Page 1

Manual

EN

Manual

Manuel

Manual

ES

FR

PT

Insufflator for Laparoscopy and Vessel Harvesting

2011/02 www.stryker.com 1000-401-015 Rev. E

Page 2

This manual contains information that is subject to copyright. All

EN

Some of the parts and equipment referred to in this manual bear registered

trademarks but are not identified as such. It should therefore not be assumed

that the absence of the trademark indicates that any given designation is not

subject to trademark protection.

Users of this product should not hesitate to point out to us any errors or unclarities in this manual.

Copyright © STRYKER ENDOSCOPY

ES

pia, microfilm u otros medios y procedimientos.

Debido al desarrollo constante de nuestros productos, nos reservamos el

derecho a llevar a cabo modificaciones técnicas sin aviso previo. El funcionamiento y el diseño podrán diferir parcialmente de la descripción en el manual.

Rogamos establezcan contacto con nosotros, si desean adquirir más información sobre este o cualquier otro producto.

Las denominaciones que son, a su vez, marcas registradas, no han sido identificadas especialmente. La falta de la identificación con marca no implica que

el producto en cuestión no posea marca comercial alguna. Asimismo, no

pueden sacarse conclusiones del presente manual, sobre la existencia o inexistencia de patentes ni modelos de utilidad.

STRYKER ENDOSCOPY agradecerá a los usuarios de los productos de STRYKER

ENDOSCOPY cualquier aviso, indicación u observación con respecto a posibles

fallos, incongruencias o explicaciones poco claras que puedan encontrarse en

el presente manual.

Copyright © STRYKER ENDOSCOPY

FR

écrite expresse de l’entreprise STRYKER ENDOSCOPY.

En raison du perfectionnement permanent de nos produits, nous nous réservons le droit de procéder à des modifications techniques sans avis préalable. Il

se peut que les fonctionnalités ou que le design des produits diffèrent partiellement de la description figurant dans le manuel. Pour de plus amples informations concernant ce produit ou d’autres produits, n’hésitez pas à nous

contacter.

Les désignations qui représentent en même temps des marques déposées

n’ont pas été spécifiquement caractérisées. L’absence du logotype ne peut en

aucun cas faire supposer que la désignation représente une marque non déposée. De la même manière, cela n’indique pas la présence de brevets ou de

modèles déposés.

STRYKER ENDOSCOPY remercie d’avance les utilisateurs de ses produits qui lui

fourniront des informations eu égard à des errata possibles ou à des imprécisions susceptibles d’être contenus dans ce présent manuel.

Copyright © STRYKER ENDOSCOPY

rights reserved. This manual should not be photocopied, duplicated on microfilm or otherwise copied or distributed, completely or in part, without the approval of STRYKER ENDOSCOPY.

Este manual contiene informaciones protegidas por el derecho

de propiedad (copyright), que forma parte de los derechos de autor. Todos los derechos están protegidos. Sin autorización por escrito de STRYKER ENDOSCOPY, este manual no podrá ser ni total

ni parcialmente reproducido ni divulgado por medio de fotoco-

Ce manuel contient des informations protégées par la législation

des droits de propriété et des droits d’auteur. Tous droits sont

protégés. Il est interdit de reproduire ou de distribuer ce manuel

- que ce soit intégralement ou partiellement par photocopie, microfilm ou autres procédés de reproduction sans l’autorisation

Este manual contém informações que estão sob protecção do Có-

PT

Em função do constante desenvolvimento dos nossos produtos, reservamo-nos

o direito a alterações técnicas, sem aviso prévio. A função bem como o design,

podem, parcialmente, diferir da descrição apresentada no manual. É favor entrar em contacto connosco, para obter informações complementares sobre este

ou outros produtos.

As designações, que também são marcas industriais, não foram identificadas

especificamente. A falta da marca industrial não significa que uma designação

seja uma marca industrial livre. Da mesma forma, não pode concluir-se se está

ou não sob a protecção de patentes ou modelos de utilidade

A STRYKER ENDOSCOPY agradece a todos os utilizadores de seus produtos, por

avisos sobre possíveis falhas ou dúvidas deste manual.

Copyright © STRYKER ENDOSCOPY

digo de Direitos do Autor. Todos os direitos estão protegidos. Sem

a permissão prévia por escrito da STRYKER ENDOSCOPY não pode

ser total ou parcialmente reproduzido, seja por fotocópia, microfilme ou qualquer outro procedimento, e tão-pouco distribuído.

Produced for/Producido parar/Produit pour/Produzido para:

Stryker Endoscopy

5900 Optical Court, San Jose

CA 95138 (USA)

(408) 754-2000 (800) 624-4422

www.stryker.com

Stryker European Rep-

REP

EC

RA/QA Manager

ZAC Satolas Green Pusignan

Av. De Satolas Green

69881 MEYZIEU Cedex France

CE marking according to directive 93/42/EEC

Identificación CE conforme a la directriz 93/42/CEE

Marquage CE conforme à la directive 93/42/CEE

EDistintivo CE conforme a Directiva 93/42/CEE

Model: F114/1200628/10000002254 04/0211/ama

Page 3

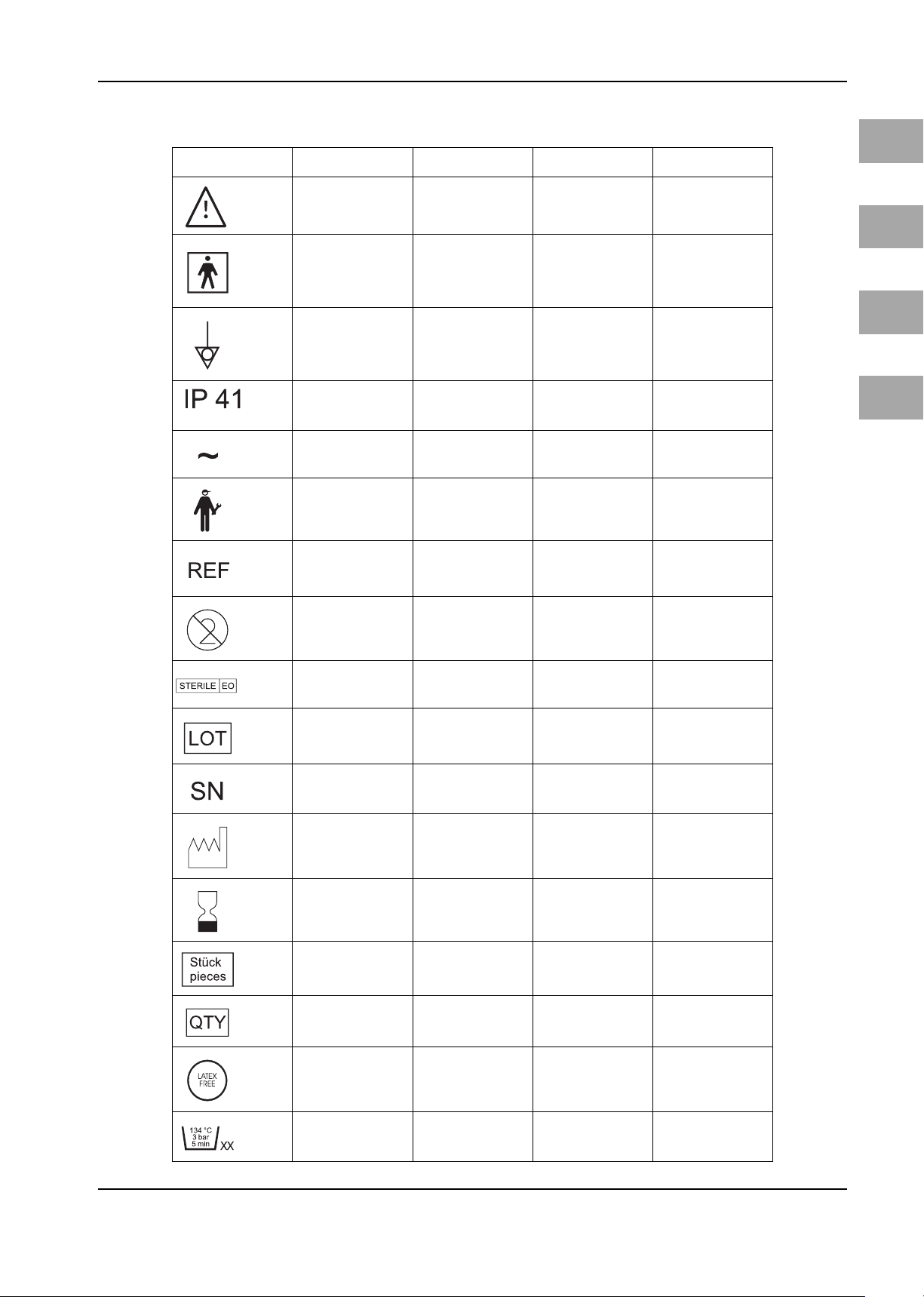

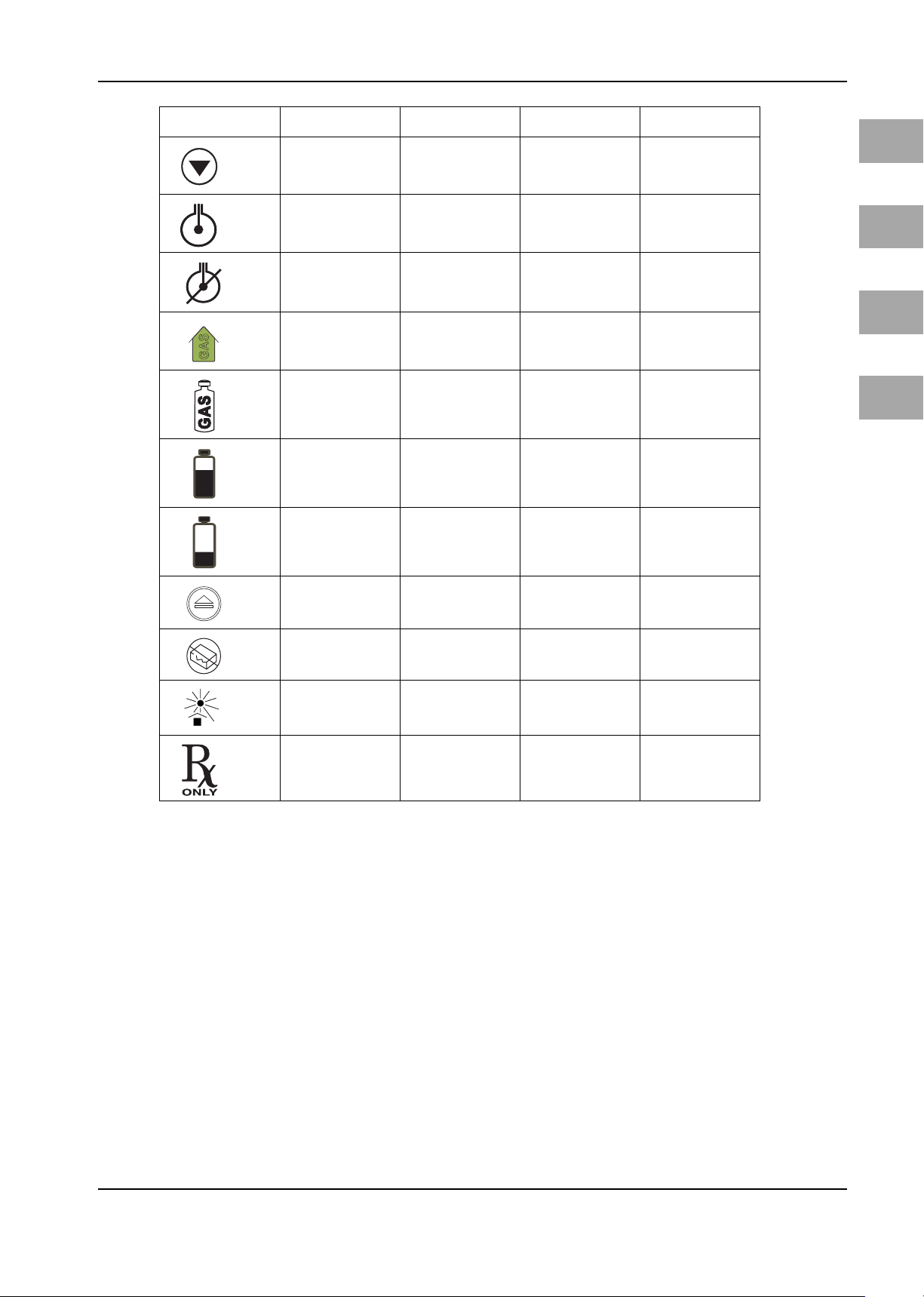

Symbols/Símbolos/Symboles/Símbolos

Symbols Símbolos Symboles Símbolos

EN

See operating manual

Symbol for type BF

equipment

Symbol for potential

equalization

Degrees of protection

provided by enclosures

(IP-Code)

Alternating current

Service

Order number Número de pedido Référence produit Refêrencia

Single use only No reutilizable Usage unique Vedada a reutilização

¡Atención! Observe la

documentación adjunta

Símbolo para un aparato

del tipo BF

Símbolo para la cone-

xión equipotencial

Grado de protección

proporcionado por los

envolventes (Código IP)

Corriente alterna Courant alternatif Corrente alternada

Servicio Service Assistência

Attention, lire la docu-

mentation jointe!

