Page 1

Publication 0300125-02 Rev. B

Isolated AC/DC (22O/24O V) Input Module

16 Discrete Inputs

Cat. No. 1771sc-IMI16

Installation Data

To the Installer This document provides information on:

• important pre-installation considerations

• power supply requirements

• installing the module

• using the indicators for troubleshooting

• module specifications

Throughout this document, we use the following symbol to make you aware

of safety considerations:

This symbol identifies information about practices or circumstances that can lead

!

Please read all the information in this document before installing the product.

This document assumes a full working knowledge of the relevant PLC.

to equipment damage, personal injury, or death. This symbol helps you identify

a hazard, avoid the hazard, and recognize the consequences.

Page 2

Installation Data

AC/DC (220/240 V) Input Module

Cat. No. 1771sc-IMI16

Important Pre-Installation

Considerations This module must be used with a 1771 Series B (or later) I/O chassis.

This module contains input filtering to limit the effects of voltage transients

caused by contact bounce and/or radiated electrical noise. This filtering cannot

be turned off. The delay due to filtering is:

• Off to On 11 ± 6 ms for AC

3 ± 2 ms for DC

• On to Off 29 ± 8 ms for AC

30 ± 7 ms for DC

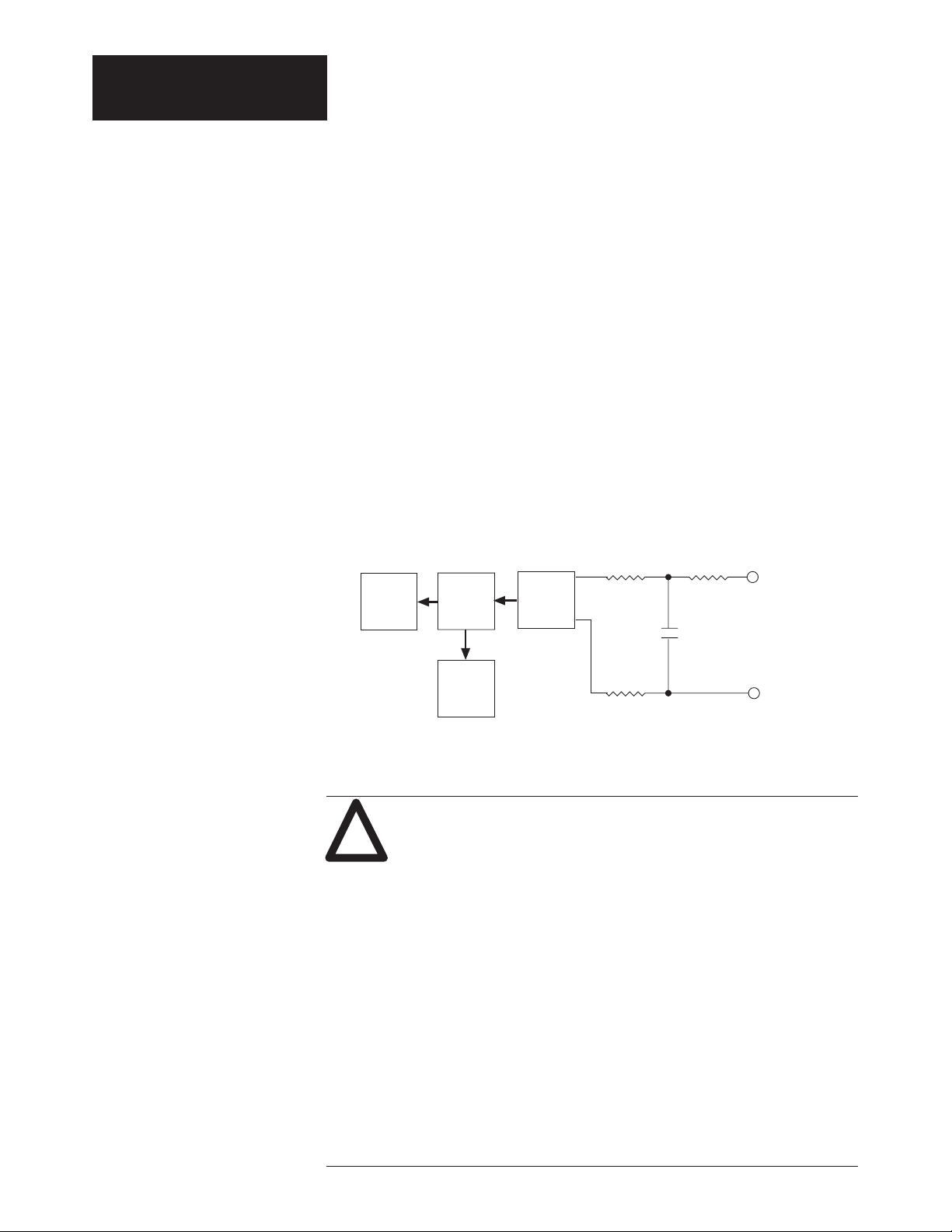

This module is designed to operate with input devices such as limit switches,

float switches, selector switches, push-buttons, and proximity switches. A

simplified schematic for this module appears in Figure 1.

