Page 1

THS7001

ProgrammableĆGain Amplifier

Evaluation Module

User’s Guide

December 1999 Mixed-Signal Products

SLOU057

Page 2

IMPORTANT NOTICE

T exas Instruments and its subsidiaries (TI) reserve the right to make changes to their products or to discontinue

any product or service without notice, and advise customers to obtain the latest version of relevant information

to verify, before placing orders, that information being relied on is current and complete. All products are sold

subject to the terms and conditions of sale supplied at the time of order acknowledgement, including those

pertaining to warranty, patent infringement, and limitation of liability.

TI warrants performance of its semiconductor products to the specifications applicable at the time of sale in

accordance with TI’s standard warranty. Testing and other quality control techniques are utilized to the extent

TI deems necessary to support this warranty . Specific testing of all parameters of each device is not necessarily

performed, except those mandated by government requirements.

CERTAIN APPLICATIONS USING SEMICONDUCTOR PRODUCTS MAY INVOLVE POTENTIAL RISKS OF

DEATH, PERSONAL INJURY, OR SEVERE PROPERTY OR ENVIRONMENTAL DAMAGE (“CRITICAL

APPLICATIONS”). TI SEMICONDUCTOR PRODUCTS ARE NOT DESIGNED, AUTHORIZED, OR

WARRANTED TO BE SUITABLE FOR USE IN LIFE-SUPPORT DEVICES OR SYSTEMS OR OTHER

CRITICAL APPLICA TIONS. INCLUSION OF TI PRODUCTS IN SUCH APPLICATIONS IS UNDERST OOD TO

BE FULLY AT THE CUSTOMER’S RISK.

In order to minimize risks associated with the customer’s applications, adequate design and operating

safeguards must be provided by the customer to minimize inherent or procedural hazards.

TI assumes no liability for applications assistance or customer product design. TI does not warrant or represent

that any license, either express or implied, is granted under any patent right, copyright, mask work right, or other

intellectual property right of TI covering or relating to any combination, machine, or process in which such

semiconductor products or services might be or are used. TI’s publication of information regarding any third

party’s products or services does not constitute TI’s approval, warranty or endorsement thereof.

Copyright 1999, Texas Instruments Incorporated

Page 3

Related Documentation From Texas Instruments

J

THS7001 Programmable-Gain Amplifier

SLOS214) This is the data sheet for the THS7001 amplifier

integrated circuit used on the EVM.

J

PowerPAD Thermally Enhanced Package

SLMA002) This is the technical brief for the special PowerPAD

package in which the THS7001 amplifier IC is supplied.

FCC Warning

This equipment is intended for use in a laboratory test environment only. It

generates, uses, and can radiate radio frequency energy and has not been

tested for compliance with the limits of computing devices pursuant to subpart

J of part 15 of FCC rules, which are designed to provide reasonable protection

against radio frequency interference. Operation of this equipment in other

environments may cause interference with radio communications, in which

case the user at his own expense will be required to take whatever measures

may be required to correct this interference.

Preface

(literature number

(literature number

Trademarks

TI is a trademark of Texas Instruments Incorporated.

PowerPAD is a trademark of Texas Instruments Incorporated.

Chapter Title—Attribute Reference

iii

Page 4

iv

Page 5

Running Title—Attribute Reference

Contents

1 General Information 1-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.1 Features 1-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2 Description 1-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.3 Programmable Gain Amplifier Gain Control 1-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.4 EVM DIP Switch Functionality 1-8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.5 EVM Circuit Configuration 1-9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.6 Using The THS7001 EVM 1-10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.7 THS7001 EVM Performance 1-11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.8 General High-Speed Amplifier Design Considerations 1-14. . . . . . . . . . . . . . . . . . . . . . . . . .

1.9 General PowerP ADt Design Considerations 1-15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.10 THS7001 EVM Specifications 1-18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2 Reference 2-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.1 THS7001 Programmable-Gain Amplifier EVM Parts List 2-2. . . . . . . . . . . . . . . . . . . . . . . . .

2.2 THS7001 EVM Board Layouts 2-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter Title—Attribute Reference

v

Page 6

Running Title—Attribute Reference

Figures

1–1 THS7001 Evaluation Module 1-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1–2 THS7001 EVM Schematic Diagram 1-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1–3 Simplified PGA Section of the THS7001 1-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1–4 THS7001 Evaluation Module Block Diagram 1-9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1–5 THS7001 EVM Preamplifier Response, VCC = ±15 V 1-11. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1–6 THS7001 EVM Preamplifier Response, VCC = ±5 V 1-11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1–7 THS7001 EVM PGA Response, VCC = ±15 V 1-12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1–8 THS7001 EVM PGA Response, VCC = ±5 V 1-12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1–9 THS7001 EVM Preamplifier + PGA Response, VCC = ±15 V 1-13. . . . . . . . . . . . . . . . . . . . . .

1–10 THS7001 EVM Preamplifier + PGA Response, VCC = ±5 V 1-13. . . . . . . . . . . . . . . . . . . . . . .

1–11 PowerPAD PCB Etch and Via Pattern 1-15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1–12 Maximum Power Dissipation vs. Free-Air Temperature 1-16. . . . . . . . . . . . . . . . . . . . . . . . . . . .

