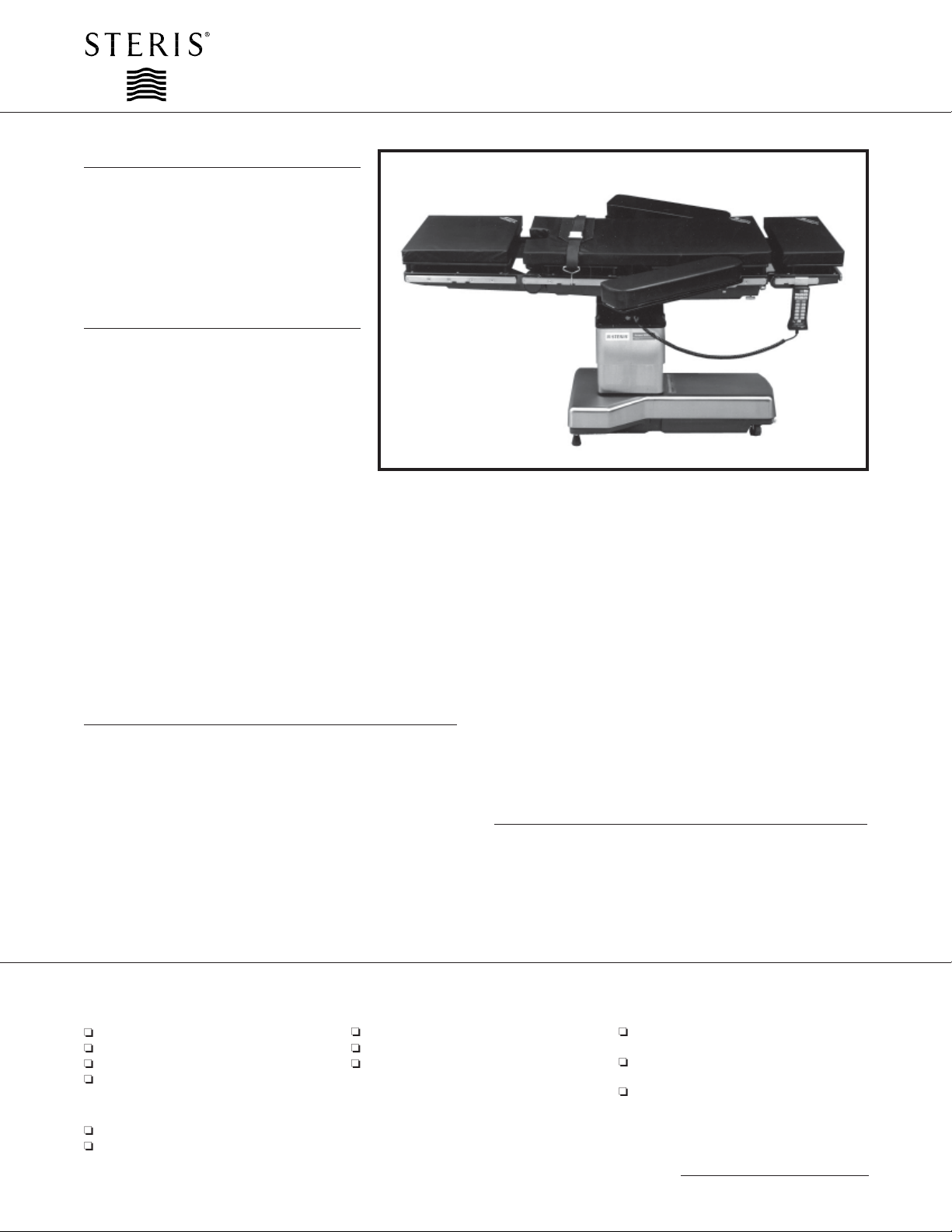

Steris AMSCO 3085 SP User manual

APPLICATION

The Amsco 3085 SP Surgical Table is a

mobile, electrohydraulically operated

surgical table designed to support all

general surgical procedures including

urology, neurology, and orthopedics with the

addition of the 3080/3085 Orthopedic

Extension.

