Page 1

Owner’s Guide 0300191-04 Rev . A

C

ONTROL

U

NIVERSAL

Catalog Number: 1756sc-IF8u

L

OGIX

A

NALOG INPUT

™

M

ODULE

Page 2

Page 3

Important Notes

1. Please read all the information in this owner’s guide before installing

the product.

2. The information in this owner's guide applies to hardware version A

and firmware version 2.0 or later.

3. This guide assumes that the reader has a full working knowledge of the

relevant processor.

Notice

The products and services described in this owner's guide are useful in a

wide variety of applications. Therefore, the user and others responsible

for applying the products and services described herein are responsible

for determining their acceptability for each application. While efforts

have been made to provide accurate information within this owner's

guide, Spectrum Controls assumes no responsibility for the accuracy,

completeness, or usefulness of the information herein.

Under no circumstances will Spectrum Controls be responsible or liable

for any damages or losses, including indirect or consequential damages

or losses, arising out of either the use of any information within this

owner's guide or the use of any product or service referenced herein.

No patent liability is assumed by Spectrum Controls with respect to the

use of any of the information, products, circuits, programming, or

services referenced herein.

The information in this owner's guide is subject to change without notice.

Limited Warranty

Spectrum Controls warrants that its products are free from defects in

material and workmanship under normal use and service, as described in

Spectrum Controls literature covering this product, for a period of 1 year.

The obligations of Spectrum Controls under this warranty are limited to

replacing or repairing, at its option, at its factory or facility, any product

which shall, in the applicable period after shipment, be returned to the

Spectrum Controls facility, transportation charges prepaid, and which

after examination is determined, to the satisfaction of Spectrum Controls,

to be thus defective.

This warranty shall not apply to any such equipment which shall have

been repaired or altered except by Spectrum Controls or which shall

have been subject to misuse, neglect, or accident. In no case shall the

liability of Spectrum Controls exceed the purchase price. The

aforementioned provisions do not extend the original warranty period of

any product which has either been repaired or replaced by Spectrum

Controls.

Page 4

Page 5

Who Should Use

This Guide

Preface

Read this preface to familiarize yourself with the rest of the owner’s

guide. This preface covers:

• who should use this guide

• what this guide covers

• related Allen-Bradley documents

• terms & abbreviations you should know

Use this guide if you design, install, program, or maintain a control system

that uses Allen-Bradley ControlLogix Controllers.

Y ou should have a basic understanding of ControlLogix products. Y ou

should also understand electronic process control and the ladder program

instructions required to generate the electronic signals that control your

application. If you do not, contact your local Allen-Bradley representative

for the proper training before using these products.

What This Guide

Covers

Related AllenBradley Documents

This guide covers the 1756sc-IF8u universal analog input module. It

contains the information you need to install, wire, use, and maintain these

modules. It also provides diagnostic and troubleshooting help should the

need arise.

T able A lists several Allen-Bradley documents that may help you as you

use these products.

Table A. Related Allen-Bradley documents

Allen-Bradley Doc. No. Title Publication Number

1756-P A72, ControlLogix Power Supply Installation

-PB72 Instructions 1756-5.1

1756-A4, ControlLogix Chassis Installation Instructions 1756-5.2

-A7, -A10,

-A13, -A17

Page 6

vi ControlLogix™ Universal Analog Input Modules

1756 Series ControlLogix Module Installation Instructions

(Each module has separate document for installation) 1756-5.5,

1756-L1, Logix5550 Controller User Manual 1756-6.5.12

-L1M1, -L1M2

1756-DHRIO ControlLogix Data Highway Plus

Communication Interface Module User Manual 1756-6.5.2

1756-ENET ControlLogix Ethernet Communication Interface

Module User Manual 1756-6.5.1

T o obtain a copy of any of the Allen-Bradley documents listed, contact

your local Allen-Bradley office or distributor .

Terms &

Abbreviations You

Should Know

Y ou should understand the following terms and abbreviations before using

this guide.

-5.42

A/D - Refers to analog-to-digital conversion. The conversion produces a

digital value whose magnitude is proportional to the instantaneous

magnitude of an analog input signal.