2–1 THS7001 EVM PC Board: Top Assembly 2-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2–2 THS7001 EVM PC Board: Top Layer 2-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2–3 THS7001 EVM PC Board: Bottom Layer 2-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

T ables

1–1 THS7001 EVM PGA Nominal Gain/Attenuation 1-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1–2 EVM DIP Switch Functionality 1-8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1–3 THS7001 EVM Jumper Settings 1-10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1–4 THS7001 EVM DIP Switch Settings 1-10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2–1 THS7001 Programmable-Gain Amplifier EVM Parts List 2-2. . . . . . . . . . . . . . . . . . . . . . . . . . . .

vi

Page 7

Chapter 1

General

Information

This chapter details the Texas Instruments (TI) THS7001

programmable-gain amplifier evaluation module (EVM), SLOP250. It includes

a list of EVM features, a brief description of the module illustrated with a

pictorial and schematic diagrams, EVM specifications, details on configuring,

connecting, and using the EVM, and a discussion on high-speed amplifier and

PowerPAD package design considerations.

Topic Page

1.1 Features 1–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2 Description 1–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.3 Programmable Gain Amplifier Gain Control 1–6. . . . . . . . . . . . . . . . . . . . .

1.4 EVM DIP Switch Functionality 1–8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.5 EVM CIrcuit Configuration 1–9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.6 Using the THS7001 EVM 1–10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.7 THS7001 EVM Performance 1–11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.8 General High-Speed Amplifier Design Considerations 1–14. . . . . . . . .

1.9 General PowerPAD Design Considerations 1–15. . . . . . . . . . . . . . . . . .

1.10 THS7001 EVM Specifications 1–18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

General Information

1-1

Page 8

Features

1.1 Features

1.2 Description

THS7001 programmable-gain amplifier EVM features include:

J

Multiple Input Configurations Set Via On Board Jumpers

J

DIP Switches Allow Quick and Easy Adjustment of Gain, Shut Down,

Reference Voltage, and Output Clamping

J

Standard BNC Connector Inputs and Outputs

J

±5-V to ±15-V Operation With 5-V Reference Input

J

Nominal 50-Ω Impedance Inputs and Outputs

J

Includes T est Points for Easy Digital Control of EVM Circuit Gain and

Operating Parameters

J

Good Example of PowerPAD Package and High-Speed Amplifier

Design and Layout

The TI THS7001 programmable-gain amplifier evaluation module (EVM) is a

complete low-noise receiver and a highly configurable programmable-gain

amplifier circuit. It consists of the TI THS7001 programmable-gain amplifier IC

and a number of passive parts, all mounted on a multilayer circuit board

(Figure 1–1).

Although the THS7001 IC was developed primarily for xDSL receiver

front-ends, a large number of different circuits can benefit from the many

features incorporated into the THS7001. This EVM illustrates a universal

design and can be used for numerous system configurations.

The EVM uses standard BNC connectors for inputs and outputs and also

includes test points for user connections and testing. It is completely

assembled, fully tested, and ready to use—just connect it to power, a signal

source, and a load (if desired).

1-2

General Information

Page 9

Figure 1–1.THS7001 Evaluation Module

SLOP250 THS7001 EVM Board

Description

J1

+V

CC

J2

C13

Pre-Amp A

Output

GND

J5

1999

R5

C6

JP1

R6

J6

Input

Texas Instruments

Input power is applied to the EVM through banana jacks J1, J2, J3, and J4. An

LC filter on each power bus isolates the EVM circuits from the external supply .

J4 provides a reference point for numerous circuit functions and draws

relatively little current. The schematic for the EVM amplifiers appears in Figure

1–2.

1

JP2

R7

C3

R1

R2

A

R9

J4J3

C15

+5 V–V

S1

PGA – A

Output

R44

VH

C21L2C5C4L1

GND

S/D

(4)

AVREF

(5)

VL

(6)

J9

+++

G2

(3)

G1

(2)

G0

R18

(1)

