STERIS Eagle CenturyTM, Millennium Series User manual

MAINTENANCE PROCEDURES

STERIS

Eagle® Century

TM

Millennium Series

Sterilizers

(02/25/2000) P-764326-797

Rev. 1

and

©1994 – 2000 STERIS. All rights reserved. Printed in U.S.A.

LIMITATIONS OF LIABILITY AND INDEMNITY

IN NO CASE, WHETHER AS A RESULT OF A BREACH OF CONTRACT, BREACH OF WARRANTY

OR TORT (INCLUDING STERIS'S OR CUSTOMER'S WILLFUL ACTS OR NEGLIGENCE OR

STRICT LIABILITY) SHALL STERIS OR CUSTOMER BE LIABLE TO THE OTHER FOR ANY

CONSEQUENTIAL OR INCIDENTAL DAMAGES INCURRED BY THE OTHER, INCLUDING, BUT

NOT LIMITED TO, LOSS OF REVENUE, PROFITS OR GOODWILL. HOWEVER, NOTHING

CONTAINED IN THIS AGREEMENT IS INTENDED TO RELIEVE EITHER STERIS OR CUSTOMER

FROM CLAIMS, LIABILITY, DAMAGES OR EXPENSES RESULTING FROM BODILY INJURY,

INCLUDING DEATH, OR FROM PROPERTY DAMAGE INCURRED DUE TO THE WILLFUL ACTS,

THE NEGLIGENCE OF OR THE STRICT LIABILITY OF THAT PARTY.

STERIS AGREES TO DEFEND, INDEMNIFY AND HOLD CUSTOMER HARMLESS FROM ANY

AND ALL CLAIMS, LIABILITY, DAMAGES OR EXPENSES DUE TO PERSONAL INJURIES,

INCLUDING DEATH, TO EMPLOYEES OF STERIS AND CUSTOMER AND TO THIRD PARTIES

AND FOR PROPERTY DAMAGE TO THE EXTENT OF THE WILLFUL ACTS OF THE NEGLIGENCE

OF STERIS OR THE STRICT LIABILITY OF STERIS CAUSED BY THE ACTS OR OMISSIONS OF

STERIS. CUSTOMER AGREES TO DEFEND, INDEMNIFY AND HOLD STERIS HARMLESS FROM

ANY AND ALL CLAIMS, LIABILITY, DAMAGES OR EXPENSES DUE TO PERSONAL INJURIES,

INCLUDING DEATH, TO EMPLOYEES OF CUSTOMER AND STERIS AND TO THIRD PARTIES

AND FROM PROPERTY DAMAGE TO THE EXTENT OF THE WILLFUL ACTS OR THE NEGLIGENCE OF CUSTOMER OR THE STRICT LIABILITY OF CUSTOMER CAUSED BY THE ACTS OR

OMISSIONS OF CUSTOMER.

WARNING - COPYING PROHIBITED

This manual is protected by Federal Copyright Law, which

provides for damages of up to $20,000, as well as

criminal fines and imprisonment, for unauthorized copying.

A Word From STERIS

This manual contains important information on

proper maintenance of the Eagle® CenturyTM and

Millennium Series Sterilizers. All personnel involved

in the use of this equipment must carefully review

and comply with the warnings, cautions and instructions contained in this manual. These instructions

are important to protect the health and safety of

personnel servicing an Eagle Century and Millennium Series sterilizer and should be retained in a

conveniently accessible area for reference.

This sterilizer is specifically designed to process

goods using only the cycles as specified in this manual.

If there is any doubt about a specific material or

product, contact the manufacturer of the product for

the recommended sterilization technique.

STERIS carries a complete line of accessories for use

with this sterilizer to simplify, organize and assure

sterility of the sterilization process. Instrument trays

and biological/chemical monitoring systems are all

available to fulfill your facility's processing needs. A

STERIS representative will gladly review these

with you.

for details.

ADVISORYADVISORY

ADVISORY

ADVISORYADVISORY

A summary of the safety precautions to be observed

when operating this equipment can be found in

Section 1 of this manual. Do not operate the sterilizer

until you have become familiar with this information.

The Scientific series of this model sterilizer is not

designed to process flammable liquids nor liquids in

containers that are not designed for sterilization.

The Health Care series of this model sterilizer is not

designed to process flammable liquids nor liquids in

containers that are not designed for sterilization.

Any alteration of the sterilizer which affects its operation will void the warranty and could violate

state and local regulations and jeopardize insurance

coverage.

SERVICE INFORMATIONSERVICE INFORMATION

SERVICE INFORMATION

SERVICE INFORMATIONSERVICE INFORMATION

A thorough preventive maintenance program is

essential to safe and proper sterilizer operation.

Comprehensive instructions for routine preventive

maintenance can be found in the

nance, P-129367-410

You are encouraged to contact STERIS concerning

our Annual Maintenance Agreement. Under the

terms of this agreement, preventive maintenance,

adjustments, and replacement of worn parts are

done on a scheduled basis to assure equipment performance at peak capability and to help avoid untimely or costly interruptions. STERIS maintains a

global staff of well equipped, factory-trained technicians to provide this service, as well as expert repair

services. Please contact your STERIS representative

, provided.

Routine Mainte-

i

764326-797

Table of Contents

Section Title Page

Section 1: Listing of Warnings and Cautions .................................. 2-1

Section 2: Cycles and Phases .......................................................... 2-1

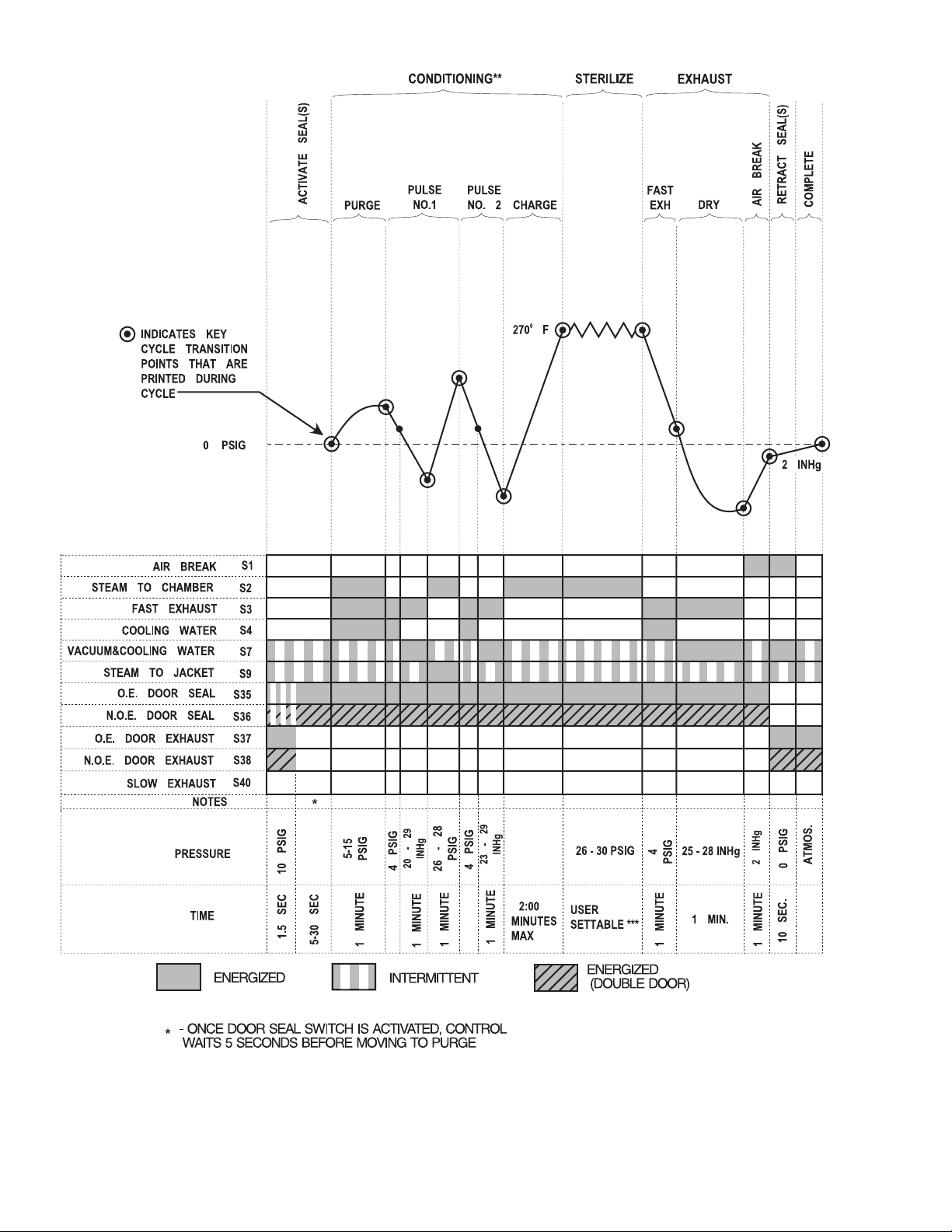

2.1 Gravity/Flash Cycle ................................................................................... 2-1

2.1.1 Jacket Temperature – Out of cycle ............................................................ 2-1

2.1.2 Activate Seal(s) .......................................................................................... 2-1

2.1.3 Purge .......................................................................................................... 2-1

2.1.4 Charge ....................................................................................................... 2-1

2.1.5 Sterilize ....................................................................................................... 2-1

2.1.6 Fast Exhaust ............................................................................................... 2-1

2.1.7 Dry .............................................................................................................. 2-1

2.1.8 Air Break..................................................................................................... 2-1

2.1.9 Retract Seals .............................................................................................. 2-1

2.1.10 Complete .................................................................................................... 2-1

2.2 Prevac/Express Cycle ................................................................................ 2-3

2.2.1 Jacket Temperature – Out of cycle ............................................................ 2-3

2.2.2 Activate Seal(s) .......................................................................................... 2-3

2.2.3 Purge .......................................................................................................... 2-3

2.2.4 Vacuum Pulse ............................................................................................ 2-3

2.2.5 Pressure Pulse ........................................................................................... 2-3

2.2.6 Charge ....................................................................................................... 2-3

2.2.7 Sterilize ....................................................................................................... 2-3

2.2.8 Fast Exhaust ............................................................................................... 2-3

2.2.9 Dry .............................................................................................................. 2-3

2.2.10 Air Break..................................................................................................... 2-3

2.2.11 Retract Seals .............................................................................................. 2-3

2.2.12 Complete .................................................................................................... 2-3

2.3 Liquid Cycle ............................................................................................... 2-5

2.3.1 Jaket Temperature – Out of cycle .............................................................. 2-5

2.3.2 Activate Seal(s) .......................................................................................... 2-5

2.3.3 Purge .......................................................................................................... 2-5

2.3.4 Charge ....................................................................................................... 2-5

2.3.5 Sterilize ....................................................................................................... 2-5

2.3.6 Exhaust....................................................................................................... 2-5

2.3.7 Retract Seal(s)............................................................................................ 2-5

2.3.8 Vapor Removal ........................................................................................... 2-5

2.3.9 Complete .................................................................................................... 2-5

2.4 Steam Flush Pressure Pulse (SFPP) Cycle (Millennium only)..................... 2-7

2.4.1 General....................................................................................................... 2-7

2.4.2 Wrappid/Express ....................................................................................... 2-7

2.4.3 Wrappid/SFPP ............................................................................................ 2-7

2.4.4 SFPP........................................................................................................... 2-7

2.5 Leak Test Cycle .......................................................................................... 2-9

2.5.1 Activate Seal(s) .......................................................................................... 2-9

iii

764326-797

Table of Contents (continued)

Section Title Page

2.5.2 Purge.......................................................................................................... 2-9

2.5.3 Vacuum Pulse ............................................................................................ 2-9

2.5.4 Pressure Pulse ........................................................................................... 2-9

2.5.5 Charge ....................................................................................................... 2-9

2.5.6 Leak Test Evacuating ................................................................................. 2-9

2.5.7 Leak Test Stabilizing .................................................................................. 2-9

2.5.8 Leak Test .................................................................................................... 2-9

2.5.9 Air Break..................................................................................................... 2-9

2.5.9 Retract Seal(s)............................................................................................ 2-9

2.5.10 Complete .................................................................................................... 2-9

Section 3: Mechanical Components ................................................ 3-1

