TPS2041A, TPS2042A, TPS2043A, TPS2044A

TPS2051A, TPS2052A, TPS2053A, TPS2054A

CURRENT-LIMITED POWER-DISTRIBUTION SWITCHES

SLVS247 – SEPTEMBER 2000

D

80-mΩ High-Side MOSFET Switch

D

500 mA Continuous Current Per Channel

D

Independent Thermal and Short-Circuit

Protection With Overcurrent Logic Output

D

Operating Range . . . 2.7 V to 5.5 V

D

CMOS- and TTL-Compatible Enable Inputs

D

2.5-ms Typical Rise Time

D

Undervoltage Lockout

D

10 µA Maximum Standby Supply Current

for Single and Dual (20 µA for Triple and

Quad)

D

Bidirectional Switch

D

Ambient Temperature Range, 0°C to 85°C

D

ESD Protection

D

UL Listed – File No. E169910

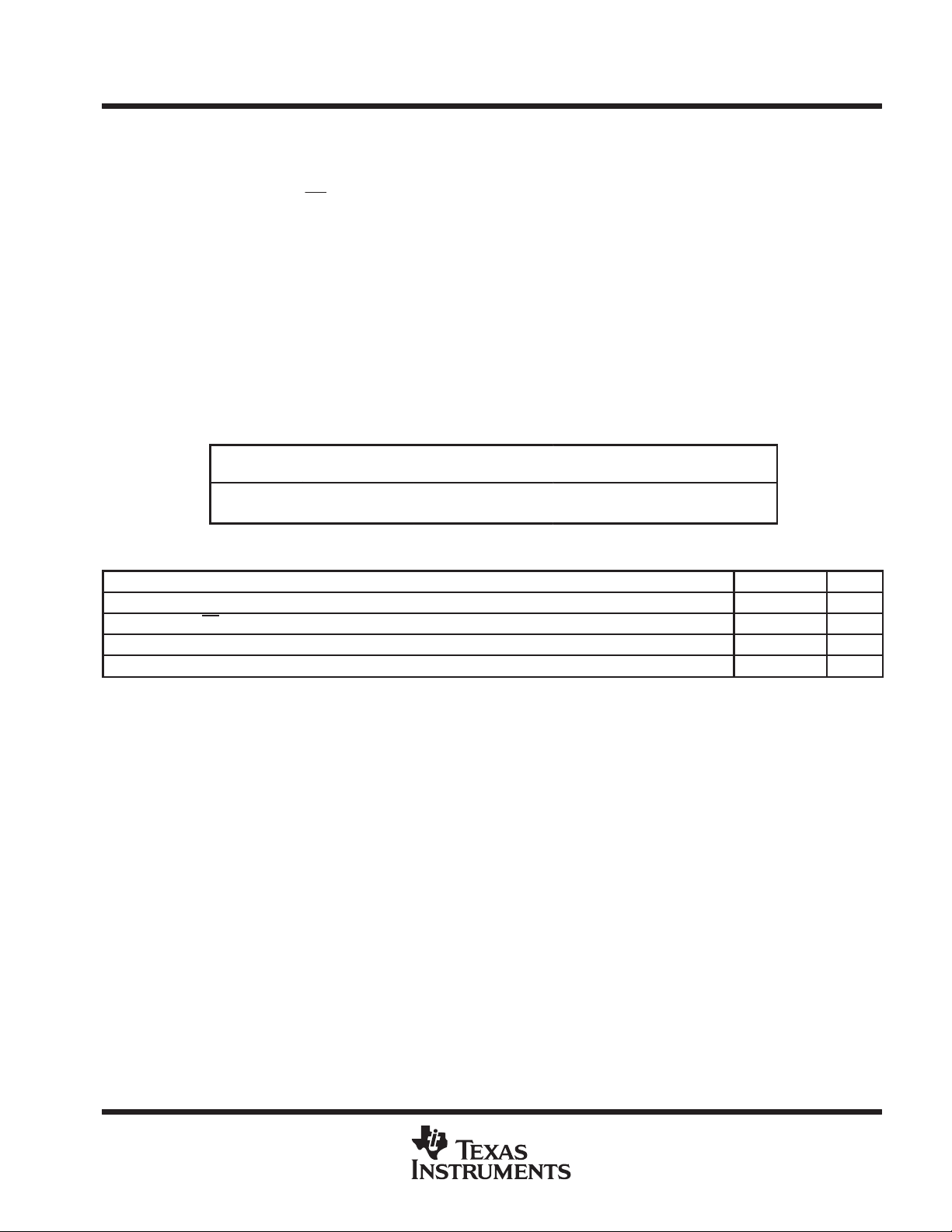

description

The TPS2041A through TPS2044A and

TPS2051A through TPS2054A power-distribution

switches are intended for applications where

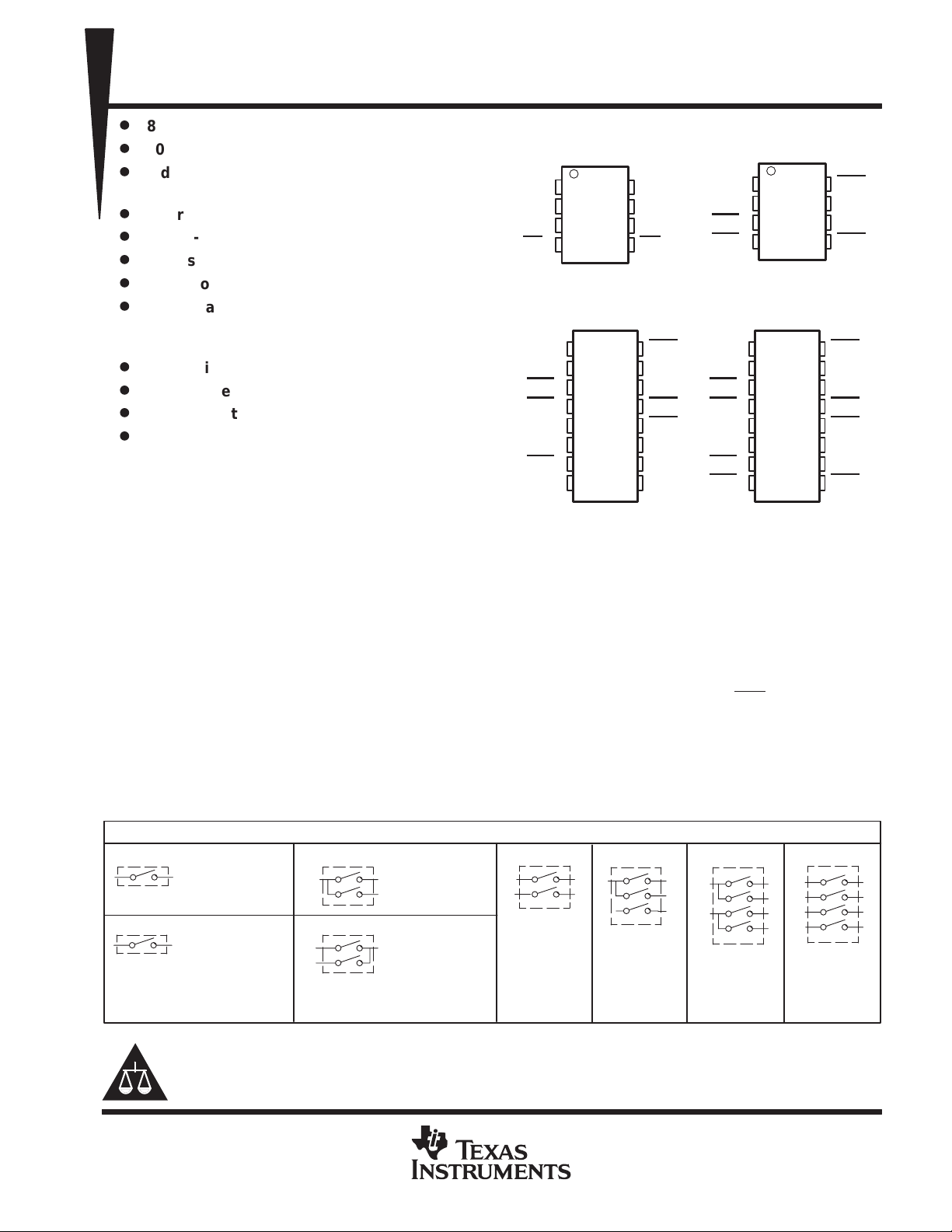

TPS2041A, TPS2051A

D PACKAGE

(TOP VIEW)

GND

GNDA

GNDB

†

NC – No connect

1

IN

2

3

IN

†

4

EN

TPS2043A, TPS2053A

D PACKAGE

(TOP VIEW)

1

IN1

2

†

EN1

EN2

EN3

All enable inputs are active high for the TPS205xA series.

IN2

NC

3

†

4

5

6

†

7

8

OUT

8

OUT

7

6

OUT

5

OC

OC1

16

OUT1

15

OUT2

14

OC2

13

OC3

12

OUT3

11

10

NC

9

NC

TPS2042A, TPS2052A

D PACKAGE

(TOP VIEW)

GND

EN1

EN2

GNDA

EN1

EN2

GNDB

EN3

EN4

1

IN

2

†

3

†

4

TPS2044A, TPS2054A

D PACKAGE

(TOP VIEW)

1

IN1

2

†

3

†

4

5

IN2

6

†

7

†

8

heavy capacitive loads and short circuits are likely to be encountered. These devices incorporate 80-mΩ

N-channel MOSFET high-side power switches for power-distribution systems that require multiple power

switches in a single package. Each switch is controlled by an independent logic enable input. Gate drive is

provided by an internal charge pump designed to control the power-switch rise times and fall times to minimize

current surges during switching. The charge pump requires no external components and allows operation from

supplies as low as 2.7 V.

16

15

14

13

12

10

OC1

8

OUT1

7

OUT2

6

5

OC2

OC1

OUT1

OUT2

OC2

OC3

OUT3

11

OUT4

9

OC4

When the output load exceeds the current-limit threshold or a short is present, these devices limit the output

current to a safe level by switching into a constant-current mode, pulling the overcurrent (OCx

) logic output low.

When continuous heavy overloads and short circuits increase the power dissipation in the switch, causing the

junction temperature to rise, a thermal protection circuit shuts off the switch to prevent damage. Recovery from

a thermal shutdown is automatic once the device has cooled sufficiently. Internal circuitry ensures the switch

remains off until valid input voltage is present. These power-distribution switches are designed to current limit

at 0.9 A.

GENERAL SWITCH CATALOG

33 mΩ, single

80 mΩ, single

PRODUCTION DATA information is current as of publication date.

Products conform to specifications per the terms of Texas Instruments

standard warranty. Production processing does not necessarily include

testing of all parameters.

TPS201xA

TPS202x

TPS203x

TPS2014

TPS2015

TPS2041

TPS2051

TPS2045

TPS2055

Please be aware that an important notice concerning availability, standard warranty, and use in critical applications of

Texas Instruments semiconductor products and disclaimers thereto appears at the end of this data sheet.

0.2 A – 2 A

0.2 A – 2 A

0.2 A – 2 A

600 mA

1 A

500 mA

500 mA

250 mA

250 mA

80 mΩ, dual

260 mΩ

IN1

IN2

1.3 Ω

OUT

TPS2042

TPS2052

TPS2046

TPS2056

TPS2100/1

IN1 500 mA

IN2 10 mA

TPS2102/3/4/5

IN1 500 mA

IN2 100 mA

500 mA

500 mA

250 mA

250 mA

80 mΩ, dual

TPS2080

TPS2081

TPS2082

TPS2090

TPS2091

TPS2092

500 mA

500 mA

500 mA

250 mA

250 mA

250 mA

80 mΩ, triple

TPS2043

TPS2053

TPS2047

TPS2057

500 mA

500 mA

250 mA

250 mA

Copyright 2000, Texas Instruments Incorporated

80 mΩ, quad

TPS2044

TPS2054

TPS2048

TPS2058

500 mA

500 mA

250 mA

250 mA

TPS2085

TPS2086

TPS2087

TPS2095

TPS2096

TPS2097

80 mΩ, quad

500 mA

500 mA

500 mA

250 mA

250 mA

250 mA

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

1

TPS2041A, TPS2042A, TPS2043A, TPS2044A

MAXIMUM CONTINUOUS

NUMBER OF

Single

Dual

0°C to 85°C

0.5

0.9

Triple

Quad

TPS2051A, TPS2052A, TPS2053A, TPS2054A

CURRENT-LIMITED POWER-DISTRIBUTION SWITCHES

SLVS247 – SEPTEMBER 2000

AVAILABLE OPTIONS

RECOMMENDED

T

A

°

†

The D package is available taped and reeled. Add an R suffix to device type (e.g., TPS2041ADR)

°

ENABLE

Active low

Active high

Active low

Active high

Active low

Active high

Active low

Active high

LOAD CURRENT

(A)

TYPICAL SHORT-CIRCUIT

CURRENT LIMIT AT 25°C

(A)

SWITCHES

p

PACKAGED DEVICES

SOIC

†

(D)

