Page 1

Changing Nylon Strings the (new, improved) Taylor Way

s more and more Taylor players succumb to the allure of our Nylon Series guitars,

calls from owners inquiring about the “proper” method of string-changing are

A

increasing. That’s as it should be; changing nylon strings differs considerably from

the process used for steel-string guitars, and there are right and wrong ways to do it.

Never fear — the procedure isn’t rocket science, and you don’t need to be a Sea Scout

with an advanced repertoire of sailing knots to pull it off with aplomb.

Let’s start with the basics. Classical and flamenco guitars are strung with

nylon strings that tie onto the bridge. This ancient system originally was

designed for “gut” strings, and there are a number of ways to tie them, some

more effective than others. Master repairman Tim Luranc and his colleagues at

Taylor have developed an outstanding protocol for this simple but often misunderstood procedure.

For best results, it’s important to understand how the strings hold onto

the bridge: the strings are looped around themselves, and the final loop must

pass “around the corner” of the back of the bridge. Now, let’s outline the

methodology in simple steps.

by Anthony Adams / photos by Rita Funk-Hoffman

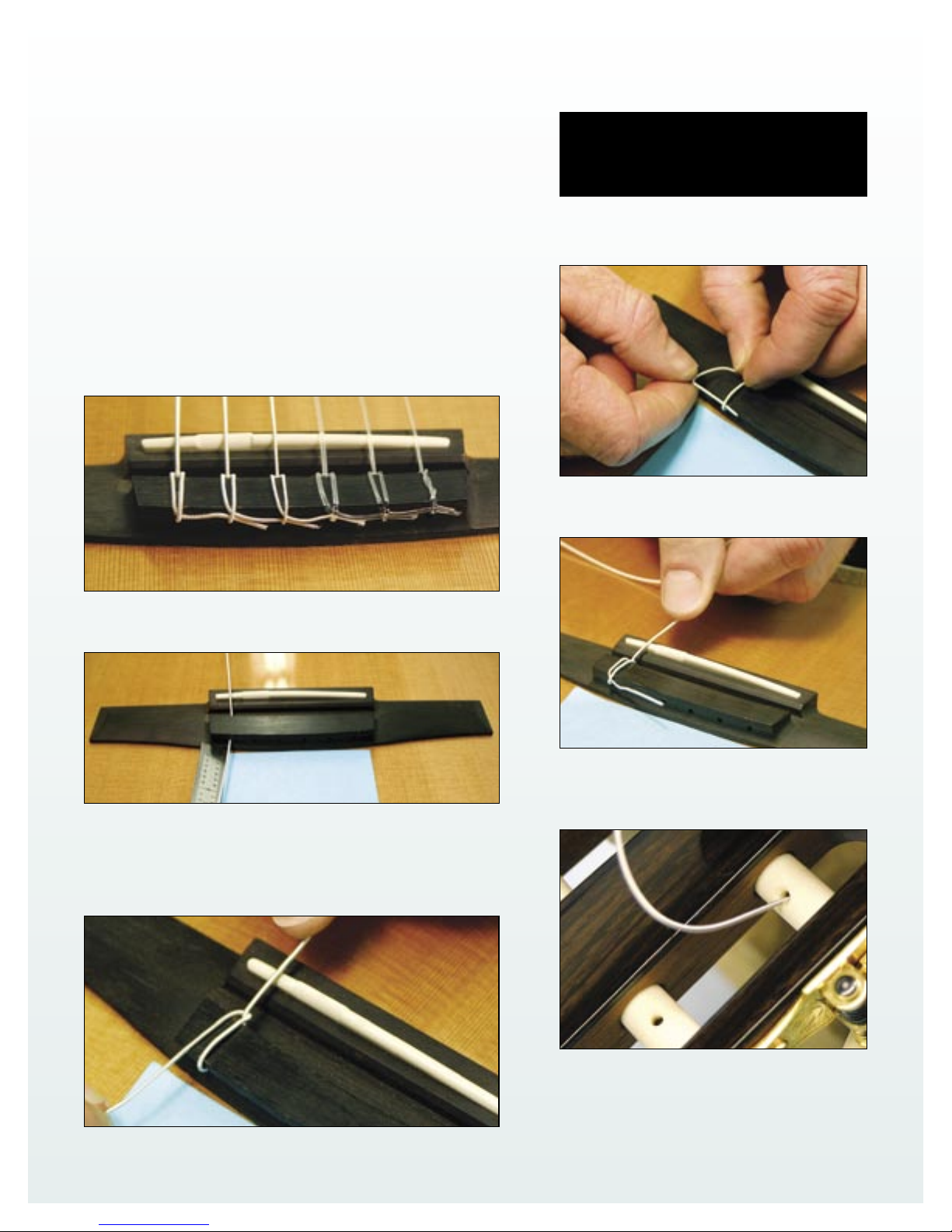

4. Pass the free end under the loop, below the back corner

of the bridge, creating a second bend in the string.

1. Here’s an example of a properly strung bridge. The string ends are looped under

to create a finished look.

2. Before putting on your new strings, we suggest that you place a Post-It note on top of

the guitar, behind the bridge, to prevent possible damage to the top while changing the

strings. Nylon strings often have one end loosely wound for greater flexibility. This

is the end that ties onto the bridge. Leave about three inches of string sticking out

behind the bridge.

5. Hold the free end down so it won’t climb up over the corner, and pull the string tight to lock it in place. Leave approximately one inch of string pulled tight behind the bridge.

3. Loop the free end under the string (from the treble side) just behind the saddle,

and pull it back toward the end of the guitar, creating a bend in the string.

6. Pass the free end of the string toward the peghead, all the

way through the tuner hole, from the top down, leaving a little

