Memory module temperature sensor

Features

■ Temperature sensor compliant with JEDEC

JC42.4

Temperature sensor

■ Temperature sensor resolution:

0.25°C (typ)/LSB

■ Temperature sensor accuracy:

– ± 1°C from +75°C to +95°C

– ± 2°C from +40°C to +125°C

– ± 3°C from –40°C to +125°C

■ ADC conversion time: 125 ms (max)

■ Supply voltage: 2.7 V to 3.6 V

■ Maximum operating supply current: 200 µA

■ Hysteresis selectable set points from: 0, 1.5, 3,

6.0°C

■ Ambient temperature sensing range: –40°C to

125°C

■ Supports bus timeout

STTS424

TDFN8 (DN)

2 mm x 3 mm (max height 0.80 mm)

Two-wire bus

■ 2-wire SMBus/I

■ Supports up to 400 kHz transfer rate

■ Does not initiate clock stretching

2

C - compatible serial interface

Packages

■ 2 mm x 3 mm TDFN8, height: 0.80 mm (max)

RoHS compliant, halogen-free

■

a. Compliant to JEDEC MO-229, WCED-3

April 2009 Rev 6 1/36

(a)

www.st.com

1

Contents STTS424

Contents

1 Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2 Serial communications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.1 Device type identifier (DTI) code . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.2 Pin descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.2.1 A0, A1, A2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.2.2 V

2.2.3 SDA (open drain) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.2.4 SCL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.2.5 EVENT

2.2.6 V

(ground) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

SS

(open drain) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

(power) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

DD

3 Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

3.1 SMBus/I2C communications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

3.2 SMBus/I

3.3 SMBus/I

2

C slave sub-address decoding . . . . . . . . . . . . . . . . . . . . . . . . . 12

2

C AC timing consideration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

3.4 SMBus timeout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

4 Temperature sensor registers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

4.1 Capability register (read-only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

4.1.1 Alarm window trip . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

4.1.2 Critical trip . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

4.2 Configuration register (read/write) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

4.2.1 Event thresholds . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

4.2.2 Interrupt mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

4.2.3 Comparator mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

4.2.4 Shutdown mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

4.2.5 Event output pin functionality . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

4.3 Temperature register (read-only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

4.3.1 Temperature format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

4.4 Temperature trip point registers (r/w) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

4.5 Manufacturer ID register (read-only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

4.6 Device ID and device revision ID register (read-only) . . . . . . . . . . . . . . . 25

2/36

STTS424 Contents

5 Maximum ratings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

6 DC and AC parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

7 Package mechanical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

8 Part numbering . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

9 Package marking information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

10 Landing pattern . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

11 Revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

3/36

List of tables STTS424

List of tables

Table 1. Signal names . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Table 2. AC SMBus and I

Table 3. Temperature sensor registers summary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Table 4. Pointer register format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Table 5. Pointer register select bits (type, width, and default values). . . . . . . . . . . . . . . . . . . . . . . . 15

Table 6. Capability register format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Table 7. Capability register bit definitions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Table 8. Configuration register format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Table 9. Configuration register bit definitions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Table 10. Hysteresis as applied to temperature movement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Table 11. Legend for Figure 9: Event output boundary timings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Table 12. Temperature register format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Table 13. Temperature register bit definitions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Table 14. Temperature trip point register format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Table 15. Alarm temperature upper boundary register format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Table 16. Alarm temperature lower boundary register format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Table 17. Critical temperature register format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Table 18. Manufacturer ID register format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Table 19. Device ID and device revision ID register format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Table 20. Absolute maximum ratings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Table 21. Operating and AC measurement conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Table 22. DC and AC characteristics - temperature sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Table 23. TDFN8 – 8-lead thin dual flat, no-lead (2 mm x 3 mm) mechanical data (DN) . . . . . . . . . . 30

Table 24. Ordering information scheme . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Table 25. Parameters for landing pattern - TDFN package (DN) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Table 26. Document revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

2

C compatibility timings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

4/36

STTS424 List of figures

List of figures

Figure 1. Logic diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Figure 2. TDFN8 connections (top view) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Figure 3. Block diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Figure 4. SMBus/I

Figure 5. SMBus/I

Figure 6. SMBus/I

Figure 7. SMBus/I

Figure 8. Hysteresis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Figure 9. Event output boundary timings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Figure 10. TDFN8 – 8-lead thin dual flat, no-lead (2 mm x 3 mm) package outline (DN) . . . . . . . . . . 30

Figure 11. Device topside marking information (TDFN-8L) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Figure 12. Landing pattern - TDFN package (DN) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

2

C write to pointer register . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2

C write to pointer register, followed by a read data word. . . . . . . . . . . . . . . . . . . 11

2

C write to pointer register, followed by a write data word . . . . . . . . . . . . . . . . . . 12

2

C timing diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

5/36

Description STTS424

1 Description

The STTS424 is targeted for DIMM modules in mobile personal computing platforms

(laptops), server memory modules, and other industrial applications. The thermal sensor

(TS) in the STTS424 is fully compliant with the JEDEC specification which defines memory

module thermal sensors requirements for mobile platforms.

The TS provides space as well as cost savings for mobile and server platform dual inline

memory modules (DIMM) manufacturers as it is packaged in the compact 2 mm x 3 mm

(height 0.80 mm) 8-lead TDFN package which is compliant to JEDEC MO-229, variation

WCED-3.

The temperature sensor includes a band gap-based temperature sensor and 10-bit analogto-digital converter (ADC) which monitor and digitize the temperature to a resolution of up to

0.25°C. The typical accuracies over these temperature ranges are:

● ±3°C (max) over the full temperature measurement range of –40°C to 125°C

● ±2°C in the +40°C to +125°C temperature range and

● ±1°C in the +75°C to +95°C temperature range

The temperature sensor in the STTS424 is specified for operating at supply voltages from

2.7 V to 3.6 V. Operating at 3.3 V, the supply current is 100 µA (typ).

The on-board sigma delta ADC converts the measured temperature to a digital value that is

calibrated in °C. For Fahrenheit applications, a lookup table or conversion routine is

required. The STTS424 is factory-calibrated and requires no external components to

measure temperature.

The digital temperature sensor component has user-programmable registers that provide

the capabilities for DIMM temperature-sensing applications. The open drain event output pin

is active when the monitoring temperature exceeds a programmable limit, or it falls above or

below an alarm window. The user has the option to set the event output as a critical

temperature output. This pin can be configured to operate in either a comparator mode for

thermostat operation or in interrupt mode.

6/36

STTS424 Serial communications

2 Serial communications

The STTS424 has a simple 2-wire SMBus/I2C-compatible digital serial interface which

allows the user to access the data in the temperature register at any time. It communicates

via the serial interface with a master controller which operates at speeds of up to 400 kHz. It

also gives the user easy access to all of the STTS424 registers in order to customize device

operation.

2.1 Device type identifier (DTI) code

The JC42.4 temperature sensor has its own unique I2C address, which ensures that there

are no compatibility or data translation issues. The DTI code is the unique 4-bit address,

'0011'.

The full I

and A2 pins. This allows up to 8 unique addresses, hence 8 STTS424 devices may be

connected on the same bus.

