Page 1

HD65G Series Gas Fryer

Dean

™

®

Models

H D165G*

H D265G

H D365G

H D465G

H D565G

H D665G

Project

Item

Quantity

CSI Sec tion 11400

Approval

Date

*Mat ching cab inet required

for opt ional filtration.

HD65G Series Gas Fryer

Standard Features

• 100-lb. (50 liter) frypot oil capacity,

6” cooking depth

• 125,000 Btu/hr input

• High efficiency Thermo-Tube design

• Thermatron® solid state controls (120V

required)

• Stainless steel frypot, front, door and sides

• Stainless steel, over-the-flue basket hanger

and 2 fry baskets: 6-1/2” x 8-3/4” x 17” (15 x

22 x 43 cm)

• Single frypot fr yer rear gas manifold is 3/4”

and multiple frypot fryer rear gas manifold

is 1”

FPH265G

Shown with optional computers,

filtration and casters

• 3/4” NPT gas connection (single units)

• Wide cold zone

• Low-profile 43” unit height

• 6” (15 cm) adjustable steel legs

Specifications

High Production, High Efficiency, Gas, Tube-Type Fryer

Designed For High Volume Frying and Maximum Fuel

Efficiency

Satisfy customers with consistently great-tasting foods. The

HD65G large capacity fr yers have a 100-lb. (50 liter) fr ypot oil

capacity, and a cooking depth of 6” (152 mm). These fr yers are specifically designed to fry bone-in chicken, other breaded produc ts,

and menu items requiring larger frying area.

Maximize your profits and make the most of your energy dollars

with innovative design changes that have improved the efficiency

of the Decathlon Fryers over 30%. Dean’s exclusive Thermo-Tube

design heating tubes have durable, stainless steel flow tube

baffles, which efficiently transfer the fryer’s 125,000 Btu/hr (31,486

kcal/hr) (37 kW ) energy input to the surrounding oil. The energy

is channeled into the oil, with less going unused up the vent.

Attainment of set cooking temperature is rapid, yet controlled. This

controlled heat-up minimizes oil breakdown, reduces idle costs

and lowers gas consumption per pound of product cooked.

Utilizes precise temperature control during heat up and recover y

to maintain oil life and safeguard the quality of the foods being

cooked. Dean’s Thermatron solid state controls assure pinpoint

accuracy of oil temperature (within plus or minus one degree) and

allow the fryer to respond instantly to changes in load conditions.

Options & Accessories

Compu-Fry computer

CM4-S segmented computer

Super Cascade built-in oil filtration

system with stainless steel screen filter

Matching cabinet and dump station

available with and without filtration

Electronic ignition for effort-free

lighting (recommended on all models)

Automatic melt cycle

Boil-out mode

Frypot covers

Splash guard

Oil disposal plumbing

Frypot washdown plumbing

11” topcap available with or without

integral marine edge

Casters

Enjoy lasting satisfaction. Dean fryers achieve long and dependable life through simplicity of design. Durable stainless steel

baffles and reliable, built-to-last high-efficiency burners keep maintenance to a minimum.

Build on Dean’s versatility to “Fit the Way You Fry”. Combine one or

more units into a batter y; add an optional built-in filtration system;

or specify a computer to help assure product consistency.

Optional Super Cascade*** built-in filtration system is available.

The system utilizes a 4GPM (15LPM) pump and has a 3” round

drain, which makes filtering fast, safe, and convenient. An 8GPM

(30LPM) pump option is available to further enhance the filtration

process. Ease-of-use encourages frequent filtering, which maximizes oil life.

Compu-Fry and CM4-S computer controls are available as options

that allow product specific cooking programming and premium

control of oil temperatures and cooking curves. The CM4-S segmented computer is specially designed to provide the sensitivity

needed for high volume, bone-in chicken. It offers 9 programmable

cooking intervals per product key, “time to filter” notification, pre programmed cooking curves and other features.

