Page 1

User's Guide

SBOU219–February 2020

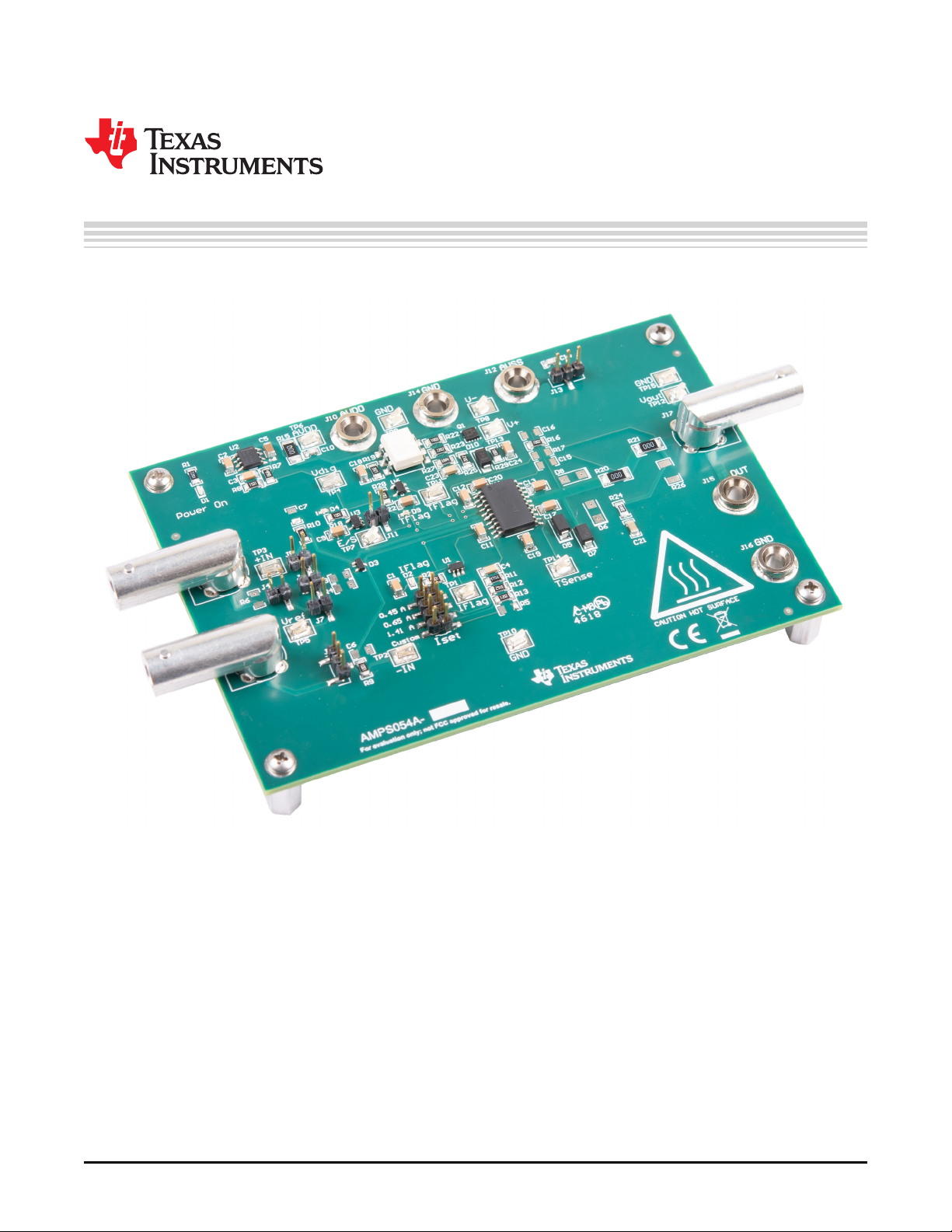

OPA564DWP-EVM

This user’s guide describes the design, operation, and use cases of the OPA564 evaluation module

(EVM) for the DWP package only; this EVM cannot be used with the OPA564 DWD package. This guide

discusses how to set up and configure the board hardware, and describes five different applications this

evaluation module can be used for. Throughout this document, the terms evaluation module, EVM, or

simply board are synonymous with the OPA564DWP-EVM. This document also includes an electrical

schematic, a printed circuit board (PCB) layout drawing, and a parts list for this EVM.

1 Overview...................................................................................................................... 3

1.1 OPA564 Overview .................................................................................................. 3

1.2 General Overview of the OPA564DWP-EVM................................................................... 3

1.3 Related Documentation from Texas Instruments............................................................... 4

2 Hardware...................................................................................................................... 5

2.1 Power Supply........................................................................................................ 5

2.2 Inputs................................................................................................................. 5

2.3 Outputs............................................................................................................... 5

2.4 Jumpers.............................................................................................................. 6

SBOU219–February 2020

Submit Documentation Feedback

Contents

Copyright © 2020, Texas Instruments Incorporated

OPA564DWP-EVM

1

Page 2

www.ti.com

2.5 LEDs.................................................................................................................. 6

2.6 Enable-Disable Feature............................................................................................ 6

2.7 Current Limitation Capability ...................................................................................... 6

3 Configuration Examples..................................................................................................... 7

3.1 Noninverting Amplifier Configuration Setup ..................................................................... 7

3.2 Inverting Amplifier Configuration Setup .......................................................................... 9

3.3 Differential Amplifier Configuration Setup...................................................................... 11

3.4 Improved Howland Current Pump Configuration Setup...................................................... 13

3.5 Bridge-Tied Load Configuration Setup ........................................................................ 15

4 Schematics, PCB Layout, and Bill of Materials......................................................................... 17

4.1 Schematics......................................................................................................... 17

4.2 PCB Layout ........................................................................................................ 18

4.3 Bill of Materials .................................................................................................... 21

List of Figures

1 Noninverting Amplifier Configuration Schematic ........................................................................ 7

2 Noninverting Operation ..................................................................................................... 8

3 Inverting Amplifier Configuration Schematic ............................................................................. 9

4 Inverting Operation......................................................................................................... 10

5 Differential Amplifier Configuration Schematic ......................................................................... 11

6 Differential Operation ...................................................................................................... 12

7 Improved Howland Current Pump Schematic .......................................................................... 13

8 Bridge-Tied Load Schematic.............................................................................................. 15

9 Bridge-Tied Load Operation .............................................................................................. 16

10 OPA564DWP-EVM Schematic .......................................................................................... 17

11 OPA564DWP-EVM, Top Layer .......................................................................................... 19

12 OPA564DWP-EVM Bottom Layer ....................................................................................... 20

1 Related Documentation ..................................................................................................... 4

2 Basic Jumper Functions .................................................................................................... 6

3 Status of the LEDs........................................................................................................... 6

4 Noninverting Configuration ................................................................................................. 7

5 Inverting Configuration ...................................................................................................... 9

6 Differential Configuration .................................................................................................. 11

7 Improved Howland Current Pump Configuration....................................................................... 13

8 Bridge-Tied Load Configuration: Board 1 ............................................................................... 15

9 Bridge-Tied Load Configuration: Board 2 ............................................................................... 16

10 Bill of Materials ............................................................................................................. 21

Trademarks

PowerPAD is a trademark of Texas Instruments.

All other trademarks are the property of their respective owners.

List of Tables

2

OPA564DWP-EVM

Copyright © 2020, Texas Instruments Incorporated

SBOU219–February 2020

Submit Documentation Feedback

Page 3

www.ti.com

1 Overview

1.1 OPA564 Overview

The OPA564 is a low-cost, high-current, operational amplifier (op amp) capable of providing up to 1.5 A of

current to an output load. The high slew rate of this op amp provides 1.3-MHz, full-power bandwidth and

excellent linearity. This monolithic integrated circuit provides high reliability in demanding powerline

communications and motor-control applications.

1.1.1 OPA564 Safety Considerations

The OPA564 op amps can use a power-supply voltage as great as 24 V in single-supply connection, or

±12 V in dual-supply connection, both of which represent a potential difference of 24 V. The possibility for

accidental electrical shock increases with the increased potential difference and the user must take

precautions to avoid contact with the PCB when live voltage is present. If circuit probing is required and

voltages are present, best practice is to apply the one hand rule. Use an insulated probe and only one

hand when probing the live circuit. Keep the other hand away from the circuit and any metal contacts in

the immediate area through that current can flow.

Power op amps can generate a lot of heat under certain operating conditions. This excess heat must be

conducted away from the amplifier in order to maintain correct operation and long life. The DWP package

contains the PowerPAD™ heat sink located on the bottom for this purpose. Still, the device under test

(DUT) might grow hot during the test; therefore, avoid contact with the DUT when the circuit is in use, or

during cool down after use.