Symbole pour un appa-

reil de type BF

Fiche équipotentielle

Degrés de protection

procurés parles enve-

loppes (Code IP)

Atenção, atentar aos

documentos de expe-

dição

Símbolo para um apare-

lho do tipo BF

Sistema para a compe-

sação do potencial

Classificação do grau de

proteção oferecido

pelas carcaças (IP)

ES

FR

PT

Sterile with ETO Esterilizado con ETO Stérilisés à l’ETO Esterilizado com ETO

Lot no.

Serial number Número de serie Numéro de série Número de série

Date of manufacture Fecha de fabricación Date of fabrication

Expiration day Utilizable hasta Date limite d’utilisation Utilizável até

Pieces, quantity Pieza, cantidad Pièces. quantité Número, quantida

Quantitiy Cantidad Quantité Quantida

Latex free Sin latex sans latex Isento de látex

Denominación

departida o lote

Numéro de lot Designação do lote

Data de fabricação

Number of autoclaving

cycles

Número de esteriliza-

ciones por autoclave

Paramètres pour la sté-

rilisation à l’autoclave

Número de esteriliza-

ções em autoclave

Page 4

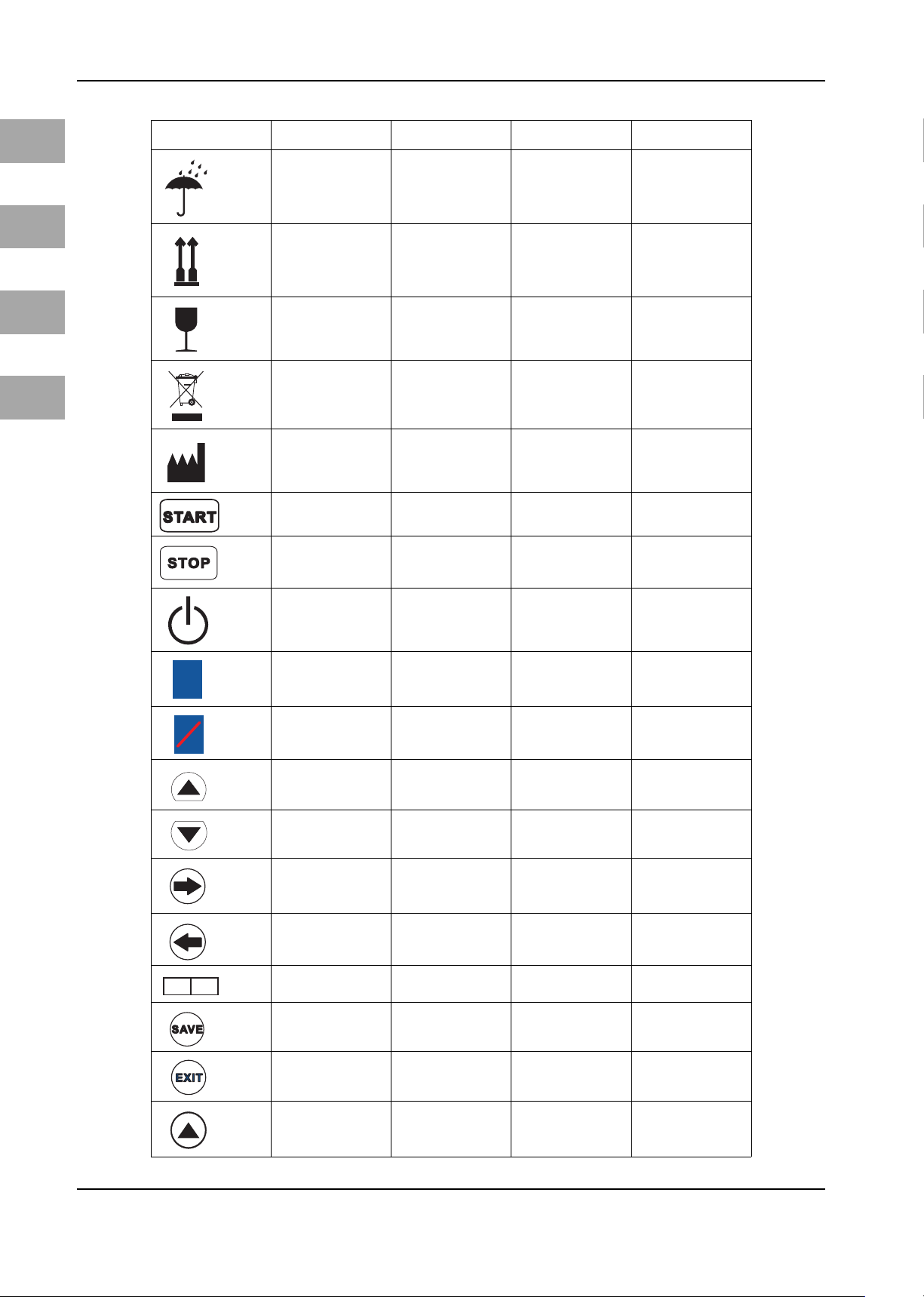

Symbols/Símbolos/Symboles/Símbolos

EN

ES

FR

PT

Symbols Símbolos Symboles Símbolos

Do not get wet

Top-Bottom Arriba-abajo Haut-bas Em cima-Em baixo

Fragile Frágil Fragile Frágil

Waste management Gestión de residuos Élimination des déchets Eliminação

Produced for Producido para Produit pour Produzido para

Start Start (Inicio) Start Start

Stop Stop (Parada) Stop Stop

Proteger contra la

humedad

Protéger de l’humidité Proteger da humidade

EC

HEATING

HEATING

REP

On/Off

Gas heater Calentador del gas Chauffage du gaz Aquecedor do gás

Gas heater error

Increase Aumento Croissant Aumento

Decrease Disminución Décroissant Descida

Forward to menu Remitir al menú Expédier au menu Enviar ao menu

Back to menu Volver al menú Retour au menu Voltar ao menu

Stryker European Repre-

sentative

Save Guardar Mémoriser Guardar

On/Off (Encendido/

Apagado)

Fallo en calentador del

gas

Representante europeo

de Stryker

On/Off (Marche /Arrêt) On/Off (Ligar/Desligar)

Erreur du chauffage du

gaz

Représentant Stryker

Europe

Erro no aquecedor do

gás

Representante Europeu

da Stryker

Exit Salida Sortie Saída

Menu - Increase Menú-Aumento Menu-Croissant Menu-Aumento

Page 5

Symbols/Símbolos/Symboles/Símbolos

Symbols Símbolos Symboles Símbolos

Menu - Decrease Menú-Disminución Menu-Décroissant Menu-Descida

EN

Real-Time Pressure Sensing in progress

Real-Time Pressure Sensing defective or deacti-

vated

House gas supply

Tank gas supply

Low gas pressure Presión de gas baja Pression de gaz basse Pressão de gás baixa

Gas pressure too low

Push to release Presione para retirar Appuyer pour retirer Premir para eliminar

Do not use if package

damaged

Real-Time Pressure Sen-

sing activada

Real-Time Pressure Sen-

sing defectuosa o

desactivada

Alimentación de gas

central

Alimentación por

botella de gas

Presión de gas dema-

siasdo baja

No utilizar si el envolto-

rio está dañado

Real-Time Pressure Sen-

sing activée

Real-Time Pressure Sen-

sing défectueuse ou

désactivée

Alimentation en gaz

centrale

Alimentation en gaz par

bouteille

Pression de gaz insuffi-

sante

Ne pas utiliser si

l’emballage est endom-

magé

Real-Time Pressure Sen-

sing activada

Real-Time Pressure Sensing danificada o desac-

tivada

Alimentação de gás

doméstico

Alimentação de gás

com uma botija de gás

Pressão de gás dema-

siado baixa

Não usar se a embala-

gem é danificada

ES

FR

PT

Keep away from hea Proteger contra el calor

Authorized for Sale or

use by Physician only

Autorizado sólo para la

venta o el uso médico

Protéger contre la cha-

leur

Autorisé seulement

pour la vente ou l’utili-

sation par un médecin

uniquement

Proteger de encontro ao

calor

Autorizado somente

para a venda ou o uso

médico

Page 6

Page 7

Table of contents

1 Important User Notes ......................................................................................................................................................... 3

2 Safety Information.............................................................................................................................................................. 4

2.1 Hazards........................................................................................................................................................................................ 5

3 Device Purpose.................................................................................................................................................................... 7

3.1 Laparoscopy Applications...................................................................................................................................................... 7

3.1.1 Using High Flow Operating Mode....................................................................................................................................... 7

3.1.2 Using Pediatric Operating Mode.......................................................................................................................................... 7

3.1.3 Using Bariatric Operating Mode.......................................................................................................................................... 8

3.1.4 Contraindications for Laparoscopy Applications............................................................................................................. 8

3.2 Using Vessel Harvest Operating Mode............................................................................................................................... 8

3.3 General Device-Inherent Dangers....................................................................................................................................... 8

3.3.1 Device-Inherent Dangers - Laparoscopy............................................................................................................................ 10

3.3.2 Device-Inherent Dangers - Vessel Harvesting.................................................................................................................. 12

4 Initial Device Startup .......................................................................................................................................................... 14

4.1 Gas connection ......................................................................................................................................................................... 14

4.1.1 Connecting a Gas Bottle......................................................................................................................................................... 15

4.1.2 Connecting to Central Gas Supply....................................................................................................................................... 15

5 Operating the Device - General.......................................................................................................................................... 16

5.1 Front of the Device................................................................................................................................................................... 16

5.2 Rear of the Device .................................................................................................................................................................... 16

5.3 Touch screen display................................................................................................................................................................ 17

5.4 Switch on Device ...................................................................................................................................................................... 18

5.5 Connecting Insufflation Tube Set........................................................................................................................................ 19

5.6 Using the Gas Heating............................................................................................................................................................ 20

5.6.1 Using the direct pressure measurement function (Real-Time Pressure Sensing RTP).......................................... 21

5.6.2 Displaying/Selecting Insufflation Operating Mode ....................................................................................................... 23

5.6.3 Setting the Nominal Pressure - General............................................................................................................................ 23

5.6.4 Setting the Nominal Flow - General ................................................................................................................................... 23

5.6.5 Gas Consumption Display...................................................................................................................................................... 24

5.6.6 Starting/Stopping Insufflation............................................................................................................................................. 24

5.6.7 Using the SIDNE Port (Optional) .......................................................................................................................................... 25

5.6.8 Turning Device Off ................................................................................................................................................................... 25

6 Using and Controlling the PNEUMO SURE High Flow Insufflator in High Flow Mode ...................................................... 26

6.1 Device-Specific Dangers when Using the PNEUMO SURE High Flow Insufflator in High Flow Operating

Mode............................................................................................................................................................................................ 26

6.2 Selecting High Flow Insufflation Mode.............................................................................................................................. 28

6.3 Presetting Nominal Pressure in High Flow Operating Mode....................................................................................... 28

6.4 Presetting Nominal Flow in High Flow Operating Mode.............................................................................................. 28