TPS2041AD

TPS2051AD

TPS2042AD

TPS2052AD

TPS2043AD

TPS2053AD

TPS2044AD

TPS2054AD

2

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

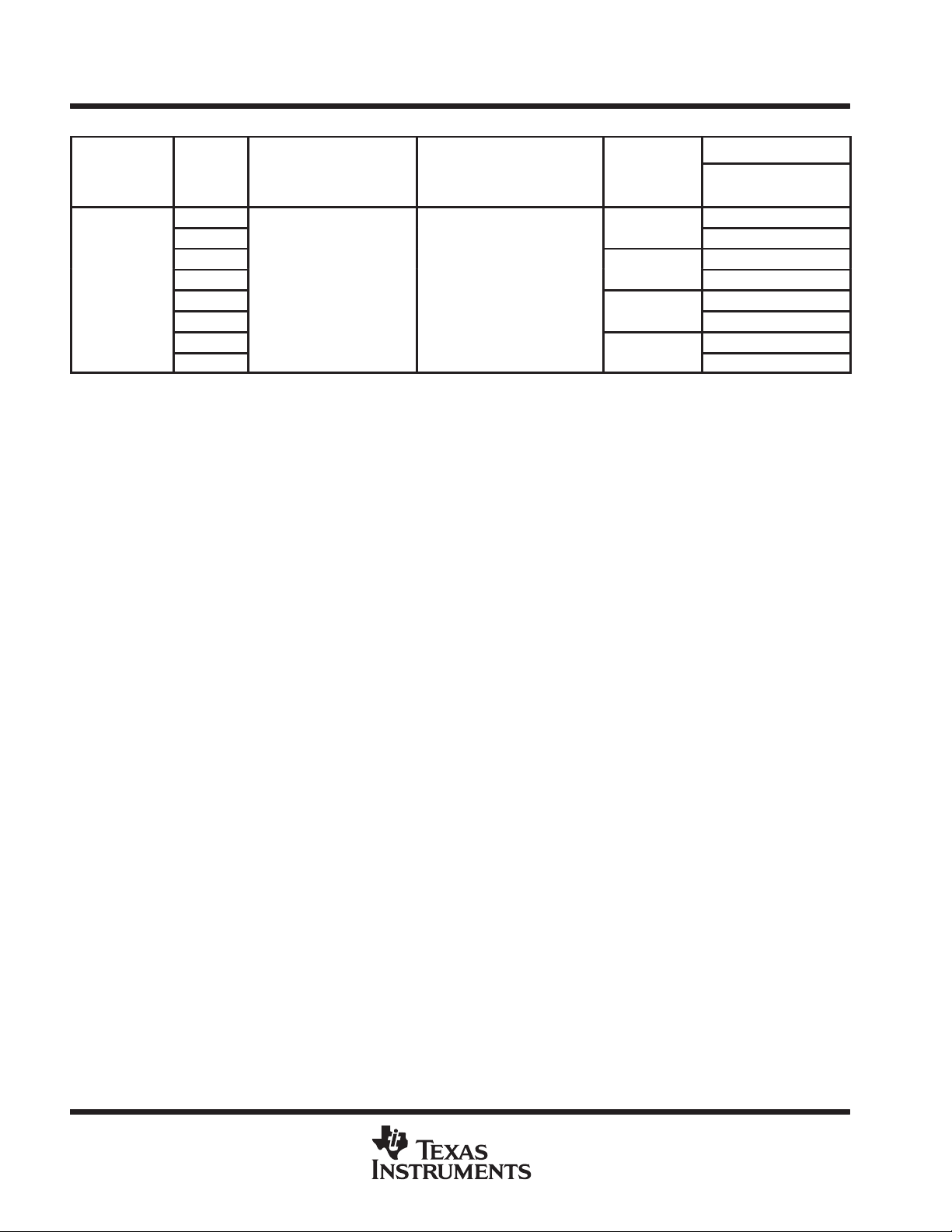

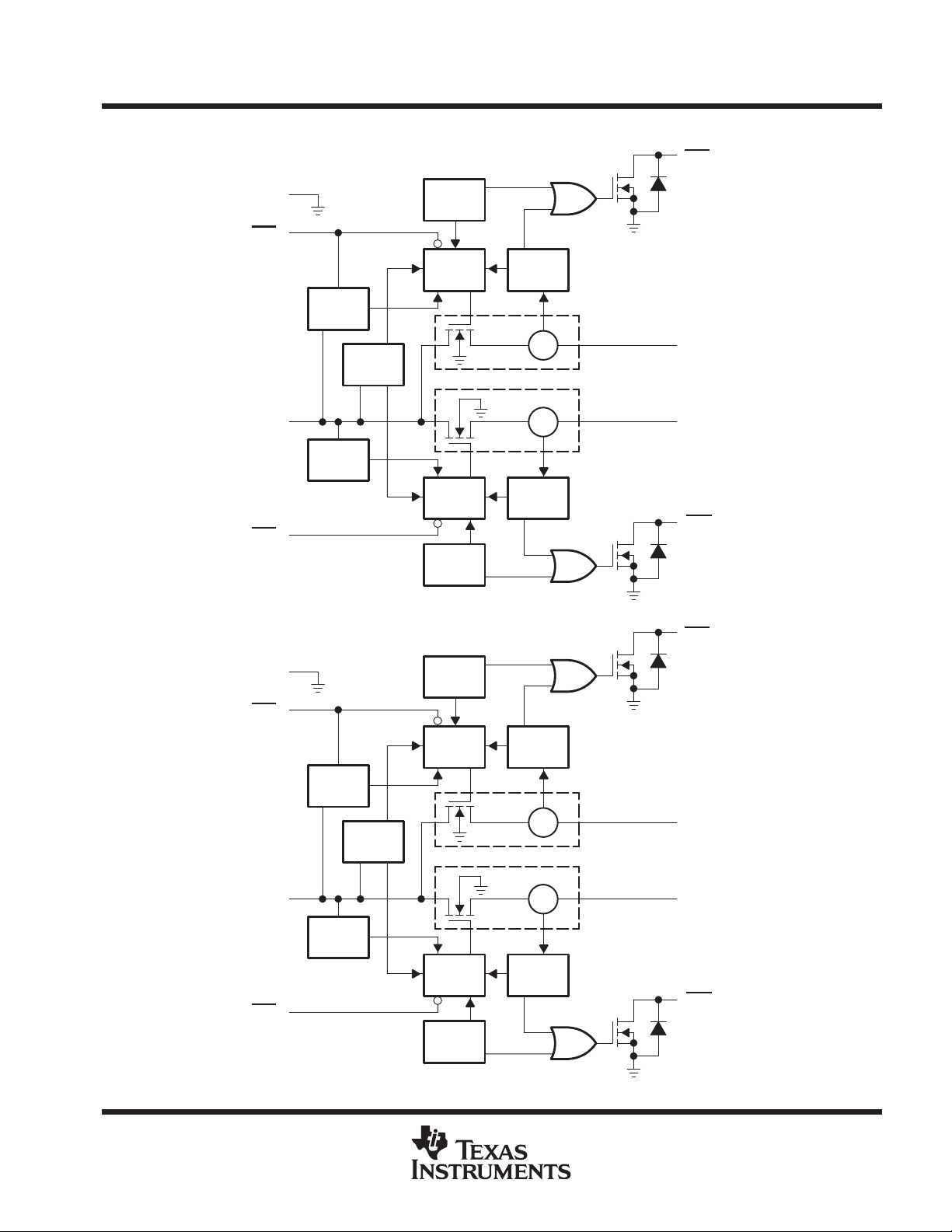

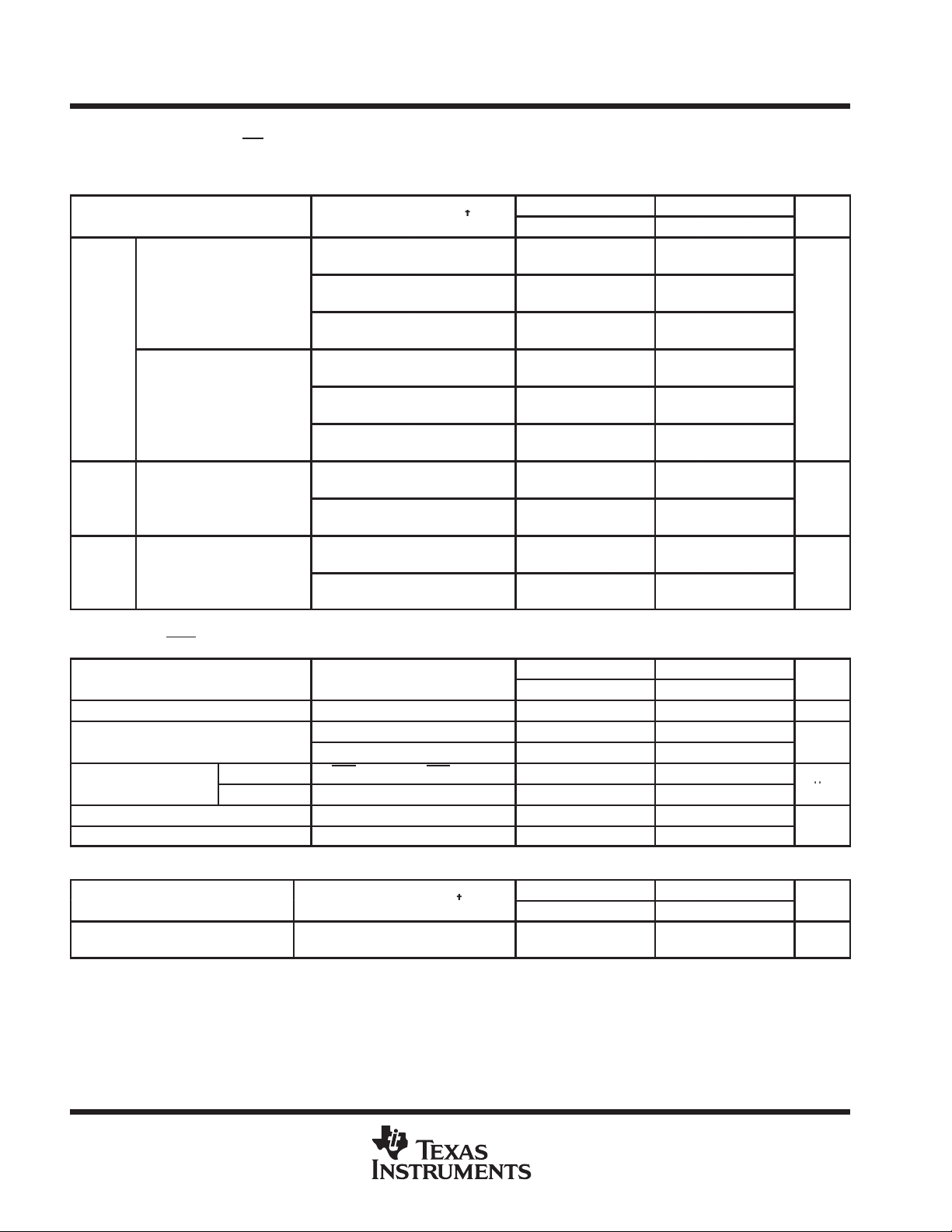

functional block diagrams

TPS2041A

IN

Charge

Pump

TPS2041A, TPS2042A, TPS2043A, TPS2044A

TPS2051A, TPS2052A, TPS2053A, TPS2054A

CURRENT-LIMITED POWER-DISTRIBUTION SWITCHES

SLVS247 – SEPTEMBER 2000

Power Switch

†

CS

OUT

TPS2042A

‡

EN

UVLO

GND

†

Current sense

‡

Active high for TPS205xA series

GND

‡

EN1

Charge

Pump

UVLO

Thermal

Sense

Driver

Driver

Thermal

Sense

Current

Limit

Power Switch

CS

Current

Limit

OC

OC1

†

OUT1

IN

Charge

Pump

‡

EN2

†

Current sense

‡

Active high for TPS205xA series

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

Driver

Thermal

Sense

CS

Current

Limit

†

OUT2

OC2

3

TPS2041A, TPS2042A, TPS2043A, TPS2044A

TPS2051A, TPS2052A, TPS2053A, TPS2054A

CURRENT-LIMITED POWER-DISTRIBUTION SWITCHES

SLVS247 – SEPTEMBER 2000

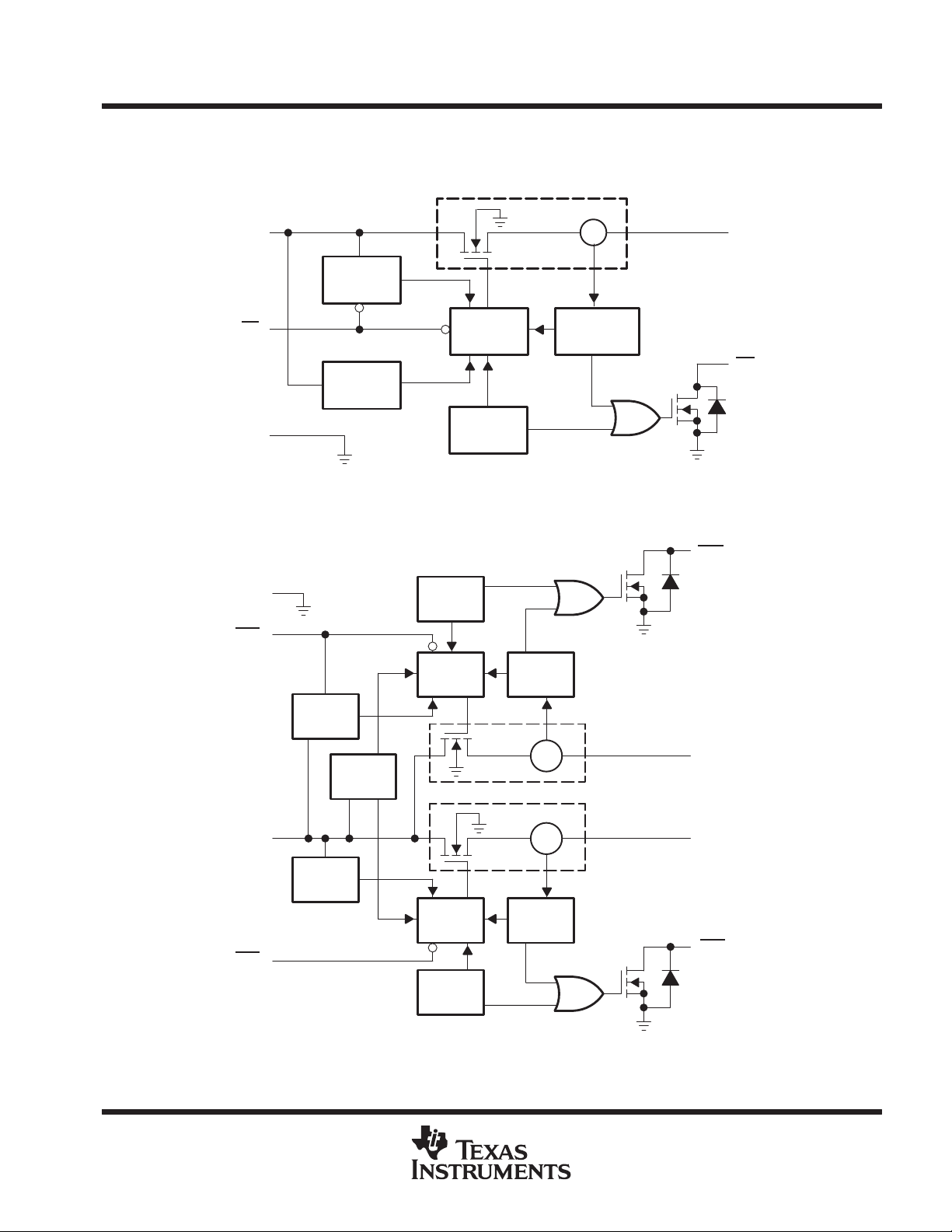

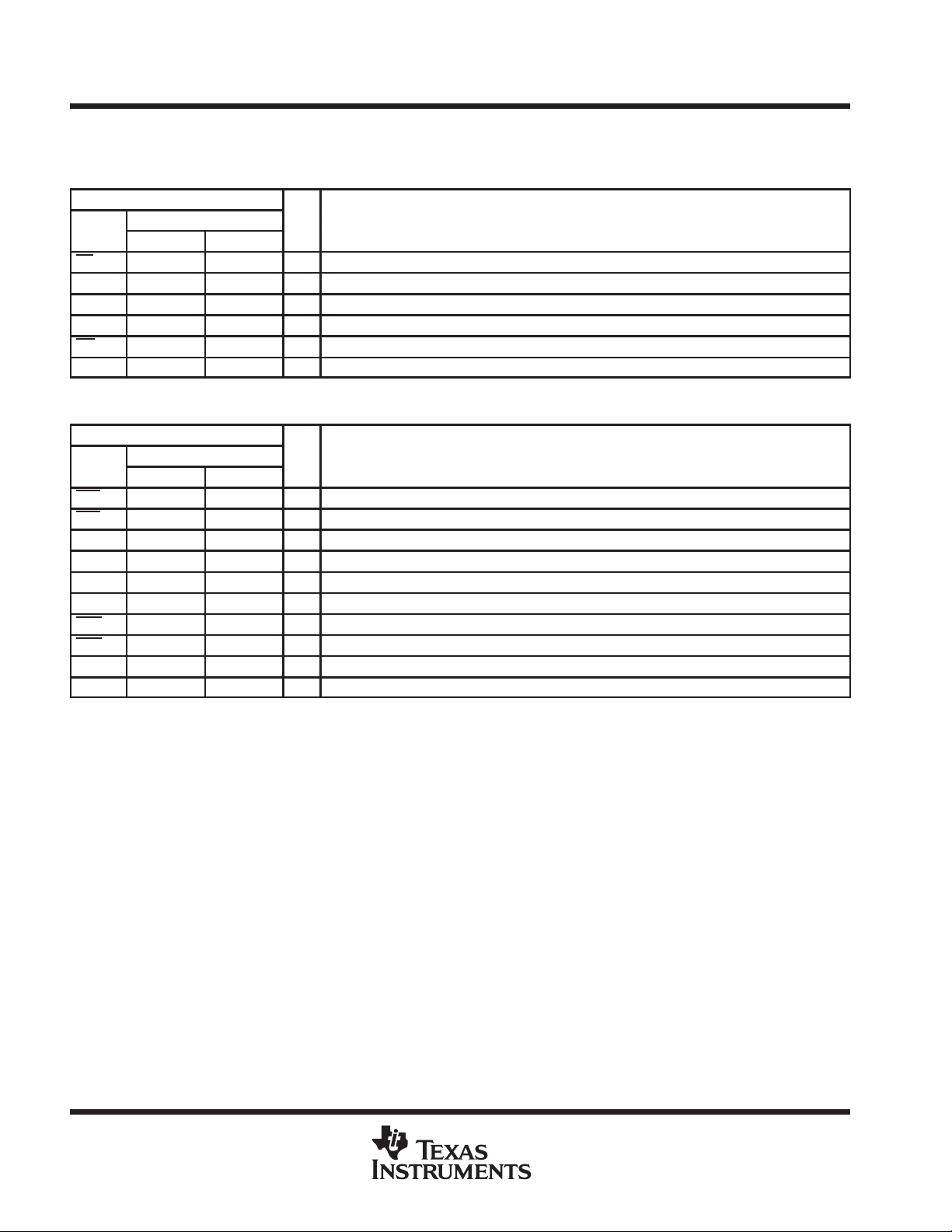

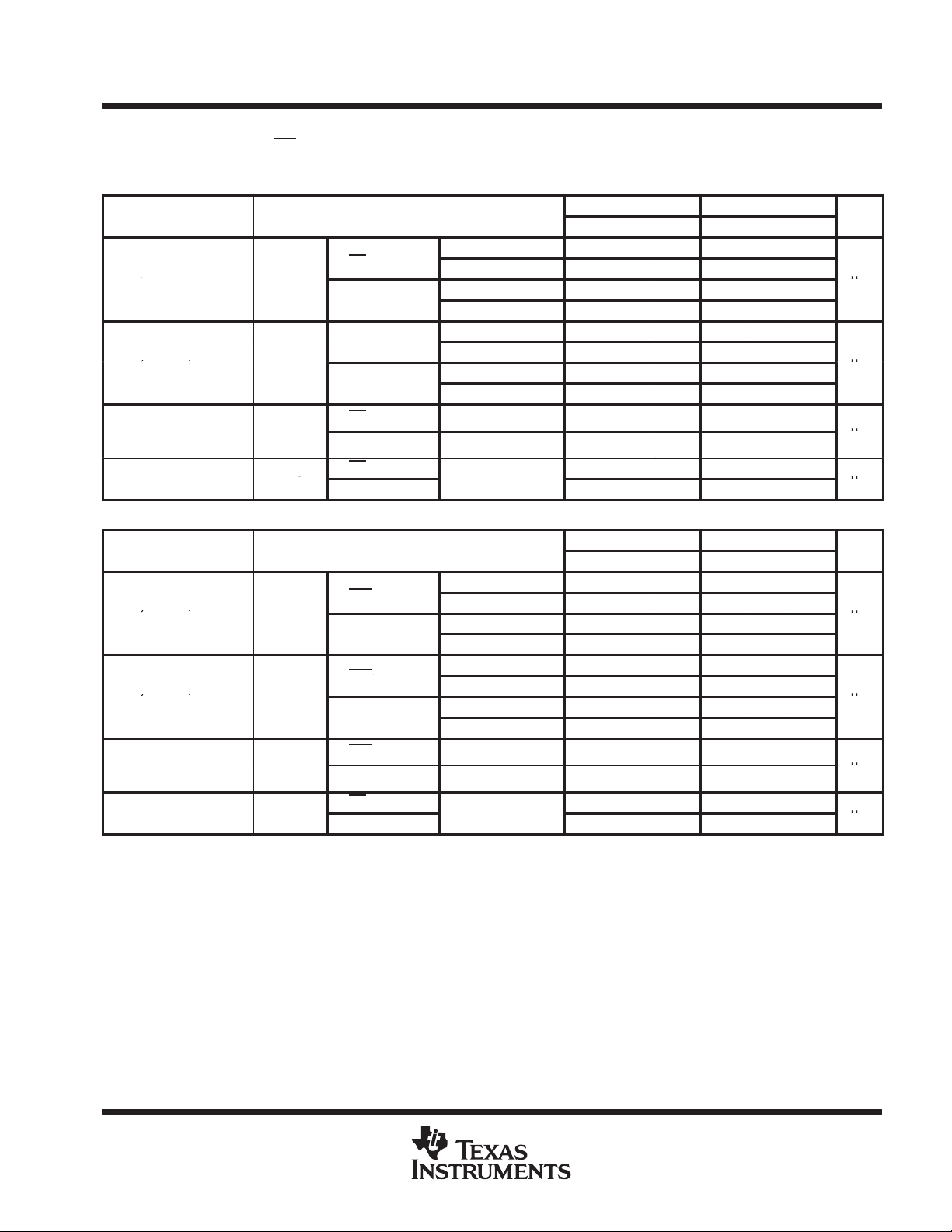

functional block diagrams

TPS2043A

OC1

GNDA

EN1

IN1

EN2

Thermal

Sense

‡

Driver

Charge

Pump

UVLO

Power Switch

Charge

Pump

Driver

‡

Thermal

Sense

Current

Limit

CS

CS

Current

Limit

†

OUT1

†

OUT2

OC2

IN2

Charge

Pump

‡

EN3

UVLO

GNDB

†

Current sense

‡

Active high for TPS205xA series

Power Switch

Driver

Thermal

Sense

CS

Current

Limit

†

OUT3

OC3

4

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

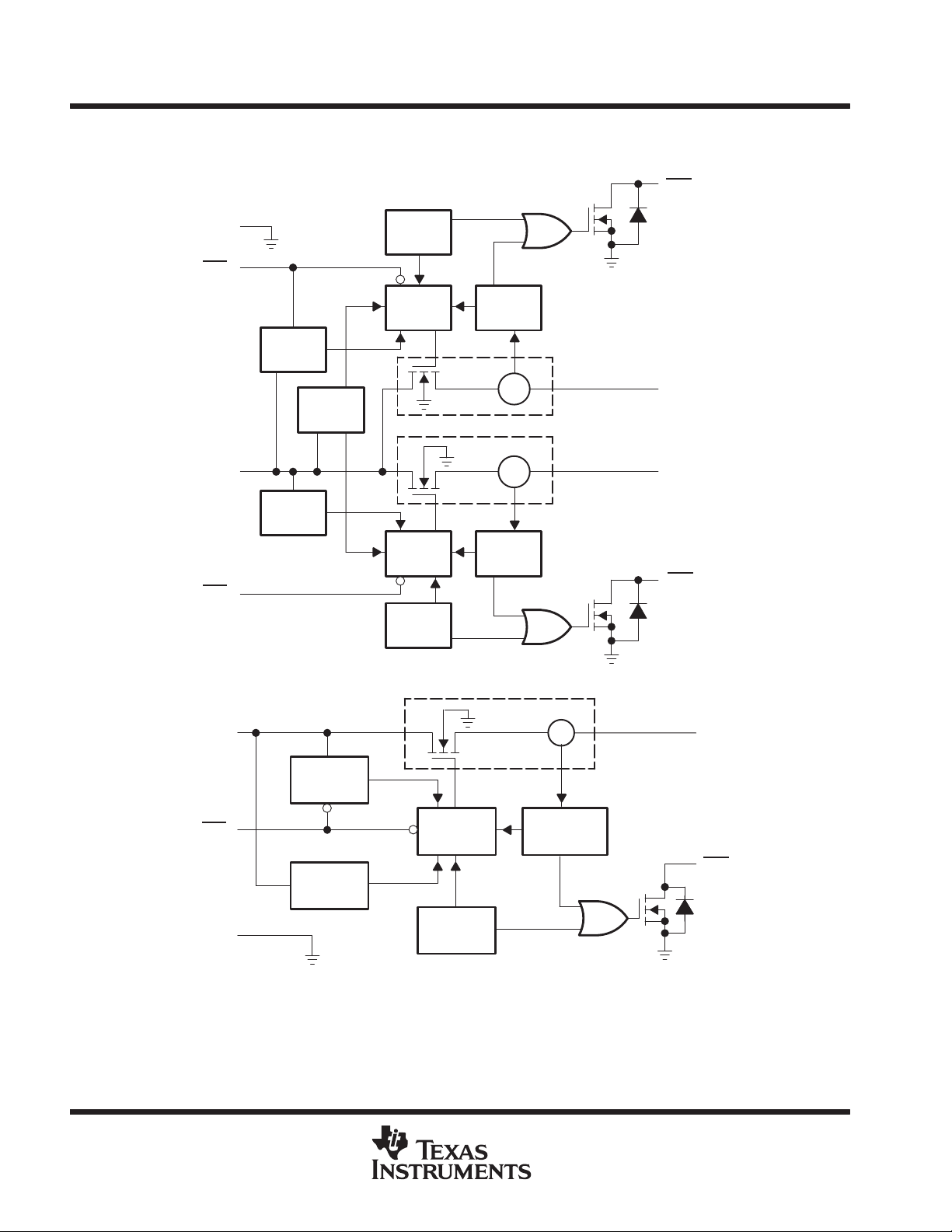

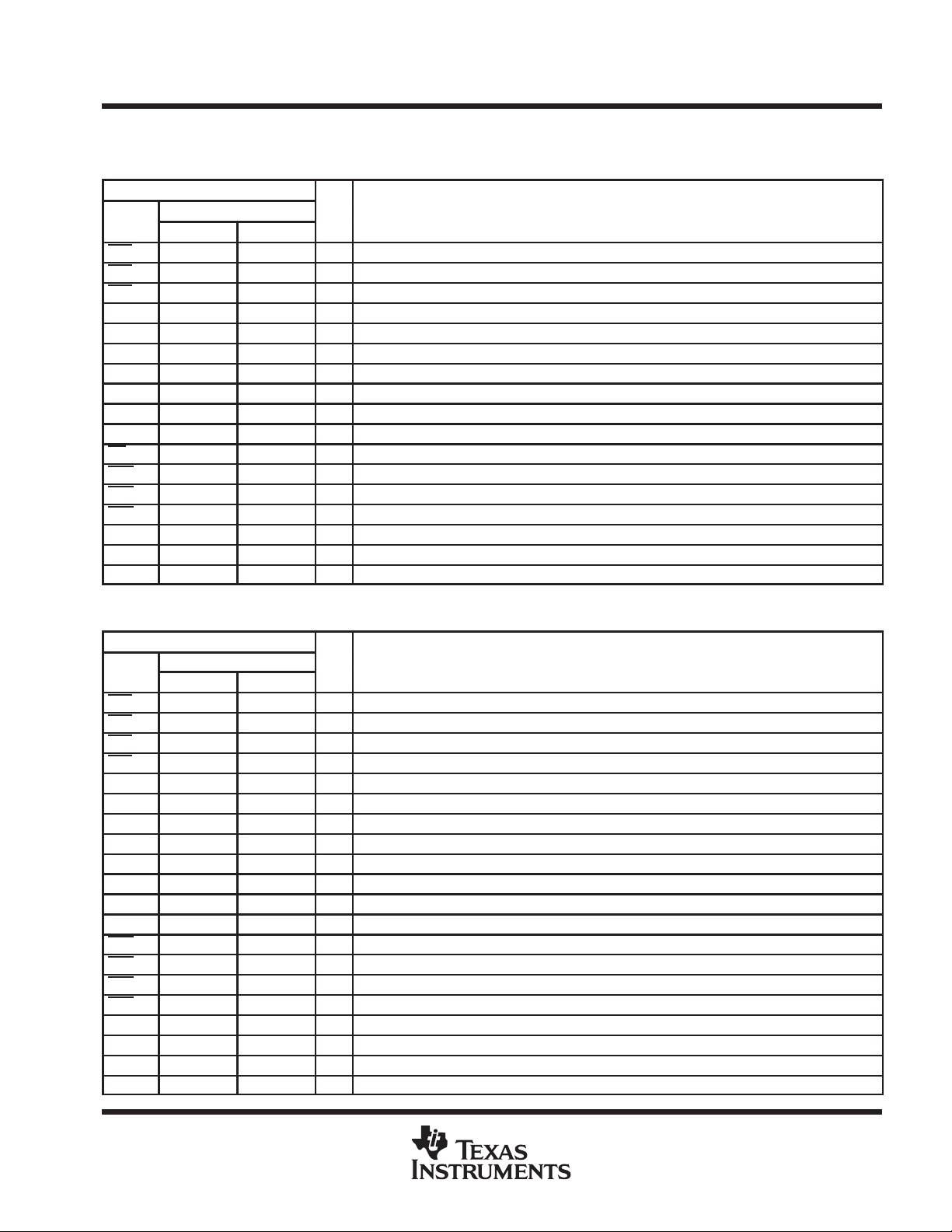

functional block diagrams

TPS2041A, TPS2042A, TPS2043A, TPS2044A

TPS2051A, TPS2052A, TPS2053A, TPS2054A

CURRENT-LIMITED POWER-DISTRIBUTION SWITCHES

SLVS247 – SEPTEMBER 2000

TPS2044A

GNDA

EN1

IN1

EN2

OC1

Thermal

Sense

‡

Driver

Charge

Pump

UVLO

Charge

Pump

Driver

‡

Thermal

Sense

Current

Limit

CS

Power Switch

CS

Current

Limit

†

OUT

1

†

OUT

2

OC2

GNDB

‡

EN3

Charge

Pump

IN2

Charge

Pump

‡

EN4

†

Current sense

‡

Active high for TPS205xA series

UVLO

Thermal

Sense

Driver

Driver

Thermal

Sense

Current

Limit

CS

Power Switch

CS

Current

Limit

OC3

†

OUT3

†

OUT4

OC4

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

5

TPS2041A, TPS2042A, TPS2043A, TPS2044A

NAME

NAME

TPS2051A, TPS2052A, TPS2053A, TPS2054A

CURRENT-LIMITED POWER-DISTRIBUTION SWITCHES

SLVS247 – SEPTEMBER 2000

Terminal Functions

TPS2041A and TPS2051A

TERMINAL

NO.

TPS2041A TPS2051A

EN 4 – I Enable input. Logic low turns on power switch.

EN – 4 I Enable input. Logic high turns on power switch.

GND 1 1 I Ground

IN 2, 3 2, 3 I Input voltage

OC 5 5 O Overcurrent. Logic output active low

OUT 6, 7, 8 6, 7, 8 O Power-switch output

TPS2042A and TPS2052A

TERMINAL

NO.

TPS2042A TPS2052A

EN1 3 – I Enable input. Logic low turns on power switch, IN-OUT1.

EN2 4 – I Enable input. Logic low turns on power switch, IN-OUT2.

EN1 – 3 I Enable input. Logic high turns on power switch, IN-OUT1.

EN2 – 4 I Enable input. Logic high turns on power switch, IN-OUT2.

GND 1 1 I Ground

IN 2 2 I Input voltage

OC1 8 8 O Overcurrent. Logic output active low, for power switch, IN-OUT1

OC2 5 5 O Overcurrent. Logic output active low, for power switch, IN-OUT2