C7

R20

U1

R8

C8

C1

C12

R23

R25

R27

R29

R41

JP3

R31

C14

C17

R24

R26

R28

R30

R32

C18, C10

C19, C9

R42

CC

General Information

1-3

Page 10

Description

5 V+15 V

JP3

J9

PGA-A

Output

C15

0.1 µF

3

2

1

R44

100 Ω

C9, 0.1 µF

R42

4.7 kΩ

R32

4.7 kΩ

C10, 0.1 µF

S1:F

TP8

R30

S1:E

S1:D

3.3 kΩ

S/D

5 V

TP7

–15 V

PGA

Figure 1–2.THS7001 EVM Schematic Diagram

PREAMPLIFIER

VH

TP5

R24, 3.3 kΩ

R26, 3.3 kΩ

R28, 3.3 kΩ

G2, TP3

5 V

S1:C

S1:B

S1:A

C17, 0.1 µF

TP2, G0

TP4, G1

+15 V

C14

C13

5 V

–15 V

0.1 µF

0.1 µF

+15 V

C8, TBD

R8

R7

J4

+5 V

CC

J3

–V

TP1

J2

GND

CC

J1

+V

+

C21

6.8 µF

L2

0.22 µH

C5

6.8 µF

+

C4

6.8 µF

+

L1

0.22 µH

R41

49.9 Ω

12

16

VO

VH

G2

18

R27, 330Ω

G1

19

R25, 330Ω

G0

U1:B

20

R23, 330 Ω

499 Ω

499 Ω

13

C19, 0.1 µF

C6, TBD

+15 V

VCC

VIN

3

R6

0 Ω

2

1

C12

0.1 µF

8

–

5

R2

TBD

JP2

3

VL

TP6

R31

49.9 Ω

R18

R29

C18, 0.1 µF

J5

Pre-amp A

R1

49.9 Ω

330 Ω

–15 V

Output

C11

TBD

VREF

–15 V

0.1 µF

15

VL

VREF

2

GND

1

SID

17

–Vcc

14

C17

TBD

R20

TBD

3

JP1

R5

4

49.9 Ω

7

U1:A

+

6

C3

TBD

1

2

R9

49.9 Ω

1-4

J6

Input A

General Information

Page 11

Description

The THS7001 EVM is equipped with BNC input and output connectors. The

input is terminated with a 50-Ω resistor to provide correct line impedance

matching (Figure 1–3). Note that using a source with a 50-Ω output impedance

will create a voltage divider at the EVM inputs. Thus, accurate knowledge of

the source output characteristics is required to determine proper input signal

amplitudes.

The output of the preamplifier stage is routed through a 50-Ω resistor to

provide proper cable impedance matching and termination impedance

matching. One of the drawbacks of using this type of impedance matching is

that it places an equivalent 100-Ω load on the output of the preamplifier.

Although the preamplifier section has a large output current capability, the

programmable gain amplifier (PGA) section has a limited current drive

capability . It is recommended that the total impedance placed on the output of

the PGA section is at least 500 Ω.

The THS7001 IC is a voltage feedback amplifier. It follows the classic

operational amplifier gain equations:

*

R

Inverting Gain

+

R

G

Noninverting Gain+1

F

R

F

)

R

G

(1)

(2)

The gain of the preamplifier can easily be changed to support different

applications by changing the resistor ratios. Although any of the components

on the EVM board can be replaced with different values, it is imperative that

the THS7001 preamplifier gain be kept to a minimum of +2 or –1 for stability

purposes. Also, component pads have been placed in convenient locations on

TBD

the PCB (shown as components with the value

in the schematic) to allow

numerous modifications to the basic EVM configuration. However, care must

be taken because the surface-mount solder pads on the board are somewhat

fragile and will not survive a large number of soldering/desoldering operations.

For independent evaluation of the preamplifier, a BNC connector directly at the

preamplifier output pin (J5) allows the user to investigate the preamplifier

independently of the PGA section.

The shutdown feature of the THS7001 IC is implemented on this EVM. The

shutdown signal is low for normal THS7001 operation. When the shutdown pin

is high (5 V), the preamplifier and the PGA section are turned off. Shutdown

on the EVM is controlled by switch S1:D, or by applying an external shutdown

signal to test point TP7 with the switch set to OFF. An isolation resistor on the

THS7001 IC shutdown control input pin is used to minimize surges in the EVM

environment and can be omitted in a final system design.

General Information

1-5

Page 12

Programmable Gain Amplifier Gain Control

1.3 Programmable Gain Amplifier Gain Control

The THS7001 IC is provided with three digital control inputs for setting the gain

of the PGA stage (G0 – G2). Standard TTL or CMOS Logic signals operate

these control inputs. The gain control inputs are not latched and respond to the

control signals in real time. Therefore, the control signals on these inputs must

remain constant if the PGA gain is to remain constant. For stand-alone

evaluation of this function, onboard DIP switches (S1:A to S1:C) are used to

control the gain of the PGA. Note that all DIP switch gain control elements must

be set to OFF if gain is to be set by digital control signals. For convenience,

test points (TP2 – TP4) are placed on each of these lines to allow easy external

connections. There are 330-Ω isolation resistors in series with each IC gain

control input pins. These were added only for surge suppression and are not

required for actual system design. Nominal gain/attenuation is shown in

Table 1–1.

Table 1–1.THS7001 EVM PGA Nominal Gain/Attenuation

G2 G1 G0 PGA Gain (dB) PGA Gain (V/V)

0 0 0 –22 0.08

0 0 1 –16 0.16

0 1 0 –10 0.32

0 1 1 –4 0.63

1 0 0 2 1.26

1 0 1 8 2.52

1 1 0 14 5.01

1 1 1 20 10

One aspect of the THS7001 PGA signal input that must be considered is that

there are internal variable resistors (R

and RG) that set the gain. The

F

resistance of RG changes from about 270 Ω (gain = +20 dB) to about 3 kΩ (gain

= –22 dB). Therefore, any source impedance at the input to the PGA amplifier

will cause a gain error to be seen at the output. A buffer/amplifier is highly

recommended to directly drive the input of the PGA section to help minimize

this effect.

Another consideration is that when the amplifier V

is connected to ground,

REF

the internal RG resistor is connected to a virtual ground. Therefore, if a

termination resistor is used on the source side, the total terminating resistance

is the parallel combination of the terminating resistance and the internal R

resistor. This, in conjunction with the series impedance problem mentioned

previously , can potentially cause a voltage mismatch between the output of a

50-Ω source and the expected PGA output voltage.

These points are illustrated by the following formula and in the simplified

diagram of the THS7001 PGA section shown in Figure 1–3.

