查询THS3112供应商

LOW-NOISE, HIGH-SPEED CURRENT FEEDBACK AMPLIFIERS

THS3112

THS3115

SLOS385 – SEPTEMBER 2001

FEATURES

Low Noise

D

– 2.9 pA/√Hz

– 10.8 pA/√Hz

– 2.2 nV/√Hz

Noninverting Current Noise

Inverting Current Noise

Voltage Noise

D Wide Supply Voltage Range ±5 V to ±15 V

D Wide Output Swing

– 25 V

Supply

Output Voltage, R

PP

= 100 Ω, ±15-V

L

D High Output Current, 150 mA (Min)

D High Speed

– 110 MHz (–3 dB, G=1, ±15 V)

– 1550 V/µs Slew Rate (G = 2, ±15 V)

D Low Distortion, G = 2

– -78 dBc (1 MHz, 2 V

, 100-Ω load)

PP

D Low Power Shutdown (THS3115)

– 300-µA Shutdown Quiescent Current Per

Channel

D Thermal Shutdown and Short Circuit

Protection

D Standard SOIC, SOIC PowerP AD , and

TSSOP PowerP AD Package

D Evaluation Module Available

APPLICATIONS

Communication Equipment

D

D Video Distribution

D Motor Drivers

D Piezo Drivers

DESCRIPTION

The THS3112/5 are low-noise, high-speed current

feedback amplifiers, ideal for any application requiring

high output current. The low noninverting current noise

of 2.9 pA/√Hz

pA/√Hz

signal resolution. The THS3112/5 can operate from

±5-V to ±15-V supply voltages, while drawing as little as

4.5 mA of supply current per channel. It offers low

–78-dBc total harmonic distortion driving 2 V

100-Ω load. The THS3115 features a low power

shutdown mode, consuming only 300-µA shutdown

quiescent current per channel. The THS3112/5 is

packaged in a standard SOIC, SOIC PowerP AD, and

TSSOP PowerPAD packages.