OUT1 7 7 O Power-switch output

OUT2 6 6 O Power-switch output

I/O DESCRIPTION

I/O DESCRIPTION

6

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

NAME

NAME

TPS2041A, TPS2042A, TPS2043A, TPS2044A

TPS2051A, TPS2052A, TPS2053A, TPS2054A

CURRENT-LIMITED POWER-DISTRIBUTION SWITCHES

Terminal Functions (Continued)

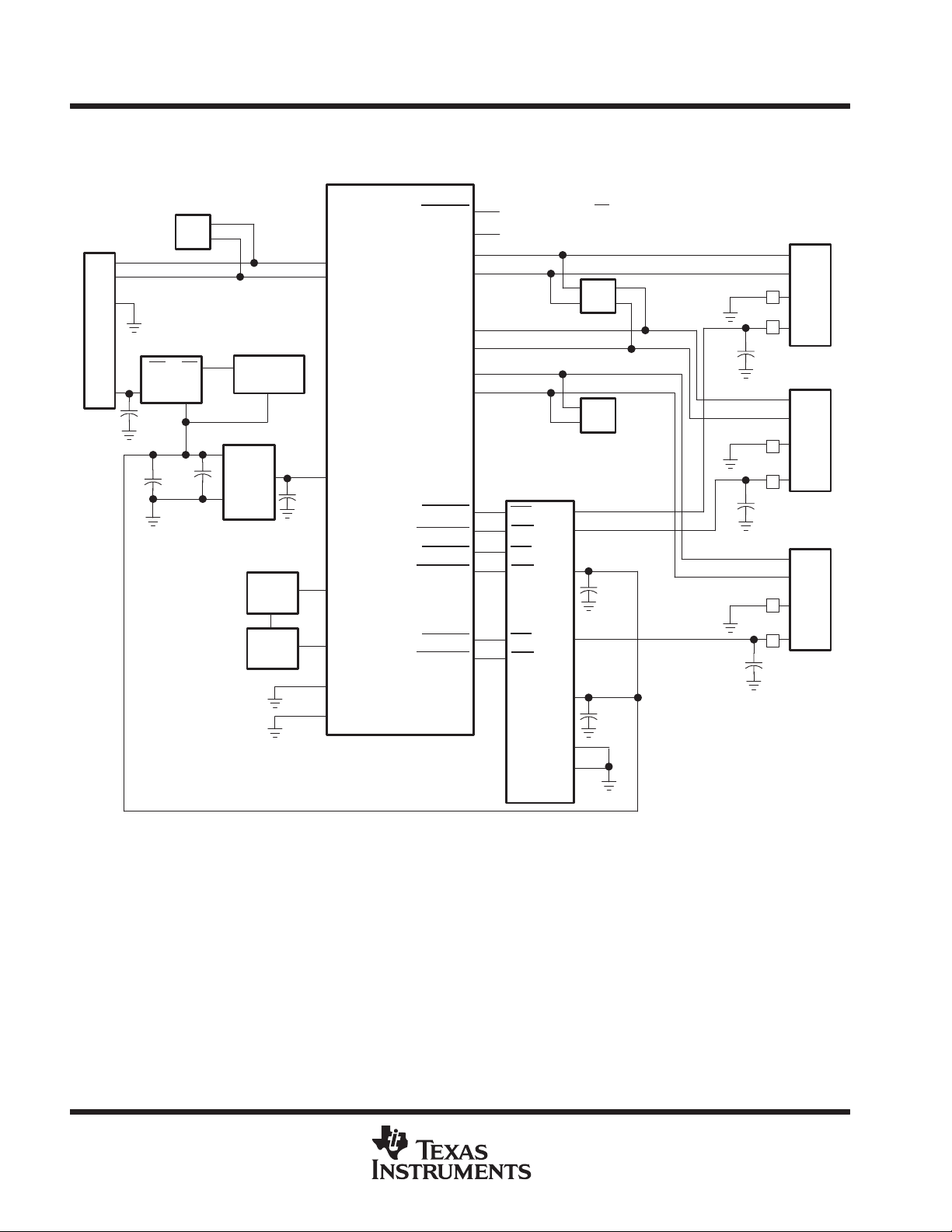

TPS2043A and TPS2053A

TERMINAL

NO.

TPS2043A TPS2053A

EN1 3 – I Enable input, logic low turns on power switch, IN1-OUT1.

EN2 4 – I Enable input, logic low turns on power switch, IN1-OUT2.

EN3 7 – I Enable input, logic low turns on power switch, IN2-OUT3.

EN1 – 3 I Enable input, logic high turns on power switch, IN1-OUT1.

EN2 – 4 I Enable input, logic high turns on power switch, IN1-OUT2.

EN3 – 7 I Enable input, logic high turns on power switch, IN2-OUT3.

GNDA 1 1 Ground for IN1 switch and circuitry.

GNDB 5 5 Ground for IN2 switch and circuitry.

IN1 2 2 I Input voltage

IN2 6 6 I Input voltage

NC 8, 9, 10 8, 9, 10 No connection

OC1 16 16 O Overcurrent, logic output active low, IN1-OUT1

OC2 13 13 O Overcurrent, logic output active low, IN1-OUT2

OC3 12 12 O Overcurrent, logic output active low, IN2-OUT3

OUT1 15 15 O Power-switch output, IN1-OUT1

OUT2 14 14 O Power-switch output, IN1-OUT2

OUT3 11 11 O Power-switch output, IN2-OUT3

I/O DESCRIPTION

SLVS247 – SEPTEMBER 2000

TPS2044A and TPS2054A

TERMINAL

NO.

TPS2044A TPS2054A

EN1 3 – I Enable input. logic low turns on power switch, IN1-OUT1.

EN2 4 – I Enable input. Logic low turns on power switch, IN1-OUT2.

EN3 7 – I Enable input. Logic low turns on power switch, IN2-OUT3.

EN4 8 – I Enable input. Logic low turns on power switch, IN2-OUT4.

EN1 – 3 I Enable input. Logic high turns on power switch, IN1-OUT1.

EN2 – 4 I Enable input. Logic high turns on power switch, IN1-OUT2.

EN3 – 7 I Enable input. Logic high turns on power switch, IN2-OUT3.

EN4 – 8 I Enable input. Logic high turns on power switch, IN2-OUT4.

GNDA 1 1 Ground for IN1 switch and circuitry.

GNDB 5 5 Ground for IN2 switch and circuitry.

IN1 2 2 I Input voltage

IN2 6 6 I Input voltage

OC1 16 16 O Overcurrent. Logic output active low, IN1-OUT1

OC2 13 13 O Overcurrent. Logic output active low, IN1-OUT2

OC3 12 12 O Overcurrent. Logic output active low, IN2-OUT3

OC4 9 9 O Overcurrent. Logic output active low, IN2-OUT4

OUT1 15 15 O Power-switch output, IN1-OUT1

OUT2 14 14 O Power-switch output, IN1-OUT2

OUT3 11 11 O Power-switch output, IN2-OUT3

OUT4 10 10 O Power-switch output, IN2-OUT4

I/O DESCRIPTION

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

7

TPS2041A, TPS2042A, TPS2043A, TPS2044A

†

TPS2051A, TPS2052A, TPS2053A, TPS2054A

CURRENT-LIMITED POWER-DISTRIBUTION SWITCHES

SLVS247 – SEPTEMBER 2000

detailed description

power switch

The power switch is an N-channel MOSFET with a maximum on-state resistance of 135 mΩ (V

Configured as a high-side switch, the power switch prevents current flow from OUT to IN and IN to OUT when

disabled. The power switch supplies a minimum of 500 mA per switch.

charge pump

An internal charge pump supplies power to the driver circuit and provides the necessary voltage to pull the gate

of the MOSFET above the source. The charge pump operates from input voltages as low as 2.7 V and requires

very little supply current.

driver

The driver controls the gate voltage of the power switch. T o limit large current surges and reduce the associated

