Stoelting U218 Service Manual

Model U218

SERVICE MANUAL

Manual No. 513637 Rev.1 Nov., 2008

This manual provides basic information about the machine. Instructions and suggestions are

given covering its operation and care.

The illustrations and specifications are not binding in detail. We reserve the right to make

changes to the machine without notice, and without incurring any obligation to modify or pro-

vide new parts for machines built prior to date of change.

DO NOT ATTEMPT to operate the machine until instructions and safety precautions in this

manual are read completely and are thoroughly understood. If problems develop or questions

arise in connection with installation, operation, or servicing of the machine, contact the com-

pany at the following location:

STOELTING, LLC Ph: 800-558-5807

502 Hwy. 67

Kiel, WI 53042 Fax: 920-894-7029

Service Manual

For U218

Stoelting Floor Model Gravity Machine

Frozen Beverage

Safety Alert Symbol:

This symbol Indicates danger, warning or caution.

Attention is required in order to avoid serious per-

sonal injury . The message that follows the symbol

contains important information about safety .

Signal Word:

Signal words are distinctive words used throughout

this manual that alert the reader to the existence and

relative degree of a hazard.

CAUTION

The signal word “CAUTION” indicates a potentially

hazardous situation, which, if not avoided, may result

in minor or moderate injury and equipment/property

damage.

A Few Words About Safety

Safety Information

Read and understand the entire manual before

operating or maintaining Stoelting equipment.

This Owner's Manual provides the operator with

information for the safe operation and maintenance of

Stoelting equipment. As with any machine, there are

hazards associated with their operation. For this

reason safety is emphasized throughout the manual.

To highlight specific safety information, the following

safety definitions are provided to assist the reader.

The purpose of safety symbols is to attract your

attention to possible dangers. The safety symbols,

and their explanations, deserve your careful attention

and understanding. The safety warnings do not by

themselves eliminate any danger. The instructions or

warnings they give are not substitutes for proper

accident prevention measures.

If you need to replace a part, use genuine S toelting

parts with the correct part number or an equivalent

part. We strongly recommend that you do not use

replacement parts of inferior quality .

WARNING

The signal word “WARNING” indicates a potentially

hazardous situation, which, if not avoided, may result

in death or serious injury and equipment/property

damage.

CAUTION

The signal word “CAUTION” not preceded by the

safety alert symbol indicates a potentially hazardous

situation, which, if not avoided, may result in equip-

ment/property damage.

NOTICE

The signal word “NOTICE” indicates information or

procedures that relate directly or indirectly to the

safety or personnel or equipment/property .

