Page 1

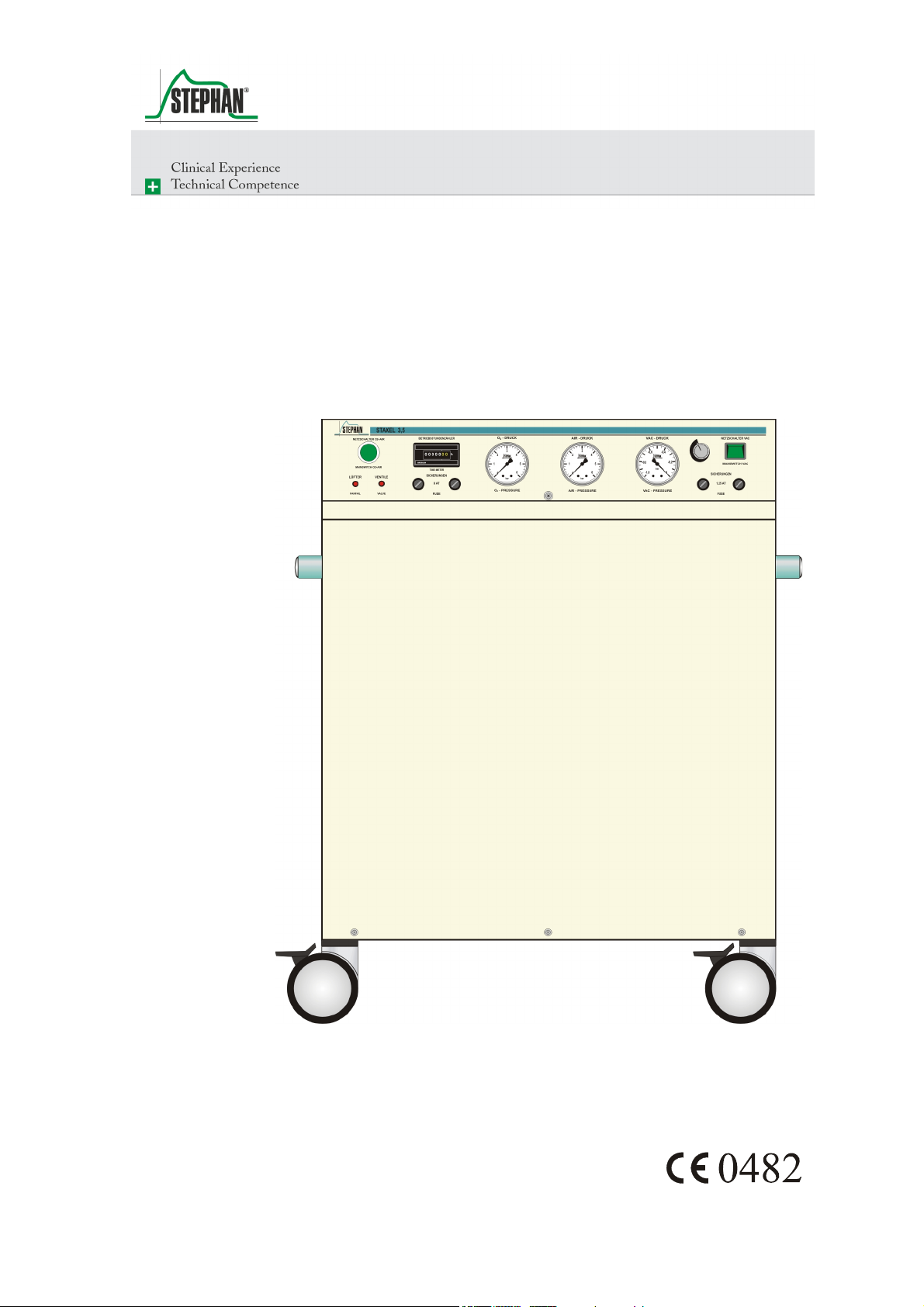

Staxel 3.5

O2AIR Energy Supply Module

Operating Manual

Page 2

Preface

Operating manual

This operating manual intends to provide clear answers to any questions

about how to use and care for S

TAXEL 3.5.

This operating manual does not contain any instructions for repairs and

installation.

In the event of any faults during operation, please contact the authorized

customer service of F. S

TEPHAN GMBH or the authorized dealer who

delivered the device to you and provided you with the initial instructions

on how the device functions and how to operate it.

The manufacturer only warrants the safety and reliability of S

TAXEL 3.5,

if it is operated in conformity with the operating manual.