electromagnetic interference (EMI) produced, the driver incorporates circuitry that controls the rise times and

fall times of the output voltage. The rise and fall times are typically in the 2-ms to 4-ms range.

enable (ENx

The logic enable disables the power switch and the bias for the charge pump, driver, and other circuitry to reduce

the supply current. The supply current is reduced to less than 10 µA on the single and dual devices (20 µA on

the triple and quad devices) when a logic high is present on ENx

(TPS205xA†). A logic zero input on ENx or a logic high on ENx restores bias to the drive and control circuits

and turns the power on. The enable input is compatible with both TTL and CMOS logic levels.

overcurrent (OCx)

The OCx

encountered. The output will remain asserted until the overcurrent or overtemperature condition is removed.

, ENx)

(TPS204xA†) or a logic low is present on ENx

open-drain output is asserted (active low) when an overcurrent or overtemperature condition is

I(IN)

= 5 V).

current sense

A sense FET monitors the current supplied to the load. The sense FET measures current more efficiently than

conventional resistance methods. When an overload or short circuit is encountered, the current-sense circuitry

sends a control signal to the driver. The driver in turn reduces the gate voltage and drives the power FET into

its saturation region, which switches the output into a constant-current mode and holds the current constant

while varying the voltage on the load.

thermal sense

The TPS204xA and TPS205xA implement a dual-threshold thermal trip to allow fully independent operation of

the power distribution switches. In an overcurrent or short-circuit condition the junction temperature rises. When

the die temperature rises to approximately 140°C, the internal thermal sense circuitry checks to determine which

power switch is in an overcurrent condition and turns off that switch, thus isolating the fault without interrupting

operation of the adjacent power switch. Hysteresis is built into the thermal sense, and after the device has cooled

approximately 20 degrees, the switch turns back on. The switch continues to cycle off and on until the fault is

removed. The (OCx

undervoltage lockout

A voltage sense circuit monitors the input voltage. When the input voltage is below approximately 2 V , a control

signal turns off the power switch.

Product series designations TPS204x and TPS205x refer to devices presented in this data sheet and not necessarily to other TI devices

numbered in this sequence.

) open-drain output is asserted (active low) when overtemperature or overcurrent occurs.

8

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

TPS2041A, TPS2042A, TPS2043A, TPS2044A

TPS2051A, TPS2052A, TPS2053A, TPS2054A

CURRENT-LIMITED POWER-DISTRIBUTION SWITCHES

SLVS247 – SEPTEMBER 2000

absolute maximum ratings over operating free-air temperature range (unless otherwise noted)

Input voltage range, V

Output voltage range, V

Input voltage range, V

Continuous output current, I

Continuous total power dissipation See Dissipation Rating Table. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Operating virtual junction temperature range, T

Storage temperature range, T

Lead temperature soldering 1,6 mm (1/16 inch) from case for 10 seconds 260°C. . . . . . . . . . . . . . . . . . . . . . .