and the low inverting current noise of 10.8

increase signal to noise ratios for enhanced

into a

PP

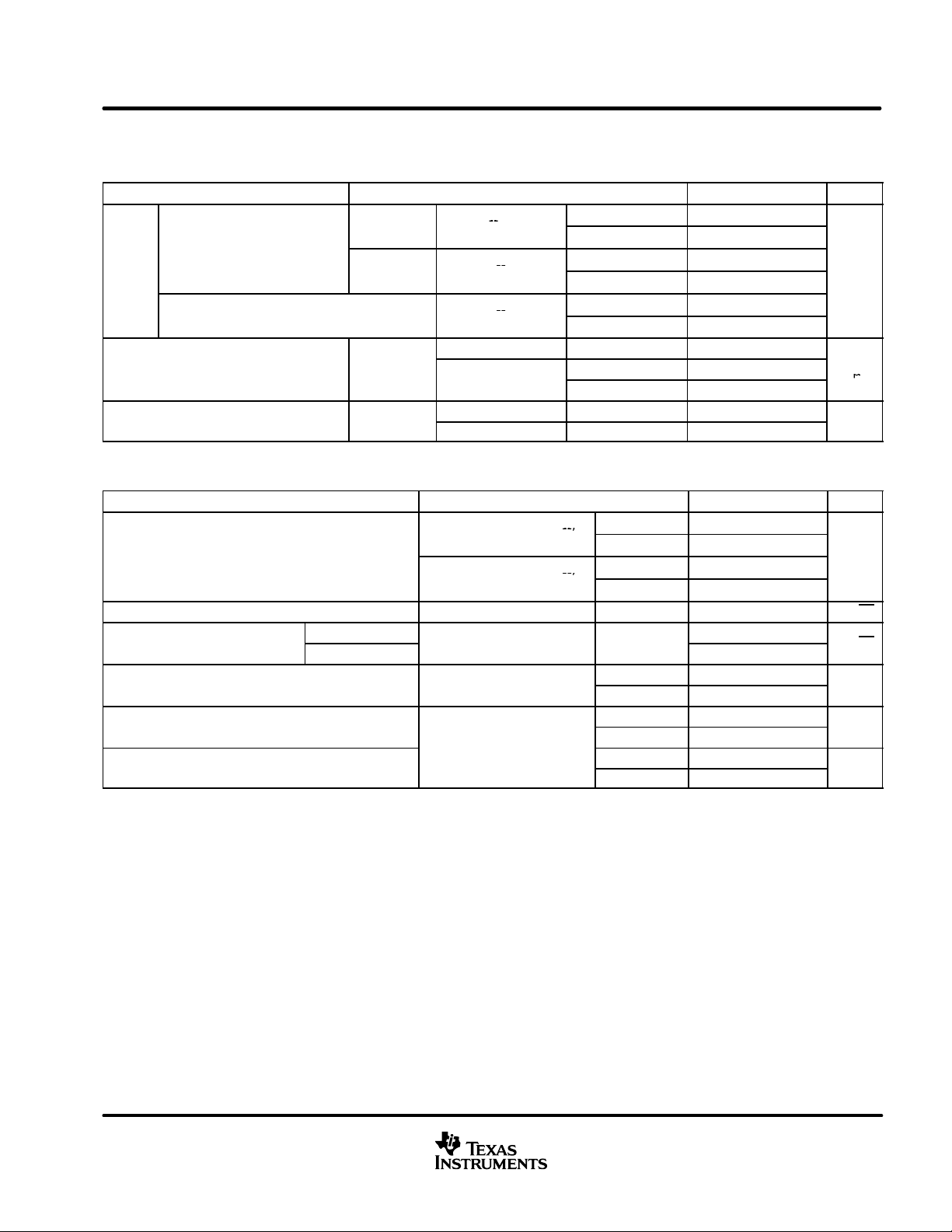

VOLTAGE NOISE AND CURRENT NOISE

100

Hz

Hz

nV/

pA/

10

– Voltage Noise –

– Current Noise –

n

I

V

PowerPAD is a trademark of Texas Instruments.

PRODUCTION DATA information is current as of publication date.

Products conform to specifications per the terms of Texas Instruments

standard warranty. Production processing does not necessarily include

testing of all parameters.

V

n

n

1

10

Please be aware that an important notice concerning availability, standard warranty, and use in critical applications of

Texas Instruments semiconductor products and disclaimers thereto appears at the end of this data sheet.

vs

FREQUENCY

VCC = ±5 V to ±15 V

TA = 25°C

I

n–

I

n+

100

1 K

f – Frequency – Hz

10 K

100 K

THS3112

SOIC (D) AND

SOIC PowerPAD

(TOP VIEW)

1 OUT

1 IN–

1 IN+

V

CC–

1

2

3

4

www.ti.com

(DDA) PACKAGE

V

8

7

6

5

CC+

2 OUT

2 IN–

2 IN+

THS3115

1 OUT

1 IN–

1 IN+

V

CC–

N/C

GND

N/C

SOIC (D) AND

(TOP VIEW)

1

14

2

13

3

12

4

11

5

10

6

7

9

8

V

CC+

2 OUT

2 IN–

2 IN+

N/C

SHUTDOWN

N/C

TSSOP PowerPAD (PWP) PACKAGE

Copyright 2001, Texas Instruments Incorporated

1

THS3112

THS3112EVM

THS3115

SLOS385 – SEPTEMBER 2001

T

A

0°C to 70°C THS3112CD THS3112CDDA THS3115CD THS3115CPWP

–40°C to 85°C THS3112ID THS3112IDDA THS3115ID THS3115IPWP

SOIC-8

(D)

AVAILABLE OPTIONS

PACKAGED DEVICE

SOIC-8 PowerPAD

(DDA)

SOIC-14

(D)

TSSOP-14

(PWP)

EVALUATION

MODULES

THS3112EVM

THS3115EVM

absolute maximum ratings over operating free-air temperature (unless otherwise noted)

Supply voltage, V

Input voltage ± V

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CC+

to V

CC–

†

33 V. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CC

Output current (see Note 1) 275 mA. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Differential input voltage ± 4 V. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Maximum junction temperature 150°C. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Total power dissipation at (or below) 25°C free-air temperature See Dissipation Ratings Table. . . . . . . . . . .

Operating free-air temperature, T

: Commercial 0°C to 70°C. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A

Industrial –40°C to 85°C. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Storage temperature, T

: Commercial –65°C to 125°C. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

stg

Industrial –65°C to 125°C. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Lead temperature 1,6 mm (1/16 inch) from case for 10 seconds 300°C. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

†

Stresses beyond those listed under “absolute maximum ratings” may cause permanent damage to the device. These are stress ratings only, and

functional operation of the device at these or any other conditions beyond those indicated under “recommended operating conditions” is not

implied. Exposure to absolute-maximum-rated conditions for extended periods may affect device reliability.

NOTE 1: The THS3112 and THS31 15 may incorporate a PowerP AD on the underside of the chip. This acts as a heatsink and must be connected

to a thermally dissipating plane for proper power dissipation. Failure to do so may result in exceeding the maximum junction temperature

which could permanently damage the device. See TI Technical Brief SLMA002 for more information about utilizing the PowerPAD

thermally enhanced package.

DISSIPATION RATING TABLE

PACKAGE

D-8 95°C/W

DDA 67°C/W 1.87 W

D-14 66.6°C/W

PWP 37.5°C/W 3.3 W

‡

This data was taken using the JEDEC proposed high-K test PCB.

For the JEDEC low-K test PCB, the θJA is168°C/W for the D-8

package and 122.3°C/W for the D-14 package.

