU

controller, from the battery, before charging,

jump starting or welding on the vehicle and/or

Sprayer.

A2677 Rev 1.5

5-1

Page 30

X20 Sprayer Reference Manual

TIP

Installing the Spray ECU 30S

Figure 5-1. Spray ECU 30S Figure 5-2. Sprayer

TIP

When mounting the Spray ECU, it is important that

the Spray ECU itself, and its connectors cannot be

accidentally damaged by moving objects.

Switchbox

1. Mount the Spray ECU (Figure 5-1), in a suitable position inside

the cab.

The Spray ECU can be mounted in any orientation.

Figure 5-3 on page 5-7 shows the in cab assembly showing Spray

ECU, Switchbox, Power Comms and Tractor Harness.

5-2

www.topconpa.com

Page 31

X20 Sprayer Reference Manual

WARNING

NOTICE

TIP

Connect the 2. Power Comms harness to the Spray ECU and route

the red and black wires to a 12 Volt battery

WARNING

Do not connect the Power Comms harness to the

battery until the installation is complete.

NOTICE

Use the cable ties provided to secure the Power

Comms Harness away from hot and moving parts,

and to avoid chaffing and wear.

Plug the 3. Switched Power connector that is located on the Power

Comms Harness, into the Switched Power connector on the X20

Power Cable

TIP

If this connection is already being used, connect it

via the A1953 Power Splitter Harness.

This connection ensures that the Spray ECU is only powered up

when the X20 console is switched ON.

Connect the end of the Power Comms Harness, that has a 4. DB

9-Pin to the next available COM Port on the back of the X20

console

Connect the other end of the Power Comms Harness to the 5.

16-Pin connector marked POWER/COMMS on the Spray ECU

A2677 Rev 1.5

5-3

Page 32

X20 Sprayer Reference Manual

TIP

6. Connect the Sprayer Switchbox (Figure 5-2 on page

5-2), to the 9-Pin connector, marked SWITCHBOX on the

Spray ECU.

Mount the Sprayer Switchbox, using the double-sided tape

supplied (or other suitable means).

TIP

Mount the Sprayer Switchbox in a position which is

easily accessible while spraying.

Installing the Spray ECU 30S Topcon Precision

Agriculture Sprayer Kits

All Topcon Precision Agriculture Sprayer kits come with their

own installation guide, which is specific to each kit. Please use the

installation guide which came with your TPA Sprayer kit.

This section is a general guide for the installation of all Topcon

Precision Agriculture Spray ECU 30S Sprayer kits.

This section will cover:

Installing the • Tractor Harness

Installing the • Sprayer Harness

Installing the • Valve Harness.

5-4

www.topconpa.com

Page 33

X20 Sprayer Reference Manual

WARNING

NOTICE

Installing the Tractor Harness

Figure 5-3 on page 5-7 shows the in cab assembly showing Spray

ECU, Switchbox, Power Comms and Tractor Harness.

Connect the Tractor Harness to the 37-Pin connector marked 1.

CONNECTOR 1 on the Spray ECU

Run the Tractor Harness from the Spray ECU to the drawBar 2.

or the back of the vehicle.

NOTICE

Ensure that the Tractor Harness is tied away from

moving, hot and sharp objects.

WARNING

Do not cut or splice the Tractor Harness, all

excess cable should be strapped away to avoid

vibration and wear.

Tractor Harness Extras

Two 37-Pin Connectors

If your Tractor Harness has two 37-Pin connectors you

would have (in step 1) connected the male pin, marked

CONNECTOR 1 to the plug marked CONNECTOR 1 on the

Spray ECU.

You will also have to plug the other 37-Pin connector

(female pins), marked CONNECTOR 2 to the plug marked

CONNECTOR 2 on the Spray ECU.

A2677 Rev 1.5

5-5

Page 34

X20 Sprayer Reference Manual

NOTICE

Please note: As a general rule the CONNECTOR 2 plug is

only required if the Sprayer:

Has more than 10 Boom Sections •

Has more than 2 tanks •

Is connecting to external switches which control the •

Boom Sections (boom sensing), eg: Boom Section

switches on a T Bar or Joy Stick or other third party

section switches.

Connector 3

Normally CONNECTOR 3 (16 pin) is only required if the

Sprayer requires extra pressure inputs, tank level sensors and

extra encoder inputs.

3-Pin Weather Pack Connector/Ground Speed

5-6

The Tractor Harness has a 3-Pin Weather Pack connector

labelled ‘Ground Speed’.

Either an A328 Shaft/Speed Sensor Kit or A449 Radar Sensor

Interface Harness (not included in this kit) can be connected

to this connector.

Typically, the Radar Sensor Interface Harness would be

connected to the Tractor Harness Ground Speed Connector.

NOTICE

Only one speed connector can be used at any one

time.

See "Connecting to a Speed Sensor", page 5-11 for installing

the Shaft/Speed Sensor Kit or Radar Interface Kit.

www.topconpa.com

Page 35

X20 Sprayer Reference Manual

A2677 Rev 1.5

Figure 5-3. General In Cab Assembly

5-7

Page 36

X20 Sprayer Reference Manual

WARNING

Installing the Sprayer Harness

Figure 5-5 on page 5-10 shows the Sprayer Harness and Valve

Harness Assembly.

Connect the connector on the Sprayer Harness to the Tractor 1.

Harness, at the back of the tractor or vehicle

Continue to run the Sprayer Harness across the Sprayer’s 2.

chassis, to the valve set

WARNING

Do not cut or splice the Sprayer Harness; all

excess cable should be strapped away to avoid

vibration and wear.

Sprayer Harness Connectors

The typical Sprayer Harness has 5 connectors (Figure 5-5 on

page 5-10), which are labelled:

• Ground Speed—connects to the Shaft/Speed Sensor Kit

(supplied in kit)

• Flow Meter 1—connects to a Flow Meter (not supplied in

kit)

• Pressure Sensor 1—connects to the Pressure Sensor

(supplied in kit)

• Reg Valve 1—connects to a Regulator Valve (not supplied

in kit)

• Valve Harness—connects to the Valve Harness (supplied in

kit).

5-8

www.topconpa.com

Page 37

X20 Sprayer Reference Manual

TIP

Please note: The Sprayer Harness may have other connectors,

refer to the Sprayer Installation kit that came with your Sprayer

kit for more information.

The Dump Valve connector may be located on the Sprayer

Harness. If the Valve Harness has an Arag Interface box

incorporated into the Valve Harness, then the Dump Valve

connector will be located on the Valve Harness.

