STERIS V.I.P. Bird User manual

V.I.P.

Bird“

Infant

(9

MVACPAPIPS

Pediatric

MODE

888 888

©

8

Proximal

Pressure

{178

tine

ONLY}

Ventilator

To,

Humidifier

Pressure

Reñel

0130

cm

420

L1208

Rev. C -

8/99

VIF.

meorconrenrs

Section

11

12

13

131

1.3.2

1.3.3

14

15

Section

2.1

2.2

2.3

2.4

1.0 - GENERAL

Warranty

User Responsibility

Introduction

Product

Application

Definition

Performance

Ordering

2.0-

WARNINGS,

Definitions

Warnings

Cautions

Notes

Description

Information

OPERATING

INFORMATION:

Lili

................................................,....

of

Repair - Maintenance

Characteristics

CAUTIONS

ν

INSTRUCTIONS

ντε

τετ

ενκτετε

and

Specifications

&

NOTES:

κκ

εεεκ ετεκ

ετεκ

κκ

ετεκ

...................,....

κών

esse.

©...

........................,..........,...4..

eee

ee

el

cen

トー

beret

eee e rene

トト

ーー

レン

tere

seta

eee

レー

バーーー

entree

1-5

2-1

2-1

2-3

24

Section

34

3.2

3.3

34

3.5

3.0 - SYSTEM

Description

+

Back

+

Front

+

Front

+

Front

Assembly

Overview

3.3.1

3.3.2

Cleaning

3.4.1

3.4.2

Troubleshooting

OPERATION:

of

Controls,

Panel

Descriptions

Panel

Control

Panel

Indicator

Panel

Alarm

Instructions

of

the V-LP.

Pneumatic

Electronic

CJeartmg

Steriization 1 に. に に に に ーー

Theory

Theory

and

Sterilization

に

Monitors,

Indicators

.........,,..............................

Descriptions

Descriptions

Descriptions

.......................,....................

Bird

Ventilator

of

Operation

of

Operation

..................

に

に に

ーーー

Guide

and

Alarms

...............

3-1

3-1

..................................

................................

-.................................

System

トー

Operation

トド

ーー

トト

ーーー

ドド

1.

トト トレ

トト

トー

.................

eee

レト

レー

トト

レレ

ーー

トト

トト

ドー

ドー

トー

レレ

3-3

3-10

3-11

3-19

3-25

ーーーー

ence

L1208

Rev. C -

August

1998

一

/一

VIP

were

SERVICE

INSTRUCTIONS

=

Section

4.1

4.2

43

44

45

4.0-

MAINTENANCE

Maintenance

Performmamce

4.2.1

4.2.2

4.2.3

VIP.

V.LP.

Disassembly

4.5.1

4.5.2

4.5.3

4.5.4

4.5.5

4.5.6

4.5.7

4.5.8

45.9

AND

SERVICE:

and

Service

Test に に.

Bacteria

Buïlt-in

User

Bird

Bird

Exhalation

Ventilator

Power

Top

Front

Auxiliary

Display

Main

Filter

Diagnostics

Verification

Tool/Equipment

15,000

Hour

..............

Valve

Mounting

Cord

Cover

Assembly

Panel

Assembly

Outlet

PCBA

PCBA

Policy

に に に に に ーー

Testing

Tests

本

........,..,....:,.......................

...................,........,..,.,.....02

(UVT)

List

................................,....

Maintenance

還

Body

P/N

Bracket

and

Bracket

Assembly

(P/N

(P/N

Assembly

P/N

20122

P/N

50040

50050

or

or

レト

トッ

トト

トス

トー

トト

トト ト トト

トー

..............,,..........,..,....

Kit

P/N

10073

10188

.............................

..................................

P/N06148

...............................

15008

..............................

P/N

20221

P/N

50250)

P/N

50260)

...................

..................

...................,.....

and

........................

ManometerAssembiyP/N09799..............................

Power

4.5.10

45.11

4.5.12

4.5.13

4.5.14

4.5.15

4.5.16

4.5.17

4.5.18

4.5.19

4.5.20

4.5.21

4.5.22

4.5.23

4.5.24

4.5.25

4.5.26

4.5.27

Board

Power

Rear

Flow

Exhalation

Safety

Jet

Proximal

Transformer

Panel

Control

Solenoid

Pump

Purge

Valve

Safety

Valve

Patient

Proximal

Pressure

Outlet

Blender

Pressure

Inlet

Block

Casting

Inlet

Elbow

100

PSI

PCBA,

Assembly

Valve

Valve

Assembly

Assembly

Assembly

Tube

Assembly

Assembly

Assembly

Manifold

Pressure

Relief

Valve

Assembly

Regulator

P/N

33519

Sealing

Pressure

Plate

P/N

Relief

P/N

50079

or

P/N

50160

...................

P/N

15114

...............................

P/N

15004

Assembly

P/N

P/N

15046

P/N

P/N

P/N

Assembly

Port

Fitting

P/N

P/N

10160

P/N

33566

....,....................,...,......4

P/N

33615

........................

Valve

.................,...........

P/N

P/N

15005

15029

15013

......................

............,...........

.........................

...............................

10091

10180

10092

............................

09754

....

P/N

10089

..................

P/N

01537

......................,......

.....................

......................,...:.

...............................

20126

........................

Live

P/N

09784

......................

トー

トーー・

41

4-2

42

4-3

45

4-10

4-12

4-13

4-14

4-14

4-14

4-15

4-16

4-17

418

4-18

4-19

4-20

4-21

4-22

4-22

4-23

4-27

4-27

4-28

-...4-29

4-30

4-30

B

4-32

4-32

—

ji

—

442M

Rav

CO.

Anne

anan

МР

TABLE

OF

CONTENTS

4.6

4.5.28

CleaningCastingBaseP/N20135............................

4.5.29

Safety

Solenoid

Assembiy

P/N

15013

4530jetPumpAssembiyP/N15009...............................

4.5.31

Oxygen

4.5.32

Air

4.5.33

Inlet

Blender

4.6.1

Blender

4.6.2

Balance

4.6.3

Valve

464

AuxiliaryOutletReassembiyP/N20221........................

4.6.5

Proportional

4.6.6

Bypass

4.6.7

Muffler

468

ValveBlock................,......

4.6.9

MicroBlender

4.6.10

Muffler

4.6.31

Bypass

4.6.12

Auxiliary

4.6.13

Front

4.6.14

Setup

4.6.15

Calibration

4.6.16

Air/Oxygen

46.17

Oxygen

4.6.18

Test

4.6.19

Calibration

4.6.20

AlarmCalibratteon

4.6.21

Inlet

4.6.22

Installation

4.6.23

Replacement

Inlet

Assembly

Inlet

Assembly

Block

Assembly

Maintenance

Assembly

Block

Block

Assembly

Module

Disassembly

Assembly

Assembly

Assembly

Outlet

and

Rear

Procedure

Tools

AnalyzerSetup/Calibraton

Equipment

Procedure

Block

Check

of

P/N

03864L

P/N

10078

P/N

33519

and

Calibration

P/N

P/N

03805

10160

P/N20153A

serrara

...........................,.....

ii

zi

cea

zia

eine

...............................,....

............................

.........................................

P/N

03319

eee

Final

Assembly

..........................................

(Left/Right

(P/N

Valve

Seat

For

Testing

/Equipment

P/N

Side,

20221)

Assembly

10160

Rear)

...............,.......,........

......................

..........................

Setup

..........................

Setup

Control

Parts

...............................:.......

10160

MicroBlender

..................

Valve

Leak

Test

.............................

Knob

Friction

..........................................

..................

0...

O-ring

....................

ellere

nie

4-38

4-41

4-42

4-44

4.46

4-52

4-52

4-53

4-56

4-56

457

4-59

4-60

4-60

4-61

4.7

Assembly

4.7.1

Oxygen

4.7.2

Air

4.7.3

Inlet

4.7.4

Jet

4.7.5

Safety

4.7.6

Ynlet

Inlet

Biock

Pump

Solenoid

Elbow

L1208

Inlet

Assembly

Assembly

Assembly

Assembly

Assembly

P/N

Rev. C -

P/N

03864L

P/N

10078

P/N33519

P/N

15009

P/N

33615

...........,...,.......................

August

1998

o

................................

..............................

................................

15013

..........................

