Page 1

Product

Folder

Sample &

Buy

Technical

Documents

Tools &

Software

Support &

Community

TMS570LS0714 16- and 32-Bit RISC Flash Microcontroller

1 Device Overview

1.1 Features

1

• High-Performance Automotive-Grade

Microcontroller (MCU) for Safety-Critical

Applications

– Dual CPUs Running in Lockstep

– ECC on Flash and RAM Interfaces

– Built-In Self-Test (BIST) for CPU and On-chip

RAMs

– Error Signaling Module With Error Pin

– Voltage and Clock Monitoring

• ARM®Cortex®-R4F 32-Bit RISC CPU

– 1.66 DMIPS/MHz With 8-Stage Pipeline

– FPU With Single and Double Precision

– 12-Region Memory Protection Unit (MPU)

– Open Architecture With Third-Party Support

• Operating Conditions

– Up to 160-MHz System Clock

– Core Supply Voltage (VCC): 1.14 to 1.32 V

– I/O Supply Voltage (VCCIO): 3.0 to 3.6 V

• Integrated Memory

– 768KB of Flash With ECC

– 128KB of RAM With ECC

– 64KB of Flash for Emulated EEPROM With

ECC

• Common Platform Architecture

– Consistent Memory Map Across Family

– Real-Time Interrupt Timer (RTI) OS Timer

– 128-Channel Vectored Interrupt Module (VIM)

– 2-Channel Cyclic Redundancy Checker (CRC)

• Direct Memory Access (DMA) Controller

– 16 Channels and 32 Peripheral Requests

– Parity for Control Packet RAM

– DMA Accesses Protected by Dedicated MPU

• Frequency-Modulated Phase-Locked Loop

(FMPLL) With Built-In Slip Detector

• IEEE 1149.1 JTAG, Boundary Scan and ARM

CoreSight™ Components

• Advanced JTAG Security Module (AJSM)

• Up to 64 General-Purpose I/O (GIO) Pins

– Up to 16 GIO Pins With Interrupt Generation

Capability

TMS570LS0714

SPNS226E –JUNE 2013–REVISED NOVEMBER 2016

• Enhanced Timing Peripherals

– 7 Enhanced Pulse Width Modulator (ePWM)

Modules

– 6 Enhanced Capture (eCAP) Modules

– 2 Enhanced Quadrature Encoder Pulse (eQEP)

Modules

• Two Next Generation High-End Timer (N2HET)

Modules

– N2HET1: 32 Programmable Channels

– N2HET2: 18 Programmable Channels

– 160-Word Instruction RAM With Parity

Protection Each

– Each N2HET Includes Hardware Angle

Generator

– Dedicated High-End Timer Transfer Unit (HTU)

for Each N2HET

• Two 12-Bit Multibuffered ADC Modules

– ADC1: 24 Channels

– ADC2: 16 Channels

– 16 Shared Channels

– 64 Result Buffers With Parity Protection Each

• Multiple Communication Interfaces

– Up to Three CAN Controllers (DCANs)

– 64 Mailboxes With Parity Protection Each

– Compliant to CAN Protocol Version 2.0A and

2.0B

– Inter-Integrated Circuit (I2C)

– 3 Multibuffered Serial Peripheral Interfaces

(MibSPIs)

– 128 Words With Parity Protection Each

– 8 Transfer Groups

– One Standard Serial Peripheral Interface (SPI)

Module

– Two UART (SCI) Interfaces, One With Local

Interconnect Network (LIN 2.1) Interface

Support

• Packages

– 144-Pin Quad Flatpack (PGE) [Green]

– 100-Pin Quad Flatpack (PZ) [Green]

1

An IMPORTANT NOTICE at the end of this data sheet addresses availability, warranty, changes, use in safety-critical applications,

intellectual property matters and other important disclaimers. PRODUCTION DATA.

Page 2

TMS570LS0714

SPNS226E –JUNE 2013–REVISED NOVEMBER 2016

1.2 Applications

• Electric Power Steering (EPS)

• Braking Systems (ABS and ESC)

• HEV and EV Inverter Systems

• Battery-Management Systems

www.ti.com

• Active Driver Assistance Systems

• Aerospace and Avionics

• Railway Communications

• Off-road Vehicles

2

Device Overview Copyright © 2013–2016, Texas Instruments Incorporated

Submit Documentation Feedback

Product Folder Links: TMS570LS0714

Page 3

www.ti.com

1.3 Description

The TMS570LS0714 device is part of the Hercules TMS570 series of high-performance automotive-grade

ARM® Cortex®-R-based MCUs. Comprehensive documentation, tools, and software are available to

assist in the development of ISO 26262 and IEC 61508 functional safety applications. Start evaluating

today with the Hercules TMS570 LaunchPad Development Kit. The TMS570LS0714 device has on-chip

diagnostic features including: dual CPUs in lockstep; CPU and memory Built-In Self-Test (BIST) logic;

ECC on both the flash and the SRAM; parity on peripheral memories; and loopback capability on most

peripheral I/Os.

The TMS570LS0714 device integrates the ARM Cortex-R4F floating-point CPU which offers an efficient

1.66 DMIPS/MHz, and has configurations which can run up to 160 MHz providing up to 265 DMIPS. The

TMS570 device supports the word invariant big-endian [BE32] format.

The TMS570LS0714 device has 768KB of integrated flash and 128KB of RAM configurations with singlebit error correction and double-bit error detection. The flash memory on this device is nonvolatile,

electrically erasable and programmable, and is implemented with a 64-bit-wide data bus interface. The

flash operates on a 3.3-V supply input (same level as the I/O supply) for all read, program, and erase

operations. The SRAM supports single-cycle read and write accesses in byte, halfword, word, and

doubleword modes throughout the supported frequency range.

The TMS570LS0714 device features peripherals for real-time control-based applications, including two

Next-Generation High-End Timer (N2HET) timing coprocessors with up to 44 total I/O terminals, seven

Enhanced PWM (ePWM) modules with up to 14 outputs, six Enhanced Capture (eCAP) modules, two

Enhanced Quadrature Encoder Pulse (eQEP) modules, and two 12-bit Analog-to-Digital Converters

(ADCs) supporting up to 24 inputs.

TMS570LS0714

SPNS226E –JUNE 2013–REVISED NOVEMBER 2016

The N2HET is an advanced intelligent timer that provides sophisticated timing functions for real-time

applications. The timer is software-controlled, using a reduced instruction set, with a specialized timer

micromachine and an attached I/O port. The N2HET can be used for pulse-width-modulated outputs,

capture or compare inputs, or general-purpose I/O (GIO). The N2HET is especially well suited for

applications requiring multiple sensor information and drive actuators with complex and accurate time

pulses. A High-End Timer Transfer Unit (HTU) can transfer N2HET data to or from main memory. A

Memory Protection Unit (MPU) is built into the HTU.

The ePWM module can generate complex pulse width waveforms with minimal CPU overhead or

intervention. The ePWM is easy to use and supports complementary PWMs and deadband generation.

With integrated trip zone protection and synchronization with the on-chip MibADC, the ePWM is ideal for

digital motor control applications.

The eCAP module is essential in systems where the accurately timed capture of external events is

important. The eCAP can also be used to monitor the ePWM outputs or to generate simple PWM when

not needed for capture applications.

The eQEP module is used for direct interface with a linear or rotary incremental encoder to get position,

direction, and speed information from a rotating machine as used in high-performance motion and

position-control systems.

The device has two 12-bit-resolution MibADCs with 24 total inputs and 64 words of parity-protected buffer

RAM each. The MibADC channels can be converted individually or can be grouped by software for

sequential conversion sequences. Sixteen inputs are shared between the two MibADCs. There are three

separate groups. Each group can be converted once when triggered or configured for continuous

conversion mode. The MibADC has a 10-bit mode for use when compatibility with older devices or faster

conversion time is desired.

Submit Documentation Feedback

Product Folder Links: TMS570LS0714

Device OverviewCopyright © 2013–2016, Texas Instruments Incorporated

3

Page 4

TMS570LS0714

SPNS226E –JUNE 2013–REVISED NOVEMBER 2016

The device has multiple communication interfaces: three MibSPIs; two SPIs; two SCIs, one of which can

be used as LIN; up to three DCANs; and one I2C module. The SPI provides a convenient method of serial

interaction for high-speed communications between similar shift-register type devices. The LIN supports

the Local Interconnect standard 2.0 and can be used as a UART in full-duplex mode using the standard

Non-Return-to-Zero (NRZ) format. The DCAN supports the CAN 2.0B protocol standard and uses a serial,

multimaster communication protocol that efficiently supports distributed real-time control with robust

communication rates of up to 1 Mbps. The DCAN is ideal for applications operating in noisy and harsh

environments (for example, automotive and industrial fields) that require reliable serial communication or

multiplexed wiring.

The I2C module is a multimaster communication module providing an interface between the

microcontroller and an I2C-compatible device through the I2C serial bus. The I2C module supports speeds

of 100 and 400 kbps.

A Frequency-Modulated Phase-Locked Loop (FMPLL) clock module is used to multiply the external

frequency reference to a higher frequency for internal use. The FMPLL provides one of the six possible

clock source inputs to the Global Clock Module (GCM). The GCM manages the mapping between the

available clock sources and the device clock domains.

The device also has an external clock prescaler (ECP) circuit that when enabled, outputs a continuous

external clock on the ECLK terminal. The ECLK frequency is a user-programmable ratio of the peripheral

interface clock (VCLK) frequency. This low-frequency output can be monitored externally as an indicator of

the device operating frequency.

www.ti.com

The Direct Memory Access (DMA) controller has 16 channels, 32 peripheral requests,

and parity protection on its memory. An MPU is built into the DMA to protect memory against erroneous

transfers.

The Error Signaling Module (ESM) monitors device errors and determines whether an interrupt or external

error signal (nERROR) is asserted when a fault is detected. The nERROR terminal can be monitored

externally as an indicator of a fault condition in the microcontroller.

With integrated functional safety features and a wide choice of communication and control peripherals, the

TMS570LS0714 device is an ideal solution for high-performance, real-time control applications with safetycritical requirements.

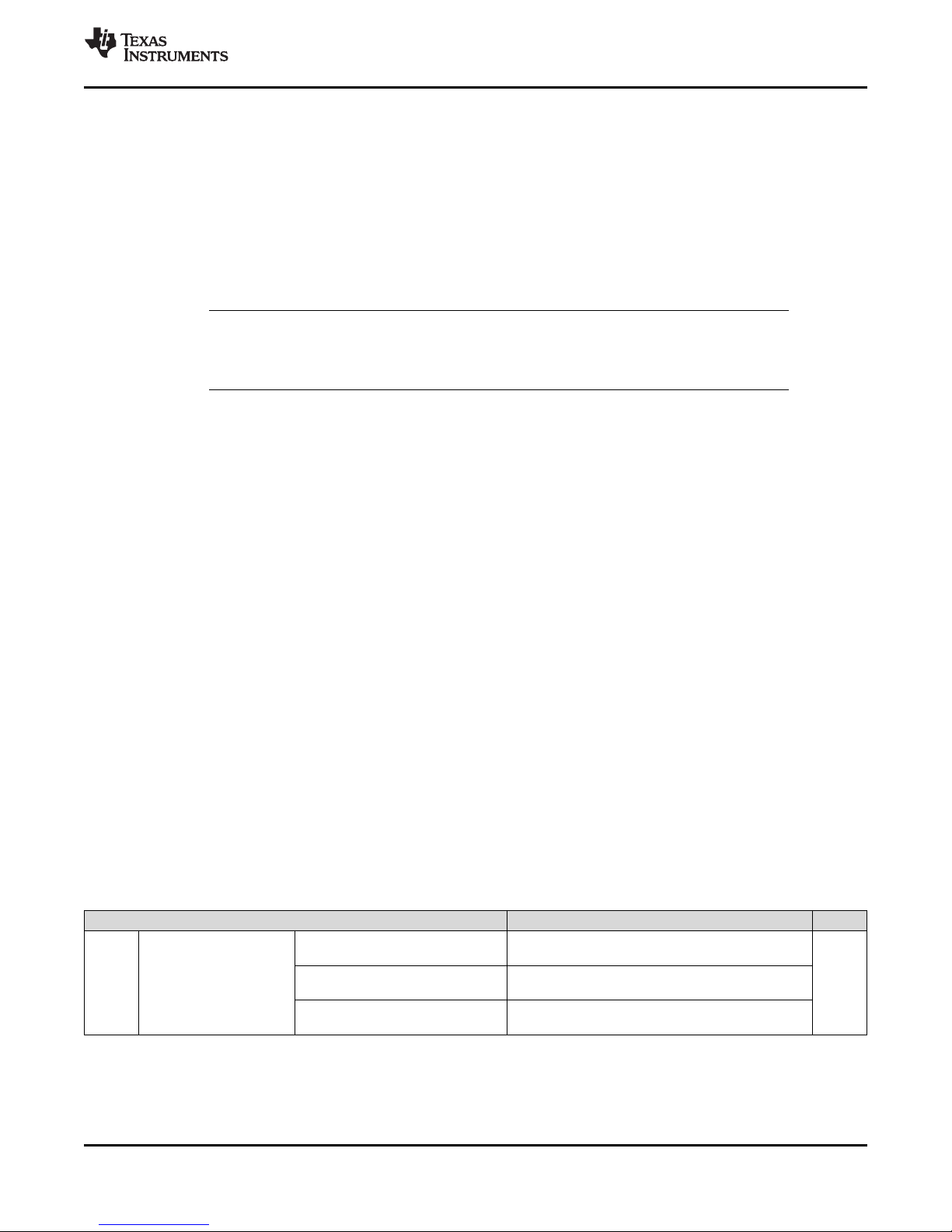

Device Information

PART NUMBER PACKAGE BODY SIZE

TMS570LS0714PGE LQFP (144) 20.0 mm × 20.0 mm

TMS570LS0714PZ LQFP (100) 14.0 mm × 14.0 mm

(1) For more information, see Section 10, Mechanical Packaging and Orderable Information.

(1)

4

Device Overview Copyright © 2013–2016, Texas Instruments Incorporated

Submit Documentation Feedback

Product Folder Links: TMS570LS0714

Page 5

HTU1 HTU2

Switched Central Resource

Main Cross Bar: Arbitration and Prioritization Control

CRC

Peripheral Central Resource Bridge

Dual Cortex-R4F

CPUs in Lockstep

Switched Central Resource

DCAN1

DCAN2

DCAN3

LIN

SCI

SPI4

64KB Flash

for EEPROM

Emulation

with ECC

MibSPI1

CAN1_RX

CAN1_TX

CAN2_RX

CAN2_TX

CAN3_RX

CAN3_TX

MIBSPI1_CLK

MIBSPI1_SIMO[1:0]

MIBSPI1_SOMI[1:0]

MIBSPI1_nCS[5:0]

MIBSPI1_nENA

SPI2

SPI2_CLK

SPI2_SIMO

SPI2_SOMI

SPI2_nCS[1:0]

SPI2_nENA

MibSPI3

MIBSPI3_CLK

MIBSPI3_SIMO

MIBSPI3_SOMI

MIBSPI3_nCS[5:0]

MIBSPI3_nENA

SPI4_CLK

SPI4_SIMO

SPI4_SOMI

SPI4_nCS0

SPI4_nENA

MibSPI5

MIBSPI5_SIMO[3:0]

MIBSPI5_SOMI[3:0]

MIBSPI5_nCS[3:0]

MIBSPI5_nENA

LIN_RX

LIN_TX

SCI_RX

SCI_TX

IOMM

PMM

VIM

RTI

DCC1

DCC2

32K

32K

128KB

with ECC

RAM

DMA

# 2

# 3

# 5

# 1

# 1

always on

Core/RAM

RAM

Core

Color Legend for Power Domains

SYS

nPORRST

nRST

ECLK

ESM

nERROR

768KB

Flash

with

ECC

Switched Central Resource

I2C

N2HET1

GIO

I2C_SCL

I2C_SDA

GIOB[7:0]

GIOA[7:0]

N2HET2[18,16]

N2HET2[15:0]

N2HET1[31:0]

N2HET1_PIN_nDIS

N2HET2_PIN_nDIS

N2HET2

MibADC1 MibADC2

AD1EVT

AD1IN[7:0]

AD2EVT

VSSAD

VCCAD

ADREFHI

ADREFLO

AD1IN[15:8] \

AD2IN[15:8]

AD2IN[7:0]

eQEP

1,2

eQEPxA

eQEPxB

eQEPxS

eQEPxI

eCAP

1..6

eCAP[6:1]

ePWM

1..7

nTZ[3:1]

