Page 1

Technical Specification Technical Specification Technical Specification

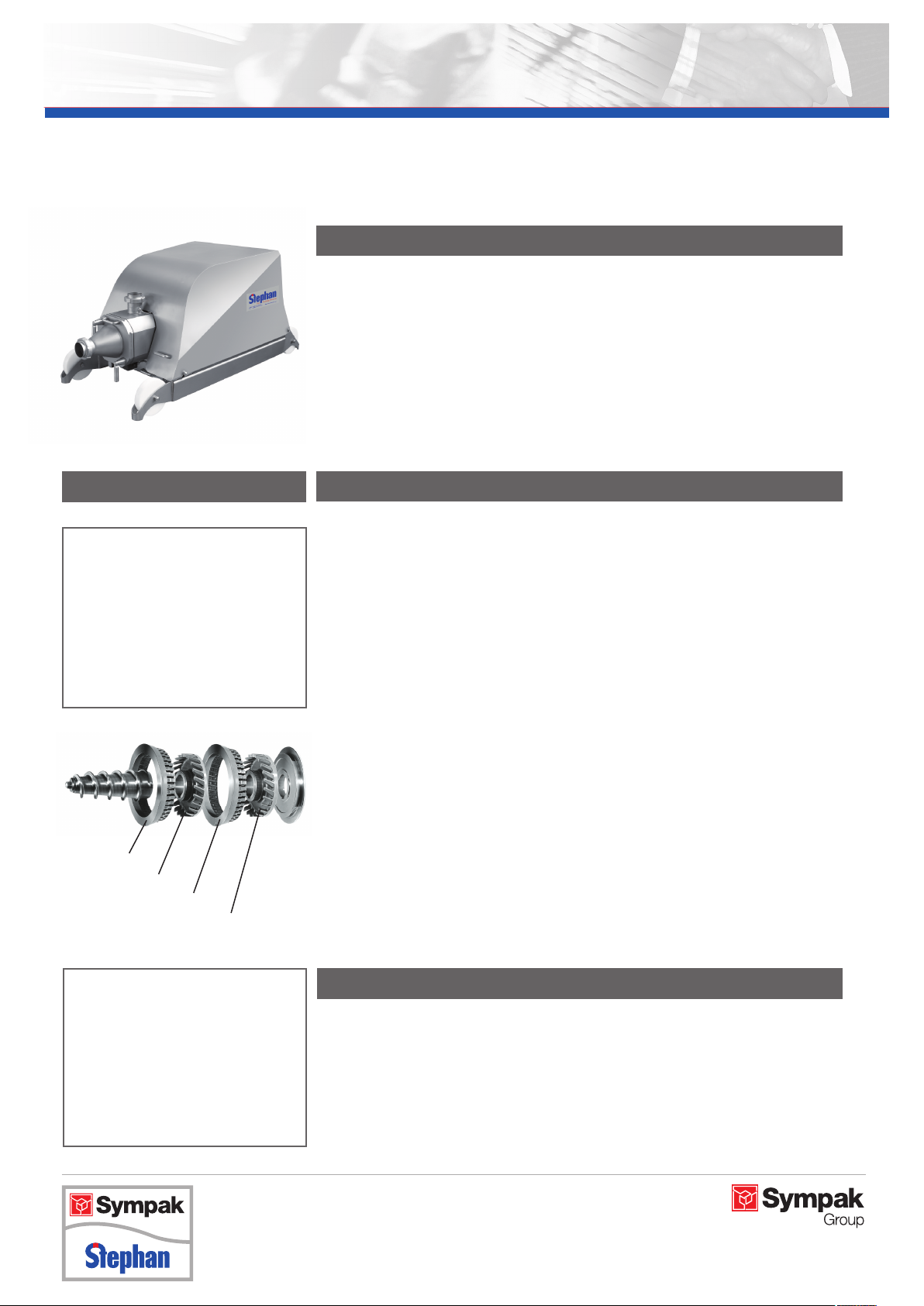

STEPHAN Microcut®MD 200

Description:

Advantages:

> Efficient fine grinding

> High throughput up to 10 t/h

> Stable emulsions

> Continuous working

> Constant product quality

> Easy to clean

Cutting Ring

Cutting Rotor I

Cutting Ring

Cutting Head II

he STEPHAN Microcut

T

of food. It combines high productivity, fine and stable emulsions with easy operation in

one compact unit.