Figure 5-4. 3-Pin Weather Pack Sensor

TIP

For testing purposes on all 3-Pin sensor connectors

(Shaft/Speed Sensor and Flow Meter) the voltage on

each pin should be:

See Figure 5-4.

A2677 Rev 1.5

Pin A: +% VDC Signal •

Pin B: Ground •

Pin C: +12VDC Sensor Power •

5-9

Page 38

X20 Sprayer Reference Manual

Figure 5-5. General Sprayer and Valve Harness assembly

5-10

www.topconpa.com

Page 39

X20 Sprayer Reference Manual

NOTICE

NOTICE

Connecting to a Speed Sensor

This installation is used if connecting an A238 Shaft/Speed Sensor

kit (for ground speed) or A449 Radar Sensor Interface Harness

(not supplied in kit) to the Ground Speed Connector on either the

Tractor Harness or Sprayer Harness.

NOTICE

Connect to only one of the Ground Speed

connectors.

Select one of the following:

Installing the Shaft/Speed Sensor kit to an un-driven wheel on •

either the Tractor Harness or Sprayer Harness

Installing the Shaft/Speed Sensor kit to the Tailshaft of a •

vehicle on either the Tractor Harness or the Sprayer Harness

Use an existing Radar Speed sensor for Ground Speed•

Installing the Shaft/Speed Sensor Kit to an

Un-Driven Wheel for Ground Speed

NOTICE

Use of a driven wheel for ground speed may be

subject to “wheel slip” and may not always reflect

true ground speed.

The Shaft/Speed Sensor and Wheel Stud Magnets can be fitted to

any un-driven ground wheel, eg: the front wheel of the tractor or

wheel on a trailing Sprayer.

The magnet activates the sensor as the wheel magnets sweep past

(Figure 5-6 on page 5-12).

A2677 Rev 1.5

5-11

Page 40

X20 Sprayer Reference Manual

TIP

NOTICE

NOTICE

NOTICE

A wheel Calibration Factor of no greater than 0.6m

(24 inches) is required. See Section

1. Glue the magnets to the wheel studs (Figure 5-6), with the

side marked with a plus (+) facing the Shaft/Speed Sensor.

TIP

Use any silicone or epoxy type adhesive to glue the

magnets to the wheel studs. Make sure you leave

adequate time for the glue to set.

NOTICE

Space the magnets equally around the wheel, on

all the available wheel studs (Figure 5-6), to ensure

accurate speed updates.

Figure 5-6. Shaft/Speed Sensor on an Un-Driven Wheel Installation

5-12

www.topconpa.com

Page 41

X20 Sprayer Reference Manual

NOTICE

NOTICE

Mount the Shaft/Speed Sensor to an existing structure on the 2.

wheel axle, ideally in a protected position to face the magnet.

NOTICE

The distance between the Shaft/Speed Sensor to

Wheel Stud Magnet needs to be 2 to 3 mm (1/16 to

1/8 inch). The Shaft/Speed Sensor must be mounted

so that the Wheel Stud Magnets pass the sensor

evenly and squarely.

To mount the Shaft/Speed sensor you can either:

Use the Mounting Bracket Assemblies (slotted brackets •

and angle brackets with hose clamps) provided (Figure

5-7 on page 5-14)

Fabricate your own mounting bracket to suit the •

Sprayer chassis.

NOTICE

There must be no movement of the sensor relative to

the magnet.

A2677 Rev 1.5

5-13

Page 42

X20 Sprayer Reference Manual

NOTICE

NOTICE

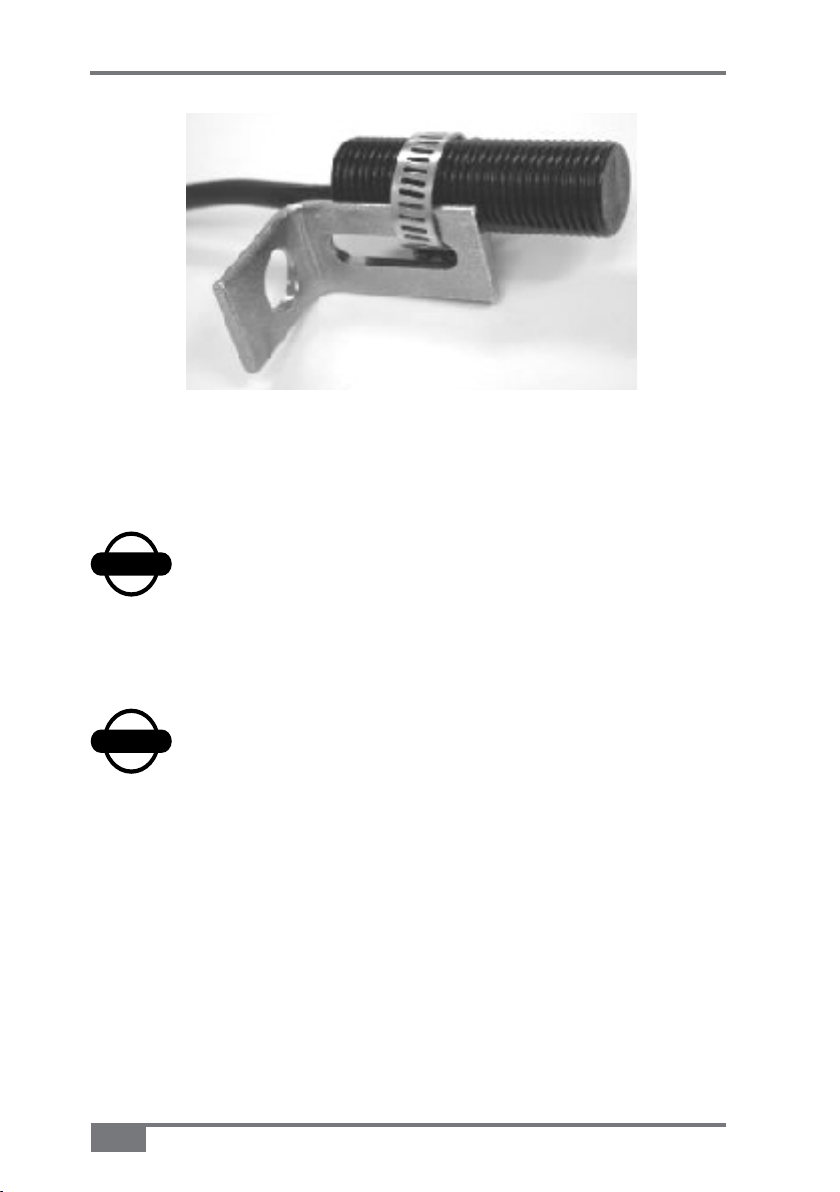

Figure 5-7. Shaft/Speed Sensor with Mounting Bracket

If necessary, protect the Shaft/Speed Sensor and wiring from

damage by welding or bolting a suitable plate over them.