SYNCO

SYNCI

ePWMxA

ePWMxB

32K

32K

www.ti.com

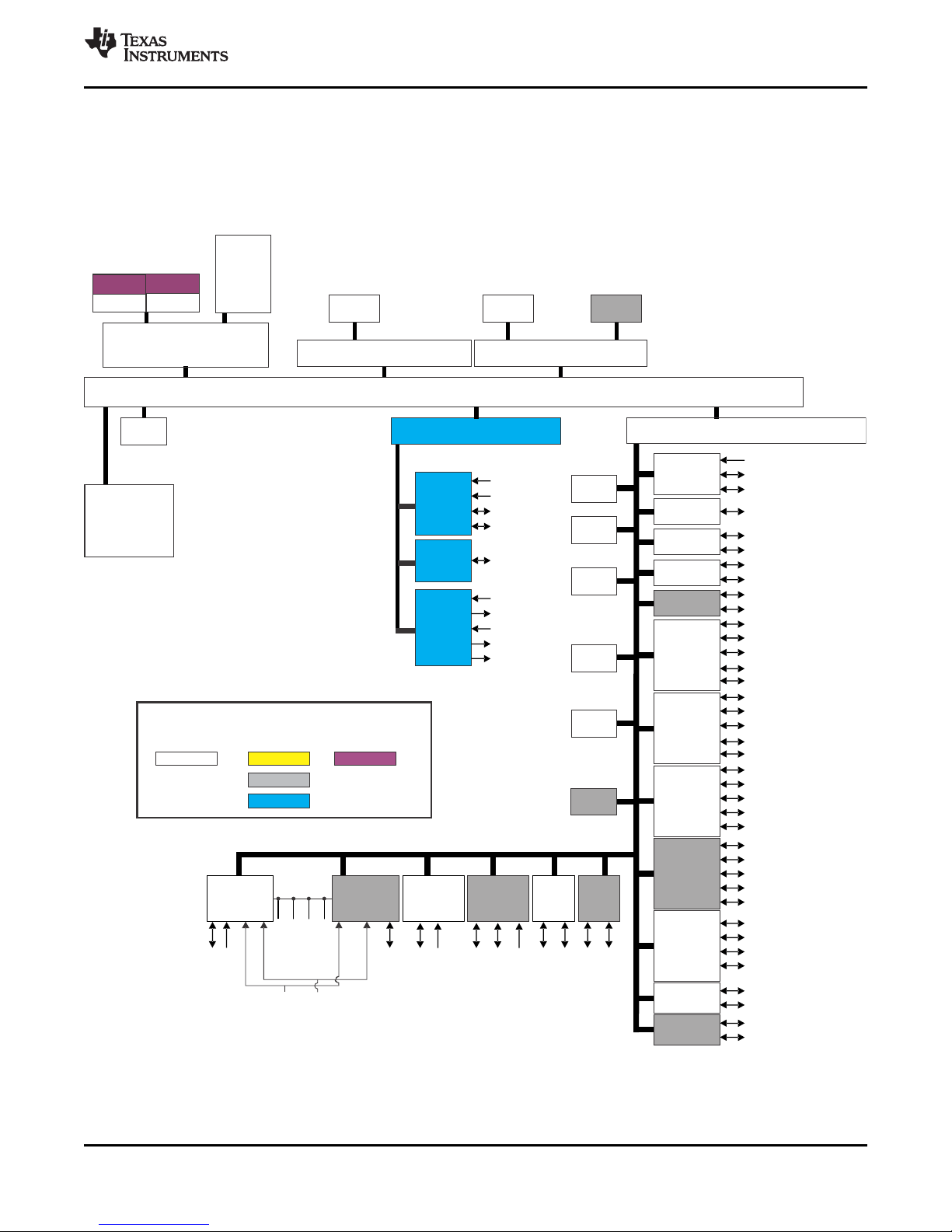

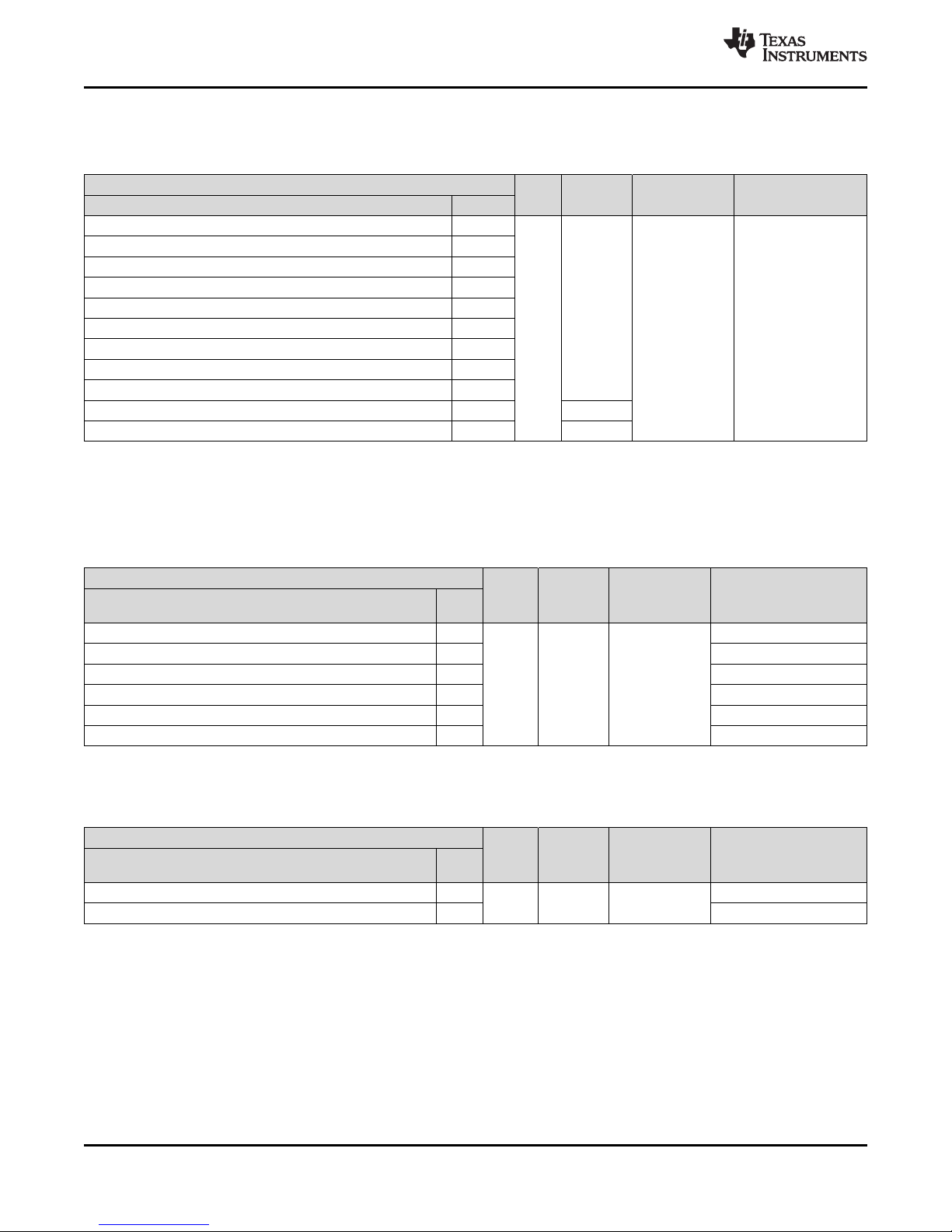

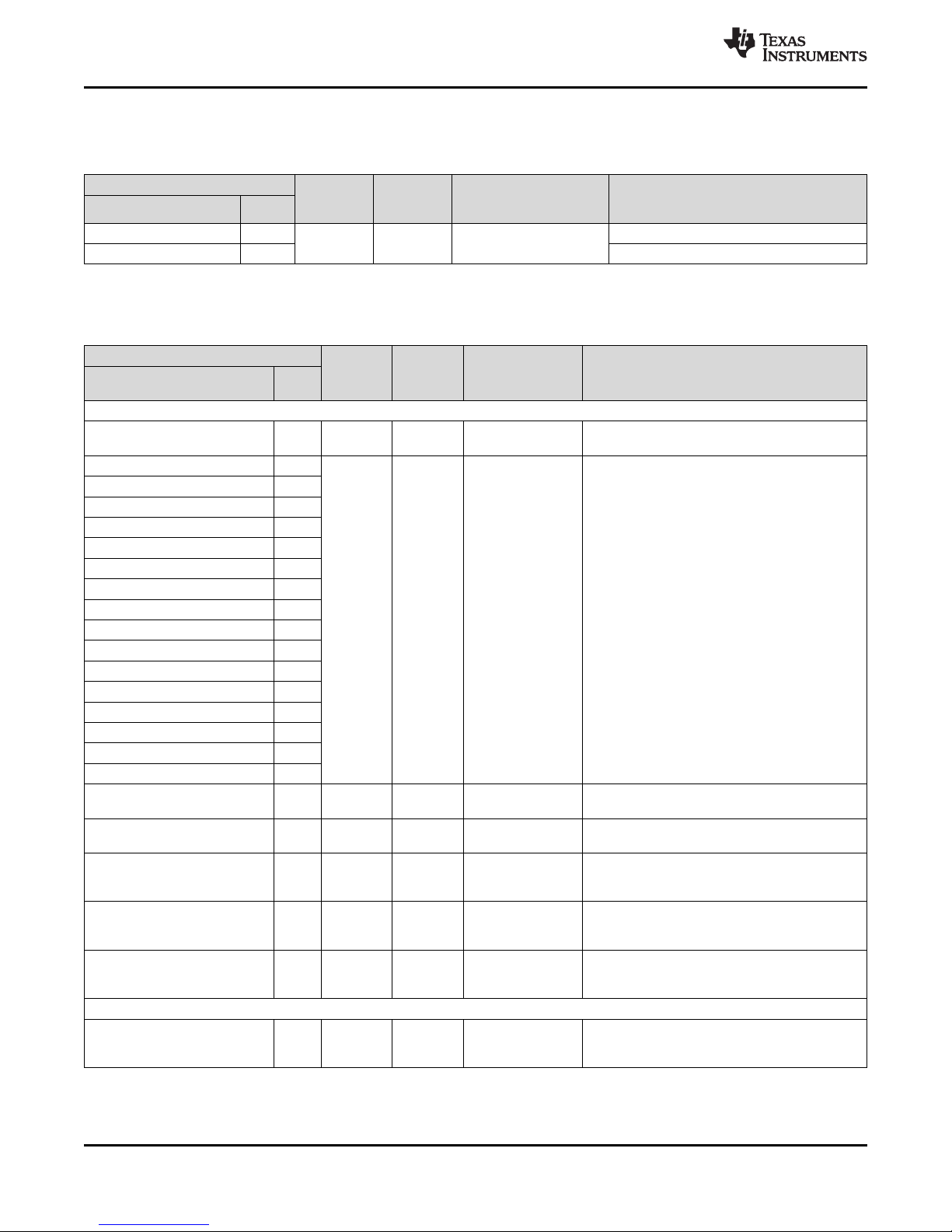

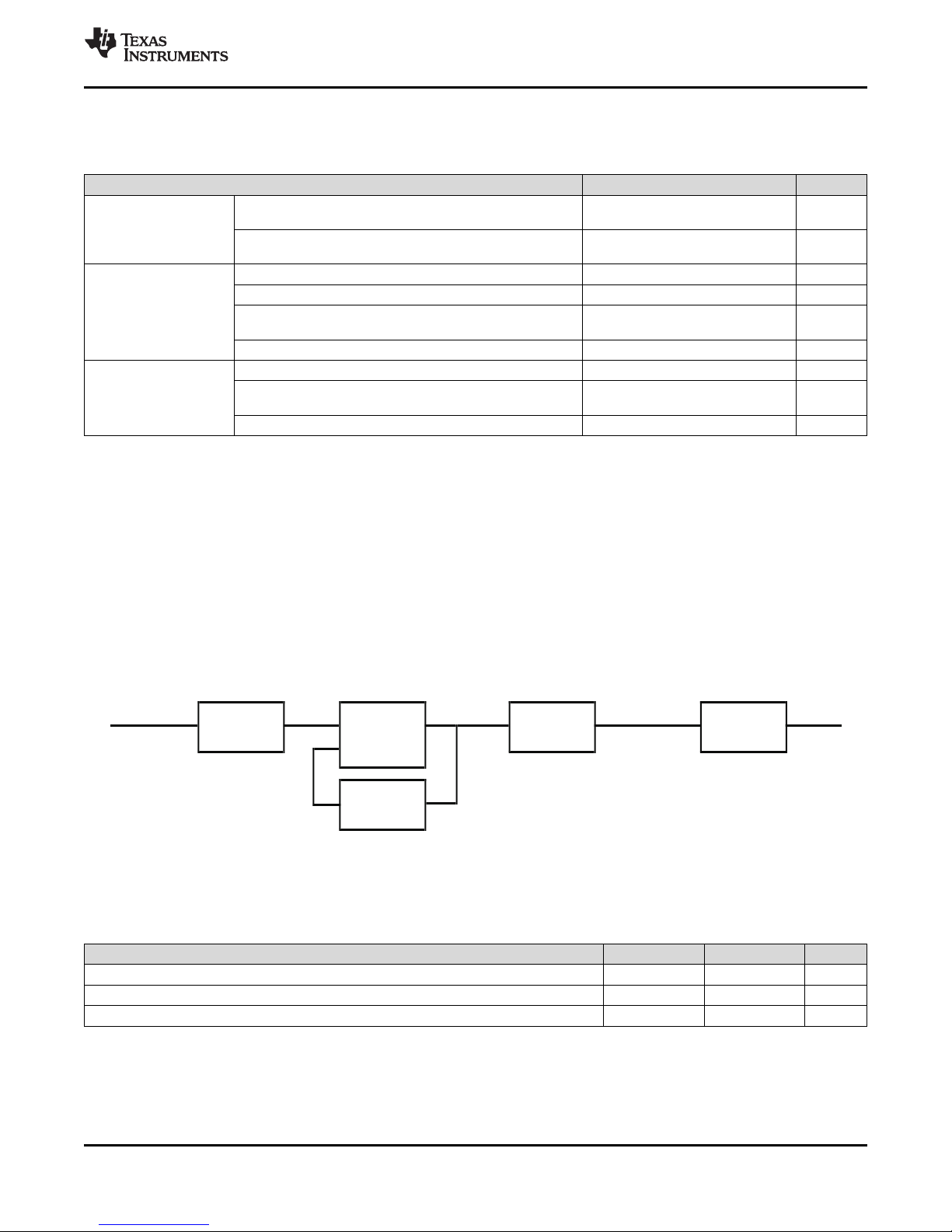

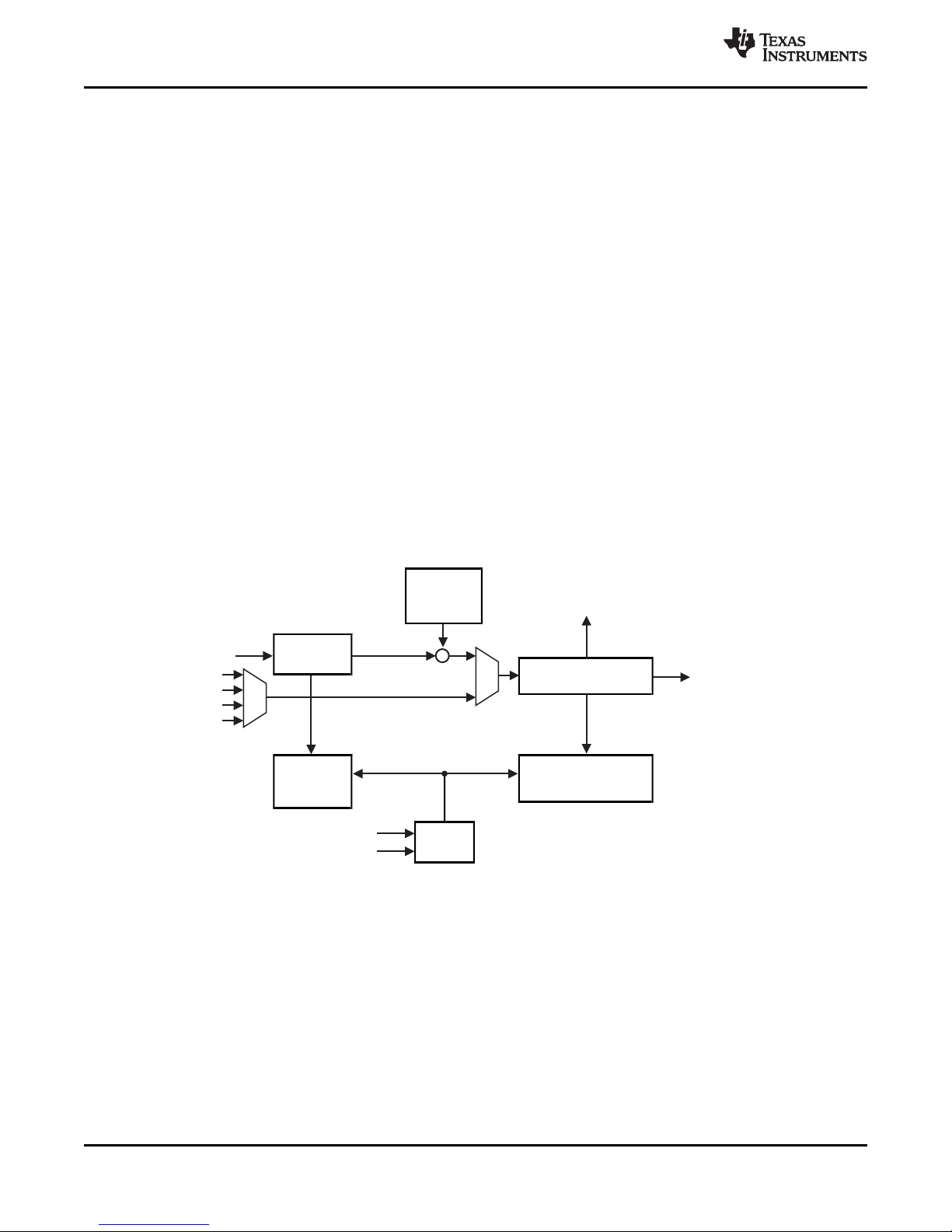

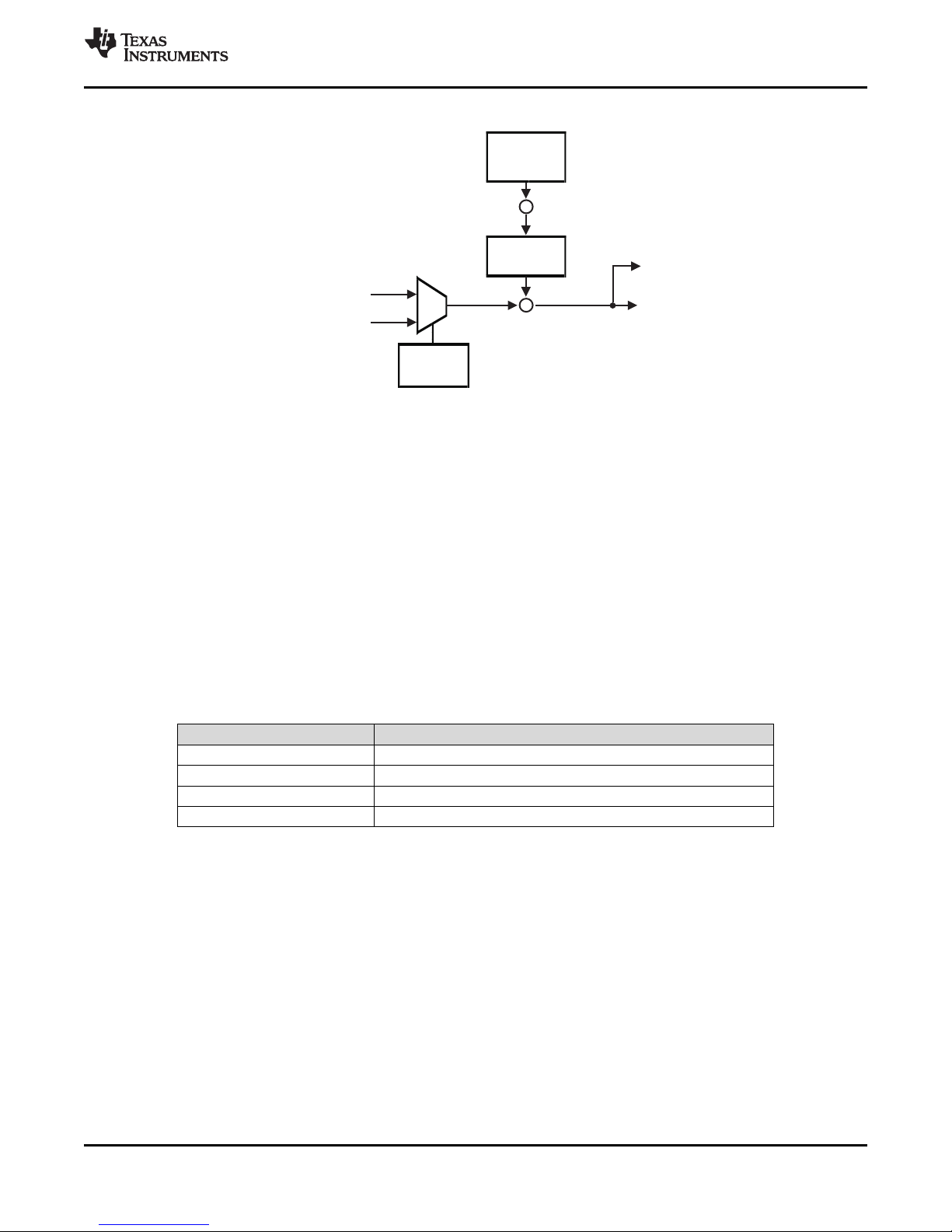

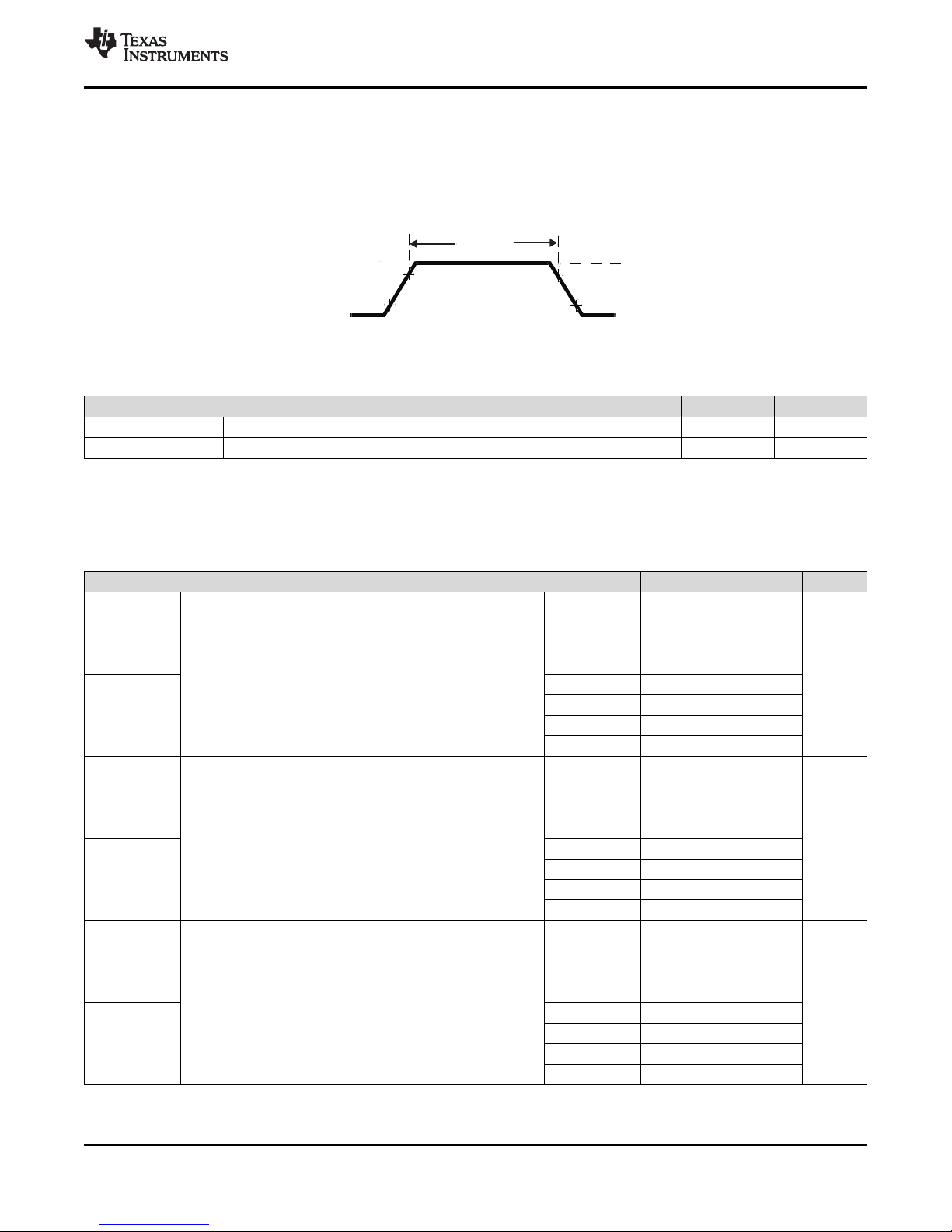

1.4 Functional Block Diagram

Figure 1-1 shows the functional block diagram of the device.

NOTE: The block diagram reflects the 144PGE package. Some functions are multiplexed or not available

in other packages. For details, see the respective terminal functions table in Section 4.2, Terminal

Functions.