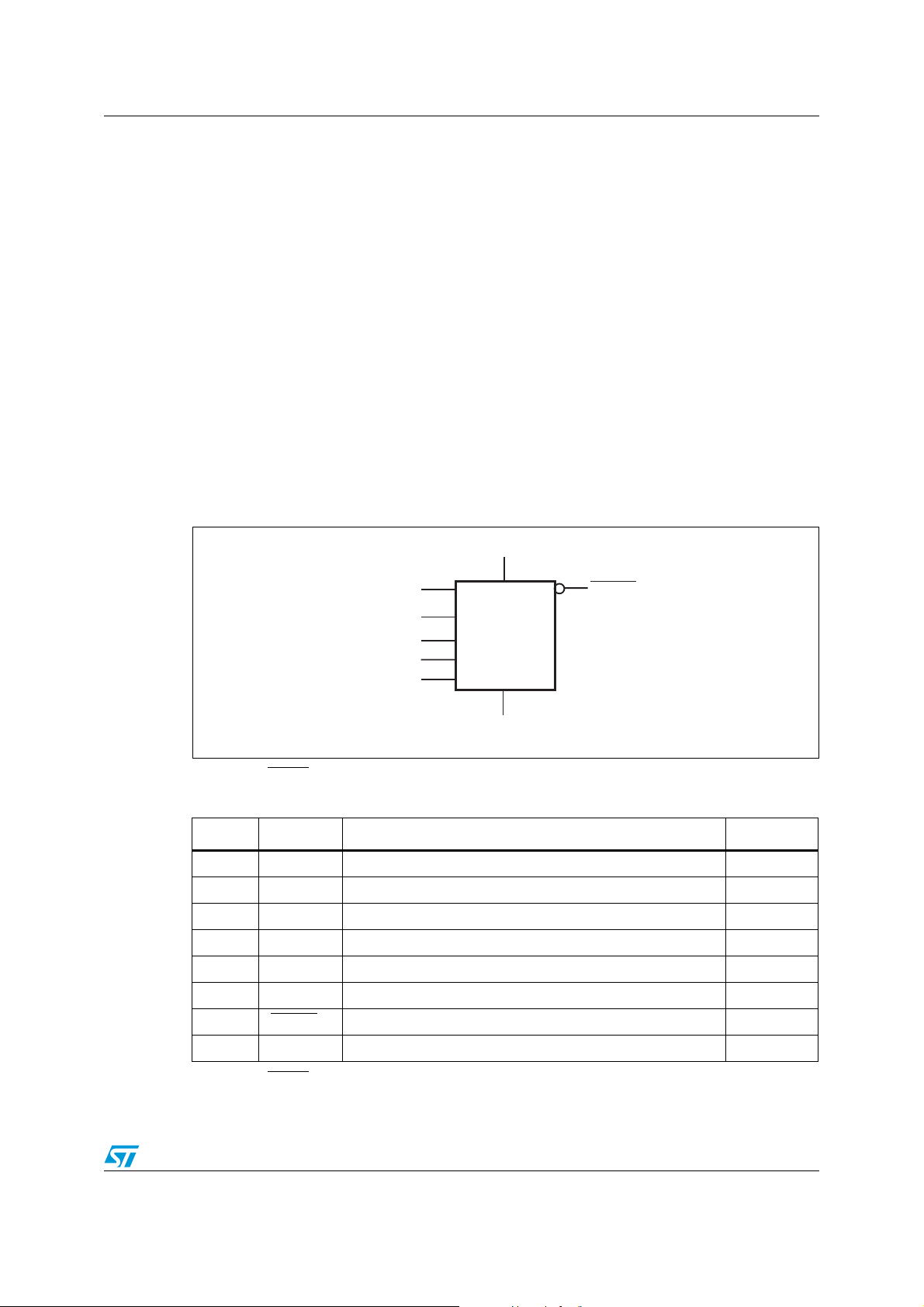

Figure 1. Logic diagram

2

C address consists of the unique DTI code and 3 bits determined by the A0, A1,

V

DD

SDA

(1)

EVENT

(1)

SCL

STTS424

V

SS

AI12947

1. SDA and EVENT are open drain.

Table 1. Signal names

A

2

A

1

A

0

Pin Symbol Description Direction

1 A0 Serial bus address selection pin. Can be tied to V

2 A1 Serial bus address selection pin. Can be tied to V

3 A2 Serial bus address selection pin. Can be tied to V

4V

SS

5SDA

Supply ground

(1)

Serial data Input/output

or VDD. Input

SS

or VDD. Input

SS

or VDD. Input

SS

6 SCL Serial clock Input

(1)

7 EVENT

Event output pin. Open drain and active-low. Output

8V

1. SDA and EVENT are open drain.

DD

Supply power (2.7 V to 3.6 V)

See Section 2.2: Pin descriptions on page 9 for details.

