Page 1

TS 830

AUTOMATIC TRANSFER SWITCHES

INSTALLATION, OPERATING &

SERVICE MANUAL

PM059 REV 6 08/05/05

9087A – 198th Street, Langley, BC Canada V1M 3B1 Telephone (604) 888-0110

Telefax (604) 888-3381 E-Mail: info@thomsontechnology.com www.thomsontechnology.com

Page 2

Page 3

TS 830 TRANSFER SWITCH

TABLE OF CONTENTS

1. PRODUCT REVISION HISTORY 1

2. EQUIPMENT STORAGE 1

3. NOTES TO INSTALLER 2

3.1. ELECTRICAL CONNECTIONS 2

3.2. TRANSFER SWITCHES WITH ADJUSTABLE OVER CURRENT PROTECTION 2

3.3. TRANSFER SWITCHES WITH MULTI-TAP VOLTAGE CAPABILITY 3

3.4. SYSTEM PHASING-HIGH LEG DELTA SYSTEMS 3

3.5. REMOTE START CONTACT FIELD WIRING 4

3.6. DIELECTRIC TESTING 5

3.7. INSTALLATION OF OPEN TYPE TRANSFER SWITCHES 5

4. GENERAL DESCRIPTION 5

4.1. PRODUCT MODEL CODE 6

5. GENERAL THEORY OF OPERATION 8

5.1. STANDARD AUTOMATIC TRANSFER SWITCH 8

5.2. TEST MODES 9

6. OVER CURRENT PROTECTION 10

7. GENERAL NOTES ON SERVICING ATS MECHANISM 10

8. TRANSFER SWITCH MECHANISM – 100 - 800 AMP (HS STYLE) 11

8.1. MANUAL OPERATION 12

9. TRANSFER SWITCH MECHANISM – 1000A- 1600 AMP (T STYLE) 12

9.1. MANUAL OPERATION 13

10. RECOMMENDED MAINTENANCE 14

11. FRONT VIEW (TYPICAL) 3 / 4 POLE 100A-400A TRANSFER MECHANISM (HS

STYLE) 15

PM059 REV 6 08/05/05 Thomson Technology

Page 4

TS 830 TRANSFER SWITCH

12. FRONT VIEW (TYPICAL) 3 / 4 POLE 100A-400A TRANSFER MECHANISM (HS

STYLE) (FRONT COVER REMOVED) 16

13. FRONT VIEW (TYPICAL) 3 / 4 POLE 630A-800A TRANSFER MECHANISM (HS

STYLE) 17

14. FRONT VIEW (TYPICAL) 3 / 4 POLE 630A-800A TRANSFER MECHANISM (HS

STYLE) (FRONT COVER REMOVED) 18

15. FRONT VIEW (TYPICAL) 3 / 4 POLE 600A-1600A TRANSFER MECHANISM 19

16. CABLE TERMINAL INFORMATION 20

17. ELECTRICAL RATINGS 20

18. TROUBLESHOOTING 21

19. REPLACEMENT PARTS 22

20. PRODUCT RETURN POLICY 23

21. NOTES 24

PM059 REV 6 08/05/05 Thomson Technology

Page 5

TS 830 TRANSFER SWITCH

1. PRODUCT REVISION HISTORY

The following information provides an historical summary of changes made to this product since the

original release.

Operating & Service Manual Version

Rev 6 08/05/05

Rev 5 07/10/10

Rev 4 07/03/26

Rev 3 04/12/21

Rev 2 04/03/10

Rev 1 03/04/15

Rev 0 02/12/20

Revision to add HS Style Mechanism 630A-800A

Revision to add HS Style Mechanism 100-400A

Revision to add MEC 310 controller

Revisions to incorporate the new model coding.

Revisions to mechanism style 1000A, 1200A & 1600A.

Revisions to text, dimensions, & cable specifications.

Original release.

Contact Thomson Technology, to obtain applicable instruction manuals or if in doubt about any

matter relating to installation, operation or maintenance. Soft copy of the most current version is

available at www.thomsontechnology.com.

NOTE: All information contained in this manual is for reference only and is subject

to change without notice.

2. EQUIPMENT STORAGE

The following procedures are required for correct storage of the transfer switch prior to installation.

CAUTION!!!

Failure to store equipment as specified may cause damage and void warranty.

Before storing, unpack sufficiently to check for concealed damage. If concealed damage is

found, notify Thomson Technology and the Carrier immediately.

Repack with the original, or equivalent packing materials. Protect from physical damage. Do

not stack.

Store indoor in a clean, dry, well-ventilated area free of corrosive agents including fumes,

salt and concrete/cement dust. Apply heat as necessary to prevent condensation.

The following storage temperature and humidity must be maintained: -20 to +70°Celsius,

95% Humidity non-condensing.

PM059 REV 6 08/05/05 1 Thomson Technology

Page 6

TS 830 TRANSFER SWITCH

3. NOTES TO INSTALLER

Before opening the transfer switch enclosure to perform any service task, or to manually transfer the

mechanism, it is imperative to isolate the transfer switch from any possible source of power. Failure

to do so may result in serious personal injury or death due to electrical shock.

CAUTION!!!

All installation and/or service work performed must be done by qualified

personnel only. Failure to do so may cause personal injury or death.

3.1. ELECTRICAL CONNECTIONS

To ensure satisfactory installation of this equipment be sure to observe "Cable Terminal

Information” regarding power cable connection tightness located in this manual.

