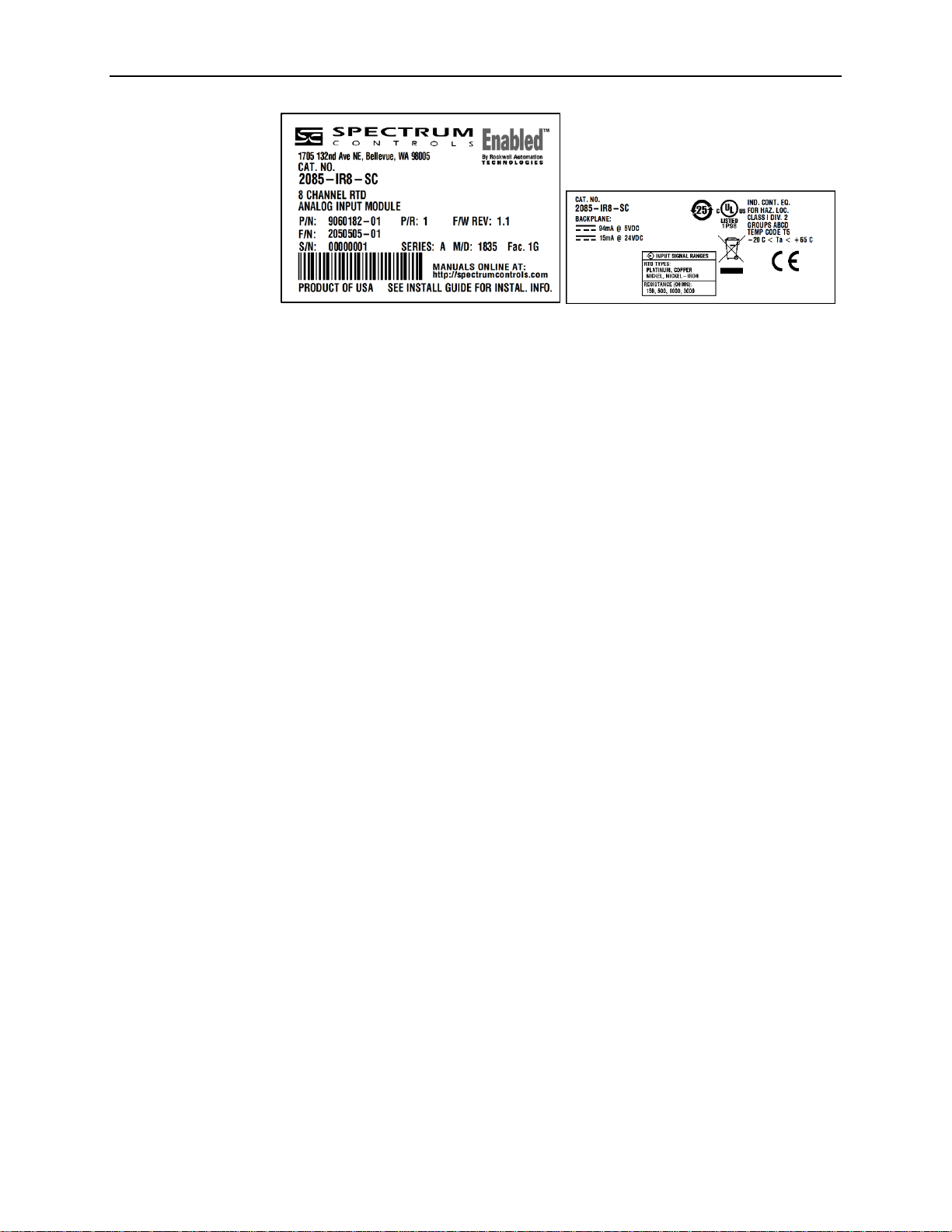

Page 1

Page 2

ii Micro800TM 8-Channel RTD and Resistance Analog Input Module

User's Manual Pub. 0300321-01 Rev. A

Important Notes

1. Please read all the information in this owner’s guide before installing the

product.

2. The information in this owner's guide applies to hardware Series A and

firmware version 1.1, or later.

3. This guide assumes that the reader has a full working knowledge of the

relevant processor.

Notice

The products and services described in this owner's guide are useful in a wide

variety of applications. Therefore, the user and others responsible for applying

the products and services described herein are responsible for determining their

acceptability for each application. While efforts have been made to provide

accurate information within this owner's guide, Spectrum Controls, Inc. assumes

no responsibility for the accuracy, completeness, or usefulness of the information

herein.

Under no circumstances will Spectrum Controls, Inc. be responsible or liable for

any damages or losses, including indirect or consequential damages or losses,

arising out of either the use of any information within this owner's guide or the

use of any product or service referenced herein.

No patent liability is assumed by Spectrum Controls, Inc. with respect to the use

of any of the information, products, circuits, programming, or services referenced

herein.

The information in this owner's guide is subject to change without notice.

Limited Warranty

Spectrum Controls, Inc. warrants that its products are free from defects in

material and workmanship under normal use and service, as described in

Spectrum Controls, Inc.’s literature covering this product, for a period of 1 year.

The obligations of Spectrum Controls, Inc. under this warranty are limited to

replacing or repairing, at its option, at its factory or facility, any product which

shall, in the applicable period after shipment, be returned to the Spectrum

Controls, Inc. facility, transportation charges prepaid, and which after

examination is determined, to the satisfaction of Spectrum Controls, Inc. to be

thus defective.

This warranty shall not apply to any such equipment which shall have been

repaired or altered except by Spectrum Controls, Inc. or which shall have been

subject to misuse, neglect, or accident. In no case shall the liability of Spectrum

Controls, Inc. exceed the purchase price. The aforementioned provisions do not

extend the original warranty period of any product which has either been repaired

or replaced by Spectrum Controls, Inc.

Page 3

Micro800TM 8-Channel RTD and Resistance Analog Input Module iii

Table of Contents

IMPORTANT NOTES ............................................................................................................................................ II

CHAPTER 1 MODULE OVERVIEW ..................................................................................................................... 1-1

SECTION 1.1 GENERAL DESCRIPTION .............................................................................................................................. 1-1

SECTION 1.2 INPUT SPECIFICATIONS ............................................................................................................................... 1-3

SECTION 1.3 DATA FORMATS ....................................................................................................................................... 1-7

SECTION 1.4 HARDWARE FEATURES .............................................................................................................................. 1-7

1.4.1 LED Blink Codes ......................................................................................................................................... 1-7

SECTION 1.5 SYSTEM OVERVIEW ................................................................................................................................... 1-8

CHAPTER 2 INSTALLATION AND WIRING .......................................................................................................... 2-1

SECTION 2.1 COMPLIANCE TO EUROPEAN UNION DIRECTIVES ............................................................................................. 2-1

2.1.1 EMC Directive ............................................................................................................................................ 2-1

SECTION 2.2 POWER REQUIREMENTS ............................................................................................................................ 2-1

SECTION 2.3 GENERAL CONSIDERATIONS ........................................................................................................................ 2-2

2.3.1 Hazardous Location Considerations .......................................................................................................... 2-2

2.3.2 Prevent Electrostatic Discharge ................................................................................................................ 2-2

2.3.3 Remove Power .......................................................................................................................................... 2-3

2.3.4 Selecting a Location .................................................................................................................................. 2-3

SECTION 2.4 MOUNTING ............................................................................................................................................. 2-3

2.4.1 Minimum Spacing ..................................................................................................................................... 2-4

2.4.2 Parts List ................................................................................................................................................... 2-4

2.4.3 Module Description ................................................................................................................................... 2-4

2.4.4 Insert Module Next to the Controller ........................................................................................................ 2-5

Wiring Diagram ................................................................................................................................................. 2-7

CHAPTER 3 CONFIGURING THE 2085-IR8-SC USING CCW .................................................................................. 3-1

SECTION 3.1 INTRODUCTION ........................................................................................................................................ 3-1

SECTION 3.2 IMPORTING A PROFILE INTO CCW SOFTWARE ................................................................................................ 3-2

SECTION 3.3 2085-IR8-SC TAB ON CCW ...................................................................................................................... 3-5

SECTION 3.4 SETTING CONFIGURATION PARAMETERS USING MCC .................................................................................... 3-7

SECTION 3.5 SOFTWARE INFORMATION ........................................................................................................................ 3-12

3.5.1 Software Versioning ................................................................................................................................ 3-12

3.5.2 Software Updates ................................................................................................................................... 3-12

3.5.3 Startup and Factory Default Conditions .................................................................................................. 3-12

3.5.4 PLC Interfaces ......................................................................................................................................... 3-12

3.5.5 Connection Types and Assembly Sizes .................................................................................................... 3-12

3.5.6 Configuration Table ................................................................................................................................ 3-13

3.5.7 Channel Configuration Bit Location Data ............................................................................................... 3-13

3.5.8 Channel Configuration Values ................................................................................................................ 3-14

3.5.9 Input Table .............................................................................................................................................. 3-15

3.5.10 Input Bit and Value Allocation .............................................................................................................. 3-15

3.5.11 Module and Channel Fault Bit and Value Description .......................................................................... 3-16

3.5.12 Software Revision ................................................................................................................................. 3-16

3.5.13 Channel Status ...................................................................................................................................... 3-16

3.5.14 Channel Data ........................................................................................................................................ 3-17

3.5.15 Output Table ......................................................................................................................................... 3-17

3.5.16 Output Bit Allocation ............................................................................................................................ 3-18

3.5.17 Output Bit Description .......................................................................................................................... 3-18

SECTION 3.6 PRODUCT FEATURES ................................................................................................................................ 3-18

User's Manual Pub. 0300321-01 Rev. A

Page 4

iv Micro800TM 8-Channel RTD and Resistance Analog Input Module

3.6.1 Data Format ............................................................................................................................................ 3-18

3.6.2 Input Type ............................................................................................................................................... 3-18

3.6.3 Channel Bias ........................................................................................................................................... 3-21

3.6.4 Channel Temperature ............................................................................................................................. 3-22

3.6.5 Connection Method ................................................................................................................................ 3-22

3.6.6 Input ADC Filter ....................................................................................................................................... 3-24

3.6.7 Open Circuit Detection ............................................................................................................................ 3-24

3.6.8 Stimulus/Response Sequences ................................................................................................................ 3-24

3.6.9 Process Alarm and Latching .................................................................................................................... 3-26

3.6.10 Under/Over Range Alarms .................................................................................................................... 3-27

3.6.11 ADC Alarm ............................................................................................................................................. 3-28

3.6.12 Channel Scan Rate ................................................................................................................................ 3-28

3.6.13 Module Specific Hardware Errors ......................................................................................................... 3-29

3.6.14 Module Specific Configuration Errors ................................................................................................... 3-29

SECTION 3.7 TECHNICAL ASSISTANCE ........................................................................................................................... 3-31

SECTION 3.8 DECLARATION OF CONFORMITY ................................................................................................................ 3-31

APPENDIX A MANUALLY IMPORTING AN AOP ................................................................................................. A-1

INDEX ............................................................................................................................................................. I-1

