Page 1

Advantages:

• Stable emulsions

• Homogeneous mixing

• User-friendliness

• Short batch times

• Constant product quality

• Easy to clean

STEPHAN Universal Machine

UM 24

Description:

• For cutting, mixing and emulsifying of food products

The STEPHAN UM 24 is employed if a single machine is required to execute reliably

and quickly a wide range of processing functions, such as cutting, fine cutting, mixing,

stirring, kneading, making purees and emulsifying and working under vacuum.

It is ideal for use in all fields of food processing, e.g. for the production of bread and

bakery products, meat and sausages, convenience food, confectionery and dairy products.

The product contact parts of bowl and cover are made of 1.4301 or similar (V2A).

The surface is bead blasted. The support is made of stainless steel, too. The working tools

are made of stainless steel and are consisting of a knife shaft and two knives as well as

a mixing baffle with PFDV scraper for manual handling. A sight glass and a lamp are

installed on the cover. The machine is equipped with a tilting device for easy product

discharge.

The main motor – equipped with frequency converter - is controlled by soft touch panel

3011. The readout appears in 2 lines in an illuminated LCD display. The operated keys are

illuminated as well. A timer is included.

The STEPHAN UM 24 is also available with bowl with double jacket for indirect cooling or

heating of the bowl contents – see different identification numbers on 2nd page.

In this case there is existing a temperature indication and the possibility to use a temperature setpoint value for shutoff by soft touch keyboard.

Please call us,

we would be pleased

to help you!

Sales and technical advice:

Phone:

+49 (0)51 51 / 583 - 786

or:

+49 (0)51 51 / 583 - 300

Accessories / options:

• 3Q8003-99 Three-phases-autotransformer

for 200-208-220-230 V/50…60 Hz

• 2N0010-05 Vacuum unit

• 3H0718-01 Vacuum pump (water)

• 3Q2019-01 Heating device - only for UM 24 with double jacket –

• 3A2838-02 Transportation facilities

Working tools:

• 3D8140-01 Knife shaft stainless steel, complete, without knives

• 2D0003-05 Set with 2 knives

• 2D0003-06 Set with 2 wave-cut knives

Page 2

STEPHAN Universal machine

UM 24

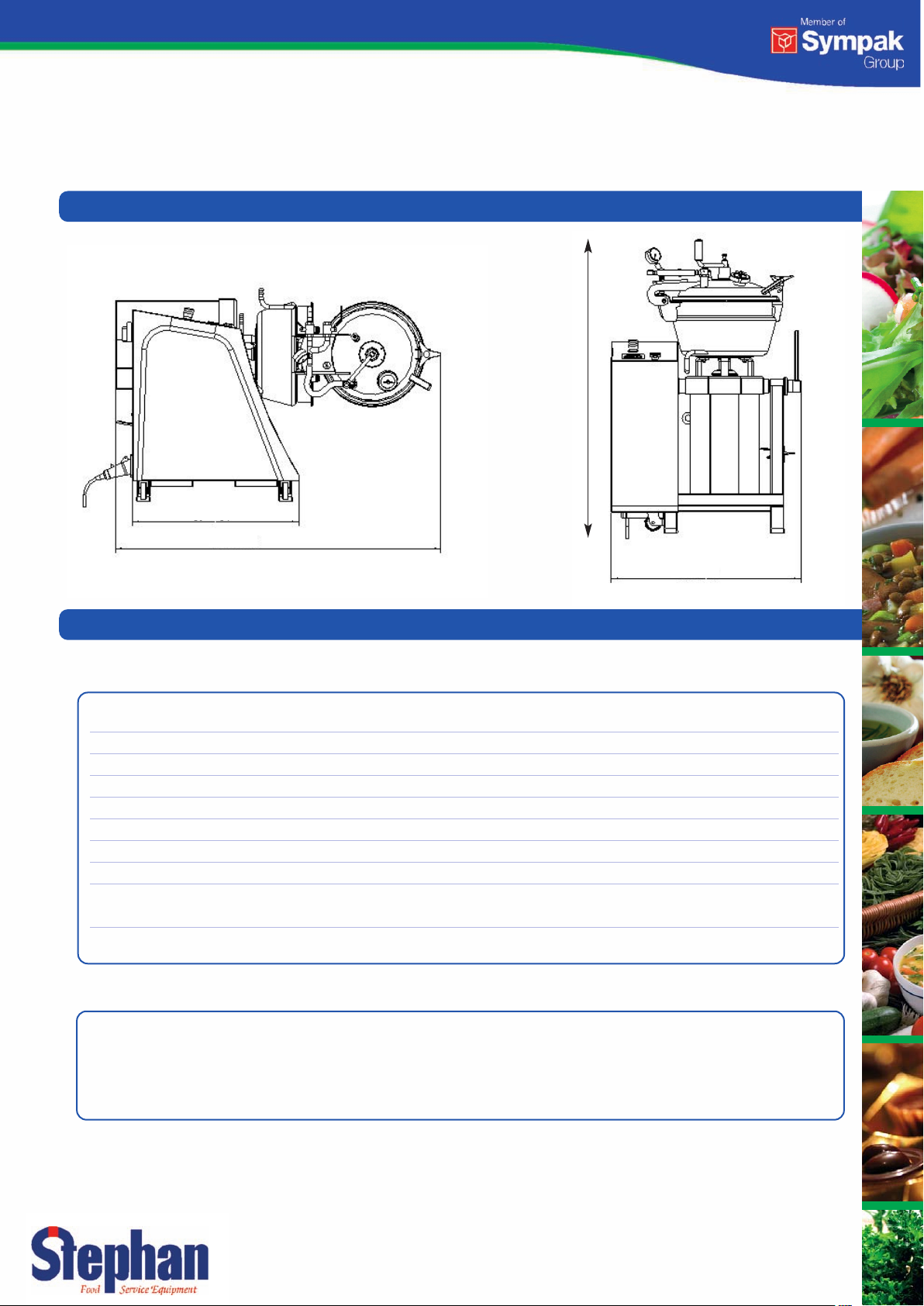

Dimensions (mm) UM 24:

approx. 750

approx. 1500

approx. 1350

approx. 860

Execution:

Bowl content/batch size

Weight of the machine net

Max. permissible operating temperature -- bowl

Max. permissible operating excess pressure -- bowl

Operating voltage

Control voltage

Fuse protection 400 V/220 V

Motor with frequency converter n = 300-3000 U/min

Material:

Bowl stainless steel bead blasted

Housing/support stainless steel bead blasted

A time-lag fuse

l ca.

kg

°C (°F)

bar (PS)

V (Hz)

V

kW

No.

No.

Order information:

STEPHAN UM 24 Order no.: UM024-F21210 400 V/50 Hz

STEPHAN UM 24 with double jacket bowl Order no.: UM024-F21220 220 V/60 Hz

30/18 max.

230

95/203

0.0

400 (50)

24

32

7.5

1.4301 (AISI 306)

1.4301 (AISI 306)

Stephan Food Service Equipment GmbH

Kuhlmannstr. 10 • 31785 Hameln / Germany

Phone: +49 (0) 51 51 / 583 - 0 • Fax: +49 (0) 51 51 / 583 - 789

info@stephan-foodservice.com • www.stephan-foodservice.com

Subject to alterations

As per october 2008 / e

Loading...

Loading...