Overview

1.2 General Overview of the OPA564DWP-EVM

This DWP package-specific OPA564 evaluation module (EVM), allows users to easily evaluate design

concepts. This EVM is easily configured as a noninverting, inverting, or difference amplifier, as an

improved Howland current pump, or as a BTL (bridge tied load) circuit. BTL requires two EVMs used

concurrently to create this circuit configuration, however. This guide discusses all individual circuit

configurations and hardware setup associated.

This EVM is based on a 5.0-inch × 3.5-inch (12.7-cm × 8.9-cm) PCB that accommodates the 20-lead,

DWP powerPAD package. This EVM cannot be used with the OPA564 DWD package.

The OPA564 can be operated with either a single supply (V+ and ground), or dual supplies (V+ and V–);

therefore, the EVM is designed to be used in either mode. A jumper (J13) sets the supply condition. The

enable-shutdown function and thermal shutdown indicator are functional with either supply arrangement;

shutdown mode is a low current, output disabled mode.

Three LEDs (green, orange, and red) indicate EVM functionality. A green LED (D1) illuminates when V+ is

applied. A red LED (D9) illuminates when the amplifier is in thermal shutdown mode (for approximately 10

µs or longer), and both the red and orange LED (D4) illuminate when the amplifier is set to shutdown

mode (through jumper J11). During normal operation, the yellow and red LEDs are off.

1.2.1 Supply Voltage Considerations for the OPA564DWP-EVM

The OPA564DWP-EVM is designed to be powered by the user’s single or dual, high-current, high-voltage

power supply. In dual-supply configuration, set the minimum V+ and V– levels at ±3.5 V. In single powersupply mode, use a minimum of V+ = 7 V for correct functionality. Do not exceed the maximum supply

voltage of 24 V in single-supply mode (V+), or ±12 V in dual-supply mode.

If required, disable the OPA564 by placing a shunt on jumper J11.

SBOU219–February 2020

Submit Documentation Feedback

Copyright © 2020, Texas Instruments Incorporated

OPA564DWP-EVM

3

Page 4

Overview

1.3 Related Documentation from Texas Instruments

This user's guide is available from the TI web site under literature number SBOU219. Any letter appended

to the literature number corresponds to the document revision that is current at the time of the writing of

this document. Newer revisions may be available from the TI web site, or call the Texas Instruments'

Literature Response Center at (800) 477-8924 or the Product Information Center at (972) 644-5580. When

ordering, please identify the document by both title and literature number.

Table 1 gives links to the OPA564 data sheet, and an in-depth Howland current pump application note.

Table 1. Related Documentation

Document Literature Number

OPA564 product data sheet SBOS372

AN-1515 A Comprehensive Study of the Howland Current Pump application note SNOA474

www.ti.com

4

OPA564DWP-EVM

Copyright © 2020, Texas Instruments Incorporated

SBOU219–February 2020

Submit Documentation Feedback

Page 5

www.ti.com

2 Hardware

This section details the purpose of the EVM connectors and jumpers, and methods of configuring the EVM

for taking measurements.

See Section 4 for the OPA564DWP-EVM schematic.

2.1 Power Supply

Power is provided to the OPA564DWP-EVM through three banana jacks: AVDD (V+), GND, and AVSS

(V–). The EVM can be configured to use a single 7-V to 24-V supply (by placing a shunt on the right-hand

side of J13, thus connecting V– to GND), or a dual ±3.5-V to ±12-V supply (by placing a shunt on the lefthand side of J13, thus connecting V– to AVSS). Use a power supply that is capable of providing at least

2× the anticipated continuous current to account for peak current conditions. Furthermore, make certain

that any cables used to carry high current are rated for such use.

2.2 Inputs

The input to the EVM may be a dc signal, an ac signal (such as that from a signal generator), or any other

signal within the common-mode voltage range. Be aware that 50-Ω termination resistors are not installed

at the EVM inputs. If necessary, external, higher-wattage BNC terminators can be added at the EVM input

connectors. Excessive power dissipation, under high input voltage conditions, can result in potential failure

of the device.

The signal presented to the inverting OPA564 input pin (Vin–) is selected through jumper J3. Vin– can be

set to GND by placing a shunt on the upper portion of J3, or a signal applied at the BNC input connector

J2 by placing a shunt on the lower portion of J3.

The signal presented to the noninverting input (Vin+) can be adjusted as follows:

• Place a shunt on J4 to connect Vin+ to a signal applied at the BNC input connector J1.

• Place a shunt on J5 to set Vin+ to GND.

• Place a shunt on J6 to set Vin+ to a voltage value midway between the two supplies.

• Place a shunt on J7 to set Vin+ to an externally set voltage (through TP5), or to offset the input voltage

by the externally set reference voltage value.

• Place a shunt on J9 to reference Vin+ to ground through a 10-kΩ resistor. This setting is necessary for

correct difference amplifier operation.

Hardware

2.3 Outputs

Output signals derived from the EVM can be monitored in a number of ways. The OPA564DWP-EVM can

be accessed through a BNC connector (J17), intended for an instrument connection (an oscilloscope, for

example) , or a pair of female banana jacks (J15, J16), intended for carrying high output current.

The OPA564 can drive a variety of loads, some of which may be large or have to dissipate a significant

amount of power. Therefore, an external load can be applied to the OPA564DWP-EVM for high-power

applications. Alternatively, for low-power applications, a load resistor can be added through the R26

footprint.

SBOU219–February 2020

Submit Documentation Feedback

Copyright © 2020, Texas Instruments Incorporated

OPA564DWP-EVM

5

Page 6

lim

1.2 V

R5 5 k

:

Hardware

2.4 Jumpers

A description of basic jumper functions is shown in Table 2. More information can be found in Section 2.

Jumper Description

J3 Selects the signal presented to the amplifier Vin– pin

J4, J5, J6 Selects the signal presented to the amplifier Vin+ pin

J7 Selects the reference voltage to the amplifier positive input (external Vref)

J8 Selects the current limit for OPA564

J9 Allows the user to reference the noninverting input to ground via a 10-kΩ resistor. Used in difference

J11 Disables or enables the OPA564 output

J13 Allows the user to select single or dual power-supply mode

2.5 LEDs

Table 3 describes the status of the LEDs during illumination. More details can be found in Section 2.

LED Description

Green Board is power on

Red The device is in thermal shutdown mode

Red + Orange The device is in shutdown mode

www.ti.com

Table 2. Basic Jumper Functions

amplifier circuit setup.

Table 3. Status of the LEDs

2.6 Enable-Disable Feature

The EVM provides a means to test the enable-disable functionality of the OPA564. Place a shunt across

J11 to disable the amplifier output stage. Remove the shunt to enable the amplifier, except when the

amplifier is in thermal shutdown mode. LEDs indicate the current EVM status (see Table 3).

2.7 Current Limitation Capability

The OPA564 maximum current output is 1.5 A, and is set by a resistor connected between the negative

supply (V–) and the amplifier Iset pin. The OPA564DWP-EVM provides the means to limit the maximum

output current through jumper J8. There are four current limit settings available:

• The top row of J8 limits the output current to 0.45 A

• The second row from the top of J8 limits the current to 0.65 A

• The third row from the top of J8 limits the current to 1.41 A

• The bottom row of J8 is used for setting the current limit using a custom resistor, R5. The equation

governing current limit is as follows:

For detailed information on limiting OPA564 output current, see the OPA564 data sheet.