User's Manual Pub. 0300321-01 Rev. A

Page 5

Preface

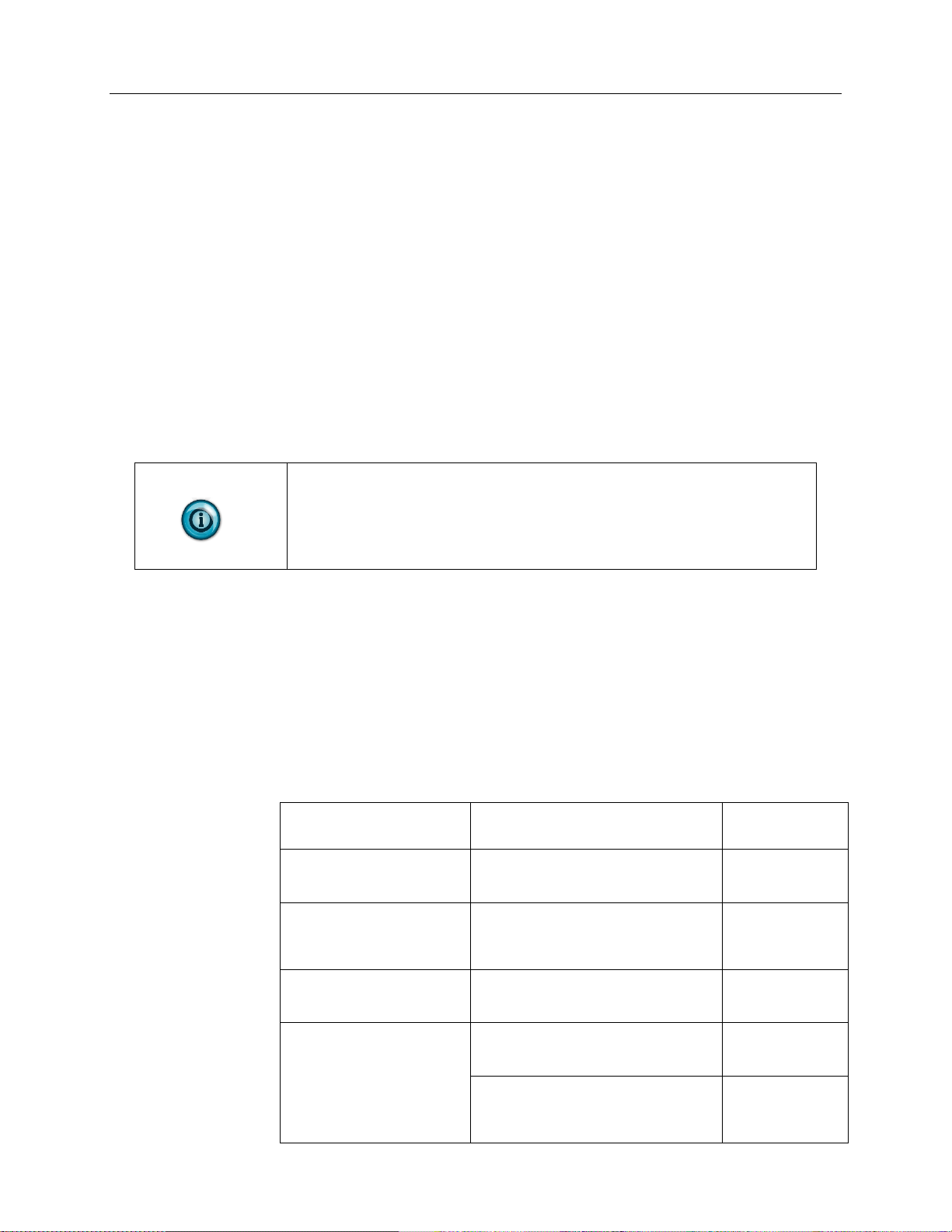

NOTE

Before you access any equipment or begin to install any IO modules,

review all safety material and warnings in the Micro830, Micro850, and

Micro870 Programmable Controllers User Manual. Be sure to review the

warnings provided in this document before you start installing a module in

a system.

For

Refer to this Document

Allen-Bradley

Pub. No.

Product outline

Micro850 Programmable Logic

Controller Product Profile

2080-PP003

Selection information

Micro800 Programmable

Controllers Family Selection

Guide

2080-SG001

General instructions for

using

Micro800 Programmable

Controllers General Instructions

2080-RM001

Installing an external

power supply

Micro800 External AC Power

Supply Installation Instructions

2080-IN001

Micro870 24V DC Expansion

Power Supply Installation

Instructions

2085-IN008

Who Should

Use This Manual

Micro800TM 8-Channel RTD and Resistance Analog Input Module v

Read this preface to familiarize yourself with the rest of the manual. This preface

covers the following topics:

• Who should use this manual

• How to use this manual

• Related documentation

• Technical support

• Documentation

• Conventions used in this manual

Use this manual if you are responsible for designing, installing, programming, or

troubleshooting control systems that use the Micro800TM 8-Channel RTD and

Resistance Analog Input Module.

How to Use

This Manual

Related

Documentation

As much as possible, we organized this manual to explain, in a task-by-task

manner, how to install, configure, program, operate and troubleshoot a control

system using the Micro800TM 8-Channel RTD and Resistance Analog Input

Module.

The table below provides a listing of publications that contain important

information about Allen-Bradley Micro800™ Expansion I/O Module systems.

User's Manual Pub. 0300321-01 Rev. A

Page 6

vi Micro800TM 8-Channel RTD and Resistance Analog Input Module

User's Manual Pub. 0300321-01 Rev. A

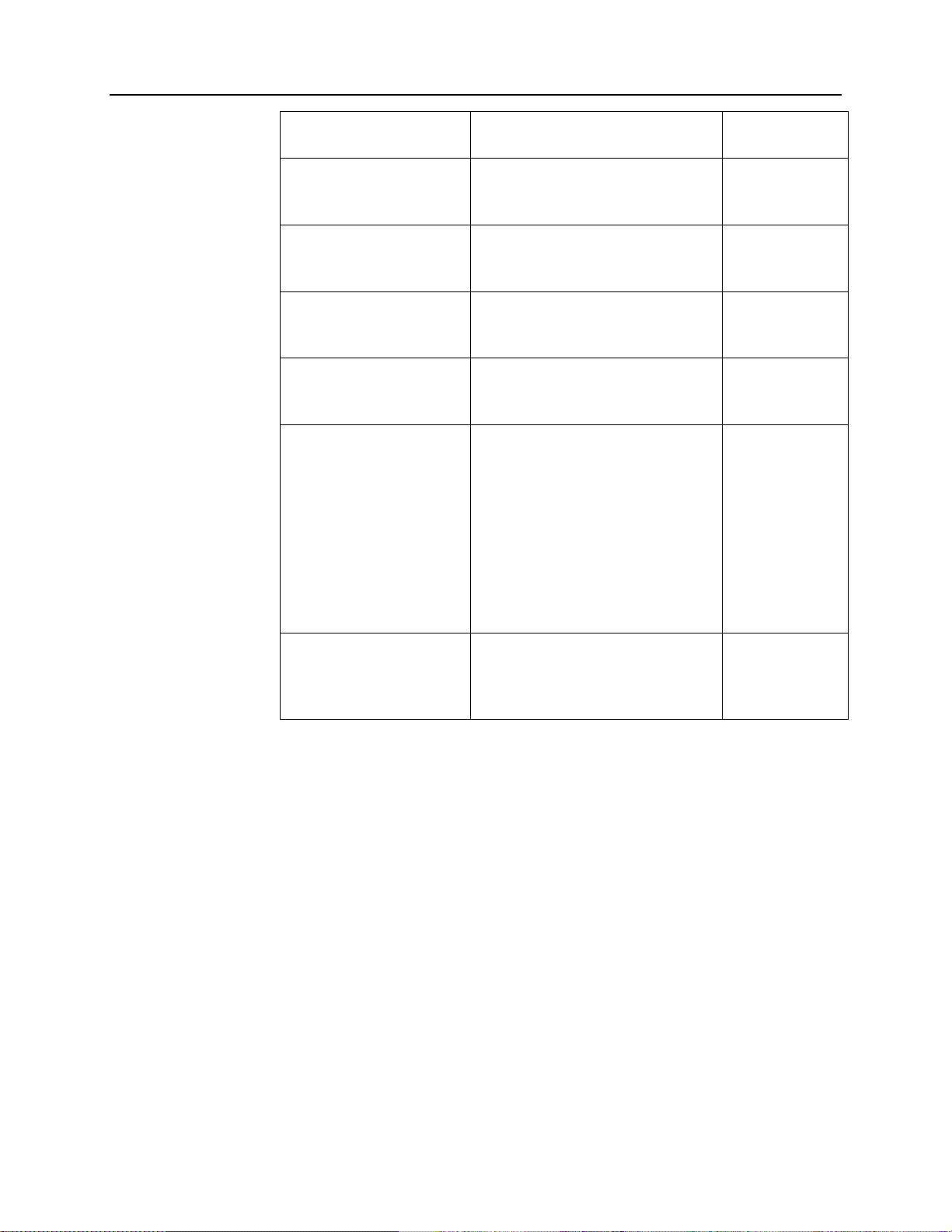

For

Refer to this Document

Allen-Bradley

Pub. No.

Installing 24-point PLC

Micro850 24-Point

Programmable Controllers

Installation Instructions

2080-IN007

Installing 48-point PLC

Micro850 48-Point

Programmable Controllers

Installation Instructions

2080-IN008

Installing 24-point PLC

Micro870 24-Point

Programmable Controllers

Installation Instructions

2080-IN012

User manual information

Micro830, Micro850, and

Micro870 Programmable

Controllers User Manual

2080-UM002

Environment and

Enclosure Information

Industrial Automation Wiring and

Grounding Guidelines, AllenBradley publication 1770-4.1, for

additional installation

requirements.

NEMA Standards publication 250

and IEC publication 60529, as

applicable, for explanations of the

degrees of protection provided by

different types of enclosure.

1770-4.1

NEMA 2502014

IEC 60529

Declarations of

conformity, certificates,

and other certification

details.

Product Certification website:

https://spectrumcontrols.com

Technical

Support

For technical support, please contact your local Rockwell Automation

TechConnect Office for all Spectrum products. Contact numbers are as follows:

• USA 440-646-6900

• United Kingdom 01908 635230

• Australia 1800-809-929

• Mexico 001-888-365-8677

• Brazil (55) 11 3618 8800

• Europe +49 211 41553 63

or send an email to

support@spectrumcontrols.com

Page 7

Micro800TM 8-Channel RTD and Resistance Analog Input Module vii

User's Manual Pub. 0300321-01 Rev. A

Documentation

If you would like a manual, you can download a free electronic version from the

Internet at www.spectrumcontrols.com

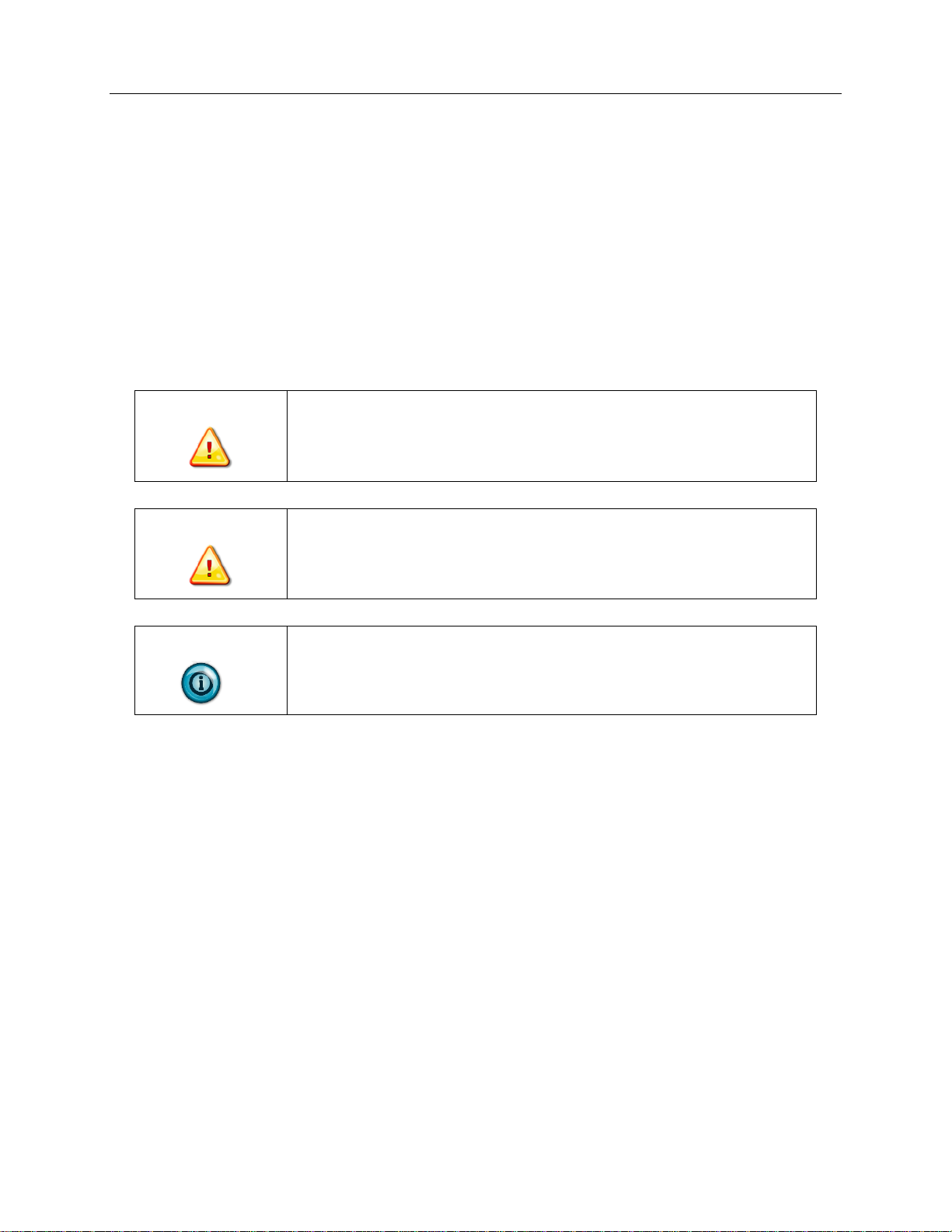

Conventions

Used in This

Manual

The following conventions are used throughout this manual:

• Bulleted lists (like this one) provide information not procedural steps.