7/36

Serial communications STTS424

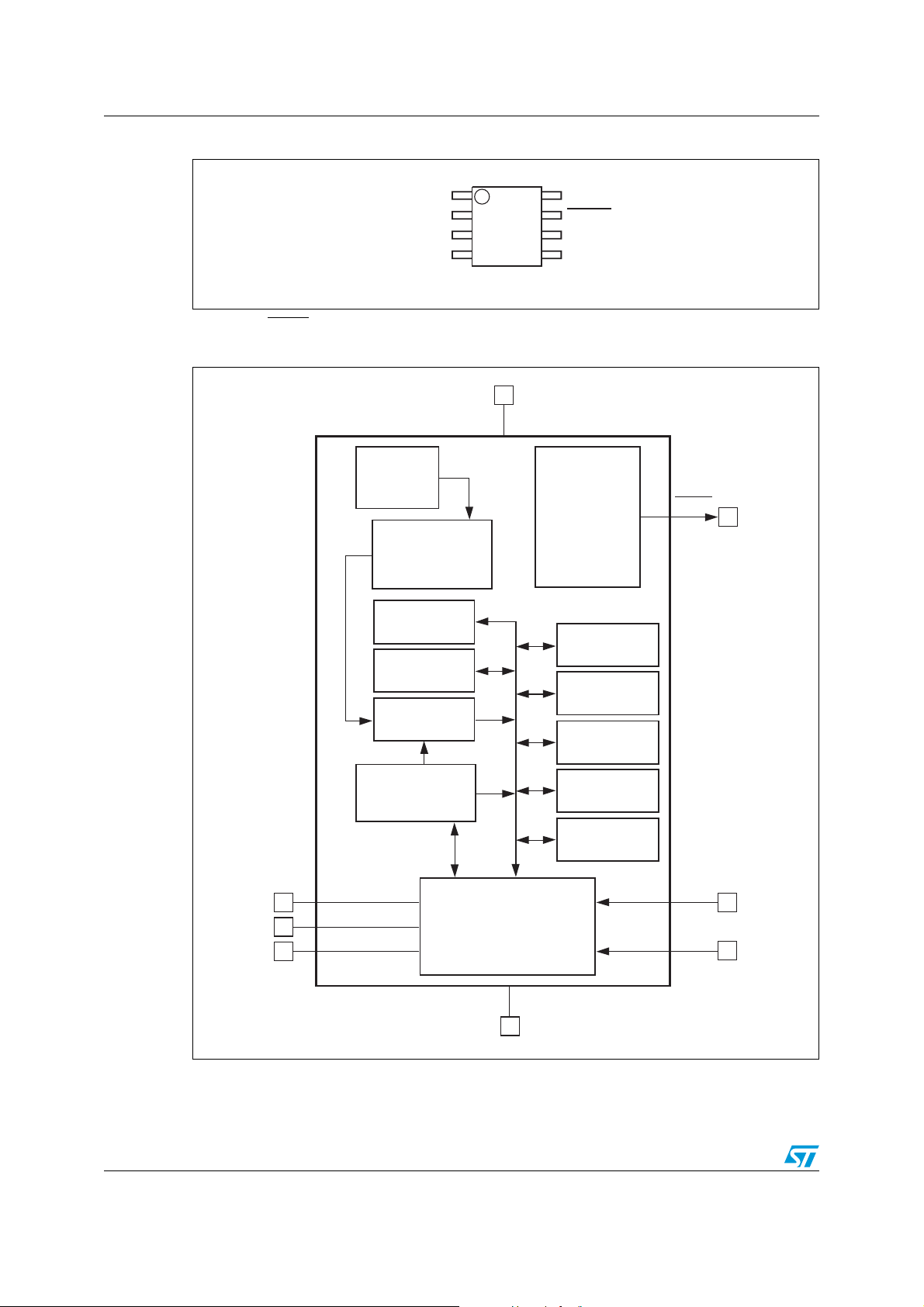

Figure 2. TDFN8 connections (top view)

1. SDA and EVENT are open drain.

Figure 3. Block diagram

Temperature

Sensor

A0

A1

A2

GND

ADC

Capability

Register

Configuration

Register

Temperature

Register

V

1

2

3

4

8

7

6

5

8

V

DD

DD

EVENT

SCL

(1)

SDA

AI12262

Logic Control

Comparator

Timing

Upper

Register

Lower

Register

Critical

Register

(1)

EVENT

7

Address Pointer

Register

A0

1

A1

2

A2

3

8/36

SMBus/I2C

Interface

V

SS

4

Manufacturer

ID

Device ID/

Revision

SCL

SDA

6

5

AI12948

STTS424 Serial communications

2.2 Pin descriptions

2.2.1 A0, A1, A2

A2, A1, and A0 are selectable address pins for the 3 LSBs of the I2C interface address.

They can be set to V

2.2.2 VSS (ground)

This is the reference for the power supply. It must be connected to system ground.

2.2.3 SDA (open drain)

This is the serial data input/output pin.

2.2.4 SCL

This is the serial clock input pin.

2.2.5 EVENT (open drain)

This output pin is open drain and active-low and functions as an alert interrupt.

or GND to provide 8 unique address selections.

DD

2.2.6 VDD (power)

This is the supply voltage pin, and ranges from +2.7 V to +3.6 V.

9/36

Operation STTS424

3 Operation

The STTS424 TS continuously monitors the ambient temperature and updates the

temperature data registers at least eight times per second. Temperature data is latched

internally by the device and may be read by software from the bus host at any time.

The SMBus/I

same bus. This means that up to 8 memory modules can be supported, given that each

module has one such slave device address slot.

After initial power-on, the configuration registers are set to the default values. The software

can write to the configuration register to set bits per the bit definitions in Section 3.1:

SMBus/I

3.1 SMBus/I2C communications

The registers in this device are selected by the pointer register. At power-up, the pointer

register is set to “00”, which is the capability register location. The pointer register latches

the last location it was set to. Each data register falls into one of three types of user

accessibility:

1. Read-only

2. Write-only and

3. WRITE/READ same address.

2

C slave address selection pins allow up to 8 such devices to co-exist on the

2

C communications.

A WRITE to this device will always include the address byte and the pointer byte. A WRITE

to any register other than the pointer register, requires two data bytes.

Reading this device is achieved in one of two ways:

● If the location latched in the pointer register is correct (most of the time it is expected

that the pointer register will point to one of the read temperature registers because that

will be the data most frequently read), then the READ can simply consist of an address

byte, followed by retrieval of the two data bytes.

● If the pointer register needs to be set, then an address byte, pointer byte, repeat start,

and another address byte will accomplish a READ.

The data byte transfers the MSB first. At the end of a READ, this device can accept either an

acknowledge (ACK) or no acknowledge (No ACK) status from the master. The No ACK

status is typically used as a signal for the slave that the master has read its last byte. This

device subsequently takes up to 125 ms to measure the temperature.

Note: STTS424 does not initiate clock stretching which is an optional I

2

C bus feature.

