Spectrum Controls 1756sc-OF8H User Manual

Owner’s Guide 0300196-02 Rev. E

CONTROLLOGIX™ HART

ANALOG MODULES

Catalog Numbers: 1756sc-IF8H, 1756sc-OF8H

Important Notes |

1) PLEASE DOWNLOAD LATEST SAMPLE PROJECT FROM |

|

OUR WEBSITE AT (www.spectrumcontrols.com). |

|

2) Please read all the information in this owner’s guide before installing |

|

the product. |

|

3) The information in this owner's guide applies to hardware Series A and |

|

firmware version 1.0 or later. |

|

4) This guide assumes that the reader has a full working knowledge of the |

|

relevant processor. |

|

Notice |

|

The products and services described in this owner's guide are useful in a |

|

wide variety of applications. Therefore, the user and others responsible |

|

for applying the products and services described herein are responsible |

|

for determining their acceptability for each application. While efforts |

|

have been made to provide accurate information within this owner's |

|

guide, Spectrum Controls assumes no responsibility for the accuracy, |

|

completeness, or usefulness of the information herein. |

|

Under no circumstances will Spectrum Controls be responsible or liable |

|

for any damages or losses, including indirect or consequential damages |

|

or losses, arising out of either the use of any information within this |

|

owner's guide or the use of any product or service referenced herein. |

|

No patent liability is assumed by Spectrum Controls with respect to the |

|

use of any of the information, products, circuits, programming, or |

|

services referenced herein. |

|

The information in this owner's guide is subject to change without notice. |

|

LimitedWarranty |

|

Spectrum Controls warrants that its products are free from defects in |

|

material and workmanship under normal use and service, as described in |

|

Spectrum Controls literature covering this product, for a period of 1 year. |

|

The obligations of Spectrum Controls under this warranty are limited to |

|

replacing or repairing, at its option, at its factory or facility, any product |

|

which shall, in the applicable period after shipment, be returned to the |

|

Spectrum Controls facility, transportation charges prepaid, and which |

|

after examination is determined, to the satisfaction of Spectrum Controls, |

|

to be thus defective. |

|

This warranty shall not apply to any such equipment which shall have |

|

been repaired or altered except by Spectrum Controls or which shall |

|

have been subject to misuse, neglect, or accident. In no case shall the |

|

liability of Spectrum Controls exceed the purchase price. The |

|

aforementioned provisions do not extend the original warranty period of |

|

any product which has either been repaired or replaced by Spectrum |

|

Controls. |

Table of Contents

Preface xi

Module Overview 1

Installing and Wiring Your Module 7

Operation Within the

ControlLogix

System 19

Who Should Use This Guide .................................................................................. |

xi |

What This Guide Covers ......................................................................................... |

xi |

Related Allen-Bradley Documents .......................................................................... |

xi |

Table A. Related Allen-Bradley documents ............................................................ |

xi |

Terms & Abbreviations You Should Know ............................................................. |

xii |

General Description .................................................................................................. |

1 |

Table 1.2 1756sc-OF8H Output Ranges .................................................................. |

2 |

Table 1.3 Hardware Features .................................................................................... |

2 |

System Overview ...................................................................................................... |

3 |

Table 1.4 Recommendations to minimize interference from radiated electrical noise4 |

|

Power Requirements ................................................................................................. |

7 |

Table 2.1 Maximum current drawn by the module ................................................... |

7 |

Using your module in the ControlLogix System ...................................................... |

8 |

Module Installation and Removal ............................................................................ |

8 |

Preventing Electrostatic Discharge .......................................................................... |

9 |

Removal and Insertion Under Power ....................................................................... |

9 |

Compliance to European Union Directives ............................................................ |

10 |

Figure 2.1 (Module insertion into a rack) ............................................................... |

11 |

Figure 2.2 (Terminal block diagram with keying) .................................................... |

12 |

Wiring Your Module .............................................................................................. |

12 |

Preparing and Wiring the Cables ........................................................................... |

13 |

Terminal Block Layout |

|

................................................................................................................................ |

14 |

Wiring Inputs to the IF8H Module ........................................................................ |

14 |

Wiring Outputs to the OF8H Module .................................................................... |

15 |

Ownership and Connections .................................................................................. |

19 |

Using RSNetWorx and RSLogix 5000 ..................................................................... |

19 |

Direct Connections ................................................................................................. |

20 |

Module Operation .................................................................................................. |

20 |

Modules in a Local Chassis ................................................................................... |

21 |

Requested Packet Interval (RPI) ............................................................................ |

21 |

Modules in a Remote Chassis ................................................................................ |

22 |

Listen-Only Mode .................................................................................................. |

22 |

Multiple Owners of Input Modules ....................................................................... |

23 |

Configuration Changes in an Input Module with Multiple Owners ...................... |

24 |

vi |

ControlLogix™ Universal Analog Input Modules |

Configuring RSLogix

5000 For The IF8H

and OF8H 25

Configuration, Data, and Status Tags for the 1756sc-IF8H 37

Configuration, Data, and Status Tags

for the 1756sc-OF8H 51

Module Installation ................................................................................................ |

25 |

Adding Your Module to a Project .......................................................................... |

25 |

Configuration Tags Overview ................................................................................ |

31 |

Input Tags Overview .............................................................................................. |

34 |

Output Tags Overview |

|

(OF8H Only) ........................................................................................................... |

35 |

Send Configuration Data to the Module ................................................................ |

