TLV5620C, TLV5620I

QUADRUPLE 8-BIT DIGITAL-TO-ANALOG CONVERTERS

SLAS110B – JANUARY 1995 – REVISED APRIL 1997

D

Four 8-Bit Voltage Output DACs

D

3-V Single-Supply Operation

D

Serial Interface

D

High-Impedance Reference Inputs

D

Programmable for 1 or 2 Times Output

Range

D

Simultaneous Update Facility

D

Internal Power-On Reset

D

Low-Power Consumption

D

Half-Buffered Output

applications

D

Programmable V oltage Sources

D

Digitally Controlled Amplifiers/Attenuators

D

Mobile Communications

D

Automatic Test Equipment

D

Process Monitoring and Control

D

Signal Synthesis

description

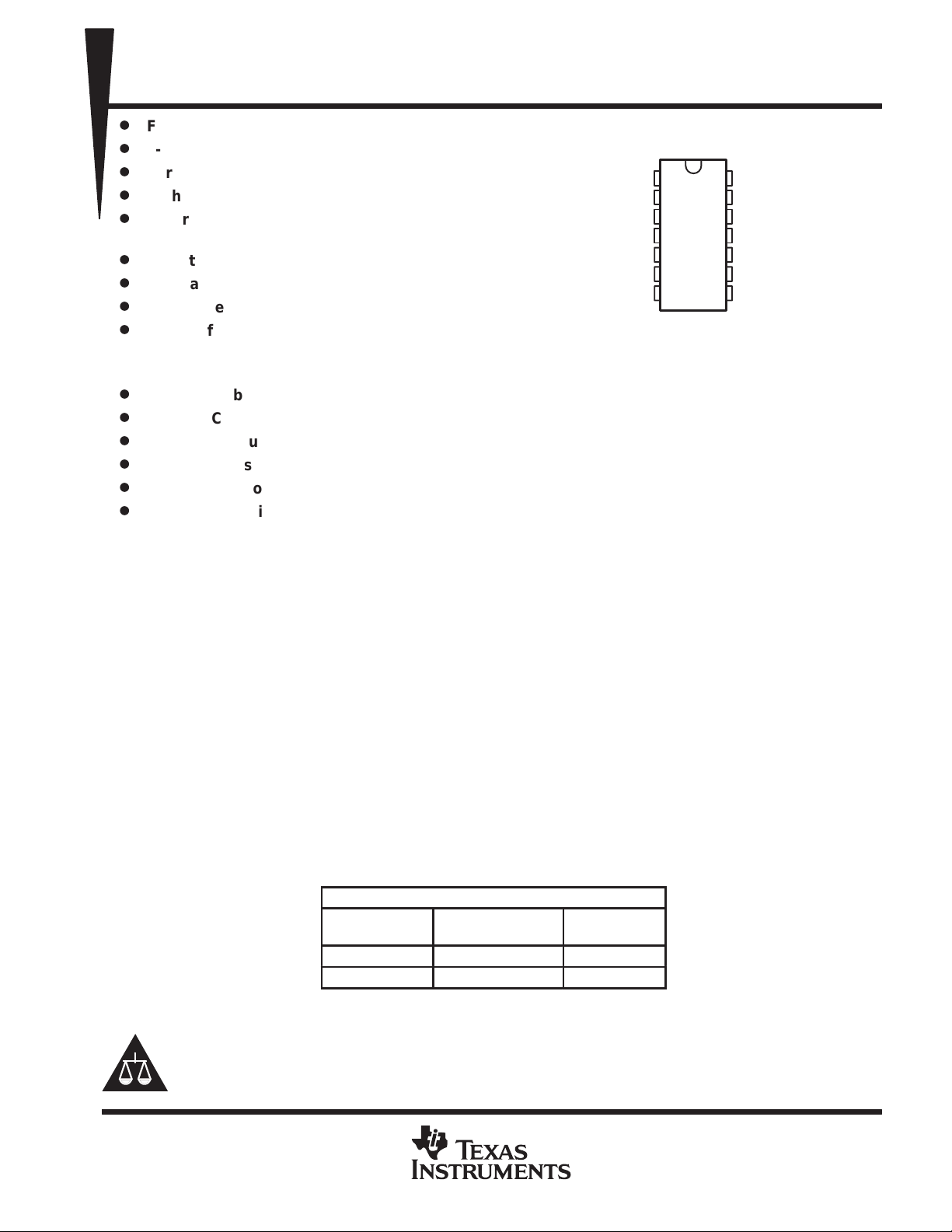

D OR N PACKAGE

(TOP VIEW)

GND

REFA

REFB

REFC

REFD

DATA

CLK

1

2

3

4

5

6

7

14

13

12

11

10

9

8

V

DD

LDAC

DACA

DACB

DACC

DACD

LOAD

The TLV5620C and TLV5620I are quadruple 8-bit voltage output digital-to-analog converters (DACs) with

buffered reference inputs (high impedance). The DACs produce an output voltage that ranges between either

one or two times the reference voltages and GND; and, the DACs are monotonic. The device is simple to use,

because it runs from a single supply of 3 V to 3.6 V. A power-on reset function is incorporated to ensure

repeatable start-up conditions.

Digital control of the TL V5620C and TLV5620I is over a simple three-wire serial bus that is CMOS compatible

and easily interfaced to all popular microprocessor and microcontroller devices. The 11-bit command word

comprises eight bits of data, two DAC select bits, and a range bit, the latter allowing selection between the times

1 or times 2 output range. The DAC registers are double buffered, allowing a complete set of new values to be

written to the device, then all DAC outputs update simultaneously through control of LDAC. The digital inputs

feature Schmitt triggers for high noise immunity.

The 14-terminal small-outline (SO) package allows digital control of analog functions in space-critical

applications. The TLV5620C is characterized for operation from 0°C to 70°C. The TLV5620I is characterized

for operation from –40°C to 85°C. The TLV5620C and TLV5620I do not require external trimming.

AVAILABLE OPTIONS

PACKAGE

T

A

0°C to 70°C TLV5620CD TLV5620CN

–40°C to 85°C TLV5620ID TLV5620IN

SMALL OUTLINE

(D)

PLASTIC DIP

(N)

Please be aware that an important notice concerning availability, standard warranty, and use in critical applications of

Texas Instruments semiconductor products and disclaimers thereto appears at the end of this data sheet.

PRODUCTION DATA information is current as of publication date.

Products conform to specifications per the terms of Texas Instruments

standard warranty. Production processing does not necessarily include

testing of all parameters.

