Page 1

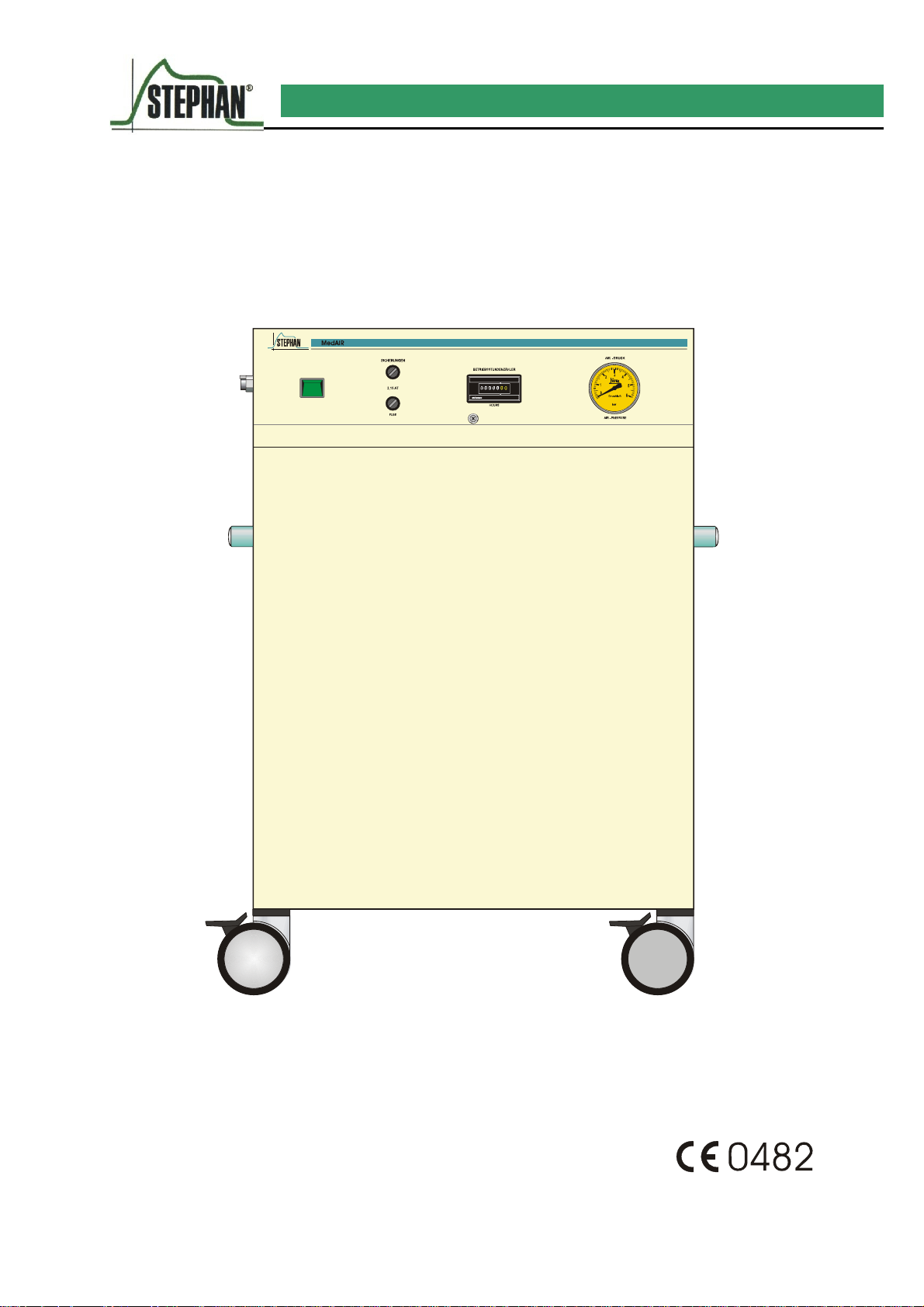

MedAir

Mobile Compressed Air Unit

h

®

Operating and service Instructions

F. STEPHAN GmbH ⋅ Medizintechnik ⋅ D-56412 Gackenbach ⋅ Kirchstr. 19 ⋅ Tel. (06439) 9125-0 ⋅ Fax (06439) 9125-111 ⋅ info@stephan-gmbh.com ⋅ www.stephan-gmbh.com

Page 2

Preface

The present Operating and service Instructions

are written to give the operator a clear and

concise guide as to the operation and care of

the MedAirs mobile compressed-air unit, and

to answer any questions that might arise.