37 |

Configuration Tags for the 1756sc-IF8H ................................................................ |

38 |

Table 5.1a ................................................................................................................ |

38 |

Table 5.1b ................................................................................................................ |

39 |

Table 5.1c ................................................................................................................ |

40 |

Table 5.1d ................................................................................................................ |

41 |

Module Filter Selection .......................................................................................... |

41 |

Input Tags .............................................................................................................. |

44 |

Table 5.3a ................................................................................................................ |

44 |

Table 5.3b ................................................................................................................ |

45 |

Table 5.3c ................................................................................................................ |

46 |

Table 5.3d ................................................................................................................ |

47 |

Accessing The Module Tags ................................................................................. |

47 |

Changing Configuration Information at the Tags .................................................. |

49 |

Send Configuration Data to the Module ................................................................ |

51 |

Configuration Tags for the 1756sc-OF8H .............................................................. |

52 |

Table 6.1a ................................................................................................................ |

52 |

Table 6.1b ................................................................................................................ |

53 |

Table 6.1c ................................................................................................................ |

54 |

Table 6.1d ................................................................................................................ |

55 |

Table 6.1e ................................................................................................................ |

56 |

Table 6.1f................................................................................................................. |

57 |

Input Tags .............................................................................................................. |

57 |

Table 6.2a ................................................................................................................ |

58 |

Table 6.2b ................................................................................................................ |

59 |

Table 6.2c ................................................................................................................ |

60 |

Table 6.2d ................................................................................................................ |

61 |

Output Tags ............................................................................................................ |

61 |

Table 6.3 .................................................................................................................. |

61 |

Accessing The Module Tags ................................................................................. |

62 |

Changing Configuration Information at the Tags .................................................. |

64 |

Enabling and Using HART on the 1756sc-IF8H and OF8H 67

Programming

Examples 99

Table of Contents |

vii |

Configuring the Modules for HART ...................................................................... |

67 |

Figure 7.1 (Channel 0 Configuration Example) ....................................................... |

68 |

Figure 7.2 (Channel 0 Configuration Example) ....................................................... |

69 |

How the Modules Send and Receive HART Data ................................................. |

69 |

Figure 7.3 (Primary, Secondary and Slave connection).......................................... |

70 |

Figure 7.4 (Connected and Unconnected messaging) ........................................... |

71 |

Figure 7.5 (Auto Acquisition Flow)........................................................................ |

72 |

Table 7.1(Packet 0) .................................................................................................. |

73 |

Table 7.2(Packet 1) .................................................................................................. |

74 |

Table 7.3 (Packet 2) ................................................................................................. |

75 |

Table 7.4 (Packet 3) ................................................................................................. |

76 |

Table 7.5 (Packet 4) ................................................................................................. |

76 |

Figure 7.6 (Demultiplexing Ladder) ........................................................................ |

77 |

Figure 7.7 (Message Instruction) ........................................................................... |

78 |

Table 7.6 (Generic CIP Configuration) .................................................................... |

79 |

Figure 7.8 (Message Configuration Dialog) ........................................................... |

79 |

Table 7.7 (Get HART Device Information Command) ............................................ |

80 |

Table 7.8 (Response If Device Information Is Not Available) ................................ |

80 |

Table 7.9 (Response When Device Information Is Available) ............................... |

81 |

Figure 7.9 (Sending a Module Specific Command Using Ladder) ......................... |

82 |

Table 7.10 (HART Suspend and Resume Command) ............................................. |

83 |

Table 7.11 (HART Suspend and Resume Reply Packet) ........................................ |

83 |

Table 7.12 (HART Pass-Through Command Request) .......................................... |

85 |

Table 7.13 (HART Pass-Through Command Request Reply) ................................ |

86 |

Table 7.14 (HART Pass-Through Command Complete Query) .............................. |

87 |

Table 7.15 (HART Pass-Through Command Complete Query Reply) ................... |

87 |

Table 7.16 (HART Pass-Through Command Complete Query - Reply Packet |

|

Structure) ................................................................................................................ |

88 |

Figure 7.10a (HART Pass-Through Request and Query Process) ........................ |

90 |

Figure 7.10b (HART Pass-Through Request and Query Process) ........................ |

91 |

Figure 7.10c (HART Pass-Through Request and Query Process) ........................ |

92 |

Figure 7.10d (HART Pass-Through Request and Query Process) ........................ |

93 |

Figure 7.10e (HART Pass-Through Request and Query Process) ........................ |

94 |

HART Protocol Overview....................................................................................... |

94 |

Figure 7.11 (HART Message Structure) ................................................................. |

94 |

Table 7.17 (Start Character Definition) ................................................................... |

95 |

Figure 7.18 (Long Frame Address) ......................................................................... |

96 |

Sending a HART Command to a Field Device via Pass-through........................... |

97 |

Figure 7.19 .............................................................................................................. |

98 |

Figure 7.20 .............................................................................................................. |

98 |

Initial Programming ................................................................................................. |

99 |

Figure 8.1 (Sample Ladder Logic) ......................................................................... |

100 |

Demultiplexing HART Data .................................................................................. |

104 |

Figure 8.2 (IF8H Demultiplexing Ladder) .............................................................. |

104 |

Figure 8.3 (OF8H Demultiplexing Ladder) ............................................................ |

105 |

Sending HART Commands Using the MSG Instruction ..................................... |