Section Description Page

1 Description and Specifications

1.1 Description.................................................................................................1

1.2 Specifications............................................................................................. 1

1.3 Modes of Normal Operation.......................................................................2

1.4 Operation During an Error Mode................................................................3

2 Installation Instructions

2.1 Safety Precautions.....................................................................................5

2.2 Shipment and Transit.................................................................................5

2.3 Machine Installation ...................................................................................5

3 Initial Set-Up and Operation

3.1 Operator”s Safety Precautions...................................................................7

3.2 Operating Controls and Indicators .............................................................7

3.3 Sanitizing ...................................................................................................8

3.4 Freeze Down and Operation ......................................................................9

3.5 Removing Mix From Machine ....................................................................9

3.6 Cleaning the Machine ................................................................................9

3.7 Disassembly of Machine Parts...................................................................10

3.8 Cleaning the Machine Parts.......................................................................11

3.9 Sanitize Machine and Machine Parts .........................................................11

3.10 Assembly of Machine.................................................................................12

3.11 Routine Cleaning .......................................................................................12

4 Maintenance and Adjustments

4.1 Machine Adjustment ..................................................................................13

4.2 Product Consistency Adjustment ...............................................................13

4.3 Continuous Drive Mode .............................................................................13

4.4 Drive Belt Tension Adjustment...................................................................13

4.5 Preventative Maintenance..........................................................................13

4.6 Extended Storage ......................................................................................14

TABLE OF

CONTENTS

Section Description Page

5 Refrigeration System

5.1 Refrigeration System .................................................................................15

5.2 Refrigerant Recovery and Evacuation........................................................15

5.3 Refrigerant Charging..................................................................................16

5.4 Compressor...............................................................................................16

5.5 Condenser .................................................................................................17

5.6 Valves........................................................................................................18

A. Thermostatic Expansion Valve (TXV)..................................................................18

B. High Pressure Cutout .......................................................................................... 19

C. Evaporator Pressure Regulator (EPR)................................................................19

D. Water Vavle (Water-Cooled Models Only)..........................................................20

5.7 Capillary Tube............................................................................................21

5.8 Filter Drier..................................................................................................21

6 Electrical and Mechanical Control Systems

6.1 Control Board.............................................................................................23

6.2 Contactor ...................................................................................................23

6.3 Drive Motor ................................................................................................24

6.4 Capacitors .................................................................................................25

6.5 Gearbox.....................................................................................................25

6.6 Condenser Fan Motor (Air-Cooled Models Onlys) .....................................26

6.7 Switches ....................................................................................................26

A. Spigot Switch.......................................................................................................26

B. Torque Switch......................................................................................................26

7 Troubleshooting

7.1 Light Indicators ..........................................................................................27

7.2 Troubleshooting .........................................................................................27

8 Replacement Parts

8.1 Decals & Lubrication ..................................................................................29

8.2 Accessories, Panels & Screws ..................................................................29

8.3 Auger Shaft & Faceplate Parts...................................................................30

8.4 Hopper Parts..............................................................................................32

8.5 Machine Front & Spigot Switch Assembly..................................................33

8.6 Left Side (Air-Cooled Shown).....................................................................34

8.7 Right Side (Water-Cooled Shown) .............................................................35

8.8 Machine Back (Water-Cooled Shown).......................................................36

8.9 Refrigeration & Wiring Diagram .................................................................37

8.10 Autofill Options...........................................................................................39

1

SECTION 1

DESCRIPTION AND SPECIFICATIONS

1.1 DESCRIPTION

The Stoelting U218 machine is available as gravity fed or

with an optional autofill kit. It is equipped with fully auto-

matic controls to provide a uniform product. The U218

machine will operate with almost any type of frozen bever-

age mix. This manual is designed to help qualified service

personnel and operators with the installation, operation

and maintenance of the Stoelting U218 machine.