R

TOTALTERMINATION

+

R

TERMINATION

R

TERMINATION

)

(R

(R

SOURCE

SOURCE

)

)

RG)

RG)

(3)

G

1-6

General Information

Page 13

Figure 1–3.Simplified PGA Section of the THS7001

No Source Impedance

V

IN

R

SOURCE

R

TERMINATION

PGA

–V

PGA

V

REF

IN

R

G

Programmable Gain Amplifier Gain Control

G0 G1 G

–

PGA

+

2

R

F

THS7001 IC

Positive

Clamp V

PGA

V

OUT

Negative

Clamp V

H

L

The PGA V

terminal is also accessible via test point TP8. Typically , the DIP

REF

switches are used to keep this point at ground. If a voltage is applied to this

terminal, then the output of the PGA section will amplify the applied reference

voltage by one plus the selected gain. Thus, the output gain due only to V

REF

will be from +0.6 dB to +21 dB according to the following formula:

V

OUT

ǒ

Ǔ

+20

V

REF

Log

ƪ

1

)ǒPGA Gain(VńV

10

Ǔ

Ǔ

ƫ

(4)

Typically, the output of the PGA will directly drive an A/D converter. Because

of the limited linear input range and saturation characteristics of most ADCs,

the PGA output incorporates a voltage clamp. These clamps are typically

connected to the power supply pins to allow a full output range. However, by

setting switch S1:F to OFF and setting jumper JP3 to the 1–2 position, the

outputs will be clamped to either +Vcc or +5V (depending on JP3) and ground.

The output can be further limited by applying an external reference voltage to

test points TP5 (VH) and TP6 (VL). The accuracy of this clamp is dependant

on the amount of current flowing through the internal clamping diodes. As is

typical with all diodes, the voltage drop across this diode increases with

current. Therefore, the accuracy of the clamp is highly dependant upon the

output voltage, the clamping voltage differences, and the output current. The

50-Ω series resistors are placed on this EVM only for surge suppression. In

a final system layout, these resistors are not required for proper operation.

General Information

1-7

Page 14

EVM DIP Switch Functionality

S1:A

A–G0

S1:B

A–G1

S1:C

A–G2

S1:D

A–S/D

S1:E

A–VREF

S1:F

VL

1.4 EVM DIP Switch Functionality

The THS7001 can be fully evaluated without any external digital control

signals applied. This is accomplished through the use of a DIP switch. The DIP

switch incorporates six SPST switches labeled A through F. The functionality

of each switch is described in Table 1–2.

Table 1–2.EVM DIP Switch Functionality

SWITCH LABEL POSITION DESCRIPTION

0 PGA Gain Bit 0 (LSB): Value = 0 (Low)

1 PGA Gain Bit 0 (LSB): Value = 1 (High)

0 PGA Gain Bit 1: Value = 0 (Low)

1 PGA Gain Bit 1: Value = 1 (High)

0 PGA Gain Bit 2 (MSB): Value = 0 (Low)

1 PGA Gain Bit 2 (MSB): Value = 1 (High)

0 Shutdown Control: Value = 0 (Low) — Active

1 Shutdown Control: V alue = 1 (High) — Shutdown

0 VREF Floating (Connect TP8 to Ext. Ref.)

1 VREF Connected to Ground

0 Low Side Clamp Ground (Connect TP6 to Ext Ref)

1 Low Side Clamp Connected to –Vcc

1-8

General Information

Page 15

1.5 EVM Circuit Configuration

The THS7001 EVM design allows evaluation of each section of the THS7001

amplifier IC separately. Configuration of the EVM is accomplished through

jumpers mounted on the module PCB. Each jumper is a three-pin header that

acts as an SPDT switch when a shunt is placed across two of the three pins

to select either of two signal routes (Figure 1–4).

Figure 1–4.THS7001 Evaluation Module Block Diagram

EVM Circuit Configuration

J6

Input A

1

3

-

Jumper JP1:

J

J

-

Jumper JP2:

J

J

1

3

VH Clamp

2

JP1

1

3

U1: B

THS7001

PGA

PGA A

Output

Preamp A

Output

J9

J5

2

JP3

JP2

5 V

15 V

2

U1:A

–

THS7001

+

Preamp

1–2 — Connects the input of the PGA (U1: B) to the input A BNC (J6),

bypassing the THS7001 preamplifier (U1:A)

2–3 — Connects the input of A-channel PGA (U1: B) to the output of

the A-channel preamplifier (U1:A)

1–2 — Connects the inverting input terminal of the preamplifier (U1:A)

to the input A BNC (J6). In order to use this functionality , components

R1, R2, and C3 must be selected and installed on the EVM by the user

2–3 — Connects the noninverting input terminal of the preamplifier

(U1:A) to the input A BNC (J6)

-

For example, to use the preamplifier as a buffer and gain:

1) Set JP1 to 2–3

2) Set JP2 to 2–3

3) Set JP3 to 2–3

4) Apply the input to input A (J6)

Jumper JP3:

J

1–2 — Connects the THS7001 IC positive clamp input pin (VH) to

+V

CC

J

2–3 — Connects the THS7001 IC positive clamp input pin (VH) to +5V

General Information

1-9

Page 16

Using the THS7001 EVM

1.6 Using the THS7001 EVM

The THS7001 EVM operates from a split power supply with voltages ranging

from ±5 V to ±15 V. It also uses 5 volt logic control signals to configure the

operation of the EVM when the DIP switches are used. The use of a single

supply for this EVM is not recommended. As shipped, the preamplifier is set

to a gain of 2 and the preamplifier directly drives the PGA stage. An

oscilloscope is typically used to view and analyze the EVM output signals.