Section 4: Electrical Components ................................................... 4-1

4.1 Century Control Theory of Operation ......................................................... 4-1

4.1.1 Main Control ............................................................................................... 4-1

4.1.2 Incoming Power Terminal Block ................................................................. 4-1

4.1.3 Power Switch .............................................................................................. 4-1

4.1.4 Line Filter .................................................................................................... 4-1

4.1.5 Connector Board ........................................................................................ 4-1

4.1.6 Power Supply ............................................................................................. 4-1

4.1.7 CPU Board ................................................................................................. 4-1

4.1.7.1 CPU Chip ................................................................................................... 4-1

4.1.7.2 Flash Memory ............................................................................................. 4-2

4.1.7.3 Static RAM ................................................................................................. 4-2

4.1.7.4 A/D Converter............................................................................................. 4-2

4.1.7.5 Battery Back-up ......................................................................................... 4-2

4.2 Main Control - CPU Board.......................................................................... 4-2

4.2.1 CPU Board Setup....................................................................................... 4-2

4.2.2 Flash Chip Change..................................................................................... 4-2

4.2.3 Jumpers ..................................................................................................... 4-3

4.2.4.1 JP-1 & JP-2 146656-185 Boards Only........................................................ 4-3

4.2.4.2 JP-1 & JP-2 146656-065/069 Boards Only................................................. 4-4

4.2.5 JP-3 ............................................................................................................ 4-4

4.2.6 JP-4 ............................................................................................................ 4-4

4.2.7 Dip Switches .............................................................................................. 4-4

4.2.8 LED Display on CPU Board ....................................................................... 4-4

4.3 Main control – Power Supply...................................................................... 4-6

4.4 MAIN CONTROL – I/O BOARD .................................................................. 4-7

4.4.1 OVERVIEW ................................................................................................. 4-7

4.4.2 I/O CONFIGURATION ................................................................................ 4-7

4.4.2 Jumper ....................................................................................................... 4-7

4.5 Display ..................................................................................................... 4-12

4.6 Touch Screen ........................................................................................... 4-12

4.7 Display Module ........................................................................................ 4-12

4.8 Display Interface Board ........................................................................... 4-12

iv

764326-797

Table of Contents (continued)

Section Title Page

4.9 Printer Board Assembly ........................................................................... 4-12

4.10 Speaker .................................................................................................... 4-12

4.11 Printer ....................................................................................................... 4-12

4.12 Paper Take Up Mechanism ...................................................................... 4-14

4.13 Analog Devices ........................................................................................ 4-14

4.13.1 RTD .......................................................................................................... 4-14

4.13.2 Pressure Transducer ................................................................................ 4-14

Section 5: Service Mode .................................................................. 5-1

5.1 Access Service Mode ................................................................................ 5-1

5.1.1 Scientific Sterilizers .................................................................................... 5-1

5.2 Access Service Mode ................................................................................ 5-2

5.2.1 Healthcare Sterilizers ................................................................................. 5-2

5.3 Calibration .................................................................................................. 5-3

5.3.1 Calibration Overview .................................................................................. 5-5

5.3.2 Calibrate Temperature ............................................................................... 5-5

5.3.2.1 Steam Method of Calibration...................................................................... 5-6

5.3.2.1a Calibrate Chamber Temperature ......................................................... 5-6

5.3.2.1b Calibrate Jacket Temperature ............................................................. 5-8

5.3.2.1c Calibrate Waste Temperature .............................................................. 5-9

5.3.2.2 Oil Bath Method of Calibration ................................................................. 5-10

5.3.2.3 Load Values Method of Temperature Calibration .................................... 5-12

5.3.3.2 Steam Method of Pressure Calibration .................................................... 5-14

5.3.3.2 External Method of Pressure Calibration .................................................. 5-15

5.3.3.3 Load Values Method of Pressure Calibration ........................................... 5-17

5.3.4 Temperature/Pressure Units .................................................................... 5-18

5.3.4.1 Pressure Units .......................................................................................... 5-18

5.3.4.2 Temperature Units .................................................................................... 5-19

5.3.5 Temperature/Pressure Verification ........................................................... 5-19

5.3.6 Calibration History .................................................................................... 5-19

5.4 Input/Output Tests ................................................................................... 5-20

5.5 Adjustments ............................................................................................. 5-21

5.5.1 Safety Valve Tests .................................................................................... 5-21

5.5.2 Door Sensor Adjustments ........................................................................ 5-21

5.5.3 Door Pressure Settings ............................................................................ 5-22

5.5.4 Leak Test .................................................................................................. 5-22

5.6 Valve History ............................................................................................ 5-22

5.6.1 Valve Service............................................................................................ 5-22

5.6.2 View Valve Actuation History .................................................................... 5-23

5.6.3 View Valve Cycle Count History ............................................................... 5-23

5.7 Alarm Maintenance .................................................................................. 5-24

5.7.1 Alarm List ................................................................................................. 5-24

5.7.2 Alarm Log ................................................................................................. 5-24

5.7.3 Show Screems ......................................................................................... 5-25

5.7.4 Pushbutton Test ....................................................................................... 5-25

v

764326-797

Table of Contents (continued)

Section Title Page

5.7.5 Battery Saver............................................................................................ 5-25

5.7.6 Configure Machine ................................................................................... 5-25

5.7.6.1 Set Configurations .................................................................................... 5-26

5.8 Change Values ......................................................................................... 5-27

Section 6: Field Test Procedure ...................................................... 6-1

6.1 General....................................................................................................... 6-1

6.1.1 Section Index ............................................................................................. 6-1

6.2 Test Instrumentation Required ................................................................... 6-1

6.3 Installation Data .......................................................................................... 6-1

6.4 Installation Verification................................................................................ 6-2

6.5 Control Setup ............................................................................................. 6-2

6.6 Loss of Power Test ..................................................................................... 6-2

6.7 Input/Output Status and Wiring Check ...................................................... 6-2

6.8 Door Check ................................................................................................ 6-3

6.9 Electric Generator Set-Up (Electric Units Only) ......................................... 6-3

6.9.1 Boiler Low Water Cutoff Test ...................................................................... 6-4

6.10 PS1 (PS2) Setting ....................................................................................... 6-4

6.11 Temperature Calibration............................................................................. 6-4

6.12 Pressure Calibration ................................................................................... 6-4

6.13 Safety Valve Test and Regulator Setting.................................................... 6-4

6.14 Leak Test (Also refer to cycle chart in Section 2 of this manual) .............. 6-4

Section 7: Steam Generator Maintenance ...................................... 7-1

7.1 STEAM GENERATOR................................................................................. 7-1

7.1.1 Heating Element/Boiler Chamber/Probe Cleaning ..................................... 7-1

7.1.2 Steam Chamber Descaling/Flush Out ........................................................ 7-1

7.2 Pressure Switch Adjustments..................................................................... 7-2

7.2.1 Adjustable Components............................................................................. 7-2

7.2.2 Pressure Switch Adjustments..................................................................... 7-2

Section 8: Maintenance Procedures ................................................ 8-1

8.1 Door............................................................................................................ 8-1

8.1.1 Removal Procedure.................................................................................... 8-1

8.1.2 Inspection................................................................................................... 8-1

8.1.3 Door System Adjustments (16" and 20", Power and Manual Doors) .......... 8-1

8.2 Door Guide ................................................................................................. 8-1

8.2.1 Counterweight Guides ............................................................................... 8-2

8.2.2 Counterweight Cable Length Adjustment .................................................. 8-3

8.2.3 Counterweight Hard Down Stop ................................................................ 8-3

8.2.4 Door Down Stop ......................................................................................... 8-4

8.2.5 Counterweight Soft Stops .......................................................................... 8-4

8.2.6 Door Balancing........................................................................................... 8-4

8.2.7 Door Drive Adjustment ............................................................................... 8-4

8.2.8 Foot Pedal .................................................................................................. 8-5

vi

764326-797

Table of Contents (continued)

Section Title Page

8.2.9 Door Up Sensor.......................................................................................... 8-6

8.2.10 Vapor Removal Solenoid Assembly ........................................................... 8-6

8.3 General Notes ............................................................................................ 8-7

8.4 Piping Manifolds......................................................................................... 8-7

8.4.1 Servicing Piping Manifolds and Components ............................................ 8-7

8.4.2 Steam Manifold .......................................................................................... 8-7

8.4.3 Exhaust Manifold ........................................................................................ 8-8

8.4.4 Removal: Exhaust Manifold ........................................................................ 8-9

8.4.5 Water Manifold ........................................................................................... 8-9

8.4.6 Removal: Water Manifold and Water Ejector Assembly ........................... 8-10

8.4.7 Removal: Heat Exchanger ....................................................................... 8-10

8.5 Control Components ................................................................................ 8-10

8.5.1 CPU Board ............................................................................................... 8-10

8.5.2 Flash Memory Chips — U13, U16, U15 and U12 .................................... 8-10

8.5.3 Battery ...................................................................................................... 8-12

8.5.4 I/O Board.................................................................................................. 8-12

8.5.5 U26 Chip .................................................................................................. 8-12

8.5.6 Relays....................................................................................................... 8-12

8.5.7 Power Supply ........................................................................................... 8-13

8.5.8 Main Control Box ...................................................................................... 8-13

8.5.9 Connector Board ...................................................................................... 8-14

8.6 Display Assembly..................................................................................... 8-14

8.6.1 Printer Board Assembly ........................................................................... 8-15

8.6.2 U8 ............................................................................................................. 8-15

8.6.3 Interface Board Assembly........................................................................ 8-15

8.6.4 U17 ........................................................................................................... 8-16

8.6.5 Display Module ........................................................................................ 8-16

8.6.6 Touch Screen ........................................................................................... 8-16

Section 9: Reference ........................................................................ 9-1

Single Door Wire Harness Tabulation ..................................................................... 9-1

Double Door Wire Harness Tabulation .................................................................... 9-2

Cable Assembly - P9/P10A (146657-774) .............................................................. 9-3

Cable Assembly - P9/P10A, P10B (146657-854) .................................................... 9-3

Cable Assembly - P10/S3, S7 (146657-773)........................................................... 9-4

Cable Assembly - P10/S3, S37, S38 ....................................................................... 9-5

Cable Assembly - J11/S2, S35, S36 (146657-74)9 ................................................. 9-6

Cable Assembly - J11/S2, S35 (146657-770) ......................................................... 9-6

Cable Assembly - P12/S4, S7 (1446657-771)......................................................... 9-7

Cable Assembly - P12/S4, S7 (1446657-743)......................................................... 9-7

Cable Assembly - S8 (136809-801) ........................................................................ 9-8

Cable Assembly - P18/LS1/LS2/LS3/LS4 (136809-697) ......................................... 9-8

Cable Assembly - P18/LS1/LS3 (136809-752) ........................................................ 9-9

Cable Assembly - P19/CS1/PS1 (136809-753) ....................................................... 9-9

Cable Assembly - P19/CS1/PS1/PS2 (136809-802) ............................................. 9-10

vii

764326-797

Table of Contents (continued)

Section Title Page

Cable Assembly - P100 (136809-755) .................................................................. 9-10

Cable Assembly - AUS (136809-756) ................................................................... 9-10

Chamber Pressure Transducer Harness Assembly (136809-751) ....................... 9-11

RTD Cable Assembly (136809-751)...................................................................... 9-11

Control box Assembly and Display Cable Assembly (146657-782) ..................... 9-12

Motor Housing Assembly (146657-837)................................................................ 9-13

Assembly - Electric Steam Generator Piping

and Wiring Package - 16" (146660-103/104) ................................................... 9-13

Assembly - Electric Steam Generator Piping

and Wiring Package - 20" (146660-105/106) ................................................... 9-13

Final Wiring Assembly (146657-842/845).............................................................. 9-15

Printer Display Control Housing (146657-786) ...................................................... 9-16

Display Control Housing, NOE (146657-850) ....................................................... 9-18

Display Control Housing Assembly (146657-850) ................................................ 9-19

Machine Schematic “Small Sterilizer”, Single Door (146657-781) ........................ 9-20

Machine Schematic “Small Sterilizer”, Double Door (146657-867) ....................... 9-22

Control Box Assembly (146657-782) .................................................................... 9-25

Steam Generator, Electric (146660-101/102)........................................................ 9-27

Assembly, Door Motor Housing (146657-837) ...................................................... 9-28

Cable Assembly - PA/PB, Early Century (136809-754) ........................................ 9-29

Cable Assembly - PA/PB, Current Century (136809-754 ...................................... 9-31

viii

764326-797

Section 1: Listing of Warnings and Cautions

The following is a listing of safety precautions which must be observed when operating or servicing this

equipment. WARNINGS indicate the potential for danger to personnel, and CAUTIONS indicate the

potential for damage to equipment. These precautions are repeated (in whole or in part), where applicable,

throughout the manual.