6.5 Performing the Function Test in High Flow Operating Mode...................................................................................... 29

6.5.1 Filling Tube System with CO2............................................................................................................................................... 31

6.6 Using the Device during Surgery......................................................................................................................................... 31

6.6.1 Insufflating with Veress Cannula......................................................................................................................................... 31

6.6.2 Insufflating with the Trocar................................................................................................................................................... 32

6.6.3 "Real-Time Pressure Sensing" functionality (RTP) ........................................................................................................... 32

6.6.4 Stop the Insufflation................................................................................................................................................................ 32

7 Using and Controlling the PNEUMO SURE High Flow Insufflator in Pediatric Operating Mode....................................... 34

7.1 Device-Specific Dangers when Using the PNEUMO SURE High Flow Insufflator in Pediatric Operating

Mode............................................................................................................................................................................................ 34

7.2 Selecting Pediatric Operating Mode................................................................................................................................... 36

7.3 Presetting Nominal Pressure in Pediatric Operating Mode......................................................................................... 36

7.4 Presetting Nominal Flow in Pediatric Operating Mode ................................................................................................ 37

7.5 Performing the Function Test in Pediatric Operating Mode before Using the Device during Surgery............ 38

7.5.1 Filling Tube System with CO2............................................................................................................................................... 40

7.6 Using the Device during Surgery......................................................................................................................................... 40

7.6.1 Insufflating with Veress Cannula......................................................................................................................................... 40

7.6.2 Insufflating with the Trocar................................................................................................................................................... 41

7.6.3 "Real-Time Pressure Sensing" functionality (RTP) ........................................................................................................... 41

7.6.4 Stop the Insufflation................................................................................................................................................................ 41

8 Using and Controlling the PNEUMO SURE XL High Flow Insufflator in Bariatric Operating Mode................................... 43

8.1 Device-Specific Dangers when Using the PNEUMO SURE High Flow Insufflator in Bariatric Operating

Mode............................................................................................................................................................................................ 43

8.2 Selecting Bariatric Operating Mode.................................................................................................................................... 45

8.3 Presetting Nominal Pressure in Bariatric Operating Mode.......................................................................................... 46

8.4 Presetting Nominal Flow in Bariatric Operating Mode................................................................................................. 46

8.5 Performing the Function Test in Bariatric Operating Mode before Using the Device during Surgery............ 47

8.5.1 Filling Tube System with CO2............................................................................................................................................... 48

8.6 Using the Device during Surgery......................................................................................................................................... 49

8.6.1 Insufflating with Veress Cannula......................................................................................................................................... 49

8.6.2 Insufflating with the Trocar................................................................................................................................................... 49

EN

Page 8

EN

8.6.3 "Real-Time Pressure Sensing" functionality (RTP) ........................................................................................................... 50

8.7 Stop the Insufflation................................................................................................................................................................ 50

9 Using and Controlling the PNEUMO SURE XL High Flow Insufflator in Vessel Harvest Operating Mode......................... 51

9.1 Device-Specific Dangers when Using the PNEUMO SURE XL High Flow Insufflator in Vessel Harvest Ope-

rating Mode ............................................................................................................................................................................... 51

9.2 Selecting Vessel Harvest Operating Mode........................................................................................................................ 52

9.3 Presetting Nominal Pressure in Vessel Harvest Operating Mode.............................................................................. 53

9.4 Presetting Nominal Flow in Vessel Harvest Operating Mode ..................................................................................... 54

9.5 Performing the Function Test in Vessel Harvest Operating Mode before Using the Device during Surgery. 54

9.5.1 Filling Tube System with CO2 ............................................................................................................................................... 55

9.6 Using the Device during Surgery......................................................................................................................................... 56

9.6.1 Insufflation with Vessel Harvest Instrument................................................................................................................... 56

9.6.2 Stop the Insufflation................................................................................................................................................................ 57

10 Configuration Menu (Overview)......................................................................................................................................... 58

10.1 Configuration menu I.............................................................................................................................................................. 60

10.1.1 Setting First Nominal Pressure............................................................................................................................................. 60

10.1.2 Setting the Venting Controls................................................................................................................................................. 61

10.1.3 Setting the Gas Supply Type.................................................................................................................................................. 62

10.1.4 Setting the Alarm Volume..................................................................................................................................................... 63

10.2 Configuration menu II............................................................................................................................................................. 64

10.2.1 Setting the Gas Flow Rates*.................................................................................................................................................. 64

10.2.2 Setting First Nominal Gas Flow*.......................................................................................................................................... 64

10.2.3 Setting the Maximum Nominal Pressure.......................................................................................................................... 65

10.2.4 Setting the Flow Safety Limit*.............................................................................................................................................. 66

10.2.5 Setting the Warning signal: Occlusion .............................................................................................................................. 66

10.3 Utility menu............................................................................................................................................................................... 66

10.3.1 Changing Display Settings..................................................................................................................................................... 67

10.3.2 Setting the Language.............................................................................................................................................................. 67

10.3.3 Checking Software Version.................................................................................................................................................... 68

10.3.4 Upgrade XL* ............................................................................................................................................................................... 69

10.3.5 Service Menu............................................................................................................................................................................. 69

11 Safety functions.................................................................................................................................................................. 70

12 Care and Maintenance........................................................................................................................................................ 74

12.1 Cleaning the Device................................................................................................................................................................. 74

12.2 Annual Inspection .................................................................................................................................................................... 74

12.3 Maintenance by Authorized Service Technician.............................................................................................................. 74

12.4 Replacing the Fuse ................................................................................................................................................................... 75

12.5 Care and Maintenance of Reusable Tube Set................................................................................................................... 75

12.5.1 Cleaning the Reusable Tube Set........................................................................................................................................... 76

12.5.2 Disinfecting the Reusable Tube Set..................................................................................................................................... 76

12.5.3 Sterilization of Reusable Tube Set ....................................................................................................................................... 76

13 Annual Inspection............................................................................................................................................................... 78

13.1 Safety Test................................................................................................................................................................................... 78

13.2 Basic Function Test (in High Flow Operating Mode)...................................................................................................... 78

13.3 Testing the Pressure Sensors in High Flow Operating Mode....................................................................................... 79

13.4 Pressure Monitoring Test in High Flow Operating Mode.............................................................................................. 80

13.5 Venting Valve Test.................................................................................................................................................................... 80

13.6 Max. Device Pressure Test...................................................................................................................................................... 81

13.7 Gas Flow Rate Test.................................................................................................................................................................... 81

14 Electromagnetic compatibility........................................................................................................................................... 82

14.1 Impact of Mobile and Portable HF Communication Devices....................................................................................... 82

14.2 Electrical Connections............................................................................................................................................................. 82

14.3 Accessories ................................................................................................................................................................................. 82

14.4 Guidelines and Manufacturer's Statement - Electromagnetic Interference Immunity....................................... 83

14.5 Guidelines and Manufacturer’s Statement – Electromagnetic Emissions.............................................................. 84

14.6 Guidelines and Manufacturer's Statement - Electromagnetic Interference Immunity - PNEUMO SURE

High Flow Insufflator .............................................................................................................................................................. 85

14.7 Recommended Safety Distances Between Portable and Mobile HF Telecommunications Devices and the

PNEUMO SURE High Flow Insufflator................................................................................................................................. 86

15 Error and Warning Messages.............................................................................................................................................. 87

16 Technical Data..................................................................................................................................................................... 89

17 Accessories for PNEUMO SURE High Flow Insufflator........................................................................................................ 90

17.1 Accessories for Sale in USA.................................................................................................................................................... 90

17.2 Accessories for Sale Outside of the USA............................................................................................................................ 91

18 Warranty and Service ......................................................................................................................................................... 93

19 Appendix............................................................................................................................................................................. 95

19.1 Test Log........................................................................................................................................................................................ 95

Index ................................................................................................................................................................................... 96

Page 9

1Important User Notes

Read the manual carefully and become familiar with the operation and function

of the device and the accessories before use during surgical procedures. Non-observance of the instructions listed in this manual can lead

• to life-threatening injuries of the patient,

• to severe injuries of the surgical team, nursing staff or service personnel, or

• to damage or malfunction of device and/or accessories.

technical data of the supplied product through continued product development.

marked with these words must be read especially attentively.

WARNING!

The safety and/or health of the patient, user, or a third party are at risk. Comply

with this warning to avoid injury to the patient, user, or third parties.

CAUTION!

These paragraphs include information provided to the operator concerning the

intended and proper use of the device or accessories.

Important User Notes

EN

Subject to technical changesThe manufacturer reserves the right to modify the appearance, graphics, and

Please noteThe words DANGER, WARNING, and NOTE carry special meanings. Sections

NOTE!

Here you will read information about the maintenance of the device or the ac-

cessories.

3

Page 10

EN

Safety Information

2 Safety Information

Federal Law (only for U.S. market) U.S. federal law restricts use of this device to use by or on the o rder of a p hysici an.

Exclusion of liability The manufacturer is not liable for direct or consequential damage and the war-

ranty is null and void if:

• the device and/or the accessories are improperly used, prepared, or maintained,

• the instructions and rules in the manual are not adhered to,

• non-authorized persons perform repairs, adjustments, or alterations on or to

the device or accessories,

• non-authorized persons open the device,

• the prescribed inspection and maintenance schedules are not adhered to.

Receipt of technical documentation from the manufacturer does not authorize

individuals to perform repairs, adjustments, or alterations on or to the device or

accessories.

Authorized service technician Only an authorized service technician may perform repairs, adjustments, or al-

terations on the device or accessories and use the service menu. Any violation will

void the manufacturer's warranty. Authorized service technicians are only

trained and certified by the manufacturer.

Care and maintenance The service and maintenance of the device and its accessories has to be carried

out as per instructions to ensure the safe operation of the device. For the protection of the patient and the operating team, check that the device is complete and

functional before each use.

Contamination Before shipping, decontaminate device and accessories in order to protect the

service personnel. Follow the instructions listed in this manual. If this is not possible,

• the product must be clearly marked with a contamination warning and

• is to be double-sealed in safety foil.

The manufacturer has the right to reject contaminated products for repair.

Waste management

This symbol indicates that the waste of electrical and electronic equipment must

not be disposed of as unsorted municipal waste and must be collected separately

instead. Please contact the manufacturer or an accordingly authorized disposal

or waste management company for further information.

4

Page 11

Safety Information

2.1 Hazards

WARNING!

Condensation / Water penetration

Protect device from moisture. Do not use if moisture has penetrated the device.

WARNING!

Original accessories

For your own safety and that of your patient, use only original accessories.

WARNING!

Check all factory settings.

Factory settings are not mandatory settings for the physician. The physician is re-

sponsible for all settings affecting the surgical procedure.

WARNING!

Technique and procedures

Only the physician can evaluate the clinical factors involved with each patient

and determine if the use of this device is indicated. The physician must deter-

mine the specific technique and procedure that will accomplish the desired clinical effect.

EN

CAUTION!

Check to make sure the available mains voltage matches the data listed on the

type label attached to the back of the device. Incorrect voltage can cause errors

and malfunctions and may destroy the device.

WARNING!

Not explosion-proof

The device is not explosion-proof. Do not use in an area where flammable anes-

thetic gases are present.

WARNING!

Risk of electrical shock

To prevent electrical shock, do not open this device. Never open this device your-

self. Refer servicing to qualified service personnel.

WARNING!

Replacing fuse

Replace the fuse only with a fuse of the same type and rating.

WARNING!

Professional qualification

This manual does not include descriptions or instructions for surgical proce-

dures/techniques. It is also not suitable for training physicians in the use of surgical techniques. Medical accessories and devices may be used only by physicians

and medical assistants under the direction of a physician with the appropriate

5

Page 12

EN

Safety Information

technical qualification.

WARNING!

Function test

The function test must be performed prior to each surgery.

WARNING!

Sterile mediums and accessories

Always work exclusively with sterile substances and mediums, sterile fluids, and

sterile accessories if so indicated.

WARNING!

Cleaning the device

Do not sterilize the device.

WARNING!

Replacement device and accessories

In case the device or any of the accessories fail during surgery, a replacement device and replacement accessories should be kept within easy reach to be able to

finish the operation with the replacement components.