This manual does not contain any information

as to repair and assembly of the system.

Should there arise any problems with the

functioning of the system, please get in touch

with the Technical Support team at F. Stephan

GmbH, or the authorized dealer from whom

you have received the equipment and received

training in its use.

The manufacturer guarantees the safety and

reliability of the MedAirs, only when the

equipment is operated in compliance with the

Operating Instructions.

F. Stephan GmbH

- Medizintechnik Kirchstraße 19

56412 Gackenbach, Germany

Technical data subject to change.

Status: February 2007

Version: V1.1

2 Operating Instructions MedAir, February 2007

Page 3

Table of Contents

Table of Contents

Table of Contents ..................................................................................................................................... 3

1. General Information....................................................................................................................... 4

1.1. Product combinations ................................................................................................................ 4

1.2. Equipment designation and manufacturer ................................................................................. 4

1.3. Designated application............................................................................................................... 4

1.4. Packaging and waste disposal................................................................................................... 4

1.5. Introduction ................................................................................................................................ 4

1.6. Abbreviations and technical terminology ................................................................................... 4

1.7. Technical Data ........................................................................................................................... 5

2. Safety Instructions ......................................................................................................................... 6

2.1. Danger warnings........................................................................................................................ 6

2.2. Caution warnings ....................................................................................................................... 6

3. Description of the Design and Functioning.................................................................................... 7

3.1. Front view................................................................................................................................... 7

3.2. Side view, left ............................................................................................................................. 8

3.3. Rear view ................................................................................................................................... 8

4. Preparing the Equipment for Operation......................................................................................... 9

4.1. Setting up the MedAir ................................................................................................................ 9

4.2. Connection to the mains power supply...................................................................................... 9

5. Operation ..................................................................................................................................... 10

6. Problems, Causes and Remedies ............................................................................................... 11

7. Care and Servicing ...................................................................................................................... 12

7.1. Cleaning ................................................................................................................................... 12

7.2. Safety technical inspections..................................................................................................... 12

7.3. Servicing .................................................................................................................................. 12

8. Accessories / Replacement Parts................................................................................................ 13

9. Warranty ...................................................................................................................................... 14

Operating Instructions MedAir, February 2007

Page 4

1 General Information

1. General Information

1.1. Product combinations

F. Stephan GmbH will not consider any

warranty claims in the event of use of

unauthorized equipment combinations with

products not licensed by the manufacturer or

approved for compatibility.

Use only those accessories and replacement

parts as found in Section

8 on page 13.

1.2. Equipment designation and manufacturer

Equipment designation: MedAir

Article number: 1 610 61 000

Manufacturer:

F. Stephan GmbH

- Medizintechnik Kirchstraße 19

D – 56412 Gackenbach, Germany

+49 (0)6439 / 9125 – 0

Fax +49 (0)6439 / 9125 – 11

info@stephan-gmbh.com

www.stephan-gmbh.com

1.3. Designated application

The MedAir generates compressed-air for use

in ventilating and anesthesia equipment that

operate with an inlet pressure of 3 to 6 bar and

producing compressed-air at 45 l/min.

The quality of the medical compressed-air

meets the requirements of DIN EN 12021

The MedAir is designed for use in dry areas

free from spray and dripping water. Moist or

wet ambient conditions can greatly impair the

functioning of the equipment.

1.4. Packaging and waste disposal

The packaging used to pack this system

consists primarily of recyclable or reuseable

materials.

The cardboard cartoning can be reused or

disposed of as waste paper.

The immediate wrapping around the system is

of CFC-free material. It can be disposed of

along with the foil using the recyclable waste

bin.

1.5. Introduction

The German Equipment Regulations (MPG),

the Medical Products Operations Act

(MPBetreibV) and the law governing technical

materials stipulate that the attention of the

user/operator must be drawn to the following

points:

• Operation of the equipment should be

carried out only by trained and

authorized personnel. A thorough

knowledge of the Operating

Instructions is a prerequisite for

operating this equipment.

• Carefully read and comply with the

Operating Instructions. Flawless

functioning of the MedAir and the

safety of the patient and operator can

only be guaranteed when these

instructions are carefully observed.

• Use the MedAir only for the purpose

as stipulated in these Operating

Instructions.