Observance of these safety precautions will minimize the risk of personal injury and/or the possible use of

improper maintenance methods which may damage the unit or render it unsafe. It is important to

understand that these precautions are not exhaustive. STERIS could not possibly know, evaluate and advise

maintenance departments of all conceivable ways in which maintenance might be done or the possible

hazardous consequences of each way.

WARNING — BURN HAZARD:

Repairs and adjustments should be attempted only by authorized persons fully acquainted with

!

this equipment. Use of inexperienced, unqualified persons to work on the equipment or the

installation of unauthorized parts could cause personal injury or result in costly damage!

Before performing any cleaning or maintenance procedures allow sterilizer, generator (if

!

applicable) and accessories to cool to room temperature .

Sterilizer and rack/shelves will be HOT after cycle is run. Always wear protective gloves and

apron (also face shield if processing liquids) when removing a processed load. Protective

!

gloves and apron must be worn when reloading sterilizer following previous operation.

A steam supply malfunction, identified by an audible (warble tone) and visual alarm, can cause

!

the sterilizer chamber to fill with scalding water.

• Do not open the door.

• Call for service immediately.

Failure to shut off the steam supply when cleaning or replacing strainers can result in serious

!

injury.

!

Jacket pressure must be at 0 psig before beginning work on the jacket trap.

Proper testing of safety valves requires that it be under pressure. Exhaust from the safety valve

!

is hot and can cause burns. Proper safety attire (gloves, eye protection, insulated overalls) as

designated by OSHA are required. Testing is to be performed by qualified service personnel only.

Do not remove the Jacket RTD for jacket calibration until the chamber and jacket gauges read

!

0 psig.

Depressurize jacket before removing jacket RTD. Always verify that chamber and jacket pressure

is at 0 psig by observing the jacket and pressure gauges behind the front access door.

!

WARNING — ELECTRIC SHOCK HAZARD:

DISCONNECT FACILITY POWER OR PLACE CONTROL DISCONNECT SWITCH, located on

control box, to OFF before removing or replacing any fuses or printed circuits boards from the

!

sterilizer's control section.

1-1

764326-797

WARNING — EXPLOSION HAZARD:

Healthcare sterilizers are not designed to process liquids.

!

Scientific sterilizers are not designed to process flammable liquids.

!

Do not use this sterilizer in the presence of flammable compounds.

!

WARNING — FALL HAZARD:

To prevent falls, keep floors dry by wiping up any spilled liquids or condensation in sterilizer

!

loading or unloading area(s).

WARNING — STERILITY ASSURANCE HAZARD:

Load sterility may be compromised if the biological air removal or air leak test indicates a

!

potential problem. If these indicators show a potential problem, refer the situation to a qualified

service technician before using the sterilizer further.

According to AAMI standards, a measured leak rate greater than 1 mm Hg/minute indicates a

!

problem with the sterilizer. Refer the situation to a qualified service technician before using the

sterilizer further.

WARNING — PERSONAL INJURY HAZARD:

Regularly scheduled preventive maintenance is required for safe and reliable operation of this

!

equipment. Contact your STERIS Service Representative to schedule preventive maintenance.

When closing the chamber door, keep hands and arms out of the door opening, and make sure

!

opening is clear of obstructions.

Before entering chamber for cleaning or servicing, turn main power switch OFF.

!

Area must be properly vented to prevent buildup of fumes. Wear eye protection and gloves when

!

pouring descaler into unit.

The sterilizer door weighs approximately 35 lbs (16") or 70 lbs (20"). Always use care when

!

removing the door. Two service persons should always be present when removing the 20" door.

CAUTION — POSSIBLE EQUIPMENT DAMAGE

Insufficient Service Clearance will make repairs more difficult and time consuming.

!

Piping sized too small may cause water hammer, resulting in damage to the sterilizer.

!

If 0 dry time is selected, sterilizer automatically initiates a vapor removal phase in place of

!

drying. This phase can still draw a vacuum to 5 in Hg. Consult manufacturer's recommendations

to ensure your equipment can withstand this depth of vacuum before selecting 0 dry time.

Never use a wire brush, abrasives or steel wool on door and chamber assembly. Do not use

!

cleaners containing chloride on stainless steel surfaces. Chloride based cleaners will deteriorate stainless steel, eventually leading to failure of the vessel.

After installation it is mandatory to brace piping at the drain funnel so that it will not move

!

vertically.

1-2

764326-797

Removing the door seal gasket with a tool such as a screwdriver (the recommended method) in

!

most cases will cut or otherwise damage the gasket so that it cannot be further used.

• Do not remove the gasket unless absolutely necessary.

• Do not use a sharp tool to install the gasket.

Allow thermostatic traps to cool to room temperature before removing cover. Since there is

!

nothing to limit expansion, the diaphragm may rupture or fatigue if trap is opened while hot.

Failure to flush generator daily could result in malfunction of the generator. Warranty on the

!

generator will be voided unless flushed daily.

Actuation at less than 75% of rated pressure can allow debris to contaminate the seat and cause

!

the safety valve to leak. A leaking safety valve must be replaced.

Whenever working under the sterilizer door, raise the door to its full up position and insert both

tethered door pins.

!

initiated.

Whenever handling electronic components, use of a grounding wrist strap is mandatory to

!

prevent static discharge damage.

Be sure the pins are subsequently removed before door actuation is

1-3

764326-797

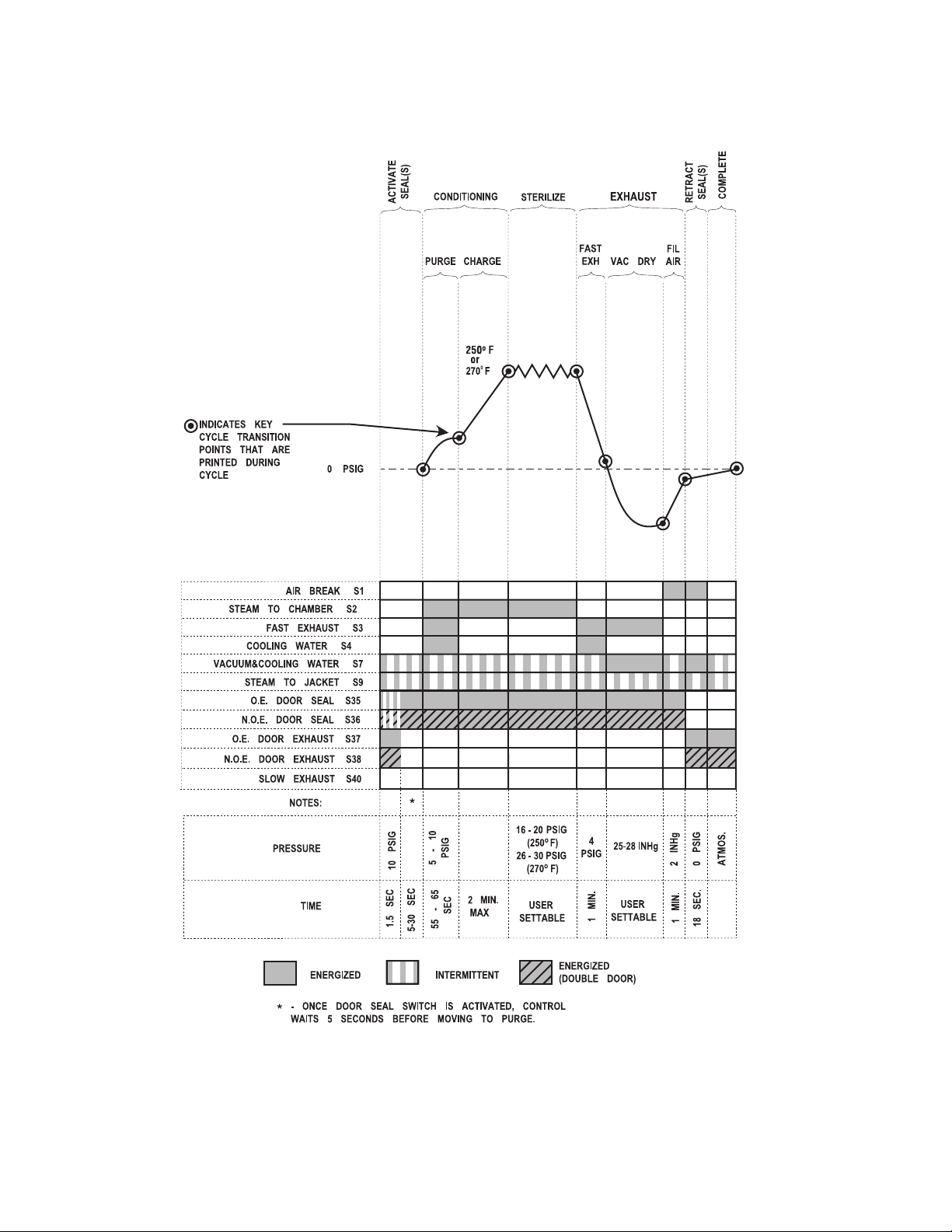

2.12.1

GRAVITY/FLASH CYCLEGRAVITY/FLASH CYCLE

2.1

GRAVITY/FLASH CYCLE

2.12.1

GRAVITY/FLASH CYCLEGRAVITY/FLASH CYCLE

Section 2: Cycles and Phases

2.1.62.1.6

2.1.6

2.1.62.1.6

Fast ExhaustFast Exhaust

Fast Exhaust

Fast ExhaustFast Exhaust

NOTE: S7 solenoid valve is used to control the waste

water temperature below 140°F. S7 will turn on any time

it is necessary to cool the waste temperature.

NOTE: The status shown on the display will change

during the cycle but the screen will remain the same for

most of the phases. The only phases which use different screens are: air break and retract because there is

no abort during these phases, and the cycle complete

phase. The status changes are shown below.

NOTE: Components shown in parentheses ( ) denote

components used only on double door sterilizers.

2.1.12.1.1

2.1.1

2.1.12.1.1

On Health Care units, the jacket is maintained at the

temperature the previous cycle was run. On Scientific units, the jacket is maintained at 115°C.

2.1.22.1.2

2.1.2

2.1.22.1.2

(38) (Door Exhaust) will be energized for 1.5 seconds. S35 (36) (Door Seal) will pulse during this

time. After 1.5 seconds S37 (38) will be deenergized

and S35 (36) will be energized. When the pressure

behind the seal reaches 10 psig and after a 5 second

delay, the cycle will advance to the Purge phase.

2.1.32.1.3

2.1.3

2.1.32.1.3

S2 (Steam to Chamber), S3 (Fast Exhaust), S4 (Cooling Water), and S35 (36) will be on. S7 (Vacuum &

Cooling Water) and S9 (Steam to Jacket) will pulse

throughout cycle to maintain effluent water temperature. S7 is normally off because S4 will keep

effluent cool. S9 will shut off if chamber pressure is

greater than 10 psig for a 265°F cycle.

2.1.42.1.4

2.1.4

2.1.42.1.4

Jacket Temperature – Jacket Temperature –

Jacket Temperature –

Jacket Temperature – Jacket Temperature –

Activate Seal(s)Activate Seal(s)

Activate Seal(s)

Activate Seal(s)Activate Seal(s)

PurgePurge

Purge

PurgePurge

ChargeCharge

Charge

ChargeCharge

Out of cycleOut of cycle

Out of cycle

Out of cycleOut of cycle

S2 will go off. S3, S4 and S35 (36) will be on.

• S7 and S9 will be intermittent while controlling

the effluent and jacket temperatures.

• Fast exhaust should last less than 1 minute.

• Wait until display shows 4 psig.

2.1.72.1.7

2.1.7

2.1.72.1.7

S4 will go off. S3, S7 and S35 (36) will be on.