F. Stephan GmbH

- Medizintechnik Kirchstrasse 19

56412 Gackenbach

Subject to technical alterations.

as of: Januar 2006

version: V1.0

2 GA-602-0106V1.0-PAE-GB © F. Stephan GmbH

Page 3

®

Contents

Contents .....................................................................................................3

1 General information ...........................................................................5

1.1 Product combination................................................................5

1.2 Device name and manufacturer ...............................................5

1.3 Proper use ................................................................................6

1.4 Packaging and waste disposal..................................................6

1.5 Introduction .............................................................................7

1.6 Abbreviations and definitions..................................................8

1.7 Technical data..........................................................................9

2 Safety instructions............................................................................11

2.1 Danger warnings....................................................................11

Contents

2.2 Warnings................................................................................12

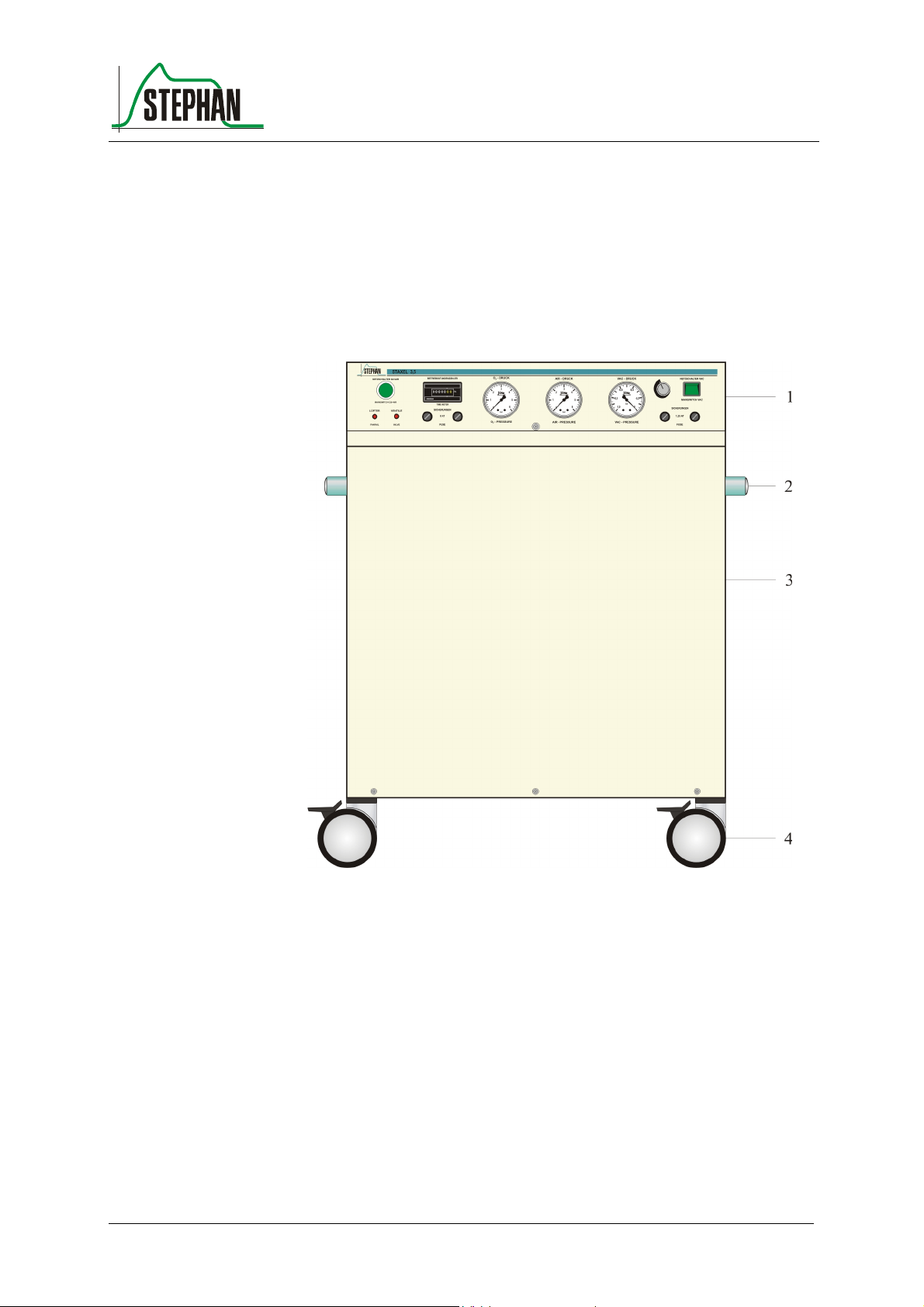

3 Structure and description of functions .............................................13

3.1 Front view..............................................................................13

3.2 Controls and display elements...............................................14

3.3 Rear view...............................................................................15

3.4 Right-hand side view .............................................................16

3.5 Left-hand side view ...............................................................17

4 Preparing for operation ....................................................................19

4.1 Erecting the device ................................................................19

4.2 Connecting to the gas and power supply ...............................20

4.2.1 Gas supply .................................................................20

4.2.2 Power supply .............................................................20

5 Test list.............................................................................................23

5.1 Test before starting the device every time .............................23

5.2 Test before every patient .......................................................23

6 Operation .........................................................................................25

6.1 Switching on..........................................................................25

6.2 Switching off .........................................................................25

6.3 Stopping the device ...............................................................25

7 Troubleshooting ...............................................................................27

8 Care and maintenance ......................................................................29

© F. Stephan GmbH GA-602-0106V1.0-PAE-GB 3

Page 4

ContentsContents

8.1 Disinfection and sterilisation .................................................29

8.1.1 Device housing, gas connections, mains lead ...........30

8.2 Safety checks .........................................................................30

8.3 Maintenance...........................................................................30