All mechanical and electrical connections must be checked for tightness prior to placing this

equipment in service to ensure proper operation and to validate applicable warranty

coverage.

3.2. TRANSFER SWITCHES WITH ADJUSTABLE OVER CURRENT

PROTECTION

Standard models of automatic transfer switches incorporate integral over current protection.

Transfer switches rated 1000A or higher are supplied with adjustable over current protection

trip units. For models of transfer switch with integral over current protection, the over current

protection must be set prior to operation. The equipment will be shipped from the factory

with a long-time current setting of 100% (of the equipment rating) and maximum short-

time/instantaneous current and time delay settings.

WARNING!

Do Not Energize this equipment until

device settings have been verified to

ensure proper system protection &

coordination. Failure to do so may

result in equipment failure.

Refer to Section 5.1.3 of this manual for additional information on operation of the Transfer

switch following an over current trip condition.

PM059 REV 6 08/05/05 2 Thomson Technology

Page 7

TS 830 TRANSFER SWITCH

Refer to information supplied with the transfer switch documentation package for adjustment

procedures on the power switching units over current protection trip unit. Contact the factory

if any additional information is required.

3.3. TRANSFER SWITCHES WITH MULTI-TAP VOLTAGE CAPABILITY

If the transfer switch has programmable multi-tap voltage capability confirm the transfer

switch has been configured for the correct system voltage prior to installation.

WARNING!

Failure to confirm and match transfer

switch voltage with the system voltage

could cause serious equipment damage.

The voltage selections and connections are shown on the engineered drawings attached to

each transfer switch. The factory default settings will be indicated on the calibration label

attached on the inside of the enclosure door (supplied loose on open style models). A blank

label is included to record the applicable settings if the configuration is changed from the

factory default settings.

To change the transfer switch configuration the following must be accomplished:

• Change voltage taps on potential transformers (PT’s) to correct system voltage (refer

to drawings)

• Change program setting in the applicable controller used on the transfer switch (e.g.

TSC 80, TSC 800, MEC 2, MEC 20, MEC 310) for nominal system voltage. Refer to

the applicable controller instruction manual for further information.

• Once the PT voltage taps and controller has been re-programmed to correct

operating voltage, the “control circuit isolation plug” on the mechanism, may be

reconnected, prior to voltage energization.

