Page 1

PositionPRO® Patient Repositioning Support

Surface

Standalone with pendant or integrated with FL27 InTouch® CC

Model Beds

2920

Operations Manual

2016/10 G.2 2920-109-001 REV G

www.stryker.com

Page 2

sample text

Page 3

Symbols

~

Operating instructions/Consult instructions for use

General warning

Caution

Catalogue number

Serial number

Manufacturer

Safe working load

Alternating current

IPX4

Dangerous voltage

Protective earth ground

Protection from liquid splash

Type B equipment providing a particular degree of protection against electric shock, particularly

regarding allowable leakage current and reliability of the protective earth connection.

Class II Per Rule 9- PositionPRO is considered an active therapeutic device intended to be used

to administer or withdraw energy to or from the body.

Medical Equipment Recognized by Underwriters Laboratories LLC With Respect to Electric

Shock, Fire, and Mechanical Hazards only in accordance with UL 60601-1: 2003 and CAN/CSAC22.2 No. 601.1-M90 updates 1 and 2.

In accordance with European Directive 2012/19/EU on Waste Electrical and Electronic

Equipment, this symbol indicates that the product must not be disposed of as unsorted municipal

waste, but should be collected separately. Contact your local distributor for disposal information.

Wash by hand

Do not dry-clean

Allow to completely air dry

Do not tumble dry

Do not iron

www.stryker.com 2920-109-001 REV G

Page 4

Symbols

Chlorinated bleach

For US Patents see www.stryker.com/patents

Do not stack more than 1 high

2920-109-001 REV G www.stryker.com

Page 5

Table of Contents

Warning/Caution/Note Definition ..................................................................................................................3

Summary of safety precautions..............................................................................................................3

Introduction..............................................................................................................................................5

Product description.............................................................................................................................. 5

Indications for use ...............................................................................................................................5

Expected service life............................................................................................................................6

Contraindications ................................................................................................................................6

Specifications.....................................................................................................................................6

Contact information ............................................................................................................................. 7

Serial number location ......................................................................................................................... 7

Product illustration...............................................................................................................................8

Date of manufacture............................................................................................................................8

Installation ...............................................................................................................................................9

Operation .............................................................................................................................................. 13

Applying the linens ............................................................................................................................ 13

Positioning the patient ........................................................................................................................ 13

Activating CPR.................................................................................................................................. 14

Resetting CPR with the optional pendant control ...................................................................................... 14

Starting and stopping max inflate with the optional pendant control.............................................................. 15

Locking and unlocking the optional pendant control.................................................................................. 15

Adjusting firmness with the optional pendant control................................................................................. 16

Starting and stopping turn assist with the optional pendant control............................................................... 17

Alarming call maintenance with the optional pendant control ...................................................................... 19

Resetting CPR with the optional InTouch footboard .................................................................................. 19

Starting and stopping max inflate with the optional InTouch footboard .......................................................... 19

Locking and unlocking with the optional InTouch footboard ........................................................................ 19

Adjusting firmness with the optional InTouch footboard ............................................................................. 20

Starting and stopping turn assist with the optional InTouch footboard ........................................................... 21

Alarming call maintenance with the optional InTouch footboard .................................................................. 23

Transferring a patient to and from the support surface.............................................................................. 23

Transporting a patient ........................................................................................................................ 24

Managing incontinence and drainage .................................................................................................... 24

Cleaning................................................................................................................................................ 25

Cleaning the control box ..................................................................................................................... 25

Cleaning the pendant ......................................................................................................................... 25

Disinfecting............................................................................................................................................ 27

Preventive maintenance ........................................................................................................................... 28

Top cover replacement....................................................................................................................... 28

Fire barrier replacement ..................................................................................................................... 28

Quick reference replacement parts............................................................................................................. 30

EMC information ..................................................................................................................................... 31

Warranty ............................................................................................................................................... 35

Warranty exclusion and damage limitations ............................................................................................ 35

www.stryker.com 2920-109-001 REV G 1

Page 6

Table of Contents

To obtain parts and service ................................................................................................................. 35

Return authorization........................................................................................................................... 35

Damaged product.............................................................................................................................. 35

International warranty clause ............................................................................................................... 35

2 2920-109-001 REV G www.stryker.com

Page 7

Warning/Caution/Note Definition

The words WARNING, CAUTION, and NOTE carry special meanings and should be carefully reviewed.

WARNING

Alerts the reader about a situation which, if not avoided, could result in death or serious injury. It may also describe

potential serious adverse reactions and safety hazards.

CAUTION

Alerts the reader of a potentially hazardous situation which, if not avoided, may result in minor or moderate injury to the

user or patient or damage to the product or other property. This includes special care necessary for the safe and

effective use of the device and the care necessary to avoid damage to a device that may occur as a result of use or

misuse.

Note: Provides special information to make maintenance easier or important instructions clearer.

Summary of safety precautions

Carefully read and strictly follow the warnings and cautions listed on this page. Service only by qualified personnel.

WARNING

• Always make sure that the operator has access to the CPR straps.

• Do not stick needles into a support surface through the support surface cover. Holes may allow body fluids to enter

the inside (inner core) of the support surface and could cause cross-contamination, product damage, or product

malfunction.

• Do not use fitted sheets with this support surface.

• Always center the patient on the support surface before starting functions. Check the patient frequently for proper

positioning and to make sure that the support surface maintains proper inflation.

• Always make sure that the tubing and wiring that is connected to the patient is long enough, stabilized, and secure

during Lateral Rotation or Turn Assist.

• Do not extubate or intubate patients during Lateral Rotation or Turn Assist. The rotation functions could interfere

with the performance of the ancillary devices.

• Always secure the support surface anchoring straps to the bed frame.

• Always raise the bed siderails before starting Turn Assist.

• Do not leave the patient unattended during Turn Assist.

• Do not exceed the safe working load of the bed frame when supporting both the patient and the support surface.

Excess weight could cause unpredictable safety and performance of this product.

• Always deflate the support surface before beginning CPR.

• Do not arm bed exit with Lateral Rotation or Turn Assist active. The patient motion and position that results from the

support surface may adversely affect bed exit system performance.

• Do not use dynamic mattress systems for stroke victims without a physician’s order.

• Do not turn a patient with unstable fractures, unstable spinal cord injuries, or those in skeletal traction.

• Always monitor the patient condition at regular intervals for patient safety.

• Do not immerse support surface or foot box in cleaning or disinfectant solutions. To avoid the risk of product

damage or patient injury.

• Do not allow fluid to pool on the support surface or foot box. Fluids can cause degradation of components and may

cause unpredictable safety and performance of this product.

www.stryker.com 2920-109-001 REV G 3

Page 8

Warning/Caution/Note Definition

Summary of safety precautions (Continued)

WARNING (CONTINUED)

• Always inspect support surface covers (top and bottom) for tears, punctures, excessive wear, and misaligned

zippers each time the covers are cleaned. If compromised, the support surface cover should be removed from

service immediately and replaced to prevent cross-contamination.

• Always perform preventative maintenance more frequently based on the usage level of the product. The life of the

support surface can be adversely affected by an increase in usage which may include more frequent cleaning and

disinfection.

• Always allow the control box to completely dry before you place the support surface on top of it.

• Always disinfect the support surface between patients, to avoid the risk of cross-contamination and infection.

• Always make sure that you wipe each product with clean water and thoroughly dry each product after cleaning.

Some cleaning agents are corrosive in nature and may cause damage to the product if you use them improperly. If

you do not properly rinse and dry the product, a corrosive residue may be left on the surface of the product that

could cause premature degradation of critical components. Failure to follow these cleaning instructions may void

your warranty.

• Always unplug the product power cord before cleaning or disinfecting to avoid the risk of shock.

CAUTION

• Improper usage of the product can cause injury to the patient or operator. Operate the product only as described in

this manual.

• Do not modify the product or any components of the product. Modifying the product can cause unpredictable

operation resulting in injury to patient or operator. Modifying the product also voids its warranty.

• Always lower the foot end section gently to avoid the risk of damage to the control box.

• Do not allow sharp objects to come into contact with the support surface that could puncture tear or cut the cover.

• Always secure all patient lines and tubing together before starting Turn Assist to prevent pulling, removal, or

breakage.

• Do not iron, dry-clean, or tumble dry the support surface covers.

• Do not power wash the support surface as this may cause malfunction and damage the product.

• Always make sure that the support surface cover is completely dry before storing, adding linens or placing a patient

on the surface. Drying the product aids in preventing the performance of the product from being impaired.

• Do not over expose the covers to higher concentration disinfectant solutions as these may degrade the covers.

• Do not use accelerated hydrogen peroxides or quaternaries that contain glycol ethers as they may damage the

cover.

4 2920-109-001 REV G www.stryker.com

Page 9

Introduction

This manual assists you with the operation or maintenance of your Stryker product. Read this manual before operating

or maintaining this product. Set methods and procedures to educate and train your staff on the safe operation or

maintenance of this product.

CAUTION

• Improper usage of the product can cause injury to the patient or operator. Operate the product only as described in

this manual.

• Do not modify the product or any components of the product. Modifying the product can cause unpredictable

operation resulting in injury to patient or operator. Modifying the product also voids its warranty.