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

Copyright 1997, Texas Instruments Incorporated

1

TLV5620C, TLV5620I

I/O

DESCRIPTION

QUADRUPLE 8-BIT DIGITAL-TO-ANALOG CONVERTERS

SLAS110B – JANUARY 1995 – REVISED APRIL 1997

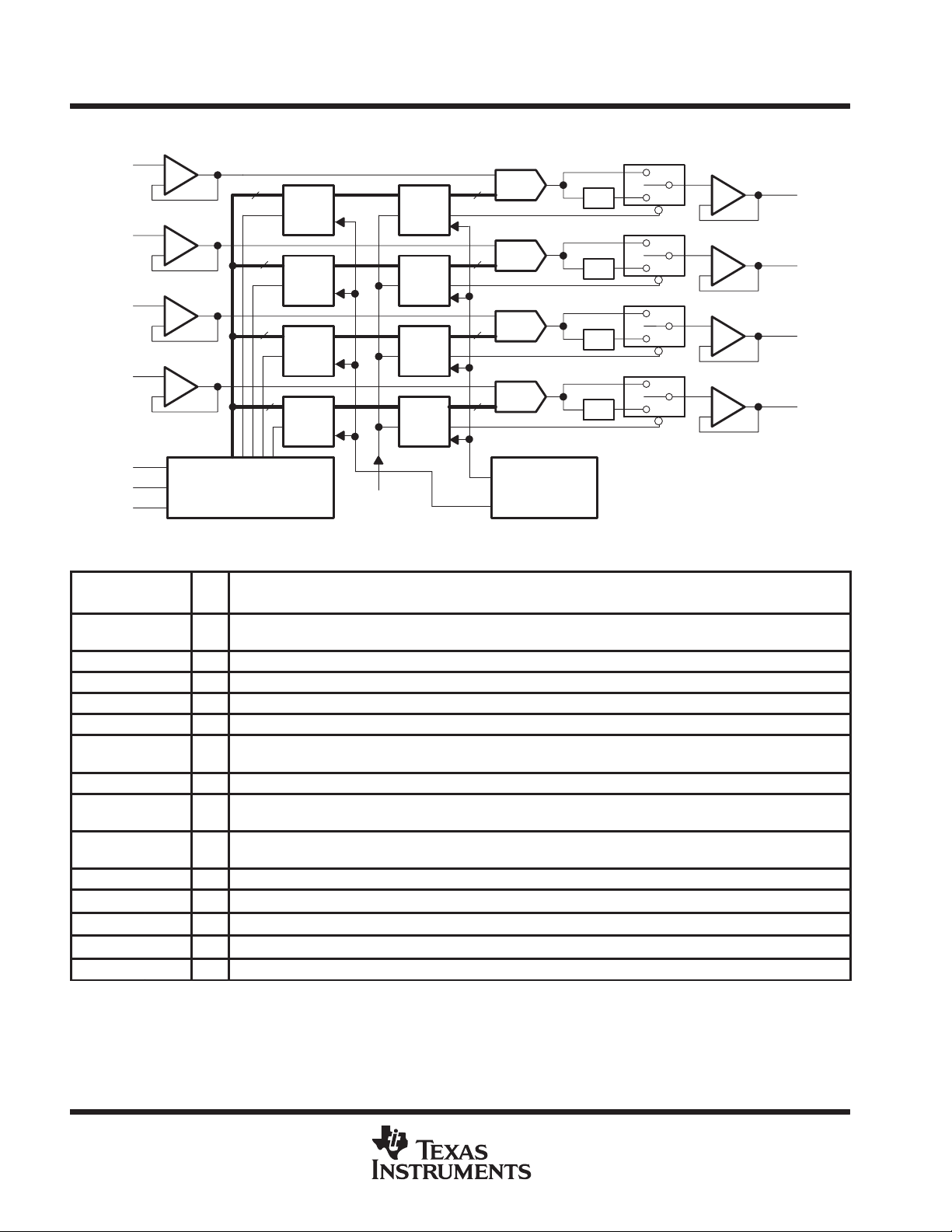

functional block diagram

2

REFA

REFB

REFC

REFD

CLK

DATA

LOAD

+

–

8 8

Latch Latch

3

+

–

8

Latch

4

+

–

8

5

+

–

8

Latch Latch

7

6

8

Serial

Interface

Latch

LatchLatch

13

LDAC

DAC

DAC

8

DAC

8

DAC

8

Power-On

Reset

× 2

× 2

× 2

× 2

+

–

+

–

+

–

+

–

12

11

10

9

DACA

DACB

DACC

DACD

Terminal Functions

TERMINAL

NAME NO.

CLK 7 I Serial interface clock. The input digital data is shifted into the serial interface register on the falling edge of the clock

applied to the CLK terminal.

DACA 12 O DAC A analog output

DACB 11 O DAC B analog output

DACC 10 O DAC C analog output

DACD 9 O DAC D analog output

DATA 6 I Serial interface digital data input. The digital code for the DAC is clocked into the serial interface register serially.

Each data bit is clocked into the register on the falling edge of the clock signal.

GND 1 I Ground return and reference terminal

LDAC 13 I Load DAC. When this signal is high, no DAC output updates occur when the input digital data is read into the serial

interface. The DAC outputs are only updated when LDAC is taken from high to low.

LOAD 8 I Serial interface load control. When the LDAC terminal is low, the falling edge of the LOAD signal latches the digital

data into the output latch and immediately produces the analog voltage at the DAC output terminal.

REFA 2 I Reference voltage input to DAC A. This voltage defines the output analog range.

REFB 3 I Reference voltage input to DAC B. This voltage defines the analog output range.

REFC 4 I Reference voltage input to DAC C. This voltage defines the analog output range.

REFD 5 I Reference voltage input to DAC D. This voltage defines the analog output range.

