ST72334xx-Auto,

ST72314xx-Auto, ST72124Jx-Auto

8-bit MCU for automotive with single voltage Flash/ROM memory,

ADC, 16-bit timers, SPI, SCI interfaces

■ Memories

– 8 or 16 Kbyte Program memory (ROM or sin-

gle voltage Flash) with readout protection and

in-situ programming (remote ISP)

– 256 bytes EEPROM Data memory (with read-

out protection option in ROM devices)

– 384 or 512 bytes RAM

■ Clock, Reset and Supply Management

– Enhanced reset system

– Enhanced low voltage supply supervisor with

3 programmable levels

– Clock sources: crystal/ceramic resonator os-

cillators or RC oscillators, external clock,

backup Clock Security System

– 4 Power Saving Modes: Halt, Active Halt,

Wait and Slow

– Beep and clock-out capabilities

■ Interrupt Management

– 10 interrupt vectors plus TRAP and RESET

– 15 external interrupt lines (4 vectors)

■ 44 or 32 I/O Ports

– 44 or 32 multifunctional bidirectional I/O lines:

– 21 or 19 alternate function lines

– 12 or 8 high sink outputs

■ 4 Timers

– Configurable watchdog timer

– Real-time base

– Two 16-bit timers with: 2 input captures (only

one on timer A), 2 output compares (only one

on timer A), External clock input on timer A,

PWM and Pulse generator modes

■ 2 Communications Interfaces

– SPI synchronous serial interface

– SCI asynchronous serial interface (LIN com-

■ 1 Analog Peripheral

– 8-bit ADC with 8 input channels (6 only on

■ Instruction Set

– 8-bit data manipulation

– 63 basic instructions

– 17 main addressing modes

– 8 x 8 unsigned multiply instruction

– True bit manipulation

■ Development Tools

– Full hardware/software development package

TQFP64

14 x 14

TQFP44

10 x 10

patible)

ST72334Jx, not available on ST72124J2)

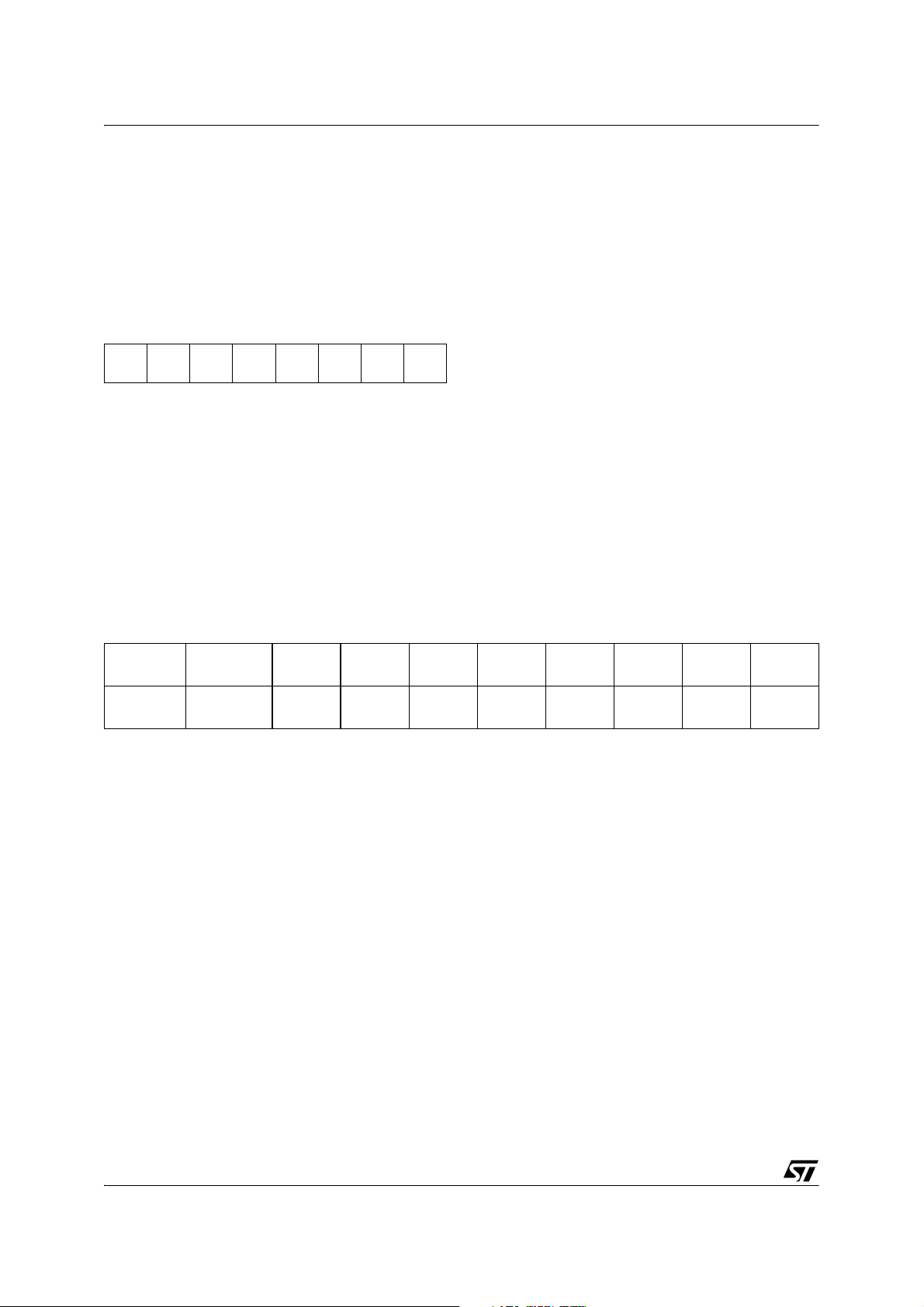

Device Summary

Features

Prog. memory

RAM (stack) 384 (256) bytes

EEPROM - 256 bytes

Peripherals

Oper. Supply 3.2V to 5.5 V

CPU Freq. Up to 8 MHz (with up to 16 MHz oscillator)

Oper. Temp. -40°C to +85°C / -40°C to +125C° Flash or ROM (-40°C to +105°C ROM only)

Packages TQFP44 TQFP64 TQFP44 TQFP64

ST72124J2

-Auto

ST72314J2

-Auto

8 Kbytes 16 Kbytes 8 Kbytes 16 Kbytes 8 Kbytes 16 Kbytes 8 Kbytes 16 Kbytes

- ADC

ST72314J4

-Auto

512 (256)

bytes

ST72314N2

-Auto

384 (256)

bytes

Watchdog, Two 16-bit Timers, SPI, SCI

ST72314N4

-Auto

Flash/ROM

512 (256)

bytes

ST72334J2

-Auto

384 (256)

bytes

ST72334J4

-Auto

512 (256)

bytes

ST72334N2

-Auto

384 (256)

bytes

ST72334N4

-Auto

512 (256)

bytes

Rev. 1

October 2007 1/150

1

Table of Contents

1 PREAMBLE: ST72C334-Auto VERSUS ST72E331 SPECIFICATION . . . . . . . . . . . . . . . . . . . . 7

2 INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3 PIN DESCRIPTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

4 REGISTER AND MEMORY MAP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

5 FLASH PROGRAM MEMORY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

5.1 INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

5.2 MAIN FEATURES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

5.3 STRUCTURAL ORGANIZATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

5.4 IN-SITU PROGRAMMING (ISP) MODE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

5.5 MEMORY READOUT PROTECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

6 DATA EEPROM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

6.1 INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

6.2 MAIN FEATURES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

6.3 MEMORY ACCESS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

6.4 POWER SAVING MODES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

6.5 ACCESS ERROR HANDLING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

6.6 REGISTER DESCRIPTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

6.7 READOUT PROTECTION OPTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

7 CENTRAL PROCESSING UNIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

7.1 INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

7.2 MAIN FEATURES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

7.3 CPU REGISTERS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

8 SUPPLY, RESET AND CLOCK MANAGEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

8.1 LOW VOLTAGE DETECTOR (LVD) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

8.2 RESET SEQUENCE MANAGER (RSM) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

8.2.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

8.2.2 Asynchronous External RESET Pin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

8.2.3 Internal Low Voltage Detection RESET . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

8.2.4 Internal Watchdog RESET . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

8.3 MULTI-OSCILLATOR (MO) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

8.4 CLOCK SECURITY SYSTEM (CSS) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

8.4.1 Clock Filter Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

8.4.2 Safe Oscillator Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

8.4.3 Low Power Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

8.4.4 Interrupts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

8.5 SUPPLY, RESET AND CLOCK REGISTER DESCRIPTION . . . . . . . . . . . . . . . . . . . . . 33

9 INTERRUPTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

9.1 NON-MASKABLE SOFTWARE INTERRUPT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

9.2 EXTERNAL INTERRUPTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

9.3 PERIPHERAL INTERRUPTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

10 POWER SAVING MODES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

10.1 INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

10.2 SLOW MODE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

150

2/150

2

Table of Contents

10.3 WAIT MODE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

10.4 ACTIVE HALT AND HALT MODES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

10.4.1Active Halt Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

10.4.2Halt Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

11 I/O PORTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

11.1 INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

11.2 FUNCTIONAL DESCRIPTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

11.2.1Input Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

11.2.2Output Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

11.2.3Alternate Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

11.3 I/O PORT IMPLEMENTATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

11.4 LOW POWER MODES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

11.5 INTERRUPTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

11.5.1Register Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

12 MISCELLANEOUS REGISTERS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

12.1 I/O PORT INTERRUPT SENSITIVITY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

12.2 I/O PORT ALTERNATE FUNCTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

12.3 REGISTERS DESCRIPTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

13 ON-CHIP PERIPHERALS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

13.1 WATCHDOG TIMER (WDG) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

13.1.1Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

13.1.2Main Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

13.1.3Functional Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

13.1.4Hardware Watchdog Option . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

13.1.5Low Power Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

13.1.6Interrupts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

13.1.7Register Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

13.2 MAIN CLOCK CONTROLLER WITH REAL-TIME CLOCK TIMER (MCC/RTC) . . . . . . . 53

13.2.1Programmable CPU clock prescaler . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

13.2.2Clock-out capability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

13.2.3Real-time clock timer (RTC) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

13.2.4Low Power Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

13.2.5Interrupts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

13.3 16-BIT TIMER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

13.3.1Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

13.3.2Main Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

13.3.3Functional Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

13.3.4Low Power Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

13.3.5Interrupts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

13.3.6Summary of Timer modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

13.3.7Register Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

13.4 SERIAL PERIPHERAL INTERFACE (SPI) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

13.4.1Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

13.4.2Main Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

13.4.3General description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

13.4.4Functional Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

3/150

3

ST72334xx-Auto, ST72314xx-Auto, ST72124Jx-Auto

13.4.5Low Power Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

13.4.6Interrupts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

13.4.7Register Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

13.5 SERIAL COMMUNICATIONS INTERFACE (SCI) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

13.5.1Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

13.5.2Main Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

13.5.3General Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

13.5.4LIN Protocol support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

13.5.5Functional Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

13.5.6Low Power Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

13.5.7Interrupts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

13.5.8Register Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

13.6 8-BIT A/D CONVERTER (ADC) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

13.6.1Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

13.6.2Main Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

13.6.3Functional Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

13.6.4Low Power Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

13.6.5Interrupts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

13.6.6Register Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

14 INSTRUCTION SET . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

14.1 ST7 ADDRESSING MODES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

14.1.1Inherent . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

14.1.2Immediate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

14.1.3Direct . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

14.1.4Indexed (No Offset, Short, Long) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

14.1.5Indirect (Short, Long) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

14.1.6Indirect Indexed (Short, Long) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

14.1.7Relative Mode (Direct, Indirect) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

14.2 INSTRUCTION GROUPS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

15 ELECTRICAL CHARACTERISTICS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

15.1 PARAMETER CONDITIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

15.1.1Minimum and Maximum values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

15.1.2Typical values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

15.1.3Typical curves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

15.1.4Loading capacitor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

15.1.5Pin input voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

15.2 ABSOLUTE MAXIMUM RATINGS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

15.2.1Voltage Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

15.2.2Current Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

15.2.3Thermal Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

15.3 OPERATING CONDITIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

15.3.1General Operating Conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

15.3.2Operating Conditions with Low Voltage Detector (LVD) . . . . . . . . . . . . . . . . . . . . 112

15.4 SUPPLY CURRENT CHARACTERISTICS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

15.4.1Run and Slow Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

15.4.2Wait and Slow Wait Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

15.4.3Halt and Active Halt Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

4/150

ST72334xx-Auto, ST72314xx-Auto, ST72124Jx-Auto

15.4.4Supply and Clock Managers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

15.4.5On-Chip Peripherals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

15.5 CLOCK AND TIMING CHARACTERISTICS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

15.5.1General Timings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

15.5.2External Clock Source . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

15.5.3Crystal and Ceramic Resonator Oscillators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

15.5.4RC Oscillators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

15.5.5Clock Security System (CSS) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 122

15.6 MEMORY CHARACTERISTICS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

15.6.1RAM and Hardware Registers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

15.6.2EEPROM Data Memory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

15.6.3Flash Program Memory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

15.7 EMC CHARACTERISTICS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 124

15.7.1Functional EMS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 124

15.7.2Absolute Electrical Sensitivity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125

15.7.3ESD Pin Protection Strategy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

15.8 I/O PORT PIN CHARACTERISTICS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

15.8.1General Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

15.8.2Output Driving Current . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 130

15.9 CONTROL PIN CHARACTERISTICS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 132

15.9.1Asynchronous RESET Pin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 132

15.9.2ISPSEL Pin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 134

15.10 TIMER PERIPHERAL CHARACTERISTICS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 135

15.10.1Watchdog Timer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 135

15.10.216-Bit Timer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 135

15.11 COMMUNICATION INTERFACE CHARACTERISTICS . . . . . . . . . . . . . . . . . . . . . . . . 136

15.11.1SPI - Serial Peripheral Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 136

15.11.2SCI - Serial Communications Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 138

15.12 8-BIT ADC CHARACTERISTICS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 139

16 PACKAGE CHARACTERISTICS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 141

16.1 PACKAGE MECHANICAL DATA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 141

16.2 THERMAL CHARACTERISTICS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 142

16.3 ECOPACK® . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 142

17 DEVICE CONFIGURATION AND ORDERING INFORMATION . . . . . . . . . . . . . . . . . . . . . . . 143

17.1 INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 143

17.2 OPTION BYTES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 143

17.2.1User Option Byte 0 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 143

17.2.2User Option Byte 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 143

17.3 TRANSFER OF CUSTOMER CODE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 144

17.4 DEVELOPMENT TOOLS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 146

17.4.1Suggested List of Socket Types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 147

17.5 ST7 APPLICATION NOTES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 147

18 IMPORTANT NOTES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 148

18.1 SCI BAUD RATE REGISTERS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 148

19 SUMMARY OF CHANGES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 149

5/150

ST72334xx-Auto, ST72314xx-Auto, ST72124Jx-Auto

To obtain the most recent version of this datasheet,

please check at www.st.com>products>technical literature>datasheet.

Please also pay special attention to the Section “IMPORTANT NOTES” on page 148

6/150

ST72334xx-Auto, ST72314xx-Auto, ST72124Jx-Auto

1 PREAMBLE: ST72C334-Auto VERSUS ST72E331 SPECIFICATION

New Features available on the ST72C334-Auto

■ 8 or 16K Flash/ROM with In-Situ Programming

and Readout protection

■ New ADC with a better accuracy and conversion

time

■ New configurable Clock, Reset and Supply

system

■ New power saving mode with real-time base:

Active Halt

■ Beep capability on PF1

■ New interrupt source: Clock security system

(CSS) or Main clock controller (MCC)

ST72C334-Auto I/O Configuration and Pinout

■ Same pinout as ST72E331

■ PA6 and PA7 are true open drain I/O ports

without pull-up (same as ST72E331)

■ PA3, PB3, PB4 and PF2 have no pull-up

configuration (all I/Os present on TQFP44)

■ PA5:4, PC3:2, PE7:4 and PF7:6 have high sink

capabilities (20mA on N-buffer, 2mA on P-buffer

and pull-up). On the ST72E331, all these pads

(except PA5:4) were 2mA push-pull pads

without high sink capabilities. PA4 and PA5

were 20mA true open drains.

New Memory Locations in ST72C334-Auto

■ 20h: MISCR register becomes MISCR1 register

(naming change)

■ 29h: new control/status register for the MCC

module

■ 2Bh: new control/status register for the Clock,

Reset and Supply control. This register replaces

the WDGSR register keeping the WDOGF flag

compatibility.

■ 40h: new MISCR2 register

7/150

ST72334xx-Auto, ST72314xx-Auto, ST72124Jx-Auto

2 INTRODUCTION

The ST72334J/N-Auto, ST72314J/N-Auto and

ST72124J-Auto devices are members of the ST7

microcontroller family. They can be grouped as fol

lows:

– ST72334J/N-Auto devices are designed for mid-

range applications with Data EEPROM, ADC,

SPI and SCI interface capabilities.

– ST72314J/N-Auto devices target the same

range of applications but without Data EEPROM.

– ST72124J-Auto devices are for applications that

do not need Data EEPROM and the ADC periph

eral.

All devices are based on a common industrystandard 8-bit core, featuring an enhanced instruc

tion set.

