Page 1

Typical Applications:

Technical Specification • Technical Specification • Technical Specification

STEPHAN Vacutherm®System V-MC 800/150

Advantages:

• Stable emulsions

• Short batch times

• Gentle as well as effective heating

• Constant specific weight

• Optimal powder dispersing

• Homogenous mixing

• Oxidation is avoided

• Constant product quality

• Good cleanability

• Easy to operate

• Expandable

Options:

• Jacketed vessel with or without insulation

• Steam injection nozzles

• Powder hoppers

• Liquid vessels

• Particulates vessels

• Direct metering for liquids

• Lifting and tilting device

• Steam conditioning unit

• Buffer tank

• Condensate recovery system

• Combination of several systems

• Batch tracing program

• Mayonnaise

• Ketchup

• Dressings, dips

• Baby food

• Classical sauces

• Pasta sauces

• Soup

• Mixing

•Dispersing • Emulsifying

• Size reduction

• Heating

• Deaerating (Vacuum)

• Cooling

• Cooking

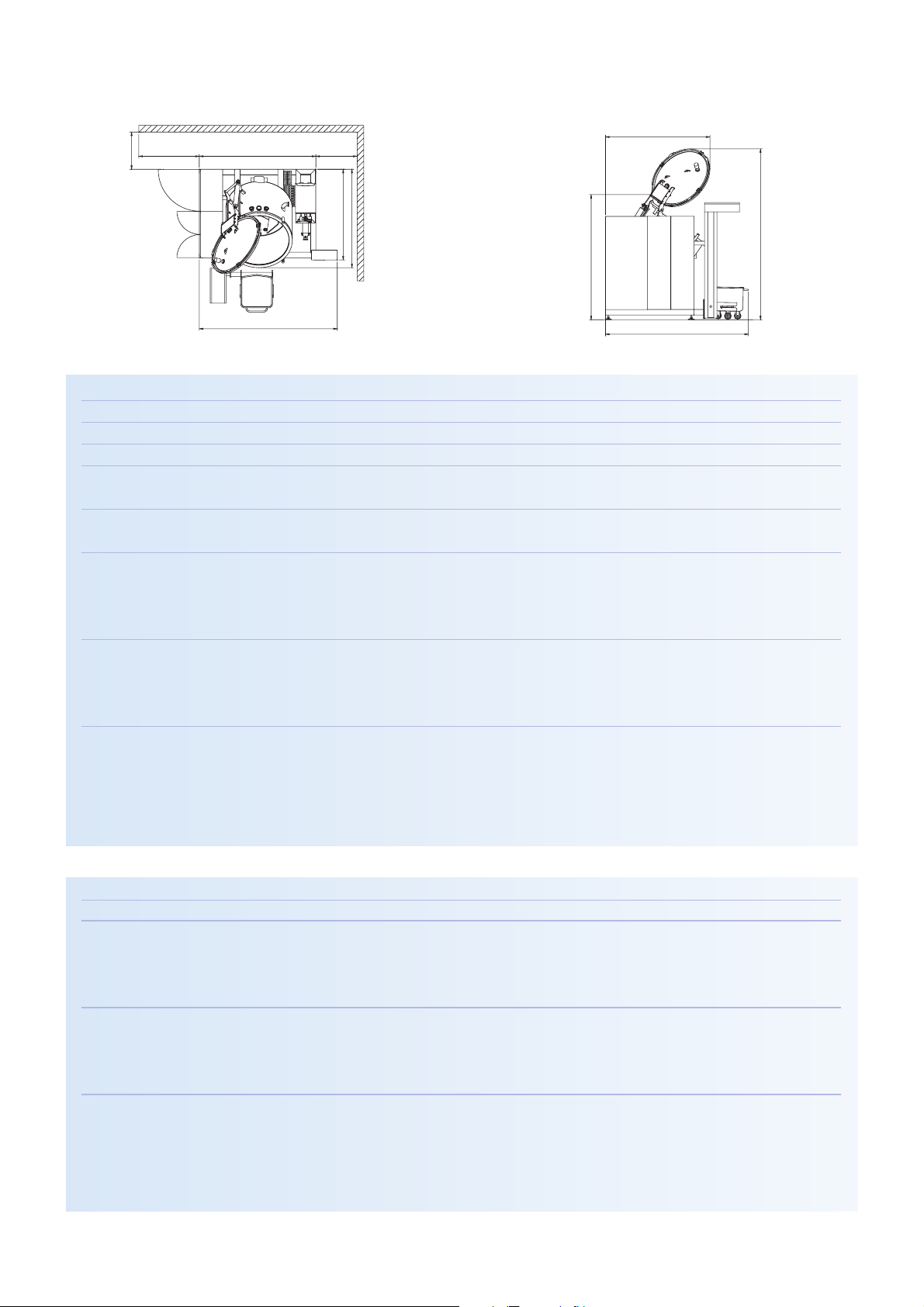

Picture: STEPHAN Vacutherm®System V-MC 400/15

Page 2

Dimensions V-MC 800/150:

Stephan Machinery GmbH & Co.

Stephanplatz 2 • D-31789 Hameln

phone: +49 (0) 51 51 / 583 - 0 • fax: +49 (0) 51 51 / 583 - 189

info@stephan-machinery.com. • www.stephan-machinery.com

Energy requirement

Machine Data:

Batch size, max.

Capacity, max.

Net weight, appr.

Max. operating temperature (Vacutherm vessel)

Max. operating pressure (vessel jacket) standard

option

Max. operating temperature (vessel jacket)

Material: • product side

• non-product side

• elastomers, product side

Shaft seals: • Vacutherm vessel

• recirculating and discharge pump

• Microcut

Connections: • compressed air

• steam supply

• water supply-recipe