θ

JA

‡

‡

TA = 25°C

POWER RATING

1.32 W

1.88 W

recommended operating conditions

Supply voltage, V

Operating free-air temperature, T

Shutdown pin input levels, relative to the GND pin

2

CC+

to V

CC–

MIN NOM MAX UNIT

Dual supply ±5 ±15

Single supply 10 30

A

C-suffix 0 70

I-suffix –40 85

High level (device shutdown) 2

Low level (device active) 0.8

www.ti.com

V

°C

V

R

F

kΩ,

R

F

750 Ω,

R

F

750 Ω,

SR

Slew rate (see Note 2), G8

R

680 Ω

V/µs

G 2, R

F

680 Ω,

G 2, R

F

680 Ω,

G = 2

f = 1 MHz

G

R

150 Ω

40 IRE modulation

THS3112

THS3115

SLOS385 – SEPTEMBER 2001

electrical characteristics over recommended operating free-air temperature range, TA = 25°C,

= ±15 V, RF = 750 Ω, RL = 100 Ω (unless otherwise noted)

V

CC

dynamic performance

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

RF = 1 kΩ,

RL = 100 Ω

Small-signal bandwidth (–3 dB)

BW RL = 100 Ω

Bandwidth (0.1 dB)

SR Slew rate (see Note 2), G=8

t

s

NOTE 2: Slew rate is defined from the 25% to the 75% output levels.

Settling time to 0.1%

G = 2

=

F

G = –1

1

G = 1

RF = 750 Ω,

G = 2

RF = 750 Ω,

G = 2

VO = 10 V

VO = 5 V

VO = 2 V

VO = 5 V

noise/distortion performance

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

G = 2, RF = 680 Ω,

VCC = ±15 V, f = 1 MHz

THD Total harmonic distortion

V

n

I

n

Input voltage noise VCC = ±5 V, ±15 V f = 10 kHz 2.2 nV/√Hz

Input current noise

Crosstalk

Differential gain error

Differential phase error

Noninverting Input

Inverting Input

G = 2, RF = 680 Ω,

VCC = ±5 V, f = 1 MHz

VCC = ±5 V, ±15 V f = 10 kHz

G = 2, f = 1 MHz,

,

VO = 2 Vpp

= 2,

40 IRE modulation

±100 IRE Ramp

NTSC and PAL

PP

PP

PP

PP

L

=

VCC = ±5 V 95

VCC = ±15 V 110

VCC = ±5 V 103

VCC = ±15 V 110

VCC = ±5 V 25

VCC = ±15 V 48

VCC = ±15 V 1550

VCC = ±5 V 820

VCC = ±15 V 1300

VCC = ±5 V 50

VCC = ±15 V 63

V

= 2 V –78

O(PP)

V

= 8 V –75

O(PP)

V

= 2 V –76

O(PP)

V

= 6 V –74

O(PP)

VCC = ±5 V –67

,

VCC = ±15 V –67

VCC = ±5 V 0.01%

VCC = ±15 V 0.01%

VCC = ±5 V 0.011°

VCC = ±15 V 0.011°

2.9

10.8

MHz

V/µs

dBc

pA/√Hz

dBc

ns

www.ti.com

3

THS3112

V

IO

V

±15 V

V

CC

CC

V

CC

V

CC

±15 V

V

±5 V

V

±15 V

THS3115

SLOS385 – SEPTEMBER 2001

electrical characteristics over recommended operating free-air temperature range, TA = 25°C,

= ±15 V, RF = 750 Ω, RL = 100 Ω (unless otherwise noted) (continued)

V

CC

dc performance

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

Input offset voltage

V

IO

I

IB

Z

OL

Channel offset voltage matching

Offset drift TA = full range 10 µV/°C

– Input bias current

+ Input bias current

Input offset current

Open loop transimpedance

VCC = ±5 V,

=

CC

V

= ±5 V,

= ±5 V,

VCC = ±15 V

VCC = ±5 V,

VCC = ±15 V

TA = 25°C 3 8

TA = full range 13

TA = 25°C 1 3

TA = full range 4

TA = 25°C 23

TA = full range 30

TA = 25°C 0.33 2

TA = full range 3

TA = 25°C 4 22

TA = full range 30

RL = 1 kΩ, 1 MΩ

mV

µA

input characteristics

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

V

ICR

CMRR Common-mode rejection ratio

R

I

C

i

Input common-mode voltage range

Input resistance

Input capacitance 2 pF

output characteristics

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

V

O

I

O

r

o

Output voltage swing

Output current drive

Output resistance open loop 14 Ω

G = 4, VI = 1 V,

=

CC

G = 4, VI = 3.4 V,

=

CC

G = 4, VI = 1.025 V,

VCC = ±5 V

G = 4, VI = 3.4 V,

VCC = ±15 V

VCC = ±5 V

VCC = ±15 V

V

= ±5 V,

= ±5 V,

VI = –2.5 V to 2.5 V

= ±15 V,

=

V

VI = –12.5 V to 12.5 V

+ Input 1.5 MΩ

– Input

,

RL = 1 kΩ, TA = 25°C 3.9

RL = 100 Ω,

RL = 1 kΩ, TA = 25°C 13.5

RL = 100 Ω,

RL = 25 Ω,

RL = 25 Ω,

TA = full range

TA = 25°C 56 62

TA = full range 54

TA = 25°C 63 67

TA = full range 60

TA = 25°C 3.6 3.8

TA = full range 3.4

TA = 25°C 12.2 13.3

TA = full range 12

TA = 25°C

±2.5 ±2.7

±12.5 ±12.7

15 Ω

100 130

175 270

V

dB

V

mA

4

www.ti.com

THS3112

THS3115

SLOS385 – SEPTEMBER 2001

electrical characteristics over recommended operating free-air temperature range, TA = 25°C,