1.2 SPECIFICATIONS

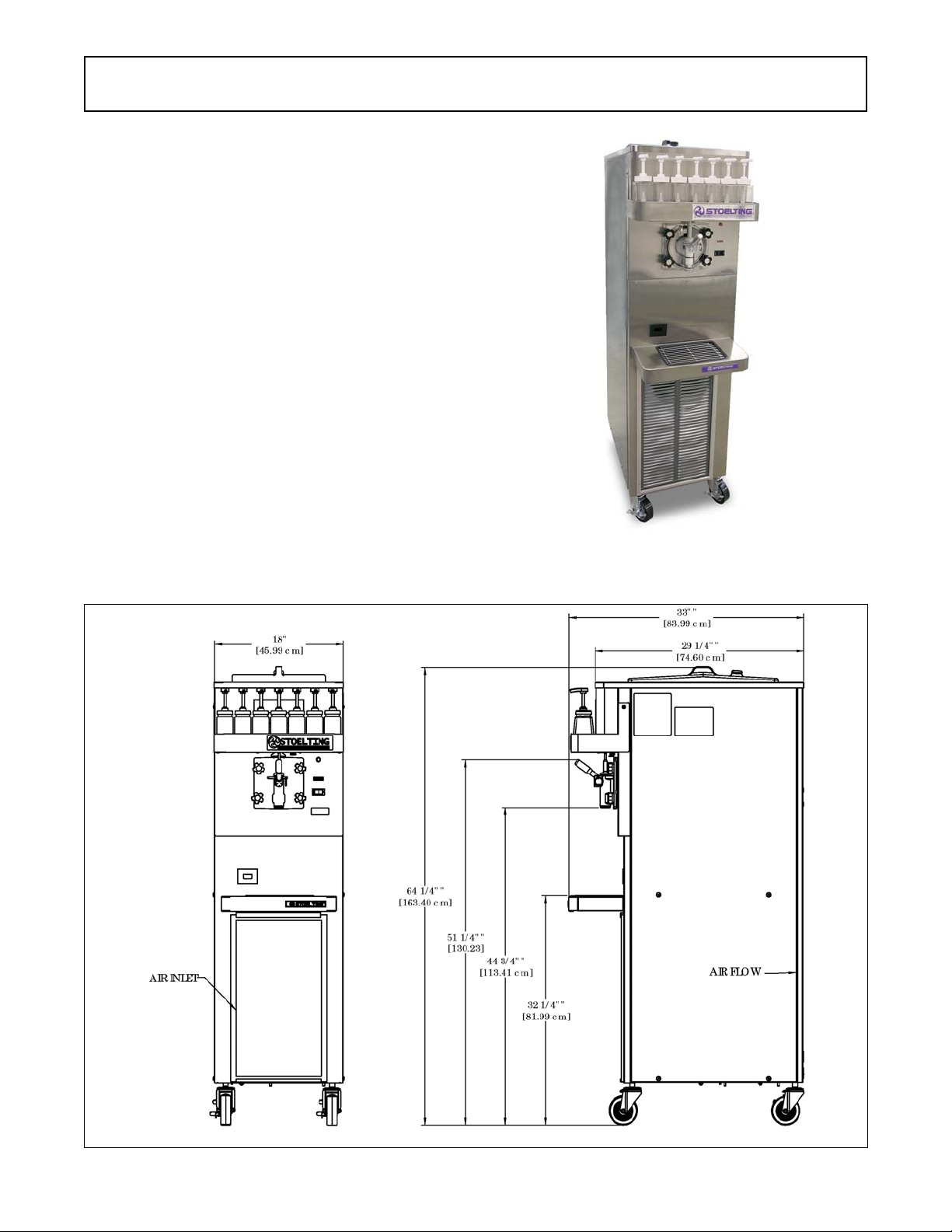

Figure 1-1 Model U218

Figure 1-2 Model U218 Dimensions

2

1.2 SPECIFICATIONS - CONTINUED

Dimensio ns

width

height

depth

Weight

Elect r i c al

running amps

con nection t ype

Compressor

Driv e M ot or

Ai r Flow

Plumbi ng Fit tings

Hopper Volum e

Freezing Cylinder

Volum e

wit h c ra te

25'' (63,5 cm)

66'' (167,6 cm )

51'' (129,5 cm )

410 lbs (18 5,9 kg)315 lbs (142,8 kg)

1 Phase, 208-2 40 VAC, 60Hz

approximatel y 12A

NEM A6- 20P power cord provided

Model U 218

33'' (83,8 cm )

64-1/2'' (163,8 cm)

18-1/4'' (46,4 cm)

Machine

2 gall on ( 8 qu ar t) , 7, 57 l iters

11,000 Btu/ h r

1/2 h p

Wat er coo led un its r equ ire 3/ 8" N .P. T . w at er and drain f ittin gs.

7 gallon (26,50 liters)

Air cooled u nits require 3" (7,6 cm ) air space a t fr on t an d ba ck.