• Insufficient care and operating error

can lead to operational failure and

accidents.

• The Operating Instructions must

always be at hand where the

equipment is being used.

Warranty claims arising from improper

operation, insufficient servicing and

maintenance shall not be acknowledged by the

manufacturer.

The manufacturer guarantees the safety and

dependability of the MedAirs, only when it is

operated in accordance with the Operating

Instructions.

1.6. Abbreviations and technical terminology

AIR medical quality compressed air

4 Operating Instructions MedAir, February 2007

Page 5

1.7. Technical Data

Ambient conditions

Operation: Temperature: 15 –40 °C

Operating pressure: max. 3.5 bar

Storage: Temperature: 15 – 40 °C

rel. humidity: 10 – 65 %

protect against moisture and humidity

store dust-free and free from frost

Electrical supply

Mains power: 230V / 50Hz

Power consumption: 250 W

Current consumtion: approx. 5A

Power output: 600 VA

1 General Information

Fuse protection: 3.15 AT

Noise level: 45 dB (A)

Operating pressure: 3.5 bar

Output flow: 0 – 45 l/min

General

Protection rating: I

Inspection / maintenance: annually or every 3500 operating hours

Dimensions (L x W x H): 500x510x1150

Weight: 50 kg

Operating position: up-right

Operating Instructions MedAir, February 2007

Page 6

2 Safety Instructions

2. Safety Instructions

The folowing safety instructions will be

repeated at all relevant sections of the

Operating Instructions and must be complied

with at all times.

Indicates a danger that, in the event

of non-compliance, could lead to

life-threatening injuries for the

patient and/or the operator.

Indicates a caution that, in the event

of non-compliance, could lead to

malfunctioning of, damage to, or

defects on the equipment, and

possibly endanger the patient.

2.1. Danger warnings

The MedAir may be operated only

by trained and authorized personnel.

The MedAir must be operated in

accordance with these Operating

Instructions.

The MedAir may not be operated in

areas exposed to a danger of

explosion.

The equipment may not be operated

without a micro-filter.

The air intake filter on the rear side

may not be covered by any objects.

In order to ensure an optimal supply

of fresh air and air circulation the

equipment is only to be operated in

an adequate sized room which is

well-ventilated and preferably dustfree. Otherwise this can be seriously

damaging to the equipment.

2.2. Caution warnings

For medical/technical equipment

with electrical connection, DIN EN

60601-1 and VDE 0751-1 are to be

complied with. Accordingly, such

equipment may only be put into

initial operation by the manufacturer

or authorized technical support

personnel.

6 Operating Instructions MedAir, February 2007

Page 7

3 Description of the Design and Functioning

3. Description of the Design and Functioning

The MedAir – compressor has dew point

reduction, grit filter, preliminary filter, bacterial

filter and an additional condensation water

extractor.

The MedAir is mobile, vibration and sound

insulated. A side rail, 25x10 mm, allows the

mounting of additional equipment.

Monitoring and operation are via a control

panel with mains power switch, operating

hours counter, fuses and pressure gauge.

3.1. Front view

1. Power switch »ON/OFF«

2. Fuses 3.15 AT

3. Operating hours counter

4. Pressure gauge

h

®

Operating Instructions MedAir, February 2007

Page 8

3 Description of the Design and Functioning

3.2. Side view, left

1. AIR – outlet coupling

3.3. Rear view

MADE IN GERMANY

1. Air intake filter matting

2. Bacterial micro-filter with the intake

sound damper positioned behind

3. Moisture micro-filter with moisture micro-

filter insert

4. Mains power connection cable

5. Drainage valve

Depending on fill level, the

condensation water is to be drained

from catch tank.

For doing this, the drainage valve

lever ( 5 ) must be pushed upwards.

8 Operating Instructions MedAir, February 2007

Page 9

4. Preparing the Equipment for Operation

4.1. Setting up the MedAir

The MedAir is designed for use in dry areas

free from spray and dripping water. Moist or

wet ambient conditions can greatly impair the

functioning of the equipment.

The ambient temperature may not exceed +40

°C.

Should the relative humidity exceed 70 %, it is

recommended that the equipment only be

operated in air-conditioned areas.

The air intake filter positioned at the rear of the

unit may not be covered by any objects.

The rear side of the unit must be at least 10 cm

from the wall.

4.2. Connection to the mains power supply

4 Preparing the Equipment for Operation

Check to determine whether the mains power

voltage matches the power voltage as

indicated on the rating plate on the unit.