нения

4-63

4-64

4-64

4-65

4-66

4-67

—

iii

—

VILF.|

mersorconente

4.7.7

100

PSI

4.7.8

Casting

4.7.9

Sealing

4.7.10

4.7.11

4.7.12

4.7.13

4.7.14

Casting

Pressure

Regulator

4.7.15

4.7.16

4.7.17

4.7.18

4.7.19

4.7.20

4.7.21

4.7.22

4.7.23

4.7.24

4.7.25

4.7.26

4.7.27

4.7.28

4.7.29

4.7.30

4.7.31

4.7.32

4.7.33

Inlet

Barbed

Purge

Safety

Exhalation

Proximal

Patient

Pressure

Jet

Pump

Safety

Flow

Proximal

Power

Blender

Rear

Power

Manometer

Display

Front

Auxiliary

Power

Pressure

Sealings

Plate

P/N

LeakTest

Regulator

Calibration

Block

Assembly

Tube

Connector

Valve

Assembly

Valve

Assembly

Valve

Pressure

Outlet

Relief

Assembly

Solenoid

Control

Panel

Valve

Tube

Transformer

Assembly

Assembly

Board

Assembly

de

Main

Panel

Assembly

Outlet

Cord

Assembly

00000

Relief

Valve

P/N

09784

........................

O-rings

20126

.....................,,....

P/N

33566

.....,.............,..,.............,..

P/N

P/N

P/N

Assembly

Port

P/N

Manifold

Valve

Assembly

P/N

Assembly

Assembly

Assembly

Assembly

P/N

P/N

P.C.B.A.

P/N

P/N

P.C.B.A.

P/N

Assembly

33519

P/N

Assembly

15046

P/N

P/N

10160

Display

P/N

..,....,.....................

00576

10180

09734

P/N

15004

50070

09799

P/N

............................

15029

.

01537

...........,...............,

P/N

10089

P/N

10092

...............................

15013

.........................

P/N

15005

10091

P/N

15008

08925

......................

15114

.....................!..........

............................,

or

50160

.......,.....................

P/N

50040,

20221

................,.......

............................

4-68

Main

P/N

50050

...4-84

o

4-85

4-87

4-88

4.8

Operational

4.8.1

Reguired

4.8.2

Preparation

4.8.3

Operational

4.8.4

Post

Operational

4.8.5

VIP.

Bird

Verification

Eguipment

Vent

L1208

Procedures

Verification

Verification

Inop

Rey.

C-

Procedures

Codes

August

K

...........

...................................

1998

NN

4-91

4-111

4-111

VI

P

TABLE

|

CONTENTS

OF

,

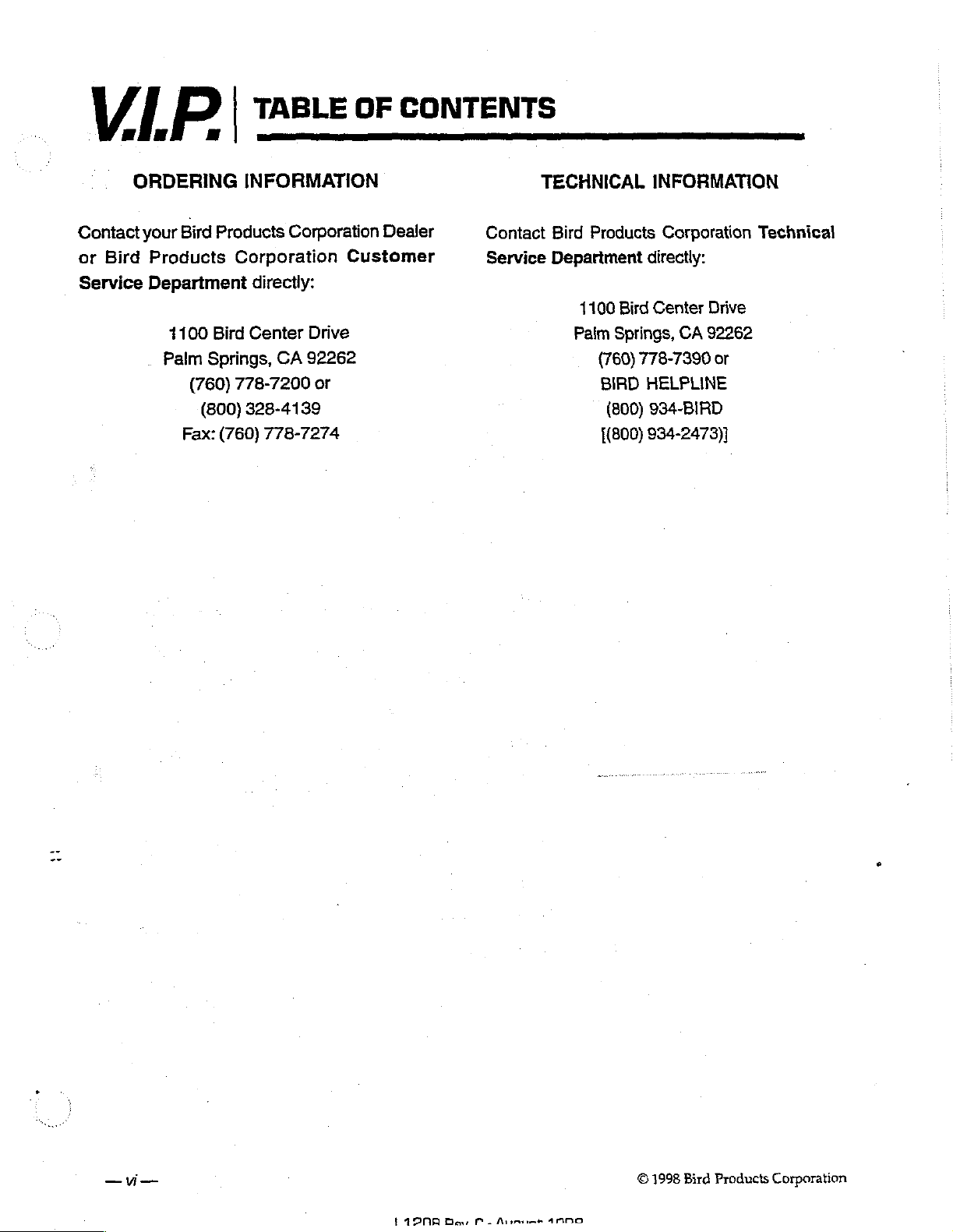

SECTION

51

5.2

53

54

55

5.6

57

5.8

5.9

5.10

5.11

SECTION

6.1

6.2

6.3

64

65

6.6

6.7

6.8

6.9

6.10

6.11

-

6.12

6.13

6.14

5.0-

SCHEMATICS

Block

Diagram,

PCBA,

Schematic,

PCBA,

Schematic,PCBA,Main,P/N50052.................................

РСВА,

Display,

Main,

Роууех

Schematic,

PCBA,

Schematic,

PCBA,

PCBA,

Panel,FrontAssembiy

Top

Manifold

Power

Power

Display,

Main

6.0-

PARTS

Cover

Base

Supply

ElhalationValve

Manifold,

Outlet

Valve

Patient

Assembly,

Safety

Valve

PurgeValveAssembly

JetPumpAssembly

Safety

ValveSolenoid

SideRailsAssembiy........................

Regulalor

6.15

6.16

6.17

6.18

6.19

6.20

6.21

Cable

Assemblies

。 MicroBlender

FlowControl

Transformer

Panel

Assembly,

TubeAssemblies

Expladed

-

DRAWINGS:

P/N

15128

P/N

50040

PCBA,

Power

Power

Assembly

V.LP

Display,

P/N

50050

Оймет,

Driver,

Driver,

DrivenP/N50162

Flow

CPU,

Flow

LIST:

Assembly

Assembly

...........................»...................

Bird

Assembiy

Assembiy

Relief

Assembly

...................-//0

........................

......................

...................................,.....

..........,.....................,,.......

P/N

50042

...........................................

Р/М

50070

.........

P/N

50072

P/N

50160

..............,.,...................

Synch,

P/N

50250

Synch.,

.....................

.....................

P/N

...

....................................»...

Adjustable

.....

ie

еее

......................

Assembly

--ϱϱϱῦ--υ--υ-υ---

Valve

Assembly

View,

...

Rear

..,.....,....,..........................,....4.

VIP

Bird

.............,...........,................

5.1

52

...................,...........

лу

иене

нааниаютяння

...........,...................