TMS570LS0714

SPNS226E –JUNE 2013–REVISED NOVEMBER 2016

Figure 1-1. Functional Block Diagram

Submit Documentation Feedback

Product Folder Links: TMS570LS0714

Device OverviewCopyright © 2013–2016, Texas Instruments Incorporated

5

Page 6

TMS570LS0714

SPNS226E –JUNE 2013–REVISED NOVEMBER 2016

www.ti.com

Table of Contents

1 Device Overview ......................................... 1

1.1 Features .............................................. 1

1.2 Applications........................................... 2

1.3 Description............................................ 3

1.4 Functional Block Diagram ............................ 5

2 Revision History ......................................... 7

3 Device Comparison ..................................... 8

3.1 Related Products ..................................... 8

4 Terminal Configuration and Functions.............. 9

4.1 Pin Diagrams ......................................... 9

4.2 Signal Descriptions ................................. 11

4.3 Pin Multiplexing...................................... 29

4.4 Buffer Type.......................................... 35

5 Specifications .......................................... 36

5.1 Absolute Maximum Ratings......................... 36

5.2 ESD Ratings ........................................ 36

5.3 Power-On Hours (POH)............................. 36

5.4 Recommended Operating Conditions............... 37

5.5 Input/Output Electrical Characteristics Over

Recommended Operating Conditions............... 38

5.6 Power Consumption Over Recommended

Operating Conditions................................ 39

5.7 Thermal Resistance Characteristics ................ 40

5.8 Timing and Switching Characteristics............... 41

6 System Information and Electrical

Specifications........................................... 43

6.1 Device Power Domains ............................. 43

6.2 Voltage Monitor Characteristics..................... 43

6.3 Power Sequencing and Power-On Reset ........... 44

6.4 Warm Reset (nRST)................................. 46

6.5 ARM Cortex-R4F CPU Information ................. 47

6.6 Clocks ............................................... 51

6.7 Clock Monitoring .................................... 58

6.8 Glitch Filters......................................... 60

6.9 Device Memory Map ................................ 61

6.10 Flash Memory ....................................... 66

6.11 Tightly Coupled RAM Interface Module ............. 69

6.12 Parity Protection for Accesses to Peripheral RAMs 69

6.13 On-Chip SRAM Initialization and Testing ........... 71

6.14 Vectored Interrupt Manager......................... 73

6.15 DMA Controller...................................... 76

6.16 Real-Time Interrupt Module......................... 78

6.17 Error Signaling Module.............................. 80

6.18 Reset/Abort/Error Sources .......................... 84

6.19 Digital Windowed Watchdog ........................ 87

6.20 Debug Subsystem................................... 88

7 Peripheral Information and Electrical

Specifications........................................... 93

7.1 I/O Timings ......................................... 93

7.2 Enhanced PWM Modules (ePWM).................. 96

7.3 Enhanced Capture Modules (eCAP)............... 102

7.4 Enhanced Quadrature Encoder (eQEP)........... 105

7.5 12-Bit Multibuffered Analog-to-Digital Converter

(MibADC)........................................... 108

7.6 General-Purpose Input/Output..................... 121

7.7 Enhanced High-End Timer (N2HET) .............. 122

7.8 Controller Area Network (DCAN) .................. 126

7.9 Local Interconnect Network Interface (LIN)........ 127

7.10 Serial Communication Interface (SCI) ............. 128

7.11 Inter-Integrated Circuit (I2C) Module .............. 129

7.12 Multibuffered / Standard Serial Peripheral

Interface............................................ 132

8 Applications, Implementation, and Layout ...... 144

8.1 TI Designs or Reference Designs ................. 144

9 Device and Documentation Support.............. 145

9.1 Getting Started and Next Steps ................... 145

9.2 Device and Development-Support Tool

Nomenclature ...................................... 145

9.3 Tools and Software ................................ 147

9.4 Documentation Support............................ 149

9.5 Community Resources............................. 149

9.6 Trademarks ........................................ 149

9.7 Electrostatic Discharge Caution ................... 150

9.8 Glossary............................................ 150

9.9 Device Identification................................ 151

9.10 Module Certifications............................... 152

10 Mechanical Packaging and Orderable

Information............................................. 157

10.1 Packaging Information ............................. 157

6

Table of Contents Copyright © 2013–2016, Texas Instruments Incorporated

Submit Documentation Feedback

Product Folder Links: TMS570LS0714

Page 7

TMS570LS0714

www.ti.com

SPNS226E –JUNE 2013–REVISED NOVEMBER 2016

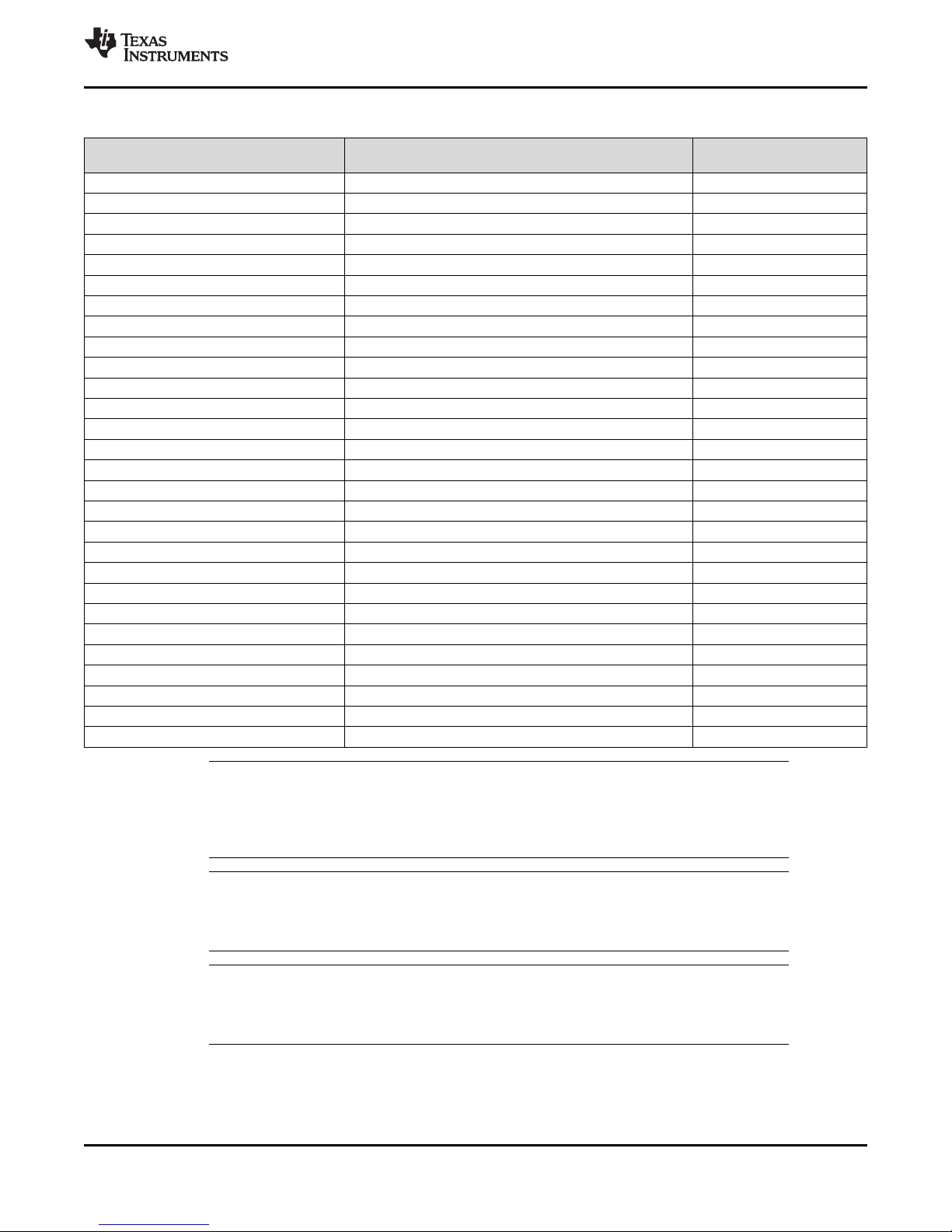

2 Revision History

NOTE: Page numbers for previous revisions may differ from page numbers in the current version.

This data manual revision history highlights the technical changes made to the SPNS226D device-specific

data manual to make it an SPNS226E revision.

Scope: Applicable updates to the TMS570LS0714 device family, specifically relating to the

TMS570LS0714 devices (Silicon Revision A), which are now in the production data (PD) stage of

development have been incorporated.

Changes from September 15, 2015 to November 1, 2016 (from D Revision (September 2015) to E Revision) Page

• GLOBAL: PZ package is now fully qualified ...................................................................................... 1

• Section 1.1 (Features): Updated/Changed the GIO pin count in GIO bullet.................................................. 1

• Section 1.1: Updated/Changed the SPI features bullet.......................................................................... 1

• Section 3.1 (Related Products): Added new section. ............................................................................ 8

• Section 4.2 (Signal Descriptions): Updated/Changed reference to Technical Reference Manual ....................... 11

• Table 4-2 (PGE Enhanced High-End Timer Modules (N2HET)): Added a description for pins 14 and 55

(N2HET1_PIN_nDIS and N2HET2_PIN_nDIS, respectively).................................................................. 13

• Table 4-20 (PZ Enhanced High-End Timer Modules (N2HET)): Added Pin 10, GIOA[5] / INT[5] / EXTCLKIN

/EPWM1A/N2HET1_PIN_nDIS.................................................................................................... 22

• Table 6-20 (Device Memory Map): Updated/Changed the FRAME SIZE column value for "Flash Data Space

ECC" under Flash Module Bus2 Interface from "768KB" to "1MB"........................................................... 62

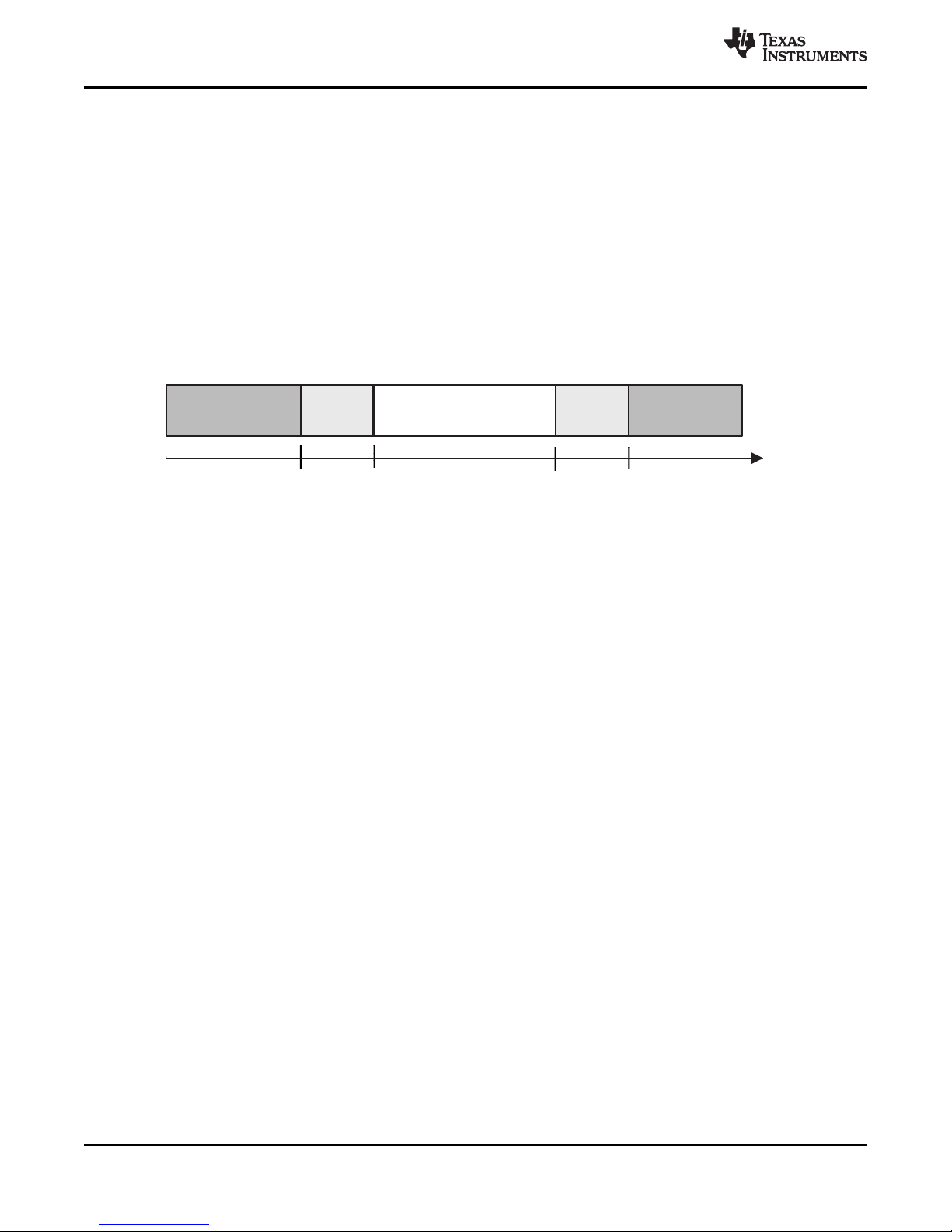

• Section 6.19 (Digital Windowed Watchdog): Added Figure 6-13, Digital Windowed Watchdog Example............... 87

• Table 7-11 (eCAPx Clock Enable Control): Updated/Changed "ePWM" to "eCAP" in MODULE INSTANCE

column............................................................................................................................... 103

• Table 7-15 (eQEPx Clock Enable Control): Updated/Changed "ePWM" to "eQEP" in MODULE INSTANCE

column............................................................................................................................... 106

• Table 7-20 (MibADC1 Trigger Event Hookup): Added lead-in paragraph referencing the table ........................ 108

• Table 7-21 (MibADC2 Event Trigger Hookup): Added lead-in paragraph referencing the table ........................ 110

• Figure 7-11 (ePWM1SOC1A Switch Implementation): Added missing ePWM1 SOC1A detailed switch

connection example and lead-in reference sentence......................................................................... 114

• Section 9.1 (Getting Started and Next Steps): Added new section......................................................... 145

• Section 9.2 (Device and Development-Support Tool Nomenclature): Moved subsection after "Getting Started

and Next Steps" subsection (new) .............................................................................................. 145

• Section 9.9.1 Added the address of the Device ID register. ................................................................. 151