= ±15 V, RF = 750 Ω, RL = 100 Ω, GND = 0 V (unless otherwise noted) (continued)

V

CC

power supply

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

VCC = ±5 V

I

CC

PSRR Power supply rejection ratio

Quiescent current (per amplifier)

VCC = ±15 V

VCC = ±5 V

VCC = ±15 V

shutdown characteristics (THS3115 only)

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

I

CC(SHDN)

t

DIS

t

EN

I

IL(SHDN)

I

IH(SHDN)

NOTE 3: Disable/enable time is defined as the time from when the shutdown signal is applied to the SHDN pin to when the supply current has

Shutdown quiescent current (per channel) V

Disable time (see Note 3) VCC = ±15 V 0.1 µs

Enable time (see Note 3) VCC = ±15 V 0.4 µs

Shutdown pin input bias current for power up VCC = ±5 V, ±15 V, V

Shutdown pin input bias current for power down VCC = ±5 V, ±15 V, V

reached half of its final value.

= 0 V, VCC = ±5 V, ±15 V 0.3 0.45 mA

GND

TA = 25°C 4.4 5.5

TA = full range 6

TA = 25°C 4.9 6.5

TA = full range 7.5

TA = 25°C 53 60

TA = full range 50

TA = 25°C 68 74

TA = full range 66

= 0 V 18 25 µA

(SHDN)

= 3.3 V 110 130 µA

(SHDN)