Attenuation – The reduction in magnitude of a signal as it passes through

a system. The opposite of gain.

Channel – Refers to one of eight, small-signal analog input interfaces to

the module’s terminal block. Each channel is configured for connection to

a input device, and has its own configuration and status words.

Chassis – See rack.

CJC - (Cold Junction Compensation) The means by which the module

compensates for the offset voltage error introduced by the temperature at

the junction between the thermocouple lead wire and the input terminal

block (the cold junction).

Common mode rejection ratio (CMRR) - The ratio of a device’s

differential voltage gain to common mode voltage gain. Expressed in dB,

CMRR is a comparative measure of a device’s ability to reject

interference caused by a voltage common to its terminal relative to

ground.

Common mode voltage – The voltage difference between the negative

terminal and analog common during normal differential operation.

Page 7

Preface vii

Cut-off frequency - The frequency at which the input signal is attenuated

3 dB by the digital filter. Frequency components of the input signal that

are below the cut-off frequency are passed with under 3 dB of attenuation

for low-pass filters.

dB (decibel) – A logarithmic measure of the ratio of two signal levels.

Digital filter - A low-pass mathmatic single order filter applied to the A/D

signal. The digital filter provides high-frequency noise rejection.

Effective resolution – The number of bits in the channel data word that

do not vary due to noise.

Local System - A control system with I/O chassis within several feet of

the processor.

LSB (least significant bit) – The bit that represents the smallest value

within a string of bits.

Mulitplexer – A switching system that allows several input signals to

share a common A/D converter.

Normal mode rejection (differential mode rejection) – A logarithmic

measure, in dB, of a device’ s ability to reject noise signals between or

among circuit signal conductors, but not between the equipment grounding

conductor or signal reference structure and the signal conductors.

Module update time – See channel update time.

Remote system - A control system where the chassis can be located

several thousand feet from the processor chassis. Chassis communication

is via the 1756-DHRIO and 1756-ENET Adapter.

Resolution – The smallest detectable change in a measurement, typically

expressed in engineering units (e.g. 0.15 °C) or as a number of bits. For

example, a 12-bit system has 4096 possible output states. It can therefore

measure 1 part in 4096. See also effective resolution.

RTD (Resistance Temperature Detector) - A temperature sensing

element with 2, 3, 4, lead wires. It uses the basic characteristics that

electrical resistance of metals increases with temperature. When a small

current is applied to the RTD, it creates a voltage that varies with

temperature. This voltage is processed and converted by the RTD module

into a temperature value.

Sampling time - The time required by the A/D converter to sample an

input channel.

Page 8

viii ControlLogix™ Universal Analog Input Modules

Step response time – The time required for the A/D signal to reach 95%

of its expected, final value, given a full-scale step change in the output

data word.

Tags - Identifiers for configuration, data, and status information found

withing the module. T ags allow the user to modify specific module

attributes and view data and status.

Update time – The time for the module to sample and convert a channel

input signal and make the resulting value available to the ControlLogix

processor.

Page 9

Table of Contents

Preface v

Module Overview

1

Installing And Wiring

Your Module 9

Who Should Use This Guide ...................................................................................v

What This Guide Covers..........................................................................................v

Related Allen-Bradley Documents ...........................................................................v

T able A. Related Allen-Bradley documents .............................................................v

Terms & Abbreviations You Should Know ............................................................. vi

General Description .................................................................................................. 1

Detailed Specifications ............................................................................................. 2

Hardware Features .................................................................................................... 3

Diagnostic LEDs....................................................................................................... 4

System Overview...................................................................................................... 4

System Operation ..................................................................................................... 5

Module Operation .................................................................................................... 5

Compatibility with Thermocouple, Current, and Millivolt Devices & Cables ......... 6

Electrostatic Damage ................................................................................................ 9

Power Requirements............................................................................................... 10

T able 2.1 Maximum current drawn by the module ................................................. 10

Module Installation and Removal .......................................................................... 10

Figure 2.1 Module insertion into a rack ................................................................ 13

Figure 2.2 T erminal block diagram with keying ..................................................... 14

Wiring Your Module .............................................................................................. 14