V

DD

14 I Positive supply voltage

2

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

TLV5620C, TLV5620I

QUADRUPLE 8-BIT DIGITAL-TO-ANALOG CONVERTERS

SLAS110B – JANUARY 1995 – REVISED APRIL 1997

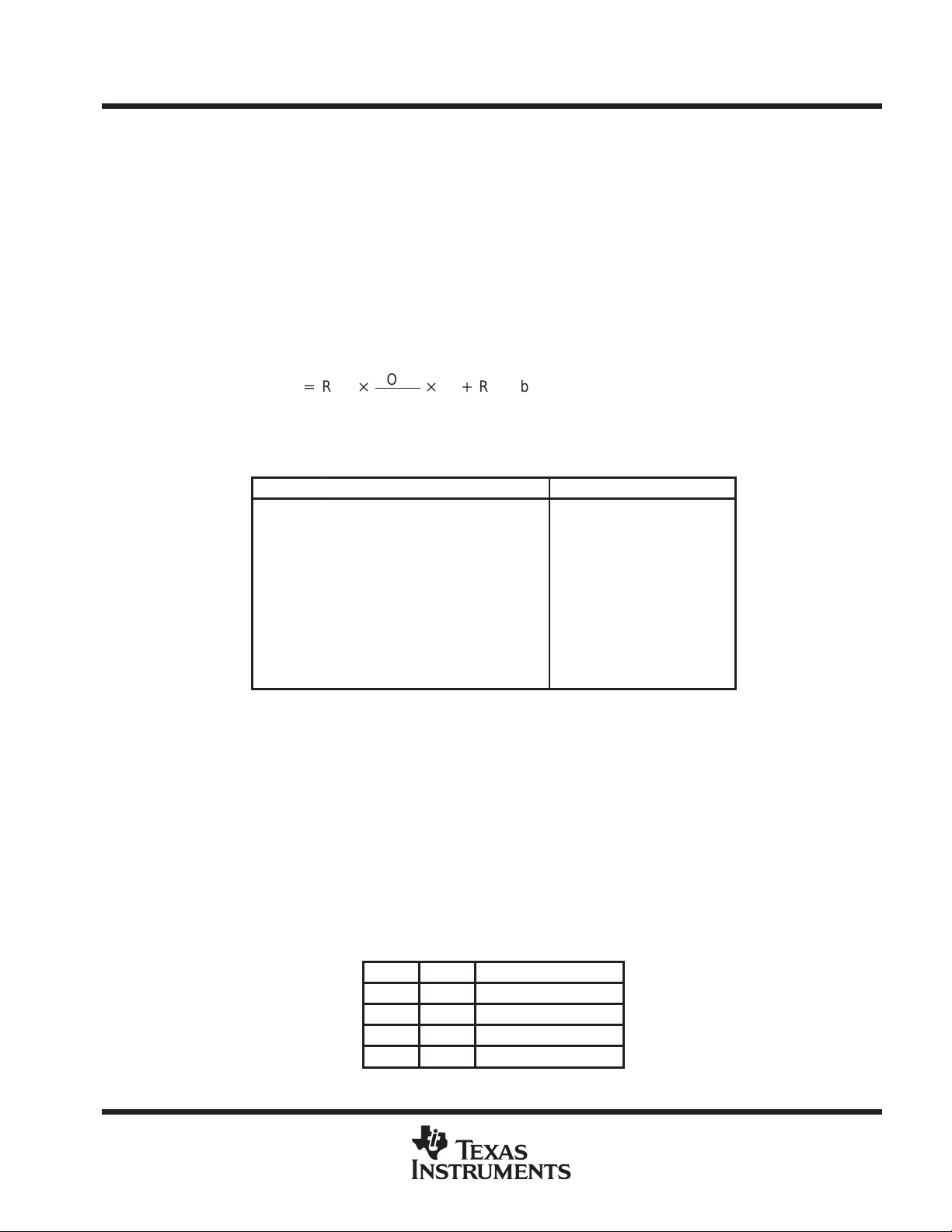

detailed description

The TLV5620 is implemented using four resistor-string DACs. The core of each DAC is a single resistor with

256 taps, corresponding to the 256 possible codes listed in T able 1. One end of each resistor string is connected

to GND and the other end is fed from the output of the reference input buffer . Monotonicity is maintained by use

of the resistor strings. Linearity depends upon the matching of the resistor segments and upon the performance

of the output buffer. Since the inputs are buffered, the DACs always presents a high-impedance load to the

reference source.

Each DAC output is buffered by a configurable-gain output amplifier, which can be programmed to times 1 or

times 2 gain.

On power up, the DACs are reset to CODE 0.

Each output voltage is given by:

VO(DACA|B|C|D)+REF

where CODE is in the range 0 to 255 and the range (RNG) bit is a 0 or 1 within the serial control word.

D7 D6 D5 D4 D3 D2 D1 D0 OUTPUT VOLTAGE

0 0 0 0 0 0 0 0 GND

0 0000001 (1/256) × REF (1+RNG)

• ••••••• •

• ••••••• •

0 1111111 (127/256) × REF (1+RNG)

1 0000000 (128/256) × REF (1+RNG)

• ••••••• •

• ••••••• •

1 1 1 1 1 1 1 1 (255/256) × REF (1+RNG)

CODE

256

(1)

RNG bit value)

Table 1. Ideal Output Transfer

data interface

With LOAD high, data is clocked into the DATA terminal on each falling edge of CLK. Once all data bits have

been clocked in, LOAD is pulsed low to transfer the data from the serial input register to the selected DAC as

shown in Figure 1. When LDAC is low, the selected DAC output voltage is updated when LOAD goes low . When

LDAC is high during serial programming, the new value is stored within the device and can be transferred to

the DAC output at a later time by pulsing LDAC low as shown in Figure 2. Data is entered MSB first. Data

transfers using two 8-clock-cycle periods are shown in Figures 3 and 4.

Table 2 lists the A1 and A0 bits and the selection of the updated DACs. The RNG bit controls the DAC output

range. When RNG = low, the output range is between the applied reference voltage and GND, and when

RNG = high, the range is between twice the applied reference voltage and GND.

Table 2. Serial Input Decode

A1 A0 DAC UPDATED

0 0 DACA

0 1 DACB

1 0 DACC

1 1 DACD

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

3

TLV5620C, TLV5620I

QUADRUPLE 8-BIT DIGITAL-TO-ANALOG CONVERTERS

SLAS110B – JANUARY 1995 – REVISED APRIL 1997

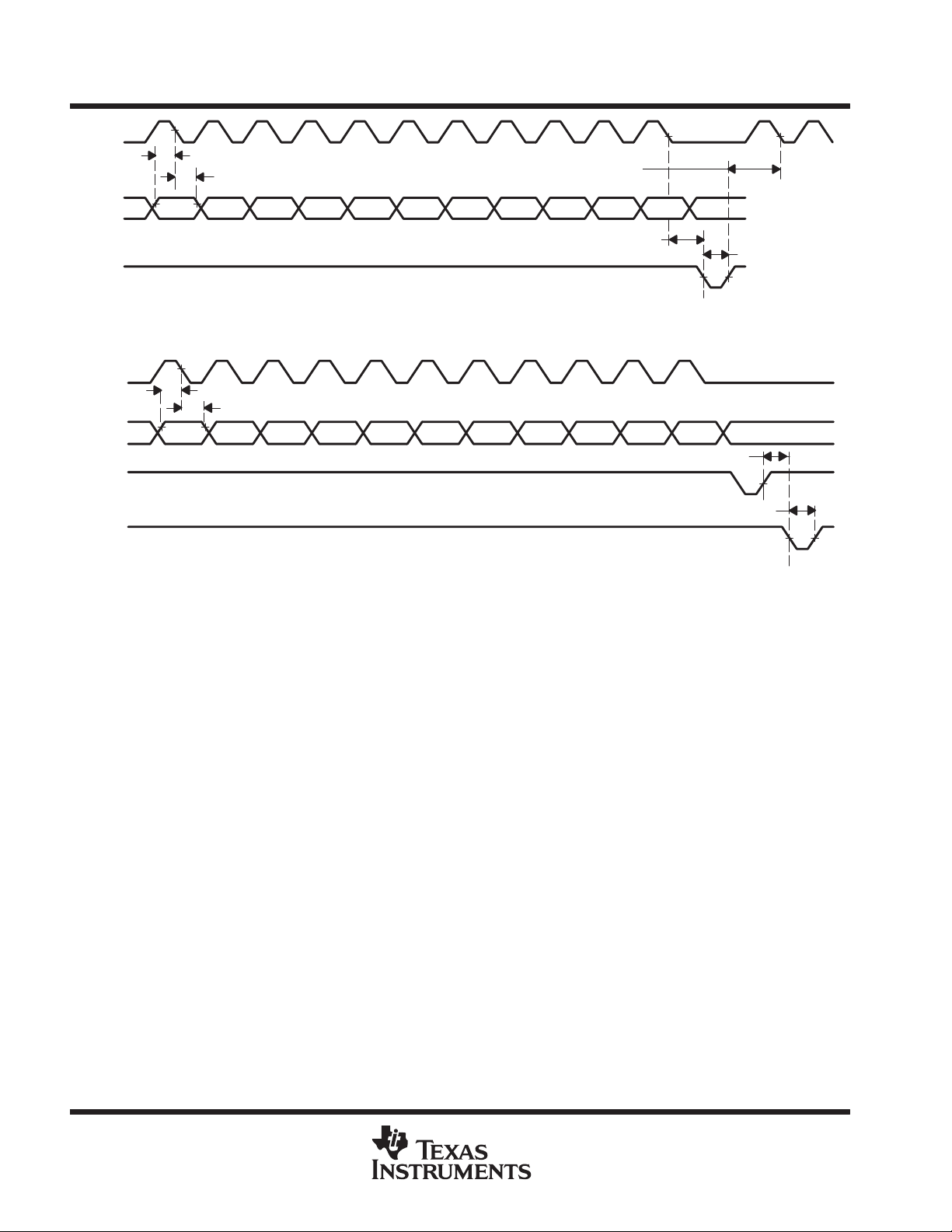

CLK

t

su(DATA-CLK)

t

v(DATA-CLK)

t

su(LOAD-CLK)