mA

dB

TYPICAL CHARACTERISTICS

Table of Graphs

FIGURE

Small signal closed loop gain vs Frequency 1 – 11, 13, 14

Gain and phase vs Frequency 12

Small signal closed loop noninverting gain vs Frequency 15, 16

Small signal closed loop inverting gain vs Frequency 17, 18

Small and large signal output vs Frequency 19, 20

Harmonic distortion

Vn, I

n

CMRR Common-mode rejection ratio vs Frequency 26

PSRR Power supply rejection ratio vs Frequency 27

Crosstalk vs Frequency 28

Z

o

SR Slew rate vs Output voltage step 30

V

IO

I

B

V

O

I

CC

Voltage noise and current noise vs Frequency 25

Output impedance vs Frequency 29

Input offset voltage

Input bias current vs Free-air temperature 33

Output voltage vs Output current 34, 35

Output voltage headroom vs Output current 36

Supply current (per channel) vs Supply voltage 37

Shutdown response 38

vs Frequency 21, 22

vs Peak–to–peak output voltage

vs Free-air temperature 31

vs Common-mode input voltage

23, 24

32

www.ti.com

5

THS3112

THS3115

SLOS385 – SEPTEMBER 2001

TYPICAL CHARACTERISTICS

SMALL SIGNAL CLOSED LOOP GAIN

vs

3

0

–3

–6

–9

–12

Small Signal Closed Loop Gain – dB

–15

0.1 1 10 100 1000

FREQUENCY

RF = 750 Ω

RF = 1.2 kΩ

G = –1,

VCC = ±5 V,

RL = 100 Ω

f – Frequency – MHz

RF = 560 Ω

Figure 1

SMALL SIGNAL CLOSED LOOP GAIN

vs

FREQUENCY

RF = 560 Ω

RF = 750 Ω

G = –4,

VCC = ±5 V,

RL = 100 Ω

1

f – Frequency – MHz

RF = 430 Ω

10 100 1000

Small Signal Closed Loop Gain – dB

15

12

9

6

3

0

–3

0.1

SMALL SIGNAL CLOSED LOOP GAIN

vs

3

0

–3

–6

–9

–12

Small Signal Closed Loop Gain – dB

–15

0.1 1 10 100 1000

FREQUENCY

RF = 750 Ω

RF = 1.2 kΩ

G = –1,

VCC = ±15 V,

RL = 100 Ω

f – Frequency – MHz

RF = 560 Ω

Figure 2

SMALL SIGNAL CLOSED LOOP GAIN

vs

21

18

15

12

9

6

3

Small Signal Closed Loop Gain – dB

0

0.1 1 10 100 1000

FREQUENCY

RF = 430 Ω

RF = 750 Ω

G = –8,

VCC = ±5 V,

RL = 100 Ω

f – Frequency – MHz

RF = 200 Ω

SMALL SIGNAL CLOSED LOOP GAIN

vs

15

12

9

6

3

0

Small Signal Closed Loop Gain – dB

–3

0.1 1 10 100 1000

FREQUENCY

RF = 560 Ω

RF = 750 Ω

G = –4,

VCC = ±15 V,

RL = 100 Ω

f – Frequency – MHz

RF = 430 Ω

Figure 3

SMALL SIGNAL CLOSED LOOP GAIN

vs

21

18

15

12

9

6

3

Small Signal Closed Loop Gain – dB

0

0.1 1 10 100 1000

FREQUENCY

RF = 750 Ω

G = –8,

VCC = ±15 V,

RL = 100 Ω

f – Frequency – MHz

RF = 200 Ω

RF = 430 Ω

Figure 4

SMALL SIGNAL CLOSED LOOP GAIN

vs

FREQUENCY

Small Signal Closed Loop Gain – dB

2

1

0

–1

–2

–3

–4

–5

–6

0.1 1

G = 1,

VCC = ±5 V,

RL = 100 Ω

RF = 750 Ω

RF = 1.1 kΩ

RF = 1 kΩ

10

f – Frequency – MHz

Figure 7

6

100 1000

Figure 5

SMALL SIGNAL CLOSED LOOP GAIN

vs

FREQUENCY

3

0

–3

–6

G = 1,

VCC = ±15 V,

–9

RL = 100 Ω

Small Signal Closed Loop Gain – dB

–12

0.1 1 10 100 1000

RF = 750 Ω

RF = 910 Ω

RF = 1.1 kΩ

f – Frequency – MHz

Figure 8

www.ti.com

Figure 6

SMALL SIGNAL CLOSED LOOP GAIN

vs

FREQUENCY

RF = 1 kΩ

RF = 750 Ω

G = 2,

VCC = ±5 V,

RL = 100 Ω

1

f – Frequency – MHz

RF = 560 Ω

10

100

Small Signal Closed Loop Gain – dB

8