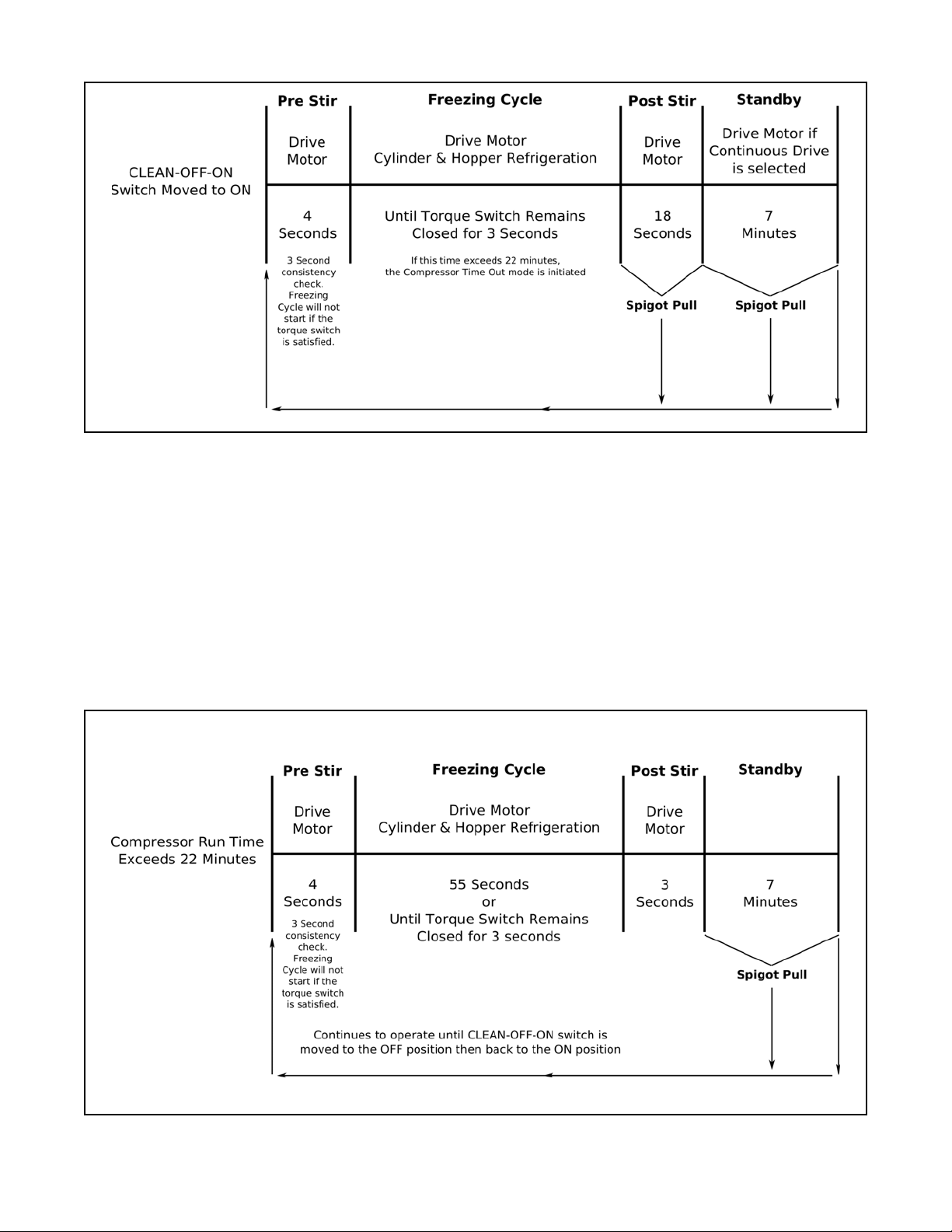

1.3 MODES OF NORMAL OPERATION

Following is an explanation of the normal operation modes

on the U218 (Refer to Figure 1-3).

NOTE

The following modes of operation are for the latest

versions of the control boards (521696.2 and

521696.1 Rev72). The older version of the control

has the following differences:

• There is no slush mode with continuous drive.

• There is no consistency check during the pre stir

in slush mode and the pre stir is 3 seconds.

• The control runs strictly on timers during an error

mode, and the cycle time during a drive motor error

is 7 minutes off/55 seconds on.

NOTE

Slush mode has two options: normal and continu-

ous drive. The normal mode saves energy. Con-

tinuous drive is used in rare situations where very

thin slush is required. With the continuous drive op-

tion selected, the drive motor will run at all times,

including standby. To change the control between

the two options, refer to section 4.3.

A. PRE STIR

When the CLEAN-OFF-ON is moved into the ON position

or when the spigot is opened, the drive motor will start a 4-

second pre stir. During the pre stir, a consistency check

will determine if the freezing cycle will begin.

B. FREEZING CYCLE

After the pre stir, a freezing cycle begins. The freezing

cycle continues until the torque rod closes the torque

switch and keeps the switch closed for 3 seconds. If

product consistency is not met within 22 minutes, the

machine will operate in the compressor time out mode

(See Section 1.4).

NOTE

If the spigot is pulled during a freezing cycle, the

22-minute timer will restart.

C. POST STIR

After the freezing cycle ends, the drive motor will continue

to run for an 18 second post stir. The post stir ensures the

product does not freeze to the cylinder. If the spigot is

opened during the post stir, the machine will check consis-

tency. If the product is at consistency, the machine will

move into standby. If the product is not at consistency, the

machine will start a freezing cycle.

D. STANDBY

After the post stir, the machine will be in standby. It will

remain in standby for 7 minutes or until the spigot is

opened.

E. DEFROST MODE

If the spigot is not opened for 3 hours, defrost mode will

begin. The auger will run for 90 seconds every 7 minutes

and the diagnostic light will remain lit. The compressor

does not operate during defrost mode. After 5.5 hours or

if the spigot is opened, normal operation mode will begin.