WARNING!

Device-inherent dangers

Read the warnings specific to this device in chapter 3.3 General Device-Inherent

Dangers.

WARNING!

Device defect

If a device defect is suspected or confirmed, do not use it. Make sure the device

can no longer be used until a qualified service technician conducts the appropriate tests and repairs.

CAUTION!

Endoscope

The device may only be connected with endoscopes designed for and featuring

the technical specification permitting such a combined use. Any utilized endoscopes must comply with the most recent versions of EC 60601-2-18 and

ISO 8600.

6

Page 13

3 Device Purpose

CO2 during diagnostics and/or therapeutical laparoscopy. High Flow operating

mode, Pediatric operating mode, and Bariatric operating mode of the device are

used in conjunction with a laparoscope to fill and distend a peritoneal cavity with

gas. Pediatric operating mode is designed specifically for use on newborns, infants, and children. Vessel Harvest operating mode is used to create a cavity

along the saphenous vein and/or the radial artery during an endoscopic vessel

harvesting procedure.

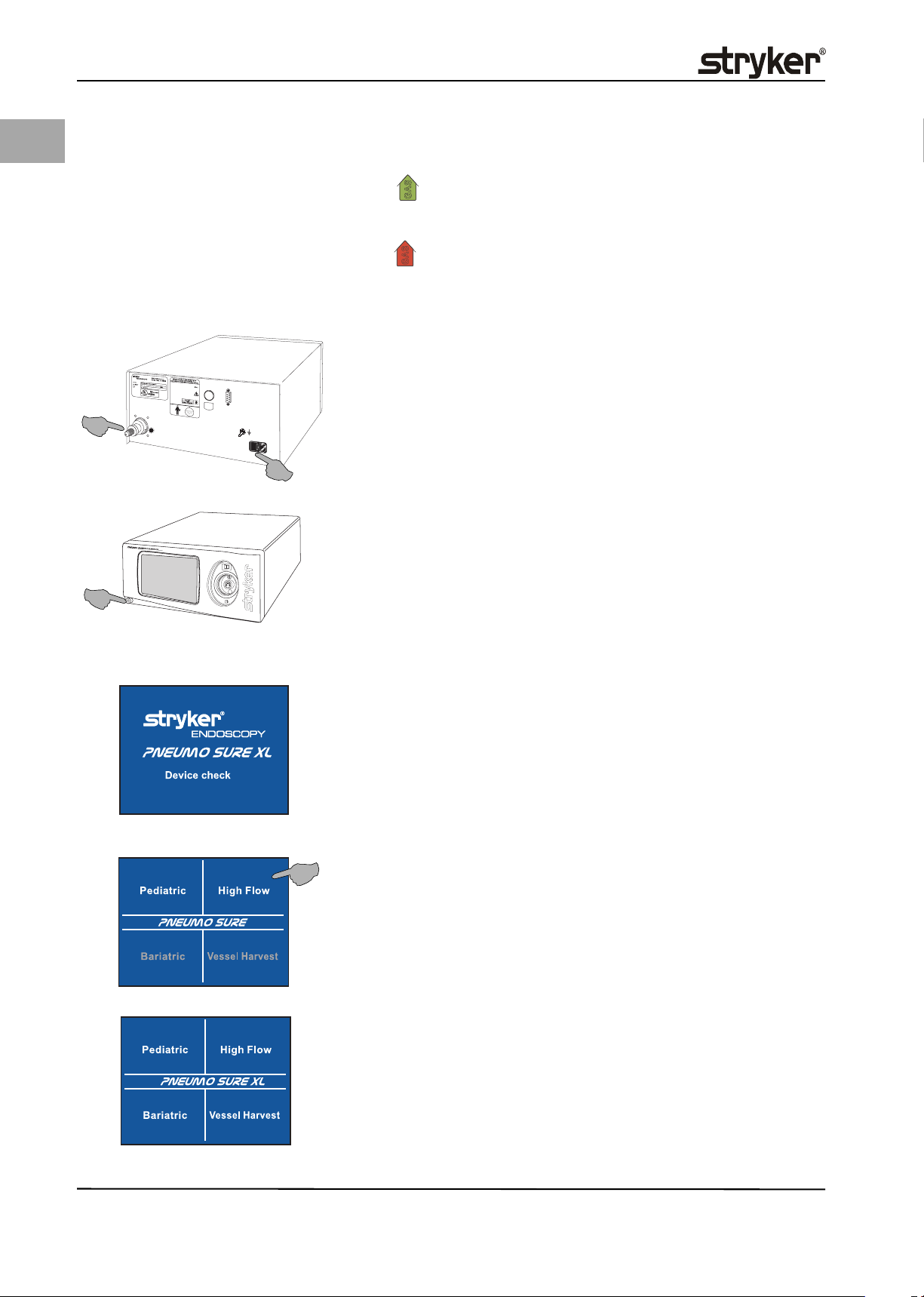

Two alternative configurations are provided:

1. PNEUMO SURE High Flow Insufflator contains the applications

High Flow operating mode -> Insufflation for adults and the

Pediatric operating mode -> Insufflation for infants and children.

2. PNEUMO SURE XL High Flow Insufflator contains the applications

High Flow operating mode -> Insufflation for adults and the

Pediatric operating mode -> Insufflation for infants and children,

Bariatric operating mode -> Insufflation for morbidly obese patients,

Vessel Harvest operating mode -> Insufflation for Vessel Harvesting proce-

dure.

Device Purpose

Intended useThe PNEUMO SURE High Flow Insufflator serves to create a cavity by insufflating

EN

The PNEUMO SURE XL configuration is available directly or via software upgrade.

High Flow operating mode, Pediatric operating mode, and Bariatric operating

mode of the device are used in conjunction with a laparoscope to fill and distend

a peritoneal cavity with gas. Bariatric operating mode is used for laparoscopic

surgery on morbidly obese patients.

Vessel Harvesting operating mode is used to create a cavity along the saphenous

vein and/or the radial artery during an endoscopic vessel harvesting procedure.

3.1 Laparoscopy Applications

3.1.1 Using High Flow Operating Mode

High Flow operating mode is designed explicitly for laparoscopies performed on

normal weight and slightly obese (BMI < 30 kg/m2) patients over the age of 14.

While in High Flow operating mode, the insufflator limits the pressure to max. 30

mm Hg and the gas flow rate to max. 40 l/min. The device measures the pressure

within the abdomen and compares the nominal with the actual abdominal pressure. The function of the device is to maintain the nominal pressure. Any overpressure within the abdomen is lowered to the preset nominal pressure by the

automatic venting system.

3.1.2 Using Pediatric Operating Mode

Pediatric operating mode is designed specifically for use on newborns, infants,

and children. While in Pediatric operating mode, the insufflator limits the pressure to max. 20 mmHg and the gas flow rate to max. 20 l/min. When used on

children, the device should be set depending on the selected nominal flow and

the age and weight of the treated child as outlined in the table below:

Age Group Weight Flow Range

Children younger than 1

year

Children between 1 and

3 years

Children between 3 and

4 years

Children between 4 and

14 years

approx. 1-9 kg 0.1 -0.5 l/min

approx. 10-15 kg 0.5 -1.0 l/min

approx. 16-19 kg 1.0 -2.0 l/min

> 20 kg > 2.0 l/min

7

Page 14

EN

Device Purpose

If the nominal flow is set too low, the nominal pressure cannot be reached. Check

for possible leaks. Due to the special operating method used during the Pediatric

application, the speed of equalizing the leak is slower than when using the High

Flow application (lower effective flow in the Pediatric application).

3.1.3 Using Bariatric Operating Mode

Bariatric operating mode is used for laparoscopies performed on severely overweight (BMI > 30 kg/m

pressure to max. 30 mm Hg and the gas flow to max. 45 l/min. This operating

mode delivers rapid insufflation of large volumes.

2

) adults. While in Bariatric mode, the insufflator limits the

3.1.4 Contraindications for Laparoscopy Applications

Contraindications The device may not be used to fill an abdomen with CO2 if a laparoscopy is con-

traindicated. Please consult the manual of your laparoscope for absolute and relative contraindications. The device is not suitable for hysteroscopic insufflations,

i.e., it may not be used to distend the uterus.

The gas flow may not exceed 14 l/min when performing a laparoscopy on infants

or patients weighing less than 25 kilos.

3.2 Using Vessel Harvest Operating Mode

WARNING!

Before using the insufflator to harvest vessels, please check whether the used in-

strument is intended for surgical procedures using CO2.

Vessel Harvest operating mode is designed for the controlled insufflation of

medical-grade CO2 when harvesting vessels (veins and arteries) during a minimally invasive procedure within the scope of heart bypass surgery. While in Vessel Harvest operating mode, the insufflator limits the pressure to max.

20 mm Hg and the gas flow rate to max. 10 l/min. Surgery to harvest vessels requires the use of a special instrument.

Contraindications The device may not be used for the endoscopic harvesting of vessels if this surgi-

cal application is contraindicated. Please consult the manual of the instrument

for absolute and relative contraindications.

3.3 General Device-Inherent Dangers

WARNING!

Positioning the patient

Always position the patient lower than the device to prevent body fluids from

leaking into the insufflation tube. Actual pressure may increase and fluid may

penetrate the insufflation tube if the patient is repositioned during surgery. If

this occurs, immediately disconnect the insufflation tube. When the patient is

repositioned onto his or her side, internal tissue may block the insufflation channel. Always insufflate through the elevated side of the patient.

WARNING!

Removing the insufflation tube

Always disconnect the insufflation tube after ending surgery and before switch-

ing off the device to prevent backflow of bodily fluids. Fluid may penetrate the

insufflation tube whenever you change the gas bottle and/or when you stop the

gas flow during the operation. If this happens, you must immediately disconnect

the insufflation tube from the trocar or from the device.

8

Page 15

WARNING!

Backflow

Body secretions or contaminated gas may backflow into the device through the

insufflation tube if

• a filter is not used,

• the actual pressure is higher than the nominal pressure or

• the automatic venting valve is activated.

WARNING!

Gas flow

A high gas flow can occur due to large leaks within the surgical system or instru-

ment. This can result in a false actual pressure reading, which in turn may endanger the patient. In case of a disrupted gas flow, you should therefore inspect

device, tube, and instruments immediately. Surgical applications should be carried out with a gas flow of 4-10 l/min. An even lower gas flow is recommended

for diagnostic purposes. It is recommended to perform endoscopies with the

lowest gas flow possible.

WARNING!

Keep filled CO2 bottle on hand

Always keep a filled CO2 bottle on hand ready for replacement. This avoids hav-

ing to interrupt surgery due to a lack of insufflation gas (see chapter 4.1.1 Connecting a Gas Bottle).

Device Purpose

EN

WARNING!

Contamination

Do not use device and/or accessories if signs of contamination are detected.

Make sure the device or/and accessories can no longer be operated until a qual-

ified service technician conducts the appropriate tests and repairs.

WARNING!

Fatigue symptoms

When there is a high level of CO2 consumption, you should make sure to supply

the operating area with enough fresh air, since an increasing CO2 level in the air

can cause the medical personnel to suffer fatigue symptoms, an inability to concentrate, unconsciousness, or even death.

WARNING!

The venting rate of the automatic venting system is limited. Always monitor the

actual pressure when using additional insufflation sources.

WARNING!

Contaminated filter

Replace a contaminated filter immediately during surgery to ensure unhindered

gas flow.

WARNING!

Connecting the tube

Always use the proper tube set for the device. The tube outlet may only be con-

9

Page 16

EN

Device Purpose

nected to instruments which are intended for intra-abdominal CO2-insufflation.

WARNING!

Electronic device control

Do not close the valve at the trocar sleeve during surgery. The electronic control

unit of the device adjusts the actual pressure as desired.

WARNING!

Medically pure CO2

Make sure to use only medically pure CO2. Other gases (i.e., helium, N2O, argon),

mixtures of gases, high pressure compressed gases, gases with entrapped liquids, or polluted gases must not be used with this device.

WARNING!

Service connection

Connected devices have to comply with the EN 60950 standard. Do not connect

a device to the service connection during surgery.

CAUTION!