Submit Documentation Feedback

Product Folder Links: TMS570LS0714

Revision HistoryCopyright © 2013–2016, Texas Instruments Incorporated

7

Page 8

TMS570LS0714

SPNS226E –JUNE 2013–REVISED NOVEMBER 2016

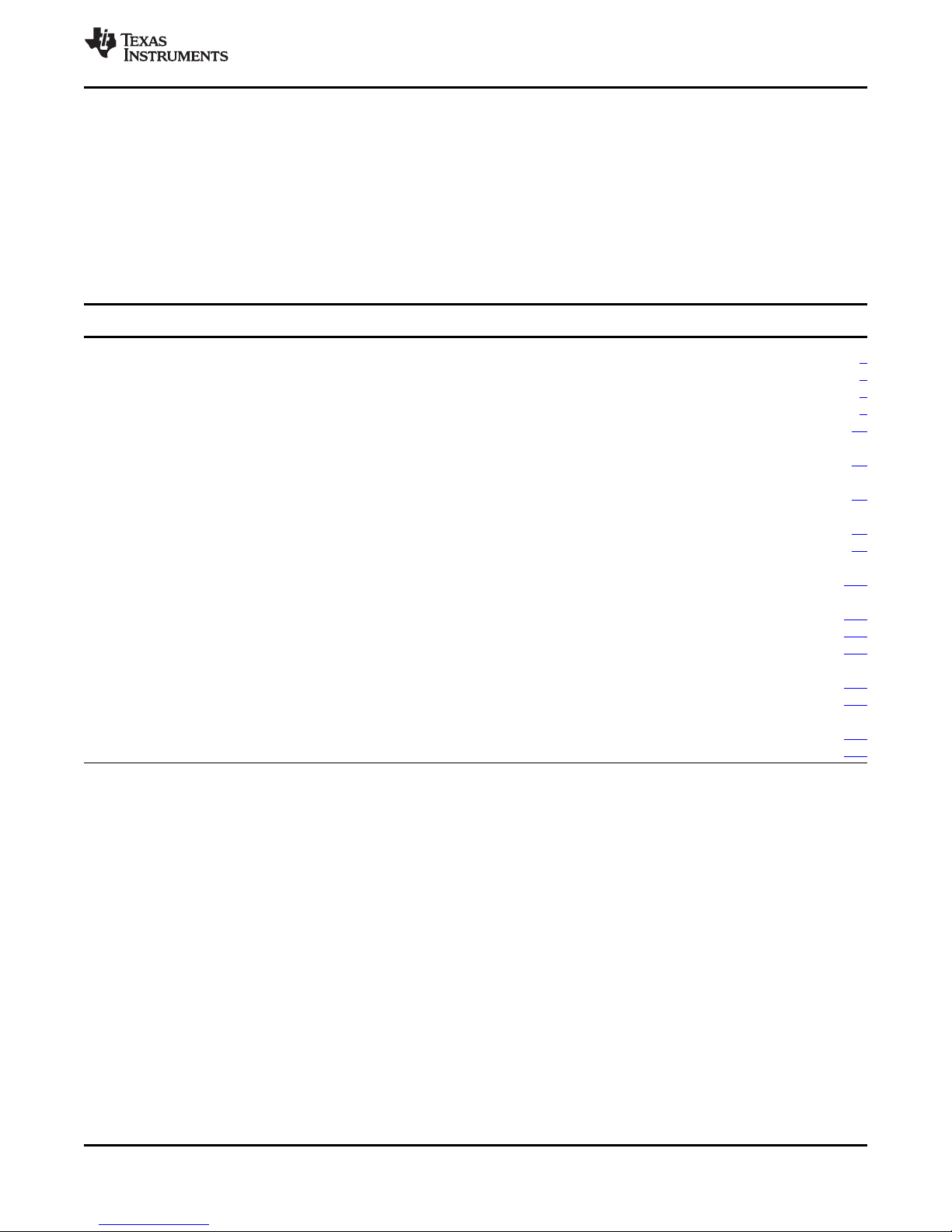

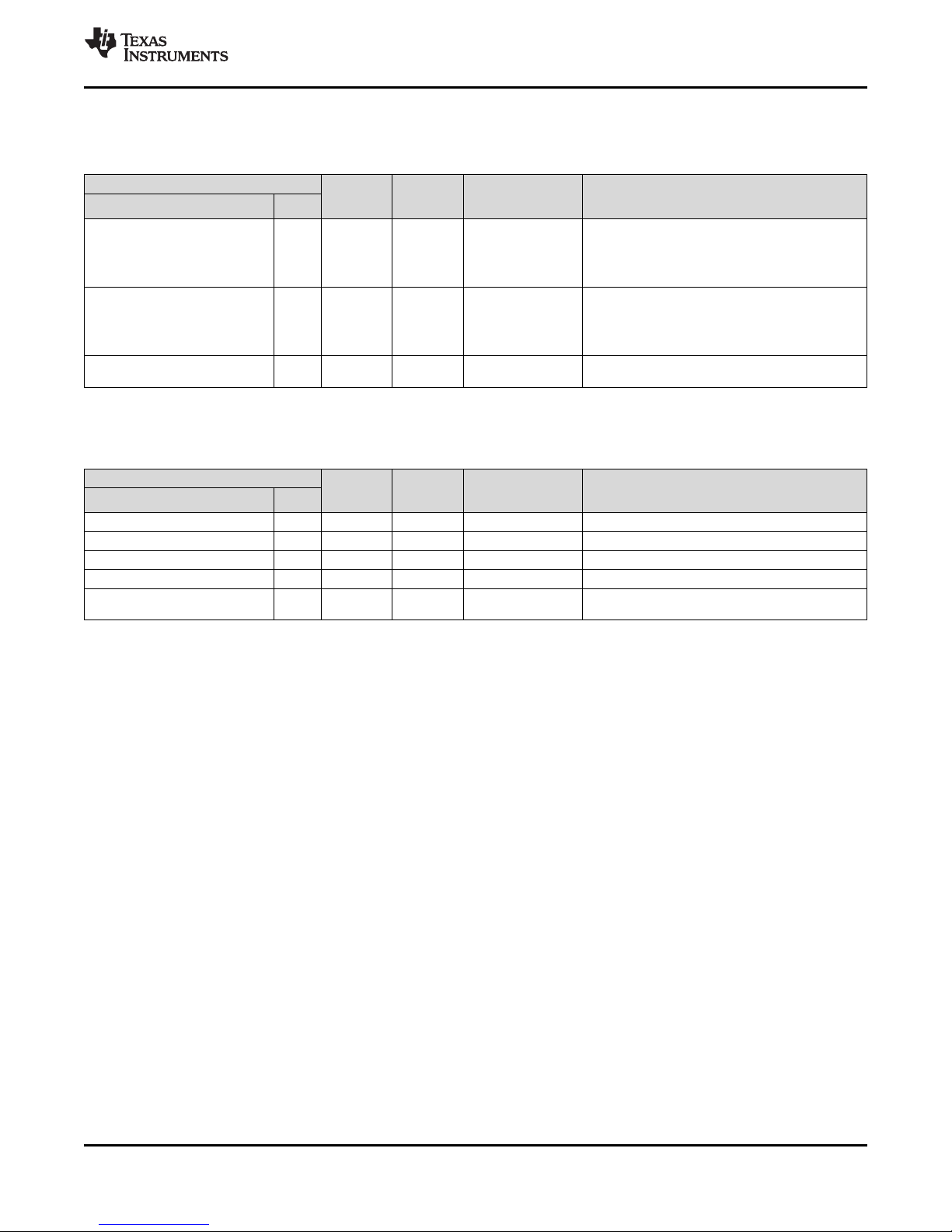

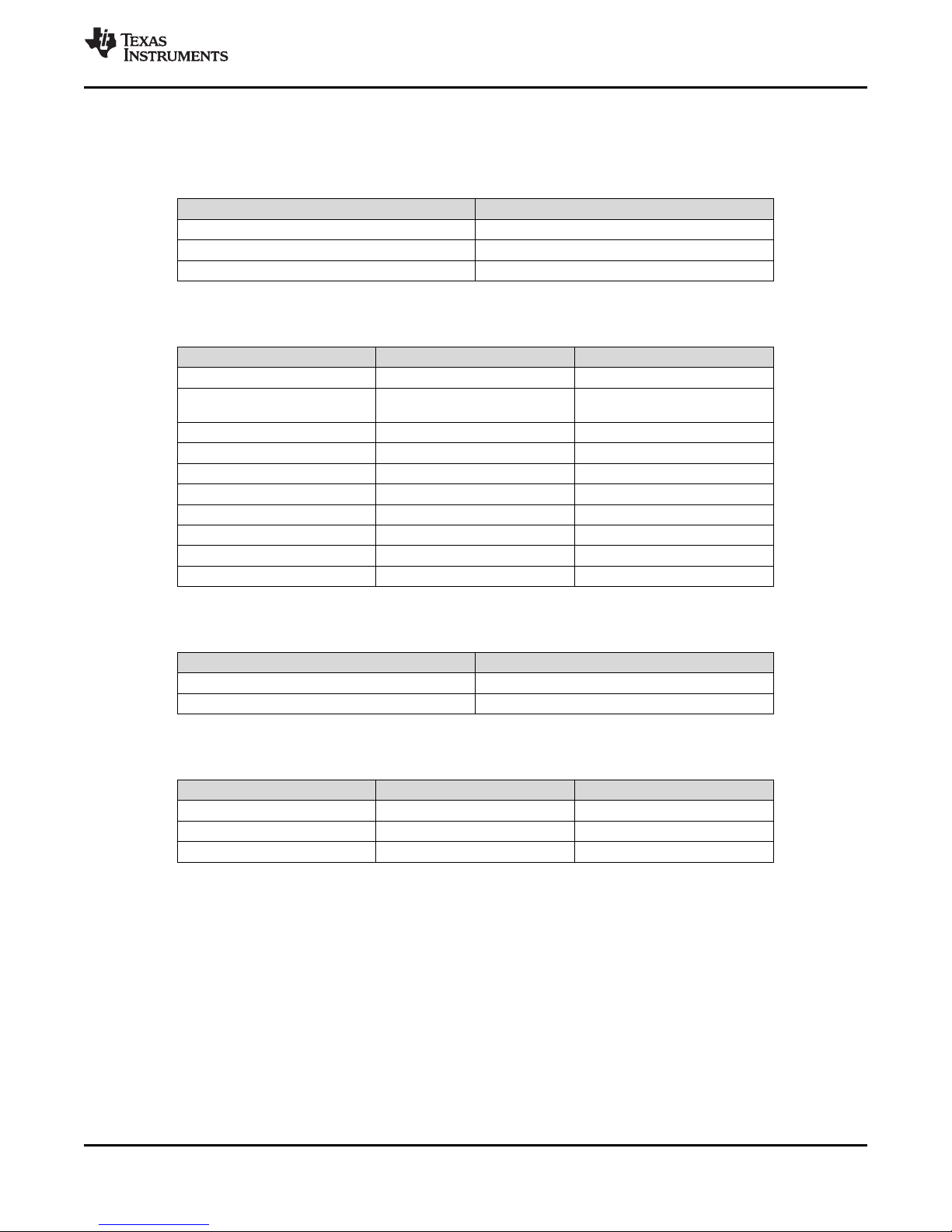

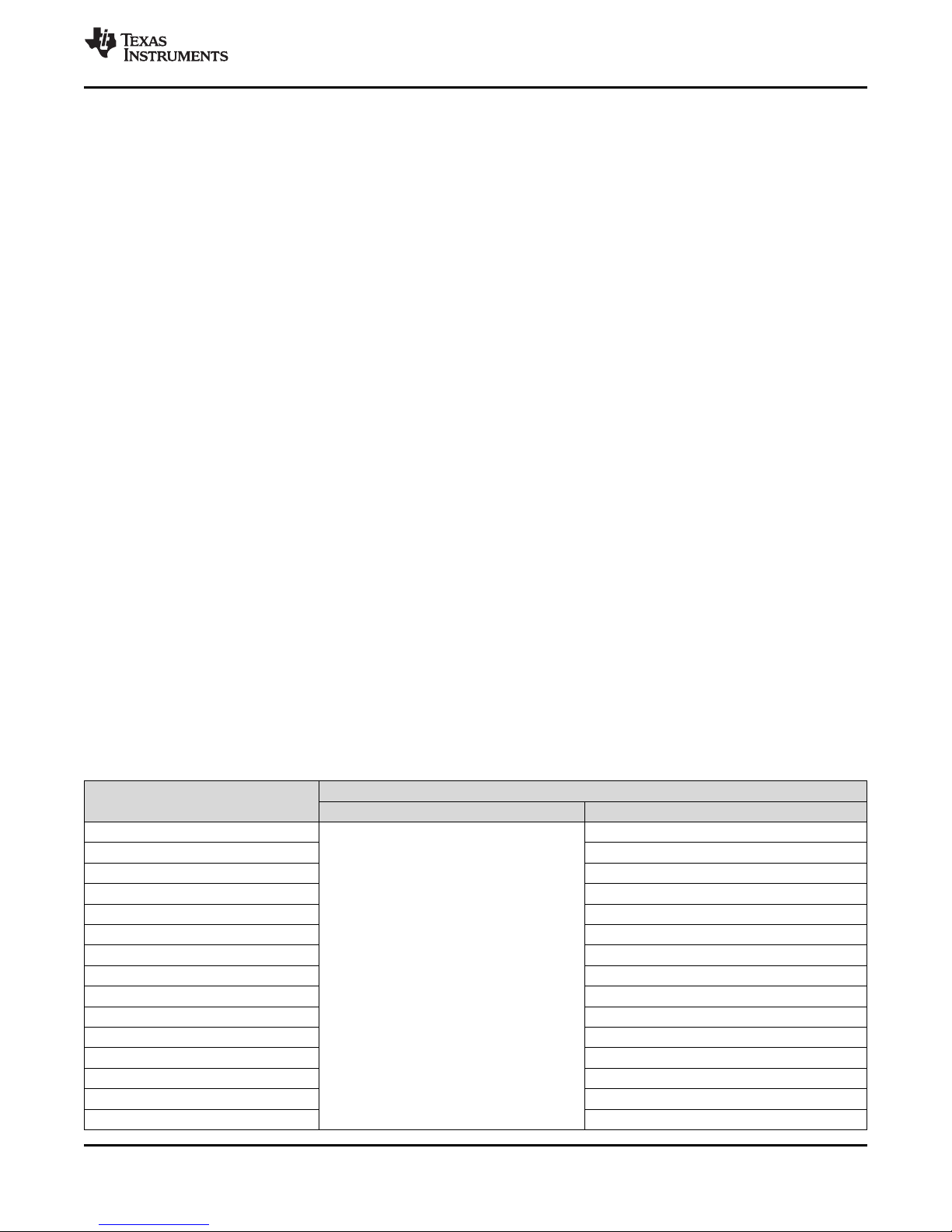

3 Device Comparison

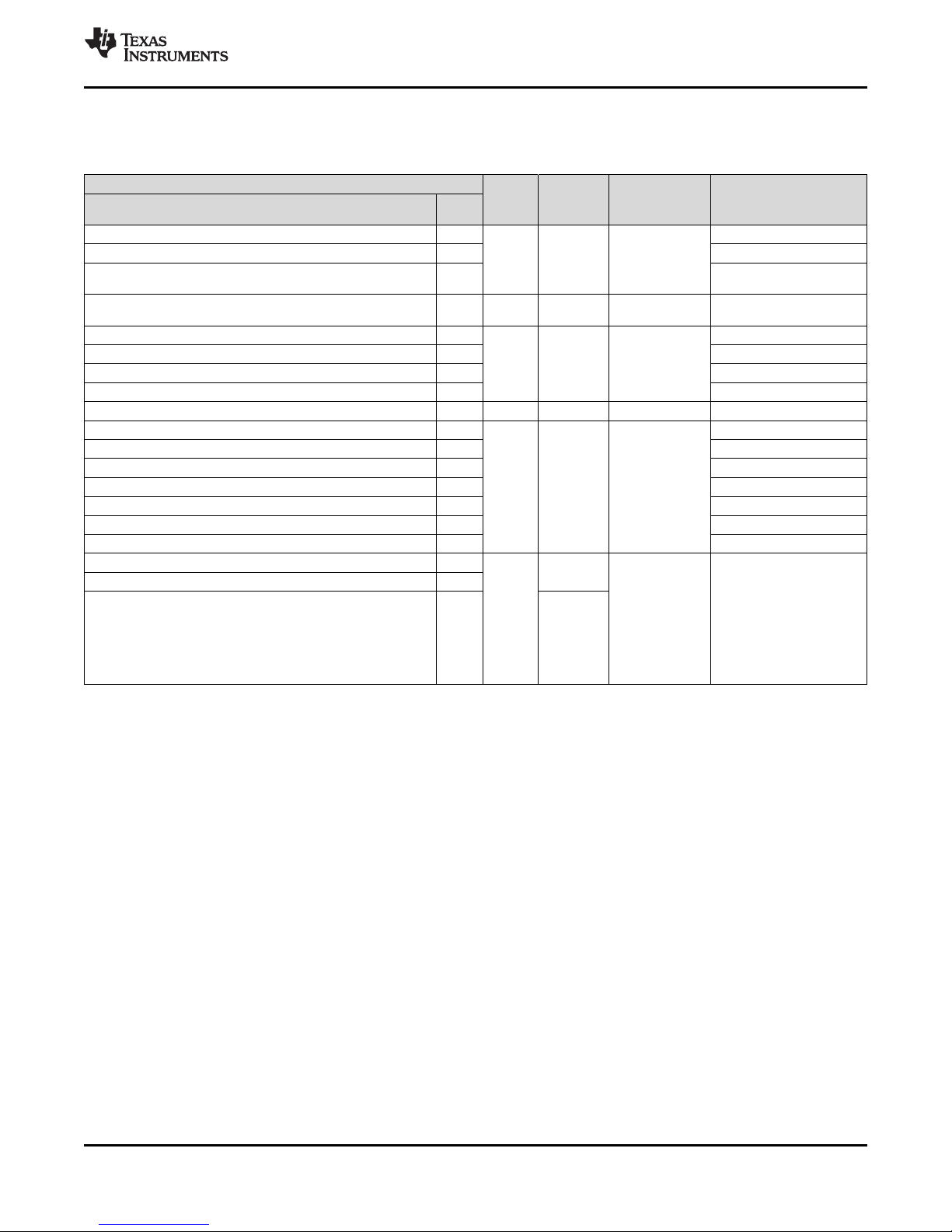

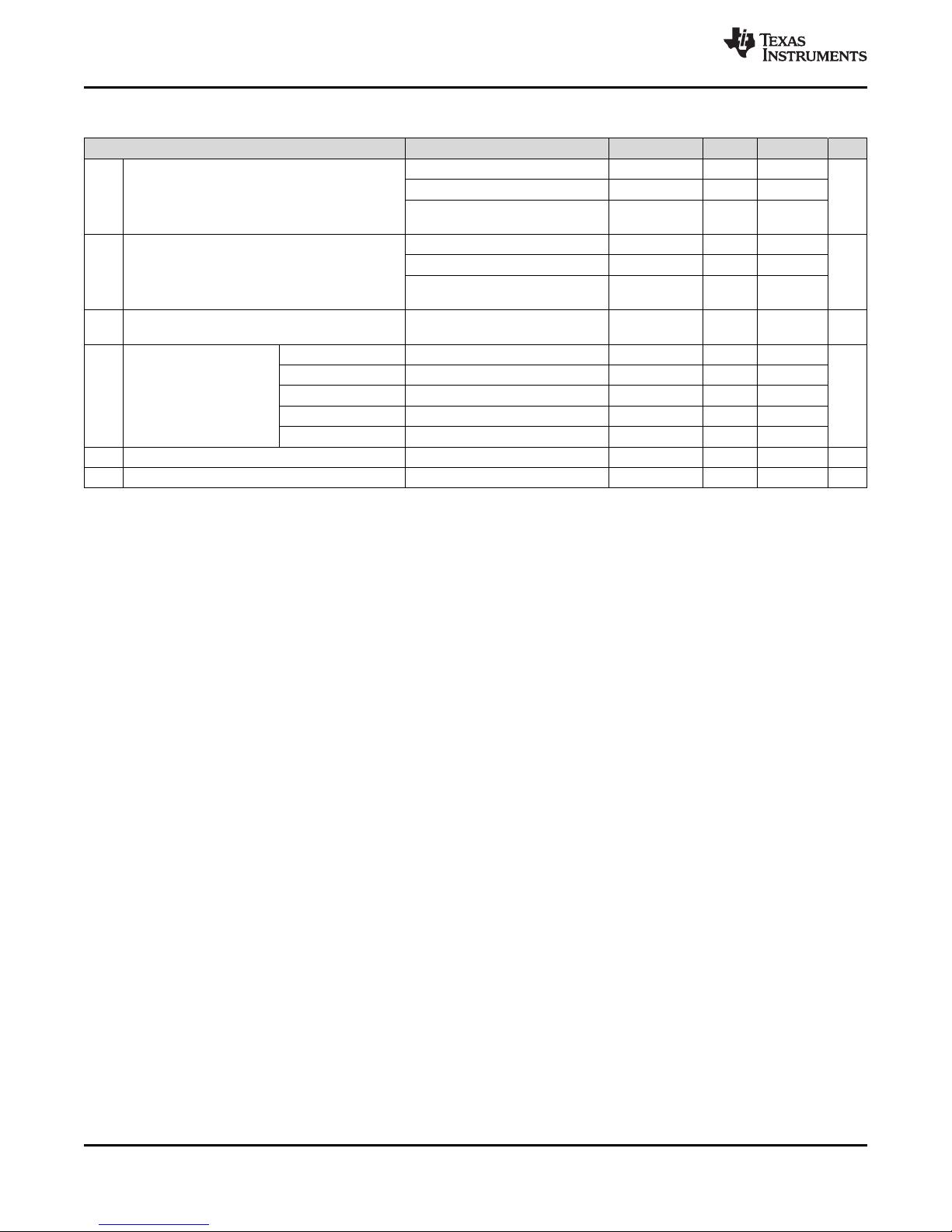

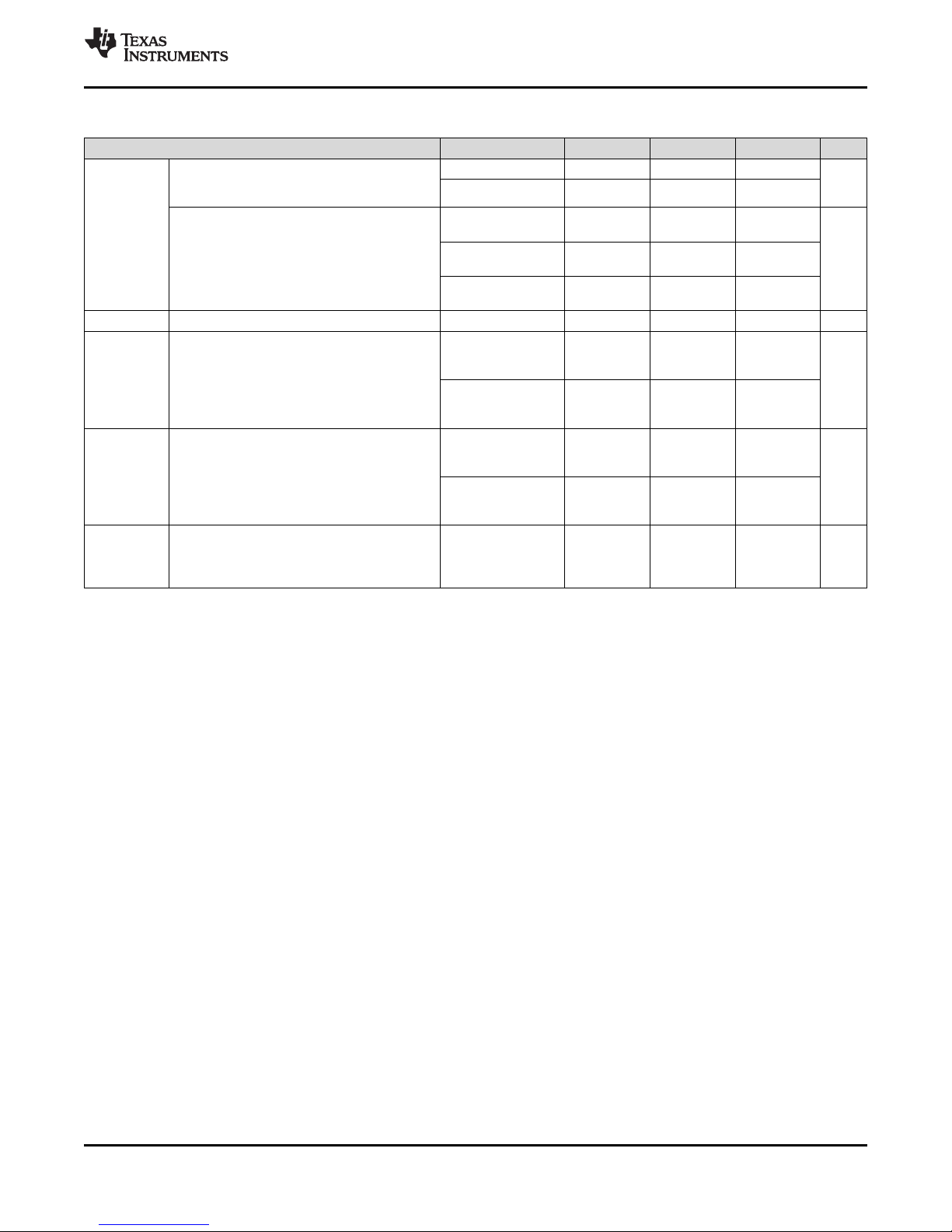

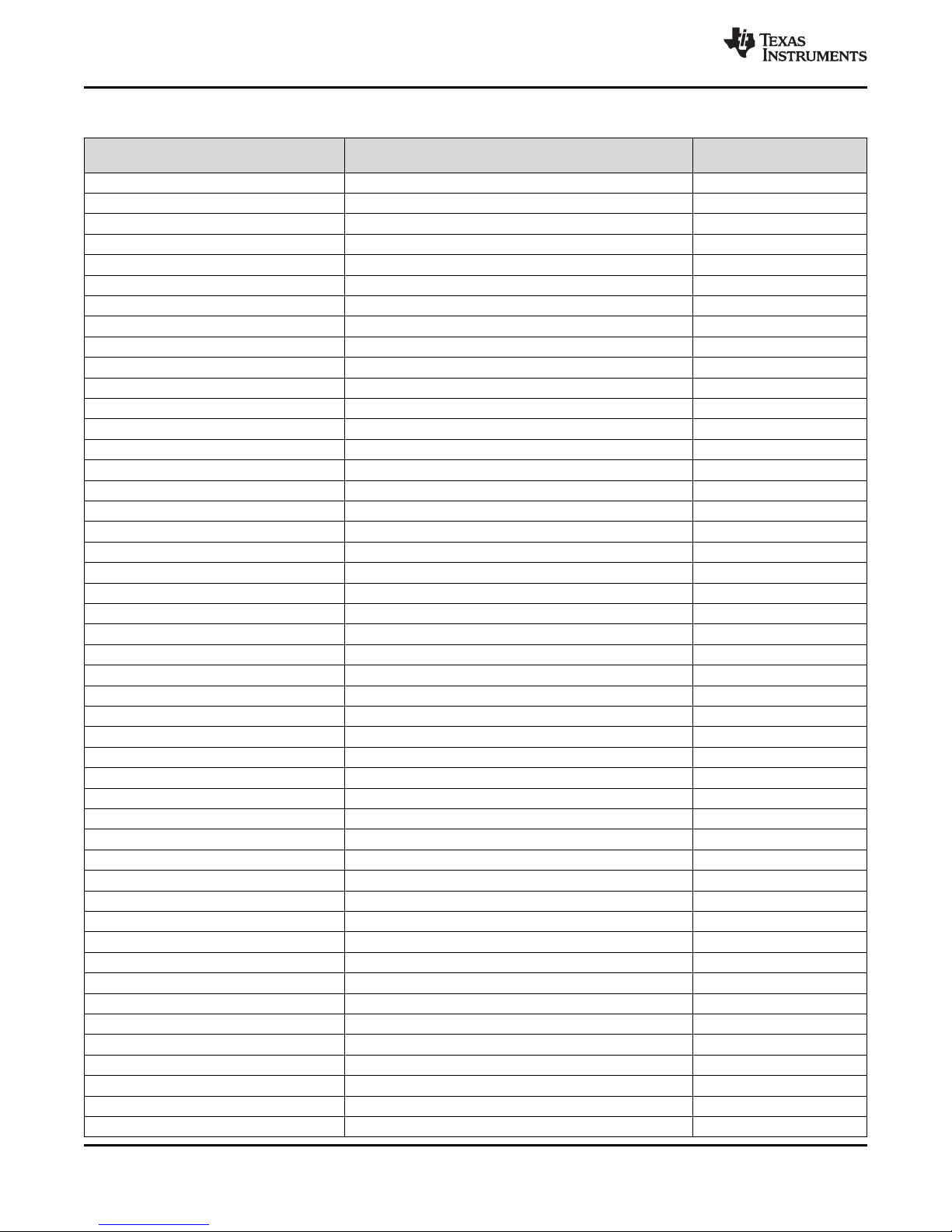

Table 3-1 lists the features of the TMS570LS0714 devices.

Table 3-1. TMS570LS0714 Device Comparison

www.ti.com

FEATURES TMS570LS DEVICES

Generic Part Number 3137ZWT

Package 337 BGA 337BGA 144 QFP 144 QFP 100 QFP 100 QFP

CPU ARM Cortex-R4F ARM Cortex-R4F ARM Cortex-R4F ARM Cortex-R4F ARM Cortex-R4F ARM Cortex-R4

Frequency (MHz) 180 180 160 160 100 80

Flash (KB) 3072 1280 1024 768 768 384

RAM (KB) 256 192 128 128 128 32

Data Flash [EEPROM]

(KB)

EMAC 10/100 10/100 – – – –

FlexRay 2-ch 2-ch – – – –

CAN 3 3 3 3 2 2

MibADC

12-bit (Ch)

N2HET (Ch) 2 (44) 2 (44) 2 (40) 2 (40) 2 (21) 1 (19)

ePWM Channels – 14 14 14 8 –

eCAP Channels – 6 6 6 4 0

eQEP Channels – 2 2 2 1 2

MibSPI (CS) 3 (6 + 6 + 4) 3 (6 + 6 + 4) 3 (5 + 6 + 1) 3 (5 + 6 + 4) 2 (5 + 1) 1 (4)

SPI (CS) 2 (2 + 1) 2 (2 + 1) 1 (1) 1 (1) 1 (1) 2

SCI (LIN) 2 (1 with LIN) 2 (1 with LIN) 2 (1 with LIN) 2 (1 with LIN) 1 (with LIN) 1 (with LIN)

I2C 1 1 1 1 – –

GPIO (INT)

EMIF 16-bit data 16-bit data – – – –

ETM (Trace) 32-bit – – – – –

RTP/DMM YES – – – – –

Operating

Temperature

Core Supply (V) 1.14 V – 1.32 V 1.14 V – 1.32 V 1.14 V – 1.32 V 1.14 V – 1.32 V 1.14 V – 1.32 V 1.14 V – 1.32 V

I/O Supply (V) 3.0 V – 3.6 V 3.0 V – 3.6 V 3.0 V – 3.6 V 3.0 V – 3.6 V 3.0 V – 3.6 V 3.0 V – 3.6 V

120 (with 16 interrupt

-40ºC to 125ºC -40ºC to 125ºC -40ºC to 125ºC -40ºC to 125ºC -40ºC to 125ºC -40ºC to 125ºC

(1)

64 64 64 64 64 16

2 x (24ch) 2 x (24ch) 2 x (24ch) 2 x (24ch) 2 x (16ch) 1 x (16ch)

capable)

101 (with 16 interrupt

1227ZWT

capable)

(1)

64 (with 10 interrupt

0914PGE

capable)

(1)

0714PGE 0714PZ 0432PZ

64 (with 10 interrupt

capable)

45 (with 9 interrupt

capable)

45 (with 8 interrupt

capable)

(1) Bolding denotes a superset device. For additional device variants, see www.ti.com/tms570

3.1 Related Products

For information about other devices in this family of products or related products, see the following links.

Products for TMS570 16-Bit and 32-Bit MCUs

An expansive portfolio of software and pin-compatible high-performance ARM®Cortex®-R-based MCU

products from 80 MHz up to 300 MHz with on-chip features that prove a high level of diagnostic coverage,

as well as provide scalability to address a wide range of applications.

