STERIS Amsco Service Manual

OPERATING INSTRUCTIONS

Amsco® Century

®

Gravity and Prevacuum Sterilizers

(11/13/06) P129367-408

STERIS Mexico

Avenida Avante 790

Parque Industrial Guadalupe

Guadalupe, Nuevo Leon, Mexico C.P. 67190

www.steris.com

© 2006– STERIS Corporation. All rights reserved. Printed in U.S.A

Table of Contents Operating Instructions 129367-408

A WORD FROM STERIS CORPORATION

This manual contains important information on proper use of this sterilizer. All

operators and department supervisors are urged to carefully review and

become familiar with the warnings, cautions and instructions contained herein.

This sterilizer is specifically designed to process goods using only the cycles

as specified in this manual. If there is any doubt about a specific material or

product, contact the manufacturer of the product for the recommended

sterilization technique.

STERIS carries a complete line of accessories for this unit to simplify, organize

and assure sterility of the sterilization process. Instrument trays, pouches and

biological/chemical monitoring systems are all available to fulfill your facility’s

processing needs. A STERIS representative will gladly review these with you.

Advisory

Service

Information

Indications for

Use

A summary of the

servicing this equipment can be found in Section 1 of this manual. Do not

operate or service the equipment until you have become familiar with this

information.

Any alteration of the sterilizer not authorized or performed by STERIS which

could affect its operation will void the warranty, could adversely affect

sterilization efficacy, could violate federal, state and local regulations and

jeopardize your insurance coverage.

A thorough preventive maintenance program is essential to safe and proper

sterilizer operation. You are encouraged to contact STERIS concerning our

Preventive Maintenance Agreement. Under terms of this agreement, preventive maintenance, adjustments, and replacement of worn parts are done on a

scheduled basis to assure equipment performance at peak capability and to

help avoid untimely or costly interruptions. STERIS maintains a nationwide staff

of well-equipped, factory-trained technicians to provide this service, as well as

expert repair services. Contact STERIS for details.

The Amsco® Century® Steam Sterilizer is designed for efficient, sterilization of

non-porous and porous, heat and moisture-stable materials used in healthcare

facilities. The Century Steam Sterilizer is available in the following configurations:

Safety Precautions

to be observed when operating and

16" x 16" x 26" Single Door Gravity

16" x 16" x 26" Double Door Gravity

20" x 20" x 38" Single Door Gravity

20" x 20" x 38" Double Door Gravity

Table of Contents Operating Instructions 129367-408

16" x 16" x 26" Single Door Prevacuum

16" x 16" x 26" Double Door Prevacuum

20" x 20" x 38" Single Door Prevacuum

20" x 20" x 38" Double Door Prevacuum

i

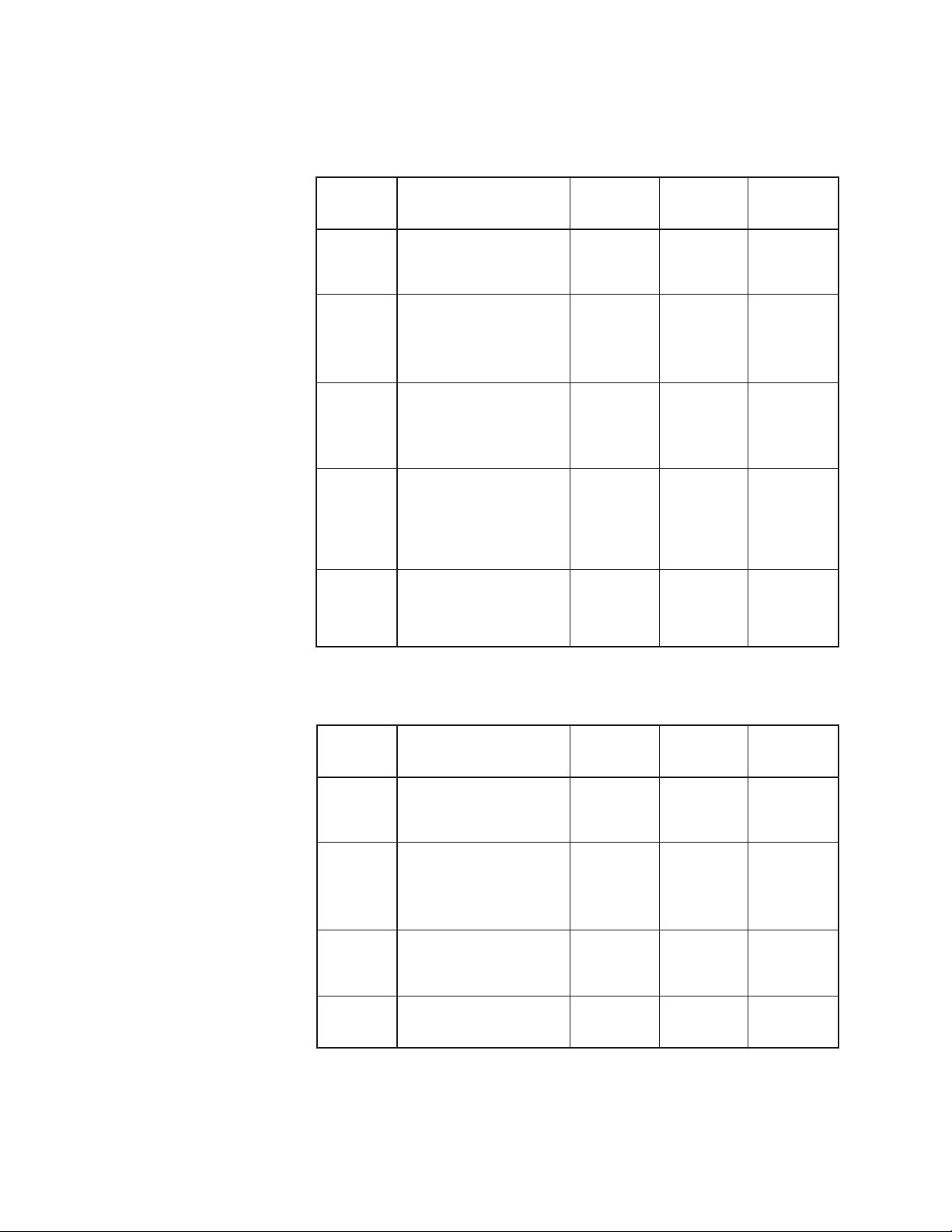

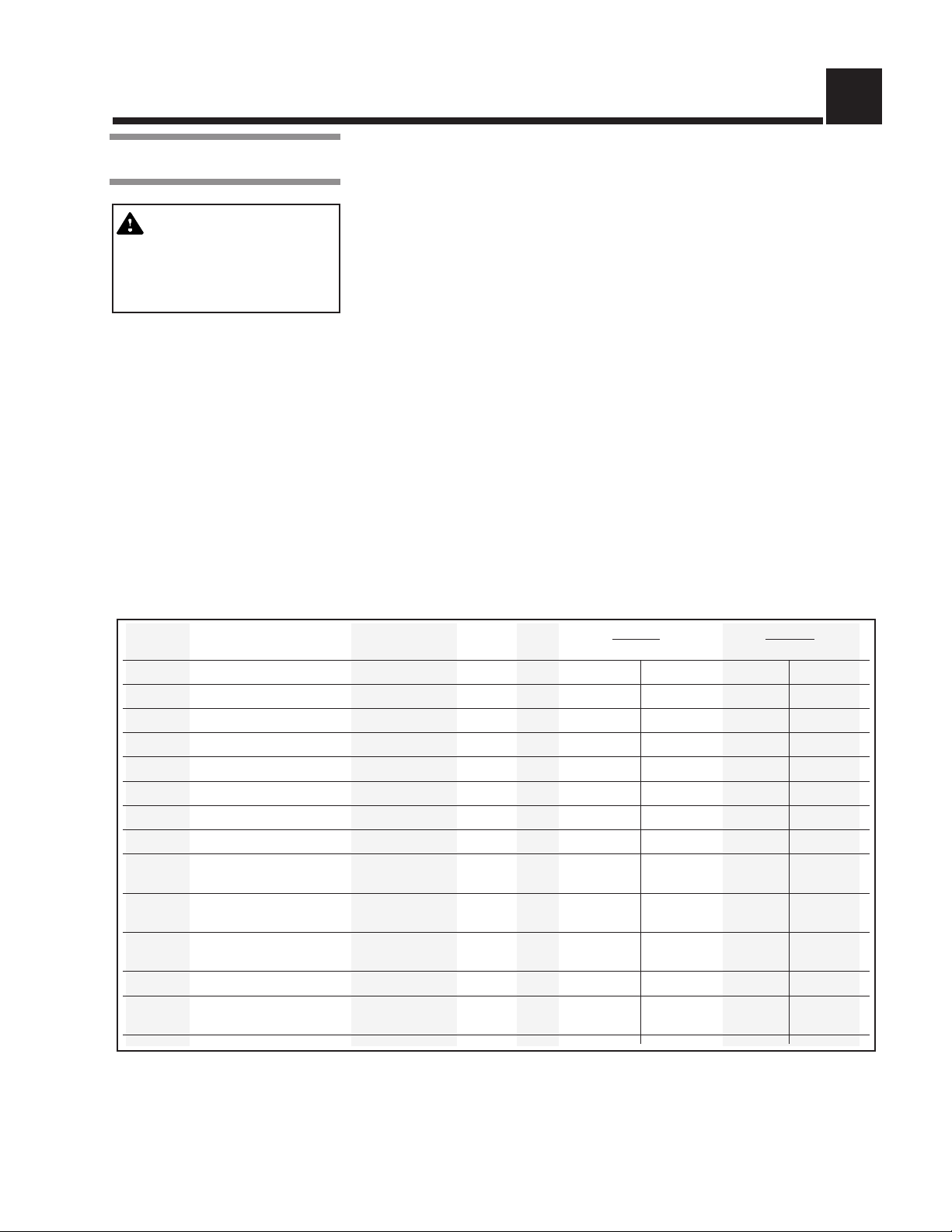

The Amsco Century Steam Sterilizer is equipped with the following factoryprogrammed sterilization cycles and cycle values:

PREVACUUM CONFIGURATION

CYCLES RECOMMENDED STERILIZE STERILIZE DRY TIME

LOADS TEMP. TIME

FLASH Unwrapped 270°F 3.0 minutes 1.0 minute

Instrument tray with (132°C)

a single instrument.

FLASH Unwrapped instrument 270°F 10 minutes 1.0 minute

tray with non-porous (132°C)

multiple instruments,

maximum weight 17lbs.

EXPRESS Single wrapped 270°F 4.0 minutes 3.0 minutes

instrument tray with (132°C)

a single instrument.

Non-porous goods only.

PREVAC Up to two double 270°F 4.0 minutes 20 minutes

1

wrapped instrument (132°C)

trays, maximum

weight 17 lbs. Up

to six fabric packs.

PREVAC Up to two double 275°F 3.0 minutes 16 minutes

wrapped instrument (135°C)

trays, maximum

weight 17 lbs.

1

Five minute Dry Time can be used for processing a single fabric pack.

GRAVITY CONFIGURATION

CYCLES RECOMMENDED STERILIZE STERILIZE DRY TIME

LOADS TEMP. TIME

FLASH Unwrapped 270°F 3.0 minutes 1.0 minute

Instrument tray with (132°C)

a single instrument.

FLASH Unwrapped instrument 270°F 10 minutes 1.0 minute

tray with non-porous (132°C)

multiple instruments,

maximum weight 17lbs.

GRAVITY Up to two double wrapped 270°F 15 minutes 30 minutes

trays, maximum (132°C)

weight 17 lbs.