DESCRIPTION

Amsco 3085 SP Surgical Tables are

available in either electric- or batterypowered configurations.

Amsco 3085 SP Surgical Tables are rated

to support 1,000 lb (454 kg) patients in

NORMAL patient orientation. Exceptions to

the 1,000 lb (454 kg) limit are as follows:

• A 500 lb (227 kg) rating applies to side tilt in

NORMAL patient orientation.

• A 500 lb (227 kg) rating applies to all REVERSE patient

orientation.

• A 400 lb (181 kg) rating applies to the 3080/3085

Orthopedic Extension accessory.

• A 400 lb (181 kg) rating applies to the Fem/Pop Board.

• A 500 lb (227 kg) rating applies to the Amsco Shoulder

Table.

NOTE: When performing surgery requiring a headrest

accessory in a REVERSED patient orientation, do not

exceed the 400 lb (181 kg) patient weight limit.

STANDARDS

Amsco 3085 SP Surgical Table is in compliance with national

and international safety standards for electromedical

equipment and meets the applicable requirements of the

following standards:

• Underwriters Laboratories (UL) Standard 2601-1 – 1st

Ed., as certified by ETL Testing Laboratories, Inc.

• Standard CSA-C22.2 No. 601.1-M90, Standard for

Electro-Medical Equipment, as certified by ETL Testing

Laboratories, Inc.

• EN 60601-1: 1993, Amendment 2, 1995, Electrical

Safety, as certified by ETL Testing Laboratories, Inc.

AMSCO® 3085 SP

SURGICAL TABLE

(Typical only - some details may vary.)

• IEC 601-1-2: 2001, Electromagnetic Compatibility, as

certified by ETL Testing Laboratories, Inc.

• EN 55011: Group I, Class B, Emissions Testing, as

certified by ETL Testing Laboratories, Inc.

• EN 60601-2-46 – 1st Ed., as certified by ETL Testing

Laboratories, Inc.

• CE marked to the Medical Device Directive, 93/42/EEC

• FDA Good Manufacturing Practices Regulations

21CFR820 for Medical Devices

• Class 1 Equipment

• Type B Equipment

• Suitable for continuous use

• IPX-4 (Fluid Ingress Protection)

FEATURES

Microprocessor Controlled Hydraulic System provides

tabletop articulation. Tables feature auxiliary override

(backup) systems for the control and hydraulic systems.

Control System uses microprocessor technology to

control the hydraulic pump motor and solenoid valves. The

primary control system consists of a “master” and a “slave”

computer. The master computer is located on the column

The Selections Checked Below Apply To This Equipment

VOLTAGE

❏ 100 VAC, 50/60 Hz

❏ 120 VAC, 50/60 Hz

❏ 220 VAC, 50/60 Hz

❏ 230/240 VAC, 50/60 Hz

POWER SOURCE

❏ Electric-Powered Table

❏ Battery-Powered Table

1

HERMES-Ready is a trademark of Computer

Motion

OPTIONS

❏ Foot Control

❏ HERMES®-Ready1 Voice Activation System*

❏ Operating Room Control System (ORCS) ACT

Interface**

ACCESSORIES

Refer to separate product literature.

* This option for Amsco 3085 SP

HERMES®-Ready1 tables only.

** This option for Amsco 3085 SP ACT

Enabled™ tables only.

PAD CONFIGURATION

❏ 2" (51 mm) TLT Pads and X-Ray Top

(standard)

❏ 2" (51 mm) Traditional Foam Pads

(replacement option only)

❏ 2" (51 mm) TLT Pads only

Item ____________________

Location(s) ______________

SD502 (09/01/06)

and selects which outputs are to be actuated based on

inputs from the hand control, optional foot control, optional

®

HERMES

-Ready1 Voice Activation System, optional ACT

Enabled™ interface to Operating Room Control Systems

(ORCS), and table sensors. The slave computer is located in

the hand control and provides user inputs (from touch pad

switches) to the master computer. It also receives feedback

signals and turns on the proper status LEDs. A sealed 24 VDC

battery is used for power backup. A secondary and separate

override control system allows operation of basic table

functions should the primary microprocessor system become

inoperative. Battery-powered auxiliary control switches

provide complete override capability during an emergency

situation.