3

F. CLEAN MODE

When the CLEAN-OFF-ON switch is in the CLEAN posi-

tion, the drive motor starts and will run for 20 minutes. After

the 20 minutes expire, the drive motor will stop and the

diagnostic light will flash three times every 4 seconds. It will

continue to flash until the CLEAN-OFF-ON switch is

moved out of the CLEAN position.

1.4 OPERATION DURING AN ERROR MODE

A. COMPRESSOR TIME OUT MODE

If the freezing cycle exceeds 22 minutes, the machine will

operate on timers. The diagnostic light will flash once

every 4 seconds (Refer to Figure 1-4).

Figure 1-3 Modes of Normal Operation

Figure 1-4 Compressor Time Out Mode

4

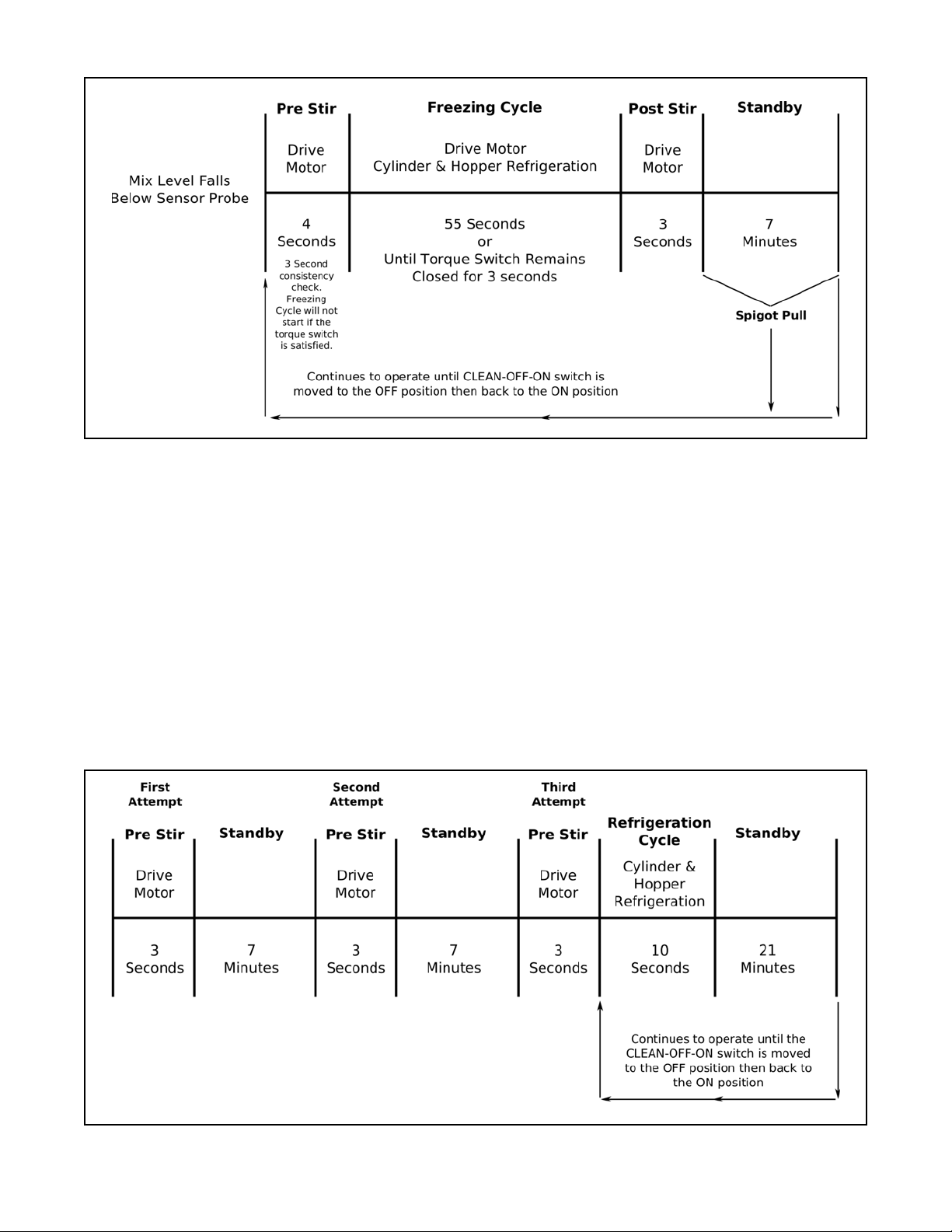

B. LOW MIX MODE

If the mix level falls below the long sensor probe in the

hopper, the machine will operate on timers. The ADD MIX

light will flash. The machine will continue to operate on

timers until the mix level in the hopper is above the sensor

probe (Refer to Figure 1-5).