.

.............................

50260

..................,...............

.............,...........,

0...

.

-

V

начинании

ーー

ルー

トード

0

ーー

ω

eee

ων νο

ドー

νν

ος

ини

53

59

5-10

5-20

5-21

5-25

5-27

5-31

5-33

+

6-10"

6-12

6-14

6-15

6-16

”

|

0.

0

eee

ae

ее

нии

6-28

GLOSSARY

Vi

P

TABLE

|

CONTENTS

OF

ORDERING

Contact

or

Bird

Service

your

Bird

Products

Products

Department

1100

Bird

Palm

Springs,

(760)

(800)

Fax:

INFORMATION

Corporation

Corporation

directly:

Center

CA

778-7200

328-4139

(760)

778-7274

Customer

Drive

92262

or

Dealer

TECHNICAL

Contact

Service

Bird

Products

Department

1100

Bird

Palm

Springs,

(760)

BIRD

(800)

[(800)

INFORMATION

Corporation

directly:

Center

778-7390

HELPLINE

934-BIRD

CA

Drive

92262

or

934-2473)]

Technical

一

W

一

Ε

ΤΦΓΗ

Des M Amine

AMD

©

1998

Bird

Products

Corporation

WARNING

This

Corporation

Products

activity

trained

CORPORATION

UNAUTHORIZED

UNAUTHORIZED

service

on

or

manual

trained

Corporation

its

authorized

products

IS

is

intended

and

REPAIRS,

PROCEDURES.

authorized

does

personnel.

NOT

not

by

other

RESPONSIBLE

for

condone

than

OR

use

service

Bird

BIRD

ANY

!

by

Bird

or

Products

PRODUCTS

REPAIRS

Products

personnel.

approve

FOR

Bird

of

service

Corporation

ANY

MADE

BY

Use

installation,

and

the

injury

shall

All

(see

Products

of

the

equipment

equipment.

including

bear

maintenance

warranty

warranty

incorrect

removal,

full

responsibility

card)

Corporation

status

part

servicing,

may

This

of

result

may

death.

performed

must

service

the

or

the

failure

checkout

in

damage

also

The

be

subject

result

purchaser

and

within

authorized

representative

unit.

to

exercise

or

or

possible

in

damage

and

installer

liability

the

for

applicable

in

advance

due

care

calibration

malfunction

to

property

of

these

the

above.

warranty

by

Bird

in

order

to

in

the

of

parts

of

and

parts

period

retain

the

Section

General

Information

1

Warranty

User

3 -

Introduction

14 | Performance

15

Ordering

μι

Responsibility

Characteristics

Information

1.0

ns

eee

and

Specifications

.....1-11

-1

Le

Î

-2

È

-15

2

V.LP

BIRD?

Infant-Pediatric

Service

Ventilator

Manual

SECTION

1.0:

GENERAL

11

WARRANTY

一

The

from

specifications

The

credit,

published

this

discovery

returned

part

day

disclose,

misuse,

Any

prevent

products

defects

liability

at

warranty

is

received

of

the

neglect,

authorization

Bird

warranties

affected

technical

the

products

INFORMATION

of

Bird

Products

in

material

for

of

Bird

the

discretion

specifications

unless

of

defects

to

Bird,

transportation

by

warranty

to

its

satisfaction,

improper

voiding

by,

as

and

advice

furnished

warranty.

no

or

and

one(1)

year.

under

this

of

Bird,

during

(A) Bird

or

failure

Bird

for

adjustment

period; and

that

installation,

of

Bird

for

hereinabove

obligation

service

by

hereunder.

Corporation

workmanship

warranty

for

the

is

promptly

to

meet

charges

(D)

such

repair

set

or

Bird

is

limited

the

parts

warranty

notified

specifications;

prepaid

no

later

Bird's

examination

defects

unauthorized

or

alteration

forth

shall

liability

or

its

shall arise

agents

(Herein

and

to

meet

:

to

that

become

period;

in

by

Buyer;

than

or

failures

by

not

be

or

in

connection

Bird)

are

warranted

the

published

replacing,

Bird

writing

(B)

four

have

repair,

the

enlarged,

grow

repairing

defective

will

not

by

Buyer

the

defective

(C) the

weeks

following

of

such

unit

not

alteration

Buyer

must

diminished

out

with

or

or

fail

to

be

liable

upon

unit

defective

or

part

been

caused

or

accident.

be

in

of

the

rendering

Buyer's

to

be

free

issuing

meet

under

or

part

unit

or

the

last

shall

by

writing

or

of

order

of

|

is

to

SP:

THE

MARK

CONSUMER

CONFIDENCE

SAFETY

u

(m

This

by

LABORATORIES,

L

COUNTS

product

ETL

TESTING

OF

WHEN

|

is

listed

INC.

*

In

damage

than

This

lubrication

shall

by

maintained

The

delivery,

1,

2.

The

without

amended

し

LIMITATIONS

no

event

shall

or

damages

the

purchase

warranty

and

not

apply

Bird

or

authorized

in

warranty

Electrical

temperature,

days

Elastomeric

over

receipt.

foregoing

stated

with

components

from

date

which

limitation,

only

OF

LIABILITIES

Bird

be

liable

of

any

price

of

any

does

not

cover

updating

if

the

accordance

the

pressure,

components

Bird

is

in

in

of

equipment

for

use

with a prescribed

above

following

for

oxygen

of

receipt.

has

not

lieu

of

any

warranty

writing

by a duly

to

Buyer

kind

based

defective

normal

equipment

is

used

in

writing

shall

extend

exceptions:

remote

monitoring

saturation

and

other

control

are

any

other

of

merchantability,

authorized

for

loss

of

profits,

upon a claim

product covered

maintenance

or

parts.

This

with

accessories

by

Bird,

or

schedule

for a period

of

or

flow

parts

or

components

warranted

warranty,

expressed

representative

loss

for

breach

hereunder.

such

as

cleaning,

warranty

or

if

the

equipment

of

maintenance.

of

one

physical

are

warranted

for

sixty

(60)

or

except

of

use,

of

warranty,

adjustment

shall

be

parts

not

manufactured

is

year

from

variables

for

subject

to

days

from

implied,

as

to

title,

of

Bird.

consequential

other

or

void

and

not

date

of

such

as

ninety

(90)

deterioration

date

of

including,

and

can

be

SECTION

1:0:

GENERAL

12

USER

INFORMATION

RESPONSIBILITY

This

product

in

this

assembled,

provided.

should

contaminated

becomes

service

Center

not

be

and

by

responsiblility

maintenance,

authorized

will

service

not

in

repaired

manual

operated,

This

product

be

used.

should

necessary,

advice

Bird

be

Palm

trained

for

improper

Bird

perform

made

Springs,

other

any

representative.

in

conformity

and

accompanying

maintained

must

be

Parts

that

are

be

replaced

Bird

recommends

to

the

nearest

California.

than

following

personnel.

malfunction

repair,

The

damage

checked

with

the

labels

and

repaired

broken,

immediately.

that a telephonic

Bird

This

written

user

that

or

following

periodically A defective

missing,

If

distributor

product

instructions

of

this

product

results

from

alteration

description

and/or

plainly

repair

or

or

or

any

improper

by

inserts,

the

instructions

worn,

or

replacement

written

the

Bird

of

its

provided

shall

anyone

of

it

contained

when

product

distorted

request

Service

parts

should

by Bird

have

the

use,

faulty

other

for

sole

than

or

an

13

INTRODUCTION

13.1

Description

The

V.LP,

an

integral

ventilation

the

¢

*

*

*

BIRD

monitoring

of

clinician

IMV/CPAP

ASSIST/CONTROL

SIMVICPAP

Pressure

Continuous

in

IMV/CPAP

Demand

*

20

to

995

is a state-of-the-art,

neonatal,

with:

with

with

Support

Flow/Demand

flow

principle

ml.

Tidal

package.

infant,

Time

Volume

available

Through a variety

and

Cycled,

with

Volume

for

Volumes

microprocessor

pediatric

Pressure

Limited

in

SIMV/CP

flow

spontaneous

patients.

Limited

Limited

Breaths

AP

principle

breathing

controlled

of

modes,

The

ventilator

Breaths

Breaths

for

spontaneous

in

device

the

with

unit

allows

provides

breathing

SIMV/CPAP

*

Oto

*

3to

Volume

150

BPM

40

LPM

Cycled

PEAK

Modes

FLOW

in

Time

Cycled

Mode, 3 to

100

LPM

in

1.3

Introduction

Description

Continued

.