Hydraulic System provides the motive force for all powered

articulations of the table. A 24-VDC electric motor drives a

0.25 gpm (0.946 lpm) nominal, 1740 psi (120 bar) nominal

capacity pump. Solenoid valves direct fluid to hydraulic

cylinders. Hydraulic oil pressure is limited by a relief valve. All

hoses are constructed of flexible thermoplastic, and all hose

and port connections are sealed with O-rings. Load holding

valves are built into all manifold ports feeding each cylinder,

except for the side tilt cylinder which has internal load holding

valves. A filter is provided to maintain oil cleanliness. A

manual foot-operated pump is provided for table operation in

case of power failure (solenoid valves would be operated from

24-VDC battery). For added patient safety, the 3085 SP

Surgical Table features a locking side-tilt cylinder design to

prevent unanticipated lateral movement. The side-tilt cylinder

incorporates a mechanical lock to back up this hydraulic

system, eliminating lateral movement until hydraulic pressure

is at the desired level.

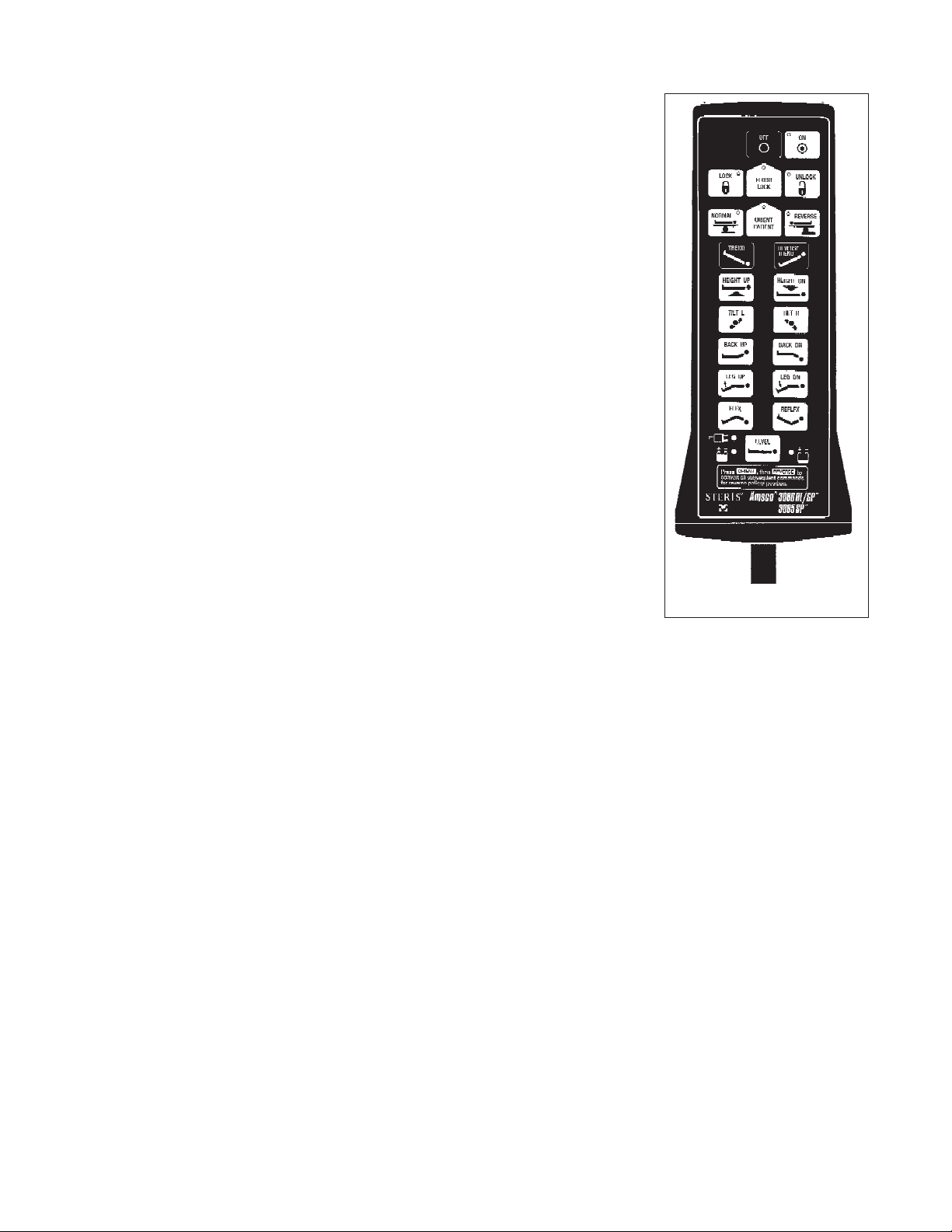

Hand Control is constructed of injection-molded black plastic

(two-piece, sealed) and is the primary control for table

operation. It has a 2' (610 mm) long coiled cord (10' [3 m]

long when extended) with molded strain reliefs on each end.

Hand control plugs into a color-coded receptacle located on

the control column top. Membrane touch switches provide

input signals to a self-contained PC board to activate all table

functions and articulations. LED indicators provide table

operation information and control diagnostic signals.

NOTE: For HERMES-Ready or ACT Enabled hand controls, the

strain relief is blue. The standard hand control has a red strain relief.

These hand controls are NOT interchangeable.

Base

is cast iron with textured enamel finish. The top is

enclosed by a two-section, welded, stainless-steel cover

that also forms a shroud for the lower portion of the column.

Four swivel casters facilitate easy table relocation and

movement. Three floor locks (tripod principle) are selfcompensating up to 1/4" (6 mm). Patient grounding/potential

equilization post and line power input plug with protective

fuses are located at the head end of the base. Manual foot

pedal (hydraulic backup), floor lock override rocker switch

and four protective circuit breakers are located on the side

of the base. Hydraulic pump/motor assembly, power control

assembly and control batteries are located within the base.