NOTE

The hopper has two probes. The longer probe moni-

tors mix level in the hopper. The shorter probe shuts

off the optional autofill system if installed.

C. DRIVE MOTOR ERROR MODE

If the control does not sense current from the drive motor

during a pre stir, the machine will go into standby mode for

7 minutes. After standby, the control will repeat the pre stir

and attempt to sense drive motor current. After the third

pre stir without sensing drive motor current, the machine

will operate on timers and the diagnostic light will flash

twice every four seconds (Refer to Figure 1-6). The

attempts to sense the drive motor current can be substi-

tuted by pulling the spigot.

Figure 1-6 Drive Motor Error Mode

Figure 1-5 Low Mix Mode

5

SECTION 2

INSTALLATION INSTRUCTIONS

2.1 SAFETY PRECAUTIONS

Do not attempt to operate the machine until the safety

precautions and operating instructions in this manual are

read completely and are thoroughly understood.

Take notice of all warning labels on the machine. The

labels have been put there to help maintain a safe working

environment. The labels have been designed to withstand

washing and cleaning. All labels must remain legible for

the life of the machine. Labels should be checked periodi-

cally to be sure they can be recognized as warning labels.

If danger, warning or caution labels are needed, indicate

the part number, type of label, location of label, and

quantity required along with your address and mail to:

STOELTING, LLC

A TTENTION: Customer Service

502 Hwy . 67

Kiel, Wisconsin 53042

2.2 SHIPMENT AND TRANSIT

The machine has been assembled, operated and in-

spected at the factory. Upon arrival at the final destination,

the entire machine must be checked for any damage

which may have occurred during transit.

With the method of packaging used, the machine should

arrive in excellent condition. THE CARRIER IS RESPON-

SIBLE FOR ALL DAMAGE IN TRANSIT, WHETHER

VISIBLE OR CONCEALED. Do not pay the freight bill until

the machine has been checked for damage. Have the

carrier note any visible damage on the freight bill. If

concealed damage and/or shortage is found later, advise

the carrier within 10 days and request inspection. The

customer must place claim for damages and/or shortages

in shipment with the carrier. Stoelting, LLC cannot make

any claims against the carrier.

2.3 MACHINE INSTALLATION

Installation of the machine involves moving the machine

close to its permanent location, removing all crating,

setting in place, assembling parts, and cleaning.

A. Uncrate the machine.

B. Accurate leveling is necessary for correct drainage

of machine barrel and to insure correct overrun.

Place a bubble level on top of the machine at each

corner to check for level condition. If adjustment

is necessary, level the machine by turning the nut

of each caster in or out.