1.3.2

*

Comprehensive

PRESSURE,

INSPIRATORY

ON/OFF

*

Comprehensive

*

Adjustable

®

Fiber

Optic

*

Optional

air

Application

The V.LP.

microprocessor

time

PRESSURE

assistor

a

constant

and

can

in

ASSIST/CONTROL

flow

the

Volume

BIRD

controlled.

or

volume

cycled.

LIMIT

controller

flow.

The

synchronized

produce

capability

peak

of 3 to

Cycled

address a broad

monitoring

MEAN

AIRWAY

TIME,

alarm

package.

alarm

loudness.

data

link.

compressor

is

electrically

Depending

The

unit

ALARM

and

delivers

ventilator

intermittent

pressures

Modes.

range

up

and

SIMV/CPAP

40

LPM

These

of

neonatal,

package,

PRESSURE,

I:E

RATIO,

and

pneumatically

on

is

pressure

is

reached.

accurately

can

provide

The

mandatory

to

120

cmH20,

in

the

Time

specifications

infant,

including

PEAK

BREATH

LEAK

COMPENSATION

powered

the

mode

of

operation,

cycled

only

unit

functions

controlled

positive

ventilation

of

20

Cycled

and

air/oxygen

airway

(SIMV).

and

has a tidal

to

995

ml.

Mode

allow

the

pediatric

INSPIRATORY

RATE,

and

it

can

when

the

HIGH

as a controller

mixtures

pressure

The

ventilator

volume

The

unit

has

and 3 to

100

ventilator

patients.

be

or

at

(CPAP),

range

peak

LPM

in

to

13.3

Definition

The

V.LP.

of

operation,

instructions

The

service

Person;

conducted

repairs,

should

SERVICES

of

operation,

Service

‘and

Maintenance

of

BIRD

calibration,

to

manual

that

is, a person

or

adjustments,

be

referred

CENTER.

personnel

Repair - Maintenance

Service

assist a qualified

authorized

refer

Manual

troubleshooting,

is

specifically

that

has

by

BIRD'S

or

procedures

to

the

BIRD

For

specific

to

the

V.LP.

should

procedures

become

contains

service

intended

attended a V.LP.

SERVICE

that

PRODUCT

operating

BIRD

thoroughly

before

attempting

pneumatic

replacement,

technician.

for

use

TRAINING

exceed

the

CORPORATION

instructions

Instruction

Manual,

familiar

service

and

by

an

BIRD

scope

electronic

and

maintenance

authorized

service

CENTER.

of

this

TECHNICAL

and

clinical

P/N

L1194.

with

the

Operating

on

this

equipment.

theories

service

seminar

Any

manual

theory

1-3

SECTION

1:

MP

GENERAL

The

WARNINGS,

attention.

Section

the

diagnosis

ventilator.

problem

subassembly.

The

manual

failures

schematic

subassemblies

Only

factory

V.LP.

analysis

training

INFORMATION

CAUTIONS,

4:

Maintenance & Service

and

repair

of

defective

This

manual

to a defective

does

on

the

printed

information

can

trained

BIRD

ventilator.

and

repair

on

how

is

subassembly

not

cover

circuit

is

be

replaced

personnel

Bird’s

at

the

to

perform

structured

provided

subassembly

and

NOTES

of

this

subassemblies

around

and

diagnosis

board

service

the

and

subassemblies;

for

the

in

the

field

should

training

15,000

hour

should

manual

replacing

attempt

level

covers

the

concept

repair

service

by

factory

diagnosis

classes

and

maintenance

be

given

the

details

of

the

V.LP.

of

isolating

that

defective

of,

for

example,

however,

technician.

trained

and

are

based

also

include

of

particular

related

BIRD

a

component

complete

Defective

personnel.

repair

of

the

on

fault

detailed

the

ventilator.

to

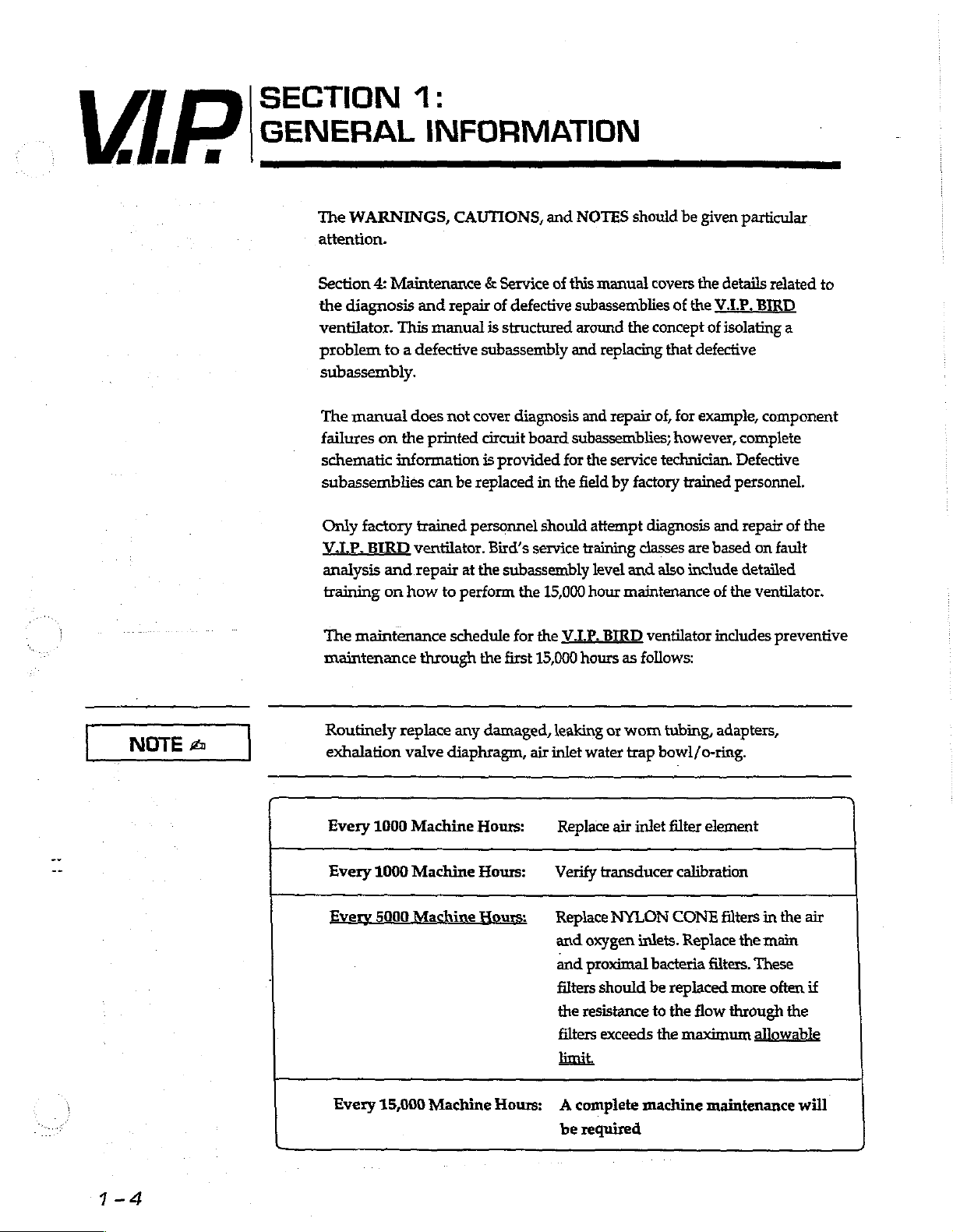

NOTE

2

The

maintenance

maintenance

Routinely

exhalation

Every

Every

very

Every

replace

1000

1000

5000

15,000

schedule

through

valve

diaphragm,

Machine

Machine

ine

Machine

for

the

the

first

15,000

any

damaged,

air

inlet

Hours:

Hours:

Hours:

and

Hours: A complete

V.LP.