Motor batteries and motor battery charger are also located

within the base on battery-powered 3085 SP Surgical

Tables.

Column is offset from the

center of the base and

includes tabletop lift

cylinder, support column

with bearing-mounted

saddle frame, hydraulic

plumbing, electrical wiring

and table control microprocessor assembly. These

components are fully

enclosed by four telescoping stainless-steel

shrouds. Each shroud

section is of two-piece

construction for service

accessibility. At the top of

the column, receptacles

are provided for the hand

control and optional foot

control on one side, and

emergency override

control switches located

on the opposite side. A

column bellows shields

user from mechanical

interfaces at the top of the

column, and seals the area

for fluid ingress protection.

Superstructure includes a

Standard Hand Control

manual gear drive for

kidney elevator, and hydraulic lines and cylinders required

to articulate the tabletop. The superstructure is bearingmounted to the column. Tabletop section frames are

constructed of cast aluminum and finished with textured

paint. Hydraulic positioning mechanisms are located

inboard from frame sides to help prevent enmeshment of

drapes.

Tabletop is 20" (508 mm) wide and divided into four hinged

sections: headrest, back, seat, and leg. All sections are

constructed of a radiolucent material, and drilled holes are

provided for attachment of optional radiographic top

sections. The seat section includes a perineal cutout. All

tabletop sections (except the headrest) are electrohydraulically positioned by solenoid-valve-actuated hydraulic

cylinders. The headrest section is positioned by a manual,

spring-loaded ratchet mechanism. A hook fastener tape strip

on the longitudinal centerline of the tabletop sections

permits instant application and removal of 2" (51 mm) thick

mattress pads. Stainless-steel side rails extend the full

length of table (including superior edge of headrest), and

are notched to receive optional accessories. Side rails will

accommodate certain previous-design STERIS table

accessories, plus exclusive 3085 table accessories

.

Headrest Section is attached to the back section for NORMAL patient orientation, or can be attached to leg section for

REVERSE patient orientation. Headrest section can be raised

or lowered 0-90° from horizontal and locked in 15° increments.

The spring-loaded handle is located under the outer end of

section for easy access.

2

Loading...

Loading...