8.3.1 Filter unit ...................................................................31

9 List of accessories............................................................................33

10 Guarantee .........................................................................................35

11 List of illustrations ...........................................................................37

12 List of tables.....................................................................................39

13 Notes ...............................................................................................41

4 GA-602-0106V1.0-PAE-GB © F. Stephan GmbH

Page 5

®

1 General information

1.1 Product combination

Combinations with other products can impair the performance and safety

of S

TAXEL 3.5.

TEPHAN GMBH rules out any warranty for unacceptable device

F. S

combinations operating with products not approved by the manufacturer

or products without certified compatibility.

Only use the accessories stated in chapter 9 on page 35.

1 General information

1.2 Device name and manufacturer

TAXEL 3.5

Device name

Manufacturer

S

F. Stephan GmbH

- Medizintechnik Kirchstrasse 19

56412 Gackenbach

(+)49 (6439) 9125 – 0

(+)49 (6439) 9125 – 111

info@stephan-gmbh.com

www.stephan-gmbh.com

© F. Stephan GmbH GA-602-0106V1.0-PAE-GB 5

Page 6

1 General information

1.3 Proper use

Oxygen concentrators provide a safe source of oxygenated air for patients

needing it. These devices increase the level of oxygen by filtering out the

nitrogen from the ambient air.

S

TAXEL 3.5 constantly generates oxygen from the ambient air and offers

an economic alternative to bottled or liquid oxygen.

S

TAXEL 3.5 is used to generate oxygen and to produce compressed air

and vacuum; it is designed primarily for operating ventilation and

anesthesia systems.

Other combinations are also available on request or order.

1.4 Packaging and waste disposal

Packaging

Return/disposal

The device packaging consists essentially of recyclable or reusable

materials.

The carton packaging can be reused or disposed of as used paper.

The wrapping consists of CFC-free padding which can be disposed of

together with the foil as recyclable plastic waste (in Germany: yellow

trash can).

F. S

TEPHAN GMBH guarantees that used devices from our company can

be returned free of charge and disposed of correctly, thus making a

contribution to the environment.

6 GA-602-0106V1.0-PAE-GB © F. Stephan GmbH

Page 7

®

1.5 Introduction

German legislation

The Medical Devices Law (MPG), the Medical Devices Operator

Ordinance (MPBetreibV) and the Law on Technical Working Equipment

stipulate that the operator's attention must be drawn to the following:

The device must only be operated by skilled staff who must have

an exact knowledge of the operating manual.

Only use the device for the intended purpose described in the

operating manual.

Read the operating manual through carefully and comply with its

instructions, because lasting safety for patient and user is only

warranted when the device is operated perfectly.

The operating manual must be kept constantly available at the

place of use.

Faulty care and operation can cause work stoppages and

accidents.

1 General information

Warranty

The manufacturer does not accept any warranty claims resulting from

incorrect operation or inadequate care and maintenance.

The manufacturer only guarantees the safety and reliability of the device

if it is operated in compliance with the operating manual.