• Numbered lists provide sequential steps or hierarchical information.

• Italic type is used for emphasis

• Bold type identifies headings and sub-headings

WARNING

Identifies information about practices or circumstances that can lead to

personal injury or death, property damage, or economic loss. These

messages help you to identify a hazard, avoid a hazard, and recognize the

consequences.

ATTENTION

Actions ou situations risquant d’entraîner des blessures pouvant être

mortelles, des dégâts matériels ou des pertes financières. Les messages «

Attention » vous aident à identifier un danger, à éviter ce danger et en

discerner les conséquences.

NOTE

Identifies information that is critical for successful application and

understanding of the product.

Page 8

viii Micro800TM 8-Channel RTD and Resistance Analog Input Module

User's Manual Pub. 0300321-01 Rev. A

Page 9

User's Manual Pub. 0300321-01 Rev. A

Chapter 1 Module Overview

This chapter describes the following topics:

• General description

• Input specifications

• Data formats

• Hardware features

• System overview

The Micro800™ 2085-IR8-SC is an isolated. 8-channel RTD/Resistance module

designed to expand the local I/O capability of Rockwell Automation Micro850

and Micro870 Systems over its Expansion I/O buses. The minimum system

requirement in which an Expansion I/O Module can be installed is a Micro850 or

Micro870 Controller and a controller power supply.

The number of 2085-IR8-SC modules that can be installed with a Micro850/870

PLC is based on the current controller firmware revision and CCW software

revision.

Section 1.1 General Description

Page 10

1-2 Chapter 1: Module Overview

User's Manual Pub. 0300321-01 Rev. A

The module provides up to eight, concurrent channels of 2-, 3-, or 4-wire RTD

and resistance measurements. It provides RTD types Pt 385, Pt 3916, Cu 426, Ni

618, Ni 672, Ni-Fe 518, and direct ohm (0-150, 0-500, 0-1000, 0-3000)

measurements.

The module provides:

• 8 input channels of RTD and resistance measurements.

• Four data formats.

• Range scaling of input data.

• Four filter frequencies.

• Units in Degrees Centigrade and Fahrenheit.

• Channel bias adjustment.

• Alarm notification on each channel status:

- Over or under range detection (from user-defined values).

- Process alarm and latching.

- Open wire detection.

- ADC communication fault.

All inputs have fault tolerance and ESD protection to avoid damage to circuitry

on the board. The modules use 50 VAC working Reinforced Insulation between

the inputs and the backplane.

The 2085-IR8-SC module uses a 20-bit Sigma-Delta analog-to-digital converter

to achieve 16-bit resolution.

Each input channel is individually configurable via Rockwell-provided

Connected Component Workbench (CCW) software for the Micro850 and

Micro870 family controllers or with the Module Configuration Converter (MCC)

utility from Spectrum Controls, Inc.

The module is factory calibrated and tested before shipping. After installation,

the modules begin operation in a default, usable condition without user

parameters first being set up or defined. During power startup, all inputs are

disabled and off until a valid configuration has been received. The default

configuration is for all channels enabled in the 3-wire, 100PT385 range with the

17 Hz filter in Engineering ×1 units.

Page 11

Chapter 1: Module Overview 1-3

User's Manual Pub. 0300321-01 Rev. A

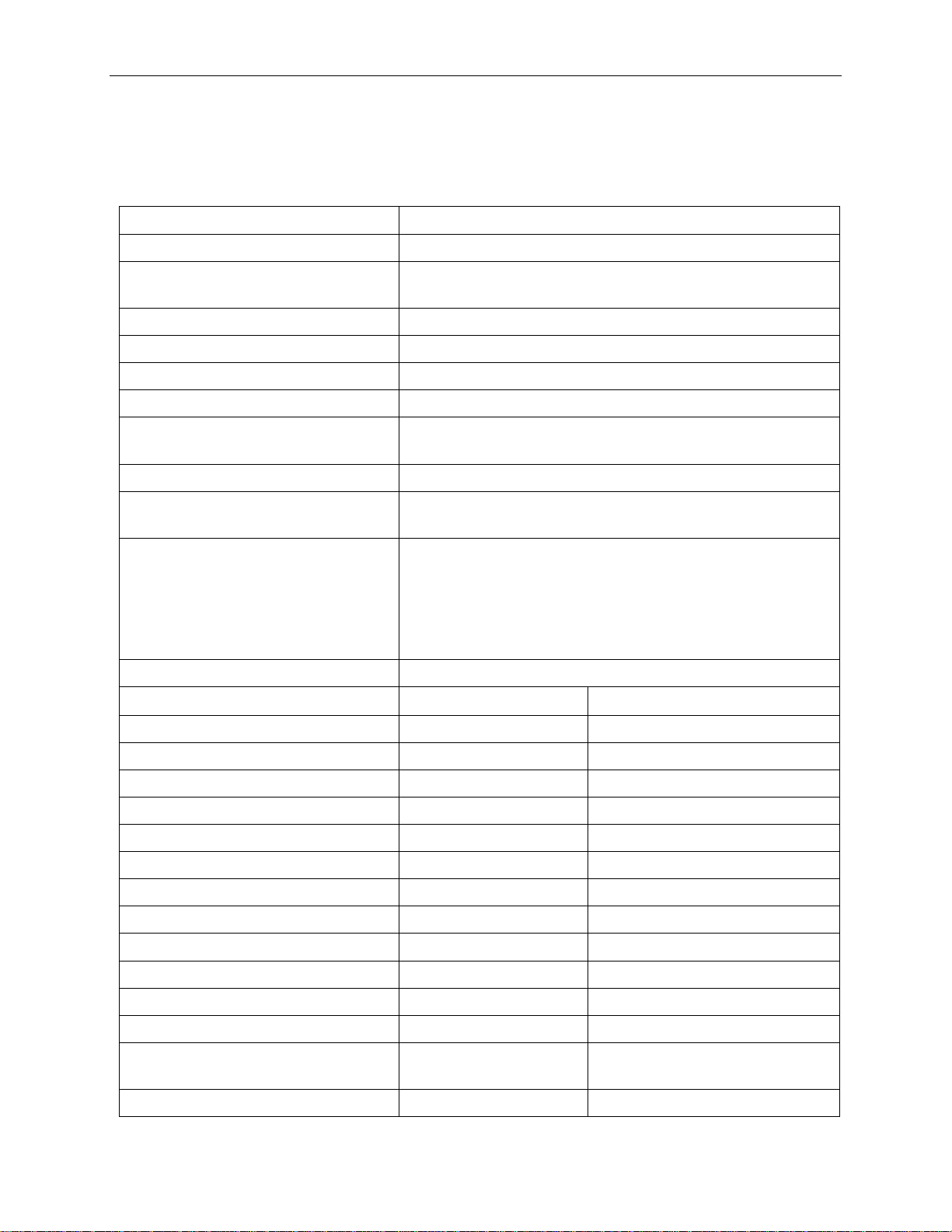

Section 1.2 Input Specifications

The 2085-IR8-SC module has the following input specifications:

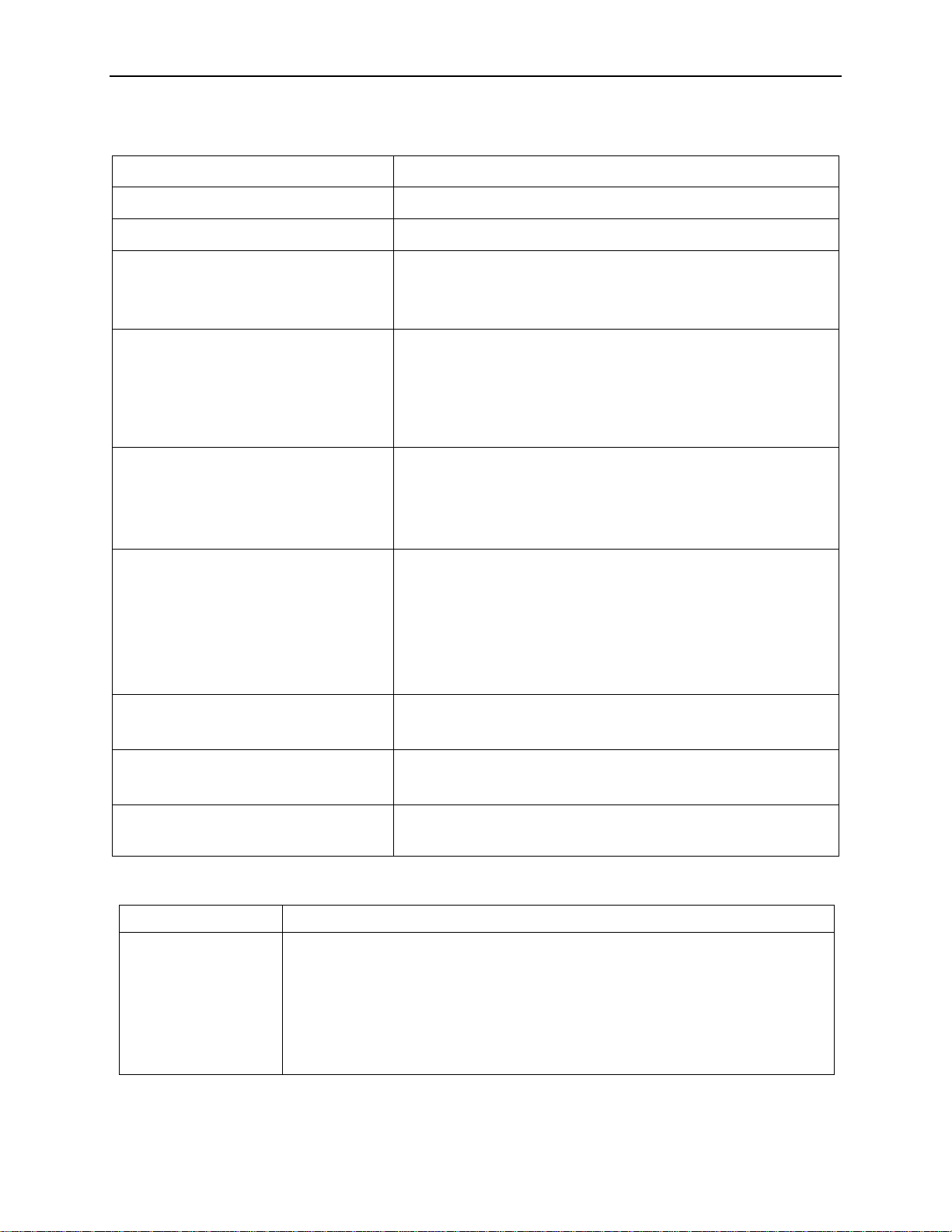

Table 1-1. Input/Performance/Environmental Requirements

Input Description

Value

Operating Temperature

-20 ºC to 65 ºC (-4 ºF to 149 ºF)

Storage/Non-Operating

Temperature

-40 ºC to 85 ºC (-40 ºF to 185 ºF)

Operating Humidity

5% to 95%, non-condensing

Storage/Non-Operating Humidity

5% to 85%, non-condensing

Vibration/Operating

10 Hz to 500 Hz, 2 G, 0.030 max peak-to-peak

Operating Shock

25 G, peak acceleration, 11±1 ms pulse, half sine

Storage/Non-Operating Shock

25 G peak acceleration, 11±1 ms pulse, half sine; 35 G for

panel mount.