The ST72C334J/N-Auto, ST72C314J/N-Auto and

ST72C124J-Auto versions feature single-voltage

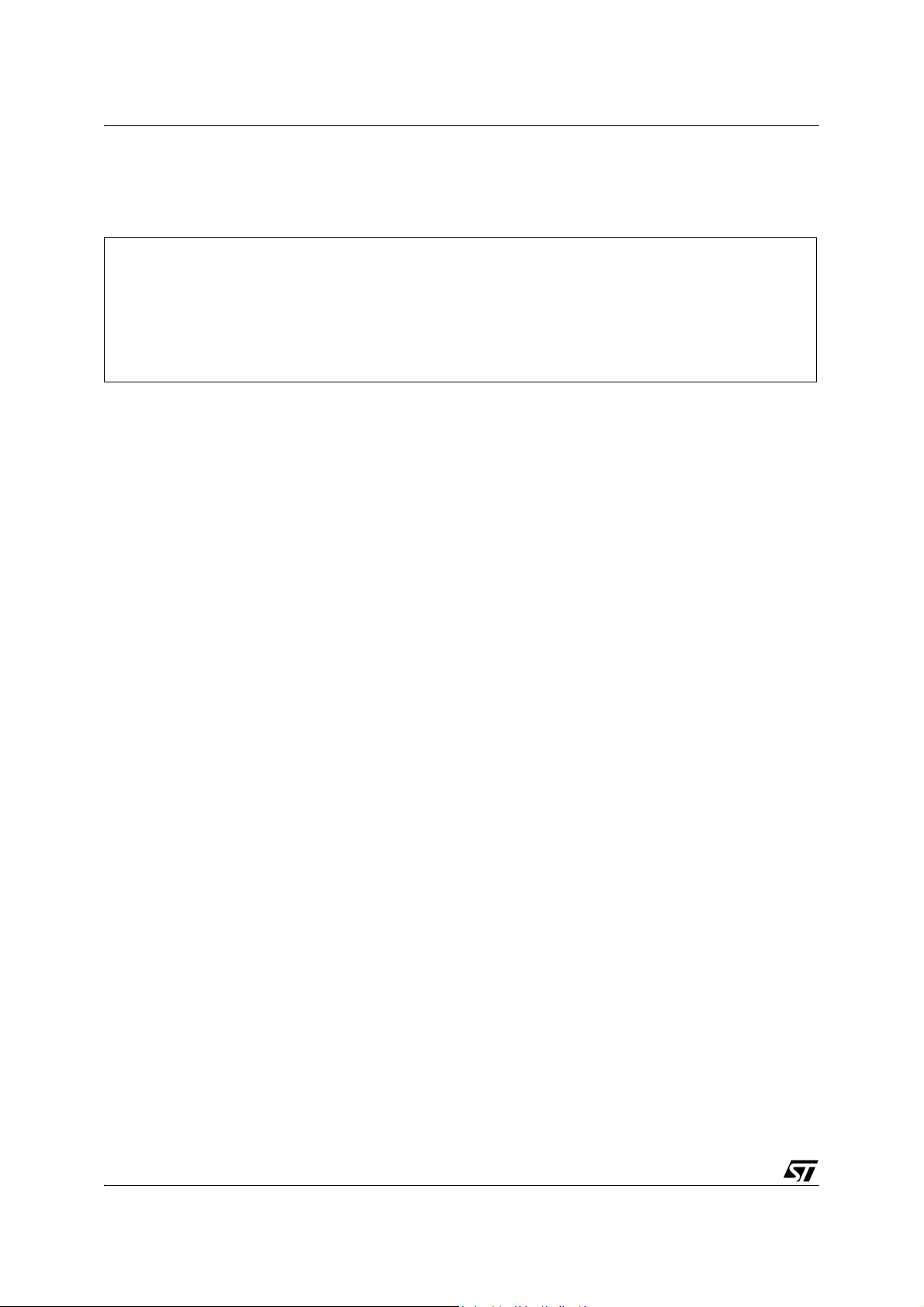

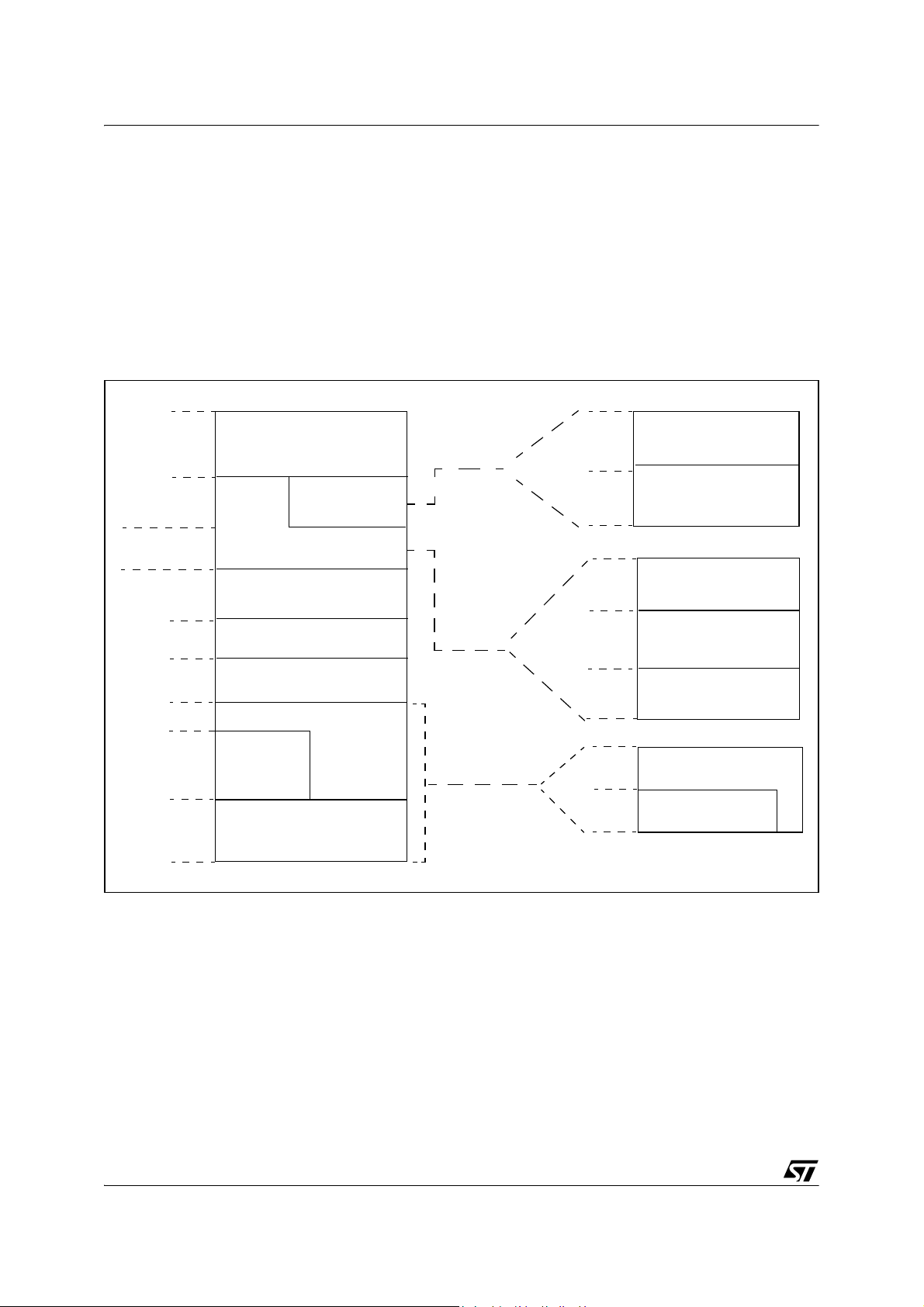

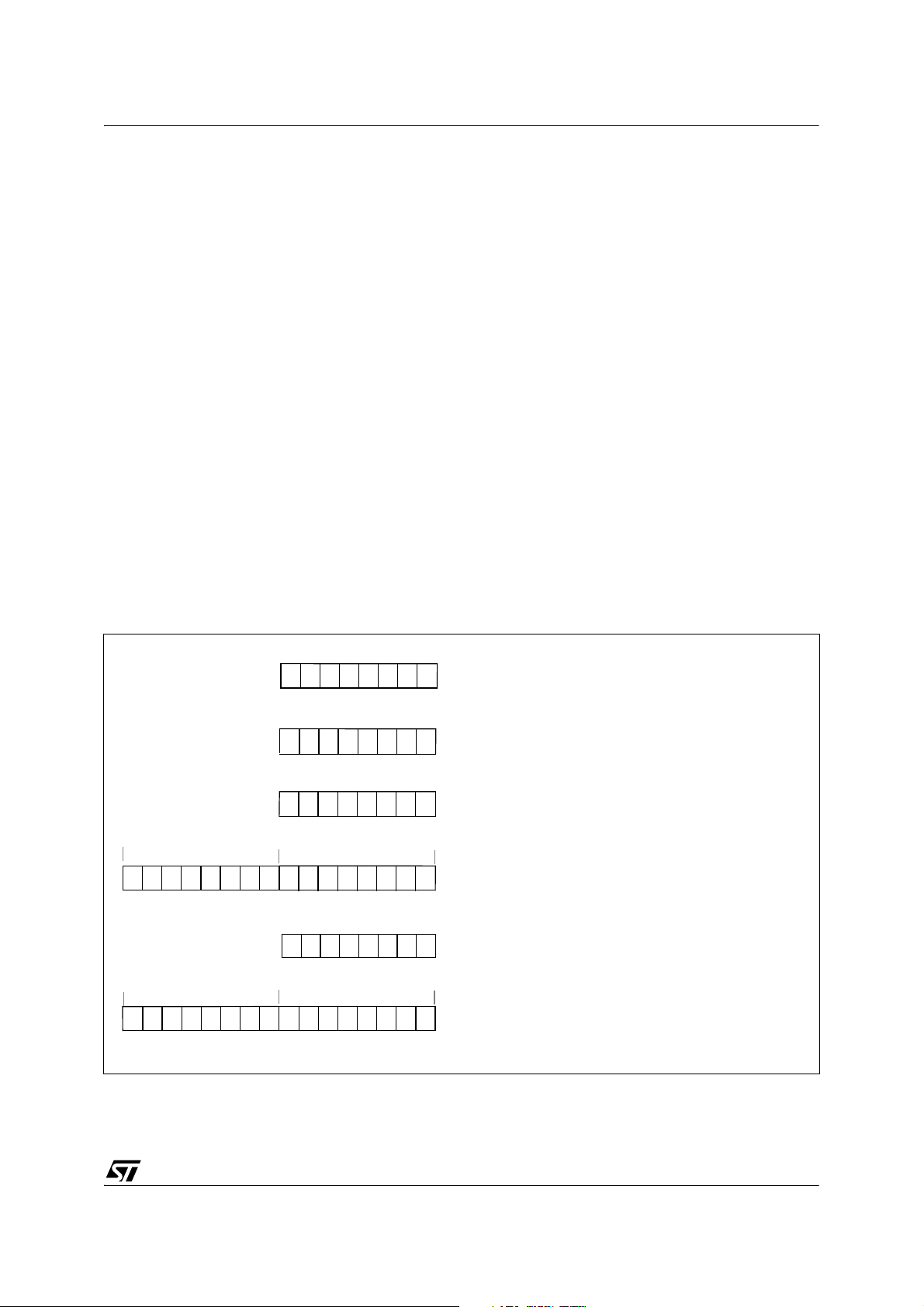

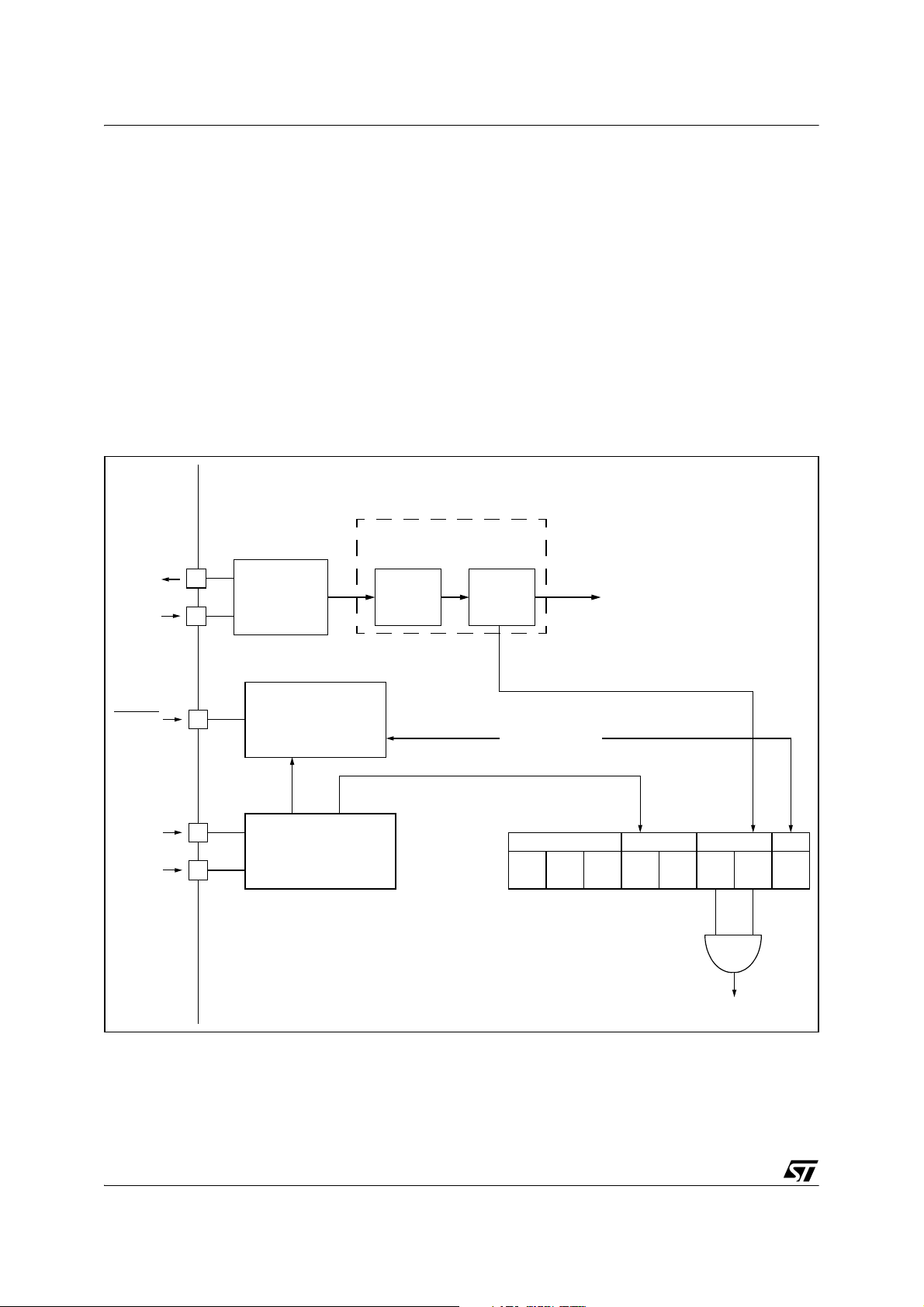

Figure 1. General Block Diagram

8-bit CORE

ALU

RESET

ISPSEL

V

DD

V

SS

CONTROL

LVD

-

-

-

Flash memory with byte-by-byte In-Situ Program

-

ming (ISP) capability.

Under software control, all devices can be placed

in Wait, Slow, Active Halt or Halt mode, reducing

power consumption when the application is in idle

or standby state.

The enhanced instruction set and addressing

modes of the ST7 offer both power and flexibility to

software developers, enabling the design of highly

efficient and compact application code. In addition

to standard 8-bit data management, all ST7 micro

controllers feature true bit manipulation, 8x8 unsigned multiplication and indirect addressing

modes.

For easy reference, all parametric data is located

Section 15 on page 108.

in

PROGRAM

MEMORY

(8 or 16 Kbytes)

RAM

(384 or 512 bytes)

OSC1

OSC2

PF7,6,4,2:0

(6-bit)

PE7:0

(6-bit for N versions)

(2-bit for J versions)

8/150

MULTI-OSC

+

CLOCK FILTER

MCC/RTC

PORT F

TIMER A

BEEP

PORT E

SCI

WATCHDOG

EEPROM

ADDRESS AND DATA BUS

(256 bytes)

PORT A

PORT B

PORT C

TIMER B

SPI

PORT D

8-bit ADC

PA7:0

(8-bit for N versions)

(5-bit for J versions)

PB7:0

(8-bit for N versions)

(5-bit for J versions)

PC7:0

(8-bit)

PD7:0

(8-bit for N versions)

(6-bit for J versions)