• S9 will be intermittent while controlling the jacket

• The Gravity and Flash cycles do not have a dry

2.1.82.1.8

2.1.8

2.1.82.1.8

S1, S35 (36) will be on.

• S7 and S9 may be intermittent while controlling

2.1.92.1.9

2.1.9

2.1.92.1.9

S1 will remain on. S35 (36) will turn off. S7, S37 (38)

will turn on. After the seal pressure switch opens

(less than 10 psig), a vacuum will be pulled for an

additional 18 seconds. If zero dry time is selected,

the door motor will energize for a few seconds to

slightly open the door to vent any excess vapor. This

vent period will last 1 minute.

2.1.102.1.10

2.1.10

2.1.102.1.10

S37 (38) will be on. S7 will be intermittent. S9 will

maintain jacket temperature at approximately 270oF;

all others will be off. A summary of the values

attained during the cycle will be printed. Open the

door(s).

DryDry

Dry

DryDry

temperature.

time, instead they use a slow vapor removal.

Air BreakAir Break

Air Break

Air BreakAir Break

the temperature of the waste water and jacket.

Retract SealsRetract Seals

Retract Seals

Retract SealsRetract Seals

CompleteComplete

Complete

CompleteComplete

S3 and S4 will go off. S2 and S35 (36) will be on. S7

and S9 will remain intermittent. Verify that chamber is charging with steam and will charge until the

sterilize set temperature value 250°F is reached. S9

will pulse, to limit overshoot, if pressure is over 15

psig for a 250°F cycle or 27 psig for a 270°F cycle.

2.1.52.1.5

2.1.5

2.1.52.1.5

S2 and S35 (36) will remain on. S9 will be intermittent while controlling temperature at set point. S7

will be intermittent while controlling temperature

of the waste water. Wait until sterilize time reaches

0:00.

SterilizeSterilize

Sterilize

SterilizeSterilize

764326-797

2-1

Figure 2-1. Gravity/Flash Cycle Graph

2-2

764326-797

2.22.2

PREVAC/EXPRESS/DART (BOWIE-PREVAC/EXPRESS/DART (BOWIE-

2.2

PREVAC/EXPRESS/DART (BOWIE-

2.22.2

PREVAC/EXPRESS/DART (BOWIE-PREVAC/EXPRESS/DART (BOWIEDICK) CYCLEDICK) CYCLE

DICK) CYCLE

DICK) CYCLEDICK) CYCLE

NOTE: S7 solenoid valve is used to control the waste

water temperature below 140°F, S7 will turn on any

time it is necessary to cool the waste temperature.

NOTE: Components shown in parentheses ( ) denote

components used only on double door sterilizers.

perature value 270°F. is reached.

2.2.72.2.7

2.2.7

2.2.72.2.7

S9 will be intermittent while controlling temperature

at set point. S2 and S35 (36) will remain on. S7 will be

intermittent while controlling temperature of the

waste water. The DART cycle is fixed at 3:30 minutes

exposure.

SterilizeSterilize

Sterilize

SterilizeSterilize

2.2.12.2.1

2.2.1

2.2.12.2.1

On Health Care units, the jacket is maintained at

the temperature the previous cycle was run. On

Scientific units, the jacket is maintained at 115°C.

2.2.22.2.2

2.2.2

2.2.22.2.2

S37 (38) (Door Exhaust) will be energized for 1.5

seconds. S35 (36) (Door Seal) will pulse during this

time. After 1.5 seconds S37 (38) will be deenergized

and S35 (36) will be energized. When the pressure

behind the seal reaches 10 psig and after a 5 second

delay, the cycle will advance to the Purge phase.

2.2.32.2.3

2.2.3

2.2.32.2.3

S2 (Steam to Chamber), S3 (Fast Exhaust), S4 (Cooling Water), and S35 (36) will be on. S7 (Vacuum

and Cooling Water) will be intermittent to maintain the effluent temperature. S9 (Steam to Jacket)

will be intermittent to maintain jacket temperature.

2.2.42.2.4

2.2.4

2.2.42.2.4

S2 turns off. After 4 psig is reached, S4 will turn off

and S7 will turn on. S9 will be intermittent while

controlling the jacket temperature. A vacuum will

be pulled on the chamber for 1 minute (after 4 psig

is reached) until 10 inHg is reached. After the

second vacuum pulse the cycle will advance to the

Charge.

Jacket Temperature – Out of cycleJacket Temperature – Out of cycle

Jacket Temperature – Out of cycle

Jacket Temperature – Out of cycleJacket Temperature – Out of cycle

Activate Seal(s)Activate Seal(s)

Activate Seal(s)

Activate Seal(s)Activate Seal(s)

PurgePurge

Purge

PurgePurge

Vacuum PulseVacuum Pulse

Vacuum Pulse

Vacuum PulseVacuum Pulse

2.2.82.2.8

2.2.8

2.2.82.2.8

S2 will go off. S3, S4 and S35 (36) will be on. S7 and

S9 will be intermittent while controlling the effluent

and jacket temperatures. Fast exhaust should last

less than 1 minute. Wait until display shows 4 psig.

2.2.92.2.9

2.2.9

2.2.92.2.9

S4 will go off. S3, S7 and S35 (36) will be on. S9 will

be intermittent while controlling the jacket temperature.

2.2.102.2.10

2.2.10

2.2.102.2.10

S1, S35 (36) will be on. S7 and S9 may be intermittent

while controlling the temperature of the waste water

and jacket.

2.2.112.2.11

2.2.11

2.2.112.2.11

S1 will remain on. S35 (36) will turn off. S7, S37 (38)

will turn on. After the seal pressure switch opens

(less than 10 psig), the vacuum will be pulled for an

additional 18 seconds.

2.2.122.2.12

2.2.12

2.2.122.2.12

S1 will turn off. S37 (38) will be on. S7 will be

intermittent while controlling the effluent temperature and S9 will maintain jacket temperature at approximately 285°F, all others will be off. A summary

of the values attained during the cycle will be printed.

Open the door(s).

Fast ExhaustFast Exhaust

Fast Exhaust

Fast ExhaustFast Exhaust

DryDry

Dry

DryDry

Air BreakAir Break

Air Break

Air BreakAir Break

Retract SealsRetract Seals

Retract Seals

Retract SealsRetract Seals

CompleteComplete

Complete

CompleteComplete

2.2.52.2.5

2.2.5

2.2.52.2.5

S3 turns off. S2, S9 and S35 (36) will be on. S7 will

be intermittent. Wait until the pressure reaches 26

psig. Vacuum pulse will repeat. (2 pulses for Express, 4 pulses for Prevac and DART cycles.)

2.2.62.2.6

2.2.6

2.2.62.2.6

S3 will go off. S2, and S35 (36) will be on. S9 will be

on for a 285°F cycle and will operate intermittently

for a 270°F. cycle, to limit overshoot. S7 will be

intermittent. Verify that chamber is charging with

steam and will charge until the sterilizer set tem-

Pressure PulsePressure Pulse

Pressure Pulse

Pressure PulsePressure Pulse

ChargeCharge

Charge

ChargeCharge

2-3

764326-797

** 2 pulses shown for Express cycle, Prevac and DART has 4 pulses.

*** DART cycle exposure is fixed at 3:30 minutes.

Figure 2-2. Prevac/Express/DART (Bowie-Dick) Cycle Graph

2-4

764326-797

2.32.3

LIQUID CYCLELIQUID CYCLE

2.3

LIQUID CYCLE

2.32.3

LIQUID CYCLELIQUID CYCLE

2.3.52.3.5

2.3.5

2.3.52.3.5

SterilizeSterilize

Sterilize

SterilizeSterilize

NOTE: S7 solenoid valve is used to control the waste

water temperature below 140oF. S7 will turn on any time

it is necessary to cool the waste temperature.

NOTE: The status shown on the display will change

during the cycle but the screen will remain the same.

Because of this, only one display will be shown and the

status changes will be explained below. The status

changes are shown below.

NOTE: Components shown in parentheses ( ) denote

components used only on double door sterilizers.

2.3.12.3.1

2.3.1

2.3.12.3.1

On Health Care units, the jacket is maintained at the

temperature the previous cycle was run. On Scientific units, the jacket is maintained at 115°C.

2.3.22.3.2

2.3.2

2.3.22.3.2

S37 (38) (Door Exhaust) will be energized for 1.5

seconds. S35 (36) (Door Seal) will pulse during this

time. After 1.5 seconds S37 (38) will be deenergized

and S35 (36) will be energized. When the pressure

behind the seal reaches 10 psig and after a 5 second

delay, the cycle will advance to the Purge phase.

2.3.32.3.3

2.3.3

2.3.32.3.3

S2 (Steam to Chamber), S3 (Fast Exhaust), S4 (Cooling Water), and S35 (36) will be on. S9 (Steam to

Jacket) will pulse throughout cycle. S7 (Vacuum &

Cooling Water) will normally be off but may pulse

to assist S4 in maintaining effluent water temperature.

2.3.42.3.4

2.3.4

2.3.42.3.4

S3 and S4 will go off. S2 and S35 (36) will be on. S7

will remain intermittent, in order to limit overshoot. S9 will pulse if pressure is above value indicated in chart below. (Note that if sterilize temperature is less than 230oF, pressure is controlled at or

below 6 psig. Verify that chamber is charging with

steam and will charge until the sterilize set temperature value is reached.

Jaket Temperature – Out of cycleJaket Temperature – Out of cycle

Jaket Temperature – Out of cycle

Jaket Temperature – Out of cycleJaket Temperature – Out of cycle

Activate Seal(s)Activate Seal(s)

Activate Seal(s)

Activate Seal(s)Activate Seal(s)

PurgePurge

Purge

PurgePurge

ChargeCharge

Charge

ChargeCharge

S9 will be intermittent while controlling temperature at set point. S2 and S35 (36) will remain on. S7

will be intermittent while controlling temperature

of the waste water. Wait until sterilize time reaches

0:00

2.3.62.3.6

2.3.6

2.3.62.3.6

S9 will turn off. S35 (36) will be on. The normally

open slow exhaust solenoid S40 will cycle ON/OFF

to maintain the correct exhaust rate. The rates are

maintained between two transition points as follows:

• From sterilize pressure to 4.2 psig the rate is 1.6

• From 4.2 psig to 5" Hg the rate is 0.6 psi/min.

NOTE: These transition rates can be adjusted for high

altitudes in the service mode.

The control monitors the pressure drop in exhaust

versus the time in exhaust to determine if the exhaust rate is too fast or too slow. If the exhaust rate

is too fast, S40 will energize (close) to slow the rate.

If the exhaust rate is too slow, S40 will deenergize

(open) and S3 will cycle ON/OFF to help drop

chamber pressure. If the pressure varies by more

than 2 psi from specification, an alarm will occur.

Once the pressure reaches 0 psig S7 will be energized to pull the chamber to a vacuum of 5 inHg at

a rate of 1.2 inHg/min by intermittently controlling

S3. S40 will be on. Once 5 inHg is reached S7 will be

deenergized and S1 (Air Break) will be energized to

break to atmospheric pressure, S3 and S40 will turn

off. Once 2 inHg is reached cycle advances to Door

Seal Retract.

2.3.72.3.7

2.3.7

2.3.72.3.7

S3, S35 (36) will turn off. S7, S38 (38) will turn on.

After the seal pressure switch opens (less than 10

psig), a vacuum will be pulled for an additional 18

seconds and once 1 inHg is reached cycle advances

to vapor removal.

2.3.8 2.3.8

2.3.8

2.3.8 2.3.8

ExhaustExhaust

Exhaust

ExhaustExhaust

psi/min.

Retract Seal(s)Retract Seal(s)

Retract Seal(s)

Retract Seal(s)Retract Seal(s)

Vapor RemovalVapor Removal

Vapor Removal

Vapor RemovalVapor Removal

Sterilize Pressure

Temperature (below this value)

less than 230°F less than 2 psig

230°F 6 psig

245°F 15 psig

255°F 21 psig

265°F 27 psig

VR1 (VR2) will turn on. S37 (S38) will remain on. S1

and S7 will turn off. This phase will last for 6

minutes.

2.3.92.3.9

2.3.9

2.3.92.3.9

S37 (38) will be on. S9 will maintain jacket temperature at approximately 115oF. A summary of the

values attained during the cycle will be printed.