Preparing and Wiring the Cables ........................................................................... 15

T erminal Block Layout............................................................................................ 16

Wiring Voltage/Current Inputs the IF8u Module................................................... 17

Wiring RTD or Resistance Sensors to the IF8u Module ....................................... 18

Wiring Thermocouples to the IF8u Module .......................................................... 20

Operation Within the

ControlLogix

System 23

Programming Your

Module 29

Ownership and Connections .................................................................................. 23

Using RSNetW orx and RSLogix 5000..................................................................... 23

Direct Connections ................................................................................................. 24

Module Operation .................................................................................................. 24

Modules in a Local Chassis ................................................................................... 25

Requested Packet Interval (RPI) ............................................................................ 25

Modules in a Remote Chassis................................................................................ 26

Listen-Only Mode .................................................................................................. 27

Multiple Owners of Input Modules ....................................................................... 27

Configuration Changes in an Input Module with Multiple Owners...................... 28

Module Installation ................................................................................................ 29

Adding Your Module to a Project .......................................................................... 29

Configuring module attributes: Configuration Tags .............................................. 34

Page 10

x ControlLogix™ Universal Analog Input Modules

Configuration, Data,

and Status Tags

37

Send Configuration Data to the Module................................................................ 37

Configuration Tags ................................................................................................. 38

Global Module Settings .......................................................................................... 38

Channel Specific Settings ....................................................................................... 43

Input Tags .............................................................................................................. 50

Fault and Status Reporting Tags ........................................................................... 50

Module Data Tags.................................................................................................. 53

Programming

Examples 55

Initial Programming................................................................................................. 55

Figure 5.1 Sample Ladder Logic ............................................................................ 56

Troubleshooting

61

Using Module Indicators to Troubleshoot............................................................ 61

Using RSLogix 5000 to Troubleshoot Your Module.............................................. 62

Module Configuration Errors ................................................................................. 64

Maintaining Your

Module

And Ensuring Safety

65

Module

Specifications

69

Ther mocouple

Descriptions 7 5

Preventive Maintenance ........................................................................................ 65

Safety Considerations ............................................................................................ 65

Electrical Specifications.......................................................................................... 69

Physical Specifications .......................................................................................... 70

Environmental Specifications................................................................................. 70

Input Specifications ............................................................................................... 70

J Type Thermocouples ........................................................................................... 75

K Type Thermocouples .......................................................................................... 77

T Type Thermocouples .......................................................................................... 79

E Type Thermocouples .......................................................................................... 81

R Type Thermocouples .......................................................................................... 83

S Type Thermocouples .......................................................................................... 84

B Type Thermocouples .......................................................................................... 86

N Type Thermocouples .......................................................................................... 87

References .............................................................................................................. 90

Page 11

Using Grounded

Junction,

Ungrounded

Junction, and

Exposed Junction

Ther mocouples 97

Programming Your

Module 101

T able of Contents xi

Thermocouple Types .............................................................................................. 97

Grounded Junction ................................................................................................. 98

Ungrounded (Insulated) Junction .......................................................................... 98

Exposed Junction ................................................................................................... 98

Isolation.................................................................................................................. 98

Module Installation .............................................................................................. 101

Adding Your Module to a Project ........................................................................ 101

Declaration of Conformity .................................................................................... 105

Page 12

xii ControlLogix™ Universal Analog Input Modules

Page 13

Chapter 1

Module Overview

This chapter describes the universal analog input module and explains how

the ControlLogix controller reads analog input data from the module. Read

this chapter to familiarize yourself further with your universal analog input

module. This chapter covers:

• general description and hardware features

• an overview of system and module operation

General Description

This module is designed exclusively for use in the Allen-Bradley

ControlLogix 1756 I/O rack systems. The module stores digitally

converted thermocouple, RTD, resistance, millivolt (mV), volt (V),

milliamp (mA), and CJC temperature analog data in its image table for

retrieval by all ControlLogix processors.

Following is a list of features available on the IF8u module that allow their

use in a wide variety of applications.