NOTICE

Damage to the front face of the Shaft/Speed Sensor

will stop the speed readout and prevent the controller

from working.

NOTICE

If the Shaft/Speed sensor is mounted on a steered

wheel, then make sure the sensor moves with the

steering mechanism, to maintain constant clearance

between the magnets and the sensor when the wheel

is turning from lock to lock.

If required, use the 3-Pin Weather Pack Extension provided, by

connecting the Shaft/Speed Sensor to either the Ground Speed

connector on the Tractor Harness or Sprayer Harness.

5-14

www.topconpa.com

Page 43

X20 Sprayer Reference Manual

NOTICE

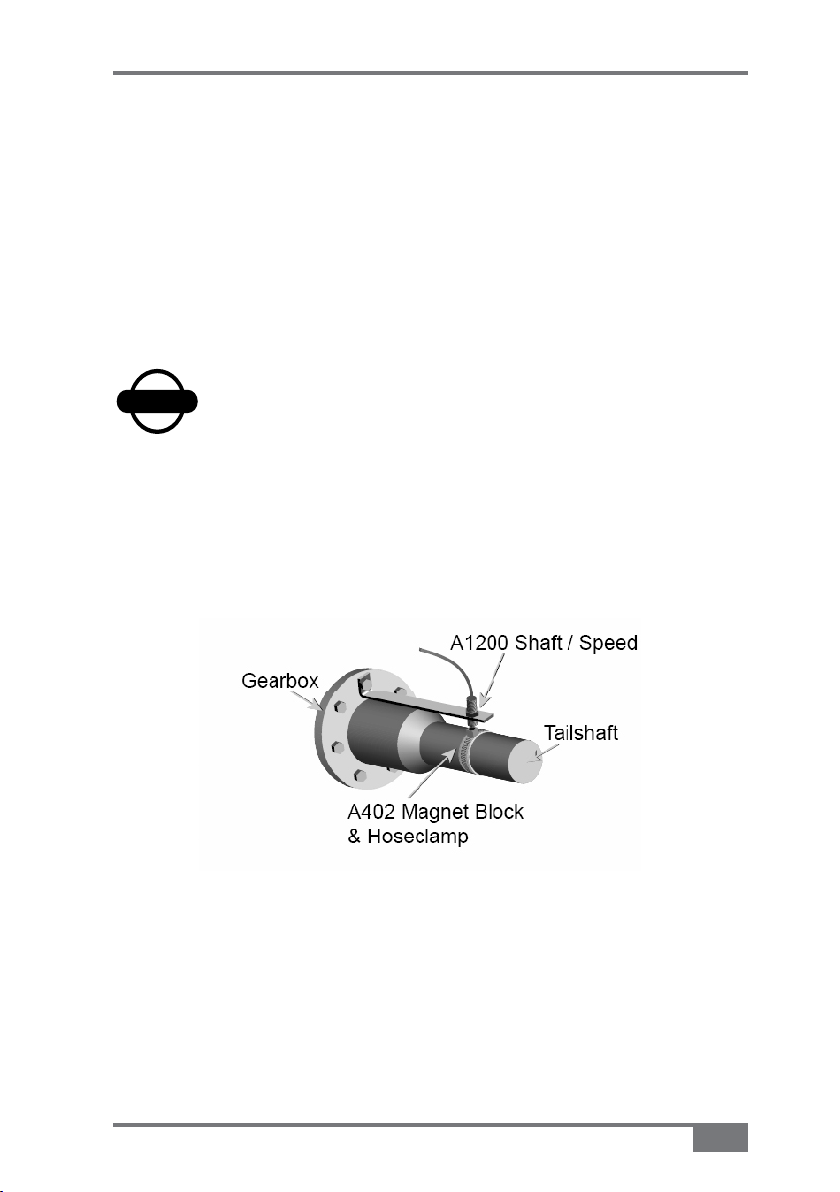

Installing the Shaft/Speed Sensor Kit to a

Tailshaft

On a tray mounted Sprayer the Shaft/Speed Sensor kit can be

used to read from the vehicle Tailshaft (Figure 5-8).

Securely 1. mount the Magnet Block on the flange, between the

Transmission Housing and Tailshaft, using the Hoseclamp or

other suitable means (Figure 5-8)

NOTICE

Do not attach the Magnet Block (Figure 5-8) directly to the

Tailshaft as its position changes, throughout its rotation.

Please note: The wheel stud magnets are not used in this

case.

Figure 5-8. Shaft/Speed Sensor installation to a Tailshaft

Securely mount the Shaft/Speed Sensor so it squarely faces 2.

the Magnet Block with a clearance of 2 to 3mm (1/16 to 1/8

inch), using an existing bolt on the transmission housing and

the supplied Mounting Brackets or other suitable means.

A2677 Rev 1.5

5-15

Page 44

X20 Sprayer Reference Manual

CAUTION

Ensure that the Shaft/Speed Sensor is firmly attached and

protected so that it cannot be damaged by wire or stones. If

necessary cover the Shaft/Speed Sensor with a plate.

If required, use the 3-Pin Weather Pack Extension provided,

by connecting the Shaft/Speed Sensor to either the Ground

Speed connector on the Tractor Harness or Sprayer Harness.

Using an Existing Radar Speed Sensor for

Ground Speed

An optional Radar Sensor Interface Harness (A449−not provided

in kit but can be ordered separately) allows direct connection to

any existing Radar Speed Sensor on the tractor.

Connect the 1. Radar Sensor Interface Harness to the Ground

Speed connector on the Tractor Harness or Sprayer

Harness

Connect the other end of the wire to the signal wire from 2.

the Radar Sensor (not provided in kit) to enable the Spray

ECU to read the speed.

CAUTION

Check the Radar Sensor Manufacturer’s manual

before attempting connection.

If required, use the Extension Harness provided, by connecting the

Radar Sensor to either the Ground Speed connector on the Tractor

Harness or Sprayer Harness.

