Page 1

* Equipment

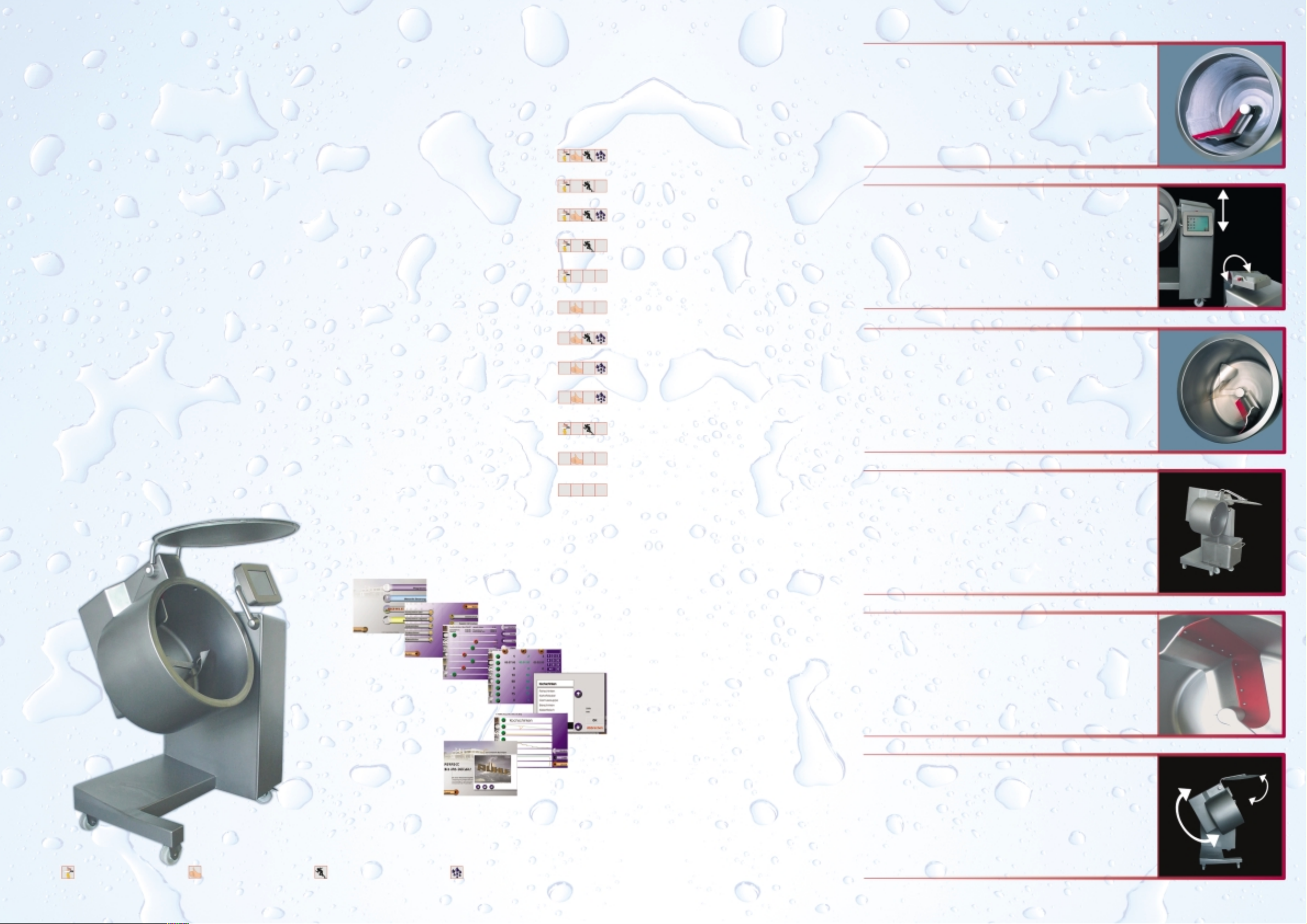

The intelligent

* 100% container insulation

* Swivel locking lid

* Swivelling the container

* Direct cooling system

* Stainless steel air canal

* Sterilisation system 90%

* Computer control Touch PC

* Bayonet arm attachment

* Scraper-pressure attachment

* CE/GS test certificate

atadlacinhceT051RKM

ezisreniatnoCertil051

.xamyticapacgnilliFertil511

htdiwenihcaMmm002.1

htpedenihcaMmm000.1-mm008

thgiehenihcaMmm001.2-mm007.1

daoldetcennoCA61/Wk3/V004

thgiewenihcaMgk016

multi-talent

The new generation of HighTech Tumblers is based on the seven year

success story of the first HighTech Tumblers. We have combined the

experience, suggestions and tips of our customers with the latest

findings of food research and technology, in order to present a

machine, which sets no limits to your creativity.

tnalooC404R

* Accessories

* Share plough - mixing arm

* CIM can be networked

* Fluid induction system

egairracrednU

mprtinuevirdmraelbairaV05-0

%nimetsysmuucavhgiH59-0

Subject to technical changes

hcihwfoot,sleehw4

enihcamehtreets

HighTech-Tumbler MKR 150

Page 2

Intelligent tumbling, mixing, marinating, salting

Direct cooling

Be it warm ham, Kasseler with bone or Schnitzel with milk, steaks to be marinated or perfect sausage

mince, this machine has no limitations because the equipment makes it possible:

PC-Control without keys, simple and comfortable with documentation

A higher range of revolutions from 1-50 rpm, for more creativity and better applications

A greater container diameter, little depth, for more movement and better results

Faster cooling with less energy consumption and very accurate temperatures

Scraping arm with complete-scraper and gentle geometry, for a process with little abrasion

Quiet drive assemblies for low noise process even under full load

Standard carriage discharge function, save, hygienic and comfortable

Little space needed and mobile, the euro-pallet size machine on wheels fits everywhere

Welded machine construction, cleaning is child’s play

High vacuum, cooled, degerminating breathing function in a stainless steel pipe

A very strong cooling unit leads the coolant directly to the container which is

perfectly insulated on all sides. These conditions allow for a very fast

