Page 1

One idea -

several versions

Benefit from the

advantages:

I The Stephan Microcut

®

is a multifunctional fine cutting

and dispersing system. The rotor stator system is

available as single stage and double stage version.

A wide range of machine layouts meets the

requirements of multitudinous segments of the food

industry. Homogenous fine cutting and emulsifying of

meat and fish can be done as well as forming emulsions

and dispersing solids in liquids.

A special layout is suitable for cutting of vegetables and

fruits as well as biscuit rework. I

Efficient fine grinding

Perfect cutting

Homogenuous mixing

Optimal powder dispersing

Stable emulsions

Constant product quality

Easy to operate

STEPHAN Microcut

®

Continuous Fine Size Reduction and

Emulsification at its Best

SSiimmppllyy fflleexxiibbllee......

Page 2

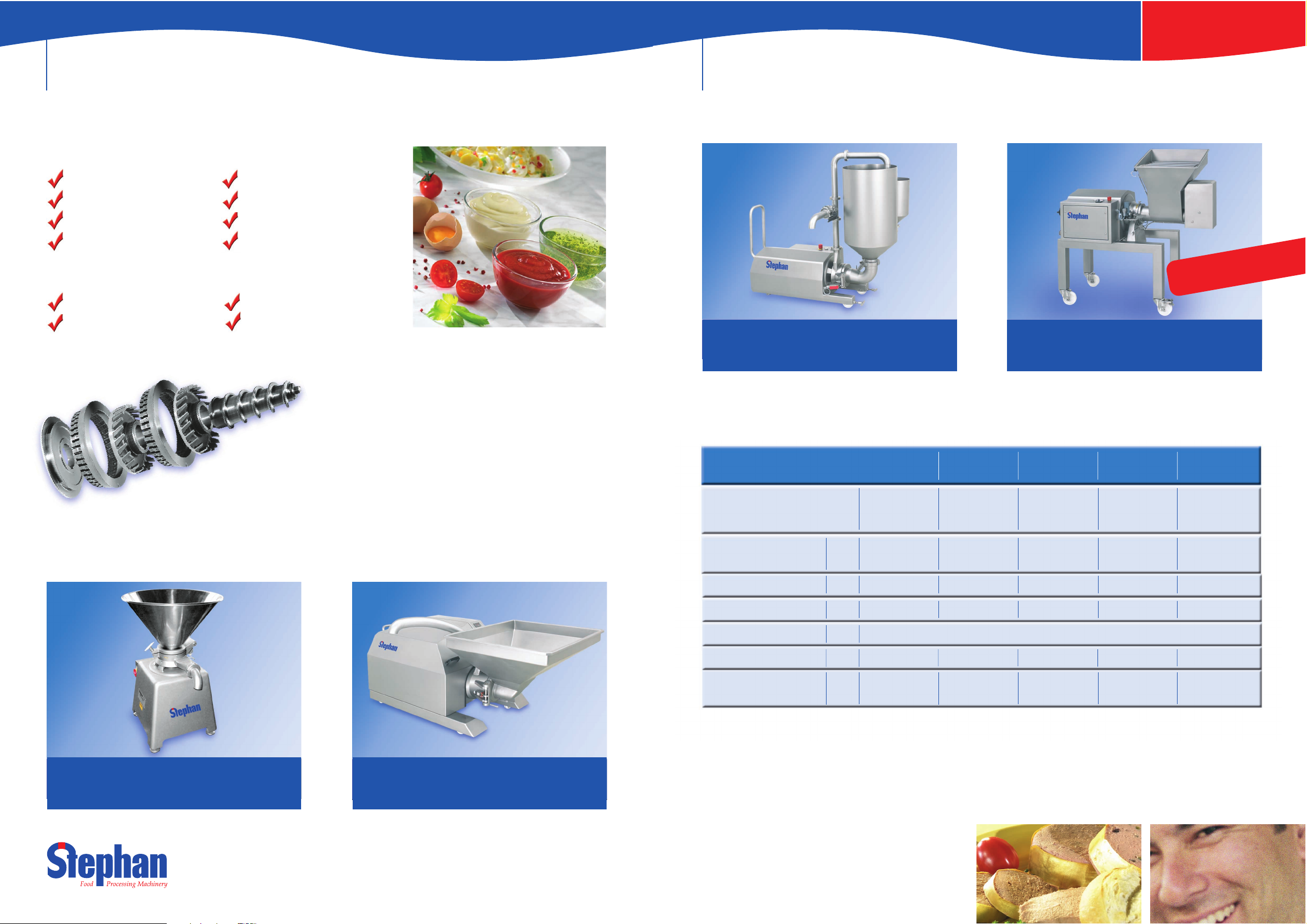

Technical Data

Applications and Processing Steps Stephan Microcut®Versions

Meat emulsions

Liver paté

Emulsions

Marinades and sauces

Cutting

Dispersing

Applications: (some examples)

Processes:

Product examples

Capacity

(heavily dependent on product)

Funnel size

Cutting system

Cutting gaps

Speed

Energy requirements

Main drive

[l/h]

l

mm

[rpm]

[kW]

1200

40/90/120

single

3000

7.5/9/11

MC

10/12/15

Type

Test Facilities

I The test facilities at our headquarters in Hameln (Germany) are available for feasibility studies and demonstration runs

of the Stephan Microcut®. I

Baby Food

Vegetable and fruit grinding

Biscuit rework grinding

Fish products

paté,

fish,

meat

1200/4500

120/150

single

3000

15/30

MCH

20/150

paté,

fish,

meat

4500/6000

150/250

double

3000

45 or 55/

75 or 90

MCH-D

150/180

paté, fish, meat,

baby food

3000

90/125/250

single

3000

5.5/7.5

MCH 10

emulsions,

marinades,

sauces

1200

[kg/h]

40

single*

3000

15

MCH 20 K

MCH 20 KVS*

vegetables and

fruits, biscuit

rework

I The long-life contactless rotor stator system allows

premium fine cutting and emulsifying effects in the same

machine.