106 |

viii |

ControlLogix™ Universal Analog Input Modules |

Troubleshooting 119

Maintaining Your Module

And Ensuring Safety 129

1756sc-IF8H Module

Specifications 133

1756sc-OF8H Module Specifications

135

Programming Your

Module 137

Additional HART Protocol Information 143

Figure 8.3a (IF8H HART Message Ladder).......................................................... |

106 |

Figure 8.3b (IF8H HART Message Ladder) ......................................................... |

107 |

Figure 8.3c (IF8H HART Message Ladder).......................................................... |

108 |

Figure 8.3d (IF8H HART Message Ladder) ......................................................... |

109 |

Figure 8.3e (IF8H HART Message Ladder).......................................................... |

110 |

Figure 8.4a (OF8H HART Message Ladder) ........................................................ |

111 |

Figure 8.4b (OF8H HART Message Ladder) ........................................................ |

112 |

Figure 8.4c (OF8H HART Message Ladder) ........................................................ |

113 |

Figure 8.4d (OF8H HART Message Ladder) ........................................................ |

114 |

Figure 8.4e (OF8H HART Message Ladder) ........................................................ |

115 |

Swap Byte Ladder ................................................................................................ |

115 |

Figure 8.5 (Converting a FLOAT Value To Its 4 byte HART Equivalent) ............ |

115 |

Converting Unpacked ASCII to Packed ASCII .................................................... |

116 |

Figure 5.6a (Packed ASCII) ................................................................................... |

117 |

Figure 5.6b (Packed ASCII) .................................................................................. |

118 |

Using Module Indicators to Troubleshoot .......................................................... |

119 |

Using RSLogix 5000 to Troubleshoot Your Module ............................................ |

120 |

Module Configuration Errors ............................................................................... |

121 |

Preventive Maintenance ...................................................................................... |

129 |

Safety Considerations .......................................................................................... |

129 |

Electrical Specifications |

|

1756sc-IF8H .......................................................................................................... |

133 |

Specifications |

|

1756sc-OF8H ........................................................................................................ |

135 |

Module Installation .............................................................................................. |

137 |

Adding Your Module to a Project ........................................................................ |

137 |

Overview ............................................................................................................... |

143 |

Message Structure ............................................................................................... |

144 |

Universal Commands ............................................................................................ |

146 |

Common Practive Commands ............................................................................... |

148 |

Status .................................................................................................................... |

152 |

Response Codes ................................................................................................... |

152 |

Declaration of Conformity .................................................................................... |

155 |

Table of Contents |

ix |

x |

ControlLogix™ Universal Analog Input Modules |

Who Should Use

This Guide

What This Guide

Covers

Related Allen-

Bradley Documents

Preface

Read this preface to familiarize yourself with the rest of the owner’s guide. This preface covers:

•who should use this guide

•what this guide covers

•related Allen-Bradley documents

•terms & abbreviations you should know

Use this guide if you design, install, program, or maintain a control system that uses Allen-Bradley ControlLogix Controllers.

You should have a basic understanding of ControlLogix products. You should also understand electronic process control and the ladder program instructions required to generate the electronic signals that control your application. If you do not, contact your local Allen-Bradley representative for the proper training before using these products.

This guide covers the 1756sc-IF8H and 1756sc-OF8H analog input and output modules with HART protocol. It contains the information you need to install, wire, use, and maintain these modules. It also provides diagnostic and troubleshooting help should the need arise.

Table A lists several Allen-Bradley documents that may help you as you use these products.

Table A. Related Allen-Bradley documents

Allen-Bradley Doc. No. |

Title |

Publication Number |

|

|

|

||

1756-PA72, ControlLogix Power Supply Installation |

|

||

-PB72 |

Instructions |

|

1756-5.1 |

1756-A4, |

ControlLogix Chassis Installation Instructions 1756-5.2 |

||

-A7, -A10, |

|

|

|

-A13, -A17 |

|

|

|

xii |

ControlLogix™ Analog HART Modules |

Terms &

Abbreviations You

Should Know

1756 Series ControlLogix Module Installation Instructions |

|

(Each module has separate document for installation) |

1756-5.5, |

|

-5.42 |

1756-L1, Logix5550 Controller User Manual |

1756-6.5.12 |

-L1M1, -L1M2 |

|

1756-DHRIO ControlLogix Data Highway Plus |

|

Communication Interface Module User Manual |

1756-6.5.2 |

1756-ENET ControlLogix Ethernet Communication Interface |

|

Module User Manual |

1756-6.5.1 |

To obtain a copy of any of the Allen-Bradley documents listed, contact your local Allen-Bradley distributor.

You should understand the following terms and abbreviations before using this guide.

A/D - Refers to analog-to-digital conversion. The conversion produces a digital value whose magnitude is proportional to the instantaneous magnitude of an analog input signal.

Attenuation – The reduction in magnitude of a signal as it passes through a system. The opposite of gain.

Channel – Refers to one of eight, small-signal analog input interfaces to the module’s terminal block. Each channel is configured for connection to a input device, and has its own configuration and status words.

Chassis – The component in which the I/O resides. The backplane connection is facilitated through a series of connectors that mate to the I/ O.

Common mode rejection ratio (CMRR) - The ratio of a device’s differential voltage gain to common mode voltage gain. Expressed in dB, CMRR is a comparative measure of a device’s ability to reject interference caused by a voltage common to its terminal relative to ground.

Common mode voltage – The voltage difference between the negative terminal and analog common during normal differential operation.