GRAVITY Up to six Fabric Packs. 250°F 30 minutes215 minutes

(121°C)

2

A 270°F (132°C) cycle adjusted to 25 minute Sterilize Time can be used for

processing fabric packs.

ii

129367-408 Operating Instructions Table of Contents

TABLE OF CONTENTS

Section

Title

A WORD FROM STERIS CORPORATION ...................................... i

1 SUMMARY OF SAFETY PRECAUTIONS ............................ 1-1

2 STERILIZATION TECHNIQUES ......................................... 2-1

2.1 General .............................................................................................................. 2-1

2.2 Special Information Regarding the Express Cycle .............................................. 2-1

2.2.1 Preparing Instruments for Express Cycle Sterilization .................................. 2-2

2.2.2 Unloading ..................................................................................................... 2-2

2.3 Special Information Regarding The Flash Cycle ................................................. 2-3

2.4 Control Measures For Verifying Sterilization Process ......................................... 2-4

2.4.1 Biological Monitors ....................................................................................... 2-4

2.4.2 Testing for Prevacuum Efficiency ................................................................ 2-4

2.5 Dart (Bowie-Dick) Test ....................................................................................... 2-5

2.6 Vacuum Leak Test ............................................................................................. 2-5

2.7 Sterilization Process Recommendations .......................................................... 2-5

3 COMPONENT IDENTIFICATION ........................................ 3-1

3.1 General .............................................................................................................. 3-2

3.2 Main Sterilizer and Cycle Controls ...................................................................... 3-2

3.3 Control Displays ................................................................................................. 3-3

3.4 Alarm Displays ................................................................................................... 3-4

3.5 Operating End Control Panel .............................................................................. 3-5

3.6 Cycle Selection Touch Screen Pads .................................................................. 3-6

3.6.1 Values Touch Screen Pads .......................................................................... 3-6

3.6.2 Abort Touch Screen Pad .............................................................................. 3-7

3.7 Printer ................................................................................................................ 3-7

3.8 Printouts ............................................................................................................. 3-8

3.9 Power Door Operation ........................................................................................ 3-9

3.10 Emergency Door Opening Procedure .............................................................. 3-10

3.11 Optional Electric Steam Generator ................................................................. 3-11

Page

4 STERILIZER OPERATION ................................................. 4-1

4.1 Before Operating the Sterilizer............................................................................ 4-1

4.2 Preparing Loads for Sterilization Cycles ............................................................ 4-2

4.3 Guidelines for Placement of Various Loads ........................................................ 4-3

4.4 Unloading the Sterilizer ....................................................................................... 4-4

4.5 Loading Car Instructions: Loading ...................................................................... 4-5

4.6 Loading Car Instructions: Unloading ................................................................... 4-6

4.7 Loading/Unloading Sterilizer Equipped With Rack and Shelves .......................... 4-6

4.8 Sterilizer (Factory) Cycle Settings ...................................................................... 4-7

4.9 270°F Flash Cycle .............................................................................................. 4-8

4.10 Gravity Cycle ................................................................................................. 4-11

4.11 270°F Express Cycle ...................................................................................... 4-14

4.12 270°F Prevac Cycle........................................................................................ 4-17

4.13 275°F Prevac Cycle........................................................................................ 4-20

4.14 DART (Bowie-Dick) Test (Prevacuum Sterilizer only) .................................... 4-23

4.15 Vacuum Leak Test (Prevacuum Sterilizer only) .............................................. 4-25

Section 4 Contents Continued On Next Page

Table of Contents Operating Instructions 129367-408

iii

TABLE OF CONTENTS (Cont'd)

Section

4.16 Optional Liquid Cycle ...................................................................................... 4-27

4.17 Sterilization Techniques for Optional Liquid Cycle .......................................... 4-30

4.18 Recommendations for Sterilizing Liquids ........................................................ 4-31

4.19 Aborting Cycles .............................................................................................. 4-32

4.20 Cycle Graphs ................................................................................................. 4-33

Title

5 STERILIZER CYCLES AND CYCLE VALUES ...................... 5-1

5.1 Sterilizer (Factory) Cycle Settings ...................................................................... 5-2

5.2 Change Values ................................................................................................... 5-3

5.3 Change Cycle Values ......................................................................................... 5-4

5.3.1 Overview ...................................................................................................... 5-4

5.3.2 Step by Step ................................................................................................ 5-4

5.4 Adjusting Sterilize Time And Dry Time ............................................................... 5-7

5.5 Change Time and Date ....................................................................................... 5-8

5.6 Change Machine Setup .................................................................................... 5-10

5.7 Access Code .................................................................................................... 5-11

5.8 Lockout ............................................................................................................ 5-13

5.9 Utilities Control ................................................................................................. 5-14

5.10 Language ........................................................................................................ 5-17

5.11 Machine Number ............................................................................................ 5-18

5.12 Time Format ................................................................................................... 5-19

5.13 Print Format ................................................................................................... 5-20

5.14 Audible Signals .............................................................................................. 5-21

5.15 Units ............................................................................................................... 5-22

5.16 Date Format ................................................................................................... 5-22

5.17 Duplicate Print ................................................................................................ 5-23

5.18 Leaving Change Values .................................................................................. 5-23

Page

LIST OF TABLES

Table

2-1 Cycle Availability ...................................................................................................................... 2-1

2-2 Item Processing Guidelines For Express Cycle ........................................................................ 2-2

3-1 Required Feed Water Quality for Carbon Steel Steam Generators .......................................... 3-12

4-1 Factory-Set Cycles and Cycle Values ....................................................................................... 4-7

4-2 Liquid Cycle Parameters ........................................................................................................ 4-30

5-1 Cycle Availability ...................................................................................................................... 5-1

5-2 Factory-Set Cycles and Cycle Values ....................................................................................... 5-2

5-3 Change Machine Setup .......................................................................................................... 5-10

iv

129367-408 Operating Instructions Table of Contents

Title

Page

!

!

!

!

!

!

!

!

!

!

!

SUMMARY OF SAFETY PRECAUTIONS 1

Following is a list of the

indicate the potential for danger to personnel, and CAUTIONS indicate the potential for damage to equipment. These

precautions are repeated (in whole or in part), where applicable, throughout the manual. This is a listing of all

Precautions

appearing in the manual. Carefully read them before proceeding to use or service the unit.

Safety Precautions

which must be observed when operating this equipment. WARNINGS

Safety

WARNING - BURN HAZARD:

When sterilizing liquids, to prevent personal injury or property damage resulting from bursting bottles and hot

fluid, you must observe the following procedures:

• Use Liquid cycle only; no other cycle is safe for processing liquids.

• Use only vented closures; do not use screw caps or rubber stoppers with crimped seals.

• Use only Type I borosilicate glass bottles; do not use ordinary glass bottles or any container not designed for

sterilization.

• Do not allow hot bottles to be jolted; this can cause hot-bottle explosions. Do not move bottles if any boiling

or bubbling is present.

It is inappropriate for a healthcare facility to sterilize liquids for direct patient contact.

Sterilizer, rack/shelves, and loading car will be hot after cycle is run. Always wear protective gloves and

apron when removing a processed load. Protective gloves and apron must be worn when reloading sterilizer

following the previous operation.

Before daily flushing of the generator, generator must be at zero psig and cooled to room temperature.

Do not attempt to open the sterilizer door if a WATER IN CHAMBER ALARM condition exists. Call a qualified

service technician before attempting to use sterilizer further.

Sterilizer operator may be severely burned by scalding water if the water level control malfunctions. The

steam generator level control may malfunction if the supply water exceeds 26,000 ohms/cm (38.5 conductivity

min.). Do not connect to treated water (e.g., distilled, reverse osmosis, deionized) unless water resistivity is

determined to be acceptable. If water exceeds 26,000 ohms/cm, contact STERIS Engineering Service for

information concerning modifications required to the generator control system.

After manual exhaust, steam may remain inside the chamber. Always wear protective gloves, apron and a

face shield when following emergency procedure to unload sterilizer. Stay as far back from the chamber opening

as possible when opening the door.

Allow sterilizer to cool to room temperature before performing any cleaning or maintenance procedures.

Failure to shut off the steam supply when cleaning or replacing strainers can result in serious injury. Jacket

pressure must be 0 psig before beginning work on the steam trap.

Proper testing of the safety valve requires the valve to be operated under pressure. Exhaust from the safety

valve is hot and can cause burns. Proper safety attire (gloves, eye protection, insulated overall) as designated

by OSHA, is required. Testing is to be performed by qualified service personnel only.

Steam may be released from the chamber when door is opened. Step back from the sterilizer each time the

door is opened to minimize contact with steam vapor.

1-1

Summary of Warnings and Cautions Operating Instructions 129367-408

WARNING – ELECTRIC SHOCK AND BURN HAZARD:

!

!

!

!

!

!

!

!

!

!

!

!

!

Disconnect all utilities to sterilizer before servicing. Do not service the sterilizer unless all utilities have been

properly locked out. Always follow OSHA Lockout-Tagout and electrical safety-related work practice standards.

(See CFR 1910.147 and .331 through .335.)

WARNING – PERSONAL INJURY HAZARD:

Avoid personal injury from bursting bottles. Liquid sterilization cycle must only be used for liquids in

borosilicate (Pyrex) flasks with vented closures.

Door must be locked and the key retained prior to entering chamber for servicing. Always follow appropriate

Lockout-Tagout and electrical safety-related work practice standards. Emergency stop switch can be depressed

and key retained on sliding door units.

WARNING - EXPLOSION HAZARD:

This sterilizer is not designed to process flammable compounds.

WARNING - SLIPPING HAZARD:

To prevent falls keep floors dry by immediately wiping up any spilled liquids or condensation in sterilizer loading

or unloading area.

WARNING – PERSONAL INJURY AND/OR EQUIPMENT DAMAGE HAZARD:

Regularly scheduled preventive maintenance is required for safe and reliable operation of this equipment.

Contact your STERIS service representative to schedule preventive maintenance.

When closing the chamber door, keep hands and arms out of the door opening and ensure opening is clear

of obstructions.

Repairs and adjustments to this equipment must be made only by fully qualified service personnel.

Maintenance performed by inexperienced, unqualified persons or installation of unauthorized parts could cause

personal injury or result in costly equipment damage.

WARNING - STERILITY ASSURANCE HAZARD:

Load sterility may be compromised if the biological indicator or air leak test indicates a potential problem.

If these indicators show a potential problem, refer the situation to a qualified service technician before using the

sterilizer further.

According to AAMI standards, a measured leak rate greater than 1.0 mm Hg/minute indicates a problem

with the sterilizer. Refer the situation to a qualified service technician before using the sterilizer further.

The Express cycle is only intended for use with a single instrument in a single wrapped instrument tray.

The Express cycle is not intended for processing porous items (except the tray wrapper).

The Flash cycle is not intended for processing porous items.

1-2

129367-408 Operating Instructions Summary of Warnings and Cautions

CAUTION - POSSIBLE EQUIPMENT DAMAGE:

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

Gasket must be fully retracted prior to operating sterilizer door.

Failure to flush generator daily could result in malfunction of the generator. Warranty on the generator will be voided

unless flushed daily.

Before flushing generator, ensure generator drain valve is fully open to prevent generator heaters from turning

on during flush phase.

If zero dry time is selected, sterilizer automatically initiates a vapor removal phase in place of drying. This phase

can still draw a vacuum to 5.0 inHg. Consult device manufacturer's recommendations to ensure devices being

processed can withstand this depth of vacuum.

Lifting the chamber float switch when cleaning the chamber may cause the sterilizer control to initiate a “Chamber

Flooded” alarm. If this alarm condition occurs, the operator must turn the control power OFF then ON to clear the

alarm. The control power switch is located in the mechanical area at the side of the sterilizer. Placing the sterilizer

in standby does not clear this alarm.

Never use a wire brush, abrasives, or steel wool on door and chamber assembly. Do not use cleaners containing

chloride on stainless-steel surfaces. Chloride-based cleaners will deteriorate stainless steel, eventually leading

to failure of the vessel.

Do not use cleaners containing chlorides on loading cars. Chloride-based cleaners will deteriorate the loading car

metal.

Sterilization of chloride-containing solutions (e.g., saline) can cause chamber corrosion and is not recommended

by the manufacturer. If, however, chloride-containing solutions must be processed, clean the chamber after each

use.

Allow thermostatic traps to cool down to room temperature before removing cover. Since there is nothing to limit

expansion, the bellows may rupture or fatigue if trap is opened while hot.

Actuation at less than 75% of rated pressure can allow debris to contaminate the seat and cause the safety valve

to leak. A leaking safety valve must be replaced.

Insufficient service clearance will make repairs more difficult and time-consuming.

Piping sized too small may cause water hammer, resulting in damage to the sterilizer.

After installation, it is mandatory to brace piping at the drain funnel so that it will not move vertically.

Make sure door opening is clear of any obstruction before closing the door(s).

Do not attempt to open sterilizer door during manual operation unless chamber is at 0 psig.

During manual operation, gasket must be fully retracted prior to operating sterilizer door.

Immediately wipe up saline solution spills on loading car, to prevent damage to stainless steel.

1-3

Summary of Warnings and Cautions Operating Instructions 129367-408

STERILIZATION TECHNIQUES 2

The information in this section is intended as a general guide to steam

2.1 General

WARNING – BURN HAZARD: It is inappropriate for

a health care facility to sterilize liquids for direct patient contact.

sterilization techniques. Also recommended is reference to the standards of the

Association for the Advancement of Medical Instrumentation (AAMI ST-46,

Steam Sterilization and Sterility Assurance, 3rd Edition

).

• Prior to sterilization, all materials and articles must be thoroughly cleaned.

• After sterilization, goods should be stored in conditions that will not compro-

mise the barrier quality of their wrapping materials.

• Always carefully segregate items which have been sterilized using conventional cycles from those sterilized using Flash or Express cycles.

IMPORTANT: The sterilization cycles listed in Table 2-1 have been validated

using techniques documented in AAMI ST-8 and AAMI ST-37. If different cycle

parameters (sterilize time and dry time only) other than those in Table 2-1 are

required, it is the responsibility of the health care facility to validate the cycle.

Reference AAMI guidelines/standards for a guide to validating sterilization

cycles and to ensure that proper sterility assurance level (SAL) as well as

moisture retention acceptance criteria are met.

NOTE: Contact your customer service representative for information on a wide

range of education/training programs designed to meet the educational needs of

health care industries.

