TEAC

AP-150

CD\DVD Disc Publishing System

Operational Manual

Re v i s i o n A . 0

Copyright

Copyright © 2008 TEAC Europe GmbH (TEAC). All rights reserved. This manual and the software described in

it are copyrighted with all rights reserved. No part of this publication may be reproduced, transmitted,

transcribed, stored in a retrieval system or translated into any language in any form by any means without

the written permission of TEACTM .

Limited Warranty

This product is warranted by TEAC Europe GmbH against defects in materials and workmanship. LENGTH

OF WARRANTY – This warranty will be effective for both labor and parts, and this warranty will be

effective for one (1) year from the date of original purchase.

WHO MAY ENFORCE THE WARRANTY - This warranty is valid only in the European Union, and enforceable

only by the original purchaser. This warranty is not valid outside the European Union. WHAT IS NOT

COVERED BY THIS WARRANTY

1. Damage to or deterioration of the external cabinet.

2. Damage resulting from accident, misuse, abuse, or neglect.

3. Damage resulting from failure to follow instructions contained in your user’s manual.

4. Damage occurring during shipment of the product (claims must be presented to the carrier).

5. Damage resulting from repair or attempted repair by anyone other than TEAC Service Department.

6. Damage resulting from modification or attempted modification of product not authorized by TEAC.

7. Damage resulting from causes other than product defects, including lack of technical skill,

competence, or experience of the user.

8. Damage to any unit that has been altered or on which the serial number has been defaced, modified

or removed.

9. Damage or malfunction resulting from installation and cabling.

10. For wireless configurations, TEAC cannot be responsible for interference or operation in locations

that restrict range.

11. Damage to or from interconnected network equipment.

12. Data integrity or loss of data.

HOW YOU CAN GET WARRANTY SERVICE

Please contact the TEAC service department for a Return Authorization number before shipping unit(s) to

TEAC. Information required for R/A request should include your name and/or company name, telephone

number, TEAC model, version and serial number(s). Return Authorization (R/A) number must be clearly

marked on the outside of each carton shipped to TEAC. Return merchandise must be packed in original

shipping containers or otherwise packed adequately to prevent damage in shipment. You are responsible for

all risk of damage to or loss of merchandise in transit to TEAC. TEAC reserves the right to reject any

merchandise that is not packaged and/or marked as instructed herein. You must pay any shipping charges if

it is necessary to ship the product for service. However, if the necessary repairs are covered by the warranty,

we will pay the return shipping charges to any destination within the European Union. Whenever warranty

service is required, you must present a copy of the original dated sales receipt as proof of warranty

coverage. Please contact us at the addresses listed at the end of this warranty statement.

WHAT TEAC WILL PAY FOR

We will pay all labor and material expenses for items covered by the warranty. Payment of shipping

charges is discussed in the next section of this warranty. LIMITATION OF IMPLIED WARRANTIES

ANY IMPLIED WARRANTIES, INCLUDING WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE, ARE LIMITED IN DURATION TO THE LENGTH OF THIS WARRANTY

EXCLUSION OF DAMAGES

TEAC’S LIABILITY FOR ANY DEFECTIVE PRODUCT IS LIMITED TO REPAIR OR REPLACEMENT OF THE PRODUCT,

AT TEAC’S OPTION. TEAC SHALL NOT BE LIABLE FOR DAMAGES BASED UPON INCONVENIENCE, LOSS OF USE

OF THE PRODUCT, LOSS OF TIME, INTERRUPTED OPERATION OR COMMERCIAL LOSS, LOST PROFITS OR ANY

OTHER DAMAGES, WHETHER INCIDENTAL, CONSEQUENTIAL, PUNITIVE OR OTHERWISE.

SOME STATES DO NOT ALLOW LIMITATIONS ON HOW LONG AN IMPLIED WARRANTY LASTS AND/ OR DO NOT

ALLOW THE EXCLUSION OR LIMITATION OF INCIDENTAL OR CONSEQUENTIAL DAMAGES, SO THE ABOVE

LIMITATIONS AND EXCLUSIONS MAY NOT APPLY TO YOU.

THIS WARRANTY GIVES YOU SPECIFIC RIGHTS, AND MAY VARY FROM SOME OF THE RIGHTS PROVIDED BY

LAW. THESE RIGHTS MAY VARY FROM STATE TO STATE.

Piracy Statement

TrueNettm and the Publishing System are designed to help you easily reproduce material for which you

own the copyright or have obtained permission from the copyright owner to make copies. Unless you own

the copyright or have permission from the copyright owner to make copies, you are violating the software

license agreement, and may be violating copyright law and be subject to payment of fines, damages and / or

other remedies. R-Quest accepts no responsibility for the use or misuse of this equipment for illegal

purposes. If you are uncertain about your rights, contact your legal advisor.

TrueNet™ (all versions)

Software License Agreement

This is a legal agreement between you and R-Quest Technologies, LLC. (“R-Quest”), covering your

use of TrueNet (the "Software"). Be sure to read the following agreement before using the

Software. BY USING THE SOFTWARE (REGARDLESS IF YOU HAVE REGISTERED THE SOFTWARE OR

NOT), YOU ARE AGREEING TO BE BOUND BY THE TERMS OF THIS AGREEMENT. IF YOU DO NOT

AGREE TO THE TERMS OF THIS AGREEMENT, DO NOT USE THE SOFTWARE.

The Software is owned by R-Quest and is protected by United States copyright laws and

international treaty provisions. Therefore, you must treat the Software like any other copyrighted

material (e.g., a book or musical recording). Paying the license fee allows you the right to use the

Software simultaneously by up to five users for TrueNet LX or 25 users for TrueNet FX.

You may not use this Software to copy copyright material without the permission of the copyright

owner. You may not rent or lease the Software, nor may you (or allow others to) modify, adapt,

translate, reverse engineer, decompile, or disassemble the Software. If you violate any part of

this agreement, your right to use this Software terminates automatically and you must then

destroy all copies of the Software in your possession.

The Software and its related documentation are provided "AS IS" and without warranty of any

kind and R-Quest expressly disclaims all other warranties, expressed or implied, including, but not

limited to, the implied warranties of merchantability and fitness for a particular purpose. Under

no circumstances shall R-Quest be liable for any incidental, special, or consequential damages

that result from the use or inability to use the Software or related documentation, even if R-

Quest has been advised of the possibility of such damages. In no event shall R-Quest liability

exceed the license fee paid, if any.

Any written or oral information or advice given by R-Quest dealers, distributors, agents or

employees will in no way increase the scope of this license or warranty. Nor may you rely on

such oral or written communication. Some states do not allow the exclusion or limitation of

implied warranties or liability for incidental or consequential damages, so the above limitation or

exclusion may not apply to you. This warranty gives you specific legal rights, and you may also

have other rights which vary from state to state.

This Agreement shall be governed by the laws of the State of California. If for any reason a court

of competent jurisdiction finds any provision of the Agreement, or portion thereof, to be

unenforceable, that provision of the Agreement shall be enforced to the maximum extent

permissible so as to affect the intent of the parties, and the remainder of this Agreement shall

continue in full force and effect.

Limited 1 Year Warranty

TEAC Europe GmbH (hereinafter “TEAC”) warrants to the original end user that the AP-150 series

equipment purchased (Product) will be free from defects in material and workmanship for a period of one

year from the date of original purchase. Any part replaced under warranty is warranted to be free from

defects in material and workmanship until the expiration of the original warranty.

TEAC further warrants that the goods sold are as described, but no promise, description, affirmation of

fact, sample model or representation, oral or written shall be part of an order, unless set forth in these

terms and conditions, or are in writing and signed by an authorized representative of TEAC.

This warranty is subject to the following further conditions:

1) This warranty is limited to the electronic and mechanical performance only, as expressly detailed

in the Product specifications and NOT to the embedded software, firmware or to third party

software.

2) This warranty shall not apply to any Products which are stored, or utilized, in harsh environmental

or electrical conditions outside TEAC’s written specifications.

3) This warranty shall be valid only if the Product was purchased by the End User from an authorized

TEAC Distributor/Reseller.

4) This warranty shall not apply to any Product which has been modified, improperly repaired,

improperly installed, altered, or disassembled.

5) This warranty shall not apply to any Product that has been subject to misuse, negligence, accident

or normal wear and tear.

6) Heavy use may require consumable items such as Recorders and Print Engines to be serviced

within the warranty period. Examples of heavy use are:

• More than 12,000 discs burned per recorder

• More than 25,000 discs printed or more than 100 ink cartridges used for the FlashJet2 Print

Engine

Such service is not covered under warranty. Parts replaced in the course of a warranty service are subject

to the same service interval requirements.

7) Removal of the TEAC Label or Serial number from the product will void this warranty.

TEAC DISCLAIMS ALL IMPLIED WARRANTIES ON THE PRODUCT, INCLUDING WITHOUT LIMITATION

WARRANTIES OF MERCHANTABILITY, PERFORMANCE AND FITNESS FOR A PARTICULAR PURPOSE. TEAC

WILL NOT BE LIABLE FOR ANY ERROR, OMISSION, DEFECT, DEFICIENCY, OR NON-CONFORMITY IN ANY

SOFTWARE. AS A RESULT, THE PRODUCT IS SOLD “AS IS”, AND THE PURCHASER ASSUMES THE ENTIRE RISK

AS TO ITS QUALITY AND PERFORMANCE, AND IT IS UP TO THE PURCHASER TO DETERMINE SUITABILITY FOR

THE INTENDED PURPOSE. THE MAXIMUM LIABILITY IN ANY CASE SHALL BE LIMITED TO THE LESSOR OF

THE PURCHASE PRICE PAID FOR THE PRODUCT OR THE TEAC PUBLISHED RETAIL PRICE AT THE TIME OF

PURCHASE.