· Removal and insertion under power (RIUP) - a system feature that

allows you to remove and insert modules while chassis power is applied

· Producer/consumer communications - an intelligent data exchange

between modules and other system devices in which each module

produces data without having been polled

· Rolling timestamp of data - 15 bit module-specific rolling timestamp with

millisecond resolution which indicates when data was sampled/applied.

This timestamp may be used to calculate the interval between channel or

updates

· System timestamp of data - 64 bit system clock places a timestamp on

the transfer of data between the module and its owner controller within

the local chassis

· IEEE 32 bit floating point format

· On-Board Features, such as custom User Scaling, Process Alarms, Rate

Alarms, Digital Filtering, and Under/Overrange Detection

· Automatic Calibration - analog I/O modules may perform autocalibration

on a channel-by-channel or module-wide basis to reduce drift inaccuracies

due to module ambient temperature changes.

· Class I/Division 2, UL, CSA, CE, and FM Agency Certification

Page 14

2 ControlLogix™ Counter Module

Detailed

Specifications

Input Ranges

The following tables provide compatibility information on the supported

thermocouple types and their associated temperature ranges, the

supported RTD types and their associated temperature ranges, as well as

the millivolt, volt, milliamp and resistance input types supported by the IF8u

module. To determine the practical temperature range of your

thermocouple, refer to the specifications in appendices A and B.

Table 1.1 Thermocouple Temperature Ranges

T ype °C Temperature Range °F Temperature Range

J -210°C to 1200°C -346°F to 2192°F

K -270°C to 1372°C -454°F to 2502°F

T -270°C to 400°C -454°F to 752°F

B 300°C to 1820°C 572°F to 3308°F

E -270°C to 1000°C -454°F to 1832°F

R 0°C to 1768°C 32°F to 3214°F

S 0°C to 1768°C 32°F to 3214°F

N -210°C to 1300°C -346°F to 2372°F

C 0°C to 2315°C 32°F to 4199°F

CJC Sensor 0°C to 90°C 32°F to 194°F

Table 1.2 RTD Temperature Ranges

Type °C Temp Range °F Temp Range

Platinum (385)

100 Ohm -200°C to +850°C -328°F to +1562°F

200 Ohm -200°C to +850°C -328°F to +1562°F

500 Ohm -200°C to +850°C -328°F to +1562°F

1000 Ohm -200°C to +850°C -328°F to +1562°F

Platinum (3916)

100 Ohm -200°C to +630°C -328°F to +1166°F

200 Ohm -200°C to +630°C -328°F to +1166°F

500 Ohm -200°C to +630°C -328°F to +1166°F

1000 Ohm -200°C to +630°C -328°F to +1166°F

Copper (426)

10 O hm -100°C to +260°C -148°F to +500°F

Nickel (618)

120 Ohm -100°C to + 260°C -148°F to +500°F

200 Ohm -100°C to + 260°C -148°F to +500°F

500 Ohm -100°C to + 260°C -148°F to +500°F

1000 Ohm -100°C to + 260°C -148°F to +500°F

Nickel (672)

120 Ohm -80°C to +260°C -112°F to + 500°F

Nickel/Iron (518)

604 Ohm -100°C to +200°C -148°F to +392°F

The digits in parenthisis following the RTD type represent the temperature coef ficient of resistance (alpha, a),

which is defined as the resistance change per Ohm per°°C. For instance, Platinum 385 refers to a platinum RTD

with a = 0.00385 Ohms/Ohm - °C, or simply 0.00385/°°C.

Page 15

Table 1.3 Millivolt Input Ranges

Stated Actual

-50 to +50 mV (-75 to +75 mV)

-150 to +150 mV (-175 to +175 mV)

0 to +5.0 V (-0.5 to +5.5 V)

1.0 to +5.0 V (0.5 to +5.5 V)

0 to 10.0 V (-0.5 to 10.0 V)

-10.0 to +10.0 V (-10.0 to +10.0 V)

Table 1.4 Current Input Ranges

4 to 20 mA (-3.5 to +21.5mA)

0 to 20 mA (0 to +21.5mA)

Table 1.5 Resistance Input Range

0 to 250 Ohms

0 to 500 Ohms

0 to 1000 Ohms

0 to 2000 Ohms

0 to 3000 Ohms

0 to 4000 Ohms

Chapter 1: Module Overview 3

Hardware Features

All eight input channels are individually configurable for RTD, resistance,

thermocouple, millivolt, volt, or milliamp input types. Each input channel

provides wire-off input, over-range, and under-range detection and

indication, when enabled.