Notes

• This manual is a permanent part of the product and should remain with the product even if the product is sold.

• Stryker continually seeks advancements in product design and quality. This manual contains the most current

product information available at the time of printing. There may be minor discrepancies between your product and

this manual. If you have any questions, contact Stryker Customer Service or Technical Support at 1-800-327-0770.

Product description

PositionPRO® is a powered pressure relief support surface with low air loss (LAL) intended for medical purposes.

PositionPRO consists of multiple air cells filled and emptied by an integrated control unit to provide changes in the

distribution of body weight for pressure relief. PositionPRO offers turn assist. See the specifications page for

compatible frames.

Indications for use

PositionPRO is intended to assist in the prevention and treatment of pressure injures (including stages 1,2,3,4,

unstageable injury, and deep tissue injury) that are associated with immobile, critically ill, injured or hospitalized human

patients.

Use PositionPRO with a mattress cover at all times. The support surface is intended to support a patient’s full body.

PositionPRO is for patient use in acute care settings, which includes critical care, step down, progressive care,

med/surg, sub acute care, and post anesthesia care unit (PACU). The patient is under the care of a physician. The

typical operator is a healthcare professional. PositionPRO is not suitable for use in the presence of a flammable

anesthetic mixture with air or with oxygen or nitrous oxide.

PositionPRO is not intended to:

• support a patient in a prone position

• be used in a home health position

• be used as a sterile product

• include a measuring function

PositionPRO is not recommended for patients with the following conditions:

• unstable fractures

• skeletal traction

• agitated patients

• severe hemoptysis

• for whom a head-down position is contraindicated, such as a head injury

• bleeding disorders

• rib fractures / fractures

• predisposed to pathological fractures

www.stryker.com 2920-109-001 REV G 5

Page 10

Introduction

Indications for use (Continued)

• for whom the techniques increased dyspnea or wheezing

• who are hemodynamically unstable

Expected service life

PositionPRO has a five year expected service life under normal use, conditions, and with appropriate periodic

maintenance.

Contraindications

Patients with spinal cord injuries

Specifications

Model Pendant 2920-100-000

Integrated 2920-500-000

Dimensions Mattress 35” x 84” x 7” 88.9 cm x 213.4 cm x 17.8

Weight

Safe working load

Power cord

Over current protection 2 fuses 5 x 20 mm, 5 AMP Slo-Blo, 250 VAC

Output flow rate 12.5 LPM (0.4 SCFM) minimum @ 30mmHg

Current leakage

Classification Class 1 Grounded Equipment

Complete system

Mattress 29 lb 13.1 kg

Pendant 1 lb 0.45 kg

Pump Box 33 lb 15 kg

Stationary

Default 22 mmHg, optimal

pressure relief

Turn Assist 300 lb 136.1 kg

15 foot, 16 AWG cord with hospital grade plug for use with wall outlet

4 foot, 16 AWG cord with hospital grade plug for use with accessory outlet

120VAC; 50-60Hz, 1AMP; Two 250V, 5A Fuses

300 uA Maximum

Class 2, FDA and Health Canada

Continuous operation- Not suitable for use in the presence of flammable anesthetic

mixture with air or with oxygen or nitrous oxide. Suitable for continuous duty.

Medical equipment: Classified with respect to electric shock, mechanical hazards only,

in accordance with UL60601-1 CAN/CSA C22.2 No. 601.1.-M90.

Electromagnetic compatibility, meets EN 60601-1-2, 2001 (CISPR II classified as Class

A, Group 1 ISM equipment)

DH29201005 with Dartex Cover

DH29201015 with Nylon Cover

DH29201010 with Dartex Cover

DH29201020 with Nylon Cover

cm

63 lb 28.6 kg

500 lb 226.8 kg

200 lb 90.7 kg

6 2920-109-001 REV G www.stryker.com

Page 11

Specifications (Continued)

104°F

(40°C)

50°F

(10°C)

158 °F

(70 °C)

-40°F

(-40°C)

A

Introduction

Flammability standards

USA 16 CFR 1632, USA 16 CFR 1633, CALTB 129, Boston BFD IX-11

Method 27.7-1979 of CAN 2-4.2 M77

Compatible frames 84” x 35” flat deck frames GoBed II®, Secure 3®, InTouch®, and Epic II®

Stryker reserves the right to change specifications without notice.

Environmental conditions

Operation Storage and transportation

Temperature

Contact information

Contact Stryker Customer Service or Technical Support at: 1-800-327-0770.

Stryker Medical

3800 E. Centre Avenue

Portage, MI 49002

USA

To view your operations or maintenance manual online, see https://techweb.stryker.com/.

Have the serial number (A) of your Stryker product available when calling Stryker Customer Service or Technical

Support. Include the serial number in all written communication.

Serial number location

www.stryker.com 2920-109-001 REV G 7

Page 12

Product illustration

A

B

C

D

E

F

G

H

Introduction

Figure 1: Product illustration

A

B D rings F Head end

C

D Foot end H Power cord

CPR straps

Foot box

E Handles

G

Integration cable

Date of manufacture

The year of manufacture is the first four digits of the serial number.

8 2920-109-001 REV G www.stryker.com

Page 13

Installation

This section explains how to install the support surface and the control box. The support surface is either equipped with

a standalone pendant control option or integrated with InTouch FL27 Critical Care Bed option. The differences are

noted in the appropriate installation steps.

1. Position the support surface onto the bed.

2. Flip the foot section toward the head end.

3. Turn the control box upside down and place the control box into the opening in the foot section of the support

surface (Figure 2 on page 9).

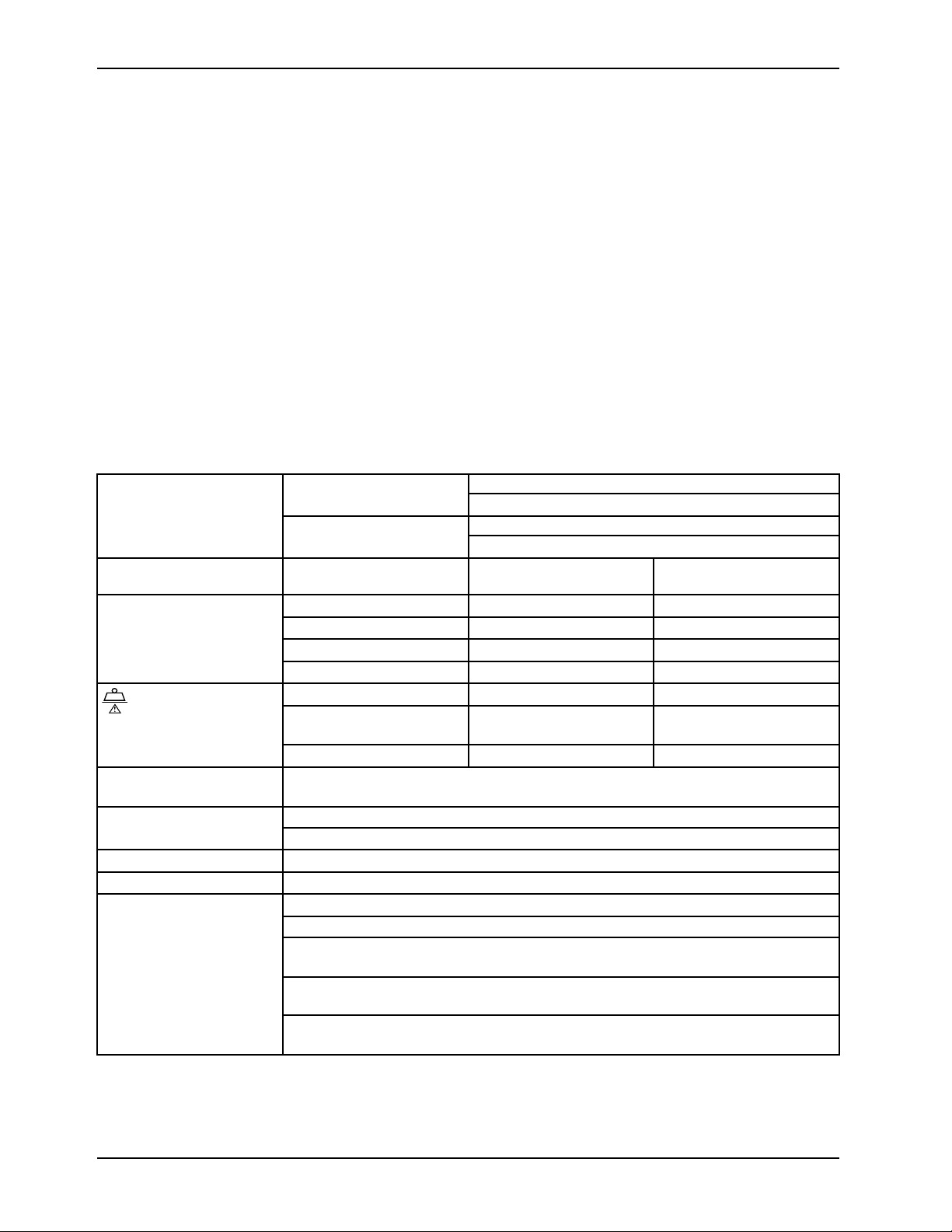

Figure 2: Insert the foot box

4. Match the outer transparent tubes colors to the manifold colors and connect them (Figure 3 on page 9) (Green,

Blue, Red, White, Black Yellow).