Figure 1

Simplified Schematic

1771

Backplane

System

Circuitry

(filtering)

56.2 k½

Opto

Isolation

250 ½

0.15 µf

AC High

or DC Positive

Input

Indication

LED

56.2 k½

AC Low

or DC Common

The module is shipped in a static-shielded container to guard against electrostatic

discharge damage. Observe the following precautions when handling the module:

CAUTION

!

ELECTROSTATICALLY SENSITIVE COMPONENTS

Observe the following precautions to guard against electrostatic damage:

¥ Wear an approved wrist strap grounding device, or touch a grounded

object to discharge yourself before handling the module.

¥ Do not touch the gold backplane connector or connector pins.

¥ If available, use a static-free work station.

¥ Keep the module in a static-shielded bag when not in use or during

shipment.

Failure to observe these precautions can degrade performance or damage the

module.

2

Page 3

Installation Data

AC/DC (220/240 V) Input Module

Cat. No. 1771sc-IMI16

Power Supply Requirements Your module receives its power from the chassis power supply through the

1771 I/0 chassis backplane. The module requires 100 mA, maximum, from the

output of this supply. Add this to the requirements of all other modules in the

I/O chassis to prevent overloading of the chassis backplane and/or backplane

power supply.

Installing The Module In this section, we tell you how to key your I/O chassis, install your module,

and connect your wiring.

Keying Your I/O Chassis

Use the plastic keying bands, shipped with each I/O chassis, to key the I/O slots

to accept only this type of module.

The module circuit board is slotted in three places on the rear edge. The position

of the keying bands on the backplane connector must correspond to these slots

in order to insert your module. You can key any connector in an I/0 chassis to

receive this module except for the left-most connector, which is reserved for

adapter or processor modules.

Place keying bands between the following numbers labeled on the backplane

connector:

• Between 2 and 4

• Between 12 and 14

You can change the position of these keys if system redesign and rewiring

makes inserting a different module necessary.

Installing The Module In Your Chassis

To install the 1771sc-IMI16 in your 1771 I/0 chassis, follow these steps:

WARNING

!

POSSIBLE EQUIPMENT DAMAGE AND OPERATION

Always remove power from the 1771 I/0 chassis backplane and wiring arm

before removing or installing an I/O module.

¥ Failure to remove power from the backplane or wiring arm can cause module

damage, degraded performance, or injury.

¥ Failure to remove power from the backplane can also cause injury or equipment

damage due to possible unexpected operation.

3

Page 4

Installation Data

AC/DC (220/240 V) Input Module

Cat. No. 1771sc-IMI16

1. Turn off power to the I/O chassis.

2. Place the module in the plastic tracks on the top and bottom of the slot that

guides the module into position.

3. Do not force the module into its backplane connector. Apply firm, even

pressure on the module to seat it properly.

4. Snap the chassis latch over the top of the module to secure its position.

5. Connect the wiring arm to the module, as detailed below.

Connecting Wiring to the Input Module

Connections to the input module are made to the 40-terminal field wiring arm

(cat. no. 1771-WN) shipped with the module (Figure 2). Attach the wiring arm

to the pivot bar on the bottom of the I/O chassis. The wiring arm pivots upward

and connects with the module so you can install or remove the module without

disconnecting the wires.

Connect your input wiring to the field wiring arm as shown in Figure 2. Each

input channel has a positive and negative terminal. Connect only one wire to

a terminal. When multiple connections to a terminal are required, use an auxiliary

terminal strip.

CE Compliance Requirements

For installations requiring CE compliance, you must do the following:

• Use a minimum wire size of 16 AWG.

• Observe the grounding guidelines provided in Allen-Bradley’s 1771 Universal

I/O Chassis Installation Data Sheet.

• Hard wire or permanently connect the PLC to the power main, or provide

a pin and sleeve (IEC 309) connector for connection to the power main.