Electrical Interference

(See chapter 14 Electromagnetic compatibility). Electrical interference with other devices or instruments was practically eliminated when developing this devic-

es and none was detected during testing. However, if you still detect or suspect

such interference, please follow these suggestions:

• Move this, the other or both devices to a different location

• Increase distance between used devices

• Consult an electro-medical expert

WARNING!

Peripheral devices

Additional peripheral equipment connected to interfaces of the medical monitor

has to meet the requirements of the following specifications: IEC 60601-2-18 /

EN 60601-2-18 for endoscopic devices and IEC 60601-1 / EN 60601-1 for electrical medical devices. All configurations have to comply with IEC 60601-1 / EN

60601-1 specifications. Whoever connects additional equipment to signal output or signal input is considered the system configurator and as such is responsible for complying with requirements of the standard IEC 60601-1 / EN 60601-1.

3.3.1 Device-Inherent Dangers - Laparoscopy

WARNING!

Because pediatric patients are especially susceptible to hypercapnia, it is recom-

mended to establish an end-tidal CO2 monitoring routine.

10

WARNING!

Gas flow limit

The gas flow may not exceed 14 l/min when performing a laparoscopy on new-

borns or patients weighing less than 25 kg (approx. 55 US pounds).

Page 17

WARNING!

Pneumolabium/pneumoscrotum

Children are at risk of a pneumolabium or pneumoscrotum.

WARNING!

Increased airway pressure/compression of the vena cava

When using the pediatric application of the device on children, an increased risk

of high airway pressure and/or compression of the vena cava (low input syndrome) exists.

WARNING!

Idiosyncratic reactions

Patients with sickle cell anemia or pulmonary insufficiency may have a higher

risk of metabolic imbalance related to excessive CO2 absorption (idiosyncratic

reaction).

WARNING!

CO2 absorption

CO2 is absorbed during insufflation (intravasation). This means the body absorbs

part of the CO2 gas used for insufflation. CO2 concentrations in the blood or respiratory system that are too high can lead to death of the patient in extreme

cases. To lower this risk, always carefully and closely monitor the patient's vital

signs during the entire insufflation process and make sure patient is breathing

well. Sufficient respiration can help avoid or limit problems with CO2. High pressure or a high gas flow promotes CO2 absorption. The abdomen is sufficiently

distended using a pressure between 10 to 15 mm Hg. Pressure values above

15 mm Hg are required for only a few cases but do increase the risk of intravasation. Never exceed the max. intra-abdominal pressure of 30 mm Hg.

Device Purpose

EN

WARNING!

Metabolic and cardiac reactions

Insufflating CO2 may result in metabolic acidosis. This can lead to cardiac irregularities expressed with the following symptoms:

• Reduced respiration with restricted diaphram function

• Hypercapnia

• Reduction of venous reflux

• Reduced cardiac output

• Metabolic acidosis

WARNING!

Hypothermia/monitoring body temperature

The gas flow can lead to a lowering of the patient's body temperature during in-

sufflation. Hypothermia during insufflation can cause heart and cardiovascular

problems. The risk for hypothermia can be significantly reduced with the use of

gas that is pre-warmed to body temperature. Always monitor the patient's body

temperature during the entire insufflation. Make especially sure that the following, hypothermia promoting, surgical conditions are avoided as best as possible:

• High gas flow due to large leaks

• Long surgeries

• Use of cold (not preheated) irrigation and infusion solutions

11

Page 18

EN

Device Purpose

WARNING!

Dehydration

Insufflation can lead to dehydration of the tissue. This can result in organ tissue

damage and cardiovascular reactions of the patient. Long surgeries and large

leaks increase the risk of dehydration (especially at the insertion points of the

trocars or when changing instruments).

WARNING!

Embolism

Improper placement of the insufflation instrument could cause insufflation of

gas into a vessel, resulting in air or CO2 embolisms. To reduce the risk of air or

CO2 embolism, perform initial insufflation at a low flow rate and ensure that the

insufflation instrument is correctly positioned. Check the position of the insufflation instrument immediately if the actual pressure rapidly reaches the nominal pressure value. CO2 embolisms can also be caused by a high intra-abdominal

pressure. Avoid high-pressure settings and close damaged blood vessels at once.

WARNING!

Additional insufflation sources

The use of additional insufflation sources increases the intra-abdominal pressure. Continuously monitor intra-abdominal pressure over the course of the en-

tire insufflation if additional sources are used.

WARNING!

Automatic venting system

Make sure the automatic venting system is activated (see chapter 10 Configura-

tion Menu (Overview), page 58) when using Pediatric application and an additional insufflation source. It is not possible to use an additional insufflation

source when the automatic venting system is deactivated.

WARNING!

Only specially trained and qualified personnel may use this device on children or

for the endoscopic vessel harvesting procedure.

3.3.2 Device-Inherent Dangers - Vessel Harvesting

WARNING!

Before using the insufflator to endoscopic harvest vessels, please check whether

the used instrument is intended for CO2 insufflation.

WARNING!

Pneumoperitoneum

When a vessel is harvested from the leg of a patient with a perforated groin, it is

possible for CO2 to reach the abdomen and cause a pneumoperitoneum. Make

sure the abdomen does not fill with CO2 during surgery.

12

WARNING!

Idiosyncratic reactions

Patients with sickle cell anemia or pulmonary insufficiency may have a higher

risk of metabolic imbalance related to excessive CO2 absorption (idiosyncratic

Page 19

reaction).

WARNING!

CO2 absorption

Due to the special surgical procedures - start of the heart bypass operation, and

the endoscopic removal of the vessel - special care has to be taken as CO2 is al-

ways absorbed through the tissue of the patient during insufflation (intravasation). This means the body absorbs part of the CO2 gas used for insufflation. CO2

concentrations in the blood or respiratory system that are too high can lead to

death of the patient in extreme cases. To lower this risk, always carefully and

closely monitor the patient's vital signs during the entire insufflation process

and make sure patient is breathing well. Sufficient respiration can help avoid or

limit problems with CO2. High pressure or a high gas flow promotes CO2 absorption.

WARNING!

Metabolic and cardiac reactions

Due to the special surgical conditions - start of the heart bypass surgery and vessel harvesting - it is especially important to remember the existing risk of meta-

bolic acidosis when insufflating with CO2. This can lead to cardiac irregularities

expressed with the following symptoms:

• Reduced respiration with restricted diaphram function

• Hypercapnia

• Reduction of venous reflux

• Reduced cardiac output

• Metabolic acidosis

Device Purpose

EN

WARNING!

Dehydration

Insufflation can lead to dehydration of the tissue. This can result in organ tissue

damage and cardiovascular reactions of the patient. Long surgeries and large

leaks increase the risk of dehydration (especially at the insertion points of the

trocars or when changing instruments).

WARNING!

Embolism

Improper placement of the insufflation instrument could cause insufflation of

gas into a vessel, resulting in air or CO2 embolisms. To reduce the risk of air or

CO2 embolism, perform initial insufflation at a low flow rate and ensure that the

insufflation instrument is correctly positioned. Check the position of the insufflation instrument immediately if the actual pressure rapidly reaches the nominal pressure value. CO2 embolisms can also be caused by a high pressure. Avoid

high-pressure settings and close damaged blood vessels at once.

WARNING!

Only specially trained and qualified personnel may use this device on children or

for the endoscopic vessel harvesting procedure.

13

Page 20

EN

Initial Device Startup

4 Initial Device Startup

Delivery inspection Always check all parts and accessories of the device immediately after receiving

the shipment. The manufacturer considers only replacement claims that have

been immediately submitted or reported to a sales representative or an authorized service company.

Setting up the device Place the device on a level surface and install in a dry environment. The ambient

temperature and humidity must meet the requirements mentioned in chapter

16 Technical Data, page 89.

WARNING!

Not explosion-proof

The device is not explosion-proof. Do not use in an area where flammable anes-

thetic gases are present.

Mains connection

CAUTION!

Check to make sure the available mains voltage matches the data listed on the

type label attached to the back of the device. Incorrect voltage can cause errors

and malfunctions and may destroy the device.

Make sure the connection data and technical specifications of the power supply

comply with DIN VDE or national requirements. The mains power supply cable

must be plugged into a properly installed safety wall plug (see DIN VDE 0107).

Read the device label located in rear of device (type plate) to determine the operating voltage of the device.

Grounding contact The power connection must be equipped with a grounding contact. Use the orig-

inal power cable (if included in scope of delivery) to establish a connection between the mains wall socket and the non-heating device plug located in the rear

of the device.

Only for U.S. operators Only use a certified (UL-listed), removable mains connection line, type SJT, mini-

mal 18 AWG, 3 leads. The plug connectors must comply with NEMA 5-15 or IEC

320/CEE22. Grounding will only be reliable if the equipment is connected to a

corresponding hospital grade socket.

Potential equalization Integrate the device into the potential equalization system as specified by local

safety rules and regulations.

4.1 Gas connection

WARNING!

Medically pure CO2

Make sure to use only medically pure CO2. Other gases (i.e., helium, N2O, argon),

mixtures of gases, high pressure compressed gases, gases with entrapped liq-

uids, or polluted gases must not be used with this device.

14

Use a high-pressure tube to connect a CO2 gas cylinder to the rear gas inlet connection or connect to centralized CO2 gas supply.

Page 21

CO

2

4.1.1 Connecting a Gas Bottle

CAUTION!

Always use a high-pressure tube to connect gas bottle and device.

The gas bottle must be in a vertical position. The gas bottle pressure may not exceed 80 bar or be less than 15 bar.

CAUTION!

Gas bottles with riser pipe can release dirt and oily fluids into the device. Do not

use a gas bottles with riser pipe.

Initial Device Startup

EN

4.1.2 Connecting to Central Gas Supply

Use the following device connectors available as additional equipment to connect to a central gas supply (house supply):

• 0620-040-003 for NIST house gas supply or

• 0620-040-002 for DISS house gas supply.

1. Attach the high-pressure tube to the gas connection.

2. Fix the high-pressure tube with the nut.

3. Tighten the nut.

The type of corresponding gas supply must be set in the configuration menu (see

chapter 10.1.3 Setting the Gas Supply Type, page 62).