10/36

STTS424 Operation

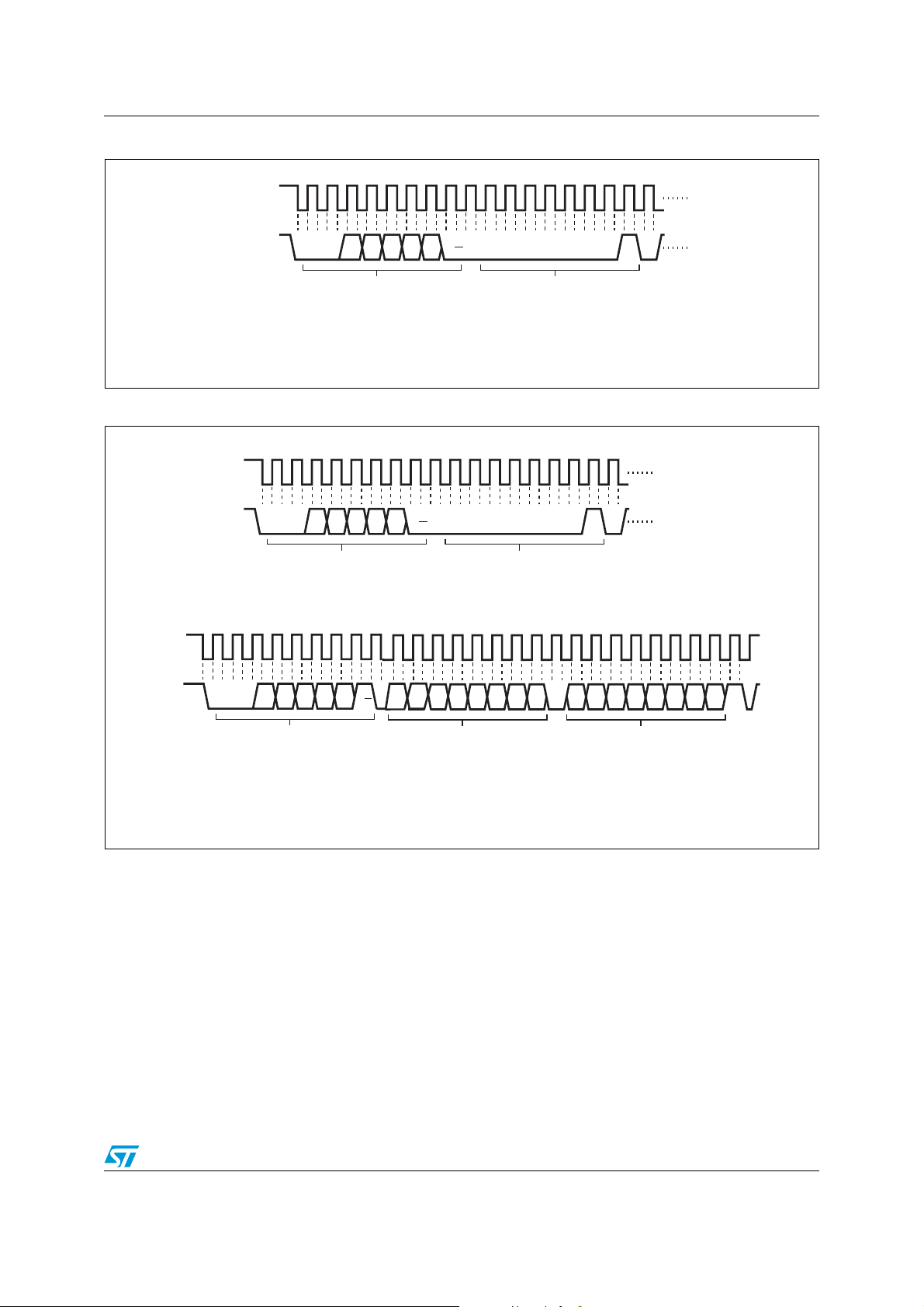

Figure 4. SMBus/I2C write to pointer register

SCL

SDA

Figure 5. SMBus/I

SCL

SDA

Master

SCL

(continued)

19

1199

0 1 1 A2 A1 A0 R/W 0 0 0 0 0 D2 D1 D0

0

Start

by

Master

Address Byte

ACK

by

STTS424

2

C write to pointer register, followed by a read data word

1199

0 1 1 A2 A1 A0 R/W 0 0 0 0 0 D2 D1 D0

0

Start

by

Address Byte

ACK

by

STTS424

1919

Pointer Byte

Pointer Byte

ACK

by

STTS424

AI12264

ACK

by

STTS424

SDA

(continued)

Repeat

Start

by

Master

0 0 1 1 A2 A1 A0

Address Byte

R/W

ACK

by

STTS424

D14D15

D13

D12

D9D10D11

D7 D6 D5 D4 D3 D2 D1 D0

D8

MSB Data Byte LSB Data Byte

ACK

by

Master

No ACK

by

Master

Stop

Cond.

by

Master

AI12265

11/36

Operation STTS424

Figure 6. SMBus/I2C write to pointer register, followed by a write data word

SCL

SDA

SCL

(continued)

SDA

(continued)

1199

0

0 1 1 A2 A1 A0 R/W 0 0 0 0 0 D2 D1 D0

Start

by

Master

Address Byte

1919

D12

D14D15

D13

MSB Data Byte LSB Data Byte

STTS424

D9D10D11

ACK

by

D8

ACK

by

STTS424

Pointer Byte

D7 D6 D5 D4 D3 D2 D1 D0

3.2 SMBus/I2C slave sub-address decoding

ACK

by

STTS424

No ACK

by

STTS424

Stop

Cond.

by

Master

AI14012

The physical address for the TS is binary 0011A2A1A0RW, whereas A2, A1, and A0

are the three slave sub-address pins, and the LSB “RW” is the READ/WRITE flag.

3.3 SMBus/I2C AC timing consideration

In order for this device to be both SMBus- and I2C-compatible, it complies to a subset of

each specification. These interoperability requirements which will enable this device to coexist with devices on either an SMBus or an I

● The SMBus minimum clock frequency is required.

● The 300 ns SMBus data hold time (THD:DAT) is required (see Figure 7 and Ta bl e 2 o n

page 13).

● The SMBus time-out is maximum 50 ms.

Note: Since the voltage levels are specified only within 3.3 V ±10%, there are no compatibility

concerns with the SMBus/I

2

C DC specifications.

2

C bus:

12/36

STTS424 Operation

Figure 7. SMBus/I2C timing diagram

tR

tF

tHIGH

tSU:DAT

C compatibility timings

S

tSU:STA

tSU:STO

P

A12266

V

IH

SCL

V

IL

tBUF

V

IH

SDA

V

IL

SP

Table 2. AC SMBus and I

tLOW

tHD:STA

tHD:DAT

2

Symbol Parameter Min Max Units

t

BUF

t

HD:STA

t

SU:STA

t

HIGH

t

LOW

t

F

t

R

t

SU:DAT

t

HD:DAT

t

SU:STO

f

SCL

t

timeout

1. For a restart condition, or following a WRITE cycle

Bus free time between stop (P) and start (S) conditions 1.3 – µs

Hold time after (repeated) start condition. After this period,

the first clock cycle is generated.

(1)

Repeated start condition setup time 1.3 – µs

0.6 – µs

Clock high period 0.6 – µs

Clock low period 1.3 – µs

Clock/data fall time – 300 ns

Clock/data rise time – 300 ns

Data setup time 100 – ns

Data hold time 300 – ns

Stop condition setup time 0.6 – µs

SMBUS/I2C clock frequency 10 400 kHz

Bus timeout 25 50 ms

3.4 SMBus timeout

The STTS424 supports the SMBus timeout feature. If the host holds SCL low for more than

25 ms, the STTS424 resets and releases the bus. This feature is turned on by default.

13/36

Temperature sensor registers STTS424

4 Temperature sensor registers

The temperature sensor component is comprised of various user-programmable registers.

These registers are required to write their corresponding addresses to the Pointer register.

They can be accessed by writing to their respective addresses (see Ta bl e 3 ). Pointer

register Bits 7-3 must always be written to '0' (see Ta bl e 4 ). This must be maintained, as not

setting these bits to '0' may keep the device from performing to specifications.

The main registers include:

● Capability register (read-only)

● Configuration register (read/write)

● Temperature register (read-only)

● Temperature trip point registers (r/w), including

– Alarm temperature upper boundary,

– Alarm temperature lower boundary, and

– Critical temperature.

● Manufacturer ID register format

● Device ID and device revision ID register format

Note: See Table 5 on page 15 for pointer register selection bit details.

Table 3. Temperature sensor registers summary

Address (Hex) Register name Power-on default

Not applicable Address pointer Undefined

Table 4. Pointer register format

MSB LSB

Bit7 Bit6 Bit5 Bit4 Bit3 Bit2 Bit1 Bit0

00000P2P1P0

00 Capability B-grade only 0x002F

01 Configuration 0x0000

02 Alarm temperature upper boundary trip 0x0000

03 Alarm temperature lower boundary trip 0x0000

04 Critical temperature trip 0x0000

05 Temperature Undefined

06 Manufacturer’s ID 0x104A

07 Device ID/revision 0x0101

Pointer/register select bits

14/36

STTS424 Temperature sensor registers

Table 5. Pointer register select bits (type, width, and default values)

P2 P1 P0 Name Register description

0 0 0 CAPA Thermal sensor capabilities B-grade only 16 R 00 2F

0 0 1 CONF Configuration 16 R/W 00 00

0 1 0 UPPER Alarm temperature upper boundary 16 R/W 00 00

0 1 1 LOWER Alarm temperature lower boundary 16 R/W 00 00

1 0 0 CRITICAL Critical temperature 16 R/W 00 00

1 0 1 TEMP Temperature 16 R 00 00

1 1 0 MANU Manufacturer ID 16 R 104A

1 1 1 ID Device ID/revision 16 R 01 01

Width

(bits)

Type

(R/W)

Default

4.1 Capability register (read-only)

This 16-bit register is read-only, and provides the TS capabilities which comply with the

minimum JEDEC 424.4 specifications (see Ta bl e 6 and Table 7 on page 16). The STTS424

provides temperatures at 0.25 resolution (10-bit).

state

(POR)

4.1.1 Alarm window trip

The device provides a comparison window with an upper temperature trip point in the alarm

upper boundary register, and a lower trip point in the alarm lower boundary register. When

enabled, the event output will be triggered whenever entering or exiting (crossing above or

below) the alarm window.