5-16

www.topconpa.com

Page 45

X20 Sprayer Reference Manual

CAUTION

NOTICE

NOTICE

Connecting to a Flow Meter

The Flow Meter (not supplied in kit) is installed between the

Regulator Valve and the Section Valves. The Flow Meter will

be installed so that it measures only the quantity of liquid being

delivered to the spray line.

NOTICE

There must be no return line to tank or pump after the

Flow Meter.

Connect the Flow Meter 3-Pin Connector to the 3-Pin 1.

connector marked Flow Meter 1 on the Sprayer Harness

(Figure 5-5 on page 5-10)

NOTICE

The Flow Meter may require a connector change to

attach to the 3-Pin connector marked Flow Meter 1 on the

Sprayer Harness. Refer to the Flow Meter manufacturer’s

specifications for correct pin allocation.

CAUTION

Care should be taken when replacing these

connectors, not to damage the Sprayer Harness or

Flow Meter and connectors should be fully circuit

tested prior to installation.

A2677 Rev 1.5

5-17

Page 46

X20 Sprayer Reference Manual

NOTICE

NOTICE

Most Flow Meters have a label on the meter body that shows the

Flow Meter Calibration Factor in pulses/volume. Eg: ‘645 ppl

(pulses per liter)’ or ‘2441 ppg (pulses per gallon)’. This means

the Flow Meter sends 645 pulses to the Spray ECU for every liter

(or 2441 pulses for every gallon) of liquid that passes through

the Flow Meter. This value is the Calibration Factor and will

be required to be entered into the Sprayer software setup (see

“Calibration Factor”, page 8-39).

NOTICE

If connecting to a Raven Flow Meter. The value marked

on the label represents pulses/10 units of liquid. Divide

this number by 10 for the correct value to enter as the

Calibration Factor into the Sprayer software setup.

Connecting to the Regulator Valve

The Regulator Valve (not supplied) is a motorized flow control

valve used to maintain the product flow to the section valves. It

will be situated between the pump and the Flow Meter.

5-18

NOTICE

All bypass or agitation return lines that return to the tank,

must be taken before the Regulating Valve, so there is

no return path after the Regulating Valve and the Flow

Sensor.

Connect the Regulator Valve’s 2-Pin connector to the 2-Pin 1.

connector marked REG Valve 1 on the Sprayer Harness

(Figure 5-5 on page 5-10), using the Regulator Valve Adaptor

Harness (A802) (Figure 5-5 on page 5-10)

www.topconpa.com

Page 47

X20 Sprayer Reference Manual

NOTICE

NOTICE

CAUTION

NOTICE

The Regulator Valve may require a connector change

to attach to the 2-Pin connector marked REG Valve 1

on the Sprayer Harness. Refer to the Regulator Valve

manufacturer’s specifications for correct pin allocation.

CAUTION

Care should be taken, when replacing these

connectors, not to damage the Sprayer Harness or

Regulator Valve and connectors should be fully circuit

tested prior to installation.

When you test the Sprayer with water you may find that the

Regulator Valve works in the opposite direction to what you

require. For example: The pressure increases when it should

decrease. You can set the Reverse Valve Direction in the Sprayer

software setup to remedy this, see “Reverse Valve Direction”, page

8-20.

Pressure Sensor Installation and Connection

1. Mount the Pressure Sensor (A092) (Figure 5-5 on page 5-10)

either upright or horizontally and support the Brass Gauge

saver

The supplied Pressure Sensor is a 5 Bar (72 psi) Pressure

Sensor.

NOTICE

To properly measure Spray Line operating pressure the

Pressure Sensor must be positioned between the Flow

Meter and the Section Valves (Figure 5-5 on page 5-10).

A2677 Rev 1.5

5-19

Page 48

X20 Sprayer Reference Manual

NOTICE

Connect the 2. Pressure Adaptor Harness (H1125) to the

connector labeled Pressure Sensor 1 on the Sprayer Harness

(Figure 5-5 on page 5-10)

Undo the two nuts ontop of the Pressure Sensor 3.

Place the two ring terminals, on the Pressure Adaptor 4.

Harness, onto the terminals on the Pressure Sensor

It does not matter which way around the terminals are

attached to the Pressure Sensor.

Replace the two nuts and tighten the nuts securely.5.

Installing the Valve Harness

Figure 5-5 on page 5-10 shows the Sprayer Harness and Valve

Harness Assembly.

The Valve Harness continues from the connector on the Sprayer

Harness and connects to the Section and Dump Valves on the

Sprayer.

The Valve Harness normally contains connectors for the section

valves, they are either: 3 Wire Section Valves, 2 Wire Section

Valves or Solenoid Valves. See “Different Valve Types”, page

5-25 for an explanation of the different types of Section Valves.

NOTICE

If the Valve Harness has an Arag Interface Box

incorporated into the Harness then the Dump Valve plug

will be on the Valve Harness.

5-20

www.topconpa.com

Page 49

X20 Sprayer Reference Manual

WARNING

NOTICE

The typical Valve Harness has the following connectors, which

are labelled as follows:

• Dump 1—connects to the Dump Valve

• Section X—connects to the Section Valves. ‘X’

represents the section number

• Sprayer Harness—connects to the Sprayer Harness.

There are different Valve Harness’, depending on which type of

Section Valves are fitted on the Sprayer.

WARNING

If the Valve harnesses need to be re-terminated,

because the connectors are different to the section

valves being connected to, then you should

ensure the Sprayer Harness is disconnected from

the Tractor Harness. Otherwise damage to the

Spray ECU will occur if the wires are shorted out

during the installation.

Connect the Valve Harness to the Sprayer Harness. 1.

NOTICE

Use the cable ties provided to secure the

Power/Comms Harness away from hot and moving

parts, and to avoid chaffing and wear.

A2677 Rev 1.5

5-21

Page 50

X20 Sprayer Reference Manual

TIP

TIP

Single Line Install

Connect the connectors marked Section X to the correct 1.

section valves

TIP

If there are too many connectors for the section

valves use the connectors with the lowest

numbers first.

• Section 1— connects to the section valve on the far left

• Section 2—connects to the next section valve, and so

forth, until all the section valves are connected to the

Valve Harness

The section valve with the highest number will operate •

the Boom Section on the far right.

5-22

2. Cable-tie the spare connectors to the Valve Harness.

Dual Line Install

Connect the connectors that operate the primary Spray 1.

Line (Spray A)

TIP

Use the lowest numbers first.