Open the door(s).

2-5

764326-797

CompleteComplete

Complete

CompleteComplete

NOTE: Transition points for slow/fast exhaust are adjustable for altitude in the service mode.

Figure 2-3. Liquid Cycle Graph

2-6

764326-797

2.42.4

STEAM FLUSH PRESSURE PULSESTEAM FLUSH PRESSURE PULSE

2.4

STEAM FLUSH PRESSURE PULSE

2.42.4

STEAM FLUSH PRESSURE PULSESTEAM FLUSH PRESSURE PULSE

(SFPP) CYCLE (SFPP) CYCLE

(SFPP) CYCLE (Millennium only)

(SFPP) CYCLE (SFPP) CYCLE

2.4.12.4.1

2.4.1

2.4.12.4.1

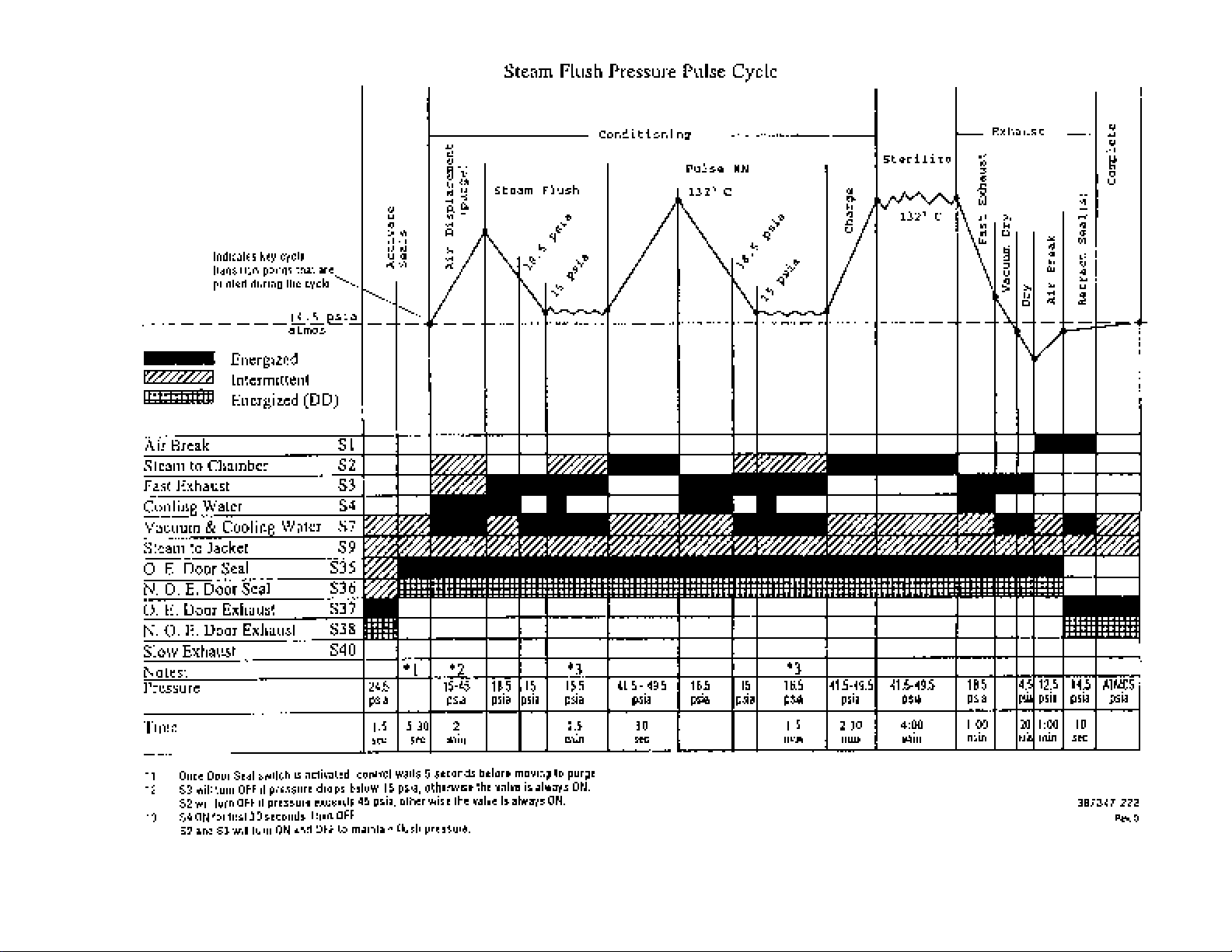

Millennium sterilizers utilize the pressure pulse

cycles developed by the former Joslyn Sterilizer

Corporation, now part of STERIS. This section

describes the operation of cycles available on Millennium sterilizers.

2.4.22.4.2

2.4.2

2.4.22.4.2

This cycle is shown on the display as WRAP/EXPR

and is a 4 minute 270oF exposure with 3 minute dry

to be used for single wrapped instrument trays. The

cycle uses two (2) steam-flush pressure pulses in the

conditioning phase.

2.4.32.4.3

2.4.3

2.4.32.4.3

This cycle is shown on the display as WRAP/SFPP

and is a 4 minute 270oF exposure with 20 minute dry

to be used for containers, single or double wrapped

instrument trays. The cycle uses two (2) steam-flush

pressure pluses in the conditioning phase. This cycle

is essentially the same as the WRAPPID/EXPRESS

except that it has a longer dry time.

2.4.42.4.4

2.4.4

2.4.42.4.4

The cycle is shown on the display as SFPP and is a 4

minute, 270oF exposure with 20 minute dry to be

used for porous items. The cycle uses three (3) stemflush pressure pulses in the conditioning phase.

This cycle is essentially the same as the WRAPPID/

SFPP except it has one additional conditioning pulse

for porous loads.

Steam-Flush Pressure Pulse Cycle GraphSteam-Flush Pressure Pulse Cycle Graph

Steam-Flush Pressure Pulse Cycle Graph

Steam-Flush Pressure Pulse Cycle GraphSteam-Flush Pressure Pulse Cycle Graph

The cycle graph shown can be used to interpret the

operation of all three steam-flush cycles used on the

Millennium sterilizer. The Millennium will operate

in the same manner as a Century with respect to

door control and sterilize phase operation. Differences occur during the conditioning phase and dry

phase and are described in the following section.

Please note the following when reviewing the cycle

graph:

1. Pressure is shown in psia (absolute pressure).

GeneralGeneral

General

GeneralGeneral

Wrappid/ExpressWrappid/Express

Wrappid/Express

Wrappid/ExpressWrappid/Express

Wrappid/SFPPWrappid/SFPP

Wrappid/SFPP

Wrappid/SFPPWrappid/SFPP

SFPPSFPP

SFPP

SFPPSFPP

This is done for familiarity since the Joslyn brand

sterilizers use psia on the display. The Millennium sterilizer can be programmed to display in

either psia (absolute) or psig (gauge) by selecting

the desired units in the CHANGE MACHINE

SETUP menu. This is operator selectable but can

be locked out with an access code. Note that if

psia is selected, all cycles will display in psia,

including Gravity and Prevac cycles. If psig is

selected, all cycles will be displayed in psig,

including the Steam-Flush cycles.

Keep the relationship of psia and psig in mind

when reviewing the descriptions that follow. Note

that at sea level atmospheric pressure is about

14.7 psig while a gauge will read 0 psig. At higher

elevations, atmospheric pressure may be 10 psia

but a gauge will still read 0 psig.

2. The conditioning phase consists of a purge phase

and two or three pulses, depending on the cycle

selected. The cycle graph shows only one pulse as

“Pulse #N“. Each of the two or three pulses are

controlled in the same manner.

3. Purge phase description – the purge is factory set

for 2 minutes and will be controlled so that pressure will not exceed 45 psia nor drop below 0.5

psi above atmospheric pressure. Once the 2 minutes has timed out, the unit will exhaust to just

above atmospheric pressure and then the chamber will be flushed by cycling the S2 and S3 valves

to maintain pressure in the chamber about 0.5 psi

above atmospheric pressure, for 1.5 minutes. The

cycle graph shows 15 psia as it assumes an atmospheric pressure of 14.5 psia. In higher elevations

the pressure will be lower, but still 0.5 psi above

atmospheric pressure. Once the timer times out

the cycle progresses to the first pulse.

4. Pulse #N description – the unit charges with

steam to 132oC setting. Once reached, the unit

exhausts to just above atmosphere and then the

chamber will be flushed by cycling the S2 and S3

valves to maintain pressure in the chamber about

1.5 psi above atmospheric. Note that the flush

that occurs during the pulses will maintain chamber pressure about 1.0 psi higher that the flush

that occurs during the purge phase. After 1.5

minutes the control continues with the next pulse

until two or three pulses (depending on cycle)

occur. After the last pulse the unit will charge to

set temperature.

5. Dry phase – the steam-flush dry phase is identical

to that of a standard Gravity and Prevac cycles

except that the dry timer does not start until the

chamber reaches 4.5 psia (about 10" Hg). The

Prevac and Gravity cycles will start the dry timer

at above atmospheric pressure.

6. S2 and S3 valve cycling – during the flushes the

control will cycle the S2 and S3 valves to maintain

pressure just above atmospheric in the chamber

within 0.5 psi of set point. The control has a

debounce feature that will prevent the valves

from chattering more frequently than every 0.5

second.

2-7

764326-797

764326-797

2-8

Figure 2-4. SFPP Cycle Graph

7. S4 and S7 valve cycling – at the beginning of each

flush the S4 valve will turn on and stay on for 30

seconds to maintain a cool temperature of the

waste water. After the 30 seconds the S7 valve

will operate to maintain waste temperatures.

2.52.5

LEAK TEST CYCLELEAK TEST CYCLE

2.5

LEAK TEST CYCLE

2.52.5

LEAK TEST CYCLELEAK TEST CYCLE

NOTE: S7 solenoid valve is used to control the waste

water temperature below 140°F. S7 will turn on any time

it is necessary to cool the waste temperature.

NOTE: Components shown in parentheses ( ) denote

components used only on double door sterilizers.

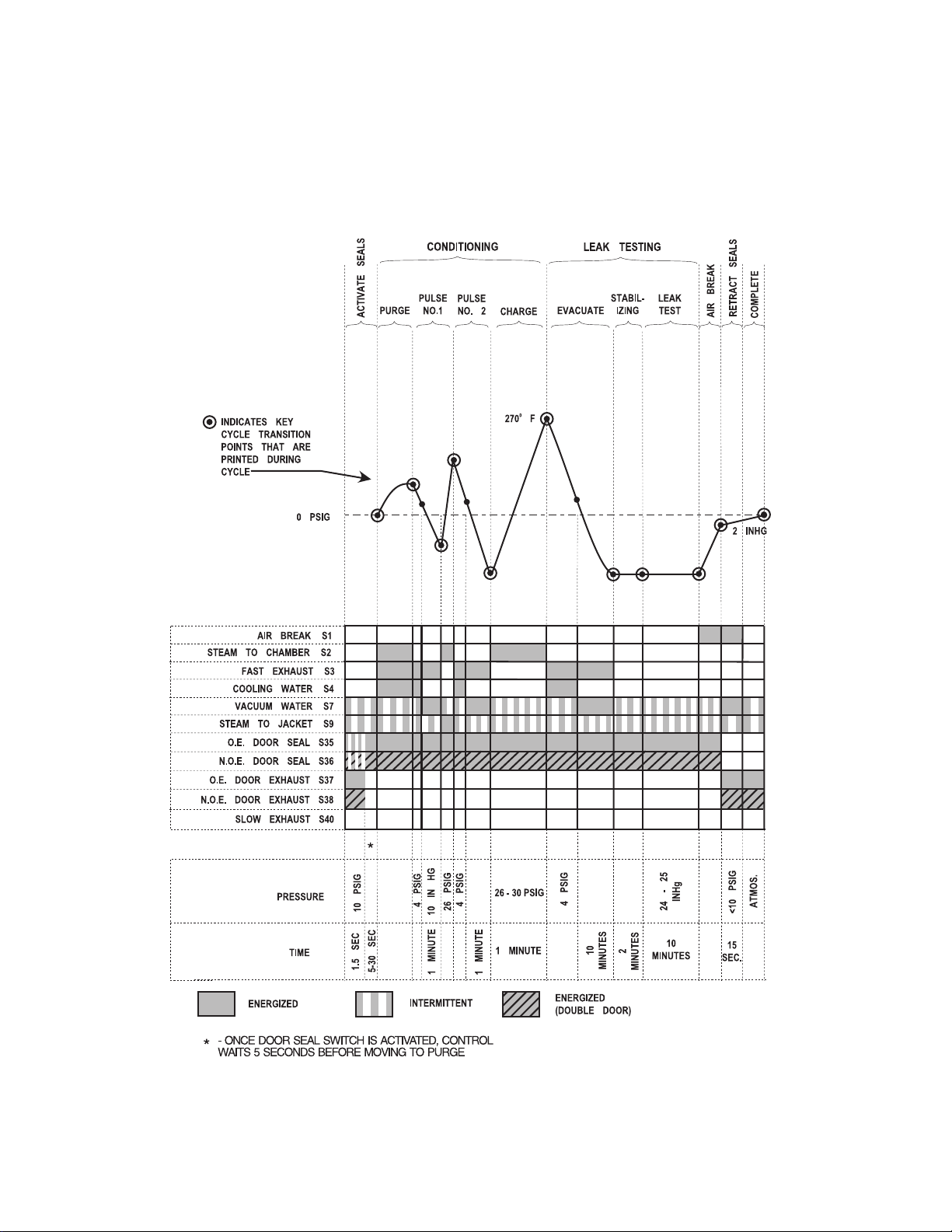

1. With the display showing the Main Menu, press

the Leak Test Cycle button.