(1)

6

OPA564DWP-EVM

Copyright © 2020, Texas Instruments Incorporated

SBOU219–February 2020

Submit Documentation Feedback

Page 7

Current

Limit

Flag

Thermal

Flag

V

DIG

V+

Enable/Shutdown

T

SENSE

Current

Limit

Set

OPA564AIDWP

R

SET

(2)

(19)

(17, 18)

±IN

+IN

(6)

(7)

(3)

(8)

(4)

(15, 16)

R20 0

R16 10 k

R

9 1

k

R10 1 k

(9)

(12)

V±

(1, 10, 11, 20)

(13, 14)

V

OUT

R21 0

R24 10

C21 10 n

+

±

(5)

VOUT

Vin+

+

www.ti.com

3 Configuration Examples

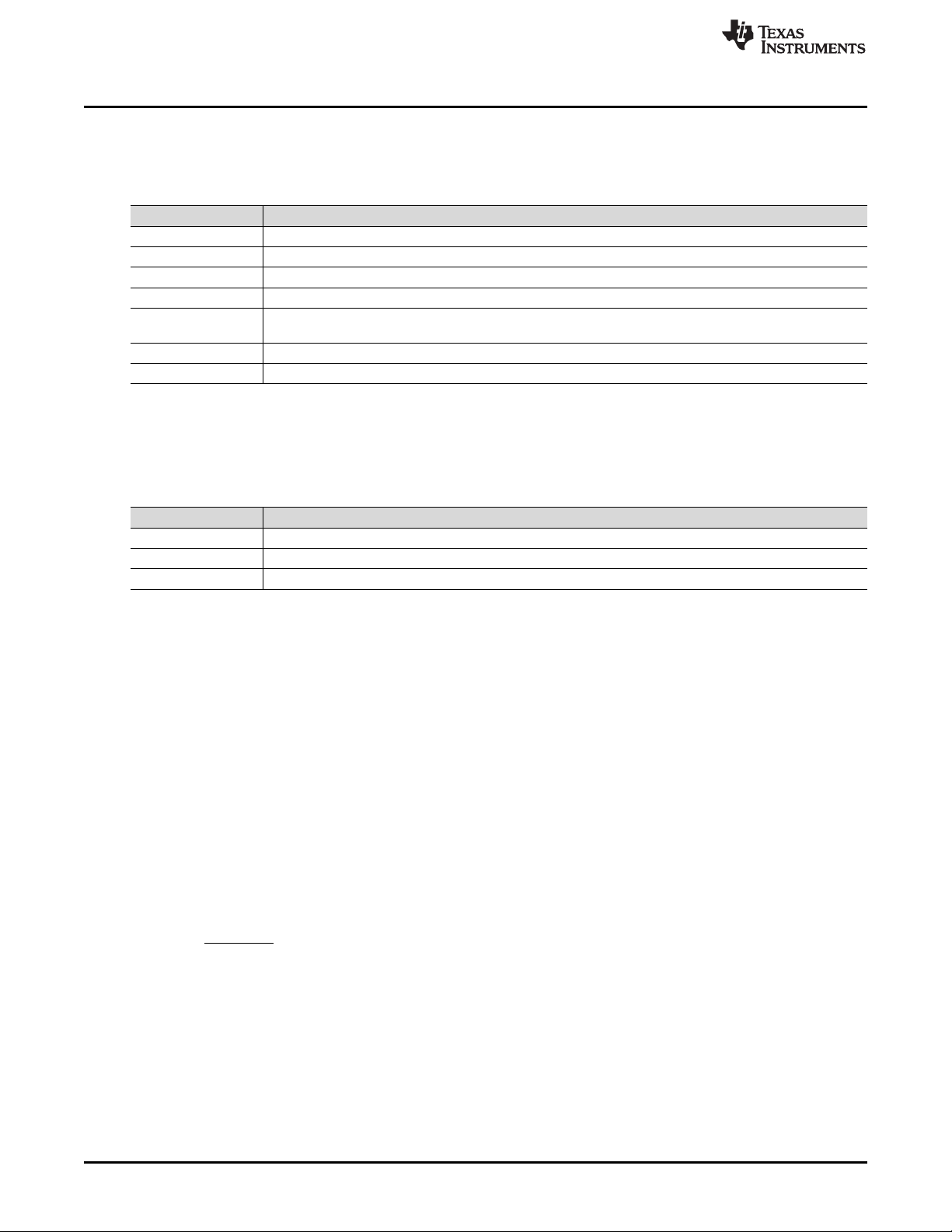

3.1 Noninverting Amplifier Configuration Setup

The EVM can be set to a noninverting amplifier configuration, as shown in Figure 1. This configuration can

be operated in dual-supply or single-supply mode.

Configuration Examples

Table 4 gives the noninverting amplifier configuration details.

Reference Setting Function

C15, C16, R17 Not installed —

R20, R21 0 Ω —

SBOU219–February 2020

Submit Documentation Feedback

Figure 1. Noninverting Amplifier Configuration Schematic

Table 4. Noninverting Configuration

J13 AVSS, GND Selects AVSS (dual supply) or GND (single supply)

J3 GND Routes Vin– across R9 to ground

J4 Vin+ Routes Vin+ across R10 to the input signal (J1)