Section 1 will operate the section on the far left of the

spray line (when facing forward) and the highest number

section valve on Line A will operate the far right Boom

Section.

www.topconpa.com

Page 51

X20 Sprayer Reference Manual

WARNING

NOTICE

TIP

WARNING

If the Valve Harness needs the connectors

replaced to suit the valve connectors, then

you should ensure that the Sprayer Harness is

disconnected from the Tractor Harness. Otherwise

damage to the Spray ECU will occur, if the wires

are shorted out during this procedure.

Connecting to the Dump Valve

The Dump Valve (not supplied in kit) is activated when all

sections are switched OFF or when the Master Switch is switched

OFF, this directs all the flow back to the tank.

NOTICE

The Dump Valve must be located between the pump

and Flow Meter.

TIP

If you notice that the Dump Valve is going in the

wrong direction, you have to swap the wires in the

Arag connector.

A2677 Rev 1.5

Connect the ARAG connector labeled 1. Dump 1 to the Dump

Valve

If the Dump Valve connector is on the Sprayer Harness,

then an adaptor will be required to connect the 4-Pin

Weather Pack to the Dump Valve. You must connect the

correct adaptor to the Dump Valve. See Table 5-1 on page

5-24 to determine which adaptor you should use.

5-23

Page 52

X20 Sprayer Reference Manual

Choosing the Correct Adaptor for the Dump Valve

Part No. Usage

Use if connecting to a 2-wire dump valve and 12V

A2266

is applied to the dump valve when the Master switch

is OFF

Use if connecting to a Solenoid Valve, with 6mm

A2267

spade terminals and 12V is applied to the dump

valve when the Master switch is OFF

A2268 Use if connecting to a 3-Wire Dump Valve and 12V

is applied to the Dump Valve when the Master is

OFF

Use when connecting to a 3-Wire Dump Valve and

A2269

12V is applied to the Dump Valve when the Master

is ON

Figure 5-1. How to Choose the Correct Adaptor for the

Dump Valve

When all the Arag connectors are in place, tighten the 2.

screw at the top of the Arag connector, using a screwdriver,

to secure the connector to the Section and Dump Valves

5-24

Tidy any excess harness, using cable ties3.

To complete the installation go to page 5-31, to connect the

Spray ECU Power/Comms Harness to the battery.

www.topconpa.com

Page 53

X20 Sprayer Reference Manual

Different Valve Types

There are three different valve types, which are:

• 2-Wire Valve—this refers to an electric section, dump or

Regulator Valve

The valve is driven by an electric motor that is able to rotate

in both directions. Two wires are connected to this type of

valve from the controller. To rotate the motor 12V is applied

to one of the wires whilst GND is applied to the other. When

opposite voltage is applied to the two wires the motor will

rotate in the opposite direction.

Common terms for this system are Reverse Polarity or

Bi-Directional.

• 3-Wire Valve—this refers to an electric section, dump or

Regulator Valve

The valve is driven by an electric motor that is able to

rotate in both directions. Unlike the 2-wire valve, the 3-wire

valve has in built changeover relays that change the motor

direction, depending on whether 12V or 0V is applied to the

signal wire.

Contsant 12V and GND are required in addition to the signal

wire.

• Solenoid Valve—this refers to electromagnetic coil type

valves.

Solenoid Valves usually consist of a coil, that when exposed

to voltage produces a magnetic field. The magnetic field

draws a needle against a spring away from its seat, to allow

liquid to flow.

A2677 Rev 1.5

5-25

Page 54

X20 Sprayer Reference Manual

Plumbing for Diaphragm Pumps for Topcon

Precision Agriculture Sprayer Kits

Figure 5-9. Plumbing for Diaphragm Pumps for TPA Sprayer Kits

5-26

www.topconpa.com

Page 55

X20 Sprayer Reference Manual

Plumbing for Centrrfical Pumps for Topcon

Precision Agriculture Sprayer Kits

Figure 5-10. Plumbing for Centrical Pumps for TPA Sprayer Kits

A2677 Rev 1.5

5-27

Page 56

X20 Sprayer Reference Manual

Installing the Spray ECU 30S Kits to an Existing

Topcon Precision Agriculture Controller

This section is for users who are replacing an existing Topcon

Precision Agriculture (I.E. KEE) MK3, MK5 Sprayer console or Spray

Rate Interface.

Before Removing the Existing Controller

Ensure that the system is functioning correctly 1.

Run the Sprayer and record the minimum and maximum 2.

pressure and flow rates attainable

Record all of the calibration factors 3.

Record all of the section width values.4.

Removing the Existing Controller

Remove the existing TPA Spray Rate Controller console or 1.

TPA Spray Rate Interface

Remove the existing Tractor Harness. 2.

Installing the Spray ECU 30S Kits

Connect the Tractor Harness to 1. Connector 1 on the Spray

ECU (Figure 5-11 on page 5-30)

The Tractor Adaptor Harness connects to the Spray ECU

and runs the Harness as far as the drawBar of the tractor or

vehicle, where a breakaway is attached so the vehicle can be

easily detached from the trailing Sprayer.

5-28

www.topconpa.com

Page 57

X20 Sprayer Reference Manual

NOTICE

WARNING

WARNING

TIP

NOTICE

Care should be taken when running the Tractor

Harness from the Spray ECU.

Lead the Harness from the Spray ECU to the back of the 2.

vehicle

TIP

Tie cable back, where possible.

WARNING

Do not cut or splice the Sprayer Harness, all

excess cable should be strapped away to avoid

vibration and wear.

Securely mount the 3. Breakaway connector above any hydraulic

outlets, to reduce the risk of oil ingress to the connectors

WARNING

Do not expose the connectors to high pressure

water or oil.

Connect the Tractor Adaptor Harness to the existing Sprayer 4.

Harness.

Refer to the console manual for installing the console to the

vehicle.

To complete the installation go to page 5-31, to connect the

Spray ECU Power/Comms Harness to the battery.