© F. Stephan GmbH GA-602-0106V1.0-PAE-GB 7

Page 8

1 General information

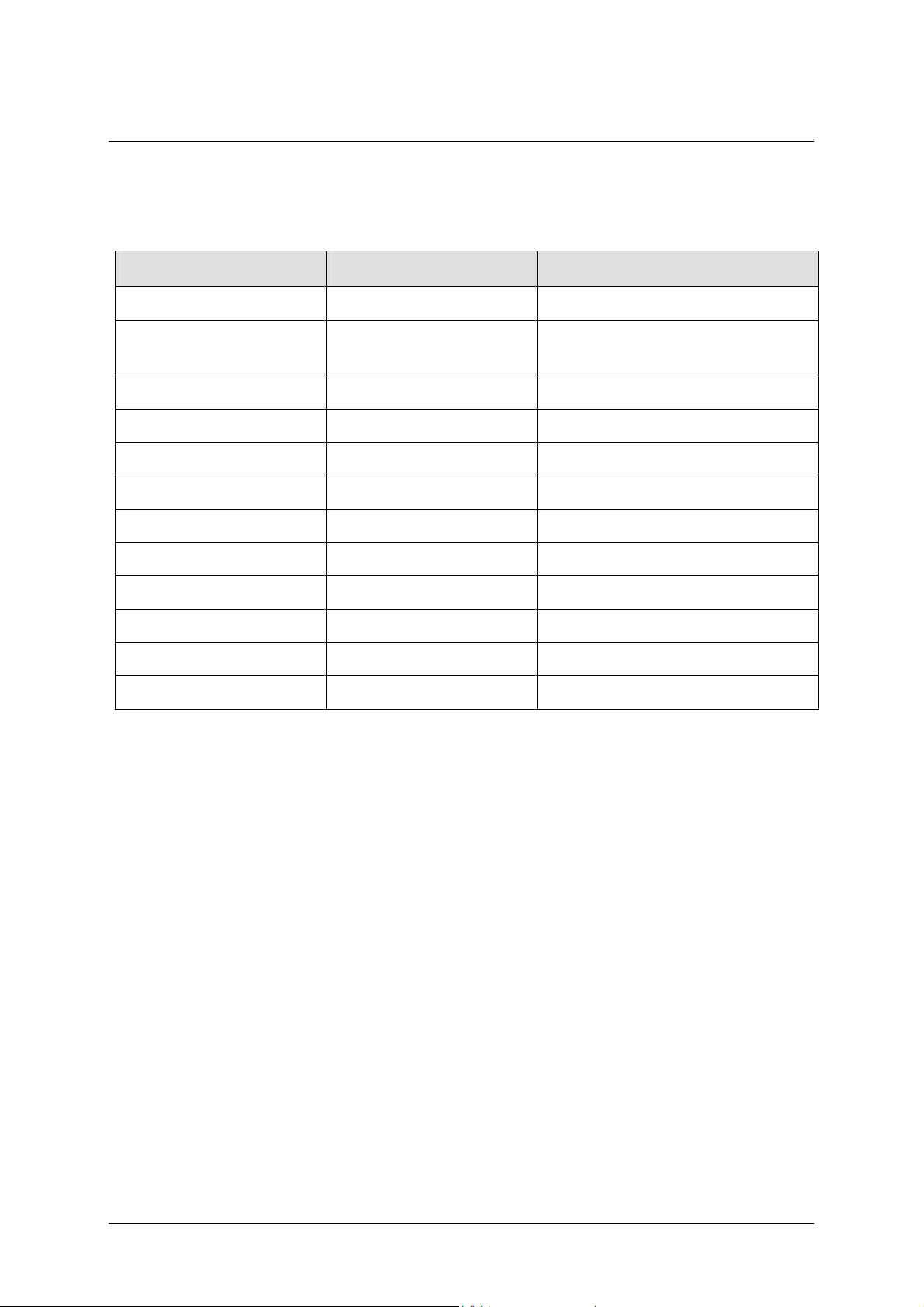

1.6 Abbreviations and definitions

Abbrevations Definition Meaning

AIR Medical compresed air

bar Unit of measurement for compressed

air

DIN German standardization institute

EN European standard

Flow Volume flow

LED Light Emitting Diode

min minutes Unit of time

O2 Oxygen

OG Upper limit

s seconds Unit of time

UG Lower limit

VAC Vacuum

Tab. 1: Abreviations and definitions

8 GA-602-0106V1.0-PAE-GB © F. Stephan GmbH

Page 9

®

1.7 Technical data

Ambient conditions

General

Operation Temperature 15 – 40 °C

Storage Temperature 5 – 60 °C

MPG class

1 General information

Rel. humidity 30 – 85 %

Air pressure 900 – 1060 hPa

Bring to room temperature before starting to

operate the device.