J5-7, J9 Open —

C6, C7 Not installed —

R10 1 kΩ —

R16 10 kΩ —

J11 Open Output is enabled

J8 0.45 A Current limit set to 0.45 A

R26 Not installed —

Copyright © 2020, Texas Instruments Incorporated

OPA564DWP-EVM

7

Page 8

Configuration Examples

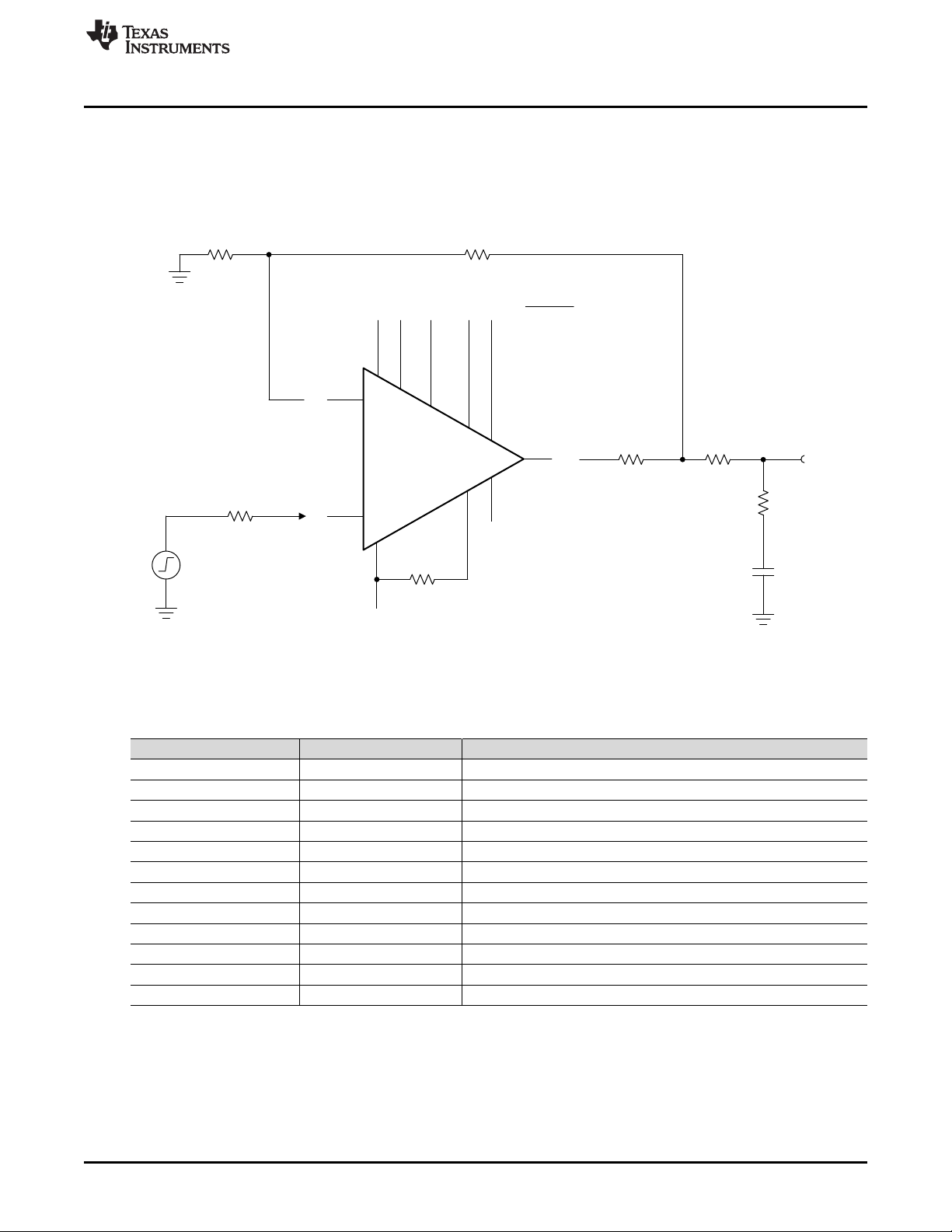

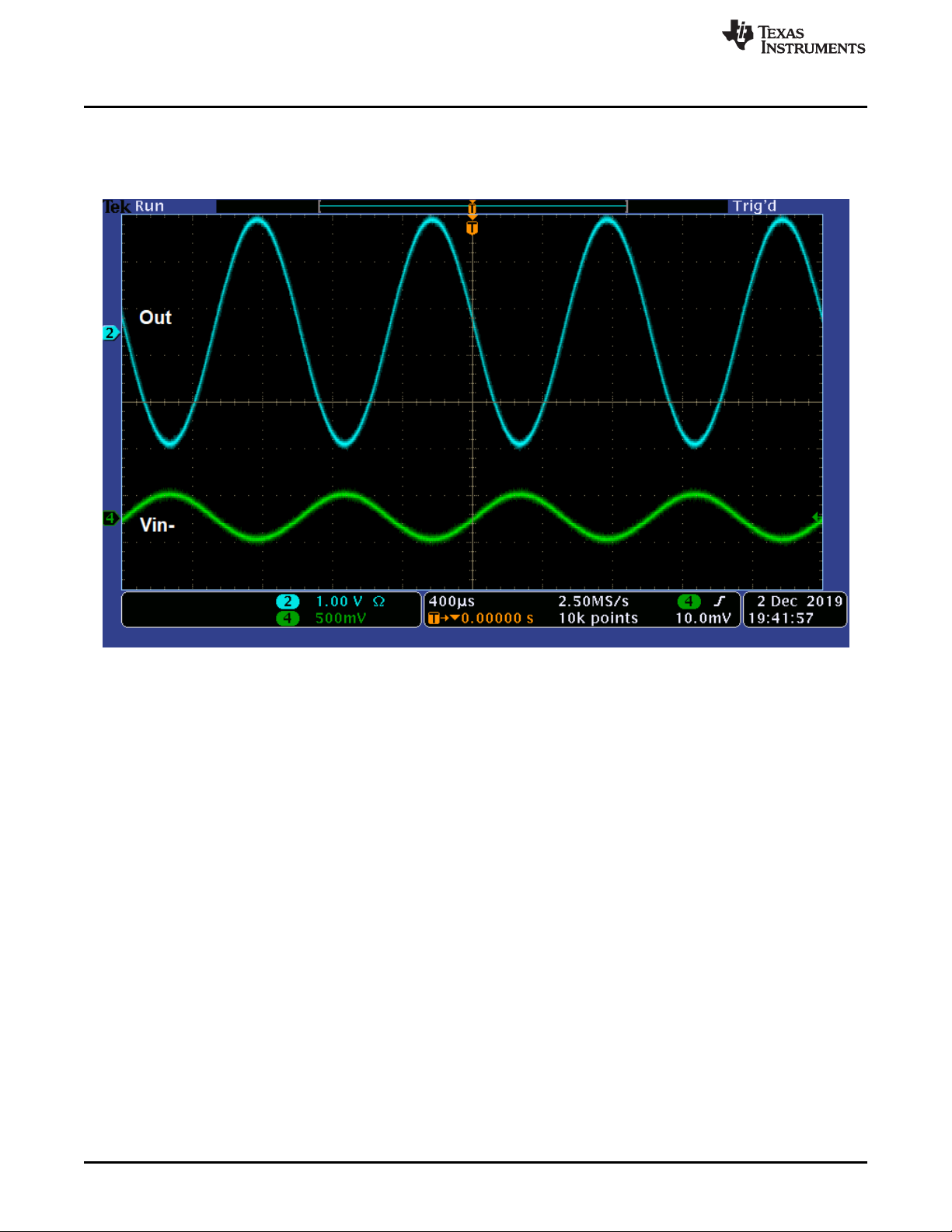

Figure 2 shows the expected results for the noninverting operation of the OPA564 with a gain of 11. A

dual supply is used, and the positive input signal is a sine wave with a peak-to-peak amplitude of 500 mV

and a frequency of 1 kHz. As expected, the output is a sine wave with 5.5-V peak-to-peak amplitude, in

phase with the input signal.

www.ti.com

Figure 2. Noninverting Operation

8

OPA564DWP-EVM

Copyright © 2020, Texas Instruments Incorporated

SBOU219–February 2020

Submit Documentation Feedback

Page 9

Current

Limit

Flag

Thermal

Flag

V

DIG

V+

Enable/Shutdown

T

SENSE

Current

Limit

Set

OPA564AIDWP

R

SET

(2)

(19)

(17, 18)

±IN

+IN

(6)

(7)

(3)

(8)

(4)

(15, 16)

R20 0

R16 10 k

R

9 1

k

R10 1 k

(9)

(12)

V±

(1, 10, 11, 20)

(13, 14)

V

OUT

R21 0

R24 10

C21 10 n

+

±

(5)

VOUT

Vin+

+

www.ti.com

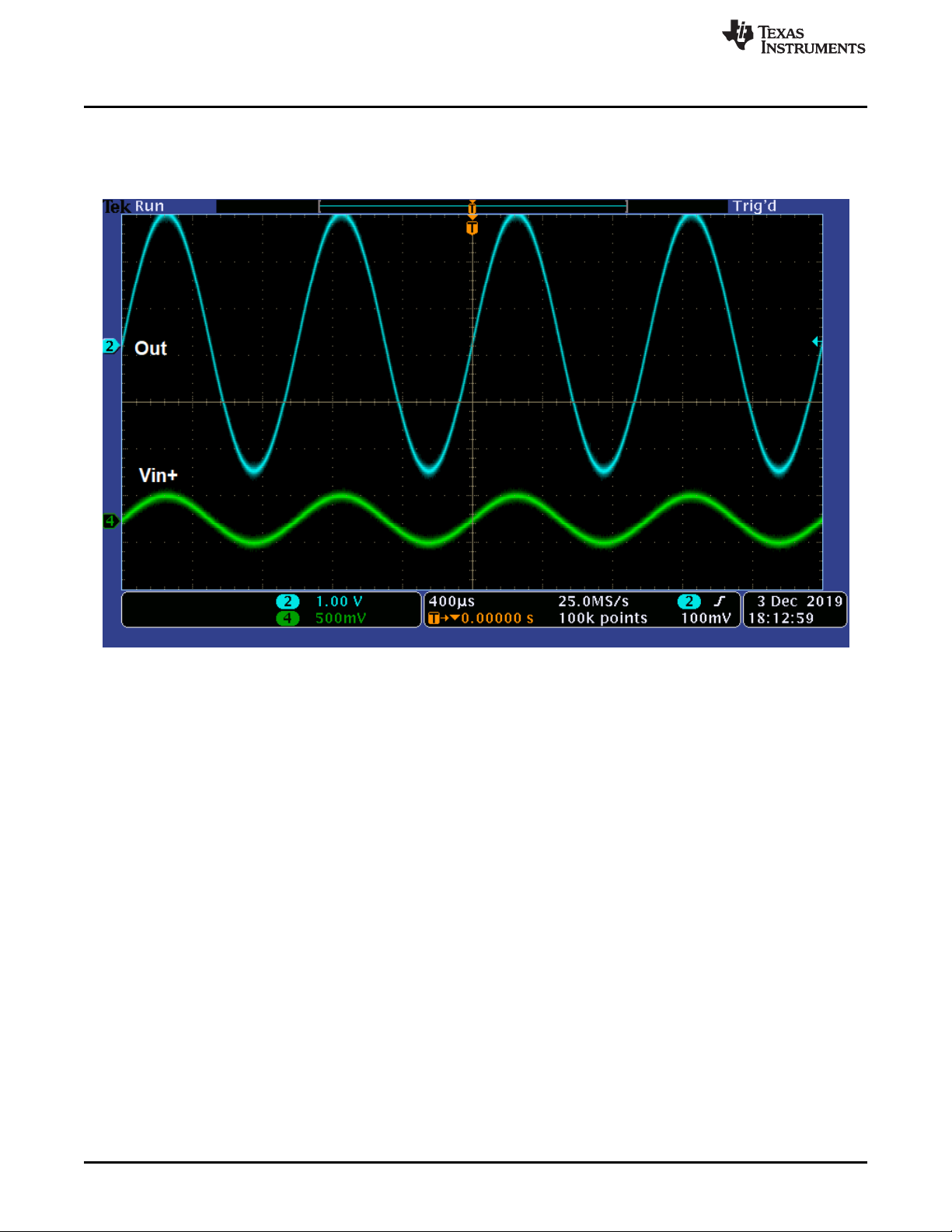

3.2 Inverting Amplifier Configuration Setup

The inverting operation configuration of the EVM is shown in Figure 3. This configuration can be operated

in dual-supply or single-supply mode.

Configuration Examples

Table 5 describes the inverting amplifier PCB configuration.