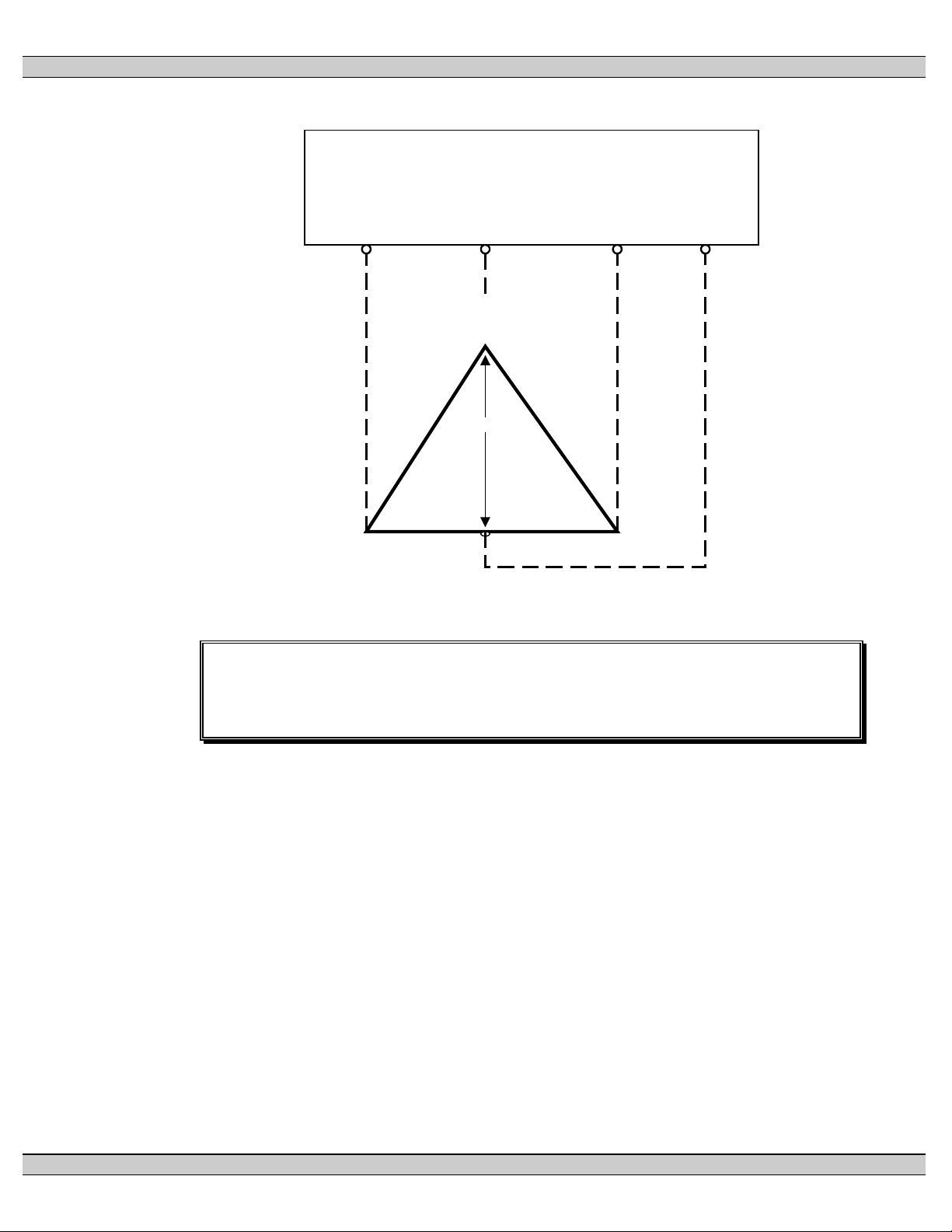

3.4. SYSTEM PHASING-HIGH LEG DELTA SYSTEMS

For systems using high leg delta 240V 3 phase 4 wire systems, connection of supply

conductors must have the correct phasing as shown below.

WARNING!

Failure to match correct system phasing

will result in serious damage to the

controller.

PM059 REV 6 08/05/05 3 Thomson Technology

Page 8

TS 830 TRANSFER SWITCH

Auto matic Transfer

Switch (Utility Supply)

PH A

(U A )

PH B

(U B )

PH C

(U C )

Neu ral

(N )

B

(O ra ng e)

(High Le g)

20 8V

C

(Ye llow )

A

(R ed )

24 0V 240V

12 0V 12 0V

N

(W hite )

CAUTION!!!

All installation and/or service work performed must be done by qualified

personnel only. Failure to do so may cause personal injury or death.

Where transfer switches are supplied without power isolation transformers (PT1 &

PT2) for ATS control logic it is essential that the orientation of phase conductors of

the supply source be arranged such that the phase of highest potential with respect

to ground is not connected to the power supply inputs to the controller (The A Phase

for both supplies). Failure to do so will result in equipment damage.

Per NEC Article 384-3 (f) “The B phase shall be that phase having the higher voltage

to ground on a 3-phase, 4-wire delta connected systems.”

3.5. REMOTE START CONTACT FIELD WIRING

For applications using TSC 80, 800 controllers, as a minimum, the remote engine

start control field wiring shall conform to the local regulatory authority on electrical

installations. Field wiring of a remote start contact from a transfer switch to a control

PM059 REV 6 08/05/05 4 Thomson Technology

Page 9

TS 830 TRANSFER SWITCH

panel should conform to the following guidelines to avoid possible controller

malfunction and/or damage.

3.5.1. Minimum #14 AWG (2.5mm2) wire size shall be used for distances up to 500ft

(150m)1). For distances exceeding 500 ft. (150m) consult Thomson

Technology.

3.5.2. Remote start contact wires should be run in a separate conduit.

3.5.3. Avoid wiring near AC power cables to prevent pick-up of induced voltages.

3.5.4. An interposing relay may be required if field-wiring distance is excessively

long (i.e. greater than 500 feet (150m) and/or if a remote contact has a

resistance of greater than 5.0 ohms.

3.5.5. The remote start contact must be voltage free (i.e. dry contact). The use of a

“powered” contact will damage the transfer controller.

3.6. DIELECTRIC TESTING

Do not perform any high voltage dielectric testing on the transfer switch with the

controller connected into the circuit, as serious damage will occur to the controller.

All AC control fuses and/or control circuit breakers or control circuit isolation plugs

connected to the controller must be removed if high voltage dielectric testing is

performed on the transfer switch.

3.7. INSTALLATION OF OPEN TYPE TRANSFER SWITCHES

Please contact Thomson Technology for additional information.

4. GENERAL DESCRIPTION

Thomson Technology TS 830 series of Automatic Transfer Switches employ two mechanically

interlocked enclosed contact power switching units and a microprocessor based controller to

automatically transfer system load to a generator supply in the event of a utility supply failure.

System load is then automatically re-transferred back to the utility supply following restoration of the

utility power source to within normal operating limits. Transfer switches with MEC 2, MEC 20 or

MEC 310 controllers installed have integral engine-genset auto start control & monitoring features

and therefore these applications do not require an engine-mounted auto start control panel.

The standard TS 830 series Automatic Transfer Switch is rated for 100% system load and does not

require upstream over current protection. Refer to Section 6 of this manual for detailed information

on over current protection.

PM059 REV 6 08/05/05 5 Thomson Technology

Page 10

TS 830 TRANSFER SWITCH

The TS 830 series transfer switch may be supplied with type TSC 80, TSC 800, MEC 310 or MEC

20 controllers as specified at equipment order. All controllers are microprocessor based which

provides all necessary control functions for fully automatic operation. The controllers are mounted

on the door of the transfer switch enclosure and operating status is shown via LED lights and/or

LCD display dependent upon controller type. For further information on the controller utilized, refer

to separate instruction manuals.

The power switching devices used for the Utility and Generator sources are operated by an

electrically driven motor mechanism in the transfer switch. The transfer switch motor utilizes the

power from the source to which the electrical load is being transferred. The mechanism provides a

positive mechanical interlock to prevent both power switching units from being closed at the same

time, which allows an interrupted “break-before-make” transfer sequence.