4.1.2 Critical trip

The device can be programmed in such a way that the event output is only triggered when

the temperature exceeds the critical trip point. The critical temperature setting is

programmed in the critical temperature register. When the temperature sensor reaches the

critical temperature value in this register, the device is automatically placed in comparator

mode, which means that the critical event output cannot be cleared by using software to set

the clear event bit.

15/36

Temperature sensor registers STTS424

Table 6. Capability register format

Bit15 Bit14 Bit13 Bit12 Bit11 Bit10 Bit9 Bit8

RFU RFU RFU RFU RFU RFU RFU RFU

Bit7 Bit6 Bit5 Bit4 Bit3 Bit2 Bit1 Bit0

RFU RFU V

C

Table 7. Capability register bit definitions

HV

TRES1 TRES0

Wider

range

Higher

precision

Bit Definition

Basic capability

0

– 0 = Alarm and critical trips turned OFF.

– 1 = Alarm and critical trips turned ON.

Accuracy

– 0 = Accuracy ±2°C over the active range and ±3°C over the monitoring range

1

(C - Grade).

– 1 = High accuracy ±1°C over the active range and ±2°C over the monitoring range

(B - Grade).

Range width

2

– 0 = Values lower than 0°C will be clamped and represented as binary value '0'.

– 1 = Temperatures below 0°C can be read and the Sign bit will be set accordingly.

Temperature resolution

4:3

– 01 = This 10-bit value is fixed for STTS424, providing temperatures at 0.25°C resolution

(LSB).

) High voltage support for A0 (pin 1)

(V

HV

5

– 1 = STTS424 supports a voltage up to 10 volts on the A0 pin (default).

Reserved

15:6

These values must be set to '0'.

Alarm and

critical trips

16/36

STTS424 Temperature sensor registers

4.2 Configuration register (read/write)

The 16 bit Configuration register stores various configuration modes that are used to set up

the sensor registers and configure according to application and JEDEC 42.4 requirements

(see Table 8 on page 17 and Table 9 on page 18).

4.2.1 Event thresholds

All event thresholds use hysteresis as programmed in register address 0x01 (bits 10 through

9) to be set when they de-assert.

4.2.2 Interrupt mode

The interrupt mode allows an event to occur where software may write a '1' to the clear

event bit (bit 5) to de-assert the event Interrupt output until the next trigger condition occurs.

4.2.3 Comparator mode

Comparator mode enables the device to be used as a thermostat. READs and WRITEs on

the device registers will not affect the event output in comparator mode. The event signal will

remain asserted until temperature drops outside the range or is re-programmed to make the

current temperature “out of range”.

4.2.4 Shutdown mode

The STTS424 features a shutdown mode which disables all power-consuming activities

(e.g. temperature sampling operations), and leaves the serial interface active. This is

selected by setting shutdown bit (bit 8) to '1'. In this mode, the devices consume the

minimum current (I

Note: Bit 8 cannot be set to '1' while bits 6 and 7 (the lock bits) are set to '1'.

The device may be enabled for continuous operation by clearing bit 8 to '0'. In shutdown

mode, all registers may be read or written to. Power recycling will also clear this bit and

return the device to continuous mode as well.

Table 8. Configuration register format

Bit15 Bit14 Bit13 Bit12 Bit11 Bit10 Bit9 Bit8

RFU RFU RFU RFU RFU Hysteresis Hysteresis

Bit7 Bit6 Bit5 Bit4 Bit3 Bit2 Bit1 Bit0

Critical

lock bit

Alarm

lock bit

), as shown in Table 22 on page 28.

SHDN

Clear

event

Event output

status

Event output

control

Critical

event only

Event

polarity

Shutdown

mode

Event

mode

17/36

Temperature sensor registers STTS424

Table 9. Configuration register bit definitions

Bit Definition

Event mode

0

– 0 = Comparator output mode (this is the default)

– 1 = Interrupt mode; when either of the lock bits is set, this bit cannot be altered until it is unlocked.

Event polarity

1

– 0 = Active-low (this is the default).

– 1 = Active-high; when either of the lock bits is set, this bit cannot be altered until it is unlocked.

Critical event only

– 0 = Event output on alarm or critical temperature event (this is the default).

2

– 1 = Event only if the temperature is above the value in the critical temperature register; when the alarm

window lock bit is set, this bit cannot be altered until it is unlocked.

Event output control

3

– 0 = Event output disabled (this is the default).

– 1 = Event output enabled; when either of the lock bits is set, this bit cannot be altered until it is unlocked.

Event status (read-only)

– 0 = Event output condition is not being asserted by this device.

4

(1)

– 1 = Event output condition is being asserted by this device via the alarm window or critical trip event.

Clear event (write-only)

5

–0 = No effect

(2)

– 1 = Clears the active Event in Interrupt mode.

Alarm window lock bit

– 0 = Alarm trips are not locked and can be altered (this is the default).

6

– 1 = Alarm trip register settings cannot be altered. This bit is initially cleared. When set, this bit returns a

logic '1' and remains locked until cleared by an internal power-on reset. These bits can be written to with a

single WRITE, and do not require double WRITEs.

Critical trip lock bit

– 0 = Critical trip is not locked and can be altered (this is the default).

7

– 1 = Critical trip register settings cannot be altered. This bit is initially cleared. When set, this bit returns a

logic '1' and remains locked until cleared by an internal power-on reset. These bits can be written to with a

single WRITE, and do not require double WRITEs.

Shutdown mode

– 0 = TS is enabled (this is the default).

8

– 1 = Shutdown TS when the shutdown, device, and A/D converter are disabled in order to save power. No

event conditions will be asserted; when either of the lock bits is set, this bit cannot be altered until it is

unlocked. However, it can be cleared at any time.

(3)

Hysteresis enable

(see Figure 8 and Ta b le 1 0 )

– 00 = Hysteresis is disabled.

10:9

– 01 = Hysteresis is enabled at 1.5°C.

– 10 = Hysteresis is enabled at 3°C.

– 11 = Hysteresis is enabled at 6°C.

1. The actual incident causing the event can be determined from the read temperature register. Interrupt events can be

cleared by writing to the clear event bit (writing to this bit will have no effect on overall device functioning.

2. Writing to this register has no effect on overall device functioning in comparator mode. When read, this bit will always return

a logic '0' result.

3. Hysteresis is also applied to the EVENT

pin functionality. When either of the lock bits is set, these bits cannot be altered.

18/36

STTS424 Temperature sensor registers

Figure 8. Hysteresis

T

H

T

L

Below Window bit

Above Window bit

1. TU = Value stored in the alarm temperature upper boundary trip register.

= Value stored in the alarm temperature lower boundary trip register.