15

Page 22

EN

Operating the Device - General

5 Operating the Device - General

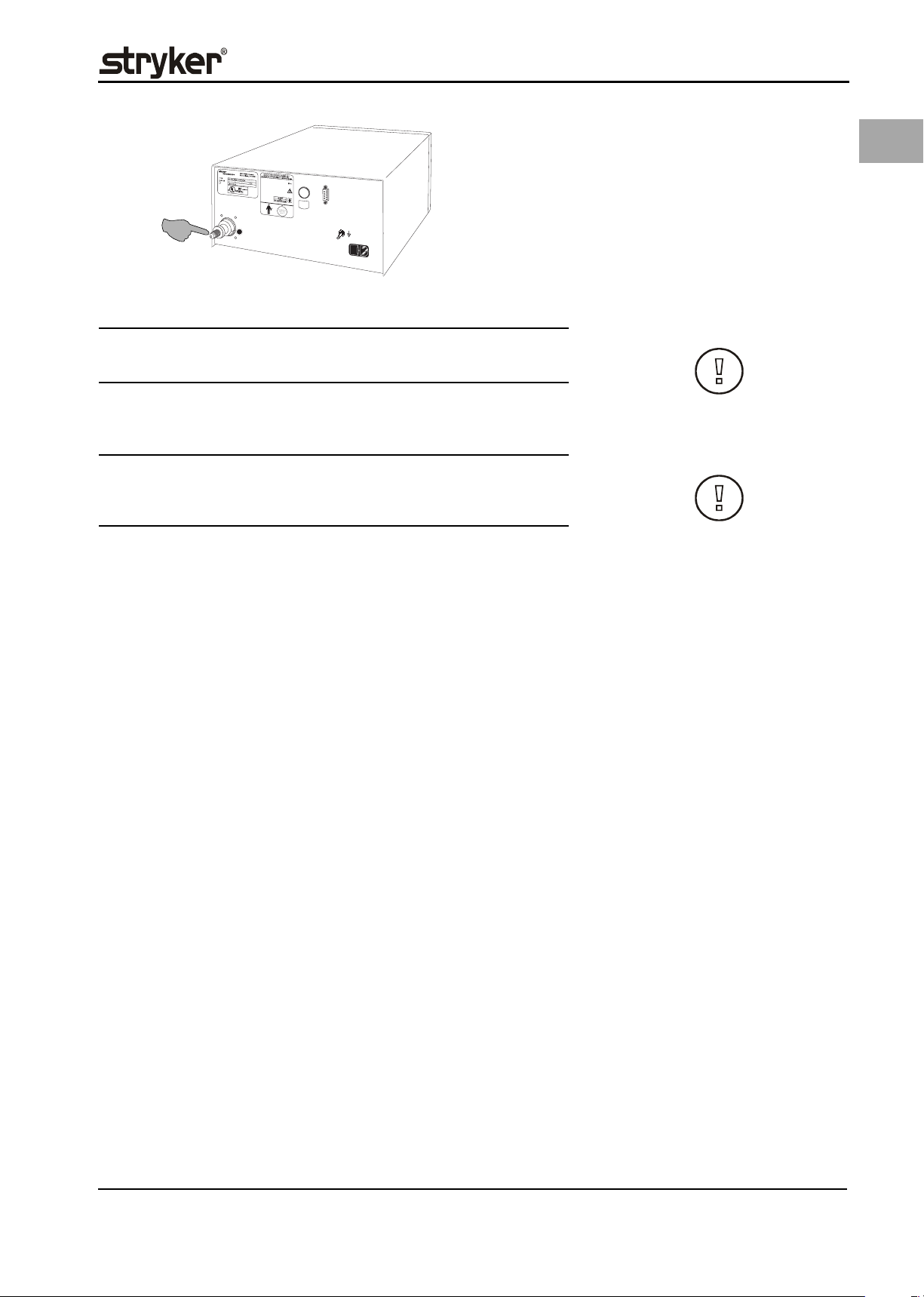

5.1 Front of the Device

Fig. 5-1 Device Front

(1) ON/OFF switch

(2) Touch screen display

(3) Insufflation tube connection

(1) (2) (3)

Fig. 5-2 Device Rear

(4) Type plate

(5) Device data plate

(6) SIDNE interface (optional)

(7) Data input/output

(8) Connection for potential equaliza-

tion

(9) Device plug

(10) Fuse holder

(11) Gas supply connection

Familiarize yourself with the control and function elements at the front of the device.

5.2 Rear of the Device

(4) (5) (6)

CO

2

(11) (9)(10)

(7) (8)

16

Familiarize yourself with the connection elements at the rear of the device.

Page 23

Operating the Device - General

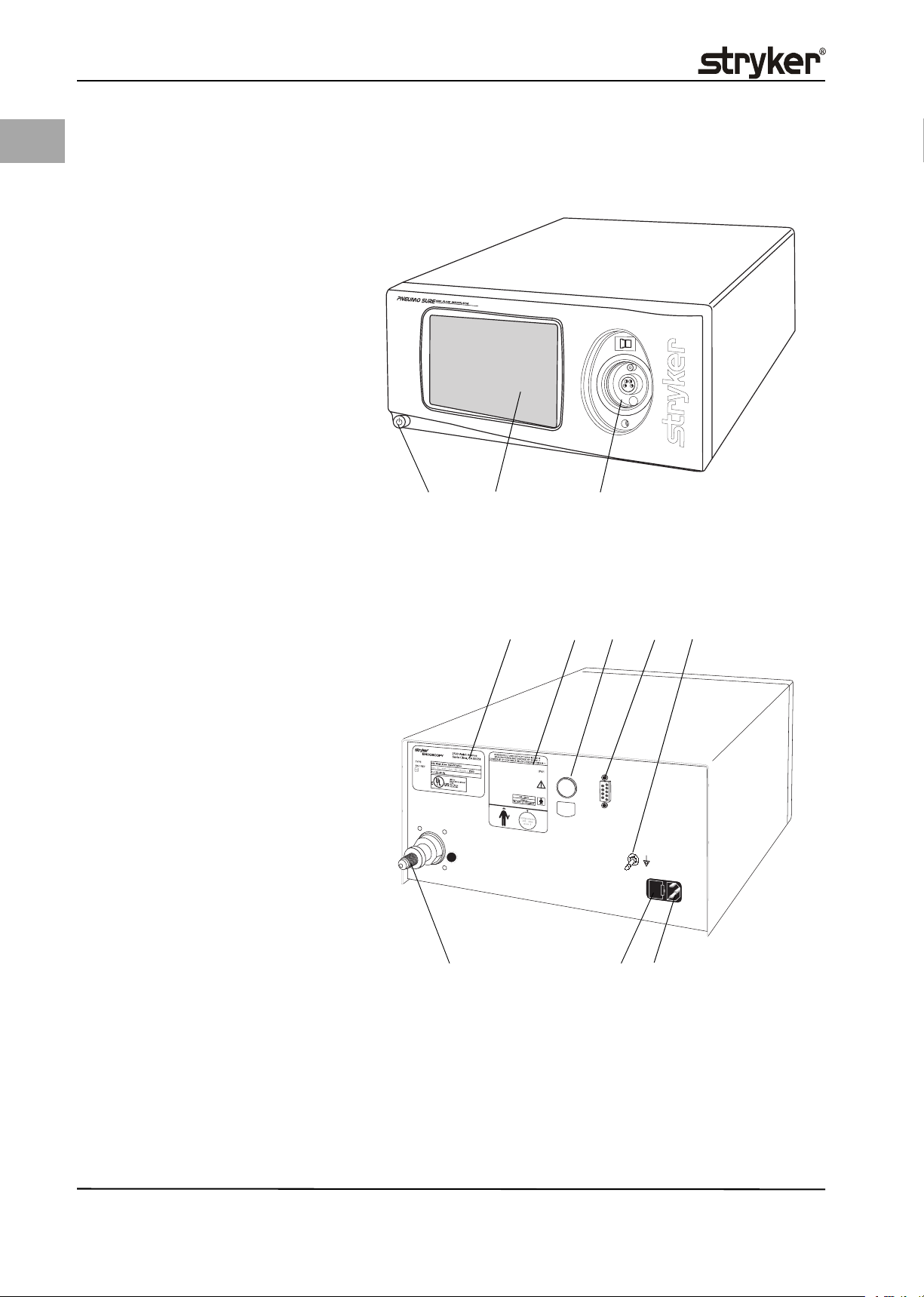

5.3 Touch screen display

(1)

(15)

(14)

(13)

Set Pressure

mm Hg

15

Actual Pressure

mm Hg

0

GAS

Mode: High Flow

Change

Mode

The above depiction of the touch screen also shows all display and function

fields. Field (9) serves as actual flow display (depicted without frame while insufflating) and also as menu function field (depicted with frame).

Field (12) serves as insufflation operating mode display (depicted without frame

while insufflating) and also as control field for selecting the insufflation operating mode (depicted with frame).

START

0.0

Liter

(4)(2) (3) (5)

Set Flow

l/min

3

HEATING

Actual

0

(6)

(7)

(8)

l/min

(9)(10)(11)(12)

EN

Fig. 5-3 Screen displays

(1) Continuous pressure reading dis-

play

(2) Gas supply display

(3) Actual pressure display

(4) Gas consumption display/func-

tion field for reset

(5) Gas heating connected/ready

(6) Increasing nominal gas flow

(7) Nominal gas flow display

(8) Decreasing nominal gas flow

(9) Actual gas flow display/ menu

function field

(10) START/STOP function field

(11) Status display/error and warning

messages

(12) Insufflation operating mode dis-

play/selecting insufflation operating mode

(13) Decreasing nominal pressure

(14) Nominal pressure display

(15) Increasing nominal pressure

Press the function field (9) or (12) depicted with frame and hold for 2 seconds to

trigger functions or set values. Additional explanations for individual elements

are presented in the subsequent respective control element descriptions.

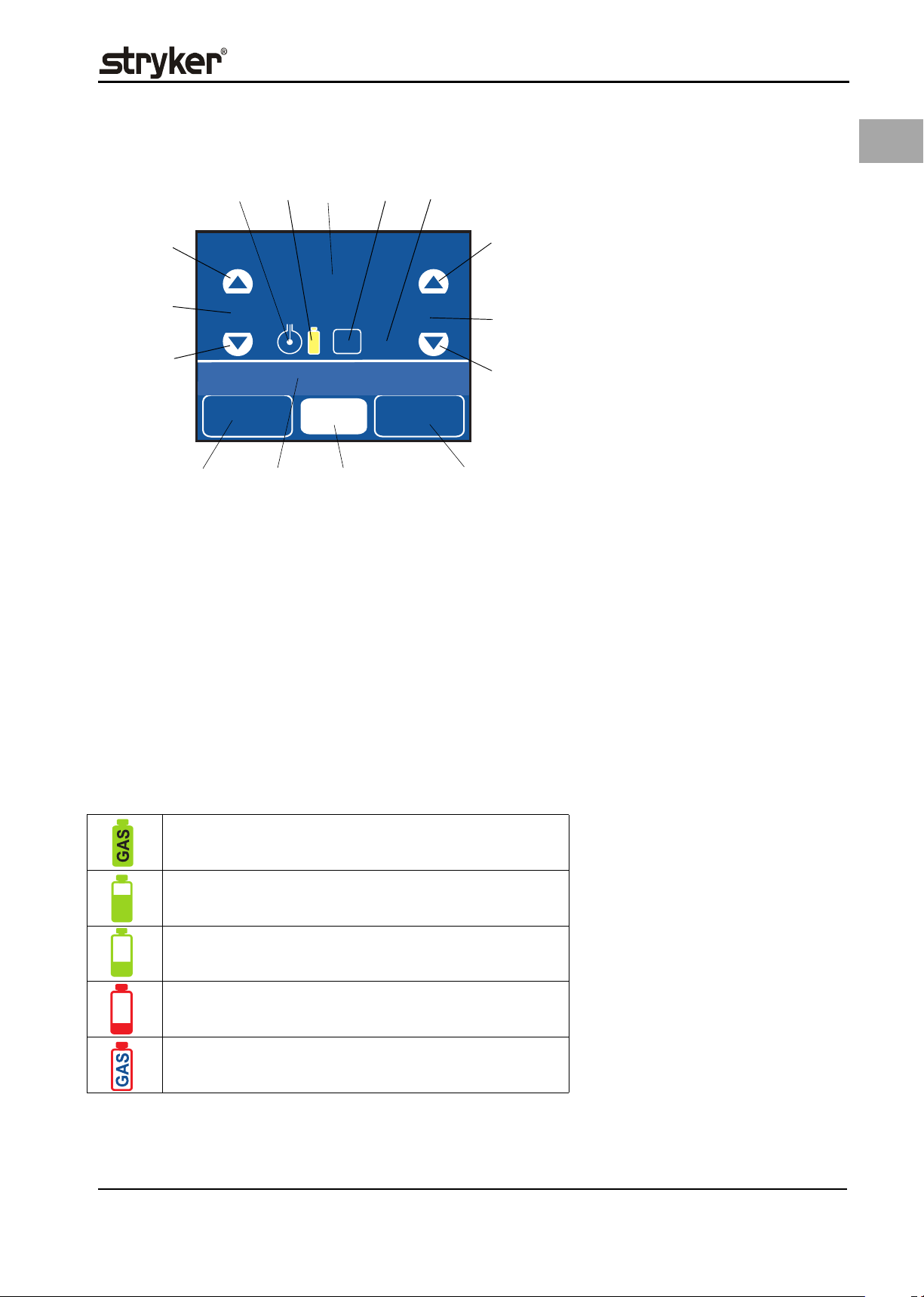

bols and acoustic signals (see chapter 11 Safety functions for gas pressure display

information).

> 50 bar

40 - 50 bar

30 - 40 bar

15 - 30 bar; Three warning signals can be heard and the message

"Change gas tank" is displayed. User is advised to obtain a replacement tank.

< 15 bar; Three warning signals can be heard and the message

"Check gas supply" is displayed. Replace gas tank immediately.