With special tools difficult products, like sinews, soft

bones and skin can be cutted in the best quality. I

Design of Stephan Microcut®:

The cutting system

Double cutting system incl.

feeding screw and feeding disc

Emulsifying

Homogenizing

Stephan Microcut®Versions

MC 10/12/15

For handicraft, small business applications

and product development

MCH a. MCH-D

High-speed cutting and emulsifying of

meat, fish and baby food

MCH 10

Emulsifying and mixing machine

MCH K

Dry/Wet Grinding of pressure sensitive,

fresh or frozen products

Size reduction 1:100

with pre-cutting system

0.05 / 0.2 / 0.35 / 0.5 / 0.7 / 0.9 / 1.25 / 1.5 / 1.8 / 2.0 / 3.0

* KVS with additional pre-cutting system

Page 3

L&S 01.06. `2e 1003

Stephan Machinery - world-wide at your disposal

SYMPAK BRANDS

Headquarter:

Stephan Machinery GmbH & Co.

Stephanplatz 2

31789 Hameln • GERMANY

phone: +49 (0) 51 51 / 5 83 - 0 • fax: +49 (0) 51 51 / 5 83 - 6 42

microcut@stephan-machinery.com

www.stephan-machinery.com

Subsidiaries/Representatives:

Stephan bvba

Sluis 11

9810 Nazareth • BELGIUM

phone: +32 (0) 9 / 3 85 83 55 • fax: +32 (0) 9 / 3 85 81 87

info@stephan-belgium.be

Sympak France Sarl - Stephan Division -

ZAC du Mandinet

Rue des Campanules

77185 Lognes • FRANCE

phone: +33 (0) 1 / 64 80 54 30 • fax: +33 (0) 1 / 60 06 74 14

sympak-france@sympak.com

Sympak Asia Pacific Pte. Ltd. - Stephan Division -

23 Tagore Lane

#03-12 Tagore 23 Warehouse

Singapore 787601 • SINGAPORE

phone: +65 / 64 55 / 76 70 • fax: +65 / 64 55 / 62 20

sympak-asiapacific@sympak.com

Sympak Inc. - Stephan Division -

1385 Armour Boulevard

Mundelein, IL 60060 • USA

phone: +1 / 8 47 / 2 47 01 82 • fax: +1 / 8 47 / 2 47 01 84

stephansales-usa@sympak.com

Stephan UK Ltd.

PO Box 162

Deeside

CH5 3SZ • UK

phone: +44 (0) 8 45 / 4 56 08 23 • fax: +44 (0) 8 45 / 4 56 08 24

info@stephan-uk.co.uk

Stephan Nederland B.V.

Plesmanweg 15

7602 PD Almelo • NETHERLANDS

phone: +31 (0) 5 46 / 87 41 11 • fax: +31 (0) 5 46 / 86 45 46

info@stephan.nl

Stephan Machinery GmbH & Co.

Sales Representative Switzerland

Mr Marcel Heeb

Gewerbehaus Tüfiwies

Schickmattweg 8

8332 Russikon • SWITZERLAND

phone: +41 (0) 44 / 9 55 06 08 • fax: +41 (0) 44 / 9 55 06 88

stephan-machinery@bluewin.ch

OOO Sympak St. Petersburg Branch Office - Stephan Division -

Business Center "Evro-Auto” 3rd Floor, Office 332

Levashovskiy Pr. Dom 13, Litera G

St. Petersburg, 197110 • RUSSIA

phone: +7 / 8 12 / 1 02 11 84 • fax: +7 / 8 12 / 1 02 11 87

sympak-stpetersburg-russia@sympak.com

Stephan Machinery Polska Sp. z o.o.

Borówiec, ul. Lesna 148

62-035 Kórnik • POLAND

phone: +48 (0) 61 / 8 17 12 01 • fax: +48 (0) 61 / 8 17 12 01

rosik@stephan-machinery.com

Sympak Latin America Ltd. (Lynkin’ SD Ltd.)

Sao Benedito Office Tower

Rua Sao Benedito, 509 Cj. 81,

04735-000 Alto da Boa Vista Sao Paulo, SP • BRAZIL

phone: +55 (11) 55 46 01 34 • fax: +55 (11) 55 46 01 78

marco@sympak.com.br

Your dealer in your country:

All content is subject to copyright and is owned and controlled by Stephan Machinery

GmbH & Co. The content may not be copied, stored (in any medium), published or

otherwise redistributed without the permission of Stephan Machinery GmbH & Co.

For further dealers please contact Stephan headquarter.

Loading...

Loading...