A2677 Rev 1.5

5-29

Page 58

X20 Sprayer Reference Manual

Figure 5-11. General Layout of Spray ECU Connecting to Existing

Topcon Precision Agriculture Sprayer Harness

5-30

www.topconpa.com

Page 59

X20 Sprayer Reference Manual

WARNING

WARNING

CAUTION

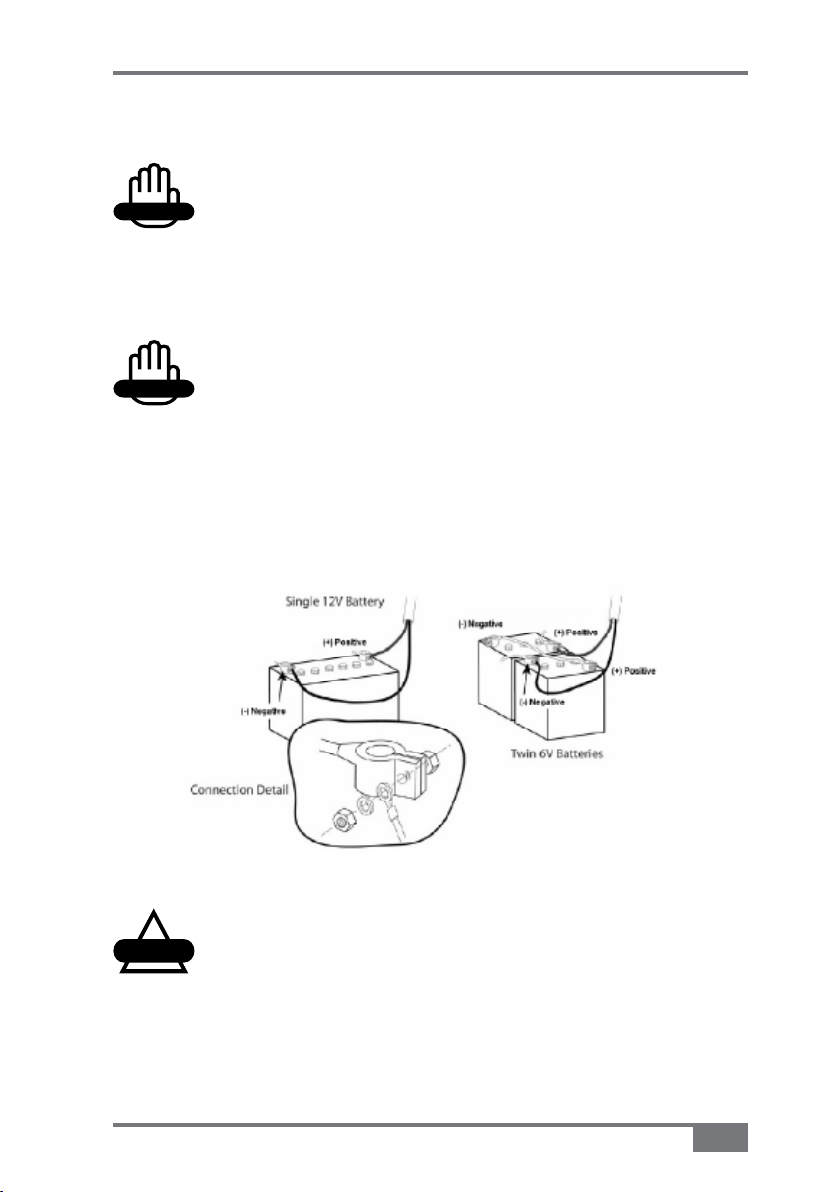

Connecting the Spray ECU to the Battery

WARNING

Do not attach the wires to the battery terminals

until the installation of the Tractor Harness,

Sprayer Harness and Valve Harness is completed.

WARNING

If your tractor uses 24 Volt batteries, you must use

a 12 Volt/15 Amp (minimum) inverter.

Connect the Power/Comms Harness directly to 12 VDC battery 1.

terminals (Figure 5-12)

Figure 5-12. Battery Conguration

CAUTION

Do not connect the Power/Comms Harness to

an alternator or starter motor as this may cause

interference or power fluctuations or surges and

may damage your system.

A2677 Rev 1.5

5-31

Page 60

X20 Sprayer Reference Manual

WARNING

WARNING

CAUTION

Attach the red wire to the positive (+) battery terminal (Figure 2.

5-12)

WARNING

Do not connect the black wire to the vehicle

chassis unless an Isolation Switch is fitted to the

negative side of the battery.

Attach the black wire to the negative (-) battery terminal (Figure 3.

5-12)

WARNING

Except for other Topcon Precision Agriculture

products do not power other equipment from the

power cable.

5-32

CAUTION

Connection to the battery terminals must be kept

clean and tight at all times.