2. T

L

3. Hys = Absolute value of selected hysteresis.

Table 10. Hysteresis as applied to temperature movement

TH - HYS

TL - HYS

AI12270

Below alarm window bit Above alarm window bit

Temperature

slope

Sets Falling T

Temperature

threshold

- HYS Rising T

L

Clears Rising T

Temperature

slope

L

Falling TH - HYS

Temperature

threshold

H

19/36

Temperature sensor registers STTS424

4.2.5 Event output pin functionality

The EVENT pin is an open drain output and requires a pull-up resistor to VDD on the system

motherboard or incorporated into the master controller.

Figure 9 shows the defined outputs of the EVENT

change.

The event outputs can be programmed to be configured as either a comparator output or as

an interrupt. This is done by enabling the output control bit (bit 3) and setting the event mode

bit (bit 0). The output pin polarity can also be specified as active-high or active-low by setting

the event polarity bit (bit 1).

When the hysteresis bit (bits 10 and 9) is enabled, hysteresis may be used to sense

temperature movement around trigger points. For example, when using the “above alarm

window” bit (temperature register bit 14, see Table 12 on page 22) and hysteresis is set to

3°C, as the temperature rises, bit 14 is set (bit 14 = 1). The temperature is above the alarm

window and the temperature register contains a value that is greater than the value set in

the alarm temperature upper boundary register (see Table 15 on page 23).

If the temperature decreases, bit 14 will remain set until the measured temperature is less

than or equal to the value in the alarm temperature upper boundary register minus 3°C (see

Figure 8 on page 19 and Table 10 on page 19 for details.

Similarly, when using the “below alarm window” bit (temperature register bit 13, see Table 12

on page 22) will be set to '0'. The temperature is equal to or greater than the value set in the

alarm temperature lower boundary register (see Table 16 on page 24). As the temperature

decreases, bit 13 will be set to '1' when the value in the temperature register is less than the

value in the alarm temperature lower boundary register minus 3°C (see Figure 8 on page 19

and Table 10 on page 19 for details).

The device will retain the previous state when entering the shutdown mode. If the device

enters the shutdown mode while the EVENT

due to the additional event output pull-down current.

correspondent to the temperature

pin is low, the shutdown current will increase

If in interrupt mode and the temperature reaches the critical temperature, the EVENT

remains asserted until the temperature drops below the critical limit minus hysteresis.

Note: Hysteresis is also applied to the EVENT

or 7) is set, these bits cannot be altered.

20/36

pin

pin functionality. When either of the lock bits (bits 6

STTS424 Temperature sensor registers

Figure 9. Event output boundary timings

T

- T

CRIT

T

UPPER

HYS

- T

T

LOWER

HYS

- T

HYS

T

T

UPPER

T

LOWER

Comparator

Interrupt

S/W Int. Clear

Event Output (active-low)

CRIT

Critical

T

T

A

T

LOWER

- T

HYS

UPPER

- T

HYS

12133574642

Table 11. Legend for Figure 9: Event output boundary timings

Event output T

bits

A

AI12271

Note Event output boundary conditions

Comparator Interrupt Critical 15 14 13

1T

2T

3T

4T

5T

6T

When T

7

of the configuration register (interrupt mode) is ignored.

A

A

A

≥ T

≥ T

≥ T

< T

A

CRIT

≥ T

A

LOWER

LOWER - THYS

> T

A

UPPER

UPPER - THYS

≥ T

A

CRIT

CRIT - THYS

and TA < T

CRIT - THYS

HLH000

LLH001

LLH010

HLH000

LLL110

LHH010

, the event output is in comparator mode and bit 0

Note: Systems that use the active high mode for event output must be wired pont-to-point between

the STTS424 and the sensing controller. Wire-OR configurations should not be used with

active high EVENT since any device pulling the event output signal low will mask the other

devices on the bus. Also note that the normal state of EVENT

in active high mode is a ‘0’

which will constantly draw power through the pull-up resistor.

21/36

Temperature sensor registers STTS424

4.3 Temperature register (read-only)

This 16-bit, read-only register stores the temperature measured by the internal band gap TS

as shown inTa bl e 1 2. The STTS424 meets the JEDEC JC42.4 mandatory 0.25°C resolution

requirement. When reading this register, the MSBs (bit 15 to bit 8) are read first, and then

the LSBs (bit 7 to bit 0) are read. The result is the current-sensed temperature. The data

format is 2s complement with one LSB = 0.25°C. The MSB has a 128°C resolution.

The trip status bits represent the internal temperature trip detection, and are not affected by

the status of the event or configuration bits (e.g. event output control or clear event). If

neither of the above or below values are set (i.e. both are 0), then the temperature is exactly

within the user-defined alarm window boundaries.

4.3.1 Temperature format

The 16-bit value used in the trip point set and temperature read-back registers is 2s

complement, with the LSB equal to 0.0625°C (see Tab le 1 3 ). For example:

1. a value of 019Ch will represent 25.75°C,

2. a value of 07C0h will represent 124°C, and

3. a value of 1E74h will represent –24.75°C

The 0.0625°C resolution is optional. Supporting a resolution of at least 0.25°C is mandatory.

All unused resolution bits will be set to zero. The MSB will have a resolution of 128°C. The

STTS424 supports the 0.25°C/LSB only.

The upper 3 bits indicate trip status based on the current temperature, and are not affected

by the event output status.

Table 12. Temperature register format

Bit

15

Above

critical

input

0 0 0 0 011111000 0 0 0 07C0 h

0 0 0 1 110110000 0 0 0 1C00 h

1. See Table 13 for explanation.

Sign

MSB

Bit

14

Above

(1)

alarm

(1)

window

Flag bits Example hex value of 07C0 corresponds to 124°C (10-bit)

Flag bits Example hex value of 1C00 corresponds to –40°C (10-bit)

Bit

13

Below

alarm

window

Bit12Bit11Bit10Bit9Bit8Bit7Bit6Bit5Bit4Bit3Bit2Bit1Bit

(1)

Temperature 0 0

LSB

0

22/36

STTS424 Temperature sensor registers

Table 13. Temperature register bit definitions

Bit Definition with hysteresis = 0

Below (temperature) alarm window

13

– 0 = Temperature is equal to or above the alarm window lower boundary temperature.

– 1 = Temperature is below the alarm window.

Above (temperature) alarm window

14

– 0 = Temperature is equal to or below the alarm window upper boundary temperature.

– 1 = Temperature is below the alarm window.

Above critical trip

15

– 0 = Temperature is below the critical temperature setting.

– 1 = Temperature is equal to or above the critical temperature setting.

4.4 Temperature trip point registers (r/w)

The STTS424 alarm mode registers provide for 11-bit data in 2s compliment format. The

data provides for one LSB = 0.25°C. All unused bits in these registers are read as '0'.

The STTS424 has three temperature trip point registers (see Tab l e 1 4):

● Alarm temperature upper boundary threshold (Tab l e 1 5),

● Alarm temperature lower boundary threshold (Ta bl e 1 6), and

● Critical temperature trip point value (Ta bl e 1 7 ).

Note: If the upper or lower boundary threshold values are being altered in-system, all interrupts

should be turned off until a known state can be obtained to avoid superfluous interrupt

activity.