Pollution Level

Meets Pollution Degree 2 requirements.

Inputs per module

Eight 2-wire, 3-wire, or 4-wire resistance, or RTD

differential input channels

Input ranges

RTD:

100 Ω, 200 Ω, 500 Ω and 1000 Ω PT385 and Pt3916,

10 0Ω Ni618, 120 Ω Ni672, 10 Ω Cu 426, 604 Ω NiFe 518

Resistance:

0-150 Ω, 0-500 Ω, 0-1000 Ω, 0-3000 Ω

Input filters

4 Hz, 17 Hz, 60 Hz, 470 Hz

RTD accuracy

Error at 25 C Max

Error over -20 C to 65 C Max

100 Ω PT385, -200 ºC to 850 ºC

±0.6

±0.9

200 Ω PT385, -200 ºC to 850 ºC

±0.5

±0.8

500 Ω PT385, -200 ºC to 850 ºC

±0.5

±0.7

1000 Ω PT385, -200 ºC to 850 ºC

±0.5

±0.7

100 Ω PT3916, -200 ºC to 630 ºC

±0.6

±0.8

200 Ω PT3916, -200 ºC to 630 ºC

±0.5

±0.7

500 Ω PT3916, -200 ºC to 630 ºC

±0.5

±0.6

1000 Ω PT3916, -200 ºC to 630 ºC

±0.5

±0.6

100 Ω Ni618, -100 ºC to 260 ºC

±0.4

±0.4

120 Ω Ni672, -80 ºC to 260 ºC

±0.3

±0.4

10 Ω Cu 426, -100 ºC to 260 ºC

±3.6

±4.0

604 Ω NiFe 518, -100 ºC to 200 ºC

±0.3

±0.4

Resistance accuracy

Error at 25 °C, (Ohms)

Max

Error over -20 °C to 65 °C,

(Ohms) Max

0 to 150 Ω

±0.2

±0.3

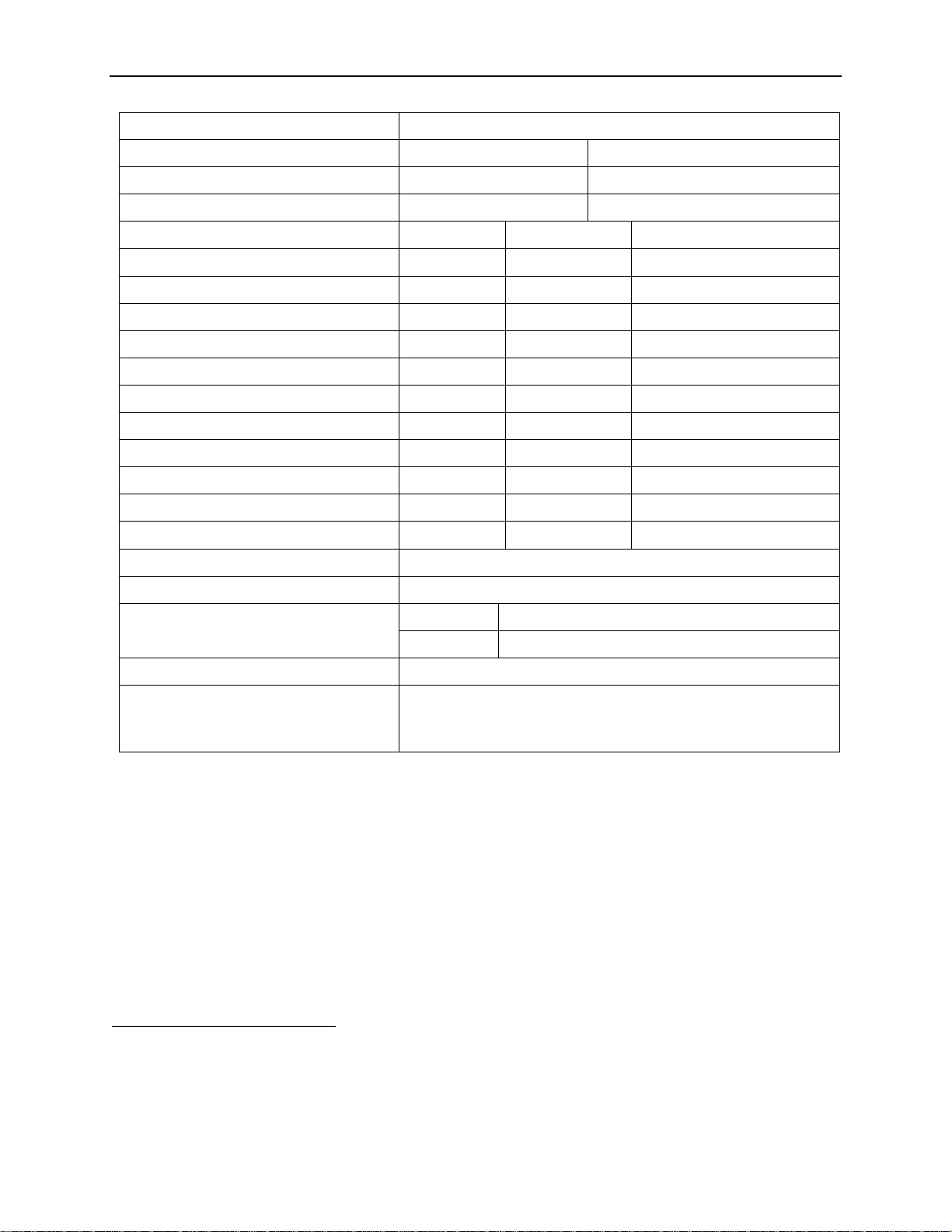

Page 12

1-4 Chapter 1: Module Overview

User's Manual Pub. 0300321-01 Rev. A

Input Description

Value

0 to 500 Ohm

±0.4

±0.5

0 to 1 kΩ

±0.6

±1

0 to 3 k Ω

±1.4

±1.8

Repeatability (at 25 ºC)

4 Hz filter

17 Hz filter

60 and 470 Hz filters1

RTD

Platinum 385

± 0.2 °C

± 0.2 °C

± 2.0 °C

Platinum 3916

± 0.2 °C

± 0.2 °C

± 2.0 °C

Copper

± 0.3 °C

± 0.3 °C

± 2.6 °C

Nickel

± 0.1 °C

± 0.1 °C

± 1.0 °C

Nickel-Iron

± 0.1 °C

± 0.1 °C

± 0.5 °C

Resistance

0 to 150 Ω

± 0.05 Ω

± 0.1 Ω

± 0.5 Ω

0 to 500 Ohm

± 0.08 Ω

± 0.15 Ω

± 0.7 Ω

0 to 1 kΩ

± 0.1 Ω

± 0.2 Ω

± 1.5 Ω

0 to 3 kΩ

± 0.2 Ω

± 0.3 Ω

± 2.0 Ω

Filters

CMRR

84 dB minimum at 50 and 60 Hz for 4 Hz and 17 Hz filters

NMRR

4 Hz filter

72 dB minimum at 50 and 60 Hz

17 Hz filter

62 dB minimum at 50 and 60 Hz

Crosstalk

-70 dB maximum

Cable resistance (applies only to 3 wire and 4-wire RTD & resistance

measurements)

25 Ω maximum, 10 Ω maximum for 10 Ω Cu 426

1

These filters do not reject 50/60 Hz. Repeatability for these filters is strongly dependent on how much 50/60 Hz noise is in the

system.

Page 13

Chapter 1: Module Overview 1-5

User's Manual Pub. 0300321-01 Rev. A

Input Description

Value

RES/RTD Current source

(Excitation current)

Excitation Current*

Range

420 µA

150 Ω, 500 Ω, 100 Ω Ni 618, 120

Ω Ni 672, 100 Ω PT 385, 200 Ω

PT 385, 100 Ω PT 3916, 200 Ω

PT 3916, 10 Ω Cu 426

210 µA

1000 Ω, 3000 Ω, 500 Ω PT 385,

1000 Ω PT 385, 500 Ω PT 3916,

1000 Ω PT 3916, 604 Ω NiFe 518

* typically, ±5% at 25 °C, ±8% from -20 °C to 65 °C

Isolation

Input to backplane isolation

50 VAC RMS working Reinforced isolation tested at 2 k

VDC for 1 minute.

Input to chassis GND isolation

50 VAC RMS working Reinforced isolation tested at 2 k

VDC for 1 minute.

Channel-to-channel, low-level

isolation

10 VDC measured between the IN-leads. Maximum voltage

between any two pins must be limited to 28 VDC.

Power Requirements

Bus +5 V (4.75 V to 5.4 V)

94 mA maximum

Bus +24 V (19.9 V to 26.4 V)

15 mA maximum

Power dissipation within module

0.9 W maximum

Peak Inrush current

Less than 150 mA at 5 V.

Less than 400 mA at 24 V.

Fault detection

Over/under range for all types.

Open Circuit detection is supported on all ranges and wire

types.

Wire Installation

Wire size

#16 to #28 AWG

Wire Strip Length

0.375 in.

Recommended Tightening Torque:

2.25 N-m (2.2 lb-in)

RoHS

Meets European RoHS component standards (January 2015

and earlier).

REACH

Meets European REACH 7 requirements.

Module Dimensions

110 mm × 87 mm × 51 mm (plastic only).

(4.33 in × 3.43 in × 2.00 in)

110 mm × 89 mm × 51 mm (with RTBs installed).

(4.33 in × 3.5 in × 2.00 in)

Page 14

1-6 Chapter 1: Module Overview

User's Manual Pub. 0300321-01 Rev. A

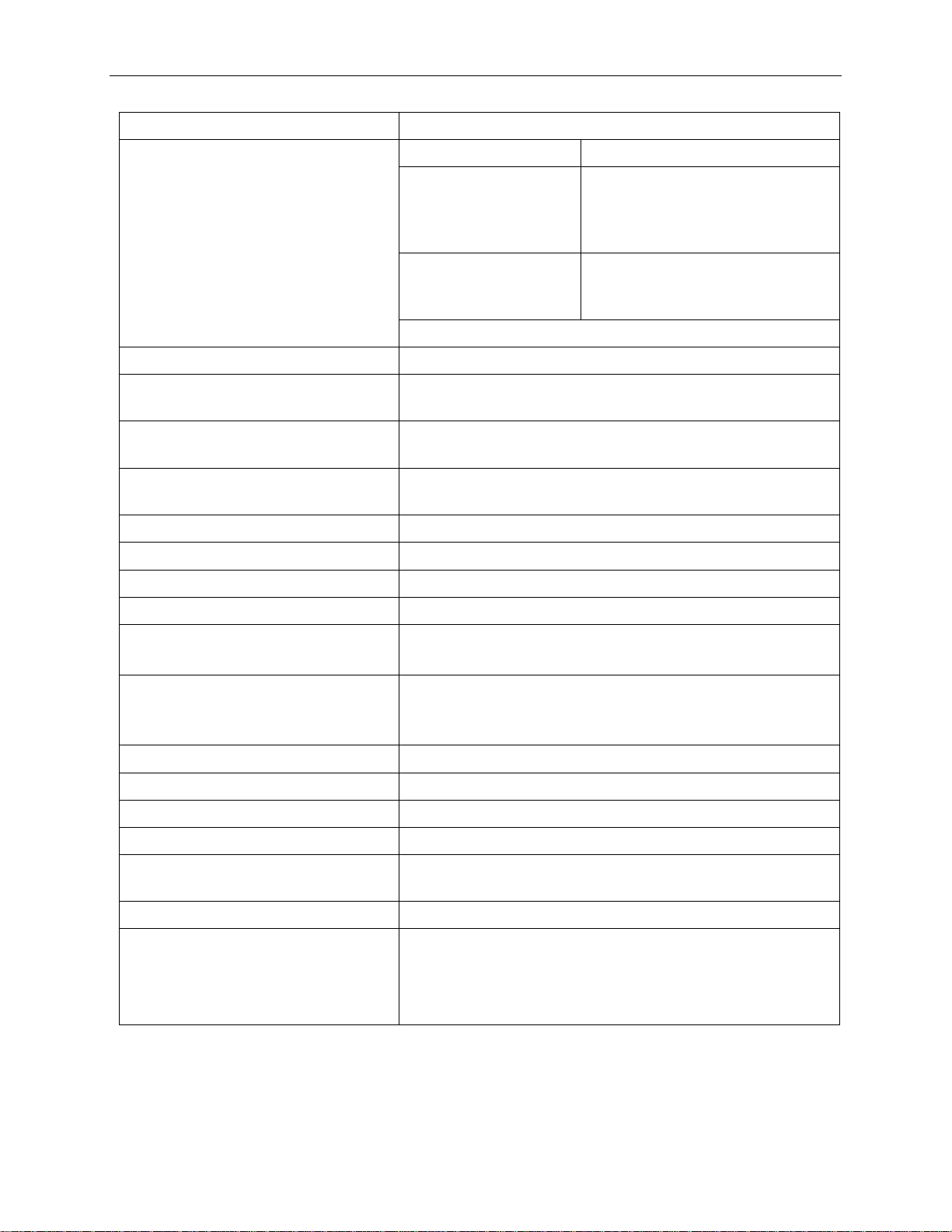

Table 1-2. EMC Specification Table

Environmental Tests

Test Level Limits

Radiated Emissions

(Enclosure) Class A, 30 MHz – 1 GHz

Conducted Emissions

Group 1, Class A (AC Mains), 150 kHz – 30 MHz

ESD immunity

(Performance Criteria B)