Electrostatic discharge (ESD) protection: Human body model MIL-STD-883C 2 kV. . . . . . . . . . . . . . . . . . . . .

†

Stresses beyond those listed under “absolute maximum ratings” may cause permanent damage to the device. These are stress ratings only, and

functional operation of the device at these or any other conditions beyond those indicated under “recommended operating conditions” is not

implied. Exposure to absolute-maximum-rated conditions for extended periods may affect device reliability.

NOTE 1: All voltages are with respect to GND.

PACKAGE

D–8 725 mW 5.9 mW/°C 464 mW 377 mW

D–16 1123 mW 9 mW/°C 719 mW 584 mW

(see Note 1) –0.3 V to 6 V. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

I(IN)

O(OUT)

I(ENx)

(see Note 1) –0.3 V to V

or V

I(ENx)

O(OUT)

J

stg

Machine model 0.2 kV. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DISSIPATION RATING TABLE

TA ≤ 25°C

POWER RATING

DERATING FACTOR

ABOVE TA = 25°C

TA = 70°C

POWER RATING

TA = 85°C

POWER RATING

+ 0.3 V. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

I(IN)

–0.3 V to 6 V. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

internally limited. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

0°C to 125°C. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

–65°C to 150°C. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

recommended operating conditions

MIN MAX UNIT

Input voltage, V

Input voltage, V

Continuous output current, I

Operating virtual junction temperature, T

I(IN)

I(EN)

or V

I(EN)

O(OUT)

(per switch) 0 500 mA

J

2.7 5.5 V

0 5.5 V

0 125 °C

†

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

9

TPS2041A, TPS2042A, TPS2043A, TPS2044A

PARAMETER

TEST CONDITIONS

†

UNIT

r

trRise time, output

ms

tfFall time, output

ms

PARAMETER

TEST CONDITIONS

UNIT

VILLow-level input voltage

IIInput current

A

PARAMETER

TEST CONDITIONS

†

UNIT

TPS2051A, TPS2052A, TPS2053A, TPS2054A

CURRENT-LIMITED POWER-DISTRIBUTION SWITCHES

SLVS247 – SEPTEMBER 2000

electrical characteristics over recommended operating junction temperature range, V

= rated current, V

I

O

I(EN)

= 0 V, V

I(EN)

= V

(unless otherwise noted)

I(IN)

I(IN)

= 5.5 V,

power switch

TPS204xA TPS205xA

MIN TYP MAX MIN TYP MAX

V

= 5 V,

I(IN)

IO = 0.5 A

Static drain-source on-state

resistance, 5-V operation

DS(on)

Static drain-source on-state

resistance, 3.3-V operation

p

p

†

Pulse-testing techniques maintain junction temperature close to ambient temperature; thermal effects must be taken into account separately.

V

= 5 V,

I(IN)

IO = 0.5 A

V

= 5 V,

I(IN)

IO = 0.5 A

V

= 3.3 V,

I(IN)

IO = 0.5 A

V

= 3.3 V,

I(IN)

IO = 0.5 A

V

= 3.3 V,

I(IN)

IO = 0.5 A

V

= 5.5 V,

I(IN)

CL = 1 µF,

V

= 2.7 V,

I(IN)

CL = 1 µF,

V

= 5.5 V,

I(IN)

CL = 1 µF,

V

= 2.7 V,

I(IN)

CL = 1 µF,

TJ = 25°C,

TJ = 85°C,

TJ = 125°C,

TJ = 25°C,

TJ = 85°C,

TJ = 125°C,

TJ = 25°C,

RL=10 Ω

TJ = 25°C,

RL=10 Ω

TJ = 25°C,

RL=10 Ω

TJ = 25°C,

RL=10 Ω

80 100 80 100

90 120 90 120

100 135 100 135

90 125 90 125

110 145 110 145

120 160 120 160

2.5 2.5

3 3

4.4 4.4

2.5 2.5

mΩ

enable input ENx or ENx

TPS204xA TPS205xA

MIN TYP MAX MIN TYP MAX

V

High-level input voltage 2.7 V ≤ V

IH

p

p

t

Turnon time CL = 100 µF, RL=10 Ω 20 20 ms

on

t

Turnoff time CL = 100 µF, RL=10 Ω 40 40

off

TPS204xA V

TPS205xA V

4.5 V ≤ V

2.7 V≤ V

I(ENx)

I(ENx)

≤ 5.5 V 2 2 V

I(IN)

≤ 5.5 V 0.8 0.8 V

I(IN)

≤ 4.5 V 0.4 0.4

I(IN)

= 0 V or V

= V

or V

I(IN)

I(ENx)

I(ENx)

= V

I(IN)

= 0 V –0.5 0.5

–0.5 0.5

µ

current limit

TPS204xA TPS205xA

MIN TYP MAX MIN TYP MAX

V

= 5 V, OUT connected to GND,

I

Short-circuit output current

OS

†

Pulse-testing techniques maintain junction temperature close to ambient temperature; thermal effects must be taken into account separately.

I(IN)

Device enabled into short circuit

0.7 1 1.3 0.7 1 1.3 A

10

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

PARAMETER

TEST CONDITIONS

UNIT

y,

A

V

V

V

0 V

y,

A

V

V

Leakage current

d

A

Reverse leakage current

g

T

25°C

A

PARAMETER

TEST CONDITIONS

UNIT

y,

A

V

V

V

V

y,

A

V

V

Leakage current

d

A

Reverse leakage current

g

T

25°C

A

TPS2041A, TPS2042A, TPS2043A, TPS2044A

TPS2051A, TPS2052A, TPS2053A, TPS2054A

CURRENT-LIMITED POWER-DISTRIBUTION SWITCHES

SLVS247 – SEPTEMBER 2000

electrical characteristics over recommended operating junction temperature range, V

= rated current, V

I

O

supply current (TPS2041A, TPS2051A)

Supply current, low-level No Load

output on OUT

Supply current, No Load

high-level output on OUT

supply current (TPS2042A, TPS2052A)

Supply current, low-level No Load

output on OUT

Supply current, No Load

high-level output on OUT

= 0 V, V

I(EN)

OUT

connecte

to ground

IN = High

impedance

OUT

connecte

to ground

IN = high

impedance

= V

I(EN)

V

= V

I(EN)

I(EN)

I(EN)

I(EN)

V

I(EN

V

I(EN)

V

I(EN

V

I(EN)

V

I(ENx

I(ENx)

I(ENx)

I(ENx)

V

I(ENx)

V

I(ENx)

V

I(EN)

V

I(EN)

I(IN)

= 0

=

=

I(IN)

= V

)

I(IN)

= 0 V –40°C ≤ TJ ≤ 125°C 100

= 0 V

)

= V

I(IN)

= V

)

I(IN)

= 0

= 0

=

I(IN)

= V

I(IN)

= 0 V –40°C ≤ TJ ≤ 125°C 100

= 0 V

= V

I(IN)

(unless otherwise noted) (continued)

I(IN)

TPS2041A TPS2051A

MIN TYP MAX MIN TYP MAX

TJ = 25°C 0.025 1

–40°C ≤ TJ ≤ 125°C 10

TJ = 25°C 0.025 1

–40°C ≤ TJ ≤ 125°C 10

TJ = 25°C 85 110

–40°C ≤ TJ ≤ 125°C 100

TJ = 25°C 85 110

–40°C ≤ TJ ≤ 125°C 100

–40°C ≤ TJ ≤ 125°C 100

°

=

J

MIN TYP MAX MIN TYP MAX

TJ = 25°C 0.025 1

–40°C ≤ TJ ≤ 125°C 10

TJ = 25°C 0.025 1

–40°C ≤ TJ ≤ 125°C 10

TJ = 25°C 85 110

–40°C ≤ TJ ≤ 125°C 100

TJ = 25°C 85 110

–40°C ≤ TJ ≤ 125°C 100

–40°C ≤ TJ ≤ 125°C 100

°

=

J

0.3

TPS2042A TPS2052A

0.3

0.3

0.3

I(IN)

= 5.5 V,

µ

µ

µ

µ

µ

µ

µ

µ

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

11

TPS2041A, TPS2042A, TPS2043A, TPS2044A

PARAMETER

TEST CONDITIONS

UNIT

y,

A

V

V

V

0 V

y,

A

V

V

Leakage current

A

g

g

T

25°C

A

TEST CONDITIONS

UNIT

y,

A

V

V

V

V

y,

A

V

V

Leakage current

A

g

g

T

25°C

A

PARAMETER

TEST CONDITIONS

UNIT

PARAMETER

TEST CONDITIONS

UNIT

TPS2051A, TPS2052A, TPS2053A, TPS2054A

CURRENT-LIMITED POWER-DISTRIBUTION SWITCHES

SLVS247 – SEPTEMBER 2000

electrical characteristics over recommended operating junction temperature range, V

= rated current, V

I

O

I(EN)

= 0 V, V

I(EN)

= V

(unless otherwise noted) (continued)

I(IN)

I(IN)

= 5.5 V,

supply current (TPS2043A, TPS2053A)

TPS2043A TPS2053A

MIN TYP MAX MIN TYP MAX

TJ = 25°C 0.05 2

I(INx)

–40°C ≤ TJ ≤ 125°C 20

TJ = 25°C 0.05 2

–40°C ≤ TJ ≤ 125°C 20

TJ = 25°C 160 200

–40°C ≤ TJ ≤ 125°C 200

TJ = 25°C 160 200

I(INx)

–40°C ≤ TJ ≤ 125°C 200

–40°C ≤ TJ ≤ 125°C 200

I(INx)

0.3

I(IN)

°

=

J

0.3

Supply current, No Load

low-level output on OUTx

Supply current, No Load

high-level output on OUTx

OUTx connected

to ground

Reverse leakage IN = high

current

impedance

V

= V

I(ENx)

= 0

I(ENx)

=

I(ENx)

=

I(ENx)

V

= V

I(ENx)

V

= 0 V –40°C ≤ TJ ≤ 125°C 200

I(ENx)

V

= 0 V

I(ENx

)

V

= V

I(ENx)

supply current (TPS2044A, TPS2054A)

PARA-

METER

Supply current, No Load

low-level output on OUTx

Supply current, No Load

high-level output on OUTx

OUTx connected

to ground

Reverse leakage IN = high

current

impedance

V

= V

I(ENx)

= 0

I(ENx)

= 0

I(ENx)

=

I(ENx)

V

= V

I(ENx

)

V

= 0 V –40°C ≤ TJ ≤ 125°C 200

I(ENx)

V

= 0 V

I(EN)

V

= V

I(EN)

I(IN)

TJ = 25°C 0.05 2

I(INx)

–40°C ≤ TJ ≤ 125°C 20

TJ = 25°C 0.05 2

–40°C ≤ TJ ≤ 125°C 20

TJ = 25°C 170 220

–40°C ≤ TJ ≤ 125°C 200

TJ = 25°C 170 220

I(INx)

–40°C ≤ TJ ≤ 125°C 200

–40°C ≤ TJ ≤ 125°C 200

I(INx)

°

=

J

TPS2044A TPS2054A

MIN TYP MAX MIN TYP MAX

0.3

0.3

undervoltage lockout

TPS204xA TPS205xA

MIN TYP MAX MIN TYP MAX

Low-level input voltage 2 2.5 2 2.5 V

Hysteresis TJ = 25°C 100 100 mV

µ

µ

µ

µ

µ

µ

µ

µ

overcurrent OC

Sink current

Output low voltage IO = 5 V, V

Off-state current

†

Specified by design, not production tested.

12

†

†

VO = 5 V 10 10 mA

OL(OC)

VO = 5 V, VO = 3.3 V 1 1 µA

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

TPS204xA TPS205xA

MIN TYP MAX MIN TYP MAX

0.5 0.5 V

TPS2041A, TPS2042A, TPS2043A, TPS2044A

TPS2051A, TPS2052A, TPS2053A, TPS2054A

CURRENT-LIMITED POWER-DISTRIBUTION SWITCHES

SLVS247 – SEPTEMBER 2000

PARAMETER MEASUREMENT INFORMATION

OUT

V

I(EN)

(5 V/div)

V

V

O(OUT)

I(EN)

t

RL CL

V

O(OUT)

TEST CIRCUIT

50%

t

on

50%

90%

10%

V

I(EN)

t

off

V

O(OUT)

VOLTAGE WA VEFORMS

r

90%

90%

10%

50%

t

on

10%

50%

90%

10%

t

f

t

off

Figure 1. Test Circuit and Voltage Waveforms

V

I(EN)

(5 V/div)

V

O(OUT)

(2 V/div)

V

= 5 V

I(IN)

TA = 25°C

CL = 0.1 µF

RL = 10 Ω

0123456

t – Time – ms

78910

Figure 2. Turnon Delay and Rise Time

with 0.1-µF Load

V

O(OUT)

(2 V/div)

V

= 5 V

I(IN)

TA = 25°C

CL = 0.1 µF

RL = 10 Ω

04812

2 6 10 14 18

t – Time – ms

16 20

Figure 3. Turnoff Delay and Fall Time

with 0.1-µF Load

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

13

TPS2041A, TPS2042A, TPS2043A, TPS2044A

TPS2051A, TPS2052A, TPS2053A, TPS2054A

CURRENT-LIMITED POWER-DISTRIBUTION SWITCHES

SLVS247 – SEPTEMBER 2000

PARAMETER MEASUREMENT INFORMATION

V

V

I(EN)

(5 V/div)

V

O(OUT)

(2 V/div)

0123456

t – Time – ms

V

= 5 V

I(IN)

TA = 25°C

CL = 1 µF

RL = 10 Ω

78910

I(EN)

(5 V/div)

V

O(OUT)

(2 V/div)

V

= 5 V

I(IN)

TA = 25°C

CL = 1 µF

RL = 10 Ω

0 2 4 6 8 10 12

t – Time – ms

14 16 18 20

V

I(EN)

(5 V/div)

I

O(OUT)

(0.5 A/div)

Figure 4. Turnon Delay and Rise Time

with 1-µF Load

V

= 5 V

I(IN)

TA = 25°C

0123456

t – Time – ms

78910

Figure 6. TPS2051A, Short-Circuit Current,

Device Enabled into Short

V

O(OUT)

(2 V/div)

I

O(OUT)

(0.5 A/div)