FILTER CONFIGURATIONS**

The wide cold zone catches crumbs and sediment from the frying

area. These particles are trapped in the cold zone where they do

not carbonize, contaminate shortening or cling to fried foods. The

bottom of the frypot is sloped toward the front and is equipped

with a 1-1/2“ (3.81 cm) full port drain valve and 3” (7.61 cm) drain

line, allowing quick oil and sediment draining.

5489 Campus Drive

Shreveport, LA 71129 USA

** or between fryer 1 and 2 in all configurations.

***Not available for HD165G.

Tel: 318-865-17 11

Tel: 1-800-221- 4583

Fax: 318-86 8-5987

E-mail: in fo@dean.enodis.com

http://dean. enodis.com

Bulletin N o. 830-0094 11/07

Litho in U.S.A. ©Frymaster, LLC

Page 2

Dean

™

®

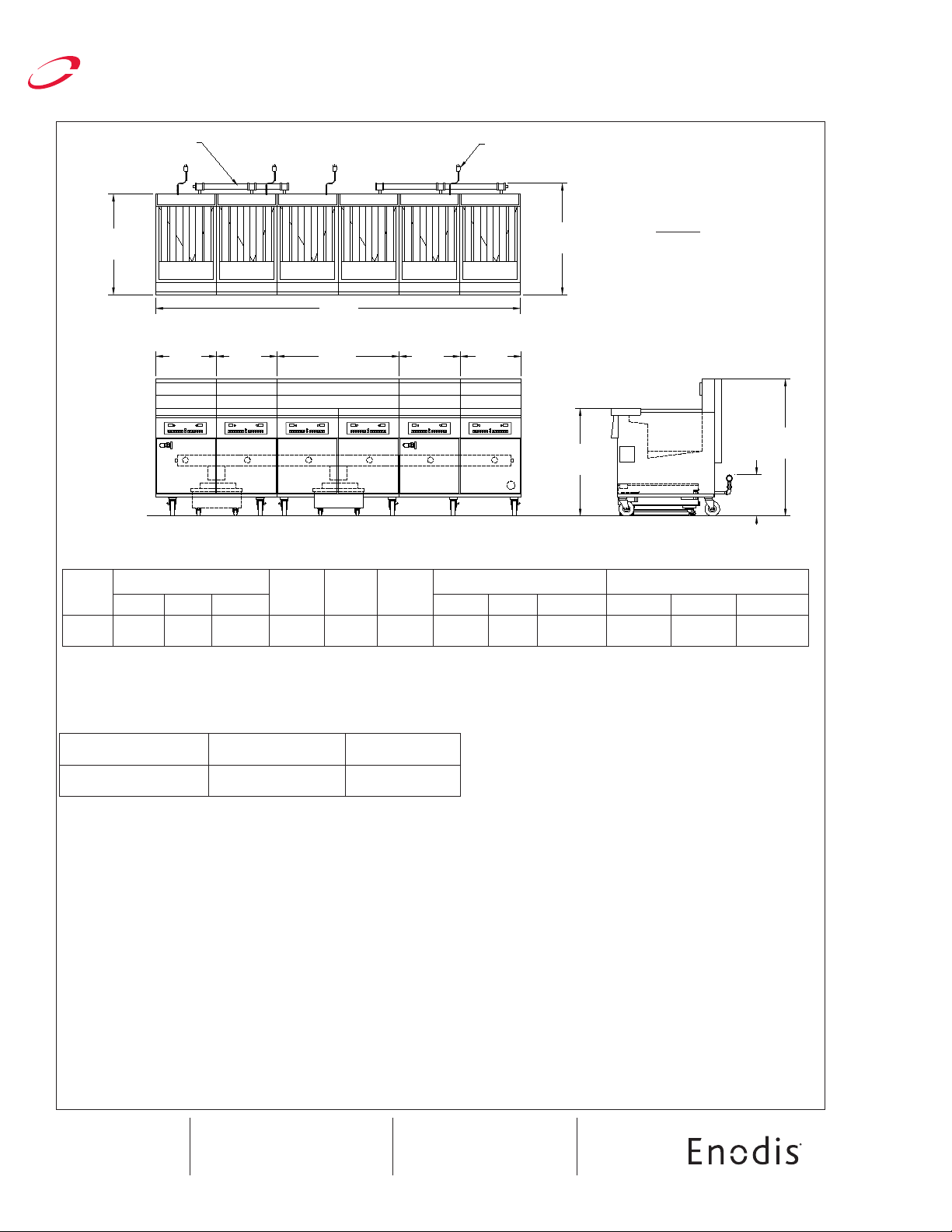

36.50

(927)

1.25 MANIFOLD (32)

(2 PLACES)

CORDSET

(4 PLACES)

40.8

(1036)

120.13

(3051)

20.0

(508)

20.0

(508)

40.0

(1016)

20.0

(508)

20.0

(508)

36.0

(914)

11.0 REF

(279)

43.0

(1092)

DIMENSION

MM

DRAWING SHOWS

OPTIONAL FILTRATION

INCHES

MM

HD65G Series Gas Fryer

DIMENSIONS

MO DEL

NO.

HD65G 43”

Min./Max. Per Fryer Oil Capacity -- 100 lbs. (50 liters)

SI ZE mm DR AIN

HE IGH T WI DTH DE PTH WE IGH T CL ASS CU BE HE IGH T WI DTH DE PTH

(1092)

20”

(508)

36.5

(927)

HE IGH T

POWER REQUIREMENTS

NAT URA L O R L P G AS

IN PUT RAT ING

125,000 BTU /hr.

(31,486 kCa l/hr. ) (36.6 kW )

INTE RNATIONAL VOLTAGES:

220/230/250

SHOR T TERM SPECIF ICATION

Shall be DEAN cool zone, deep fat, high efficiency fryer, Model