The machine is suitable for many applications in the food industry, e.g. for meat, pâté

and other emulsions. The products can be frozen, fresh or cooked.

he machine is characterised by high performance, low energy consumption and the

T

reliable Stephan Rotor-Stator cutting system. High quality meat for sausages can be

produced with a capacity up to 10 t/h. The design complies to the newest hygienic

guidelines and safety regulations.

®

D 200 is suitable for fine cutting as well as for emulsifying

M

Working Tools:

For the STEPHAN Microcut

available. The cutting gap corresponds to the average particle size (depending on

the product).

Use closed cutting rings for product with fibres or sinews! Cutting gaps in mm

Description Cutting gap in mm Article number

Cutting Ring open 0.20 3D0220-72

Cutting Ring open 0.35 3D0220-73

Cutting Ring open 0.50 3D0220-74

Cutting Ring open 0.70 3D0220-75

Cutting Ring open 0.90 3D0220-76

Cutting Ring open 1.30 3D0220-77

Cutting Ring open 2.70 3D0220-81

Cutting Ring open 3.00 3D0220-82

Cutting Ring open 6.00 3D0220-83

Cutting Ring closed 0.20 3D0220-72

Cutting Ring closed 0.35 3D0220-73

Cutting Ring closed 0.50 3D0220-74

Cutting Ring closed 0.70 3D0220-75

Description Teeth Article number

Cutting Rotor I 27 3D0405-20

Cutting Rotor II 27 3D0405-30

®

MD 200 cutting rings with cutting gaps as follows are

Sales and Advice:

Phone:

+49 (5151) 583-216

Fax:

+49 (5151) 583-642

Email:

microcut@stephan-machinery.com

Stephan Machinery GmbH

Stephanplatz 2

31789 Hameln / GERMANY

Phone: +49 (5151)583-0 - Fax:+49(5151) 583-189

Email: info@stephan-machinery.com

www.stephan-machinery.com

Accessoires / Options:

- Funnel 300 l with hinge in connection with fast

feeding spiral at the main motor shaft: MD200-Axxxx

- Discharge tube 1500 mm to left or right side: MD200-xAxxx

Page 2

Technical Specification Technical Specification Technical Specification

STEPHAN Microcut®MD 200

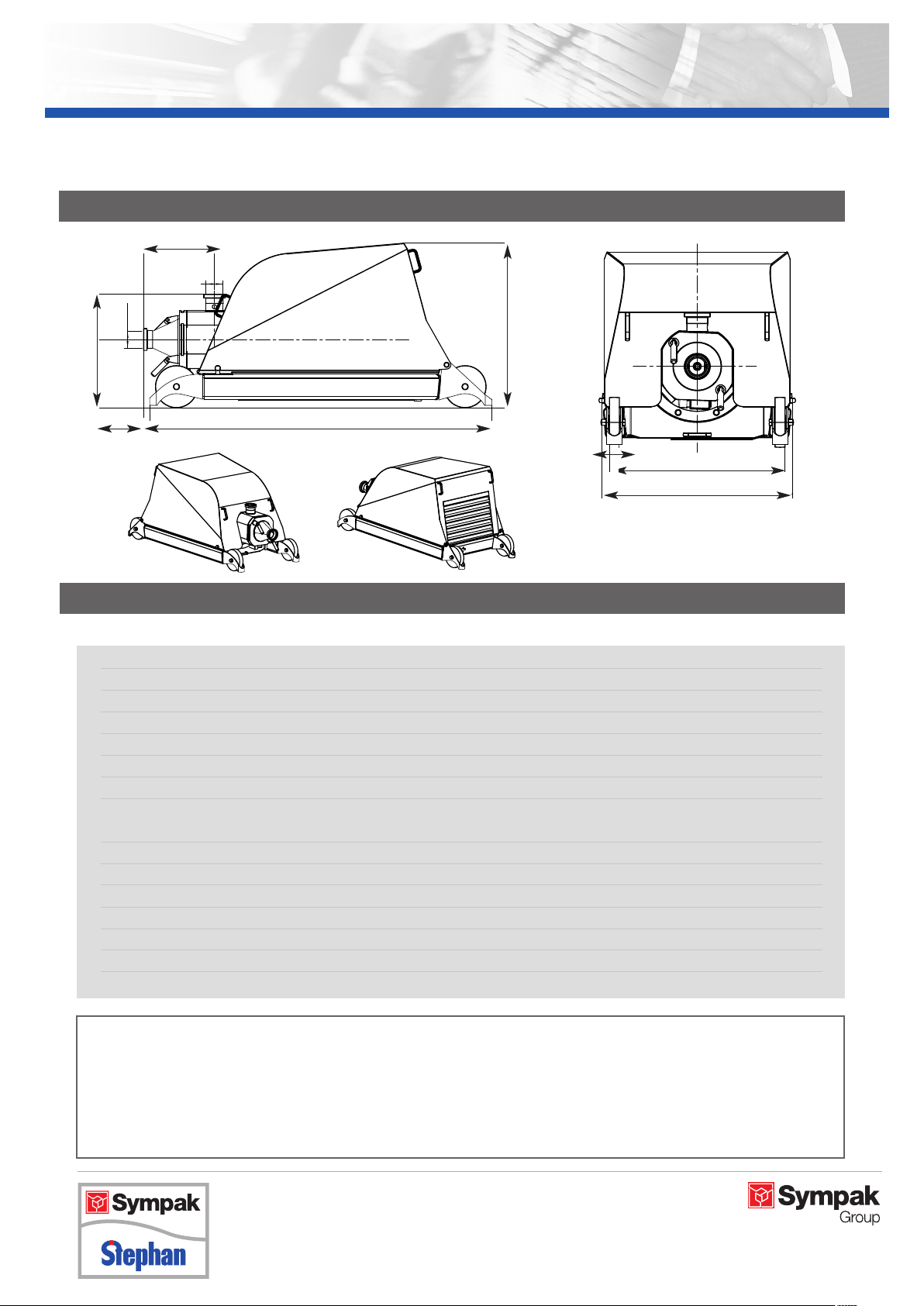

Dimensions (mm) MD 200:

approx. 422

DN100

DN100

approx. 405 ca. 269

approx. 37

approx. 2033

Machine Data:

Output approximate (depending on the product)

Product entry via tube connection DIN 11862

Product exit via tube connection DIN 11862

Control voltage

Operating voltage / Frequency

Fuse protection (with delay)

Power consumption

Main motor speed (50 Hz)

Main motor speed (60 Hz)

Electrical standard

Noise level

Net weight of the machine

Tare weight national transport, air freight

Tare weight see freight

Packaging size national transport, air freight

Packaging size see freight

approx. 978

kg/h

mm

V(Hz)

kW

rpm

rpm

dB(A)

kg

kg

kg

m

m

approx. 50

approx. 880

approx. 954

Inline 110 kW

10,000

DN100

DN100

V

400/50, 460/60

A

24AC

0

110

3000

3600

IEC, UL

Inline 135 kW

10,000

DN100

DN100

400/50, 460/60

0

135

3000

3600

IEC, UL

< 80

1500

Order Information:

STEPHAN Microcut®MD 200 Inline 110 kW, DN100/DN100 Order No.: MD200-PPAAA 400 V/50 Hz

STEPHAN Microcut®MD 200 Inline DN100/DN100 ME200-PPAAA 400 V/50 Hz

STEPHAN Microcut®MD 200 300 l-funnel 110 kW, DN100/DN100 MD200-AAAAA 400 V/50 Hz

STEPHAN Microcut®MD 200 300 l-funnel 135 kW, DN100/DN100 ME200-AAAAA 400 V/50 Hz

Stephan Machinery GmbH

Stephanplatz 2

31789 Hameln / GERMANY

Phone: +49 (5151) 583-0 - Fax: +49(5151)583-189

Email: info@stephan-machinery.com

www.stephan-machinery.com

Loading...

Loading...