The E xpress cycle

only

on prevacuum sterilizers, and is not provided on gravity sterilizers.

is an abbreviated prevacuum cycle that is intended for use

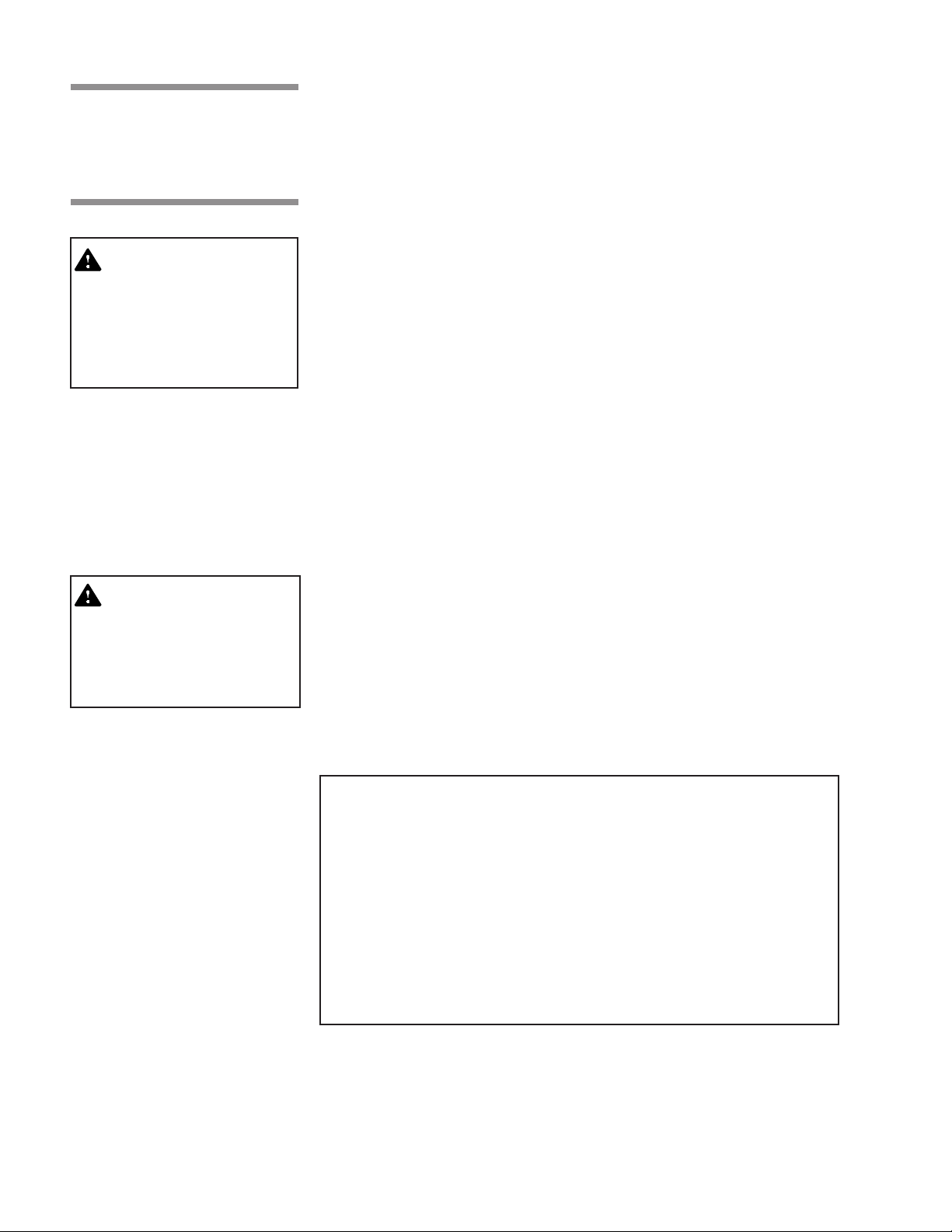

Table 2-1. Cycle Availability

Cycle Sterilize Sterilize Dry Prevac Gravity

Type Load Temperature Time Time Default Optional Default Optional

Gravity* Full Load Fabric Packs 270°F 25 min 15 min X X

Gravity* Full Load Fabric Packs 250°F 30 min 15 min X X

Gravity* Full Load Instrument Trays 270°F 15 min 30 min X X

Gravity* Full Load Instrument Trays 250°F 30 min 30 min X X

Liquid* Three 1000ml Bottles 250°F 45 min N/A X X

Prevac* Single Fabric Pack 270°F 4 min 5 min X N/A N/A

Prevac* Full Load Instrument Trays 270°F 4 min 20 min X N/A N/A

Prevac* Full Load Instrument Trays 275°F 3 min 16 min X N/A N/A

Flash** Unwrapped, Non-porous

Express** Single-wrapped

Flash Unwrapped, Non-porous

DART* Bowie-Dick Test Pack 270°F 3 1/2 min 1 min X N/A N/A

Leak*

Test None N/A N/A N/A X N/A N/A

Instrument Tray 270°F 3 min 1 min X X

Instrument Tray 270°F 4 min 3 min X N/A N/A

Instrument Tray 270°F 10 min 1 min X X

*Cycles qualified to AAMI ST-8

**Cycles qualified to AAMI ST-37

2-1

Sterilization Techniques Operating Instructions 129367-408

2.2 Special

Information

Regarding the

Express Cycle

Appropriate parameters for sterilization are preset by STERIS. It is designed

to permit sterilization using a single instrument in a single

or textile, but not a peel pouch) on the instrument tray.

Rationale: The single wrapper serves to confine and contain the sterilized item

from environmental contaminants that may be encountered enroute from the

sterilizer to the point of use. A single wrapped item sterilized with the Express

cycle does not have a shelf life.

wrapper (non-woven

WARNING – STERILITY

ASSURANCE HAZARD:

The Express cycle is only

intended for use with a

single instrument in a

single wrapped instrument tray.

2.2.1 Preparing

Instruments for

Express Cycle

Sterilization

WARNING – STERILITY

ASSURANCE HAZARD:

The Express cycle is not

intended for processing

porous items (except the

tray wrapper).

The Express cycle is useful in providing quick turnaround of an instrument

using the wrapped technique for transport from the sterilizer to the point of use.

Instrument trays processed using the Express cycle are intended for immediate

use.

Decontaminate and then prepare a surgical instrument (open and/or disassembled), and place in a perforated or mesh bottom instrument tray. Only nonporous items (except for the wrapper) should be processed using this cycle.

Items with lumens (e.g., needles for injection and diagnostics or metal suction

cannulae) are considered porous items, and must not be processed using this

cycle.

The Express cycle has fewer prevacuum pulses so air removal and subsequent

steam contact within lumens may be difficult to achieve.

Table 2-2. Item Processing Guidelines for Express Cycle

Examples of non-porous items that can be processed using the

Express cycle:

• Forceps,

• Needle Holders,

• Scissors and other routine metal instruments.

Examples of porous items that CANNOT be processed using the

Express cycle:

• Towels,

• Rubber or Plastic Items,

• Items with Lumens,

• Items with sliding parts that prevent sterilant contact with surfaces.

2-2

129367-408 Operating Instructions Sterilization Techniques

2.2.2 Unloading Use instrument processed in an Express cycle immediately. Do not store for

later use.

When opening and unloading the sterilizer at the conclusion of the Express

cycle always use aseptic techniques. Sterile towels and sterile gloves are used

to remove the tray from the sterilizer. The still-wrapped tray is transported to the

point of use, being careful not to contact any unsterile surfaces. The tray is

placed on a previously draped sterile surface field and the wrapper opened by

the circulating nurse. The draping material used must be impervious to liquids

and able to withstand contact with hot surfaces.

To shorten the sterilization process, drying time has been reduced in the

Express cycle. Thus, the single wrapper will appear dry at the conclusion of

the cycle, but the content of the package will, in all probability, still be wet with

condensation formed during sterilization. Water will penetrate the wrapper,

especially on the under side of the tray because of gravity. The wrapper only

serves the function of protecting the tray and its content from particulate matter

encountered on the way from the sterilizer to the point of use.

Any moisture present can strike through the wrapper, so procedures should be

developed to avoid contamination by contact with unsterile surfaces. For

example:

• Wear sterile gloves and use sterile towels as “pot holders” when removing

the goods from the sterilizer.

• Never place the wrapped tray on an unsterile surface.

2.3 Special

Information

Regarding The

Flash Cycle

WARNING – STERILITY

ASSURANCE HAZARD:

The Flash cycle is not intended for processing porous items.

The Flash Cycle

Amsco® Century® prevacuum and gravity configurations. The Flash cycle has

been designed to sterilize an unwrapped item at sterilization parameters preset

by STERIS. There is no storage or shelf life of flash sterilized items.

Rationale: The Flash Cycle is intended for sterilizing an unwrapped item

intended for immediate use (e.g. a dropped instrument). In any method of

sterilization, it is important to adhere to good processing practices. This is

particularly important in flash sterilization.

Preparing Instruments For Flash Cycle Sterilization

As prescribed in AAMI ST-37, prior to flash sterilization of a dropped

instrument, ensure the item is free of soil by the appropriate decontamination

procedure. The flash sterilized item then must be transferred immediately,

using aseptic technique, from the sterilizer to the actual point of use, usually

the sterile field in an ongoing sterile procedure.

Use items processed in a Flash Cycle immediately. Do not store the processed

items for later use.

is an abbreviated gravity cycle

and is provided on both the

2-3

Sterilization Techniques Operating Instructions 129367-408

2.4 Control

Measures For

Verifying

Sterilization

Process

2.4.1 Biological Monitors

As part of the operator's verification of the sterilization process,

biological indicators may be used to demonstrate that sterilization

conditions have been met.

NOTE: Contact STERIS for information on specific biological indicators

recommended for use with this sterilizer.

A live spore test utilizing

form of biological monitoring. This type of product utilizes controlled

populations of a controlled resistance, so that survival time and kill

time can be demonstrated.

To verify the process, insert the biological indicator in a test pack and

place pack on the bottom shelf. Run test pack through a typical cycle.

On completion, forward test pack and monitor to appropriate personnel

for evaluation. Refer to AAMI guidelines to conduct routine biological

monitoring.

G. stearothermophilus

is the most reliable

2.4.2 Testing for

Prevacuum Efficiency

WARNING – STERILITY

ASSURANCE HAZARD:

Load sterility may be compromised if the biological

indicator or air leak test

indicates a potential problem. If these indicators

show a potential problem,

refer the situation to a

qualified service technician before using the sterilizer further.

Run a Dart® (Bowie-Dick test) cycle daily before processing any loads. The

first prevacuum cycle of each day should be used to test the adequacy of

air removal from the chamber and load, so that steam can penetrate the

load. It is not a test for adequate exposure to heat in terms of time-attemperature.

Tests such as the Bowie-Dick or the Dart® (Daily Air Removal Test)* are

designed to document the removal of residual air from a sample challenge

load.

In the case of these tests, following exposure in a prevacuum sterilizing

cycle, the pack is opened, the indicator examined and conclusions are

drawn as to the pattern of residual air, if any, that remained in the pack

during the sterilizing cycle. Any indication of a malfunction must be

reported to the supervisor. Sterilizer should not be used during this time.

* Available from STERIS.

.

2-4

129367-408 Operating Instructions Sterilization Techniques

2.5 Dart (BowieDick) Test

2.6 Vacuum Leak Test

Conduct a residual air test (e.g., Bowie-Dick test) at the beginning of each day

according to the AAMI standard ST-46. STERIS can provide a product called

Dart® (Daily Air Removal Test), designed to be as sensitive as the standard

AAMI Bowie-Dick test pack in detecting air leaks. Refer to instructions for

running Dart test given in Section 4 of this manual. If a Dart is not available,

construct Bowie-Dick test package in accordance with instructions given in

AAMI standard ST-8.

Run the Vacuum Leak test cycle daily or weekly. This test measures the

integrity of the sealed pressure vessel and associated piping to assure air is

not being admitted to the sterilizer during the vacuum draw downs. Refer to

appropriate cycle description in Section 4 of this manual.

WARNING – STERILITY

ASSURANCE HAZARD:

According to AAMI standards, a measured leak

rate greater than 1.0 mm

Hg/minute indicates a

problem with the sterilizer.

Refer the situation to a

qualified service technician before using the sterilizer further.

2.7 Sterilization

Process

Recommendations

After running a vacuum leak test, a value or leak rate will be printed on the printer

tape. This value will help define a trend over a period of time if the integrity of

the system begins to deteriorate (i.e., allowing air to enter the system). By

running a vacuum leak test cycle daily or weekly, the operator or maintenance

personnel can always monitor the air tightness of the system and make repairs

or adjustments when necessary.

NOTE: A leak rate of greater than 1.0 mmHg per minute indicates a problem with

the sterilizer that must be addressed.

Saturated steam is a well controlled, reliable method for processing items which

can withstand the temperatures and pressures associated with steam sterilization. The requirements for achieving reproducible results are well known by

many users, but are not always understood by all users.

The condition most likely to result in sterilization problems is a failure to remove

all of the air from the items being processed. For example, placing an empty

beaker or bowl in an upright position in a gravity displacement sterilizer may

result in the object not being sterilized, or may require exceptionally long

sterilization times. This problem is because air has almost twice the density as

does saturated steam under the same conditions. Thus, the air sits in the

bottom of the container, and the steam forms a stable layer over the air. This

effect is similar to oil forming a stable layer over water. As long as there is no

mechanism for actively mixing the two, the bottom of the container will only see

dry heat, which is not an effective sterilization method at the temperatures

typically used in steam processes.