2. Connect absolute gauge to chamber. Keep ball

valve closed at this time. Close door(s) if necessary.

2.5.12.5.1

2.5.1

2.5.12.5.1

S37 (38) (Door Exhaust) will be energized for 1.5

seconds. S35 (36) (Door Seal) will pulse during this

time. After 1.5 seconds S37 (38) will be deenergized

and S35 (36) will be energized. When the pressure

behind the seal reaches 10 psig and after a 5 second

delay, the cycle will advance to the Purge phase.

2.5.22.5.2

2.5.2

2.5.22.5.2

S2 (Steam to Chamber), S3 (Fast Exhaust), S4 (Cooling Water), and S35 (S36) will be on. S7 (Vacuum &

Cooling Water) will pulse to maintain waste water

temperature. S7 is normally off. S9 (Steam to Jacket)

will be intermittent.

Activate Seal(s)Activate Seal(s)

Activate Seal(s)

Activate Seal(s)Activate Seal(s)

PurgePurge

Purge

PurgePurge

2.5.52.5.5

2.5.5

2.5.52.5.5

S3 and will go off. S2 will be on. S7 will be intermittent to maintain effluent temperature. S9 will be on

unless the pressure is greater than 27 psig, at which

time it will pulse. Verify that chamber is charging

with steam and will charge until 270.1°F is reached.

2.5.62.5.6

2.5.6

2.5.62.5.6

S2 will turn off. S3, S4 and S35 (36) will be on until

4 psig is reached. Then S4 turns off and S7 turns on.

S9 will be intermittent while controlling the jacket

temperature. Wait for 10 minutes.

NOTE: If 20 inHg is not reached in 10 minutes, the Leak

Test is aborted because of insufficient vacuum. The

leak must be fixed and Leak Test repeated.

2.5.72.5.7

2.5.7

2.5.72.5.7

S3 will turn off. S7 and S9 will be intermittent to

maintain effluent and jacket temperatures. The chamber will stabilize for 2 minutes before starting the

leak test count down.

2.5.82.5.8

2.5.8

2.5.82.5.8

S9 will be intermittent while controlling the jacket

temperature. S7 may be intermittent while controlling the temperature of the waste water. The sterilizer will time for 10 minutes. At the end of 10

minutes S1 will turn on.

2.5.92.5.9

2.5.9

2.5.92.5.9

S1, S35 (36) will be on. S7 and S9 may be intermittent

while controlling the temperature of the waste water and jacket.

ChargeCharge

Charge

ChargeCharge

Leak Test EvacuatingLeak Test Evacuating

Leak Test Evacuating

Leak Test EvacuatingLeak Test Evacuating

Leak Test StabilizingLeak Test Stabilizing

Leak Test Stabilizing

Leak Test StabilizingLeak Test Stabilizing

Leak TestLeak Test

Leak Test

Leak TestLeak Test

Air BreakAir Break

Air Break

Air BreakAir Break

2.5.32.5.3

2.5.3

2.5.32.5.3

S2 turns off. After 4 psig is reached, S4 will turn off

and S7 will turn on.

• S9 will be intermittent while controlling the jacket

2.5.42.5.4

2.5.4

2.5.42.5.4

S3 turns off. S2, S9 and S35 (36) will be on. Wait until

the pressure reaches 26 psig. Vacuum pulse will

repeat.

Vacuum PulseVacuum Pulse

Vacuum Pulse

Vacuum PulseVacuum Pulse

temperature. A vacuum will be pulled on the

chamber for 1 minute (after 4 psig is reached)

until 10 inHg is reached. After the second vacuum

pulse the cycle advances to the Charge.

Pressure PulsePressure Pulse

Pressure Pulse

Pressure PulsePressure Pulse

764326-797

2.5.102.5.10

2.5.10

2.5.102.5.10

S35 (36) will turn off. S7, S37(38) will turn on. After

the seal pressure switch opens (less than 10 psig),

the vacuum will be pulled for an additional 18

seconds.

2.5.112.5.11

2.5.11

2.5.112.5.11

S37 (38) will be on; S7 will control waste temperature and S9 will maintain jacket temperature at

approximately 270°F. S1 will turn off. A summary of

the values attained during the cycle will be printed.

Open the door(s).

2-9

Retract Seal(s)Retract Seal(s)

Retract Seal(s)

Retract Seal(s)Retract Seal(s)