C15, C16, R17 Not installed —

SBOU219–February 2020

Submit Documentation Feedback

Figure 3. Inverting Amplifier Configuration Schematic

Table 5. Inverting Configuration

Reference Setting Function

J13 AVSS, GND Selects AVSS (dual supply) or GND (single supply)

J3 Vin– Routes Vin– across R9 to input signal through J2

J5 GND Routes Vin+ across R10 to ground

J4, J6-7, J9 Open —

C6, C7 Not installed —

R9 1 kΩ —

R16 10 kΩ —

J11 Open Output is enabled

J8 0.45 A Current limit set to 0.45 A

R20, R21 0 Ω —

R26 Not installed —

Copyright © 2020, Texas Instruments Incorporated

OPA564DWP-EVM

9

Page 10

Configuration Examples

Figure 4 shows the expected results for the inverting operation of the OPA564 with a gain of –10. A dual

supply is used, and the negative input signal is a sine wave with a peak-to-peak amplitude of 500 mV and

a frequency of 1 kHz. As expected, the output is a sine wave with 5-V peak-to-peak amplitude, 180° out of

phase with the input signal.

www.ti.com

Figure 4. Inverting Operation

10

OPA564DWP-EVM

Copyright © 2020, Texas Instruments Incorporated

SBOU219–February 2020

Submit Documentation Feedback

Page 11

Current

Limit

Flag

Thermal

Flag

V

DIG

V+

Enable/Shutdown

T

SENSE

Current

Limit

Set

OPA564AIDWP

R

SET

(2)

(19)

(17, 18)

±IN

+IN

(6)

(7)

(3)

(8)

(4)

(15, 16)

R20 0

R16 10 k

R

9 1

k

R10 1 k

(9)

(12)

V±

(1, 10, 11, 20)

(13, 14)

V

OUT

R21 0

R24 10

C21 10n

+

±

(5)

VOUT

Vin+

+

R14 10 k

Vin±

+

www.ti.com

3.3 Differential Amplifier Configuration Setup

The EVM can also be set to a difference amplifier configuration, as shown in Figure 5. Both inputs are

driven in this mode, and the output is the difference between these inputs gained up by a factor of 10.

This configuration can be operated in dual-supply or single-supply mode.

Configuration Examples

Table 6 describes the differential amplifier PCB configuration.

Reference Setting Function

C15, C16, R17 Not installed —

R20, R21 0 Ω —

SBOU219–February 2020

Submit Documentation Feedback

Figure 5. Differential Amplifier Configuration Schematic

Table 6. Differential Configuration

J13 AVSS, GND Selects AVSS (dual supply) or GND (single supply)

J3 Vin– Routes Vin– across R9 to input signal via J2

J4 Vin+ Routes Vin+ across R10 to the input signal (J1)

J5-7 Open —

J9 GND References Vin+ to GND through R14

Copyright © 2020, Texas Instruments Incorporated

R14 10 kΩ —

C6, C7 Not installed —

R9, R10 1 kΩ —

R16 10 kΩ —

J11 Open Output is enabled

J8 0.45 A Current limit set to 0.45 A

R26 Not installed —

OPA564DWP-EVM

11

Page 12

Configuration Examples

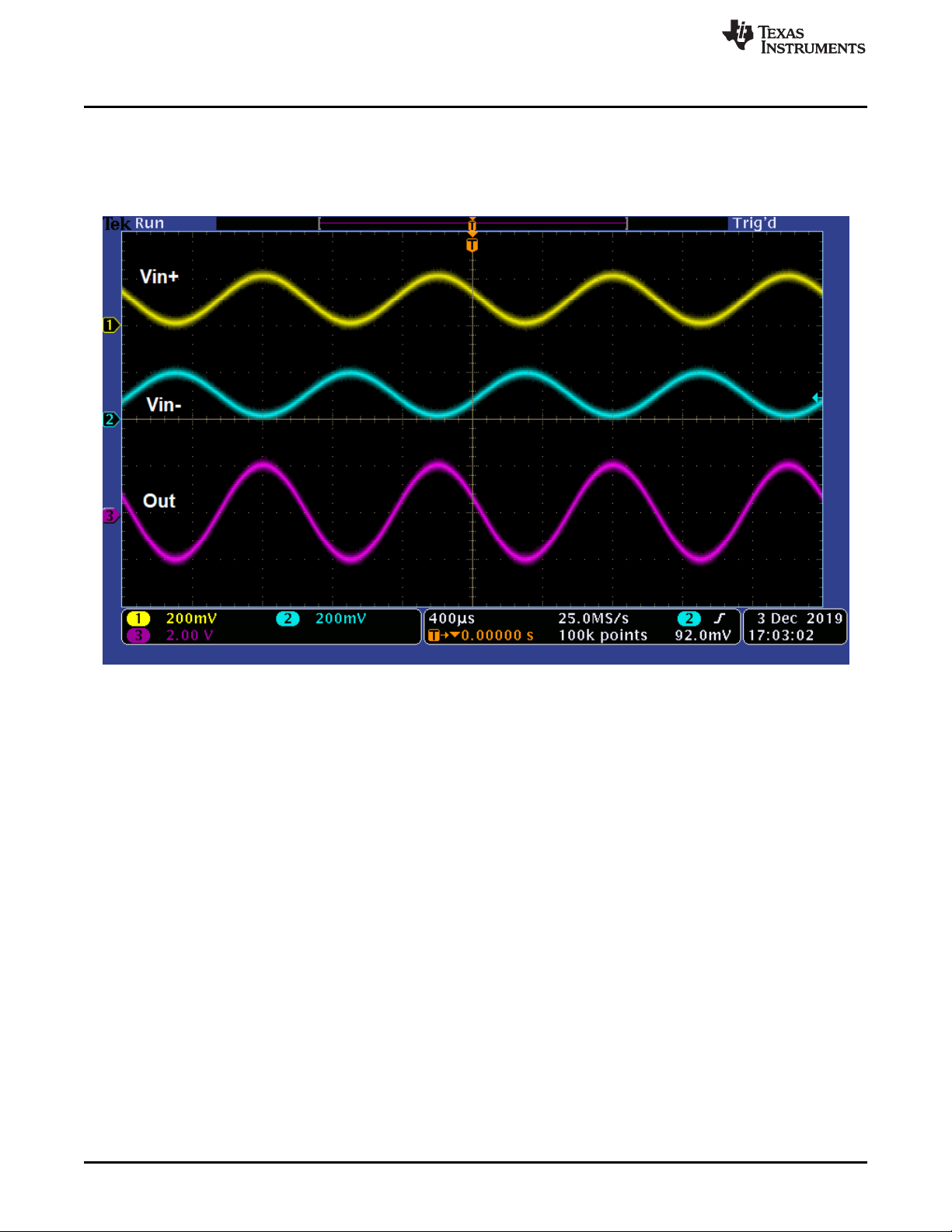

Figure 6 shows the expected results for the differential operation of the OPA564 with a gain of 10. Dual

supply is used. The input signals are sinusoids with a peak-to-peak amplitude of 200 mV and a frequency

of 1 kHz. The negative input signal has a phase shift of 180° relative to the positive input signal. As

expected, the difference of the input signals is amplified by a factor of 10, resulting in a sinusoid of 4-V

peak-to-peak amplitude in phase with Vin+, on the output.

www.ti.com

Figure 6. Differential Operation

12

OPA564DWP-EVM

Copyright © 2020, Texas Instruments Incorporated

SBOU219–February 2020

Submit Documentation Feedback

Page 13

Current

Limit

Flag

Thermal

Flag

V

DIG

V+

Enable/Shutdown

T

SENSE

Current

Limit

Set

OPA564AIDWP

R

SET

(2)

(19)

(17, 18)

±IN

+IN

(6)

(7)

(3)

(8)

(4)

(15, 16)

R20 0

R16 1 k

R

9 10

k

R10 10 k

(9)

(12)

V±

(1, 10, 11, 20)

(13, 14)

V

OUT

R21 1

R24 10

C21 10 n

+

±

(5)