Rel. humidity 10 – 100 %

Air pressure 700 – 1060 hPa

Store in a protected, dust-free place protected

from moisture and frost

II b

Power supply

Specifications

Protection class

Inspection/maintenance

cycle

Dimensions (WxHxD)

Weight

I type B as per DIN EN 60601-1 :March 1996

annual

610 x 820 x 680 mm

122 kg

Mains Connection 230 V AC

50 – 60 Hz

Input power 6 A

Device fuses 2 x 8 AT

2 x 1.25 AT

Absorber unit Pressure 2.2 bar

Changeover cycle 11 s

Flushing time 2 s

O2 AIR

System pressure 5.2 bar 5.2 bar

Output pressure 3.8 bar 3.8 bar

Consumption 6 l/min 8 l/min

Max. consumption 7 l/min 13 l/min

© F. Stephan GmbH GA-602-0106V1.0-PAE-GB 9

Page 10

1 General information

Compressed air

compressor

Compressor for post-

compression

Flat fan

Parameters

Voltage

Motor speed/output

Capacitor

Voltage

Motor speed/output

Capacitor

Voltage

Motor speed

Input power

Noise level

Dimensions

Pressure gauge O

230 V / 50 Hz

1350 rpm / 435 Watt

15 μF

230 V / 50 Hz

1390 rpm / 435 Watt

15 μF

230 V / 50 Hz

2800 rpm

45 VA

48 dB

150 ∅ x 55 mm

0 – 6 bar

2

AIR 0 – 6 bar

VAC -1 – 0 bar

O

concentration

2

Monitoring

Flow [l/min] O2 concentration [%]

1 – 2 95

3 – 6 94

7 90

8 88

9 80

Tab. 2: Available O2 concentration at corresponding flow

Parameter Unit UG OG

Pressure sensor bar 2.5 5.5

Temperature sensor °C 45

Pressure relief valve bar 5,5

Tab. 3: Alarm limits

Alarm visual, acoustic

10 GA-602-0106V1.0-PAE-GB © F. Stephan GmbH

Page 11

®

2 Safety instructions

Refers to instructions drawing attention to important facts.

The following safety instructions are repeated at relevant points in the

operating manual and must always be heeded.

Refers to dangers which, if not heeded, can result in life-threatening

injuries to the patient and/or operator.

Danger

2 Safety instructions

Refers to warnings which, if not heeded, can result in malfunctions,

damage or defects in the device, which can possibly also put the patient at

Warning

Caution

danger.

Refers to precautions which, if not heeded, can result in damage to the

device and its accessories.

2.1 Danger warnings

The device must be operated according to the instructions in this

operating manual.

Danger

S

TAXEL 3.5 is not certified for use in explosion-risk areas.

Danger

© F. Stephan GmbH GA-602-0106V1.0-PAE-GB 11

Page 12

2 Safety instructions

Danger

S

TAXEL 3.5 must not be operated in the vicinity of naked flames or

glowing objects, given the increased explosion risk from the

concentration of pure oxygen in the device.

The device must not be used when damaged. Disconnect from the mains.

Danger

Always disconnect the device from the mains immediately in any

dangerous situations or when technical faults occur.

Danger

2.2 Warnings

When moving the device, ensure that the wheel brakes have been

released and are applied again when set upright.

Warning

DIN EN 60601-1 resp. VDEO 0751-1 must be heeded in particular for

medical technical devices with electrical connection. Accordingly, these

Warning

devices must only be repaired by the manufacturer or an entity explicitly

authorized for this purpose by the manufacturer.

The provisions of DIN EN 60601-1 must be heeded when connecting

external electrical devices.

Warning

Only the authorized customer service of F. S

TEPHAN GMBH is allowed to

alter, modify, repair or open the device. This also includes replacing the

Warning

bacteria filter, intake filter and intake filter mat in accordance with the

operating manual. Use only spare parts from F. S

TEPHAN GMBH for

maintenance.