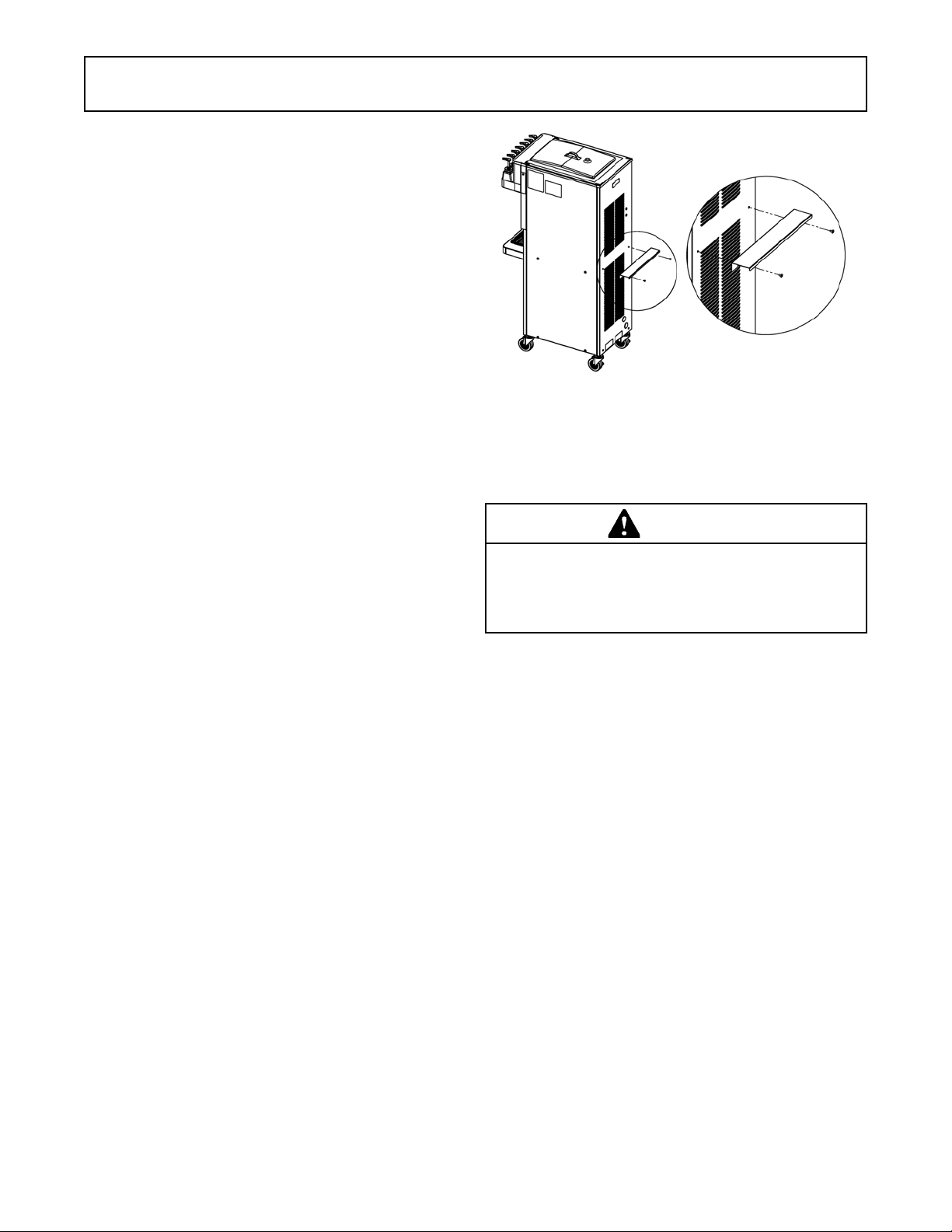

C. Correct ventilation is required. Install the rear air

baffle to provide the 3” clearance at the front and

back (Refer to Figure 2-1). Remove the rear panel

screws and use them to attach the baffle. The

machine can be placed side-by-side next to other

equipment.

D. Place the CLEAN-ON-OFF switch in the OFF

position.

E. Connect the power cord to the proper power

supply. The plug on the U218 is designed for 208-

240 volt / 20 amp duty. Check the nameplate on

your machine for proper supply. The unit must be

connected to a properly grounded receptacle.

The electrical cord furnished as part of the machine

has a three prong grounding type plug. The use of

an extension cord is not recommended, if

necessary use one with a size 12 gauge or heavier

with ground wire. Do not use an adapter to

circumvent the grounding requirement.

WARNING

Do not alter or deform electrical plug in any way.

Altering the plug to fit into an outlet of different con-

figuration may cause fire, risk of electrical shock,

product damage and will void warranty .

Figure 2-1 Rear Air Baffle

6

7

SECTION 3

INITIAL SET-UP AND OPERATION

3.1 OPERATOR’S SAFETY PRECAUTIONS

SAFE OPERATION IS NO ACCIDENT; observe these

rules:

A. Know the machine. Read and understand the

Operating Instructions.

B. Notice all warning labels on the machine.

C. Wear proper clothing. Avoid loose fitting garments,

and remove watches, rings or jewelry that could

cause a serious accident.

D. Maintain a clean work area. Avoid accidents by

cleaning up the area and keeping it clean.

E. Stay alert at all times. Know which switch, push

button or control you are about to use and what

effect it is going to have.

F. Disconnect electrical cord for maintenance. Never

attempt to repair or perform maintenance on the

machine until the main electrical power has been

disconnected.

G. Do not operate under unsafe operating conditions.

Never operate the machine if unusual or excessive

noise or vibration occurs.

3.2 OPERATING CONTROLS AND INDICATORS

Before operating the machine, it is required that the

operator know the function of each operating control.

Refer to Figure 3-1 for the location of the operating

controls on the machine.