Cut-off frequency - The frequency at which the input signal is attenuated 3 dB by the digital filter. Frequency components of the input signal that

Preface xiii

are below the cut-off frequency are passed with under 3 dB of attenuation for low-pass filters.

Channel Update Time -

dB (decibel) – A logarithmic measure of the ratio of two signal levels.

Digital filter - A low-pass mathmatic single order filter applied to the A/ D signal. The digital filter provides high-frequency noise rejection.

Effective resolution – The number of bits in the channel data word that do not vary due to noise.

HART - Highway Addressable Remote Transducer

Local System - A control system with I/O chassis within several feet of the processor.

LSB (least significant bit) – The bit that represents the smallest value within a string of bits.

Multiplexer – A switching system that allows several input signals to share a common A/D converter.

Normal mode rejection (differential mode rejection) – A logarithmic measure, in dB, of a device’s ability to reject noise signals between or among circuit signal conductors, but not between the equipment grounding conductor or signal reference structure and the signal conductors.

Module update time – The amount of time that one data acquisition cycle takes place and it reported to the PLC processor.

Remote system - A control system where the chassis can be located several thousand feet from the processor chassis. Chassis communication is via the 1756-CNB or 1756-ENET Adapter.

Resolution – The smallest detectable change in a measurement, typically expressed in engineering units (e.g. 0.15 °C) or as a number of bits. For example, a 12-bit system has 4096 possible output states. It can therefore measure 1 part in 4096. See also effective resolution.

Sampling time - The time required by the A/D converter to sample an input channel.

xiv |

ControlLogix™ Analog HART Modules |

Step response time – The time required for the A/D signal to reach 95% of its expected, final value, given a full-scale step change in the output data word.

Tags - Identifiers for configuration, data, and status information found within the module. Tags allow the user to modify specific module attributes and view data and status.

Unconnected Message - A ControlNet-based message that is sent without intervention with the PLC controller.

Update time – The time for the module to sample and convert a channel input signal and make the resulting value available to the ControlLogix processor.

Chapter 1

Module Overview

This chapter describes the functionality of the modules and explains how the ControlLogix controller reads/writes analog data from the modules and how HART data is derived from the modules. Read this chapter to familiarize yourself further with your analog module. This chapter covers:

•general description and hardware features

•an overview of system and module operation

General Description This module is designed exclusively for use in the Allen-Bradley ControlLogix 1756 I/O rack systems. The HART input module, 1756scIF8H, stores digitally converted volt (V) and milliamp (mA) analog data and HART field instrument data in its image table for retrieval by all ControlLogix processors. The HART output module, 1756sc-OF8H, produces voltage or current output for control and maintains a dialog with HART-compatible field instruments

Following is a list of features available on the IF8H and OF8H modules that allow their use in a wide variety of applications.

·Removal and insertion under power (RIUP) - a system feature that allows you to remove and insert modules while chassis power is applied

·Producer/consumer communications - an intelligent data exchange between modules and other system devices in which each module produces data without having been polled

·Rolling time stamp of data - 15 bit module-specific rolling timestamp with millisecond resolution which indicates when data was sampled/applied. This timestamp may be used to calculate the interval between channel updates.

·System timestamp of data - 64 bit system clock places a timestamp on the transfer of data between the module and its owner controller within the local chassis

·IEEE 32 bit floating point format

·On-Board Features, such as custom User Scaling, Process Alarms, Rate Alarms, Digital Filtering, and Under/Overrange Detection

·User Calibration - analog I/O modules may be calibrated by the user to accommodate application related errors.

·Class I/Division 2, UL, CSA, CE, and FM Agency Certification

2 |

ControlLogix™ Analog HART Modules |

Input Ranges

The following tables provide compatibility information on the supported millivolt and voltage input and output types supported by the modules.

Table 1.1 1756sc-IF8H Input Ranges

0 |

to 5 V |

(0 |

to |

+5.125 |

V) |

|

|

|

|

||

0 |

to 10 V |

(0 to +10.25 V) |

|

||

|

|

||||

-10 to +10 V |

(-10.25 to +10.25 V) |

||||

|

|

|

|||

4 |

to 20 mA |

(3.42 to +20.58 mA) |

|||

|

|

|

|

|

|

0 |

to 20 mA |

(0 |

to |

+20.58 |

mA) |

|

|

|

|

|

|

Table 1.2 1756sc-OF8H Output Ranges

-10 |

to +10 V |

(-10.4 |

to +10.4 V) |

0 to |

20 mA |

(0 to |

+21.5 mA) |

|

|

|

|

Eight channels are individually configurable for voltage or current input/ output types. Each channel provides wire-off input, over-range, and under-range detection and indication, when enabled.

Hardware Features

The modules fit into any single slot within a ControlLogix modular system. The modules use a unique generic profile which may be configured using your RSLogix 5000 programming software.

The modules utilize a removable terminal block, that provides connections for the eight channels. The module is configured through RSLogix 5000 software, defining current or voltage inputs/outputs.