V

DDA

V

SSA

ST72334xx-Auto, ST72314xx-Auto, ST72124Jx-Auto

3 PIN DESCRIPTION

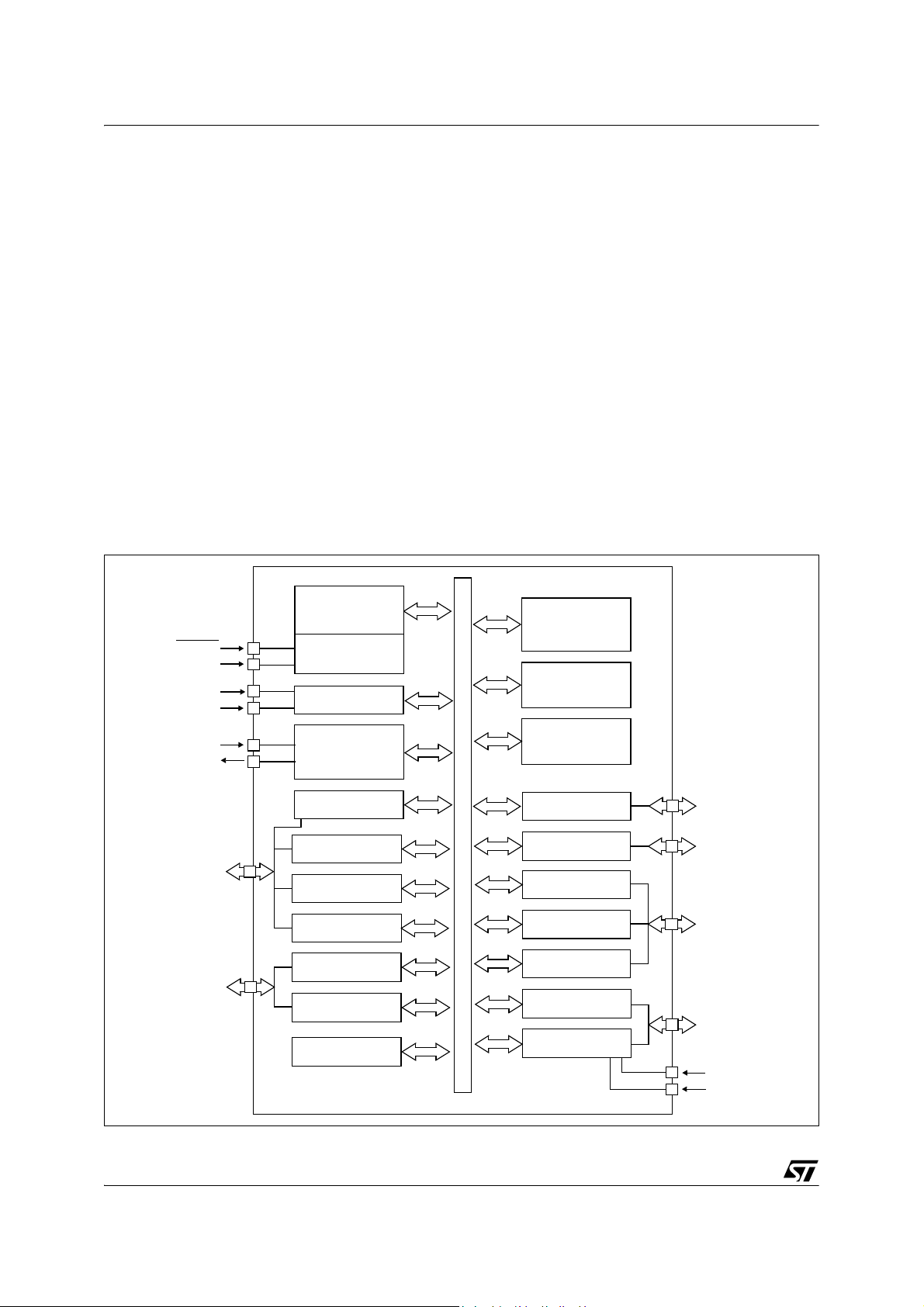

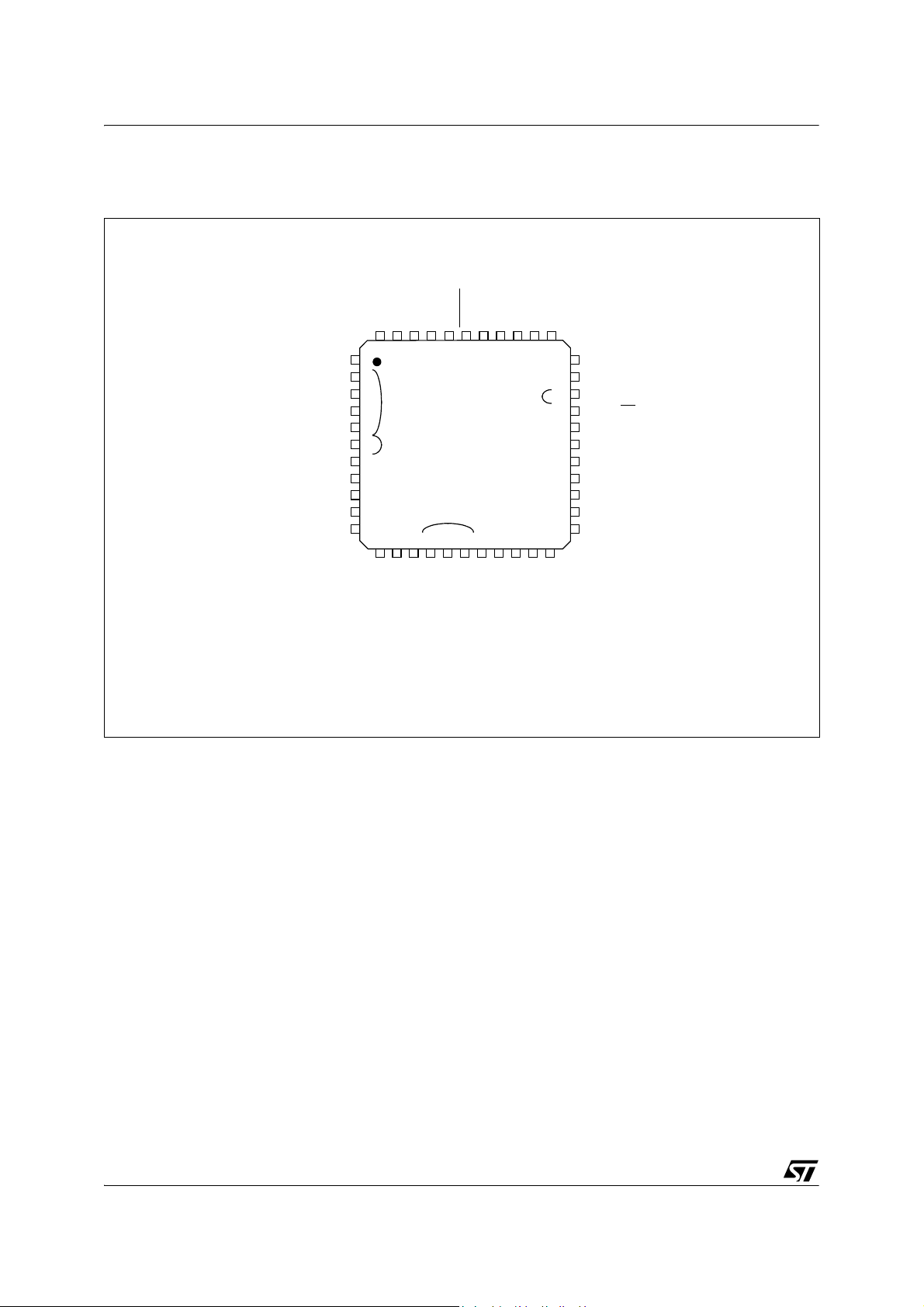

Figure 2. 64-Pin TQFP Package Pinout (N versions)

(HS) PE4

(HS) PE5

(HS) PE6

(HS) PE7

PB0

PB1

PB2

PB3

PB4

PB5

PB6

PB7

AIN0 / PD0

AIN1 / PD1

AIN2 / PD2

AIN3 / PD3

_2

DD

NCNCPE1 / RDI

64 63 62 61 60 59 58 57 56 55 54 53 52 51 50 49

1

V

PE0 / TDO

_2

SS

OSC1

OSC2

V

NCNCRESET

ISPSEL PA7 (HS)

PA6 (HS)

2

3

4

5

6

ei2

7

ei0

8

9

10

ei3

11

12

13

14

DD_3

V

ei1

SS_3

V

MCO / PF0

PF2

BEEP / PF1

NC

NC

15

16

17 18 19 20 21 22 23 24 29 30 31 3225 26 27 28

SSA

DDA

V

V

AIN4 / PD4

AIN5 / PD5

AIN6 / PD6

AIN7 / PD7

OCMP1_A / PF4

PA5 (HS)

46

45

44

43

ICAP1_A / (HS) PF6

PA4 (HS)

V

48

SS_1

V

47

DD_1

PA3

PA2

PA1

PA0

PC7 / SS

42

PC6 / SCK / ISPCLK

41

PC5 / MOSI

40

PC4 / MISO / ISPDATA

39

PC3 (HS) / ICAP1_B

38

PC2 (HS) / ICAP2_B

37

PC1 / OCMP1_B

36

PC0 / OCMP2_B

35

V

34

SS_0

V

33

DD_0

EXTCLK_A / (HS) PF7

(HS) 20mA high sink capability

associated external interrupt vector

ei

x

9/150

ST72334xx-Auto, ST72314xx-Auto, ST72124Jx-Auto

PIN DESCRIPTION (Cont’d)

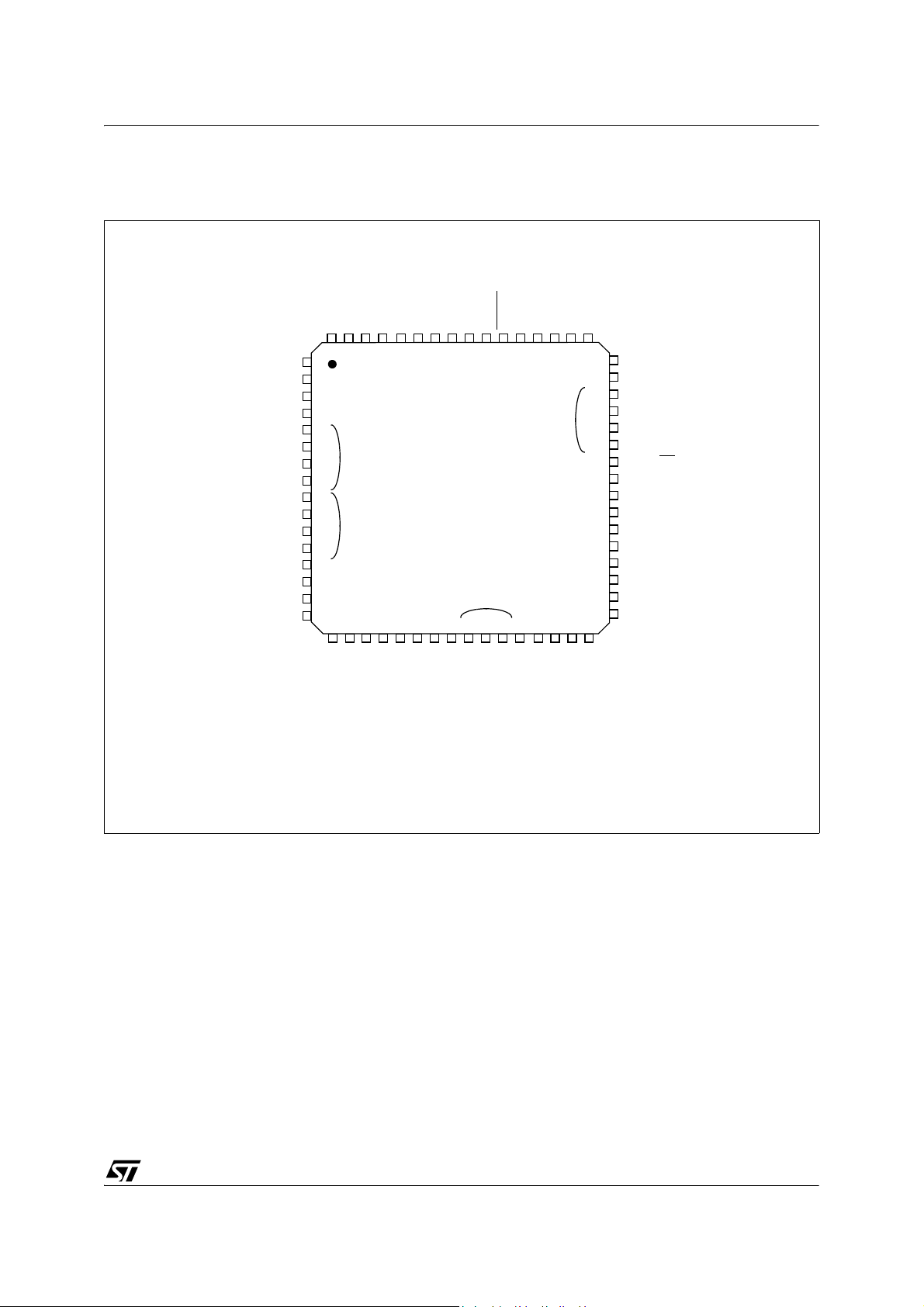

Figure 3. 44-Pin TQFP Package Pinout (J versions)

PE1 / RDI

PB0

PB1

PB2

PB3

PB4

AIN0 / PD0

AIN1 / PD1

AIN2 / PD2

AIN3 / PD3

AIN4 / PD4

_2

DD

PE0 / TDO

V

44 43 42 41 40 39 38 37 36 35 34

1

_2

SS

V

RESET

ISPSEL PA7 (HS)

OSC1

OSC2

PA6 (HS)

2

3

ei2

4

ei0

5

ei3

6

7

8

9

DDA

V

ei1

19 20 21 22

SSA

V

PF2

MCO / PF0

BEEP / PF1

10

11

12 13 14 15 16 17 18

AIN5 / PD5

OCMP1_A / PF4

ICAP1_A / (HS) PF6

EXTCLK_A / (HS) PF7

PA5 (HS)

DD_0

V

PA4 (HS)

V

33

SS_1

V

32

DD_1

PA3

31

PC7 / SS

30

PC6 / SCK / ISPCLK

29

PC5 / MOSI

28

PC4 / MISO / ISPDATA

27

PC3 (HS) / ICAP1_B

26

PC2 (HS) / ICAP2_B

25

PC1 / OCMP1_B

24

PC0 / OCMP2_B

23

SS_0

V

(HS) 20mA high sink capability

eixassociated external interrupt vector

10/150

ST72334xx-Auto, ST72314xx-Auto, ST72124Jx-Auto

PIN DESCRIPTION (Cont’d)

For external pin connection guidelines, refer to Section 15 "ELECTRICAL CHARACTERISTICS" on page

108.

Legend / Abbreviations for Table 1:

Type: I = input, O = output, S = supply

Input level: A = Dedicated analog input

In/Output level: C = CMOS 0.3VDD/0.7VDD,

CT= CMOS 0.3VDD/0.7VDD with input trigger

Output level: HS = 20mA high sink (on N-buffer only)

Port and control configuration:

– Input: float = floating, wpu = weak pull-up, int = interrupt

– Output: OD = open drain

2)

, PP = push-pull

Refer to Section 11 "I/O PORTS" on page 40 for more details on the software configuration of the I/O

ports.

The RESET configuration of each pin is shown in bold. This configuration is valid as long as the device is

in reset state.

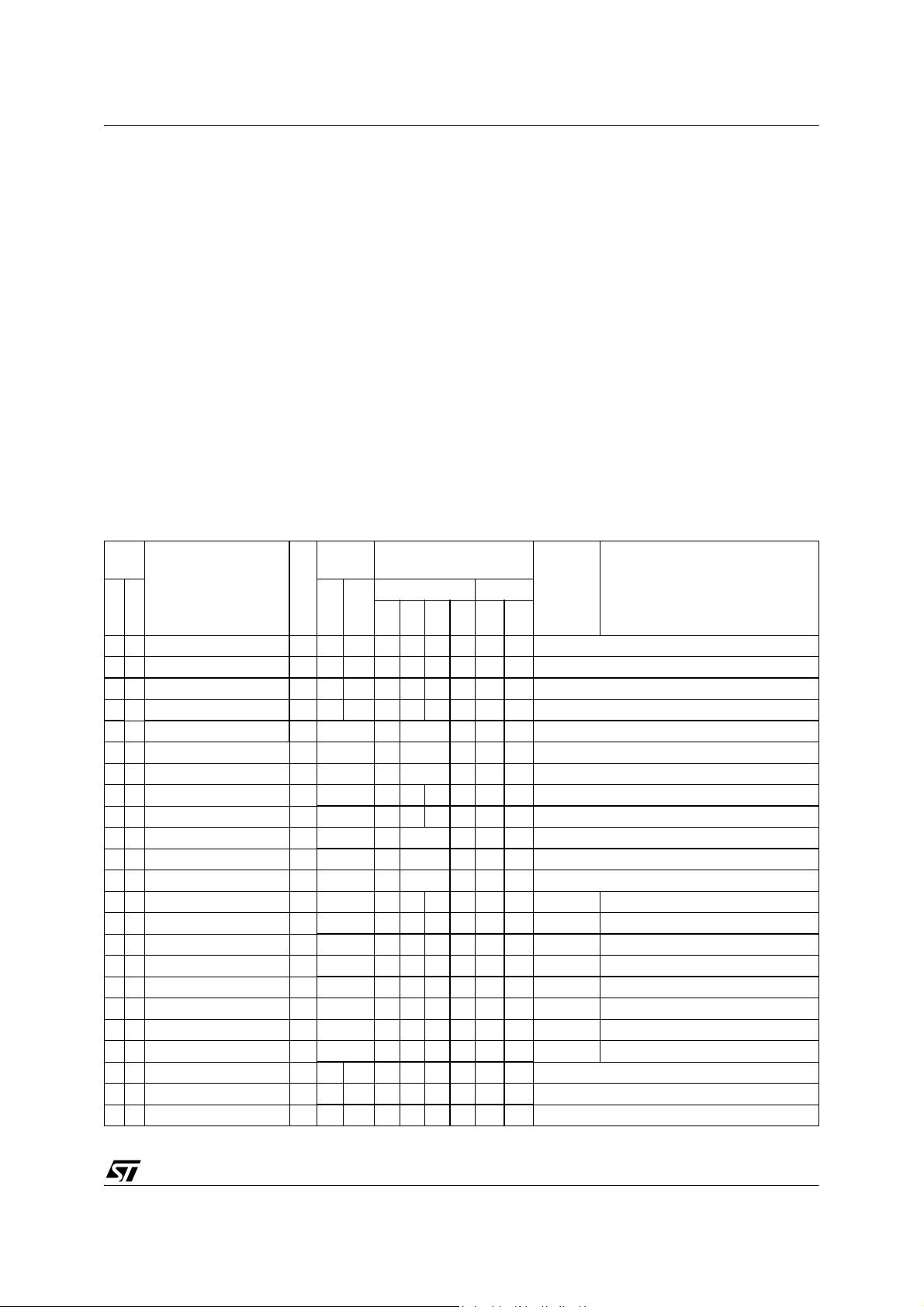

Table 1. Device Pin Description

1)

, ana = analog

Pin

No.