7

6

5

4

3

2

1

0

0.1

Figure 9

1000

THS3112

THS3115

SLOS385 – SEPTEMBER 2001

TYPICAL CHARACTERISTICS

SMALL SIGNAL CLOSED LOOP GAIN

vs

FREQUENCY

RF = 1 kΩ

G = 2,

VCC = ±15 V,

RL = 100 Ω

1

f – Frequency – MHz

RF = 560 Ω

RF = 750 Ω

10 100 1000

Small Signal Closed Loop Gain – dB

9

6

3

0

–3

–6

–9

0.1

Figure 10

SMALL SIGNAL CLOSED LOOP GAIN

vs

FREQUENCY

Small Signal Closed Loop Gain – dB

21

18

15

12

9

6

3

0

0.1

RF = 430 Ω

RF = 750 Ω

G = 8,

VCC = ±5 V,

RL = 100 Ω

1

f – Frequency – MHz

10

RF = 200 Ω

100 1000

Figure 13

SMALL SIGNAL CLOSED LOOP GAIN

vs

15

12

9

6

3

0

Small Signal Closed Loop Gain – dB

–3

0.1 1 10 100 1000

FREQUENCY

RF = 560 Ω

RF = 750 Ω

G = 4,

VCC = ±15 V,

RL = 100 Ω

f – Frequency – MHz

RF = 430 Ω

RF = 1 kΩ

Figure 11

SMALL SIGNAL CLOSED LOOP GAIN

vs

21

18

15

12

9

6

3

Small Signal Closed Loop Gain – dB

0

0.1 1 10 100 1000

FREQUENCY

RF = 750 Ω

RF = 430 Ω

G = 8,

VCC = ±15 V,

RL = 100 Ω

f – Frequency – MHz

RF = 200 Ω

Figure 14

GAIN AND PHASE

vs

FREQUENCY

RF = 560 Ω

RF = 750 Ω

G = 4,

VCC = ±15 V,

RL = 100 Ω

1

f – Frequency – MHz

RF = 430 Ω

RF = 1 kΩ

10

Gain and Phase – dB

15

12

9

6

3

0

–3

0.1

Figure 12

SMALL SIGNAL CLOSED LOOP

NONINVERTING GAIN

vs

RF = 560 Ω

RF = 750 Ω

RF = 1 kΩ

VCC = ±5 V,

RL = 100 Ω

f – Frequency – MHz

FREQUENCY

RF = 250 Ω

20

15

10

5

0

–5

–10

–15

10 100 1000

Small Signal Closed Loop Non Inverting Gain – dB

Figure 15

100 1000

SMALL SIGNAL CLOSED LOOP

NONINVERTING GAIN

vs

RF = 430 Ω

RF = 750 Ω

RF = 1 kΩ

VCC = ±5 V,

RL = 100 Ω

f – Frequency – MHz

FREQUENCY

RF = 200 Ω

21

18

15

12

9

6

3

0

–3

–6

–9

–12

–15

10 100 1000

Small Signal Closed Loop Non Inverting Gain – dB

Figure 16

SMALL SIGNAL CLOSED LOOP

INVERTING GAIN

vs

RF = 560 Ω

RF = 750 Ω

VCC = ±5 V,

RL = 100 Ω

f – Frequency – MHz

FREQUENCY

RF = 430 Ω

21

18

15

12

9

6

3

0

–3

–6

–9

–12

–15

Small Signal Closed Loop Inverting Gain – dB

10 100 1000

Figure 17

www.ti.com

SMALL SIGNAL CLOSED LOOP

INVERTING GAIN

vs

RF = 560 Ω

RF = 750 Ω

VCC = ±15 V,

RL = 100 Ω

f – Frequency – MHz

FREQUENCY

RF = 430 Ω

21

18

15

12

9

6

3

0

–3

–6

–9

–12

–15

Small Signal Closed Loop Inverting Gain – dB

10 100 1000

Figure 18

7

THS3112

THS3115

SLOS385 – SEPTEMBER 2001

TYPICAL CHARACTERISTICS

SMALL AND LARGE SIGNAL OUTPUT

vs

18

)

PP

(V

12

6

0

–6

–12

–18

Small and Large Signal Output – dB

–24

0.1 1 10 100 1000

FREQUENCY

4 V

VCC = ±5 V, G = 2

PP

RF = 680 Ω, RL = 100 Ω

2 V

PP

1.125 V

PP

0.711 V

PP

0.4 V

PP

0.125 V

PP

f – Frequency – MHz

Figure 19

HARMONIC DISTORTION

vs

–20

–40

–60

–80

Harmonic Distortion – dB

–100

5th Harmonic

–120

0.1 1 10 100

FREQUENCY

G = 2,

RF = 680 Ω,

RL 100 Ω,

VCC = ±15 V,

V

= 2 V

O(PP)

f – Frequency – MHz

2nd Harmonic

3rd Harmonic

4th Harmonic

SMALL AND LARGE SIGNAL OUTPUT

vs

4 V

PP

f – Frequency – MHz

FREQUENCY

VCC = ±15 V, G = 2

RF = 680 Ω, RL = 100 Ω

2 V

PP

1.125 V

PP

0.711 V

PP

0.4 V

PP

0.125 V

PP

18

)