Note: For the purpose of this manual, the following standard nomenclature is utilized:

• Utility: to indicate the source of primary power

• Generator: to indicate the source of standby power

• Power switching device: to indicate the transfer switch power switching device

4.1. PRODUCT MODEL CODE

The type of TS 830 series transfer switch supplied is identified by way of a 21 digit product

code which appears on the equipment rating plate (MODEL) on the door of the transfer

switch, and on the transfer switch drawings. The model code structure and definitions are as

follows:

PM059 REV 6 08/05/05 6 Thomson Technology

Page 11

TS 830 TRANSFER SWITCH

ffff

G - 120240

(DELTA)

H - 220/380

2

ffff

S - 380

2

A - NEMA1, BEIGE

1

B - NEMA2, BEIGE

1

C - NEMA12, BEIGE

1

D - NEMA3R SD, BEIGE

1

E - NEMA3R DD, BEIGE

1

1

FOR PEAK PLUS ENCLOSURE COLOR

2

FOR 50 Hz APPLICATION

ffff

1 2 4 6 7 8 9 10 11 12 13 14 15 17 18 19 20 21

T S 8

1-3. SERIES

TS - TRANSFER SWITCH E - 120/208 U - INSULATED CASE DRAW-OUT SWITCH

4 & 5. MODEL

83 - 830 SWITCH

6. POLES M - 277/480 C/W ELECTRONIC & GF TRIP (800-3200A)

2 - 2 POLE

3 - 3 POLE P - 208

4 - 4 POLE Q - 220 19. GENERATOR SWITCHING DEVICE

7. CONFIGURATION TYPE

A - ATS U - 415 TRIP (100-800A)

X - SPECIAL P - MOLDED CASE SWITCH C/W ELECTRONIC

8 - 11. AMPERAGE 1 - TSC80 Q - INSULATED CASE, FIX MOUNT SWITCH

0100 2 - TSC800 (800A-3200A)

0250 4 - MEC2 (PCC) R - INSULATED CASE, FIX-MOUNT SWITCH

0400 5 - MEC20 (PCC) C/W ELECTRONIC TRIP (800-3200A)

0630 6 - PGC4000 U - INSULATED CASE DRAW-OUT SWITCH

0800 7 - NONE (MANUAL) (800 - 3200A)

1000 8 - MEC 310 (PCC) V - INSULATED CASE DRAW-OUT SWITCH

1200 9 - MEC 320 C/W ELECTRONIC TRIP (800 - 4000A)

1600 W - INSULATED CASE, DRAW-OUT SWITCH

2000 17. ENCLOSURE TYPE C/W ELECTRONIC & GF TRIP (800-3200A)

2500

3200

12. APPLICATION

A - STANDARD ATS

C - DUAL SOURCE F - NEMA4X DD, STAINLESS STEEL

P - POWER CONTROL CENTRE (PCC) G - NONE (OPEN STYLE) 21. ATS CONNECTION CONFIGURATION

S - PEAK PLUS X - SPECIAL A - STANDARD

X - SPECIAL B - ALTERNATE B (1000-1600A)

13. OPERATION TYPE K - MOLDED CASE SWITCH (100 - 1200 A) D - ALTERNATE D (1000-1600A)

1 - OPEN TRANSITION M - MOLDED CASE SWITCH C/W THER-MAG E - ALTERNATE E (800-3200A)

2 - MANUAL ELEC. OP. TRIP (100-800A) F - ALTERNATE F (800-3200A)

4 - CLOSED TRANSITION (SOFT LOAD) N - MOLDED CASE SWITCH C/W ELECTRONIC G - ALTERNATE G (800-3200A)

X - SPECIAL TRIP (250-1200A) X - SPECIAL

14 . SAFETY STANDARD & GF TRIP (250-1200A) NOTES

X - NOT APPLICABLE Q - INSULATED CASE, FIX MOUNT SWITCH

15 . VOLTAGE R - INSULATED CASE, FIX-MOUNT SWITCH

1

3 WIRE

D - 120/240

5 16

3

3

4 WIRE (GROUNDED NEUTRAL)

F - 127/220 (800 - 3200A)

J - 240/415 W - INSULATED CASE, DRAW-OUT SWITCH

3

3 WIRE

R - 240 K - MOLDED CASE SWITCH (100 - 1200 A)

V - 480 N - MOLDED CASE SWITCH C/W ELECTRONIC

X - SPECIAL TRIP (250-1200A)

16. CONTROLLER

18. UTILITY SWITCHING DEVICE

P - MOLDED CASE SWITCH C/W ELECTRONIC

(800A-3200A) IS ASA #61 GREY

C/W ELECTRONIC TRIP (800-3200A)

18. UTILITY SWITCHING DEVICE CONTINUED

V - INSULATED CASE DRAW-OUT SWITCH

C/W ELECTRONIC TRIP (800 - 4000A)

X - SPECIAL

M - MOLDED CASE SWITCH C/W THER-MAG

& GF TRIP (250-1200A)

X - SPECIAL

20. POWER CONNECTIONS

A - STANDARD

X - SPECIAL

C - ALTERNATE C (1000-1600A)

PM059 REV 6 08/05/05 7 Thomson Technology

Page 12

TS 830 TRANSFER SWITCH

5. GENERAL THEORY OF OPERATION

5.1. STANDARD AUTOMATIC TRANSFER SWITCH

5.1.1. NORMAL OPERATION

When utility supply voltage drops below a preset nominal value (adjustable from 70%

to 100% of nominal) on any phase, an engine start delay circuit will be initiated and

the transfer to utility supply signal will be removed (i.e. contact opening). Following

expiry of the engine start delay period (adjustable from 0 to 60 sec.) an engine start

signal (contact closure) will be given.