1) Ensure that all power supplies are set to

connections to the THS7001 EVM.

2) Select the operating voltage for the EVM and connect appropriate split

power supplies to the banana jacks on the module marked

–VCC

(J3).

3) Connect a 5-V power supply to the banana jack marked

OFF

before making power supply

+V

CC

+5 V

(J1) and

(J4).

4) Connect all power supply grounds to the banana jack marked

5) Connect an oscilloscope probe to the PGA–A amplifier output BNC (J9).

Connecting directly to J9 with a 50-Ω nominal impedance cable and probe

is not recommended. The output drive capability of the PGA is very limited.

Such a connection will load the output excessively, reducing the output

voltage range of the amplifier and is not a true measurement of the

amplifier performance.

6) Set EVM jumpers as shown in Table 1–3.

Table 1–3.THS7001 EVM Jumper Settings

JP1 JP2 JP3

2–3 2–3 2–3

7) Set DIP switch S1 as shown in Table 1–4.

Table 1–4.THS7001 EVM DIP Switch Settings

SWITCH S1 LABEL POSITION

S1:A G0 0

S1:B G1 0

S1:C G2 1

S1:D S/D 0

S1:E VREF 1

S1:F VL 1

GND

(J2).

8) Set the power supplies to ON.

9) Connect a signal input to the INPUT A BNC (J6).

Note that each input connector on this EVM is terminated with a 50-Ω resistor

to ground. With a 50-Ω source impedance, the voltage seen by the THS7001

amplifier IC on the EVM will be ½ the source signal voltage applied to the EVM

input connector.

10) Verify the output signal on the oscilloscope using a high-impedance probe

— a voltage gain of approximately 2.5 to 1 should be observed.

1-10

General Information

Page 17

1.7 THS7001 EVM Performance

Figure 1–5 shows the typical frequency and phase response the THS7001

EVM preamplifier with ±15-V supplies and Figure 1–6 shows the typical

frequency and phase response of the THS7001 EVM preamplifier with ±5-V

supplies. Typical –3 dB bandwidth of the preamplifier with a ±15-V power

supply is 100 MHz and 90 MHz with a ±5-V power supply.

Figure 1–5.THS7001 EVM Preamplifier Response, VCC = ±15 V

7

Amplitude

6

THS7001 EVM Performance

60

30

5

4

3

2

Output Amplitude – dB

1

VO = 0.4 Vp–p

0

RL = 150 Ω

–1

100k 1M 10M 100M

Phase

f – Frequency – Hz

Figure 1–6.THS7001 EVM Preamplifier Response, VCC = ±5 V

7

6

5

4

3

Amplitude

Phase

500M

0

–30

–60

–90

–120

–150

–180

60

30

0

–30

–60

Output Phase – °

2

Output Amplitude – dB

1

VO = 0.4 Vp–p

0

RL = 150 Ω

–1

100k 1M 10M 100M

f – Frequency – Hz

General Information

500M

–90

–120

–150

–180

Output Phase – °

1-11

Page 18

THS7001 EVM Performance

Figure 1–7 shows the typical frequency and phase response of the THS7001

EVM PGA with ±15-V supplies and Figure 1–8 shows the typical frequency

and phase response of the THS7001 EVM PGA with ±5-V supplies. This data

was collected with the gain set to +2 dB. Typical –3 dB bandwidth is 70 MHz

with a ±5-V power supply and 80 MHz with a ±15-V power supply.

Figure 1–7.THS7001 EVM PGA Response, VCC = ±15 V

4

360

3

Amplitude

2

1

0

–1

Output Amplitude – dB

–2

–3

–4

100k 1M 10M 100M

Phase

VO = 0.4 Vp–p

RL = 150 Ω

f – Frequency – Hz

Figure 1–8.THS7001 EVM PGA Response, VCC = ±5 V

4

3

2

1

Amplitude

500M

315

270

225

180

135

90

45

0

360

315

270

225

Output Phase – °

1-12

0

–1

Output Amplitude – dB

–2

–3

–4

100k 1M 10M 100M

Phase

VO = 0.4 Vp–p

RL = 150 Ω

f – Frequency – Hz

180

135

90

45

0

500M

General Information

Output Phase – °

Page 19

THS7001 EVM Performance

Figure 1–9 shows the typical frequency and phase response of the THS7001

EVM preamplifier + PGA with ±15-V supplies and Figure 1–10 shows the

typical frequency and phase response of the THS7001 EVM preamplifier +

PGA with ±5-V supplies. This data was collected with the preamplifier directly

driving the PGA input. The PGA was set to a gain of +2 dB. Typical –3 dB

bandwidth is 70 MHz with a ±5-V power supply and 80 MHz with a ±15-V

power supply.