R17 1 k

R Ext

10

A

+

A-Meter

VOUT

Vin+

+

www.ti.com

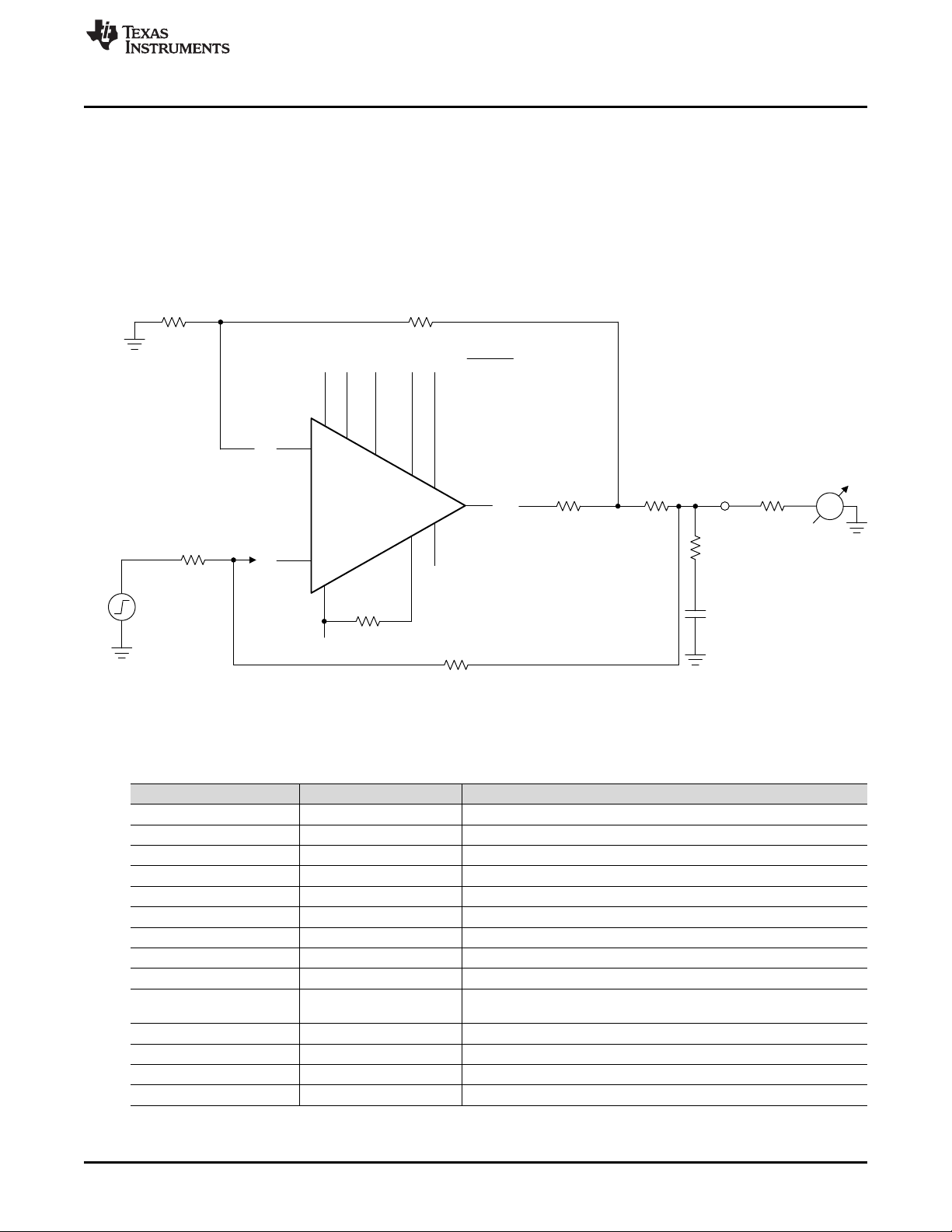

3.4 Improved Howland Current Pump Configuration Setup

The OPA564DWP-EVM can also be configured as an improved Howland current pump, delivering precise

current to a load. The output current can be adjusted from very low (in microamp range) to the maximum

output current of the device (1.5 A), as long as the amplifier does not exceed the absolute maximum

ratings (such as output voltage swing, slew rate, and so on.). Detailed information on the basic and

improved Howland current pump can be found in the AN1515 A Comprehensive Study of the Howland

Current Pump application note.

The improved Howland current pump is applied by configuring the EVM according to the schematic shown

in Figure 7. This default configuration delivers approximately 100 mA of current for every 1 V of input.

Configuration Examples

Table 7 shows the improved Howland current pump PCB configuration.

Reference Setting Function

SBOU219–February 2020

Submit Documentation Feedback

Figure 7. Improved Howland Current Pump Schematic

Table 7. Improved Howland Current Pump Configuration

J13 AVSS Selects AVSS (dual supply)

J3 GND Routes Vin– across R9 to ground

J4 Vin+ Routes Vin+ across R10 to the input signal (J1)

J5-7, J9 Open —

C6, C7 Not installed —

R9, R10 10 kΩ —

R16, R17 1 kΩ —

C15, C16 Not installed —

J11 Open Output is enabled

J8

R20 0 Ω —

R21 1 Ω —

R26 Not installed —

R Ext 10 Ω —

0.45 A, 0.65 A, 1.41 A or

custom value

Copyright © 2020, Texas Instruments Incorporated

Sets the current limit to 0.45 A, 0.65 A, 1.41 A, or a custom current

limit value through R5

OPA564DWP-EVM

13

Page 14

out

1.000 V 0 V 1.000 k

1.000 10.00 k

:

§ ·

¨ ¸

: :

© ¹

R9 R10

R16 R17 R21

out

(Vin+) (Vin ) R16

R21 R9

u

Configuration Examples

Some of the OPA564DWP-EVM resistors are different than in the three previous amplifier configurations

to accommodate the improved Howland current pump circuit. The mathematical relationship between the

resistors outlined in the AN-1515 application report must be observed to maintain correct output current

from the pump.

The output current is established by Equation 2:

The mathematical relationship to be observed is shown in Equation 3:

According to Equation 3, if R9 = R10, then R16 = R17 + R21.

For a default setup:

• Let R9 = R10 = 10.00 kΩ, R16 = 1.000 kΩ, and R21 = 1.000 Ω.

• Then, R17 = R16 – R21 = 1.000 kΩ – 1.000 Ω = 999 Ω ≅ 1.000 kΩ

• R17 is not populated with the 1.000-kΩ resistor.

• R21, a 0-Ω resistor, is replaced and populated with the 1.000-Ω resistor.

• Apply Equation 2 to solve for I

The improved Howland current pump configured with these resistor values sources an output current of

0.1 A when 1.000 V is applied to the OPA564 Vin+ input. If Vin+ is increased to 2.000 V, the output

current doubles to 0.2 A. If dual polarity supplies, such as ±12 V, are being used with the OPA564DWPEVM, and the polarity of Vin+ is reversed or the positive voltage is applied to Vin–, the output current

reverses direction. In this case, the OPA564 sinks 0.1 A. Keep in mind that with any current source that

includes the improved Howland current source, an output load must be provided for the load current to

flow through. A specific range of load resistances from a minimum of 0 Ω to a maximum value set by

Ohm's law. The maximum is limited by the OPA564 maximum output voltage swing (V

output current (I

in Equation 4:

out

), or mathematically stated: R

out

LOAD(MAX)

= V

out(MAX)

/ I

out

www.ti.com

(2)

(3)

(4)

) and the pump

out

.

14

OPA564DWP-EVM

Copyright © 2020, Texas Instruments Incorporated

SBOU219–February 2020

Submit Documentation Feedback

Page 15

Current

Limit

Flag

Thermal

Flag

V

DIG

V+

Enable/Shutdown

T

SENSE

Current

Limit

Set

OPA564AIDWP

R

SET

(2)

(19)

(17, 18)

±IN

+IN

(6)

(7)

(3)

(8)

(4)

(15, 16)

R20 0

R16 10 kR9 1 k

R10 k

(9)

(12)

V±

(1, 10, 11, 20)

(13, 14)

V

OUT

Current

Limit

Flag

Thermal

Flag

V

DIG

V+

Enable/Shutdown

T

SENSE

Current

Limit

Set

OPA564AIDWP

R

SET

(2)

(19)

(17, 18)

±IN

+IN

(6)

(7)

(3)

(8)

(4)

(15, 16)

R20 0

R16 1 kR9 1 k

R10 1 k

(9)

(12)

(1, 10, 11, 20)

(13, 14)

V

OUT

R21 0

R Ext 35

R24

10

C21

10 n

R21 0

VOUT1

VOUT2

+

±

(5)

(5)

Vin+

+

R24 10

C21 10 n

www.ti.com

3.5 Bridge-Tied Load Configuration Setup

Another configuration that can be used with the OPA564DWP-EVM is the bridge-tied load (BTL).

However, this configuration requires two EVMs. The first EVM must be set up in a noninverting amplifier

configuration, and the second in an inverting amplifier configuration, Figure 8. This configuration can be

operated in dual-supply or single-supply mode.

Configuration Examples

Table 8 and Table 9 describe the bridge-tied load configuration for the first and second PCB, respectively.