The module fits into any single slot for I/O modules in a ControlLogix

modular system. The module has a unique generic profile which may be

configured using your RSLogix 5000 programming software.

The module utilizes one removable terminal block, that provides

connections for the eight input channels. There are two cold-junction

compensation (CJC) sensors that compensate for the cold junction at

ambient temperature rather than at freezing (0°C). There are eight current

sources for supplying the RTD or resistance sensors. The module is

configured through RSLogix 5000 software, defining R TD, resistance,

current or voltage input paths.

Page 16

4 ControlLogix™ Counter Module

Table 1.6 Hardware Features

Hardware Function

OK LED Displays communication and fault status of the module

Cal LED Displays a fault condition

Side Label (Nameplate) Provides module information

Removable T erminal Block Provides electrical connection to input devices

Door Label Permits easy terminal identification

Self Locking T abs Secure module in chassis slot

Terminal Block Switch Locks the R TB to the module.

Diagnostic LEDs

System Overview

The module contains diagnostic LEDs that help you identify the source of

problems that may occur during power-up or during normal operation.

Power-up and diagnostics are explained in Chapter 7, Testing Your

Module.

The module communicates with the ControlLogix processor and receives

+5 Vdc and +24 Vdc power from the system power supply through the

parallel backplane interface. You may install as many universal modules in

the system as the power supply can support. Channels (0 through 7) can

receive input signals from RTDs, resistance sources, thermocouples,

millivolt, volt, or milliamp devices. When configured for thermocouple input

types, the module converts analog input voltages into cold-junction

compensated and linearized, digital temperature readings. The module uses

the National Institute of Standards and T echnology (NIST) linearization

tables based on ITS-90 for thermocouple linearization.

When configured for R TD input types, the module converts the analog

input voltages into digital temperature readings, based on the alpha type,

wire type, and ohms specified. The standards used are the JIS C 16041997 for the Pt 385 R TD types, the JIS C 1604-1989 for the Pt 3916 RTD

types, SAMA RC21-4-1966 for the 10. Cu 426 RTD, DIN 43760 Sept.

1987 for the 120. Ni 618 RTD, and MINCO Application Aid #18 May

1990 for the 120. Ni 672 RTD.When configured for millivolt, volt, milliamp,

or resistance analog inputs, the module converts the analog values directly

into floating point values. For those input types, the module assumes that

the input signal is linear prior to input into the module.

Page 17

Chapter 1: Module Overview 5

Table 1.6 Hardware Features

Hardware Function

OK LED Displays communication and fault status of the module

Cal LED Displays a fault condition

Side Label (Nameplate) Provides module information

Removable T erminal Block Provides electrical connection to input devices

Door Label Permits easy terminal identification

Self Locking T abs Secure module in chassis slot

Terminal Block Switch Locks the R TB to the module.

System Operation

Module Operation

At power-up, the module checks internal circuits, memory , and basic

functions. During this time the Cal LED remains on. If the module does

not find any faults, it turns off the Cal LED. After completing power-up

checks, the module wait for a connection to an owner controller then valid

channel configuration data from your ladder logic program. After channel

configuration data is transferred, and one or more channels are enabled,

the module continuously converts the inputs to floating point data for use in

your ladder program.

Each time the module reads an input channel, the module tests that data

for a fault, i.e. over-range, or under-range condition. If it detects an

overrange or under-range condition, the module sets a unique bit in the

status tags.

The module’s input circuitry consists of eight differential analog inputs,

multiplexed into an A/D converter. The A/D converter reads the analog

input signals and converts them to floating point values.. The input circuitry

also continuously samples the CJC sensors, if not disabled and

compensates for temperature changes for thermocouples at the cold

junction (terminal block). The sensors must be Spectrum Controls supplied

temperature sensors. The module will not accept other CJC sensor inputs,

and thermocouple inputs will not function properly if incorrect CJC sensors

are used. Two CJC sensors are shipped with each module.