Figure 1–9.THS7001 EVM Preamplifier + PGA Response, VCC = ±15 V

10

315

9

8

7

6

5

Output Amplitude – dB

4

3

100k 1M 10M 100M

Amplitude

Phase

VO = 0.4 Vp–p

RL = 500 Ω

500M

f – Frequency – Hz

Figure 1–10. THS7001 EVM Preamplifier + PGA Response, VCC = ±5 V

10

9

8

7

6

Amplitude

Phase

270

225

180

135

90

45

0

315

270

225

180

135

Output Phase – °

5

Output Amplitude – dB

4

VO = 0.4 Vp–p

RL = 500 Ω

3

100k 1M 10M 100M

f – Frequency – Hz

90

45

0

500M

Output Phase – °

General Information

1-13

Page 20

General High-Speed Amplifier Design Considerations

1.8 General High-Speed Amplifier Design Considerations

The THS7001 EVM layout has been designed and optimized for use with

high-speed signals and can be used as an example when designing THS7001

applications. Careful attention has been given to component selection,

grounding, power supply bypassing, and signal path layout. Disregard of these

basic design considerations could result in less than optimum performance of

the THS7001 IC.

Surface-mount components were selected because of the extremely low lead

inductance associated with this technology. Also, because surface mount

components are physically small, the layout can be very compact. This helps

minimize both stray inductance and capacitance.

Tantalum power supply bypass capacitors (C4, C5, and C21) at the power

input pads help supply currents for rapid, large signal changes at the amplifier

output. The 0.1 µF power supply bypass capacitors (C1 1, C12, C18, and C19)

were placed as close as possible to the IC power input pins in order to keep

the PCB trace inductance to a minimum. This improves high-frequency

bypassing and reduces harmonic distortion.

A proper ground plane on both sides of the PCB should always be used with

high-speed circuit design. This provides low-inductive ground connections for

return current paths. In the area of the preamplifier input pins, however, the

ground plane was removed to minimize stray capacitance and reduce ground

plane noise coupling into these pins. This is especially important for the

inverting pin while the amplifier is operating in the noninverting mode. Because

the voltage at this pin swings directly with the noninverting input voltage, any

stray capacitance would allow currents to flow into the ground plane, causing

possible gain error and/or oscillation. Capacitance variations at the amplifier

IC input pin of less than 1 pF can significantly affect the response of the

amplifier.

In general, it is always best to keep signal lines as short and as straight as

possible. Sharp 90_ corners should generally be avoided — round corners or

a series of 45_ bends should be used, instead. Stripline techniques should

also be incorporated when signal lines are greater than 1 inch in length. These

traces should be designed with a characteristic impedance of either 50 Ω or

75 Ω, as required by the application. Such signal lines should also be properly

terminated with an appropriate resistor.

Finally , proper termination of all inputs and outputs should be incorporated into

the layout. Unterminated lines, such as coaxial cable, can appear to be a

reactive load to the amplifier IC. By terminating a transmission line with its

characteristic impedance, the amplifier’s load then appears to be purely

resistive, and reflections are absorbed at each end of the line. Another

advantage of using an output termination resistor is that capacitive loads are

isolated from the amplifier output. This isolation helps minimize the reduction

in amplifier phase-margin and improves the amplifier stability for improved

performance such as reduced peaking and settling times.

1-14

General Information

Page 21

General PowerPADt Design Considerations

1.9 General PowerPADt Design Considerations

The THS7001 IC is mounted in a special package incorporating a thermal pad

that transfers heat from the IC die directly to the PCB. The PowerP ADpackage

is constructed using a downset leadframe. The die is mounted on the

leadframe but is electrically isolated from it. The bottom surface of the lead

frame is exposed as a metal thermal pad on the underside of the package and

makes physical contact with the PCB. Because this thermal pad is in direct

physical contact with both the die and the PCB, excellent thermal performance

can be achieved by providing a good thermal path away from the thermal pad

mounting point on the PCB.

Although there are many ways to properly heatsink this device, the following

steps illustrate the recommended approach as used on the THS7001 EVM,

which is built on a multilayer PCB with an internal ground plane.

1) Prepare the PCB with a top side etch pattern as shown in Figure 1–11.

There should be etch for the leads as well as etch for the thermal pad.

Figure 1–11. PowerPAD PCB Etch and Via Pattern

Thermal pad area (0.12 x 0.17) with 8 vias

(Via diameter = 13 mils)

2) Place 8 holes in the area of the thermal pad. These holes should be 13 mils

in diameter. They are kept small so that solder wicking through the holes

is not a problem during reflow.

3) Additional vias under the package, but outside the thermal pad area, will

improve heat transfer but are not required. These holes should be 25 mils

in diameter. They may be larger because they are not in the area to be

soldered so that wicking is not a problem.

4) Connect all holes, the 8 within the thermal pad area and any others outside

the pad area, to the internal ground plane.

5) When connecting these holes to the ground plane, do not use the typical

web or spoke via connection methodology . Web connections have a high

thermal resistance connection that is useful for slowing the heat transfer

during soldering operations. This makes the soldering of vias that have

plane connections easier. However, in this application, low thermal

resistance is desired for the most efficient heat transfer. Therefore, the

holes under the THS7001 package should make their connection to the

internal ground plane with a complete connection around the entire

circumference of the plated through hole.

General Information

1-15

Page 22

General PowerPADt Design Considerations

6) The top-side solder mask should leave exposed the terminals of the

package and the thermal pad area with its holes. Any larger holes outside

the thermal pad area, but still under the package, should be covered with

solder mask.

