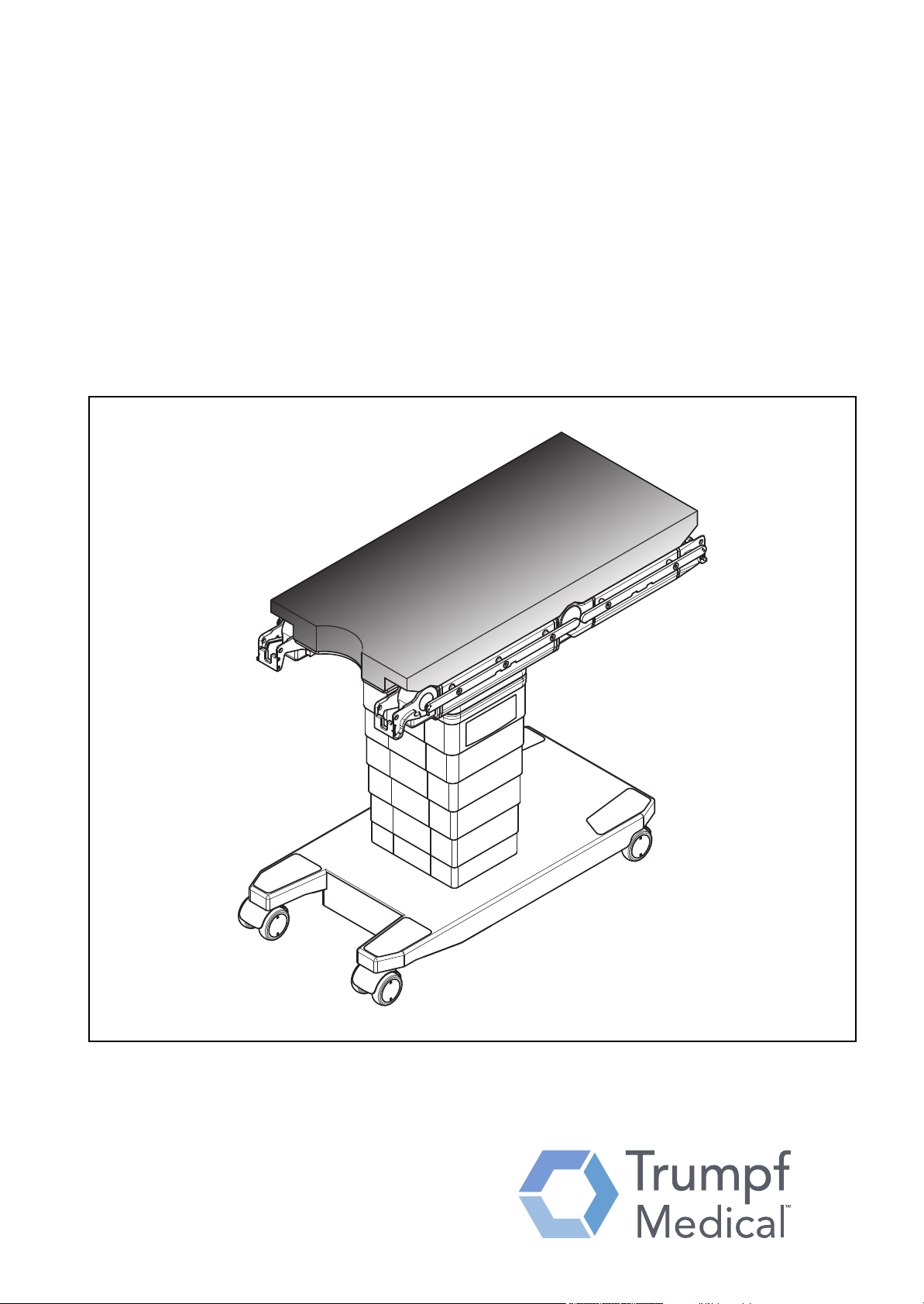

STERIS TruSystem 7000 User manual

TruSystem 7000 Operating Table

Service Manual

Translation of the original German service manual

CE mark/Conformity: This is a Class I medical device according to the Council Directive 93/

42/EEC concerning medical devices and is compliant with the Directive version currently in force

at the time of product sale. The manufacturer declares the conformity of this product with the

essential requirements of the Council Directive 93/42/EEC concerning medical devices

according to Appendix I, as well as the implementation of an assessment procedure required for

Class I product conformity under Appendix VII and documents this with the CE mark.

ETL mark: Intertek tested the product for the USA and Canada. ETL classification regarding risk

of electric shock and fire, as well as mechanical hazard in accordance with ULSTD 60601-1;

CAN/CSA STD C22.2 NO.601.1.

Manufacturer and

distributor

Sales TRUMPF Medizin Systeme GmbH + Co. KG

Telephone +49 89 80907–0

Fax +49 89 80907–40020

Technical Customer

Service

Telephone +49 3671 586–41199

Fax +49 3671 586–41175 +49 3671 586–41175

E-mail Service@trumpfmedical.com Service.wwo@trumpfmedical.com

TRUMPF Medizin Systeme GmbH + Co. KG

Carl–Zeiss–Straße 7–9

07318 Saalfeld

Germany

www.trumpfmedical.com

Benzstraße 26

82178 Puchheim

Germany

Germany other countries

+49 3671 586–41911

(24 hr service hotline)

We at TRUMPF Medical are constantly improving our products.

Therefore, we reserve the right to make changes to the format, equipment, and technology at any time.

Reprinting, copying or translating this document, in whole or in part, is forbidden without the express written

permission of TRUMPF Medizin Systeme GmbH + Co. KG.

TRUMPF Medizin Systeme GmbH + Co. KG expressly reserves all rights under copyright law.

Within the bounds of the legal requirements, the manufacturer is responsible for the technical safety characteristics

of this apparatus only if the maintenance, repairs, and modifications to this apparatus are performed by him or

by someone appointed by him and in accordance with his instructions.

© TRUMPF Medizin Systeme GmbH + Co. KG Revision level: 2016–10–06

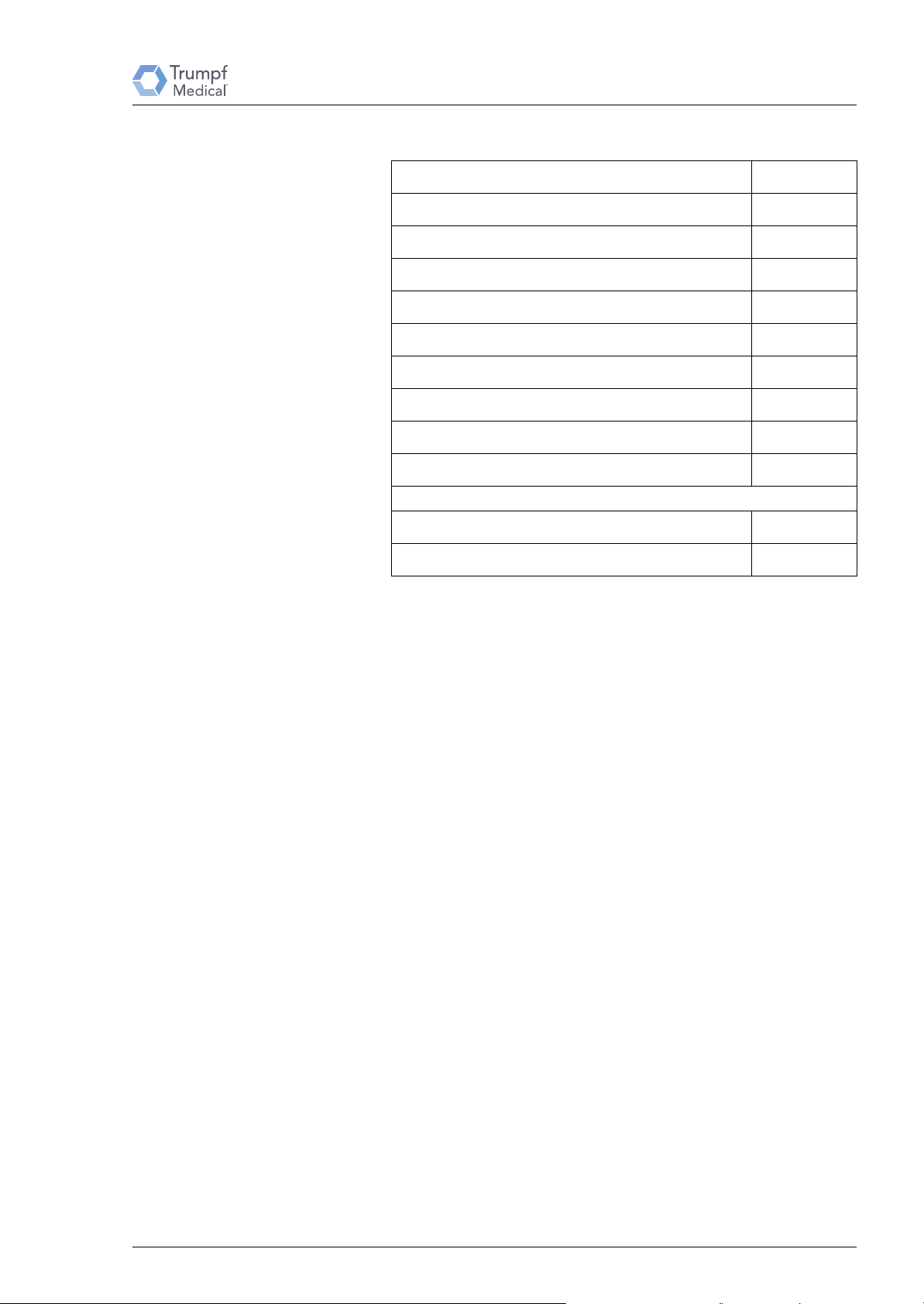

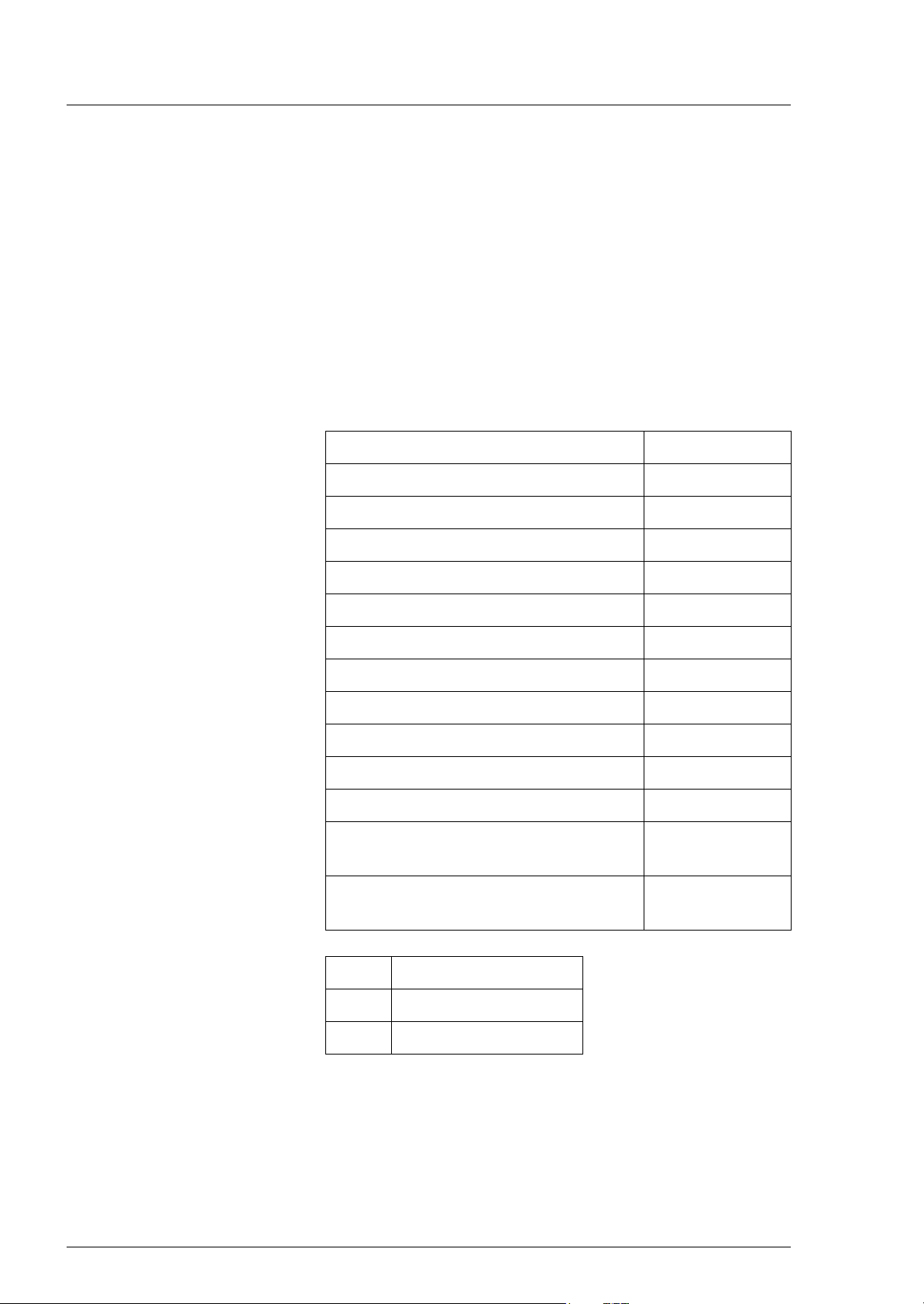

This service manual applies to the following sales units:

Product name Mat. no.

TruSystem 7000 1841046

TruSystem 7000 V 1841050

Operating table TruSystem 7000 U 1604788

TruSystem 7000 (MBW) 1841048

TruSystem 7000 (MBW) V 1841082

Operating table TruSystem 7000 U (MB) 1604786

TruSystem 7000 (dV) 1841049

TruSystem 7000 (dV) V 1841083

Operating table TruSystem 7000 U (dV) 1723633

Cable remote control TS7000 U 1767067

Cable remote control TS7000 U (dV) 1798326

Service Manual TruSystem 7000 Operating Table – 1 764 986 – 10/2016

Service Manual TruSystem 7000 Operating Table – 1 764 986 – 10/2016

Contents

Contents

1 Important Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2 Safety information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

2.1 Safety during repair work . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

2.2 Liability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

2.3 Disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

2.4 Explanation of Symbols. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

2.5 Glossary. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

2.6 Operating Table Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

3 Remote control ▸System◂ (secured) menu . . . . . . . . . . . . . . . . . . . . . . . 19

4 Test procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

5 Safety information for the batteries (#1533137) . . . . . . . . . . . . . . . . . 24

6 Tools, measuring equipment and auxiliary tools . . . . . . . . . . . . . . . . . . 26

7 Preparing the Operating Table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

8 Open and close the lower column cover . . . . . . . . . . . . . . . . . . . . . . . . 30

9 Open and close the top column cover . . . . . . . . . . . . . . . . . . . . . . . . . . 31

10 Disconnecting and reconnecting the internal power supply on the

operating table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

11 Emergency adjustment for the lift . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

12 Mechanical parts of the table top . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

12.1 Table top . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

12.2 Pad plate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

12.3 Center box cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

12.4 Leg section gear box. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

12.4.1 Operating table without side rail at the joint . . . . . . . . . . . . . . . . . . . . . . . . . . 42

12.4.2 Operating table with side rail at the joint. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

12.5 Back section gear box . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

12.6 Energy chain . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

12.7 Linear guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

12.8 Toothed rack . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

12.9 Longitudinal travel toothed belt. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

12.10 Retrofit kit for the side rail of the leg section joint . . . . . . . . . . . . . . . . . . . . . . . 54

13 Electrical parts of the table top . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

13.1 Motor controller circuit board. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

13.2 Communications controller circuit board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

13.3 Battery on the communications controller circuit board. . . . . . . . . . . . . . . . . . 60

13.4 Drive unit for leg section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Service Manual TruSystem 7000 Operating Table – 1 764 986 – 10/2016 5

Contents

13.5 Leg section motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .63

13.6 Back section drive unit (back section bar) . . . . . . . . . . . . . . . . . . . . . . . . . . . . .65

13.7 Back section motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .67

13.8 Longitudinal travel motor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .69

13.9 CAN distributor circuit board (center box) . . . . . . . . . . . . . . . . . . . . . . . . . . . .71

13.10 CAN distributor circuit board (bar) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .72

13.11 Endolight interface circuit board. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .74

14 Mechanical parts of the column . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

14.1 Column cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .75

14.2 Metal panel with the column keypad . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .77

14.3 Bellows . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .78

14.4 Frame (connection ring) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .79

14.5 Toothed belt from the Trendelenburg drive . . . . . . . . . . . . . . . . . . . . . . . . . . . .81

14.6 Toothed belt from the tilt right drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .84

14.7 Toothed belt from the tilt left drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .87

14.8 Main cardan . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .90

14.9 Ratchet brace . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .91

14.10 Telescopic spindle. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .93

14.10.1 Telescopic spindle - Variant 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .93

14.10.2 Telescopic spindle - Variant 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .96

14.11 Toothed belt from the main drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

14.12 Toothed washer of the telescopic spindle . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

15 Electrical parts of the column . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

15.1 Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

15.2 Power supply unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

15.3 Power supply socket . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

15.4 Column keypad. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

15.5 Speaker . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

15.6 Lift motor assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

15.7 Trendelenburg assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

15.8 Tilt right assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 122

15.9 Tilt left assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125

15.10 Trendelenburg motor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 128

15.11 Tilt right motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 130

15.12 Tilt left motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 132

15.13 Connector / power supply / relay board (power supply socket). . . . . . . . 134

15.14 Column controller circuit board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 135

15.15 Cardan with sensor (Trendelenburg drive) . . . . . . . . . . . . . . . . . . . . . . . . . . 137

15.16 ISM module circuit board. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 139

15.16.1 Option A . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 139

15.16.2 Option B . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 139

15.17 Retrofit ISM module (Mat. No. 2064680) . . . . . . . . . . . . . . . . . . . . . . . . . . 141

16 Mechanical parts of the table base . . . . . . . . . . . . . . . . . . . . . . . . . . . 143

16.1 Wheel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 144

16.2 Hinged foot on wheel (floor lock) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 146

6 Service Manual TruSystem 7000 Operating Table – 1 764 986 – 10/2016

Contents

17 Electrical parts of the table base . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 148

17.1 Drive unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 149

17.2 Control module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 152

17.3 Line power socket . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 154

17.4 Power input fuses. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 155

17.5 Buttons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 156

18 Hydraulic parts of the table base. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 158

18.1 Information on the hydraulics system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 158

18.2 Refilling oil in the assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 160

18.3 Bleeding the hydraulic system. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 161

18.4 Coil on the pump assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 163

18.5 Locking cylinder with hose . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 166

18.6 Hose #1 through #4 with coupling (on the locking cylinder). . . . . . . . . . . . 169

18.7 Assembly with valve block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 174

19 Cabling overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 177

20 Table top cables. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 180

20.1 Ground wire_24 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 181

20.2 Cable W174 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 183

20.3 Cable W165 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 184

20.4 Cable W166 and W167 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 185

20.5 Cable W168 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 187

20.6 Cable W169 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 188

20.7 Cable W170 and W171 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 189

20.8 Coupling point sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 191

20.8.1 Operating table without side rail at the joint . . . . . . . . . . . . . . . . . . . . . . . . . 191

20.8.2 Operating table with side rail at the joint. . . . . . . . . . . . . . . . . . . . . . . . . . . . 192

20.9 OR sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 195

20.10 Cable W193 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 196

20.11 Cable W190/W191 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 198

21 Column cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 199

21.1 Cable W104 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 200

21.2 Cable W159 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 203

21.3 Cable W160 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 205

21.4 Cable W161 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 207

21.5 Cable W164 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 209

21.6 Cable W134 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 213

21.7 Cable W172 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 215

21.8 Cable W173 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 217

21.9 Cable W107 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 219

21.10 Cable W108 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 221

21.11 Cable W109 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 223

21.12 Cable W110 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 225

21.13 Reset switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 227

21.14 Power sensor on the Trendelenburg drive . . . . . . . . . . . . . . . . . . . . . . . . . . . 229

21.15 Cable adapter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 230

Service Manual TruSystem 7000 Operating Table – 1 764 986 – 10/2016 7

Contents

21.15.1 Option A . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 230

21.15.2 Option B . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 230

22 Table base cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 232

22.1 Cable W150 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 233

22.2 Cable W151 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 236

22.3 Cable W152 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 238

22.4 Cable W153 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 240

22.5 Cable W154 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 242

22.6 Cable W155 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 244

22.7 Cable W177 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 247

22.8 Cable W156 and W158 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 249

22.9 Cable W157 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 251

22.10 Cable W175 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 253

22.11 Cable W162 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 256

22.12 Ground wire _25 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 258

23 Quick-connect coupling on the assembly . . . . . . . . . . . . . . . . . . . . . . . 260

24 Adjustment and calibration tasks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 262

24.1 Adjusting the spindle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 262

24.2 Align the bars . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 265

24.3 Calibrate leg section motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 266

24.4 Calibrate back section motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 266

24.5 Calibrate longitudinal travel motor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 267

24.6 Calibrate tilt / Trendelenburg motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 267

24.7 Calibrate lift motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 268

25 Control units. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 269

26 Technical assistance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 270

26.1 Operating conditions in battery-operated mode. . . . . . . . . . . . . . . . . . . . . . 270

26.2 Audio signals operating status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 271

26.3 Visual error signals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 272

26.4 Status display on the battery LED . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 274

26.5 Monitoring tilt and Trendelenburg position angles . . . . . . . . . . . . . . . . . . . . 275

27 Components with serial numbers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 276

28 Fuse overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 279

29 Torque overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 280

30 Maintenance and repair . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 281

30.1 Maintenance log content . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 281

30.2 List of high-wear parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 283

31 Lubrication schedule. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 284

31.1 Column . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 284

31.2 Table top . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 284

8 Service Manual TruSystem 7000 Operating Table – 1 764 986 – 10/2016

Contents

31.3 Table base. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 285

31.4 Components (leg section for example) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 285

32 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 286

33 Functional overview of electrical components . . . . . . . . . . . . . . . . . . . 291

34 Circuit diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 295

35 Hydraulics Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 299

36 Service Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 303

Service Manual TruSystem 7000 Operating Table – 1 764 986 – 10/2016 9

Contents

10 Service Manual TruSystem 7000 Operating Table – 1 764 986 – 10/2016

1Important Information

This manual and any repair steps specified herein must be observed

and followed. Repairs may be performed only by service

technicians from TRUMPF Medizin Systeme GmbH + Co. KG or by

personnel authorized, trained, and certified by Trumpf Medical.

Only the repairs and settings listed in this guide or known to you

from the appropriate service training by our technical support

service may be performed! Repairs not covered in these instructions

may be performed only after consulting with the TRUMPF Medical

Technical Service department or by Trumpf Medical itself.

Unauthorized or provisional repairs are not permitted even if a

customer so requests. All laws, legal regulations and standards must

be observed and adhered to. Only use original spare parts

designated by Trumpf Medical as spare parts. Defective parts that

are not in proper working order must be replaced with original

spare parts, even if it is beyond the scope of the repair order! After

repairs, return cables to their original installed positions and avoid

any shearing or crushing. After each repair, recheck the electrical

connections against the circuit diagram before performing a

functional test. After all repairs or adjustments, a functional test has

to be performed in accordance with these instructions or relevant

standards. Recheck the position of the cables during and following

all equipment positions!

Important Information

Germany

Only deliver the device to the customer in the tested state with

full functionality! Hand-over to the customer must be effected in

writing with confirmation from the customer. The functionality

must be demonstrated to the customer!

Proper use of and instructions on how to operate the TruSystem

7000 operating table can be found in the instruction manual.

The Service Center will be grateful for any corrections and tips for

more efficient repairs. For questions or feedback please contact:

TRUMPF Medizin Systeme GmbH + Co. KG

Technical Customer Service

Carl-Zeiss-Str. 7–9

07318 Saalfeld

Germany

Telephone +49 3671 586–41199

(24 hr service hotline)

Fax 03671 586 –41175

E-mail Service@trumpfmedical.com

Internet www.trumpfmedical.com

Service Manual TruSystem 7000 Operating Table – 1 764 986 – 10/2016 11

Important Information

Other countries

Telephone +49 3671 586–41911

Fax + 49 3671 586–41175

E-mail Service.wwo@trumpfmedical.com

Internet www.trumpfmedical.com

12 Service Manual TruSystem 7000 Operating Table – 1 764 986 – 10/2016

2 Safety information

2.1 Safety during repair work

• Important: use only stainless-steel screws of strength class 70 on

the operating table! Comply with the torque specified for

tightening screws.

•For all screws ≥ M4 without split lock washers, use a mediumstrength screw locking agent. Notice, the agent can be

loosened again by heating the screws with a hair dryer.

• Protective work clothing:

Do not wear clothing which can become caught in the

equipment. Shirt and jacket sleeves should be buttoned or rolled

up.

Tie or put up long hair.

Tuck the ends of scarves, ties or shawls into your clothing or pin

them down. Loose clothing can be a hazard!

For activities that are moderately dangerous for the eyes, wear

protective glasses (e.g., for soldering work or when removing

taut springs and fasteners, when hammering in or hammering out

pins or similar parts).

Safety information

Protection against

infection

• Do not perform any activity that may put other people in danger

or that can make the device a source of danger!

• Store removed housing and other machine parts in a safe place

while working. Always store tools or removed parts in such a

way that no one can stumble and fall over them. Keep the area

around the device clean and tidy during and after maintenance

work.

• Do not let any screws, nuts or other parts fall into the column.

Immediately remove any parts that fell in. Parts that have not

been removed can damage other components or cables when

the OR table is adjusted. Important! The operating table may not

be released to the customer if parts fell in and were not removed.

• After performing work, reattach protective devices and replace

them if necessary. This includes, for example, covers, cable ties,

cable mounts, cable shields, ground and potential conductor

connections, and power connections. Check connection of

equipotential bonding conductor/grounding cable in

accordance with the applicable standards.

• Risk of infection throughout the entire hospital! Follow all safety

measures, behavioral rules and hygiene requirements. Follow

the requirements of the medical facility for protecting against

infection.

Service Manual TruSystem 7000 Operating Table – 1 764 986 – 10/2016 13

Liability

• Perform maintenance and repair work only on disinfected

operating tables! Disinfection is performed by the medical

facility.

• Perform work in the OR area only with appropriate

authorization.

• Immediately seek a physician in the event of a complaint of

possible infection. Inform the doctor you were working in a

hazardous area - even if this was several months prior.

Prevention against

infection

2.2 Liability

2.3 Disposal

• Ask the doctor about possible risks and discuss how to avoid

them in your work as a medical service technician.

• Get a hepatitis B inoculation if advised by a physician. A booster

shot is required every 3 to 5 years. The incubation period for

hepatitis B is 1 to 6 months!

TRUMPF Medizin Systeme GmbH + Co. KG IS LIABLE ONLY for

reliable and proper functionality of the operating table IF

• installation, modification, and repairs are performed by

Trumpf Medical service technicians or by personnel authorized,

trained, and certified by Trumpf Medical.

• the operating table is used properly in accordance with the

instruction manual.

The products must be recycled in an environmentally friendly

manner. Disposal, including that of individual parts, must be

environmentally friendly, i.e., in accordance with the legal

regulations currently in force. For information on proper disposal of

old equipment, please contact either Technical Service at

Trumpf Medical, your local sales representative, or the appropriate

national agency Trumpf Medical will take back your old equipment

or products that are defective or no longer used. For detailed

information, contact Technical Service.

When decommissioning an operating table, the lithium ion batteries

have to be removed by a Trumpf Medical service technician or a

person trained and authorized by Trumpf Medical. Return removed

and unusable batteries in suitable packaging to Trumpf Medical

Technical Service. Important: the returns must be declared as

hazardous materials of class 9/UN3480! Trumpf Medical will

take responsibility for the environmentally proper disposal of the

battery.

14 Service Manual TruSystem 7000 Operating Table – 1 764 986 – 10/2016

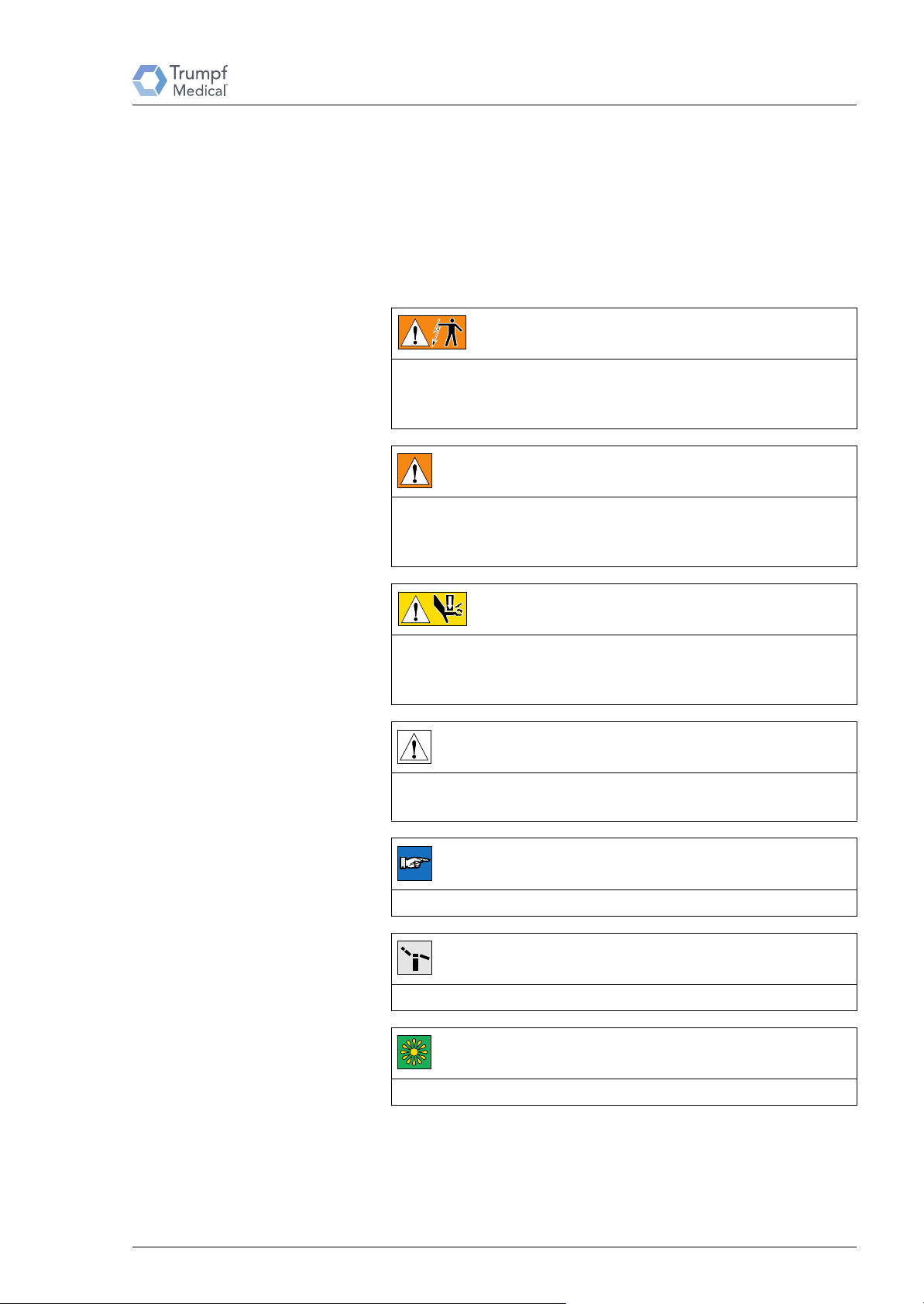

2.4 Explanation of Symbols

Important information in these repair instructions is marked with

symbols and keywords. Keywords such as DANGER, WARNING

or CAUTION indicate the level of danger involved. The symbols

emphasize the message visually. Additional symbols can indicate

injury hazards or danger to life and limb. The measures to prevent

hazards must be observed.

Refers to a directly imminent danger that will result in death or

serious injuries if the appropriate precautionary measures are not

taken.

Refers to a directly imminent danger that can result in death or

serious injuries if the appropriate precautionary measures are not

taken.

Explanation of Symbols

DANGER

Risk of death (for example, electric shock)!

WARNING

Risk of death!

CAUTION

Risk of injury (for example, crushing)!

Refers to a possible danger that can lead to slight to moderate

injury or damage to the equipment if the appropriate precautionary

measures are not taken.

CAUTION

Risk of material damage!

Refers to a possible danger that can lead to equipment damage if

the appropriate precautionary measures are not taken.

NOTE

Additional useful information and tips.

TEST

Performing functional tests, measurements and tests

ENVIRONMENT

Information on environmentally friendly disposal.

Service Manual TruSystem 7000 Operating Table – 1 764 986 – 10/2016 15

Glossary

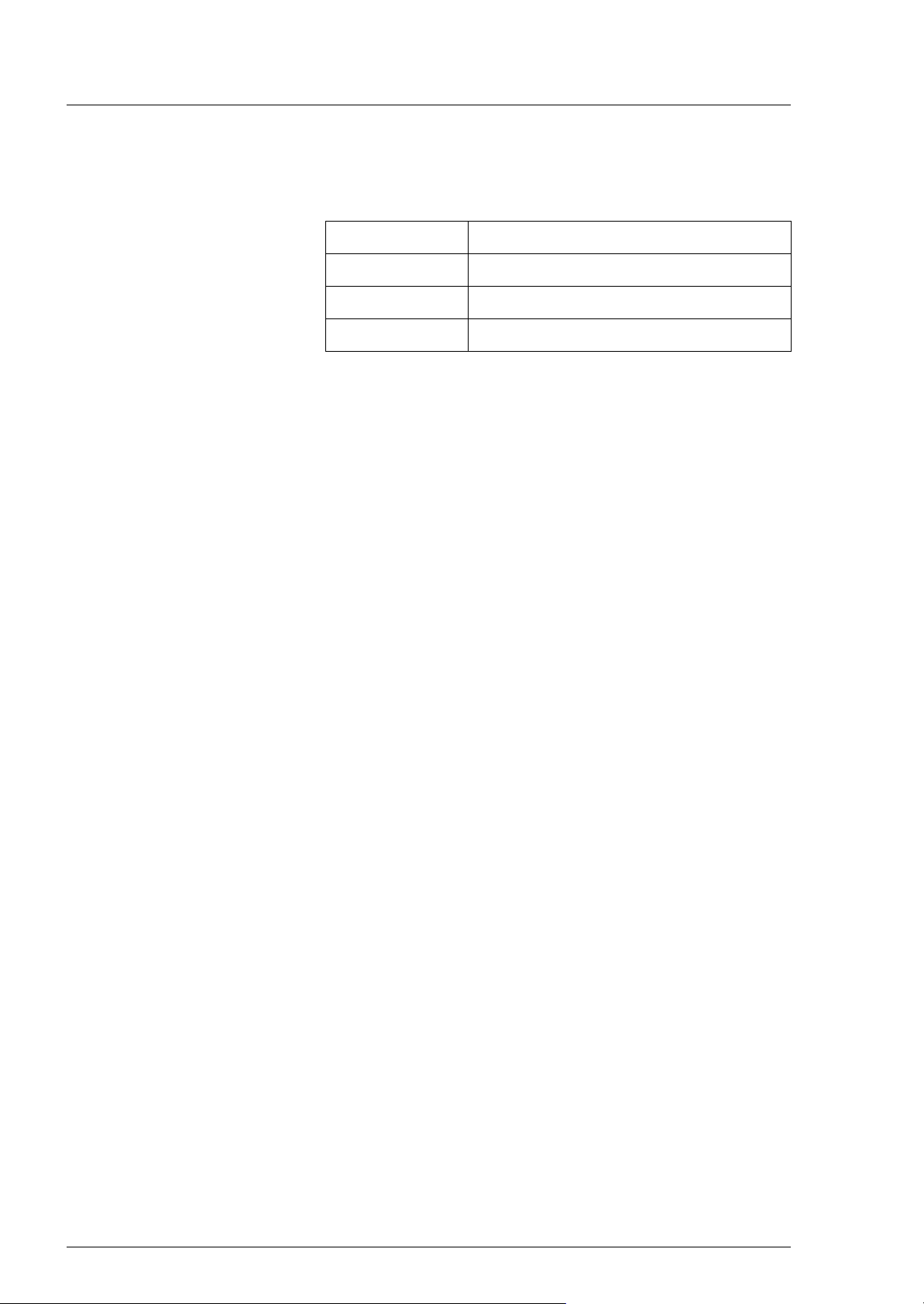

2.5 Glossary

The following terms and abbreviations are used in these repair

instructions:

Abbreviation Explanation

#Material number

Trumpf Medical TRUMPF Medizin Systeme GmbH + Co. KG

Service Center Technical Service at Trumpf Medical

16 Service Manual TruSystem 7000 Operating Table – 1 764 986 – 10/2016

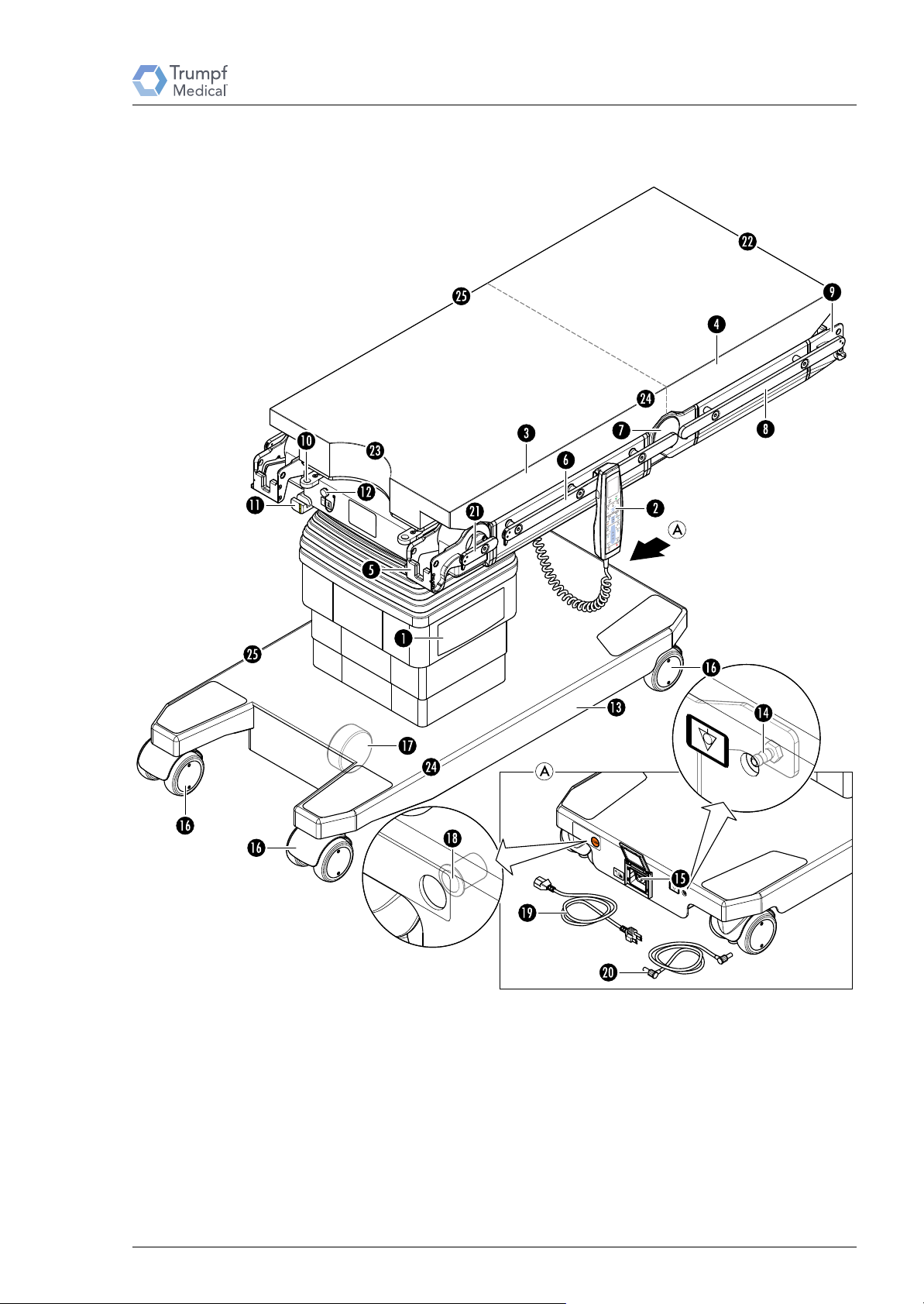

2.6 Operating Table Overview

Operating Table Overview

Key:

[1] Column keypad

[2] Remote control

[3] Seat section

[4] Back section

[5] Motorized leg section joint with fixture L

[6] Side rail for seat section

[7] Motorized back section joint

Service Manual TruSystem 7000 Operating Table – 1 764 986 – 10/2016 17

Operating Table Overview

Key:

[8] Side rail for back section

[9] Fixture S

[10] Insertion opening for extension adapter

[11] Bayonet locking mechanism for extension adapter

[12] Control unit connector socket (head and foot end)

[13] Table base

[14] Connector pin for equipotential bonding cable

[15] Connector socket for power cable

[16] wheel

[17] Wheel for table base support (directional travel/drive mode)

[18] Key for emergency release of the table 's base (under the

label)

[19] Power cable

[20] Equipotential bonding cable

[21] Side rail for leg section joint

*1

[22] Head end

[23] Foot end

[24] Left side

[25] Right side

*1

not available on all operating table variants

18 Service Manual TruSystem 7000 Operating Table – 1 764 986 – 10/2016

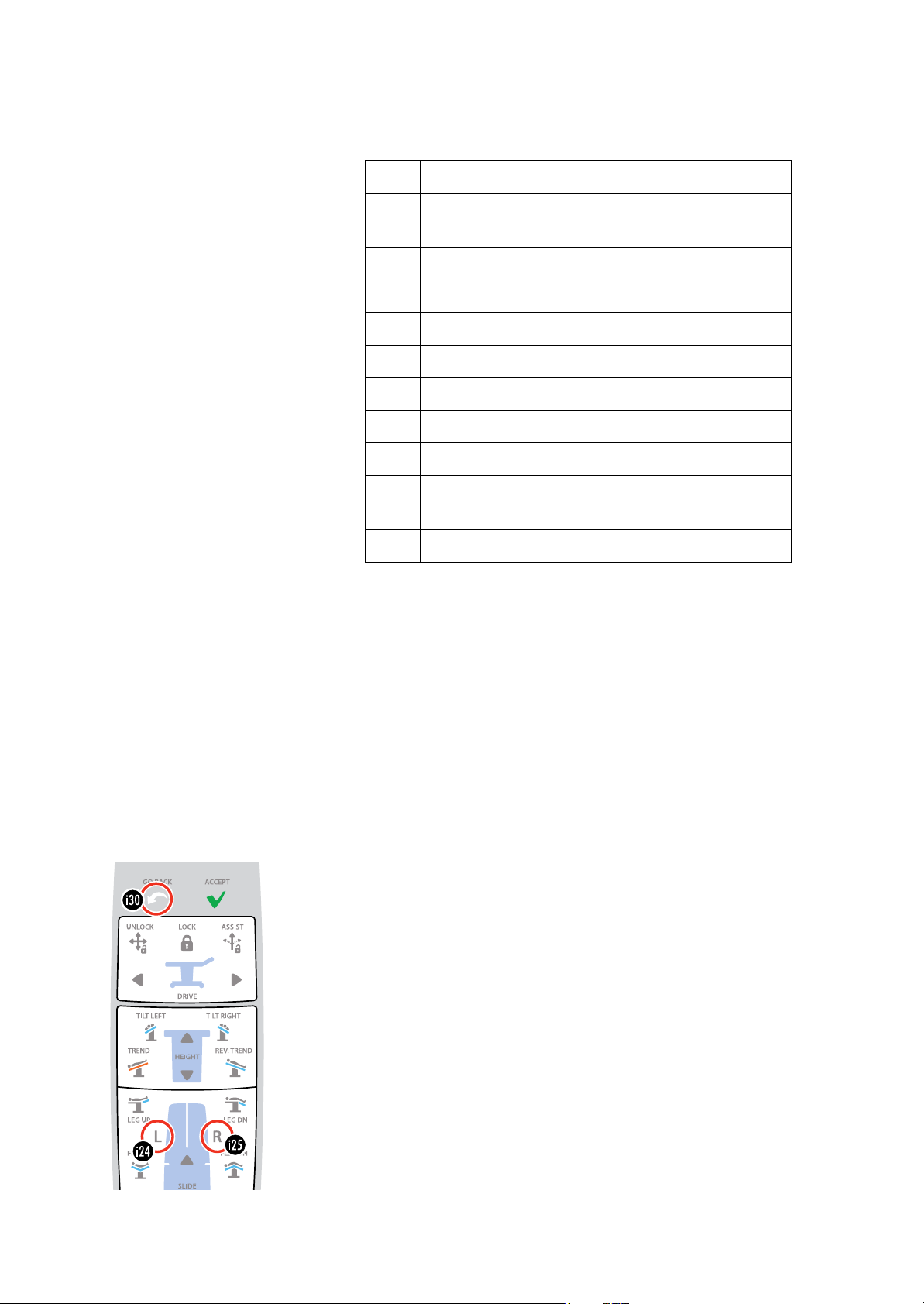

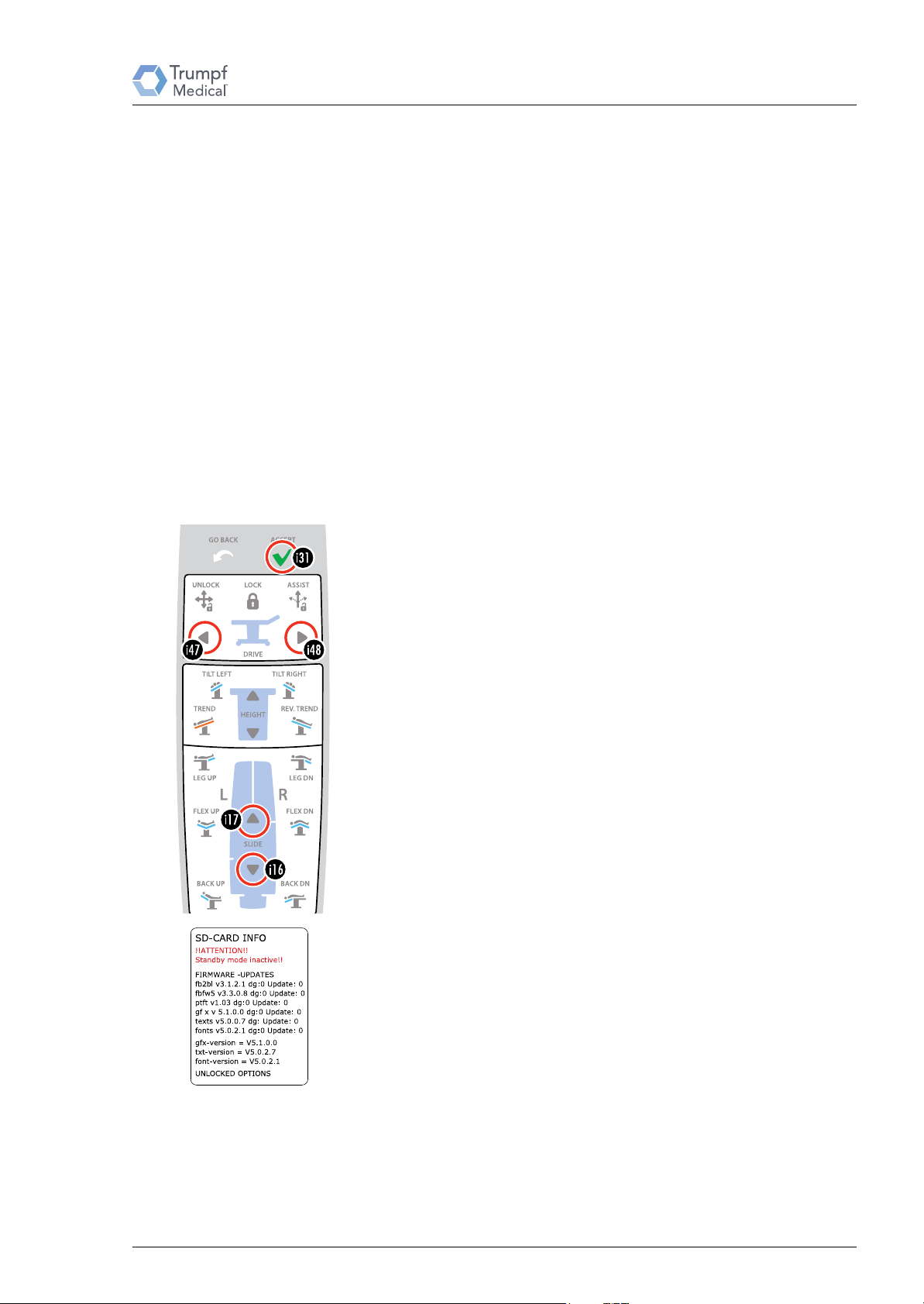

Remote control ▸System◂ (secured) menu

3Remote control ▸System◂ (secured) menu

The ▸System◂ menu and its functions are available only with the

Cable remote control TS7000 U (#1767067).

The ▸System◂ (secured) submenu is located under the ▸Settings◂

menu item on the touch screen. This menu item is passwordprotected and accessible only to trained Trumpf Medical service

technicians. The password, which is set at the factory, is available

from the Service Center.

The individual numbers (0 to 9) of the password (code) are set

using the arrow keys [i16]/[i17]/[i47] and [i48]. The cursor

flashes at the currently active position. After it is entered, confirm the

password with the OK [i31] key.

The ▸System◂ menu contains the following displays and settings:

–1. ▸Display of HW/SW states◂

–2. ▸Block RC on Key Error◂

–3. ▸Show Key Error Status◂

–4. ▸Component Test◂

–5. ▸Motion Sensor Test◂

–6. ▸Key test FB◂

–7. ▸LED test FB◂

–8. ▸Start Flash update◂

–9. ▸Error memory exp.◂ (export)

– 10. ▸End emergency mode◂

– 11. ▸Reset or table◂

– 12. ▸Factory defaults◂

– 13. ▸Network address◂

– 14. ▸Set IR code◂

– 15. ▸Change password◂

– 16. ▸Acceleration sensor active◂

– 17. ▸Display battery state◂

– 18. ▸ISM parameters◂

– 19. ▸SD Card Info◂

– 20. ▸Show all messages◂

– 21. ▸Touch sensors inactive◂

– 22. ▸Test touch sensors◂

– 23. ▸Request service mode◂

NOTE

Standby mode is switched off for most of the settings in the

▸Settings◂ menu.

Service Manual TruSystem 7000 Operating Table – 1 764 986 – 10/2016 19

Remote control ▸System◂ (secured) menu

1. ▸Display of HW/SW states◂

Line Meaning

1 Hardware state and software version of the

application

2 Serial number

3 Graphics version

4Text version

5 Character set version

6 Upper shell software version

7 Boot loader version

8 Software package version

9 Motor controller and communication processor

version (presently without function)

10 Radio module software version

2. ▸Block RC on Key Error◂

This function can be used to block remote control if a keyboard

error was determined.

3. ▸Show Key Error Status◂

The display shows which key has an error.

4. ▸Component Test◂

The menu item delivers a function test for all hardware

components (touch, motion sensor). Do not make any settings

using this menu item.

5. ▸Motion Sensor Test◂

Tilt sensor test

6. ▸Key test FB◂

The key test function lets you check the functionality of the

individual keys on the remote control, except for the

ANCEL [i30] key. The key functions are not executed. When

C

the key is pressed, the (hexadecimal) key code is shown on the

display. No key code is shown for the keys that select joints

(L [i24]/R [i25]).

7. ▸LED test FB◂

During the remote control LED test, the background illumination

of the individual keys is tested in sequence.

8. ▸Start Flash update◂

No function at this time.

20 Service Manual TruSystem 7000 Operating Table – 1 764 986 – 10/2016

Remote control ▸System◂ (secured) menu

9. ▸Error memory exp.◂ (export)

No function at this time.

10. ▸End emergency mode◂

No function at this time.

11. ▸Reset or table◂

No function at this time.

12. ▸Factory defaults◂

No function at this time.

13. ▸Network address◂

The LAN and W-LAN IP address is shown.

Important: the IP address must be read from right to left. For

example, 1.2.3.4 is shown on the display. The correct IP

address is 4.3.2.1.

14. ▸Set IR code◂

No function at this time.

15. ▸Change password◂

You can change the password that has been set at the factory.

The individual numbers (0 to 9) of the password are set using

the arrow keys [i16]/[i17]/[i47] and [i48]. The cursor flashes

at the currently active position. After it is entered, confirm the

password with the O

K [i31] key.

16. ▸Acceleration sensor active◂

The motion sensor can be switched off if frequent shaking in the

area prevents standby mode. The sensor for activating the

remote control from the standby mode is active when the

display is marked by an * (asterisk). To activate or deactivate

the sensor press the OK [i31] key.

17. ▸Display battery state◂

Function is not active.

18. ▸ISM parameters◂

Function is not active.

19. ▸SD Card Info◂

Menu item delivers information on the version of the text and

graphics files.

20. ▸Show all messages◂

The operating table transmits system information in an

encrypted code to the remote control. The most important

system information (e.g., error messages, status reports) are

stored in plain text messages and are displayed on the remote

control. Upon activating the ▸Show all messages◂ function, all

system information is displayed. The ▸Show all messages◂ is

Service Manual TruSystem 7000 Operating Table – 1 764 986 – 10/2016 21

Remote control ▸System◂ (secured) menu

21. ▸Touch sensors inactive◂

22. ▸Test touch sensors◂

23. ▸Request service mode◂

identified by an * (asterisk). To activate or deactivate (normal

state) the messages press the O

K [i31] key.

Function is not active.

Touch screen fields are shown on the display. When one of

the individual fields is touched, the respective active field is

marked yellow.

Activate service mode

22 Service Manual TruSystem 7000 Operating Table – 1 764 986 – 10/2016

4 Test procedures

Test procedures

As the medical products from Trumpf Medical are distributed

worldwide, uniform guidelines for electrical retesting should be

used.

According to the IEC 60601-1 standard, the limit values according

to the CF classification apply when testing applied parts. Based on

the design type, the Trumpf Medical electric operating tables only

include one applied part of Class B.

Furthermore, the Trumpf Medical product-specific prescribed retests

and safety checks are obligatory.

Germany International

In Germany, initial testing and

retesting of electrical devices

are governed by the stipulations

of the accident prevention

regulation BGV A3.

VDE 0751-1 is the standard that

In countries with different

national legislation, the countryspecific standards and

guidelines for the retesting of

electrical medical devices are

mandatory.

serves as the basis for retesting

of electrical medical devices.

Therefore in accordance with

the VDE 0751-1 standard noted

above, the specifications based

on IEC 60601-1 are definitive

for Trumpf Medical medical

devices.

All maintenance work must be carried out with the help of the

maintenance protocol and take into consideration the spare or

wearing parts list and the lubrication plan (see page 284).

Conduct a complete functional test after service work is completed.

Service Manual TruSystem 7000 Operating Table – 1 764 986 – 10/2016 23

Safety information for the batteries (#1533137)

5 Safety information for the batteries (#1533137)

The TruSystem 7000 operating table contains two lithium ion

batteries. Because of their size (number of individual cells plugged

in, amount of lithium contained), they are classified as a hazardous

material. There is a risk of explosion in case of fire. As a result, there

are legal ordinances regarding the handling, deployment, and

installation of this type of battery.

The lithium ion batteries were specially developed by

Trumpf Medical. An electronic protective circuit on a circuit board

in the housing monitors the threshold values of the current / voltage

data. The electrical connection outward is provided through a

7W2 D-Sub socket.

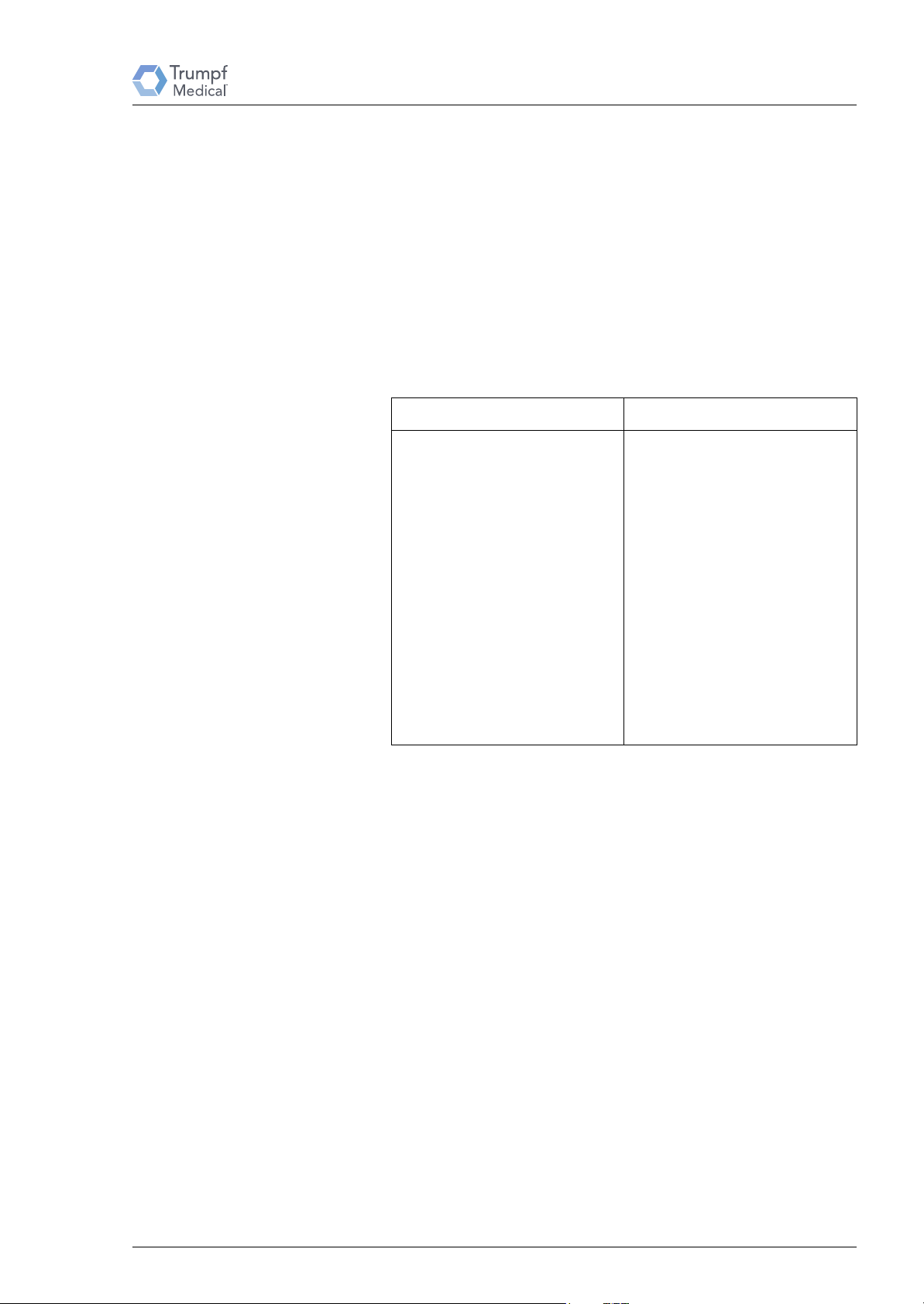

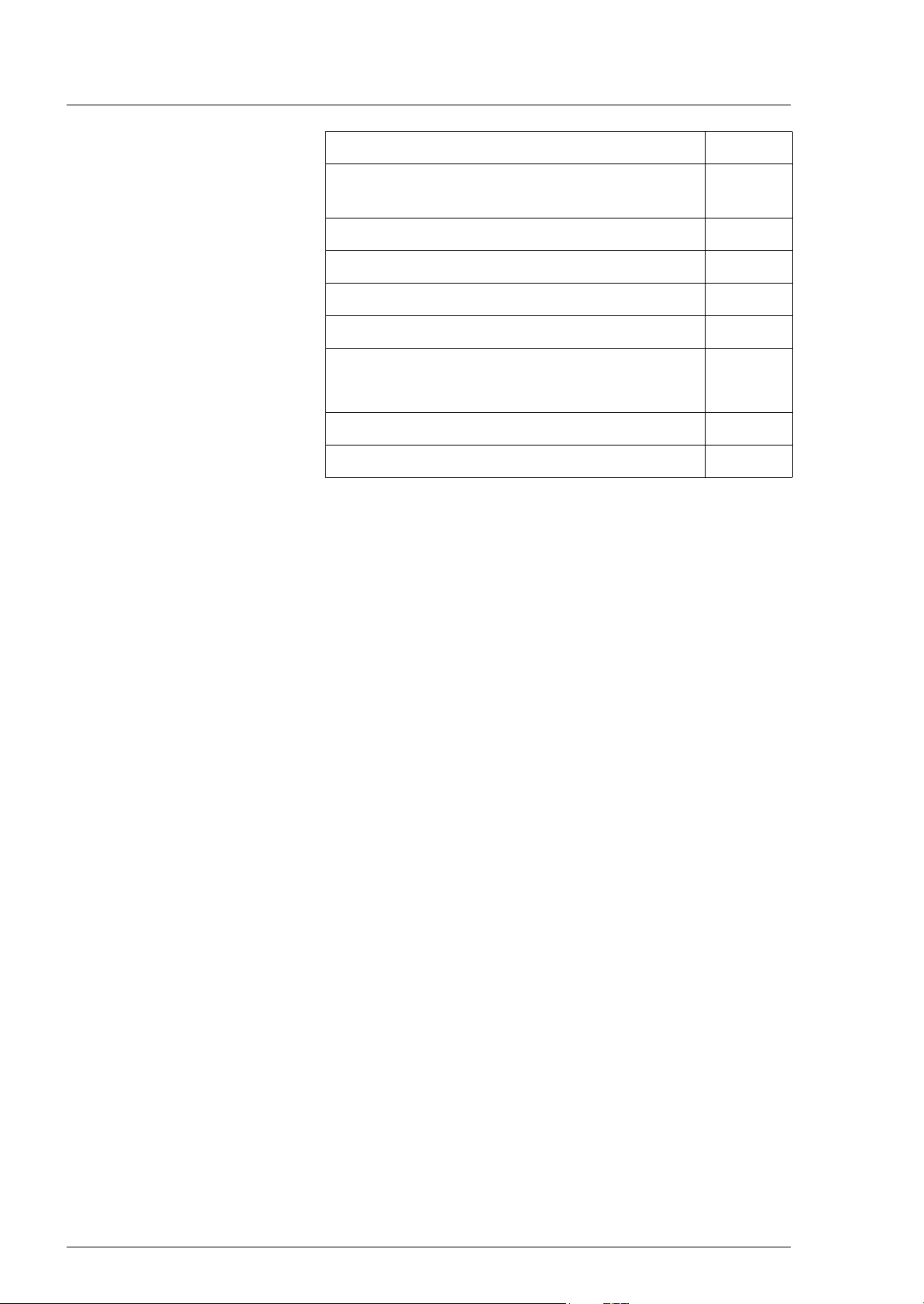

Technical parameters Threshold values

Nominal voltage (3.7 V/cell) 40.7 V

Nominal capacity (2.4 Ah/cell) 4.8 Ah

Handling on/in

operating table

Working voltage range 37 V…45.1 V

Shutdown undervoltage (2.4 V / cell) approx. 26 V

Shutdown overvoltage (4.35 V / cell) approx. 48 V

Shutdown overcurrent 20 A

Self-discharge current with active battery 180 μA

Max. discharge current over 2 min. 8 A

Max. continuous discharge current 4.8 A

Charging time with 3 A charge current Approx. 3 hrs

Storage temperature range – 40 °C to 80 °C

Max. internal battery temperature during

discharge

Max. internal battery temperature during

charge

Battery Position

1on power supply

60 °C

40 °C

2 on lift motor

The battery is connected using cable W134 (#1538234) for

battery 1 and W172 (#1538235) for battery 2. The battery is

directly connected or disconnected using the corresponding

connection cable in the operating table. There are no special

measures, such as a connection sequence on the power supply. A

24 Service Manual TruSystem 7000 Operating Table – 1 764 986 – 10/2016

Safety information for the batteries (#1533137)

battery is inserted or removed using the carrying strap. The column

base has two diagonal guide pins that position the battery housing.

Battery 1 is secured in place by a special plate (battery

bracket_power supply). Battery 2 is secured by the spiral cable

holder_rear.

Storage For extended battery storage, the manufacturer recommends a

charge level of approx. 40 %. For storage, as a guide

Trumpf Medical recommends a no-load voltage of approx. 43 V

for the battery charge level. Batteries should be stored in a cool, dry

place.

Charging/

discharging

The batteries are usually charged in the operating table by the

power supply. During external charging, the maximum charge

current equals 2.4 A. The maximum charge voltage of 45.1 V may

not be exceeded. A rechargeable battery is full (stops charging)

when the charging current falls below 100 mA for at least 1 minute.

The maximum discharge current for a period of no more than 2

minutes may not exceed 8 A. Important: there is no temperature

monitoring when the battery is used as an external energy source.

The threshold temperatures may not be exceeded.

To prevent hazards, the battery state is monitored automatically in

the operating table.

Transport All batteries must undergo a Trumpf Medical certified safety test

before being released for general use. To ship a battery, use the

manufacturer's special transport packaging (reusable packaging).

Disposal Return removed and unusable batteries in suitable packaging to

Trumpf Medical Technical Service. Important: the returns must be

declared as hazardous materials of class 9/UN3480!

Trumpf Medical will take responsibility for the environmentally

proper disposal of the battery.

Service Manual TruSystem 7000 Operating Table – 1 764 986 – 10/2016 25

Tools, measuring equipment and auxiliary tools

6 Tools, measuring equipment and auxiliary tools

Tools

Basic tools and equipment

Allen wrench set

Open wrench set

Philips head screwdriver

Slotted screwdriver

Side cutting pliers

Nylon mallet

Thickness gauge

Retainer ring pliers

Circlip pliers with check screw

Slide hammer

Special tools Mat. no.

Torque wrench 2 Nm to 150 Nm

Measurement

equipment

(T) Hook wrench

for removing the leg section and back section motor

Product name Mat. no.

Multimeter

Cable tester

Electronic spirit level

Secutest SIII

(T) TS7000 lifting drive gauge

for setting the level position on the lifting motor

(T) TS7500 additional drives gauge

for setting the level position on the auxiliary drive motor

(T) Belt tension meter

to check the toothed belt tension on the Trendelenburg

and longitudinal travel motor

1484981

1729967

1525774

1798264

Spring balance

to check the toothed belt tension on the Trendelenburg

and tilt motor

26 Service Manual TruSystem 7000 Operating Table – 1 764 986 – 10/2016

Tools, measuring equipment and auxiliary tools

Product name Mat. no.

Auxiliary tools

(T) Adjustment gauge TS7000

1817764

for aligning the two bars

(T) Overlay for joint setting TS7500

1525777

Support point for the spirit level (for example when

setting the level position on the back section motors).

At least two overlays are required.

Product name Mat. no.

(T) Multifunction tool

1553708

for placing the operating table on its side

(T) Star wheel

1800121

for placing the operating table on its side

(T) Spring balance bracket

1814183

to set the toothed belt tension on the Trendelenburg

and tilt motor

M6x60 retaining screw

Lubricants and

additives

for securing the column cover

M5 clamping screw

to set the toothed belt tension on the Trendelenburg

and tilt motor

2 M8x60 retaining screws

for securing the telescopic spindle during emergency

adjustment of the lift

Cable tie

Product name Mat. no.

Terostat MS 939 adhesive 4150068

Loctite 5203 sealant 4150054

Loctite 5699 sealant 4150065

omniFIT 100 M screw locking agent 4150018

omniFIT 200 M screw locking agent 4150020

Thread-locking adhesive UHU weak fast 4150046

Thermal grease 4150060

Service Manual TruSystem 7000 Operating Table – 1 764 986 – 10/2016 27

Tools, measuring equipment and auxiliary tools

Product name Mat. no.

THERMOPLEX® ALN 250 EP low-viscosity gear

1483750

grease

®

TURMOGREASE

LI 802 EP special grease 1473385

TURMOPLEX® L220 lubricant 4150047

PROFI-TURBO-GREASE® spray 4150050

Klüberlectric KR 44-120 1557674

Castrol Hyspin DSP 32

1864008

Mineral oil (viscosity of 32) for refilling the assembly

Care and cleaning kit 4159014

Alcohol (degreasing agent)

28 Service Manual TruSystem 7000 Operating Table – 1 764 986 – 10/2016

7 Preparing the Operating Table

Before beginning repair work, prepare the operating table in

accordance with the following work steps:

Preparing the Operating Table

1.

CAUTION

Danger of infection!

Note to hygienic conditions at the site, and clarify any

questions concerning protection against infection with the

doctor in charge. Before beginning work, have the medical

facility confirm that all necessary measures for protection

against infection have been implemented. Perform repairs

only after protection of personnel against infection is ensured.

2. Lock operating table (brake)

3. Move to the level position on the operating table.

4. Remove all table components and accessories from the

operating table and store them in a safe place.

5. Move the operating table to the most elevated position.

6. Disconnect the operating table from the external power supply

(first remove the power cable plug from the insulated contact

receptacle and then from the connection socket on the table

base).

7. Remove the pad from the table top so that it is not damaged

during repair.

During repair work, do not make any adjustments to the operating

table except those explicitly specified.

Service Manual TruSystem 7000 Operating Table – 1 764 986 – 10/2016 29

Open and close the lower column cover

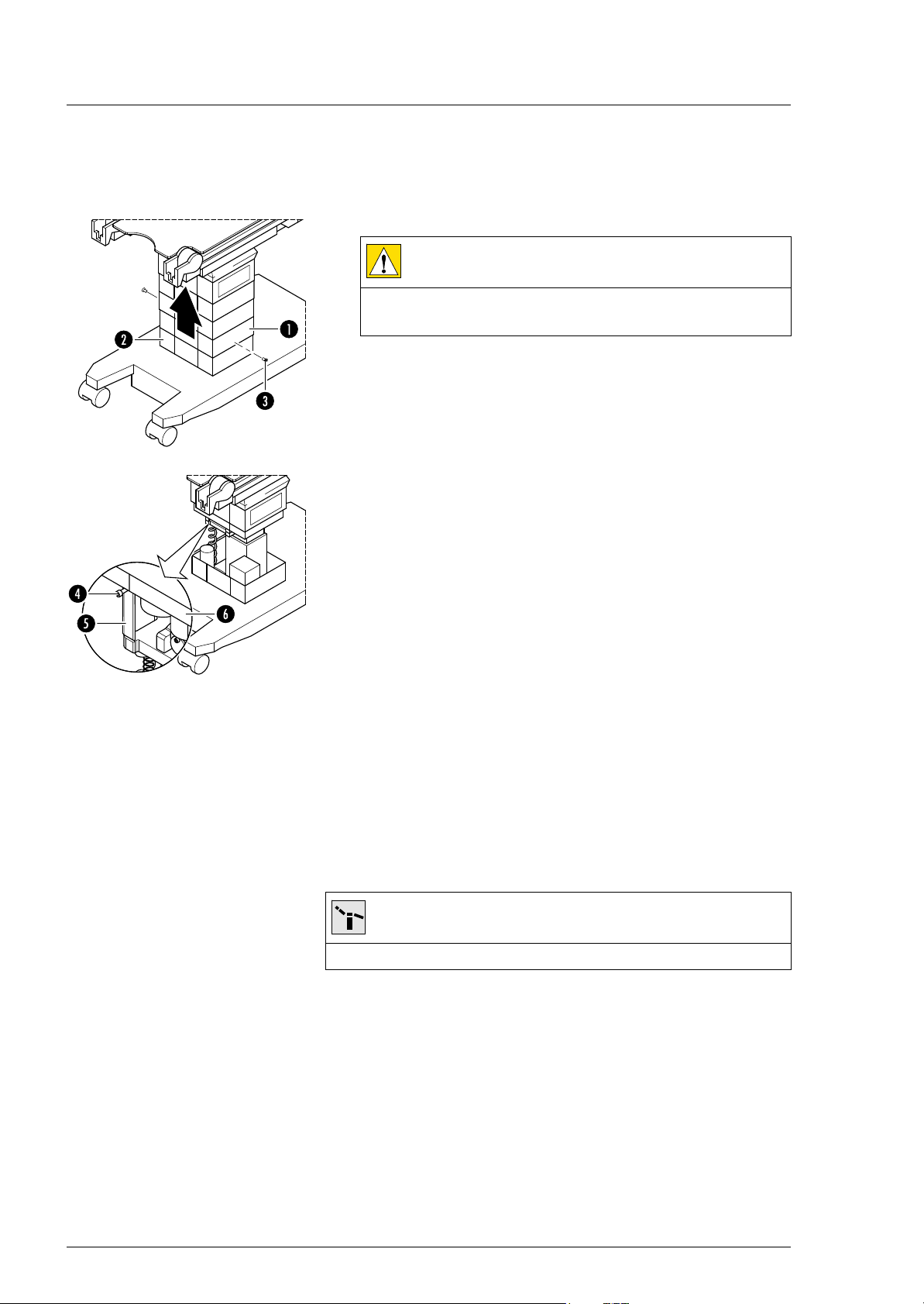

8 Open and close the lower column cover

Open 1. Prepare the operating table (see chapter 7 on page 29).

2. Turn off the operating table.

CAUTION

Risk of injury due to capacitor voltage.

Switch off repeatedly if needed. No LEDs may be illuminated

on the column keypad!

3. Disconnect the lowest column cover [1] from the pot [2] (2

screws [3]).

4. Carefully slide the column cover upward, tighten the retaining

screw [4] on the Trendelenburg assembly [5], and place the

column cover [6] on the retaining screw.

Close 1. Grasp the column cover, remove the holding screw from the

Trendelenburg assembly and guide the cover carefully

downward.

2. Install the lowest column cover on the pot (2 screws).

3. Put on the pad.

4. Switch on the operating table at the column keypad.

5. Connect the operating table to the external power supply.

TEST

Perform a function test.

30 Service Manual TruSystem 7000 Operating Table – 1 764 986 – 10/2016

Loading...

Loading...