6 kV Indirect (Coupling Plate)

6 kV Contact Discharge (to points of initial contact)

8 kV Air Discharge (to points of initial contact)

Radiated Immunity

10 V/M with 200 Hz square-wave 50% Pulse 100% AM at 900

and at 1890 MHz

10 V/M with 1 kHz sine-wave 80% AM from 80…2000 MHz

10 V/M with 1 kHz sine-wave 80% AM from 2000…6000

MHz

EFT/B immunity

(Performance Criteria B)

Signal Ports:

±2 kV @ 5 kHz for 5 minutes, Criteria B

Power Ports:

±2 kV @ 5 kHz for 5 minutes, Criteria B

Surge transient immunity

(Performance Criteria B)

Signal Ports:

±2 kV line-earth {CM} at 2 Ω on shielded ports

Power Ports

±2 kV CM at 12 Ω

±1 kV DM at 2 Ω

Conducted RF immunity

(Performance Criteria A)

10 VRMS with 1 kHz sine wave 80% AM from 150 kHz…80

MHz on signal and power ports

Magnetic Field

(Performance Criteria A)

30 Arms/m

AC Mains Voltage Dips, Interruptions

and Variations

Follow the 61000-4-11.

Table 1-3. Safety Test Specification Table

Safety Tests

Industry Standards

UL Safety

UL 61010-2-201 Safety Requirements for Electrical Equipment for

Measurement, Control, and Laboratory Use - Part 2-201: Particular

Requirements for Control Equipment (NRAQ, NRAQ7)

cUL CAN/CSA C22.2 No. 61010-1-12 (Safety Requirements for Electrical

Equipment for Measurement, Control,

and Laboratory Use – Part 1: General Requirements)

Page 15

Chapter 1: Module Overview 1-7

User's Manual Pub. 0300321-01 Rev. A

UL Hazardous

Locations

ULH ANSI/ISA–12.12.01–2007 Nonincendive Electrical Equipment for Use

in Class I, Division 2 Hazardous (Classified) Locations (NRAG)

cULH CSA C22.2 No. 213-M1987 - Non-incendive Electrical Equipment for

use in Class I Division 2 Hazardous Locations - March 1987 (NRAG7)

Temp code T5 or better, Pollution degree 2, gas groups a, b, c, & d

CE EMC Directive

IEC 61131-2 Programmable Controllers: Third Edition 2007-02, Clause 8

IEC 61000-6-2: Generic Industrial Immunity

IEC 61000-6-4: Generic Industrial Emissions

Section 1.3 Data Formats

There are four data input types:

• Engineering units ×1

• Engineering units ×10

• Raw/proportional count

• Percentage Full Scale

Section 1.4 Hardware Features

Channels are wired as differential inputs. Open-circuit detection is available in

the form of open circuit inputs on all ranges and wire types. Inputs are protected

from electrostatic discharge up to 6 kV for indirect and contact discharge, 8 kV

for air discharge.

1.4.1 LED Blink Codes

A 2085-IR8-SC module uses a single, green OK LED to show power or module

operational status.

When startup is completed, and all internal tests have passed, the LED is solid

GREEN. If the LED remains off, there is an error with the module: it may not

have power, or the module failed to pass the self-test.

Table 1-4 LED Status Indicators

Indicator

State

Description

Fast blink

green

Offline mode. This means the module has power but

not yet been configured. Use CCW to download the

configuration, then module will go into run mode.

Module OK

LED Status

Off

No power applied to device or the module may have

failed to pass its self-test.

Solid

Green

RUN mode. Module has power runs normally.

Page 16

1-8 Chapter 1: Module Overview

User's Manual Pub. 0300321-01 Rev. A

Indicator

State

Description

Blinking

Green

LED blink status:

1. Internal use only.

2. Internal use only.

3: Calibration Data Invalid.

4: Serial Number Invalid.

5: Indicates ADC communication error.

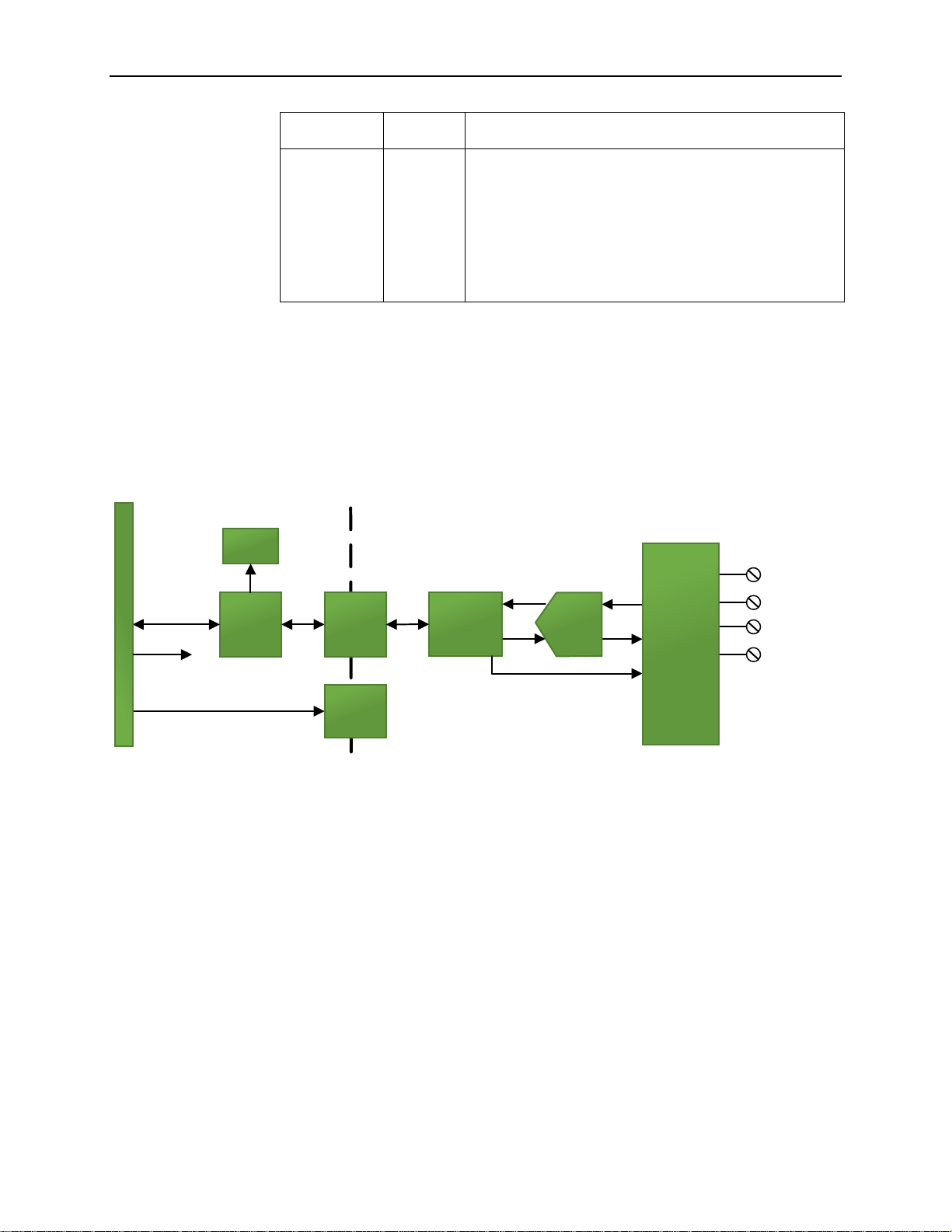

Section 1.5 System Overview

The 2085-IR8-SC module is expected to operate indefinitely. It does not require

periodic maintenance or calibration. The module communicates to the controller

through the bus interface. The module also receives 5 VDC and 24 VDC through

the bus interface.

Block diagram:

Isolator

Isolated

DC-DC

Converter

EXCx

Sense+x

RTNx

SENSE-x

Backplane

ASIC

Backplane

Communication

.

.

.

x8

channels

Processor

50VAC

Working

Reinforced

Isolation

5V DC

24V DC

(used by backplane

circuitry)

Status

Indicator

2085 Backplane

8 Input

Channels

ESD

Protection,

Channel

Multiplexing,

& Signal

Conditioning

RTB pins

A/D

Converter

Page 17

Section 2.1

WARNING

The backplane power and the analog inputs of the device shall only be

supplied by an Isolated Secondary Limited Energy Low Voltage source.

Compliance to

European

Union Directives

Chapter 2

Installation and Wiring

This chapter will cover:

• Compliance to European union directives

• Power requirements

• General considerations

• Installing the module

• Field wiring connections

This product is approved for installation within the European Union and EEA

regions. It has been designed and tested to meet the following directives.

2.1.1 EMC Directive

The 2085-IR8-SC is tested to meet Council Directive 2014/30/EU

Electromagnetic Compatibility (EMC) and the following standards, in whole or

in part, documented in a technical construction file:

• IEC 61000-6-4 Electromagnetic compatibility (EMC)–Part 6-4: Generic

standards–Emission standard for industrial environments

• IEC 61000-6-2 Electromagnetic compatibility (EMC)–Part 6-2: Generic

standards–Immunity for industrial environments

• EN 61131-2 Programable controllers - Part 2: Equipment requirements

and tests

Section 2.2 Power Requirements

The module receives power through the bus interface from the +5 VDC/+24

VDC system power supply, and a 24 VDC field power supply. Both must be

present for the module to operate.

Current rating at + 5 V is 94 mA maximum; for +24 V it is 15 mA maximum.

User's Manual Pub. 0300321-01 Rev. A

Page 18

2-2 Chapter 2: Installation and Wiring

User's Manual Pub. 0300321-01 Rev. A

Power rating is 0.9 Watts maximum:

5 VDC

24 VDC

94 mA

15 mA

Section 2.3 General Considerations

The 2085-IR8-SC module is suitable for use in an industrial environment when

installed in accordance with these instructions. Specifically, this equipment is

intended for use in clean, dry environments Pollution degree 22.

2.3.1 Hazardous Location Considerations

This equipment is suitable for use in Class I, Division 2, Groups A, B, C, D or

non-hazardous locations only. The following WARNING statement applies to

use in hazardous locations.

WARNING

EXPLOSION HAZARD

• Substitution of components may impair suitability for Class I,

Division 2; Class II, Division 2; and Class III, Division 2. Do not

replace components or disconnect equipment unless power has

been switched off or the area is known to be non-hazardous.

• Do not connect or disconnect components unless power has been

switched off or the area is known to be non-hazardous.

• This product must be installed in an enclosure.

• All wiring must comply with N.E.C. article 501-4(b), 502-4(b), or

503-3(b), as appropriate for Class I, Class II, and Class III

equipment.

2.3.2 Prevent Electrostatic Discharge

WARNING

Electrostatic discharge can damage integrated circuits or semiconductors if

you touch I/O expansion port connector pins or the terminal block on the

module. Follow these guidelines when you handle the module:

• Touch a grounded object to discharge static potential.

• Wear an approved wrist-strap grounding device.

• Do not touch the port connector or connector pins.

• Do not touch circuit components inside the module.

• If available, use a static-safe work station.

• When it is not in use, keep the module in its static-shield bag.