7) Apply solder paste to the exposed thermal pad area and all of the

operational amplifier terminals.

8) With these preparatory steps in place, the THS7001 is simply placed in

position and run through the solder reflow operation as any standard

surface-mount component. This results in a part that is properly installed.

The actual thermal performance achieved with the THS7001 in its PowerP AD

package depends on the application. In the example above, if the size of the

internal ground plane is approximately 3 inches × 3 inches, then the expected

thermal coefficient, θ

power dissipation is shown in Figure 1–12 and is calculated by the following

formula:

T

MAX–TA

PD+

ǒ

q

JA

Where:

P

= Maximum power dissipation of THS7001 (watts)

D

T

= Absolute maximum junction temperature (150°C)

MAX

T

= Free-ambient air temperature (°C)

A

θ

= θ

JA

JC +

θ

CA

θJC= Thermal coefficient from die junction to case (1.4 °C/W)

θCA= Thermal coefficient from case to ambient air (°C/W)

, is about 32.6_C/W. For a given θJA, the maximum

JA

Ǔ

Figure 1–12. Maximum Power Dissipation vs Free-Air Temperature

MAXIMUM POWER DISSIPATION

vs

FREE-AIR TEMPERATURE

9

8

7

6

5

4

3

2

Maximum Power Dissipation – W

θJA = 74.4°C/W

1

2 oz Trace and Copper Pad

without Solder

0

–40 –20 0 20 80 1006040

TA – Free-Air Temperature – °C

Tj = 150°C

θJA = 32.6°C/W

2 oz Trace and

Copper Pad

with Solder

1-16

General Information

Page 23

General PowerPADt Design Considerations

Even though the THS7001 EVM PCB is different from the one in the example

above, the results should give an idea of how much power can be dissipated

by the PowerP AD IC package. The THS7001 EVM is a good example of proper

thermal management when using PowerPAD-mounted devices.

Correct PCB layout and manufacturing techniques are critical for achieving

adequate transfer of heat away from the PowerP AD IC package. More details

on proper board layout can be found in the

Amplifier

data sheet (SLOS214). For more general information on the

THS7001 Programmable-Gain

PowerPAD package and its thermal characteristics, see the Texas

Instruments Technical Brief,

PowerPAD Thermally Enhanced Package

(SLMA002).

General Information

1-17

Page 24

THS7001 EVM Specifications

1.10 THS7001 EVM Specifications

Supply voltage range, ±V

Supply current, I

Input voltage, V

I

CC

CC

Output drive, THS7001 Preamplifier, I

Output drive, THS7001 PGA, I

O

O

±5 V to ±15 V. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Continuous total power dissipation at TA = 25°C 3.8 W, max. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

For complete THS7001 amplifier IC specifications and parameter measurement information, and additional application information, see the THS7001

data sheet, TI Literature Number SLOS214.

12 mA, typ. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

±VCC, max. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

95 mA, typ. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

50 mA, typ. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-18

General Information

Page 25

Chapter 2

Reference

This chapter includes a parts list and PCB layout illustrations for the THS7001

EVM.

T opic Page

2.1 THS7001 Dual Differential Line Drivers and Receivers

EVM Parts List

2.2 THS7001 EVM Board Layouts 2–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Reference

2-1

Page 26

THS7001 Programmable-Gain Amplifier EVM Parts List

2.1 THS7001 Programmable-Gain Amplifier EVM Parts List

Table 2–1.THS7001 EVM Parts List

Reference Description Size Qty

C4, C5, C21 CAPACITOR, 6.8 µF, 35V, 20%, TANTALUM, SM 3 (SPRAGUE) 293D685X9035D2T

C9 – C15,

C17 – C19

L1, L2 INDUCTOR, 0.22 µH AXIAL, THRU HOLE 2 (DELEVAN) DN41221/

J5, J6, J9 CONNECTOR, BNC 50 OHM VERTICAL PC MOUNT

J1 – J4 JACK, BANANA RECEPTACLE, FOR 0.025″ DIA.

JP1 – JP3 HEADER, 3 PIN, 0.1″ CTRS., 0.025″ SQ. PINS 3 (DIGI–KEY) S1021–36–ND

P1 – P3 SHORTING JUMPERS, 0.1″ CTRS, FOR 0.025″ SQ.

SW1 6PST DIP SWITCH

R6 RESISTOR, 0 Ω, 1/8 W, 1% SM 0805 1

R18, R31,

R41

R5, R9 RESISTOR, 49.9 Ω, 1/8 W, 1% SM 1206 2

R44 RESISTOR, 100 Ω, 1/8 W, 1% SM 1206 1

R23, R25,

R27, R29

R7, R8 RESISTOR, 499 Ω, 1/10 W, 1% SM 0805 2

R24, R26,

R28, R30

R32, R42 RESISTOR, 4.7 K Ω, 1/10 W, 5% SM 0805 2

U1 IC, THS7001CPWP 1 (TI) THS7001CPWP

TP2 – TP8 TEST POINT, (RED) 7 (F ARNELL) 240-345

TP1 TEST POINT, (BLACK) 1 (FARNELL) 240-333

R1, R2, R20 RESISTOR, X OHMS, SM

C3, C6

C7, C8

PCB1 PCB, THS7001 EVM (SLOP250) 1

†

The values of these components are to be determined by the user in accordance with the application requirements.