______. Only _____” (_____cm) wide, 100 lb. (50 liters) oil capacity, requiring 125,000 BTU/hr. (31,486 kCa l/hr. ) (36.6 kW )

natural or LP gas input (3/4” N .P.T. conn ection).

GA S

CO NNE CTI ON

3/4” N.P.T.

reg ulat or not re quir ed

mm

12.5”

(317.5)

NO. OF

TU BES

FR YIN G

AR EA

5 1 8” x 1 8”

(46 x 46)

EL ECT RICA L

RE QUI REM ENT

120V/60~1ø - 3/5A

cm

335 lbs.

(152 kg)

SH IPP ING IN FO DI MEN SIO NS mm

85 39.7 cu. ft. 5 5”

NOTES:

CLEARANCE INFORMATION

A minimum of 24” (610 mm) should be provided at the front of the

unit for servicing and proper operation, and 6” (152 mm) between the

sides and rear of the fryer to any combustible material.

POWER CORDS: On 1 to 3 battery units, 1 power cords supplied

NOTE: Add 1 additional power cord for filtration.

STANDAR D ACCESSORIES

• 6” adjustable legs

• Rack-type basket support

• Basket hanger

• Two twin baskets or one full basket

On 4 and 5 battery units, 2 power cords supplied

On 6 batter y units, 3 power cords supplied

(1397)

29”

(737)

43”

(1092)

Model #_________ ______

CSI Secti on 11400

5489 Campus Drive

Shreveport, LA 71129 USA

We reserve the right to change specifications appearing in this bulletin without incurring any obligation for equipment previously or subsequently sold.

Tel: 318-865-17 11

Tel: 1-800-221- 4583

Fax: 318-86 8-5987

E-mail: in fo@dean.enodis.com

http://dean. enodis.com

Bulletin N o. 830-0094 11/07

Litho in U.S.A. ©Frymaster, LLC

Loading...

Loading...