BIRD

hours

leaking

Replace

Verify

Replace

and

filters

the

filters

be

or

water

transducer

oxygen

proximal

should

resistance

exceeds

required

ventilator

as

follows:

worn

trap

air

inlet

NYLON

inlets.

bacteria

be

to

machine

includes

tubing,

bowl/o-ring.

filter

replaced

the

the

adapters,

element

calibration

CONE

filters

Replace

filters.

more

flow

through

maximum

maintenance

the

These

allowable

preventive

in

the

air

main

often

if

the

will

1.4

Performance

Characteristics

and

1.3

Introduction

Specifications

Maintenance

Continued

—

14

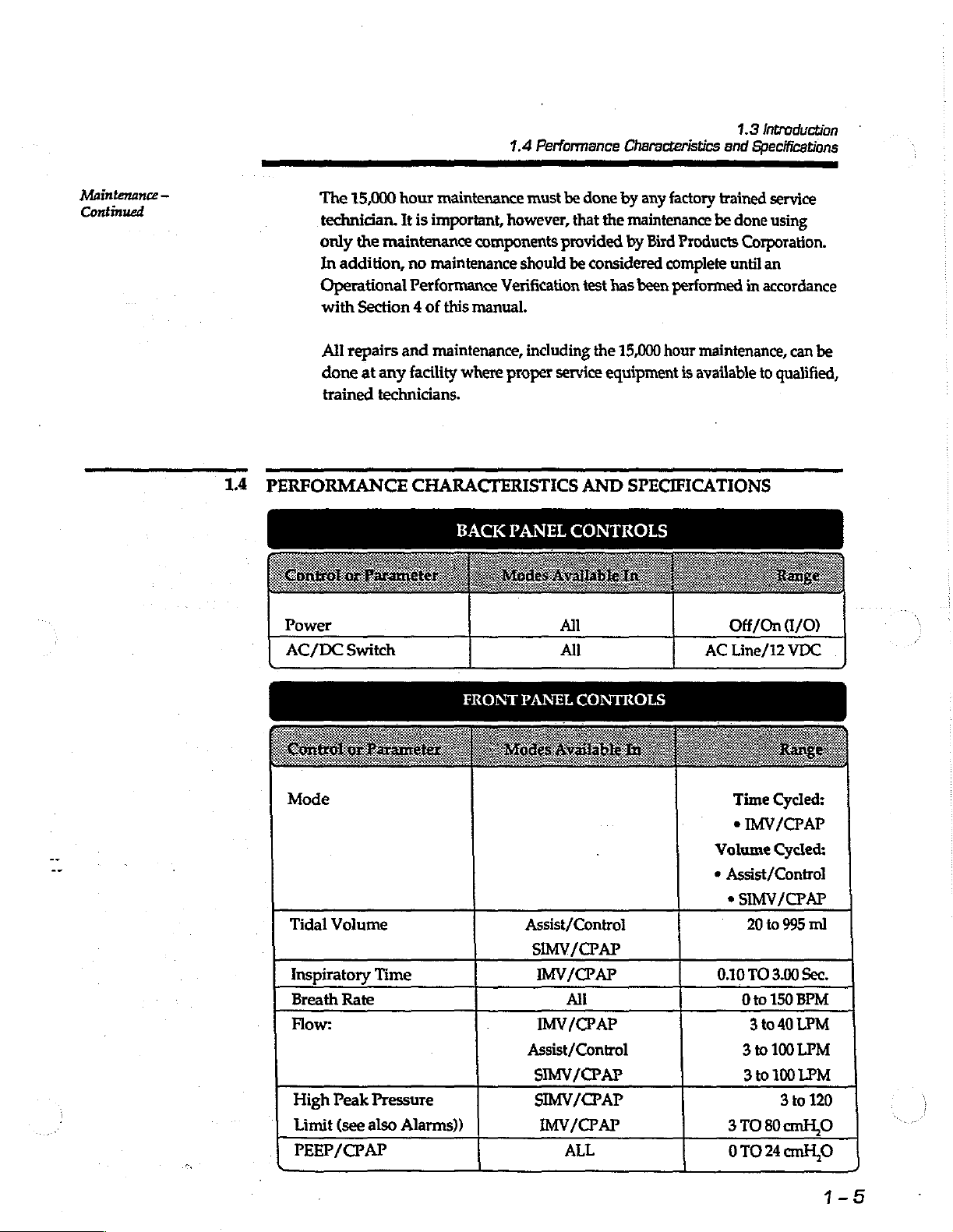

PERFORMANCE

The

technician.

only

In

Operational

with

All

done

trained

Power

AC/DC

15,000

addition,

repairs

Switch

hour

It

the

maintenance

no

Performance

Section 4 of

and

at

any

facility

technicians.

CHARACTERISTICS

maintenance

is

important,

components

maintenance

this

manual.

maintenance,

where

must

be

done

however,

should

Verification

including

proper

that

provided

be

considered

test

the

service

AND

by

any

factory

the

maintenance

by

Bird

Products

complete

has

been

performed

15,000

hour

equipment

SPECIFICATIONS

is

trained

be

maintenance,

available

AC

service

done

using

Corporation.

until

an

in

accordance

can

to

qualified,

Off/On

Line/12

(1/0)

VDC

be

Tidal

Volume

Breath

Flow:

High

Limit

PEEP/CPAP

Rate

Peak

(see

Time

Pressure

also

Alarms))

Assist/Control

SIMV/CPAP

IMV/CPAP

All

IMV/CPAP

Assist/Control

SIMV/CPAP

SIMV/CPAP

IMV/CPAP

ALL

Time

Cycled:

*

IMV/CPAP

Volume

*

Assist/Control

0.10

Cycled:

*

SIMV/CPAP

20

to

995

TO

3.00

Oto

150

3

to

40

3

to

100

3

to

100

3

3

TO

80

ml

Sec.

BPM

LPM

LPM

LPM

to

120

0TO24cmHO

cmH,O

1-5

SECTION

1:

GENERAL

VIP

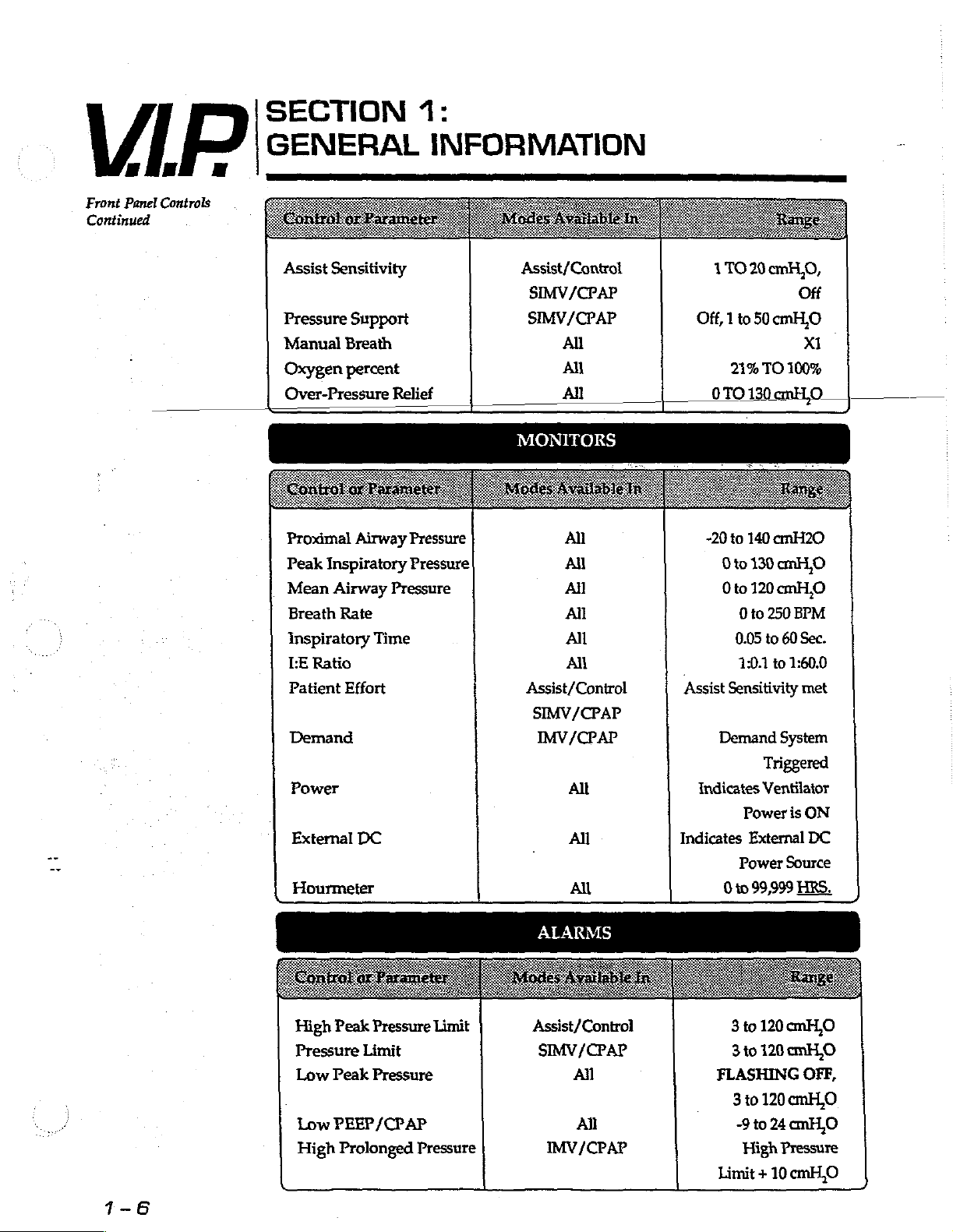

Front

Panel

Controls

Continued

Assist

Pressure

Manual

Oxygen

Over-Pressure

Proximal

Peak

Mean

Breath

Inspiratory

LE

Ratio

Patient

Demand

Power

External

し

Hourmeter

Sensitivity

Support

Breath

percent

Airway

Inspiratory

Airway

Rate

Effort

DC

Relief

Pressure

Pressure

Pressure

Time

INFORMATION

Assist/Control

SIMV/CPAP

SIMV/CPAP

All

All

All

MONITORS

All

All

All

All

All

All

Assist/Control

SIMV/CPAP

IMV/CPAP

Alt

All

All

1TO2

Off, 1 to

21%

0TO130

-20

to

0

to

0to

0

0.05

1:0.1

Assist

Sensitivity

Demand

Indicates

Power

Indicates

Power

0

to

mão,

Off

50

cmH,O

XI

TO

100%

cmHO

140

cmH20

130

emH,O

120cmHO

to

250

BPM

to

60 Sec.

to

1:60.0

met

System

Triggered

Ventilator

is

ON

External

99,999

DC

Source

HRS,

ES

High

Pressure

Low

Low

High

Peak

Peak

PEEP/CPAP

Prolonged

Pressure

Limit

Pressure

Limit

Pressure

ALARMS

Assist/Control

SIMV/CPAP

IMV/CPAP

AM

All

3

3

FLASHING

3

-9 to

Limit + 10

to

120

to

120

to

120cmH

24

High

cmHLO

cmH,O

OFF,

O

cmH,O

Pressure

cmH,O

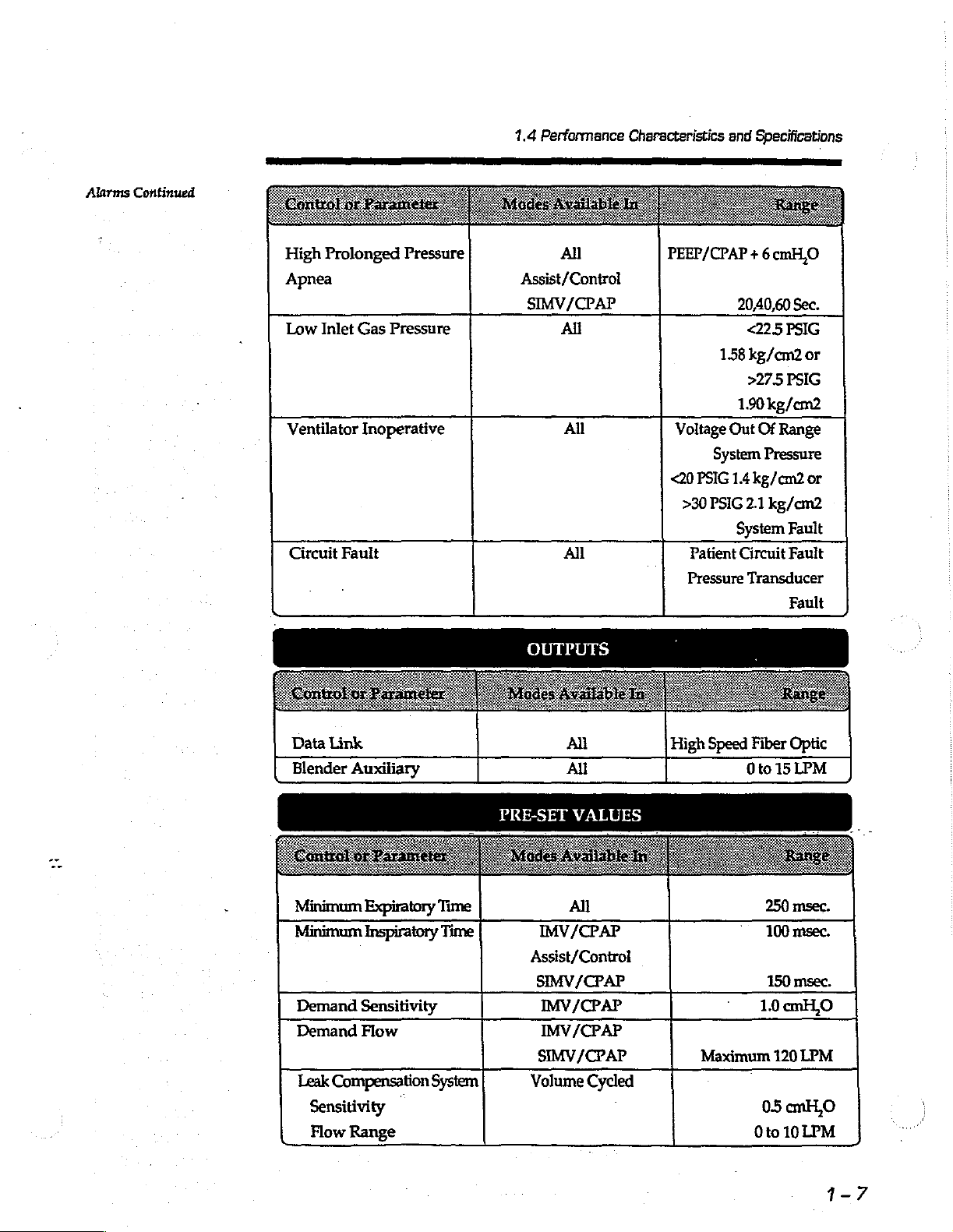

Alarms

Continued

High

Prolonged

Apnea

Low

Inlet

Gas

Ventilator

Circuit

、

Inoperative

Fault

Pressure

Pressure

1.4

Performance

Assist/Control

SIMV/CPAP

All

All

All

All

Characteristics

PEEP/CPAP

Voltage

<20

and

1.58

Out

System

PSIG

1.4

>30

PSIG

System

Patient

Pressure

20,40,60

1.90

Circuit

Specifications

+ 6

cmH,O

Sec.

<225

PSIG

kg/cm2

>275

Of

kg/cm2

2.1

Transducer

or

PSIG

kg/cm2

Range

Pressure

or

kg/cm2

Fault

Fault

Fault

/

K

Minimum

Data

Link

Blender

Minimum

Demand

Demand

Leak

Compensation

Sensitivity

Flow

Auxiliary

Expiratory

Inspiratory

Sensitivity

Flow

System

Range

Time

Time

OUTPUTS

All

All

All

IMV/CPAP

Assist/Control

SIMV/CPAP

IMV/CPAP

IMV/CPAP

SIMV/CPAP

Volume

Cycled

|

High

Speed

0

Maximum

Fiber

Optic

to

15

250

100

150

1.0cmHO

120

05

emH,O

Oto

10

LPM

msec.

msec.

msec.