TQFP64

Pin Name

TQFP44

Level Port

Type

Input

Input Output

Output

float

Main

function

(after

int

wpu

ana

OD

PP

reset)

1 - PE4 (HS) I/O CTHS X X X X Port E4

2 - PE5 (HS) I/O CTHS X X X X Port E5

3 - PE6 (HS) I/O CTHS X X X X Port E6

4 - PE7 (HS) I/O CTHS X X X X Port E7

5 2 PB0 I/O C

6 3 PB1 I/O C

7 4 PB2 I/O C

8 5 PB3 I/O C

9 6 PB4 I/O C

10 - PB5 I/O C

11 - PB6 I/O C

12 - PB7 I/O C

13 7 PD0/AIN0 I/O C

14 8 PD1/AIN1 I/O C

15 9 PD2/AIN2 I/O C

16 10 PD3/AIN3 I/O C

17 11 PD4/AIN4 I/O C

18 12 PD5/AIN5 I/O C

19 - PD6/AIN6 I/O C

20 - PD7/AIN7 I/O C

21 13 V

22 14 V

23 - V

DDA

SSA

DD_3

S Analog Power Supply Voltage

S Analog Ground Voltage

S Digital Main Supply Voltage

X ei2 X X Port B0

T

X ei2 X X Port B1

T

X ei2 X X Port B2

T

X ei2 X X Port B3

T

X ei3 X X Port B4

T

X ei3 X X Port B5

T

X ei3 X X Port B6

T

X ei3 X X Port B7

T

X X X X X Port D0 ADC Analog Input 0

T

X X X X X Port D1 ADC Analog Input 1

T

X X X X X Port D2 ADC Analog Input 2

T

X X X X X Port D3 ADC Analog Input 3

T

X X X X X Port D4 ADC Analog Input 4

T

X X X X X Port D5 ADC Analog Input 5

T

X X X X X Port D6 ADC Analog Input 6

T

X X X X X Port D7 ADC Analog Input 7

T

Alternate function

11/150

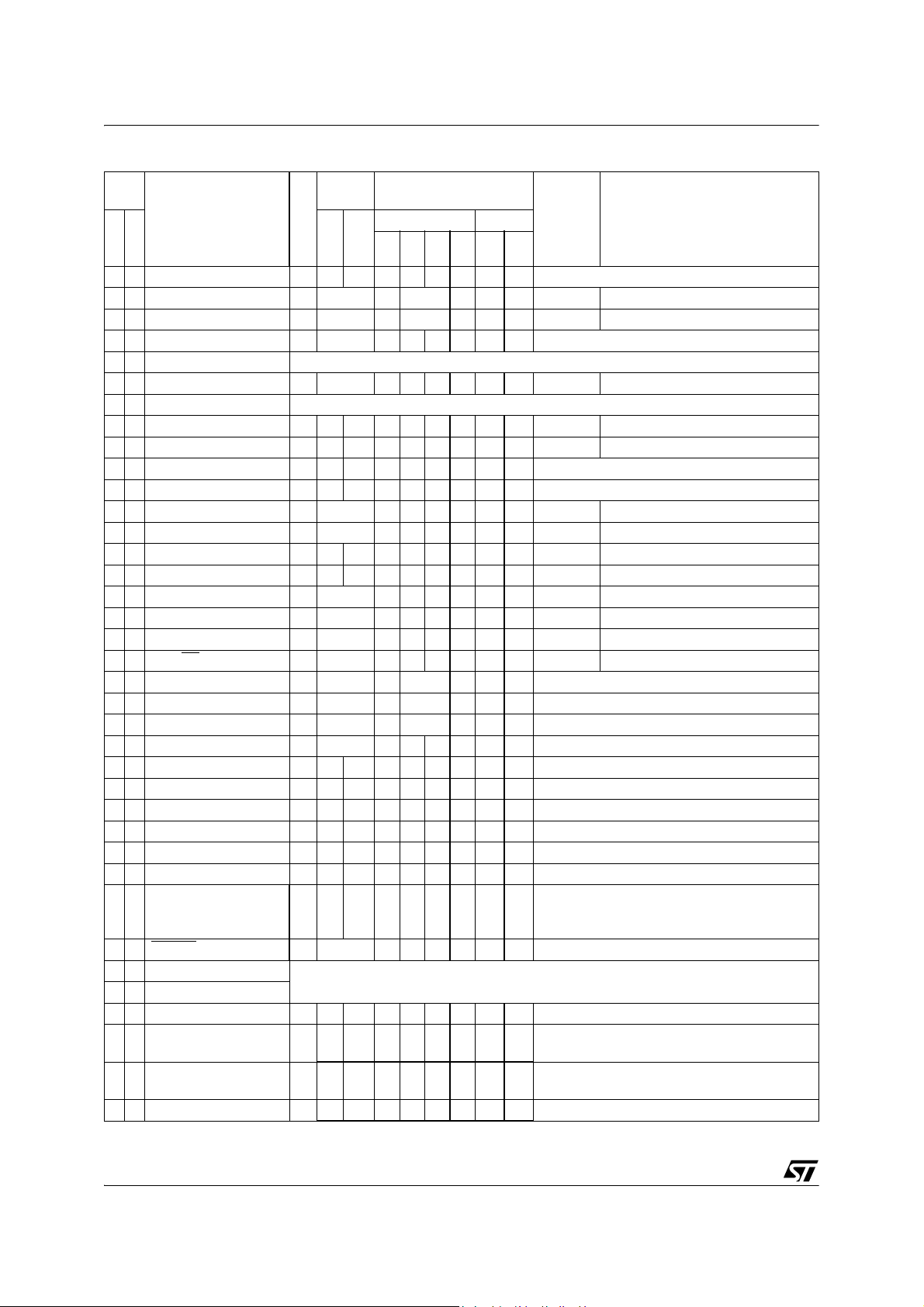

ST72334xx-Auto, ST72314xx-Auto, ST72124Jx-Auto

Pin

No.

Pin Name

TQFP64

TQFP44

24 - V

SS_3

25 15 PF0/MCO I/O C

26 16 PF1/BEEP I/O C

27 17 PF2 I/O C

Level Port

Type

Input

Input Output

Output

float

int

wpu

ana

OD

function

PP

Main

(after

reset)

Alternate function

S Digital Ground Voltage

X ei1 X X Port F0 Main clock output (f

T

X ei1 X X Port F1 Beep signal output

T

X ei1 X X Port F2

T

OSC

/2)

28 - NC Not Connected

29 18 PF4/OCMP1_A I/O C

X X X X Port F4 Timer A Output Compare 1

T

30 - NC Not Connected

31 19 PF6 (HS)/ICAP1_A I/O CTHS X X X X Port F6 Timer A Input Capture 1

32 20 PF7 (HS)/EXTCLK_A I/O CTHS X X X X Port F7 Timer A External Clock Source

33 21 V

34 22 V

DD_0

SS_0

35 23 PC0/OCMP2_B I/O C

36 24 PC1/OCMP1_B I/O C

S Digital Main Supply Voltage

S Digital Ground Voltage

X X X X Port C0 Timer B Output Compare 2

T

X X X X Port C1 Timer B Output Compare 1

T

37 25 PC2 (HS)/ICAP2_B I/O CTHS X X X X Port C2 Timer B Input Capture 2

38 26 PC3 (HS)/ICAP1_B I/O CTHS X X X X Port C3 Timer B Input Capture 1

39 27 PC4/MISO I/O C

40 28 PC5/MOSI I/O C

41 29 PC6/SCK I/O C

42 30 PC7/SS I/O C

43 - PA0 I/O C

44 - PA1 I/O C

45 - PA2 I/O C

46 31 PA3 I/O C

47 32 V

48 33 V

DD_1

SS_1

S Digital Main Supply Voltage

S Digital Ground Voltage

X X X X Port C4 SPI Master In / Slave Out Data

T

X X X X Port C5 SPI Master Out / Slave In Data

T

X X X X Port C6 SPI Serial Clock

T

X X X X Port C7 SPI Slave Select (active low)

T

X ei0 X X Port A0

T

X ei0 X X Port A1

T

X ei0 X X Port A2

T

X ei0 X X Port A3

T

49 34 PA4 (HS) I/O CTHS X X X X Port A4

50 35 PA5 (HS) I/O CTHS X X X X Port A5

51 36 PA6 (HS) I/O CTHS X T Port A6

52 37 PA7 (HS) I/O CTHS X T Port A7

Must be tied low in user mode. In programming

53 38 ISPSEL I

mode when available, this pin acts as In-Situ

Programming mode selection.

54 39 RESET I/O C X X Top priority non maskable interrupt (active low)

55 - NC

56 - NC

57 40 V

SS_3

58 41 OSC2

59 42 OSC1

60 43 V

DD_3

S Digital Ground Voltage

3)

3)

O

I

S Digital Main Supply Voltage

Not Connected

Resonator oscillator inverter output or capacitor input for RC oscillator

External clock input or Resonator oscillator inverter input or resistor input for RC oscillator

12/150

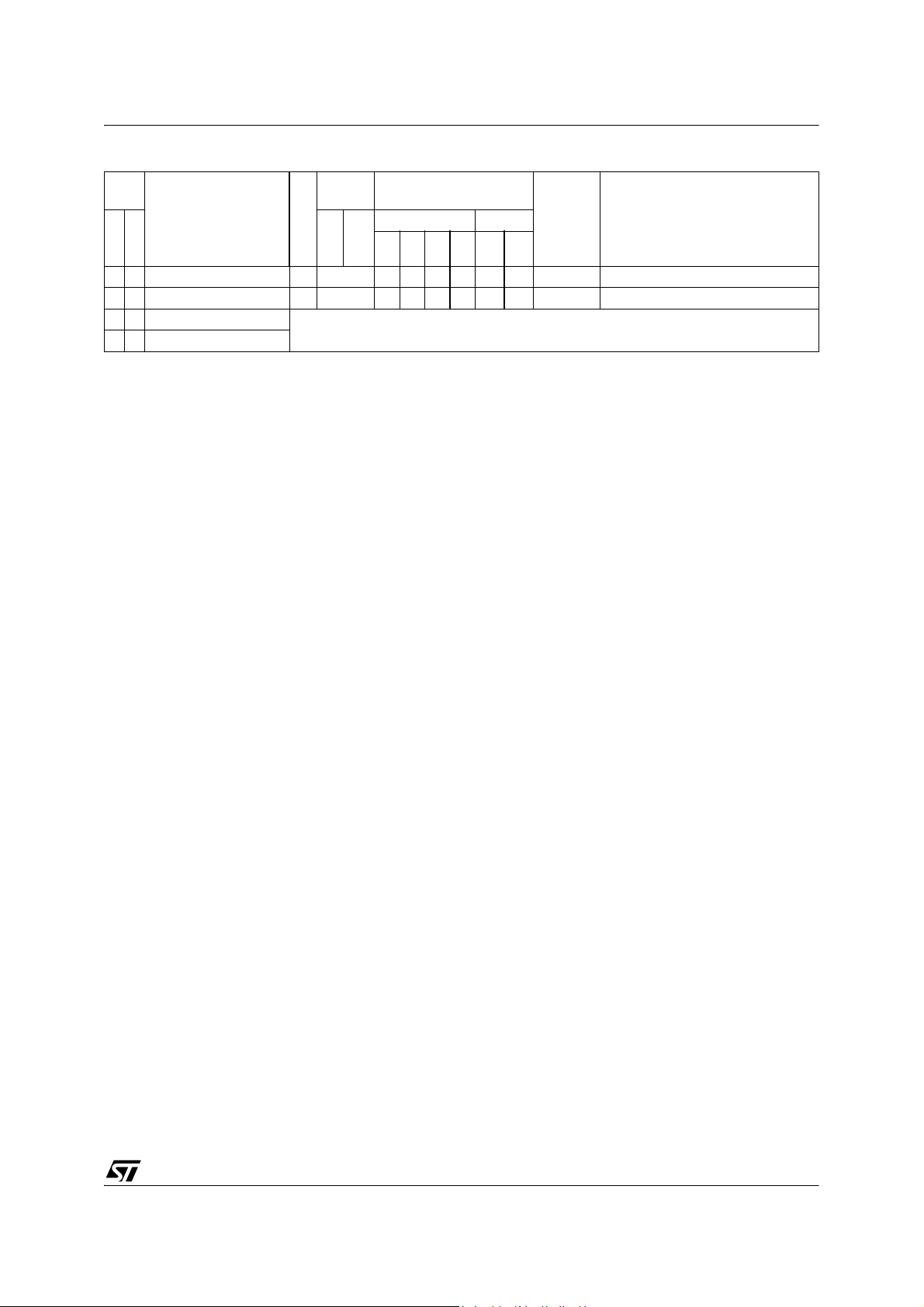

ST72334xx-Auto, ST72314xx-Auto, ST72124Jx-Auto

Pin

No.

Pin Name

TQFP64

TQFP44

61 44 PE0/TDO I/O C

62 1 PE1/RDI I/O C

63 - NC

64 - NC

Level Port

Type

Input

T

T

Input Output

Output

float

X X X X Port E0 SCI Transmit Data Out

X X X X Port E1 SCI Receive Data In

Main

function

(after

int

wpu

ana

OD

reset)

PP

Not Connected

Alternate function

Notes:

1. In the interrupt input column, “eix” defines the associated external interrupt vector. If the weak pull-up

column (wpu) is merged with the interrupt column (int), then the I/O configuration is pull-up interrupt input,

else the configuration is floating interrupt input.

2. In the open drain output column, “T” defines a true open drain I/O (P-Buffer and protection diode to V

are not implemented). See Section 11 "I/O PORTS" on page 40 and Section 15.8 "I/O PORT PIN CHAR-

DD

ACTERISTICS" on page 129 for more details.

3. OSC1 and OSC2 pins connect a crystal or ceramic resonator, an external RC, or an external source to

the on-chip oscillator see

Section 3 "PIN DESCRIPTION" on page 9 and Section 15.5 "CLOCK AND TIM-

ING CHARACTERISTICS" on page 117 for more details.

13/150

ST72334xx-Auto, ST72314xx-Auto, ST72124Jx-Auto

4 REGISTER AND MEMORY MAP

As shown in the Figure 4, the MCU is capable of

addressing 64 Kbytes of memories and I/O registers.

The available memory locations consist of 128

bytes of register locations, 384 or 512 bytes of

RAM, up to 256 bytes of data EEPROM and 4 or

Kbytes of user program memory. The RAM

8

Figure 4. Memory Map

0000h

007Fh

0080h

01FFh

027Fh

0200h / 0280h

0BFFh

0C00h

0CFFh

0D00h

BFFFh

C000h

E000h

FFDFh

FFE0h

FFFFh

HW Registers

(see Table 2)

384 bytes RAM

512 bytes RAM

Reserved

256 bytes Data EEPROM

Reserved

16 Kbytes

8 Kbytes

Program

Memory

Interrupt and Reset Vectors

(see Table 6 on page 35)

Program

Memory

space includes up to 256 bytes for the stack from

0100h to 01FFh.

The highest address bytes contain the user reset

and interrupt vectors.

IMPORTANT: Memory locations marked as “Reserved” must never be accessed. Accessing a reserved area can have unpredictable effects on the

device.

0080h

00FFh

0100h

01FFh

0080h

00FFh

0100h

01FFh

0200h

027Fh

C000h

E000h

FFFFh

Short Addressing RAM

Zero page

(128 bytes)

Stack or

16-bit Addressing RAM

(256 bytes)

Short Addressing RAM

Zero page

(128 bytes)

Stack or

16-bit Addressing RAM

(256 bytes)

16-bit Addressing

RAM

16 Kbytes

8 Kbytes

14/150

REGISTER AND MEMORY MAP (Cont’d)

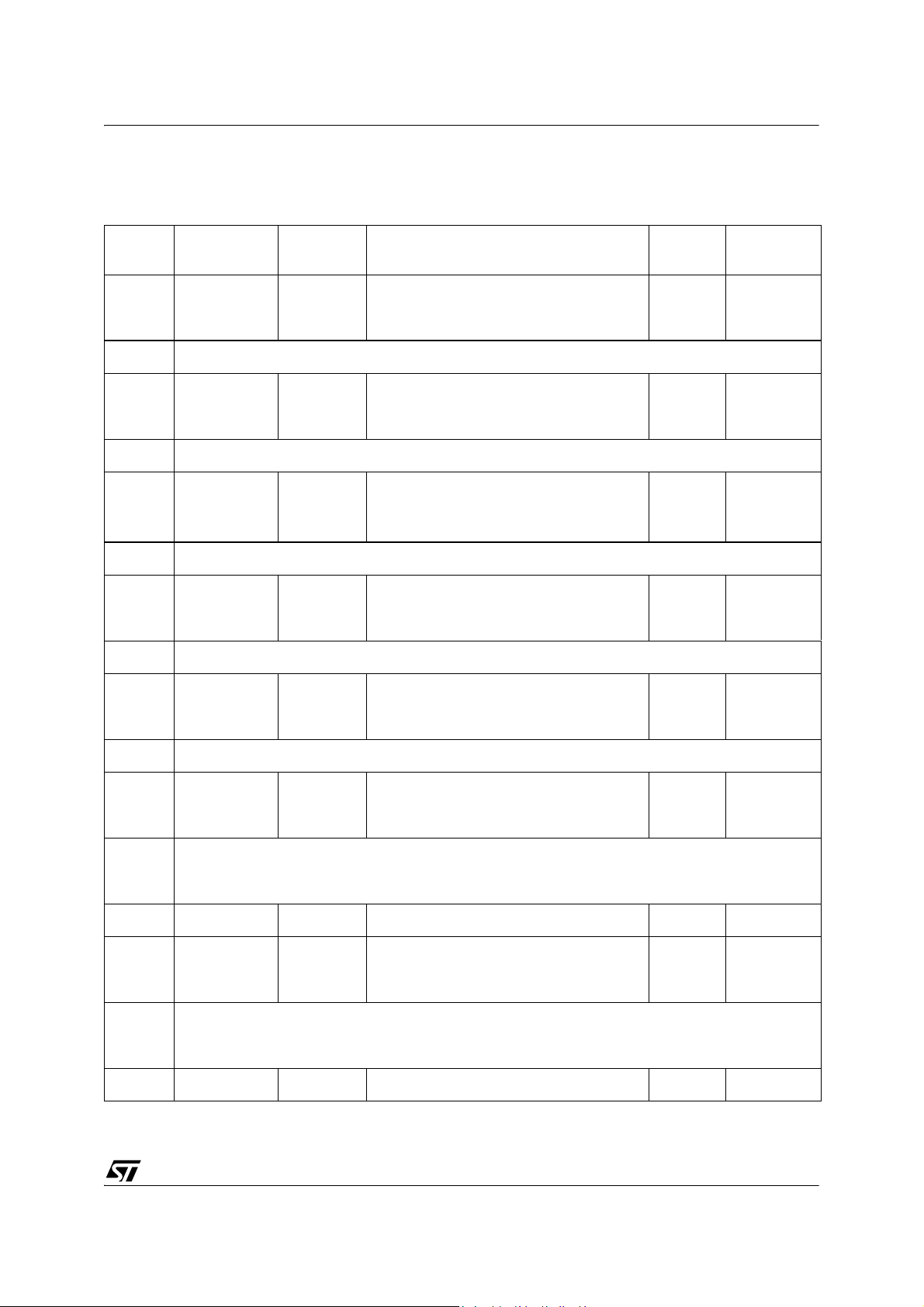

Table 2. Hardware Register Map

ST72334xx-Auto, ST72314xx-Auto, ST72124Jx-Auto

Address Block

0000h

0001h

Port A

0002h

Register

Label

PADR

PADDR

PAOR

Register Name

Port A Data Register

Port A Data Direction Register

Port A Option Register

0003h Reserved Area (1 byte)