TEAC RESERVES THE RIGHT, AT TEAC’s SOLE DISCRETION, TO REFUSE TO PROVIDE, OR TO DISCONTINUE

PROVIDING TECHNICAL SUPPORT IF TEAC KNOWS, OR HAS REASON TO BELIEVE THAT SUCH TECHNICAL

SUPPORT WILL AID CIRCUMVENTING ENCRYPTION OR COPY PROTECTION TECHNOLOGY, OR OTHERWISE

ATTEMPTING TO VIOLATE THE LAWS OF ANY COUNTRY. TEAC SHALL NOT BE LIABLE FOR CIRCUMVENTING,

OR ATTEMPTING TO CIRCUMVENT SUCH TECHNOLOGY USING TEAC PRODUCTS, OR OTHERWISE AIDING

ANY ATTEMPT TO VIOLATE THE LAWS OF ANY COUNTRY.

TEAC SHALL NOT BE HELD LIABLE FOR THE INTEGRITY AND/OR LONGEVITY OF ANY TEXT, GRAPHICS, BAR

CODES OR COMBINATION THEREOF THAT ARE PRODUCED, GENERATED OR OTHERWISE TRANDFERRED TO

THE MEDIA BY THE USE OF TEAC PROVIDED PRODUCTS, NOR IS TEAC LIABLE FOR THE INTEGRITY, VIABILITY

OR LONGEVITY OF THE DATA ENCODED ON THE MEDIA.

TEAC SHALL IN NO EVENT BE LIABLE FOR DIRECT, INDIRECT, SPECIAL, INCIDENTAL, CONTINGENT, OR

CONSEQUENTIAL DAMAGES RESULTING FROM ANY DEFECT IN THE PRODUCT OR ITS DOCUMENTATION

INCLUDING DAMAGES FROM LOSS OF DATA, EVEN IF TEAC OR AN AUTHORIZED TEAC DEALER HAS BEEN

ADVISED OF THE POSSIBILITY OF SUCH DAMAGES. YOU AGREE THAT TEAC’s LIABILITY ARISING OUT OF

CONTRACT, NEGLIGENCE, STRICT LIABILITY IN TORT OR WARRANTY SHALL NOT EXCEED THE LESSOR OFANY

AMOUNTS PAID BY YOU FOR THIS PRODUCT OR THE TEAC PUBLISHED PRICE.

Any written or oral information or advice given by TEAC’s dealers, distributors, agents or employees will in

no way increase the scope of this warranty. Nor may you rely on such oral or written communication.

Some states do not allow exclusions or limitations of implied warranties or liability for incidental or

consequential damages, so the above limitations or exclusions may not apply to you. This warranty gives

you specific legal rights, and you may also have other rights that vary from state to state.

Purchaser’s Remedies

If an TEAC Distributor/Reseller or an End User desires to make a warranty Claim, the Distributor/Reseller or

End User shall, if requested by TEAC, ship the Product to TEAC’s authorized service facility, postage or

freight prepaid. TEAC shall, at its option, take one of the following two courses of action for any Products

which TEAC determines are defective in materials or workmanship:

1) Repair the Product with either new or refurbished parts; or

2) Replace with a new Product.

And if to a US Lower 48 Address (any United States address in the lower 48 contiguous states), ship the

product to the End User or to the authorized TEAC Distributor via Fed Ex Ground or other similar

transportation method freight prepaid.

PURCHASER’S REMEDIES SHALL BE LIMITED EXCLUSIVELY TO THE RIGHT OF REPLACEMENT OR REPAIR AS

PROVIDED AND DOES NOT INCLUDE ANY LABOR COST OR REPLACEMENT AT END USER’S SITE. TEAC SHALL

NOT BE LIABLE FOR ANY CONSEQUENTIAL DAMAGES RESULTING FROM ANY BREACH OF THIS WARRANTY,

INCLUDING WITHOUT LIMITATION, ANY DAMAGES RESULTING FROM PROPERTY DAMAGE, PERSONAL

INJURY OR BUSINESS INTERRUPTION.

Governing Law and Venue

The sale and purchase of Products covered hereby and all terms and conditions of this Warranty shall be

governed by the laws of the State of California, and any disputes hereunder shall be venued in the El

Dorado County District Courts in California.

If Your Product Requires Support

If your product requires servicing, you should first contact the place of purchase and request support. If

the service request cannot be completed by the place of purchase, you should contact TEAC directly using

one of the following methods:

E-Mail: dps-support@TEAC.de

Telephone: +49(611) 7158 657

Fax: +49(611) 7158 4657

Before shipping any item to TEAC, first obtain an RMA (Return Material Authorization) Number from TEAC

support. This number must be placed on the outside of the product packaging where it can be easily found

otherwise the item will be refused and returned at the sender’s expense.

All products returned to TEAC under warranty MUST be in original TEAC supplied packaging. If you do not

have the original packaging, new packaging can be supplied for a charge. Please contact TEAC for the cost

of replacement packaging, which may vary based on the product, and your location. Your warranty will be

voided if original TEAC packaging is not used.

Within the first 30 days of warranty, if to a US Lower 48 Address, TEAC will cover the cost of shipping to

the TEAC factory via Fed Ex Ground or other similar transportation method; otherwise you are responsible

for the cost of shipping the product to TEAC.

During the warranty period, if to a US Lower 48 Address, TEAC will cover the cost of returning the repaired

product to you via Fed Ex Ground or other similar transportation method. If you require a more urgent

transportation method, upgrades can be arranged for a charge, which in all cases must be pre-paid.