There are two traditional methods for enhancing the sterilization of solid bottom

containers in gravity displacement cycles. These are:

• Place 1.0 mL of water for each liter of volume in the bottom of each container.

The expansion of the water into steam as the product is heated will force most

of the air out of the object, thus allowing steam to reach all surfaces and effect

sterilization.

• The better, more reliable method is to orient all objects in a manner which

would allow water to flow out. When the steam enters the chamber, it will tend

to layer over the air. However, the object is now oriented so the air can flow

out. As the air flows out of the container, it will be replaced by the steam. The

steam can now reach all surfaces and effect sterilization.

2-5

Sterilization Techniques Operating Instructions 129367-408

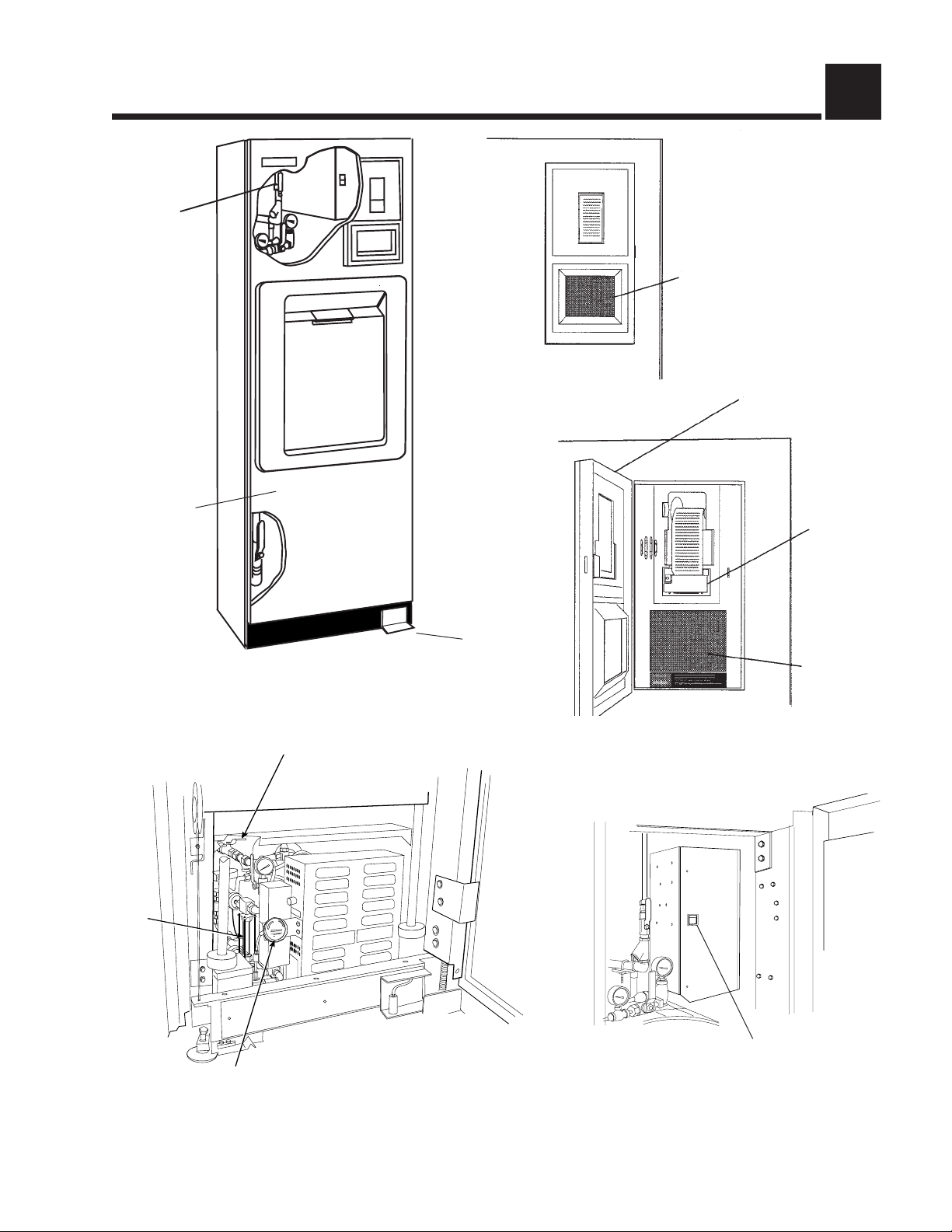

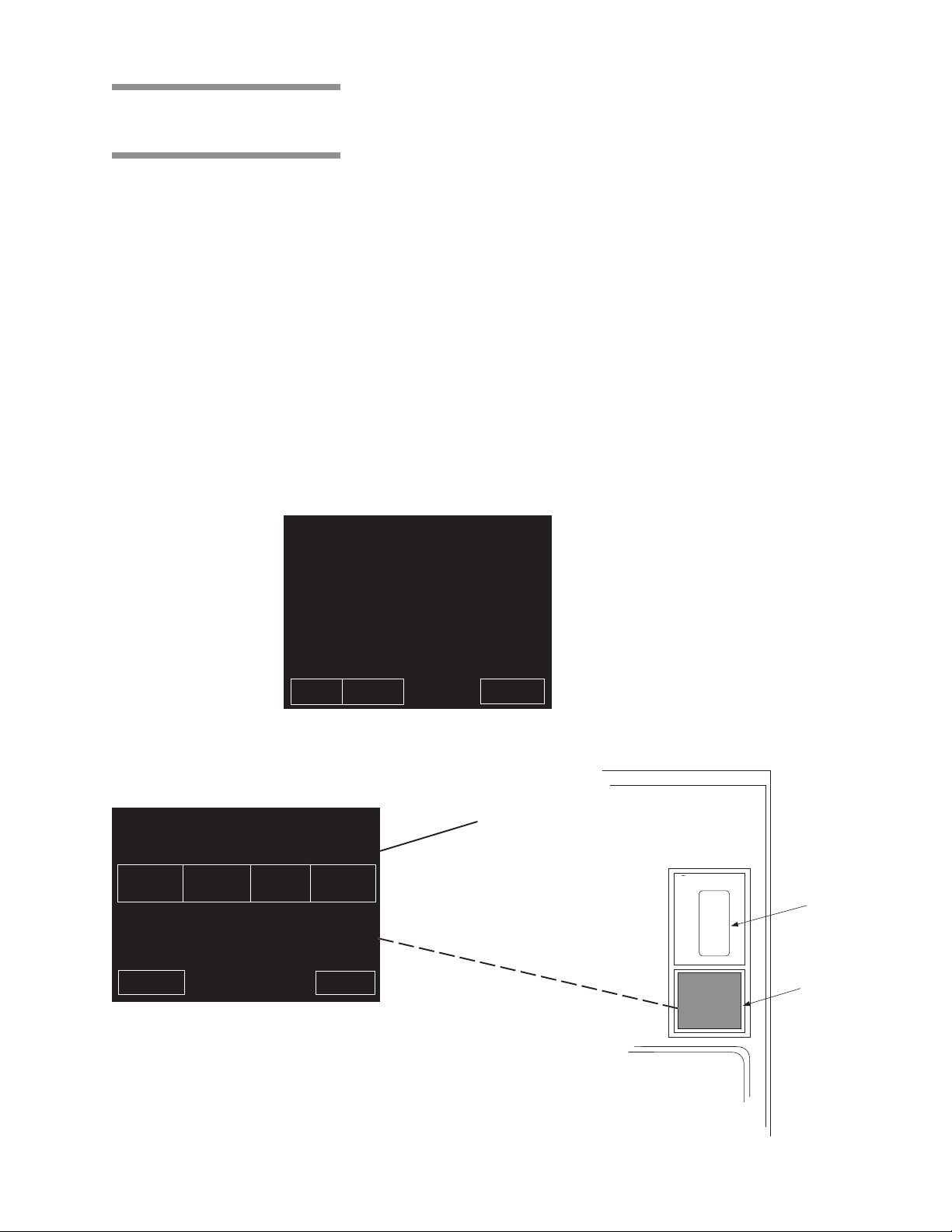

COMPONENT IDENTIFICATION 3

Steam

Supply

Valve

Touch Screen

Access Panel

(Front panel of

unit is hinged

for service

access)

Century Sterilizer

Generator Water

Supply Valve

Foot Pedal

Century Control Panel

Century Control Panel w/Door Open

Control Access

Door

Printer

Touch Screen

Sight

Glass

JACKET

CHAMBER

Optional Electric

Steam Generator

Generator Drain Valve

Main Power Disconnect Switch.

This should be left on at all times.

Figure 3-1. Amsco® Century® Sterilizer Components

Component Identification Operating Instructions 129367-408

3-1

3.1 General

Use this manual to become familiar with control locations and functions before

operating the sterilizer (refer to Fig. 3-1). The controls for this sterilizer are

contained within the control touch screen. Control touch pads appear on the

screen as needed during each operation. Available controls change as the

sterilizer steps through different operations.