Table 1.3 Hardware Features

Hardware |

Function |

|

|

OK LED |

Displays communication and fault status |

Cal LED |

Displays a calibration related condition |

Side Label (Nameplate) |

Provides module information |

Removable Terminal Block |

Electrical connection to devices |

Door Label |

Permits easy terminal identification |

Self Locking Tabs |

Secure module in chassis slot |

Terminal Block Switch |

Locks the RTB to the module. |

Chapter 1: Module Overview |

3 |

|

Diagnostic LEDs |

|

The modules contain diagnostic LEDs that help you identify the source of |

|

problems that may occur during power-up or during normal operation. |

|

Power-up and diagnostics are explained in Chapter 9, Testing Your |

|

Module. |

System Overview |

The modules communicate with the ControlLogix processor and receive |

|

+5 Vdc and +24 Vdc power from the system power supply through the |

|

backplane interface. You may install as many modules in the system as |

|

the power supply can support. |

|

The 1756sc-IF8H has 8 channels that can receive voltage and current |

|

signals from volt or milliamp devices. When configured for volt or |

|

milliamp analog inputs, the module converts the analog values directly into |

|

floating point values. For those input types, the module assumes that the |

|

input signal is linear prior to input into the module. |

|

The 1756sc-OF8H has 8 channels that can output volt or millivolt signals |

|

to drive field sensors. |

|

Both modules support HART communication. Communication is |

|

independent of the analog acquisition and control phase. |

|

System Operation |

|

At power-up, the modules check internal circuits, memory, and basic |

|

functions. During this time the Cal LED remains on. If the module does |

|

not find any faults, it turns off the Cal LED. |

|

After completing power-up checks, the modules wait for a connection to |

|

an owner controller then valid channel configuration data from your ladder |

|

logic program. After channel configuration data is transferred, and one or |

|

more channels are enabled, the module channels are available to your |

|

ladder program. |

|

Each time the 1756sc-IF8H reads an input channel, the module tests that |

|

data for a fault, i.e. over-range, or under-range condition. If it detects an |

|

open-circuit (wire off), over-range or under-range condition, the module |

|

sets a unique bit in the status tags. |

4 |

ControlLogix™ Analog HART Modules |

Module Operation

The 1756sc-IF8H module’s input circuitry consists of eight differentialended analog inputs, multiplexed to two A/D converters. The A/D converters read the analog input signals and convert them to floating point values.

The 1756sc-OF8H has 8 channels that are routed to two quad D/A converters which output the control signal.

HART communication is independent of the analog operation. Each of the eight channels are multiplexed to one modem.

Compatibility with Current Devices and Cables

The modules are compatible with a variety of voltage and current devices with an input or output 0-5V, 0-10V, ±10V, 0-20mA, and 4-20mA.

To minimize interference from radiated electrical noise, we recommend twisted-pair and highly shielded cables such as the following:

Table 1.4 Recommendations to minimize interference from radiated electrical noise

For This Type of Device |

We Recommend This Cable (or equivalent) |

|

|

V, mA devices |

Belden 8761, shielded, twisted-pair |

|

|

Chapter 1: Module Overview |

5 |

This page is intentionally left blank.

6 |

ControlLogix™ Analog HART Modules |

This page is intentionally left blank.

Chapter2

Installing and Wiring Your Module

Read this chapter to install and wire your module. This chapter covers:

•avoiding electrostatic damage

•determining power requirements

•installing the module

•wiring signal cables to the module’s terminal block

!Electrostatic Damage

Electrostatic discharge can damage semiconductor devices inside this module if you touch backplane connector pins. Guard against electrostatic damage by observing the following precautions:

Power Requirements

The module receives its power through the ControlLogix chassis backplane from the fixed or modular +5 VDC and +24 VDC chassis power supply. The maximum current drawn by the module is shown in the table below.

Table 2.1 Maximum current drawn by the module

Module |

5VDC Amps |

24VDC Amps |

1756sc-IF8H |

0.300 |

0.070 |

1756sc-OF8H |

0.200 |

0.230 |

8 |

ControlLogix™ Analog HART Modules |

Using your module in the ControlLogix

System Place your module in any slot of a ControlLogix chassis or modular expansion chassis.

An analog I/O module translates an analog signal into or from a corresponding digital representation which controllers can easily operate on for control purposes.

A ControlLogix I/O module mounts in a ControlLogix chassis and uses a

Removable Terminal Block (RTB) to connect all field-side wiring.

Before you install and use your module you should have already:

·installed and grounded a 1756 chassis and power supply.

·ordered and received an RTB for your application.

Important: RTBs are not included with your module purchase.

Specify Allen Bradley Part Number:

1756sc-IF8H - 1756-TBCH - 36 position screw terminals 1756-TBS6H - 36 position press terminals 1492-AIFM8-3

1492-ACABLE-UC (Differential Voltage)

1492-ACABLE-UD (Differential Current)

1756sc-OF8H - 1756-TBNH - 20 position screw terminals 1756-TBSH - 20 position press terminals 1492-AIFM8-3

1492-ACABLE-WB

Module Installation and

Removal When installing the module in a chassis, it is not necessary to remove the terminal blocks from the module. However, if the terminal blocks are

Chapter 2: Installing And Wiring Your Module |

9 |

removed, use the write-on label located on the side of the terminal blocks to identify the module location and type.

Preventing

Electrostatic

Discharge This module is sensitive to electrostatic discharge.

!ATTENTION: Electrostatic discharge can damage integrated circuits or

semiconductors if you touch backplane connector pins. Follow these guidelines when you handle the module:

·Touch a grounded object to discharge static potential

·Wear an approved wrist-strap grounding device

·Do not touch the backplane connector or connector pins

·Do not touch circuit components inside the module

·If available, use a static-safe work station

·When not in use, keep the module in its static-shield box

Removal and Insertion

Under Power

These modules are designed to be installed or removed while chassis

power is applied.