Table of Contents

1. Using TrueNet

1.1 Starting TrueNet via a Web Browser

1.2 How to find the System IP Adress

1.3 Default Login and Password

1.4 Home Page Area

1.4.1 Main Job Area

1.4.2 Loader Status

1.4.3 Media Status

1.4.4 Hopper Types

1.4.5 Network Status / Transfer Status

1.4.6 Ink Levels

1.4.7 Left Menu Bar

1.4.7.1 New Job

1.4.7.2 Edit Job

1.4.7.3 Delete Job

1.4.7.4 Disc Sets

1.4.7.5 System Images

1.4.7.6 Label Designer

1.4.7.7 User Settings

1.4.7.8 Administration

1.4.8 Creating a New Job

1.4.8.1 Job Reference

1.4.8.2 Quantity

1.4.8.3 Media

1.4.8.4 Disc Image

1.4.8.4.1 Local Image

1.4.8.4.2 System Image

1.4.8.4.3 Create Data Disc

1.4.8.4.3.1 File System

1.4.8.4.3.2 Media Type

1.4.8.4.3.3 Volume Label

1.4.8.4.3.4 New Folder

1.4.8.4.3.5 Disc Space Used Bar

1.4.8.4.4 Read New Master

1.4.8.4.5 Disc Set

1.4.8.5 Print Image

1.4.8.5.1 Local PRN

1.4.8.5.2 System PRN

1.4.8.5.3 Local Template

1.4.8.5.4 System Template

1.4.8.5.5 Create Label

1.4.8.5.6 About Template Files

1.4.8.6 Priority

1.4.8.7 Write Speed

1.4.9 Job Setting

1.4.9.1 Copy

1.4.9.2 Compare

1.4.9.3 Audit

1.4.9.4 Print

1.4.9.5 Fast Start

1.4.9.6 No Overlap

1.4.10 E-Mail Settings (all systems)

1.4.11 Dynamic Printing (TrueNet FX Only)

1.4.11.1 Embedded Label Tags

1.4.11.2 Dynamic User Form Fields

1.4.11.3 Dynamic Mail Merge Fields

1.4.11.4 Serialization

1.4.12 Editing Jobs

1.4.12.1 Changing the Quantity

1.4.12.2 Job Priority

1.4.12.3 Enable Compare / Audit

1.4.12.4 Enable / Disable No Overlap

1.4.12.5 E-Mail Notification Settings

1.4.13 System Images

1.4.13.1 Getting a Disc Image from the System

1.4.13.2 Sending an Disc Image to the System

1.4.13.3 Sending a Print Image to the System

1.4.13.4 Sending a Print Template to the System

1.4.13.5 Renaming an Image

1.4.13.6 Deleting an Image

1.4.13.7 Refreshing the Display

1.4.14 Disc Sets

1.4.14.1 Creating a Set

1.4.14.1.1 Add

1.4.14.1.2 Modify

1.4.14.1.3 Delete

1.4.14.1.4 Move Up / Move Down

1.4.14.1.5 Reverse

1.4.15 Using a Disc Set

1 . 4 .1 6 Using a Disc Set

2 The Label Designer

2.1 Overview – Limitations of the browser environment

2.2 Label Designer – Main Window Overview

2.3 Creating a Basic Label

2.4 Creating a Print Image (PRN)

2.5 Adding Text to a Design

2.6 Adjusting the Template Dimensions

2.6.1 Disc Margin

2.6.2 Hub Size

2.7 Saving as a Template

2.8 Creating a Design from Scratch

2.9 Displaying Rulers

3 User Settings

3.1 Password

3.2 E-Mail

3.3 Language

3.4 View Job Queue

3.5 Defaults

3.5.1 Disc Images

3.5.2 Labels

3.5.3 PRN Images

3.5.4 Set Files

3.5.5 CSV (Used by TrueNet FX Only)

3.5.6 Logging

4 Administrator Guide

4.1 System Setup

4.2 Hopper Settings

4.3 Retaining Rejects inside the machine – Rotating Hoppers

4.4 Sticky Disc Mode

4.5 Thresholds

4.6 Images Backup

4.6.1 Running Backup

4.6.2 Running Restore

4.7 E-Mail Server

4.7.1 Authentication

4.7.2 Copy-All E-Mails

4.7.3 Console E-Mail

4.8 Network

4.8.1 DHCP

4.8.2 System Name

4.9 Recorders

4.10 Time & Date

4.11 Logging

4.12 Firmware

4.13 System License

4.14 Printer Settings

4.15 PIP – Product Improvement Program

4.16 Users

4.16.1 SysAdmin

4.16.2 Administrator

4.16.3 User

4.16.4 User Name

4.16.5 Password / Confirm

4.16.6 E-Mail

4.16.7 Language

4.16.8 Max Priority

4.16.9 Max User Jobs (Quota)

4.16.10 Max Quantity per Job (Quota)

4.16.11 Max Combined Job Quantity (Quota)

4.16.12 Enabled

4.16.13 Administrator

4.16.14 View Job Queue

4.16.15 Allow Fast Start

4.16.16 Allow No Overlap

4.16.17 Edit User

4.16.18 Delete User

4.16.19 Backup

4.16.20 Restore

4.16.21 Save

4.16.22 Cancel

5 Optimizing your browser for TrueNet

5.1 Windows Vista & XP

5.2 Mac OSX

6 TrueNet Error Messages & Troubleshooting

7 Administration (Via the LCD/Touchpad)

7.1 Setup Menu

7.2 Job Options

7.2.1 Burn Discs

7.2.2 Compare Master

7.2.3 Compare Copy

7.2.4 Audit Copy

7.2.5 Ask Quantity

7.2.6 Async Copying

7.2.7 Check Blank Size

7.2.8 Master Drive

7.2.9 Printer

7.2.10 Stop Reject Full

7.2.11 Last Char Name

7.3 Network Setup

7.3.1 Network Active

7.3.2 DHCP

7.3.3 Set Network Name

7.3.4 Duplicator IP (DHCP = No)

7.3.5 Network Mask (DHCP = No)

7.3.6 DNS Server (DHCP = No)

7.3.7 Gateway IP Address (DHCP = No)

7.4 Time & Date

7.4.1 Set Time

7.4.2 Set Date

7.4.3 Set Date Format

7.5 Password Setup

8 Using the System in Standalone Mode

8.1 Turning On

8.2 Keyboard

8.3 LCD Display

8.4 Menu Structure

8.4.1 Copy

8.4.2 Compare

8.4.3 Image Menu

8.4.4 Load New Master

8.4.5 List Images

8.4.6 Show HD Free Space

8.4.7 Delete Image

8.4.8 Defragment HD

8.5 Utilities Menu

8.5.1 Hard Disk Utilities

8.5.1.1 Show HD Free Space

8.5.1.2 Show HD Info

8.5.1.3 Defrag HD

8.5.2 Firmware Utilities

8.5.2.1 Load System F/W

8.5.2.2 Load F/W XMODEM

8.5.2.3 Load F/W From USB

8.5.2.4 Load Drive F/W

8.5.2.5 Load Loader F/W

8.5.3 Loader Utilities

8.6 System Information

8.6.1 PCA Info

8.6.2 Writer Info

8.6.3 Hard Drive Info

8.6.4 Autoloader Info

8.7 Upgrade License

8.7.1 Show Current Key

8.7.2 Enter New Key

8.8 Quick Start Copying

8.9 Quick Start Comparing

9 TrueView

9.1 What is TrueView?

9.2 Supported Operating Systems

9.3 Installing TrueView

9.4 Running TrueView

1. Using TrueNet

1.1 Starting TrueNet via a Web Browser

TrueNet is loaded directly from the System using a Java-enabled web browser. To login

to the AP-150 using your web browser you will need four things:

1. A Computer with a Java-enabled Web Browser

2. The address of the System (this could be an IP address, or a Domain name)

3. Your Login Name (the factory default login is ‘admin’)

4. Your User Password (the factory default password is ‘admin’)

1.2 How to find the System IP Address

If the AP-150 is already in Network Mode, hold the

STOP

key until the message ‘Stop

(Y/N)’ appears. The current IP address will be shown on the bottom line of the LCD. If

you do not touch any keys for 30 seconds, the System will return to the ‘Online’ display.

Alternatively, press the NO key (a menu will appear) then the

STOP

key to exit the menu

and return to Network Mode.

If the System is at the main menu, use the down cursor key to move to the “Network

Mode” menu item and press

ENTER

to enter Network Mode. The System will display the

current IP address on the LCD for a few seconds, and then enter Network Mode.

The System must be in Network Mode to accept jobs from TrueNet.

1.3 Default Login and Password

The factory default login name is ‘admin’, and the default password is also ‘admin’.

However, if your System administrator has changed this login, or has created individual

user login/password settings, your System administrator will provide you with the new

login name and password. If you are the System administrator, please refer to the

Administrator Guide section (later in this manual) for complete setup information.

Once you have the System IP address, login and password information, open the web

browser and enter the IP address of the System in the browser address bar, just as if you

were accessing any other web site.

After a few moments the browser may display a Java logo, and a dialog box informing you

that you are loading a digitally signed Java Applet, signed by TEAC Technologies, the

manufacturer of the AP-150 and TrueNet. The purpose of this dialog is to let you know

that this applet will allow you to move data between your computer and the System.

This dialog box will appear every time you log on to TrueNet unless you click the check

box “Always Trust (the address of the System) from this Publisher”. By selecting this box

you are telling your browser that it is OK to load TrueNet in the future without having to

view this dialog. Click the Run button to proceed.

If for any reason the words ‘Requires Java’ appear on your browser window, this means

that your browser does not have Java enabled. To install the Java plug-in within your

browser, visit www.java.com.

After a few seconds, the TrueNet login screen will appear. Enter your login name and

password and click on the ‘Login’ button. A few moments later the main TrueNet screen

will appear.

1.4 Home Page Area

The Home Page display may vary

depending on the specific model

you purchased. The Home Page

shown here is TrueNet LX on the

AP-150 which has four assignable

hoppers.

1.4.1 Main Job Area

This area of the screen is where

your jobs will appear, showing the

current status and progress of the

job. Any job reference you entered will also be shown, making it easy to keep track of

many jobs at the same time.

There are five main areas of the screen. The first is the Job Status window. This is the

largest area, and is where the status of all visible jobs will be shown. Depending on the

settings selected by the administrator, it may be that you cannot see all the other jobs on

the System. This is to provide some level of confidentiality between users on the System.

If the administrator allows you to see other jobs, you still have the option of viewing just

your own jobs by selecting to View Job Queue in User Settings. This may be desirable

when there are many jobs on the System, and you are looking down a long list for yours.

Turning off other people’s jobs makes yours the only ones displayed.

1.4.2 Loader Status

The current status of the System autoloader is shown whenever the user (or

administrator) is logged in to the System via TrueNet. Normally the status will show ‘OK’,

indicating that the System is ready. If the System is unable to operate normally, an error

message will be displayed (usually highlighted in red), and appropriate action must be

taken by the user to correct the problem.

An example is when the door is open, and the error message “Loader Status : Door Is

Open” is displayed. The System will not operate with the door open, so action must be

taken to close the door before normal operation can be resumed. See the section on

error messages for more information about this.

1.4.3 Media Status

The AP-150 has a very flexible hopper system, allowing the administrator to choose

different media types available in each of the input hoppers depending on the recorder

options purchased. The current options for CD/DVD machines are:

CD

DVD SL (single layer 4.7GB)

DVD DL (dual layer 8.5GB)

If the System was purchased with Blu-ray capability then the following media types will

also be available:

BD SL (Blu-ray single layer 25GB)

BD DL (Blu-ray dual layer 50GB)

The administrator is free to designate the hopper and media types as required. For

convenience, there are some predefined hopper configurations that allow very easy

selection and setup. For more information on media types see the Administrator Guide

section.

1.4.4 Hopper Types

The current hopper types and approximate

number of discs in each hopper are shown in the

hopper status display. Input hoppers that have

levels above the administrator-defined low-media

threshold will appear green, and input hoppers (or

‘group of input hoppers’) that are below this threshold will turn red. A ‘group of input

hoppers’ is where more than one hopper has the same input media type. As an example,

if there are two input hoppers with CD media, the hoppers will only turn red once the

combined number of discs in both hoppers falls below the administrator-defined lowmedia threshold. See Administrator Guide: Thresholds for more information about

System thresholds, which also affect e-mail notifications for low media and low ink levels.

Once output hoppers reach almost full, they will turn red to indicate they are almost full

and will soon need attention.

The output hoppers will display the number of discs placed in that hopped since the door

was last opened. The system will reset this count to zero whenever the door is opened.

Each hopper will have a media type associated with it and the current function of that

hopper is also indicated in the form of ‘Input’, or ‘Output’. Note that some hopper

configurations will allow a hopper to change from an ‘Input’ to an ‘Output’ automatically

once the input becomes empty. This feature is known as ‘rotating hoppers’ and the

hopper display will automatically update to show the new configuration. Hoppers can be

reset back to their original state at any time by opening the System door, emptying the

burned media, and placing new blank media in to the hoppers originally designated as

input. Once the door is closed, choose ‘Reset Hoppers = Yes’ on the System

LCD/Touchpad. By default the AP-150 does not operate in rotating hopper mode, and

this must be enabled by an administrator.

1.4.5 Network Status / Transfer Status

The current network status is shown at all times except for during file transfer. The

network status should be either ‘Online’ or ‘Offline’, and indicates the availability of the

System for network transfers and job control.

During image transfer the network status is replaced by the image file transfer status,

with the information being updated approximately once per second during a transfer

operation. The status will typically show the number of megabytes transferred so far,

and the total number of megabytes to send. At the same time, a progress bar will appear

on the main screen (not shown above), together with an approximate time remaining

based on the amount of data transferred so far, and the total amount left to transfer.