DATA

LOAD

CLK

DATA

LOAD

LDAC

A1 A0 RNG D7 D6 D5 D4 D3 D2 D1 D0

t

su(CLK-LOAD)

DAC Update

Figure 1. LOAD-Controlled Update (LDAC = Low)

t

su(DATA-CLK)

t

v(DATA-CLK)

A1 A0 RNG D7 D6 D5 D4 D3 D2 D1 D0

t

su(LOAD-LDAC)

Figure 2. LDAC-Controlled Update

t

w(LOAD)

t

w(LDAC)

DAC Update

4

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

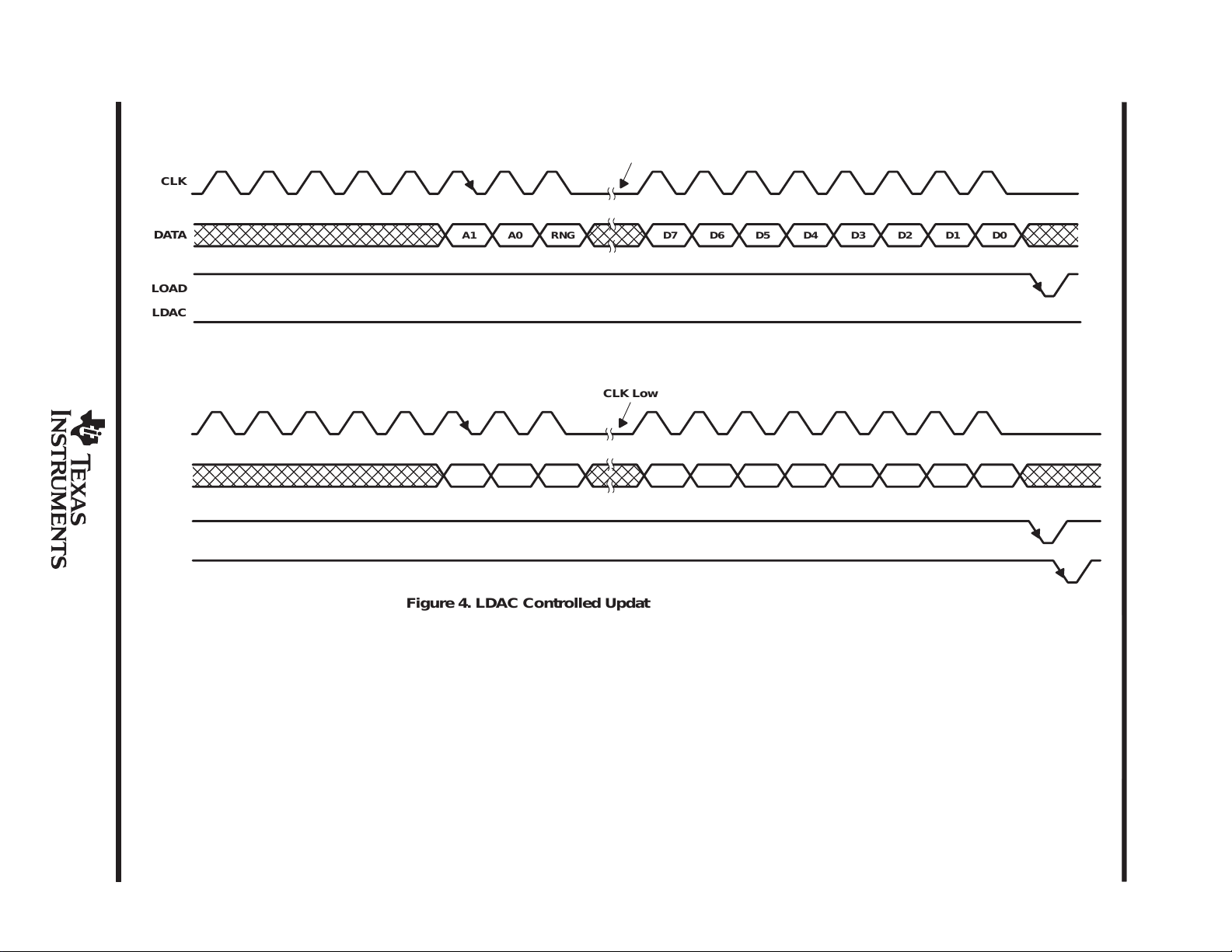

CLK

CLK Low

POST OFFICE BOX 655303 DALLAS, TEXAS 75265

• 5

DATA

LOAD

LDAC

CLK

DATA

LOAD

LDAC

A1 A0 RNG D7 D6 D5 D4 D3 D2 D1 D0

Figure 3. Load Controlled Update Using 8-Bit Serial Word (LDAC = Low)

CLK Low

A1 A0 RNG D7 D6 D5 D4 D3 D2 D1 D0

Figure 4. LDAC Controlled Update Using 8-Bit Serial Word

QUADRUPLE 8-DIGITAL-TO-ANALOG CONVERTERS

SLAS110B – JANUAR Y 1995 – REVISED APRIL 1997

TLV5620C, TLV5620I

TLV5620C, TLV5620I

QUADRUPLE 8-BIT DIGITAL-TO-ANALOG CONVERTERS

SLAS110B – JANUARY 1995 – REVISED APRIL 1997

linearity, offset, and gain error using single-end supplies

When an amplifier is operated from a single supply , the voltage offset can still be either positive or negative. With

a positive offset voltage, the output voltage changes on the first code change. With a negative offset the output

voltage may not change with the first code depending on the magnitude of the offset voltage.

The output amplifier, therefore, attempts to drive the output to a negative voltage. However, because the most

negative supply rail is ground, the output cannot drive below ground and clamps the output at 0 V.

The output voltage remains at zero until the input code value produces a sufficient positive output voltage to

overcome the negative offset voltage, resulting in the transfer function shown in Figure 5.

Output

Voltage

0 V

Negative

Offset

DAC Code

Figure 5. Effect of Negative Offset (Single Supply)

This offset error , not the linearity error, produces this breakpoint. The transfer function would have followed the

dotted line if the output buffer could drive below ground.

For a DAC, linearity is measured between zero-input code (all inputs 0) and full-scale code (all inputs 1) after

offset and full scale are adjusted out or accounted for in some way . However , single-supply operation does not

allow for adjustment when the offset is negative due to the breakpoint in the transfer function. So the linearity

is measured between full-scale code and the lowest code that produces a positive output voltage. The code is

calculated from the maximum specification for the negative offset.