• water supply-jacket in and out

• drain connection

Installed energy, appr.

Operating voltage / Protection

Drive motors: • mixing element, speed controlled

• discharge pump, speed controlled

• Microcut, speed controlled

• vacuum pump

Steam: • theoretical requirement

• recommended supply

• steam supply pressure standard

option

Water: • water supply pressure

• water supply - recipe -

• water supply - vacuum pump -

• water supply - jacket

• CIP supply - spray head Vacutherm vessel

(l)

(l/h)

(kg)

0

C (0F)

barg (PSI)

barg (PSI)

0

C (0F)

0

C (0F)

kW

V/Hz / A

kW

kW

kW

kW

kg/h

kg/h

barg (PSI)

barg (PSI)

barg (PSI)

l/h

l/h

l/h

l/h

800

3200

3200

95 (203)

4 (58)

10 (146)

150 (302)

180 (356)

1.4571 (AISI 316) or similar,

except MC-tools (304)

1.4301 (AISI 304) or similar

HNBR, EPDM, FKM, Viton, PVDF

single mechanical seal

single mechanical seal

sealing rings;

option: double mechanical seal

G

1

/4”

DN 40, DIN 11850, row 2, welding end

DN 40, DIN 11850, row 2, welding end

DN 40, DIN 11850, row 2, welding end

DN 65, DIN 11851 connection piece

48

400/50 / 100 A, slow

5.5

5.5

22

1.5

750

900

8 - 10 (116 - 145)

11 - 12 (160 - 175)

4 (58)

12000

240

10000

12000

Subject to alterations

as per March 2006

Technical Specification • Technical Specification • Technical Specification

approx. 800

approx. 800

approx. 2500

approx. 1945

approx. 1300

approx. 2960

approx. 2110

approx. 2240

approx. 3670

approx. 3065

approx. 2685

overall hight with lid open: 3670 mm

L&S 03.06. ‘3e 5028

approx. 800

approx. 1300

approx. 2500

approx. 800

approx. 1945

approx. 2110

approx. 2960

approx. 2240

approx. 3065

approx. 2685

approx. 3670

Loading...

Loading...