Page 18

6 ControlLogix™ Counter Module

Compatibility with

Ther mocouple,

Current, and Millivolt

Devices & Cables

The module is compatible with the following standard types of

thermocouples: B, E, J, K, N, R, S, T and C and extension wire. Refer to

appendices B and C for details. The module is also compatible with a

variety of voltage and current devices with an output of ±50, ±150 mV, 05V , 1-5V, 0-10V , ±10V, 0-20mA, and 4-20mA. T o minimize interference

from radiated electrical noise, we recommend twisted-pair and highly

shielded cables such as the following:

Table 1.7 Recommendations to minimize interference from radiated

electrical noise

For This Type of Device We Recommend This Cable (or equivalent)

Thermocouple Type J EIL Corp. J20-5-502

Thermocouple T ype K EIL Corp. K20-5-510

Thermocouple T ype T EIL Corp. T20-5-502

Other Thermocouple T ypes consult with EIL Corp or other manufacturers mV, V , mA devices Belden 8761,

shielded, twisted-pair Compatibility with RTD and Resistance devices and cables

The module is compatible 100. Platinum 385, 200. Platinum 385, 500.

Platinum 385, 1000. Platinum 385, 100. Platinum 3916, 200. Platinum 3916,

500. Platinum 3916, 1000. Platinum 3916, 10. Copper 426, 120. Nickel

618 and 120. Nickel 672 R TD types and resistance inputs, and 3 possible

wire types (2 wire, 3 wire, or 4 wire). Each RTD input individually

supports three input pins on the terminal block: one excitation current

source (EXC+), one sense positive (IN+) and one sense negative (IN-).

Only those pins are connected that are required by the selected R TD or

resistance wire type. For 2, 3, or 4 wire configurations, the module can

support a maximum combined cable length associated with an overall

cable impedance of 25 ohms or less without exceeding its input limitations.

The accuracy specifications provided herein do not include errors

associated with unbalanced cable impedance.

Since the operating principle of the RTD and resistance inputs is based on

the measurement of resistance, take special care in selecting your input

cable. For 2-wire or 3-wire configuration, select a cable that has a

consistent impedance throughout its entire length. For 2-wire

configurations, we recommend that you use Belden #9501 (or

equivalent). For 3-wire configurations, we recommend that you use

Belden #9533 (or equivalent) for short installation runs (less than 100

feet) or use Belden #83503 (or equivalent) for longer runs (greater than

100 feet) and in high humidity environments.

Page 19

Chapter 1: Module Overview 7

Table 1.8 Cable Specifications

Description Belden #9501 Belden#9533 Belden#83503

For 2-wire RTDs and 3-wire RTDs and 3-wire R TDs and

potentiometers. potentiometers. Short potentiometers.

When used? Long runs less than 100 feet runs greater than 100

Page 20

8 ControlLogix™ Counter Module

Page 21

Electrostatic

Damage

Chapter 2

Installing And Wiring Y our Module

Read this chapter to install and wire your module. This chapter covers:

• avoiding electrostatic damage

• determining power requirements

• installing the module

• wiring signal cables to the module’s terminal block

Electrostatic discharge can damage semiconductor devices inside this

module if you touch backplane connector pins. Guard against electrostatic

damage by observing the following precautions:

CAUTION

!

ELECTROSTATICALLY SENSITIVE COMPONENTS

• Before handling the module, touch a grounded

object to rid yourself of electrostatic charge.

• When handling the module, wear an approved wrist strap

grounding device.

• Handle the module from the front, away from the

backplane connector. Do not touch backplane connector pins.

• Keep the module in its static-shield container when not in

use or during shipment.

Failure to observe these precautions can deg rade the

module’s performance or cause permanent dama ge.

Page 22

10 ControlLogix™ Universal Analog Input Module

Power

Requirements

The module receives its power through the ControlLogix chassis

backplane from the fixed or modular +5 VDC and +24 VDC chassis

power supply . The maximum current drawn by the module is shown in the

table below .