Figure 3: Connect tubes by color

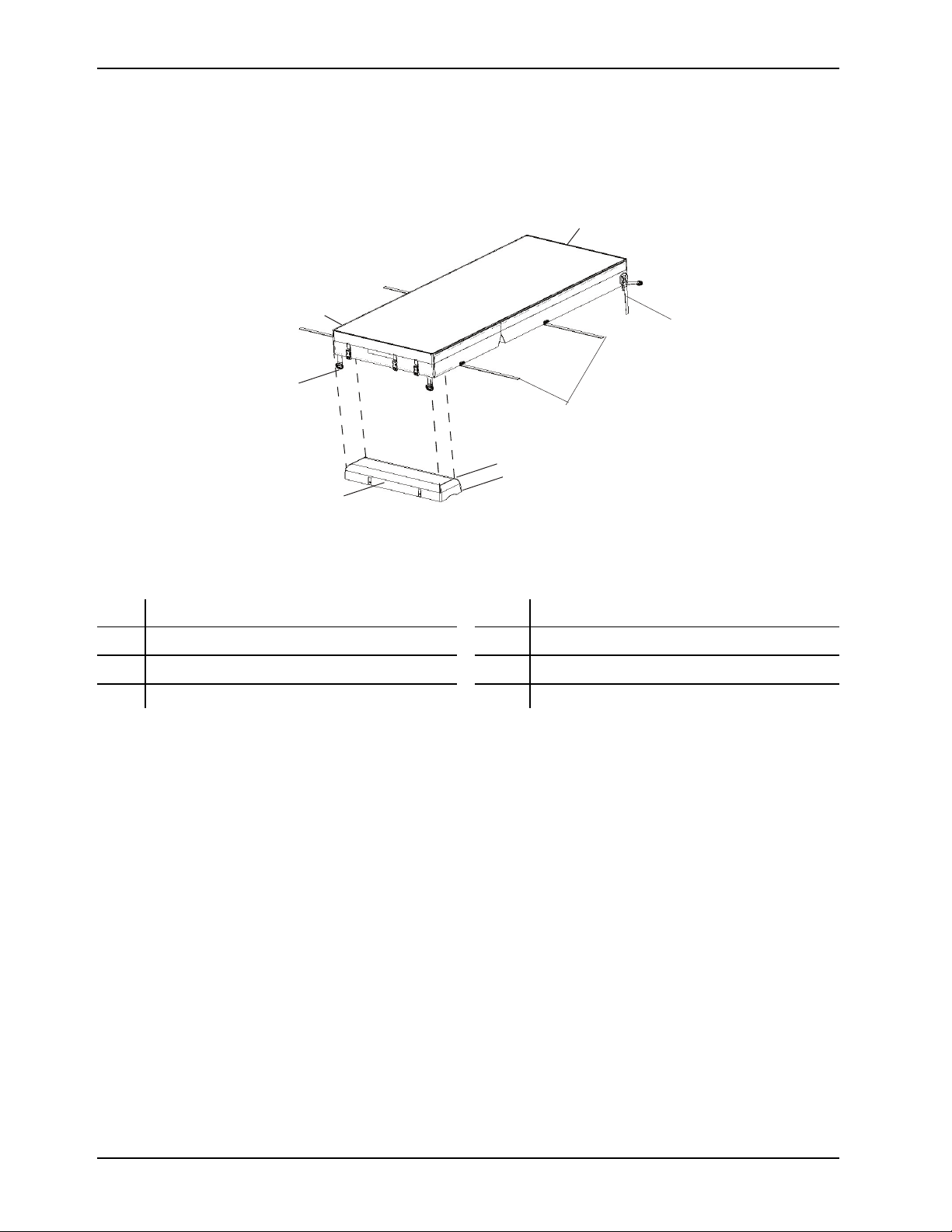

5. Connect the tilt sensor cables.

a. Align the white dots on the tilt sensor cable connectors.

b. Twist the tilt sensor cables clockwise to fasten (Figure 4 on page 10).

www.stryker.com 2920-109-001 REV G 9

Page 14

Installation

Figure 4: Connect the tilt sensor cables

6. Connect the pendant cable (Figure 5 on page 10).

Note: The pendant cable for the InTouch FL27 bed is QDF27-1534.

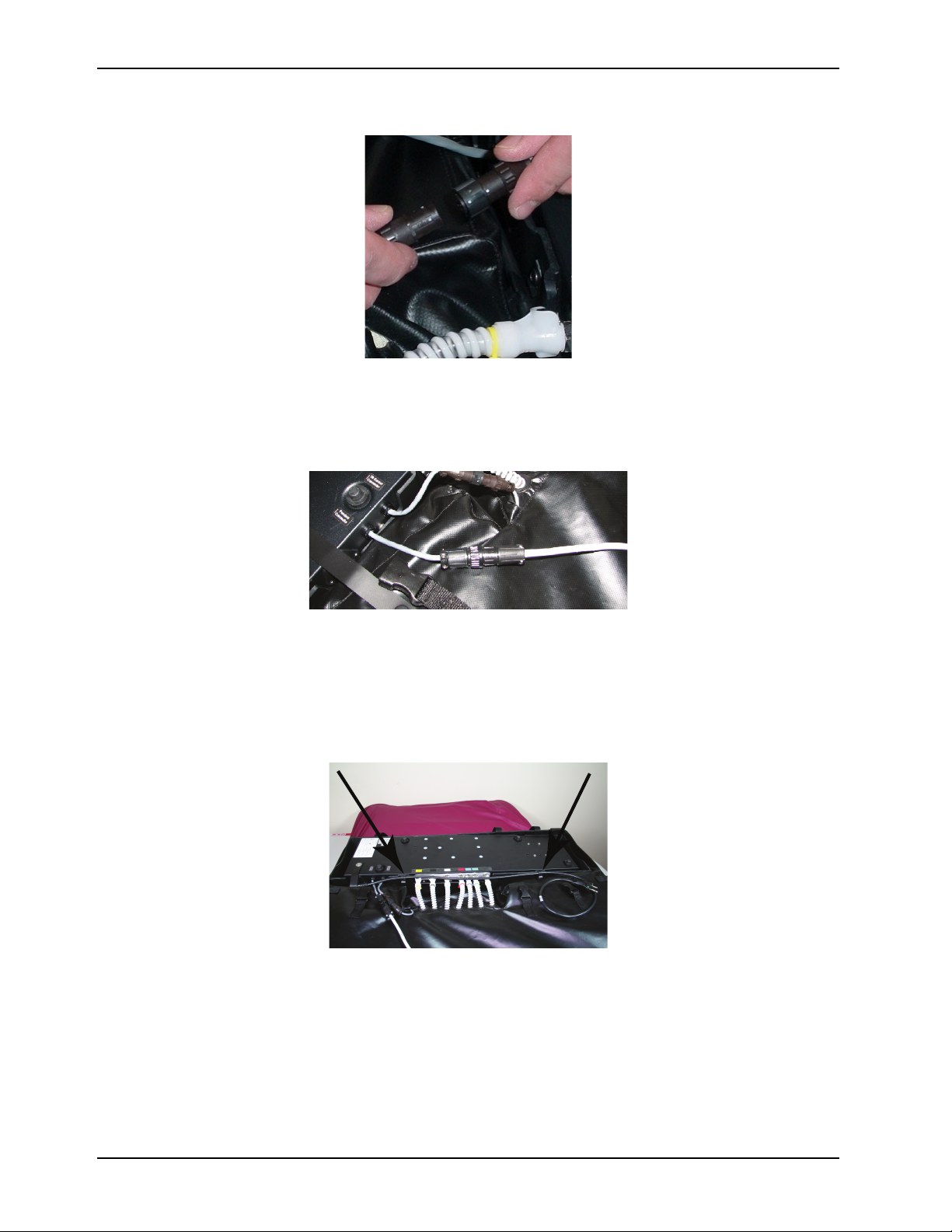

Figure 5: Connect the pendant cable

7. Connect the power cord (4 in. or 15 in.) and turn the switch to the ON or 1 position.

Note: The switch is under the power cord.