Figure 5. Turnoff Delay and Fall Time

with 1-µF Load

V

= 5 V

I(IN)

TA = 25°C

01020 30405060

t – Time – ms

70 80 90 100

Figure 7. TPS2051A, Threshold Trip Current

with Ramped Load on Enabled Device

14

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

TPS2041A, TPS2042A, TPS2043A, TPS2044A

TPS2051A, TPS2052A, TPS2053A, TPS2054A

CURRENT-LIMITED POWER-DISTRIBUTION SWITCHES

SLVS247 – SEPTEMBER 2000

PARAMETER MEASUREMENT INFORMATION

V

O(OC)

(5 V/div)

I

O(OUT)

(0.5 A/div)

Figure 8. OC Response With Ramped Load

V

O(OC)

(5 V/div)

V

I(IN)

TA = 25°C

Ramp = 1 A/100 ms

0 20 40 60 80 100 120

t – Time – ms

on Enabled Device

= 5 V

140 160 180 200

V

= 5 V

I(IN)

TA = 25°C

V

I(EN)

(5 V/div)

I

O(OUT)

(0.2 A/div)

V

O(OC)

(5 V/div)

470 µF

220 µF

100 µF

V

= 5 V

I(IN)

TA = 25°C

RL = 10 Ω

0 2 4 6 8 10 12

t – Time – ms

14 16 18 20

Figure 9. Inrush Current with 100-µF, 220-µF

and 470-µF Load Capacitance

V

= 5 V

I(IN)

TA = 25°C

I

O(OUT)

(0.5 A/div)

0 1000 2000 3000 4000 5000

t – Time – µs

Figure 10. 4-Ω Load Connected to Enabled Device

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

I

O(OUT)

(1 A/div)

0 200 400 600 800 1000

t – Time – µs

Figure 11. 1-Ω Load Connected

to Enabled Device

15

TPS2041A, TPS2042A, TPS2043A, TPS2044A

TPS2051A, TPS2052A, TPS2053A, TPS2054A

CURRENT-LIMITED POWER-DISTRIBUTION SWITCHES

SLVS247 – SEPTEMBER 2000

TYPICAL CHARACTERISTICS

TURNON DELAY TIME

3.5

3.2

2.9

2.6

Turnon Delay Time – ms

2.3

2

2.5 3 3.5 4 4.5

3

CL = 1 µF

RL = 10 Ω

TA = 25°C

2.7

vs

INPUT VOLTAGE

VI – Input Voltage – V

Figure 12

RISE TIME

vs

INPUT VOLTAGE

CL = 1 µF

RL = 10 Ω

TA = 25°C

5 5.5 6

TURNOFF DELAY TIME

vs

INPUT VOLTAGE

12

CL = 1 µF

RL = 10 Ω

TA = 25°C

10

8

Turnon Delay Time – ms

6

4

2.5 3 3.5 4 4.5 5 5.5 6

VI – Input Voltage – V

Figure 13

FALL TIME

vs

INPUT VOLTAGE

2.2

CL = 1 µF

RL = 10 Ω

2.1

TA = 25°C

2

– Rise Time – ms

t

r

16

2.4

2.1

1.8

2.5 3 3.5 4 4.5 5 5.5 6

VI – Input Voltage – V

Figure 14

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

1.9

1.8

– Fall Time – ms

t

f

1.7

1.6

1.5

2.5 3 3.5 4 4.5 5 5.5 6

VI – Input Voltage – V

Figure 15

TPS2041A, TPS2042A, TPS2043A, TPS2044A

TPS2051A, TPS2052A, TPS2053A, TPS2054A

CURRENT-LIMITED POWER-DISTRIBUTION SWITCHES

SLVS247 – SEPTEMBER 2000

TYPICAL CHARACTERISTICS

SUPPLY CURRENT, OUTPUT ENABLED

vs

JUNCTION TEMPERATURE

100

Aµ

90

V

80

V

I(IN)

70

60

V

= 3.3 V

– Supply Current, Output Enabled –

50

I(IN)

I

40

–40 0 25 85 125

I(IN)

TJ – Junction Temperature – °C

I(IN)

= 4.5 V

= 5 V

V

V

I(IN)

I(IN)

= 2.7 V

= 5.5 V

Figure 16

STATIC DRAIN-SOURCE ON-STATE RESISTANCE

vs

Ω

160

140

120

100

80

60

40

20

– Static Drain-Source On-State Resistance – m

0

0 25 85 125

DS(on)

r

JUNCTION TEMPERATURE

IO = 0.5 A

V

= 2.7 V

I(IN)

V

= 3 V

I(IN)

V

= 5 V

I(IN)

TJ – Junction Temperature –°C

V

I(IN)

V

I(IN)

= 4.5 V

= 3.3 V

Figure 18

SUPPLY CURRENT, OUTPUT DISABLED

vs

JUNCTION TEMPERATURE

160

140

120

100

80

V

V

I(IN)

60

40

– Supply Current, Output Disabled – nA

20

I(IN)

I

0

–40 0 25 85 125

TJ – Junction Temperature – °C

V

I(IN)

= 3.3 V

I(IN)

= 2.7 V

V

V

I(IN)

= 4.5 V

Figure 17

INPUT-TO-OUTPUT VOLTAGE

vs

LOAD CURRENT

70

TA = 25°C

= 4.5 V

V

I(IN)

60

V

50

V

40

30

– Input-to-Output Voltage – mV

20

O(OUT)

V

–

10

I(IN)

V

0

100 200 300 400 500

I(IN)

= 3.3 V

I(IN)

IL – Load Current – A

Figure 19

I(IN)

= 5 V

= 2.7 V

V

I(IN)

= 5.5 V

= 5 V

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

17

TPS2041A, TPS2042A, TPS2043A, TPS2044A

TPS2051A, TPS2052A, TPS2053A, TPS2054A

CURRENT-LIMITED POWER-DISTRIBUTION SWITCHES

SLVS247 – SEPTEMBER 2000

TYPICAL CHARACTERISTICS

SHORT-CIRCUIT OUTPUT CURRENT

vs

JUNCTION TEMPERATURE

1.2

V

= 5.5 V

1.1

V

= 4.5 V

I(IN)

1

0.9

V

= 2.7 V

I(IN)

0.8

– Short-circuit Output Current – A

0.7

OS

I

0.6

–40

TJ – Junction Temperature – °C

V

= 5 V

I(IN)

0

25 85 125

I(IN)

V

I(IN)

= 3.3 V

1.2

1.16

1.12

1.08

Threshold Trip Current – A

1.04

1

2.5 3 3.5 4 4.5 5 5.5 6

Figure 20

UNDERVOLTAGE LOCKOUT

vs

JUNCTION TEMPERATURE

2.35

2.3

Start Threshold

250

sµ

200

THRESHOLD TRIP CURRENT

vs

INPUT VOLTAGE

TA = 25°C

Load Ramp = 1 A/10 ms

VI – Input Voltage – V

Figure 21

CURRENT-LIMIT RESPONSE

vs

PEAK CURRENT

V

= 5 V

I(IN)

TA = 25°C

2.25

2.2

2.15

UVLO – Undervoltage Lockout – V

2.1

–40 0 25 85 125

TJ – Junction Temperature – °C

Figure 22

18

150

Stop Threshold

100

Current Limit Response –

50

0

0 2.5 5 7.5 10 12.5

Peak Current – A

Figure 23

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

TPS2041A, TPS2042A, TPS2043A, TPS2044A

TPS2051A, TPS2052A, TPS2053A, TPS2054A

CURRENT-LIMITED POWER-DISTRIBUTION SWITCHES

SLVS247 – SEPTEMBER 2000

APPLICATION INFORMATION

TPS2041A

0.1 µF

2,3

IN

5

OC

4

EN

GND

1

OUT

6,7,8

0.1 µF 22 µF

Load

Power Supply

2.7 V to 5.5 V

Figure 24. T ypical Application (Example, TPS2041A)

power-supply considerations

A 0.01-µF to 0.1-µF ceramic bypass capacitor between INx and GND, close to the device, is recommended.

Placing a high-value electrolytic capacitor on the output pin(s) is recommended when the output load is heavy .

This precaution reduces power-supply transients that may cause ringing on the input. Additionally , bypassing

the output with a 0.01-µF to 0.1-µF ceramic capacitor improves the immunity of the device to short-circuit

transients.

overcurrent

A sense FET is employed to check for overcurrent conditions. Unlike current-sense resistors, sense FETs do

not increase the series resistance of the current path. When an overcurrent condition is detected, the device

maintains a constant output current and reduces the output voltage accordingly. Complete shutdown occurs

only if the fault is present long enough to activate thermal limiting.

Three possible overload conditions can occur. In the first condition, the output has been shorted before the

device is enabled or before V

has been applied (see Figure 6). The TPS204xA and TPS205xA sense the

I(IN)

short and immediately switch into a constant-current output.

In the second condition, a short or an overload occurs while the device is enabled. At the instant the overload

occurs, very high currents may flow for a short time before the current-limit circuit can react. After the

current-limit circuit has tripped (reached the overcurrent trip threshhold) the device switches into

constant-current mode.

In the third condition, the load has been gradually increased beyond the recommended operating current. The

current is permitted to rise until the current-limit threshold is reached or until the thermal limit of the device is

exceeded (see Figure 7). The TPS204xA and TPS205xA are capable of delivering current up to the current-limit

threshold without damaging the device. Once the threshold has been reached, the device switches into its

constant-current mode.

OC response

The OC open-drain output is asserted (active low) when an overcurrent or overtemperature condition is

encountered. The output will remain asserted until the overcurrent or overtemperature condition is removed.

Connecting a heavy capacitive load to an enabled device can cause momentary false overcurrent reporting from

the inrush current flowing through the device, charging the downstream capacitor. The TPS204xA and

TPS205xA family of devices are designed to reduce false overcurrent reporting. An internal overcurrent

transient filter eliminates the need for external components to remove unwanted pulses. Using low-ESR

electrolytic capacitors on the output lowers the inrush current flow through the device during hot-plug events

by providing a low-impedance energy source, also reducing erroneous overcurrent reporting.

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

19

TPS2041A, TPS2042A, TPS2043A, TPS2044A

TPS2051A, TPS2052A, TPS2053A, TPS2054A

CURRENT-LIMITED POWER-DISTRIBUTION SWITCHES

SLVS247 – SEPTEMBER 2000

APPLICATION INFORMATION

TPS2041A

GND

IN

IN

EN

OUT

OUT

OUT

OC

Figure 25. Typical Circuit for OC Pin (Example, TPS2041A)

power dissipation and junction temperature

The low on-resistance on the n-channel MOSFET allows small surface-mount packages, such as SOIC, to pass

large currents. The thermal resistances of these packages are high compared to those of power packages; it

is good design practice to check power dissipation and junction temperature. Begin by determining the r

of the N-channel MOSFET relative to the input voltage and operating temperature. As an initial estimate, use

the highest operating ambient temperature of interest and read r

power dissipation per switch can be calcultaed by:

PD+

r

DS(on)

2

I

V+

R

DS(on)

pullup

from Figure 18. Using this value, the

DS(on)

Depending on which device is being used, multiply this number by the number of switches being used. This step

will render the total power dissipation from the N-channel MOSFETs.

Finally, calculate the junction temperature:

TJ+

PD

R

)

JA

T

A

q

Where:

T

= Ambient Temperature °C

A

R

= Thermal resistance SOIC = 172°C/W (for 8 pin), 111°C/W (for 16 pin)

θJA

PD = Total power dissipation based on number of switches being used.

Compare the calculated junction temperature with the initial estimate. If they do not agree within a few degrees,

repeat the calculation, using the calculated value as the new estimate. Two or three iterations are generally

sufficient to get a reasonable answer.

thermal protection

Thermal protection prevents damage to the IC when heavy-overload or short-circuit faults are present for

extended periods of time. The faults force the TPS204xA and TPS205xA into constant-current mode, which

causes the voltage across the high-side switch to increase; under short-circuit conditions, the voltage across

the switch is equal to the input voltage. The increased dissipation causes the junction temperature to rise to high

levels. The protection circuit senses the junction temperature of the switch and shuts it off. Hysteresis is built

into the thermal sense circuit, and after the device has cooled approximately 20 degrees, the switch turns back

on. The switch continues to cycle in this manner until the load fault or input power is removed.

The TPS204xA and TPS205xA implement a dual thermal trip to allow fully independent operation of the power

distribution switches. In an overcurrent or short-circuit condition the junction temperature will rise. Once the die

temperature rises to approximately 140°C, the internal thermal sense circuitry checks which power switch is

in an overcurrent condition and turns that power switch off, thus isolating the fault without interrupting operation

of the adjacent power switch. Should the die temperature exceed the first thermal trip point of 140°C and reach

160°C, both switches turn off. The OC open-drain output is asserted (active low) when overtemperature or

overcurrent occurs.

20

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

TPS2041A, TPS2042A, TPS2043A, TPS2044A

TPS2051A, TPS2052A, TPS2053A, TPS2054A

CURRENT-LIMITED POWER-DISTRIBUTION SWITCHES

SLVS247 – SEPTEMBER 2000

APPLICATION INFORMATION

undervoltage lockout (UVLO)

An undervoltage lockout ensures that the power switch is in the off state at power up. Whenever the input voltage

falls below approximately 2 V, the power switch will be quickly turned off. This facilitates the design of

hot-insertion systems where it is not possible to turn off the power switch before input power is removed. The

UVLO will also keep the switch from being turned on until the power supply has reached at least 2 V, even if

the switch is enabled. Upon reinsertion, the power switch will be turned on, with a controlled rise time to reduce

EMI and voltage overshoots.

universal serial bus (USB) applications

The universal serial bus (USB) interface is a 12-Mb/s, or 1.5-Mb/s, multiplexed serial bus designed for

low-to-medium bandwidth PC peripherals (e.g., keyboards, printers, scanners, and mice). The four-wire USB

interface is conceived for dynamic attach-detach (hot plug-unplug) of peripherals. Two lines are provided for

differential data, and two lines are provided for 5-V power distribution.

USB data is a 3.3-V level signal, but power is distributed at 5 V to allow for voltage drops in cases where power

is distributed through more than one hub across long cables. Each function must provide its own regulated 3.3 V

from the 5-V input or its own internal power supply.