!ATTENTION: When you insert or remove a module while backplane power is

applied, an electrical arc may occur. An electrical arc can cause personal injury or property damage by:

·sending an erroneous signal to your system’s field devices causing unintended machine motion or loss of process control.

·causing an explosion in a hazardous environment.

Repeated electrical arcing causes excessive wear to contacts on both the module and its mating connectors. Worn contacts may create electrical resistance that can affect module operation.

10 |

ControlLogix™ Analog HART Modules |

Compliance to European Union

Directives If this product bears the CE marking, it is approved for installation within the European Union and EEA regions. It has been designed and tested to meet the following directives.

EMC Directive

This product is tested to meet Council Directive 89/336/EEC Electromagnetic Compatibility (EMC) and the following standards, in whole or in part, documented in a technical construction file:

EN 61010-1 and EN 61131-2, EN61000-6-2:2001, EN61000-6-4:2001

EN61010-1:2001

This product is intended for use in an industrial environment.

Low Voltage Directive

This product is tested to meet Council Directive 73/23/EEC Low Voltage, by applying the safety requirements of EN 61131-2 Programmable Controllers, Part 2 - Equipment Requirements and Tests.

For specific information required by , EN61131-2:1994 + A11:1996 + A12:2000, see the appropriate sections in this publication, as well as the followingAllen-Bradley publications:

·Industrial Automation Wiring and Grounding Guidelines For Noise Immunity, publication 1770-4.1

·Automation Systems Catalog, publication B111

This equipment is classified as open equipment and must be installed (mounted) in an enclosure during operation as a means of providing safety protection.

!CAUTION

POSSIBLE EQUIPMENT OPERATION

ATTENTION: The module is designed to support Removal and Insertion Under

Power (RIUP). However, when you remove or insert an RTB with field-side power applied, unintended machine motion or loss of process control can occur.

Exercise extreme caution when using this feature.

|

Chapter 2: Installing And Wiring Your Module |

11 |

|

|

|

!WARNING

These modules are to be used only with the Allen-Bradley 1756 ControlLogix

System.

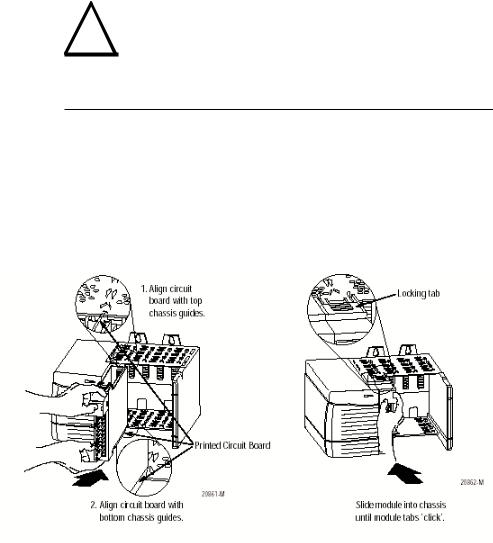

To insert your module into the rack, follow these steps:

1. Align the circuit board of your module with the card guides at the top and bottom of the chassis.

Figure 2.1 (Module insertion into a rack)

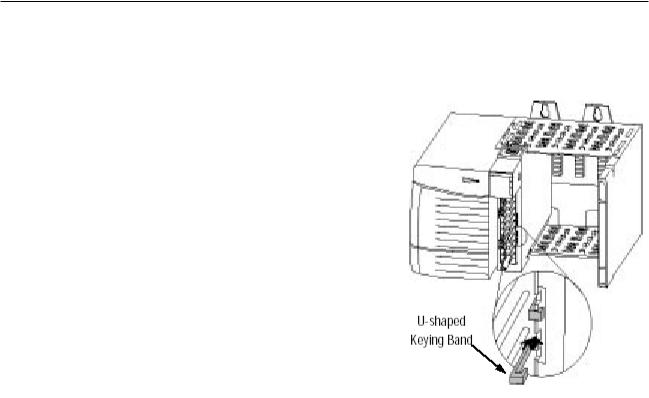

2. Key the RTB in positions that correspond to unkeyed module positions. Insert the wedge-shaped tab on the RTB with the rounded edge first. Push the tab onto the RTB until it stops.

Keying the Removable Terminal Block

Key the RTB to prevent inadvertently connecting the incorrect RTB to your module.

When the RTB mounts onto the module, keying positions will match up. For example, if you place a U-shaped keying band in position #4 on the module, you cannot place a wedge-shaped tab in #4 on the RTB or your RTB will not mount on the module.

We recommend that you use a unique keying pattern for each slot in the chassis.

12ControlLogix™ Analog HART Modules

1.Insert the U-shaped band with the longer side near the terminals. Push the band onto the module until it snaps into place.