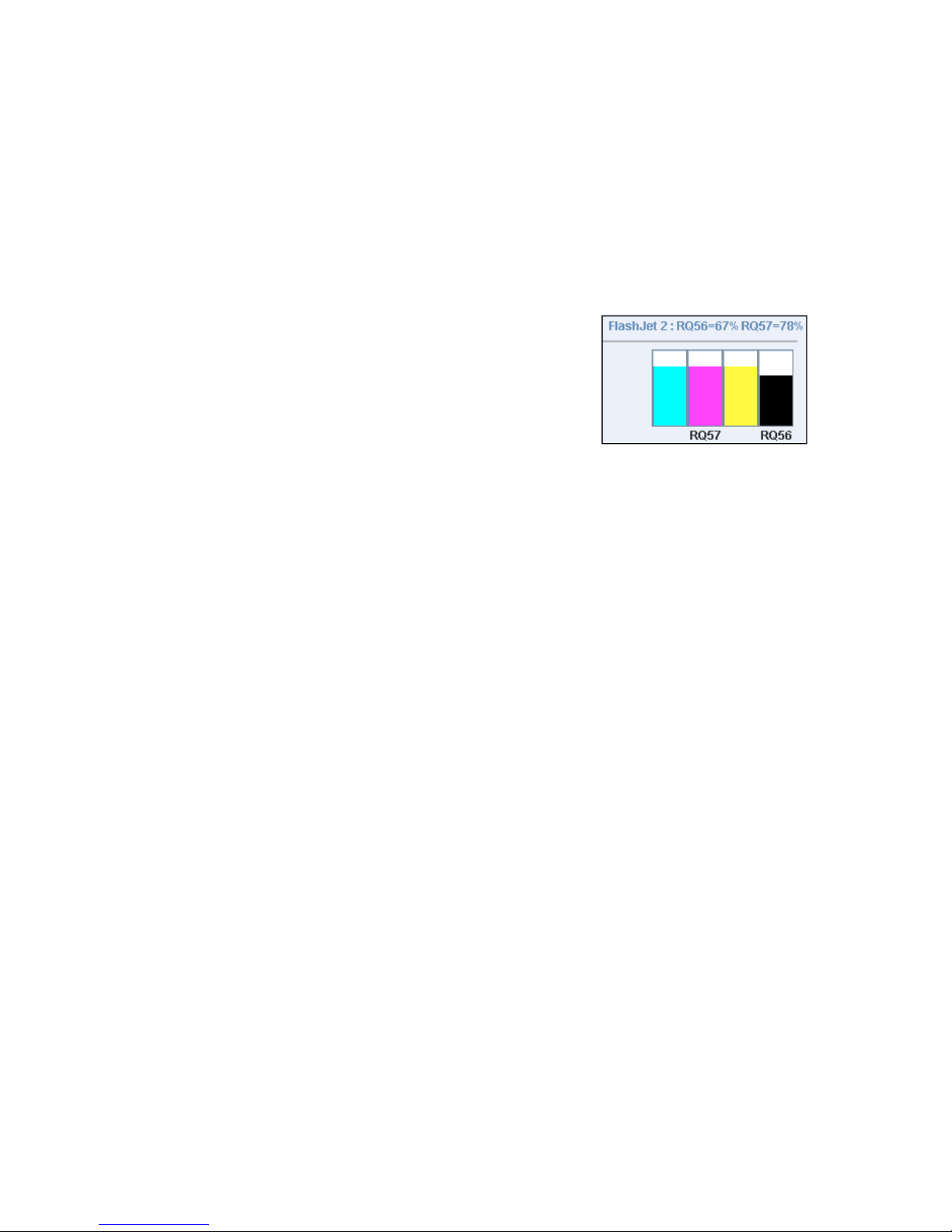

1.4.6 Ink Levels

The level of ink remaining is displayed graphically to make

it easy to recognize low ink status. The level is also

displayed in text form just above the graphic display. The

AP-150 includes an embedded FlashJet2 print engine, and

the bars represent the RQ56 (Black) and RQ57 (Color)

cartridge types.

1.4.7 Left Menu Bar

The left menu bar allows access to the various functions available within TrueNet. To

select an item in the menu, move the mouse over the item and single-click that item.

Each item in the menu will change color as the mouse is moved over it to show which

menu item would be activated if selected by the single mouse click.

If you are logged in as a System Administrator an additional menu (Administration) will

appear below ‘User Settings’ (which is the settings for the current user – see ‘User

Settings’ for more information). When this menu item is selected, the System Setup

window will open. See the Administrator Guide section for more information on System

Setup.

1.4.7.1 New Job

Selecting New Job on the left menu bar will launch the Create New Job dialog box. This is

only one of four ways to activate the Create New Job dialog box. You could also doubleclick the main Job Status area (do not double-click on a job because this will bring up the

Edit Job dialog!), or you can right-click in the same Job Status area. If there are jobs

already present in the Job Status area, right-clicking on any job will activate a pop-up

menu which also includes a Create New Job menu item.

1.4.7.2 Edit Job

Selecting a job in the Job Status window (single-click the job) followed by the Edit Job

item on the left menu bar will launch the Edit Job dialog box. This is one of three ways to

launch the Edit Job function. The other ways are to double-click the job in the Job Status

window or to right-click the job and choose ‘Edit Job’ from the pop-up menu that

appears. Editing a job allows real time changes to be made to a job that has already been

submitted, including changes to disc quantities, job priorities, and adding or removing

Compare/Audit functions. Additional functions include stopping a running job, restarting

a stopped job or starting a master disc reading. For more information on editing jobs,

see the Editing Jobs section.

1.4.7.3 Delete Job

To delete a job, select the job in the main Job Status window (single-click the job) then

select the ‘Delete Job’ item on the left menu bar. Another way to delete a job is to rightclick on the job and select ‘Delete Job’ from the pop-up menu that appears. Running jobs

cannot be deleted. If a job is running, it must first be stopped. Jobs in an error state,

jobs that have completed (‘Done’) and jobs that are in a ‘Queued’ state can all be

deleted. Note that when a job is deleted, any temporary disc images or print images that

were created as part of the job (and sent to the System as part of the New Job function)

will automatically be deleted from the System’s local storage.

1.4.7.4 Disc Sets

Disc Sets provide a way to select a Disc image and Print image together as a ‘Set’. This

allows the user to select the Set instead of having to find and select the disc image and

print image individually. TrueNet LX allows up to 3 discs per set. TrueNet FX allows up to

25 discs to be added to each Set. Disc sets make it easy to produce multi disc sets

without having to create a different job for each disc in the set.

1.4.7.5 System Images

The System Images dialog box can be accessed via the left menu bar and is used to select,

rename, delete or transfer images to/from the System internal storage. In most cases,

image transfers will be done automatically when you create new jobs, but the System

Images dialog box provides a way of doing this manually. It is also available in a limited

form from within the Create New Job dialog box to allow you to select images already

located on the System’s internal storage as part of a duplication or print job. This dialog

box shows the image name, type (CD/DVD/BD/Print/Template) and image size of all

images available on the System for use in duplication and/or printing jobs.

1.4.7.6 Label Designer

The Label Designer provides a way to create labels within the browser environment

without the need to learn complicated graphics editing packages, install printer drivers

on your local computer, or produce PRN files for use in printing jobs.

The Label Designer includes easy-to-use functions for creating both static and dynamic

text fields, simple graphics primitives as well as importing many standard graphics files

(e.g. JPEG, TIFF, PNG, BMP, etc.) for use as both background images and image inserts.

Labels can include automated tags for showing the Date and Time on the printed surface

of the disc, together with full support for both serialization and dynamic text (mailmerge) functions, and User-Defined Form Field Prompts.

The Label Designer can be launched from the left menu bar, or from the Create Job

Dialog for label creation as part of a wider Create New Job function. Designs are stored

as label template files and can be re-used over and over again, even with different printer

types simultaneously (which is something you can’t do with a PRN file!). For more

information see the Label Designer section.

1.4.7.7 User Settings

Each user has their own settings, including passwords, e-mail address and other shortcut

directory options. The user can edit many of the administrator assigned options by

selecting the User Settings menu from the left menu bar. See the section on ‘User

Settings’ for more information.

1.4.7.8 Administration

If you are logged on to the System as an administrator an additional menu item

(Administration) will appear and the end of the menu list in the left menu bar. By

selecting this menu item the System Setup dialog will appear and allow the general

administration of the System via a series of ‘tabs’.

1.4.8 Creating a New Job

Running a publishing, duplication or printing

job on the System is very easy and takes just

a few mouse clicks. Jobs are created using

the ‘Create New Job’ dialog.

Selecting New Job on the left menu bar will

launch the Create New Job dialog box, and is

only one of four different ways to activate

this dialog box. You can also double-click

the main Job Status area (do not double-click

on a job because this will bring up the Edit

Job dialog!), or you can right-click in the same Job Status area. If there are jobs already

present in the Job Status area, right-clicking on any job will activate a pop-up menu which

also includes a Create New Job menu item.

Once you have selected all the required options, e.g. the disc image, print image,

quantity, etc., click the Start button to start the job.

1.4.8.1 Job Reference

The job reference is for user convenience only. It is not used by the System for anything

other than to help the user identify and keep track of their jobs. Any combination of

letters and numbers may be entered up to a maximum of 20 characters. This reference

will show as part of the Job Status, and may be seen by other System users if that is

allowed by the administrator. This field can also be automatically printed on a disc label

produced using the Label Designer (and saved/used as a template) when using the

dynamic tags fields. See “Dynamic Printing Using TrueNet FX” for more information.

Typical uses for Job Reference could include customer order number or internal job

tracking numbers. However, the use of this field is entirely optional.

1.4.8.2 Quantity

Enter a number between 1 and 9999 as the number of copies/prints required in this job.

Note that the administrator may restrict the number of discs allowed per job, and if you

request more than the designated limit, a warning will appear and the quantity will be

reduced to the maximum permitted number. All jobs, except those using dynamic ‘mailmerge’ labels can have their quantities edited after the job has been created, while the

job is running, and even after a job has already completed the requested number of

discs.

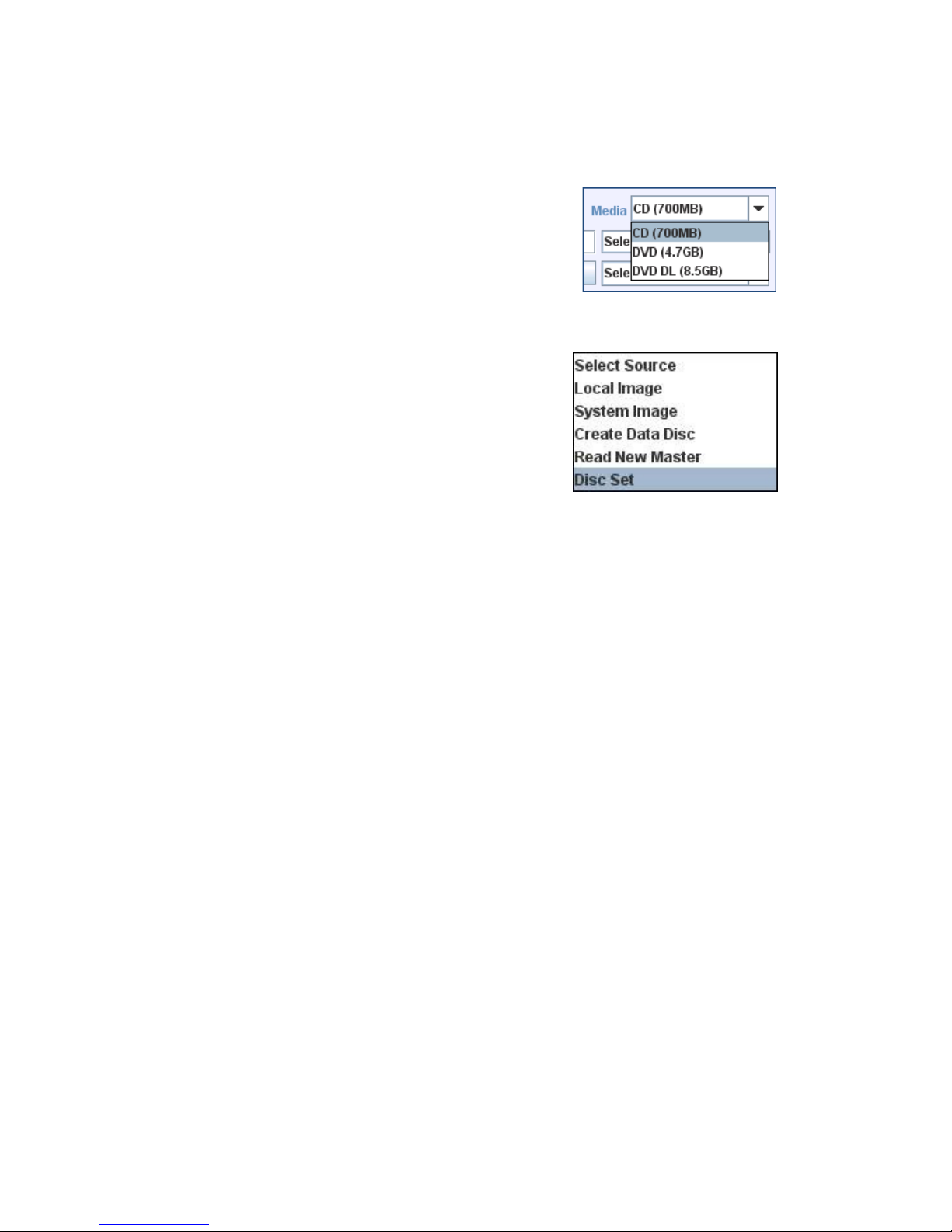

1.4.8.3 Media

The Media selector will include all the media types available

in the System at this time. If you are using a System image,

or an image that was originally created from a master disc

using the System reader, the media type is already

embedded within the image file, and the media type will be

selected automatically for you. However, if you are creating a new data disc, or selecting

an ISO image file as part of a job, you must select the media type required before starting

the job. Note that the media type can also be changed

while creating a data disc (see Create Data Disc). Once a

job has been started, the media type can no longer be

changed.

1.4.8.4 Disc Image

The Disc Image selector provides a convenient way to

select one of several possible sources for the disc image

data.

1.4.8.4.1 Local Image

If you want to make copies from an ISO file created by another mastering application

(e.g. Data or Video authoring package), or you have a disc image originally created in the

System reader and then transferred to your local hard disk, you should select Local

Image. A File Open dialog box will allow you to select the file by browsing your computer

for the file. If you have designated a ‘shortcut’ directory to your image files (See User

Settings: Shortcuts) the File Open dialog box will automatically open in that directory. If

you have not set the shortcut yet, the File Open dialog box will typically open up in your

user home directory.

If you select an ISO image file, TrueNet then asks you what type of media this ISO file is

being targeted for, e.g. CD or DVD, or if you have purchased the Blu-ray option, then BD

will also be available. It is important that you select the correct media type, or you may

end up with unusable discs.

If you select an TEAC Image File (.rqi) then the media type will automatically be selected

using the embedded image file information. This media selection cannot be changed.

1.4.8.4.2 System Image

The System can store many master disc images on its internal hard disk system. The

storage capacity will depend on the model and options purchased. Images stored on the

System are available for any user to select as part of their jobs. Storing an image on the

System has the advantage that no time is required transferring the disc image to the

System prior to starting a new job, and users who regularly run repeated jobs of the same

disc images can take advantage of this to speed up starting repeated jobs.

Selecting System Image will launch the System Images dialog box and allow you to select

an image on the System. To select an image, single-click on the image name and then

click the OK button. The media type is automatically detected from the selected image.

1.4.8.4.3 Create Data Disc

TrueNet includes a drag & drop

mastering tool that allows you to

create ISO 9660 data discs within the

browser window. When you select

this option a new Create Data Disc

window will appear.

You can browse your local computer

and all of the available directories

including hard drives and network

resources from this window. When

you find the files that you want to

copy, drag them from the left

window into the right window.

1.4.8.4.3.1 File System

The currently supported file systems include ISO9660 (strict) and ISO9660 + Joliet (allows

long file names), UDF 1.02 (for DVD Video) and UDF 2.60 (for Blu-ray Video).

1.4.8.4.3.2 Media Type

Select the type of media you will be recording to here. All available media types will be

listed here based on your input media hopper setup.

1.4.8.4.3.3 Volume Label

This is where you can label your disc volume.

1.4.8.4.3.4 New Folder

Select this button to add a new folder in your new master.

1.4.8.4.3.5 Disc Space Used Bar

This graphical indicator will build left to right in green showing the approximate size of

your data in comparison to the total size of your selected media capacity.

1.4.8.4.4 Read New Master

If you have a master disc that you need to make copies of, place the disc on top of the

first input hopper and then select Read New Master in TrueNet as the source of the disc

image. Once selected, the cursor will automatically move to the Disc Image name entry

box to allow you to enter the image name to use. This image name can be any

combination of letters or numbers up to 14 characters long. Once the Create New Job

dialog has been completed (i.e. by choosing the Start button) the job will be created in a

‘Need Master’ state. To start the master reading, right-click on the job (in the Job Status

window) and choose Start Reading from the pop-up menu, or double-click the job and

choose the Start Reading button from within the Edit Job dialog box.

Unless other options are chosen, a Read New Master job will read a master to the System

internal storage and then stop (job completed). To start copying immediately once the

master has been read, select the ‘Copy’ checkbox within the Create New Job dialog box at

the same time you select to read a new master, and enter a copy quantity. You may also

select a print image to print on to the copies made.

It is also possible to add the Copy flag, and add a quantity to this read job by editing the

job after it is created, but you will not be able to add a print image once you leave the

Create New Job dialog box. If you want to print on the copies that are started

automatically after a read master is complete, remember to select a print image before

starting the job.

1.4.8.4.5 Disc Set

Multi disc sets can be produced (in disc set order) by selecting a single set entity. Up to

100 discs can be added to a ‘Set’. For more information on Disc Sets, please see the Disc

Sets section.

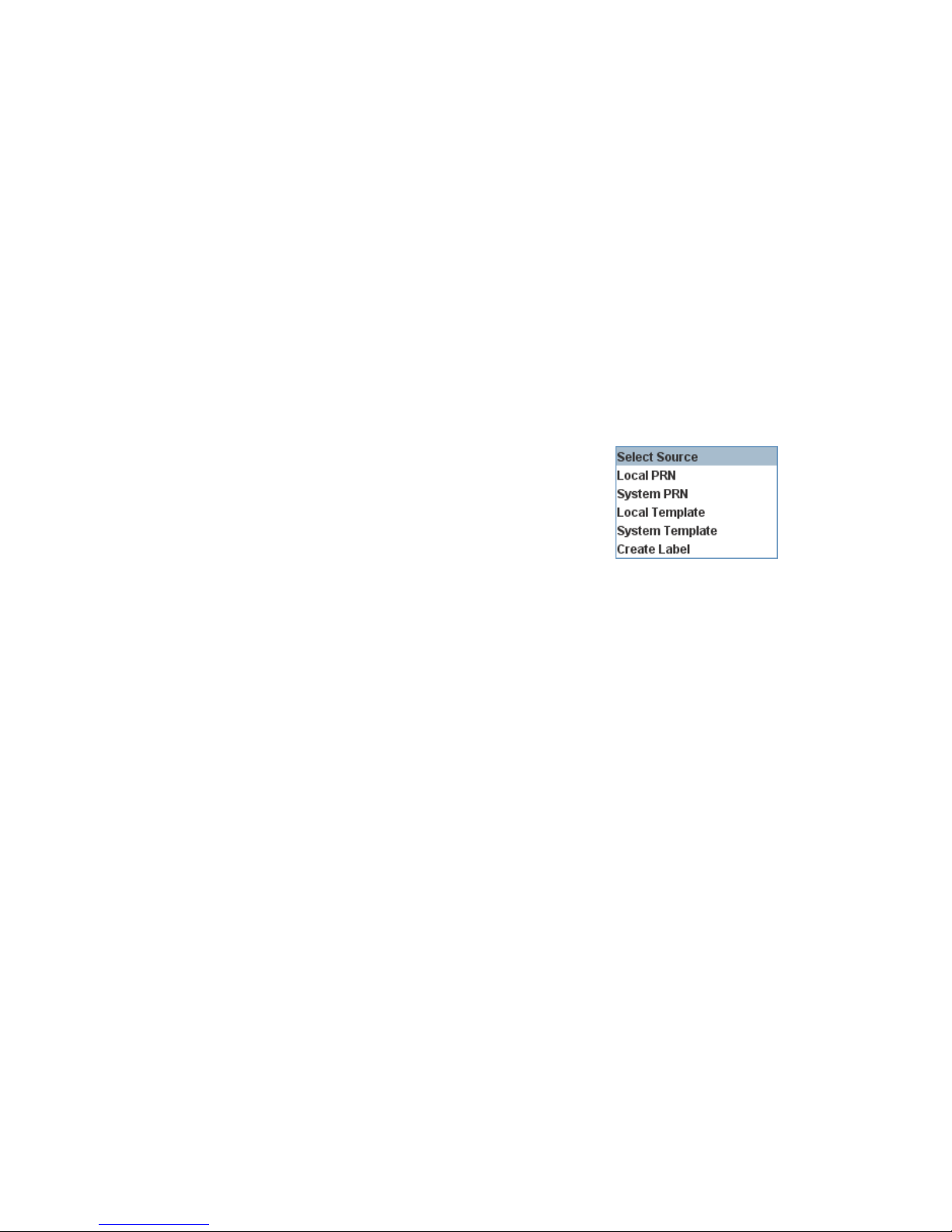

1.4.8.5 Print Image

The AP-150 includes a built-in disc printer (FlashJet2) so that

discs can be printed automatically as part of the copy process.

There are several sources for print images, and the Print Image

selector allows you to choose which one to use.

1.4.8.5.1 Local PRN

If you already have a PRN file created by another label designer application (and using

the proper printer driver) you should choose ‘Local PRN’. A File Open dialog box will

allow you to browse for the PRN file. If you selected a shortcut directory as part of the

System Setup then the File Open dialog box will open in your shortcut directory,

otherwise it will open in your home directory.

It is important that the correct PRN file type is selected, and if you are in any doubt,

please contact your authorized TEAC reseller for more information about PRN files.

TrueNet includes a built in Label Designer that does not need to use PRN files if you are

using one of the supported printers.

1.4.8.5.2 System PRN

If you have a print image file already stored on the System’s internal storage, you can

select it as part of a job. Choosing ‘System PRN’ will launch the System Images dialog box

and allow you to choose the file by single-clicking on the file name, and then clicking the

OK button.

Note that print image files stored on the System are in PRN format, and if you choose to

copy these images to your local hard disk for offline storage, you would choose Local PRN

to re-use them when starting a new job.

1.4.8.5.3 Local Template

TrueNet includes a Label Designer that stores label designs as ‘template’ files. These can

be used by TrueNet to create print images in real time when starting a new job. Selecting

Local Template will launch the File Open dialog box and allow you to select any template

(.rpt) file. If you have selected a shortcut directory for your template files in User

Settings, the File Open dialog box will open at that shortcut directory; otherwise it will

open at your user home directory. See the section on Dynamic Printing Using TrueNet

FX.

1.4.8.5.4 System Template

Labels designed using the TrueNet label designer can be stored on the System HDD and

retrieved as part of creating a new job. See the section on Dynamic Printing Using

TrueNet FX.

1.4.8.5.5 Create Label

TrueNet includes a label editor allowing you to create label designs within the browser

environment. The label editor is covered in detail later in this user guide, so only the

basics are covered here. Selecting the Create Label option will launch the Label Designer

in a new window. Once you have created your new design, click on the Save & Exit

button on the tool bar to exit the designer. Save & Exit will prompt you for a template

file name. If you have designated a shortcut directory in User Settings the File Save

dialog box will open there, otherwise it will open in your user home directory. Once the

template file is saved the Create New Job dialog will automatically select the saved file,

and change your selection to Local Template (remember the file was now saved as a

template file).

1.4.8.5.6 About Template Files

Template files offer a wealth of options, including serialization, dynamic ‘mail-merge’

functions and User-Defined Form Fields, so further reading about the Label Designer is

recommended.

1.4.8.6 Priority

A priority is assigned to all jobs on the System. The

Administrator will set the user priority levels when creating

the user account. The options include Low, Normal, High

and Highest. The default setting for all jobs is ‘Normal’.

Different priorities cause the job to be placed at different

places within the job queue as follows:

Highest – The job is placed at the very top of the queue and as soon as a recorder

becomes free, this will be the next job to run.

High – This job is placed above all normal priority jobs, but after all other high priority

jobs.

Normal – This is placed in the queue at the end of the current list of Normal priority jobs,

but ahead of all Low priority jobs.

Low – This is placed as the very last job in the queue.

1.4.8.7 Write Speed

The System has user selectable write (recording)

speeds, according to the type or recorders fitted. The

available write speeds are shown in the Write Speed

selector, and may vary based on the media type

selected. As an example, selecting CDs may allow up to a 48x write speed, whereas

selecting DVD media may limit the speed to 16x or 18x. In any event, if the user selects a

speed that is higher than the media is rated for (e.g. selecting 16x write speed when

using 4x DVD media) the System will automatically reduce the write speed to match the

media. This setting should be considered as the ‘maximum’ speed, rather than the

definitive write speed to use.

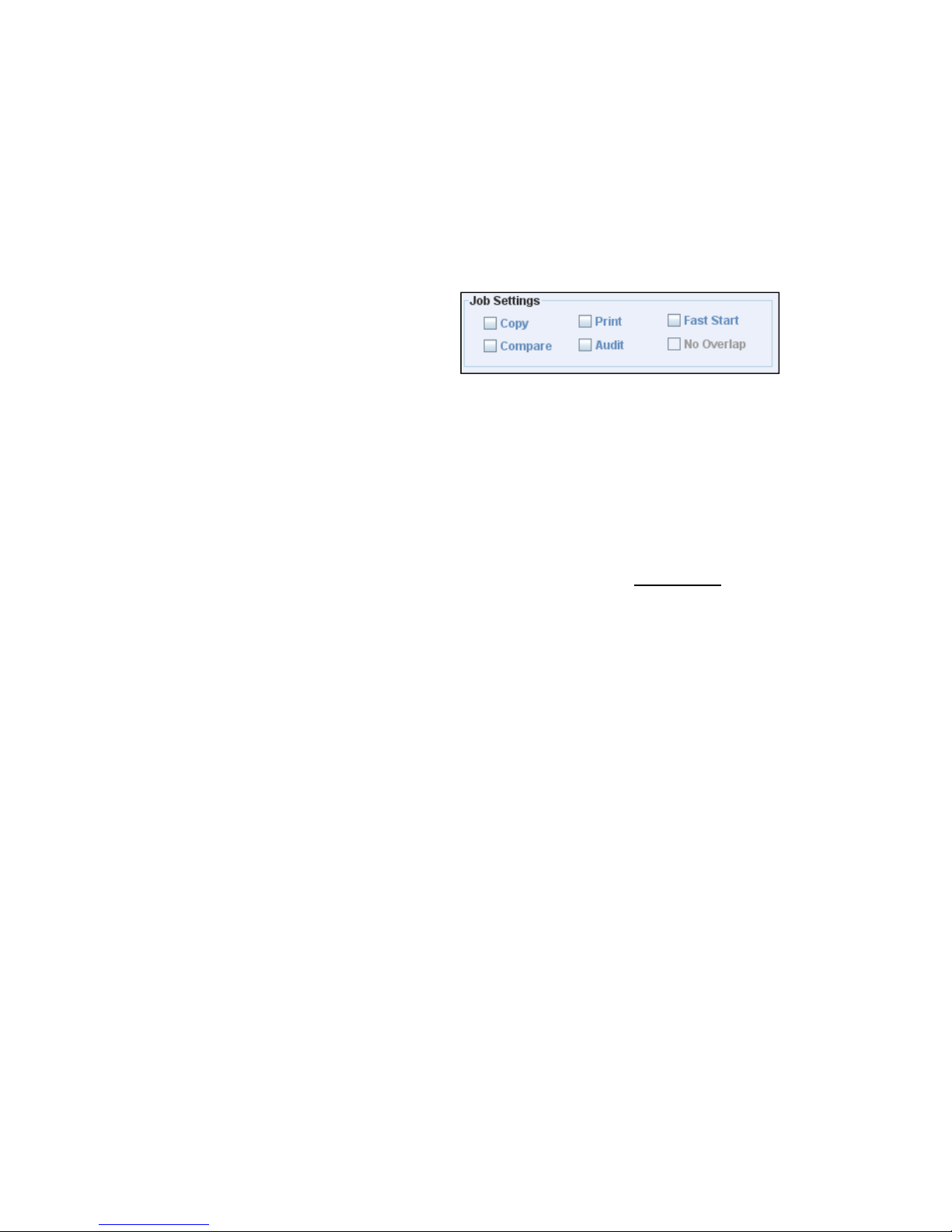

1.4.9 Job Settings

Starting a job in TrueNet can be very

simple, and many users will never need to

venture further than selecting an image,

entering a quantity and clicking Start.

However, for those wanting to use the System to its full potential, additional options are

included. Many job features can be enabled and disabled directly within the Create New

Job dialog box.

1.4.9.1 Copy

For your convenience the Copy check box is selected automatically when you choose a

disc image (Local, System, or Create Data Disc), but is not selected if you choose ‘Read

New Master’. If you want to make copies of a master disc as soon as the master is read,

select the Copy check box and enter a quantity in the Quantity box.

If you are selecting a disc image to ‘Compare’ copies to, but don’t want to write any

copies as part of this job you should make sure the Copy check box is not selected.

Once a Copy job has been created, the Copy flag cannot be removed.

1.4.9.2 Compare

If you want the System to compare the data on a copied disc against a master data disc

check the Compare check box. Selecting the Compare function as part of a Copy job will

cause the System to first write the data to the blank media, then re-read all the data on

the copied disc and compare it (bit for bit) against the master image. If any part of the

data is incorrect the disc will be rejected.

The Compare function can be used on its own, without the Copy function, to allow you to

compare discs already produced against a master image.

Comparing discs to the master image can significantly increase the time it takes to

produce discs, because it requires that the copied disc is 100% read again after being

created. Often, DVD media can be written faster than it can be read, so a full Compare

may take more than twice as long as a Copy without Compare. However, performing a

full (100%) Compare is the only way to guarantee that the copy discs are free from data

defects.

The Compare function can be enabled/disabled via the Edit Job function at any time

before a job starts, or while it is running! Users may choose to start a Copy job with

Compare enabled, and after a few discs when they are satisfied that everything is normal,

they can disable the Compare function to speed up the duplication process. In addition,

the Audit function can be used as a fast alternative to Compare.

1.4.9.3 Audit

Audit provides a fast way to ensure that the disc in the recorder has actually been

recorded without performing a time consuming full Compare option. The Audit function

will read the start of the disc and then read the end of the disc to make sure that both

the start and end are fully recorded. This adds only a few seconds to the copy time.

Audit can be enabled or disabled at any time during a Copy job via the Edit Job dialog.

Audit and Compare are mutually exclusive, meaning you can only have one of them

selected at any given time.

The Audit function can only be used in conjunction with Copy, and cannot be used as a

standalone operation.

1.4.9.4 Print

The Print check box is automatically selected when a print image (Local PRN, System PRN

or Template) is selected.

1.4.9.5 Fast Start

The Fast Start option allows the System to load blank media and start writing as soon as

the disc image begins transmitting over the network. This feature can save huge

amounts of time when sending large image files (e.g. 50GB Blu-ray) because without Fast

Start the entire image needs to be moved to the System before the job can begin. It is

recommended for use only where you have a fast (recommended Gigabit) and reliable

connection to the System, and where not many other users are logged on (which can

create a busy network). If you are on a slow or unreliable connection, or if the network

the System is connected to is extremely busy, Fast Start is not recommended. If you find

that image transfers are failing due to network time out problems, do not use Fast Start.

This option may be disabled by the Administrator on a user-by-user basis.

1.4.9.6 No Overlap

If the System is running multiple jobs at the same time, it is possible to have jobs

interwoven (mixed) in the output hoppers. To prevent jobs from being mixed, and to

force this job to wait until all of the jobs ahead of it in the queue are completed and to

force all jobs below in the queue to wait until this job is completed, choose the ‘No

Overlap’ feature.

Under normal running conditions all discs from this No Overlap job will now be together

as consecutive discs in the output hoppers. The only time that this option can be

overridden is where a higher priority job is sent to the machine after this job has already

started. The higher priority job will always take precedence even over No Overlap jobs.

1.4.10 E-Mail Settings (all systems)

TrueNet provides easy access to the System

e-mail notification options (Email

notifications must be enabled by the

Administrator before any e-mails can be

sent by the System). The Create New Job

dialog box includes an ‘Email’ tab (top left)

that gives access to your personal e-mail

selections. Select the e-mails you want to

receive for this job, and if you want to

receive these e-mails for all jobs, click on

the ‘Set Default’ button to set this selection as your default choice. Once a default has

been set, you will not need to select your e-mail options again unless you want to change

them. To select all e-mails with a single click, click the ‘All’ button, and to deselect all emails click the ‘None’ button.

Once enabled, the user has the option to receive e-mails based on the following events:

1. Job Started – Sent to advise you that your job has started to run.

2. Job Completed – Sent to advise you that your job is now complete and your discs

are ready for collection.

3. Job Modified – Sent if your job is modified in any way, either by you or by an

administrator. Modifications to jobs include changes to job quantities,

Audit/Compare flags, job priorities, etc.

4. Loader Error – Sent if for any reason the job has encountered an error which

requires user attention.

5. Low Media – Sent when the administrator-defined low input media threshold is

reached for the type of media your job is using. This will be sent even if your job

is not yet running to advise you that your job may be delayed if media is not

refilled soon.

6. Hopper Empty – Sent when the System no longer has any input media for the type

of media used on your job. This will also be sent even if this error occurs before

your job has started to warn you that your job is being delayed because the

System is out of media.

7. Low Printer Supplies – Sent when the printer supplies of ink or ribbon have

reached the administrator defined threshold for low print supplies. This will be

sent even if it occurs before your job is running to advise that your job may be

delayed.

8. Delayed/Resumed – Sent when your job is delayed by another job ahead of yours

in the queue.

1.4.11 Dynamic Printing (TrueNet FX Only)

1.4.11.1 Embedded Label Tags

Label Templates may contain user-embedded tags that are automatically replaced by

specific System or user information when the template is selected as part of a new job.

The supported tags are:

%Time% - Every instance of this text within the selected template will be replaced by the

user’s computer time at the time the template is used to create a new job. Note that this

will remain constant through the job, even if the job is later restarted, paused or

resumed.

%Date% - Every instance of this text will be replaced by the user’s computer date at the

time the template is used to create a new job. Note that this will remain constant

through the job, even if the job is later restarted, paused or resumed. The date format

(DD/MM/YYYY, MM/DD/YYYY or YYYY/MM/DD) is set by the administrator in the

Administration: Time & Date tab.

%JobOwner%

by the user’s login name.

%JobDesc%

the text entered in to the Job Reference box i

entered, the text is not replaced and will print as shown.

These tags provide an easy way to add simple tracking information to discs at run

Labels can be previewed prior to starting a job using the

For more information on creating and editing labels using the TrueNet Label Designer,

see the Label Designer section.

1.4.

TrueNet FX Label Templates provide an easy way

to automatically prompt users to complete

spe

label template. This allows specific corporate

design templates to be created (and optionally

stored on the System storage) with dynamic text

fields, without every user needing to create

and/or edit their own l

Form fields are defined as ‘user prompts’.

Enclosing any text between two ‘#’ characters

automatically creates a user

and whenever the template is used in a job, the

user is automatically prompted for data to fill

those fields

Patient: #Patient Name#

then every time the template is selected, a dialog will appear prompting for the text field

‘Patient Name’. Up to 99 form fields can be added to a label template, and the

prompt for all fields at the same time, using the user

prompt.

In the example label shown here, the

following form fields have been defined

(bottom of the label):

#Patient Name#

#Doctor#

#Date Of Birth#

#Departme

#Treatment#

-

11.2

Dynamic User Form Fields

cific label form fields when printing from a

. For example, if a template contains the following text:

nt#

- Every instance of this text within the selected template will be replaced

Every instance of this text within the selected template will be replaced by

abels.

-

defined form field,

n the Create New Job dialog. If no text is

button.

-

defined field name as a user

-time.

dialog will

Selecting this template as part of a job would generate the following prompt for the user

to complete:

Entering the text shown in the ‘User

Text’ boxes (right) would produce the

label shown below.

N

ote how the data entered in t

Entry dialog has been merged with the label,

replacing the form fields.

Label Templates can be previewed using the

button.

If the data is entered incorrectly, the data can

be edited using the

New Job dialog. For

creating and editing labels using the TrueNet

Label Designer, see the Label Designer section.

1.4.11

.3

TrueNet FX can ‘mail

when starting a job using an appropriately

designed template.

each disc individually in the job from a CSV or

other delimited file. This means that each

label in the job can be unique. Using this

method, it is easy to merge data exported

from a database or spreadsheet program such

as Mic

rosoft

Access to the mail merge functions is via the

‘Dynamic Printing’ tab in the create new job dialog. This tab is present only on FX

systems.

Creating Dynamic Labels ready for Mail Merge is easy. When creating a label, add a

numbered fiel

should be numbered sequentially starting at ‘1’, so that %1% would be the first merge

field, %2% would be the second, %3% would be the third and so on.

Example: Merging a CSV fi

the data is in the form:

Line 1 Field 1

Line 2 Field 2

Line 3 Field 3

Etc…

Dynamic Mail Merge Fields

®

Excel.

d surrounded by percent (%) characters for each field to be merged. Fields

,

Line 1 Field 2

,

Line 2 Field 2

,

Line 3 Field 2

button in the Create

more information on

-

merge’ data to a label

Unique data is merged for

le that was exported from Microsoft

,

Line 1 Field 3

,

Line 2 Field 3

,

Line

he Label Field

3 Field 3

,

Line 1 Field 4

,

Line 2 Field 4

,

Line 3 Field 4

®

Excel (as a CSV file) where

In this example there are

on the label template (%1%, %2%, %3%, %4%). Where more fields exist in the CSV file

than the template, the extra fields in the CSV

fields in the CSV file than the template, any extra template fields are filled with blank

spaces.

To select the import data click the ‘Browse’ button, then select the file that contains the

data to be imported. Th

the supported delimiter characters (see below). Click the ‘Test’ button to read the first

line of data from the file (starting at the line in the ‘Start Line’ input box). The number of

fields found on that line is shown, followed by a preview of the label with the mail merge

data added. Click once anywhere on the preview label to close the preview. If the Start

Line is incorrect, change the start line in the dialog and re

Supported delimiters are a Comma, Colon, Semi Colon or a Tab. The chosen delimiter can

also be saved as the default delimiter for future jobs.

A data import file must contain a line of data for each disc produced by this job. Each

disc will includ

insufficient lines in the import file an error will be generated. Additional/surplus lines are

ignored.

Using the ‘Start Line’ input box, the data can be parsed differently each

e.g. enter ‘1’ to start at line 1 for this job of (e.g.) 100 discs, then next time enter 101 to

start at line 101 for the second job of 100 discs, then line 201 for the following job and so

on. All data on lines prior to the start line

Once the data

data set to the job.