LPM

LPM

J

1-7

{

|

VI

NEN

p

м

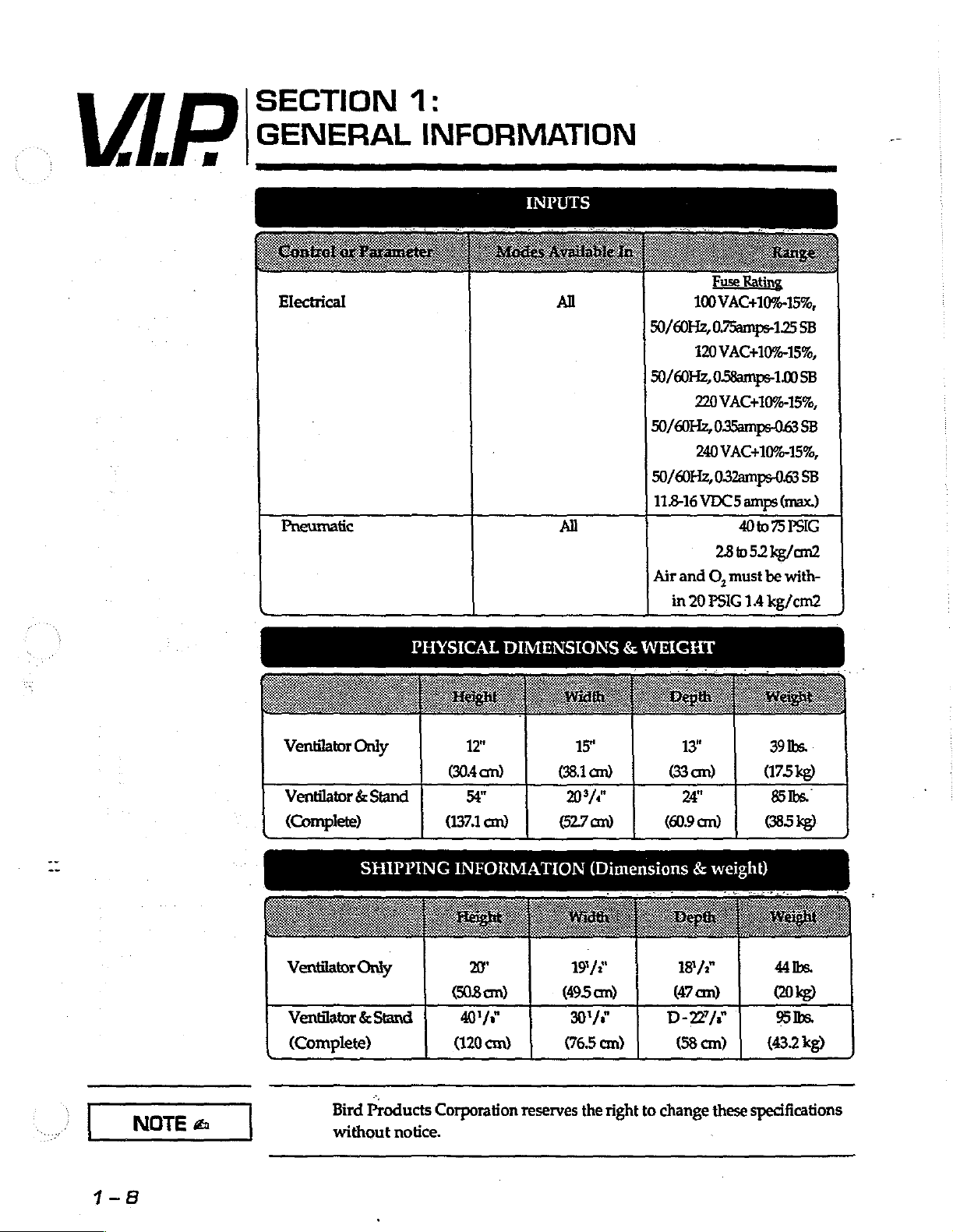

SECTION

GENERAL

Electrical

Pneumatic

し

1:

INFORMATION

INPUTS

All

All

Fuse

Rating

100

VAC+10%-15%,

50/60Hz,

50/60Hz,

50/60Hz,

50/60Hz,

11.8-16

Air

0.75amps-1.25

120

VAC+10%-15%,

0.58amps-1.00

220

VAC+10%-15%,

0.35amps-0.63

240

VAC+10%-15%,

0.32amps-0.63

VDC5

281052

and

O,

in

20

PSIG

amps

40

must

14

(max.)

to

75

PSIG

ke/cm2

be

with-

kg/cm2

SB

SB

SB

SB

J

—

PHYSICAL

Ventilator

Ventilator & Stand

し

(Complete)

o

Ventilator

Ventilator & Stand

|

(Complete)

NOTE

«

Bird

without

Only

SHIPPING

Only

Products

notice.

G04

(137.1

INFORMATION

(08

(120

Corporation

12"

an)

54"

cm)

2"

cm)

a

cm)

DIMENSIONS

15" 13"

(38.1

209/1 24"

(527

19/2

(95

my

(76.5

reserves

the

&

WEIGHT

cm)

cm)

(Dimensions & weight)

an)

cm)

right

to

G3

cm)

(60.9

cm)

18,7

(47

cm)

D-2/s

(58

cm)

change

(175

(385

о

these

specifications

39

Ibs.

kg)

ss.

kg)

eme

44

№5.

(20 kg)

95

Ibs.

(43.2

kg)

1.5

Ordering

Information

15

ORDERING

M

r

INFORMATION

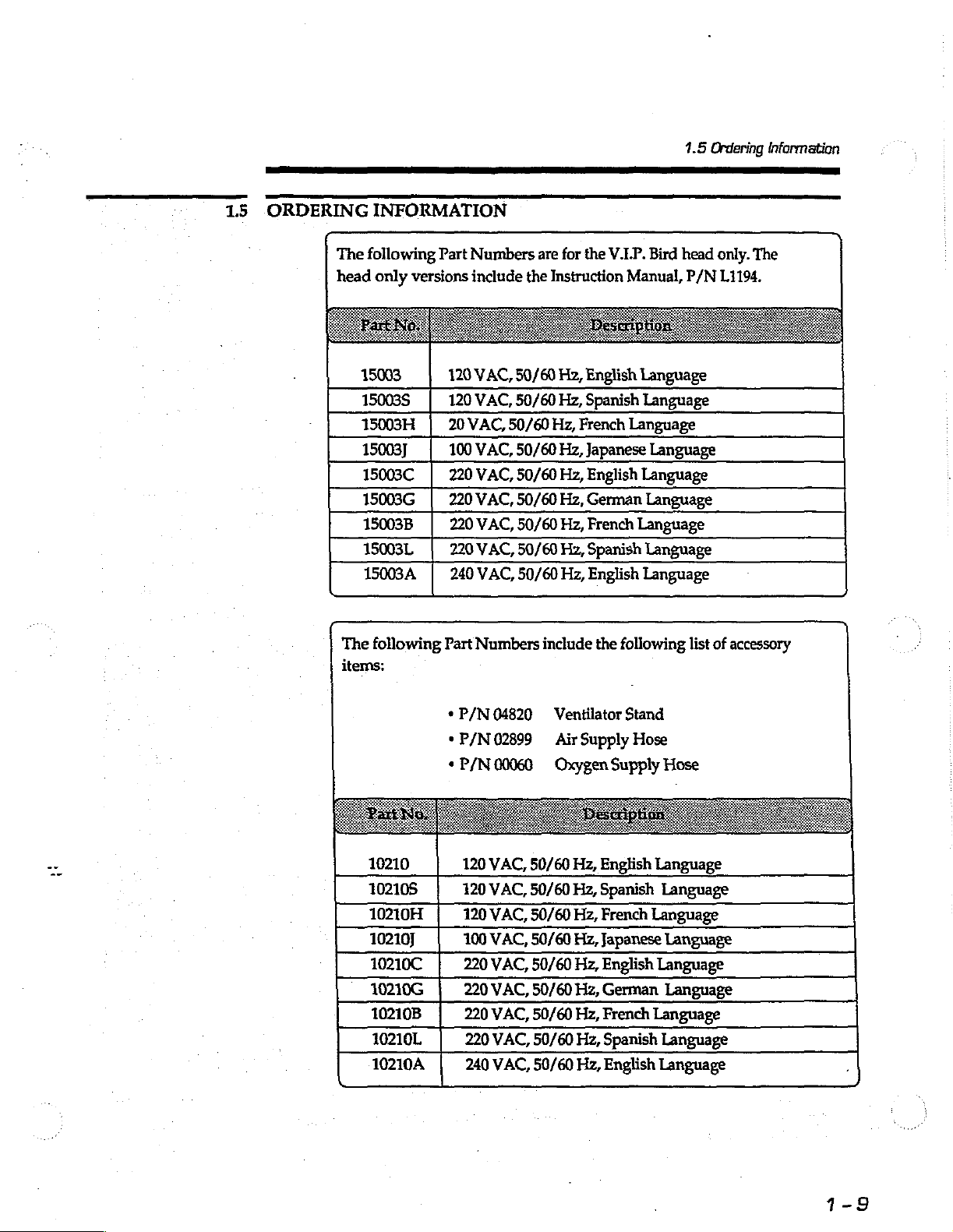

The

following

head

only

15003

150035

15003H | 20VAC,50/60

15003]

15003C

15003G | 220

15003B

15003L

15003A

Part

Numbers

versions

include

120

VAC,

120

VAC,

100

VAC,

220

VAC,

VAC,

220

VAC,

220

VAC,

240

VAC,

The

following

items:

Part

Numbers

are

for

the

V.LP.