12 GA-602-0106V1.0-PAE-GB © F. Stephan GmbH

Page 13

®

3 Structure and description of functions

3 Structure and description of functions

3.1 Front view

Fig. 1: Front view

1 Controls and display elements 3 Housing jacket

2 Handles 4 Rollers (4, 2 can be fixed)

© F. Stephan GmbH GA-602-0106V1.0-PAE-GB 13

Page 14

3 Structure and description of functions

3.2 Controls and display elements

Fig. 2: Controls and display elements

1 Mains switch "On/Off" for O

2 Operating hours counter for O

3 Pressure gauge for O

pressure display

2

and AIR

2

and AIR generation

2

4 Pressure gauge for AIR pressure display

5 Pressure gauge for VAC pressure display

6 Knob for regulating the vacuum

7 Mains switch "On/Off" for VAC

8 Fuse for VAC generation

9 Fuse for O

and AIR generation

2

10 Visual alarm for failure of electronic components or switching valves

11 Visual alarm for overheating

14 GA-602-0106V1.0-PAE-GB © F. Stephan GmbH

Page 15

®

3.3 Rear view

3 Structure and description of functions

Fig. 3: Rear view

1 Intake filter mat 5 Membrane dryer

2 Power sockets (230 V AC) 6 Acoustic alarm

3 Connection lead 7 Water separator

4 Filter 8 Filter unit

© F. Stephan GmbH GA-602-0106V1.0-PAE-GB 15

Page 16

3 Structure and description of functions

3.4 Right-hand side view

Fig. 4: Right-hand side view

1 O

outlet 2 AIR outlet

2

16 GA-602-0106V1.0-PAE-GB © F. Stephan GmbH

Page 17

®

3.5 Left-hand side view

3 Structure and description of functions

Fig. 5: Left-hand side view

1 O

outlet 3 VAC outlet

2

2 AIR outlet

© F. Stephan GmbH GA-602-0106V1.0-PAE-GB 17

Page 18

Page 19

®

4 Preparing for operation

4.1 Erecting the device

S

TAXEL 3.5 with rollers

S

Caution

TAXEL 3.5 is supplied on rollers.

The front rollers of the device are equipped with parking brakes to

prevent any unintended movement of S

Press lightly on the brake lever to activate the parking brake by blocking

the rollers. Lift the brake lever with the tip of your foot to release the

parking brake again.

When moving the device, ensure that the wheel brakes have been

released and are applied again when set upright.

TAXEL 3.5.

4 Preparing for operation

Information

S

TAXEL 3.5 must only be erected and operated in dry, well-ventilated

rooms with low dust levels. Moist or wet environments can drastically

impair the functioning of the device. Ensure in particular that there are no

containers filled with water or similar in the immediate vicinity.

When choosing the site for erecting the device, make sure there is easy

access for operation, cleaning and maintenance.

The ambient temperature should never exceed +40° C. For relative

humidity levels exceeding 70%, it is advisable to operate the device only

in air-conditioned rooms.

The air intake grids on the back of the device must not be covered or any

objects placed on them.

There should be spacing of at least 10 cm to the wall at the rear of the

device.

© F. Stephan GmbH GA-602-0106V1.0-PAE-GB 19

Page 20

4 Preparing for operation

R

4.2 Connecting to the gas and power supply

4.2.1 Gas supply

Check the pressure gauge on the front to see whether there is sufficient

pressure. The needle must show more than 3 bar.

Connections for O

and

2

AI

The outlets for O

connections are quick-release couplings which lock automatically when

connected.

To pull the tube out of the connection, at the same time press the

unlocking pin on top of the connection.

Connection for VAC

The outlet for vacuum is on the right of the device. The connection is a

1/8" tube nozzle. Simply insert the tube to the intake unit.

4.2.2 Power supply

S

TAXEL 3.5 runs on 230 V AC.

1. Connect the mains lead at the rear of the device to the power socket

on the wall.

2. Switch on the power switch "On/Off" for O

the device. The switch lights up green.

3. Switch the power switch "On/Off" for VAC on the front of the device.

The switch lights up green.

and AIR are on the two sides of STAXEL 3.5. The

2

and AIR on the front of

2

Electrical accessories

Electrical accessories can be connected to the 4 auxiliary power sockets.

The auxiliary power sockets are switched on with the mains switch

"On/Off" for O

and AIR on the front of the device.

2

When in use, S

TAXEL 3.5 can only have max. 4 user-accessible auxiliary

power sockets.

Warning

20 GA-602-0106V1.0-PAE-GB © F. Stephan GmbH

Page 21

®

Warning

Warning

4 Preparing for operation

No not connect any further multiple power sockets, e.g. socketa dapters,

to the auxiliary power sockets.

Mains failure also means failure of the auxiliary power sockets,

© F. Stephan GmbH GA-602-0106V1.0-PAE-GB 21

Page 22

Page 23

®

f

5 Test list

5 Test list

All relevant tests must be carried out before using the device. The staff

carrying out the test must have exact knowledge of the operating manual.

Prerequisites for the

test

5.1 Test before starting the device every time

Check pressure

The device is completely assembled and connected up.