2

Pollution Degree 2 is an environment where, normally, only non-conductive pollution occurs except that occasionally

a temporary conductivity caused by condensation is expected.

Page 19

Chapter 2: Installation and Wiring 2-3

User's Manual Pub. 0300321-01 Rev. A

2.3.3 Remove Power

WARNING

Remove power before removing or inserting this module. When you

remove or insert a module with power applied, an electrical arc may occur.

An electrical arc can cause personal injury or property damage by:

• Sending an erroneous signal to your system’s field devices,

causing unintended machine motion.

• Causing an explosion in a hazardous environment.

• Causing an electrical arc. Electrical arcing causes excessive wear

to contacts on both the module and its mating connector and may

lead to premature failure.

2.3.4 Selecting a Location

Reducing Noise

Most applications require installation in an industrial enclosure to reduce the

effects of electrical interference. Analog channels are highly susceptible to

electrical noise. Electrical noise coupled to the analog channels will reduce the

performance (accuracy) of the module. Group your modules to minimize adverse

effects from radiated electrical noise and heat. Consider the following conditions

when selecting a location for the analog module. Position the module:

• Away from sources of electrical noise such as hard-contact switches,

relays, and AC motor drives.

• Away from modules which generate significant radiated heat. Refer to

the module’s heat dissipation specification.

In addition, route shielded, twisted-pair analog input wiring away from any high

voltage I/O wiring.

Section 2.4 Mounting

WARNING

Keeping module free of debris and avoiding overheating:

• Do not remove protective debris strip until after the module and

all other equipment near the module is mounted and the wiring is

complete.

• Once wiring is complete, and the module is free of debris,

carefully remove protective strip.

• Failure to remove strip before operating can cause overheating.

Page 20

2-4 Chapter 2: Installation and Wiring

User's Manual Pub. 0300321-01 Rev. A

2.4.1 Minimum Spacing

Maintain spacing from enclosure walls, wire ways, adjacent equipment, etc.

Allow 50.8 mm (2 in.) of space on all sides for adequate ventilation, as shown:

2.4.2 Parts List

Your package contains one Micro800 Expansion I/O 2085-IR8-SC Module and

one Quick Start Guide.

2.4.3 Module Description

Description

Description

1

Mounting screw hole/mounting foot

4

Module interconnect latch

2

Removable Terminal Block (RTB)

5

DIN rail mounting latch

3

RTB hold down screws

6

I/O Status LED

You can choose to wire the expansion I/O module before installing it next to the

controller or wire it once the module is secured in place.

Place the module next to the controller against the panel where you are mounting

it. Make sure the controller and module are spaced properly.

3

2

4

1

6

5

3

3

1

Page 21

Chapter 2: Installation and Wiring 2-5

User's Manual Pub. 0300321-01 Rev. A

NOTE

• This equipment is considered Group 1, Class A industrial

equipment according to IEC/CISPR 11. Without appropriate

precautions, there may be difficulties with electromagnetic

compatibility in residential and other environments due to

conducted and radiated disturbance.

• Be careful when stripping wires. Wire fragments that fall into the

controller could cause damage. Once wiring is complete, make

sure the controller is free of all metal fragments before removing

the protective debris strip.

• Do not wire more than 2 conductors on any single terminal.

• If you insert or remove the expansion I/O module while power is

on, an electrical arc can occur. This could cause an explosion in

hazardous location installations. Be sure that power is removed or

the area is nonhazardous before proceeding.

• Cable length should be less than 10 meters.

2.4.4 Insert Module Next to the Controller

Follow the instructions to insert and secure the expansion I/O module to the

controller:

NOTE

The module expansion may only be mounted horizontally.

NOTE

For environments with greater vibration and shock concerns, use the panel

mounting method, instead of DIN rail mounting.

Mounting Dimensions and DIN Rail Mounting

150 mm (5.91 in.)

44.5 mm (1.75 in.)

Micro850 Controller

2085-IR8-SC

Bus terminator

89 mm

(3.50 in.)

Page 22

2-6 Chapter 2: Installation and Wiring

User's Manual Pub. 0300321-01 Rev. A

You can install the module on DIN rails of dimension 35 mm × 7.5 mm × 1 mm

(EN 50 022-35×7.5), or on a panel.

WARNING

Hazard of intermittent grounding.

This product is grounded through the DIN rail to chassis ground. To

assure proper grounding, use zinc-plated, yellow-chromate steel DIN

rail. Using other DIN rail materials such as aluminum or plastic, that

can corrode, oxidize, or are poor conductors, may result in improper

or intermittent grounding.

Use the correct DIN rail type, and secure DIN rail to mounting surface

approximately every 200 mm (7.8 in.) and use end-anchors appropriately.

1. Before mounting the module on a DIN rail, use a flat-bladed screwdriver

in the DIN rail latch and pry it downwards until it is in the unlatched

position.

2. Hook the top of the DIN rail mounting area of the module onto the DIN

rail, and then press the bottom until the module snaps onto the DIN rail.

3. Push the DIN rail latch back into the latched position. Use DIN rail end

anchors for vibration or shock environments.

4. Snap the module into the module bay.

5. Using a screwdriver, tighten the 10…12 mm (0.39…0.47 in.) M3 self-

tapping screw to torque specifications: 0.25 N-m (2.2 lb-in).

Panel Mounting

The preferred mounting method is to use two M4 (#8) screws per module. Hole

spacing tolerance is ±0.4 mm (0.016 in.). For mounting dimensions, refer to

Micro830, Micro850, and Micro870 Programmable Controllers User Manual

2080-UM002.

To install:

6. Place the module next to the controller against the panel where you are

mounting the module.

7. Mark drilling holes through the mounting screw holes and mounting feet,

and then remove the module.

8. Drill the holes at the markings.

9. Replace the module and mount it. Leave the protective debris strip in

place until you are finished wiring the module, and any other devices.

Page 23

Chapter 2: Installation and Wiring 2-7

User's Manual Pub. 0300321-01 Rev. A

Wiring Diagram

WARNING

Hazard of damage to the terminal connector.

The Spectrum Controls RTB hold down and terminal screws must be

tightened by hand using the guidelines. They must not be tightened using a

power tool. Use a screwdriver of 0.8 × 2 mm and tighten to no more than

0.25 N-m (2.2 lb-in) torque.

Failure to follow these guidelines may result in damage to your connector.

Wire the module using the following images, which explain the layout of the 2row, 18-pin terminal block, and the associated wiring diagrams for the various

input signals and the Micro800 Expansion I/O 2085-IR8 module.

RTB1

Name

1

EXC0

2

SENSE+0

3

RTN0

4

SENSE-0

5

EXC1

6

SENSE+1

7

RTN1

8

SENSE-1

9

NC

10

NC

11

EXC2

12

SENSE+2

13

RTN2

14

SENSE-2

15

EXC3

16

SENSE+3

17

RTN3

18

SENSE-3

RTB2

Name

19

EXC4

20

SENSE+4

21

RTN4

22

SENSE-4

23

EXC5

24

SENSE+5

25

RTN5

26

SENSE-5

27

EXC6

28

SENSE+6

29

RTN6

30

SENSE-6

31

EXC7

32

SENSE+7

33

RTN7

34

SENSE-7

35

NC

36

NC

Page 24

2-8 Chapter 2: Installation and Wiring

User's Manual Pub. 0300321-01 Rev. A

2-wire Res./RTD Input 3-wire Res./RTD Input

RTN

EXC

SENSE+

+

-

SENSE-

RTN

EXC

SENSE+

SENSE-

4-wire Res./RTD Input

RTN

EXC

SENSE+

SENSE-

Terminal Block Input signal descriptions are as follows:

RTB1

Name

Desc.

RTB2

Name

Desc.

1

EXC0

Ch. 0 Excitation Current

19

EXC4

Ch. 4 Excitation Current

2

SENSE+0

Ch. 0 Positive Sense Lead

20

SENSE+4

Ch. 4 Positive Sense Lead

3

RTN0

Ch. 0 Return Current Path

21

RTN4

Ch. 4 Return Current Path

4

SENSE-0

Ch. 0 Negative Sense Lead

22

SENSE-4

Ch. 4 Negative Sense Lead

5

EXC1

Ch. 1 Excitation Current

23

EXC5

Ch. 5 Excitation Current

6

SENSE+1

Ch. 1 Positive Sense Lead

24

SENSE+5

Ch. 5 Positive Sense Lead

7

RTN1

Ch. 1 Return Current Path

25

RTN5

Ch. 5 Return Current Path

8

SENSE-1

Ch. 1 Negative Sense Lead

26

SENSE-5

Ch. 5 Negative Sense Lead

9

NC

No Connect

27

EXC6

Ch. 6 Excitation Current

10

NC

No Connect

28

SENSE+6

Ch. 6 Positive Sense Lead

11

EXC2

Ch. 2 Excitation Current

29

RTN6

Ch. 6 Return Current Path

12

SENSE+2

Ch. 2 Positive Sense Lead

30

SENSE-6

Ch. 6 Negative Sense Lead

13

RTN2

Ch. 2 Return Current Path

31

EXC7

Ch. 7 Excitation Current

14

SENSE-2

Ch. 2 Negative Sense Lead

32

SENSE+7

Ch. 7 Positive Sense Lead

15

EXC3

Ch. 3 Excitation Current

33

RTN7

Ch. 7 Return Current Path

16

SENSE+3

Ch. 3 Positive Sense Lead

34

SENSE-7

Ch. 7 Negative Sense Lead

17

RTN3

Ch. 3 Return Current Path

35

NC

No Connect

18

SENSE-3

Ch. 3 Negative Sense Lead

36

NC

No Connect

Page 25

User's Manual Pub. 0300321-01 Rev. A

Chapter 3

Configuring the 2085-IR8-SC

Using CCW

This chapter covers the following subjects:

• How to use Connected Components Workbench (CCW) and optionally

ModuleConfigConverter.exe software to configure the Module.

• Analog Data and Status settings.

• Data Links settings.

• Setting configuration parameters and associated values.

Section 3.1 Introduction

You use CCW software (v 9.00.00 and above) to configure the 2085-IR8-SC

Expansion I/O Module. Spectrum Controls, Inc. provides a custom configuration

software utility that you may use to provide configuration settings to the profile.

You then send the configuration setup to the module.

Your controller firmware must be at v. 9.011 and above as well.

The Micro850/870 Controller (Bus master) subsystem is located at the left end of

the bus. This subsystem is comprised of:

• Micro800 Controller

• Micro800 Expansion I/O Modules

• 2085-ECR Bus Terminator

Optional:

• 2080-PS120-240VAC Power Supply (separate module or built-in the

main controller).

• 2080 Expansion Modules

• 2085-EP24VDC Expansion Power Supply for Micro870 Controller.

Page 26

3-2 Chapter 3: Configuring the Micro800 Expansion I/O 2085-IR8-SC Using CCW

User's Manual Pub. 0300321-01 Rev. A

Section 3.2 Importing a Profile into CCW Software

You use the module’s add-on-profile to configure your module. The profile is

available in the CCW software. If not available, or a newer revision is released,

see Appendix A about how to manually import a module AOP to CCW.

To view information about the profile:

1. Use RA’s Module Profile Tool 2.0. This tool may be launched from

within CCW by selecting the Module Profile Tool option from the

CCW Tools menu:

2085-IR8-SC

8-Channel

RTD & R Analog Input Module

Micro850/870

Controller

Micro800

Expansion

I/O

Modules

PC Workstation

with CCW Program

and 2085-IR8-SC

RTD

Pt 385/3916, Cu 426,

Ni 618/672, NiFe 518

2080

Expansion

I/O

Modules

Micro800 Expansion I/O Module Backplane

2080

Expansion

I/O module

Backplane

USB/Ethernet

Connection

User

Resistance

150, 500, 1 k, 3 kΩ

Page 27

Chapter 3: Configuring the Micro800 Expansion I/O 2085-IR8-SC Using CCW 3-3

User's Manual Pub. 0300321-01 Rev. A

2. When prompted by Windows User Account Control, to confirm that you

wish to run the program, click Yes button.

If necessary, confirm with the Windows operating system that you wish

to run the software. The Module Profile Tool dialog appears:

3. Select the row showing the module catalog name, and then click the

View button.

The View Module Profile window appears:

The first tab of the window provides the module identity information.