6

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

Operating free-air temperature, T

°C

equivalent inputs and outputs

INPUT CIRCUIT OUTPUT CIRCUIT

TLV5620C, TLV5620I

QUADRUPLE 8-BIT DIGITAL-TO-ANALOG CONVERTERS

SLAS110B – JANUARY 1995 – REVISED APRIL 1997

V

DD

DAC

Voltage Output

I

SINK

60 µA

Typical

GND

V

ref

Input

V

DD

Output

Range

Select

_

+

× 1

84 kΩ

× 2

84 kΩ

Input from

Decoded DAC

Register String

To DAC

Resistor

String

GND

absolute maximum ratings over operating free-air temperature range (unless otherwise noted)

Supply voltage (VDD – GND) 7 V. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Digital input voltage range GND – 0.3 V to VDD + 0.3 V. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Reference input voltage range, VID GND – 0.3 V to VDD + 0.3 V. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Operating free-air temperature range, TA: TLV5620C 0°C to 70°C. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TLV5620I –40°C to 85°C. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Storage temperature range, T

Lead temperature 1,6 mm (1/16 inch) from case for 10 seconds 260°C. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

†

Stresses beyond those listed under “absolute maximum ratings” may cause permanent damage to the device. These are stress ratings only, and

functional operation of the device at these or any other conditions beyond those indicated under “recommended operating conditions” is not

implied. Exposure to absolute-maximum-rated conditions for extended periods may affect device reliability.

–50°C to 150°C. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

stg

†

recommended operating conditions

MIN NOM MAX UNIT

Supply voltage, V

High-level input voltage, V

Low-level input voltage, V

Reference voltage, V

Load resistance, R

Setup time, data input, t

Valid time, data input valid after CLK↓, t

Setup time, CLK eleventh falling edge to LOAD, t

Setup time, LOAD↑ to CLK↓, t

Pulse duration, LOAD, t

Pulse duration, LDAC, t

Setup time, LOAD↑ to LDAC↓,t

CLK frequency 1 MHz

p

DD

IH

IL

[A|B|C|D], x1 gain VDD–1.5 V

ref

L

su(DATA-CLK)

w(LOAD)

w(LDAC)

p

(see Figures 1 and 2) 50 ns

v(DATA-CLK)

su(LOAD-CLK)

(see Figure 1) 250 ns

(see Figure 2) 250 ns

su(LOAD-LDAC)

A

(see Figures 1 and 2) 50 ns

su(CLK-LOAD)

(see Figure 1) 50 ns

(see Figure 2) 0 ns

TLV5620C 0 70

TLV5620I –40 85

(see Figure 1) 50 ns

2.7 3.3 5.25 V

0.8 V

DD

0.8 V

10 kΩ

V

°

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

7

TLV5620C, TLV5620I

Each DAC output

C

pF

QUADRUPLE 8-BIT DIGITAL-TO-ANALOG CONVERTERS

SLAS110B – JANUARY 1995 – REVISED APRIL 1997

electrical characteristics over recommended operating free-air temperature range,

V

= 3 V to 3.6 V, V

DD

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

I

IH

I

IL

I

O(sink)

I

O(source)

i

I

DD

I

ref

E

L

E

D

E

ZS

E

FS

PSRR Power-supply sensitivity See Notes 7 and 8 0.5 mV/V

NOTES: 1. Integral nonlinearity (INL) is the maximum deviation of the output from the line between zero and full scale (excluding the effects

High-level input current VI = V

Low-level input current VI = 0 V ±10 µA

Output sink current

Output source current

Input capacitance 15

Reference input capacitance 15

Supply current VDD = 3.3 V 2 mA

Reference input current VDD = 3.3 V, V

Linearity error (end point corrected) V

Differential linearity error V

Zero-scale error V

Zero-scale error temperature coefficient V

Full-scale error V

Full-scale error temperature coefficient V

of zero code and full-scale errors).

2. Differential nonlinearity (DNL) is the difference between the measured and ideal 1 LSB amplitude change of any two adjacent codes.

Monotonic means the output voltage changes in the same direction (or remains constant) as a change in the digital input code.

3. Zero-scale error is the deviation from zero voltage output when the digital input code is zero.

4. Zero-scale error temperature coefficient is given by: ZSETC = [ZSE(T

5. Full-scale error is the deviation from the ideal full-scale output (V

6. Full-scale error temperature coefficient is given by: FSETC = [FSE(T

7. Zero-scale error rejection ratio (ZSE-RR) is measured by varying the VDD voltage from 4.5 V to 5.5 V dc and measuring the effect

of this signal on the zero-code output voltage.

8. Full-scale error rejection ratio (FSE-RR) is measured by varing the VDD voltage from 3 V to 3.6 V dc and measuring the effect of

this signal on the full-scale output voltage.

= 2 V, × 1 gain output range (unless otherwise noted)

ref

DD

p

= 1.5 V ±10 µA

ref

= 1.25 V, × 2 gain, See Note 1 ±1 LSB

ref

= 1.25 V, × 2 gain, See Note 2 ±0.9 LSB

ref

= 1.25 V, × 2 gain, See Note 3 0 30 mV

ref

= 1.25 V, × 2 gain, See Note 4 10 µV/°C

ref

= 1.25 V, × 2 gain, See Note 5 ±60 mV

ref

= 1.25 V, × 2 gain, See Note 6 ±25 µV/°C

ref

) – ZSE(T

max

– 1 LSB) with an output load of 10 kΩ.

ref

) – FSE (T

max

min

min

)]/V

)]/V

20 µA

1 mA

× 106/(T

ref

× 106/(T

ref

max

max

– T

– T

±10 µA

).

min

).

min

p

operating characteristics over recommended operating free-air temperature range,

V

= 3 V to 3.6 V, V

DD

Output slew rate CL = 100 pF RL = 10 kΩ 1 V/µs

Output settling time To ±0.5 LSB, CL = 100 pF, RL = 10 kΩ, See Note 9 10 µs

Large-signal bandwidth Measured at –3 dB point 100 kHz

Digital crosstalk CLK = 1-MHz square wave measured at DACA-DACD –50 dB

Reference feedthrough See Note 10 –60 dB

Channel-to-channel isolation See Note 11 –60 dB

Reference input bandwidth See Note 12 100 kHz

NOTES: 9. Settling time is the time between a LOAD falling edge and the DAC output reaching full-scale voltage within ± 0.5 LSB starting from

an initial output voltage equal to zero.

10. Reference feedthrough is measured at any DAC output with an input code = 00 hex with a V

11. Channel-to-channel isolation is measured by setting the input code of one DAC to FF hex and the code of all other DACs to 00 hex

with V

12. Reference bandwidth is the –3 dB bandwidth with an input at V

input = 1 V dc + 1 VPP at 10 kHz.

ref

= 2 V, × 1 gain output range (unless otherwise noted)

ref

TEST CONDITIONS MIN TYP MAX UNIT

= 1.25 V dc + 2 VPP and with a digital input code of full-scale.

ref

input = 1 V dc + 1 VPP at 10 kHz.