Table 2.1. Maximum current dr awn by the module

5VDC Amps 24VDC Amps

0.230 0.075

Using your module in the ControlLogix System

Place your module in any slot of a ControlLogix modular, or modular

expansion chassis.

Module Installation

and Removal

An analog I/O module translates an analog signal into, or from, a

corresponding digital representation which controllers can easily operate

on for control purposes.

A ControlLogix I/O module mounts in a ControlLogix chassis and uses a

Removable T erminal Block (R TB) to connect all field-side wiring.

Before you install and use your module you should have already:

· installed and grounded a 1756 chassis and power supply.

· ordered and received an RTB for your application.

Important: RTBs are not included with your module purchase.

Specify Allen Bradley Part Number:

1756-TBCH - 36 position screw terminals

1756-TBS6H - 36 position press terminals

When installing the module in a chassis, it is not necessary to remove the

terminal blocks from the module. However, if the terminal blocks are

removed, use the write-on label located on the side of the terminal blocks

to identify the module location and type.

Page 23

Chapter 2: Installing And Wiring Y our Module 11

Preventing Electrostatic Discharge

This module is sensitive to electrostatic discharge.

AA

TTENTION:TTENTION:

A

TTENTION:

AA

TTENTION:TTENTION:

circuits or semiconductors if you touch backplane connector

!

pins. Follow these guidelines when you handle the module:

· Touch a grounded object to discharge static potential

· Wear an approved wrist-strap grounding device

· Do not touch the backplane connector or connector pins

· Do not touch circuit components inside the module

· If available, use a static-safe work station

· When not in use, keep the module in its static-shield box

Electrostatic discharge can damage integrated

Removal and Insertion Under Power

These modules are designed to be installed or removed while chassis

power is applied.

AA

TTENTION:TTENTION:

A

TTENTION:

AA

TTENTION:TTENTION:

backplane power is applied, an electrical arc may occur. An

!

electrical arc can cause personal injur y or property damage

by:

· sending an erroneous signal to your system’s field devices

causing unintended machine motion or loss of process

control.

· causing an explosion in a hazardous environment.

Repeated electrical arcing causes excessive wear to contacts

on both the module and its mating connectors. Worn contacts

may create electrical resistance that can affect module

operation.

When you insert or remove a module while

Compliance to European Union Directives

If this product bears the CE marking, it is approved for installation within

the European Union and EEA regions. It has been designed and tested to

meet the following directives.

EMC Directive

This product is tested to meet Council Directive 89/336/EEC

Electromagnetic Compatibility (EMC) and the following standards, in

whole or in part, documented in a technical construction file:

Page 24

12 ControlLogix™ Universal Analog Input Module

EN 61010-1 and EN 61131-2, EN61000-6-2:2001, EN61000-6-4:2001

EN61010-1:2001

This product is intended for use in an industrial environment.

Low Voltage Directive

This product is tested to meet Council Directive 73/23/EEC Low Voltage,

by applying the safety requirements of EN 61131-2 Programmable

Controllers, Part 2 - Equipment Requirements and Tests.

For specific information required by , EN61131-2:1994 + A1 1:1996 +

A12:2000, see the appropriate sections in this publication, as well as the

following Allen-Bradley publications:

· Industrial Automation Wiring and Grounding Guidelines For Noise

Immunity , publication 1770-4.1

· Automation Systems Catalog, publication B1 11

This equipment is classified as open equipment and must be installed

(mounted) in an enclosure during operation as a means of providing safety

protection.

CAUTION

POSSIBLE EQUIPMENT OPERATION

!

AA

TTENTION:TTENTION:

A

TTENTION:

AA

TTENTION:TTENTION:

and Insertion Under Power (RIUP). However, when you remove

or insert an RTB with field-side power applied,

macmac

hine motion or loss ofhine motion or loss of

mac

hine motion or loss of

macmac

hine motion or loss ofhine motion or loss of

Exercise extreme caution when using this feature.

WARNING

The 1756sc-IF8U module is to be used only with the Allen-

!

Bradley 1756 ControlLogix System.