Companion Products for TMS570LS0714

Review products that are frequently purchased or used with this product.

8

Device Comparison Copyright © 2013–2016, Texas Instruments Incorporated

Submit Documentation Feedback

Product Folder Links: TMS570LS0714

Page 9

1

108

234

5

GIOA[1]

nTRST

109

144

110

111

112

113

114

115

116

117

118

119

120

121

AD1IN[10] / AD2IN[10]

122

123

124

125

126

127

128

129

130

131

132

133

134

135

136

137

138

139

140

141

142

143

72

71

70

69

68

67

66

65

64

63

62

61

60

59

58

57

56

55

54

53

52

51

50

49

48

47

46

45

44

43

42

41

40

39

38

37

678

9

10111213141516171819202122

232324252627272829303132333435

36

107

106

105

104

103

102

101

100

999897969594939291908988878685848382818079787776757473

GIOB[3]

GIOA[0]

N2HET1[11]

FLTP1

FLTP2

GIOA[2]

VCCIO

VSS

CAN3RX

CAN3TX

GIOA[5]

N2HET1[22]

GIOA[6]

VCC

OSCIN

Kelvin_GND

OSCOUT

VSS

GIOA[7]

N2HET1[01]

N2HET1[03]

N2HET1[0]

VCCIO

VSS

VSS

VCC

N2HET1[02]

N2HET1[05]

N2HET1[07]

TEST

N2HET1[09]

N2HET1[4]

MIBSPI3NCS[1]

N2HET1[06]

N2HET1[13]

MIBSPI1NCS[2]

N2HET1[15]

VCCIO

VSS

VSS

VCC

nPORRST

VSS

VCC

VCC

VSS

MIBSPI3SOMI

MIBSPI3SIMO

MIBSPI3CLK

MIBSPI3NENA

MIBSPI3NCS[0]

VSS

VCC

AD1IN[16] / AD2IN[0]

AD1IN[17] / AD2IN[01]

AD1IN[0]

AD1IN[07]

AD1IN[18] / AD2IN[02]

AD1IN[19] / AD2IN[03]

AD1IN[20] / AD2IN[04]

AD1IN[21] / AD2IN[05]

ADREFHI

ADREFLO

VSSAD

VCCAD

AD1IN[09] / AD2IN[09]

AD1IN[01]

AD1IN[02]

AD1IN[03]

AD1IN[11] / AD2IN[11]

AD1IN[04]

AD1IN[12] / AD2IN[12]

AD1IN[05]

AD1IN[13] / AD2IN[13]

AD1IN[06]

AD1IN[22] / AD2IN[06]

AD1IN[14] / AD2IN[14]

AD1IN[08] / AD2IN[08]

AD1IN[23] / AD2IN[07]

AD1IN[15] / AD2IN[15]

AD1EVT

VCC

VSS

CAN1TX

CAN1RX

N2HET1[24]

N2HET1[26]

MIBSPI1SIMO

MIBSPI1SOMI

MIBSPI1CLK

MIBSPI1NENA

MIBSPI5NENA

MIBSPI5SOMI[0]

MIBSPI5SIMO[0]

MIBSPI5CLK

VCC

VSS

VSS

VCCIO

N2HET1[08]

N2HET1[28]

TMS

TDI

TDO

TCK

RTCK

VCC

VSS

nRST

nERROR

N2HET1[10]

ECLK

VCCIO

VSS

VSS

VCC

N2HET1[12]

N2HET1[14]

GIOB[0]

N2HET1[30]

CAN2TX

CAN2RX

MIBSPI1NCS[1]

LINRX

LINTX

GIOB[1]

VCCP

VSS

VCCIO

VCC

VSS

N2HET1[16]

N2HET1[18]

N2HET1[20]

GIOB[2]

VCC

VSS

MIBSPI1NCS[0]

www.ti.com

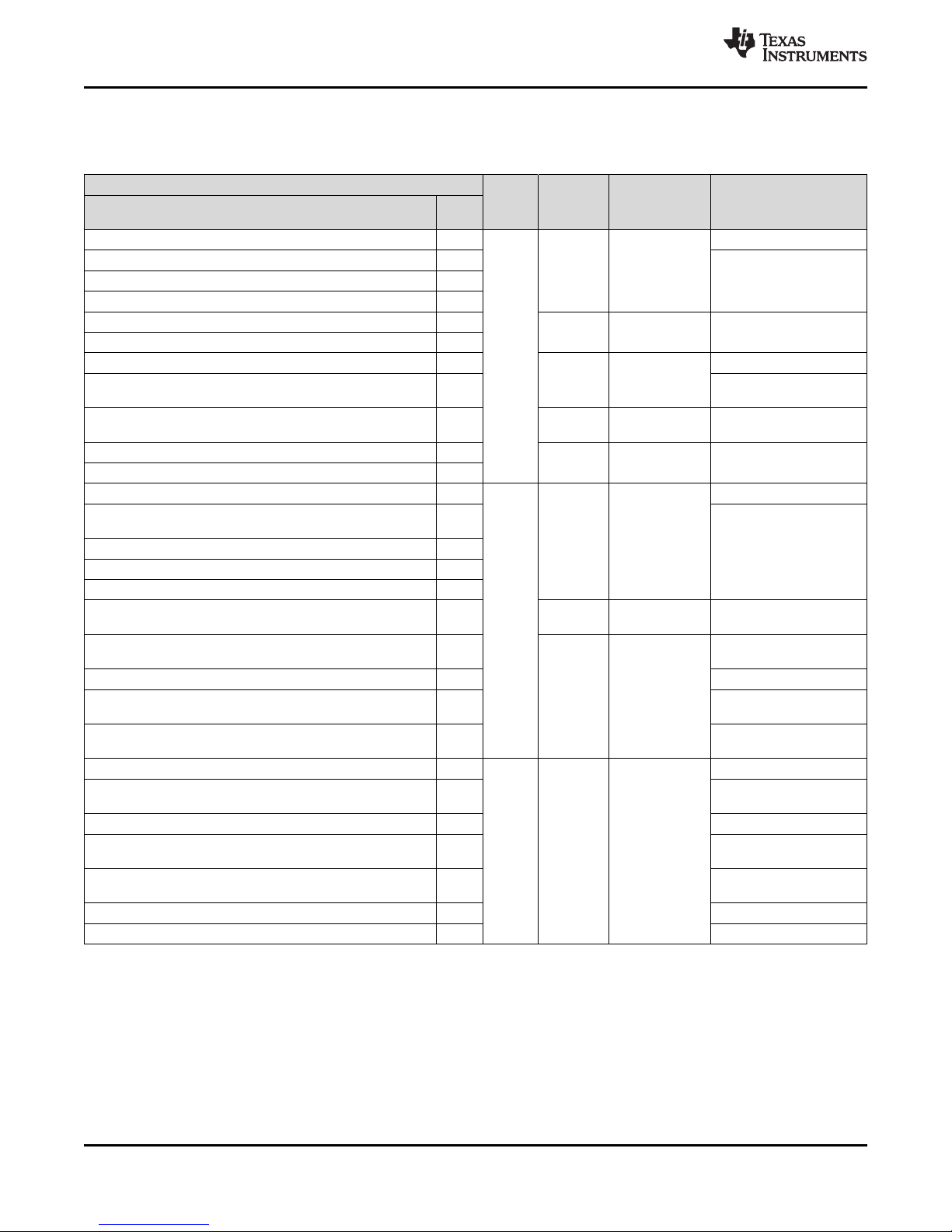

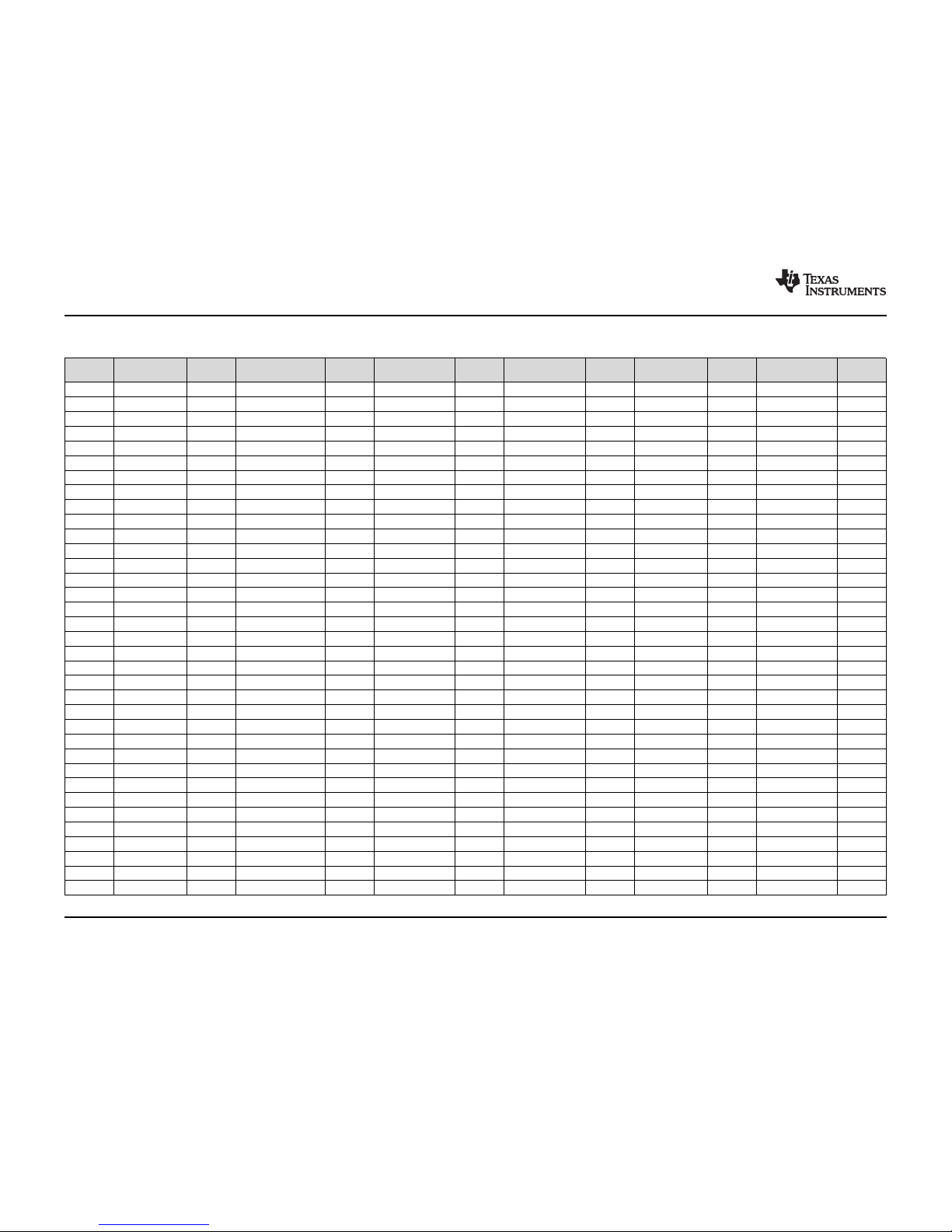

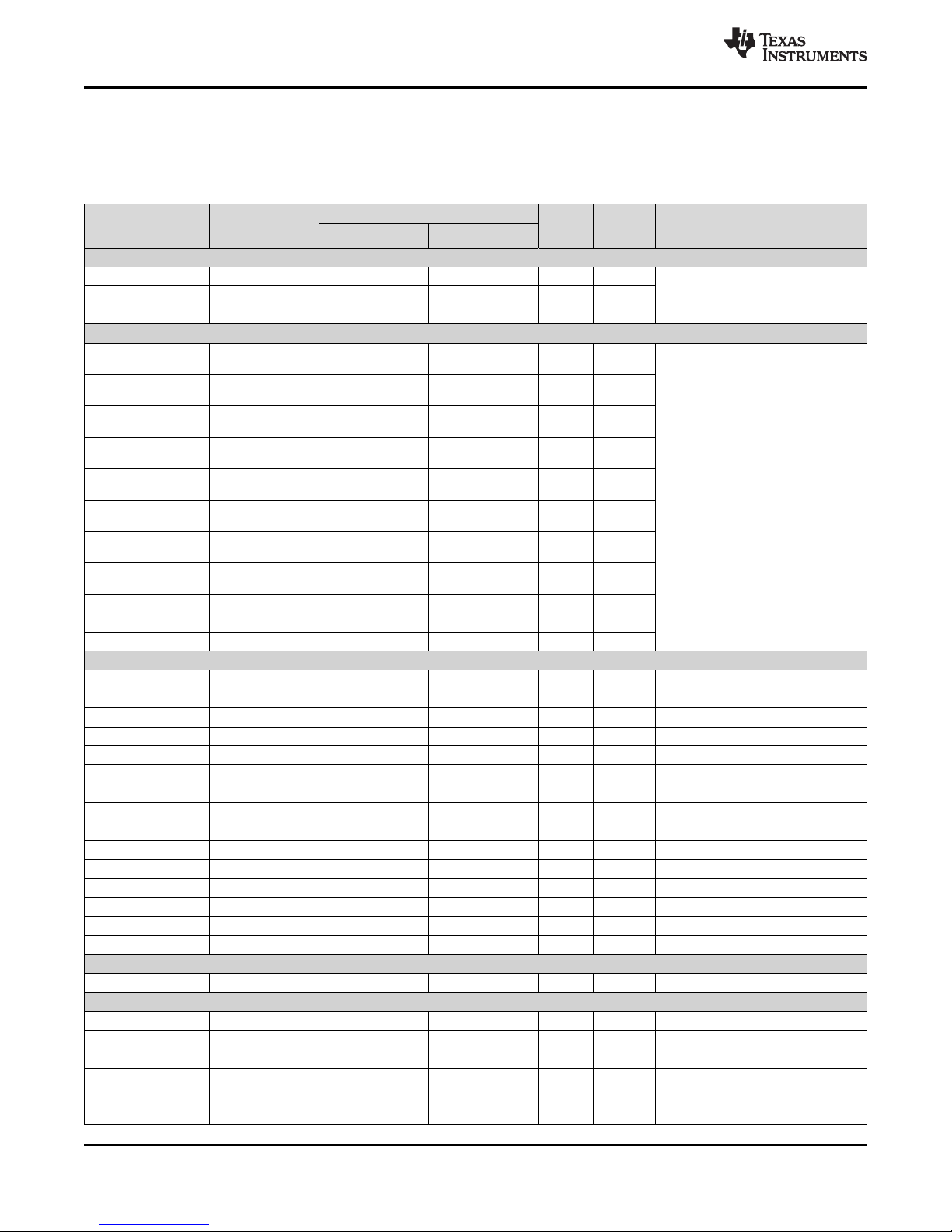

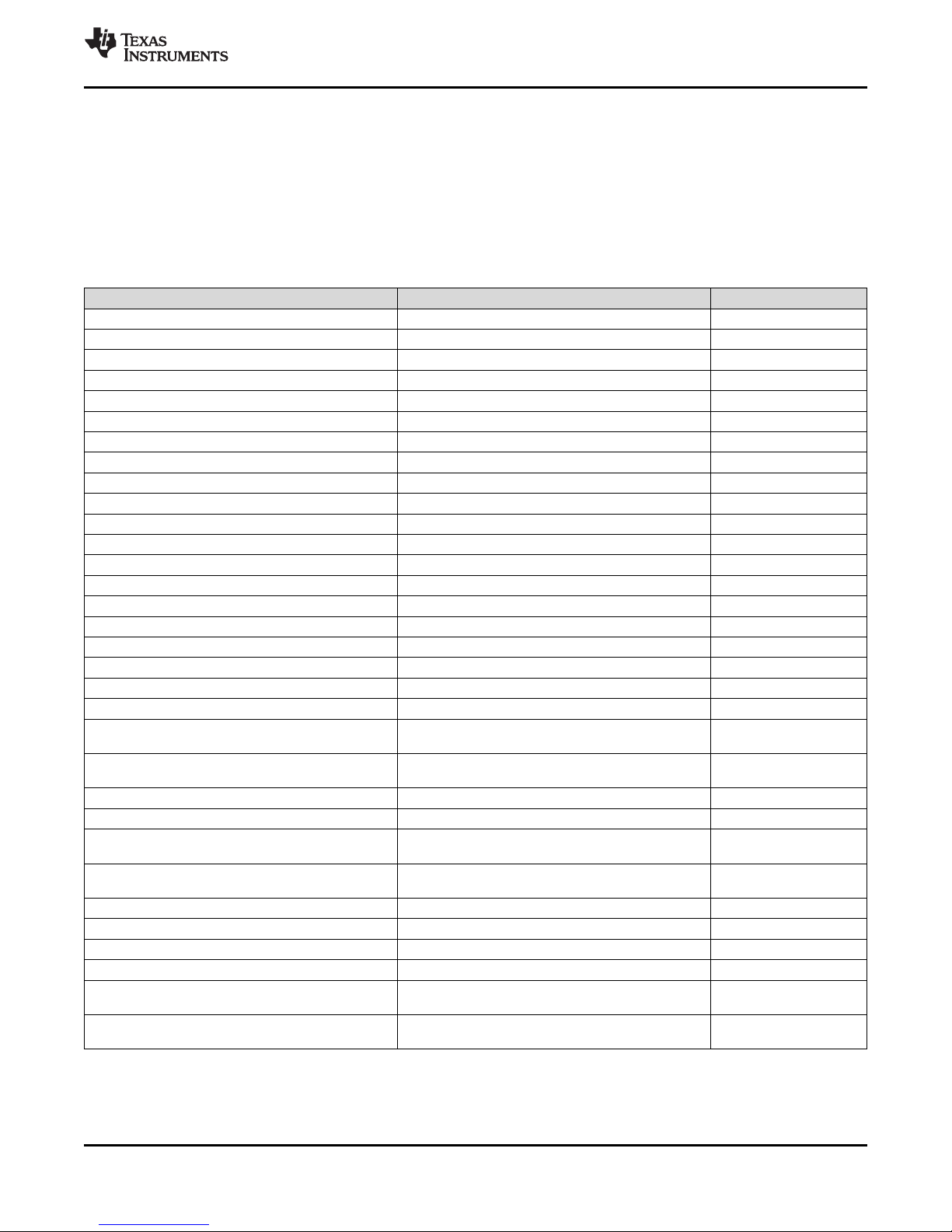

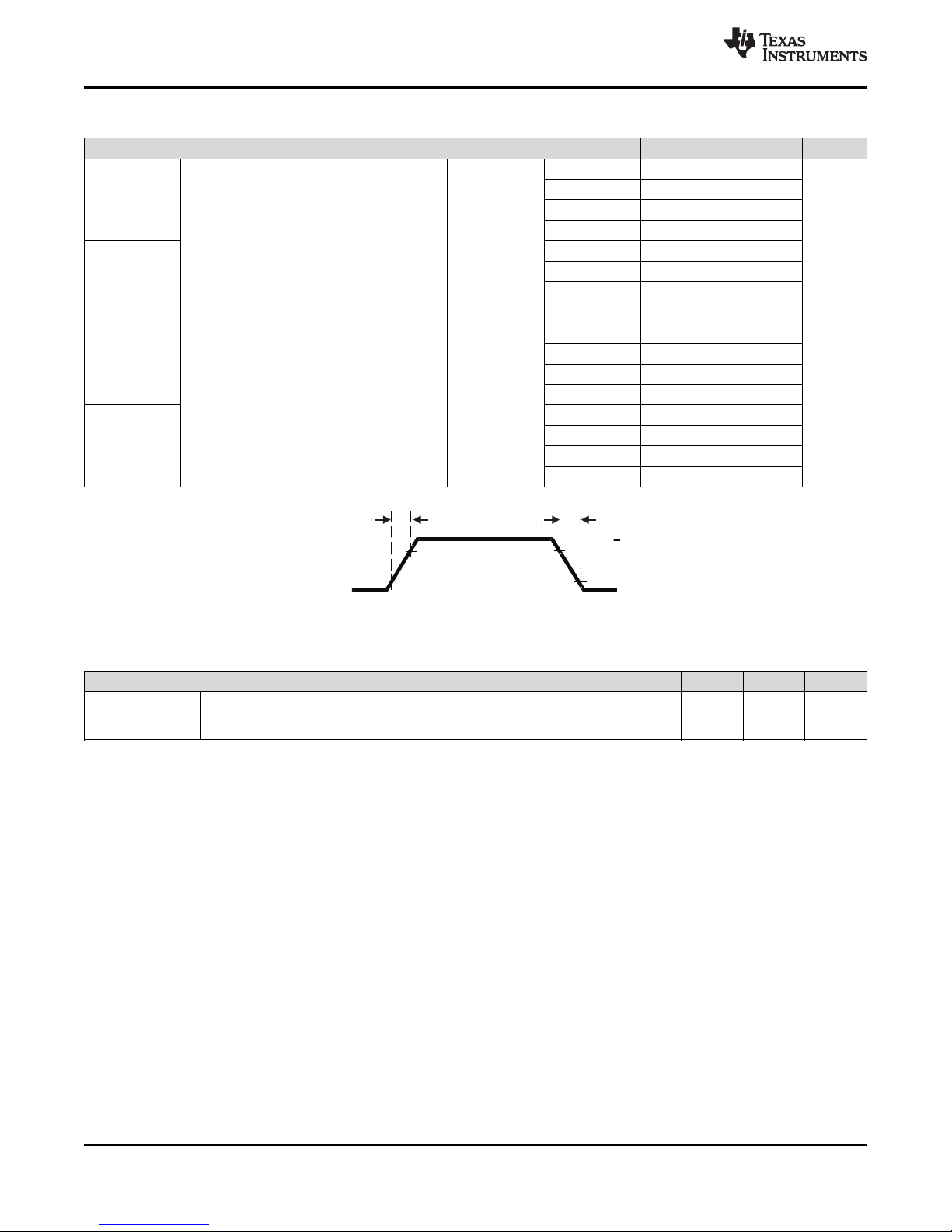

4 Terminal Configuration and Functions

4.1 Pin Diagrams

4.1.1 PGE QFP Package Pinout (144-Pin)

TMS570LS0714

SPNS226E –JUNE 2013–REVISED NOVEMBER 2016

A. Pins can have multiplexed functions. Only the default function is shown in Figure 4-1.

Figure 4-1. PGE QFP Package Pinout (144-Pin)

Submit Documentation Feedback

Product Folder Links: TMS570LS0714

Terminal Configuration and FunctionsCopyright © 2013–2016, Texas Instruments Incorporated