Figure 2.2 (Terminal block diagram with keying)

Wiring Your Module |

Follow these guidelines to wire your input signal cables: |

|

• Power, input, and output (I/O) wiring must be in accordance with |

|

Class 1, Division 2 wiring methods [Article 501-4(b) of the National |

|

Electrical Code, NFPA 70] and in accordance with the authority |

|

having jurisdiction. |

|

• Peripheral equipment must be suitable for the location in which it is |

|

used. |

|

• Route the field wiring away from any other wiring and as far as |

|

possible from sources of electrical noise, such as motors, |

|

transformers, contactors, and ac devices. As a general rule, allow at |

|

least 6 in. (about 15.2 cm) of separation for every 120 V of power. |

|

• Routing the field wiring in a grounded conduit can reduce electrical |

|

noise further. |

|

• If the field wiring must cross ac or power cables, ensure that they |

|

cross at right angles. |

|

• To limit the pickup of electrical noise keep signal wires as far from |

|

power and load lines as possible. |

|

• For improved immunity to electrical noise, use Belden 8761 (shielded, |

|

twisted pair) or equivalent wire for millivolt sensors |

Chapter 2: Installing And Wiring Your Module |

13 |

•Ground the shield drain wire at only one end of the cable. The preferred location is at the shield connections at the ControlLogix chassis. (Refer to IEEE Std. 518, Section 6.4.2.7 or contact your sensor manufacturer for additional details.)

•Keep all unshielded wires as short as possible.

•To limit overall cable impedance, keep input cables as short as possible. Locate your I/O chassis as near to the sensors as your application will permit.

•Tighten screw terminals with care. Excessive tightening can strip a screw.

•Follow system grounding and wiring guidelines found in your ControlLogix Installation and Operation Manual.

Preparing and Wiring

the Cables To prepare and connect cable leads and drain wires, follow these steps:

1.At each end of the cable, strip some casing to expose individual wires.

2.Trim signal wires to 5-inch lengths beyond the cable casing. Strip about 3/16 inch (4.76 mm) of insulation to expose the ends of the wires.

3.At the module-end of the cables (see figure above):

-extract the drain wire and signal wires

-remove the foil shield

-bundle the input cables with a cable strap

4.Connect pairs of drain wires together, Channels 0 and 1, Channels 2 and 3, Channels 4 and 5, Channels 6 and 7. Keep drain wires as short as possible.

5.Connect the drain wires to the grounding lug on the PLC chassis.

6.Connect the signal wires of each channel to the terminal block. Important: Only after verifying that your connections are correct for each channel, trim the lengths to keep them short. Avoid cutting leads too short.

7.At the source-end of cables from voltage devices:

-remove the drain wire and foil shield

-apply shrink wrap as an option

14ControlLogix™ Analog HART Modules

-connect to devices keeping the leads short

Important: If noise persists, try grounding the opposite end of the cable, instead (Ground one end only.)

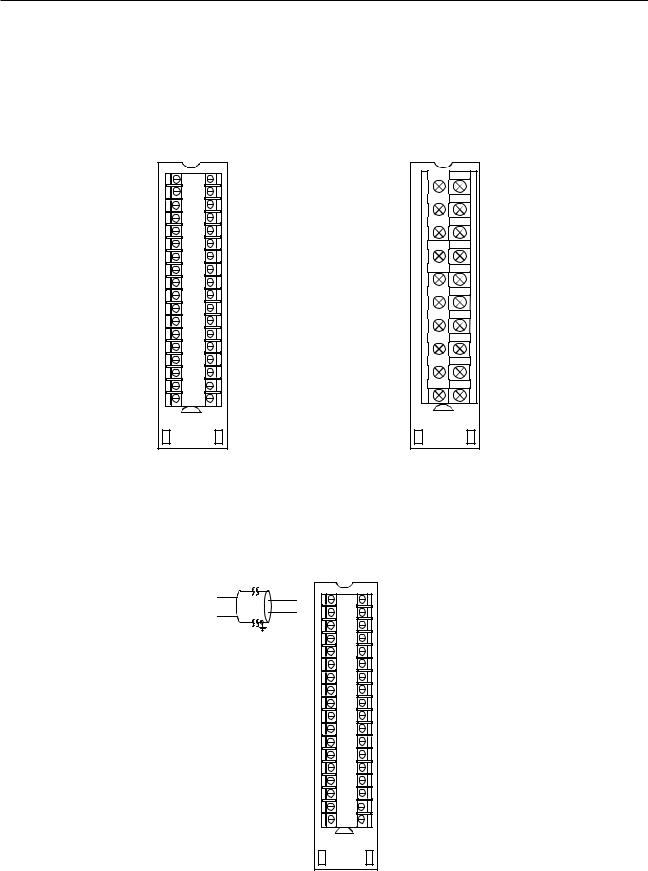

Terminal Block Layout

The following figure shows the general terminal block layout. The input signal type will determine which pins are used.

IN0+ |

2 |

1 |

I RTN-0 |

IN0- |

4 |

3 |

NC |

IN1+ |

6 |

5 |

I RTN-1 |

IN1- |

8 |

7 |

NC |

RTN |

10 |

9 |

RTN |

IN2+ |

12 |

11 |

I RTN-2 |

IN2- |

14 |

13 |

NC |

IN3+ |

16 |

15 |

I RTN-3 |

IN3- |

18 |

17 |

NC |

IN4+ |

20 |

19 |

I RTN-4 |

IN4- |

22 |

21 |

NC |

IN5+ |

24 |

23 |

I RTN-5 |

IN5- |

26 |

25 |

NC |

RTN |

28 |

27 |

RTN |

IN6+ |

30 |

29 |

I RTN-6 |

IN6- |

32 |

31 |

NC |

IN7+ |

34 |

33 |

I RTN-7 |

IN7- |

36 |

35 |

NC |

2 |

1 |

VOUT-4 |

VOUT-0 |

4 |

3 |

IOUT-4 |

IOUT-0 |

6 |

5 |

RTN |

RTN |

8 |

7 |

VOUT-5 |

VOUT-1 |

10 |

9 |

IOUT-5 |

IOUT-1 |

12 |

11 |

VOUT-6 |

VOUT-2 |

14 |

13 |

IOUT-6 |

IOUT-2 |

16 |

15 |

RTN |

RTN |

18 |

17 |

VOUT-7 |

VOUT-3 |

20 |

19 |

IOUT-7 |

IOUT-3 |

Wiring Inputs to the

IF8H Module

Voltage Inputs - Voltage inputs use the terminal block pins labelled IN+# and IN-#.