CompleteComplete

Complete

CompleteComplete

Figure 2-5. Vacuum Leak Cycle Graph

2-10

764326-797

764326-797

3-1

Strainer

ST-2

Steam Supply

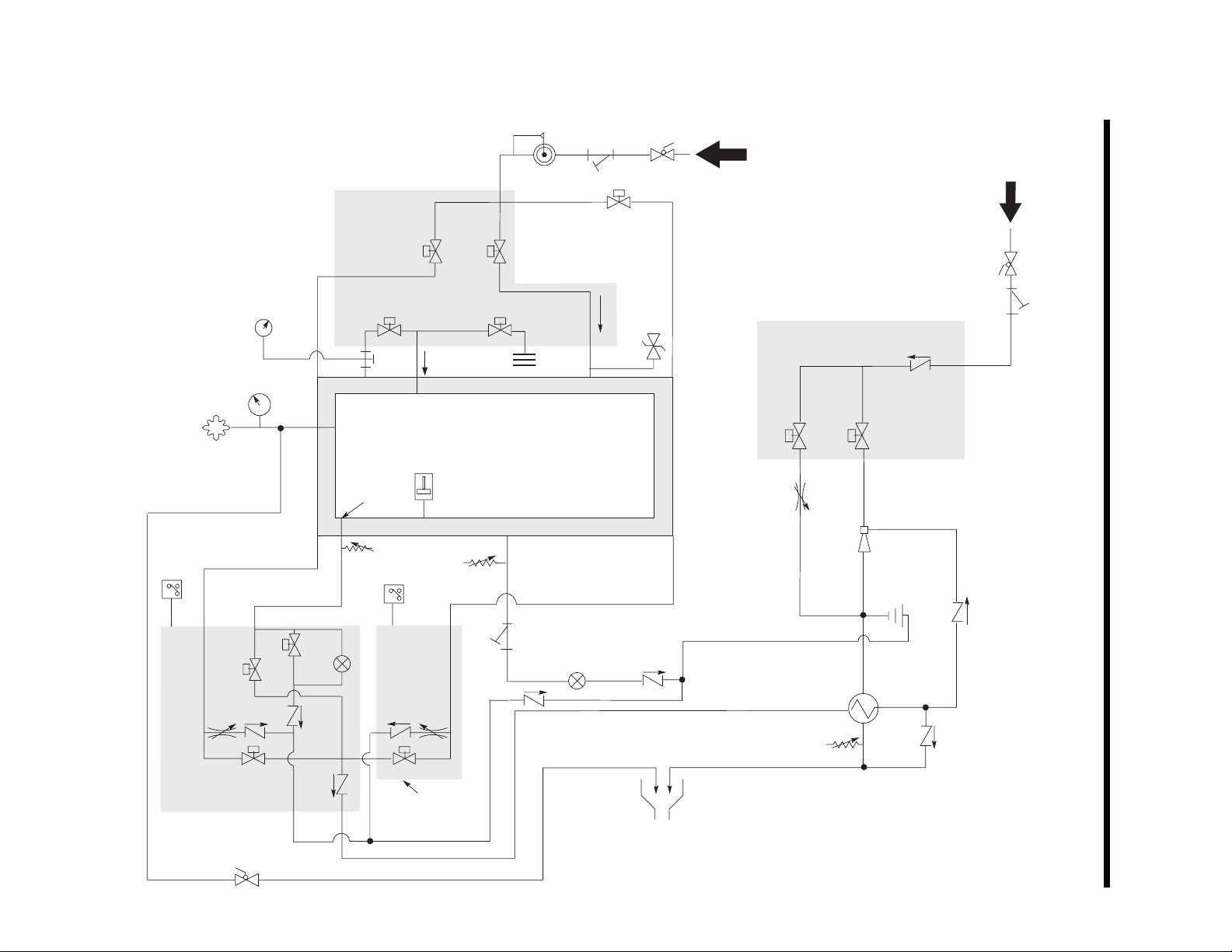

Figure 3-1. Piping Schematic for Health Care Century and Millennium Sterilizers

Manifold

S-35

S-9

1

PR-1

Regulator

2

Double Door

Option

S-36

M-2

Ball

Valve

97-100% Vapor Quality

297 -325 F Temp. Range

6

Safety

Valve

RV-1

3

Door

Seal

Non-Operating End

Door

Seal

CK-3

CP

Pressure

Transducer

O.E. Door Seal

Pressure Switch

PS-1

10

PG-2

Jacket

Pressure

Gauge

Chamber

Pressure

11

S-3

PG-1

Gauge

Door

Seal

Door

Seal

S-40

TR-1

S-2

5

Operating End

ST-4

Chamber RTD

PS-2

S-1

15

4

Air

Filter

F-1

JACKET

CHAMBER

Chamber

Water

CS-1

Sensor

JACKET

Jacket RTD

12

ST-3

Strainer

Steam

Trap

TR-2

CK-14

FC-2

Exhaust

Manifold

CK-6

S-37

M-3

CK-4

CK-8

14

Emergency

Exhaust

Valve

12

13

14

CK-7

16

S-38

FC-3

Double

Door

Option

WASTE

<

T

140 F

0

STEAM

50-80 psig

00

FC-1

Water

Supply

Manifold

S-4

9

EJ-1

Vacuum

Water

Ejector

HX-1

Heat

Exchanger

Drain

RTD

S-7

8

Steam

Diffuser

F-2

CK-5

W/Max 15 GPM

ST-1

Strainer

7

CK-1

CK-2

30-50 psig

0

70 F Temp

WATER

M-1

Ball

Valve

Section 3: Mechanical Components

764326-797

3-2

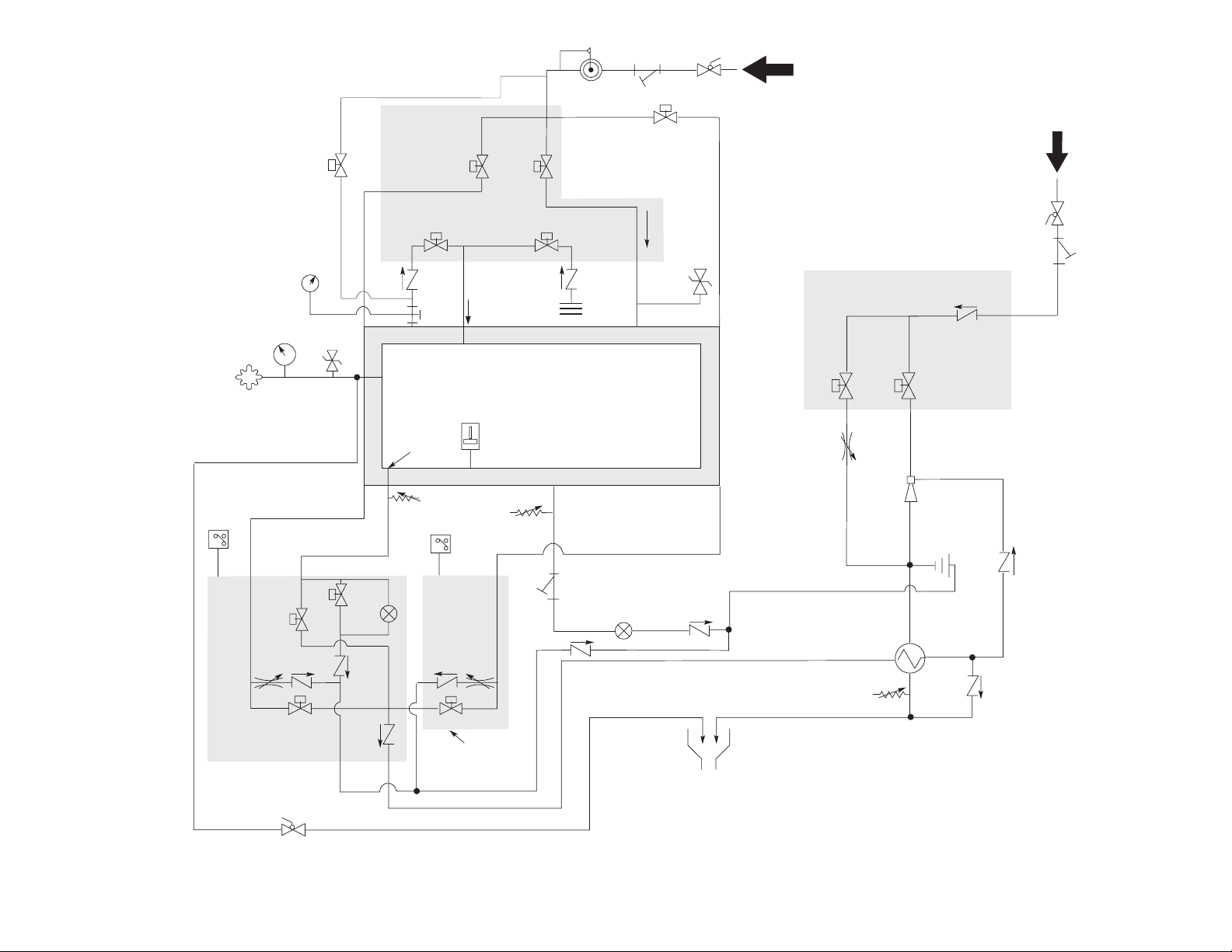

Steam Supply

Manifold

S-8

Figure 3-2. Piping Schematic for Scientific Century Sterilizers

6

PG-2

Jacket

Pressure

Gauge

Door Seal

CP

Pressure

Transducer

O.E. Door Seal

Pressure Switch

Chamber

Pressure

Gauge

PG-1

RV-2

Chamber

Safety

Valve

Door Seal

PS-1

10

11

S-40

S-3

CK-6

FC-2

TR-1

CK-4

12

S-37

CK-8

M-3

14

Emergency

Exhaust

Valve

Exhaust

Manifold

Operating End

ST-4

14

13

S-35

S-2

CK-4

4

5

Chamber RTD

PS-2

CK-7

FC-3

16

S-38

Double

Option

S-9

JACKET

CHAMBER

Chamber

CS-1

JACKET

12

Door

Water

Sensor

CK-14

1

S-1

Air

Filter

PR-1

Regulator

2

15

CK-9

Jacket RTD

ST-3

Strainer

F-1

Strainer

Steam

Trap

TR-2

ST-2

S-36

Double Door

Option

3

M-2

Ball

Valve

Safety

Valve

RV-1

Non-Operating End

CK-3

WASTE

<

T

140 F

0

97-100% Vapor Quality

00

297 -325 F Temp. Range

Door

Seal

Door

Seal

STEAM

50-80 psig

FC-1

Exchanger

Drain

Water

Supply

Manifold

S-4

9

EJ-1

Vacuum

Water

Ejector

HX-1

Heat

RTD

S-7

8

Steam

Diffuser

F-2

CK-5

W/Max 15 GPM

ST-1

Strainer

7

CK-1

CK-2

30-50 psig

0

70 F Temp

WATER

M-1

Ball

Valve

3-3

764326-797

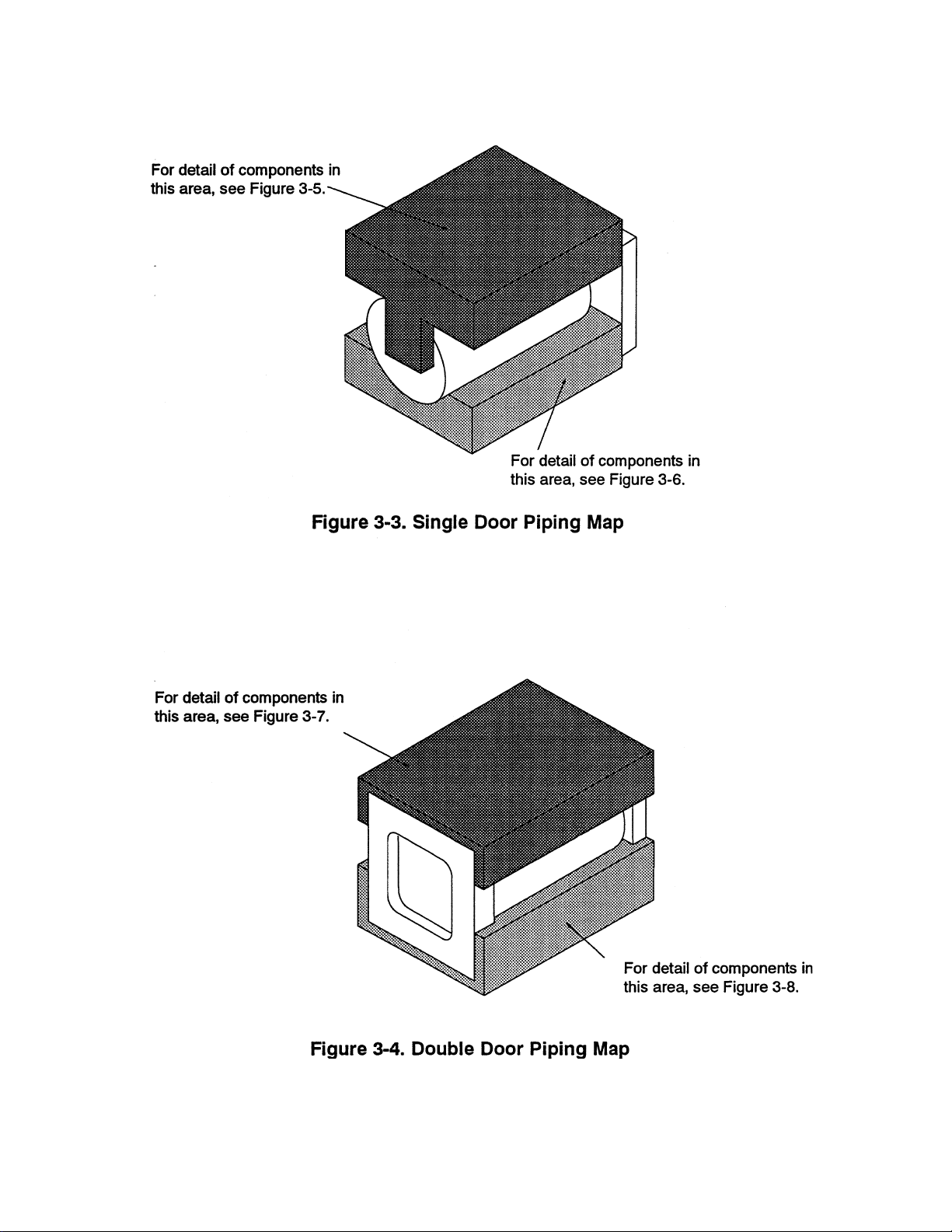

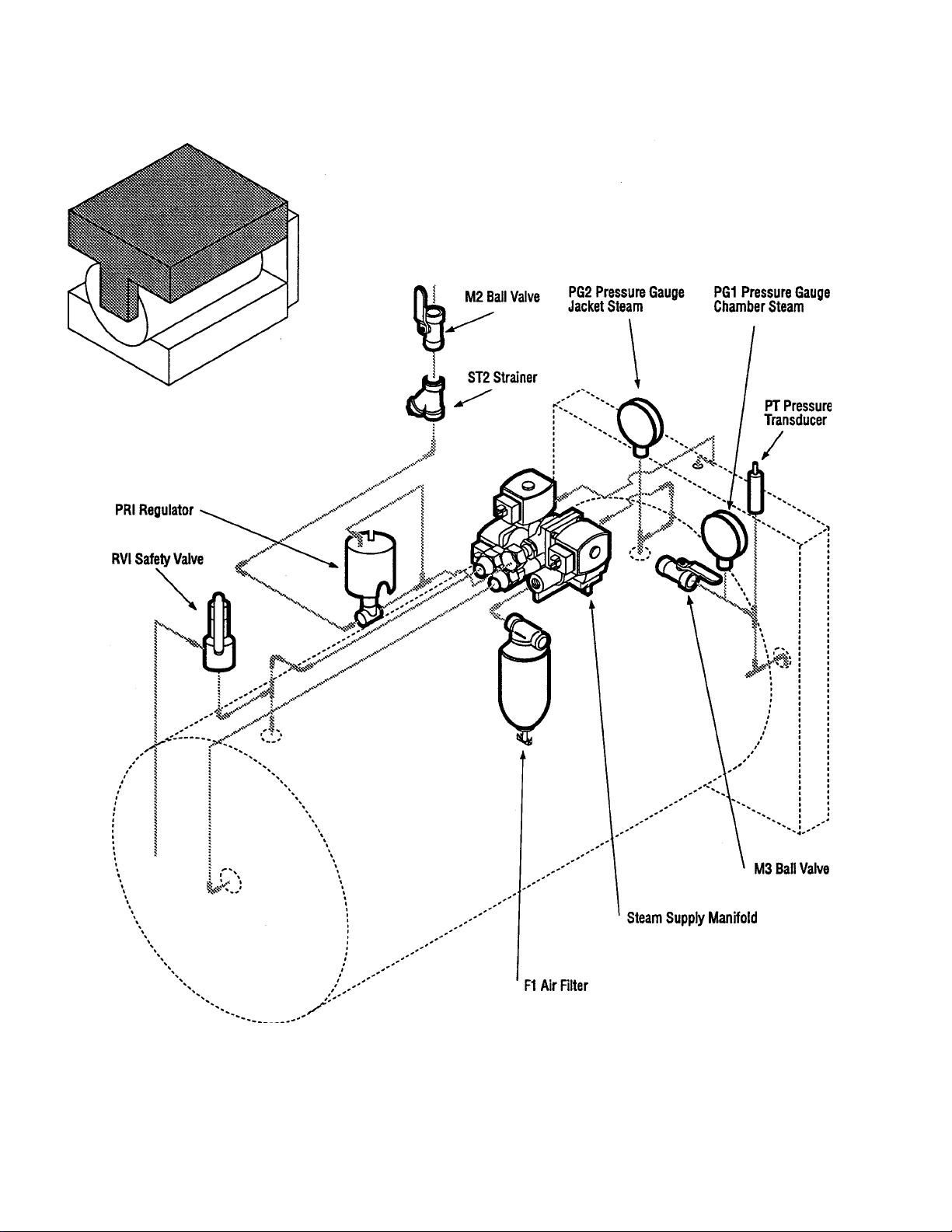

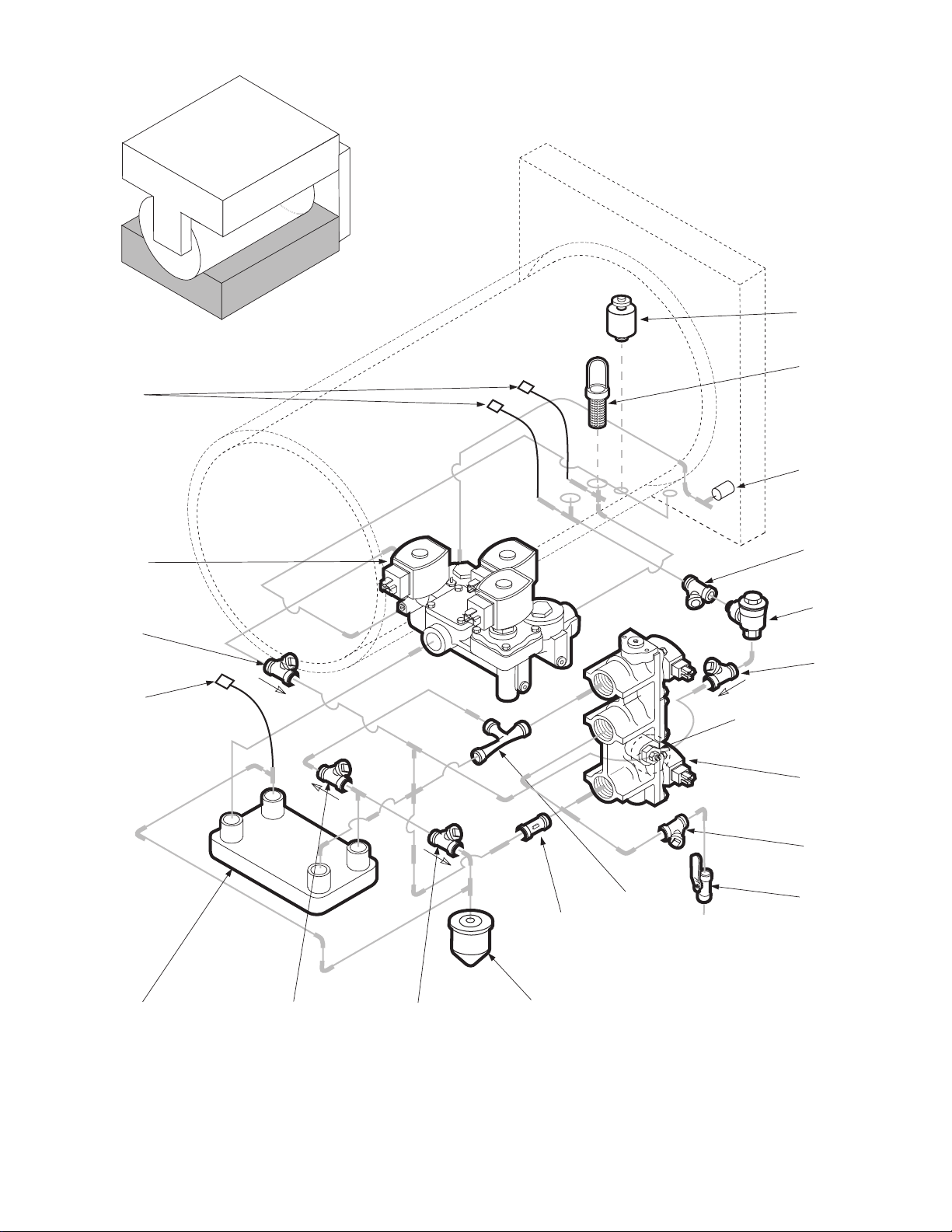

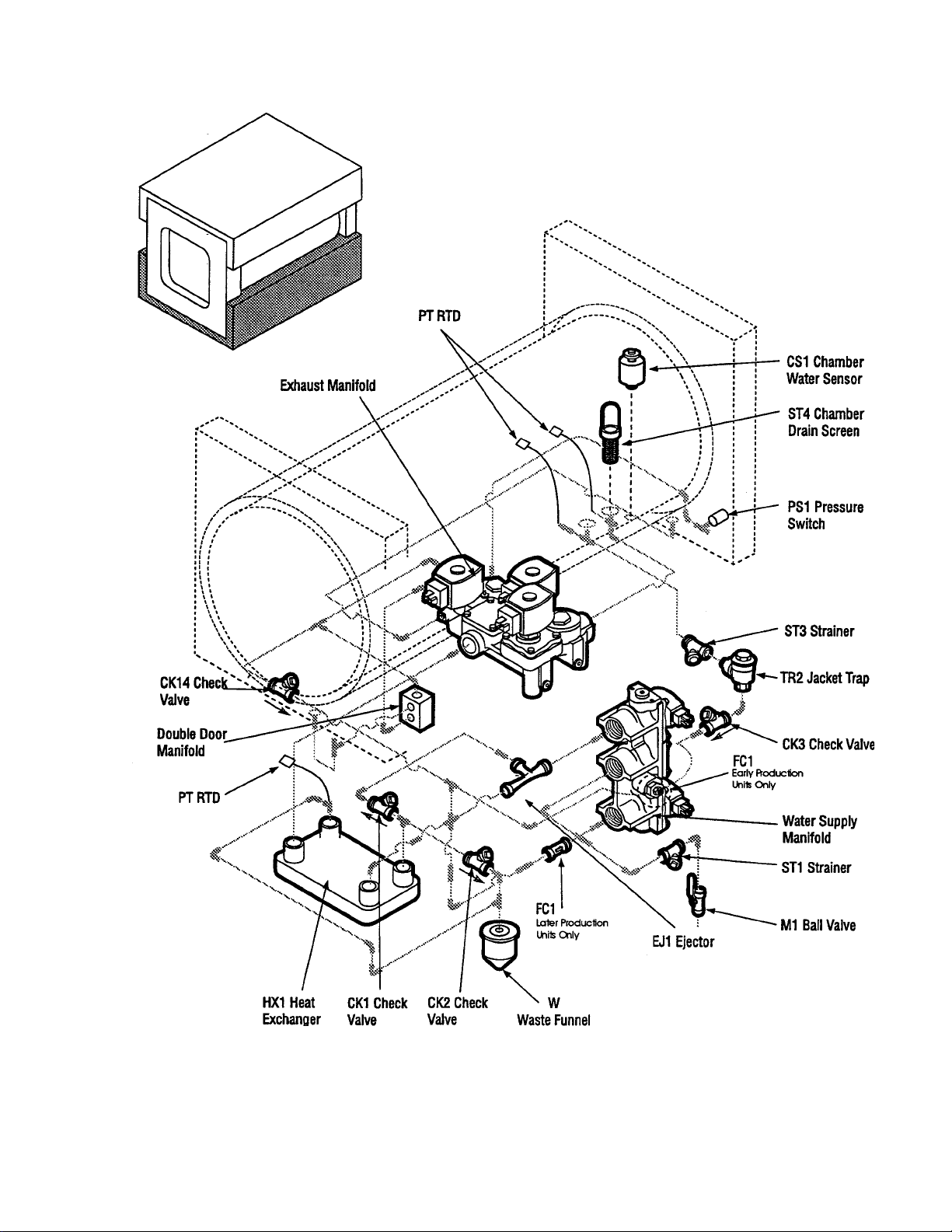

Figure 3-5. Single Door Upper Level Piping Components

3-4

764326-797

TP RTD

CS1 Chamber

Water Sensor

ST4 Chamber

Drain Screen

PS1 Pressure

Switch

Exhaust

Manifold

CK14 Check Valve

TP RTD

HX1 Heat Exchanger

ST3 Strainer

TR2 Jacket

Trap

CK3 Check

Valve

FC1

Early Production

Units Only

Water Supply

Manifold

ST1 Strainer

FC1

Later Production

Units Only

EJ1 Ejector

M1 Ball Valve

W

CK2 Check ValveCK1 Check Valve

Waste Funnel

Figure 3-6. Single Door Lower Level Piping Components

3-5

764326-797

M2 Ball Valve

PR1 Pressure Regulator

RV1 Steam Valve

ST2 Strainer

S36 Solenoid Valve

PG2 Jacket

Pressure Gauge

PG1 Chamber

Pressure Gauge

PT Pressure

Transducer

F1 Air Filter

Figure 3-7. Double Door Upper Level Piping Components

3-6

764326-797

M3 Ball Valve

Steam Supply Manifold

Figure 3-8. Double Door Lower Level Piping Components

3-7

764326-797

Section 4: Electrical Components

4.14.1

CENTURY CONTROL THEORY OFCENTURY CONTROL THEORY OF

4.1

CENTURY CONTROL THEORY OF

4.14.1

CENTURY CONTROL THEORY OFCENTURY CONTROL THEORY OF OPERATIONOPERATION

OPERATION

OPERATIONOPERATION

The Century series sterilizer uses a control made up