This equipment is intended for use in over-voltage category II installation (see

IEC 364-4-443), where the rated mains supply voltage does not exceed 1 kVac

(50/60 Hz) or 1.5 kVdc. If the input power is rated above these levels, ensure

that your system is isolated from the power main by an isolation transformer

(or equivalent over-voltage device) that has CE approval or approval from a

European test agency.

You must also protect against electrical shock by installing the I/O chassis in

an enclosure with an IP20 to IP29 rating per IEC 529. The enclosure should

have warning labels (hazard symbol 417-IEC-5036) and/or a mechanical

disconnect to minimize the risk of accidental shock during maintenance. Use

an enclosure that can only be opened with a key or tool.

4

Page 5

Installation Data

AC/DC (220/240 V) Input Module

Cat. No. 1771sc-IMI16

Figure 2

Connection Diagram

Terminal Function *

1 Input 00 +

2 Input 00 -

L1

220/240 V

AC/DC Supply

L2

AC Low

or DC Common

WARNING

!

EXPLOSION HAZARD

Never connect or disconnect equipment

while circuit is live unless area is known to

be non-hazardous.

Failure to observe these precautions can cause

equipment damager, personal injury or death.

2

L2

4

6

8

10

12

14

16

18

20

22

24

26

28

30

32

34

36

38

40

L1

220/240 VAC High

or DC Positive

WARNING

!

HIGH LEAKAGE CURRENT

Before wiring field devices to your module,

ensure that the PLC has been properly

grounded

Failure to observe this precaution can cause

equipment damage or personal injury.

(Actual wiring runs in this direction.)

Always follow the applicable codes and

laws in your area.

3 Input 01 +

4 Input 01 -

5 Input 02 +

6 Input 02 -

7 Input 03 +

8 Input 03 -

9 Not used

10 Not used

11 Input 04 +

12 Input 04 -

13 Input 05 +

14 Input 05 -

15 Input 06 +

16 Input 06 -

17 Input 07 +

18 Input 07 -

19 Not used

20 Not used

21 Input 10 +

22 Input 10 -

23 Input 11 +

24 Input 11 -

25 Input 12 +

26 Input 12 -

27 Input 13 +

28 Input 13 -

29 Not used

30 Not used

31 Input 14 +

32 Input 14 -

33 Input 15 +

34 Input 15 -

35 Input 16 +

36 Input 16 -

37 Input 17 +

38 Input 17 -

39 Not used

40 Not used

* Input numbers are

shown in octal.

5

Page 6

Installation Data

AC/DC (220/240 V) Input Module

Cat. No. 1771sc-IMI16

Important: You can use an AC (220/240 V) Output Module (cat. no. 1771scOMI16) to drive terminals on the 1771sc-IMI16, as sho wn in Figure 3. Use the

same AC power source to power both modules to ensure proper phasing

and prevent module damage. (Note: the 1771sc-OMI16 is an isolated output

module.)

Figure 3

Driving an Input with an Output

AC/DC (220/240 V)

Isolated Input Module

(Cat. No. 1771sc-IMI16)

2

4

6

8

10

12

14

16

18

20

22

24

26

28

30

32

34

36

38

40

AC (220/240 V)

Isolated Output Module

(Cat. No. 1771sc-OMI16)

2

4

6

8

10

12

14

16

18

20

22

24

26

28

30

32

34

36

38

40

220 VAC

L2

AC low

Supply

L1

AC high

6

Page 7

Installation Data

AC/DC (220/240 V) Input Module

Cat. No. 1771sc-IMI16

Using the Indicators

For Troubleshooting The front panel of your module contains one green module active indicator and

16 red channel active indicators (Figure 4). After successfully communicating

with the PLC, the module will illuminate the green module active indicator.

The 16 red status indicators illuminate when the associated input channel is

active (on).

This module contains no user-serviceable parts, and should be returned to the

factory for repair if necessary.

Note that these modules contain components which are susceptible to damage

from electrostatic discharge (ESD). An electrostatic charge can accumulate on

the surface of ordinary plastic wrapping or cushioning material. In the unlikely

event that a module should need to be returned to Spectrum Controls,

please ensure that the unit is enclosed in approved ESD packaging (such

as a static-shielding / metallized bag or black conductive container).

Spectrum Controls reserves the right to void the warranty on any unit that is

improperly packaged for shipment.

For further information or assistance, please contact your local distributor, or

call the Spectrum Controls Customer Satisfaction department at (425) 7469481 from 8:00 A.M. to 5:00 P.M. Pacific Time.