0004h

0005h

0006h

Port C

PCDR

PCDDR

PCOR

Port C Data Register

Port C Data Direction Register

Port C Option Register

0007h Reserved Area (1 byte)

0008h

0009h

000Ah

Port B

PBDR

PBDDR

PBOR

Port B Data Register

Port B Data Direction Register

Port B Option Register

000Bh Reserved Area (1 byte)

000Ch

000Dh

000Eh

Port E

PEDR

PEDDR

PEOR

Port E Data Register

Port E Data Direction Register

Port E Option Register

000Fh Reserved Area (1 byte)

0010h

0011h

0012h

Port D

PDDR

PDDDR

PDOR

Port D Data Register

Port D Data Direction Register

Port D Option Register

Reset

Status

1)

00h

00h

00h

1)

00h

00h

00h

1)

00h

00h

00h

1)

00h

00h

00h

1)

00h

00h

00h

Remarks

R/W

R/W

2)

R/W

R/W

R/W

R/W

R/W

R/W

2)

R/W

R/W

R/W

2)

R/W

R/W

R/W

2)

R/W

0013h Reserved Area (1 byte)

0014h

0015h

0016h

Port F

PFDR

PFDDR

PFOR

Port F Data Register

Port F Data Direction Register

Port F Option Register

00h

00h

00h

1)

R/W

R/W

R/W

0017h

to

Reserved Area (9 bytes)

001Fh

0020h MISCR1 Miscellaneous Register 1 00h R/W

0021h

0022h

0023h

SPI

SPIDR

SPICR

SPISR

SPI Data I/O Register

SPI Control Register

SPI Status Register

xxh

0xh

00h

R/W

R/W

Read Only

0024h

to

Reserved Area (5 bytes)

0028h

0029h MCC MCCSR Main Clock Control / Status Register 01h R/W

15/150

ST72334xx-Auto, ST72314xx-Auto, ST72124Jx-Auto

Address Block

Register

Label

Register Name

Reset

Status

002Ah WATCHDOG WDGCR Watchdog Control Register 7Fh R/W

002Bh CRSR Clock, Reset, Supply Control / Status Register 000x 000x R/W

002Ch Data-EEPROM EECSR Data-EEPROM Control/Status Register 00h R/W

002Dh

0030h

0031h

0032h

0033h

0034h

0035h

0036h

0037h

0038h

0039h

003Ah

003Bh

003Ch

003Dh

003Eh

003Fh

TIMER A

TACR2

TACR1

TASR

TAIC1HR

TAIC1LR

TAOC1HR

TAOC1LR

TACHR

TACLR

TAACHR

TAACLR

TAIC2HR

TAIC2LR

TAOC2HR

TAOC2LR

Timer A Control Register 2

Timer A Control Register 1

Timer A Status Register

Timer A Input Capture 1 High Register

Timer A Input Capture 1 Low Register

Timer A Output Compare 1 High Register

Timer A Output Compare 1 Low Register

Timer A Counter High Register

Timer A Counter Low Register

Timer A Alternate Counter High Register

Timer A Alternate Counter Low Register

Timer A Input Capture 2 High Register

Timer A Input Capture 2 Low Register

Timer A Output Compare 2 High Register

Timer A Output Compare 2 Low Register

Reserved Area (4 bytes)

00h

00h

xxh

xxh

xxh

80h

00h

FFh

FCh

FFh

FCh

xxh

xxh

80h

00h

Remarks

R/W

R/W

Read Only

Read Only

Read Only

R/W

R/W

Read Only

Read Only

Read Only

Read Only

Read Only 3)

Read Only

R/W

R/W

3)

3)

3)

0040h MISCR2 Miscellaneous Register 2 00h R/W

0041h

0042h

0043h

0044h

0045h

0046h

0047h

0048h

0049h

004Ah

004Bh

004Ch

004Dh

004Eh

004Fh

0050h

0051h

0052h

0053h

0054h

0055h

0056h

0057h

0058h

006Fh

TIMER B

SCI

TBCR2

TBCR1

TBSR

TBIC1HR

TBIC1LR

TBOC1HR

TBOC1LR

TBCHR

TBCLR

TBACHR

TBACLR

TBIC2HR

TBIC2LR

TBOC2HR

TBOC2LR

SCISR

SCIDR

SCIBRR

SCICR1

SCICR2

SCIERPR

SCIETPR

Timer B Control Register 2

Timer B Control Register 1

Timer B Status Register

Timer B Input Capture 1 High Register

Timer B Input Capture 1 Low Register

Timer B Output Compare 1 High Register

Timer B Output Compare 1 Low Register

Timer B Counter High Register

Timer B Counter Low Register

Timer B Alternate Counter High Register

Timer B Alternate Counter Low Register

Timer B Input Capture 2 High Register

Timer B Input Capture 2 Low Register

Timer B Output Compare 2 High Register

Timer B Output Compare 2 Low Register

SCI Status Register

SCI Data Register

SCI Baud Rate Register

SCI Control Register 1

SCI Control Register 2

SCI Extended Receive Prescaler Register

Reserved area

SCI Extended Transmit Prescaler Register

Reserved Area (24 bytes)

00h

00h

xxh

xxh

xxh

80h

00h

FFh

FCh

FFh

FCh

xxh

xxh

80h

00h

C0h

xxh

00xx xxxx

xxh

00h

00h

---

00h

R/W

R/W

Read Only

Read Only

Read Only

R/W

R/W

Read Only

Read Only

Read Only

Read Only

Read Only

Read Only

R/W

R/W

Read Only

R/W

R/W

R/W

R/W

R/W

R/W

16/150

ST72334xx-Auto, ST72314xx-Auto, ST72124Jx-Auto

Address Block

0070h

0071h

0072h

to

007Fh

ADC

Register

Label

ADCDR

ADCCSR

Register Name

Data Register

Control/Status Register

Reserved Area (14 bytes)

Reset

Status

xxh

00h

Remarks

Read Only

R/W

Legend: x=undefined, R/W=read/write

Notes:

1. The contents of the I/O port DR registers are readable only in output configuration. In input configuration, the values

of the I/O pins are returned instead of the DR register contents.

2. The bits corresponding to unavailable pins are forced to 1 by hardware, affecting accordingly the reset status value.

These bits must always keep their reset value.

3. External pin not available.

17/150

ST72334xx-Auto, ST72314xx-Auto, ST72124Jx-Auto

5 FLASH PROGRAM MEMORY

5.1 INTRODUCTION

Flash devices have a single voltage non-volatile

Flash memory that may be programmed in-situ (or

plugged in a programming tool) on a byte-by-byte

basis.

5.2 MAIN FEATURES

■ Remote In-Situ Programming (ISP) mode

■ Up to 16 bytes programmed in the same cycle

■ MTP memory (Multiple Time Programmable)

■ Readout memory protection against piracy

5.3 STRUCTURAL ORGANIZATION

The Flash program memory is organized in a single 8-bit wide memory block which can be used for

storing both code and data constants.

The Flash program memory is mapped in the upper part of the ST7 addressing space and includes

the reset and interrupt user vector area.

5.4 IN-SITU PROGRAMMING (ISP) MODE

The Flash program memory can be programmed

using Remote ISP mode. This ISP mode allows

the contents of the ST7 program memory to be up

dated using a standard ST7 programming tools after the device is mounted on the application board.

This feature can be implemented with a minimum

number of added components and board area im

pact.

An example Remote ISP hardware interface to the

standard ST7 programming tool is described be

low. For more details on ISP programming, refer to

the ST7 Programming Specification.

Remote ISP Overview

The Remote ISP mode is initiated by a specific sequence on the dedicated ISPSEL pin.

The Remote ISP is performed in three steps:

– Selection of the RAM execution mode

– Download of Remote ISP code in RAM

– Execution of Remote ISP code in RAM to pro-

gram the user program into the Flash

Remote ISP hardware configuration

In Remote ISP mode, the ST7 has to be supplied

with power (V

and VSS) and a clock signal (os-

DD

cillator and application crystal circuit for example).

This mode needs five signals (plus the VDD signal

if necessary) to be connected to the programming

tool. This signals are:

– RESET: device reset

–VSS: device ground power supply

– ISPCLK: ISP output serial clock pin

– ISPDATA: ISP input serial data pin

– ISPSEL: Remote ISP mode selection. This pin

must be connected to V

board through a pull-down resistor.

on the application

SS

If any of these pins are used for other purposes on

the application, a serial resistor has to be imple

mented to avoid a conflict if the other device forces

the signal level.

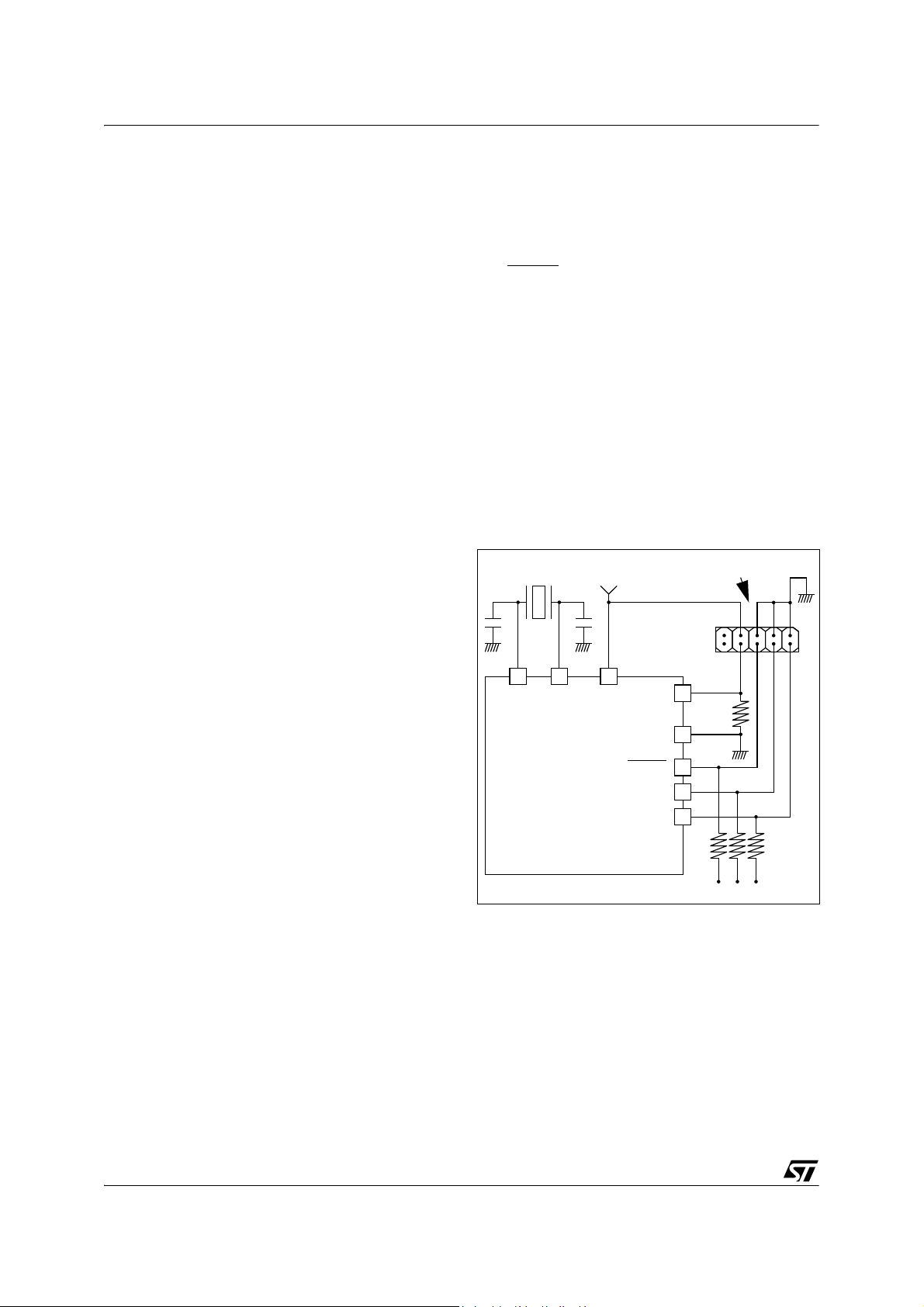

Figure 5 shows a typical hardware interface to a

standard ST7 programming tool. For more details

on the pin locations, refer to the device pinout de

scription.

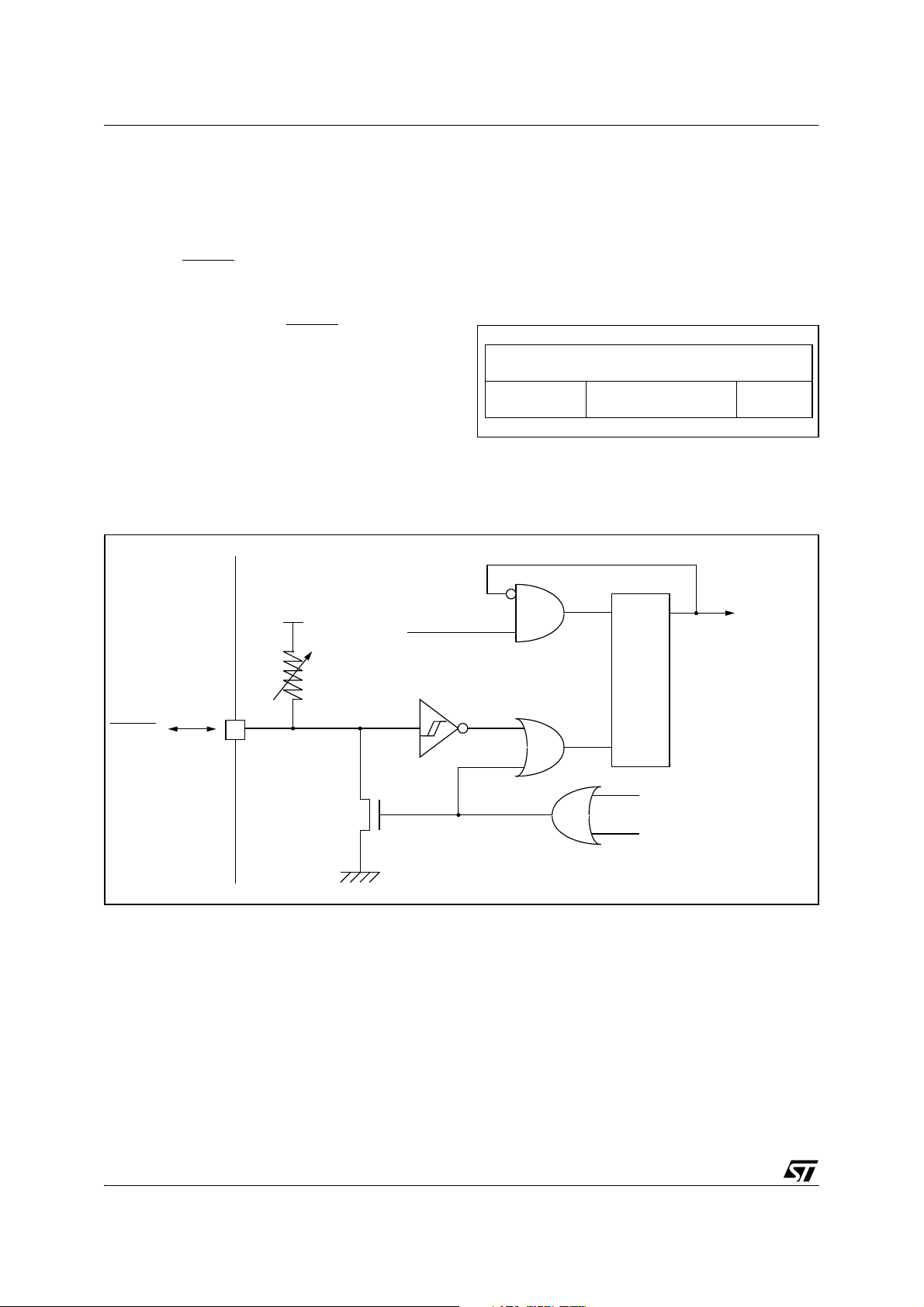

Figure 5. Typical Remote ISP Interface

HE10 CONNECTOR TYPE

XTAL

C

L0

C

L1

-

OSC1

OSC2

TO PROGRAMMING TOOL

ISPSEL

DD

V

V

10KΩ

SS

-

RESET

-

ST7

ISPCLK

ISPDATA

APPLICATION

5.5 MEMORY READOUT PROTECTION

The readout protection is enabled through an option bit.

For Flash devices, when this option is selected,

the program and data stored in the Flash memory

are protected against readout piracy (including a

re-write protection). When this protection option is

removed the entire Flash program memory is first

automatically erased. However, the EEPROM

data memory (when available) can be protected

only with ROM devices.

-

-

1

47KΩ

18/150

6 DATA EEPROM

ST72334xx-Auto, ST72314xx-Auto, ST72124Jx-Auto

6.1 INTRODUCTION

The Electrically Erasable Programmable Read

Only Memory can be used as a non-volatile backup for storing data. Using the EEPROM requires a

basic access protocol described in this chapter.