The USB specification defines the following five classes of devices, each differentiated by power-consumption

requirements:

D

Hosts/self-powered hubs (SPH)

D

Bus-powered hubs (BPH)

D

Low-power, bus-powered functions

D

High-power, bus-powered functions

D

Self-powered functions

Self-powered and bus-powered hubs distribute data and power to downstream functions. The TPS204xA and

TPS205xA can provide power-distribution solutions for many of these classes of devices.

host/self-powered and bus-powered hubs

Hosts and self-powered hubs have a local power supply that powers the embedded functions and the

downstream ports (see Figures 26 and 27). This power supply must provide from 5.25 V to 4.75 V to the board

side of the downstream connection under full-load and no-load conditions. Hosts and SPHs are required to have

current-limit protection and must report overcurrent conditions to the USB controller. T ypical SPHs are desktop

PCs, monitors, printers, and stand-alone hubs.

USB

Control

Power Supply

3.3 V 5 V

0.1 µF

2, 3

5

4

TPS2041A

IN

OC

EN

GND

OUT

7

0.1 µF 120 µF

Downstream

USB Ports

D+

D–

V

BUS

GND

Figure 26. Typical One-Port Solution

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

21

TPS2041A, TPS2042A, TPS2043A, TPS2044A

TPS2051A, TPS2052A, TPS2053A, TPS2054A

CURRENT-LIMITED POWER-DISTRIBUTION SWITCHES

SLVS247 – SEPTEMBER 2000

APPLICATION INFORMATION

Power Supply

USB

Controller

3.3 V 5 V

0.1 µF

11

13

12

2

6

3

4

7

9

8

TPS2044A

IN1

IN2

OC1

EN1

OC2

EN2

OC3

EN3

OC4

EN4

GNDA

OUT1

OUT2

OUT3

OUT4

GNDB

1

15

14

11

10

5

+

+

+

+

33 µF

33 µF

33 µF

33 µF

Downstream

USB Ports

D+

D–

V

BUS

GND

D+

D–

V

BUS

GND

D+

D–

V

BUS

GND

D+

D–

V

BUS

GND

Figure 27. T ypical Four-Port USB Host/Self-Powered Hub

Bus-powered hubs obtain all power from upstream ports and often contain an embedded function. The hubs

are required to power up with less than one unit load. The BPH usually has one embedded function, and power

is always available to the controller of the hub. If the embedded function and hub require more than 100 mA

on powerup, the power to the embedded function may need to be kept off until enumeration is completed. This

can be accomplished by removing power or by shutting off the clock to the embedded function. Power switching

the embedded function is not necessary if the aggregate power draw for the function and controller is less than

one unit load. The total current drawn by the bus-powered device is the sum of the current to the controller, the

embedded function, and the downstream ports, and it is limited to 500 mA from an upstream port.

22

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

TPS2041A, TPS2042A, TPS2043A, TPS2044A

TPS2051A, TPS2052A, TPS2053A, TPS2054A

CURRENT-LIMITED POWER-DISTRIBUTION SWITCHES

SLVS247 – SEPTEMBER 2000

APPLICATION INFORMATION

low-power bus-powered functions and high-power bus-powered functions

Both low-power and high-power bus-powered functions obtain all power from upstream ports; low-power

functions always draw less than 100 mA; high-power functions must draw less than 100 mA at power up and

can draw up to 500 mA after enumeration. If the load of the function is more than the parallel combination of

44 Ω and 10 µF at power up, the device must implement inrush current limiting (see Figure 28).

Power Supply

D+

D–

V

BUS

GND

USB

Control

10 µF

3.3 V

0.1 µF

2,3

5

4

TPS2041A

IN

OC

EN

GND

1

OUT

6, 7, 8

0.1 µF 10 µF

Internal

Function

Figure 28. High-Power Bus-Powered Function (Example, TPS2041A)

USB power-distribution requirements

USB can be implemented in several ways, and, regardless of the type of USB device being developed, several

power-distribution features must be implemented.

D

Hosts/self-powered hubs must:

– Current-limit downstream ports

– Report overcurrent conditions on USB V

D

Bus-powered hubs must:

– Enable/disable power to downstream ports

– Power up at <100 mA

– Limit inrush current (<44 Ω and 10 µF)

D

Functions must:

– Limit inrush currents

– Power up at <100 mA

The feature set of the TPS204xA and TPS205xA allows them to meet each of these requirements. The

integrated current-limiting and overcurrent reporting is required by hosts and self-powered hubs. The logic-level

enable and controlled rise times meet the need of both input and output ports on bus-power hubs, as well as

the input ports for bus-power functions (see Figures 29 through 32).

BUS

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

23

TPS2041A, TPS2042A, TPS2043A, TPS2044A

TPS2051A, TPS2052A, TPS2053A, TPS2054A

CURRENT-LIMITED POWER-DISTRIBUTION SWITCHES

SLVS247 – SEPTEMBER 2000

APPLICATION INFORMATION

TUSB2040

Hub Controller

Upstream

Port

D +

D –

GND

5 V

SN75240

TPS2041A

OC EN

IN

1 µF

0.1 µF

4.7 µF

A

B

OUT

C

D

GND

5 V Power

Supply

TPS76333

IN

3.3 V

GND

48-MHz

Crystal

Tuning

Circuit

4.7 µF

DP0

DM0

V

CC

XTAL1

XTAL2

OCSOFF

GND

BUSPWR

GANGED

DP1

DM1

DP2

DM2

DP3

DM3

DP4

DM4

PWRON1

OVRCUR1

PWRON2

OVRCUR2

PWRON3

OVRCUR3

PWRON4

OVRCUR4

Tie to TPS2041A EN

TPS2041A

EN

OC

TPS2041A

EN

OC

TPS2041A

EN

OC

TPS2041A

EN

OC

IN

OUT

IN

OUT

IN

OUT

IN

OUT

ABC

D

SN75240

ABC

D

SN75240

0.1 µF

0.1 µF

0.1 µF

0.1 µF

Input

Ferrite Beads

Ferrite Beads

Ferrite Beads

Ferrite Beads

Downstream

Ports

D +

D –

GND

5 V

†

33 µF

D +

D –

GND

5 V

†

33 µF

D +

D –

GND

5 V

†

33 µF

D +

D –

GND

5 V

†

USB rev 1.1 requires 120 µF per hub.

Figure 29. Hybrid Self/Bus-Powered Hub Implementation, TPS2041A

24

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

33 µF

†

TPS2041A, TPS2042A, TPS2043A, TPS2044A

TPS2051A, TPS2052A, TPS2053A, TPS2054A

CURRENT-LIMITED POWER-DISTRIBUTION SWITCHES

SLVS247 – SEPTEMBER 2000

APPLICATION INFORMATION

TUSB2040

Hub Controller

Upstream

Port

D +

D –

GND

5 V

TPS2041A

OC EN

IN

1 µF

0.1 µF

4.7 µF

SN75240

A

C

B

D

OUT

GND

5 V Power

Supply

TPS76333

IN

3.3 V

GND

48-MHz

Crystal

Tuning

Circuit

4.7 µF

DP0

DM0

V

CC

XTAL1

XTAL2

OCSOFF

GND

BUSPWR

GANGED

DP1

DM1

DP2

DM2

DP3

DM3

DP4

DM4

PWRON1

OVRCUR1

PWRON2

OVRCUR2

PWRON3

OVRCUR3

PWRON4

OVRCUR4

Tie to TPS2042A EN

ABC

SN75240

ABC

SN75240

TPS2042A

EN1

OUT1

OUT2

OC1

EN2

OC2

IN

TPS2042A

EN1

OUT1

OUT2

OC1

EN2

OC2

IN

Input

D

D

0.1 µF

0.1 µF

Ferrite Beads

Ferrite Beads

Ferrite Beads

Ferrite Beads

Downstream

Ports

D +

D –

GND

5 V

†

33 µF

D +

D –

GND

5 V

†

33 µF

D +

D –

GND

5 V

†

33 µF

D +

D –

GND

†

USB rev 1.1 requires 120 µF per hub.

Figure 30. Hybrid Self/Bus-Powered Hub Implementation, TPS2042A

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

33 µF

5 V

†

25

TPS2041A, TPS2042A, TPS2043A, TPS2044A

TPS2051A, TPS2052A, TPS2053A, TPS2054A

CURRENT-LIMITED POWER-DISTRIBUTION SWITCHES

SLVS247 – SEPTEMBER 2000

APPLICATION INFORMATION

TUSB2040

Hub Controller

Upstream

Port

D +

D –

GND

5 V

1/2 SN75240

TPS2041A

OC EN

IN

1 µF

0.1 µF

4.7 µF

A

B

OUT

C

D

GND

5 V Power

Supply

TPS76333

IN

3.3 V

GND

48-MHz

Crystal

Tuning

Circuit

4.7 µF

DP0

DM0

V

CC

XTAL1

XTAL2

OCSOFF

GND

BUSPWR

GANGED

DP1

DM1

DP2

DM2

DP3

DM3

DP4

DM4

PWRON1

OVRCUR1

PWRON2

OVRCUR2

PWRON3

OVRCUR3

Tie to TPS2043A EN

ABC

SN75240

ABC

1/2 SN75240

TPS2043A

EN1

OUT1

OUT2

OC1

EN2

OC2

IN1

EN3

OUT3

OC3

IN2

Input

D

D

0.1 µF

0.1 µF

Ferrite Beads

Ferrite Beads

Ferrite Beads

Downstream

Ports

D +

D –

GND

5 V

†

47 µF

D +

D –

GND

5 V

†

47 µF

D +

D –

GND

5 V

†

47 µF

†

USB rev 1.1 requires 120 µF per hub.

Figure 31. Hybrid Self/Bus-Powered Hub Implementation, TPS2043A

26

GNDA

GNDB

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

TPS2041A, TPS2042A, TPS2043A, TPS2044A

TPS2051A, TPS2052A, TPS2053A, TPS2054A

CURRENT-LIMITED POWER-DISTRIBUTION SWITCHES

SLVS247 – SEPTEMBER 2000

APPLICATION INFORMATION

TUSB2040

Hub Controller

Upstream

Port

D +

D –

GND

5 V

SN75240

TPS2041A

OC EN

IN

1 µF

0.1 µF

4.7 µF

A

B

OUT

C

D

GND

5 V Power

Supply

TPS76333

IN

3.3 V

GND

48-MHz

Crystal

Tuning

Circuit

4.7 µF

DP0

DM0

V

CC

XTAL1

XTAL2

OCSOFF

GND

BUSPWR

GANGED

DP1

DM1

DP2

DM2

DP3

DM3

DP4

DM4

PWRON1

OVRCUR1

PWRON2

OVRCUR2

PWRON3

OVRCUR3

PWRON4

OVRCUR4

Tie to TPS2041 EN

ABC

SN75240

ABC

SN75240

TPS2044A

EN1

OUT1

OUT2

OC1

EN2

OC2

IN1

EN3

OUT3

OUT4

OC3

EN4

OC4

IN2

GNDA

GNDB

Input

D

D

0.1 µF

0.1 µF

Ferrite Beads

Ferrite Beads

Ferrite Beads

Ferrite Beads

Downstream

Ports

D +

D –

GND

5 V

†

33 µF

D +

D –

GND

5 V

†

33 µF

D +

D –

GND

5 V

†

33 µF

D +

D –

GND

5 V

†

USB rev 1.1 requires 120 µF per hub.

Figure 32. Hybrid Self/Bus-Powered Hub Implementation, TPS2044A

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

33 µF

†

27

TPS2041A, TPS2042A, TPS2043A, TPS2044A

TPS2051A, TPS2052A, TPS2053A, TPS2054A

CURRENT-LIMITED POWER-DISTRIBUTION SWITCHES

SLVS247 – SEPTEMBER 2000

APPLICATION INFORMATION

generic hot-plug applications (see Figure 33)

In many applications it may be necessary to remove modules or pc boards while the main unit is still operating.

These are considered hot-plug applications. Such implementations require the control of current surges seen

by the main power supply and the card being inserted. The most effective way to control these surges is to limit

and slowly ramp the current and voltage being applied to the card, similar to the way in which a power supply

normally turns on. Due to the controlled rise times and fall times of the TPS204xA and TPS205xA, these devices

can be used to provide a softer start-up to devices being hot-plugged into a powered system. The UVLO feature

of the TPS204xA and TPS205xA also ensures the switch will be off after the card has been removed, and the

switch will be off during the next insertion. The UVLO feature insures a soft start with a controlled rise time for

every insertion of the card or module.

PC Board

Power

Supply

2.7 V to 5.5 V

1000 µF

Optimum

0.1 µF

TPS2041A

GND

IN

IN

EN

OUT

OUT

OUT

OC

Block of

Circuitry

Overcurrent Response

Figure 33. T ypical Hot-Plug Implementation (Example, TPS2041A)

By placing the TPS204xA and TPS205xA between the VCC input and the rest of the circuitry , the input power

will reach these devices first after insertion. The typical rise time of the switch is approximately 2.5 ms, providing

a slow voltage ramp at the output of the device. This implementation controls system surge currents and

provides a hot-plugging mechanism for any device.

28

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

TPS2041A, TPS2042A, TPS2043A, TPS2044A

TPS2051A, TPS2052A, TPS2053A, TPS2054A

CURRENT-LIMITED POWER-DISTRIBUTION SWITCHES

SLVS247 – SEPTEMBER 2000

MECHANICAL DATA

D (R-PDSO-G**) PLASTIC SMALL-OUTLINE PACKAGE

14 PIN SHOWN

0.050 (1,27)

14

1

0.069 (1,75) MAX

A

0.020 (0,51)

0.014 (0,35)

0.010 (0,25)

0.004 (0,10)

DIM

8

7

PINS **

0.010 (0,25)

0.157 (4,00)

0.150 (3,81)

M

0.244 (6,20)

0.228 (5,80)

Seating Plane

0.004 (0,10)

8

14

0.008 (0,20) NOM

0°–8°

16

Gage Plane

0.010 (0,25)

0.044 (1,12)

0.016 (0,40)

A MAX

A MIN

NOTES: A. All linear dimensions are in inches (millimeters).