8. Fasten the straps over the power cord.

9. Install the power cord in the two retaining clips (Figure 6 on page 10).

Figure 6: Retaining clips

10. Fasten the three retaining straps.

10 2920-109-001 REV G www.stryker.com

Page 15

Installation

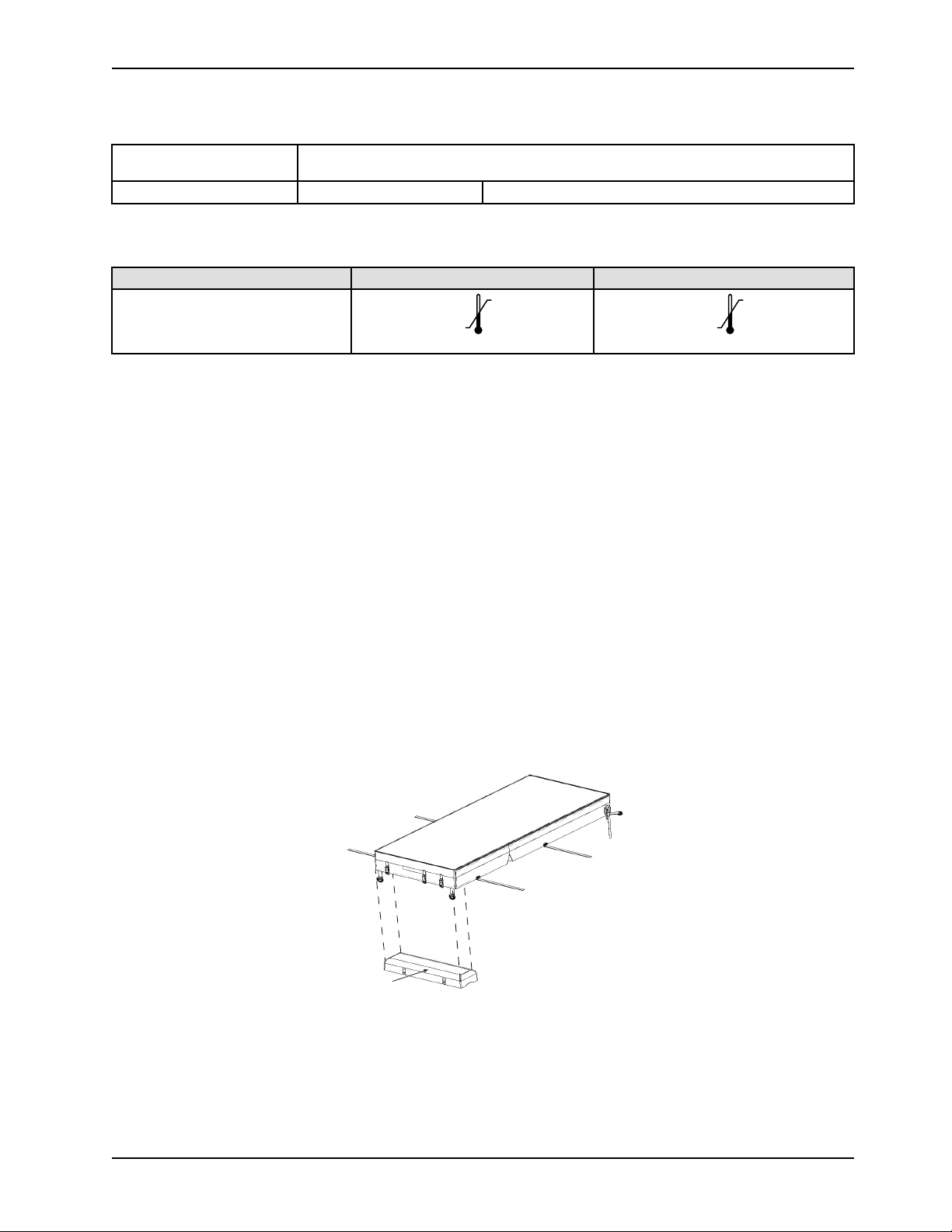

11. Carefully rotate the foot end control box and support surface into the flat position (Figure 7 on page 11).

CAUTION

Always lower the foot end section gently to avoid the risk of damage to the control box.

Figure 7: Installation complete and ready to flip

12. Fasten all four of the retaining straps to secure the support surface to the bed frame (Installation on page 9Figure 9

on page 11).

Figure 8: Strap locations

Figure 9: Fasten the retaining straps

13. Install the clip for the pendant standalone optional control in one of the two locations listed below (Figure 10 on

page 11) and (Figure 11 on page 12).

a. Siderails

Figure 10: Pendant on siderails

b. Footboard

www.stryker.com 2920-109-001 REV G 11

Page 16

Installation

Figure 11: Pendant on footboard

Note: Always plug the hospital grade three-prong plug into a properly grounded receptacle to protect against

shock hazard. Grounding reliability can be achieved only when a hospital grade receptacle is used.

14. Connect the power cord to the power source.

15. Calibrate the bed following the procedures in the InTouch maintenance manual.

12 2920-109-001 REV G www.stryker.com

Page 17

Operation

Applying the linens

WARNING

• Always make sure that the operator has access to the CPR straps.

• Do not stick needles into a support surface through the support surface cover. Holes may allow body fluids to enter

the inside (inner core) of the support surface and could cause cross-contamination, product damage, or product

malfunction.

• Do not use fitted sheets with this support surface.

To apply the linens:

1. Apply the linens using the “D” rings for the flat sheet.

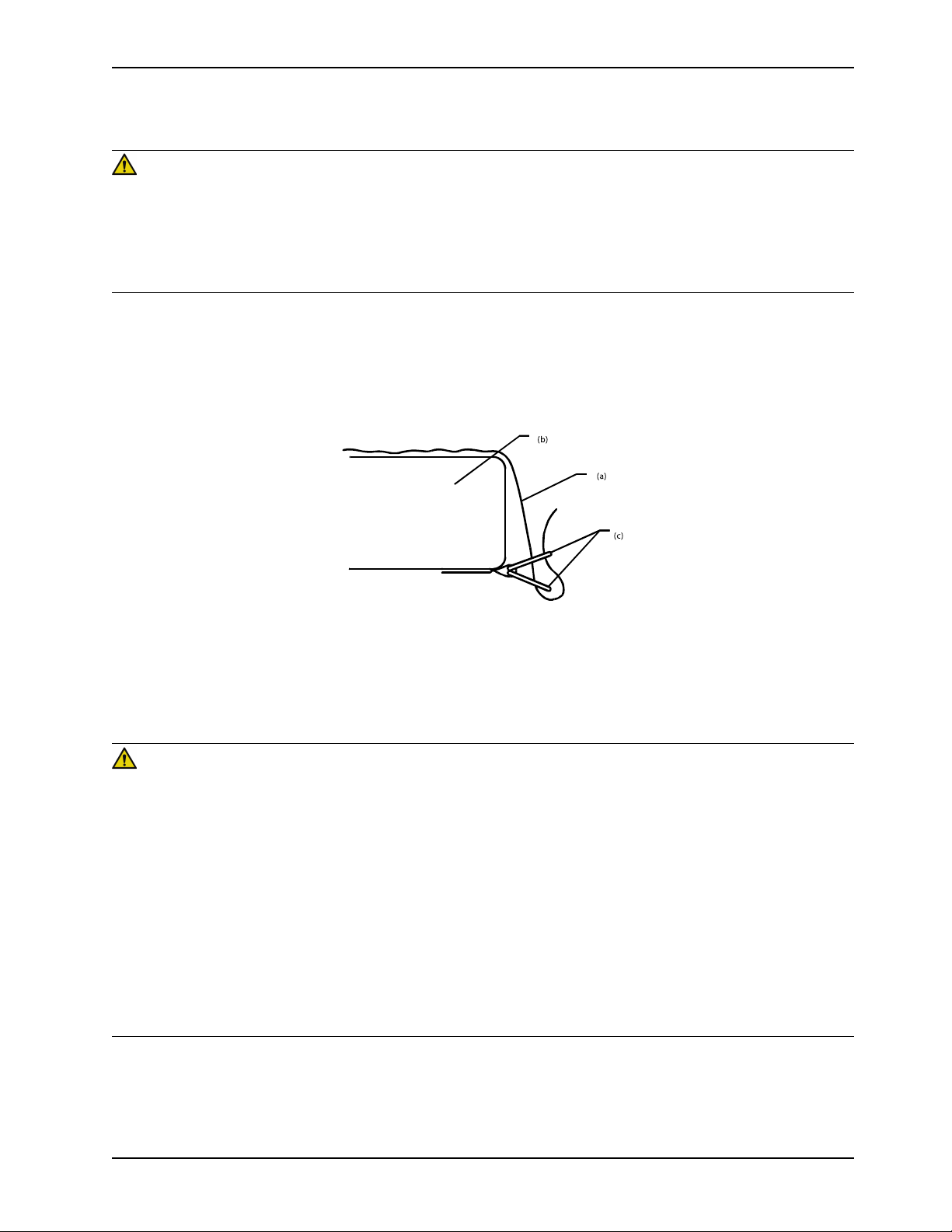

2. Thread the four linen corners through the “D” rings (c) attached to the support that are surface to secure the linens

(a) to the mattress (b).

Figure 12: Apply linens

Note: Do not pull the linens tight. Keep the linens loose and as smooth as possible on top of the support surface to

effectively use the Turn Assist and Lateral Rotation functions.

Positioning the patient

WARNING

• Always center the patient on the support surface before starting functions. Check the patient frequently for proper

positioning and to make sure that the support surface maintains proper inflation.

• Always make sure that the tubing and wiring that is connected to the patient is long enough, stabilized, and secure

during Lateral Rotation or Turn Assist.

• Do not extubate or intubate patients during Lateral Rotation or Turn Assist. The rotation functions could interfere

with the performance of the ancillary devices.

• Always secure the support surface anchoring straps to the bed frame.

• Always raise the bed siderails before starting Turn Assist.

• Do not leave the patient unattended during Turn Assist.

• Do not exceed the safe working load of the bed frame when supporting both the patient and the support surface.

Excess weight could cause unpredictable safety and performance of this product.

• Always deflate the support surface before beginning CPR.

www.stryker.com 2920-109-001 REV G 13

Page 18

Operation

Positioning the patient (Continued)

CAUTION

• Do not allow sharp objects to come into contact with the support surface that could puncture tear or cut the cover.

To position the patient:

1. Place the patient in the center of the support surface, aligning the patient’s head toward the head board.

2. Check the patient frequently during Turn Assist and Lateral Rotation for proper positioning and support surface

inflation.

Activating CPR

When CPR is activated, the manifold bladder deflates, the pump is off and all of the valves are energized. CPR

activation is detected by a fast drop of pressure in a short period of time.

WARNING

Always make sure that the operator has access to the CPR straps.

Pull the red CPR strap (Figure 13 on page 14) that is located on the left and right side of the head end of the mattress.

You can activate one or either of the straps.

Note: The CPR visual alarm LED turns red. The CPR alarm LED continues to flash to indicate that a hazardous situation

has been detected. The CPR alarm LED will continue to flash until you reset the alarm.

Figure 13: CPR Strap

Resetting CPR with the optional pendant control

When you activate the CPR, the pendant CPR LED starts flashing red without an audible alert.

To reset the CPR:

1. Reinsert the red CPR straps by pulling down on the strap.

2. Press the Stop button and the Increase Firmness (+) button simultaneously to reset the CPR alarm. The support

surface will begin to reinflate.

14 2920-109-001 REV G www.stryker.com

Page 19

Operation

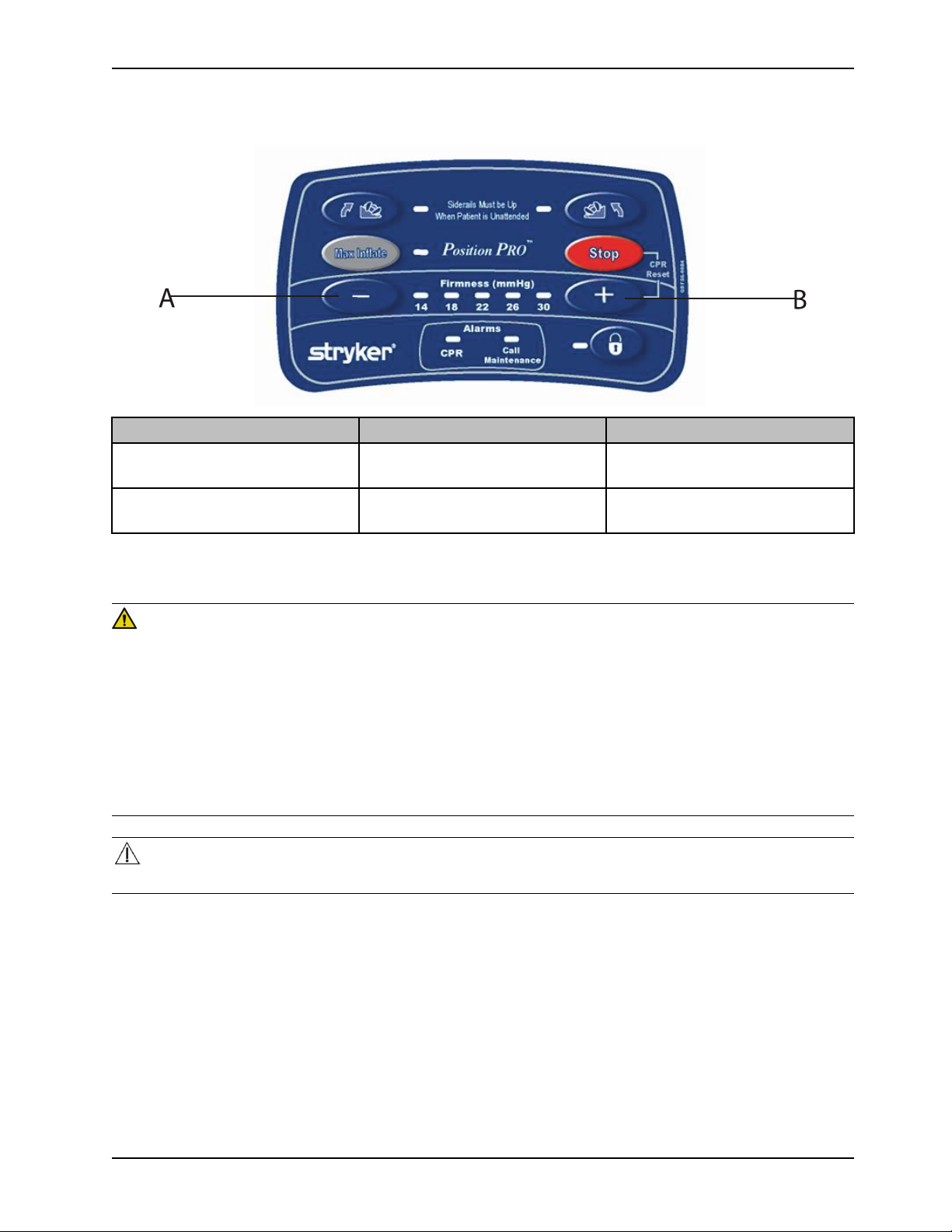

A

Resetting CPR with the optional pendant control (Continued)

Button Name Function

A

Stop and Firmness Increase (+)

Press both buttons at the same time

to reset the CPR.

Starting and stopping max inflate with the optional pendant control

To start Max Inflate:

Press the Max Inflate button to inflate the air bladders to the maximum level to aid in patient boosts and patient

transfers.

To stop Max Inflate:

Press the Max Inflate button to stop inflation.

Note: If Max Inflate has been on longer than 30 minutes, the alarm will sound, and the support surface will return to the

default firmness setting.

Locking and unlocking the optional pendant control

To Lock:

Press the Lock button to prevent options from being selected on the pendant after you have activated the functions.

To Unlock:

Press the Unlock button to allow the selection of options.

Note: When selected, the lock icon LED illuminates red.

www.stryker.com 2920-109-001 REV G 15

Page 20

Operation

A

B

C

Locking and unlocking the optional pendant control (Continued)

Button Name Function

A Max Inflate

Inflates the support surface to

maximum pressure (60 mmHg)

B

C

Stop

Lock Out / Unlock

Press once to return to previous

firmness setting

Press to lock all pendant functions

Press again to unlock all pendant

functions.

Adjusting firmness with the optional pendant control

You can adjust the support surface firmness settings for patient comfort. The product has five levels of firmness

settings that range from 14 mmHg to 30 mmHg. The default of 22 mmHg provides optimal pressure relief for patients up

to 200 lb. For average sized patients, 18-22mmHg is recommended.

Notes

• For larger patients, higher settings are recommended.

The increase firmness (+) and decrease firmness (-) buttons are inactive when Turn Assist or Max Inflate is active.

16 2920-109-001 REV G www.stryker.com

Page 21

Operation

Adjusting firmness with the optional pendant control (Continued)

Button Name Function

A Increase Firmness (+)

Increases the firmness level of the

support surface

B Decrease Firmness (-)

Decreases the firmness level of the

support surface

Starting and stopping turn assist with the optional pendant control

WARNING

• Do not arm bed exit with Lateral Rotation or Turn Assist active. The patient motion and position that results from the

support surface may adversely affect bed exit system performance.

• Always raise the bed siderails before starting Turn Assist, to avoid the risk of patient fall.

• Do not use dynamic mattress systems for stroke victims without a physician’s order.

• Do not turn a patient with unstable fractures, unstable spinal cord injuries, or those in skeletal traction.

• Do not extubate or intubate patients during Lateral Rotation or Turn Assist. The rotation functions could cause

interference with the performance of the ancillary devices.

• Do not leave the patient unattended during Turn Assist.

CAUTION

Always secure all patient lines and tubing together before starting Turn Assist to prevent pulling, removal, or breakage.

To prepare for Turn Assist:

1. Secure the patient lines, tubing, and power cords.

2. Center the patient on the support surface.

www.stryker.com 2920-109-001 REV G 17

Page 22

Operation

A

B

C

Starting and stopping turn assist with the optional pendant control (Continued)

3. Raise all the siderails on the bed.

Button Name Function

A Turn Assist Left

B

C

Turn Assist Right

Stop Turn Assist

Assists in turning the patient to the

left

Assists in turning the patient to the

right

• Press the Stop button after to

pause Turn Assist in any position.

• Press the Stop button twice to

deactivate Turn Assist in any

position.

• Press the Turn Assist Left button

or the Turn Assist Right button to

continue.

Notes

• PositionPRO can turn a 300 lb patient up to 40°.

• You can use the Turn Assist therapy with a timer so therapy can last up to 120 minutes without the need to

calculate the time the patient has been receiving this therapy.

• When patient is unattended, the warning illuminates when you activate the Left or Right Turn Assist function and

you have not raised the siderails.

• Right and left locations are from the perspective of the patient.

• Turn Assist Right or Left LEDs illuminate green when activated and remain illuminated after the function is complete.

• Turn Assist Right and Left LEDs blink when in process.

• Turn Assist will hold in a turned position for 2 hours if the Stop button is not pressed twice; after 2 hours have

passed, the support surface will return to flat.

18 2920-109-001 REV G www.stryker.com

Page 23

Operation

A

Alarming call maintenance with the optional pendant control

The alarm conditions Call Maintenance LED illuminates red and flashes to indicate when a hazardous situation has been

detected. Review the Error Alarms section and call appropriate technical support personnel.

Resetting CPR with the optional InTouch footboard

To reset CPR:

Reinsert the red CPR straps by pulling down on the strap.

Button Name Function

A

Reset CPR Tap to reset the CPR alarm

Starting and stopping max inflate with the optional InTouch footboard

To start Max Inflate:

Tap Max Inflate to inflate the air bladders to the maximum level to aid in patient boosts and patient transfers.

To stop Max Inflate:

Tap Max Inflate to stop the inflation.

Note:

If Max Inflate has been on longer than 30 minutes, the alarm will sound, and the support surface will return to the default

firmness setting.

Locking and unlocking with the optional InTouch footboard

To Lock:

Tap Lock to prevent options from being selected on the InTouch footboard after you have activated the functions.

To Unlock:

Tap Unlock to allow the selection of options.

Note: When selected, the lock icon LED illuminates red.

www.stryker.com 2920-109-001 REV G 19

Page 24

Operation

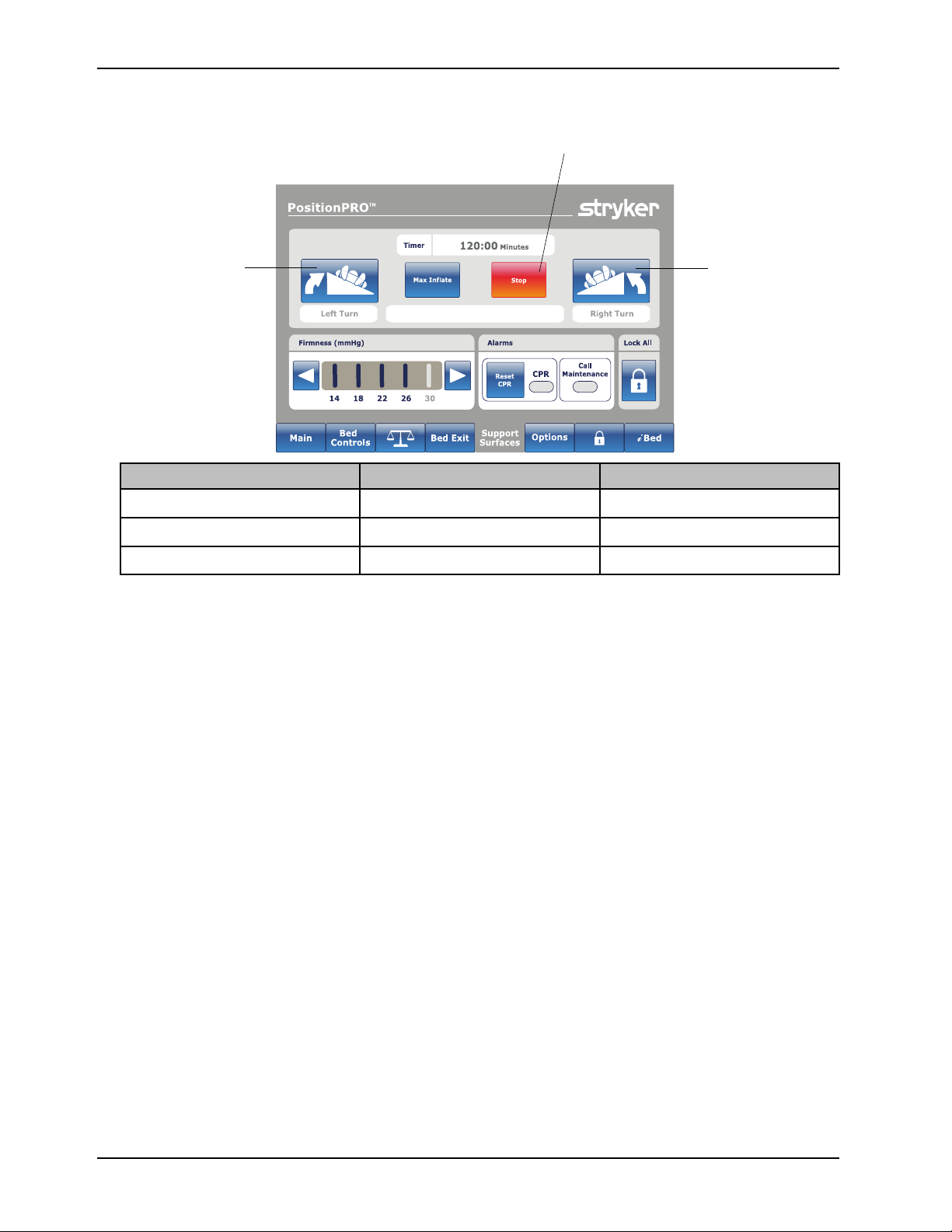

A

B

C

Locking and unlocking with the optional InTouch footboard (Continued)

Button Name Function

A Max Inflate

Tap to inflate the support surface to

maximum pressure (60 mmHg).

B

C

Stop

Lock Out / Unlock

Tap once to return to previous

firmness setting.

Tap to lock all pendant functions.

Tap again to unlock all pendant

functions.

Adjusting firmness with the optional InTouch footboard

The support surface firmness settings may be adjusted for patient comfort requirements. The product has five levels of

firmness settings that range from 14 mmHg to 30 mmHg. The default of 22 mmHg will provide optimal pressure relief for

patients up to 200 lb. For average sized patients, 18-22mmHg is recommended.

Notes

• For larger patients, higher settings are recommended.

• Firmness increase and decrease are inactive when Turn Assist and Max Inflate are active.

20 2920-109-001 REV G www.stryker.com

Page 25

Operation

A

B

Adjusting firmness with the optional InTouch footboard (Continued)

Button Name Function

A Firmness Increase

Increases the firmness level of the

support surface

B Firmness Decrease

Decreases the firmness level of the

support surface

Starting and stopping turn assist with the optional InTouch footboard

WARNING

• Always raise the bed siderails before beginning Turn Assist, to avoid the risk of patient fall.

• Do not use dynamic mattress systems for stroke victims without a physician’s order.

• Do not turn a patient with unstable fractures, unstable spinal cord injuries, or those in skeletal traction.

• Do not extubate or intubate patients during Lateral Rotation or Turn Assist. The rotation functions could cause

interference with the performance of the ancillary devices.

• Do not leave the patient unattended during Turn Assist.

CAUTION

Always secure all patient lines and tubing together before starting Turn Assist to prevent pulling, removal, or breakage.

To prepare for Turn Assist:

1. Secure the patient lines, tubing, and power cords.

2. Center the patient on the support surface.

3. Raise all the siderails on the bed.

4. Tap either the Turn Assist Left or the Turn Assist Right.

www.stryker.com 2920-109-001 REV G 21

Page 26

Operation

A

B

C

Starting and stopping turn assist with the optional InTouch footboard (Continued)

Button Name Function

A Turn Assist Left

Opens the left turn assist window

B

C

5. Tap Increase(+) or Decrease (-) to increase or decrease the turn time.

6. Tap Start button to start turn assist.

7. Tap Back button to access the Stop button.

Notes

• PositionPRO can turn a 300 lb patient up to 40°.

• Right and left locations are from the perspective of the patient.

If you do not tap Continue Turn, Turn Assist will hold in a turned position for 2 hours, after 2 hours have passed the

support surface will return to flat.

Turn Assist Right Opens the right turn assist window

Stop Stop Turn Assist

22 2920-109-001 REV G www.stryker.com

Page 27

Operation

A

B

C

D

Starting and stopping turn assist with the optional InTouch footboard (Continued)

Button Name Function

A Start

A

A

B

C Decrease Time Decreases the timer

D Back

Hold (Not Shown)

Continue Turn (Not Shown)

Increase Time

Starts Turn Assist and switches to

Hold

Pauses Turn Assist and switches to

Continue Turn

Continues Turn Assist and switches

to Hold

Increases the timer up to a maximum

of 120:00 minutes

Returns to the Support Surfaces

main screen to access the Stop

button to deactivate the Turn Assist

Alarming call maintenance with the optional InTouch footboard

The alarm conditions Call Maintenance LED illuminates red and flashes to indicate a hazardous situation has been

detected. Review the Error Alarms section and call appropriate technical support personnel.

Transferring a patient to and from the support surface

To transfer a Patient:

1. Lock the brakes on both of the platforms that the patient is being transferred to and from (beds or stretchers).

2. Position the patient along the center line of the support surface.

3. Press the Max Inflate button until the support surface has reached maximum inflation.

4. Adjust the height of both platforms to the same level.

5. Transfer the patient following all applicable safety rules and institution protocols for patient and operator safety.

6. Press the Stop button to turn off Max Inflate.

www.stryker.com 2920-109-001 REV G 23

Page 28

Operation

Transporting a patient

Note: Do not use Turn Assist while transporting a patient.

To transporting a patient:

1. Unplug the support surface power cord and the bed power cord from the power source.

2. Stow the power cords to avoid the risk of entanglement during transport.

3. Raise and lock the siderails.

4. Transport the patient following all applicable safety rules and institution protocols to for patient and operator safety.

5. Plug the support surface power cord and the bed power cord into properly grounded, hospital grade power outlets

when you have reached the patient destination.

Note: The support surface will maintain air pressure for up to four hours while unplugged.

Managing incontinence and drainage

WARNING

Always monitor the patient condition at regular intervals for patient safety.

You can use disposable diapers or incontinence pads to manage incontinence. Always provide appropriate skin care

after each incontinence episode.

24 2920-109-001 REV G www.stryker.com

Page 29

Cleaning

WARNING

• Always unplug the support surface power cord before cleaning or disinfecting to avoid the risk of shock.

• Do not immerse support surface or foot box in cleaning or disinfectant solutions. To avoid the risk of product

damage or patient injury.

• Do not allow fluid to pool on the support surface or foot box. Fluids can cause degradation of components and may

cause unpredictable safety and performance of this product.

• Always inspect support surface covers (top and bottom) for tears, punctures, excessive wear, and misaligned

zippers each time the covers are cleaned. If compromised, the support surface cover should be removed from

service immediately and replaced to prevent cross-contamination.

• Always perform preventative maintenance more frequently based on the usage level of the product. The life of the

support surface can be adversely affected by an increase in usage which may include more frequent cleaning and

disinfection.

CAUTION

• Do not iron, dry-clean, or tumble dry the support surface covers.

• Do not power wash the support surface as this may cause malfunction and damage the product.

• Always make sure that the support surface cover is completely dry before storing, adding linens or placing a patient

on the surface. Drying the product aids in preventing the performance of the product from being impaired.

Always follow hospital protocol for cleaning and disinfecting.

To clean the support surface covers between patient uses, follow these steps in order:

1. Unplug the support surface before cleaning.

2. Lift up the foot section of the support surface to clean the bottom surface.

3. Using a clean, soft, damp cloth, wipe the support surface covers with a mild soap and water solution to remove

foreign material.

4. Wipe the support surface covers with a clean, dry cloth to remove any excess liquid or cleaning agent.

Cleaning the control box

WARNING

Always allow the control box to completely dry before you place the support surface on top of it.

To clean the control box:

1. Unplug the support surface before cleaning.

2. Using a clean, soft, damp cloth, wipe the control box with a mild soap and water solution.

3. Wipe the control box with a clean, dry cloth to remove any excess liquid or cleaning agents.

4. Thoroughly rinse and dry the control box after cleaning.

5. Disinfect the control box with a hospital grade disinfectant as necessary.

Cleaning the pendant

1. Unplug the pendant before cleaning.

2. Using a clean, soft, damp cloth, wipe down the pendant using a mild soap and water solution to remove foreign

materials.

3. Wipe down the pendant with a clean, dry cloth to remove any excess liquid or cleaning agents.

www.stryker.com 2920-109-001 REV G 25

Page 30

Cleaning

Cleaning the pendant (Continued)

4. Care must be taken to thoroughly rinse and dry the pendant following cleaning.

5. Disinfect as necessary with a hospital grade disinfectant after cleaning has been completed.

26 2920-109-001 REV G www.stryker.com

Page 31

Disinfecting

WARNING

• Always disinfect the support surface between patients, to avoid the risk of cross-contamination and infection.

• Always make sure that you wipe each product with clean water and thoroughly dry each product after cleaning.

Some cleaning agents are corrosive in nature and may cause damage to the product if you use them improperly. If

you do not properly rinse and dry the product, a corrosive residue may be left on the surface of the product that

could cause premature degradation of critical components. Failure to follow these cleaning instructions may void

your warranty.

• Do not allow fluid to pool on the support surface or foot box. Fluids may cause degradation of components and may

cause unpredictable safety and performance of this product.

• Always unplug the product power cord before cleaning or disinfecting to avoid the risk of shock.

CAUTION

• Always completely dry the support surface covers before storing, adding linens, or placing a patient on the surface.

Failure to remove excess disinfectant may degrade the cover material.

• Do not over expose the covers to higher concentration disinfectant solutions as these may degrade the covers.

• Do not use accelerated hydrogen peroxides or quaternaries that contain glycol ethers as they may damage the

cover.

Prerequisite: Minimum of two operators are required to disinfect the support surface.

Suggested Disinfectants:

• Quaternaries

• Phenolic Disinfectants

• Chlorinated Bleach Solution (5.25% sodium hypochlorite at 1:100 dilution)

• 70% Isopropyl Alcohol

To disinfect the support surface covers after each patient use, follow these steps in order:

1. Unplug the support surface.

2. Thoroughly clean and dry the support surface covers (see Cleaning on page 25) before disinfectants are applied.

3. Apply recommended disinfectant solution by spray or pre-soaked wipes (do not soak the support surface).

Note: Make sure that you follow the disinfectant’s instructions for appropriate contact time and rinsing

requirements.

4. Wipe the support surface covers with a clean, dry cloth to remove any excess liquid or disinfectant.

5. Allow the support surface covers to dry completely before returning to service. Air dry, if possible.

www.stryker.com 2920-109-001 REV G 27

Page 32

Preventive maintenance

At a minimum, check all items listed during annual preventive maintenance for all Stryker Medical products. You may

need to perform preventive maintenance checks more frequently based on your level of product usage.

Note: Clean and disinfect the exterior of the support surface before inspection, if applicable.

Inspect the following items:

Zipper and covers are free of tears, cuts, holes or other openings

Fully unzip the cover to inspect the inside surface and core for signs of staining due to fluid ingress or

contamination

Pendant controls function properly

Max Inflate functions properly

Turn Assist functions properly

Left and Right CPR releases function properly

All electrical connections function properly

Power cord and plug are free of damage

Air cells are free of excessive wear, cracks, tears, or other damage

Fire barrier cover for excessive wear

All connectors are free of damage

Notes

• It is recommended to replace cells every six months.

• Replace worn or damaged components as necessary.

Product Serial Number:

Completed by:

Date:

Top cover replacement

Tools Required:

None

Procedure:

1. Unplug the support surface power cord from the power source.

2. Unzip the support surface top cover and discard.

3. Replace with new top cover and zip all sides.

4. Plug the support surface into a power source.

5. Verify proper operation of the support surface before returning it to service.

Fire barrier replacement

Tools Required:

• Diagonal pliers

• Utility knife

• Zip tie gun

Procedure:

28 2920-109-001 REV G www.stryker.com

Page 33

Preventive maintenance

Fire barrier replacement (Continued)

1. Raise the bed height to the full up position.

2. Lower the fowler and gatch sections to the full down positions.

3. Unplug the support surface from the power source.

4. Unplug one of the CPR plugs to deflate the bladder.

5. Unzip the top cover and fold it off to the side.

6. Pull the fire barrier off starting from the head end pulling down to the foot end, working it from the left to the right

while pulling it down.

7. Discard the fire barrier.

8. Starting at the foot end, roll the new fire barrier up and slide the fire barrier over the crib assembly.

Note: Align the fire barrier on the crib before sliding over the crib assembly.

9. Carefully slide the fire barrier up the crib assembly, working from side to side, to make sure that the fire barrier is

tight on the crib assembly.

10. Align the crib assembly on top of the bottom part of the cover.

Note: Spread the excess fire barrier material equally below the crib assembly at the head end.

11. Fold and align the top cover over the top of the crib assembly.

12. Zip the cover to close. Start at the head end patient right corner and stop at the foot end patient right corner.

13. Verify proper operation before returning the product to service.

www.stryker.com 2920-109-001 REV G 29

Page 34

Quick reference replacement parts

These parts are currently available for purchase. Call Stryker Customer Service: 1-800-327-0770 for availability and

pricing.

Part Name Part Number

Clip QDF2082

Pendant

Pump 56-0541

Transformer

Manifold Valve Assembly

Control Board

Top Cover, Dartex, Standalone Mattress

Top Cover, Dartex, Integrated Mattress, (with FL27 InTouch Critical

Care Bed)

Power Cord, 4 foot QDF8087

Power Cord, 15 foot QDF8088

Fan 56-0509

Sub Assembly Line Choke

Sub Assembly Tilt Sensor

Fire barrier 56-0670

QDF2081

56-0047

56-0503

56-0280

56-0274

56-0528

56-0243

56-0287

30 2920-109-001 REV G www.stryker.com

Page 35

EMC information

Guidance and manufacturer’s declaration - Electromagnetic Immunity

PositionPRO is suitable for use in the electromagnetic environment specified below. The customer or the user of

PositionPRO should make sure that it is used in such an environment.