ref

8

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

TLV5620C, TLV5620I

QUADRUPLE 8-BIT DIGITAL-TO-ANALOG CONVERTERS

SLAS110B – JANUARY 1995 – REVISED APRIL 1997

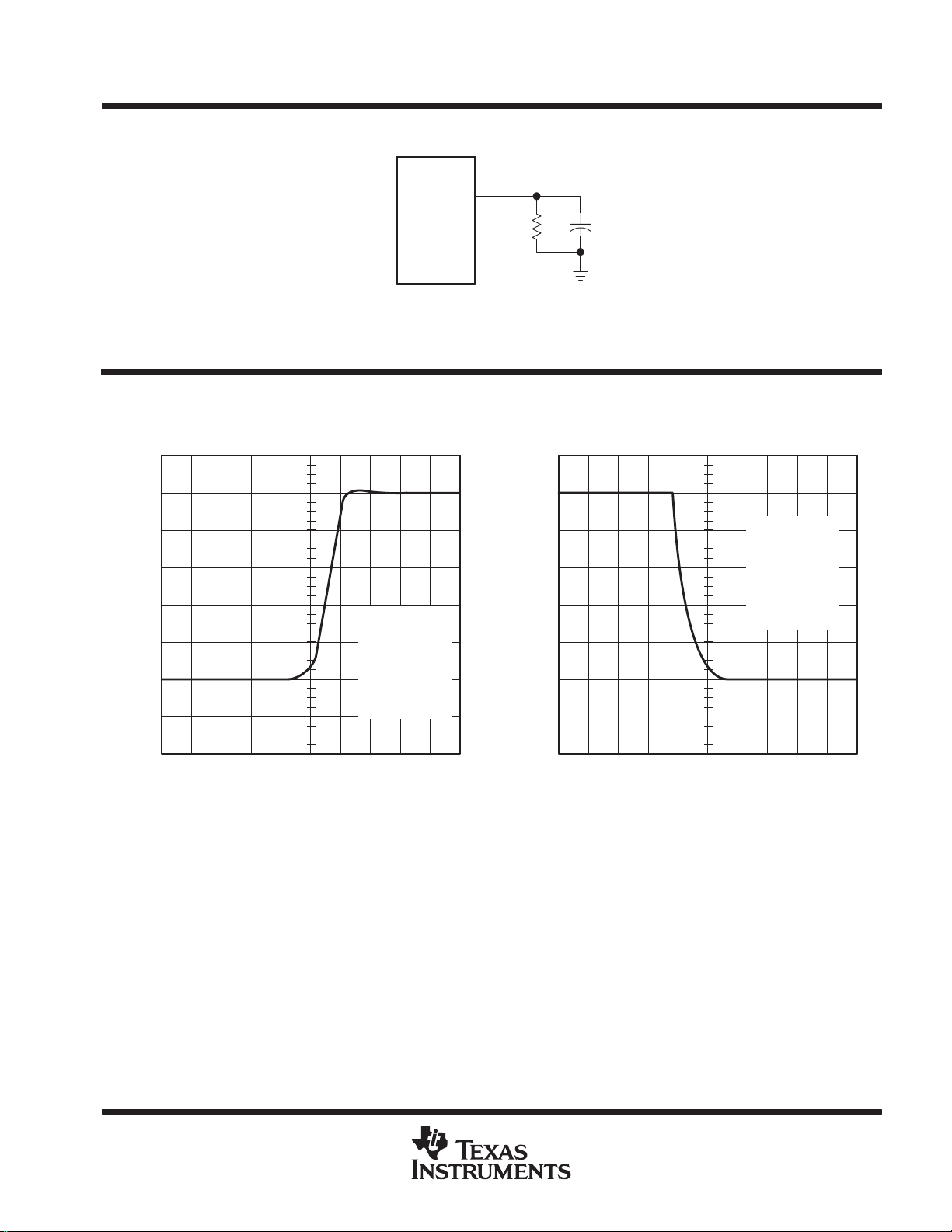

PARAMETER MEASUREMENT INFORMATION

TLV5620

DACA

DACB

DACC

DACD

Figure 6. Slew, Settling Time, and Linearity Measurements

TYPICAL CHARACTERISTICS

10 kΩ

CL = 100 pF

POSITIVE RISE TIME AND SETTLING TIME

3

2.5

2

1.5

1

0.5

– Output Voltage – V

O

V

0

–0.5

–1

024681012

Time – µs

NOTE A: Rise time = 2.05 µs, positive slew rate = 0.96 V/µs, settling

time = 4.5 µs.

VDD = 3 V

TA = 25°C

Code 00 to

FF Hex

Range = ×2

V

= 1.25 V

ref

(see Note A)

14 16 18 20

Figure 7

NEGATIVE FALL TIME AND SETTLING TIME

3

2.5

2

1.5

1

0.5

– Output Voltage – V

O

V

0

–0.5

–1

024681012

Time – µs

NOTE A: Fall time = 4.25 µs, negative slew rate = 0.46 V/µs, settling

time = 8.5 µs.

VDD = 3 V

TA = 25°C

Code FF to

00 Hex

Range = ×2

V

= 1.25 V

ref

(see Note A)