PP

12

6

0

–6

–12

–18

Small and Large Signal Output – dB (V

–24

0.1 1 10 100 1000

Figure 20

HARMONIC DISTORTION

vs

PEAK-TO-PEAK OUTPUT VOLTAGE

–10

G = 2,

RF = 680 Ω,

RL 100 Ω,

–30

VCC = ±5 V,

f = 1MHz

–50

2nd Harmonic

3rd Harmonic

–70

Harmonic Distortion – dB

–90

–110

012345678

VPP – Peak-to-Peak Output Voltage – V

2nd Harmonic

4th Harmonic

5th Harmonic

HARMONIC DISTORTION

vs

FREQUENCY

–20

G = 2,

RF = 680 Ω,

RL 100 Ω,

VCC = ±5 V,

–40

VO = 2 V

PP

Harmonic Distortion – dB

–60

–80

–100

–120

3rd Harmonic

4th Harmonic

5th Harmonic

0.1 1 10 100

f – Frequency – MHz

2nd Harmonic

Figure 21

HARMONIC DISTORTION

vs

PEAK-TO-PEAK OUTPUT VOLTAGE

–70

2nd Harmonic

–80

–90

–100

Harmonic Distortion – dB

–110

0123456789

VPP – Peak-to-Peak Output Voltage – V

3rd Harmonic

5th Harmonic

4th Harmonic

G = 2,

RF = 680 Ω,

RL 100 Ω,

VCC = ±15 V,

f = 1MHz

Figure 22

VOLTAGE NOISE AND CURRENT NOISE

vs

FREQUENCY

Hz

nV/

– Voltage Noise –

V

100

Hz

pA/

10

– Current Noise –

V

n

n

I

1

10

VCC = ±5 V to ±15 V

TA = 25°C

I

n+

n

100

f – Frequency – Hz

I

n–

1 K

10 K

Figure 25

8

100 K

Figure 23

COMMON-MODE REJECTION RATIO

vs

80

70

60

50

40

30

20

10

0

CMRR – Common-Mode Rejection Ratio – dB

0.1 1 10 100

FREQUENCY

VCC = ±15 V

VCC = ±5 V

f – Frequency – MHz

G = 2,

RL 100 Ω,

RF = 1 kΩ

Figure 26

www.ti.com

Figure 24

POWER SUPPLY REJECTION RATIO

vs

70

60

50

PSRR – ±5 V

40

30

20

10

0

PSRR – Power Supply Rejection Ratio – dB

0.1 1 10 100

FREQUENCY

PSRR – ±15 V

f – Frequency – MHz

G = 2,

RL = 100 Ω,

RF = 680 Ω

Figure 27

F

THS3112

THS3115

SLOS385 – SEPTEMBER 2001

TYPICAL CHARACTERISTICS

CROSSTALK

vs

FREQUENCY

0

G = 2,

–10

VCC = ±5 V to ±15 V,

RL = 100 Ω,

–20

RF = 680 Ω

–30

–40

–50

–60

Crosstalk – dBc

–70

–80

–90

–100

0.1 1 10 100 1000

f – Frequency – MHz

Figure 28

INPUT OFFSET VOLTAGE

vs

FREE-AIR TEMPERATURE

0

VCC = ±15 V,

VCM = 0 V,

–1

RL = 100 Ω

–2

–3

–4

– Input Offset Voltage – mV

IO

–5

V

–6

–40 –20 0 20 40 60 80

TA – Free-Air Temperature – °C

OUTPUT IMPEDANCE

vs

100

Ω

10

1

– Output Impedance –

0.1

O

Z

0.01

0.1 1 10 100 1000

FREQUENCY

VCC = ±5 V to ±15 V,

RF = 1 kΩ

f – Frequency – MHz

1800

G = 2

1600

RF = 680 Ω,

RL = 100 Ω,

sµ

1400

TA = 25°C

V/

1200

1000

800

600

SR – Slew Rate –

400

200

0

024681012

Figure 29

INPUT OFFSET VOLTAGE

vs

COMMON-MODE INPUT VOLTAGE

10

5

0

–5

– Input Offset Voltage – mV

–10

IO

V

–15

85

–15 –10 –50 5 1015

VCM – Common-Mode Input Voltage – V

VCC = ±15 V,

TA = 25°C,

RL= 100 Ω

9

8

Aµ

7

6

5

4

VCC = ±5 V, I

3

– Input Bias Current –

2

IB

I

1

0

–40 –20 0 20 40 60 80

SLEW RATE

vs

OUTPUT VOLTAGE STEP

VCC = ±15 V

VCC = ±5 V

VO – Output Voltage Step – V

Figure 30

INPUT BIAS CURRENT

vs

FREE-AIR TEMPERATURE

VCC = ±15 V, I

IB–

VCC = ±5 V, I

TA – Free-Air Temperature – °C

IB+

VCC = ±15 V, I

IB–

IB+

85

Figure 31

OUTPUT VOLTAGE

vs

OUTPUT CURRENT

5

4.5

4

3.5

3

2.5

2

1.5

– Output Voltage – V

O

V

VCC = ±5 V,

1

RF = 750 Ω

0.5

TA = 25°C

0

0 50 100 150 200 250

IO – Output Current – mA

Figure 34

Figure 32

OUTPUT VOLTAGE

vs

15

13.5

12

– Output Voltage – V

10.5

O

V

9

OUTPUT CURRENT

VCC = ±15 V,

RF = 750 Ω

TA = 25°C

0 50 100 150 200 250

IO – Output Current – mA

Figure 35

www.ti.com

Figure 33

OUTPUT VOLTAGE HEADROOM

vs

OUTPUT CURRENT

5

|VCC| – |VO|

4.5

VCC = ±15 V and ±5 V

TA = 25°C

4

G = 4,

3.5

RF = 750 Ω

3

2.5

2

1.5

1

Output Voltage Headroom – |V|

0.5

0

0 50 100 150 200 250

IO – Output Current – |mA|

Figure 36

9

THS3112

THS3115

SLOS385 – SEPTEMBER 2001

TYPICAL CHARACTERISTICS

SUPPLY CURRENT (PER CHANNEL)

vs

SUPPLY VOLTAGE

TA = 85°C

TA = 25°C

TA = –40°C

0 2.5 5 7.5 10 12.5 15

VCC – Supply Voltage – ±V

– Supply Current (Per Channel) – mA

CC

I

16

14

12

10

8

6

4

2

0

Figure 37

SHUTDOWN RESPONSE

5

4

3

2

1

– Output Voltage – V

O

0

V

VCC = ±15 V

G = 8

RF = 330 Ω

RF = 100 Ω

VI = 0.5 VDC

012345678910

t – Time – ns

Figure 38

2

1.5

1

0.5

0

Shutdown Pulse – V

10

www.ti.com

THS3112

THS3115

SLOS385 – SEPTEMBER 2001

MECHANICAL DATA

D (R-PDSO-G**) PLASTIC SMALL-OUTLINE PACKAGE

14 PINS SHOWN

0.050 (1,27)

14

1

0.069 (1,75) MAX

A

0.020 (0,51)

0.014 (0,35)

0.010 (0,25)

0.004 (0,10)

DIM

8

7

PINS **

0.010 (0,25)

0.157 (4,00)

0.150 (3,81)

M

0.244 (6,20)

0.228 (5,80)

Seating Plane

0.004 (0,10)

8

14

0.008 (0,20) NOM

0°–ā8°

16

Gage Plane

0.010 (0,25)

0.044 (1,12)

0.016 (0,40)

A MAX

A MIN

NOTES: A. All linear dimensions are in inches (millimeters).