Voltage Input

+V

- V

IN0+ |

2 |

1 |

I RTN-0 |

IN0- |

4 |

3 |

NC |

IN1+ |

6 |

5 |

I RTN-1 |

IN1- |

8 |

7 |

NC |

RTN |

10 |

9 |

RTN |

IN2+ |

12 11 |

I RTN-2 |

|

IN2- |

14 13 |

NC |

|

IN3+ |

16 15 |

I RTN-3 |

|

IN3- |

18 17 |

NC |

|

IN4+ |

20 19 |

I RTN-4 |

|

IN4- |

22 21 |

NC |

|

IN5+ |

24 23 |

I RTN-5 |

|

IN5- |

26 25 |

NC |

|

RTN |

28 27 |

RTN |

|

IN6+ |

30 29 |

I RTN-6 |

|

IN6- |

32 31 |

NC |

|

IN7+ |

34 33 |

I RTN-7 |

|

IN7- |

36 35 |

NC |

|

Note: All terminals marked RTN are connected internally.

Chapter 2: Installing And Wiring Your Module |

15 |

Current Inputs - Current inputs use the terminal block pins labelled IN+#, IN-#, and I RTN-#. Note that HART communication is only active with current inputs.

2 Wire Current Input |

|

|

|

|

|||

|

|

2 Wire |

|

|

|

|

|

|

|

XMTR |

|

|

|

|

|

24V DC+ |

|

+ - |

IN0+ |

2 |

1 |

I RTN-0 |

|

|

|

||||||

Power |

|

|

|

|

|

|

|

Supply - |

|

|

IN0- |

4 |

3 |

NC |

|

|

|

|

IN1+ |

6 |

5 |

I RTN-1 |

|

4 Wire Current Input |

IN1- |

8 |

7 |

NC |

|||

RTN |

10 |

9 |

RTN |

||||

|

+ |

|

|||||

24V DC+ |

+ |

IN2+ |

12 |

11 |

I RTN-2 |

||

4 Wire |

|

|

|

|

|||

Power |

XMTR |

|

|

|

|

||

Supply - |

- |

- |

IN2- |

14 |

13 |

NC |

|

|

|

|

IN3+ |

16 |

15 |

I RTN-3 |

|

|

|

|

IN3- |

18 |

17 |

NC |

|

|

|

|

IN4+ |

20 |

19 |

I RTN-4 |

|

|

|

|

IN4- |

22 |

21 |

NC |

|

|

|

|

IN5+ |

24 |

23 |

I RTN-5 |

|

|

|

|

IN5- |

26 |

25 |

NC |

|

|

|

|

RTN |

28 |

27 |

RTN |

|

|

|

|

IN6+ |

30 |

29 |

I RTN-6 |

|

|

|

|

IN6- |

32 |

31 |

NC |

|

|

|

|

IN7+ |

34 |

33 |

I RTN-7 |

|

|

|

|

IN7- |

36 |

35 |

NC |

|

Note: All terminals marked RTN are connected internally.

Note: When using current inputs, if multiple (-) terminals are connected together, the channel to channel isolation will be compromised (i.e. this would be considered a single ended wiring configuration). If a single ended wiring configuration is to be utilized, the (-) terminals should also be connected to the RTN to maintain module accuracy.

Differential Current |

|

|

|

Channel |

Terminals |

Channel |

Terminals |

Channel 0 |

IN0+, IN0-, iRTN0 |

Channel 4 |

IN4+, IN4-, iRTN4 |

Channel 1 |

IN1+, IN1-, iRTN1 |

Channel 5 |

IN5+, IN5-, iRTN5 |

Channel 2 |

IN2+, IN2-, iRTN2 |

Channel 6 |

IN6+, IN6-, iRTN6 |

Channel 3 |

IN3+, IN3-, iRTN3 |

Channel 7 |

IN7+, IN7-, iRTN7 |

Differential Voltage |

|

|

|

Channel |

Terminals |

Channel |

Terminals |

Channel 0 |

IN0+, IN0- |

Channel 4 |

IN4+, IN4- |

Channel 1 |

IN1+, IN1- |

Channel 5 |

IN5+, IN5- |

Channel 2 |

IN2+, IN2- |

Channel 6 |

IN6+, IN6- |

Channel 3 |

IN3+, IN3- |

Channel 7 |

IN7+, IN7- |

16 |

ControlLogix™ Analog HART Modules |

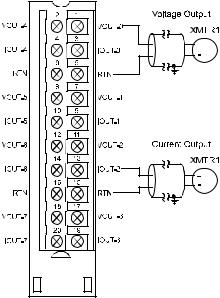

Wiring Outputs to the

OF8H Module

The OF8H module supports voltage and current outputs.

Voltage Outputs - Voltage outputs use the terminal block pins labelled

VOUT-# and RTN

Current Outputs - Current outputs use the terminal block pins labelled

IOUT-# and RTN

Note: HART communication is only active with current outputs.

Loading...

Loading...