temperature regulation and a very precise adaptation to all temperature

requirements. This and a little bit of HighTech control make new product

qualities possible.

Computer-comfort

The operating panel is easily adjusted to any body height. The Touch-PC

control is up-to-date computer technology, it´s easy to operate and it controls

and documents every minute of the aeration, the revolution rate, the

degermination and the container position. This flexible intelligence of the MKR

150 leads to the best results and can even be controlled from the office.

Mixing and kneeding

The automatic swingable process container with a large diameter, a revolution

range up to 50 rpm and a gently kneeding mixing arm. These are the best

conditions to solve all mixing tasks with perfect results, from seafood salad to

coarse Bratwurst mince and Döner Kebap.

Bayonet catch for tumbling and mixing arm, the fastest way to change attachments

2 years guarantee, because we know what quality and reliability means

Standard carriage size

There is so much space under the process container, that all sizes of Euro boxes

and up to 200 litre standard carriages can be positioned underneath. This makes

complete and comfortable discharging possible without product falling to the

floor. And because the boxes and carriages stand underneath the machine and

not in front of it, you can reach deep inside the container without any problems.

The scraping arm

The tumbling arm is shaped in a way that guarantees gentle action on the meat

and sensitive materials and, with a range of 1 to 50 rpm, allows all kinds of

processes. The scraper supplements these properties with perfect scraping of all

container surfaces, so that abrasion doesn´t start at all.

Automatic movements

Better quality

of results

Easier operation

control

Higher

performance

The container lid is moved fully automatic or with the push of a button.The

process container moves fully automatic or with a push of a button. This not

only makes work child´s play, but the process programs guarantee a process in

always the right container position. This is very important, because each

container position has a different process intensity.

Better hygiene

comfort

Loading...

Loading...