Once the engine starts, the transfer switch controller will monitor the generator

voltage and frequency levels. Once the generator voltage and frequency rises above

preset values (adjustable from 70% to 95% of nominal), the engine warmup timer will

be initiated. Once the warmup timer expires (adjustable from 0 to 60 sec.), the

Transfer to Generator Supply signal (contact closure) will be given to the transfer

switch mechanism. The load will then transfer from the utility supply to the generator

supply via the motor driven mechanism.

The generator will continue to supply the load until the utility supply has returned.

The retransfer sequence is completed as follows: when the utility supply voltage is

restored to above the preset values (adjustable from 70% to 95% of nominal) on all

phases, a transfer return delay circuit will be initiated. Following expiry of the Utility

Return Timer (adjustable from 0 to 30 min.), the Transfer to Generator Supply signal

will be removed (contact opening), and then the Transfer to Utility Supply signal

(contact closure) will be given to the transfer switch mechanism. The load will then

retransfer the load from the generator supply back to the utility supply. Note: For

transfer switches with TSC 80/800 controllers, a neutral delay timer circuit will delay

the transfer sequence in the neutral position (i.e. both power switching devices open)

until the neutral time delay period expires (adjustable from 0 to 60 sec.).

An engine cooldown timer circuit will be initiated once the load is transferred from the

generator supply. Following expiry of the cooldown delay period (adjustable from 0

to 30 min.), the engine start signal will be removed (contact opening) to initiate

stopping of the generator set. Note: For transfer switches with MEC 2/20, MEC 310

controllers, engine start signal is internal to the controller.

PM059 REV 6 08/05/05 8 Thomson Technology

Page 13

TS 830 TRANSFER SWITCH

5.1.2. OVER CURRENT TRIP (TSC 80/TSC 800 CONTROLLERS)

Should the utility power switching device trip open due to an over current condition,

TSC 80 or TSC 800 transfer controller will initiate an engine start signal and will

permit transfer of the load to the generator supply. The utility source will be locked

out and the load will remain on the generator supply until the TSC 80/TSC 800 alarm

signal is manually reset.

Refer to the TSC 80 & TSC 800 Instruction Manuals for further details on Transfer

Fail operation.

Should the generator power switching device trip open due to an over current

condition, TSC 80/TSC 800 transfer controller will initiate transfer of the load to the

utility supply. The generator source will be locked out and the load will remain on the

utility supply until the TSC 80/TSC 800 alarm signal is manually reset.

5.1.3. OVER CURRENT TRIP (MEC 2/MEC 20/MEC 310 CONTROLLERS)

Should the utility power switching device trip open due to an overcurrent condition,

the generator will not automatically start and transfer on load. The generator must be

started and transferred on load manually.

Should the generator power switching device trip open due to an overcurrent

condition, the generator will shutdown and the load will automatically return to the

utility supply if its voltage is normal. Note: for automatic transfer to utility, the transfer

switch must be factory ordered with a “gen breaker tripped” auxiliary contact inside

the generator power switching device and must be wired to the gen set controllers

shutdown alarm circuits.

Refer to the Gen Set controller instruction manual for further details on manual

operation or shutdown-reset operation.

5.2. TEST MODES

The transfer switch may be tested utilizing the controller pushbuttons or optional test switch.

A simulated utility power failure condition will be activated when the test mode is selected.

The transfer switch will operate as per a normal utility power fail condition.

The transfer switch will remain on generator supply until the test mode is terminated. It will

then immediately transfer back to the utility supply and then continue to operate the

PM059 REV 6 08/05/05 9 Thomson Technology

Page 14

TS 830 TRANSFER SWITCH

generator set for its cooldown period then stop. Note: The transfer switch will automatically

return to the utility supply (if within nominal limits) if the generator set fails while in the test

mode.

6. OVER CURRENT PROTECTION

Thomson Technology TS 830 series of Automatic Transfer Switches are supplied standard with

integral over current protection.

The type of over current protection utilized is dependent upon ATS amperage size and optional

features specified. For transfer switches rated 100A through 800A, over current protection is non-

adjustable thermal-magnetic type trip units. For transfer switches rated 1000A through 1600A over

current protection is adjustable electronic type with long time & instantaneous trip unit elements with

optional ground fault protection elements.

Note: For models of transfer switch with adjustable integral over current protection trip units, the

over current protection must be set prior to operation. The equipment will be shipped from the

factory with a long-time current setting of 100% (of the equipment rating) and maximum

instantaneous/short-time/ground fault (if supplied) current and time delay settings.

WARNING!

Do Not Energize this equipment until

device settings have been verified to

ensure proper system protection &

coordination. Failure to do so may result

in equipment failure.

7. GENERAL NOTES ON SERVICING ATS MECHANISM

(See CAUTION! on Page #2)

When performing any service work on the transfer mechanism, it is imperative that the following be

observed:

7.1. To maintain mechanical integrity, ensure that:

• All limit switches linkages are correctly adjusted to provide full travel of the power

switching device toggles without exerting unnecessary forces associated with

excessive travel. Ensure that power switching device travel far enough to reset

any internal trip unit (it is more important for the toggle to go fully in the "off"

direction, than in the "on" direction).