Gas supply displaysThe status of the gas supply is monitored by the device and indicated with sym-

Gas supply with gas bottleThe following gas bottle pressures are displayed:

If gas supply pressure declines further, there are warnings to remind the user to

replace the gas tank immediately. Five warning signals can be heard and the

message "Check gas supply" is displayed at < 5 bar and again at 0 bar. Insufflation

stops at 0 bar.

17

Page 24

EN

Operating the Device - General

House gas supply The following house gas supply pressures are displayed:

House gas supply pressure OK

(green)

House gas supply pressure too low

(red)

5.4 Switch on Device

1. Connect with mains power supply.

2. Connect the gas supply to the gas connection port and open the gas supply.

(2)

(3)

CO

2

(1)

3. Press the ON/OFF switch. The device switches on.

4. After being switched on, the device performs a device check. The touch screen

depicts the company logo as well as the lines PNEUMO SURE respectively

PNEUMO SURE XL ->Device check ->Device OK is visible for 3 seconds after

the successful completion of the device check. In case the device check failed

and error message is displayed please see chapter 15 Error and Warning Messages for advises.

5. The display depicts an insufflation operating modes overview. Unavailable

operating modes are depicted in gray and cannot be selected. Press the respective function field to select the corresponding desired operating mode

(e.g. High Flow).

18

Page 25

Operating the Device - General

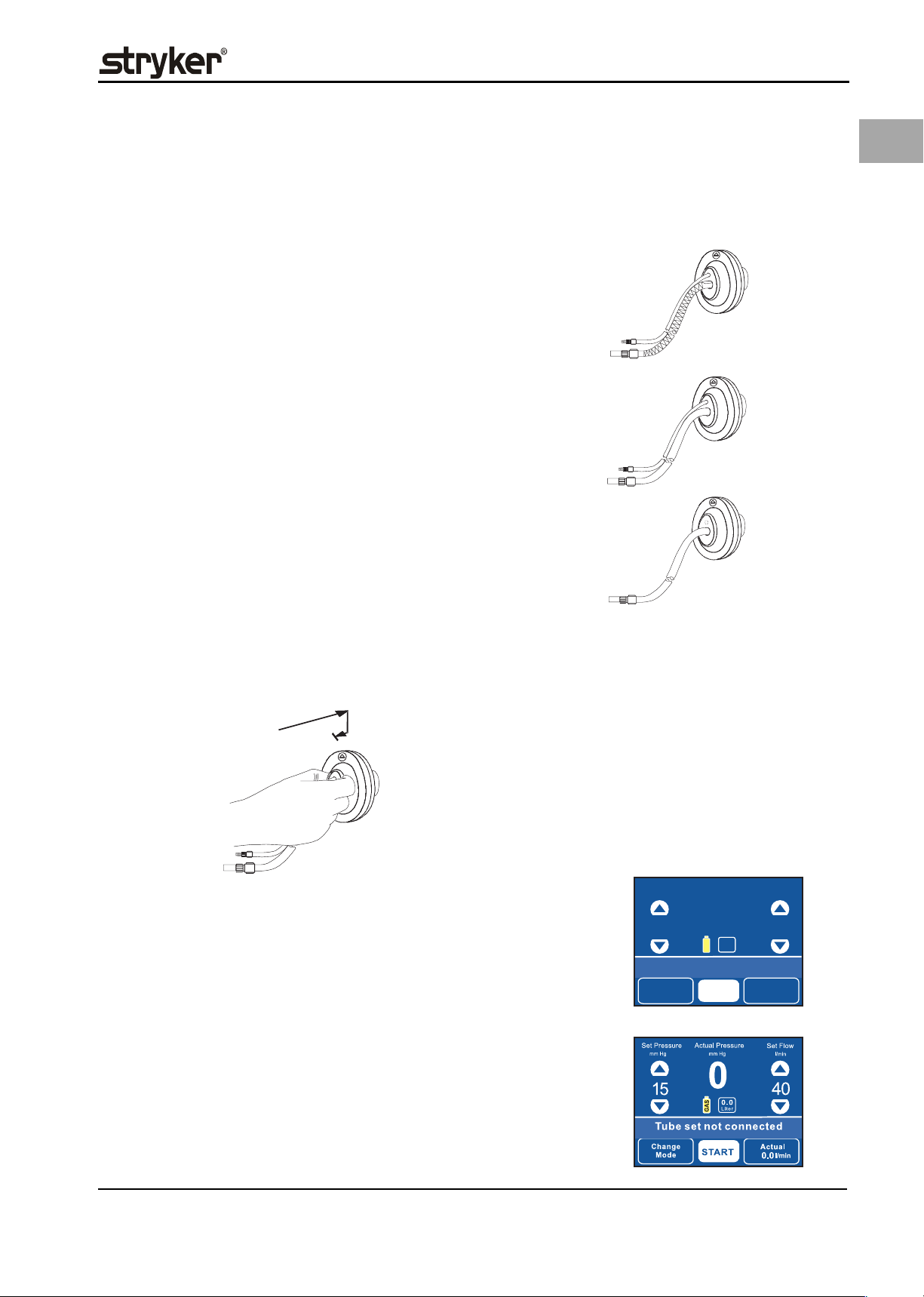

5.5 Connecting Insufflation Tube Set

Three different insufflation tube set types can be connected to the insufflation

tube connection at the front of the device (see Fig. 5-1 Device Front, page 16,

(3)).

Heated tube set with

Real-Time Pressure

Sensing (RTP)

High Flow tube set

with Real-Time Pressure Sensing (RTP)

High Flow II tube set Disposable (single use) insufflation tube set with:

Disposable (single use) insufflation tube set with:

• Filter

• Gas heating

• Measuring tube for direct pressure measurement

(RTP)

Disposable (single use) insufflation tube set with:

• Filter

• Measuring tube for direct pressure measurement

(RTP)

• Filter

EN

connection at the front of the device until it snaps firmly into place.

• A short acoustic warning signal is emitted,

• the message Tube set connected is displayed,

• a check mark is displayed.

If the tube is accidentally unlatched by pressing twice or if the tube is removed

during insufflation:

• 2 long acoustic warning signal are emitted,

• the message Tube set not connected is displayed,

Connecting the tube setInsert the plug of the insufflation tube set correctly into the insufflation tube set

Set Pressure

mm Hg

Actual Pressure

mm Hg

15

Change

Mode

ü

0.0

GAS

Liter

Tube set connected

START

START

Set Flow

Actual

0

l/min

3

l/min

19

Page 26

EN

Operating the Device - General

Removing the tube set Press the plug of the insufflation tube in the direction of the device. This releases

the snap-in latch and you are now able to remove the insufflation tube set.

• 2 long acoustic warning signal are emitted,

• the message Tube set not connected is displayed,

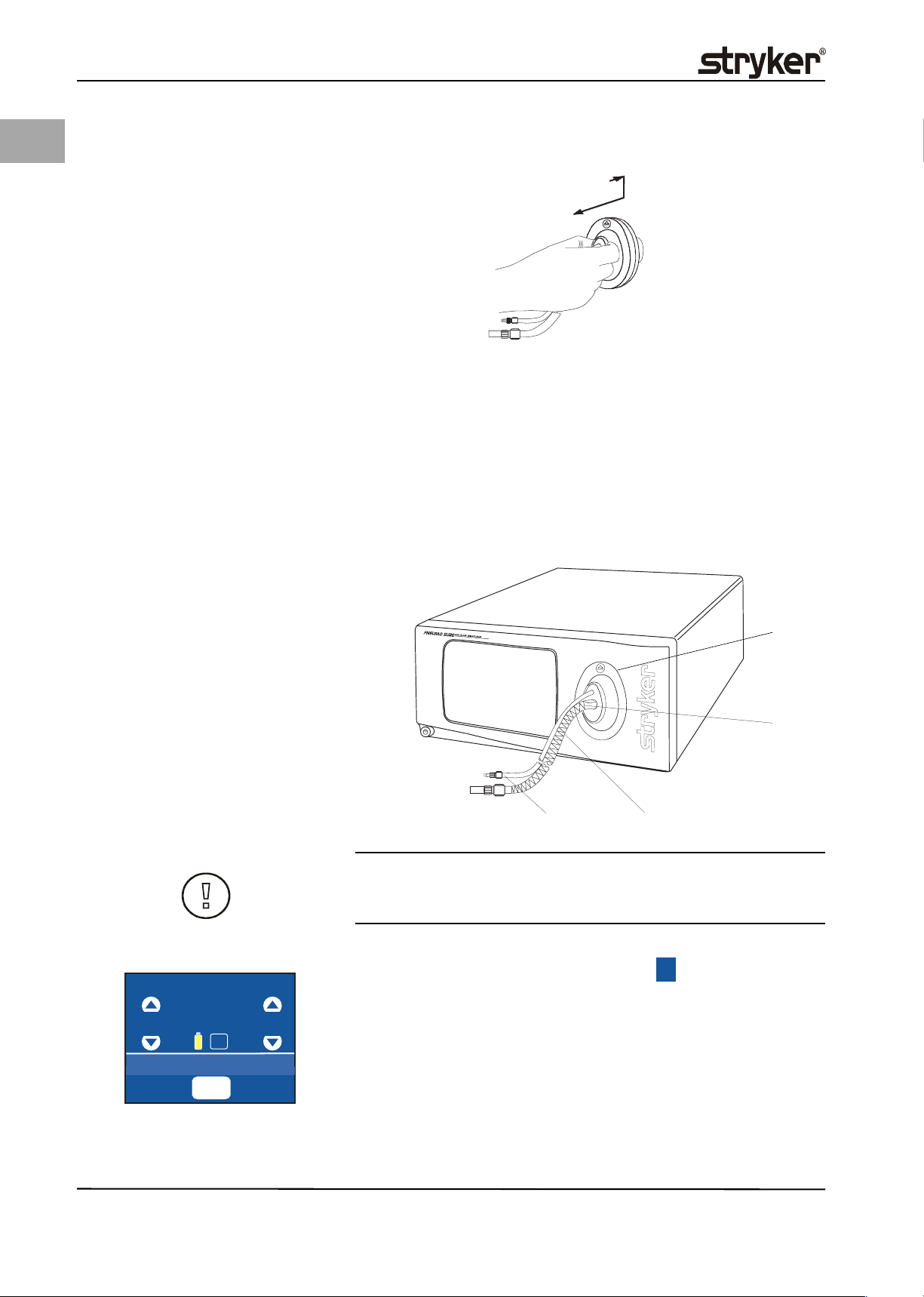

5.6 Using the Gas Heating

Connecting the gas heating Use the heating tube to insufflate lukewarm gas (37° C).

1. Switch device on.

2. Connect an insufflation tube with gas heating (Heated tube set with RealTime Pressure Sensing (RTP).

The heating module is located directly in the insufflation tube.

Fig. 5-4 Connecting the gas heating

(1) Plug for insufflation tube with gas

heating

(2) Internal heating

(1)

(3) Insufflation tube

(4) Measuring tube

(2)

(4)

(3)

CAUTION!

Do not subject the heater tube to direct heat (e.g., operating room lamp, en-

doscop with light source) or high room temperatures.

Gas heating display The device automatically determines whether a tube set with or without gas

Set Pressure

mm Hg

Actual Pressure

mm Hg

Set Flow

l/min

heating is connected. The display depicts a symbol and the status line reads

Gas heater OK after the successful detection of the corresponding tube set.