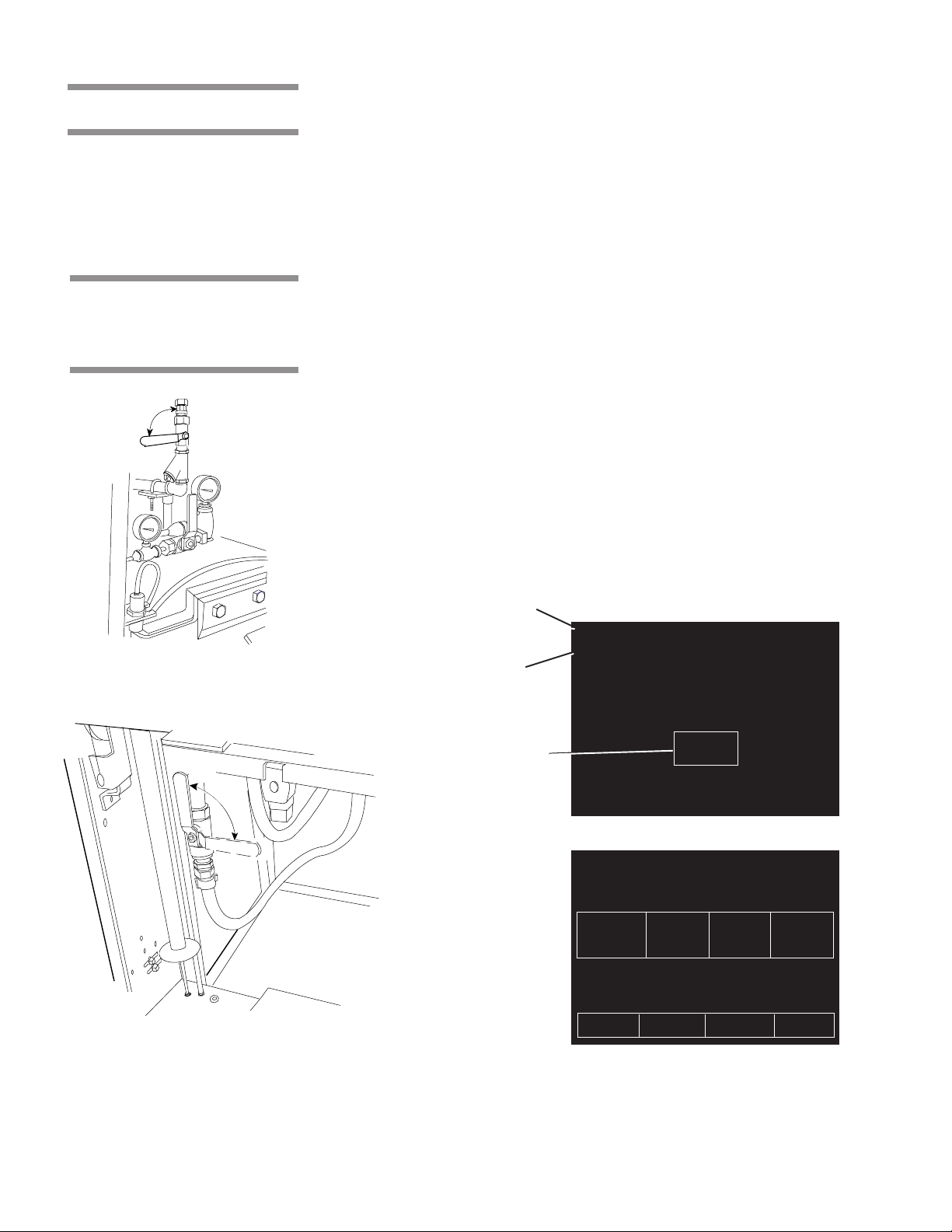

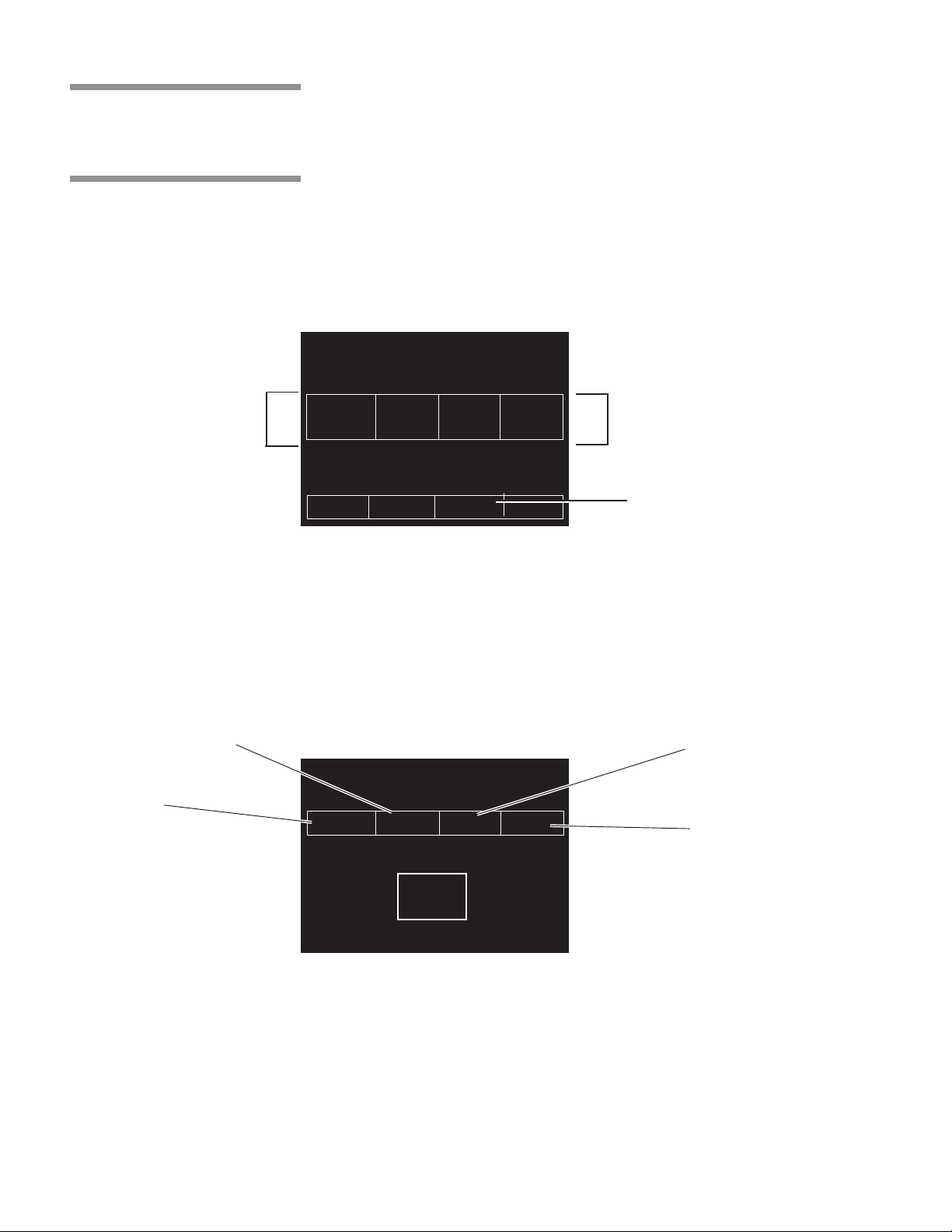

3.2 Main Sterilizer

and Cycle

Controls

Open

Closed

JACKET

CHAMB ER

Steam Supply Valve

••

• Main Power Disconnect Switch

••

(refer to Fig. 3-1) – Located behind the

access door, on the main control box, this switch disconnects power to the

control. Under normal operation, this switch is left in the open position at

all times.

••

• Steam Supply Valve – This is located behind the front access door, above

••

the chamber door. Refer to Figure 3-2. Ensure this is in the open position

before trying to operate the sterilizer.

••

• Water Supply Valve – This is located behind the front access door, below

••

the chamber door. Refer to Figure 3-2. Ensure this is in the open position

before trying to operate the sterilizer.

••

• Steam Generator Control – The optional integral electric steam generator

••

(if present) is located in the space below the sterilizer chamber. The

generator is automatically turned on by the sterilizer’s control when the

sterilizer is turned on. Refer to the instructions later in this section before

operating a sterilizer equipped with an integral steam generator.

Sterilizer Status

STATUS ............ STANDBY 0

TIME .................. 00:00 AM

Current

Time & Date

DATE ................. 00-0 0-00

Open

Touch Screen

Pad—Press to Turn

the Sterilizer ON

ON

Standby Screen

STATUS ............ DOOR OPEN 1

Closed

Water Supply Valve

TEMP ................. 000F

PRESS ............... 00 PSIG

12 34

FLASH FLASH EXPRESS PREVAC

270F 270F 270F 270F

S=03M S=10M S=04M S=04M

D=01M D=01M D=03M D=20M

00:00 AM 00-00-00

PAPER MORE

FEED CYCLES

MENU STANDBY

ON Screen

Figure 3-2. Main Sterilizer and Cycle Controls

3-2

129367-408 Operating Instructions Component Identification

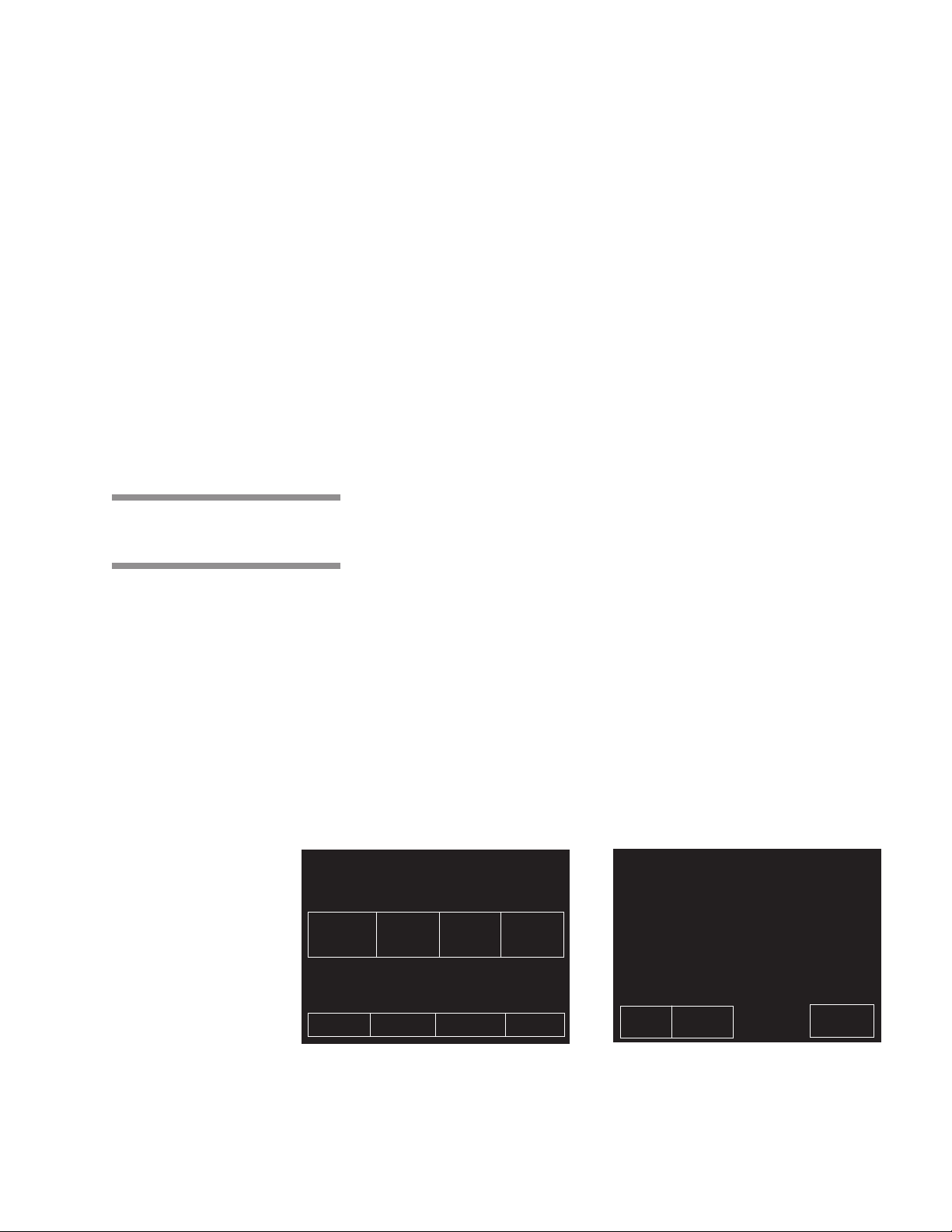

3.3 Control Displays

» Generator Water Supply Valve (refer to Fig. 3-1) – This valve should

always be open. Ensure it is open before attempting to operate the

sterilizer.

» Generator Drain Valve (refer to Fig. 3-1) – This should be opened once

a day, while generator is at room temperature, to flush the generator of

residual solids (present in most water) that may have accumulated in

the generator’s boiler. After the boiler has been flushed ensure the

drain valve is then closed. Refer to instructions later in this section.

••

• Sterilizer Control Touch Pad

••

––

– This is visible on the control touch screen

––

whenever the sterilizer is in Standby mode. Refer to Figure 3-2.

NOTE: Screen touch pads respond to very slight pressure, and only need to be

pressed lightly.

The sterilizer enters operating mode when the ON touch pad is pressed.

This touch pad switches the sterilizer control between Standby and Ready

conditions (Standby mode is usually used at night when the sterilizer is not

being operated—steam is turned off and machine cools, saving energy).

A screen reference number appears in the upper right corner of each display.

Numbers are used for reference only, and do not relate to the operating

sequence of the screen.

Control displays can be divided into two categories, those occurring when the

sterilizer is “out-of-cycle” and those occurring when the sterilizer is "in-cycle".

Typical out-of-cycle and in-cycle displays are shown in Figure 3-3.

• Out-of-cycle displays are used to start cycles, or set up and adjust

sterilizer operation. With the exception of the cycle starting displays, most

out-of-cycle displays will only be used occasionally. Detailed instructions

for adjusting the sterilizer operating parameters are in Section 5 of this

manual.

• Generally, when the sterilizer is in-cycle, displays appear automatically

and, unless an abnormal conditions occurs, require no special attention or

instructions. In-cycle displays tell the operator at what temperature and

pressure the sterilizer chamber is operating, show the current cycle phase

and indicate when the processing cycle is complete. For more details

about operating cycles, refer to Section 4 of this manual.

STATUS ............ DOOR OPEN 1

TEMP ................. 000F

PRESS ............... 00 PSIG

12 34

FLASH FLASH EXPRESS PREVAC

270F 270F 270F 270F

S=03M S=10M S=04M S=04M

D=01M D=01M D=03M D=20M

00:00 AM 00-00-00

PAPER MORE

FEED CYCLES

MENU STANDBY

Out-of-Cycle In-Cycle

STATUS ............ STERILIZE 00:00 4

TEMP ................ 000 F

PRESS ............. 00 PSIG

CYCLE .............. 1, FLASH, 270F, S=03M, D=01M

PROJECTED CYCLE COMPLETION TIME:

0:00

MINUTES SECONDS

PAPER STATUS

FEED PRINT

ABORT

Figure 3-3. Typical In and Out-Of-Cycle Display

3-3

Component Identification Operating Instructions 129367-408

3.4 Alarm Displays

Alarm displays tell operators and technicians when the sterilizer is experiencing an abnormal condition. Alarm conditions can be caused by failure of utility

supplies or sterilizer components. Section 5 of ROUTINE MAINTENANCE

MANUAL (P129367-410), details the steps an operator can take to solve most

alarm conditions. Typical alarm displays are shown in Figure 3-4.

When an alarm occurs during cycle operation, a display appears on the screen,

accompanied by an audible tone. This display indicates the problem as

determined by control sensors, and lists a brief troubleshooting list. The

operator should follow the instructions on the screen, if possible. If these

instructions fail to clear the alarm, consult your departmental supervisor or a

trained service technician before using the sterilizer further.

STATUS ............ ALARM! 205

→ CHAMBER: 70.0 F 00.0 psig

STERILIZER WILL:

→ AUTOMATICALLY TRY TO COMPLETE CYCLE

OPERATOR INSTRUCTIONS:

1. SILENCE ALARM

2. CHECK STEAM SUPPLY VALVE

3. IF ALARM RECURS, CALL SERVICE

SILENCE

STATUS ............ SERVICE INFORMATION: 206

→→

→ CHAMBER DID NOT REACH STERILIZE

→→

CAUSES AND CORRECTION:

1. STEAM PRESSURE LESS THAN 50 PSIG

2. STEAM REGULATOR MALFUNCTION

2. SOLENOID VALVE MALFUNCTION

3. CONTROL OUT OF CALIBRATION

TOO LONG IN CHARGE

→→

→ IF CLOSED, OPEN VALVE

→→

ABORT

ALARM PRINT FEED HELP

TEMPERATURE WITHIN ALLOTTED TIME

→→

→ CHECK STEAM SUPPLY PIPING

→→

→→

→ REPAIR

→→

→→

→ REPAIR S09

→→

→→

→ REPAIR S02

→→

→→

→ RECALIBRATE (CONTACT QUALIFIED

→→

SERVICE PERSON)

ABORT

STATUS PAPER

TOO LONG IN CHARGE

PAPER

FEED

SERVICE

EXIT

Figure 3-4. Typical Alarm Displays

3-4

129367-408 Operating Instructions Component Identification

3.5 Operating End Control Panel

STATUS ............ STERILIZE 00:00 4

TEMP ................ 000 F

PRESS ............. 00 PSIG

CYCLE .............. 1, FLASH, 270F, S=03M, D=01M

A sterilizer equipped with two doors, will also be equipped with two control

panels. The control panel at the loading door of the sterilizer is referred to as

the "operating end control," the control panel located at the unloading door is

referred to as the "non-operating end control."