A. Spigot Switch

The spigot switch will automatically start the auger

drive and refrigeration systems when the spigot is

opened to dispense product. When the spigot is

closed, the drive motor and compressor will remain

on until the product in the freezing cylinder reaches

the proper consistency.

B. CLEAN-OFF-ON Switch

The CLEAN-OFF-ON switch is used to supply

power to the control circuit. When the switch is in

the OFF (middle) position, power will not be

supplied to the control board or refrigeration

WARNING

High voltage will shock, burn or cause death. The

OFF-ON switch must be placed in the OFF position

prior to disassembling for cleaning or servicing. Do

not operate machine with cabinet panels removed.

Figure 3-1 Machine Controls

Diagnostic

Light

Add Mix

Indicator

Clean/Off/On

Switch

8

system. When the switch is in the ON position, the

machine will operate in the freezing mode. When

the switch is in the CLEAN position, all refrigeration

will stop and the auger will start rotating.

C. ADD MIX Light

The ADD MIX light will flash to alert the operator

to a low mix condition. It does so by monitoring the

mix level in the hopper. When the ADD MIX light

is flashing, refill hopper immediately.

NOTE

Failure to refill hopper immediately may result in

operational problems.

D. Diagnostic Light

The Diagnostic Light will flash if an error occurs.

The light will flash once if there is a compressor

error. There will be two quick flashes if there is an

auger error. And there will be three quick flashes

if the machine is left in clean mode for more than

20 minutes. Refer to the troubleshooting section

for details.

E. Consistency Adjustment Screw

The Consistency Adjustment Screw increases or

decreases product consistency. A tension spring

is connected to the screw and changes the amount

of torque needed to complete a refrigeration cycle.

Turn the screw clockwise to increase consistency

or counterclockwise to decrease consistency.

F. Front Door Safety Switch

The front door safety switch prevents the auger

from turning when the front door is removed. The

switch is open when the door is not in place and

closed when the door is properly installed.

G. Autofill Kit - Optional (Part 2187317)

The autofill kit is used with a pump to keep the

hopper filled. The autofill kit is for use with non-

potentially hazardous food substances; non-dairy.

Refer to Section 8 for Autofill options.

3.3 SANITIZING

Sanitizing must be done after the machine is cleaned and

just before the hopper is filled with mix. Sanitizing the night

before is not effective. However, you should always clean

the machine and parts after each use.

The United States Department of Agriculture and

the Food and Drug Administration require that all

cleaning and sanitizing solutions used with food pro-

cessing equipment be certified for this use.

When sanitizing the machine, refer to local sanitary regu-

lations for applicable codes and recommended sanitizing

products and procedures. The frequency of sanitizing

must comply with local health regulations.

Mix sanitizer according to manufacturer’s instructions to

provide a 100 parts per million strength solution. Mix

sanitizer in quantities of no less than 2 gallons (7.5 liters)

of 90° to 110°F (32° to 43°C) water. Allow sanitizer to

contact the surfaces to be sanitized for 5 minutes. Any

sanitizer must be used only in accordance with the

manufacturer’s instructions.

In general, sanitizing may be conducted as follows:

A. Prepare Stera-Sheen Green Label Sanitizer or

equivalent according to manufacturer’s

instructions to provide a 100 ppm strength solution.

Mix the sanitizer in quantities of no less than 2

gallons of 90° to 110°F (32° to 43°C) water. Check

the strength of the sanitizing solution. Use a

chlorine test strip and color chart to make sure the

solution has 100 ppm. Any sanitizer must be used

only in accordance with the manufacturer’s

instructions.

B. Pour the sanitizing solution into the hopper and

place the switch in the CLEAN position. Check for

leaks. Place the switch in the CLEAN position.

Check for leaks.

C. Clean the sides of the hopper and the underside

of the hopper cover using a soft bristle brush

dipped in the sanitizing solution (Refer to Figure 3-

2).

D. After five minutes, place a bucket under the spigot

and open spigot to drain most sanitizing solution.

Leave a small amount of the sanitizing solution in

the freezing cylinder. Place the switch in the OFF

(middle) position.

CAUTION

Do not allow sanitizer to remain in contact with stain-

less steel machine parts for prolonged periods. Pro-

longed contact of sanitizer with machine may cause

corrosion of stainless steel parts.

Figure 3-2 Brush Hopper

Loading...

Loading...