Note: While jobs created using dynamic mail merge functions can be edited in real time,

the quantity within the job cannot be increased. This is because TrueNet FX creates a

sealed print bundle that contains the print data for all discs when

it is not possible to append additional print file data to this bundle later.

For more information on creating and editing labels using the TrueNet Label Designer,

see the Label Designer section.

1.4.1

In additio

automatically. The serial number is always inserted on the label as the first field of any

Mail Merge operation. This means that the serial number is always placed in the %1%

Mail Merg

the Mail Merge data will be placed in the field %2% onwards when Serialization is active.

To preview the label (including the data that will be merged on the first disc) click

the preview button in the Create New J

1.4

Serialization

n to regular Mail Merge functions, disc labels can also be serialized

e field. If additional Mail Merge data is being imported as part of the same job,

e the data merged from exactly one line of the import file. If there are

-

file, Delimiter and Start Line have been set, click the OK button to add this

four

fields on each line, so

is should be a plain ASCII text file with fields delimited by one of

are ignored.

ob Dialog.

four

file are ignored. Where there are fewer

ob Dialog.

merge fields would be required

-

test if requi

the job is created, and

red.

time a job is run,

Serial numbers are generated starting with the ‘Start Number’ entered in to the

Se

rialization dialog, and incremented by 1 for each disc in the job. To use more

complicated serialization number sequences, create an ASCII text file with one serial

number per line and import it as a Dynamic Mail Merge instead of using the built in

Serial

ization function.

The built in Serialization allows up to 8 digits, with or without leading zeros. As an

example, an 8 digit number sequence starting at 1000 with leading zeros would produce

the following sequence:

00001000

00001001

00001002

etc.

Wit

hout leading zeros, this sequence would be:

1000

1001

1002

etc.

There can be only one serial number generated for each disc in the job, but this serial

number can placed on the label multiple times, e.g. as simple text, and a bar code.

Once the serial nu

the Create New Job dialog box.

To preview the serial number on the label click the

dialog, then click once anywhere in the preview window to close the pre

For more information on creating and editing labels using the TrueNet Label Designer,

see the Label Designer section.

1.4.12

Editing Jobs

Editing jobs is possible not only for jobs

that are queued, but also for jobs that

are currently running, and

that have completed (increasing the

quantity will re

the additional discs required).

There are three ways to launch the Edit

Job dialog box. Select the job in the Job

Status window by single

and th

en select Edit Job from the left

menu bar. Another way is to double

click a job in the Job Status window and select Edit Job from the pop

-

queue the job to run only

en select Edit Job from the left

mber information has been entered, click the OK button to return to

even for jobs

-

clicking on it,

-

click on a job in the Job Status window, or to right

button in the Create New Job

-

up menu.

view.

-

1.4.12.1 Changing the Quantity

You can change the quantity of most jobs at any time by entering the new quantity in the

Quantity box. The exception to this is where the job includes dynamic mail-merge or

serialization. This is because the print bundle was created and sealed prior to starting

the job, and it is therefore not possible to increase the number of discs required because

there would be no print labels available for the extra discs. However, changing quantities

is the only limitation that applies to such dynamic jobs. All other changes can be applied.

If you want to simply add a number of additional discs to the job, right-click on the

Quantity box and a new ‘Add’ box will appear. Simply enter the additional quantity in to

this box and this number will be added to the original quantity. Select the Update button

when done.

1.4.12.2 Job Priority

The priority of a job can be changed at any time. By selecting an alternative priority

setting and clicking Update, the job will be updated and moved within the job queue

appropriate to the new setting. The priority levels are controlled by administrators, and

not all users will have the ability to select all priority levels.

To send a job to the very front of the queue, select ‘Highest’ as the priority level. This

will put it into the very next available drive, even in the middle of a running job.

1.4.12.3 Enable Compare / Audit

The Compare and Audit functions can be enabled and disabled in real time. They will not

affect the discs currently in the Audit/Compare phase, but will affect all discs that are

part of this job that are currently in the write phase, and all discs loaded from here on.

Audit and Compare functions are mutually exclusive. Selecting one will deselect the

other. For more information on Compare and Audit functions see Creating a New Job.

1.4.12.4 Enable / Disable No Overlap

The No Overlap function can be enabled or disabled by selecting the check box. The No

Overlap function will make sure that all the discs from this job are placed consecutively in

the output hopper. Note that this function can be overridden by a higher priority job

being run after this job has already started.

1.4.12.5 E-Mail Notification Settings

All the e-mail notification selections available

when creating a new job can also be added

or removed while editing jobs. To enable a

notification type, select the check box. To

disable a notification type, deselect the

checkbox.

1.4.13 System Images

The System Images dialog box can be used to

view the images that are stored on the

System’s internal storage, as well as for

transferring images to and from the System

as required.

Each image shown includes its name, image type (Print/Template/CD/DVD/BD) and

approximate size in Megabytes. All images shown are available for use as part of

duplication and/or print jobs.

In addition to the normal view, there is an option to view the temporary images stored

on the System as part of user jobs. These files are not available to select for use in other

jobs, and are automatically deleted when a job is deleted (usually by the user).

1.4.13.1 Getting a Disc Image from the System

To transfer an image located on the System’s internal storage from the System to your

local computer (or other network storage), select the image and click on the ‘Get Image’

button. A Save File dialog box will appear allowing you to choose the name and location

for the image file. Do not change the file extension given to the files when saving, or

they may not be correctly recognized by TrueNet in the future.

1.4.13.2 Sending an Disc Image to the System

Images previously moved from the System to your local computer or other network

storage can be sent back to the System at any time using the System Images dialog box

(assuming there is enough internal hard disk space on the System). To transfer an image

from your local computer (or other network storage) to the System, select the ‘Send

Image’ button. A File Open dialog box will appear allowing you to choose the file you

wish to send to the System. Select the file and click the ‘Open’ button. If the file is an

ISO, you will be asked to select the intended media type (CD/DVD/BD). After selecting

the media type and clicking the OK button, a progress meter will appear displaying the

progress of the transfer.

ISO images (or some other binary disc images) can also be sent to the System using this

option, and they will be converted to .rqi (TEAC Image) images on-the-fly. Once an image

has been sent to the System, the image is no longer a raw ISO file.

Note that ISO image files must be Mode 1 (2048 bytes per logical block). No other image

type (e.g. CD-XA or Audio) is supported at this time.

Raw Disc images produced by most Video Authoring packages will meet the standards

required for TrueNet to use them without any further modification. The images must

however be uncompressed, because TrueNet will not modify the contents of the ISO/Raw

image files in any way.

1.4.13.3 Sending a Print Image to the System

TrueNet will allow the import of pre-built PRN files. Print image files previously moved

from the System to your local computer or other network storage are in PRN file format.

Be sure to only send PRN files intended for the printer type installed in your System.

Other PRN file types will not work and may cause damage to the printer which is not

covered by warranty.

To transfer a print image from your local computer (or other network storage) to the

System, select the ‘Send Print’ button. A File Open dialog box will appear allowing you to

choose the print file you wish to send to the System. Select the file and click the ‘Open’

button. A progress meter will appear displaying the progress of the transfer.

1.4.13.4 Sending a Print Template to the System

TrueNet will allow a Print Template (.rpt) file to be stored on the System for use when

creating new jobs. The System does not directly print the Template file, but instead will

retrieve the Template file from the System at run time in order to create a usable PRN file

suitable for the installed printer (only TEAC printers are supported by this feature).

To transfer a print template from your local computer (or other network storage) to the

System, select the ‘Send Print’ button. A File Open dialog box will appear allowing you to

choose the print template you wish to send to the System. Select the file and click the

‘Open’ button. A progress meter will appear displaying the progress of the transfer.

1.4.13.5 Renaming an Image

To rename an image on the System’s internal storage, select the image and click the

‘Rename’ button. Enter the new name (any combination of letters, numbers, or spaces

up to 14 characters) and click OK.

1.4.13.6 Deleting an Image

To delete an image, select it and click the ‘Delete’ button. Note that images that are

currently in use by a job, or used by a ‘Set’ (see Disc Sets) will not be deleted. Where

images are used by a Set, you will need to delete the Set first.

1.4.13.7 Refreshing the Display

If you have reason to believe that the images on the System are not the same as currently

displayed in this dialog box, click the Refresh button.

1.4.14 Disc Sets

A Disc Set is a user-defined collection of disc and print images, organized in to a product

‘Set’. The user need only select the 'Set', and all disc and print images within that Set are

produced automatically in ‘Disc Set’ order. TrueNet LX allows up to 3 discs per Set and

TrueNet FX allows up to 25 discs per set.

1.4.14.1 Creating a Set

To create a Set, select ‘Disc Sets’ on the left menu bar. A

Disc Sets dialog box will open, showing all the Sets

currently on the System.

Sets that are already on the System can be edited,

renamed, or deleted using the buttons located here.

To create a new Set, click the ‘Create Set’ button. A

‘Create Disc Set’ dialog box will open and allow disc and print images to be added.

Enter a name for this Disc Set. Up to 14 characters are allowed.

1.4.14

.1.1

To add a disc and print image to the Set, click

the ‘Add’ button. A new dialog will appear

allowing both the disc and print image to be

selected fr

your computer hard disk) or images that are

already on the System. Any local images

selected as part of a Set will be moved to the

System automatically when the Set is saved.

Once the disc and print images have been se

the Set. The images will now be listed in the ‘Create Disc Set’ dialog.

1.4.14

.1.2

To modify the discs in a Set, choose the ‘Modify’ button. The ‘Choose Set Images’ dialog

will re-

open showing the dis

images as required, then click OK to save.

1.4.14

.1.3

To delete a disc and print image from the Set, click on the disc/print image to select it,

then click on the ‘Delete’ button.

1.4.14

.1.4