HEATING

20

15

Mode

High Flow

0

0.0

Liter

GAS

Gas heater OK

STOP

HEATING

Actual

3

3

l/min

Page 27

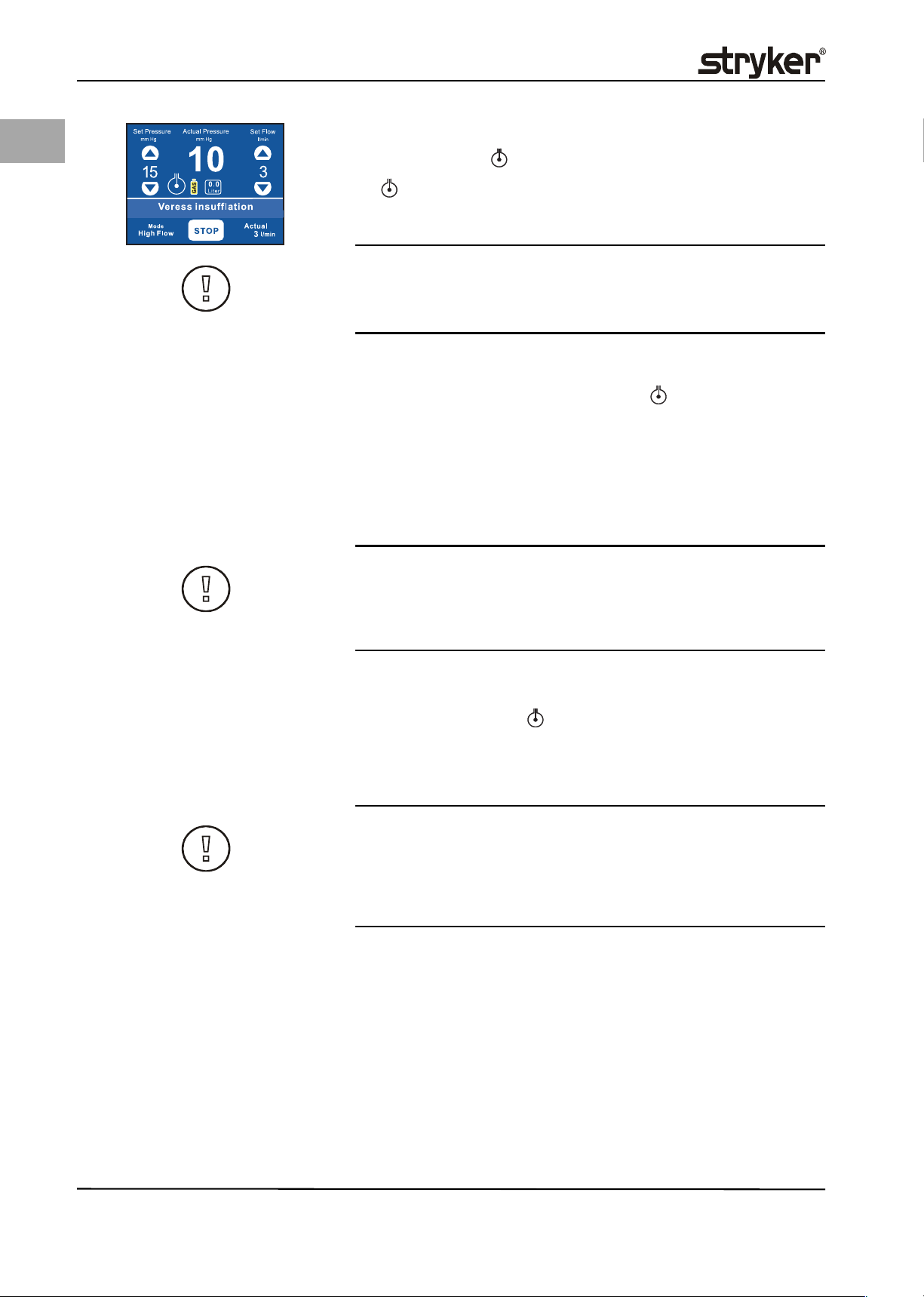

Press the START function field. The gas is automatically heated to 37 °C.

2. Stopping gas heating:

Press the STOP function field. Gas heating is switched off.

3. Pull the tube set plug from the device connection.

Operating the Device - General

Gas heating ON/OFF1. The gas heating is automatically started at the START of the insufflation:

EN

Incorrect/defective heating tubeWhen a defective heating tube set is used,

• the display depicts a crossed out symbol

HEATING

•the text line reads Gas heater defective <-> Call service,

• and an acoustic signal is emitted (3 short beeps).

Insufflation can be continued in this case, but the heating function is not available.

caused for exemple by external heat sources. If the temperature sensor measures a temperature >42°C, the status field of the display depicts Gas tempera-

ture >42 °C; 3 accoustic signals are emitted in addition, the HEATING symbol is

crossed out . Insufflation and the heating function are halted. After 3 seconds,

the display depicts Disconnect luer lock alternating with Cool down tube until

HEATING

the insufflation is manually restarted.

WARNING!

Unplug the cable of the heating tube from the device if the temperature sensor

measures a gas temperature exceeding >42 °C. Hot gas in the abdomen can lead

to serious injuries.

1. Disconnect the insufflation tube from the trocar or Veress needle.

2. Press the START function field. The device insufflates without heating the

gas.

3. Let hot gas escape until the tube is only warm to the touch and then reconnect the device again.

4. Continue surgery without gas heating.

Set Pressure

Actual Pressure

mm Hg

15

Gas heater defective

Change

Mode

mm Hg

0

0.0

Liter

GAS

START

HEATING

Set Flow

3

Actual

0

l/min

l/min

Gas temperature exceeds 42 °CThe device is equipped with a temperature sensor to protect against overheating,

Set Pressure

mm Hg

15

Actual Pressure

Cool down tube

Change

Mode

mm Hg

0

0.0

Liter

GAS

START

HEATING

Set Flow

Actual

0

l/min

3

l/min

and back on after approx. 10 seconds have expired. Gas heating is reactivated.

2. Should the error message be displayed again, you can continue using the device without gas heating by observing the risks for hypothermia.

3. Call an authorized service technician to check/fix the gas heating.

5.6.1 Using the direct pressure measurement function (Real-Time

Pressure Sensing RTP)

The insufflation tube sets "Heated tube set with Real-Time Pressure Sensing

(RTP)" and "High Flow tube set with Real-Time Pressure Sensing (RTP)" are

equipped with a sensor line which enables continuous measuring of the abdominal pressure. The insufflation line must be connected to one trocar and the measuring line (sensor line) to a second trocar. This set-up enables the PNEUMO SURE

XL High Flow Insufflator to directly measure the actual abdominal pressure while

in High Flow-, Pediatric- and Bariatric operating mode. The "Real-Time Pressure

Sensing" is deactivated during the Vessel Harvest operating mode. The use of an

insufflation tube without a second measurement/sensor line only allows the intermittent measuring of the pressure.

Insufflation is initially always started intermittently. Availability of the "Real-

Check gas heating after surgery1. Check gas heating after surgery using a different tube. Turn the device off

Pull apart at seam as

much as needed

at second trocar

at insufflation trocar

21

Page 28

EN

Operating the Device - General

Time Pressure Sensing" functionality is checked automatically. If this is the case,

the device switches to a continuous mode. This is indicated by the corresponding

symbol on the display:

The symbol is removed if continuous pressure measurement is currently not

possible or if insufflation is stopped.

CAUTION!

A closed, obstructed or disconnected pressure sensing line will disable the real-

time pressure sensing function. In this case the device will operate in the conventional intermittent insufflation mode.

Error detection and monitoring of the "RealTime Pressure Sensing (RTP)" function

The continuous pressure measurement function is verified during the initial device self check. Should a defect within the measuring system be detected, three

acoustic warning signals are emitted. The symbol is crossed out and the status line reads as follows: RTP defective / Call Service.

A detected defect within continuous pressure measurement does not generally

hinder use of the device, however without the RTP function. Disconnect the measuring channel and perform the surgery in the intermittent insufflation mode.

The acoustic warning on the defective RTP will be emitted with every activation/

deactivation of the insufflation as long as the pressure measurement function

remains defective.

CAUTION!

Do not attach a trocar to the pressure measurement / sensor line if the message

"RTP defective / Call Service" is displayed. Perform surgery only in the conven-

tional intermittent insufflation mode without using the real-time pressure sensing function.

In case of a closed sensor line or with pressure on the sensor or the insufflation

line during the initial device self check the real-time pressure sensing function

will not be activated and the will be crossed out. Three acoustic warning signals are emitted, the status line readsas follows: RTP deactivated. The device can

be operated in the conventional intermittent insufflation mode. In order to activate the RTP function the sensor line must be cleared, possible pressure released

and the device rebooted by turning it off and back on.

Leakage detection with function "RealTime Pressure Sensing (RTP)"

22

CAUTION!

When working with a tube set permitting the use of the RTP function, please

make sure that both lines are open upon activation of the device and there is

pressure neither on the sensor line nor on the insufflation line. Otherwise the

real-time pressure sensing function (RTP) will not be recognized and activated

during the initial device self check.

In case of an occlusion or a leakage in the sensor line during insufflation the device will automatically switch from the RTP operating mode into the conventional intermittent insufflation mode.

If the system detects a leak at the RTP connection regardless of the insufflation

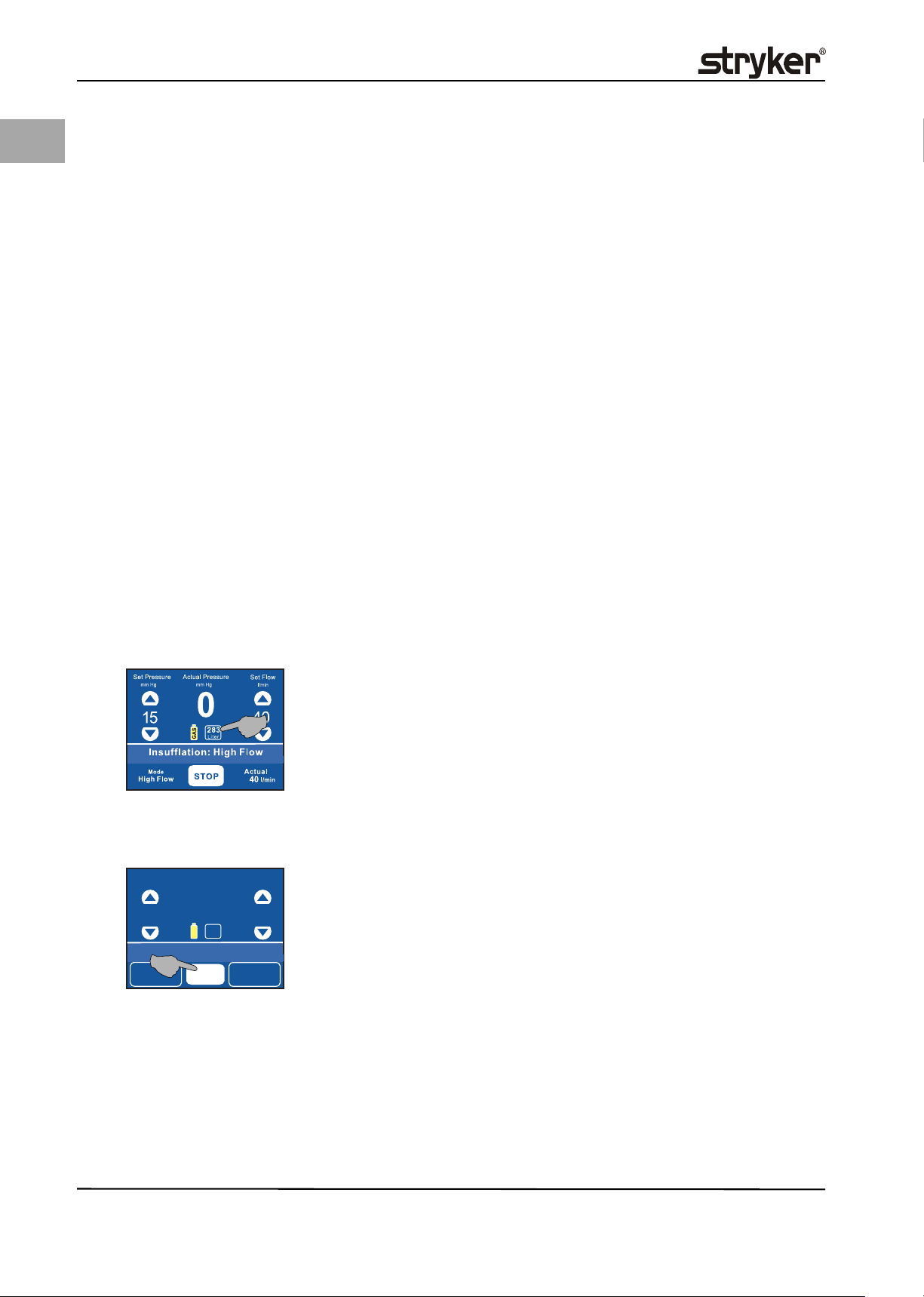

mode: