Steris Harmony LA Service manual

MAINTENANCE MANUAL

Harmony LA™ Surgical Lighting and Visualization

System

(06/22/05) P764330-226

A Word From STERIS Corporation

ADVISORY INDICATIONS FOR USE

The operation and maintenance procedures recommended by STERIS® are described in this manual.

Only these recommended maintenance procedures

should be followed.

A listing of the safety precautions to be observed

when operating and servicing this equipment can be

found in Section 1 of this manual. Do not operate or

service this equipment until you have become familiar with this information.

Any alteration of this equipment not authorized or

performed by STERIS Engineering Service which

could affect its operation will void the warranty,

could adversely affect sterilization efficacy, could

violate federal, state, and local regulations, and could

jeopardize your insurance coverage.

The Harmony

tion System is a variable pattern, variable intensity

surgical lighting fixture designed to provide visible

illumination of the surgical field or the patient for the

operating room staff.

TM

LA Surgical Lighting and Visualiza-

© 2005, STERIS Corporation All rights reserved. Printed in U.S.A.

i

764330-226

Table of Contents

Section Title Page

Section 1: Listing of Safety Precautions..........................................................................1-1

1.1 Definition of Symbols ..................................................................................................................................1-4

Section 2: General Information ..........................................................................................2-1

2.1 General Description..................................................................................................................................... 2-1

2.2 Harmony LA 300/500/700 Lighthead Optical Performance ........................................................................... 2-1

2.3 Special Consumables ................................................................................................................................. 2-2

Section 3: Operating Instructions.....................................................................................3-1

3.1 General Instructions ....................................................................................................................................3-1

3.1.1 To Adjust Lighthead Intensity Levels: ................................................................................................ 3-1

3.1.2 Control Center ...................................................................................................................................3-1

3.1.3 Surgeon’s Control Buttons.................................................................................................................3-2

3.2 Harmony LA 500 Lighthead Lamp Failure Indications ..................................................................................3-2

3.3 Harmony LA 500 Lighthead Positioning ....................................................................................................... 3-3

3.4 Harmony LA 500 Lighthead Pattern Adjustment .......................................................................................... 3-4

3.5 Lighthandle and Lighthandle Cover .............................................................................................................. 3-4

3.5.1 Installing and Using Lighthandle and Lighthandle Cover ................................................................... 3-4

3.5.2 Metal Sterilizable Handle ................................................................................................................. 3-6

3.6 Harmony LA Monitor Arms .......................................................................................................................... 3-7

3.7 Install Flat Panel Monitor Yoke Handle Disposable Sterile Covers ...............................................................3-8

3.8 Video Camera Installation or Removal .........................................................................................................3-9

3.8.1 Installation .......................................................................................................................................3-9

3.8.2 Removal .......................................................................................................................................... 3-9

3.9 Lighthead Positioning with Video Camera .................................................................................................... 3-9

3.10 Video Camera Operation.......................................................................................................................... 3-10

3.10.1 HERMES-Ready Control Center .................................................................................................. 3-10

3.10.2 Optional Foot Control ................................................................................................................... 3-10

3.11 Guidelines for Maximizing Video Image ...................................................................................................3-11

3.11.1 Engage Manual Focus ................................................................................................................. 3-11

3.12 DeepSite control center status indicators ................................................................................................ 3-12

3.12.1 Intensity Level Status ................................................................................................................... 3-12

3.12.2 Lamp Life Status .......................................................................................................................... 3-12

Section 4: Service Mode ....................................................................................................4-1

4.1 Service mode procedure ............................................................................................................................. 4-1

4.2 Service Menu 1 Screen ............................................................................................................................... 4-1

4.3 Service Menu 2 Screen ............................................................................................................................... 4-2

4.4 Service Menu 3 Screen ............................................................................................................................... 4-3

Section 5: Theory of Operation .........................................................................................5-1

5.1 Suspension System .................................................................................................................................... 5-1

5.2 Major System Components .........................................................................................................................5-1

5.2.1 Harmony LA 500 LightHead ............................................................................................................. 5-1

5.2.2 Harmony LA 300 Lighthead ..............................................................................................................5-1

5.2.3 Harmony LA 700 Lighthead ..............................................................................................................5-1

5.2.4 Flat Panel Monitor Arm .................................................................................................................... 5-1

5.2.5 CRT Monitor Arm............................................................................................................................. 5-1

5.2.6 DeepSite Arm .................................................................................................................................. 5-2

5.2.7 Ambient Light .................................................................................................................................. 5-2

iii

764330-226

Section Title Page

Section 5: Theory of Operation (continued)

5.3 Control System ...........................................................................................................................................5-2

5.4 Lamp Power Explanation .............................................................................................................................5-2

5.5 Lamp Startup Explanation ...........................................................................................................................5-2

5.6 Lighthead BTU Output .................................................................................................................................5-3

5.7 Serial Number Explanation .......................................................................................................................... 5-3

5.8 Harmony LA Worldwide Release Control System Theory of Operation ......................................................... 5-3

Section 6: Inspection and Maintenance............................................................................6-1

6.1 General ....................................................................................................................................................... 6-1

6.2 Cleaning the Equipment ..............................................................................................................................6-1

6.2.1 Cleaning Implements ........................................................................................................................ 6-3

6.2.2 Areas To Be Cleaned......................................................................................................................... 6-3

6.2.3 General Cleaning/Disinfecting Procedure .......................................................................................... 6-3

6.2.4 Cleaning the Lens ............................................................................................................................. 6-3

6.2.5 Recommended Sterilization Techniques for the Metal Sterile Handle .................................................6-3

6.2.6 Cleaning Hand-held Control ............................................................................................................... 6-4

6.3 Lamp Replacement ..................................................................................................................................... 6-4

6.3.1 Replace Harmony LA 500 and LA 700 Lamps .................................................................................. 6-4

6.3.2 Reset Harmony LA 700 Lampholder ................................................................................................ 6-7

6.6.1 Reset Harmony LA 700 Lampholder ................................................................................................ 6-7

6.4 Routine Inspection ...................................................................................................................................... 6-8

6.5 Preventive Maintenance Guide ................................................................................................................... 6-8

6.6 Troubleshooting ........................................................................................................................................... 6-8

Section 7: Field Test Procedure .........................................................................................7-1

7.1 General ....................................................................................................................................................... 7-1

7.1.1 Special Tools Required ...................................................................................................................... 7-1

7.2 Scope ......................................................................................................................................................... 7-2

7.3 General Test ................................................................................................................................................ 7-2

7.4 Mechanical Test .......................................................................................................................................... 7-2

7.5 Optical Test (Harmony LA 500 & 700).......................................................................................................... 7-2

7.6 Suspension System Field Test Procedure ...................................................................................................7-3

7.7 Wall Control Field Test Procedure ................................................................................................................ 7-4

Section 8: Component Repair and Replacement.............................................................8-1

8.1 Brake Adjustment (all locations) .................................................................................................................. 8-1

8.2 Light or monitor Spring Arm Spring Tension Adjustment ..............................................................................8-2

8.2.1 Light Spring Arm.............................................................................................................................. 8-2

8.2.2 Monitor Spring Arm.......................................................................................................................... 8-2

8.3 Commutator Troubleshooting ....................................................................................................................... 8-2

8.4 Knuckle Cover Removal (Any) and Assembly .............................................................................................8-3

8.5 De-install harmony LA 500 Lighthead from the Suspension Arm ................................................................. 8-3

8.5.1 Before Installing Monitor Spring Arm ................................................................................................ 8-4

8.6 Removal of the Control Center Front Panel .................................................................................................. 8-5

8.7 Control Center Precautions ......................................................................................................................... 8-6

8.8 Commutator Replacement (Main Suspension, not spring arm) .................................................................... 8-7

8.9 Voltage Adjustment on Power Supply ......................................................................................................... 8-8

8.10 Electrical Connector Repair (Suspension System) ....................................................................................8-8

8.11 Using Test Harness to Isolate Wiring Faults ............................................................................................... 8-8

iv

764330-226

Section Title Page

Section 8: Component Repair and Replacement (continued)

8.12 Lens Clip Replacement Procedures ...........................................................................................................8-9

8.13 Use of Brake Ring Centering Tool for Harmony LA Lights ........................................................................ 8-12

8.14 Installation Instructions for Harmony LA Wedge Lock Shim Kit ............................................................... 8-13

8.14.1 Choosing Appropriate Shim ......................................................................................................... 8-13

8.15 Discoloration of Lightheads ..................................................................................................................... 8-14

8.16 Using Jumper Wires ................................................................................................................................ 8-14

8.16.1 Using Jumper Wires 755717-334 .................................................................................................. 8-14

8.16.2 Using Jumper Wires 755717-352 and 755717-353 ........................................................................ 8-14

8.16.3 Using Jumper Wire 755717-302 For Troubleshooting Harmony LA Camera System ...................... 8-15

Section 9: Illsutrated Parts Breakdown ............................................................................9-1

v

764330-226

List of Illustrations

Description Page Number

Section 3: Operating Instructions

Figure 3-1. Harmony Control Center Main Menu ................................................................................................ 3-1

Figure 3-2. Lighthead Surgeon’s Control Buttons (Harmony LA 500 Lighthead with Standard Handle Shown) .... 3-2

Figure 3-3. Lamp Status LED ............................................................................................................................ 3-2

Figure 3-4. Suspension Positioning ................................................................................................................... 3-3

Figure 3-5. Light Pattern Adjustment ................................................................................................................. 3-4

Figure 3-6. Standard Lighthandle ....................................................................................................................... 3-5

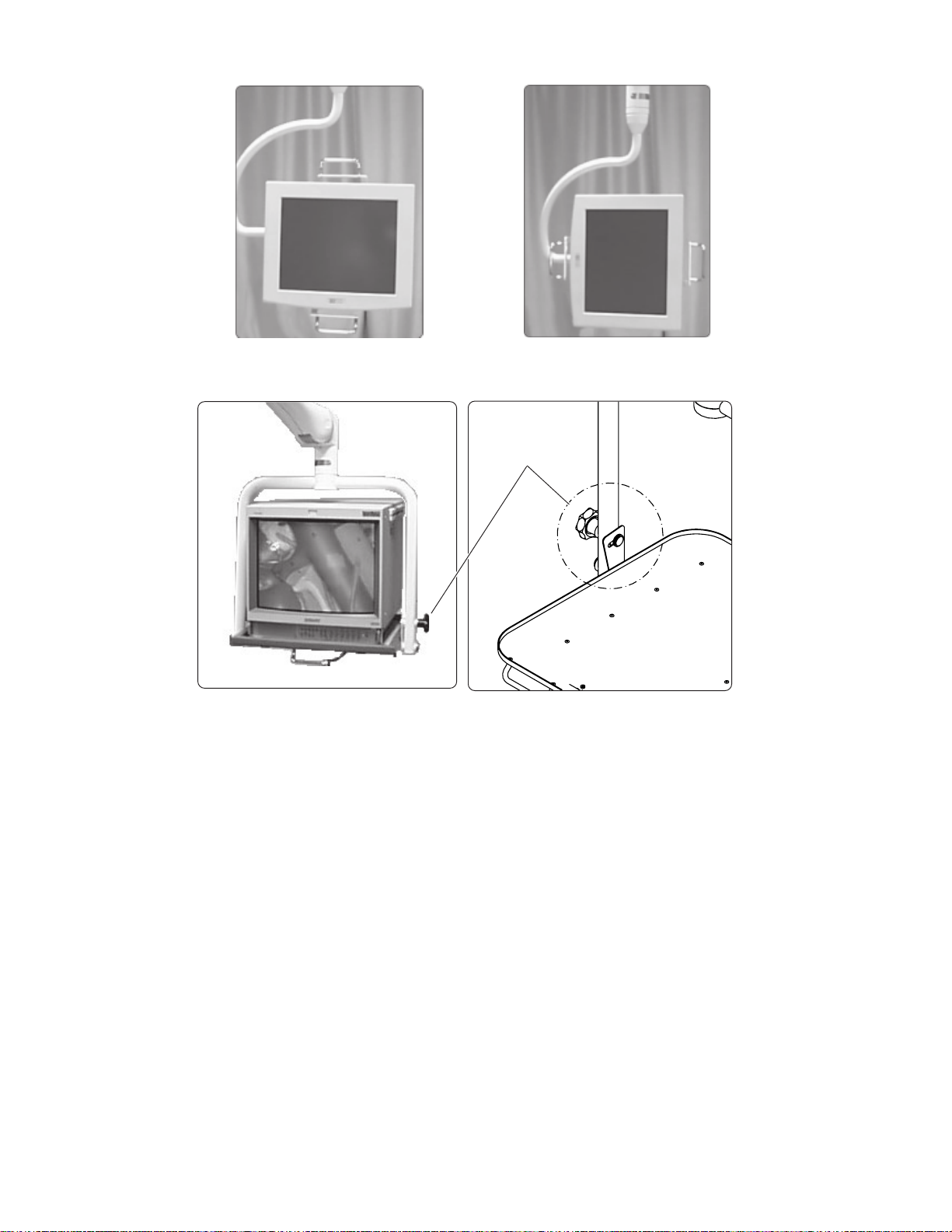

Figure 3-7. Harmony Monitor Configurations ...................................................................................................... 3-7

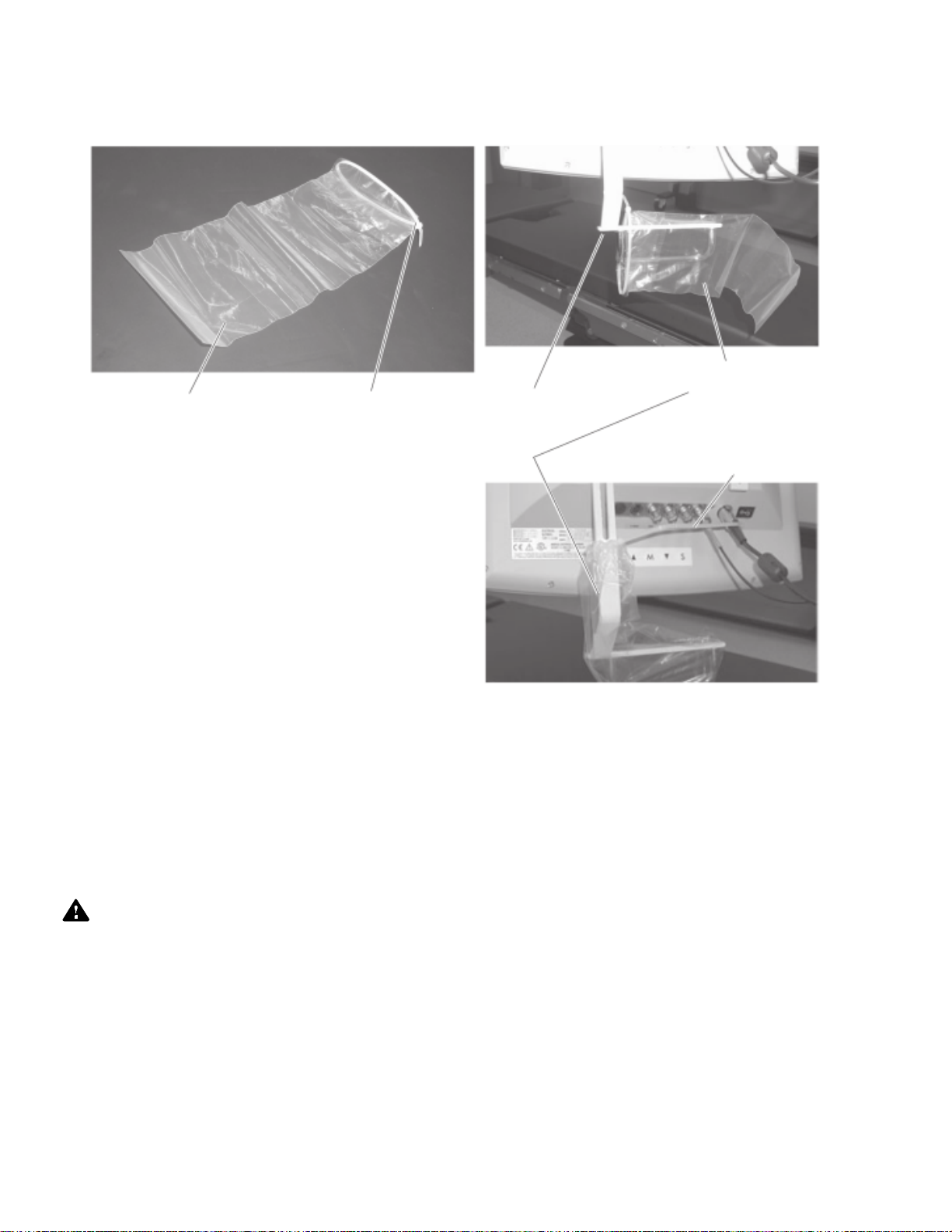

Figure 3-8. Installing Disposable Sterile Monitor Handle Covers ........................................................................ 3-8

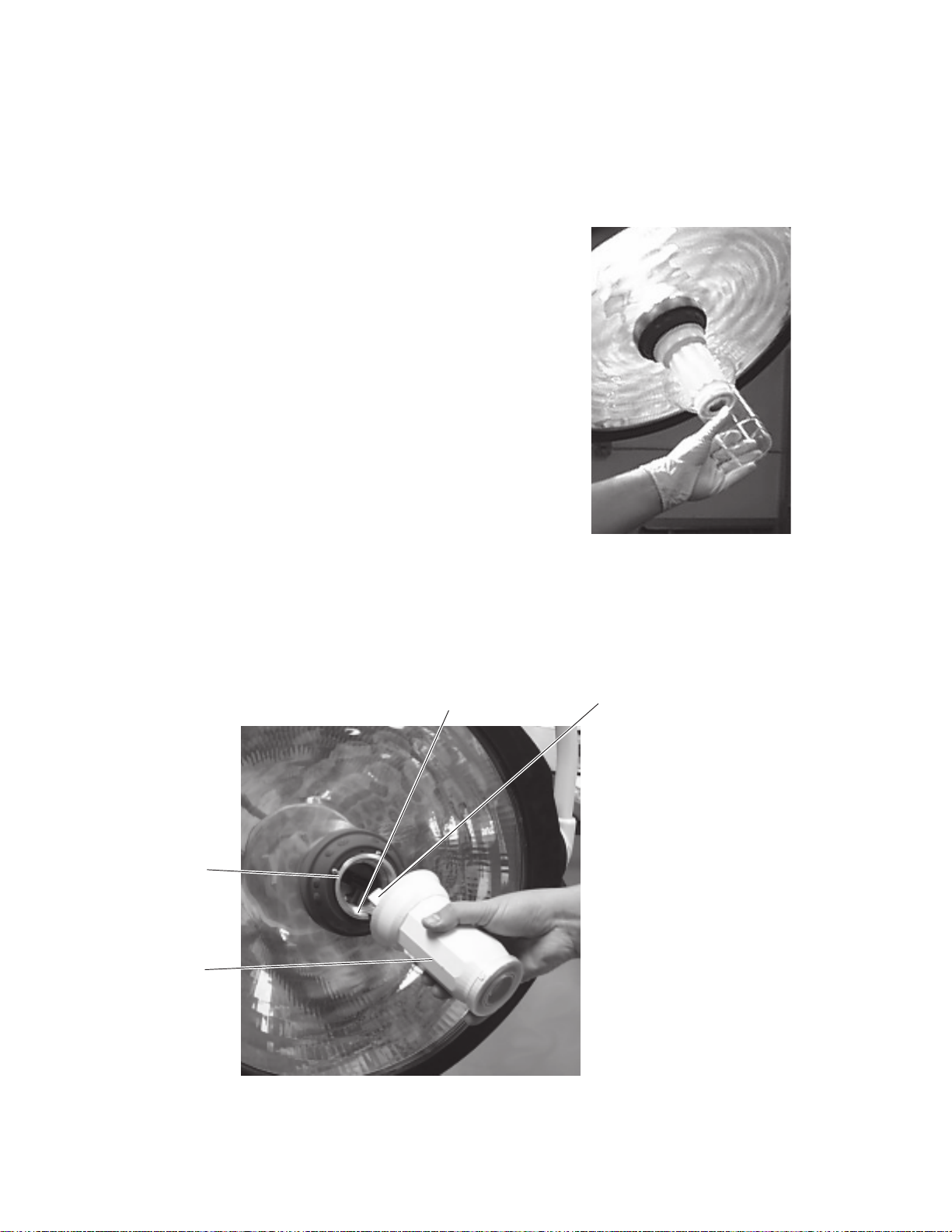

Figure 3-9. Optional Camera Installation ...........................................................................................................3-9

Figure 3-10. Install Camera Disposable Sterile Cover ........................................................................................ 3-9

Figure 3-11. Optional Camera Controllers ........................................................................................................ 3-11

Figure 3-12. DeepSite Control Center Indicators .............................................................................................. 3-12

Section 4: Service Mode

Figure 4-1. Service Menu 1 Screen .................................................................................................................... 4-1

Figure 4-2. Service Menu 2 Screen .................................................................................................................... 4-2

Figure 4-3. Service Menu 3 Screen .................................................................................................................... 4-3

Section 5: Theory of Operation

Figure 5-1. View of Global Control Power Status Boards ................................................................................... 5-4

Figure 5-2. Wedge Lock and Vertical Tube ......................................................................................................... 5-6

Figure 5-3. Typical Harmony LA System ........................................................................................................... 5-7

Figure 5-4. Domestic Medium/Large Lighthead Board Controller ........................................................................ 5-7

Figure 5-5. Domestic Harmony System Block Diagram .....................................................................................5-8

Figure 5-6. Domestic Deepsite Illuminator Box .................................................................................................. 5-8

Figure 5-7. Domestic Master Control Board w/DeepSite Interface Board & Analog Video Interface Board ......... 5-9

Figure 5-8. Domestic LCD Interface Board w/Membrane Switch Panel, Service Port AUX Port,

IR Receiver, & Foot Control Assembly ........................................................................................... 5-10

Figure 5-9. Domestic Power Supply & Power Status Module ........................................................................... 5-11

Figure 5-10. Domestic Remote Power Module ................................................................................................. 5-12

Figure 5-11. Domestic Hub Interface Board ..................................................................................................... 5-13

Figure 5-12. Domestic Hub Power Circuit ........................................................................................................ 5-13

Figure 5-13. Domestic Schematic ................................................................................................................... 5-14

Figure 5-14. Domestic Small Lighthead Controller Board ................................................................................. 5-15

Figure 5-15. Domestic Lighthead Camera Module ............................................................................................ 5-15

Figure 5-16. Domestic Video & Power Kits ...................................................................................................... 5-16

Figure 5-17. Global Medium/Large Lighthead Board Controller ......................................................................... 5-17

Figure 5-18. Global Harmony System Block Diagram ...................................................................................... 5-17

Figure 5-19. Global Deepsite Illuminator Box ................................................................................................... 5-18

Figure 5-20. Global Master Control Board w/DeepSite Interface Board & Analog Video Interface Board .......... 5-18

Figure 5-21. Global LCD Interface Board w/Membrane Switch Panel, Service Port AUX Port,

IR Receiver, & Foot Control Assembly ........................................................................................... 5-19

Figure 5-22. Global Power Supply & Power Status Module .............................................................................. 5-20

Figure 5-23. Global Remote Power Module ...................................................................................................... 5-21

vi

764330-226

List of Illustrations (Continued)

Description Page Number

Section 5: Theory of Operation (Continued)

Figure 5-24. Global Hub Interface Board .......................................................................................................... 5-21

Figure 5-25. Global Hub Power Circuit ............................................................................................................. 5-22

Figure 5-26. Global Schematic ........................................................................................................................ 5-23

Figure 5-26. Global Small Lighthead Controller Board ...................................................................................... 5-23

Figure 5-27. Global Lighthead Camera Module ................................................................................................ 5-23

Figure 5-28. Global Power & Video Kits ........................................................................................................... 5-24

Section 6: Inspection and Maintenance

Figure 6-1. Areas To Be Cleaned ....................................................................................................................... 6-2

Figure 6-2. Lamp Status LED ............................................................................................................................ 6-4

Figure 6-3. Lamp Replacement Procedure (Harmony LA 500 Lighthead Shown) ................................................ 6-6

Figure 6-4. Reset Harmony LA 700 Lampholder Lamp Position ......................................................................... 6-7

Section 7: Field Test Procedure

Figure 7-1. Inspect Wire Routing ........................................................................................................................7-2

Figure 7-2. Place Light Meter on Table ...............................................................................................................7-2

Figure 7-3. Check Secondary Spindle Stops ..................................................................................................... 7-3

Figure 7-4. Check Safety Ring and Safety Ring Pins ........................................................................................ 7-4

Figure 7-5. Check Hub Insterface Board Mounting and Connections ................................................................. 7-4

Section 8: Component Repair and Replacement

Figure 8-1. Adjust Lighthead/Yoke Brake Tension .............................................................................................. 8-1

Figure 8-2. Adjust Support Arm/Spring Arm Brake Tension ................................................................................ 8-1

Figure 8-3. Adjust Spring Arm/Yoke Brake Tension ............................................................................................8-1

Figure 8-4. Adjust Upper Support Arm Brake Tension ........................................................................................ 8-1

Figure 8-5. Remove Cover to Access Spring Arm Tension Adjustment .............................................................. 8-2

Figure 8-6. Adjust Spring Arm Tension ...............................................................................................................8-2

Figure 8-7. Monitor Spring Arm Tension Adjustment Access ............................................................................. 8-2

Figure 8-8. Harmony Wall Control ON/OFF Switch............................................................................................. 8-3

Figure 8-9. Push Spring Arm and Lighthead Toward Floor .................................................................................. 8-3

Figure 8-10. Safety Screw Locations ................................................................................................................. 8-4

Figure 8-11. Remove Lighthead .........................................................................................................................8-4

Figure 8-12. Gently Pull Wires from Lighthead. .................................................................................................. 8-5

Figure 8-13. Ensure Connections Are Secure .................................................................................................... 8-5

Figure 8-14. Fold Wiring into Loop ..................................................................................................................... 8-5

Figure 8-15. Tuck Looped Wires into Yoke Tube .................................................................................................. 8-5

Figure 8-16. Ensure Looped Wires are Dressed Away from any Moving Parts. ................................................ 8-5

Figure 8-17. Monitor Spring Arm Safety Pin Location ........................................................................................ 8-5

Figure 8-18. Loosen Screws at Top of Control Center Cover .............................................................................. 8-5

Figure 8-18. Remove Control Center Bottom Screws .........................................................................................8-6

Figure 8-19. Commutator Componenets Arragned for Assembly........................................................................ 8-7

Figure 8-20. Commutator ...................................................................................................................................8-8

Figure 8-21. Voltage Adjustment Screw............................................................................................................. 8-8

Figure 8-22. Wiring Fault Test Harness .............................................................................................................. 8-8

Figure 8-23. Check Clips ................................................................................................................................... 8-9

Figure 8-24. Check Lens Clips For Clearance .................................................................................................... 8-9

Figure 8-25. Lens Clip Clearance Detail View .................................................................................................... 8-9

vii

764330-226

List of Illustrations (Continued)

Description Page Number

Section 8: Component Repair and Replacement (Continued)

Figure 8-26. Recenter Reflector ....................................................................................................................... 8-10

Figure 8-27. Reposition Lens Assembly Using Lighthandle .............................................................................. 8-10

Figure 8-28. Rotate Lighthandle to Check for Binding ...................................................................................... 8-10

Figure 8-29. Lens Clips to Be Removed ......................................................................................................... 8-10

Figure 8-30. Check Lens Clip Alignment .......................................................................................................... 8-11

Figure 8-31. Insert Allen Wrenches into Lens Clips ......................................................................................... 8-11

Figure 8-32. Lift Lens Using Spare Lens Clip ................................................................................................... 8-11

Figure 8-33. Insert Spare Lens Clip ................................................................................................................. 8-11

Figure 8-34. Remove Lens Clip ....................................................................................................................... 8-11

Figure 8-35. Remove Allen Wrench ................................................................................................................. 8-12

Figure 8-36. Lide in New Lens Clip .................................................................................................................. 8-12

Figure 8-37. Wedge Lock Details ..................................................................................................................... 8-13

Section 9: Illustrated Parts Breakdown

Figure 9-1A. Harmony LA Surgical Light And Visualization Assembly, Complete............................................... 9-4

Figure 9-1B. Harmony LA Surgical Light And Visualization System Covers ....................................................... 9-6

Figure 9-2. Harmony LA Ceiling Plate Assembly ............................................................................................... 9-8

Figure 9-3A. Harmony LA Extension Arms - Dual Spindle ............................................................................... 9-11

Figure 9-3B. Harmony LA Extension Arms - Triple Spindle .............................................................................. 9-12

Figure 9-3C. Harmony LA Extension Arms - Triple Spindle With Spacer........................................................... 9-13

Figure 9-3D. Harmony LA Extension Arms - Dual Spindle With Spacer ............................................................ 9-14

Figure 9-4. Harmony LA Extension Arm For Flat Panel Or CRT Monitor .......................................................... 9-16

Figure 9-5A. Harmony LA Yoke - For Flat Panel Monitor .................................................................................. 9-18

Figure 9-5B. Harmony LA Yoke - For CRT Monitor ........................................................................................... 9-20

Figure 9-6. Harmony LA Spring Arms For FPM And CRT ................................................................................ 9-22

Figure 9-7. Harmony LA Spring Arm/Yoke - For Medium Lighthead.................................................................. 9-24

Figure 9-8A. Harmony LA 500 Lighthead ......................................................................................................... 9-26

Figure 9-8B. Harmony LA 700 Lighthead ......................................................................................................... 9-28

Figure 9-8C. Harmony LA Optical Hub ............................................................................................................. 9-30

Figure 9-9A. Harmony LA Wall Control Assembly ............................................................................................ 9-33

Figure 9-9B. Harmony LA Wall Control Assembly - Cables (Table) ................................................................... 9-34

Figure 9-9C. Harmony LA Wall Control Panel Assembly .................................................................................. 9-36

Figure 9-9D. Harmony LA Wall Control Panel Assembly (Global)...................................................................... 9-38

Figure 9-9E. Harmony LA Master Controller Assembly .................................................................................... 9-40

Figure 9-9F. Harmony LA LCD Display Assembly ............................................................................................ 9-42

Figure 9-10. Remote Power Module Assembly ................................................................................................ 9-44

Figure 9-11. Remote Power Module - Panel Assembly..................................................................................... 9-46

Figure 9-12. Remote Power Module Assembly with Auto Change Over (Global) .............................................. 9-48

Figure 9-13. Remote Power Module Back-Up Power Status Assembly Panel (Global) ..................................... 9-50

Figure 9-14. Low Profile Control Assembly ...................................................................................................... 9-52

Figure 9-15. Panel & Component Assembly (Low Profile) ................................................................................ 9-54

Figure 9-16. Harmony LA 500 Mobile Stand Assembly .................................................................................... 9-56

Figure 9-17. Mobile Stand Base Assembly ...................................................................................................... 9-58

Figure 9-18A. Custom Cable Kits (Table) ......................................................................................................... 9-60

Figure 9-18B. Custom Cable Kits (Table) ......................................................................................................... 9-60

Figure 9-18C. Custom Cable Kits (Table) ......................................................................................................... 9-61

viii

764330-226

List of Tables

Description Page Number

Section 2: General Information

Table 2-1. Lighthead Performance Data ............................................................................................................. 2-1

Table 2-1. Special Consumables........................................................................................................................2-2

Section 4: Service Mode

Table 4-1. Default Control Center Settings ......................................................................................................... 4-3

Section 5: Theory Of Operation

Table 5-1. Lighthead: Large Socket: Primary and Secondary ........................................................................... 5-2

Table 5-2. Lighthead: Medium Socket: Primary ................................................................................................ 5-2

Table 5-3. Lighthead: Medium Socket: Secondary ........................................................................................... 5-3

Table 5-4. Lighthead: Small Socket: Primary ...................................................................................................5-3

Section 6: Inspection and Mainenance

Table 6-1. Troubleshooting Guide ....................................................................................................................... 6-9

Table 6-2. Harmony Lighting and Visualization System Preventive Maintenance Guide ................................... 6-18

ix

764330-226

Section 1: Listing of Safety Precautions

The following Safety Precautions must be observed when operating or servicing this surgical lighting system.

WARNING indicates the potential for personal injury and CAUTION indicates the potential for damage to

equipment. For emphasis, certain Safety Precautions are repeated throughout the manual. It is important to

review ALL Safety Precautions before operating or servicing the unit.

Strictly following these Safety Precautions enhances your ability to safely and effectively utilize the unit and

helps the customer avoid improper maintenance methods which may damage the unit or render it unsafe. It

is important to understand that these Safety Precautions are not exhaustive; customers are encouraged to

develop their own safety policies and procedures to enhance and compliment these Safety Precautions.

WARNING – ELECTRIC SHOCK AND BURN HAZARD:

Disconnect all utilities to lighting fixture before servicing. Do not install the lighting fixture unless all utilities

have been properly locked out. Always follow OSHA Lockout-Tagout and electrical safety-related work

practice standards. (See 29 CFR 1910.147 and .331 through .335.)

Do not remove covers or perform service other than as described in this equipment manual. Refer servicing

to qualified service personnel. (Maintenance Manual P764330-226.)

WARNING – EXPLOSION HAZARD:

Do not use lighting fixture in the presence of flammable anesthetics.

WARNING – PINCH AND CRUSH HAZARD:

Do not pinch fingers between the structural plate and the vertical tube as the assembly is lifted.

The safety ring must be installed.

Pinch points are created during extreme articulation of the suspension system. Do not place hands on or near

the suspension knuckle during lighthead articulations.

WARNING –IMPACT HAZARD:

Do not remove tension screw from the spring arm joint until the lighthead has been securely installed onto

the spring arm. Note: This warning applies at both installation and de-installation procedures.

WARNING – PERSONAL INJURY HAZARD:

Do not attempt to replace the lamp unless power is turned off and the lighthead has cooled sufficiently.

Do not attempt to clean lighthead unless power is turned off and the lighthead has cooled sufficiently.

Do not remove monitor-arm safety pin until monitor is installed.

Monitor extension arm must have monitor (or equivalent counterweight) installed to keep arm in required

positions while installing sliding guards.

Avoid looking directly at high-intensity light, whether at the lamp or directly at the lighthead. Eye injury may

result.

1-1

764330-226

WARNING – POSSIBLE PATIENT INJURY HAZARD:

Failure to engage the lighthandle cover completely may result in cover falling from lighthead during the

procedure.

WARNING – BIOHAZARD:

Sterile disposables are intended for single use only.

Universal precautions must be observed when disposing of any single use disposable item.

WARNING – DISPOSAL HAZARD:

This product contains materials which may require disposal through appropriately licensed and permitted

hazardous waste management firms.

CAUTION – POSSIBLE EQUIPMENT DAMAGE:

Use of any disinfectant solution OTHER than those listed below may cause discoloration or deformation on

the polycarbonate lens surface: Coverage® Spray HBV, Coverage® HBV Concentrate, T.B.Q.®, or Coverage

Plus®, CoverageTM Spray Disinfectant Cleaner, or Germicidal Cloth. Cleaning solutions other than those listed

have NOT been tested for compatibility or effectiveness. Always follow manufacturer instructions for

concentrations and use of cleaning products.

Use only recommended cleaning/disinfecting and/or anti-static agents on this light. Some degree of staining,

pitting, and/or discoloration could occur if a phenolic-, iodophor-, or glutaraldehyde-based disinfectant is

used on the surfaces of this light. Also, use of alcohol or aerosol spray cleaner/disinfectants (e.g., Lysol®)

containing a substantial amount of alcohol in the formula can damage the polycarbonate lens.

Prevent leakage of fluids into interior of lighthead.

Avoid discoloration of control center keypad and display. Do not clean control center with Betadine® solutions

or allow such solutions to contact keypad and display surfaces.

Do not scratch optical coating on accessible portions of optic assembly when cleaning; always wear rubber

gloves and use only a clean, white, lint-free cloth when wiping internal surfaces.

Appropriate components of this lighting system have been tested and found in compliance with IEC 60601-

1-2 (1st Edition 1993-04), Medical Electrical Equipment – Part 1: General Requirements for Safety;

Electromagnetic Compatibility (EMC). There is, however, a potential for electromagnetic or other interference

between this equipment and other devices. Should you experience interference, relocate this device or

minimize the use of the affected equipment while this device is in operation.

Do not touch the glass portion of the lamp with bare fingers. Skin oils can cause deterioration of material

leading to possible failure of the lamp.

Accurate measurement and calculation in finding the point where the first hole is drilled for the safety ring is

of critical importance in correctly installing the vertical tube. Check all measurements and calculations twice

before drilling the first hole.

Do not pinch wires that exit the vertical tube as the assembly is lifted. Gently route wires from the vertical tube

out of the way as the suspension system is lifted into place.

1-2

764330-226

CAUTION – POSSIBLE EQUIPMENT DAMAGE (Continued):

Do not pinch wire on the ceiling structure or vertical tube.

During all mounting steps, ensure wires are not pinched between mechanical components of suspension,

spring arms, or lightheads.

Harness connectors must be slipped into expandable sheathe before routing through monitor yoke.

• Failure to use sheath may cause connector damage during routing.

• Slip sheathe only far enough onto the harness to protect connector bundle. If sheathe is slipped too far onto

the harness, removing it after routing may be difficult.

Do not touch glass portion of lamp with bare fingers. Skin oils can cause deterioration of material leading to

possible failure of the lamp.

Sliding guards may be damaged if not installed properly into internal grooves.

On early light systems, the wire clamp must be loosened to allow the wiring within the vertical tube to be free.

1-3

764330-226

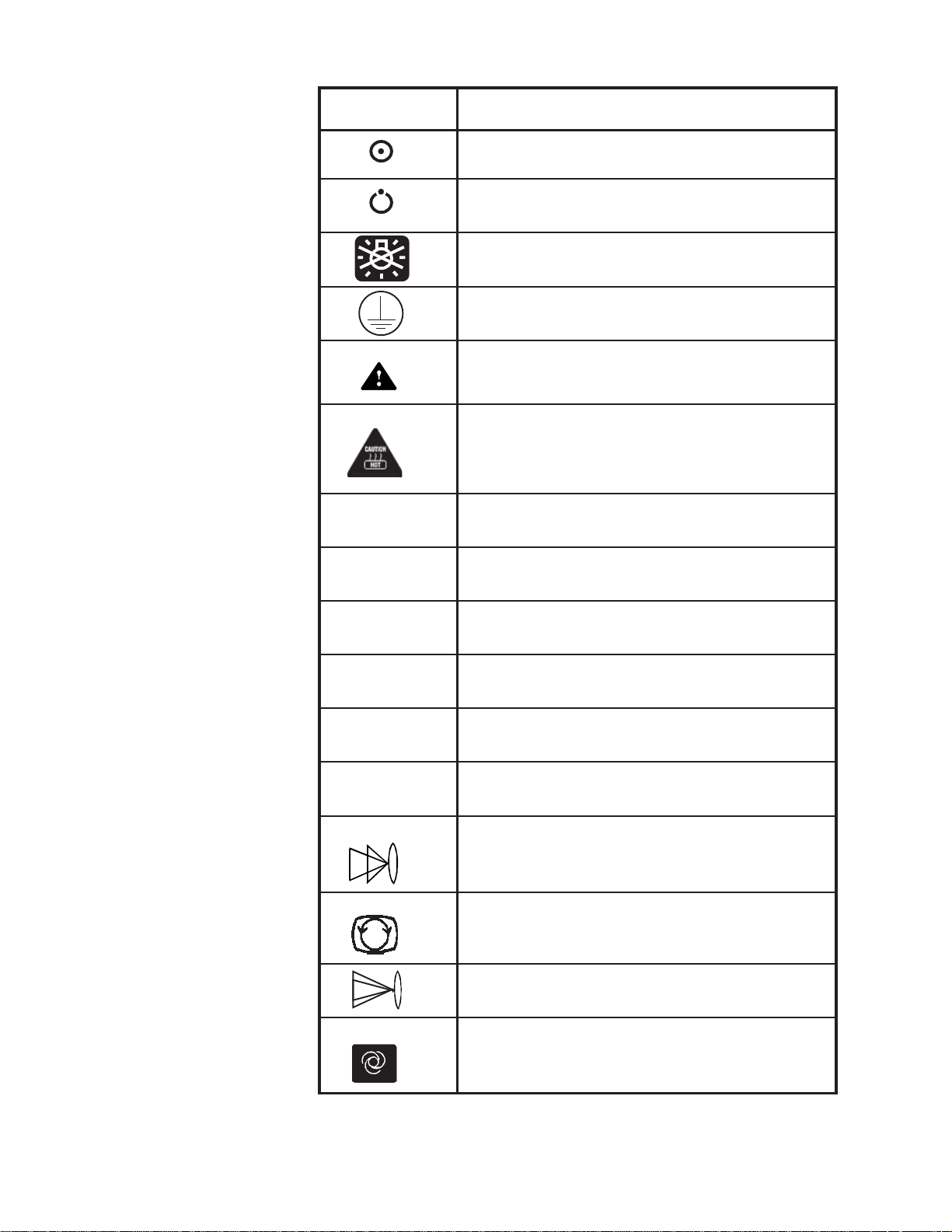

1.1 DEFINITION OF SYMBOLS

Symbol Definition

ON

STANDBY

Lamp Out

Protective Earth (Ground)

Attention, consult manual for further instructions

Hot

SER. NO. Serial Number of Unit

V~ Voltage Rating of Unit, Alternating Current

A Amperage Rating of Unit

Hz Frequency Rating of Unit

+ Increase Intensity (Surgeon's Control Buttons)

- Decrease Intensity (Surgeon's Control Buttons)

Zoom

Rotate

Manual Focus

1-4

764330-226

Auto Focus

Section 2: General Information

The product literature included in this section contains factual data relating to the principal characteristics of the Harmony™ LA Surgical Lighting and

2.2 HARMONY LA 300/500/700 LIGHTHEAD OPTICAL PERFORMANCE

Visualization System.

The literature is informative rather than instructional.

It provides and conveys, through text and illustrations, a general concept of the equipment, its purpose,

limitations, and technical applications.

Important: Values are typical for the small pattern

size at highest intensity setting (unless otherwise

noted) at 39-3/8" (1m) from the lighthead. Definitions

and measurements are in accordance with

IEC 60601-2-41.

2.1 GENERAL DESCRIPTION

The Harmony LA Surgical Lighting and Visualization System is a variable pattern, variable intensity

surgical lighting fixture designed to provide visible

illumination of the surgical field or the patient for the

operating room staff.

Table 2-1. Lighthead Performance Data

Harmony LA 300 Harmony LA 500 Harmony LA 700

Central

Illuminance 2,180 – 5,500 fc 5,480 – 13,470 fc 5,480 – 14,860 fc

(range for intensity (23,500 – 59,000 lux) (59,000 – 145,000 lux) (59,000 – 160,000 lux)

settings 1-7)

Pattern Size

D

10

D

50

8" (200 mm) 6 –11" (150 – 280 mm) 6 –13" (150 – 330 mm)

4" (100 mm) 3 – 6" (80 – 150 mm) 3 – 6.5" (80 – 165 mm)

Depth of

Illumination > 60" (> 1520 mm) 43" (1090 mm) 36" (910 mm)

Peak total

Irradiance < 250 W/m

2

< 700 W/m

2

< 650 W/m

2

Color

Temperature 4,400 K 4,400 K 4,400 K

Color Rendering

Index (CRI) 94 94 94

Shadow Control

Single Mask: 0% 31% 56%

Double Mask: 66% 43% 47%

Cavity: 100% 100% 96%

Single mask w/ cavity: 0% 32% 51%

Double mask w/ cavity: 68% 44% 44%

Average

Lamp Life 1,000 hr. 1,200 hrs 1,200 hrs

at mid-range intensity

2-1

764330-226

2.3 SPECIAL CONSUMABLES

Table 2-1. Special Consumables

Part Description Part Number

Touch-up Paint – 2 Fl.oz R001801-141

Installation Instructions,

Standard Mounting P129382-396

Installation Instructions,

Harmony LA 500 Mobile

Floor Stand P129382-280

M.M. DeepSite P764330-210

Installation Instructions

Harmony DeepSite Mobile

Floor Stand P129382-281

Operator Manual,

Harmony LA 500 P129382-106

Pre-In-Service Check List,

Harmony LA 500 P764330-529

Uncrating Instructions,

Harmony LA 500 P129382-395

Sterile Cover,

Harmony LA Light Handle

Camera, Single Pack, 8/Box LB60-00

Plastic Lighthandle LB20

Lighthandle Cover (Sterile,

Single Pack; 10 to a pack) LB41

Monitor Handle Cover

(Sterile, Single Pack;

20 per case) LB70

Flat Panel Monitor Handle

Cover (Sterile, Dual Pack;

20 per case) LB71

Harmony LA 500/700 Lamp LB11

Replacement Lamp for

Mobile Stand DeepSite

Illuminator LB12

2-2

764330-226

Section 3: Operating Instructions

3.1 GENERAL INSTRUCTIONS

The wall-mounted Harmony™ LA Control Center

allows the user to adjust the lighthead intensity level

(brightness) by pressing a membrane switch (or “button”). An identifying number on the control display

corresponds to the same number on the lighthead

suspension arm. Additionally, each lighthead has its

own “onboard” intensity controls, located on the

above the lighthandle adjacent to the lens. These

controls are usually referred to as the surgeon’s

control buttons or as the surgeon’s control. (See

Figure 3-2.)

3.1.1 To Adjust Lighthead Intensity Levels:

WARNING-EXPLOSION HAZARD: Do not use

in the presence of flammable anesthetics.

1. Press ON touch pad.

2. Intensity levels for one or two lightheads can be

controlled from one control center. A lighthead’s

surgeon’s control buttons adjust the intensity level

for that lighthead.

Important: Avoid control center faults. Do not continuously press and hold any control center buttons

for more than 15 seconds.

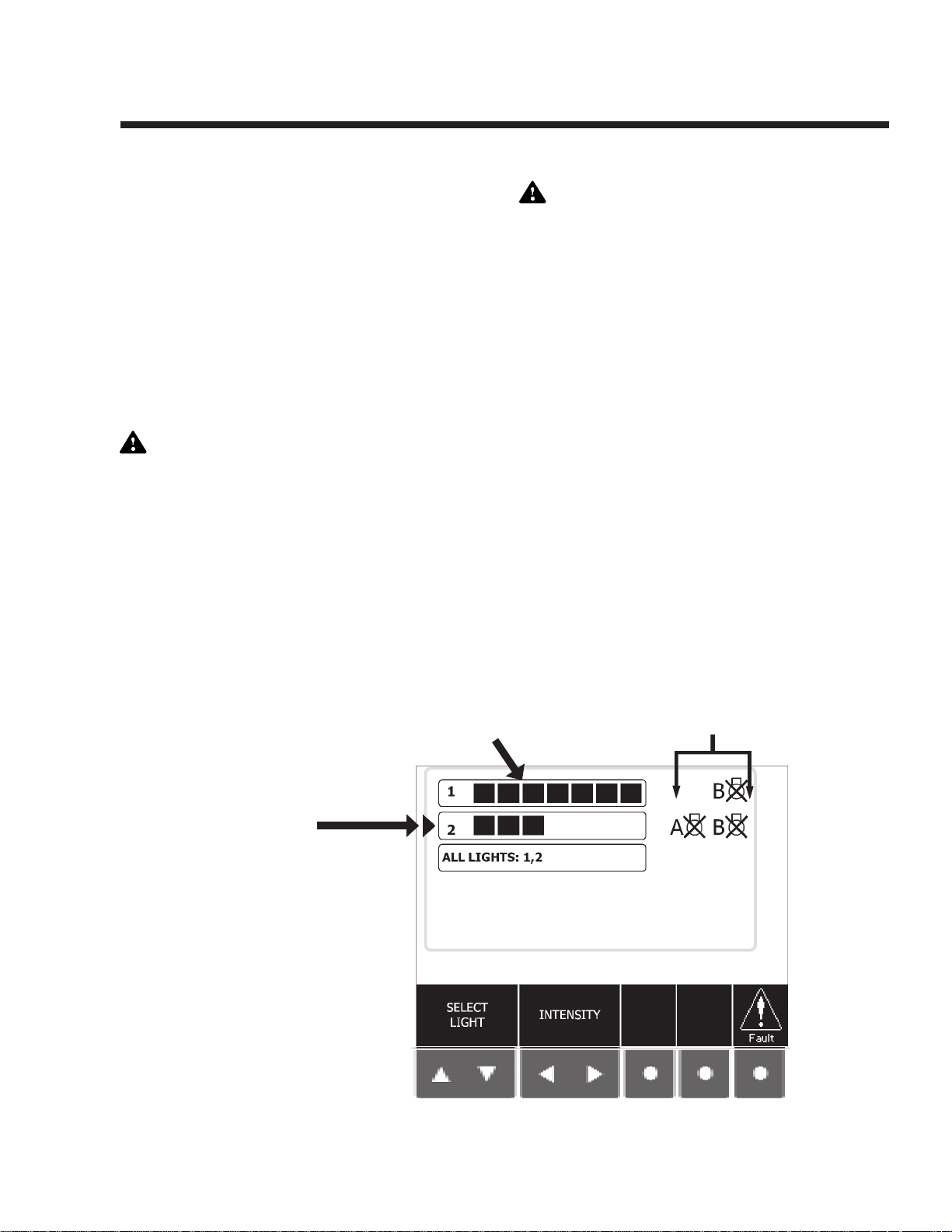

3.1.2 Control Center

WARNING-EXPLOSION HAZARD: Do not use

in the presence of flammable anesthetics.

See Figure 3-1.

1. Use the “Select Light” touch pads to move the

display indicator up or down until it aligns with

the appropriate lighthead.

2. Once the lighthead is selected, press either the

button to increase light intensity level, or the button to decrease light intensity level.

3. If “All Lights” is selected, intensity for all lightheads in the system is increased or decreased

simultaneously.

NOTE: For longer lamp life, use lowest intensity level

suitable for surgical procedure.

Indicates Selected

Lighthead

Lighthead Intensity

Status

Lamp Status

Figure 3-1. Harmony Control Center Main Menu

Indicators

3-1

764330-226

Surgeon's

Control

Buttons

Figure 3-2. Lighthead Surgeon’s Control Buttons (Harmony LA 500 Lighthead with Standard

Handle Shown)

3.1.3 Surgeon’s Control Buttons (See Figure 3-2)

1. Grasp the handle of the appropriate lighthead. A

ring of membrane buttons (bumps) are located on

the control bezel adjacent to the lighthead lens.

2. Press any of the surgeon’s control buttons molded

with “+” symbols to increase the lighthead intensity. Press any of the surgeon’s control buttons

molded with “-” symbols to decrease lighthead

intensity.

NOTE: For longer lamp life, use lowest intensity level

suitable for surgical procedure.

3. To turn lighthead OFF.

a. At the control center: press the “Select Light”

button until indicator points to the appropriate

lighthead on the display. Press the “Decrease

Intensity” button until the light goes out.

b. At the lighthead, press and hold any of the “-”

membrane buttons untilthe light goes out.

NOTE: Press the decrease intensity button (-) on

the lighthead surgeon’scontrol for an additional 5

seconds, to turn off all lightheads in the system.

nity.

A Lamp Status LED is located on the lighthead (see

Figure 3-3). If this LED is flashing, it indicates that

the lighthead is using the backup lamp and the

primary lamp should be replaced.

Check the lamp status LED each time the surgical

light is used.

A secondary lamp inside Harmony LA 500 lightheads automatically turns on when the primary

lamp fails.

If the lamp status LED is blinking, replace the failed

lamp(s). (See Lamp Replacement, Section 6.) After

the lamp is replaced and power restored to the

lighthead, the primary lamp lights, the LED stops

blinking and the graphic display changes to “lamp

ready.”

3.2 HARMONY LA 500 LIGHTHEAD

LAMP FAILURE INDICATIONS

The main display screen on the control center indicates lamp status for the system lightheads. The

display indicates the status of both the primary and

secondary lamps for each lighthead. A failed lamp

should always be changed at the earliest opportu-

764330-226

Check Lamp Status

LED on Lighthead

Figure 3-3. Lamp Status LED

3-2

3.3 HARMONY LA 300/500/700

Monitor Arm Positioning

Lighthead Positioning

LIGHTHEAD POSITIONING

CAUTION: Do not bump lightheads into walls

or other equipment.

Lightheads can be positioned by using either the

sterile handle, or by grasping the non-sterile handle

around the lighthead housing. The following two

paragraphs describe the positioning characteristics

of the lighthead from outside or within the sterile

field. To optimize shadow control, position the lighthead as appropriate before starting the intended

surgical procedure.

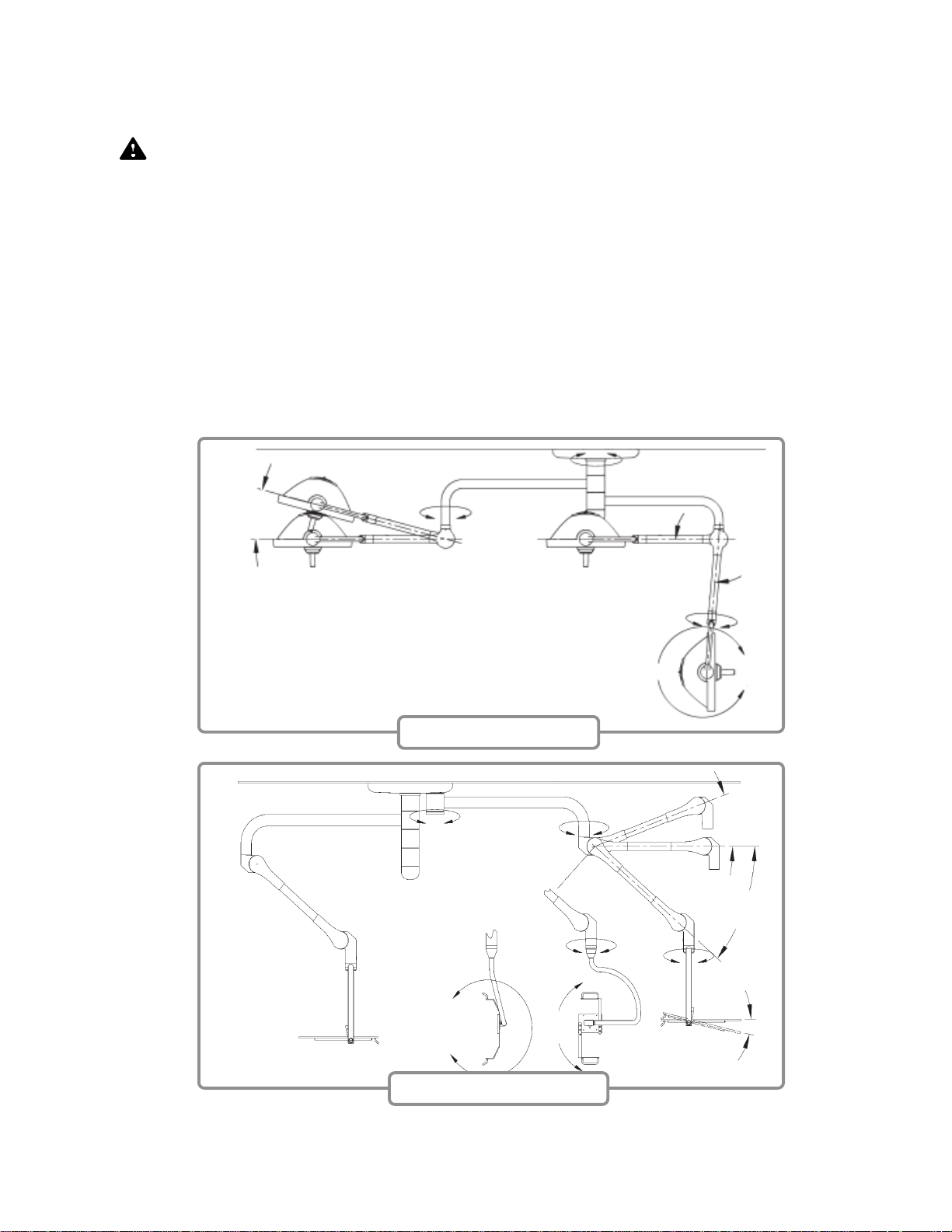

Lighthead may (1) rotate continuously around vertical suspension tube; (2)rotate continuously around

central hub; (3) rotate continuously about suspen-

sion arm; (4) tilt forward or backward in yoke approximately 310°; and (5) move up or down by

pivoting at suspension elbow 15° up, and 85° down

until vertical tube and suspension arm describe a

straight line.

Monitor arms are capable of the following articulations: (1) rotate 300° at the central or secondary

spindle; (2) rotate 330° at the horizontal extension

arm; (3) rotate 320° a the yoke transition; (4) move

up or down by pivoting at spring arm knuckle 20°

up, and 40° down. Flat panel yoke also allows (5) tilt

forward 15° or backward 75° in yoke. Additionally,

the flat panel yoke can be rotated for either portrait

or landscape display. See Figure 3-4.

15°

Typical

300°

Unlimited

330°

320°

85°

Typical

Unlimited

310°

20°

40°

320°

75° Up

15° Down

180°

Portrait to

Landscape

Figure 3-4. Suspension Positioning

3-3

764330-226

13°

Rotate Handle

to Decrease

Rotate Handle

to Increase

Figure 3-5. Light Pattern Adjustment

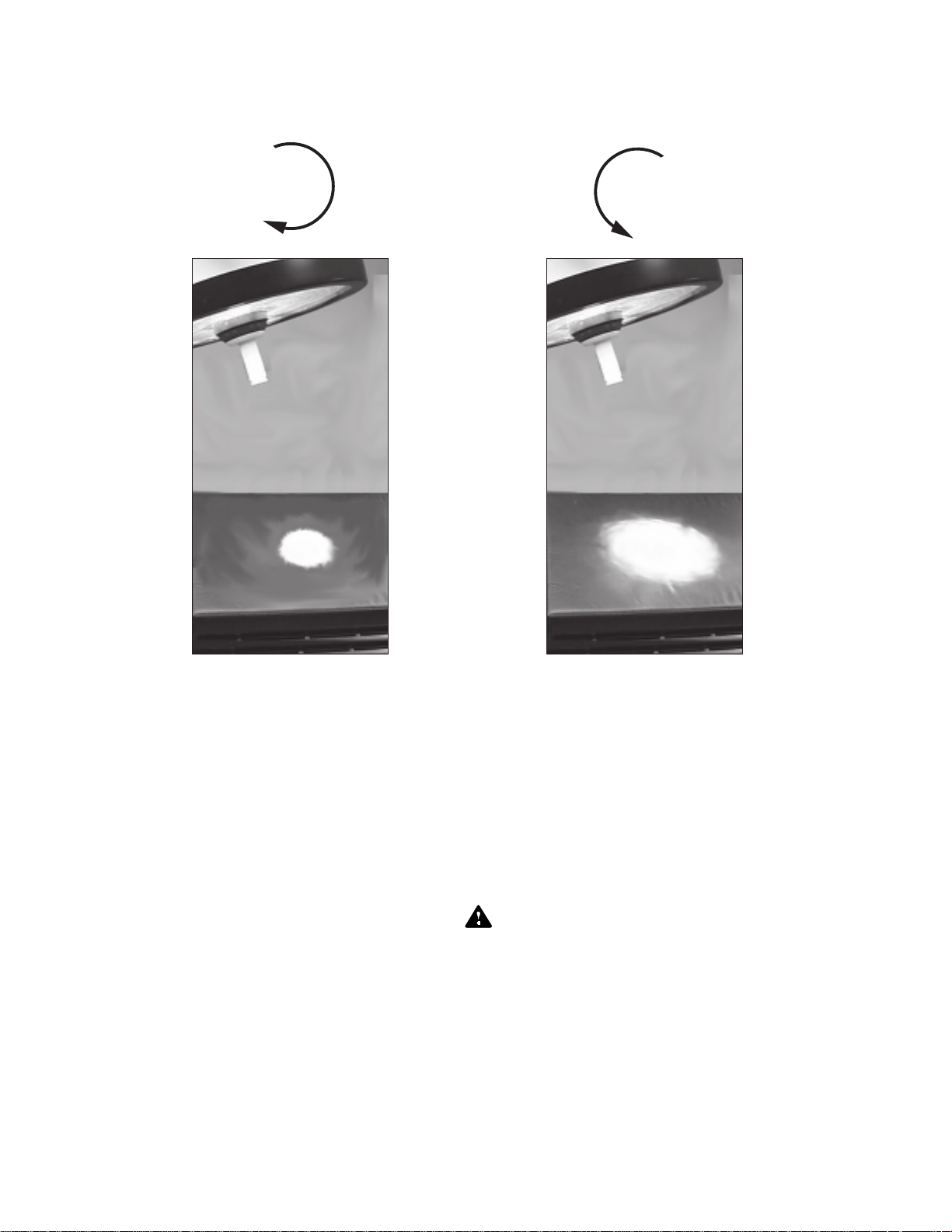

3.4 HARMONY LA 500 LIGHTHEAD

PATTERN ADJUSTMENT

The illumination pattern for each lighthead can be

adjusted to any diameter between the minimum and

the maximum.

Adjust the light pattern by rotating the lighthandle

clockwise to decrease pattern size.

Rotate the handle counterclockwise to increase pattern size.

NOTE: Typical lighthead positioning is above and slightly

behind the surgeon’s right or left shoulder.

3.5 LIGHTHANDLE AND LIGHTHANDLE COVER

3.5.1 Installing and Using Lighthandle and

Lighthandle Cover

WARNING – POSSIBLE PATIENT INJURY

HAZARD: Failure to engage the lighthandle

cover completely may result in cover falling

from lighthead during the procedure.

Lighthandles are used to position Harmony LA 500

lightheads, allow access to intensity control on each

lighthead, and to adjust lighthead pattern size. To

3-4

764330-226

avoid accidental contact with the non-sterile

surgeon’s control buttons, the lighthandle should

always be used with a disposable, sterile lighthandle

cover (available separately from STERIS®).

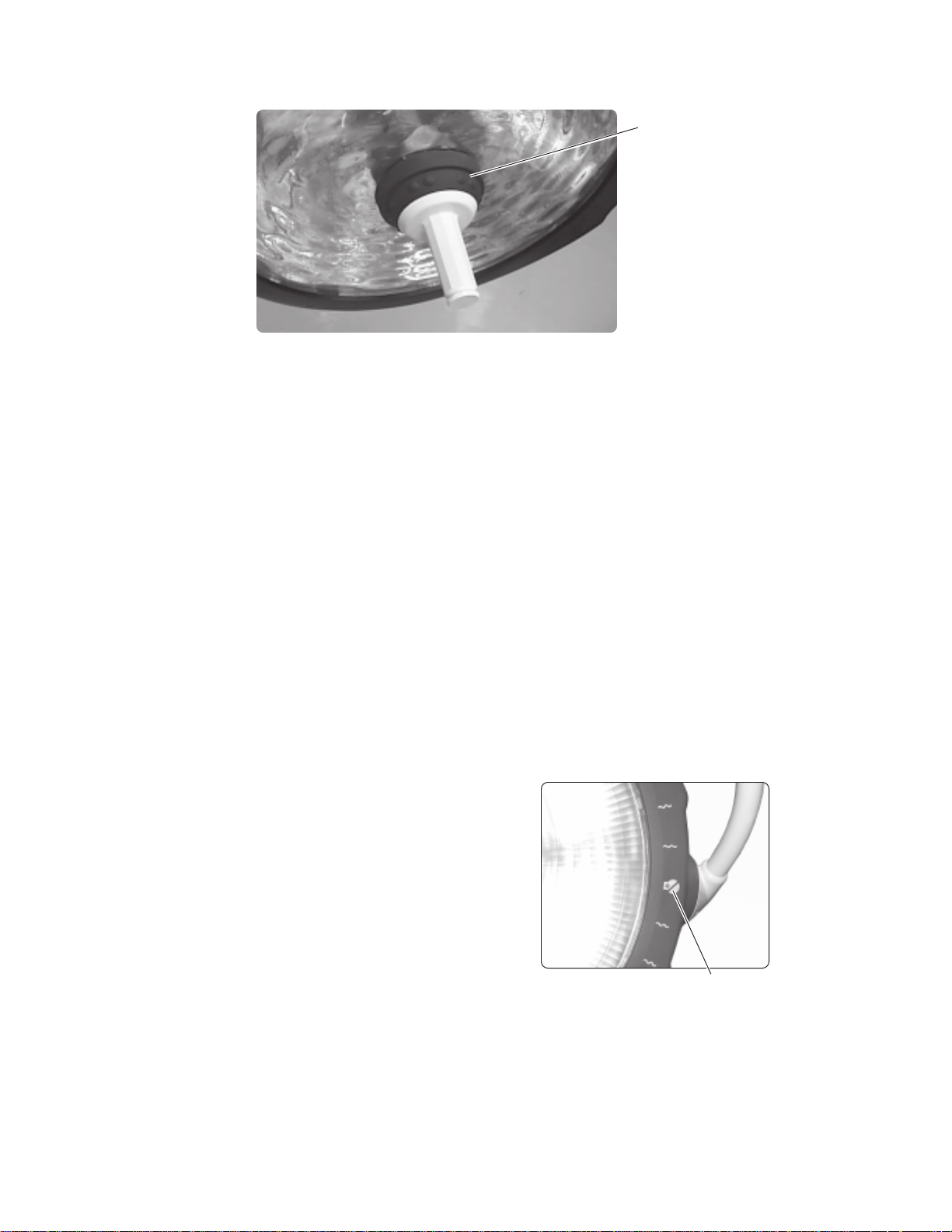

• If the lighthandle adapter is not already in place,

align the tab on the adapter with the channel in

the mounting ring and thread the adapter in until

fully engaged. (See Figures 3-6a and 3-6b.)

• Prior to starting a procedure, ensure that the

lighthandle is in place. Install the lighthandle by

threading onto the adapter and firmly tightening.

(See Figure 3-6c.)

Surgeon's Control Buttons

• Remove the sterile lighthandle cover from its

packaging and install onto the lighthandle. (See

Figure 3-6d.)

• To ensure the lighthandle cover remains in place

during the procedure, the groove in the cover

must be fully engaged with the groove in the

lighthandle.

• The lighthandle can be removed for cleaning or

sterilization by unscrewing it from the handle

adapter. The lighthandle can be sterilized using

standard hospital cycles. Do not use the lighthead during a sterile procedure unless a disposable cover is installed on the lighthandle.

Lighthandle

Adapter

Align Tab on Handle

Adapter with Channel in

Mounting Ring

Figure 3-6a.

Figure 3-6b.

Lighthandle

Adapter

Lighthandle

Figure 3-6c.

Push Cover

Completely onto

Lighthandle

Disposable

Lighthandle

Cover

Figure 3-6. Standard Lighthhandle

3-5

764330-226

Figure 3-6d.

3.5.2 METAL STERILIZABLE HANDLE

WARNING-STERILITY ASSURANCE HAZARD: Do not use the surgeon’s control buttons unless a disposable sterile cover is

installed. If the sterilizable lighthandle

(metal) is used without a disposable cover,

the surgeon’s control buttons are not protected by a sterile covering.

The metal sterilizable handle is used to position the

Harmony LA lighthead and to adjust the light pattern size. The sterilizable handle may be used in

place of a disposable sterile lighthandle cover.

The plastic lighthandle should be removed prior to

installing the metal sterilizable handle. To do so,

simply unscrew it from the threaded handle adapter.

Prior to starting a procedure, install a clean, steril-

ized metal handle by screwing it onto the threaded

handle adapter. Ensure handle is firmly tightened

prior to use. The gap between the flange on the metal

steriliizable handle and the surgeon’s control buttons prevent accidental contact with the non-sterile

surface of the buttons.

The metal sterilizable handle can be removed for

sterilization by unscrewing it from the adapter.

The metal sterilizable handle can be sterilized using

standard hospital cycles steam cycles intended for

lumens. Always sterilize handle between surgical

procedures.

3-6

764330-226

CRT Monitor Support Arm

Flat Panel Montior Support Arm with

Monitor in Landscape Position

Figure 3-7. Harmony Monitor Configurations

Flat Panel Montior Support Arm with

Monitor in Portrait Position

Adjust CRT Monitor

Shelf by Loosening/

Tightening Knob

3.6 HARMONY LA MONITOR ARMS

The Harmony LA Surgical Lighting and Visualization System can be equipped with one or two monitor supportarms. Monitor arms can be included in

the Harmony system either as the uppermostarm on

the central spindle, or as the secondary spindle arm.

Refer to 3.3 Harmony LA Lighthead Positioning for

positioning range details. See Figure 3-4.

Refer to separate Operating Instructions supplied

with the monitor.

Signal and monitor power wiring is provided at the

installation with each monitor support arm.

Input signals to monitors can be routed through the

suspension wiring froman external video source

(not by STERIS).

3-7

764330-226

Disposable Sterile Cover Closure Tie Monitor Yoke Handle

Figure 3-8. Installing Disposable Sterile Monitor Handle Covers

Guide Disposable Cover

Over Handle Until Handle Is

Fully Covered

Cut Off and Discard Excess

Closure Tie, If Desired.

3.7 INSTALL FLAT PANEL MONITOR

YOKE HANDLE DISPOSABLE

STERILE COVERS

WARNING – BIOHAZARD: Sterile disposables are intended for single use only. Universal precautions must be observed when

disposing of any single use disposable item.

Important: Use new covers for each handle for each

procedure where the monitor will be used. Covers

are sterile and shipped in a protective wrapper.

Wear sterile gloves when removing covers from

packaging. When installing covers, follow

sterilityassurance procedures as outlined by facility

protocols.

764330-226

Refer to Figure 3-8.

1. Remove cover from packaging.

2. Pull the cover until it fully covers the handle.

3. Pull closure tie until tight enough to prevent

cover from slipping down the handle.

4. Repeat procedure for second handle.

3-8

3.8 VIDEO CAMERA INSTALLATION OR REMOVAL

3.9 LIGHTHEAD POSITIONING WITH VIDEO CAMERA

3.8.1 Installation

1. Rotate lighthead until lens faces the room ceiling.

2. Remove the standard handle by unthreading it

from the support mounting ring.

3. The camera is secured to the lighthead by threading it into the same support used by the standard

handle.

a. Align the post with recess. This should align

system connector properly. Install camera as-

sembly to lighthead.

b. Select Camera Menu 1 on the control center.

c. Verify that all functions of the camera operate

correctly using the control center. Verify func-

tions using the optional wireless hand-held

control or optional foot control, if applicable.

4. Once camera functions are verified, press the OFF

touch pad on the face of the control center.

3.8.2 Removal

1. Rotate lighthead until perpendicular to floor.

2. Unthread camera housing from mounting ring

and remove.

When the lighthead is used with a camera, a dispos-

able sterile cover is placed over the camera housing. (Sterile cover is available from STERIS.)

Figure 3-10. Insta ll Camera Disposable

Sterile Cover

3. Install standard handle.

Threaded

Mounting Ring

Optional Video

Camera

Alignment Recess

Alignment Post

Figure 3-9. Optional Camera Installation

3-9

764330-226

3.10 VIDEO CAMERA OPERATION

The optional video camera is integrated into a removable handle that can be fitted to any Harmony

LA 500 or 700 lighthead. Whenever the video option

is used, a separated sterile disposable cover must be

fitted over the camera before each procedure. This

cover allows the camera to be grasped and used in

the same way as a standard handle, including positioning the lighthead for optimal illumination, adjusting lighthead intensity and pattern size, as well

as positioning the video image field for the best view

of the procedure. The sterile cover must be removed

from the camera and discarded after each procedure.

Video and control signals are turned on or off at the

control center; any of the optional remote control

units (see below) provide similar control functions.

The control center also provides additional control

for video brightness and contrast, color gain, stillimage capture and time and date display.

Three optional remote devices can control camera

functions: a hand-held wireless control, Hermes

voice-activated control (verbal commands and handheld pendant), or a foot control.

The control center functions by transmitting signals

via a control cable to the camera located in the

lighthead.

The optional wireless control functions by transmitting infrared signals to the control center. To initiate

camera functions with either control, press the appropriate touch pad on the control face panel. The

hand-held control’s IR (infrared) transmitter must

be within approximately 15 feet maximum and 50° of

the control center receiver. The control touch pads

are used to control the following camera functions:

Zoom–for determining the level of detail visible in

the image field. The Zoom function adjusts the image field continuously between two extremes:

+ (Telephoto). At extreme telephoto, the camera

captures an image showing great detail in a

small area.

NOTE: At extreme telephoto, any motion of the lighthead/camera will be exaggerated (jerky). The field of

focus has little depth at this extreme, forcing the Auto

Focus function (if enabled) to refocus the camera when

any object (such as a hand) enters the image field, or if

camera position is adjusted. The camera is also sensitive to light level changes at extreme telephoto.

– (Wide Angle). At extreme wide angle, the cam-

era captures a large, image with less detail than

telephoto.

NOTE: At extreme wide angle, the image field possesses a greater depth of focus and less sensitivity to

light level changes.

Rotate–Use this function to change orientation of

the video field. Image field can be rotated in either

clockwise or counterclockwise directions.

Bright–Use this function to affect the overall bright-

ness (or darkness ) of the video image. The Bright

control can be set to adjust itself automatically.

Manual Focus–Use this function to manually set the

focus for close-up shots or other special applications. The Auto Focus function must be toggled off

to enable manual focusing. Adjust the clarity of

focus by pressing the + or – touch pads.

NOTE:

subject;

+

touch pad moves the lens slightly closer to

–

touch pad moves the lens slightly away from

subject.

Auto Focus – Use this function to toggle Auto Focus

on or off. When Auto Focus is ON, the camera

automatically focuses on the object in the image

field closest to the camera lens. When Auto Focus is

turned OFF, the camera maintains focus on the last

object upon which it was focused, until Auto Focus

is turned back on.

NOTE: It may be necessary to toggle Auto Focus OFF

when using the camera at extreme telephoto (close up),

to prevent the camera from refocusing on hands and

other objects introduced into the image field while

videoing procedures.

Red Gain/Blue Gain – These controls are used to

adjust image color settings, and are intended to

allow the user to compensate for changes in color

temperature provided by differing light sources.

The gain control can be set to adjust automatically.

3.10.1HERMES-Ready Control Center

The Hermes Control Center functions by transmitting signals through an interface cable connected to

the wall control. When used, the interface cable

should be routed to avoid surgical personnel foot

traffic. The control center is intended to allow personnel within the sterile field to operate all camera

functions using verbal commands or a hand-held

pendant. Refer to the Hermes operating manual for

more information.

3.10.2Optional Foot Control

The foot control functions by transmitting signals

through a cable connected to the control center.

When the foot control is used, the cable should be

routed to avoid surgical personnel foot traffic. The

foot control is intended to allow personnel within

3-10

764330-226

the sterile field to operate the zoom and rotation

Amsco® SQ240 SurgiVision

TM

Surgical Lighting and Video System

ZOOM RO TATE

functions of the camera.

NOTE: Zooming completely out causes image distortion within the illuminated area.

Foot control is used to control zoom and rotation

functions. Press on appropriate sides of foot pedals

to activate foot control functions. Functions controlled through the foot control unit are identical to

those controlled through the optional hand-held

wireless control or control center.

3.11 GUIDELINES FOR MAXIMIZING

VIDEO IMAGE

The following steps will aid in maximizing video

imaging effectiveness.

1. Energize the light at medium setting on the control center, and position the lighthead approximately 39" (1000 mm) from the surgical site.

2. Using the hand-held remote, or the control center,

zoom in or out (+ or -) until the desired image fills

the viewing screen of the monitor.

3. If the light pattern (white circle) does not fill the

monitor’s screen (shaded square), the image inside the pattern will be distorted.

4. Reposition the camera to orient the focal point

(center of the desired image) at the center of the

viewing screen.

Adjust zoom and rotation as needed:

5. The camera may be zoomed to the full 10x zoom

and rotation orientation adjusted as needed.

6. Clockwise and/or counterclockwise orientation

is adjusted by using the curved arrow(s) on the

hand-held control, the control center or the optional foot control.

3.11.1Engage Manual Focus

As instruments are introduced to and removed from

the surgical field, the auto focus will attempt to

focus on the nearest object, possibly causing the

image to blur intermittently. To prevent this effect,

once the camera has been positioned and focused

onto the surgical site, the manual focus mode may be

engaged to maintain image clarity during the procedure.

For deep cavity illumination, it may be necessary to

engage the manual focus to focus beyond the nearest

object (i.e., the surface area surrounding the incision) so that the desired image can be viewed clearly.

Optional Hand-held Wireless

Remote Control

Figure 3-11. Optional Camera Controllers

Optional Foot Control

3-11

764330-226

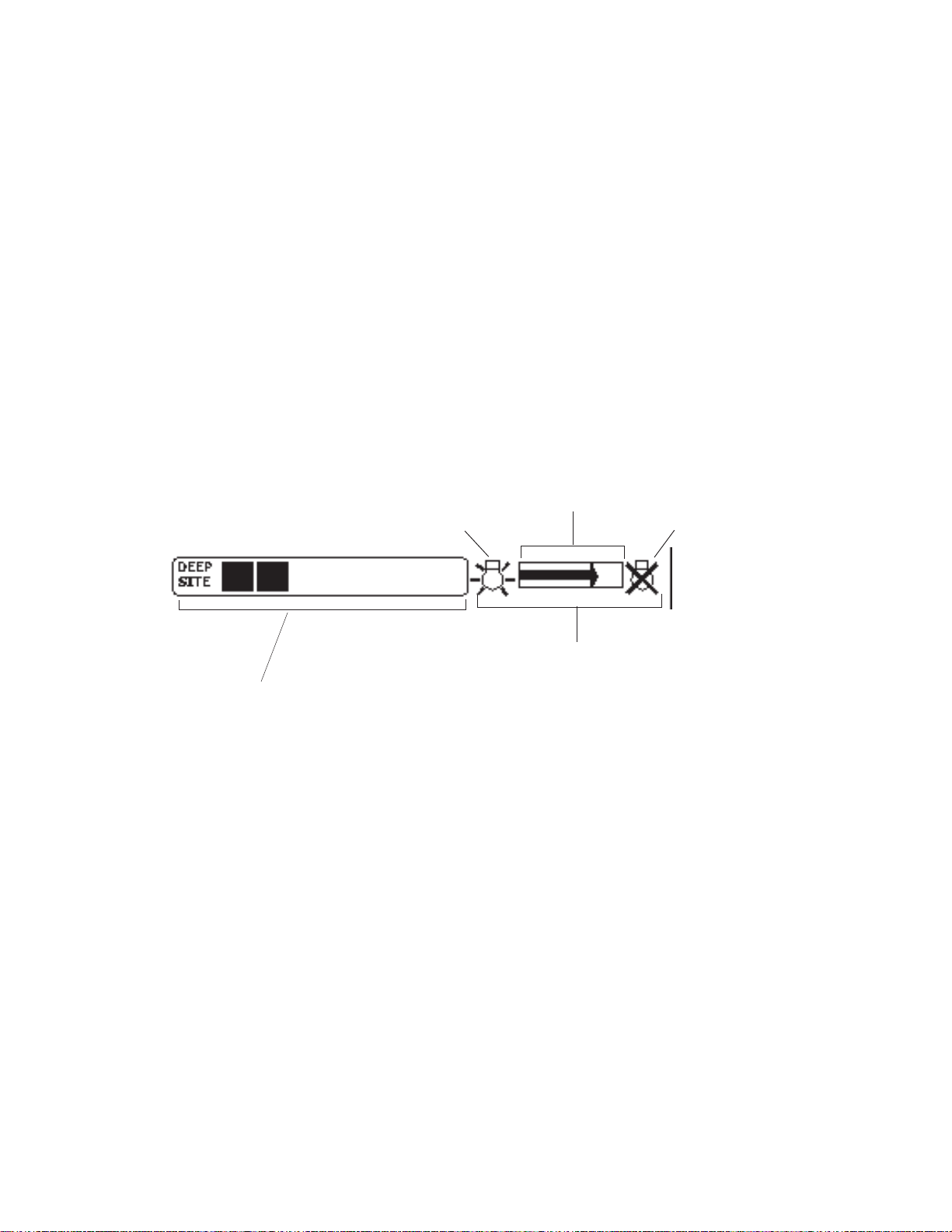

3.12 DeepSite CONTROL CENTER STATUS INDICATORS

NOTE: See DeepSite Maintenance Manual P764330210 for more information on the DeepSite Light.

3.12.1Intensity Level Status

This shows the current intensity level of the DeepSite

light.

3.12.2Lamp Life Status

The DeepSite lighthead uses a high-intensity

Xenonlamp module as a light source. The Harmony

LA Surgical Lighting and Visualization System can

track the approximate life remaining for this lamp

module and display it at the Control Center.

NOTE: Refer to Lamp Replacement procedure in Section 6 of this manual when it becomes necessary to

replace the lamp.

Approximate Lamp Life

Used/Remaining

New Lamp

Spent Lamp

DeepSite Intensity Status

Indicator

Figure 3-12. DeepSite Control Center Indicators

DeepSite Lamp Life

Status Indicator

3-12

764330-226

Section 4: Service Mode

4.1 SERVICE MODE PROCEDURE

4.2 SERVICE MENU 1 SCREEN

Service screens shall be available to service personnel

for diagnostics and firmware updates of the wall

control and lighthead units. The service screens shall

be accessible by performing the following sequence:

1. Turn power ON by pressing systems button.

2. Bring up the System Menu by pressing systems

button.

3. Push and hold the ON button used to place the Wall

Control Unit into the Active Mode.

4. Depress the Select Function Up button.

After performing the sequence described above, the

first of a series of Service Menus shall be displayed.

Service Menu 1, shown in Figure 4-1, is used to read

the firmware part number and revision for the wall

control unit and all installed lightheads.

1. The context-sensitive switch under the "Lights"

description field shall change the LCD display to

the Light Control screen.

2. The context-sensitive switch under the "Menu 2"

description field shall change the LCD display to

the Service Menu 2 screen.

3. The pointer (triangle on left side of lighthead) shall

not be affected by the depression of the Up/Down

button.

4. The Left/Right buttons under the lighthead field

shall select the lighthead whose firmware part

numbers are to be displayed. If a lighthead is not

installed, the message "Not Installed" shall be displayed in the area where the firmware part numbers are displayed.

5. The lighthead numbers shall correspond to the

serial communication port/head numbers at the

Hub Interface PWB.

6. The three TYPES of lightheads shall be Small, Medium, or Large.

Figure 4-1. Service Menu 1 Screen

4-1

764330-226

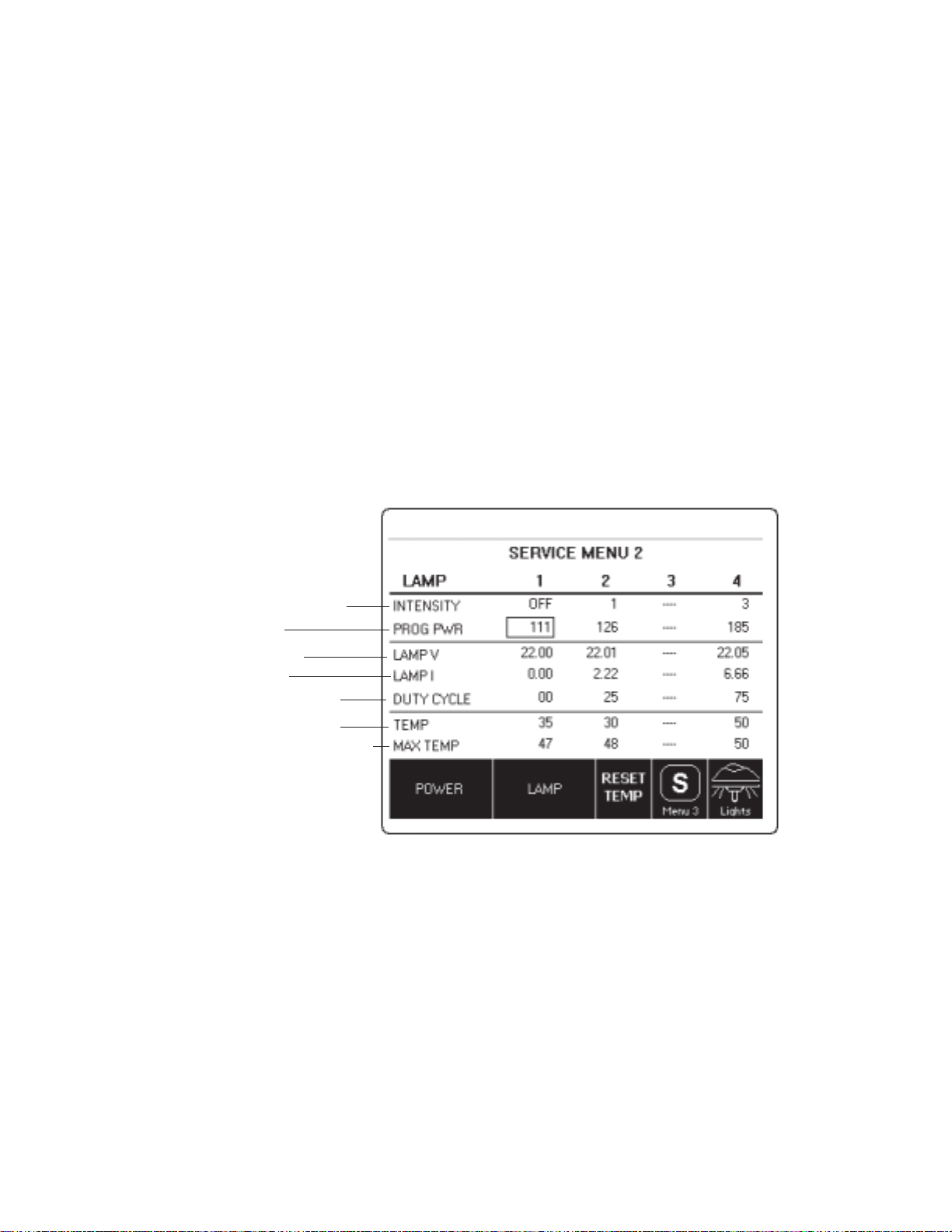

4.3 SERVICE MENU 2 SCREEN

Service Menu 2, shown in Figure 4-2, shall be used to

display the programmed power and operating performance for all of the lighthead units installed.

1. The context-sensitive switch under the "Lights"

description field shall change the LCD display to

the Light Control screen.

2. The context-sensitive switch under the "Menu 3"

description field shall change the LCD display to

the Service Menu 3 screen.

3. The context switch Reset Temp shall send a command to all lightheads to clear the stored maximum

temperature reading.

4. The Lamp numbers shall correspond to the serial

communication port/Head numbers at the Hub

Interface PWB.

5. The Left/Right buttons under Lamp shall be used

to select the lighthead lamp whose intensity is to be

selected with the Up/Down buttons.

6. The Up/Down buttons under Power shall be used

to adjust the intensity (from off to a maximum

intensity of 7) of the selected lighthead lamp. Depressing and holding the Down button for more

that two seconds shall turn the lamp off. If a lamp

is off, depressing the Up button shall turn the lamp

on at its last intensity setting.

7. The duty cycle listed is in units of percent and is

rounded off to the nearest integer (less than 0.5% is

rounded down, 0.5% or greater is rounded up).

Intensity Setting of Lighthead 1-7

Power in Watts

Lamp Voltage in 22-24 V

Current to Lamp

Duty Cycle of Lamp Control Board

Temperature on Control Board, °C

Maximum Temperature seen on Control Board, °C

Figure 4-2. Service Menu 2 Screen

4-2

764330-226

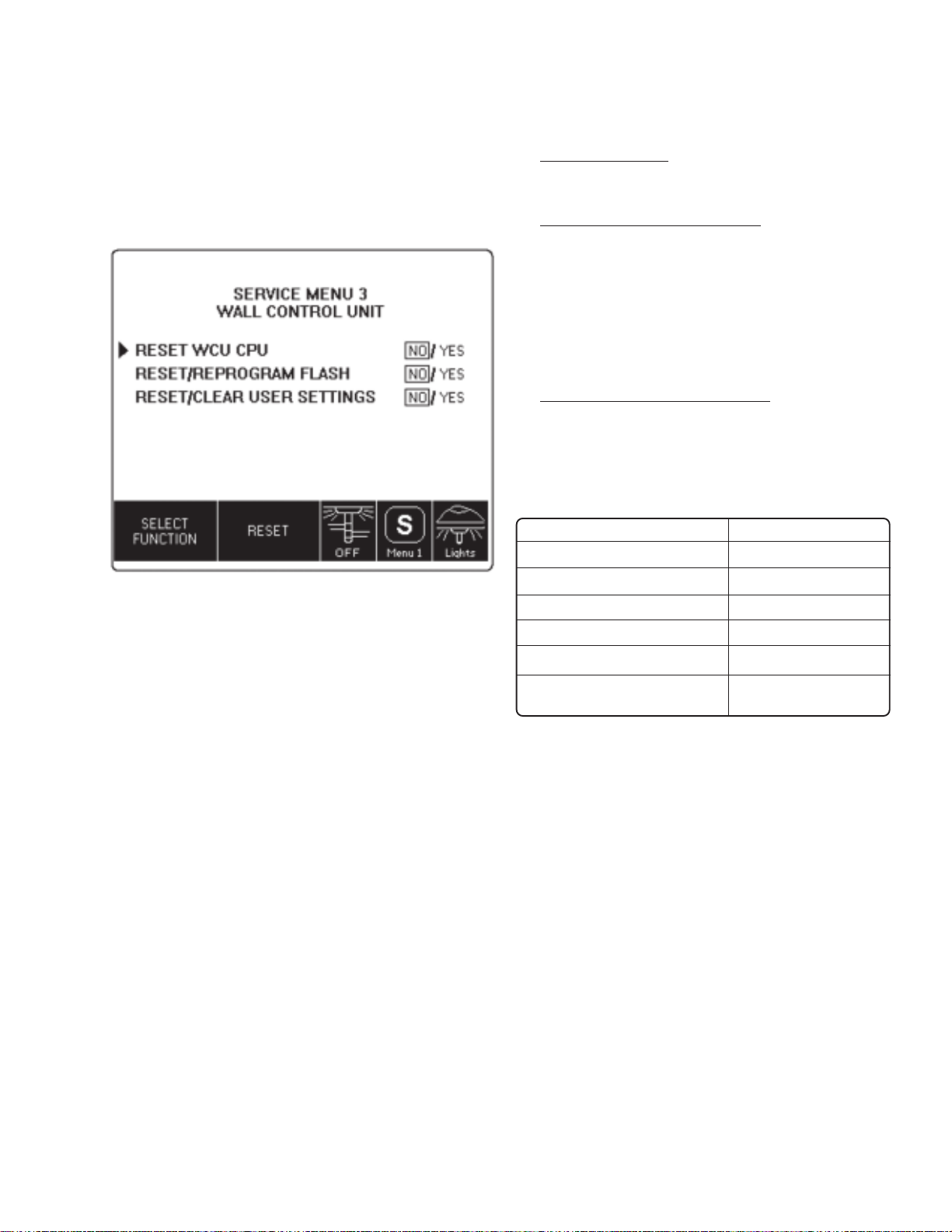

4.4 SERVICE MENU 3 SCREEN

Service Menu 3, shown in Figure 4-3, shall be used to

force the Wall Control Unit to undergo a soft reset,

place the unit into a mode for reprogramming Flash

memory with updated firmware, or reinitialize user

settings, such as lamp intensities, in non-volatile

RAM.

5. Depressing the Right buttons under Reset shall

cause the Wall Control Unit to reset and perform

the selected function.

RESET WCU CPU – The WCU performs the same

startup, testing, and display of messages as if the

power was applied to the system.

RESET/REPROGRAM FLASH – After changing

screen choice to "Yes," the WCU will startup and

wait for a new application to be downloaded from

a PC running STERIS AppLoad. As an alternative,

the power can be turned off (at the incoming ac

voltage rocker switch in the rough-in box) to the

wall control, the AppLoad program started, then

upon turning the wall control back on, the software

will automatically download.

RESET/CLEAR USER SETTING – The WCU performs the same startup, testing, and display of

messages as if the power was applied to the system.

The only difference is that the user settings for the

following will be set to default values.

Table 4-1. Control Center Default Values

LANGUAGE: ENGLISH

Figure 4-3. Service Menu 3 Screen

1. The context-sensitive switch under the "Lights"

description field shall change the LCD display to

the Light Control screen described in SECTION 4.2.

2. The context-sensitive switch under the "Menu 1"

description field shall change the LCD display to

the Service Menu 1 screen described in SECTION 4.2.

3. Control of the Ambient Light is described in SECTION

5.2.7.

4. The Up/Down buttons under the Select Function

shall select the type of Wall Control Reset.

AMBIENT LIGHT NOT INSTALLED

AMBIENT LIGHT MODE MANUAL

AMBIENT LIGHT OFF

CAMERA ZOOM SPEED 3

CAMERA FOCUS SPEED 1

LCD CONTRAST Nominal

4-3

764330-226

Loading...

Loading...