Figure 4

Status indicators

Notice

The products and services described in this publication are useful in a wide

variety of applications. Therefore, the user and others responsible for applying

the products and services described herein are responsible for determining

their acceptability for each application. While efforts have been made to provide

accurate information within this publication, Spectrum Controls assumes no

responsibility for the accuracy, completeness, or usefulness of the information

contained herein. Under no circumstances will Spectrum Controls be responsible

or liable for any damages or losses, including indirect or consequential damages

or losses, arising out of either the use of any information contained within this

publication or the use of any product or service referenced herein. No patent

liability is assumed by Spectrum Controls with respect to the use of any of the

information, products, circuits, programming, or services referenced herein.

The information contained in this publication is subject to change without notice.

Limited Warranty

Spectrum Controls warrants that its products are free from defects in material

and workmanship under normal use and service, as described in Spectrum

Controls literature covering this product, for a period of 1 year. Spectrum Controls

obligations under this warranty are limited to replacing or repairing, at its option,

at its factory or facility, any product which shall, in the applicable period after

shipment, be returned to the Spectrum Controls facility, transportation charges

prepaid, and which after examination is determined, to the satisfaction of

Spectrum Controls, to be thus defective. This warranty shall not apply to any

such equipment which shall have been repaired or altered except by Spectrum

Controls or which shall have been subject to misuse, neglect, or accident. In

no case shall Spectrum Controls liability exceed the purchase price. The

aforementioned provisions do not extend the original warranty period of any

product which has either been repaired or replaced by Spectrum Controls.

ACTIVE

00 10

01 11

02 12

03 13

04 14

05 15

06 16

07 17

Module Active Indicator (green)

Channel Active Indicators (red), 00 to 17 (octal)

7

Page 8

Installation Data

AC/DC (220/240 V) Input Module

Cat. No. 1771sc-IMI16

U.S.A. Headquarters

Spectrum Controls, Inc., P.O. Box 5533

Bellevue, Washington 98006

Fax: (425) 641-9473 ¥ Tel: (425) 746-9481

Specifications (Cat. No. 1771sc-IMI16)

Inputs per Module 16 (isolated)

Module Location 1771 I/O chassis

Nominal Input Voltage 220/240 VAC @ 50/60 Hz

250 VDC

Nominal Input Current

@ 220 VAC, 50 Hz 11.44 mA

@ 220 VAC, 60 Hz 14.08 mA

@ 250 VDC 2.16 mA

Input Signal Delay See page 1 of this publication.

On-state Current (minimum)

@ 159 VAC, 50 Hz 6.30 mA

@ 159 VAC, 60 Hz 8.00 mA

@ 184 VDC 1.30 mA

On-state Voltage (range) 159 to 264 VAC

184 to 276 VDC

Off-state Current (maximum)

@ 70 VAC 2.8 mA

@ 50 VDC 0.35 mA

Off-state Voltage (maximum) 70 VAC; 50 VDC

Input Impedance 250 ½ in series with a parallel combination of

0.15 µF and 112.4 k½

Power Dissipation 11.5 W max.; 0.10 W min.

Thermal Dissipation 39.2 BTU/hr max.; 0.34 BTU/hr min.

Backplane Current 100 mA max.

Isolation Voltage 1500 VAC channel-to-channel

1500 VAC channel-to-backplane

Environmental Conditions

Operational Temperature 0¡ to 60¡C (32¡ to 140¡F)

Storage Temperature -40¡ to +85¡C ( -40¡ to 185¡F)

Relative Humidity 5 to 95% (without condensation)

Certifications CE per Council Directives 89/336/EEC for EMC

and 73/23/EEC for Low Voltage

Conductors Wire Size 14 gage stranded, maximum

3/64 inch insulation, maximum

Category 1

2

Keying Between 2 and 4

Between 12 and 14

Field Wiring Arm A-B Catalog #1771-WN

Wiring Arm Screw Torque 7 to 9 inch-pounds

1

Max. with all 16 inputs turned on (100% duty cycle); Min. with no inputs turned on.

2

Use this conductor-category information for planning conductor routing as described

in the system-level installation manual.

The Encompass logo is a trademark of Allen-Bradley Company, Inc. © 1998 Spectrum Controls,

Inc. All rights reserved. Specifications subject to change without notice. Printed in U.S.A.

Publication 0300125-02 Rev. B August 1998

1

1

Loading...

Loading...