PM059 REV 6 08/05/05 10 Thomson Technology

Page 15

TS 830 TRANSFER SWITCH

• Mechanical interlocking is correct when one power switching opens well before

the other should close.

• All fasteners are adequately tightened.

• The operating linkages are not damaged or bent, and that all bearing points

operate freely.

7.2. To maintain electrical integrity, ensure that:

• All electrical connections, especially power connections, are clean and

adequately tightened. Corroded or loose power connections will cause

destructive heating, and may cause premature tripping.

• All insulating devices are in place and in good condition.

• No moisture or other contamination is present.

• Electrical conductors are adequately secured away from moving parts.

• On HS style transfer switch mechanisms, check nylock nuts on bolt pivot points.

Operation arms should move freely without excessive play.

7.3. To maintain operational integrity, ensure that:

• All control devices are in good condition and correctly calibrated.

• All control devices are adequately secured in their plug-in fixtures.

Only qualified personnel should undertake service work. Failure to correctly maintain an

automatic transfer switch may present a hazard to life and equipment. Full operational

testing must be done prior to placing a transfer switch in service subsequent to any

maintenance or repair. Any service work involving electrical components requires high-

potential testing to ensure that required insulation levels have been maintained.

8. TRANSFER SWITCH MECHANISM – 100 - 800 Amp (HS Style)

Note: Refer to product drawings in sections 11-14for identification of Transfer Switch Mechanism

style supplied with the Transfer Switch.

The transfer mechanism consists primarily of the transfer gear motor, a drive hub assembly, and

two power switching device operating arms.

The reversible transfer gear motor drives the drive hub assembly, which in turn moves the power

switching device operating arms. The power switching device toggles are set inside the operating

arm slots and are moved by them. There are two limit switches, which are contacted by the

operating arms (one for each direction of travel), which disconnect the transfer motor power supply

when the power switching devices have attained full travel. Should limit switch adjustment be

required, it is advisable to consult Thomson Technology for further information.

The transfer switch mechanism has three possible positions:

a) Utility power switching device closed and generator power switching device open;

PM059 REV 6 08/05/05 11 Thomson Technology

Page 16

TS 830 TRANSFER SWITCH

b) Generator power switching device closed and utility power switching device open;

c) Both utility and generator power switching devices open, but NEVER both utility and

generator power switching devices closed at the same time.

8.1. MANUAL OPERATION

DANGER!!!!

Arc Flash and Shock Hazard. Will cause severe injury or death.

Do not open equipment until ALL power sources are disconnected

This equipment must be installed and serviced only by qualified electrical

personnel utilizing safe work practices and appropriate Personal Protective

Equipment (PPE). Failure to do so may cause personal injury or death

Isolate the transfer switch from all sources of supply before opening the enclosure for

manual operation. With all sources of power de-energized to the transfer switch, the control

circuit isolation plug can be unplugged to prevent subsequent operation. The control circuit

isolation plug is located on the inner side of the transfer switch enclosure door.

To operate manually, turn the operating handle on the front of the mechanism and rotate to

the desired position.

Automatic operation may be regained by replacing the control circuit isolation plug. With all

sources of power de-energized to the transfer switch, the control circuit isolation plug can be

re-connected. The drive system will operate the transfer switch to the required position.

9. TRANSFER SWITCH MECHANISM – 1000A- 1600 Amp (T Style)

The transfer mechanism consists primarily of the transfer motor, a hub assembly, two operating

rods and two power switching device operating yokes.

The reversible transfer motor drives the hub assembly, which in turn moves the operating rods that

are connected to the power switching device operating yokes. The power switching device toggles

are set inside the yokes and are moved by them. There are two limit switches, which are contacted

by the operating yokes (one for each direction of travel), which disconnect the transfer motor power

supply when the power switching devices have attained full travel. The adjuster screws located on

PM059 REV 6 08/05/05 12 Thomson Technology

Page 17

TS 830 TRANSFER SWITCH

the yoke determines the operating point of these limit switches. Should adjustment be required, it is

advisable to consult Thomson Technology for further information.

The transfer switch mechanism has three possible positions:

a) Utility power switching device closed and generator power switching device open;

b) Generator power switching device closed and utility power switching device open;

d) Both utility and generator power switching devices open, but NEVER both utility and

generator power switching devices closed at the same time.

9.1. MANUAL OPERATION

(See CAUTION! on Page #2)

Isolate the transfer switch from all sources of supply before opening the enclosure for

manual operation. With all sources of power de-energized to the transfer switch, the control

circuit isolation plug (PL12) can be unplugged to prevent subsequent operation.

To operate manually, pull the release plunger and operate the handle in the desired

direction.

Automatic operation may be regained by replacing the isolation plug. With all sources of

power de-energized to the transfer switch, the control circuit isolation plug (PL12) can be re-

connected. The drive system is self-engaging and will operate the transfer switch to the

required position. (See manual operation instruction on front of transfer switch mechanism.)

PM059 REV 6 08/05/05 13 Thomson Technology

Page 18

TS 830 TRANSFER SWITCH

10. RECOMMENDED MAINTENANCE

(See CAUTION! on Page #2)

10.1. DO NOT perform dielectric tests on the equipment with the control components in the

circuit.

10.2. Check if control components are tight in sockets.

10.3. Periodically inspect all terminals (load, line and control) for tightness. Re-torque all

bolts, nuts and other hardware. Clean or replace any contact surfaces that are dirty,

corroded or pitted.

10.4. Transfer switches should be in a clean, dry and moderately warm location. If signs of

moisture are present, dry and clean transfer switch. If there is corrosion, try to clean

it off. If cleaning is unsuitable, replace the corroded parts. Should dust and/or debris

gather on the transfer switch, brush, vacuum, or wipe clean. DO NOT blow dirt into

power switching devices.

10.5. Test the transfer switch operation. While the unit is exercising, check for freedom of

movement, hidden dirt, corrosion or any excessive wear on the mechanical operating

parts. Ensure that the power switching device travel is correct.

10.6. Verify all program settings on the controller as per the calibration label or

programming sheets.

10.7. Transfer Mechanism 100-800A HS Style –lubrication of drive hub/operator arm

interface. Use high viscosity moly lubricant

10.8. Transfer Mechanism 1000A-1600A (T Style) - ensure that the manual handle moves

freely on the hub when the lock pin is disengaged. If lubrication is necessary, apply

medium weight (SAE 20) oil sparingly.

10.9. Transfer Mechanism 1000A-1600A (T-Style) - yoke pivot bearings and rod ends are

permanently lubricated and do not require maintenance.

10.10. The motor and gearbox are permanently lubricated, and should not require attention

under normal operating circumstances.

PM059 REV 6 08/05/05 14 Thomson Technology

Page 19

TS 830 TRANSFER SWITCH

11. FRONT VIEW (TYPICAL) 3 / 4 POLE 100A-400A TRANSFER

MECHANISM (HS Style)

PM059 REV 6 08/05/05 15 Thomson Technology

Page 20

TS 830 TRANSFER SWITCH

12. FRONT VIEW (TYPICAL) 3 / 4 POLE 100A-400A TRANSFER

MECHANISM (HS Style) (Front Cover Removed)

PM059 REV 6 08/05/05 16 Thomson Technology

Page 21

TS 830 TRANSFER SWITCH

13. FRONT VIEW (TYPICAL) 3 / 4 POLE 630A-800A TRANSFER

MECHANISM (HS Style)

PM059 REV 6 08/05/05 17 Thomson Technology

Page 22

TS 830 TRANSFER SWITCH

14. FRONT VIEW (TYPICAL) 3 / 4 POLE 630A-800A TRANSFER

MECHANISM (HS Style) (Front Cover Removed)

PM059 REV 6 08/05/05 18 Thomson Technology

Page 23

TS 830 TRANSFER SWITCH

15. FRONT VIEW (TYPICAL) 3 / 4 POLE 600A-1600A TRANSFER

MECHANISM

PM059 REV 6 08/05/05 19 Thomson Technology

Page 24

TS 830 TRANSFER SWITCH

16. CABLE TERMINAL INFORMATION

CONNECTION TIGHTNESS

TERMINAL RATING

BASIC MODEL

QTY

PER

PHASE

RANGE

TERMINAL

MOUNTING

SCREW

TS 83xA-0100 1 #2–4/0

TS 83xA-0250 1 #6–350MCM 150 275

TS 83xA-04001 2 2/0–500MCM 72 275

TS 83xA-06301 2 2/0–500MCM 72 275

TS 83xA-08001 3 2/0–500MCM 110 375

TS 83xA-10001 4 4/0–500MCM 375 375

TS 83xA-12001 4 4/0–500MCM 375 375

TS 83xA-16001 4 #2–600MCM 375 375

1. Optional terminal ratings are available in some models – Consult Thomson Technology.

2. For other model types not shown, contact Thomson Technology for further information.

(In-lbs)

CABLE

CLAMP

120 50

17. ELECTRICAL RATINGS

100A

MODEL TYPE

Rated short circuit breaking

capacity (Icu) kA @400V

Withstand rating fuse

protected (kA)

Rated service short circuit

breaking capacity (Ics) kA

@400V

Mechanical endurance

(Number of Operations)

(HS

Style)

50 65 65 80 65 50 50

100 100 100 100 100 100 100

42 48 48 60 48 50 50

7000 6000 4000 4000 4000 2500 2500

250A

(HS

style)

400A

(HS

Style)

630A (HS Style) 800A

(HS Style)

1000/1200A

(T Style)

1600A

(T

Style)

PM059 REV 6 08/05/05 20 Thomson Technology

Page 25

TS 830 TRANSFER SWITCH

18. TROUBLESHOOTING

CAUTION!!!

All trouble shooting/ service work performed must be done by qualified

personnel only. Failure to do so may cause personal injury or death.

Note: An optional hand held, plug-in Service Display Module (SDM) is available for the TSC 80

Transfer Controller. The SDM module provides an LCD screen to display additional detailed

information on the operation and settings of the TSC 80 controller for simplified servicing/trouble

shooting procedures. For detailed information, refer to the separate SDM module instruction manual

(PM065).

Symptom

Will not re-transfer to utility source

upon restoration

Will not transfer to generator source

upon failure of utility source

Possible Causes

- Isolation plug out

- A test mode has been activated (check controller)

- Utility voltage is below the pre-programmed limits (check utility

source for adequate voltage)

- A loose control connection

- Faulty motor limit switch

- Defective motor

- Controller has incorrect voltage programming jumper setting for

correct system voltage

- Defective controller (verify output signals with circuit board

mounted diagnostic LED’s)

- TSC 80/800 Controller has “Transfer Fail” alarm activated as

indicated by flashing Load on Utility LED. Determine cause of

alarm and rectify before TSC is reset

- Isolation plug out

- Generator set not producing enough voltage/frequency or

output circuit breaker open

- Controller has incorrect voltage programming jumper setting for

correct system voltage

- Warm-up time delay function has not timed out yet (verify

controller timer setting)

- A loose control connection

Transfer to generator source without a

power failure in the utility source

PM059 REV 6 08/05/05 21 Thomson Technology

- Faulty motor limit switch

- Defective motor

- Defective controller (verify output signals with circuit board

mounted diagnostic LED’s)

TSC 80/800 Controller has “Transfer Fail” alarm activated as

indicated by flashing Load on Generator LED. Determine

cause of alarm and rectify before TSC 80 is reset

-

A test mode has been activated Utility supply voltage is slightly

-

below voltage sensing setpoints.

Page 26

Symptom

TS 830 TRANSFER SWITCH

Possible Causes

Will not re-transfer to utility source

upon restoration

Generator does not start up or stop

when it should

No time delay when there should be

Power is not available at the load

terminals but the utility or generator

power switching device appears to be

closed to a live source

- Limit switch incorrectly adjusted

- Isolation plug out

Verify controller has correct voltage programming jumper

setting for system voltage

- Defective controller (verify output signals with circuit board

mounted diagnostic LED’s)

- TSC 80/800-Utility power switching device has tripped due to

an over current condition and controller alarm activated as

indicated by flashing Load on Utility LED. Determine cause of

alarm and rectify before controller is reset.

- Verify remote engine control panel is set for automatic mode

- Verify time delay setting of the controller

- The power switching device's over current protection unit has

opened due to a fault on the system. ”. Correct the fault, and

manually reset the power switching device in the transfer

switch by moving it off and then on again with the manual

operating handle

-

The transfer switch has completed a

transfer, but the motor has overheated

and the internal thermal protector has

opened

Limit switch failure or improper adjustment has failed to

disconnect motor

Binding or jamming of the transfer mechanism

-

19. REPLACEMENT PARTS

Replacement parts are available for the transfer switch as follows:

Note

When ordering replacement parts please provide the

following information:

-Transfer Switch Model code (e.g. TS 873AA0200AS)

-Transfer Switch Serial Number (e.g. W-022345)

The above information can be found on the transfer

switch equipment rating plate located on the outside of

the ATS door.

PM059 REV 6 08/05/05 22 Thomson Technology

Page 27

TS 830 TRANSFER SWITCH

Component Description

MEC 310 Controller MEC310AXX1 Must configure program settings to

TSC 80 Controller Board 005712 Must set Program Jumper prior to

TSC 80 Lexan Faceplate 005336 Contact Thomson Technology

TSC 80 Rear Cover 005707

Thomson Technology

Part Number

Comments

match original controller settings

use. Refer to TSC 80 Instruction

Manual.

Service Dept for installation

procedures.

Limit Switch 1 n/o, 1 n/c (all

ATS Models)

Transfer Switch Motor (T Style

(1000A-1200A) 120V 1/10 hp 1

PH

120VAC Auxiliary Plug-in

Relay, 11 pin Square (UX/GX)

120VAC Auxiliary Plug-in Timer 001515 Must ensure coil voltage is correct

100VA Control Transformer 002159

For other parts not listed, please contact Thomson Technology.

004929 Must install and adjust for proper

operation before use. Contact

Thomson Technology Service Dept

for installation/adjustment

procedures

001075 Motor is supplied with gear box

assembly. Contact Thomson

Technology Service Dept for

installation procedures

001278 Must ensure coil voltage is correct

20. PRODUCT RETURN POLICY

Thomson Technology uses a Return Material Authorization (RMA) process. Please complete the

Return Authorization Request Form (available on our web page) for return of goods, warranty

replacement/repair of defective parts, or credit consideration and fax to the appropriate department.

Returns only: Sales Fax (604) 888-5606

Warranty replacement/Warranty Repair: Service Fax (604) 888-3370.

Upon receipt of your request, Thomson Technology will confirm with a copy of our Order

Acknowledgement via fax advising the RMA number which should be used to tag the defective

controller prior to shipment.

PM059 REV 6 08/05/05 23 Thomson Technology

Page 28

TS 830 TRANSFER SWITCH

21. NOTES

________________________________________________________________________

________________________________________________________________________

________________________________________________________________________

________________________________________________________________________

________________________________________________________________________

________________________________________________________________________

________________________________________________________________________

________________________________________________________________________

________________________________________________________________________

________________________________________________________________________

________________________________________________________________________

________________________________________________________________________

________________________________________________________________________

________________________________________________________________________

________________________________________________________________________

________________________________________________________________________

________________________________________________________________________

________________________________________________________________________

________________________________________________________________________

________________________________________________________________________

________________________________________________________________________

________________________________________________________________________

________________________________________________________________________

________________________________________________________________________

________________________________________________________________________

________________________________________________________________________

________________________________________________________________________

________________________________________________________________________

________________________________________________________________________

________________________________________________________________________

_______________________________________________________________________

PM059 REV 6 08/05/05 24 Thomson Technology

Loading...

Loading...