Page 1

Technical Specification • Technical Specification • Technical Specification

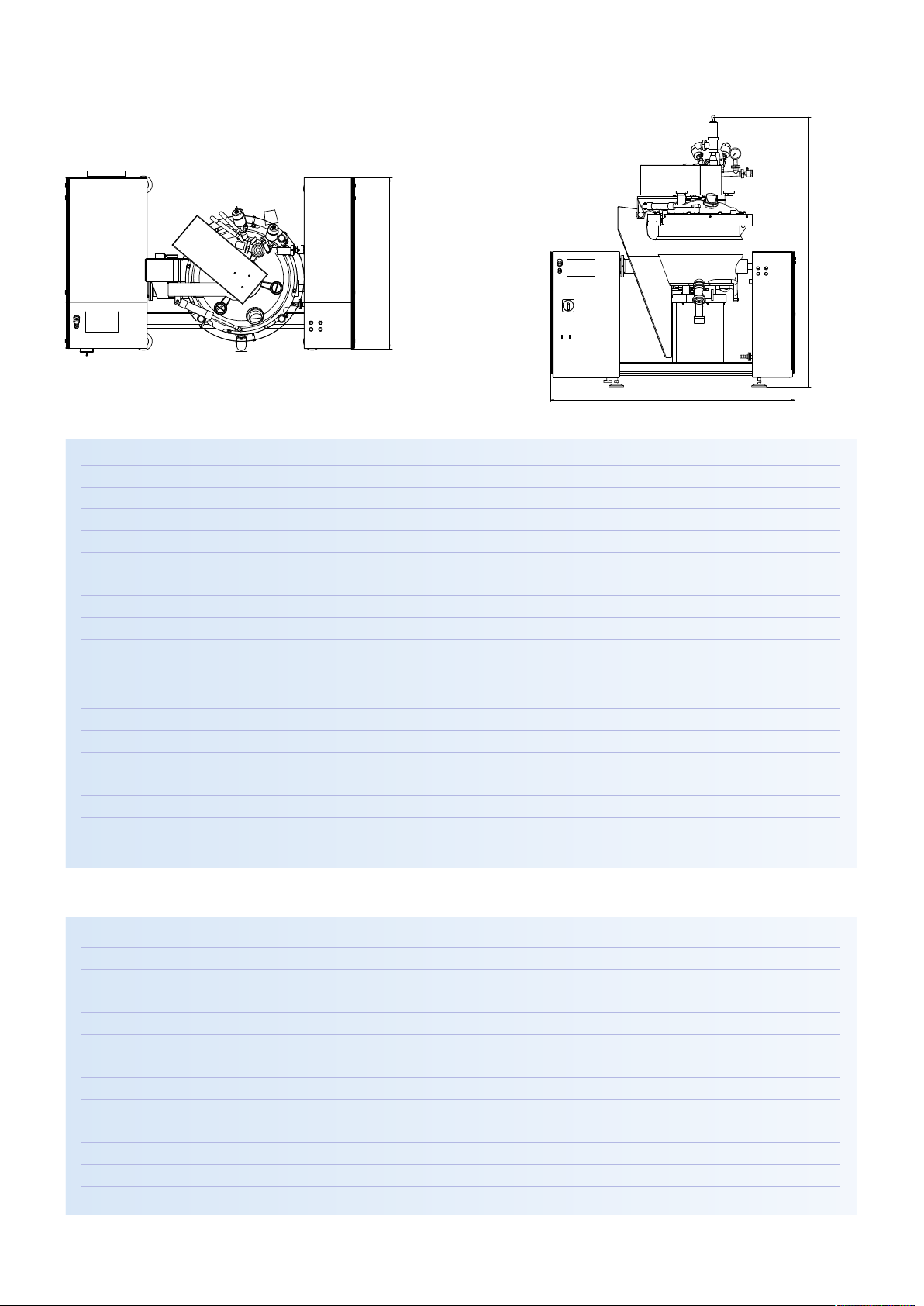

Universal Machine UM/SK 200

• Mixing

• Cooling

Picture: STEPHAN UM/SK 200

• Dispersing • Emulsifying

• Size Reduction

• Heating

• Deaerating (Vacuum)

• Cooking under vacuum / under pressure

Typical Applications:

• Processed Cheese

• All kinds of fresh cheese preparations

• Dressings, sauces

• Baby food

• Confectionery fillings

• Butter preparations

• Almond paste, marzipan

• Mayonnaise, ketchup

Advantages:

• Short batch times

• Configurable for many different applications

• Complete product emptying

(minimal losses)

• Energy efficient

• Very few manual operating procedures

• Easy to integrate in a production line

• Production data can be easily transferred

to external systems

• Traceability of historical production data

• PLC controlled process sequences

Options:

• Vacuum condensor for cooling and

dehumidifying

• Charging device

• Discharge pump

• Discharge tank

Standard Execution:

• Frequency controlled main drive

included

• Discharge fitting included

• Axial face seal, double active for

main motor shaft included

• Siemens PLC and touch panel

included

Page 2

Technical Specification • Technical Specification • Technical Specification

Dimensions UM/SK 200:

Machine Data:

Bowl content

Batch quantity (product-dependant)

Net weight of machine

Max. vacuum in the bowl

Max. over pressure in the bowl

Max. operating temperature in the bowl

Max. operating pressure in the double jacket

Max. operating temperature in the double jacket

Min./max. compressed air

Guide values for the steam connection

Steam supply

Steam feeding-pressure

Steam pressure at the machine

Steam supply connection

Material specification

Shaft sealings

discharge height - tilting

discharge height - valve

overall height with lid open: 2500 mm

2367

1270

2144

(l) approx.

(l) max.

kg

bar (PSI)

bar (PSI)

°C (°F)

bar (PSI)

°C (°F)

bar (PSI)

kg/h

bar (PSI)

bar (PSI)

DN

(according to design) 1,400

1.5 (21.75)

2.0 (28.44)

6-8 (85-114)

6-8 (85-114)

2-3.5 (28-50)

200

150-170

-1 (-14.22)

125 (257)

133 (271)

300

32

product contact parts 1.4404/

AISI 316 L/or higher

standard: axial face seal

mm

mm

690

690

Energy requirement

Main motor, frequency controlled

Mixing buffle drive n = 24 min

Vacuum pump

Installed energy

Steam – injection

Steam – double jacket

Water – vacuum pump

Water requirement for recipe

Connection for water (recipe)

Connection for compressed air

Voltage

Stephan Machinery GmbH

Stephanplatz 2 • D-31789 Hameln

phone: +49 (0) 51 51 / 583 - 0 • fax: +49 (0) 51 51 / 583 - 189

info@stephan-machinery.com • www.stephan-machinery.com

-1

kW

kW

kW

kW approx.

kg/h

kg/h

l/h approx.

l/min approx.

bar

DN

inch

V/Hz

55

1.5

0.75

58

240

depends on

product/batch/process

120

60

min 4

32

3/8”

400/50

Subject to alterations

as per January 2008

L&S 01.08. ‘5e 5030

Loading...

Loading...