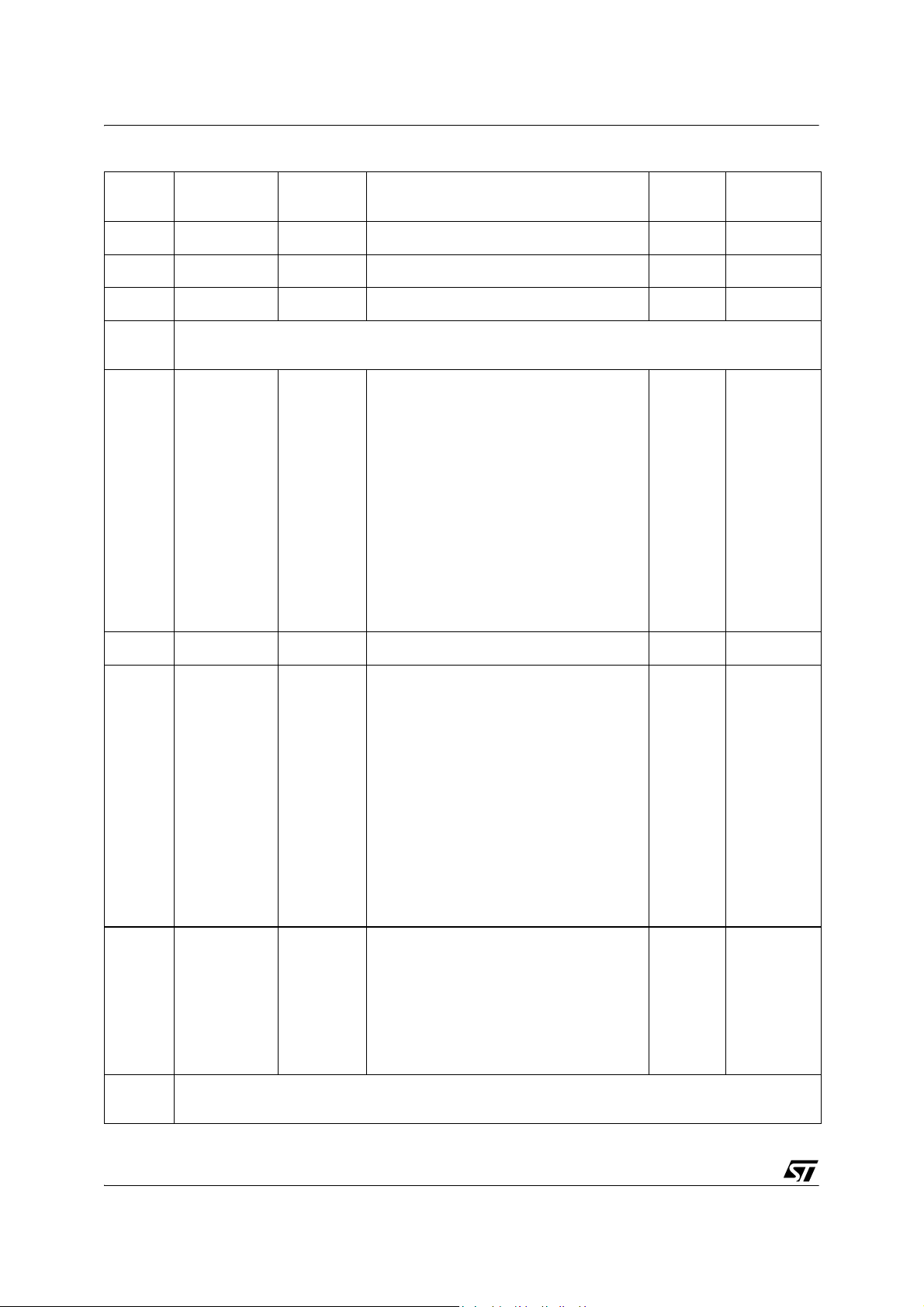

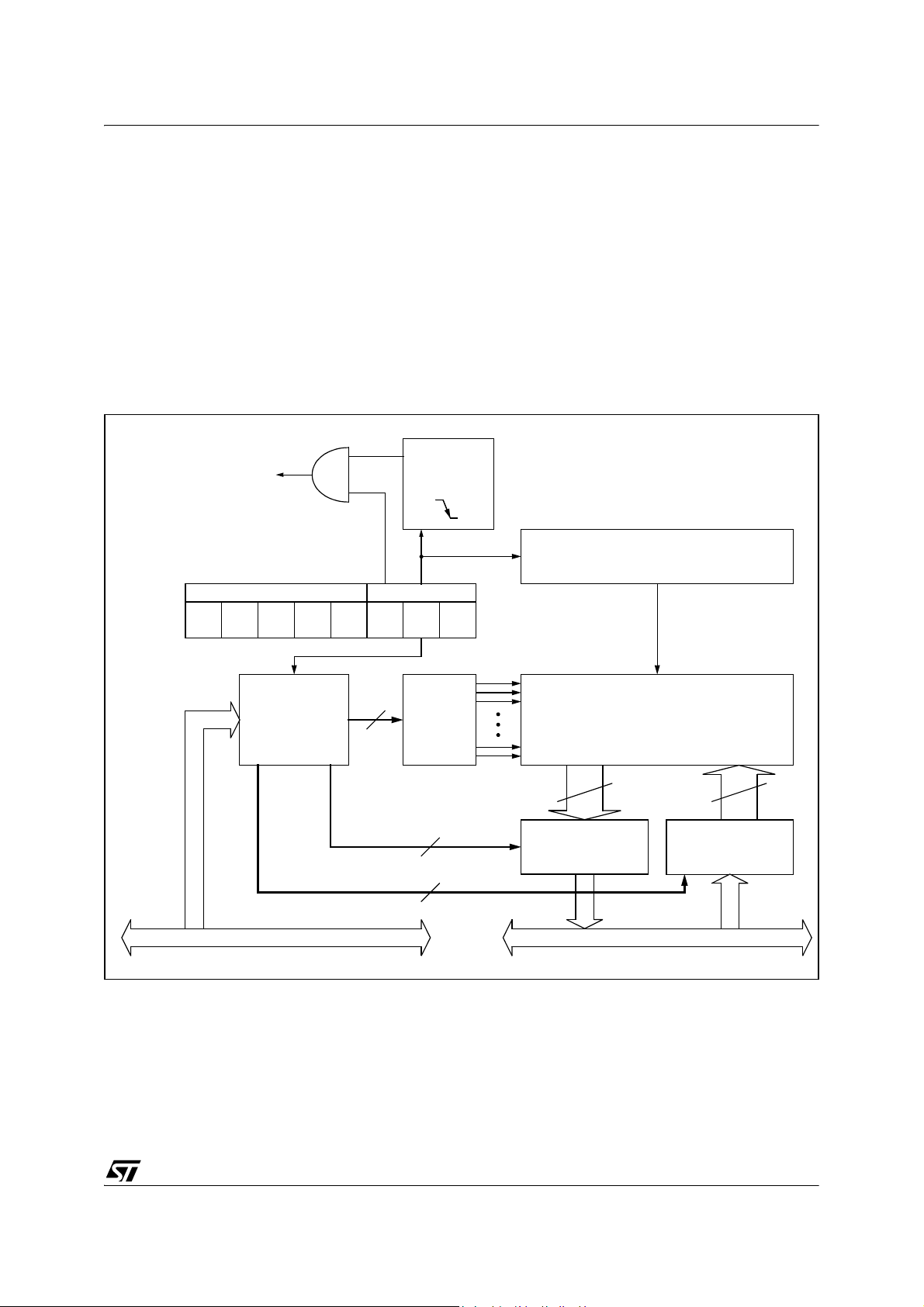

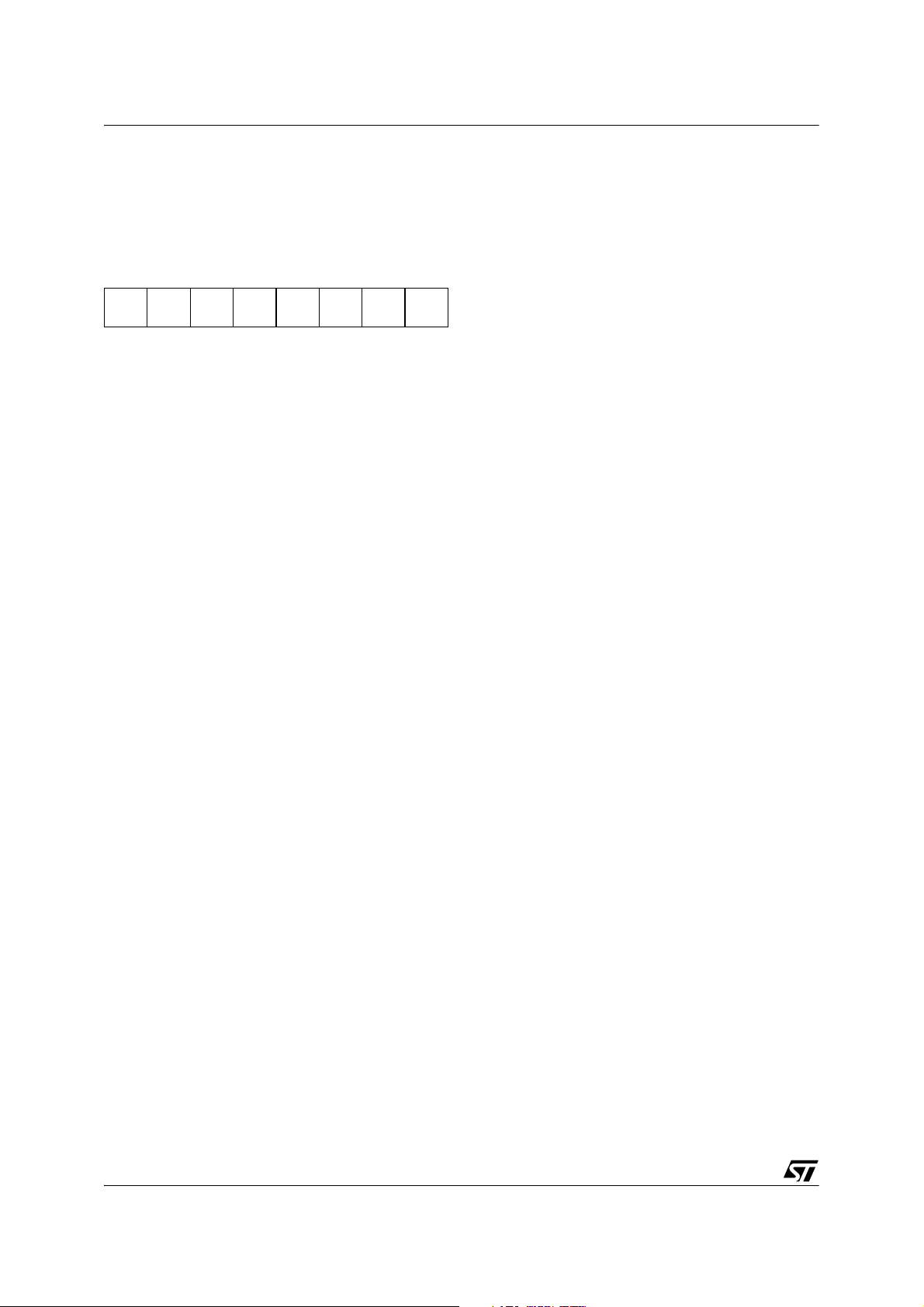

Figure 6. EEPROM Block Diagram

FALLING

EEPROM INTERRUPT

EECSR

IE LAT00 0 0 0 PGM

EDGE

DETECTOR

EEPROMRESERVED

6.2 MAIN FEATURES

■ Up to 16 bytes programmed in the same cycle

■ EEPROM mono-voltage (charge pump)

■ Chained erase and programming cycles

■ Internal control of the global programming cycle

duration

■ End of programming cycle interrupt flag

■ Wait mode management

HIGH VOLTAGE

PUMP

ADDRESS

DECODER

ADDRESS BUS

4

ROW

DECODER

4

4

MEMORY MATRIX

(1 ROW = 16 x 8 BITS)

DATA

MULTIPLEXER

EEPROM

128128

16 x 8 BITS

DATA LATCHES

DATA BUS

19/150

ST72334xx-Auto, ST72314xx-Auto, ST72124Jx-Auto

DATA EEPROM (Cont’d)

6.3 MEMORY ACCESS

The Data EEPROM memory read/write access

modes are controlled by the LAT bit of the EEP

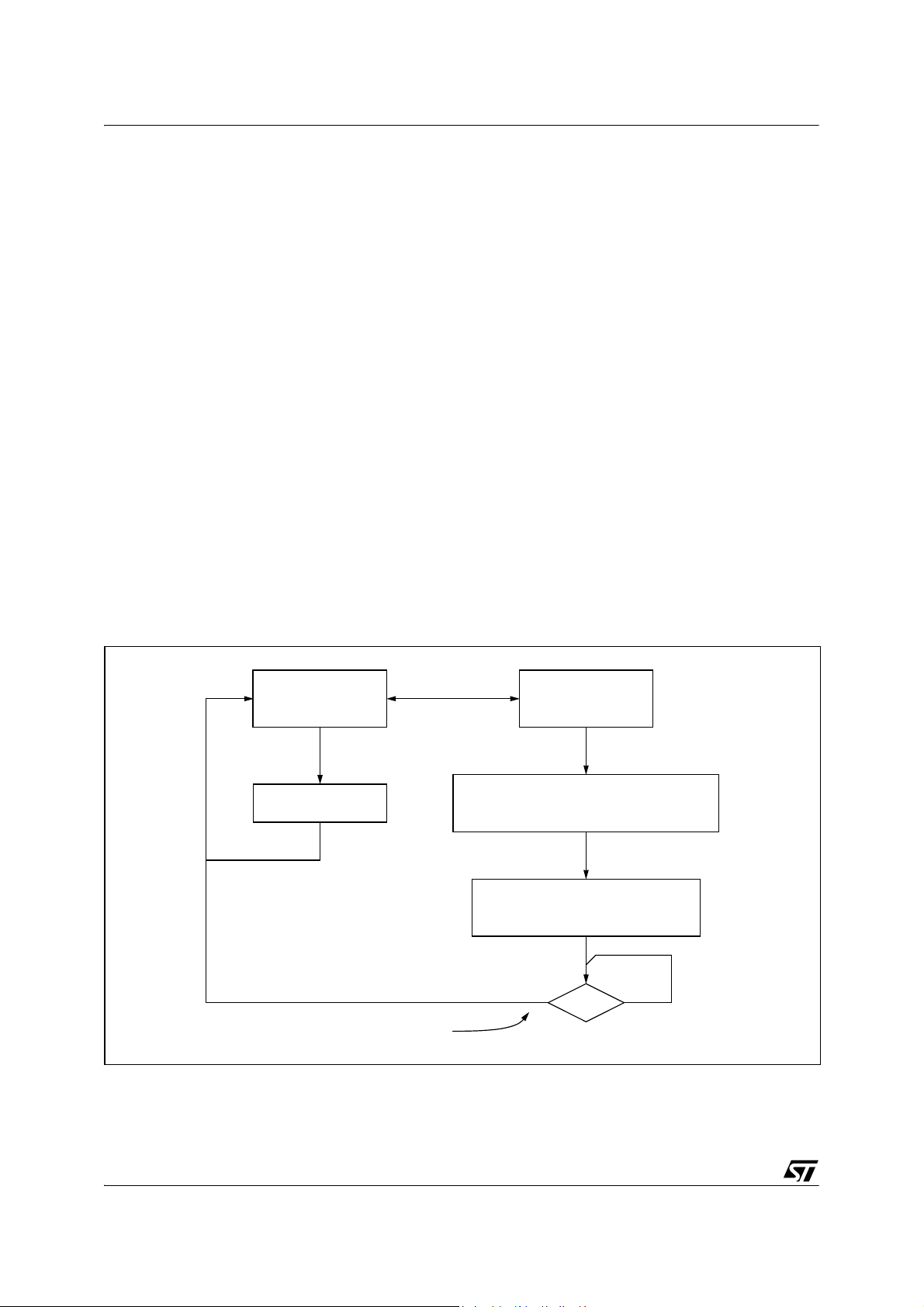

ROM Control/Status register (EECSR). The flowchart in Figure 7 describes these different memory

access modes.

Read Operation (LAT=0)

The EEPROM can be read as a normal ROM location when the LAT bit of the EECSR register is

cleared. In a read cycle, the byte to be accessed is

put on the data bus in less than 1 CPU clock cycle.

This means that reading data from EEPROM

takes the same time as reading data from

EPROM, but this memory cannot be used to exe

cute machine code.

Write Operation (LAT=1)

To access the write mode, the LAT bit has to be

set by software (the PGM bit remains cleared).

When a write access to the EEPROM area occurs,

the value is latched inside the 16 data latches ac

cording to its address.

Figure 7. Data EEPROM Programming Flowchart

When PGM bit is set by the software, all the previous bytes written in the data latches (up to 16) are

programmed in the EEPROM cells. The effective

high address (row) is determined by the last EEP

ROM write sequence. To avoid wrong programming, the user must take care that all the bytes

written between two programming sequences

have the same high address: only the four Least

Significant Bits of the address can change.

At the end of the programming cycle, the PGM and

LAT bits are cleared simultaneously, and an inter

rupt is generated if the IE bit is set. The Data EEPROM interrupt request is cleared by hardware

when the Data EEPROM interrupt vector is

fetched.

Note: Care should be taken during the programming cycle. Writing to the same memory location

will over-program the memory (logical AND be

tween the two write access data result) because

the data latches are only cleared at the end of the

programming cycle and by the falling edge of LAT

bit.

It is not possible to read the latched data.

This note is illustrated by the Figure 8.

READ MODE

LAT=0

PGM=0

READ BYTES

IN EEPROM AREA

INTERRUPT GENERATION

IF IE=1 0 1

CLEARED BY HARDWARE

WRITE MODE

LAT=1

PGM=0

WRITE UP TO 16 BYTES

IN EEPROM AREA

(with the same 11 MSB of the address)

START PROGRAMMING CYCLE

LAT=1

PGM=1 (set by software)

LAT

20/150

DATA EEPROM (Cont’d)

ST72334xx-Auto, ST72314xx-Auto, ST72124Jx-Auto

6.4 POWER SAVING MODES

Wait mode

The Data EEPROM can enter Wait mode on execution of the WFI instruction of the microcontroller.

The Data EEPROM will immediately enter this

mode if there is no programming in progress, oth

erwise the Data EEPROM will finish the cycle and

then enter Wait mode.

Halt mode

The Data EEPROM immediately enters Halt mode

if the microcontroller executes the HALT instruc

tion. Therefore the EEPROM will stop the function

in progress, and data may be corrupted.

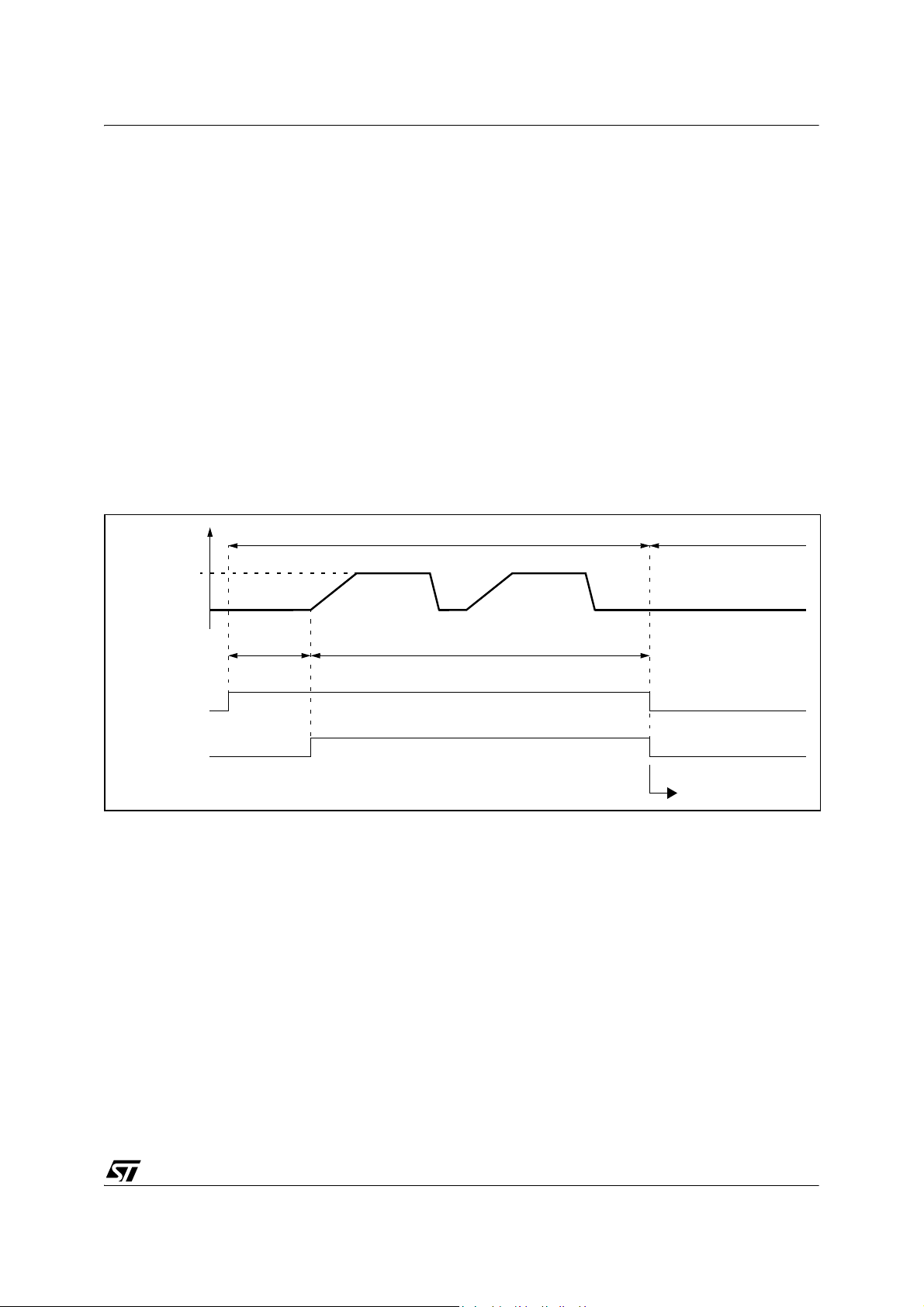

Figure 8. Data EEPROM Programming Cycle

READ OPERATION NOT POSSIBLE

INTERNAL

PROGRAMMING

VOLTAGE

ERASE CYCLE WRITE CYCLE

WRITE OF

DATA LATCHES

6.5 ACCESS ERROR HANDLING

If a read access occurs while LAT=1, then the data

bus will not be driven.

If a write access occurs while LAT=0, then the

data on the bus will not be latched.

If a programming cycle is interrupted (by software/

RESET action), the memory data will not be guar

anteed.

READ OPERATION POSSIBLE

t

PROG

-

EEPROM INTERRUPT

LAT

PGM

21/150

ST72334xx-Auto, ST72314xx-Auto, ST72124Jx-Auto

DATA EEPROM (Cont’d)

6.6 REGISTER DESCRIPTION

Bit 1 = LAT Latch Access Transfer

This bit is set by software. It is cleared by hard-

CONTROL/STATUS REGISTER (CSR)

Read / Write

Reset Value: 0000 0000 (00h)

7 0

ware at the end of the programming cycle. It can

only be cleared by software if PGM bit is cleared.

0: Read mode

1: Write mode

Bit 0 = PGM Programming control and status

0 0 0 0 0 IE LAT PGM

This bit is set by software to begin the programming

cycle. At the end of the programming cycle, this bit

is cleared by hardware and an interrupt is generated

Bit 7:3 = Reserved, forced by hardware to 0.

if the ITE bit is set.

0: Programming finished or not yet started

1: Programming cycle is in progress

Bit 2 = IE Interrupt enable

This bit is set and cleared by software. It enables the

Data EEPROM interrupt capability when the PGM

bit is cleared by hardware. The interrupt request is

Note: if the PGM bit is cleared during the programming cycle, the memory data is not guaranteed

automatically cleared when the software enters the

interrupt routine.

0: Interrupt disabled

1: Interrupt enabled

Table 3. Data EEPROM Register Map and Reset Values

Address

(Hex.)

002Ch

Register

Label

EECSR

Reset Value 0 0 0 0 0

7 6 5 4 3 2 1 0

IE

0

RWM

0

PGM

0

6.7 READOUT PROTECTION OPTION

The Data EEPROM can be optionally readout protected in ST72334 ROM devices (see option list on

22/150

page 145). ST72C334 Flash devices do not have

this protection option.

7 CENTRAL PROCESSING UNIT

ST72334xx-Auto, ST72314xx-Auto, ST72124Jx-Auto

7.1 INTRODUCTION

This CPU has a full 8-bit architecture and contains

six internal registers allowing efficient 8-bit data

manipulation.

7.2 MAIN FEATURES

■ 63 basic instructions

■ Fast 8-bit by 8-bit multiply

■ 17 main addressing modes

■ Two 8-bit index registers

■ 16-bit stack pointer

■ Low power modes

■ Maskable hardware interrupts

■ Non-maskable software interrupt

7.3 CPU REGISTERS

The six CPU registers shown in Figure 9 are not

present in the memory mapping and are accessed

by specific instructions.

Figure 9. CPU Registers

70

RESET VALUE = XXh

70

RESET VALUE = XXh

70

RESET VALUE = XXh

Accumulator (A)

The Accumulator is an 8-bit general purpose register used to hold operands and the results of the

arithmetic and logic calculations and to manipulate

data.

Index Registers (X and Y)

In indexed addressing modes, these 8-bit registers

are used to create either effective addresses or

temporary storage areas for data manipulation.

(The Cross-Assembler generates a precede in

struction (PRE) to indicate that the following instruction refers to the Y register.)

The Y register is not affected by the interrupt automatic procedures (not pushed to and popped from

the stack).

Program Counter (PC)

The program counter is a 16-bit register containing

the address of the next instruction to be executed

by the CPU. It is made of two 8-bit registers PCL

(Program Counter Low which is the LSB) and PCH

(Program Counter High which is the MSB).

ACCUMULATOR

X INDEX REGISTER

Y INDEX REGISTER

-

15 8

RESET VALUE = RESET VECTOR @ FFFEh-FFFFh

15

RESET VALUE = STACK HIGHER ADDRESS

PCH

RESET VALUE =

7

70

1C11HI NZ

1X11X1XX

70

8

PCL

0

PROGRAM COUNTER

CONDITION CODE REGISTER

STACK POINTER

X = Undefined Value

23/150

ST72334xx-Auto, ST72314xx-Auto, ST72124Jx-Auto

CPU REGISTERS (Cont’d)

CONDITION CODE REGISTER (CC)

Read/Write

Reset Value: 111x1xxx

7 0

1 1 1 H I N Z C

The 8-bit Condition Code register contains the interrupt mask and four flags representative of the

result of the instruction just executed. This register

can also be handled by the PUSH and POP in

structions.

These bits can be individually tested and/or controlled by specific instructions.

Bit 4 = H Half carry

This bit is set by hardware when a carry occurs be-

tween bits 3 and 4 of the ALU during an ADD or

ADC instruction. It is reset by hardware during the

same instructions.

0: No half carry has occurred.

1: A half carry has occurred.

This bit is tested using the JRH or JRNH instruction. The H bit is useful in BCD arithmetic subroutines.

Bit 3 = I Interrupt mask

This bit is set by hardware when entering in interrupt or by software to disable all interrupts except

the TRAP software interrupt. This bit is cleared by

software.

0: Interrupts are enabled.

1: Interrupts are disabled.

This bit is controlled by the RIM, SIM and IRET instructions and is tested by the JRM and JRNM instructions.

Note: Interrupts requested while I is set are

latched and can be processed when I is cleared.

By default an interrupt routine is not interruptible

because the I bit is set by hardware at the start of

the routine and reset by the IRET instruction at the

end of the routine. If the I bit is cleared by software

in the interrupt routine, pending interrupts are

serviced regardless of the priority level of the cur

rent interrupt routine.

Bit 2 = N Negative

This bit is set and cleared by hardware. It is repre-

sentative of the result sign of the last arithmetic,

logical or data manipulation. It is a copy of the 7

bit of the result.

0: The result of the last operation is positive or null.

1: The result of the last operation is negative

(that is, the most significant bit is a logic 1).

This bit is accessed by the JRMI and JRPL instructions.

-

Bit 1 = Z Zero

This bit is set and cleared by hardware. This bit indicates that the result of the last arithmetic, logical

or data manipulation is zero.

0: The result of the last operation is different from

zero.

1: The result of the last operation is zero.

This bit is accessed by the JREQ and JRNE test

instructions.

Bit 0 = C Carry/borrow

This bit is set and cleared by hardware and soft-

ware. It indicates an overflow or an underflow has

occurred during the last arithmetic operation.

0: No overflow or underflow has occurred.

1: An overflow or underflow has occurred.

This bit is driven by the SCF and RCF instructions

and tested by the JRC and JRNC instructions. It is

also affected by the “bit test and branch”, shift and

rotate instructions.

-

th

24/150

ST72334xx-Auto, ST72314xx-Auto, ST72124Jx-Auto

CENTRAL PROCESSING UNIT (Cont’d)

Stack Pointer (SP)

Read/Write

Reset Value: 01 FFh

15 8

0 0 0 0 0 0 0 1

7 0

SP7 SP6 SP5 SP4 SP3 SP2 SP1 SP0

The Stack Pointer is a 16-bit register which is always pointing to the next free location in the stack.

It is then decremented after data has been pushed

onto the stack and incremented before data is

popped from the stack (see

Since the stack is 256 bytes deep, the 8th most

significant bits are forced by hardware. Following

an MCU Reset, or after a Reset Stack Pointer in

struction (RSP), the Stack Pointer contains its reset value (the SP7 to SP0 bits are set) which is the

stack higher address.

Figure 10).

-

The least significant byte of the Stack Pointer

(called S) can be directly accessed by a LD in

-

struction.

Note: When the lower limit is exceeded, the Stack

Pointer wraps around to the stack upper limit, with

out indicating the stack overflow. The previously

stored information is then overwritten and there

fore lost. The stack also wraps in case of an underflow.

The stack is used to save the return address during a subroutine call and the CPU context during

an interrupt. The user may also directly manipulate

the stack by means of the PUSH and POP instruc

tions. In the case of an interrupt, the PCL is stored

at the first location pointed to by the SP. Then the

other registers are stored in the next locations as

shown in

Figure 10.

– When an interrupt is received, the SP is decre-

mented and the context is pushed on the stack.

– On return from interrupt, the SP is incremented

and the context is popped from the stack.

A subroutine call occupies two locations and an interrupt five locations in the stack area.

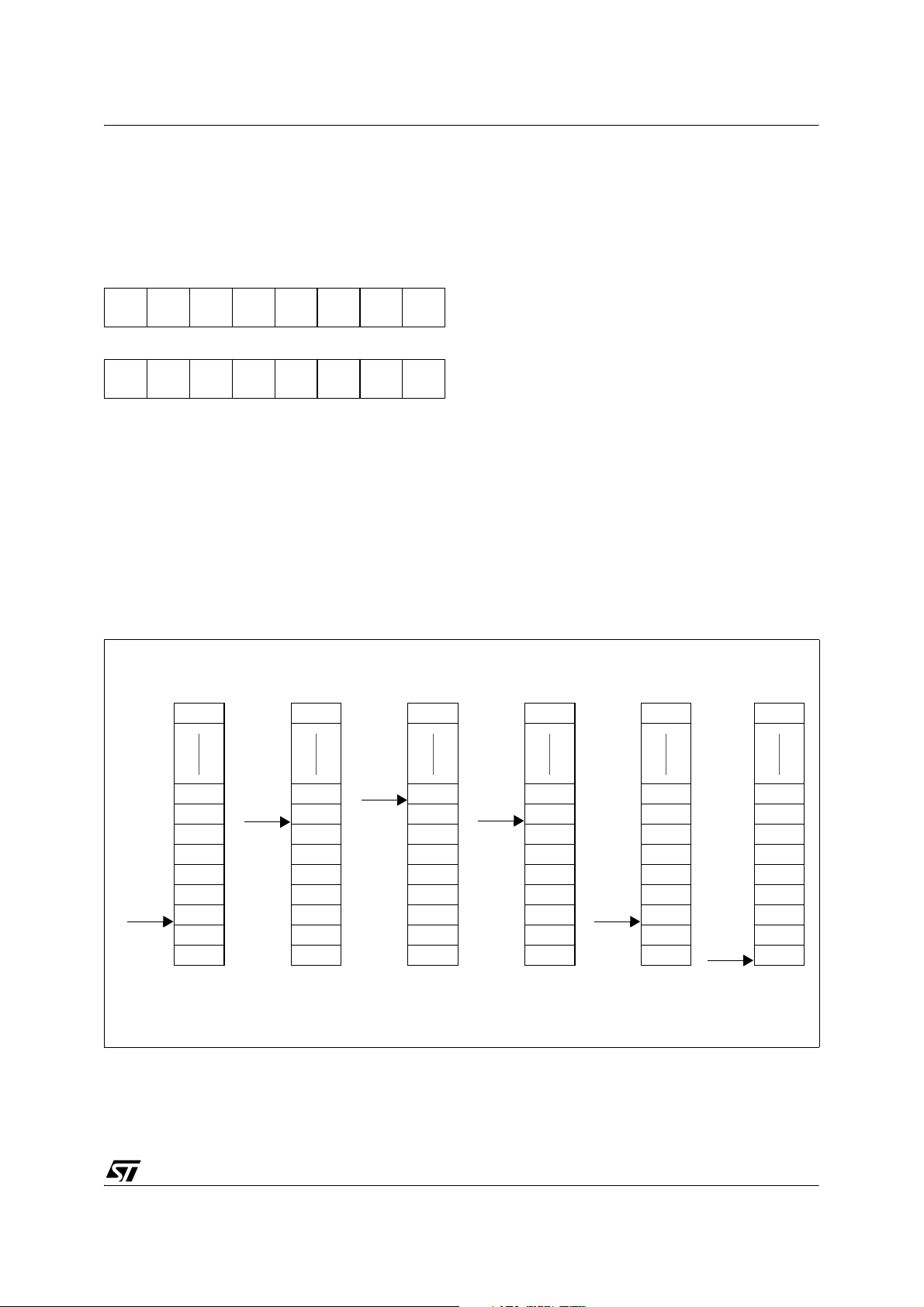

Figure 10. Stack Manipulation Example

@ 0100h

SP

@ 01FFh

CALL

Subroutine

SP

PCH

PCL

Stack Higher Address = 01FFh

Stack Lower Address =

Interrupt

Event

SP

CC

A

X

PCH

PCL

PCH

PCL

0100h

PUSH Y POP Y IRET

SP

Y

CC

A

X

PCH

PCL

PCH

PCL

CC

A

X

PCH

PCL

PCH

PCL

SP

PCH

PCL

RET

or RSP

SP

25/150

ST72334xx-Auto, ST72314xx-Auto, ST72124Jx-Auto

8 SUPPLY, RESET AND CLOCK MANAGEMENT

The ST72334J/N-Auto, ST72314J/N-Auto and

ST72124J-Auto microcontrollers include a range

of utility features for securing the application in crit

ical situations (for example, in case of a power

brown-out), and reducing the number of external

components. An overview is shown in

Figure 11.

See Section 15 "ELECTRICAL CHARACTERIS-

TICS" on page 108 for more details.

Main Features

■ Supply Manager with main supply low voltage

detection (LVD)

■ Reset Sequence Manager (RSM)

Figure 11. Clock, Reset and Supply Block Diagram

CLOCK SECURITY SYSTEM

(CSS)

OSC2

OSC1

MULTI-

OSCILLATOR

(MO)

CLOCK

FILTER

■ Multi-Oscillator (MO)

– 4 Crystal/Ceramic resonator oscillators

– 1 External RC oscillator

– 1 Internal RC oscillator

■ Clock Security System (CSS)

– Clock Filter

– Backup Safe Oscillator

SAFE

OSC

f

OSC

TO

MAIN CLOCK

CONTROLLER

RESET

V

DD

V

SS

RESET SEQUENCE

MANAGER

(RSM)

LOW VOLTAGE

DETECTOR

(LVD)

CRSR

FROM

WATCHDOG

PERIPHERAL

LVD

IE D00 0 0 RF RF

CSS INTERRUPT

CSS WDG

26/150

8.1 LOW VOLTAGE DETECTOR (LVD)

ST72334xx-Auto, ST72314xx-Auto, ST72124Jx-Auto

To allow the integration of power management

features in the application, the Low Voltage Detec

tor function (LVD) generates a static reset when

the V

supply voltage is below a V

DD

reference

IT-

value. This means that it secures the power-up as

well as the power-down keeping the ST7 in reset.

The V

than the V

to avoid a parasitic reset when the MCU starts run

reference value for a voltage drop is lower

IT-

reference value for power-on in order

IT+

ning and sinks current on the supply (hysteresis).

The LVD Reset circuitry generates a reset when

is below:

V

DD

–V

when VDD is rising

IT+

–V

when VDD is falling

IT-

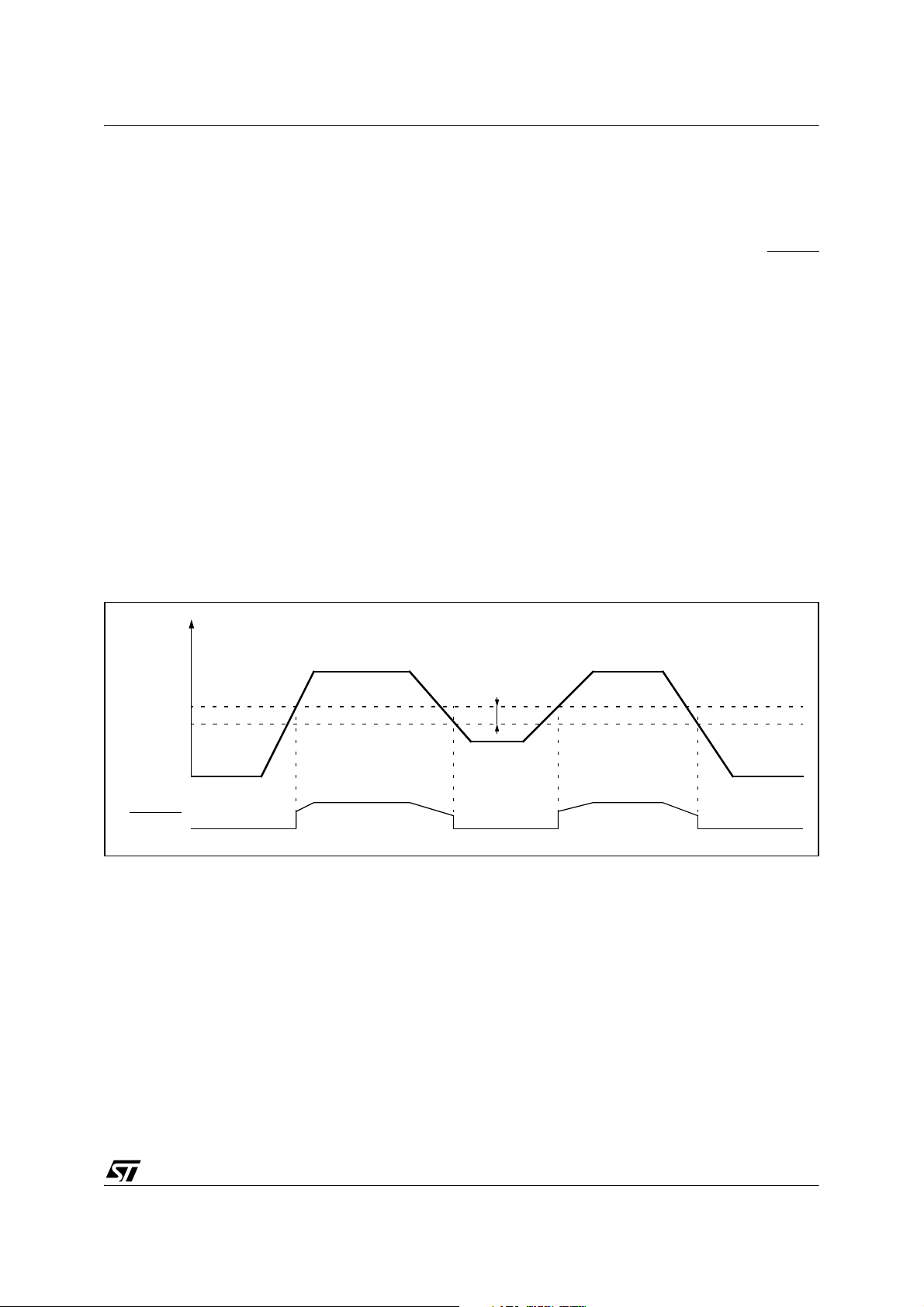

The LVD function is illustrated in the Figure 12.

Provided the minimum VDD value (guaranteed for

the oscillator frequency) is above V

, the MCU

IT-

can only be in two modes:

– under full software control

– in static safe reset

Figure 12. Low Voltage Detector vs Reset

V

DD

In these conditions, secure operation is always ensured for the application without the need for external reset hardware.

During a Low Voltage Detector Reset, the RESET

pin is held low, thus permitting the MCU to reset

other devices.

Notes:

1. The LVD allows the device to be used without

any external RESET circuitry.

2. Three different reference levels are selectable

through the option byte according to the applica

tion requirement.

LVD application note

Application software can detect a reset caused by

the LVD by reading the LVDRF bit in the CRSR

register.

This bit is set by hardware when a LVD reset is

generated and cleared by software (writing zero).

-

V

IT+

V

IT-

RESET

V

hyst

27/150

ST72334xx-Auto, ST72314xx-Auto, ST72124Jx-Auto

8.2 RESET SEQUENCE MANAGER (RSM)

8.2.1 Introduction

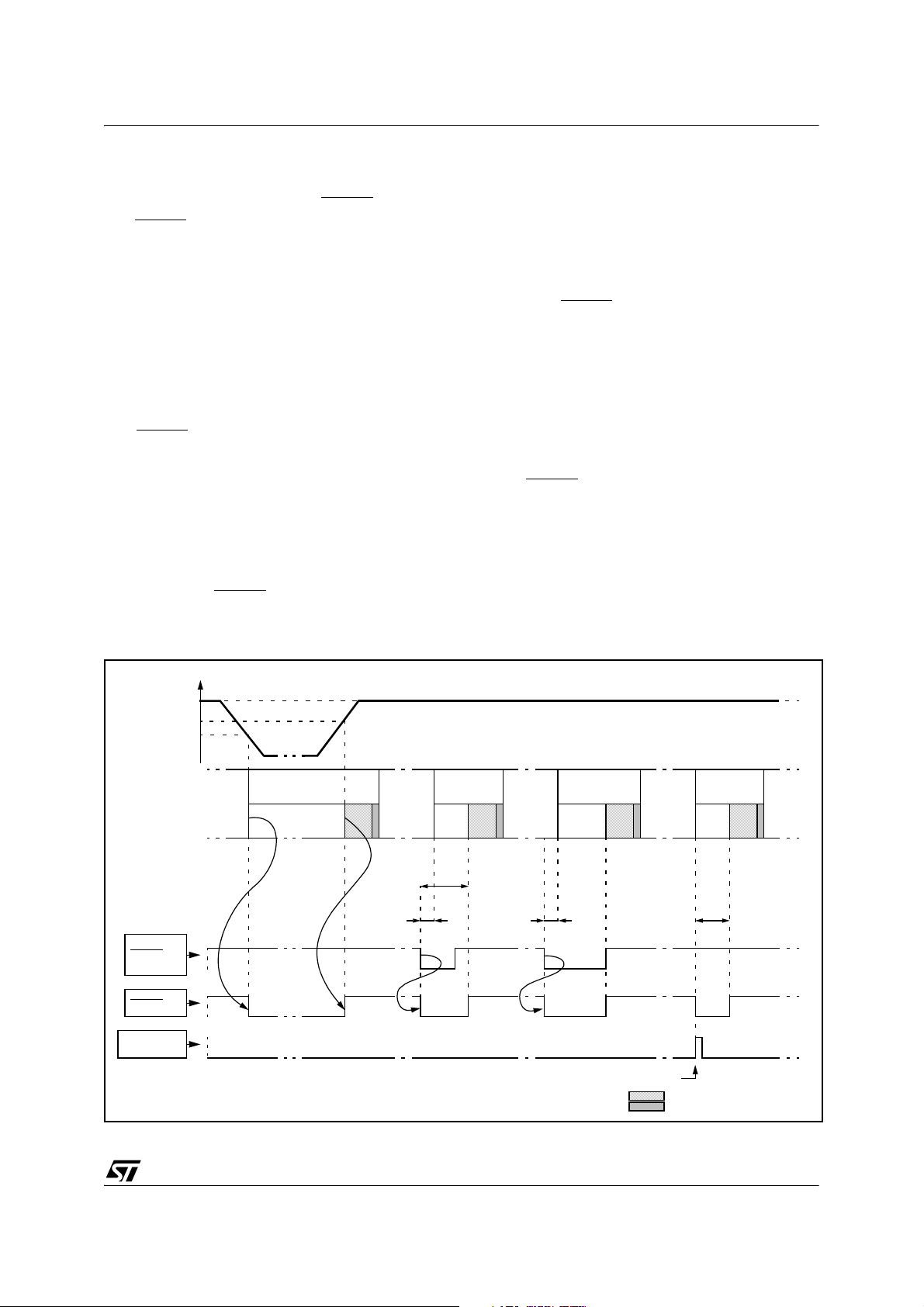

The reset sequence manager includes three RESET sources as shown in Figure 14:

■ External RESET source pulse

■ Internal LVD RESET (Low Voltage Detection)

■ Internal WATCHDOG RESET

These sources act on the RESET pin and it is always kept low during the delay phase.

The RESET service routine vector is fixed at addresses FFFEh-FFFFh in the ST7 memory map.

The basic RESET sequence consists of three

phases as shown in

■ Delay depending on the RESET source

■ 4096 CPU clock cycle delay

■ RESET vector fetch

Figure 13:

Figure 14. Reset Block Diagram

V

DD

f

CPU

The 4096 CPU clock cycle delay allows the oscillator to stabilise and ensures that recovery has

taken place from the Reset state.

The RESET vector fetch phase duration is 2 clock

cycles.

Figure 13. RESET Sequence Phases

RESET

DELAY

INTERNAL RESET

4096 CLOCK CYCLES

FETCH

VECTOR

INTERNAL

RESET

RESET

R

ON

COUNTER

WATCHDOG RESET

LVD RESET

28/150

RESET SEQUENCE MANAGER (Cont’d)

ST72334xx-Auto, ST72314xx-Auto, ST72124Jx-Auto

8.2.2 Asynchronous External RESET Pin

The RESET pin is both an input and an open-drain

output with integrated R

This pull-up has no fixed value but varies in ac

weak pull-up resistor.

ON

cordance with the input voltage. It can be pulled

low by external circuitry to reset the device. See

ELECTRICAL CHARACTERISTICS section for

more details.

A RESET signal originating from an external

source must have a duration of at least t

h(RSTL)in

order to be recognized. This detection is asynchro

in

nous and therefore the MCU can enter reset state

even in Halt mode.

The RESET pin is an asynchronous signal which

plays a major role in EMS performance. In a noisy

environment, it is recommended to follow the

guidelines mentioned in the

ELECTRICAL CHAR-

ACTERISTICS section.

Two RESET sequences can be associated with

this RESET source: short or long external reset

pulse (see

Figure 15).

Starting from the external RESET pulse recognition, the device RESET pin acts as an output that

is pulled low during at least t

w(RSTL)out

.

Figure 15. RESET Sequences

8.2.3 Internal Low Voltage Detection RESET

Two different RESET sequences caused by the internal LVD circuitry can be distinguished:

■ Power-On RESET

■ Voltage Drop RESET

The device RESET pin acts as an output that is

pulled low when V

V

DD<VIT-

(falling edge) as shown in Figure 15.

DD<VIT+

The LVD filters spikes on V

(rising edge) or

larger than t

DD

g(VDD)

to

avoid parasitic resets.

8.2.4 Internal Watchdog RESET

The RESET sequence generated by an internal

Watchdog counter overflow is shown in

Figure 15.

Starting from the Watchdog counter underflow, the

device

low during at least t

RESET pin acts as an output that is pulled

w(RSTL)out

.

V

V

EXTERNAL

RESET

SOURCE

RESET PIN

WATCHDOG

RESET

IT+

IT-

V

DD

RUN

LVD

RESET

DELAY

RUN

t

w(RSTL)out

t

h(RSTL)in

SHORT EXT.

RESET

DELAY

LONG EXT.

RESET

RUN RUN

DELAY

t

h(RSTL)in

WATCHDOG UNDERFLOW

WATCHDOG

RESET

RUN

DELAY

t

w(RSTL)out

INTERNAL RESET (4096 T

FETCH VECTOR

CPU

)

29/150

ST72334xx-Auto, ST72314xx-Auto, ST72124Jx-Auto

8.3 MULTI-OSCILLATOR (MO)

The main clock of the ST7 can be generated by

four different source types coming from the multioscillator block:

■ an external source

■ 4 crystal or ceramic resonator oscillators

■ an external RC oscillator

■ an internal high frequency RC oscillator

Each oscillator is optimized for a given frequency

range in terms of consumption and is selectable

through the option byte. The associated hardware

configuration are shown in

Table 4. Refer to the

ELECTRICAL CHARACTERISTICS section for

more details.

External Clock Source

In this external clock mode, a clock signal (square,

sinus or triangle) with ~50% duty cycle has to drive

the OSC1 pin while the OSC2 pin is tied to ground.

Crystal/Ceramic Oscillators

This family of oscillators has the advantage of producing a very accurate rate on the main clock of

the ST7. The selection within a list of four oscilla

tors with different frequency ranges has to be done

by option byte in order to reduce consumption. In

this mode of the multi-oscillator, the resonator and

the load capacitors have to be placed as close as

possible to the oscillator pins in order to minimize

output distortion and start-up stabilization time.

The loading capacitance values must be adjusted

according to the selected oscillator.

These oscillators are not stopped during the RESET phase to avoid losing time in the oscillator

start-up phase.

the drawback of a lower frequency accuracy. Its

frequency is in the range of several MHz. This op

tion should not be used in applications that require

accurate timing.

In this mode, the two oscillator pins have to be tied

to ground.

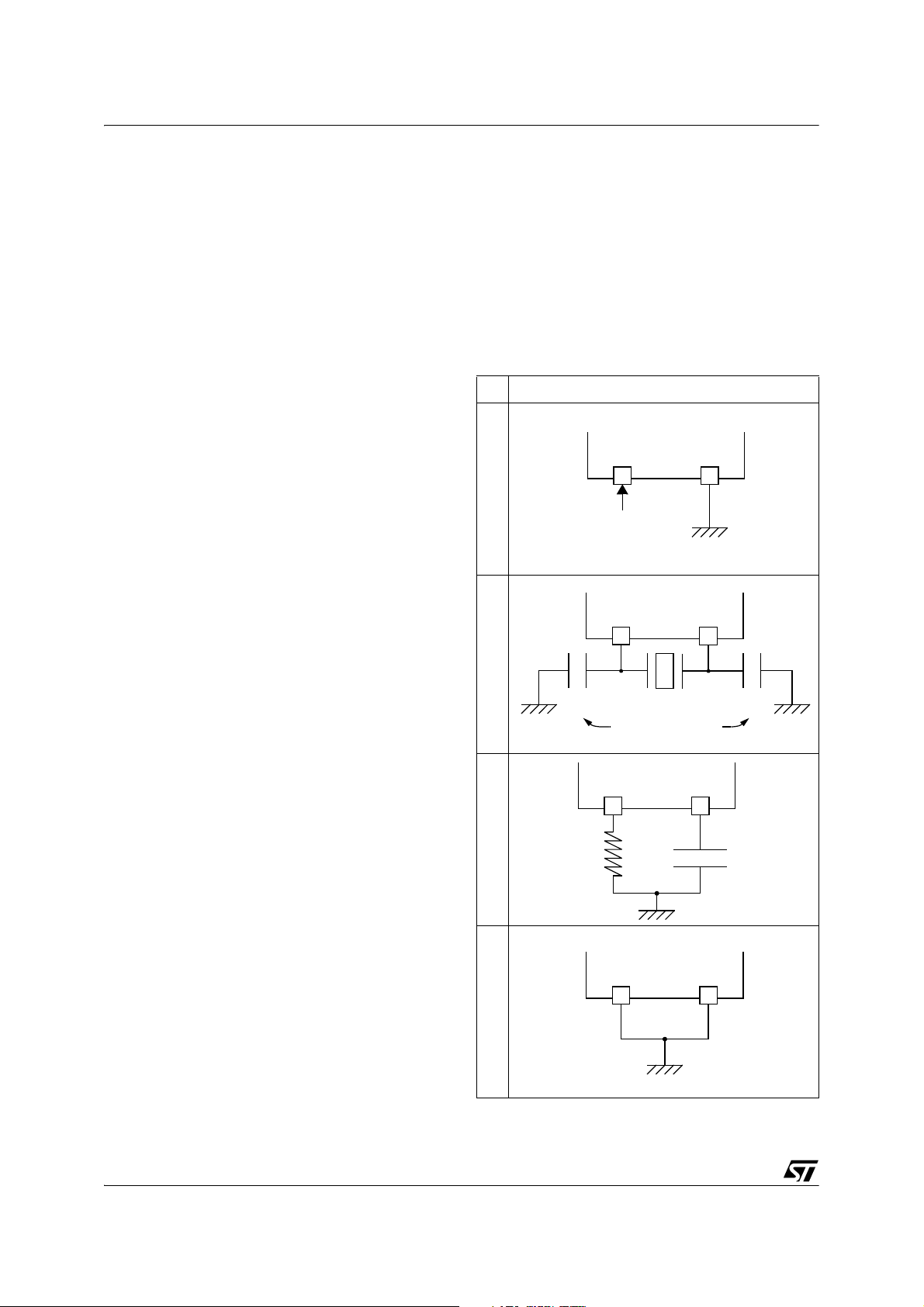

Table 4. ST7 Clock Sources

Hardware Configuration

ST7

OSC1 OSC2

External ClockCrystal/Ceramic ResonatorsExternal RC OscillatorInternal RC Oscillator

EXTERNAL

SOURCE

OSC1 OSC2

C

L1

OSC1 OSC2

LOAD

CAPACITORS

ST7

ST7

C

L2

-

External RC Oscillator

This oscillator allows a low cost solution for the

main clock of the ST7 using only an external resis

tor and an external capacitor. The frequency of the

external RC oscillator (in the range of some MHz)

is fixed by the resistor and the capacitor values.

Consequently in this MO mode, the accuracy of

the clock is dependent on V

, TA, process varia-

DD

tions and the accuracy of the discrete components

used. This option should not be used in applica

tions that require accurate timing.

Internal RC Oscillator

The internal RC oscillator mode is based on the

same principle as the external RC oscillator includ

ing the resistance and the capacitance of the device. This mode is the most cost effective one with

30/150

R

EX

C

EX

-

OSC1 OSC2

ST7

-

-

Loading...

Loading...