of the following sub-sections:

1. Main Control

2. Display

• Operating End

• Non Operating End

3. Analog Devices

4.1.14.1.1

4.1.1

4.1.14.1.1

The Main Control is mounted behind the sterilizer

access door, the Display Module is mounted on the

access door and swings out with the door when

opened. Analog devices are located in the piping.

Connections between these items are by quick disconnect cables. The only hard wiring involved in the

sterilizer is for the customer’s 120 VAC power connection.

Refer to schematic 146657-782, 146657-867, and

146657-781 throughout the following:

Main ControlMain Control

Main Control - box has an access door fastened with

Main ControlMain Control

1/4 turn screws. Consists of the following:

4.1.24.1.2

4.1.2

4.1.24.1.2

Main ControlMain Control

Main Control

Main ControlMain Control

Incoming Power Terminal BlockIncoming Power Terminal Block

Incoming Power Terminal Block

Incoming Power Terminal BlockIncoming Power Terminal Block

4.1.54.1.5

4.1.5

4.1.54.1.5

Interfaces incoming 120 VAC, Power Supply, CPU

board, I/O board, and all external components. The

Connector Board contains only traces and connectors. There are no fuses or serviceable components

on the board.

4.1.64.1.6

4.1.6

4.1.64.1.6

Receives filtered 120 VAC from J15A on the Connector Board at J3A on the Power Supply.

• Outputs on J3B are - 15V, +12V, +15V, and +5V.

• Outputs on J2 and J4 are +24V. The J2 powers the

• There are 2 fuses on the power supply, Fl and F2.

• The power supply is a switching type. Should an

Connector BoardConnector Board

Connector Board

Connector BoardConnector Board

Power SupplyPower Supply

Power Supply

Power SupplyPower Supply

control box fan motor.

These fuses are on the incoming AC side of the

power supply. If either fuse fails, it is due to a

catastrophic internal failure of the power supply

(eg, shorted transformer). The fuse does not blow

due to an output overload or short circuit. If the

fuse fails, the power supply is bad.

output overload occur (eg, short circuit on the

output), the power supply automatically drops

voltage to prevent power supply and circuit damage. Recovery after a fault is automatic on power

up or power down.

Three position block for connection of the 120 VAC

incoming power. Power is fed into the box through

a knock-out on the side or top of the control box.

Block is located in the upper left hand corner of the

control box.

4.1.34.1.3

4.1.3

4.1.34.1.3

ON/OFF switch to control power from terminal

block to line filter. A parallel tap off the power

switch feeds unfiltered 120 VAC to J13 on the Connector Board. This unfiltered 120 VAC is fed to P9

plug to power the steam generator. This is the only

device on the Century sterilizer using unfiltered AC

power.

4.1.44.1.4

4.1.4

4.1.44.1.4

Feeds fused (F3), filtered 120 VAC to J14 on the

Connector Board. All components on the Century

sterilizer, except for the feed to the steam generator,

use filtered AC power.

Power SwitchPower Switch

Power Switch

Power SwitchPower Switch

Line FilterLine Filter

Line Filter

Line FilterLine Filter

4.1.74.1.7

4.1.7

4.1.74.1.7

The CPU board is made up of the following: CPU

8OC186EC high integration processor (U1), Flash

Memory, A/D Converter, RAM Memory and Battery Back-up.

4.1.7.14.1.7.1

4.1.7.1

4.1.7.14.1.7.1

The block layout of the CPU (U1) is shown in Figure

4-1. This design allows the unit to be connected to

various computer devices, such as floppy disk drives,

modems and desktop or portable personal computers. Unit now has the ability to be programed by a

floppy disk, serial interface from a modem or personal computer.

CPU BoardCPU Board

CPU Board

CPU BoardCPU Board

CPU ChipCPU Chip

CPU Chip

CPU ChipCPU Chip

4-1

764326-797

Loading...

Loading...