www.topconpa.com

Page 61

X20 Sprayer Reference Manual

Getting Started

Warnings

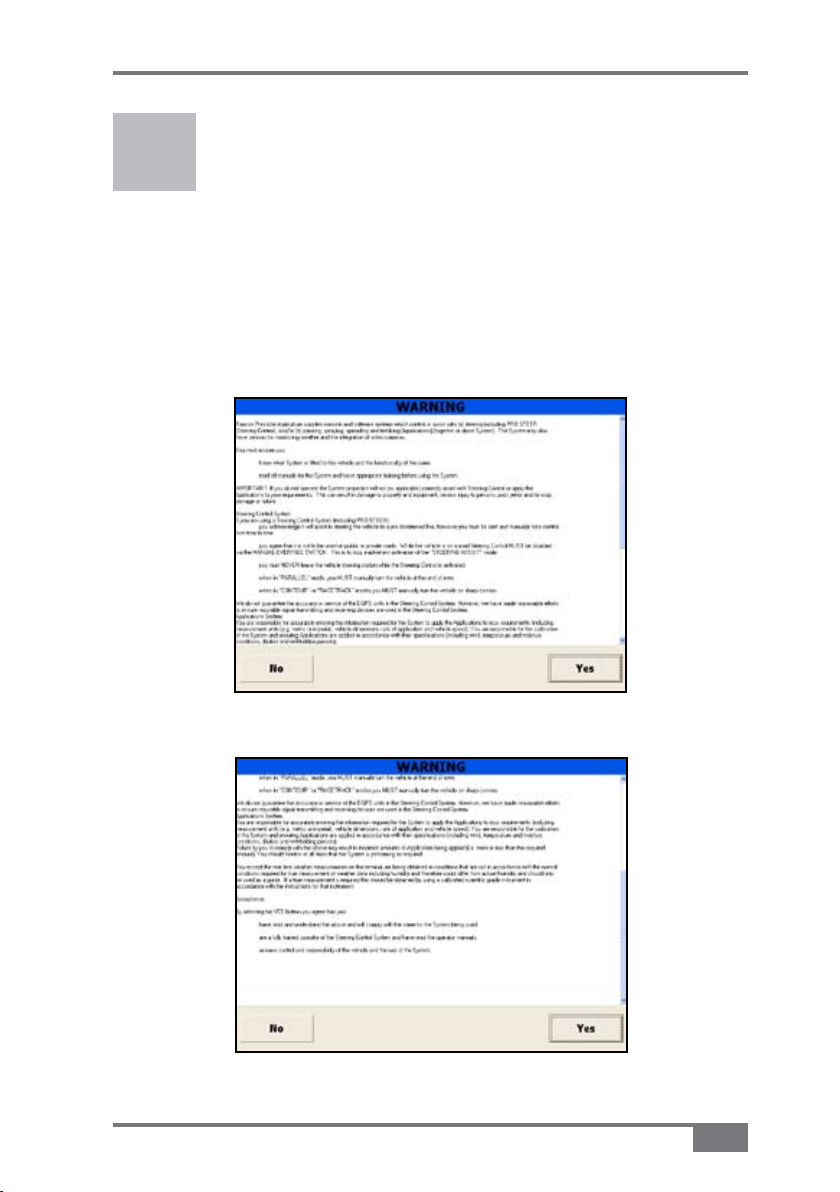

The first window that is displayed when your console starts up is a

Warning page (Figure 6-1 and 6-2).

Figure 6-1. Warning Window Part I

Figure 6-2. Warning Window Part II

A2677 Rev 1.5

6-1

Page 62

X20 Sprayer Reference Manual

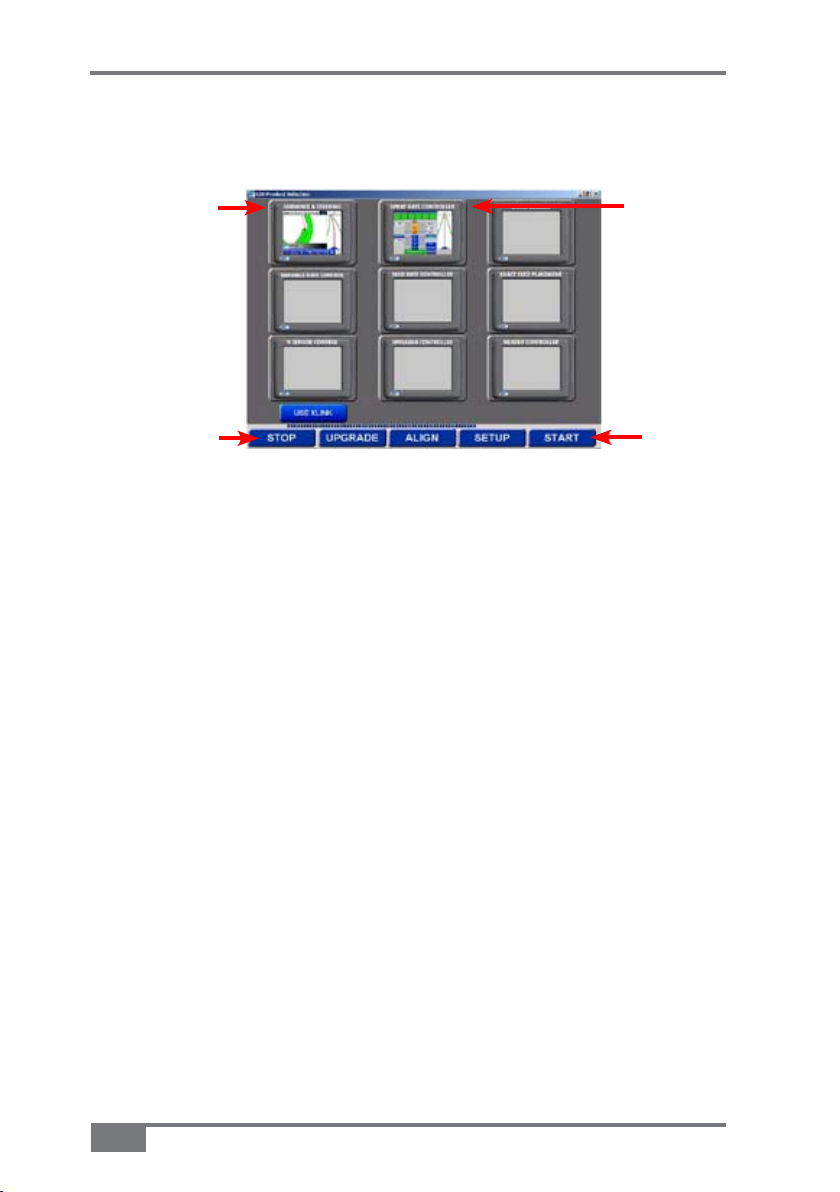

Starting the X20 Console

Guidance

screen icon

Spray

Controller

screen icon

Stop

button

Figure 6-3. X20 Product Selection Screen

Switch the X20 console on by pressing the green 1. Power button

on the rear of the console

Read and understand the warnings (page 6-1) and select 2. Yes to

continue or No to shutdown

Press 3. Stop when the X20 Product Selection screen (Figure 6-3)

is displayed

Start

button

6-2

www.topconpa.com

Page 63

X20 Sprayer Reference Manual

Using Spray Controller Only

Please note: This operators manual assumes that Guidance and

Spray Controller are being used together. To use Guidance and

Spray Controller together see “For use of Spray Controller and

Guidance”, on this page.

Press the 4. Spray Controller screen icon (Figure 6-3 on

page 6-2)

Using Spray Controller and Guidance

Please note: This operators manual assumes that Guidance

and Spray Controller are being used together.

4. Press the Spray Controller screen icon and

Guidance screen icon (Figure 6-3 on page 6-2)

Press the Start button (Figure 6-3 on page 6-2)

The Spray Controller and Guidance (if selected) software will be

loaded.