Remove all tubes from the connections

Visually check the pressure gauge for O

All pressure must be in the correct range ( > 3 bar ).

and AIR

2

Check condition o

device

Check the device for any signs of damage

Check the mains lead and electrical devices for any external signs of

damage

Visually check the LEDs

5.2 Test before every patient

concentration

2

Danger

Check O

Visually check the pressure gauge for O

All pressure must be in the correct range ( > 3 bar )

The device must not be used if it fails any of the tests!

and AIR

2

© F. Stephan GmbH GA-602-0106V1.0-PAE-GB 23

Page 24

Page 25

®

6 Operation

6.1 Switching on

Only switch the device on if it is not pressurized!

1. Switch on the mains switch "On/Off" for O2 and AIR on the front of

the device.

2. S

TAXEL 3.5 starts to generate oxygen and compressed air

3. The pressure in the corresponding pressure gauges for oxygen and

compressed air on the front panel increases to 3.5 bar.

6 Operation

4. Switch on the mains switch "On/Off" for VAC on the front of the

device.

5. S

TAXEL 3.5 starts to generate vacuum.

6.2 Switching off

1. Switch off the mains switch "On/Off" for O

the device.

2. Pressure is released from the tanks.

3. Switch off the mains switch "On/Off" for VAC on the front of the

device.

6.3 Stopping the device

1. Switch off the mains switch "On/Off" for O

the device.

and AIR on the front of

2

and AIR on the front of

2

2. Pressure is released from the tanks.

3. Switch off the mains switch "On/Off" for VAC on the front of the

device.

4. Remove all tubes from the connections.

5. Disconnect the device from the mains.

© F. Stephan GmbH GA-602-0106V1.0-PAE-GB 25

Page 26

Page 27

®

7 Troubleshooting

Fault Cause Remedy

No pressure for O2 and

compressed air, acoustic alarm

Initial pressure of O2 or

compressed air falls below 2.5

bar, acoustic alarm

Red LED "Visual overheating

alarm" (Fig. 2) on, the device

stops working

No power supply

Fuse defect

Fine filter clogged

Gas consumption too high

Compressor defect

Tube leaks

STAX EL 3.5 overheated

Insufficient air flow to cool

the capacitor

Check power supply

Replace fuse

Replace fine filter

Reduce gas consumption

Inform F. S

customer service

Replace filter mat

Check that fan works

properly, replace if necessary

7 Troubleshooting

TEPHAN GMBH

Red LED "Visual alarm for

failure of electronic component

or switching valves« (Fig. 2) is

on

O2 concentration falls below

minimum value

Tab. 4: Troubleshooting

Valves not switching correctly

Electronic component defect

Compressor defect

Supply tube torn off

Balance of pressure between

the two absorber tanks no

longer balanced

Outdated absorber tanks

Inform F. S

TEPHAN GMBH

customer service

Readjust absorber

Flow too high

Replace absorber tanks

© F. Stephan GmbH GA-602-0106V1.0-PAE-GB 27

Page 28

Page 29

®

8 Care and maintenance

8.1 Disinfection and sterilisation

As with operation of the device, it must only be cleaned and disinfected

by instructed members of staff.

Caution

Proceed with routine cleaning at regular intervals according to the local

hospital routine.

All disposable parts must be disposed of in an environment-friendly

manner according to the local hospital routine.

8 Care and maintenance

Caution

Caution

Caution

All instrument and surface disinfectants based on alcohol and aldehyde

may be used.

Do not use deoxygenating or dechlorinating disinfectants or disinfectants

containing phenol or its derivatives.

Amino derivatives can damage soft plastics (tubes).

All used disinfectants must be certified in accordance with relevant

environmental legislation.

Always comply with the regulations for handling cleaning agents and

disinfectants issued by the Professional Association.

When using cleaning agents and disinfectants, pay attention to correct

concentrations and reaction times as otherwise damage to the materials

cannot be ruled out.

When using effective substances other than those stated, please contact

the manufacturer of the disinfectant to obtain compatibility confirmation.

Caution

© F. Stephan GmbH GA-602-0106V1.0-PAE-GB 29

Page 30

8 Care and maintenance

8.1.1 Device housing, gas connections, mains lead

Cleaning

Procedure

Wiping disinfection

1. Wipe down the surfaces with ready made-up disinfectant solution

(surface disinfectant).

2. The cloth should be no more than damp.

3. No moisture must be allowed to penetrate in the device.

8.2 Safety checks

Safety checks are to be carried out every twelve months by the

manufacturer or the authorized customer service for F. S

8.3 Maintenance

For reasons of device safety, it is advisable to proceed with maintenance

of S

TAXEL 3.5 after every approx. 1000 operating hours but at least every

twelve months together with the safety checks.

TEPHAN GMBH.

Maintenance is to be carried out by the authorized customer service for F.

S

TEPHAN GMBH.