CAPACITOR, 0.1 µF, CERAMIC, 10%, SM 0805 10 (MuRata) GRM40–X7R104K25

JACK, THRU HOLE

HOLE

PINS

(CTS 219 NST Series Gold Finish)

RESISTOR, 49.9 Ω, 1/10 W, 1% SM 0805 3

RESISTOR, 330 Ω 1/10 W , 5% SM 0805 4

RESISTOR, 3.3 K Ω, 1/10 W, 5% SM 0805 4

†

CAPACITOR, X µF, 10% CERAMIC

4–40 THREAD HEX STANDOFFS 0.625” LENGTH,

0.250” OD

4–40 THREAD HEX SCREWS 4

†

0805 3

0805 4

Manufacturer/Distributor

Part Number

(DIGI-KEY) DN41221-ND

3 (MOUSER) 523–31–5329

4 (NEWARK) 35F865

3

1 (DIGI–KEY) CT2196MST–ND

4 (MOUSER) 534–1804

2-2

Reference

Page 27

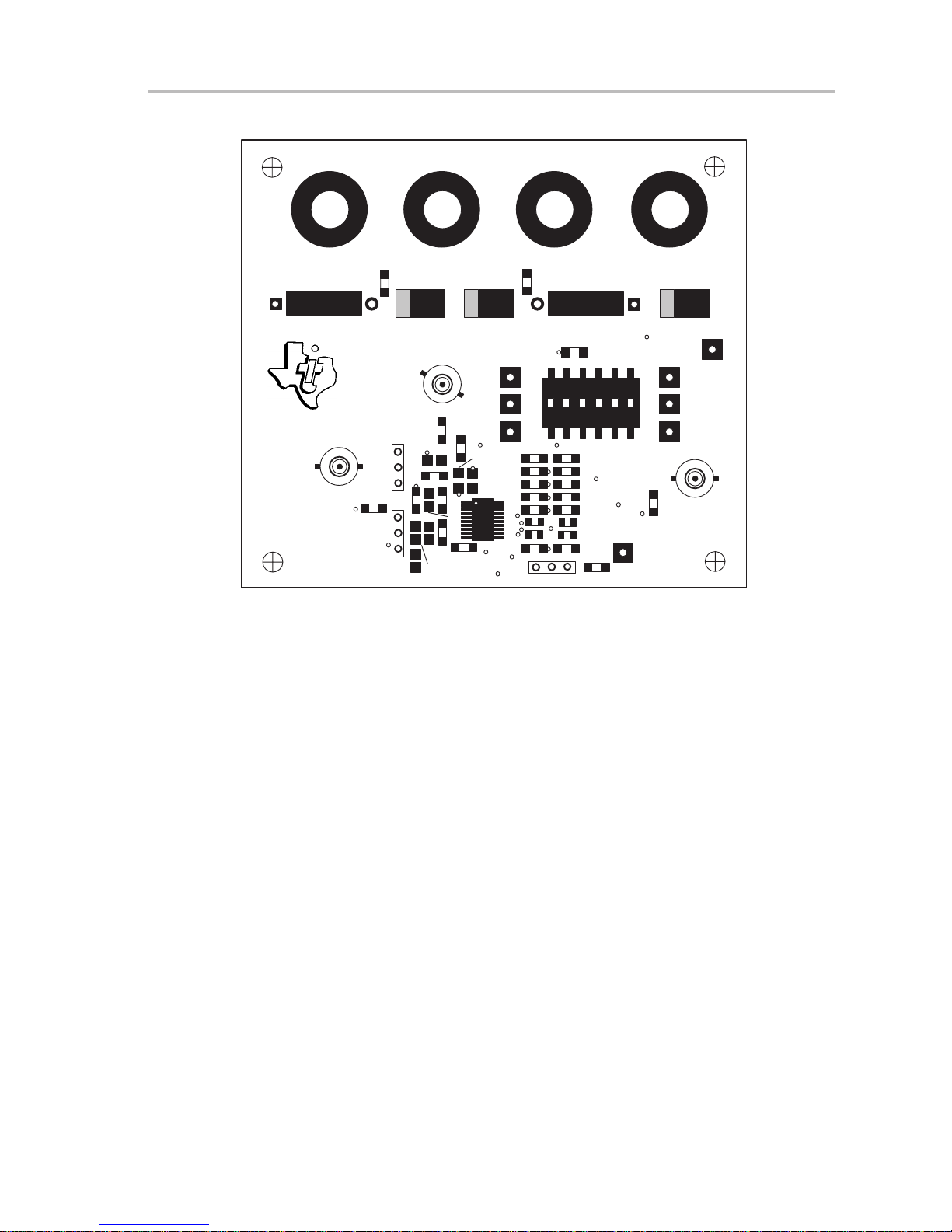

2.2 THS7001 EVM Board Layouts

Board layout examples of the THS7001 EVM PCB are shown in the following

illustrations. They are not to scale and appear here only as a reference.

Figure 2–1.THS7001 EVM PC Board: Top Assembly

THS7001 EVM Board Layouts

Figure 2–2.THS7001 EVM PC Board: Top Layer

Reference

2-3

Page 28

THS7001 EVM Board Layouts

Figure 2–3.THS7001 EVM PC Board: Bottom Layer (Top VIew)

2-4

Reference

Loading...

Loading...