Make sure that the mains power switch

"ON/OFF is in the OFF position.

Plug the mains power connection cable found

at the rear of the unit into the wall socket-outlet

in the room.

Operating Instructions MedAir, February 2007

Page 10

5 Operation

5. Operation

To turn on the unit, press the "ON/OFF switch

found at the front side of MedAirs to on

position.

After switching on the unit, the ventilator of the

MedAirs is activated which ensures adequate

cooling of the unit's interior. Generation of

compressed air begins approximately 10

seconds after that. The compressor of the

MedAirs builds up an operating pressure of

3.8 bar in approximately 4 seconds.

The pressure gauge on the front side of the

unit shows the pressure at the AIR outlet.

The outlet connection coupling is positioned on

the left side of the MedAirs unit.

10 Operating Instructions MedAir, February 2007

Page 11

6 Problems, Causes and Remedies

6. Problems, Causes and Remedies

Problem Cause Remedy

No pressure No mains power Check mains power connection

Micro-filter is dirty or clogged.

Outlet pressure falls below 1.5 bar

Leakage in line.

Defective compressor

Gas usage is too high

Pressure continuously below 3.5

bar

Intake sound damper is dirty

Defective pressure safety valve

Not functioning Mains power failure

Replace micro-filter

Contact Technical Support

Reduce gas usage

Replace intake sound damper

Replace defective presurre

safety valve

The equipment automatically

restarts after a response delay of

10 seconds.

Operating Instructions MedAir, February 2007

Page 12

7 Care and Servicing

7. Care and Servicing

7.1. Cleaning

For reasons of hygiene, the unit should

regularly be cleaned with a wipe disinfectant

using a commercially available household

detergent or disinfectant (e.g. Sagrotan).

The intake filter matting and the bacterial

micro-filter must be replaced every 6 months or

after every 500 operating hours.

The intake sound damper should be replaced

when found dirty or at least every 6 months.

7.2. Safety technical inspections

Safety technical inspections as well as

checking the quality of air generated are to be

carried out annually or after 3500 operating

hours by the manufacturer or by the authorized

Technical Support team of F. STEPHAN.

7.3. Servicing

For reasons of safety, it is recommended that

the servicing of the MedAirs be carried out

annually in conjunction with the safety

technical inspections.

Servicing is to be carried out only by the

authorized Technical Support team of F.

STEPHAN.

Only original replacement parts supplied by F.

STEPHAN are to be used.

12 Operating Instructions MedAir, February 2007

Page 13

8. Accessories / Replacement Parts

Replacement parts:

Item. Article number Article desription Servicing intevals

1 1 804 60 007 Fuses 3.15 AT when defect

2 1 600 61 123 Intake filter matting semiannually / 500 op. hours

3 1 600 60 115 Bacterial micro-filter semiannually / 500 op. hours

4 1 600 40 046 Intake sound damper semiannually / dirt degree

5 1 925 60 362 Moisture micro-filter

insert yearly

6 1 950 60 031 O-Ring 4.47 x 1.78 for

nippel coupling, AIR when leakage detected

Items 1 to 6 can be ordered in a set (Art.No. : 1 610 61 500), which is sufficient for three years.

The set additionally includes a replacement parts case and diverse small parts

8 Accessories / Replacement Parts

.

1 1 602 61 112 Connection hose for compressed air, length 3 m 1

2 1 600 40 010 Shock-proof socket rail, 4-fold mounted on

rear of unit 1

3 1 600 61 050 Stand with upper monitor console 700 x 400mm

mobile with 4 double castors, 100mm, antistatic 1

4 1 600 60 214 Compressed air membrane drier ( with grating 1μm and

micro-filter 0.01 μm) 1

5 1600 60 215 Micro-filter with float divertor 1

Optional accessories:

Item Article number Article description Quantity

Operating Instructions MedAir, February 2007

Page 14

9 Warranty

9. Warranty

The manufacturer grants a warranty of 24

months, beginning at purchase date.

Modifications or repair work may only be

carried out by the manufacturer, F. Stephan

GmbH, or authorized technicians. Otherwise

the warranty becomes void.

Warranty shall also become void as a result of

improper use and treatment of the equipment.

14 Operating Instructions MedAir, February 2007

Page 15

Personal Notes

Notes

Operating Instructions MedAir, February 2007

Loading...

Loading...