This information is described in greater detail in Module Identity, later

in this section.

4. To view software language availability, module description, and a help

file for the module, click the Resources tab.

Page 28

3-4 Chapter 3: Configuring the Micro800 Expansion I/O 2085-IR8-SC Using CCW

User's Manual Pub. 0300321-01 Rev. A

The Resources tab appears:

The window lists the language chosen for the module, and the module

description. You may also use this tab to access the help file provided for

the module.

5. To view default configuration information, click the Default

Configuration tab:

6. The enabled checkbox shown on the bottom of the tab indicates that the

software provides the service for launching the MCC utility to help you

configure your module. More information is described in Setting

Configuration Parameters Using MCC, later in this section.

Page 29

Chapter 3: Configuring the Micro800 Expansion I/O 2085-IR8-SC Using CCW 3-5

User's Manual Pub. 0300321-01 Rev. A

Section 3.3 2085-IR8-SC Tab on CCW

Before you start, if needed, install the latest version of Rockwell Automation’s

Connected Components Workbench (CCW) Standard Edition.

NOTE

Using the Module Profile Tool to import the 2085-IR8 AOP into CCW

software is necessary only if you are using a CCW version earlier than

11.00.00. For information on manually importing an AOP file, see

Appendix A. For Version 11.00.00 and later, the module is already

available as a selection from the CCW Expansion Modules drop-down

menu:

To add the module to your project, and see its configuration parameters on the

CCW configuration tab:

7. From your CCW project, load the module AOP to a first Available slot

from the Expansion Modules drop-down list.

8. Once the module AOP is loaded, to view the associated variables, click

the Module Catalog Name option.

Page 30

3-6 Chapter 3: Configuring the Micro800 Expansion I/O 2085-IR8-SC Using CCW

User's Manual Pub. 0300321-01 Rev. A

The same variables can also be found on the CCW Global Variables Tab:

9. To view the configuration tab, click the Configuration option:

• Maximum Length. Shows maximum number of words available.

Each word is 16-bit.

Page 31

Chapter 3: Configuring the Micro800 Expansion I/O 2085-IR8-SC Using CCW 3-7

User's Manual Pub. 0300321-01 Rev. A

• Configuration. The textbox lists out the whole module configuration

value.

• Radix. The drop-down menu contains the following number formats

for indicating module configuration value. Options are:

- Hex. Default option. Characters represented as hexadecimal.

Example: 0×7FFF as 32767 in decimal format.

- ASCII: Characters represented as ASCII. Example: \7F\FF

- Binary: Characters represented as 0 and 1. Example:

0111111111111111

- Decimal. Characters represented as decimals. Example:

327673

• Launch. Use to populate the file path field. The file path lets you

enter the file path for opening the MCC utility program to assist you

in configuring the module. Use the Browse ellipse to navigate to

where the utility is stored. Then click the Launch button to start the

utility.

Section 3.4 Setting Configuration Parameters Using MCC

You may create the configuration for each channel using the utility provided by

Spectrum Controls, Inc. You download the utility from the Spectrum Controls

website at www.spectrumcontrols.com.

NOTE

It is recommended that when you generate your configuration, that you

use the Binary Radix selection. If you choose the Decimal Radix, the

utility is unable to work with negative values.

You may create the configuration for each channel using the MCC utility

provided by Spectrum Controls, Inc. You download the utility from the Spectrum

Controls website at https://www.spectrumcontrols.com.

To use the MCC utility:

1. The first time you configure a Spectrum Controls 2085 analog module,

you must provide the file path of the utility to the CCW software.

3

The valid range for the Decimal Radix indication is from 0 to 65535. It does not accept negative values. If

you need to receive negative values, select the Hex Radix option instead.

Page 32

3-8 Chapter 3: Configuring the Micro800 Expansion I/O 2085-IR8-SC Using CCW

User's Manual Pub. 0300321-01 Rev. A

2. Navigate to the CCW Configuration Tab and click in the file path

textbox below the Launch button.

The Browse button appears.

3. Click the button, navigate to the directory where you installed the CCW

program, and select the ModuleConfigConverter tool located in the

Spectrum Tool directory:

Example. C:\Program Files (x86)\Rockwell

Automation\CCW\SpectrumTool

4. To run the tool, click Launch. The Module Config Converter dialog

appears:

5. Select the 2085-IR8-SC module from the drop-down menu, and click

OK:

Page 33

Chapter 3: Configuring the Micro800 Expansion I/O 2085-IR8-SC Using CCW 3-9

User's Manual Pub. 0300321-01 Rev. A

The 2085-IR8-SC Configuration Setup dialog appears:

6. View and specify the following options as needed. See Channel

Configuration Bit locations listed later in this section for details on the

settings for every configuration bit:

• Chan. Lists number of input channel from 0 to 7.

• Enable. Specifies whether to enable use of this channel. Enabled by

default (checkbox enabled).

• Input Type. Specifies which input type to use. Select type from

drop-down list. 100 Ω Platinum 385 is default:

• Data Format. Specifies which data format to use for reporting input

values. Default is Engineering Units X1:

• Temp Units. Specifies the temperature units the module reports in

Centigrade or Fahrenheit. Default is Centigrade:

Page 34

3-10 Chapter 3: Configuring the Micro800 Expansion I/O 2085-IR8-SC Using CCW

User's Manual Pub. 0300321-01 Rev. A

• Connection. Defines connection type. Default is 3-Wire With

Compensation:

• Filter. Specifies which filter to use. Default is 17 Hz.

• Open Circuit Response. Specifies how to respond to an open circuit

condition. Default is Upscale4.

• Process Alarm . Specifies whether a warning on under- or over-

range detection (from user-defined values) is turned on for the

channel, disabled, or enabled for both alarm and latch.

• Process Alarm High. Specify over range value of a user-defined

value for the module to monitor.

• Process Alarm Low. Specify under range value of a user-defined

pair of high and low values for the module to monitor.

• Channel Bias. Specifies individual channel bias values. Default bias

is 0. Range may be -32768 to 32767.

4

The Disable option is only available for voltage measurement.

Page 35

Chapter 3: Configuring the Micro800 Expansion I/O 2085-IR8-SC Using CCW 3-11

User's Manual Pub. 0300321-01 Rev. A

7. When finished making selections, click Generate.

The Configuration Text dialog appears with your configuration settings

for all the channels.

You can manually copy the settings and paste it to the textbox of the

CCW Configuration tab5.

8. To automatically copy the generated settings into the textbox of the

CCW Configuration tab, have the textbox visible on the monitor screen,

and then click Copy to CCW button5.

9. The utility copies the configuration settings and shows it inside the

textbox.

10. Download the CCW project to controller and start to run the module

operation.

5

It is recommended that before manually or automatically pasting your configuration settings to the textbox

of the CCW Configuration tab, be sure to select the Hex Radix indication on both software packages. The

CCW software is unable to receive negative values under Decimal Radix indication.

Page 36

3-12 Chapter 3: Configuring the Micro800 Expansion I/O 2085-IR8-SC Using CCW

User's Manual Pub. 0300321-01 Rev. A

Section 3.5 Software Information

3.5.1 Software Versioning

The software version tracks major and minor revisions for end users.

The shipped software version begins at version 1.1.

Once released, the major revision is typically incremented if new features are

introduced to the product. Otherwise only the minor revision is incremented.

3.5.2 Software Updates

In-field updating of the software by the end user is not supported.

3.5.3 Startup and Factory Default Conditions

After the module boots and before the initial configuration is received, the

module holds the default configuration as specified in the Configuration

Assembly. There is no input data communication and no signal outputting before

the controller goes into run mode. The default configuration is for all channels

enabled in the 3-wire, 100PT385 range with the 17 Hz filter in Engineering ×1

units.

3.5.4 PLC Interfaces

The 2085 platform treats all data on an I/O module as a member of a named

Array of Words.

Module Identity

The following values will be stored in the Vendor ID, Product_Type,

Product_Code, Series_Rev, and Mod_Features arrays:

Parameter

Description

Vendor ID

58 (Spectrum Controls) [0×03A]

Product Type

10 (Analog) [0×0A]

Product Code

119 [0×77]

Series Rev

50208 [0×C420] (First release revision

is 1.1)

Module Catalog String

2085-IR8-SC

3.5.5 Connection Types and Assembly Sizes

The size of each assembly is listed in the table below. Each word takes 2 bytes.

These values are stored in the Mod_Size array:

Table

Size (words)

Configuration Assembly

32

Input Assembly

14

Output Assembly

1

Page 37

Chapter 3: Configuring the Micro800 Expansion I/O 2085-IR8-SC Using CCW 3-13

User's Manual Pub. 0300321-01 Rev. A

3.5.6 Configuration Table

The configuration table size for the module is 32 words. Each Configuration Bit

is formed in an unsigned 16-bit Data Type. Each value input is assigned to a

signed 16-bit Data Type with a range of -32768 to +32767.

Word Index

Tag Name for 2085-IR8-SC (32 Words)

Config. 0

Ch0 Configuration Bits

Config. 1

Ch0 Process Alarm High Value

Config. 2

Ch0 Process Alarm Low Value

Config. 3

Ch0 Channel Bias Value

…

Ch1 to Ch6 Configurations

Config. 28

Ch7 Configuration Bits

Config. 29

Ch7 Process Alarm High Value

Config. 30

Ch7 Process Alarm Low Value

Config. 31

Ch7 Channel Bias Value

3.5.7 Channel Configuration Bit Location Data

Feature

Option

Decimal

Value

Configuration Bit

15

14

13

12

11

10 9 8 7 6 5 4 3 2 1 0

Channel

Enable

Enable

0

0

Disable

1

1

Input Type

Pt 385 100 Ω

0 0 0 0 0

Pt 385 200 Ω

1 0 0 0 1

Pt 385 500 Ω

2 0 0 1 0

Pt 385 1000 Ω

3 0 0 1 1

Pt 3916 100 Ω

4 0 1 0 0

Pt 3916 200 Ω

5 0 1 0 1

Pt 3916 500 Ω

6 0 1 1 0

Pt 3916 1000 Ω

7 0 1 1 1

Cu 426 10 Ω

8 1 0 0 0

Ni 618 100 Ω

9 1 0 0 1

Ni 672 120 Ω

10 1 0 1 0

NiFe 518 604 Ω

11 1 0 1 1

150 Ω

12 1 1 0 0

500 Ω

13 1 1 0 1

1000 Ω

14 1 1 1 0

3000 Ω

15 1 1 1 1

Data Format

Engineering Units ×1

0

0

0

Engineering Units ×10

1 0 1

Page 38

3-14 Chapter 3: Configuring the Micro800 Expansion I/O 2085-IR8-SC Using CCW

User's Manual Pub. 0300321-01 Rev. A

Feature

Option

Decimal

Value

Configuration Bit

15

14

13

12

11

10 9 8 7 6 5 4 3 2 1 0

Raw/Proportional Data

2 1 0

Percentage Range

3 1 1

Temperature

Scale6

°C

0

0

°F 1 1

Connection

Method

3-wire with compensation

0

0

0

4-wire

1 0 1

2-wire

2 1 0

Invalid

NA

NA

Filter

Frequency

17 Hz

0

0

0 4 Hz

1 0 1

62 Hz

2 1 0

470 Hz

3 1 1

Open Circuit

Detection

Upscale

0 0

0 Downscale

1 0 1

Zero

2 1 0

Disable

3 1 1

Process Alarm

& Latching

Both Disabled

0 0 0 Alarm Enabled Only

1 0 1

Alarm & Latching Enabled

2 1 0

Invalid

NA

NA

3.5.8 Channel Configuration Values

The module provides 3 words for you to enter each channel’s Process Alarm

High value, Process Alarm Low value, and Channel Bias value. Each value is

specified as a full-scale integer which starts from -32768 to +32767. See the

related information in the Process Alarm and Latching feature and the Channel

Bias sections later in this manual.

Feature

Type

Length

Process Alarm High

INT

1 word

Process Alarm Low

INT

1 word

Channel Bias

INT

1 word

6

Effective only when the “Input Type” of the selected input channel is configured to use “RTD”

type and EU×1 or EU×10 Data Format.