Table 14. Temperature trip point register format

Default

state

(POR)

P2 P1 P0 Name Register description

Width

(bits)

Type

(R/W)

0 1 0 UPPER Alarm temperature upper boundary 16 R/W 00 00

0 1 1 LOWER Alarm temperature lower boundary 16 R/W 00 00

1 0 0 CRITICAL Critical temperature 16 R/W 00 00

Table 15. Alarm temperature upper boundary register format

Sign

MSB

LSB

Bit15Bit14Bit13Bit12Bit11Bit10Bit9Bit8Bit7Bit6Bit5Bit4Bit3Bit2Bit1Bit

0 0 0 Alarm window upper boundary temperature 0 0

0

23/36

Temperature sensor registers STTS424

Table 16. Alarm temperature lower boundary register format

Sign

MSB

Bit15Bit14Bit13Bit12Bit11Bit10Bit9Bit8Bit7Bit6Bit5Bit4Bit3Bit2Bit1Bit

0 0 0 Alarm window lower boundary temperature 0 0

Table 17. Critical temperature register format

Sign

MSB

Bit15Bit14Bit13Bit12Bit11Bit10Bit9Bit8Bit7Bit6Bit5Bit4Bit3Bit2Bit1Bit

0 0 0 Critical temperature trip point 0 0

4.5 Manufacturer ID register (read-only)

The manufacturer’s ID (programmed value 104Ah) in this register is the STMicroelectronics

identification provided by the Peripheral Component Interconnect Special Interest Group

(PCiSIG).

LSB

0

LSB

0

Table 18. Manufacturer ID register format

Bit15 Bit14 Bit13 Bit12 Bit11 Bit10 Bit9 Bit8

00010000

Bit7 Bit6 Bit5 Bit4 Bit3 Bit2 Bit1 Bit0

01001010

24/36

STTS424 Temperature sensor registers

4.6 Device ID and device revision ID register (read-only)

The device IDs and device revision IDs are maintained in this register. The register format is

shown in Ta bl e 1 9 . The device IDs and device revision IDs are currently '0' and will be

incremented whenever an update of the device is made.

Table 19. Device ID and device revision ID register format

Bit15 Bit14 Bit13 Bit12 Bit11 Bit10 Bit9 Bit8

0000000 1

Device ID

Bit7 Bit6 Bit5 Bit4 Bit3 Bit2 Bit1 Bit0

00000001

Device revision ID

25/36

Maximum ratings STTS424

5 Maximum ratings

Stressing the device above the ratings listed in the absolute maximum ratings table may

cause permanent damage to the device. These are stress ratings only and operation of the

device at these or any other conditions above those indicated in the operating sections of

this specification is not implied. Exposure to absolute maximum rating conditions for

extended periods may affect device reliability. Refer also to the STMicroelectronics SURE

Program and other relevant quality documents.

Table 20. Absolute maximum ratings

Symbol Parameter Value Unit

T

STG

T

SLD

V

IO

V

DD

V

OUT

I

O

P

D

θ

JA

1. Reflow at peak temperature of 255°C to 260°C for < 30 seconds (total thermal budget not to exceed 180°C

for between 90 to 150 seconds).

Storage temperature –60 to 150 °C

(1)

Lead solder temperature for 10 seconds 260 °C

Input or output voltage - all pins VSS – 0.3 to VDD + 0.5 V

Supply voltage VSS – 0.3 to 6.5 V

Output voltage VDD + 0.5 V

Output current 10 mA

Power dissipation 320 mW

Thermal resistance 130 °C/W

26/36

STTS424 DC and AC parameters

6 DC and AC parameters

This section summarizes the operating measurement conditions, and the dc and ac

characteristics of the device. The parameters in the DC and AC characteristics tables that

follow, are derived from tests performed under the measurement conditions summarized in

Table 21: Operating and AC measurement conditions. Designers should check that the

operating conditions in their circuit match the operating conditions when relying on the

quoted parameters.

Table 21. Operating and AC measurement conditions

Parameter Conditions Unit

V

supply voltage - temperature sensor 2.7 to 3.6 V

DD

Operating temperature –40 to 125 °C

Input rise and fall times ≤ 5ns

Input pulse voltages 0.2 to 0.8V

Input and output timing reference voltages 0.3 to 0.7V

DD

DD

V

V

27/36

DC and AC parameters STTS424

Table 22. DC and AC characteristics - temperature sensor

Sym Description Test condition

V

DD

(1)

Supply voltage 2.7 3.3 3.6 V

VDD supply current, active

temperature conversions

I

VDD supply current,

DD

SCL/SDA = V

100 kHz 40 µA

DD

communication only

400 kHz 100 µA

(3)

at 125°C 1.0 3.0 µA

I

I

SINK

I

IH

V

DD1

, I

POR

(no conversions)

Shutdown mode supply current,

serial port inactive

DN package

SMBUS output low sink current SDA forced to 0.6 V 6 mA

Input/output leakage current ±2 µA

IL

Power on reset (POR) threshold VDD falling edge: 2.0 V

+75°C < TA < +95°C ±0.5 ±1.0 °C

B-grade

Accuracy for corresponding

range 2.7V ≤ V

DD

≤ 3.6V

+40°C < T

–40°C < T

< +125°C ±1.0 ±2.0 °C

A

< +125°C ±2.0 ±3.0 °C

A

Resolution 10-bit temperature data

t

CONV

T

HYS

Conversion time 10-bit 125 ms

Hysteresis Default value 500 mV

3.0 V ≤ VDD ≤ 3.6 V;

V

SMBus/I

Low level voltage EVENT

OL1

2

C interface

EVENT;

= 2.1 mA

I

OL

Min Typ

100 200 µA

(2)

Max Unit

0.25

°C/L

SB

10 bits

0.4 V

V

V

C

f

SCL

t

TIMEOUT

V

L

V

1. Guaranteed operating temperature for DN package: TA = –40°C to 125°C; VDD = 2.7 V to 3.6 V (except where noted).

2. Typical numbers taken at V

3. TDFN package max 0.80 mm height.

Input logic high

IH

Input logic low

IL

SMBus/I2C Input capacitance 5 pF

IN

SMBus/I2C clock frequency 10 400 kHz

SMBus timeout 25 50 ms

Allowable voltage on pin A0 10 V

HV

Leakage on pin A0 in

AO

overvoltage state

Low level voltage SDA IOL = 6 mA 0.6 V

OL2

= 3.3 V, TA = 25°C.

DD

3.0 V ≤ V

3.0 V ≤ V

≤ 3.6 V;

DD

SCL, SDA

≤ 3.6 V;

DD

SCL, SDA

2.1 V

0.8 V

500 µA

28/36

STTS424 Package mechanical data

7 Package mechanical data

In order to meet environmental requirements, ST offers these devices in different grades of

ECOPACK

specifications, grade definitions and product status are available at: www.st.com.

ECOPACK

®

packages, depending on their level of environmental compliance. ECOPACK®

®

is an ST trademark.