A single-door sterilizer is equipped with an "operating end control," only.

NOTE: Except for the presence of the printer (which is only present at the

operating end of the unit), control panels at both ends of the unit are similar and

each can be used to start or abort the sterilizer.

The operating end control panel (see Fig. 3-5) is used to:

••

• Select and start cycles.

••

••

• Abort cycles.

••

••

• Set cycles and cycle values.

••

••

• Obtain status printouts (see “Printer” paragraph later in this section).

••

The operating end control includes a printer for cycle documentation.

Cycle status and control messages are shown on a 30 column x 40 line graphics

display. Cycles can be started or aborted using the touch screen pads. Cycles

and cycle values can be set using the Change Values procedure (accessible

from the sterilizer MENU screen). If changing cycle values becomes necessary, refer to Section 5 of this manual.

PROJECTED CYCLE COMPLETION TIME:

PAPER STATUS

FEED PRINT

When in-cycle, the display shows a status of the sterilizer,

status of the cycle, and large numbers indicate the

approximate time remaining in the current cycle.

STATUS ............ MENU 2

TEMP ................. 128F

PRESS ............... 0 PSIG

CHANGE

TIME

DATE

PAPER

FEED

CHANGE CHANGE DUPLICATE

&

CYCLE MACHINE PRINT

VALUES SETUP

EXIT

Menu Screen

0:00

MINUTES SECONDS

ABORT

Typical Menu Screen

AMSCO Time

00:00:00

AMSCO Time

00:00:00

AMSCO Time

00:00:00

AMSCO Time

00:00:00

AMSCO Time

00:00:00

AMSCO Time

00:00:00

Cycle

Cycle

Printout

Printout

Touch

Touch

Screen

Screen

Figure 3-5. Operating End Control Panel

3-5

Component Identification Operating Instructions 129367-408

3.6 Cycle

Selection Touch

Screen Pads

Press to StartPress to Start

Press to Start

Press to StartPress to Start

(Select) Cycles(Select) Cycles

(Select) Cycles

(Select) Cycles(Select) Cycles

Four cycle selection touch pads are shown on the screen in Figure 3-6. These

pads display the basic parameters of the cycle (cycle name, sterilization

exposure temperature, sterilization exposure time and dry time), additional

cycles may be selected by pressing MORE CYCLES. Details on individual

cycles are in Section 4.8.

Up to seven additional cycles can be programmed and displayed. It is the

responsibility of the healthcare facility to validate the cycle. Reference AAMI

for guidelines and standards for a guide to validating sterilization cycles and

to ensure that proper sterility assurance level (SAL) as well as moisture retention

acceptance criteria are met.

STATUS ............ DOOR OPEN 1

TEMP ................. 000F

PRESS ............... 00 PSIG

12 34

FLASH FLASH EXPRESS PREVAC

270F 270F 270F 270F

S=03M S=10M S=04M S=04M

D=01M D=01M D=03M D=20M

00:00 AM 00-00-00

PAPER MORE

FEED CYCLES

MENU STANDBY

Press to StartPress to Start

Press to Start

Press to StartPress to Start

(Select) Cycles(Select) Cycles

(Select) Cycles

(Select) Cycles(Select) Cycles

Press for More CyclesPress for More Cycles

Press for More Cycles

Press for More CyclesPress for More Cycles

3.6.1 Values Touch Screen Pads

Sterilization ExposureSterilization Exposure

Sterilization Exposure

Sterilization ExposureSterilization Exposure

TemperatureTemperature

Temperature

TemperatureTemperature

Cycle NameCycle Name

Cycle Name

Cycle NameCycle Name

Figure 3-6. Cycle Selection Touch Pads

These touch screen pads are accessed through the MENU screen by pressing

CHANGE CYCLE VALUES. The values touch pads are used for changing the

operating values used in cycles, changing the cycles displayed on the cycle

selection menus, and for changing the operating settings of the sterilizer.

Instructions for changing sterilizer cycle parameters are in Section 5 of this

manual.

Sterilization ExposureSterilization Exposure

Sterilization Exposure

Sterilization ExposureSterilization Exposure

TimeTime

Time

TimeTime

Dry TimeDry Time

Dry Time

Dry TimeDry Time

SELECT ITEM TO CHANGE

1 TEMP STER DRY

FLASH 270 F 03 M 01 M

EXIT

11

Figure 3-7. Values Touch Screen Pads

3-6

129367-408 Operating Instructions Component Identification

3.6.2 Abort Touch Screen Pad

The ABORT touch screen pad is used to end a cycle before it finishes normally.

A cycle only needs to be aborted if an abnormal condition or a control problem

develops during the cycle. Pressing ABORT causes the sterilizer chamber to

depressurize (if pressurized), or Air Break (if in vacuum), the door seal

deactivates, the control prompts the operator to open the door, and the

sterilizer returns to its normal out-of-cycle state. If an abnormal condition

persists after fully aborting the cycle, contact your supervisor or a qualified

service technician before trying to operate the sterilizer further.

STATUS ............ STERILIZE 00:00 4

TEMP ................ 000 F

PRESS ............. 00 PSIG

CYCLE .............. 1, FLASH, 270F, S=03M, D=01M

PROJECTED CYCLE COMPLETION TIME:

Figure 3-8. Cycle AbortTouch Screen Pad

3.7 Printer

PAPER PRINT

FEED STATUS

0:00

MINUTES SECONDS

ABORT

Abort Touch

Screen Pad

Refer to Figure 3-1.

Printer records all cycle data on 2-1/4 inch wide single-ply paper. See ROUTINE

MAINTENANCE MANUAL

(P129367-410)

for paper changing procedure.

Printer functions controlled by touch screen pads are as follows:

• Paper Feed — Press to feed out paper from the roll stored inside the

control. Accessible during all phases of operation, including alarm

conditions. Press and hold for continuous feed.

• Duplicate Print

— Press to obtain a complete duplicate printout of the last

previously run cycle (when unit is not in cycle). This touch pad is only visible

on the screen during Complete and Change Values menu. The Duplicate

Print touch screen pad is not visible upon first power-up of the day.

• Status Print — Press to obtain a printout of current cycle phase and

conditions (when unit is in cycle). This touch pad is only visible during cycle

operation.

• Print Values — Press to obtain a printout of all currently set cycles and

cycle values. Only accessible when the unit is not in cycle. This touch

screen pad appears on Change Values menu only.

3-7

Component Identification Operating Instructions 129367-408

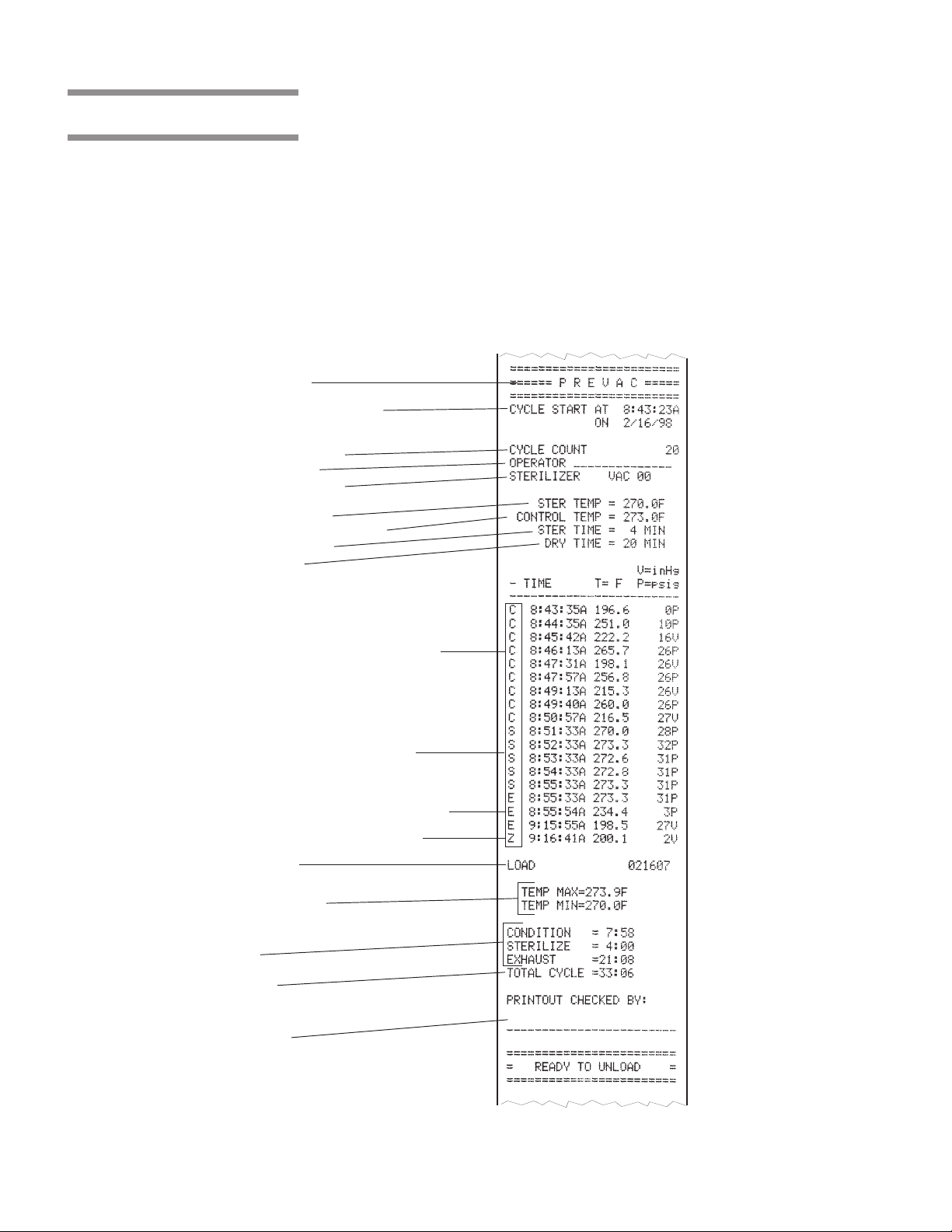

3.8 Printouts

Cycle Type

Cycle Start Time & Date

Total Cycle Count

Operator I.D.

Machine Number

Sterilize Temp.

Control Overdrive Temp.

Sterilize Time

Dry Time

Refer to Figure 3-9.

The printout reports useful information about each cycle the sterilizer runs. This

includes the load number, which is a unique identifying code. Each load

number is printed in the following format: a two digit month (e.g., January = 01),

a two digit day (e.g., second day of any given month = 02) and a two digit daily

cycle count (e.g., third cycle of the day = 03). In our examples the complete

load number would then be 010203.

During the cycle, status lines on the printouts show the time the line was printed,

chamber temperature and the level of vacuum or pressure in the chamber. Each

status line also begins with a letter code. This code indicates during which

cycle phase the print line occurred, or what kind of event caused the print line

to occur.

Refer below to see other features of the printout.

Additional Status Print Codes:

F = Alarm (Failure)

L = Leak Test (Vacuum or Hold)

D = Demand Print (Print Status)

Load Number

Sterilize Temp. Min./Max.

Time in Phase

Total Cycle Time

Review and verify critical cycle

parameters were achieved during

processing, then sign printout to

indicate verification.