Bird

head

only.

The

the

Instruction

50/60

Hz,

50/60

Hz,

Hz,

French

50/60

Hz,

50/60

Hz,

50/60

Hz,

50/60

Hz,

50/60

Hz,

50/60

Hz,

include

Manual,

English

Spanish

Japanese

English

German

French

Spanish

English

Language

Language

Language

Language

the

following

Language

Language

Language

Language

Language

P/N

L1194.

list

of

accessory

¢

P/N

04820 = Ventilator

*

P/N

02899 — Air

+

P/N

00060

10210

102105

10210H

10210]

10210C

10210G

10210B

10210L | 220

10210A

120

VAC,

120

VAC,

120

VAC,

100

VAC,

220

VAC,

220

VAC,

220

VAC,

VAC,

240

VAC,

50/60

50/60

50/60

50/60

50/60

50/60

50/60

Supply

Oxygen

Hz,

Hz,

Hz,

Hz,

Hz,

Hz,

Hz,

50/60

Hz,

50/60

Hz,

Stand

Hose

Supply

English

Spanish

French

Japanese

English

German

French

Spanish

English

Hose

Language

Language

Language

Language

Language

Language

Language

Language

Language

SECTION

1:

VIP

Optional

Accessories:

GENERAL

r

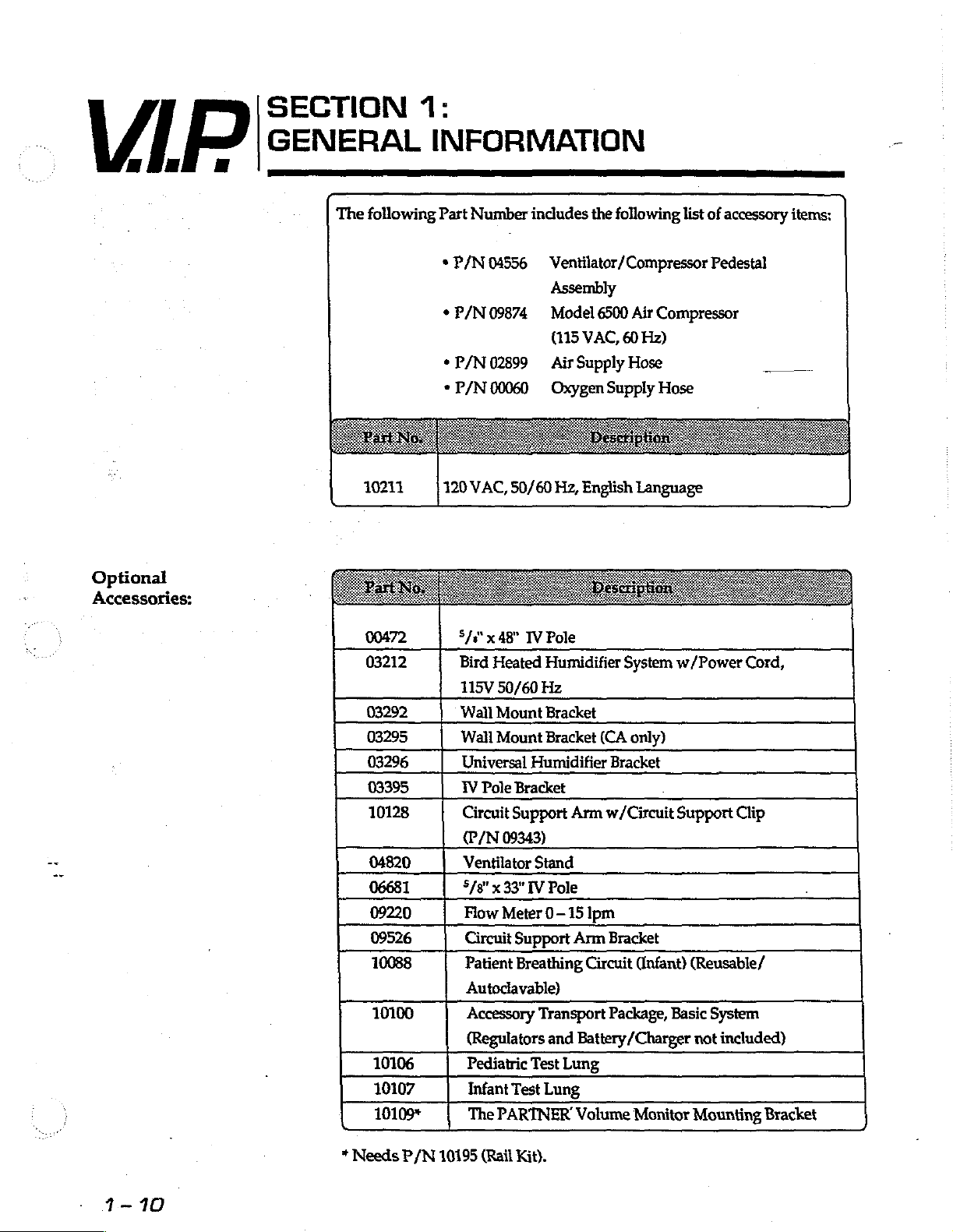

The

following

fa

10211

INFORMATION

Part

Number

*

P/N04556 | Ventilator/Compressor

»

P/N

*

P/N

*

P/N

09874

02899

00060

includes

the

following

Assembly

Model6500

(115

VAC,

60

Air

Supply

Oxygen

Hose

Supply

list

Air

Compressor

Hz)

Hose

of

accessory

Pedestal

items:

]

00472

03212

03292

03295

03296

03395

10128

04820

06681

09220

09526

10088

10100

10106

10107

し

10109*

*

Needs

P/N

10195

5/8 x 48”

Bird

115V

Wall

Wall

Universal

IV

Circuit

(P/N

Ventilator

5/8" x 33"

Flow

Circuit

Patient

Autoclavable)

Accessory

(Regulators

Pediatric

Infant

The

IV

Heated

50/60

Mount

Mount

Pole

Bracket

Support

09343)

IV

Meter

Support

Breathing

Test

PARTNER’

(Rail

Kit).

Pole

Humidifier

Hz

Bracket

Bracket

Humidifier

Stand

Pole

0-15

Transport

and

Test

Lung

(CA

Arm

Ipm

Arm

Circuit

Battery

Lung

Volume

System

Bracket

w/Circuit

Bracket

Package,

w/Power

only)

Support

(Infant)

Basic

/Charger

Monitor

Cord,

Clip

(Reusable/

System

not

included)

Mounting

Bracket

1-10

1.5

Ordering

Information

Optional

Continued

Accessories

10110

10134

10139*

10174R

10175R

10188

10194

10195

15050

15060

20107D

10175R

SS

Transport

Charger,

Patient

Autoclavable)

V.LP.

Pediatric

Monitor

Infant

Exhalation

Front

Rail

Hospital

The

Exhalation

Flow

Package,

115V

Breathing

BIRD

Flow

Flow

Panel

Kit

(V.LP.

Grade

PARTNER

Trigger

Complete

50/60

Circuit

Tray

Sensor

Sensor

Valve

Body

Protective

Top

Cover)

Outlet

Volume

Valve

Diaphragm

Sensor

w/Regulators

Hz

(Pediatric)

(for

the

PARTNER

Cover

Strip

Monitor

and

Battery/

(Reusable/

Volume

*

Needs

P/N

10195

(Rail

Kit).

Section

Warnings,

Cautions

&

21

Definitions

22

Warnings...

23 で auone

Notes

2.4

Notes

mn

mens

2.0

2e

2-1

2-3

24

1

V.I.P

BIRD®

Infant-Pediatric

Ventilator

Loading...

Loading...