29/36

Package mechanical data STTS424

Figure 10. TDFN8 – 8-lead thin dual flat, no-lead (2 mm x 3 mm) package outline (DN)

DA_ME

(a)

Table 23. TDFN8 – 8-lead thin dual flat, no-lead (2 mm x 3 mm) mechanical data (DN)

mm inches

Sym

Min Typ Max Min Typ Max

A 0.70 0.75 0.80 0.028 0.030 0.031

A1 0.00 0.00 0.05 0.000 0.000 0.002

A3 0.20 0.005

b 0.20 0.25 0.30 0.008 0.010 0.012

D 1.95 2.00 2.05 0.075 0.078 0.079

D2 1.35 1.40 1.45 0.053 0.055 0.057

E 2.95 3.00 3.05 0.116 0.118 0.120

E2 1.25 1.30 1.35 0.049 0.051 0.053

e 0.50 0.020

L 0.30 0.35 0.40 0.012 0.014 0.016

ddd 0.08 0.003

1. JEDEC MO-229, variation WCED-3 proposal

(1)

a. JEDEC MO-229, variation WCED-3 proposal

30/36

STTS424 Part numbering

8 Part numbering

Table 24. Ordering information scheme

Example: STTS424 B DN 3 F

Device type

STTS424

Grade

B: Maximum accuracy 75°C to 95°C = ± 1°C

Package

DN = TDFN8 (2 mm x 3 mm) (0.80 mm max height)

Temperature range

3 = –40°C to 125°C

Shipping method

®

F = ECOPACK

E = ECOPACK

package, tape & reel packing

®

package, tube packing

For other options, or for more information on any aspect of this device, please contact the

ST sales office nearest you.

31/36

Package marking information STTS424

9 Package marking information

Figure 11. Device topside marking information (TDFN-8L)

424B

(1)

1. TDFN package identifier

DN = 0.80 mm (package height)

2. Traceability codes

P = Plant code

Y = Year

WW = Work Week

DN

PYWW

(2)

ai13910b

32/36

STTS424 Landing pattern

10 Landing pattern

The landing pattern recommendations for the TDFN package (DN) are shown in Figure 12.

The preferred implementation with wide corner pads enhances device centering during

assembly, but a narrower option is defined for modules with tight routing requirements.

Figure 12. Landing pattern - TDFN package (DN)

e4

e2

e/2

e

L

K

e/2

E3

E3

D2

D2/2

K

L

b2

b4

K2

b

K2

D2/2

b

K2

E2/2

E2

E2/2

ai14000

33/36

Landing pattern STTS424

Ta bl e 2 5 lists variations of landing pattern implementations, ranked as “preferred”, and

minimum acceptable” based on the JEDEC proposal.

Table 25. Parameters for landing pattern - TDFN package (DN)

Dimension

Parameter Description

Min Nom Max

D2 Heat paddle width 1.40 - 1.60

E2 Heat paddle height 1.40 - 1.60

E3 Heat paddle centerline to contact inner locus 1.00 - -

L Contact length 0.70 - 0.80

K Heat paddle to contact keepout 0.20 - -

K2 Contact to contact keepout 0.20 - -

e Contact centerline to contact centerline pitch for inner contacts - 0.50 -

b Contact width for inner contacts 0.25 - 0.30

e2

b2 Corner contact width, “minimum acceptable option”

e4 Landing pattern centerline to outer contact centerline, “preferred” option

b4 Corner contact width, “preferred” option

1. Minimum acceptable option to be used when routing prevents preferred width contact.

2. Preferred option to be used when possible.

Landing pattern centerline to outer contact centerline, “minimum

acceptable” option

(1)

(1)

(2)

-0.50-

0.25 - 0.30

(2)

-0.60-

0.45 - 0.50

34/36

STTS424 Revision history

11 Revision history

Table 26. Document revision history

Date Revision Changes

17-Apr-2007 1 Initial release.

09-May-2007 2 Updated Ta b le 3 , 5, 6, 7, 22, 23, and 24.

04-June-2007 3 Updated Ta bl e 2 2 .

02-Jul-2007 4 Added POR threshold values to Ta bl e 2 2.

Added TDFN package (cover page, Figure 10, Tab l e 2 3 ) and landing

pattern recommendations (Figure 12, Ta b l e 2 5 ); updated Section 1,

22-Oct-2008 5

01-Apr-2009 6

Section 4.3.1; Ta b le 2 , 3, 5, 7, 11, 19, 20, 22, 25, and Figure 2, 4, 5,

11; added Figure 6; removed all TSSOP8 and DFN8 package

references throughout datasheet.

Updated Features on cover page, Section 3.1, Section 3.3,

Section 4.2.5, Section 6, Ta b le 3 , 5, 9, 12, 22.

35/36

STTS424

Please Read Carefully:

Information in this document is provided solely in connection with ST products. STMicroelectronics NV and its subsidiaries (“ST”) reserve the

right to make changes, corrections, modifications or improvements, to this document, and the products and services described herein at any

time, without notice.

All ST products are sold pursuant to ST’s terms and conditions of sale.

Purchasers are solely responsible for the choice, selection and use of the ST products and services described herein, and ST assumes no

liability whatsoever relating to the choice, selection or use of the ST products and services described herein.

No license, express or implied, by estoppel or otherwise, to any intellectual property rights is granted under this document. If any part of this

document refers to any third party products or services it shall not be deemed a license grant by ST for the use of such third party products

or services, or any intellectual property contained therein or considered as a warranty covering the use in any manner whatsoever of such

third party products or services or any intellectual property contained therein.

UNLESS OTHERWISE SET FORTH IN ST’S TERMS AND CONDITIONS OF SALE ST DISCLAIMS ANY EXPRESS OR IMPLIED

WARRANTY WITH RESPECT TO THE USE AND/OR SALE OF ST PRODUCTS INCLUDING WITHOUT LIMITATION IMPLIED

WARRANTIES OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE (AND THEIR EQUIVALENTS UNDER THE LAWS

OF ANY JURISDICTION), OR INFRINGEMENT OF ANY PATENT, COPYRIGHT OR OTHER INTELLECTUAL PROPERTY RIGHT.

UNLESS EXPRESSLY APPROVED IN WRITING BY AN AUTHORIZED ST REPRESENTATIVE, ST PRODUCTS ARE NOT

RECOMMENDED, AUTHORIZED OR WARRANTED FOR USE IN MILITARY, AIR CRAFT, SPACE, LIFE SAVING, OR LIFE SUSTAINING

APPLICATIONS, NOR IN PRODUCTS OR SYSTEMS WHERE FAILURE OR MALFUNCTION MAY RESULT IN PERSONAL INJURY,

DEATH, OR SEVERE PROPERTY OR ENVIRONMENTAL DAMAGE. ST PRODUCTS WHICH ARE NOT SPECIFIED AS "AUTOMOTIVE

GRADE" MAY ONLY BE USED IN AUTOMOTIVE APPLICATIONS AT USER’S OWN RISK.

Resale of ST products with provisions different from the statements and/or technical features set forth in this document shall immediately void

any warranty granted by ST for the ST product or service described herein and shall not create or extend in any manner whatsoever, any

liability of ST.

ST and the ST logo are trademarks or registered trademarks of ST in various countries.

Information in this document supersedes and replaces all information previously supplied.

The ST logo is a registered trademark of STMicroelectronics. All other names are the property of their respective owners.

© 2009 STMicroelectronics - All rights reserved

STMicroelectronics group of companies

Australia - Belgium - Brazil - Canada - China - Czech Republic - Finland - France - Germany - Hong Kong - India - Israel - Italy - Japan -

Malaysia - Malta - Morocco - Singapore - Spain - Sweden - Switzerland - United Kingdom - United States of America

www.st.com

36/36

Loading...

Loading...