9

Page 10

MIBSPI1nCS[1]

VCCP

LINRX

VCCIO

ECLK

RTCK

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

N2HET1[6]

MIBSPI1nCS[2]

VCCIO

VSS

VCC

nPORRST

VCC

VSS

MIBSPI3nENA

AD1IN[21]

TCK

MIBSPI3nCS[0]

MIBSPI1nCS[3]

AD1IN[0]

AD1IN[7]

AD1IN[20]

VSSAD/ADREFLO

AD1IN[9]

VCCAD/ADREFHI

AD1IN[1]

AD1IN[10]

VSS

VCC

CAN2RX

CAN2TX

VCC

VSS

nERROR

nRST

TDO

TDI

nTRST

VSS

LINTX

MIBSPI3CLK

ADEVT

VSS

CAN1T X

CAN1RX

MIBSPI1SOMI

MIBSPI1CLK

MIBSPI1nENA

SPI2SOMI

SPI2SIMO

SPI2CLK

MIBSPI1nCS

TMS

VCC

MIBSPI1SIMO

VCCIO

25

24

23

22

212019

18

17

16

15

14

13

12

11

10

9

876

5

4

3

2

1

51

52

54

55

56

57

58

59

606162

63

64

65

66

67

68

69

70

71

72

73

74

75

53

GIOA[3]/INT[3]

VSS

VCCIO

TEST

VSS

KELVIN_GND

OS CIN

VC C

GIOA[6]/INT[6]

GIOA[5]/INT[5]

GIOA[2]/INT[2]

FLTP2

FLTP1

GIOA[4]/INT[4]

OSCOUT

100

99

98

97

96

95

94

93

92

91

90

89

88

87

86

85

84

83

82

81

80

79

78

77

76

VSS

VC C

VSS

MIBSPI3SOMI

MIBSPI3SIMO

AD1IN[16]

AD1IN[17]

N2HET1[4]

N2HET1[2]

N2HET1[0]

N2HET1[22]

N2HET1[24]

N2HET1[10]

N2HET1[8]

N2HET1[14]

N2HET1[12]

N2HET1[16]

N2HET1[18]

SPI2nCS[0]

AD1IN[2]

AD1IN[3]

AD1IN[11]

AD1IN[8]

AD1IN[6]

AD1IN[4]

AD1IN[5]

TMS570LS0714

SPNS226E –JUNE 2013–REVISED NOVEMBER 2016

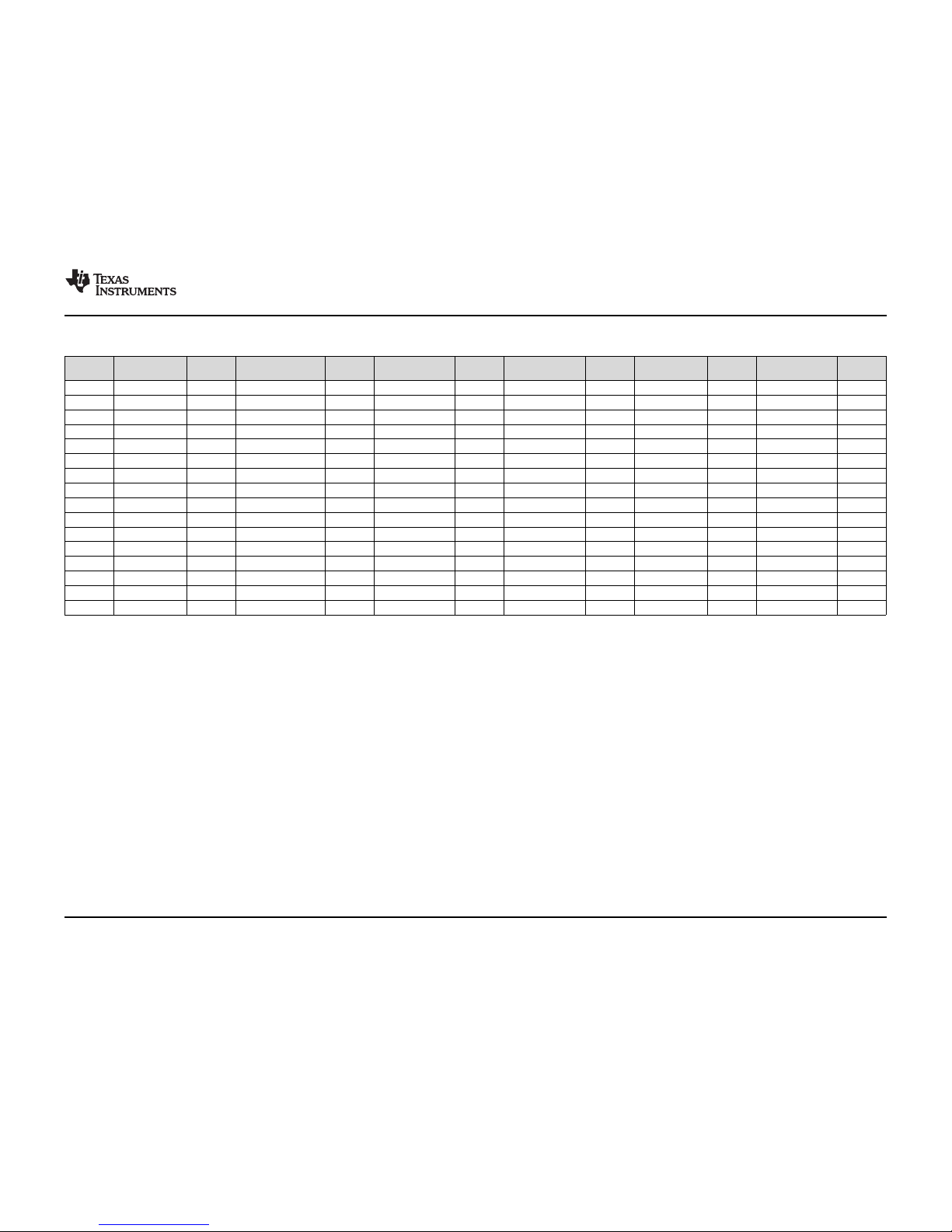

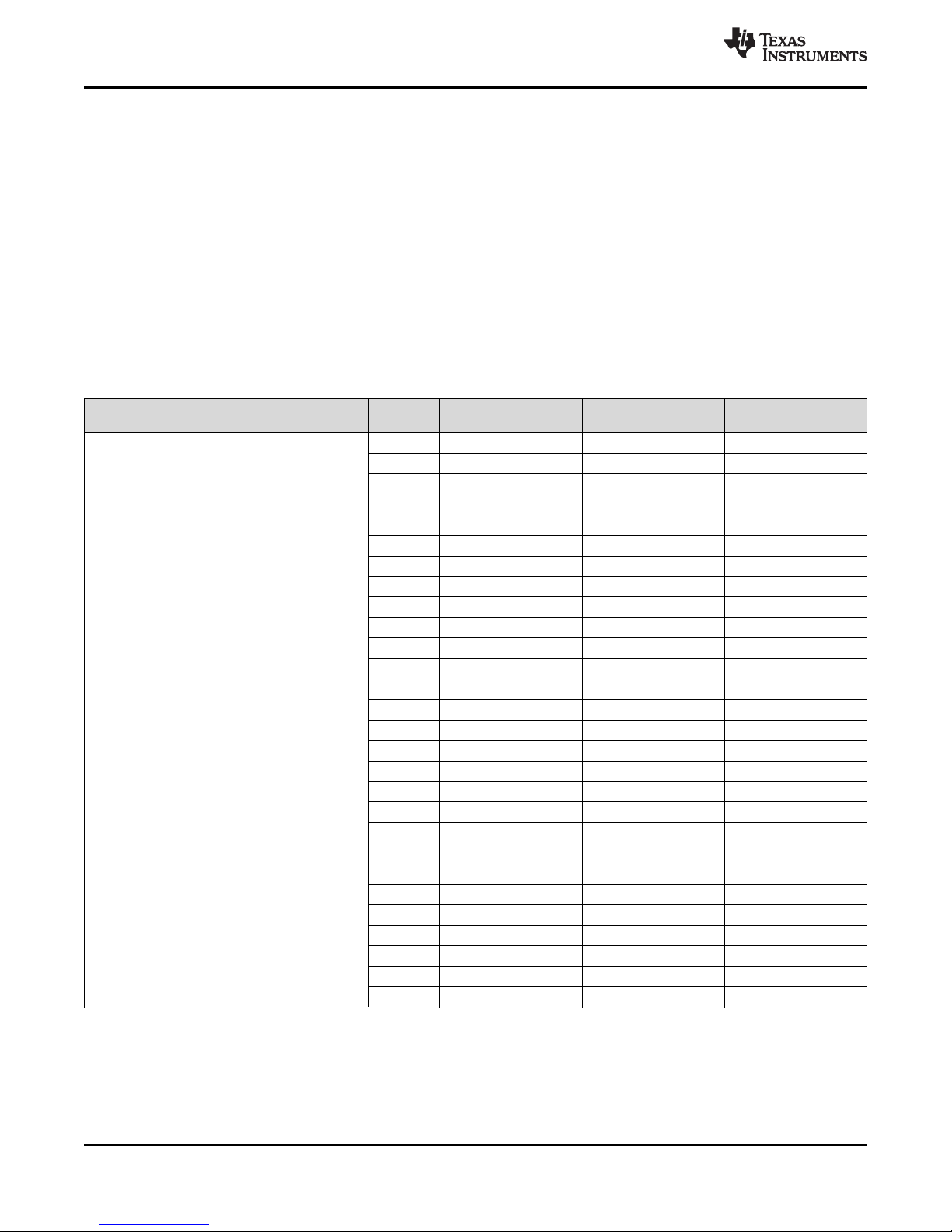

4.1.2 PZ QFP Package Pinout (100-Pin)

www.ti.com

10

Terminal Configuration and Functions Copyright © 2013–2016, Texas Instruments Incorporated

Figure 4-2. PZ QFP Package Pinout (100-Pin)

Submit Documentation Feedback

Product Folder Links: TMS570LS0714

Page 11

www.ti.com

4.2 Signal Descriptions

The signal descriptions section shows pin information in module function order per package.

Section 4.2.1 and Section 4.2.2 identify the external signal names, the associated pin or ball numbers

along with the mechanical package designator, the pin or ball type (Input, Output, I/O, Power, or Ground),

whether the pin or ball has any internal pullup/pulldown, whether the pin or ball can be configured as a

GIO, and a functional pin or ball description. The first signal name listed is the primary function for that

terminal (pin or ball). The signal name in Bold is the function being described. For information on how to

select between different multiplexed functions, see Section 4.3, Pin Multiplexing or see the I/O Multiplexing

and Control Module (IOMM) chapter of the TMS570LS09x/07x 16/32-Bit RISC Flash Microcontroller

Technical Reference Manual (SPNU607).

All I/O signals except nRST are configured as inputs while nPORRST is low and immediately

after nPORRST goes high.

All output-only signals are configured as high impedance while nPORRST is low, and are

configured as outputs immediately after nPORRST goes high.

While nPORRST is low, the input buffers are disabled, and the output buffers are high

impedance.

TMS570LS0714

SPNS226E –JUNE 2013–REVISED NOVEMBER 2016

NOTE

In the Terminal Functions tables of Section 4.2.1 and Section 4.2.2, the RESET PULL

STATE is the state of the pullup or pulldown while nPORRST is low and immediately after

nPORRST goes high. The default pull direction may change when software configures the

pin for an alternate function. The PULL TYPE is the type of pull asserted when the signal

name in bold is enabled for the given terminal.

Submit Documentation Feedback

Product Folder Links: TMS570LS0714

Terminal Configuration and FunctionsCopyright © 2013–2016, Texas Instruments Incorporated

11

Page 12

TMS570LS0714

SPNS226E –JUNE 2013–REVISED NOVEMBER 2016

4.2.1 PGE Package Terminal Functions

4.2.1.1 Multibuffered Analog-to-Digital Converters (MibADCs)

Table 4-1. PGE Multibuffered Analog-to-Digital Converters (MibADC1, MibADC2)

www.ti.com

Terminal Signal

Signal Name 144

Type

Reset Pull

State

Pull Type Description

PGE

ADREFHI

(1)

66 Power – None ADC high reference

supply

ADREFLO

VCCAD

VSSAD

AD1EVT 86 I/O Pulldown Programmable,

MIBSPI3NCS[0]/AD2EVT/GIOB[2]/

EQEP1I/N2HET2_PIN_nDIS

(1)

(1)

(1)

67 Power ADC low reference supply

69 Power Operating supply for ADC

68 Ground

ADC1 event trigger input,

20 µA

55 I/O Pullup Programmable,

20 µA

or GIO

ADC2 event trigger input,

or GIO

AD1IN[0] 60 Input – None ADC1 analog input

AD1IN[01] 71

AD1IN[02] 73

AD1IN[03] 74

AD1IN[04] 76

AD1IN[05] 78

AD1IN[06] 80

AD1IN[07] 61

AD1IN[08] / AD2IN[08] 83 Input – None ADC1/ADC2 shared

AD1IN[09] / AD2IN[09] 70

analog inputs

AD1IN[10] / AD2IN[10] 72

AD1IN[11] / AD2IN[11] 75

AD1IN[12] / AD2IN[12] 77

AD1IN[13] / AD2IN[13] 79

AD1IN[14] / AD2IN[14] 82

AD1IN[15] / AD2IN[15] 85

AD1IN[16] / AD2IN[0] 58

AD1IN[17] / AD2IN[01] 59

AD1IN[18] / AD2IN[02] 62

AD1IN[19] / AD2IN[03] 63

AD1IN[20] / AD2IN[04] 64

AD1IN[21] / AD2IN[05] 65

AD1IN[22] / AD2IN[06] 81

AD1IN[23] / AD2IN[07] 84

MIBSPI3SOMI[0]/AWM1_EXT_ENA/ECAP2 51 Output Pullup – AWM1 external analog

mux enable

MIBSPI3SIMO[0]/AWM1_EXT_SEL[0]/ECAP3 52 Output Pullup – AWM1 external analog

mux select line0

MIBSPI3CLK/AWM1_EXT_SEL[1]/EQEP1A 53 Output Pullup – AWM1 external analog

mux select line0

(1) The ADREFHI, ADREFLO, VCCAD and VSSAD connections are common for both ADC cores.

12

Terminal Configuration and Functions Copyright © 2013–2016, Texas Instruments Incorporated

Submit Documentation Feedback

Product Folder Links: TMS570LS0714

Page 13

www.ti.com

4.2.1.2 Enhanced High-End Timer (N2HET) Modules

Table 4-2. PGE Enhanced High-End Timer (N2HET) Modules

TERMINAL

SIGNAL NAME

N2HET1[0]/SPI4CLK/EPWM2B 25

N2HET1[01]/SPI4NENA/N2HET2[8]/EQEP2A 23

N2HET1[02]/SPI4SIMO[0]/EPWM3A 30

N2HET1[03]/SPI4NCS[0]/N2HET2[10]/EQEP2B 24

N2HET1[04]/EPWM4B 36

N2HET1[05]/SPI4SOMI[0]/N2HET2[12]/EPWM3B 31

N2HET1[06]/SCIRX/EPWM5A 38

N2HET1[07]/N2HET2[14]/EPWM7B 33

N2HET1[08]/MIBSPI1SIMO[1]/ 106

N2HET1[09]/N2HET2[16]/EPWM7A 35

N2HET1[10]/nTZ3 118

N2HET1[11]/MIBSPI3NCS[4]/N2HET2[18]/EPWM1SYNCO 6

N2HET1[12] 124

N2HET1[13]/SCITX/EPWM5B 39

N2HET1[14] 125

N2HET1[15]/MIBSPI1NCS[4]/ECAP1 41

N2HET1[16]/EPWM1SYNCI/EPWM1SYNCO 139

MIBSPI1NCS[1]/N2HET1[17]/EQEP1S 130 Pullup

N2HET1[18]/EPWM6A 140 Pulldown

MIBSPI1NCS[2]/N2HET1[19] 40 Pullup

N2HET1[20]/EPWM6B 141

N2HET1[22] 15

MIBSPI1NENA/N2HET1[23]/ECAP4 96 Pullup

N2HET1[24]/MIBSPI1NCS[5] 91 Pulldown

MIBSPI3NCS[1]/N2HET1[25] 37 Pullup

N2HET1[26] 92 Pulldown

MIBSPI3NCS[2]/I2CSDA/N2HET1[27]/nTZ2 4 Pullup

N2HET1[28] 107 Pulldown

MIBSPI3NCS[3]/I2CSCL/N2HET1[29]/nTZ1 3 Pullup

N2HET1[30]/EQEP2S 127 Pulldown

MIBSPI3NENA/MIBSPI3NCS[5]/N2HET1[31]/EQEP1B 54 Pullup

GIOA[5]/EXTCLKIN1/EPWM1A/N2HET1_PIN_nDIS 14 Pulldown

GIOA[2]/N2HET2[0]/EQEP2I 9

GIOA[6]/N2HET2[4]/EPWM1B 16

GIOA[7]/N2HET2[6]EPWM2A 22

N2HET1[01]/SPI4NENA//N2HET2[8] 23

N2HET1[03]/SPI4NCS[0]/N2HET2[10]/EQEP2B 24

N2HET1[05]/SPI4SOMI[0]/N2HET2[12]/EQEP3B 31

N2HET1[07]/N2HET2[14]/EPWM7B 33

N2HET1[09]/N2HET2[16] 35

N2HET1[11]/MIBSPI3NCS[4]/N2HET2[18]/EPWM1SYNCO 6

MIBSPI3NCS[0]/AD2EVT/GIOB[2]/EQEP1l/N2HET2_PIN_nDIS 55 Pullup

144

PGE

SIGNAL

TYPE

I/O

I/O

RESET

PULL

STATE

Pulldown

Pulldown

Pulldown

TMS570LS0714

SPNS226E –JUNE 2013–REVISED NOVEMBER 2016

DESCRIPTION

PULL TYPE

N2HET1 timer input

capture or output

compare, or GIO.

Programmable,

20 µA

Programmable,

20 µA

Each terminal has a

suppression filter with a

programmable duration.

Disable selected PWM

outputs

N2HET2 timer input

capture or output

compare, or GIO

Each terminal has a

suppression filter with a

programmable duration.

Disable selected PWM

outputs

Submit Documentation Feedback

Product Folder Links: TMS570LS0714

Terminal Configuration and FunctionsCopyright © 2013–2016, Texas Instruments Incorporated

13

Page 14

TMS570LS0714

SPNS226E –JUNE 2013–REVISED NOVEMBER 2016

4.2.1.3 Enhanced Capture Modules (eCAP)

www.ti.com

Table 4-3. PGE Enhanced Capture Modules (eCAP)

TERMINAL

SIGNAL NAME

N2HET1[15]/MIBSPI1NCS[4]/ECAP1 41

MIBSPI3SOMI[0]/AWM1_EXT_ENA/ECAP2 51

MIBSPI3SIMO[0]/AWM1_EXT_SEL[0]/ECAP3 52

MIBSPI1NENA/N2HET1[23]/ECAP4 96

MIBSPI5NENA/MIBSPI5SOMI[1]/ECAP5 97

MIBSPI1NCS[0]/MIBSPI1SOMI[1]/ECAP6 105

144

PGE

SIGNAL

TYPE

I/O

RESET

PULL

STATE

Pulldown

Pullup

(1)

PULL TYPE DESCRIPTION

Enhanced Capture Module 1

I/O

Enhanced Capture Module 2

I/O

Enhanced Capture Module 3

Fixed, 20 µA

I/O

Enhanced Capture Module 4

I/O

Enhanced Capture Module 5

I/O

Enhanced Capture Module 6

I/O

(1) These signals, when used as inputs, are double-synchronized and then optionally filtered with a 6-cycle VCLK4-based counter.

4.2.1.4 Enhanced Quadrature Encoder Pulse Modules (eQEP)

Table 4-4. PGE Enhanced Quadrature Encoder Pulse Modules (eQEP)

TERMINAL

SIGNAL NAME

MIBSPI3CLK/AWM1_EXT_SEL[1]/EQEP1A 53 Input

MIBSPI3NENA/MIBSPI3NCS[5]/N2HET1[31]/EQEP1B 54 Input Enhanced QEP1 Input B

MIBSPI3NCS[0]/AD2EVT/GIOB[2]/EQEP1I/N2HET2_PIN_nDIS 55 I/O Enhanced QEP1 Index

MIBSPI1NCS[1]/N2HET1[17]//EQEP1S 130 I/O Enhanced QEP1 Strobe

N2HET1[01]/SPI4NENA/N2HET2[8]/EQEP2A 23 Input

N2HET1[03]/SPI4NCS[0]/N2HET2[10]/EQEP2B 24 Input Enhanced QEP2 Input B

GIOA[2]/N2HET2[0]/EQEP2I 9 I/O EnhancedQEP2 Index

N2HET1[30]/EQEP2S 127 I/O Enhanced QEP2 Strobe

144

PGE

SIGNAL

TYPE

(1) These signals are double-synchronized and then optionally filtered with a 6-cycle VCLK4-based counter.