14 16 18 20

Figure 8

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

9

TLV5620C, TLV5620I

QUADRUPLE 8-BIT DIGITAL-TO-ANALOG CONVERTERS

SLAS110B – JANUARY 1995 – REVISED APRIL 1997

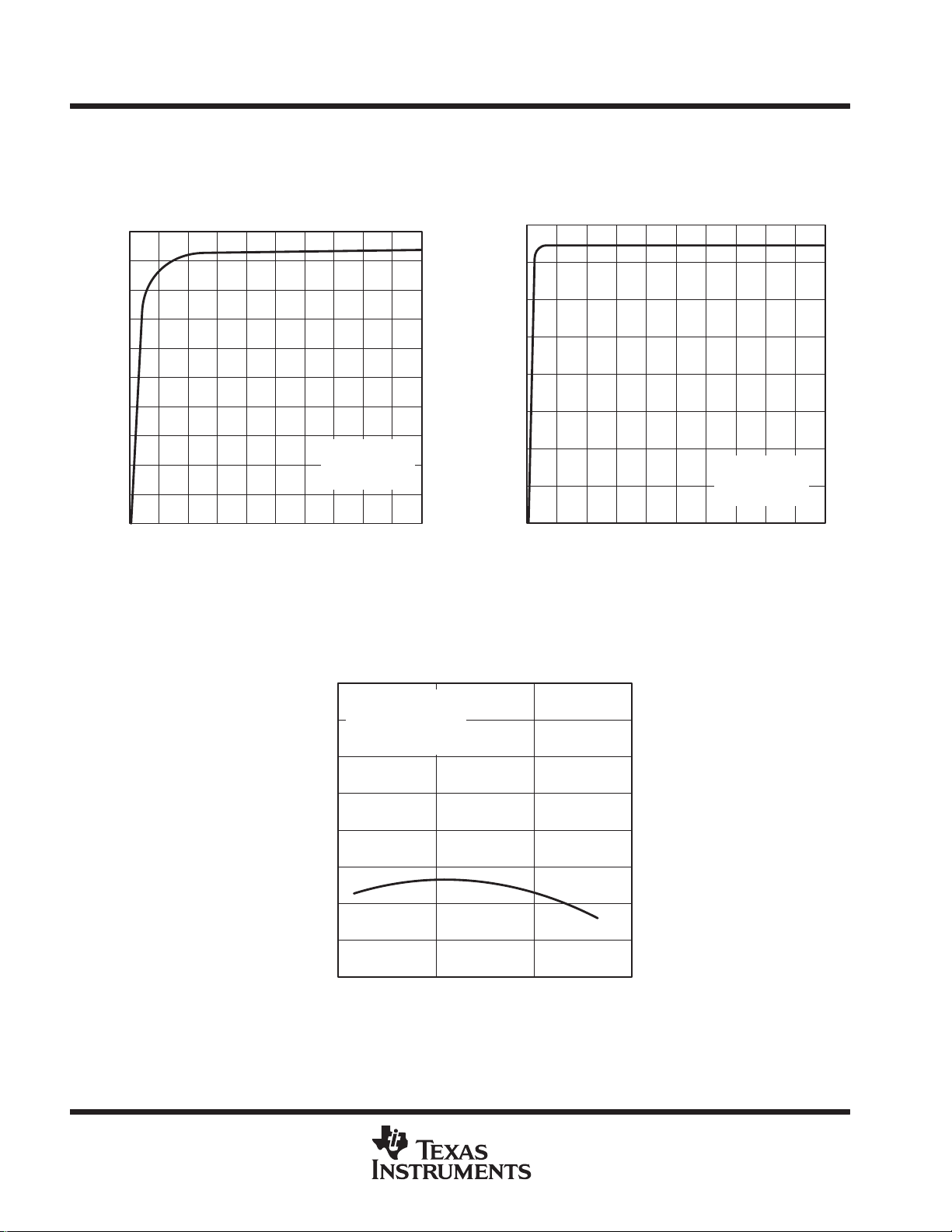

TYPICAL CHARACTERISTICS

DAC OUTPUT VOLTAGE

3

2.8

2.6

2.4

2.2

2

1.8

1.6

– DAC Output Voltage – V

O

V

1.4

1.2

1

0 102030405060

RL – Output Load – kΩ

vs

OUTPUT LOAD

Figure 9

VDD = 3 V,

V

= 1.5 V,

ref

Range = 2x

70 80 90 100

DAC OUTPUT VOLTAGE

OUTPUT LOAD

1.6

1.4

1.2

1

0.8

0.6

– DAC Output Voltage – V

O

V

0.4

0.2

0

0102030405060

RL – Output Load – kΩ

vs

Figure 10

VDD = 3 V,

V

= 1.5 V,

ref

Range = 1x

70 80 90 100

SUPPLY CURRENT

vs

TEMPERATURE

1.2

Range = ×2

Input Code = 255

1.15

VDD = 3 V

V

= 1.25 V

ref

1.1

1.05

1

0.95

– Supply Current – mA

0.9

DD

I

0.85

0.8

–50 0 50 100

t – Temperature – °C

Figure 11

10

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

TLV5620C, TLV5620I

QUADRUPLE 8-BIT DIGITAL-TO-ANALOG CONVERTERS

SLAS110B – JANUARY 1995 – REVISED APRIL 1997

APPLICATION INFORMATION

TLV5620

DACA

DACB

DACC

DACD

NOTE A: Resistor R w 10 kΩ

_

+

R

Figure 12. Output Buffering Scheme

V

O

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

11

TLV5620C, TLV5620I

QUADRUPLE 8-BIT DIGITAL-TO-ANALOG CONVERTERS

SLAS110B – JANUARY 1995 – REVISED APRIL 1997

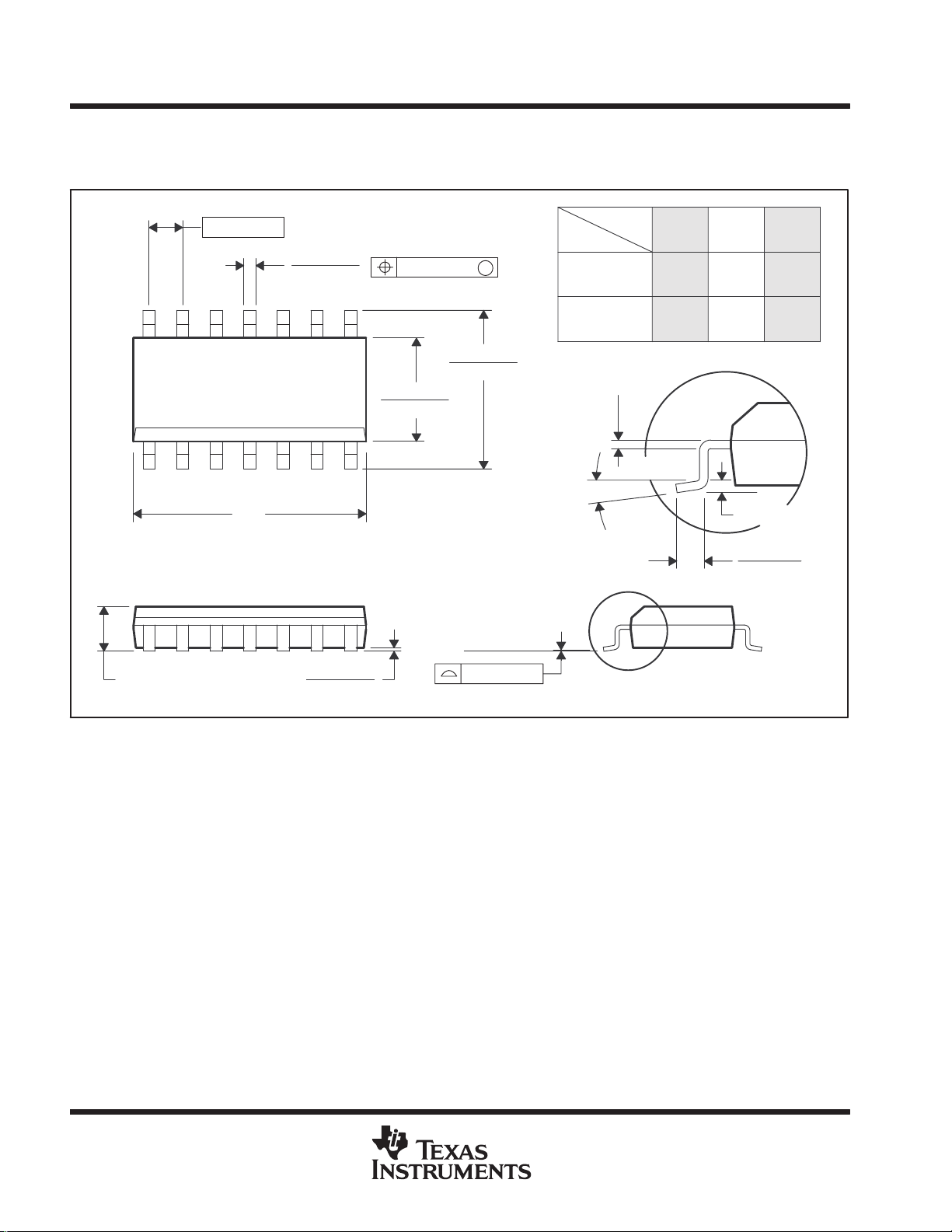

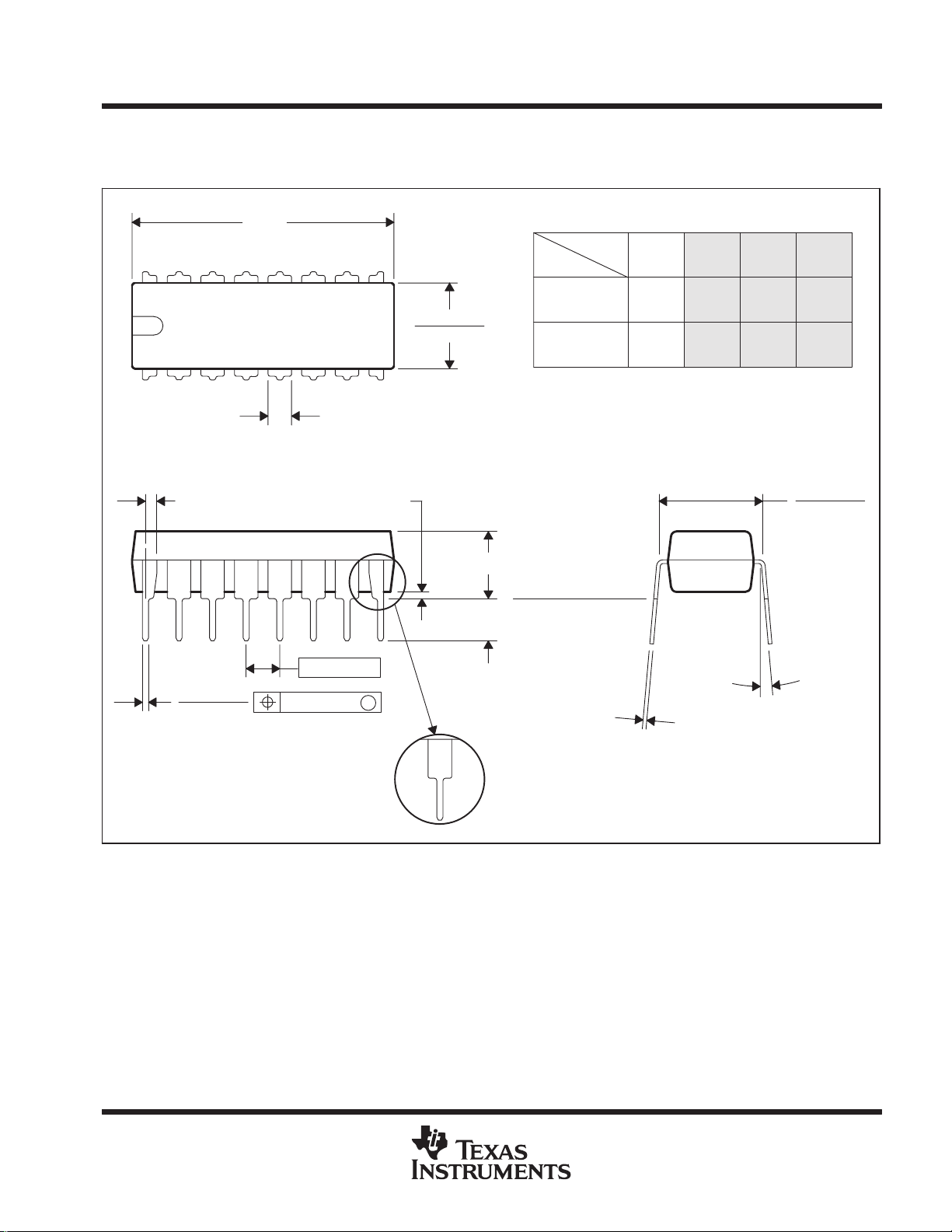

MECHANICAL DATA

D (R-PDSO-G**) PLASTIC SMALL-OUTLINE PACKAGE

14 PIN SHOWN

14

1

0.069 (1,75) MAX

0.050 (1,27)

A

0.020 (0,51)

0.014 (0,35)

0.010 (0,25)

0.004 (0,10)

8

7

0.010 (0,25)

0.157 (4,00)

0.150 (3,81)

M

0.244 (6,20)

0.228 (5,80)

Seating Plane

0.004 (0,10)

PINS **

DIM

A MAX

A MIN

0.008 (0,20) NOM

Gage Plane

0°–8°

8

0.197

(5,00)

0.189

(4,80)

14

0.344

(8,75)

0.337

(8,55)

0.010 (0,25)

0.044 (1,12)

0.016 (0,40)

4040047/B 10/94

16

0.394

(10,00)

0.386

(9,80)

NOTES: A. All linear dimensions are in inches (millimeters).

B. This drawing is subject to change without notice.

C. Body dimensions do not include mold flash or protrusion not to exceed 0.006 (0,15).

D. Four center pins are connected to die mount pad

E. Falls within JEDEC MS-012

12

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

TLV5620C, TLV5620I

QUADRUPLE 8-BIT DIGITAL-TO-ANALOG CONVERTERS

SLAS110B – JANUARY 1995 – REVISED APRIL 1997

MECHANICAL DATA

N (R-PDIP-T**) PLASTIC DUAL-IN-LINE PACKAGE

16 PIN SHOWN

A

16

9

PINS **

DIM

14

16

18

20

1

0.035 (0,89) MAX

0.021 (0,53)

0.015 (0,38)

0.070 (1,78) MAX

0.020 (0,51) MIN

0.100 (2,54)

0.010 (0,25)

A MAX

0.260 (6,60)

0.240 (6,10)

8