Board 1: Noninverting Amplifier

SBOU219–February 2020

Submit Documentation Feedback

C15, C16, R17 Not installed —

Figure 8. Bridge-Tied Load Schematic

Table 8. Bridge-Tied Load Configuration: Board 1

Reference Setting Function

J13 AVSS, GND

J3 GND Routes Vin– across R9 to ground

J4 Vin+

J5-7, J9 Open —

C6, C7 Not installed —

R9, R10 1 kΩ —

R16 10 kΩ —

J11 Open Output is enabled

J8 0.45 A Current limit set to 0.45 A

R20, R21 0 Ω —

R26 Not installed —

Copyright © 2020, Texas Instruments Incorporated

Selects AVSS (dual supply) or GND

(single supply)

Routes Vin+ across R10 to the input

signal (J1)

OPA564DWP-EVM

15

Page 16

Configuration Examples

Board 2: Inverting Amplifier

Reference Setting Function

J13 AVSS, GND

J3 Vin–

J5 GND Routes Vin+ across R10 to ground

J4, J6-7, J9 Open —

C6, C7 Not installed —

R9 1 kΩ —

R16 1 kΩ —

C15, C16, R17 Not installed —

J11 Open Output is enabled

J8 0.45 A Current limit set to 0.45 A

R20, R21 0 Ω —

R26 Not installed —

As mentioned earlier, the BTL circuit consists of one noninverting and one inverting amplifier stage. By

default, the noninverting stage is set up with a gain of 11; whereas, the inverting stage is set with a gain of

–1.Given that the inverting input comes from the output of the noninverting stage, the total gain of the

inverting stage is therefore –11. Combining the outputs of the two stages gives double the amplification, a

total gain of 22.

Figure 9 shows the expected results for the bridge-tied load operation of the OPA564, used in dual-supply

mode. Input signal Vin+ of the first board is a sinusoid with a peak-to-peak amplitude of 100 mV and a

frequency of 1 kHz. The final output signal is taken across an external 35-Ω connecting output of the first

board with the output of the second board. As expected, a difference of one sinusoid with a gain of 11 and

another with the gain of –11, gives an input signal amplification factor of 22. A 100-mV peak-to-peak

amplitude input signal is amplified to a sinusoid of 2.2-V peak-to-peak amplitude, 180° out of phase with

the input signal.

www.ti.com

Table 9. Bridge-Tied Load Configuration: Board 2

Selects AVSS (dual supply) or GND (single

supply)

Routes Vin– across R9 to input signal

through J2

16

OPA564DWP-EVM

Figure 9. Bridge-Tied Load Operation

Copyright © 2020, Texas Instruments Incorporated

SBOU219–February 2020

Submit Documentation Feedback

Page 17

V-

1

V+

2

TFLAG

3

E/S

4

IN+

5

IN-

6

VDIG

7

IFLAG

8

ISET

9

V-

10

V-

11

TSENSE

12

V-PWR

13

V-PWR

14

VOUT

15

VOUT

16

V+ PWR

17

V+ PWR

18

V+ PWR

19

V-

20

EP

21

OPA564AIDWP

U4

J14

GND

J10

AVDD

V-

12.0k

R13

31.6k

R12

47.5k

R11

680pF

C4

Iset

1

2

D1

V+

V-

2.20k

R1

TP6

AVDD

GND

0

R15

AVDD

V-

J12

AVSS

TP8

V-

1

2

3

J13

GND

AVSS

TP9

GND

TP10

GND

GND

IN1OUT

2

OUT

3

4

NC5OUT

6

OUT

7

NC

8

ADJ

U2

V-

0.1uF

C2

AVDD

V-

TP4

Vdig

Vdig

V-

499

R7

1.50k

R8

6800pF

C3

Vdig

0.1uF

C11

GND

V+

0.1uF

C12

GND

E/S

TflagIflag

Iset

Tsense

GND

V-

0.1uF

C13

GND

V+

D5

1

2

345

J1

Vin+

1

2

345

J2 Vin-

GND

1

2

3

J3

-IN Select

GND

TP2

-IN

GND

1

2

J4

Vin+

1

2

J5

GND

1

2

J6

Userselect Vref

1

2

J7

Vref

V+

V-

DNI

R3

DNI

R4

1.00k

R10

TP3

+IN

GND

DNI

C7

GND

DNI

C6

GND

1.00k

R9

DNI

C15

DNI

C16

10.0k

R16

TP5

Vref

D6

DNI

GND

1

3

2

D3

V-

AVDD

J16

GND

GND

DNI

R26

0.01uF

C21

10.0

R24

GND

J15

OUT

0

R200R21

R17

DNI

0.1uF

C17

D8

DNI

GND

D7

V- V-

GND

1

2 5

43

6

U5

4N38SR2M

Vdig

0.1uF

C18

3.92k

R19

100k

R22

22.0k

R23

21.0k

R25

351

2

4

678

9

Q1

100k

R29

0.1uF

C24

D10

V+

TP13

V+

V-

1.00M

R27

1000pF

C23

1

2

D2

IFlag

42

U1A

VCC5GND

3

NC

1

U1B

Vdig

1.00k

R2

V-

0.1uF

C1

Vdig V-

Iflag

TP1

IFlag

1

2

D9

TFlag

42

U6A

VCC5GND

3

NC

1

U6B

1.00k

R28

Vdig

Tflag

V-

V-

0.1uF

C22

Vdig

TP11

TFlag

Tsense

TP14

TSense

42

U3A

VCC5GND

3

NC

1

SN74LVC1G04DBVR

U3B

V-

0.1uF

C9

Vdig

1

2

D4

1.00k

R18

1

2

J11

Disable

E/S

TP7

E/S

V-

GND

1uF

C5

GND

V-

0.1uF

C19

0.1uF

C20

GND

47pF

C10

47pF

C14

1

234

5

J17

Vout

GND

TP12

Vout

TP15

GND

DNI

R5

1

2345678

J8

Iset

DNI

R6

GND

10.0k

R14

1

2

J9 Vin+

GND

www.ti.com

4 Schematics, PCB Layout, and Bill of Materials

4.1 Schematics

The schematic of the EVM, including the enable and shutdown and LED circuits, is shown in Figure 10.

Schematics, PCB Layout, and Bill of Materials

SBOU219–February 2020

Submit Documentation Feedback

Figure 10. OPA564DWP-EVM Schematic

Copyright © 2020, Texas Instruments Incorporated

OPA564DWP-EVM

17

Page 18

Schematics, PCB Layout, and Bill of Materials

4.2 PCB Layout

The EVM top and bottom layers are illustrated in Figure 11 and Figure 12, respectively.

Three banana jacks supply power to the EVM (see Section 2.2) . J13 is used to set operation to single

supply or dual supply.

Voltage inputs, Vin+ and Vin–, are on the left-hand side of the board. Jumpers J3 to J6 are used for

setting the input voltage value. Test point TP5 is used to supply reference voltage to the board. Jumper J7

can then be used to offset Vin+ by reference voltage value. Jumper J9 is used for referencing the

noninverting input to ground using a 10-kΩ resistor. This setup is used for difference amplifier operation.

R16, R17, C15, C16 are user-selectable op amp feedback components. R20 and R21 are the output

current-limiting resistors. R20 and R21 are set to 0 Ω by default, but can be adjusted to act as isolation

resistors for improved stability or to set the output current when the device is configured as an improved

Howland current pump (see Section 3.4). However, setting R20 or R21 to value greater than 0 Ω creates a

low-pass filter with the output compensation consisting of R24 and C21.

Vout (pins 15 and 16 of OPA564) can be accessed through connector J17, as well as through banana

jack J15 (see Section 2.3). Jack J16 is set to GND; thus, reading the output signal from J15 and J16 with

an oscilloscope is very convenient. Two super fast diodes (D6 and D8) are used for output protection.

Additionally, the board contains two empty footprints (D5 and D6) that can be used to add power-supply

protection diodes or transient voltage suppressor (TVS) diodes.

www.ti.com

18

OPA564DWP-EVM

Copyright © 2020, Texas Instruments Incorporated

SBOU219–February 2020

Submit Documentation Feedback

Page 19

www.ti.com

Schematics, PCB Layout, and Bill of Materials

SBOU219–February 2020

Submit Documentation Feedback

Figure 11. OPA564DWP-EVM, Top Layer

Copyright © 2020, Texas Instruments Incorporated

OPA564DWP-EVM

19

Page 20

Schematics, PCB Layout, and Bill of Materials

www.ti.com

20

OPA564DWP-EVM

Figure 12. OPA564DWP-EVM Bottom Layer

Copyright © 2020, Texas Instruments Incorporated

SBOU219–February 2020

Submit Documentation Feedback

Page 21

www.ti.com

4.3 Bill of Materials

Table 10 lists the bill of materials (BOM).