RESET

PULL

STATE

Pullup

Pulldown

PULL TYPE DESCRIPTION

Fixed, 20 µA

(1)

Enhanced QEP1 Input A

Enhanced QEP2 Input A

14

Terminal Configuration and Functions Copyright © 2013–2016, Texas Instruments Incorporated

Submit Documentation Feedback

Product Folder Links: TMS570LS0714

Page 15

TMS570LS0714

www.ti.com

SPNS226E –JUNE 2013–REVISED NOVEMBER 2016

4.2.1.5 Enhanced Pulse-Width Modulator Modules (ePWM)

Table 4-5. PGE Enhanced Pulse-Width Modulator Modules (ePWM)

TERMINAL

SIGNAL NAME

GIOA[5]/EXTCLKIN1/EPWM1A/N2HET1_PIN_nDIS 14

GIOA[6]/N2HET2[4]/EPWM1B 16 Enhanced PWM1 Output B

N2HET1[11]/MIBSPI3NCS[4]/N2HET2[18]/EPWM1SYNCO 6

N2HET1[16]/EPWM1SYNCI/EPWM1SYNCO 139 Input Pullup Fixed, 20 µA

GIOA[7]/N2HET2[6]/EPWM2A 22

N2HET1[0]/SPI4CLK/EPWM2B 25 Enhanced PWM2 Output B

N2HET1[02]/SPI4SIMO[0]/EPWM3A 30 Enhanced PWM3 Output A

N2HET1[05]/SPI4SOMI[0]/N2HET2[12]/EPWM3B 31 Enhanced PWM3 Output B

MIBSPI5NCS[0]/EPWM4A 32 Output Pullup – Enhanced PWM4 Output A

N2HET1[04]/EPWM4B 36

N2HET1[06]/SCIRX/EPWM5A 38 Enhanced PWM5 Output A

N2HET1[13]/SCITX/EPWM5B 39 Enhanced PWM5 Output B

N2HET1[18]/EPWM6A 140 Enhanced PWM6 Output A

N2HET1[20]/EPWM6B 141 Enhanced PWM6 Output B

N2HET1[09]/N2HET2[16]/EPWM7A 35 Enhanced PWM7 Output A

N2HET1[07]/N2HET2[14]/EPWM7B 33 Enhanced PWM7 Output B

MIBSPI3NCS[3]/I2CSCL/N2HET1[29]/nTZ1 3

MIBSPI3NCS[2]/I2CSDA/N2HET1[27]/nTZ2 4

N2HET1[10]/nTZ3 118 Pulldown

SIGNAL

144

PGE

TYPE

Output Pulldown –

Output Pulldown –

Output Pulldown –

Input

RESET

PULL

STATE

Pullup

PULL TYPE DESCRIPTION

Enhanced PWM1 Output A

External ePWM Sync Pulse

Output

External ePWM Sync Pulse

Output

Enhanced PWM2 Output A

Enhanced PWM4 Output B

Trip Zone Inputs 1, 2 and 3.

These signals are either

connected asynchronously to

the ePWMx trip zone inputs,

Fixed, 20 µA

or double-synchronized with

VCLK4, or doublesynchronized and then filtered

with a 6-cycle VCLK4-based

counter before connecting to

the ePWMx trip zone inputs.

Submit Documentation Feedback

Product Folder Links: TMS570LS0714

Terminal Configuration and FunctionsCopyright © 2013–2016, Texas Instruments Incorporated

15

Page 16

TMS570LS0714

SPNS226E –JUNE 2013–REVISED NOVEMBER 2016

4.2.1.6 General-Purpose Input/Output (GIO)

Table 4-6. PGE General-Purpose Input/Output (GIO)

www.ti.com

Terminal

Signal Name 144 PGE

GIOA[0] 2

GIOA[1] 5

GIOA[2]/N2HET2[0]/EQEPII 9

GIOA[5]/EXTCLKIN1/EPWM1A/N2HET1_PIN_nDIS 14

GIOA[6]/N2HET2[4]/EPWM1B 16

GIOA[7]/N2HET2[6]/EPWM2A 22

GIOB[0] 126

GIOB[1] 133

GIOB[2] 142

MIBSPI3NCS[0]/AD2EVT/GIOB[2]/EQEP1I/N2HET2_PIN_nDIS 55

GIOB[3] 1 Pulldown

(1) GIOB[2] cannot output a level on to pin 55. Only the input functionality is supported so that the application can generate an interrupt

whenever the N2HET2_PIN_nDIS is asserted (driven low). Also, a pullup is enabled on the input. This is not programmable using the

GIO module control registers.

Signal

(1)

Type

I/O

Reset Pull

State

Pulldown

Pullup

Pull Type Description

General-purpose I/O.

Programmable,

20 µA

All GIO terminals are

capable of generating

interrupts to the CPU

on rising / falling /

both edges.

4.2.1.7 Controller Area Network Controllers (DCAN)

Table 4-7. PGE Controller Area Network Controllers (DCAN)

Terminal Signal

Signal Name 144

PGE

CAN1RX 90 I/O Pullup Programmable,

CAN1TX 89 CAN1 transmit, or GIO

CAN2RX 129 CAN2 receive, or GIO

CAN2TX 128 CAN2 transmit, or GIO

CAN3RX 12 CAN3 receive, or GIO

CAN3TX 13 CAN3 transmit, or GIO

Type

Reset Pull

State

Pull Type Description

CAN1 receive, or GIO

20 µA

4.2.1.8 Local Interconnect Network Interface Module (LIN)

Table 4-8. PGE Local Interconnect Network Interface Module (LIN)

Terminal Signal

Signal Name 144

LINRX 131 I/O Pullup Programmable,

LINTX 132 LIN transmit, or GIO

16

Terminal Configuration and Functions Copyright © 2013–2016, Texas Instruments Incorporated

Type

PGE

Submit Documentation Feedback

Product Folder Links: TMS570LS0714

Reset Pull

State

Pull Type Description

LIN receive, or GIO

20 µA

Page 17

www.ti.com

4.2.1.9 Standard Serial Communication Interface (SCI)

Table 4-9. PGE Standard Serial Communication Interface (SCI)

TMS570LS0714

SPNS226E –JUNE 2013–REVISED NOVEMBER 2016

Terminal Signal

Signal Name 144

PGE

N2HET1[06]/SCIRX/EPWM5A 38 I/O Pulldown Programmable,

N2HET1[13]/SCITX/EPWM5B 39 SCI transmit, or GIO

Type

Reset Pull

State

Pull Type Description

SCI receive, or GIO

20 µA

4.2.1.10 Inter-Integrated Circuit Interface Module (I2C)

Table 4-10. PGE Inter-Integrated Circuit Interface Module (I2C)

Terminal Signal

Signal Name 144

PGE

MIBSPI3NCS[2]/I2CSDA/N2HET1[27]/nTZ2 4 I/O Pullup Programmable,

MIBSPI3NCS[3]/I2CSCL/N2HET1[29]/nTZ1 3 I2C serial clock, or GIO

Type

Reset Pull

State

Pull Type Description

I2C serial data, or GIO

20 µA

4.2.1.11 Standard Serial Peripheral Interface (SPI)

Table 4-11. PGE Standard Serial Peripheral Interface (SPI)

Terminal Signal

Signal Name 144

PGE

N2HET1[0]/SPI4CLK/EPWM2B 25 I/O Pulldown Programmable,

N2HET1[03]/SPI4NCS[0]/N2HET2[10]/EQEP2B 24 SPI4 chip select, or GIO

N2HET1[01]/SPI4NENA/N2HET2[8]/EQEP2A 23 SPI4 enable, or GIO

N2HET1[02]/SPI4SIMO[0]/EPWM3A 30 SPI4 slave-input master-

N2HET1[05]/SPI4SOMI[0]/N2HET2[12]/EPWM3B 31 SPI4 slave-output master-

Type

Reset Pull

State

Pull Type Description

SPI4 clock, or GIO

20 µA

output, or GIO

input, or GIO

Submit Documentation Feedback

Product Folder Links: TMS570LS0714

Terminal Configuration and FunctionsCopyright © 2013–2016, Texas Instruments Incorporated

17

Page 18

TMS570LS0714

SPNS226E –JUNE 2013–REVISED NOVEMBER 2016

4.2.1.12 Multibuffered Serial Peripheral Interface Modules (MibSPI)

Table 4-12. PGE Multibuffered Serial Peripheral Interface Modules (MibSPI)

www.ti.com

Terminal Signal

Signal Name 144

PGE

MIBSPI1CLK 95 I/O Pullup Programmable,

MIBSPI1NCS[0]/MIBSPI1SOMI[1]/ECAP6 105 MibSPI1 chip select, or

MIBSPI1NCS[1]/N2HET1[17]//EQEP1S 130

MIBSPI1NCS[2]/N2HET1[19]/ 40

N2HET1[15]/MIBSPI1NCS[4]/ECAP1 41 Pulldown Programmable,

N2HET1[24]/MIBSPI1NCS[5] 91

MIBSPI1NENA/N2HET1[23]/ECAP4 96 Pullup Programmable,

MIBSPI1SIMO[0] 93 MibSPI1 slave-in master-

N2HET1[08]/MIBSPI1SIMO[1] 106 Pulldown Programmable,

MIBSPI1SOMI[0] 94 Pullup Programmable,

MIBSPI1NCS[0]/MIBSPI1SOMI[1]/ECAP6 105

MIBSPI3CLK/AWM1_EXT_SEL[1]/EQEP1A 53 I/O Pullup Programmable,

MIBSPI3NCS[0]/AD2EVT/GIOB[2]/EQEP1I/N2HET2_PIN_nDIS55 MibSPI3 chip select, or

MIBSPI3NCS[1]/N2HET1[25] 37

MIBSPI3NCS[2]/I2CSDA/N2HET1[27]/nTZ2 4

MIBSPI3NCS[3]/I2CSCL/N2HET1[29]/nTZ1 3

N2HET1[11]/MIBSPI3NCS[4]/N2HET2[18]/EPWM1SYNCO 6 Pulldown Programmable,

MIBSPI3NENA /MIBSPI3NCS[5]/N2HET1[31]/EQEP1B 54 Pullup Programmable,

MIBSPI3NENA/MIBSPI3NCS[5]/N2HET1[31]/EQEP1B 54 MibSPI3 enable, or GIO

MIBSPI3SIMO[0]/AWM1_EXT_SEL[0]/ECAP3 52 MibSPI3 slave-in master-

MIBSPI3SOMI[0]/AWM1_EXT_ENA/ECAP2 51 MibSPI3 slave-out master-

MIBSPI5CLK 100 I/O Pullup Programmable,

MIBSPI5NCS[0]/EPWM4A 32 MibSPI5 chip select, or

MIBSPI5NENA/MIBSPI5SOMI[1]/ECAP5 97 MibSPI5 enable, or GIO

MIBSPI5SIMO[0]/MIBSPI5SOMI[2] 99 MibSPI5 slave-in master-

MIBSPI5SOMI[0] 98 MibSPI5 slave-out master-

MIBSPI5NENA/MIBSPI5SOMI[1]/ECAP5 97 MibSPI5 SOMI[0], or GIO

MIBSPI5SIMO[0]/MIBSPI5SOMI[2] 99 MibSPI5 SOMI[0], or GIO

Type

Reset Pull

State

Pull Type Description

20 µA

20 µA

20 µA

20 µA

20 µA

20 µA

20 µA

20 µA

20 µA

MibSPI1 clock, or GIO

GIO

MibSPI1 chip select, or

GIO

MibSPI1 enable, or GIO

out, or GIO

MibSPI1 slave-in master-

out, or GIO

MibSPI1 slave-out master-

in, or GIO

MibSPI3 clock, or GIO

GIO

MibSPI3 chip select, or

GIO

MibSPI3 chip select, or

GIO

out, or GIO

in, or GIO

MibSPI5 clock, or GIO

GIO

out, or GIO

in, or GIO

18

Terminal Configuration and Functions Copyright © 2013–2016, Texas Instruments Incorporated

Submit Documentation Feedback

Product Folder Links: TMS570LS0714

Page 19

www.ti.com

SPNS226E –JUNE 2013–REVISED NOVEMBER 2016

4.2.1.13 System Module Interface

Table 4-13. PGE System Module Interface

TERMINAL

SIGNAL NAME

nPORRST 46 Input Pulldown 100 µA

nRST 116 I/O Pullup 100 µA

nERROR 117 I/O Pulldown 20 µA

144

PGE

SIGNAL

TYPE

RESET

PULL

STATE

PULL TYPE DESCRIPTION

TMS570LS0714

Power-on reset, cold reset

External power supply monitor

circuitry must drive nPORRST

low when any of the supplies

to the microcontroller fall out

of the specified range. This

terminal has a glitch filter.

See Section 6.8.

System reset, warm reset,

bidirectional.

The internal circuitry indicates

any reset condition by driving

nRST low.

The external circuitry can

assert a system reset by

driving nRST low. To ensure

that an external reset is not

arbitrarily generated, TI

recommends that an external

pullup resistor is connected to

this terminal.

This terminal has a glitch

filter. See Section 6.8.

ESM Error Signal

Indicates error of high

severity. See Section 6.8.

4.2.1.14 Clock Inputs and Outputs

Table 4-14. PGE Clock Inputs and Outputs

Terminal Signal

Signal Name 144

Type

PGE

OSCIN 18 Input – None From external

KELVIN_GND 19 Input Kelvin ground for oscillator

OSCOUT 20 Output To external

ECLK 119 I/O Pulldown Programmable,

GIOA[5]/EXTCLKIN1/EPWM1A /N2HET1_PIN_nDIS 14 Input Pulldown 20 µA External clock input #1

Reset Pull

State

Pull Type Description

crystal/resonator, or

external clock input

crystal/resonator

External prescaled clock

20 µA

output, or GIO.

Submit Documentation Feedback

Product Folder Links: TMS570LS0714

Terminal Configuration and FunctionsCopyright © 2013–2016, Texas Instruments Incorporated

19

Page 20

TMS570LS0714

SPNS226E –JUNE 2013–REVISED NOVEMBER 2016

4.2.1.15 Test and Debug Modules Interface

Table 4-15. PGE Test and Debug Modules Interface

www.ti.com

Terminal Signal

Signal Name 144

PGE

TEST 34 Input Pulldown Fixed, 100 µA Test enable. This terminal

nTRST 109 Input JTAG test hardware reset

RTCK 113 Output - None JTAG return test clock

TCK 112 Input Pulldown Fixed, 100 µA JTAG test clock

TDI 110 Input Pullup JTAG test data in

TDO 111 Output Pulldown JTAG test data out

TMS 108 Input Pullup JTAG test select

Type

Reset Pull

State

Pull Type Description

must be connected to

ground directly or via a

pulldown resistor.

4.2.1.16 Flash Supply and Test Pads

Table 4-16. PGE Flash Supply and Test Pads

Terminal Signal

Signal Name 144

PGE

VCCP 134 3.3-V

FLTP1 7 – – None Flash test pads. These

FLTP2 8

Type

Power

Reset Pull

State

– None Flash pump supply

Pull Type Description

terminals are reserved for

TI use only. For proper

operation these terminals

must connect only to a

test pad or not be

connected at all [no

connect (NC)].

4.2.1.17 Supply for Core Logic: 1.2V nominal

Table 4-17. PGE Supply for Core Logic: 1.2V nominal

Terminal Signal

Signal Name 144

VCC 17 1.2-V

VCC 29

VCC 45

VCC 48

VCC 49

VCC 57

VCC 87

VCC 101

VCC 114

VCC 123

VCC 137

VCC 143

20

Terminal Configuration and Functions Copyright © 2013–2016, Texas Instruments Incorporated

Submit Documentation Feedback

Product Folder Links: TMS570LS0714

PGE

Type

Power

Reset Pull

State

– None Core supply

Pull Type Description

Page 21

www.ti.com

4.2.1.18 Supply for I/O Cells: 3.3V nominal

Table 4-18. PGE Supply for I/O Cells: 3.3V nominal

TMS570LS0714

SPNS226E –JUNE 2013–REVISED NOVEMBER 2016

Terminal Signal

Signal Name 144

PGE

VCCIO 10 3.3-V

VCCIO 26

VCCIO 42

VCCIO 104

VCCIO 120

VCCIO 136

Type

Power

Reset Pull

State

– None Operating supply for I/Os

Pull Type Description

4.2.1.19 Ground Reference for All Supplies Except VCCAD

Table 4-19. PGE Ground Reference for All Supplies Except VCCAD

Terminal Signal

Signal Name 144

PGE

VSS 11 Ground – None Ground reference

VSS 21

VSS 27

VSS 28

VSS 43

VSS 44

VSS 47

VSS 50

VSS 56

VSS 88

VSS 102

VSS 103

VSS 115

VSS 121

VSS 122

VSS 135

VSS 138

VSS 144

Type

Reset Pull

State

Pull Type Description

Submit Documentation Feedback

Product Folder Links: TMS570LS0714

Terminal Configuration and FunctionsCopyright © 2013–2016, Texas Instruments Incorporated

21

Page 22

TMS570LS0714

SPNS226E –JUNE 2013–REVISED NOVEMBER 2016

4.2.2 PZ Package Terminal Functions

4.2.2.1 High-End Timer (N2HET) Modules

Table 4-20. PZ Enhanced High-End Timer (N2HET) Modules

TERMINAL SIGNAL

SIGNAL NAME 100 PZ

N2HET1[0]/ SPI4CLK / EPWM2B 19 I/O Pulldown Programmable,

N2HET1[2] / SPI4SIMO / EPWM3A 22

N2HET1[4] / EPWM4B 25

N2HET1[6] / SCIRX / EPWM5A 26

N2HET1[8] / MIBSPI1SIMO[1] 74

N2HET1[10] / nTZ3 83

N2HET1[12] 89

N2HET1[14] 90

N2HET1[16] / EPWM1SYNCI /

EPWM1SYNCO

MIBSPI1nCS[1] / N2HET1[17] / EQEP1S 93 Pullup

N2HET1[18] / EPWM6A 98 Pulldown

MIBSPI1nCS[2] / N2HET1[19] 27 Pullup

MIBSPI1nCS[3] / N2HET1[21] 39

N2HET1[22] 11 Pulldown

MIBSPI1nENA / N2HET1[23] / ECAP4 68 Pullup

N2HET1[24] / MIBSPI1nCS[5] 64 Pulldown

MIBSPI3nENA / MIBSPI3nCS[5] /

N2HET1[31] / EQEP1B

GIOA[5] / INT[5] / EXTCLKIN

/EPWM1A/N2HET1_PIN_nDIS

GIOA[2] / INT[2] / N2HET2[0] / EQEP2I 5 Pulldown

GIOA[3] / INT[3] / N2HET2[2] 8

GIOA[6] / INT[6] / N2HET2[4] / EPWM1B 12

GIOA[7] / INT[7] / N2HET2[6] / EPWM2A 18

97

37 Pullup

10 Pulldown Disable selected PWM outputs

TYPE

RESET

PULL

STATE

PULL TYPE DESCRIPTION

20 µA

www.ti.com

N2HET2 timer input capture or output

compare, or GIO.

Each terminal has a suppression filter with a

programmable duration.

Timer input capture or output compare. The N2HET

applicable terminals can be programmed as

general-purpose input/output (GIO).

N2HET2 timer input capture or output

compare, or GIO.

Each terminal has a suppression filter with a

programmable duration.

Timer input capture or output compare. The N2HET

applicable terminals can be programmed as

general-purpose input/output (GIO).

4.2.2.2 Enhanced Capture Modules (eCAP)

Table 4-21. PZ Enhanced Capture Modules (eCAP)

Terminal Signal

Signal Name 100

MIBSPI3SOMI[0] /

AWM1_EXT_ENA / ECAP2

MIBSPI3SIMO[0] /

AWM1_EXT_SEL[0] / ECAP3

MIBSPI1NENA / N2HET1[23] /

ECAP4

MIBSPI1NCS[0] /

MIBSPI1SOMI[1] / ECAP6

22

Terminal Configuration and Functions Copyright © 2013–2016, Texas Instruments Incorporated

PZ

34 I/O Pullup Fixed, 20 µA Enhanced Capture Module 2 I/O

35 Enhanced Capture Module 3 I/O

68 Enhanced Capture Module 4 I/O

73 Enhanced Capture Module 6 I/O

Type

Reset Pull

State

Pull Type Description

Submit Documentation Feedback

Product Folder Links: TMS570LS0714

Page 23

www.ti.com

SPNS226E –JUNE 2013–REVISED NOVEMBER 2016

4.2.2.3 Enhanced Quadrature Encoder Pulse Modules (eQEP)

Table 4-22. PZ Enhanced Quadrature Encoder Pulse Modules (eQEP)

TERMINAL

SIGNAL NAME

MIBSPI3CLK / AWM1_EXT_SEL[1] /

EQEP1A

MIBSPI3nENA / MIBSPI3nCS[5] /

N2HET1[31] / EQEP1B

MIBSPI3nCS[0] / AD2EVT / GIOB[2]

/ EQEP1I/N2HET2_PIN_nDIS

MIBSPI1nCS[1] / N2HET1[17] /

EQEP1S

GIOA[2] / INT[2] / N2HET2[0] /

EQEP2I

SIGNAL

100 PZ

36 I/O Pullup Fixed, 20 µA Enhanced QEP1 Input A

37 Enhanced QEP1 Input B

38 Enhanced QEP1 Index

93 Enhanced QEP1 Strobe

5 Pulldown Enhanced QEP2 Index

TYPE

RESET

PULL

STATE

PULL TYPE DESCRIPTION

4.2.2.4 Enhanced Pulse-Width Modulator Modules (ePWM)

Table 4-23. PZ Enhanced Pulse-Width Modulator Modules (ePWM)

TERMINAL

SIGNAL NAME 100 PZ

GIOA[5] / INT[5] / EXTCLKIN /

EPWM1A/N2HET1_PIN_nDIS

GIOA[6] / INT[6] / N2HET2[4] /

EPWM1B

N2HET1[16] / EPWM1SYNCI /

EPWM1SYNCO

N2HET1[16] / EPWM1SYNCI /

EPWM1SYNCO

GIOA[7] / INT[7] / N2HET2[6] /

EPWM2A

N2HET1[0] / SPI4CLK / EPWM2B 19 Enhanced PWM2 Output B

N2HET1[2] / SPI4SIMO / EPWM3A 22 Enhanced PWM3 Output A

N2HET1[4] / EPWM4B 25 Enhanced PWM4 Output B

N2HET1[6] / SCIRX / EPWM5A 26 Enhanced PWM5 Output A

N2HET1[18] / EPWM6A 98 Enhanced PWM6 Output A

N2HET1[10] / nTZ3 83 Input Pulldown Trip Zone 1 input 3

SIGNAL

TYPE

10 Output Pulldown – Enhanced PWM1 Output A

12 Pulldown Enhanced PWM1 Output B

97 Input Pulldown Fixed, 20 µA External ePWM Sync Pulse Input

97 Output Pulldown – External ePWM Sync Pulse Output

18 Enhanced PWM2 Output A

RESET

PULL

STATE

PULL TYPE DESCRIPTION

TMS570LS0714

Submit Documentation Feedback

Product Folder Links: TMS570LS0714

Terminal Configuration and FunctionsCopyright © 2013–2016, Texas Instruments Incorporated

23

Page 24

TMS570LS0714

SPNS226E –JUNE 2013–REVISED NOVEMBER 2016

4.2.2.5 General-Purpose Input/Output (GIO)

Table 4-24. PZ General-Purpose Input/Output (GIO)

www.ti.com

Terminal Signal

Signal Name 100

GIOA[0] / INT[0] 1 I/O Pulldown Programmable,

GIOA[1] / INT[1] 2

GIOA[2] / INT[2] / N2HET2[0] /

EQEP2I

GIOA[3] / INT[3] / N2HET2[2] 8

GIOA[4]/ INT[4] 9

GIOA[5] / INT[5] / EXTCLKIN /

EPWM1A/ N2HET1_PIN_nDIS

GIOA[6] / INT[6] / N2HET2[4] /

EPWM1B

GIOA[7] / INT[7] / N2HET2[6] /

EPWM2A

MIBSPI3nCS[0] / AD2EVT /

GIOB[2] /

EQEP1I/N2HET2_PIN_nDIS

PZ

10

12

18

38 I/O General-purpose input/output

Type

5

Reset Pull

State

Pull Type Description

GIOA

20 µA

GIOB

General-purpose input/output

All GPIO terminals are capable of generating

interrupts to the CPU on rising/falling/both edges.