Page 39

Chapter 3: Configuring the Micro800 Expansion I/O 2085-IR8-SC Using CCW 3-15

User's Manual Pub. 0300321-01 Rev. A

3.5.9 Input Table

The input table size for the module is 16 words. Each channel data is assigned to

a signed 16-bit data byte and displays value between -32768 to +32767. The

actual display value is clamped by each Input Type limit, or by the signed 16-bit

data byte, whichever comes first. Other status indication bits, fault bits, and

software revision information are in an unsigned 16-bit Data Type.

Word

Index

Tag Name for

2085-IR8-SC (14 Words)

AI_00

Ch0 Data

AI_01

Ch1 Data

AI_02

Ch2 Data

AI_03

Ch3 Data

AI_04

Ch4 Data

AI_05

Ch5 Data

AI_06

Ch6 Data

AI_07

Ch7 Data

AI_08

Ch1 Status

Ch 0 Status

AI_09

Ch3 Status

Ch 2 Status

AI_10

Ch5 Status

Ch 4 Status

AI_11

Ch7 Status

Ch 6 Status

AI_12

Module Status

AI_13

Software Revision

3.5.10 Input Bit and Value Allocation

Status &

Reading

Indication

Word

Index

High Byte

Low Byte

Bits

15

14

13

12

11

10 9 8 7 6 5 4 3 2 1 0

Ch0 Data

AI_00

Signed INT

Ch1 Data

AI_01

Signed INT

Ch2 Data

AI_02

Signed INT

Ch3 Data

AI_03

Signed INT

Ch4 Data

AI_04

Signed INT

Ch5 Data

AI_05

Signed INT

Ch6 Data

AI_06

Signed INT

Ch7 Data

AI_07

Signed INT

Ch 1 & 0

Status

AI_08

-

OC

OR

UR

PAH

PAL

ADC

FT1 - OC

OR

UR

PAH

PAL

ADC

FT0

Ch 3 & 2

Status

AI_09

-

OC

OR

UR

PAH

PAL

ADC

FT3 - OC

OR

UR

PAH

PAL

ADC

FT2

Ch 5 & 4

Status

AI_10

-

OC

OR

UR

PAH

PAL

ADC

FT5 - OC

OR

UR

PAH

PAL

ADC

FT4

Page 40

3-16 Chapter 3: Configuring the Micro800 Expansion I/O 2085-IR8-SC Using CCW

User's Manual Pub. 0300321-01 Rev. A

Status &

Reading

Indication

Word

Index

High Byte

Low Byte

Bits

15

14

13

12

11

10 9 8 7 6 5 4 3 2 1 0

Ch 7 & 6

Status

AI_11

-

OC

OR

UR

PAH

PAL

ADC

FT7 - OC

OR

UR

PAH

PAL

ADC

FT6

Module &

Channel

Fault

AI_12

MF

CAL

SN

Unused

- - - - - - -

-

Software

Revision

AI_13

Signed INT

3.5.11 Module and Channel Fault Bit and Value Description

Module and Channel Fault

Name

Description

Unused

Bits marked as Not Used are set to 0.

CAL

Invalid Cal Data

The stored calibration data or checksum is corrupt or invalid.

The module must be factory calibrated before it will operate normally.

SN

Invalid Serial Number Data

The stored serial number checksum is corrupt or invalid.

The module must be factory calibrated before it will operate normally.

MF

Module Fault

Set as global fault if any channel fault.

3.5.12 Software Revision

Name

Description

Displayed as an integer value. Example: 1101 is version 1.1.01

3.5.13 Channel Status

Channel Status

Name

Description

FT<n>

Channel Fault <Channel>

Channel Fault bit. If a bit is set (1) then there is an error associated with that

input channel.

ADC<n>

ADC Communication Failure or PGA Connection Failure

When set to 1, indicates there is a channel ADC communication failure or PGA

connection error. This is a hardware fault.

PAL<n>

Process Alarm Low

When set to 1, indicates the channel input value is less than or equal to the

user-defined Process Alarm Low Value in the configuration table.

Page 41

Chapter 3: Configuring the Micro800 Expansion I/O 2085-IR8-SC Using CCW 3-17

User's Manual Pub. 0300321-01 Rev. A

Channel Status

Name

Description

PAH<n>

Process Alarm High

When set to 1, indicates the channel input value is greater than or equal to the

user-defined Process Alarm High Value in the configuration table.

UR<n>

Under Range

When set to 1, indicates the channel input reading is less than or equal to the

minimum point of the selected Input Type range or the Data Type low limit,

-32768.

OR<n>

Over Range

When set to 1, indicates the channel input reading is greater than or equal to the

maximum point of the selected Input Type range or the Data Type high limit,

+32767.

OC<n>

Open Circuit

When set to 1, indicates the channel connection on the terminal block is open.

Unused

Bits marked as Not Used are set to 0.

3.5.14 Channel Data

Channel Data

Length

Name

Description

1 word

Ch<n>

Data

Channel Input Data <Channel>

The Data Type for the Channel Input Data is a signed 16-bit integer. The

integer ranges from -32768 to +32767.

See additional indication information about the Under/Over Range Alarm

feature and information about the Open Circuit Detection.

3.5.15 Output Table

The output table size for the module is 1 word. The 16 bits in each word are the

control bits on clearing the Low and High Process Alarm Latches for 8 channels

a group. To operate the control bits, see the information about the Process Alarm

and Latching feature.

Word

Index

Tag Name for

2085-IR8-SC (1 Word)

AO_00

Ch 7:0 Clear High/Low Process

Alarm Latch

Page 42

3-18 Chapter 3: Configuring the Micro800 Expansion I/O 2085-IR8-SC Using CCW

User's Manual Pub. 0300321-01 Rev. A

3.5.16 Output Bit Allocation

Process

Alarm

Latch

Word

Index

High Byte

Low Byte

Bits

15

14

13

12

11

10 9 8 7 6 5 4 3 2 1 0

Ch 7:0

AO_0

0 CH7

CL

7

CH

6

CL

6

CH

5

CL

5

CH

4

CL

4

CH

3

CL

3

CH

2

CL

2

CH

1

CL

1

CH

0

CL

0

3.5.17 Output Bit Description

AO_00: Clear High/Low Process Alarm Latches

Bit

Name

Description

Even

CL<n>

Clear Low Process Alarm Latch

0: Normal Operation

1: Clear low process alarm latch

Odd

CH<n>

Clear High Process Alarm Latch

0: Normal Operation

1: Clear high process alarm latch

Section 3.6 Product Features

The following sections provide information on user-configurable parameters.

3.6.1 Data Format

The Data Format is used to define the display scale of the measured input data.

Each channel can display different formats, based on user-defined choices. This

module provides four options for channel input display:

Index

Data Format

Note

0

Engineering Unit ×1

Default

1

Engineering Unit ×10

2 Raw/Proportional

3

Percentage Full Scale

3.6.2 Input Type

The maximum range to display a measured input data in the input table is from 32768 to +32767 as a signed 16-bit integer. The actual range is scaled to fit the

selected Input Type. For example, the valid range for Pt 385 types is from -200°C

to 850°C. In Engineering Unit ×1 format, the valid display range is from -2000 to

8500, which provides the resolution down to 1 decimal place.

Page 43

Chapter 3: Configuring the Micro800 Expansion I/O 2085-IR8-SC Using CCW 3-19

User's Manual Pub. 0300321-01 Rev. A

The defined, data display resolution for each input type is listed in the following

table. If the Data Format of the Input Type supports the resolution up to after the

decimal point, the fractional part of the input reading is shifted up to display in

integers:

Input Type

EUx1

EUx10

Raw Prop

Percentage

RTD

1 decimal point (DP)

Integer

56K

10 K

Resistance

2 DP for 150 Ω

1 DP for 500/1 K/3 K Ω

1 DP for 150 Ω

Integer for 500/1 K/3 K

Ω

10.5 K

In Engineering Unit ×10 format, the valid display range is from -200 to 850 in

integers. The Raw/Proportional format provides 65 K resolution based on the

valid range in EU×1 format of the selected Input Type. The same scaling

requirement applies to the Percentage format, which has 10 K resolution.

Index

Selection

Note

0

Pt 385 100 Ω

Default

1

Pt 385 200 Ω

2

Pt 385 500 Ω

3 Pt 385 1000 Ω

4 Pt 3916 100 Ω

5 Pt 3916 200 Ω

6 Pt 3916 500 Ω

7 Pt 3916 1000 Ω

8 Cu 426 10 Ω

9 Ni 618 100 Ω

10

Ni 672 120 Ω

11

NiFe 518 604 Ω

12

150 Ω

13

500 Ω

14

1000 Ω

15

3000 Ω

Range points and limits for Input Types are provided in the following table. For

each Input Type, the limits are set to the maximum and minimum values of its

range:

Input Type

Input Value

Condition

EU x1

EU x10

Raw Prop

Percentage

RTD

100 Ω

Pt

0.385

850.00 °C

High Limit

8500

850

32767

10000

850.00 °C

High Range

8500

850

32767

10000

-200.00 °C

Low Range

-2000

-200

-32768

0

-200.00 °C

Low Limit

-2000

-200

-32768

0

200 Ω

850.00 °C

High Limit

8500

850

32767

10000

Page 44

3-20 Chapter 3: Configuring the Micro800 Expansion I/O 2085-IR8-SC Using CCW

User's Manual Pub. 0300321-01 Rev. A

Input Type

Input Value

Condition

EU x1

EU x10

Raw Prop

Percentage

RTD

Pt

0.385

850.00 °C

High Range

8500

850

32767

10000

-200.00 °C

Low Range

-2000

-200

-32768

0

-200.00 °C

Low Limit

-2000

-200

-32768

0

500 Ω

Pt

0.385

850.00 °C

High Limit

8500

850

32767

10000

850.00 °C

High Range

8500

850

32767

10000

-200.00 °C

Low Range

-2000

-200

-32768

0

-200.00 °C

Low Limit

-2000

-200

-32768

0

1000 Ω

Pt

0.385

850.00 °C

High Limit

8500

850

32767

10000

850.00 °C

High Range

8500

850

32767

10000

-200.00 °C

Low Range

-2000

-200

-32768

0

-200.00 °C

Low Limit

-2000

-200

-32768

0

100 Ω

Pt

0.3916

630.00 °C

High Limit

6300

630

32767

10000

630.00 °C

High Range

6300

630

32767

10000

-200.00 °C

Low Range

-2000

-200

-32768

0

-200.00 °C

Low Limit

-2000

-200

-32768

0

200 Ω

Pt

0.3916

630.00 °C

High Limit

6300

630

32767

10000

630.00 °C

High Range

6300

630

32767

10000

-200.00 °C

Low Range

-2000

-200

-32768

0

-200.00 °C

Low Limit

-2000

-200

-32768

0

500 Ω

Pt

0.3916

630.00 °C

High Limit

6300

630

32767

10000

630.00 °C

High Range

6300

630

32767

10000

-200.00 °C

Low Range

-2000

-200

-32768

0

-200.00 °C

Low Limit

-2000

-200

-32768

0

1000 Ω

Pt

0.3916

630.00 °C

High Limit

6300

630

32767

10000

630.00 °C

High Range

6300

630

32767

10000

-200.00 °C

Low Range

-2000

-200

-32768

0

-200.00 °C

Low Limit

-2000

-200

-32768

0

10 Ω

Cu

0.426

260.00 °C

High Limit

2600

260

32767

10000

260.00 °C

High Range

2600

260

32767

10000

-100.00 °C

Low Range

-1000

-100

-32768

0

-100.00 °C

Low Limit

-1000

-100

-32768

0

100 Ω

Ni

0.618

260.00 °C

High Limit

2600

260

32767

10000

260.00 °C

High Range

2600

260

32767

10000

-100.00 °C

Low Range

-1000

-100

-32768

0

-100.00 °C

Low Limit

-1000

-100

-32768

0

Page 45

Chapter 3: Configuring the Micro800 Expansion I/O 2085-IR8-SC Using CCW 3-21

User's Manual Pub. 0300321-01 Rev. A

Input Type

Input Value

Condition

EU x1

EU x10

Raw Prop

Percentage

RTD

120 Ω

Ni

0.672

260.00 °C

High Limit

2600

260

32767

10000

260.00 °C

High Range

2600

260

32767

10000

-80.00 °C

Low Range

-800

-80

-32768

0

-80.00 °C

Low Limit

-800

-80

-32768

0

604 Ω

Ni-Fe

0.518

200.00 °C

High Limit

2000