Conditioning

• Charge

• Vacuum Pulses

Sterilize

Exhaust & Dry

Complete

3-8

129367-408 Operating Instructions Component Identification

Figure 3-9. Typical Printout

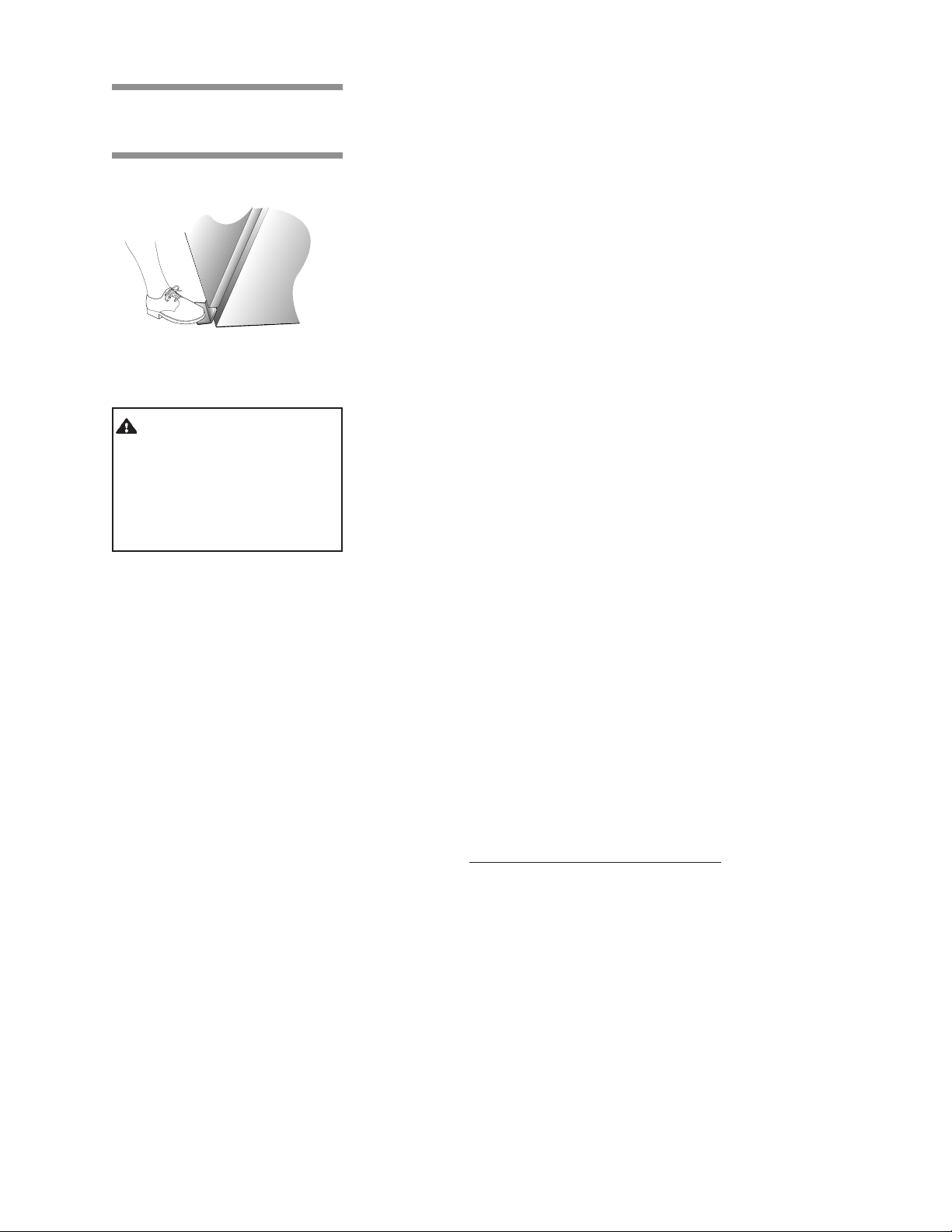

3.9 Power Door Operation

The sterilizer door is operated at the foot pedal (refer to Fig. 3-10).

• Pressing the foot pedal while the door is in the closed (up) position causes

the door to open (lower).

• Pressing the foot pedal while the door is in the open (lowered) position,

causes the door to close (by raising).

NOTE: The foot pedal only provides control of the visible door. For double-door

units, the foot pedal cannot be used to control the door at the opposite end of

the sterilizer.

Figure 3-10. Foot Pedal

WARNING - PERSONAL INJURY HAZARD: When clos-

ing the chamber door keep

hands and arms out of the

door opening and ensure

opening is clear of any

obstructions.

Important:

Operation of Power Door if Motor Fails

If the power door cannot be operated using the foot pedal (such as during a

power failure or if the drive mechanism is damaged), it is still possible to

operate the door manually.

Keep the door closed when the unit is not in use.

Using hand pressure, pull up or push down on the handle to operate the door.

Increased effort is required on the part of the operator to slide the door. Do not

try to raise or lower door rapidly as fast operation may damage the door drive

mechanism.

NOTE: If the power fails, and pressure remains in the sterilizer chamber, refer

to Section 3.10, Emergency Door Opening Procedure.

3-9

Component Identification Operating Instructions 129367-408

3.10 Emergency

Door Opening

Procedure

WARNING – BURN HAZARD: Do not attempt to

open sterilizer door if a

water in chamber alarm

condition exists.

This procedure should only be used when pressure remains in the sterilizer

chamber, and the door cannot be opened normally because the sterilizer has

lost either electrical or water utilities. This emergency door opening procedure

can be used to retrieve a load in the chamber. This procedure requires pushing

on the door cover to retract the door seal into the groove, then pushing the door

downward manually.

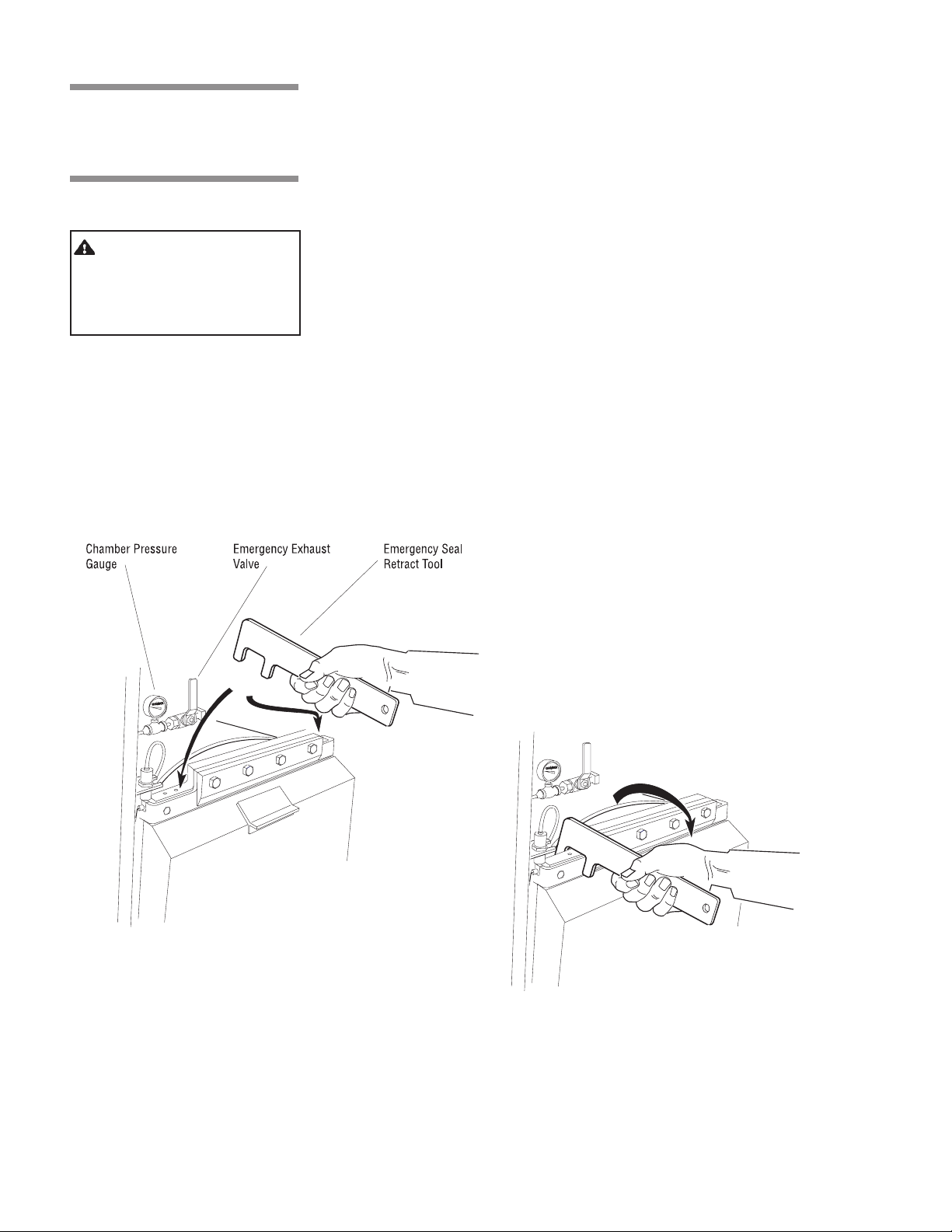

Procedure:

1. Swing open the access panel of the sterilizer. Open the emergency exhaust

hand valve until chamber exhausts to 0.0 psig. See Figure 3-11.

2. Using the door release tool provided, press on the upper left hand and right

hand corners of the chamber door (see Fig. 3-11). The door should give

inward slightly, indicating that the seal has been pushed into the groove.

The door must “bottom out” against the metal end-frame of the sterilizer

chamber.

3. Close the access panel of the sterilizer.

4. Press down on the door handle to lower the door. The door will slide stiffly,

so be prepared to press down hard.

5. Once the door is open, do not use the sterilizer until the unit has been

examined by a qualified service technician. Further use without attention

may damage the sterilizer.

6. Close the emergency exhaust valve.

Figure 3-11. Emergency Door Opening Procedure

3-10

129367-408 Operating Instructions Component Identification

3.11 Optional

Electric Steam

Generator

CAUTION – POSSIBLE

EQUIPMENT DAMAGE:

Failure to flush generator

on a daily basis could result in generator malfunction.

If a building steam source is not available, the sterilizer may be equipped with

an electric steam generator. The generator automatically converts water to

steam using electric heat. The steam created is then used to power the

sterilizer.

Steam generators are highly susceptible to mineral scaling if the supplied water

has any level of hardness. Refer to Table 3-1 for water quality requirements.

IMPORTANT: Regardless of the hardness level of supplied water, the generator must be flushed every day before use to prevent mineral scaling or carryover

of debris into the chamber.

ATTENTION: Warranty on this steam generator will be voided unless daily

flushing procedures are performed.

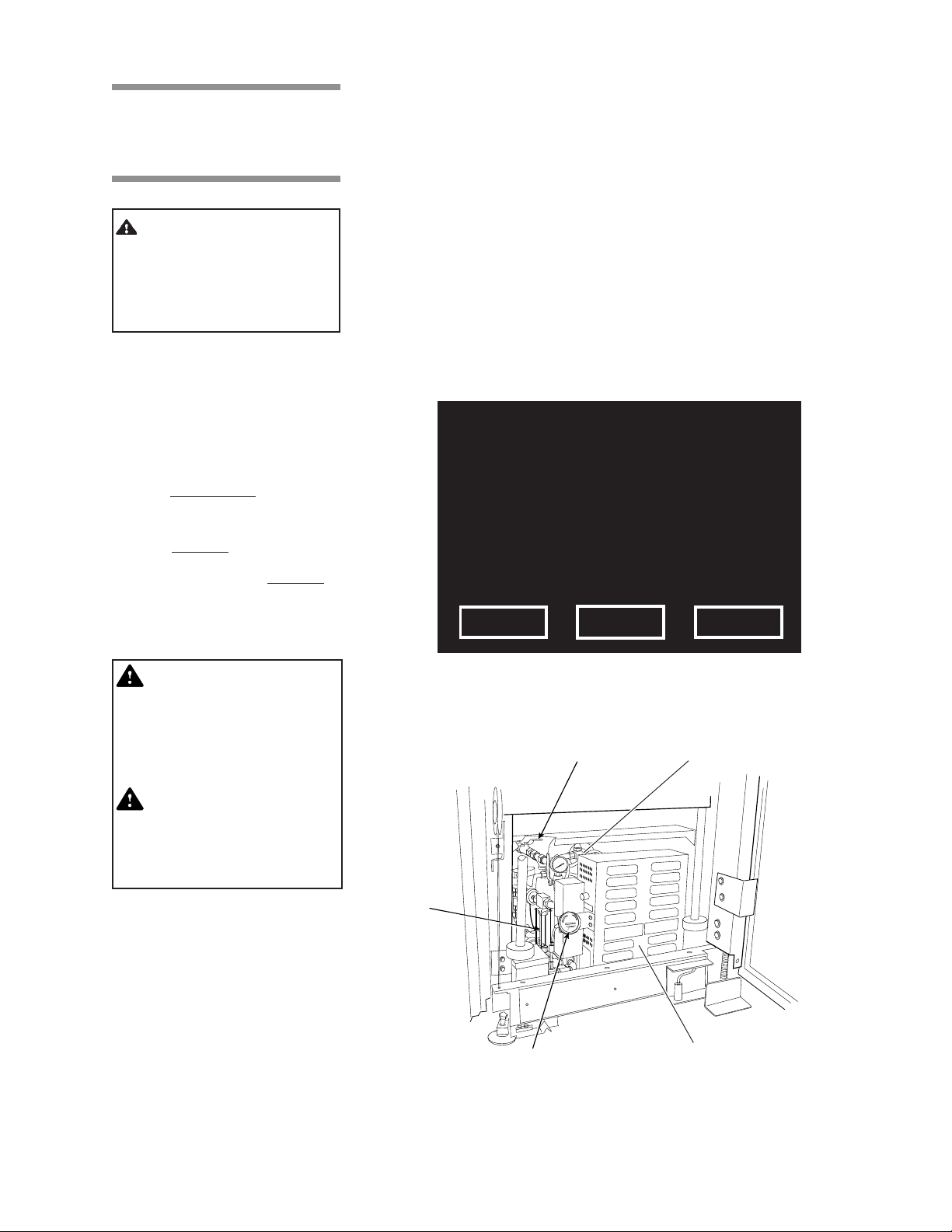

Daily Generator Start Up Procedure

1. Press the ON button on the sterilizer touch screen (screen #0). Display

advances to screen #72. Instructions on how to flush the generator are listed

on screen #72.