B. This drawing is subject to change without notice.

C. Body dimensions do not include mold flash or protrusion, not to exceed 0.006 (0,15).

D. Falls within JEDEC MS-012

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

0.197

(5,00)

0.189

(4,80)

0.344

(8,75)

0.337

(8,55)

0.394

(10,00)

0.386

(9,80)

4040047/D 10/96

29

PACKAGE OPTION ADDENDUM

www.ti.com

PACKAGING INFORMATION

Orderable Device Status

TPS2041AD NRND SOIC D 8 75 Green (RoHS &

TPS2041ADG4 NRND SOIC D 8 75 Green (RoHS &

TPS2041ADR NRND SOIC D 8 2500 Green(RoHS &

TPS2041ADRG4 NRND SOIC D 8 2500 Green(RoHS &

TPS2042AD NRND SOIC D 8 75 Green (RoHS &

TPS2042ADG4 NRND SOIC D 8 75 Green (RoHS &

TPS2042ADR NRND SOIC D 8 2500 Green(RoHS &

TPS2042ADRG4 NRND SOIC D 8 2500 Green(RoHS &

TPS2043AD NRND SOIC D 16 40 Green (RoHS &

TPS2043ADG4 NRND SOIC D 16 40 Green (RoHS &

TPS2043ADR NRND SOIC D 16 2500 Green (RoHS &

TPS2043ADRG4 NRND SOIC D 16 2500 Green (RoHS &

TPS2044AD NRND SOIC D 16 40 Green (RoHS &

TPS2044ADG4 NRND SOIC D 16 40 Green (RoHS &

TPS2044ADR NRND SOIC D 16 2500 Green (RoHS &

TPS2044ADRG4 NRND SOIC D 16 2500 Green (RoHS &

TPS2051AD NRND SOIC D 8 75 Green (RoHS &

TPS2051ADG4 NRND SOIC D 8 75 Green (RoHS &

TPS2051ADR NRND SOIC D 8 2500 Green(RoHS &

TPS2051ADRG4 NRND SOIC D 8 2500 Green(RoHS &

TPS2052AD NRND SOIC D 8 75 Green (RoHS &

TPS2052ADG4 NRND SOIC D 8 75 Green (RoHS &

TPS2052ADR NRND SOIC D 8 2500 Green(RoHS &

TPS2052ADRG4 NRND SOIC D 8 2500 Green(RoHS &

TPS2053AD NRND SOIC D 16 40 Green (RoHS &

(1)

Package

Type

Package

Drawing

Pins Package

Qty

Eco Plan

no Sb/Br)

no Sb/Br)

no Sb/Br)

no Sb/Br)

no Sb/Br)

no Sb/Br)

no Sb/Br)

no Sb/Br)

no Sb/Br)

no Sb/Br)

no Sb/Br)

no Sb/Br)

no Sb/Br)

no Sb/Br)

no Sb/Br)

no Sb/Br)

no Sb/Br)

no Sb/Br)

no Sb/Br)

no Sb/Br)

no Sb/Br)

no Sb/Br)

no Sb/Br)

no Sb/Br)

no Sb/Br)

(2)

Lead/Ball Finish MSL Peak Temp

CU NIPDAU Level-1-260C-UNLIM

CU NIPDAU Level-1-260C-UNLIM

CU NIPDAU Level-1-260C-UNLIM

CU NIPDAU Level-1-260C-UNLIM

CU NIPDAU Level-1-260C-UNLIM

CU NIPDAU Level-1-260C-UNLIM

CU NIPDAU Level-1-260C-UNLIM

CU NIPDAU Level-1-260C-UNLIM

CU NIPDAU Level-1-260C-UNLIM

CU NIPDAU Level-1-260C-UNLIM

CU NIPDAU Level-1-260C-UNLIM

CU NIPDAU Level-1-260C-UNLIM

CU NIPDAU Level-1-260C-UNLIM

CU NIPDAU Level-1-260C-UNLIM

CU NIPDAU Level-1-260C-UNLIM

CU NIPDAU Level-1-260C-UNLIM

CU NIPDAU Level-1-260C-UNLIM

CU NIPDAU Level-1-260C-UNLIM

CU NIPDAU Level-1-260C-UNLIM

CU NIPDAU Level-1-260C-UNLIM

CU NIPDAU Level-1-260C-UNLIM

CU NIPDAU Level-1-260C-UNLIM

CU NIPDAU Level-1-260C-UNLIM

CU NIPDAU Level-1-260C-UNLIM

CU NIPDAU Level-1-260C-UNLIM

4-Aug-2008

(3)

Addendum-Page 1

PACKAGE OPTION ADDENDUM

www.ti.com

Orderable Device Status

(1)

Package

Type

Package

Drawing

Pins Package

Qty

Eco Plan

TPS2053ADG4 NRND SOIC D 16 40 Green (RoHS &

(2)

Lead/Ball Finish MSL Peak Temp

CU NIPDAU Level-1-260C-UNLIM

4-Aug-2008

(3)

no Sb/Br)

TPS2053ADR NRND SOIC D 16 2500 Green (RoHS &

CU NIPDAU Level-1-260C-UNLIM

no Sb/Br)

TPS2053ADRG4 NRND SOIC D 16 2500 Green (RoHS &

CU NIPDAU Level-1-260C-UNLIM

no Sb/Br)

TPS2054AD NRND SOIC D 16 40 Green (RoHS &

CU NIPDAU Level-1-260C-UNLIM

no Sb/Br)

TPS2054ADG4 NRND SOIC D 16 40 Green (RoHS &

CU NIPDAU Level-1-260C-UNLIM

no Sb/Br)

TPS2054ADR NRND SOIC D 16 2500 Green (RoHS &

CU NIPDAU Level-1-260C-UNLIM

no Sb/Br)

TPS2054ADRG4 NRND SOIC D 16 2500 Green (RoHS &

CU NIPDAU Level-1-260C-UNLIM

no Sb/Br)

(1)

The marketing status values are defined as follows:

ACTIVE: Product device recommended for new designs.

LIFEBUY: TI has announced that the device will be discontinued, and a lifetime-buy period is in effect.

NRND: Not recommended for new designs. Device is in production to support existing customers, but TI does not recommend using this part in

a new design.

PREVIEW: Device has been announced but is not in production. Samples may or may not be available.

OBSOLETE: TI has discontinued the production of the device.

(2)

Eco Plan - The planned eco-friendly classification: Pb-Free (RoHS), Pb-Free (RoHS Exempt), or Green (RoHS & no Sb/Br) - please check

http://www.ti.com/productcontent for the latest availability information and additional product content details.

TBD: The Pb-Free/Green conversion plan has not been defined.

Pb-Free (RoHS): TI's terms "Lead-Free" or "Pb-Free" mean semiconductor products that are compatible with the current RoHS requirements

for all 6 substances, including the requirement that lead not exceed 0.1% by weight in homogeneous materials. Where designed to be soldered

at high temperatures, TI Pb-Free products are suitable for use in specified lead-free processes.

Pb-Free (RoHS Exempt): This component has a RoHS exemption for either 1) lead-based flip-chip solder bumps used between the die and

package, or 2) lead-based die adhesive used between the die and leadframe. The component is otherwise considered Pb-Free (RoHS

compatible) as defined above.

Green (RoHS & no Sb/Br): TI defines "Green" to mean Pb-Free (RoHS compatible), and free of Bromine (Br) and Antimony (Sb) based flame

retardants (Br or Sb do not exceed 0.1% by weight in homogeneous material)

(3)

MSL, Peak Temp. -- The Moisture Sensitivity Level rating according to the JEDEC industry standard classifications, and peak solder

temperature.

Important Information and Disclaimer:The information provided on this page represents TI's knowledge and belief as of the date that it is

provided. TI bases its knowledge and belief on information provided by third parties, and makes no representation or warranty as to the

accuracy of such information. Efforts are underway to better integrate information from third parties. TI has taken and continues to take

reasonable steps to provide representative and accurate information but may not have conducted destructive testing or chemical analysis on

incoming materials and chemicals. TI and TI suppliers consider certain information to be proprietary, and thus CAS numbers and other limited

information may not be available for release.

In no event shall TI's liability arising out of such information exceed the total purchase price of the TI part(s) at issue in this document sold by TI

to Customer on an annual basis.

Addendum-Page 2

PACKAGE MATERIALS INFORMATION

www.ti.com

TAPE AND REEL INFORMATION

19-Mar-2008

*All dimensions are nominal

Device Package

Type

TPS2041ADR SOIC D 8 2500 330.0 12.4 6.4 5.2 2.1 8.0 12.0 Q1

TPS2042ADR SOIC D 8 2500 330.0 12.4 6.4 5.2 2.1 8.0 12.0 Q1

TPS2043ADR SOIC D 16 2500 330.0 16.4 6.5 10.3 2.1 8.0 16.0 Q1

TPS2044ADR SOIC D 16 2500 330.0 16.4 6.5 10.3 2.1 8.0 16.0 Q1

TPS2051ADR SOIC D 8 2500 330.0 12.4 6.4 5.2 2.1 8.0 12.0 Q1

TPS2052ADR SOIC D 8 2500 330.0 12.4 6.4 5.2 2.1 8.0 12.0 Q1

TPS2053ADR SOIC D 16 2500 330.0 16.4 6.5 10.3 2.1 8.0 16.0 Q1

TPS2054ADR SOIC D 16 2500 330.0 16.4 6.5 10.3 2.1 8.0 16.0 Q1

Package

Drawing

Pins SPQ Reel

Diameter

(mm)

Reel

Width

W1 (mm)

A0 (mm) B0 (mm) K0 (mm) P1

(mm)W(mm)

Pin1

Quadrant

Pack Materials-Page 1

PACKAGE MATERIALS INFORMATION

www.ti.com

19-Mar-2008

*All dimensions are nominal

Device Package Type Package Drawing Pins SPQ Length (mm) Width (mm) Height (mm)

TPS2041ADR SOIC D 8 2500 340.5 338.1 20.6

TPS2042ADR SOIC D 8 2500 340.5 338.1 20.6

TPS2043ADR SOIC D 16 2500 333.2 345.9 28.6

TPS2044ADR SOIC D 16 2500 333.2 345.9 28.6

TPS2051ADR SOIC D 8 2500 340.5 338.1 20.6

TPS2052ADR SOIC D 8 2500 340.5 338.1 20.6

TPS2053ADR SOIC D 16 2500 333.2 345.9 28.6

TPS2054ADR SOIC D 16 2500 333.2 345.9 28.6

Pack Materials-Page 2

IMPORTANT NOTICE

Texas Instruments Incorporated and its subsidiaries (TI) reserve the right to make corrections, modifications, enhancements, improvements,

and other changes to its products and services at any time and to discontinue any product or service without notice. Customers should

obtain the latest relevant information before placing orders and should verify that such information is current and complete. All products are

sold subject to TI’s terms and conditions of sale supplied at the time of order acknowledgment.

TI warrants performance of its hardware products to the specifications applicable at the time of sale in accordance with TI’s standard

warranty. Testing and other quality control techniques are used to the extent TI deems necessary to support this warranty. Except where

mandated by government requirements, testing of all parameters of each product is not necessarily performed.

TI assumes no liability for applications assistance or customer product design. Customers are responsible for their products and

applications using TI components. To minimize the risks associated with customer products and applications, customers should provide

adequate design and operating safeguards.

TI does not warrant or represent that any license, either express or implied, is granted under any TI patent right, copyright, mask work right,

or other TI intellectual property right relating to any combination, machine, or process in which TI products or services are used. Information

published by TI regarding third-party products or services does not constitute a license from TI to use such products or services or a

warranty or endorsement thereof. Use of such information may require a license from a third party under the patents or other intellectual

property of the third party, or a license from TI under the patents or other intellectual property of TI.

Reproduction of TI information in TI data books or data sheets is permissible only if reproduction is without alteration and is accompanied

by all associated warranties, conditions, limitations, and notices. Reproduction of this information with alteration is an unfair and deceptive

business practice. TI is not responsible or liable for such altered documentation. Information of third parties may be subject to additional

restrictions.

Resale of TI products or services with statements different from or beyond the parameters stated by TI for that product or service voids all

express and any implied warranties for the associated TI product or service and is an unfair and deceptive business practice. TI is not

responsible or liable for any such statements.

TI products are not authorized for use in safety-critical applications (such as life support) where a failure of the TI product would reasonably

be expected to cause severe personal injury or death, unless officers of the parties have executed an agreement specifically governing

such use. Buyers represent that they have all necessary expertise in the safety and regulatory ramifications of their applications, and

acknowledge and agree that they are solely responsible for all legal, regulatory and safety-related requirements concerning their products

and any use of TI products in such safety-critical applications, notwithstanding any applications-related information or support that may be

provided by TI. Further, Buyers must fully indemnify TI and its representatives against any damages arising out of the use of TI products in

such safety-critical applications.

TI products are neither designed nor intended for use in military/aerospace applications or environments unless the TI products are

specifically designated by TI as military-grade or "enhanced plastic." Only products designated by TI as military-grade meet military

specifications. Buyers acknowledge and agree that any such use of TI products which TI has not designated as military-grade is solely at

the Buyer's risk, and that they are solely responsible for compliance with all legal and regulatory requirements in connection with such use.

TI products are neither designed nor intended for use in automotive applications or environments unless the specific TI products are

designated by TI as compliant with ISO/TS 16949 requirements. Buyers acknowledge and agree that, if they use any non-designated

products in automotive applications, TI will not be responsible for any failure to meet such requirements.

Following are URLs where you can obtain information on other Texas Instruments products and application solutions:

Products Applications

Amplifiers amplifier.ti.com Audio www.ti.com/audio

Data Converters dataconverter.ti.com Automotive www.ti.com/automotive

DSP dsp.ti.com Broadband www.ti.com/broadband

Clocks and Timers www.ti.com/clocks Digital Control www.ti.com/digitalcontrol

Interface interface.ti.com Medical www.ti.com/medical

Logic logic.ti.com Military www.ti.com/military

Power Mgmt power.ti.com Optical Networking www.ti.com/opticalnetwork

Microcontrollers microcontroller.ti.com Security www.ti.com/security

RFID www.ti-rfid.com Telephony www.ti.com/telephony

RF/IF and ZigBee® Solutions www.ti.com/lprf Video & Imaging www.ti.com/video

Mailing Address: Texas Instruments, Post Office Box 655303, Dallas, Texas 75265

Copyright © 2008, Texas Instruments Incorporated

Wireless www.ti.com/wireless

Loading...

Loading...