slack. Make sure the top side of the tuner hole is pointed at a

slight upward angle, toward the peghead.

Page 2

7. Loop the free end of the string up and around the top of

the tuner roller and pass it under itself.

11. Loop the free end of the A string over the untrimmed end

of the low-E string to hold it neatly in position.

8. Hold a little tension on the string with your upright right

fist (to create the correct amount of slack) as you pull the loop

tight against the roller with your left hand. The bend should be

in the top of the tuner hole to lock the string in position.

9. Tighten the string, winding it toward the outside of the

rollers, over the tail of the string. Guide the string so that it is

neatly coiled and doesn’t rub on the edges of the peghead. Tune

to pitch. For best tuning, use a maximum of 4-6 wraps, and then

snip the excess string end.

12. Loop the free end under the string just behind the

saddle and pull it back toward the end of the guitar, creating a

bend in the string, as in Step 3.

13. Snip the excess from the 6th (E) string, making sure the

remainder of the string is a little shorter than the distance to

the next hole. Next, put on the 4th (D) string, using the same

method as with the 6th and 5th strings.

10. Pull the A (5th) string into position.

14. The slippery treble strings require a bit more care to

keep them tight, but the technique is substantially the same.

You can insert the string either way through the holes in the

bridge. The high-E (treble) string has an additional loop to

avoid slippage. Begin by looping the string under itself.

Page 3

15. Loop the string under itself a second time.

16. Make sure the free end passes under the string below

the corner of the bridge when you pull it tight. It will come

loose if you don’t keep one end below the corner.

A view of the strings from behind the peghead.

17. As with the other strings, stick the high-E string

through the hole in the tuner, then lock, tighten, and snip,

as in Steps 6-9.

18. After tuning to pitch, snip the excess from the

B and high-E strings.

Tim Luranc holding a newly strung Taylor NS guitar.

fter changing strings, use your thumbs and forefingers to gently stretch each

A

string across its entire length. Tune the string to pitch and repeat the stretch-

ing procedure two or three times. ■

Loading...

Loading...