Pressing STOP TIMER stops flush

phase and resets timer to three

minutes.

Pressing CANCEL bypasses flush

phase and advances display to

screen #1. Do not press CANCEL

unless generator has already been

flushed that day.

WARNING – BURN HAZARD: Before daily flushing

of the generator, generator must be at zero psig

and cooled to room temperature.

CAUTION – POSSIBLE

EQUIPMENT DAMAGE:

Before flushing generator,

ensure generator drain

valve is fully open.

FLUSH GENERATOR

THE GENERATOR SHOULD BE FLUSHED

EVERY DAY.

TO FLUSH GENERATOR:

1. VERIFY GENERATOR PRESSURE

IS 0 psig.

2. OPEN GENERATOR MANUAL DRAIN VALVE.

3. PRESS START TIMER TO BEGIN

FLUSH PHASE.

4. ALLOW GENERATOR TO FLUSH FOR 5

MINUTES.

FLUSH TIMER: 5:00

START

TIMER

STOP

TIMER

CANCEL

72

2. Check generator pressure gauge (see Fig. 3-12). Generator must be at

0.0 psig and room temperature before flushing.

Water Supply Valve to

the Generator

Water-level

Sight Glass

Generator Pressure Gauge

Generator Drain Valve

Generator Electric Box

Figure 3-12. Optional Steam Generator

3-11

Component Identification Operating Instructions 129367-408

NOTE: If generator is not at 0.0 psi, the Flush can be bypassed by pressing

CANCEL, however the flush should not be bypassed on a continuous basis or

else damage to the generator may occur. Failure to flush the generator on a daily

basis will void the generator warranty.

To ensure generator is at 0.0 psig the sterilizer can be shut off at end of the day

and by next morning the unit will be able to be flushed. Approximately seven

hours are required for generator to cool down to less than 140°F.

3. Open drain valve on the side of the generator electric box (see Fig. 3-12).

4. Verify that the water supply valve to the sterilizer is open.

5. Ensure the water supply valve to the generator is open (see Fig. 3-12).

6. Press START TIMER on screen #72. Water automatically flushes through

the generator and out the drain for 3.0 minutes. Flush timer on screen #72

counts down time remaining in the flush phase.

7. After 5.0 minutes, alarm buzzer sounds and display advances to screen

#73. Instructions on how to restart the generator are listed on screen #73.

73

WARNING – BURN HAZARD:

FLUSHING OF GENERATOR COMPLETE

TO RESTART GENERATOR:

1. CLOSE GENERATOR MANUAL

DRAIN VALVE.

2. PRESS CONTINUE TO START THE

GENERATOR AND ADVANCE TO

THE MAIN MENU.

CONTINUE

Sterilizer operator may be severely burned by scalding water if the water level control

malfunctions. The steam generator level control may malfunction if the supply water

exceeds 26,00 ohms/cm

(38.5 micromhos conductivity min.). Do not connect to

8. Close the generator drain valve.

9. Press CONTINUE on screen #73. Generator automatically fills to the proper

level and starts to heat. Display screen advances to the Main Menu screen

(#1). Allow ten minutes warm-up time once generator starts to fill.

10. Close front cabinet panel.

NOTE: The generator must be flushed every day before use.

treated water (e.g., distilled,

reverse osmosis, deionized)

unless water resistivity is determined to be acceptable. If

water exceeds 26,000 ohms/

cm, contact STERIS for information concerning modifications required to the generator control system.

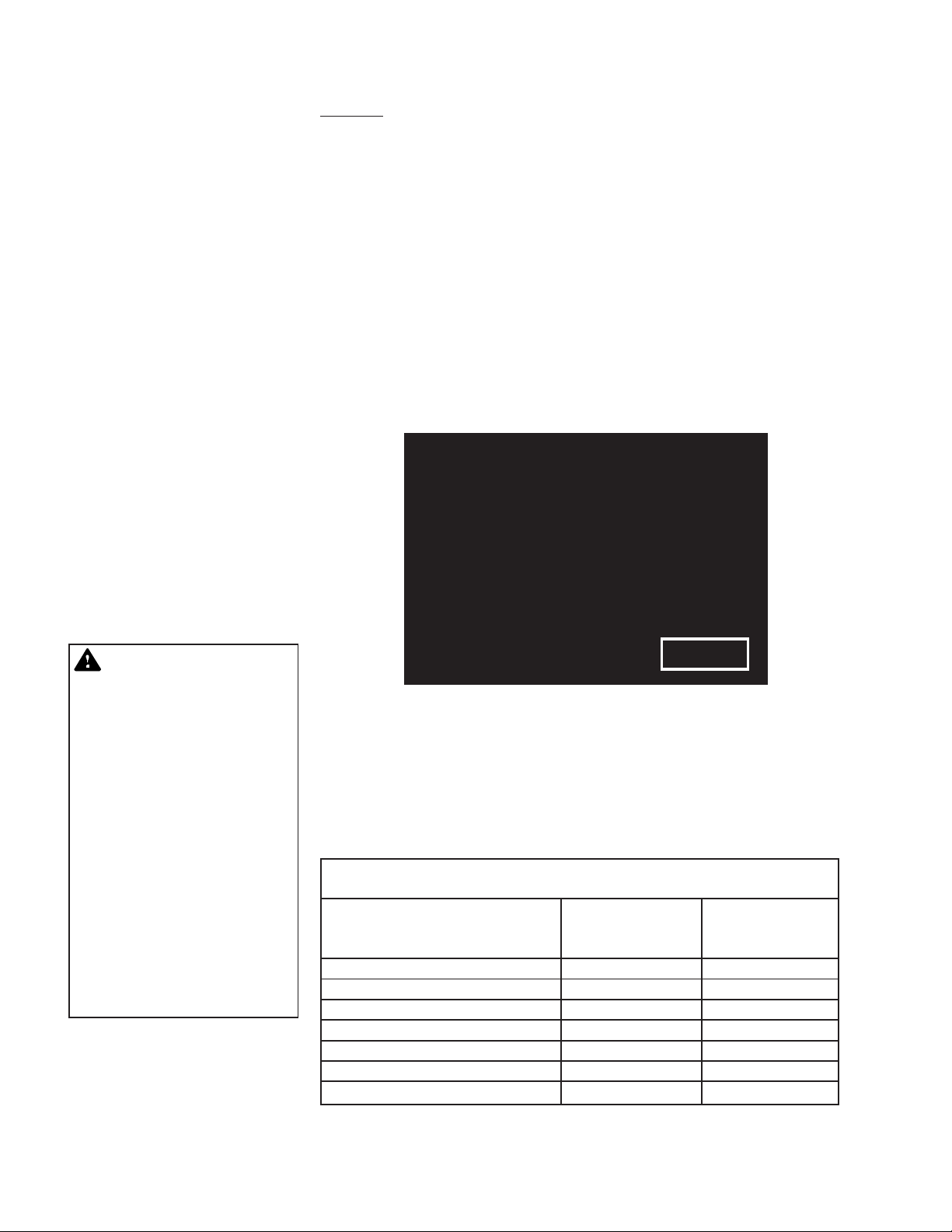

Total Hardness as CaCO3* 0-17 mg/L 130 mg/L

Total Dissolved Solids 50-150 mg/L 250 mg/L

Total Alkalinity as CaCO

Resistivity - ohms/cm 2000-6000 26000

*17.1 mg/L = 1 grain hardness

Table 3-1. Required Feed Water Quality for

Carbon Steel Steam Generators

Nominal Maximum

Condition Conditions Conditions

Temperature as supplied 140° F (60° C)

3

pH 6.8-7.5 6.5-8.5

Total Silica 0.1-1.0 mg/L 2.5 mg/L

50-100 mg/L 180 mg/L

3-12

129367-408 Operating Instructions Component Identification

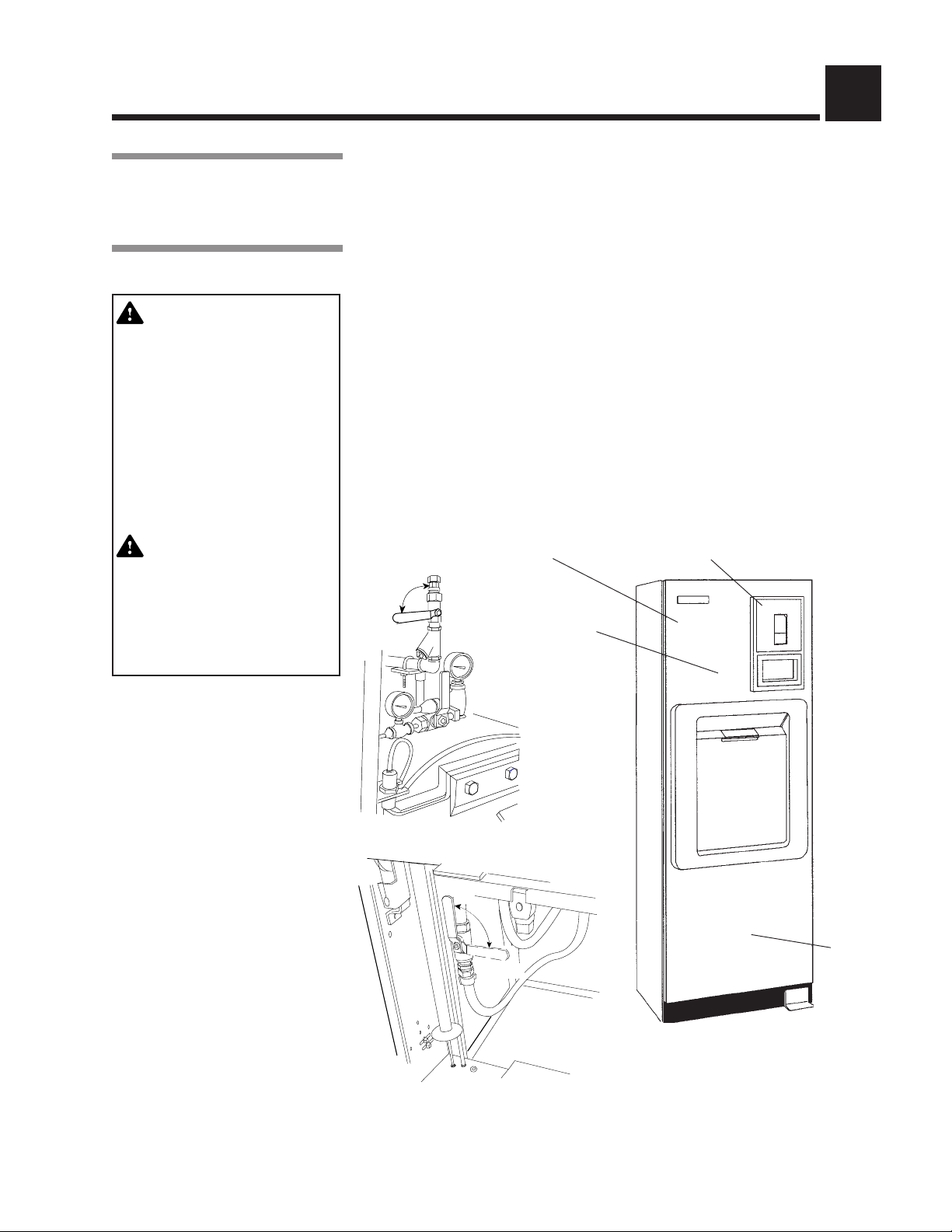

STERILIZER OPERATION 4

Operate sterilizer by referring to the appropriate cycle description in this

4.1 Before

Operating the

Sterilizer

WARNING – BURN HAZARD: Sterilizer, rack/

shelves, and loading car

will be hot after cycle is

run. Always wear protective gloves and apron

when removing a processed load. Protective

gloves and apron must be

worn when reloading sterilizer following the previous operation.

WARNING – SLIPPING

HAZARD: To prevent falls

keep floors dry by immediately wiping up any

spilled liquids or condensation in sterilizer loading

or unloading area.

section. The steps described on the next three pages are general instructions

that apply to all cycle operations.

1. Press ON touch screen pad on the sterilizer control display.

• The printer records the time and date that the power is turned ON.

2. Open chamber door

a. Check that drain strainer is clean and in place and that chamber

interior is clean. See ROUTINE MAINTENANCE MANUAL

(P129367-410)

if cleaning is necessary.

b. Close chamber door.

3. Open access door on the operating end of the sterilizer — refer to

Figure 4-1. Turn on steam (Fig. 4-1a) and water (Fig. 4-1b) supplies. Close

access door.

• Steam enters jacket and begins to warm chamber.

4. Open control access door.

Control

Access

Door

Closed

Open

JACKET

Access

Panel

Steam

Supply

Valve

(4-1a)

CHAMB ER

4-1a Steam Supply Valve

Open

Water

Supply

Closed

Valve

(4-1b)

4-1b Water Supply Valve

Figure 4-1. Steam Valves

Sterilizer Operation Operating Instructions 129367-408

4-1

Loading...

Loading...