Immunity test

IEC 60601 test level

Compliance level

Electromagnetic

environment guidance

Electrostatic Discharge

(ESD)

IEC 61000-4-2

Electrostatic fast transient/

burst

IEC 61000-4-4 *

Surge

IEC 61000-4-5 *

Voltage dips, voltage

variations and short

interruptions on power

supply input lines

IEC 61000-4-11 *

+6 kV contact

+8 kV air

+2 kV for power supply

lines

+1 kV for input/ output

lines

+8 kV differential mode

+2 kV common mode

<5%Ut (>95% dip in Ut)

for 0.5 cycle

40%Ut (60% dip in Ut)

for 5 cycles

70%Ut (30% dip in Ut)

for 25 cycles

<5% Ut (>95% dip in Ut)

+6 kV contact

+8 kV air

+2 kV for power supply

lines

+1 kV for input/ output

lines

+8 kV differential mode

+2 kV common mode

<5%Ut (>95% dip in Ut)

for 0.5 cycle

40%Ut (60% dip in Ut)

for 5 cycles

70%Ut (30% dip in Ut)

for 25 cycles

<5% Ut (>95% dip in Ut)

Floors should be wood,

concrete, or ceramic tile. If

floors are covered with

synthetic material, the

relative humidity should be

at least 30%.

Main power quality should

be that of a typical

commercial or hospital

environment.

Main power quality is that

of typical commercial

and/or hospital

environment.

Main power quality should

be that of a typical

commercial and/or hospital

environment. If the user of

PositionPRO requires

continued operation during

power main interruptions, it

is recommended that the

device be powered from an

uninterrupted power supply

or a battery.

for 5 sec

Power frequency (50/60 Hz)

magnetic field

IEC 61000-4-8

Note: U

PositionPRO is intended for use in an electromagnetic environment in which radiated RF disturbances are controlled.

The customer or the user of PositionPRO can help prevent electromagnetic interferences by maintaining a minimum

distance between portable and mobile RF communications equipment (transmitters) and PositionPRO as

recommended below, according to the maximum output power of the communications equipment.

www.stryker.com 2920-109-001 REV G 31

is the a.c. mains voltage prior to applications of the test level.

T

Recommended separation distances between portable and mobile RF communications equipment and

3 A/m 3 A/m

PositionPRO.

for 5 sec

Power frequency magnetic

fields should be at levels

characteristic of a typical

location in a typical

commercial and/or hospital

environment.

Page 36

(Continued)

EMC information

Rated maximum output power of

transmitter

W

150 kHz to 80 MHz

d=[3.5/V1]√P

0.01 0.12 0.12 0.23

0.1 0.38 0.38 0.73

1

10 3.8 3.8 7.3

100 12 12 23

For transmitters rated at a maximum output power not listed above, the recommended separation distance d in

meters (m) can be estimated using the equation applicable to the frequency of the transmitter, where P is the

maximum output power rating of the transmitter in watts (W) according to the transmitter manufacturer.

Note: At 80 MHz and 800 MHz, the separation distance for the higher frequency range applies.

Note: These guidelines may not apply in all situations. Electromagnetic propagation is affected by absorption and

reflection from structures, objects and people.

1.2 1.2 2.3

Separation distance according to frequency of transmitter

m

80 MHz to 800 MHz

d=[3.5/E1]√P

800 MHz to 2.5 GHz

d=[7/E1]√P

PositionPRO is suited for use in the electromagnetic environment specified below. The customer or the user of

PositionPRO should make sure that it is used in such an environment.

Immunity test

IEC 60601 test level

Compliance level

Electromagnetic environment - guidance

32 2920-109-001 REV G www.stryker.com

Page 37

(Continued)

Conducted RF IEC

61000- 4-6 *

Radiated RF

IEC 61000-4-3

3 Vrms

150 kHz to 80 MHz

3 V/m

80 MHz to 2.5 GHz

EMC information

3 Vrms

3 V/m

Portable and mobile RF communications

equipment should be used no closer to any

part of PositionPRO, including cables, than

the recommended separation distance

calculated from the equation appropriate for

the frequency of the transmitter.

Recommended Separation Distance

d=1.2√P

d=1.2√P

80 MHz to 800 MHz

d=2.3√P

800 MHz to 2.5 GHz

where P is the maximum output power rating

of the transmitter in watts (W) according to

the transmitter manufacturer and d is the

recommended separation distance in metres

(m).

Field strengths from fixed RF transmitters,

as determined by an electromagnetic site

a

survey,

should be less than the compliance

level in each frequency range.

b

Interference may occur in the vicinity of

equipment marked with the following symbol:

Note:

At 80 MHz and 800 MHz, the higher frequency range applies.

Note:

These guidelines may not apply in all situations. Electromagnetic propagation is affected by absorption and reflection

from structures, objects and people.

a

Field strengths from fixed transmitters, such as base stations for radio (cellular/cordless) telephones and land mobile

radios, amateur radio, AM and FM radio broadcast, and TV broadcast cannot be predicted theoretically with accuracy.

To assess the electromagnetic environment due to fixed RF transmitters, an electromagnetic site survey should be

considered. If the measured field strength in the location in which PositionPRO is used exceeds the applicable RF

compliance level above, PositionPRO should be observed to verify normal operation. If abnormal performance is

observed, additional measures may be necessary, such as reorienting or relocating PositionPRO.

b

Over the frequency range 150 kHz to 80 MHz, field strengths are less than 3 V/m.

Guidance and manufacturer’s declaration - Electromagnetic Emissions

PositionPRO is intended for use in an electromagnetic environment specified below. The customer or the user of

PositionPRO should make sure that it is used in such an environment.

www.stryker.com 2920-109-001 REV G 33

Page 38

(Continued)

EMC information

Emissions test

RF Emissions

CISPR 11

RF Emissions

CISPR 11

Harmonic Emissions

IEC 61000-3-2

Voltage Fluctuations

Flicker Emissions

IEC 61000-3-3

Compliance

Group 1

Class A

Class A

Complies

PositionPRO uses RF energy only for its internal

function. Therefore, its RF emissions are very low

and are not likely to cause any interference in

nearby electronic equipment.

PositionPRO is suitable for use in all

establishments other than domestic and those

directly connected to the public low voltage power

supply network that supplies buildings used for

domestic purposes.

Electromagnetic environment

WARNING

This equipment/system is intended for use by health care professionals only. This equipment/system may cause radio

interference or may disrupt the operation of nearby equipment. It may be necessary to take mitigation measures, such

as reorienting or relocating PositionPRO or shielding the location.

34 2920-109-001 REV G www.stryker.com

Page 39

Warranty

Stryker Medical, a division of Stryker Corporation (“Stryker”), warrants that it Stryker Model 2920 PositionPRO®

product will be free from defects in material and workmanship for a period of two years after the date of delivery.

Stryker’s obligation under this warranty is expressly limited to supplying replacement parts and labor for, or replacing at

its option, any product which is , in the sole discretion of Stryker, found to be defective. If requested by Stryker, products

or parts for which a warranty claim is made shall be returned prepaid to the factory. Any improper use or any alteration

or repair by others in such manner as in Stryker’s judgement affects the product materially and adversely shall void this

warranty. Any repair of Stryker products using parts not provided or authorized by Stryker shall void this warranty. No

employee or representative of Stryker is authorized to change this warranty in any way.

Stryker Model 2920, PositionPRO product is designed for a five year expected service life under normal use, conditions,

and with appropriate periodic maintenance as described in the maintenance manual for each device.

The above noted warranty periods apply only to the original purchaser of the product and begin on the date of delivery

to such original purchaser.

Warranty exclusion and damage limitations

The express warranty set forth herein is the only warranty applicable to the product. Any and all other warranties,

whether express or implied, including any implied warranty of merchantability or fitness for a particular purpose

are expressly excluded by Stryker. In no event shall Stryker be liable for incidental or consequential damages.

To obtain parts and service

Stryker products are supported by a nationwide network of dedicated Stryker Field Service Representatives. These

representatives are factory trained, available locally, and carry a substantial spare parts inventory to minimize repair

time. Simply call your local representative or call Stryker Customer Service at 1-800-327-0770.

Return authorization

Product cannot be returned without prior approval from the Stryker Customer Service Department. An authorization

number will be provided which must be printed on the returned product. Stryker reserves the right to charge shipping

and restocking fees on returned product. Special, modified, or discontinued products are not subject to return.

Damaged product

ICC Regulations require that claims for damaged product must be made within fifteen (15) days of receipt of the product.

Do not accept damaged shipments unless such damage is noted on the delivery receipt at the time of receipt. Upon

prompt notification, Stryker will file a freight claim with the appropriate carrier for damages incurred. Claims will be

limited in amount to the actual replacement cost. In the event that this information is not received by Stryker within the

fifteen (15) day period following the delivery of the product, or the damage was not noted on the delivery receipt at the

time of receipt, the customer will be responsible for payment of the original invoice in full within thirty (30) days of

receipt. Claims for any incomplete shipments must be made within thirty (30) days of invoice.

International warranty clause

This warranty reflects U.S. domestic policy. Warranty outside the U.S. may vary by country. Contact your local Stryker

Medical representative for additional information.

www.stryker.com 2920-109-001 REV G 35

Page 40

Page 41

Page 42

Stryker Medical

3800 E. Centre Avenue

Portage, MI 49002

USA

2016/10

2920-109-001 REV G

www.stryker.com

Loading...

Loading...