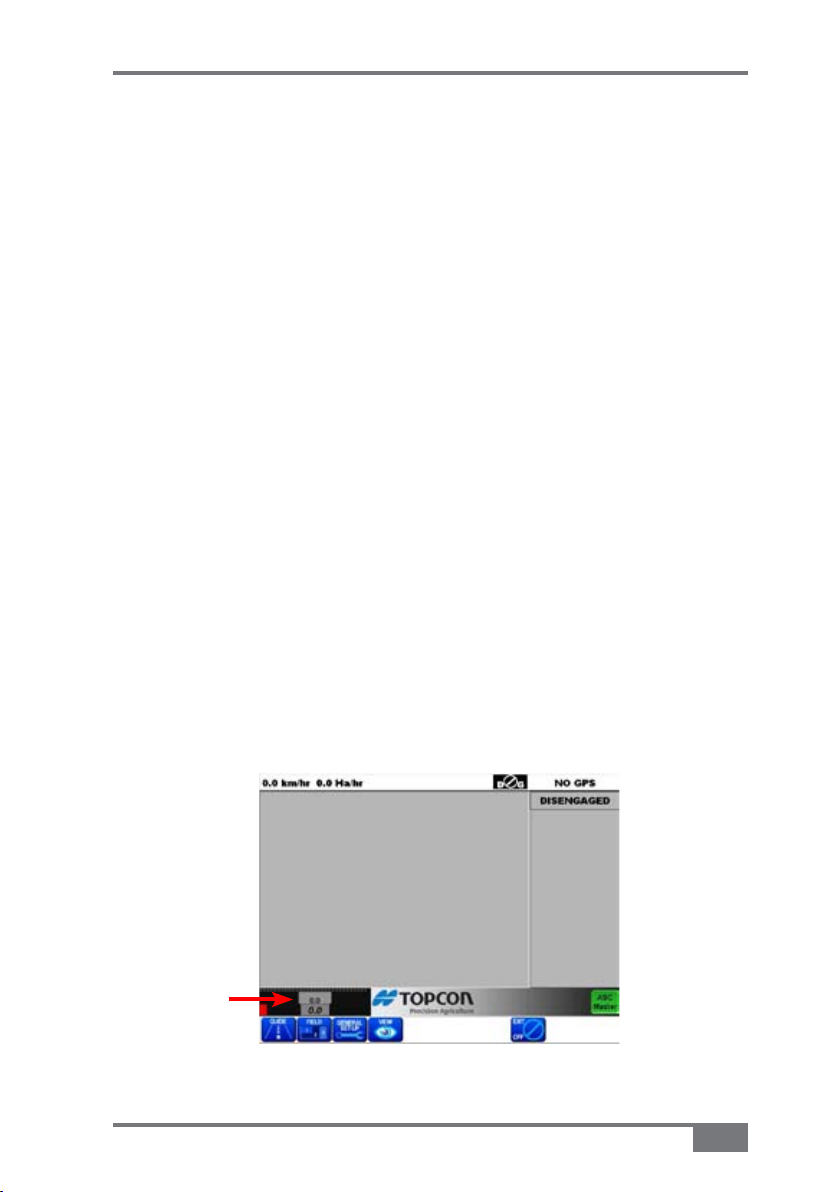

The Guidance screen (Figure 6-4) (if Guidance was selected) will

be displayed.

Sprayer

icon

Figure 6-4. Guidance Screen Showing

Sprayer Icon

A2677 Rev 1.5

6-3

Page 64

X20 Sprayer Reference Manual

Select the 5. Sprayer icon

The Sprayer Working screen (Figure 6-5) will be displayed.

Please note: If you selected to display the Spray Controller

only then the Sprayer Working screen (Figure 6-5) will be

displayed after Step 4, instead of the Guidance screen (Figure

6-4 on page 6-3).

Sprayer

Menu

Figure 6-5. Sprayer Working Screen

Sprayer

Logo

Options

button

Main Menu

Button

About Spray Rate Controller Window

When the Sprayer Working screen (Figure 6-5) is displayed the

Sprayer Menu (Figure 6-5) will be displayed on the right side of the

screen.

Press the 1. Sprayer Logo (Figure 6-5)

An About Spray Rate Controller window (Figure 6-6 on page

6-5) will be displayed.

6-4

www.topconpa.com

Page 65

X20 Sprayer Reference Manual

Software

Version

Registration

Register

Button

Figure 6-6. About Spray Rate

Controller window

The About Spray Rate Controller window displays:

The Spray Rate Controller • software version number—this

version number may be requested by a Topcon Precision

Agriculture service person.

The Spray ECU version number will be displayed, when the

console is connected to the Spray ECU.

Whether the Sprayer software is • registered or unregistered

The • Enable Lockout button (see "Enable Lockout" page

10-21)

Close • button—when selected the Sprayer Working screen

(Figure 6-5 on page 6-4) will be displayed again.

Close

Button

Registering the Sprayer Software

If the Sprayer software is unregistered you must contact your local

Topcon Precision Agriculture dealer.

A2677 Rev 1.5

6-5

Page 66

X20 Sprayer Reference Manual

Overview of the Sprayer Working Screen

Functions

Front boom

Back boom

Spraying

Indicators

for Front

Line

Pressure

Readout

Manual

Control

Volume

‘Min. Flow’

or Nozzle

Min Flow

indicator

Spraying Indicators

Boom Sections (ON/OFF)

-Up to 30 sections

Switches

all boom

sections

ON /OFF

Returns to

the Main Menu

screen

for Back Line

Figure 6-7. Sprayer Working screen

Main Menu

Screen

Ground

Speed

Sub total area

Tank Indicator

Sub-total

volume (or

weight)

Automatic

Control

Activates all

data on the

right side

of the screen

Displays

number

6-6

Tank

Displays products being applied

Displays volume left in Tank 1

Displays volume left in Tank 1 graphically

Displays Application Rate units

Current Application Rate

Increase the rate on the go

Preset Rate 1

Preset Rate 2

Decrease the Rate on the go

www.topconpa.com

Page 67

X20 Sprayer Reference Manual

• Boom Sections—displays the number of Boom Sections selected.

If Dual line is selected (see "Lines", page 8-25) dual boom

is shown, showing the front and back lines; the top line

representing the front line and the bottom line representing the

back line.

If Single line is selected (see "Lines", page 8-25) then only a

single line of sections will be displayed.

The Boom Sections are numbered starting from the left side of

the spray line, with the far left Section Valve being section valve

‘1’.

The Boom Sections can be switched ON/OFF, either by touching

the Boom Section on the Sprayer Working screen (Figure 6-7)

on page 6-6) or by switching the Boom Sections switches ON/

OFF on the External Switchbox.

Table 6-1 shows what different color Boom Sections and

Spraying Indicators indicate about their status.

Boom Sections and Spraying Indicators Color Indicators

Boom

Section

A2677 Rev 1.5

Spraying

Indicator

Table 6-1. Color indicators

Meaning

Boom Sections are switched OFF.

Boom Sections are switched ON but the

Low Speed Shutoff speed has not been

reached or Master is OFF

Boom Sections are switched ON, the Low

Speed Shutoff speed has been reached,

ready to start spraying.

Boom Section is ready for spraying but

Master Switch is OFF.

Master Switch is ON and Boom Section

valve is spraying.

6-7