0.200 (5,08) MAX

0.125 (3,18) MIN

M

0.010 (0,25) NOM

A MIN

Seating Plane

0.775

(19,69)

0.745

(18,92)

0.775

(19,69)

0.745

(18,92)

0.920

(23.37)

0.850

(21.59)

0.975

(24,77)

0.940

(23,88)

0.310 (7,87)

0.290 (7,37)

0°–15°

NOTES: A. All linear dimensions are in inches (millimeters).

B. This drawing is subject to change without notice.

C. Falls within JEDEC MS-001 (20-pin package is shorter than MS-001)

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

14 Pin Only

4040049/C 7/95

13

IMPORTANT NOTICE

T exas Instruments and its subsidiaries (TI) reserve the right to make changes to their products or to discontinue

any product or service without notice, and advise customers to obtain the latest version of relevant information

to verify, before placing orders, that information being relied on is current and complete. All products are sold

subject to the terms and conditions of sale supplied at the time of order acknowledgement, including those

pertaining to warranty, patent infringement, and limitation of liability.

TI warrants performance of its semiconductor products to the specifications applicable at the time of sale in

accordance with TI’s standard warranty. Testing and other quality control techniques are utilized to the extent

TI deems necessary to support this warranty . Specific testing of all parameters of each device is not necessarily

performed, except those mandated by government requirements.

CERTAIN APPLICA TIONS USING SEMICONDUCT OR PRODUCTS MAY INVOLVE POTENTIAL RISKS OF

DEATH, PERSONAL INJURY, OR SEVERE PROPERTY OR ENVIRONMENTAL DAMAGE (“CRITICAL

APPLICATIONS”). TI SEMICONDUCTOR PRODUCTS ARE NOT DESIGNED, AUTHORIZED, OR

WARRANTED TO BE SUITABLE FOR USE IN LIFE-SUPPORT DEVICES OR SYSTEMS OR OTHER

CRITICAL APPLICA TIONS. INCLUSION OF TI PRODUCTS IN SUCH APPLICATIONS IS UNDERST OOD TO

BE FULLY AT THE CUSTOMER’S RISK.

In order to minimize risks associated with the customer’s applications, adequate design and operating

safeguards must be provided by the customer to minimize inherent or procedural hazards.

TI assumes no liability for applications assistance or customer product design. TI does not warrant or represent

that any license, either express or implied, is granted under any patent right, copyright, mask work right, or other

intellectual property right of TI covering or relating to any combination, machine, or process in which such

semiconductor products or services might be or are used. TI’s publication of information regarding any third

party’s products or services does not constitute TI’s approval, warranty or endorsement thereof.

Copyright 1999, Texas Instruments Incorporated

Loading...

Loading...