4.2.2.6 Controller Area Network Interface Modules (DCAN1, DCAN2)

Table 4-25. PZ Controller Area Network Interface Modules (DCAN1, DCAN2)

Terminal Signal

Signal Name 100

PZ

CAN1RX 63 I/O Pullup Programmable,

CAN1TX 62 CAN1 Transmit, or GPIO

CAN2RX 92 I/O Pullup Programmable,

CAN2TX 91 CAN2 Transmit, or GPIO

Type

Reset Pull

State

Pull Type Description

DCAN1

CAN1 Receive, or general-purpose I/O (GPIO)

20 µA

DCAN2

CAN2 Receive, or GPIO

20 µA

24

Terminal Configuration and Functions Copyright © 2013–2016, Texas Instruments Incorporated

Submit Documentation Feedback

Product Folder Links: TMS570LS0714

Page 25

TMS570LS0714

www.ti.com

SPNS226E –JUNE 2013–REVISED NOVEMBER 2016

4.2.2.7 Standard Serial Peripheral Interfaces (SPI2 and SPI4)

Table 4-26. PZ Standard Serial Peripheral Interfaces (SPI2 and SPI4)

Terminal Signal Type Reset Pull

Signal Name 100 PZ

SPI2CLK 71 I/O Pullup Programmable, 20 µA SPI2 Serial Clock, or GPIO

SPI2nCS[0] 23 SPI2 Chip Select, or GPIO

SPI2SIMO 70 SPI2 Slave-In-Master-Out, or GPIO

SPI2SOMI 69 SPI2 Slave-Out-Master-In, or GPIO

The drive strengths for the SPI2CLK, SPI2SIMO and SPI2SOMI signals are selected individually by configuring the respective SRS bits of the SPIPC9 register

fo SPI2.

SRS = 0 for 8mA drive (fast). This is the default mode as the SRS bits in the SPIPC9 register default to 0.

SRS = 1 for 2mA drive (slow)

N2HET1[0] / SPI4CLK / EPWM2B 19 I/O Pulldown Programmable, 20 µA SPI2 Serial Clock, or GPIO

N2HET1[2] / SPI4SIMO / EPWM3A 22 SPI2 Slave-In-Master-Out, or GPIO

State

Pull Type Description

SPI2

SPI4

4.2.2.8 Multibuffered Serial Peripheral Interface (MibSPI1 and MibSPI3)

Table 4-27. PZ Multibuffered Serial Peripheral Interface (MibSPI1 and MibSPI3)

Terminal Signal

Signal Name 100 PZ

MIBSPI1CLK 67 I/O Pullup Programmable, 20 µA MibSPI1 Serial Clock, or GPIO

MIBSPI1nCS[0]/MIBSPI1SOMI[1]/

ECAP6

MIBSPI1nCS[1]/N2HET1[17]/

EQEP1S

MIBSPI1nCS[2]/N2HET1[19] 27

MIBSPI1nCS[3]/N2HET1[21] 39

MIBSPI1nENA/N2HET1[23]/

ECAP4

MIBSPI1SIMO[0] 65 MibSPI1 Slave-In-Master-Out, or GPIO

N2HET1[8]/MIBSPI1SIMO[1] 74

MIBSPI1SOMI[0] 66 MibSPI1 Slave-Out-Master-In, or GPIO

MIBSPI1nCS[0]/MIBSPI1SOMI[1]/

ECAP6

MIBSPI3CLK/AWM1_EXT_SEL[1]/

EQEP1A

MIBSPI3nCS[0]/AD2EVT/GIOB[2]/

EQEP1I/N2HET2_PIN_nDIS

MIBSPI3nENA/MIBSPI3nCS[5]/

N2HET1[31]/EQEP1B

MIBSPI3nENA/MIBSPI3nCS[5]/

N2HET1[31]/EQEP1B

MIBSPI3SIMO[0]/AWM1_EXT_SEL[0]/

ECAP3

MIBSPI3SOMI[0]/AWM1_EXT_ENA/

ECAP2

73 MibSPI1 Chip Select, or GPIO

93

68 MibSPI1 Enable, or GPIO

73

36 I/O Pullup Programmable, 20 µA MibSPI3 Serial Clock, or GPIO

38 MibSPI3 Chip Select, or GPIO

37

37 MibSPI3 Enable, or GPIO

35 MibSPI3 Slave-In-Master-Out, or GPIO

34 MibSPI3 Slave-Out-Master-In, or GPIO

Type

Reset Pull

State

MibSPI1

MibSPI3

Pull Type Description

Submit Documentation Feedback

Product Folder Links: TMS570LS0714

Terminal Configuration and FunctionsCopyright © 2013–2016, Texas Instruments Incorporated

25

Page 26

TMS570LS0714

SPNS226E –JUNE 2013–REVISED NOVEMBER 2016

4.2.2.9 Local Interconnect Network Controller (LIN)

Table 4-28. PZ Local Interconnect Network Controller (LIN)

www.ti.com

TERMINAL

SIGNAL NAME 100 PZ

LINRX 94 I/O Pullup Programmable, 20 µA LIN Receive, or GPIO

LINTX 95 LIN Transmit, or GPIO

SIGNAL

TYPE

RESET

PULL

STATE

PULL TYPE DESCRIPTION

4.2.2.10 Multibuffered Analog-to-Digital Converter (MibADC)

Table 4-29. PZ Multibuffered Analog-to-Digital Converter (MibADC)

Terminal Signal

Signal Name 100

AD1EVT 58 I/O Pulldown Programmable,

AD1IN[0] 42 Input – – Analog Inputs

AD1IN[1] 49

AD1IN[2] 51

AD1IN[3] 52

AD1IN[4] 54

AD1IN[5] 55

AD1IN[6] 56

AD1IN[7] 43

AD1IN[8]/AD2IN[8] 57

AD1IN[9]/AD2IN[9] 48

AD1IN[10]/AD2IN[10] 50

AD1IN[11]/AD2IN[11] 53

AD1IN[16]/AD2IN[0] 40

AD1IN[17]/AD2IN[1] 41

AD1IN[20]/AD2IN[4] 44

AD1IN[21]/AD2IN[5] 45

ADREFHI/VCCAD 46 Input/

ADREFLO/VSSAD 47 Input/

MIBSPI3SOMI[0]/AWM1_EXT_

ENA/

ECAP2

MIBSPI3SIMO[0]/AWM1_EXT_

SEL[0]/

ECAP3

MIBSPI3CLK/AWM1_EXT_SEL

[1]/

EQEP1A

MIBSPI3nCS[0]/AD2EVT/GIOB[

2]/

EQEP1I/N2HET2_PIN_nDIS

PZ

34 AWM external analog mux enable

35 AWM external analog mux select line 0

36 AWM external analog mux select line1

38 I/O ADC2 Event Trigger or GPIO

Type

Power

Ground

Reset Pull

State

– – ADC High Reference Level/ADC Operating

– – ADC Low Reference Level/ADC Supply Ground

Pull Type Description

MibADC1

ADC1 Event Trigger or GPIO

20 µA

Supply

MibADC2

26

Terminal Configuration and Functions Copyright © 2013–2016, Texas Instruments Incorporated

Submit Documentation Feedback

Product Folder Links: TMS570LS0714

Page 27

TMS570LS0714

www.ti.com

SPNS226E –JUNE 2013–REVISED NOVEMBER 2016

4.2.2.11 System Module Interface

Table 4-30. PZ System Module Interface

TERMINAL

SIGNAL NAME 100 PZ

nPORRST 31 Input Pullup 100 µA

nRST 81 I/O Pullup 100 µA

nERROR 82 I/O Pulldown 20 µA

SIGNAL

TYPE

RESET

PULL

STATE

PULL TYPE DESCRIPTION

Power-on reset, cold reset External power supply

monitor circuitry must drive nPORRST low when any of

the supplies to the microcontroller fall out of the

specified range. This terminal has a glitch filter. See

Section 6.8.

The external circuitry can assert a system reset by

driving nRST low. To ensure that an external reset is not

arbitrarily generated, TI recommends that an external

pullup resistor is connected to this terminal. This

terminal has a glitch filter. See Section 6.8.

ESM Error Signal. Indicates error of high severity. See

Section 6.8.

4.2.2.12 Clock Inputs and Outputs

Table 4-31. PZ Clock Inputs and Outputs

TERMINAL

SIGNAL NAME 100 PZ

OSCIN 14 Input – – From external crystal/resonator, or external clock input

KELVIN_GND 15 Input – – Dedicated ground for oscillator

OSCOUT 16 Output – – To external crystal/resonator

ECLK 84 I/O Pulldown Programmable, 20 µA External prescaled clock output, or GIO.

GIOA[5]/INT[5]/EXTCLKIN/EPWM1A

/N2HET1_PIN_nDIS

SIGNAL

TYPE

10 Input Pulldown 20 µA External Clock In

RESET

PULL

STATE

PULL TYPE DESCRIPTION

Submit Documentation Feedback

Product Folder Links: TMS570LS0714

Terminal Configuration and FunctionsCopyright © 2013–2016, Texas Instruments Incorporated

27

Page 28

TMS570LS0714

SPNS226E –JUNE 2013–REVISED NOVEMBER 2016

4.2.2.13 Test and Debug Modules Interface

Table 4-32. PZ Test and Debug Modules Interface

TERMINAL

SIGNAL NAME 100 PZ

nTRST 76 Input Pulldown Fixed, 100 µA JTAG test hardware reset

RTCK 80 Output – – JTAG return test clock

TCK 79 Input Pulldown Fixed, 100 µA JTAG test clock

TDI 77 I/O Pullup Fixed, 100 µA JTAG test data in

TDO 78 I/O Pulldown Fixed, 100 µA JTAG test data out

TMS 75 I/O Pullup Fixed, 100 µA JTAG test select

TEST 24 I/O Pulldown Fixed, 100 µA

SIGNAL

TYPE

RESET

PULL

STATE

PULL TYPE DESCRIPTION

Test enable. This terminal must be connected to ground

directly or via a pulldown resistor.

4.2.2.14 Flash Supply and Test Pads

Table 4-33. PZ Flash Supply and Test Pads

www.ti.com

Terminal Signal

Signal Name 100

Type

Reset Pull

State

Pull Type Description

PZ

VCCP 96 3.3-V

Power

– – Flash external pump voltage (3.3 V). This

terminal is required for both Flash read and Flash

program and erase operations.

FLTP1 3 Input – – Flash Test Pins. For proper operation this

FLTP2 4 Input – –

terminal must connect only to a test pad or not be

connected at all [no connect (NC)].

The test pad must not be exposed in the final

product where it might be subjected to an ESD

event.

4.2.2.15 Supply for Core Logic: 1.2-V Nominal

Table 4-34. PZ Supply for Core Logic: 1.2-V Nominal

Terminal Signal

Signal Name 100

Type

PZ

VCC 13 1.2-V

VCC 21

Power

VCC 30

VCC 32

VCC 61

VCC 88

VCC 99

Reset Pull

Pull Type Description

State

– – Digital logic and RAM supply

4.2.2.16 Supply for I/O Cells: 3.3-V Nominal

Table 4-35. PZ Supply for I/O Cells: 3.3-V Nominal

Terminal Signal

Signal Name 100

VCCIO 6 3.3-V

VCCIO 28

VCCIO 60

VCCIO 85

28

Terminal Configuration and Functions Copyright © 2013–2016, Texas Instruments Incorporated

PZ

Type

Reset Pull

State

Pull Type Description

– – I/O Supply

Power

Submit Documentation Feedback

Product Folder Links: TMS570LS0714

Page 29

www.ti.com

4.2.2.17 Ground Reference for All Supplies Except VCCAD

Table 4-36. PZ Ground Reference for All Supplies Except VCCAD

TMS570LS0714

SPNS226E –JUNE 2013–REVISED NOVEMBER 2016

Terminal Signal

Signal Name 100

PZ

VSS 7 Ground – – Device Ground Reference. This is a single

VSS 17

VSS 20

VSS 29

VSS 33

VSS 59

VSS 72

VSS 86

VSS 87

VSS 100

Type

Reset Pull

State

Pull Type Description

ground reference for all supplies except for the

ADC Supply.

4.3 Pin Multiplexing

This microcontroller has several interfaces and uses extensive multiplexing to bring out the functions as

required by the target application. The multiplexing is mostly on the output signals. A few inputs are also

multiplexed to allow the same input signal to be driven in from a selected terminal.

4.3.1 Output Multiplexing

Table 4-37 and Table 4-38 show the pin multiplexing control x register (PINMMRx) and the associated bit

fields that control each pin mux function.

Submit Documentation Feedback

Product Folder Links: TMS570LS0714

Terminal Configuration and FunctionsCopyright © 2013–2016, Texas Instruments Incorporated

29

Page 30

Copyright © 2013–2016, Texas Instruments IncorporatedTerminal Configuration and Functions

Submit Documentation Feedback

Product Folder Links: TMS570LS0714

30

TMS570LS0714

SPNS226E –JUNE 2013–REVISED NOVEMBER 2016

www.ti.com

Table 4-37. Multiplexing for Outputs on 144-Pin PGE Package(1)

144-PIN

PGE

DEFAULT

FUNCTION

CTRL1 OPTION 2 CTRL2 OPTION 3 CTRL3 OPTION 4 CTRL4 OPTION 5 CTRL5 OPTION 6 CTRL6

86 AD1EVT 10[0]

2 GIOA[0] 0[8]

5 GIOA[1] 1[0]

9 GIOA[2] 2[0] N2HET2[0] 2[3] EQEP2I 2[4]

14 GIOA[5] 2[24] EXTCLKIN1 2[25] EPWM1A 2[26]

16 GIOA[6] 3[16] N2HET2[4] 3[17] EPWM1B 3[18]

22 GIOA[7] 4[0] N2HET2[6] 4[1] EPWM2A 4[2]

126 GIOB[0] 18[24]

133 GIOB[1] 21[8]

1 GIOB[3] 0[0]

105 MIBSPI1NCS[0] 13[24] MIBSPI1SOMI[1] 13[25] ECAP6 13[28]

130 MIBSPI1NCS[1] 20[16] N2HET1[17] 20[17] EQEP1S 20[20]

40 MIBSPI1NCS[2] 8[8] N2HET1[19] 8[9]

96 MIBSPI1NENA 12[16] N2HET1[23] 12[17] ECAP4 12[20]

53 MIBSPI3CLK 33[24] AWM1_EXT_SEL[1] 33[25] EQEP1A 33[26]

55 MIBSPI3NCS[0] 9[16] AD2EVT 9[17] GIOB[2] 9[18] EQEP1I 9[19]

37 MIBSPI3NCS[1] 7[8] N2HET1[25] 7[9]

4 MIBSPI3NCS[2] 0[24] I2C_SDA 0[25] N2HET1[27] 0[26] nTZ2 0[27]

3 MIBSPI3NCS[3] 0[16] I2C_SCL 0[17] N2HET1[29] 0[18] nTZ1 0[19]

54 MIBSPI3NENA 9[8] MIBSPI3NCS[5] 9[9] N2HET1[31] 9[10] EQEP1B 9[11]

52 MIBSPI3SIMO 33[16] AWM1_EXT_SEL[0] 33[17] ECAP3 33[18]

51 MIBSPI3SOMI 33[8] AWM1_EXT_ENA 33[9] ECAP2 33[10]

100 MIBSPI5CLK 13[16]

32 MIBSPI5NCS[0] 27[0] EPWM4A 27[2]

97 MIBSPI5NENA 12[24] MIBSPI5SOMI[1] 12[28] ECAP5 12[29]

99 MIBSPI5SIMO[0] 13[8] MIBSPI5SOMI[2] 13[12]

98 MIBSPI5SOMI[0] 13[0]

25 N2HET1[0] 5[0] SPI4CLK 5[1] EPWM2B 5[2]

23 N2HET1[01] 4[16] SPI4NENA 4[17] 4[19] N2HET2[8] 4[20] EQEP2A 4[21]

30 N2HET1[02] 5[8] SPI4SIMO 5[9] EPWM3A 5[10]

24 N2HET1[03] 4[24] SPI4NCS[0] 4[25] 4[27] N2HET2[10] 4[28] EQEP2B 4[29]

36 N2HET1[04] 33[0] EPWM4B 33[1]

31 N2HET1[05] 5[16] SPI4SOMI 5[17] N2HET2[12] 5[18] EPWM3B 5[19]

38 N2HET1[06] 7[16] SCIRX 7[17] EPWM5A 7[18]

33 N2HET1[07] 6[0] N2HET2[14] 6[3] EPWM7B 6[4]

Page 31

Copyright © 2013–2016, Texas Instruments Incorporated Terminal Configuration and Functions

Submit Documentation Feedback

Product Folder Links: TMS570LS0714

31

TMS570LS0714

www.ti.com

SPNS226E –JUNE 2013–REVISED NOVEMBER 2016

Table 4-37. Multiplexing for Outputs on 144-Pin PGE Package(1) (continued)

144-PIN

PGE

DEFAULT

FUNCTION

CTRL1 OPTION 2 CTRL2 OPTION 3 CTRL3 OPTION 4 CTRL4 OPTION 5 CTRL5 OPTION 6 CTRL6

106 N2HET1[08] 14[0] MIBSPI1SIMO[1] 14[1]

35 N2HET1[09] 6[16] N2HET2[16] 6[17] EPWM7A 6[20]

118 N2HET1[10] 17[0] nTZ3 17[4]

6 N2HET1[11] 1[8] MIBSPI3NCS[4] 1[9] N2HET2[18] 1[10] EPWM1SYNCO 1[13]

124 N2HET1[12] 17[16]

39 N2HET1[13] 8[0] SCITX 8[1] EPWM5B 8[2]

125 N2HET1[14] 18[8]

41 N2HET1[15] 8[16] MIBSPI1NCS[4] 8[17] ECAP1 8[18]

139 N2HET1[16] 34[0] EPWM1SYNCI 34[1] EPWM1SYNCO 34[2]

140 N2HET1[18] 34[8] EPWM6A 34[9]

141 N2HET1[20] 34[16] EPWM6B 34[17]

15 N2HET1[22] 3[8]

91 N2HET1[24] 11[24] MIBSPI1NCS[5] 11[25]

92 N2HET1[26] 12[0]

107 N2HET1[28] 14[8]

127 N2HET1[30] 19[8] EQEP2S 19[11]

(1) The CTRLx columns contain a value of type x[y], which indicates the pin multiplexing control x register (PINMMRx) and the associated bit field [y].

Page 32

Copyright © 2013–2016, Texas Instruments IncorporatedTerminal Configuration and Functions

Submit Documentation Feedback

Product Folder Links: TMS570LS0714

32

TMS570LS0714

SPNS226E –JUNE 2013–REVISED NOVEMBER 2016

www.ti.com

(1) The CTRLx columns contain a value of type x[y], which indicates the pin multiplexing control x register (PINMMRx) and the associated bit field [y].

Table 4-38. Multiplexing for Outputs on 100-Pin PZ Package

(1)

100-PINPZDEFAULT

FUNCTION

CTRL1 OPTION 2 CTRL2 OPTION 3 CTRL3 OPTION 4 CTRL4 OPTION 5 CTRL5 OPTION 6 CTRL6

2 GIOA[1]/INT[1] 1[0]

5 GIOA[2]/INT[2] 2[0] N2HET2[0] 2[3] EQEP2I 2[4]

10 GIOA[5]/INT[5] 2[24] EXTCLKIN1 2[25] EPWM1A 2[26]

12 GIOA[6]/INT[6] 3[16] N2HET2[4] 3[17] EPWM1B 3[18]

18 GIOA[7]/INT[7] 4[0] N2HET2[6] 4[1] EPWM2A 4[2]

73 MIBSPI1NCS[0] 13[24] MIBSPI1SOMI[1] 13[25] ECAP6 13[28]

93 MIBSPI1NCS[1] 20[16] N2HET1[17] 20[17] EQEP1S 20[20]

27 MIBSPI1NCS[2] 8[8] N2HET1[19] 8[9]

68 MIBSPI1NENA 12[16] N2HET1[23] 12[17] ECAP4 12[20]

36 MIBSPI3CLK 33[24] AWM1_EXT_SEL[1] 33[25] EQEP1A 33[26]

38 MIBSPI3NCS[0] 9[16] AD2EVT 9[17] GIOB[2] 9[18] EQEP1I 9[19]

37 MIBSPI3NENA 9[8] MIBSPI3NCS[5] 9[9] N2HET1[31] 9[10] EQEP1B 9[11]

35 MIBSPI3SIMO[0] 33[16] AWM1_EXT_SEL[0] 33[17] ECAP3 33[18]

34 MIBSPI3SOMI[0] 33[8] AWM1_EXT_ENA 33[9] ECAP2 33[10]

19 N2HET1[0] 5[0] SPI4CLK 5[1] EPWM2B 5[2]

22 N2HET1[02] 5[8] SPI4SIMO 5[9] EPWM3A 5[10]

25 N2HET1[04] 33[0] EPWM4B 33[1]

26 N2HET1[06] 7[16] SCIRX 7[17] EPWM5A 7[18]

74 N2HET1[08] 14[0] MIBSPI1SIMO[1] 14[1]

83 N2HET1[10] 17[0] nTZ3 17[4]

97 N2HET1[16] 34[0] EPWM1SYNCI 34[1] EPWM1SYNCO 34[2]

98 N2HET1[18] 34[8] EPWM6A 34[9]

64 N2HET1[24] 11[24] MIBSPI1NCS[5] 11[25]

Page 33

www.ti.com

4.3.2 Multiplexing of Inputs

Some signals are connected to more than one terminal, the inputs for these signals can come from any of