Designator Quantity Description PartNumber Manufacturer

C1, C2, C9, C11, C12,

C13, C17, C18, C19,

C20, C22, C24

C3 1 CAP, CERM, 6800 pF, 50 V, +/- 10%,

C4 1 CAP, CERM, 680 pF, 50 V, +/- 10%,

C5 1 CAP, CERM, 1 uF, 50 V, +/- 10%, X7R,

C10, C14 2 CAP, CERM, 47 pF, 50 V, +/- 5%,

C21 1 CAP, CERM, 0.01 uF, 50 V, +/- 10%,

C23 1 CAP, CERM, 1000 pF, 1000 V, +/- 10%,

D1 1 LED, Green, SMD LTST-C190GKT Lite-On

D2 1 LED, Orange, SMD LTST-C190KFKT Lite-On

D3 1 Diode, Schottky, 40 V, 0.2 A, SOT-23 BAS40-04-7-F Diodes Inc.

D4 1 LED, Yellow, SMD LY L29K-H1K2-26-Z OSRAM

D5, D7 2 Diode, Ultrafast, 50 V, 1 A, SMA ES1A-13-F Diodes Inc.

D9 1 LED, Red, SMD LS L29K-G1J2-1-Z OSRAM

D10 1 Diode, TVS, Uni, 12 V, SMA SMAJ12A Littelfuse

H1, H3, H5, H8 4 2203 Keystone

H2, H4, H6, H7 4 MACHINE SCREW PAN PHILLIPS 4-40 PMSSS 440 0025 PH B&F Fastener

J1, J2, J17 3 Connector, TH, BNC Right angle, 50

J3, J13 2 Header, 100mil, 3x1, Gold, SMT TSM-103-01-L-SV Samtec

J4, J5, J6, J7, J9, J11 6 Header, 100mil, 2x1, Gold with Tin Tail,

J8 1 Header, 2.54mm, 4x2, Gold, SMT TSM-104-01-L-DV Samtec

J10, J12, J14, J15, J16 5 Standard Banana Jack, Uninsulated,

Q1 1 MOSFET, P-CH, -20 V, -15 A,

R1 1 RES, 2.20 k, 1%, 0.25 W, 1206 RC1206FR-072K2L Yageo America

R2, R9, R10, R18, R28 5 RES, 1.00 k, 1%, 0.25 W, 1206 RC1206FR-071KL Yageo America

R7 1 RES, 499, 1%, 0.25 W, 1206 RC1206FR-07499RL Yageo America

R8 1 RES, 1.50 k, 1%, 0.25 W, 1206 RC1206FR-071K5L Yageo America

R11 1 RES, 47.5 k, 1%, 0.25 W, 1206 RC1206FR-0747K5L Yageo America

R12 1 RES, 31.6 k, 1%, 0.25 W, 1206 RC1206FR-0731K6L Yageo America

R13 1 RES, 12.0 k, 1%, 0.25 W, 1206 RC1206FR-0712KL Yageo America

R14, R16 2 RES, 10.0 k, 1%, 0.25 W, 1206 RC1206FR-0710KL Yageo America

R15, R20, R21 3 RES, 0, 5%, 0.75 W, AEC-Q200 Grade

R19 1 RES, 3.92 k, 1%, 0.25 W, 1206 RC1206FR-073K92L Yageo America

R22, R29 2 RES, 100 k, 1%, 0.25 W, 1206 RC1206FR-07100KL Yageo America

R23 1 RES, 22.0 k, 1%, 0.25 W, 1206 RC1206FR-0722KL Yageo America

R24 1 RES, 10.0, 1%, 0.25 W, 1206 RC1206FR-0710RL Yageo America

Table 10. Bill of Materials

12 CAP, CERM, 0.1 uF, 50 V, +/- 10%,

X7R, 1206

X7R, 1206

X7R, 1206

1206

C0G/NP0, 0805

X7R, 1206

X7R, 1206

ohm gold

SMT

5.5mm

DNH0008A (VSONP-8)

0, 2010

Schematics, PCB Layout, and Bill of Materials

C1206C104K5RACTU Kemet

12065C682KAT2A AVX

CC1206KRX7R9BB681 Yageo America

C3216X7R1H105K160AB TDK

GQM2195C1H470JB01D MuRata

12065C103KAT2A AVX

CC1206KKX7RCBB102 Yageo America

Supply

5413631-2 AMP

TSM-102-02-L-SV Samtec

575-4 Keystone

CSD25402Q3A Texas Instruments

CRCW20100000Z0EF Vishay-Dale

SBOU219–February 2020

Submit Documentation Feedback

Copyright © 2020, Texas Instruments Incorporated

OPA564DWP-EVM

21

Page 22

Schematics, PCB Layout, and Bill of Materials

Designator Quantity Description PartNumber Manufacturer

R25 1 RES, 21.0 k, 1%, 0.25 W, 1206 RC1206FR-0721KL Yageo America

R27 1 RES, 1.00 M, 1%, 0.25 W, 1206 MCR18EZHF1004 Rohm

TP1, TP2, TP3, TP4,

TP5, TP6, TP7, TP8,

TP9, TP10, TP11,

TP12, TP13, TP14,

TP15

U1, U3, U6 3 Single Inverter, DBV0005A, LARGE

U2 1 Adjustable Regulator with 3.7 to 38 V

U4 1 1.5 A, 17 MHz, Power Operational

U5 1 Optocoupler, 4.17 kV, 20% min CTR,

C6, C7, C15, C16 0 CAP, CERM, 0.1 uF, 50 V, +/- 10%,

D6, D8 0 Diode, TVS, Uni, 12 V, SMA SMAJ12A Littelfuse

FID1, FID2, FID3 0 Fiducial mark. There is nothing to buy or

R3, R4, R17 0 RES, 10.0 k, 1%, 0.25 W, 1206 RC1206FR-0710KL Yageo America

R5 0 RES, 12.0 k, 1%, 0.25 W, 1206 RC1206FR-0712KL Yageo America

R6 0 RES, 1.00 k, 1%, 0.25 W, 1206 RC1206FR-071KL Yageo America

R26 0 RES, 0, 5%, 0.75 W, AEC-Q200 Grade

15 Test Point, Compact, SMT 5016 Keystone

T&R

Input and 1.2 to 32 V Output, 0 to 125

degC, 8-Pin SOIC (D), Green (RoHS &

no Sb/Br)

Amplifier, 7 to 24 V, -40 to 125 degC,

20-pin SOP (DWP20), Green (RoHS &

no Sb/Br)

SMT

X7R, 1206

mount.

0, 2010

www.ti.com

Table 10. Bill of Materials (continued)

SN74LVC1G04DBVR Texas Instruments

LM317LCD Texas Instruments

OPA564AIDWP Texas Instruments

4N38SR2M Fairchild

Semiconductor

C1206C104K5RACTU Kemet

N/A N/A

CRCW20100000Z0EF Vishay-Dale

22

OPA564DWP-EVM

Copyright © 2020, Texas Instruments Incorporated

SBOU219–February 2020

Submit Documentation Feedback

Page 23

IMPORTANT NOTICE AND DISCLAIMER

TI PROVIDES TECHNICAL AND RELIABILITY DATA (INCLUDING DATASHEETS), DESIGN RESOURCES (INCLUDING REFERENCE

DESIGNS), APPLICATION OR OTHER DESIGN ADVICE, WEB TOOLS, SAFETY INFORMATION, AND OTHER RESOURCES “AS IS”

AND WITH ALL FAULTS, AND DISCLAIMS ALL WARRANTIES, EXPRESS AND IMPLIED, INCLUDING WITHOUT LIMITATION ANY

IMPLIED WARRANTIES OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE OR NON-INFRINGEMENT OF THIRD

PARTY INTELLECTUAL PROPERTY RIGHTS.

These resources are intended for skilled developers designing with TI products. You are solely responsible for (1) selecting the appropriate

TI products for your application, (2) designing, validating and testing your application, and (3) ensuring your application meets applicable

standards, and any other safety, security, or other requirements. These resources are subject to change without notice. TI grants you

permission to use these resources only for development of an application that uses the TI products described in the resource. Other

reproduction and display of these resources is prohibited. No license is granted to any other TI intellectual property right or to any third

party intellectual property right. TI disclaims responsibility for, and you will fully indemnify TI and its representatives against, any claims,

damages, costs, losses, and liabilities arising out of your use of these resources.

TI’s products are provided subject to TI’s Terms of Sale (www.ti.com/legal/termsofsale.html) or other applicable terms available either on

ti.com or provided in conjunction with such TI products. TI’s provision of these resources does not expand or otherwise alter TI’s applicable

warranties or warranty disclaimers for TI products.

Mailing Address: Texas Instruments, Post Office Box 655303, Dallas, Texas 75265

Copyright © 2020, Texas Instruments Incorporated

Loading...

Loading...