After 10,000 operating hours, arrange for a general overhaul to be carried

out by the authorized customer service for F. S

Only use spare parts from F. S

TEPHAN GMBH for maintenance.

TEPHAN GMBH.

30 GA-602-0106V1.0-PAE-GB © F. Stephan GmbH

Page 31

®

8.3.1 Filter unit

Fig. 6: Exploded drawing intake filter

8 Care and maintenance

Changing the bacteria

filter

1 Holder 4 Intake filter

2 3-ply bacteria filter 5 Housing flange

3 Stainless steel fine sieve 6 Tube for housing flange

The bacteria filter for room air must be replaced and the intake filter mat

cleaned every 10 days or after every 250 operating hours. Please note that

these intervals can be drastically reduced depending on the contamination

levels in the ambient air.

At the beginning, please check the condition of the bacteria filter every 23 days to reduce the changing intervals if necessary. The bacteria filter

must be changed when it goes gray.

1. Pull the holder out of the housing flange.

2. Remove the 3-ply bacteria filter and replace with a new bacteria filter

(in S

TAXEL 3.5 spare parts set).

3. Replace the holder again.

Check the intake filter integrated in the intake filter housing every time

after changing the 3-ply bacteria filter. If the bacteria filter is changed too

late, the intake filter can become clogged with dust particles so that the

air supply to the compressors is drastically reduced. This can result in a

rapid fall in the O

concentration of STAXEL 3.5.

2

© F. Stephan GmbH GA-602-0106V1.0-PAE-GB 31

Page 32

8 Care and maintenance

Changing the intake

filter

1. Pull the holder out of the housing flange.

2. Remove the 3-ply bacteria filter.

3. Remove the stainless steel fine sieve.

4. Unscrew the intake filter and screw in a new one (in S

spare parts set).

5. Put the stainless steel fine sieve in again.

6. Insert the 3-ply bacteria filter.

7. Put the holder back in again.

The intake filter cannot be cleaned!

TAXEL 3.5

32 GA-602-0106V1.0-PAE-GB © F. Stephan GmbH

Page 33

®

9 List of accessories

Pos. Designation Art. No. Quantity (ea)

1 Fuses 8 A ( T ) 1 804 60 026 2

2 Fuses 1.25 A ( T ) 1 804 60 004 2

3 3-ply bacteria ultra-fine filter 1 600 60 115 6

4 Intake filter mat 1 600 61 123 6

5 Intake silencer & bacteria

filter

6 O ring 4.47 x 1.78 EPDM 1 950 60 031 10

7 Filter insert for moisture

filter

9 List of accessories

1 600 40 046 6

1 925 60 362 3

Tab. 5: List of accessories

© F. Stephan GmbH GA-602-0106V1.0-PAE-GB 33

Page 34

Page 35

®

10 Guarantee

The manufacturer F. S

the date of purchase.

Any intervention in the device or repairs must only be carried out by F.

S

TEPHAN GMBH or an authorized expert. Otherwise the guarantee

becomes null and void.

The guarantee also becomes null and void if the device is handled

incorrectly.

10 Guarantee

TEPHAN GMBH grants a 24 month guarantee from

© F. Stephan GmbH GA-602-0106V1.0-PAE-GB 35

Page 36

Page 37

®

11 List of illustrations

Fig. 1: Front view.................................................................................... 13

Fig. 2: Controls and display elements ..................................................... 14

Fig. 3: Rear view..................................................................................... 15

Fig. 4: Right-hand side view ................................................................... 16

Fig. 5: Left-hand side view ..................................................................... 17

Fig. 6: Exploded drawing intake filter .................................................... 31

11 List of illustrations

© F. Stephan GmbH GA-602-0106V1.0-PAE-GB 37

Page 38

Page 39

®

12 List of tables

Tab. 1: Abreviations and definitions......................................................... 8

Tab. 2: Available O2 concentration at corresponding flow ..................... 10

Tab. 3: Alarm limits ................................................................................ 10

Tab. 4: Troubleshooting .......................................................................... 27

Tab. 5: List of accessories....................................................................... 33

12 List of tables

© F. Stephan GmbH GA-602-0106V1.0-PAE-GB 39

Page 40

Page 41

®

13 Notes

13 Notes

© F. Stephan GmbH GA-602-0106V1.0-PAE-GB 41

Page 42

F. Stephan GmbH

- Medizintechnik Kirchstrasse 19

56412 Gackenbach

(+)49 (6439) 9125 – 0

(+)49 (6439) 9125 – 111

info@stephan-gmbh.com

www.stephan-gmbh.com

Loading...

Loading...