B. This drawing is subject to change without notice.

C. Body dimensions do not include mold flash or protrusion, not to exceed 0.006 (0,15).

D. Falls within JEDEC MS-012

0.197

(5,00)

0.189

(4,80)

www.ti.com

0.344

(8,75)

0.337

(8,55)

0.394

(10,00)

0.386

(9,80)

4040047/D 10/96

11

THS3112

THS3115

SLOS385 – SEPTEMBER 2001

MECHANICAL INFORMATION

DDA (S–PDSO–G8) Power PADt PLASTIC SMALL-OUTLINE

1,27

85

14

4,98

4,80

0,49

0,35

3,99

3,81

1,68 MAX

M

0,10

6,20

5,84

Seating Plane

Thermal Pad

(See Note D)

0,20 NOM

0°–8°

Gage Plane

0,25

0,89

0,41

1,55

1,40

NOTES: A. All linear dimensions are in millimeters.

B. This drawing is subject to change without notice.

C. Body dimensions do not include mold flash or protrusion not to exceed 0,15.

D. The package thermal performance may be enhanced by bonding the thermal pad to an external thermal plane.

This pad is electrically and thermally connected to the backside of the die and possibly selected leads.

PowerPAD is a trademark of Texas Instruments.

0,13

0,03

0,10

4202561/A 02/01

12

www.ti.com

THS3112

THS3115

SLOS385 – SEPTEMBER 2001

MECHANICAL DATA

PWP (R-PDSO-G**) PowerPAD PLASTIC SMALL-OUTLINE

20 PINS SHOWN

0,65

20

1

1,20 MAX

0,30

0,19

11

4,50

4,30

10

A

0,15

0,05

PINS **

DIM

M

0,10

6,60

6,20

Seating Plane

0,10

1614

Thermal Pad

(See Note D)

20

0,15 NOM

0°–ā8°

Gage Plane

0,25

0,75

0,50

2824

A MAX

A MIN

NOTES: A. All linear dimensions are in millimeters.

B. This drawing is subject to change without notice.

C. Body dimensions do not include mold flash or protrusions.

D. The package thermal performance may be enhanced by bonding the thermal pad to an external thermal plane.

This pad is electrically and thermally connected to the backside of the die and possibly selected leads.

E. Falls within JEDEC MO-153

PowerPAD is a trademark of Texas Instruments Incorporated.

5,10

4,90

5,10

4,90

6,60

6,40

7,90

7,70

9,80

9,60

4073225/F 10/98

www.ti.com

13

IMPORTANT NOTICE

Texas Instruments Incorporated and its subsidiaries (TI) reserve the right to make corrections, modifications,

enhancements, improvements, and other changes to its products and services at any time and to discontinue

any product or service without notice. Customers should obtain the latest relevant information before placing

orders and should verify that such information is current and complete. All products are sold subject to TI’s terms

and conditions of sale supplied at the time of order acknowledgment.

TI warrants performance of its hardware products to the specifications applicable at the time of sale in

accordance with TI’s standard warranty . Testing and other quality control techniques are used to the extent TI

deems necessary to support this warranty . Except where mandated by government requirements, testing of all

parameters of each product is not necessarily performed.

TI assumes no liability for applications assistance or customer product design. Customers are responsible for

their products and applications using TI components. T o minimize the risks associated with customer products

and applications, customers should provide adequate design and operating safeguards.

TI does not warrant or represent that any license, either express or implied, is granted under any TI patent right,

copyright, mask work right, or other TI intellectual property right relating to any combination, machine, or process

in which TI products or services are used. Information published by TI regarding third–party products or services

does not constitute a license from TI to use such products or services or a warranty or endorsement thereof.

Use of such information may require a license from a third party under the patents or other intellectual property

of the third party , or a license from TI under the patents or other intellectual property of TI.

Reproduction of information in TI data books or data sheets is permissible only if reproduction is without

alteration and is accompanied by all associated warranties, conditions, limitations, and notices. Reproduction

of this information with alteration is an unfair and deceptive business practice. TI is not responsible or liable for

such altered documentation.

Resale of TI products or services with statements different from or beyond the parameters stated by TI for that

product or service voids all express and any implied warranties for the associated TI product or service and

is an unfair and deceptive business practice. TI is not responsible or liable for any such statements.

Mailing Address:

Texas Instruments

Post Office Box 655303

Dallas, Texas 75265

Copyright 2002, Texas Instruments Incorporated

Copyright © Each Manufacturing Company.

All Datasheets cannot be modified without permission.

This datasheet has been download from :

www.AllDataSheet.com

100% Free DataSheet Search Site.

Free Download.

No Register.

Fast Search System.

www.AllDataSheet.com

Loading...

Loading...