The module is designed to support Removal

unintendedunintended

unintended

unintendedunintended

pr pr

pr

pr pr

ocess ocess

ocess

ocess ocess

contrcontr

ol can occurol can occur

contr

ol can occur.

contrcontr

ol can occurol can occur

Page 25

Chapter 2: Installing And Wiring Y our Module 13

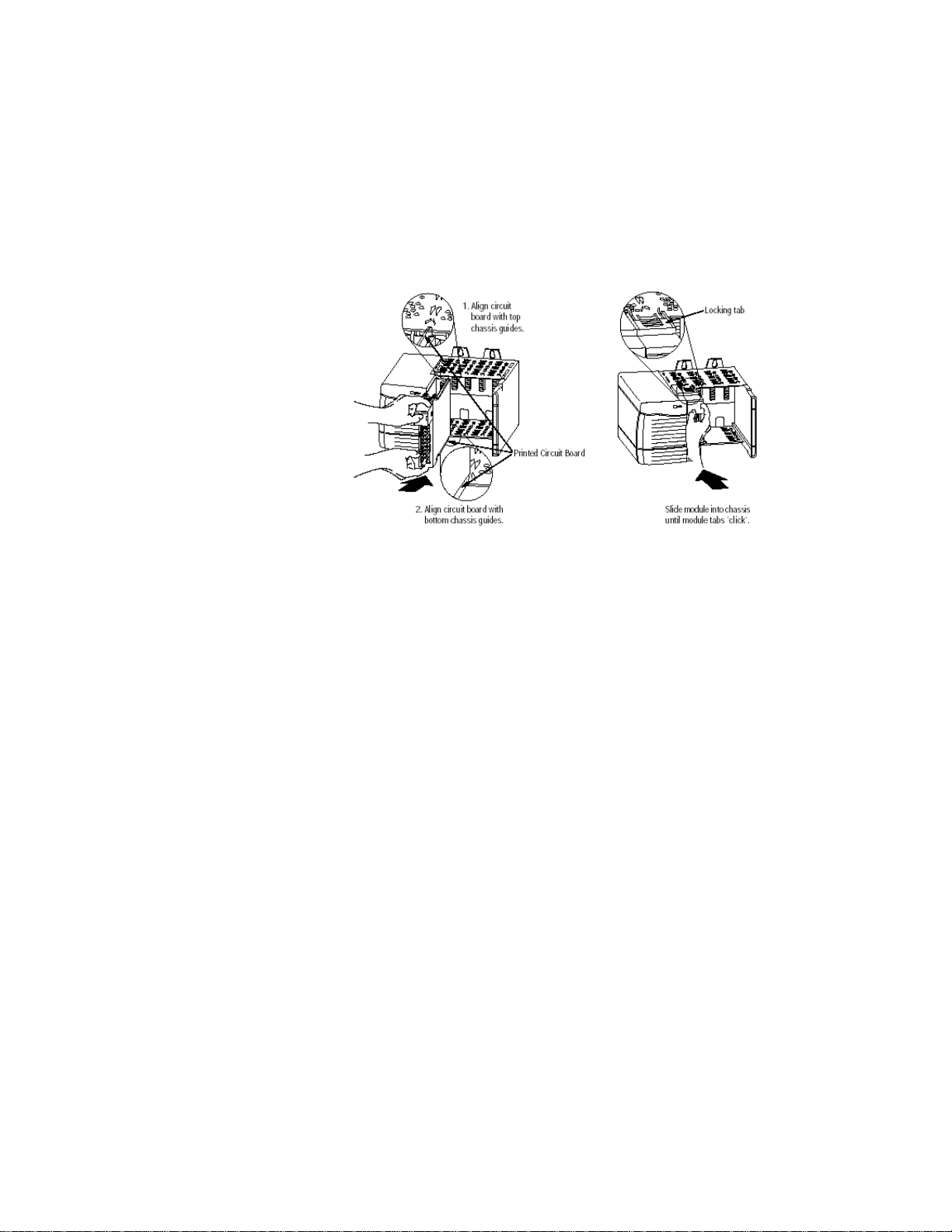

T o insert your module into the rack, follow these steps:

1. Align the circuit board of your module with the card guides at the top

and bottom of the chassis.

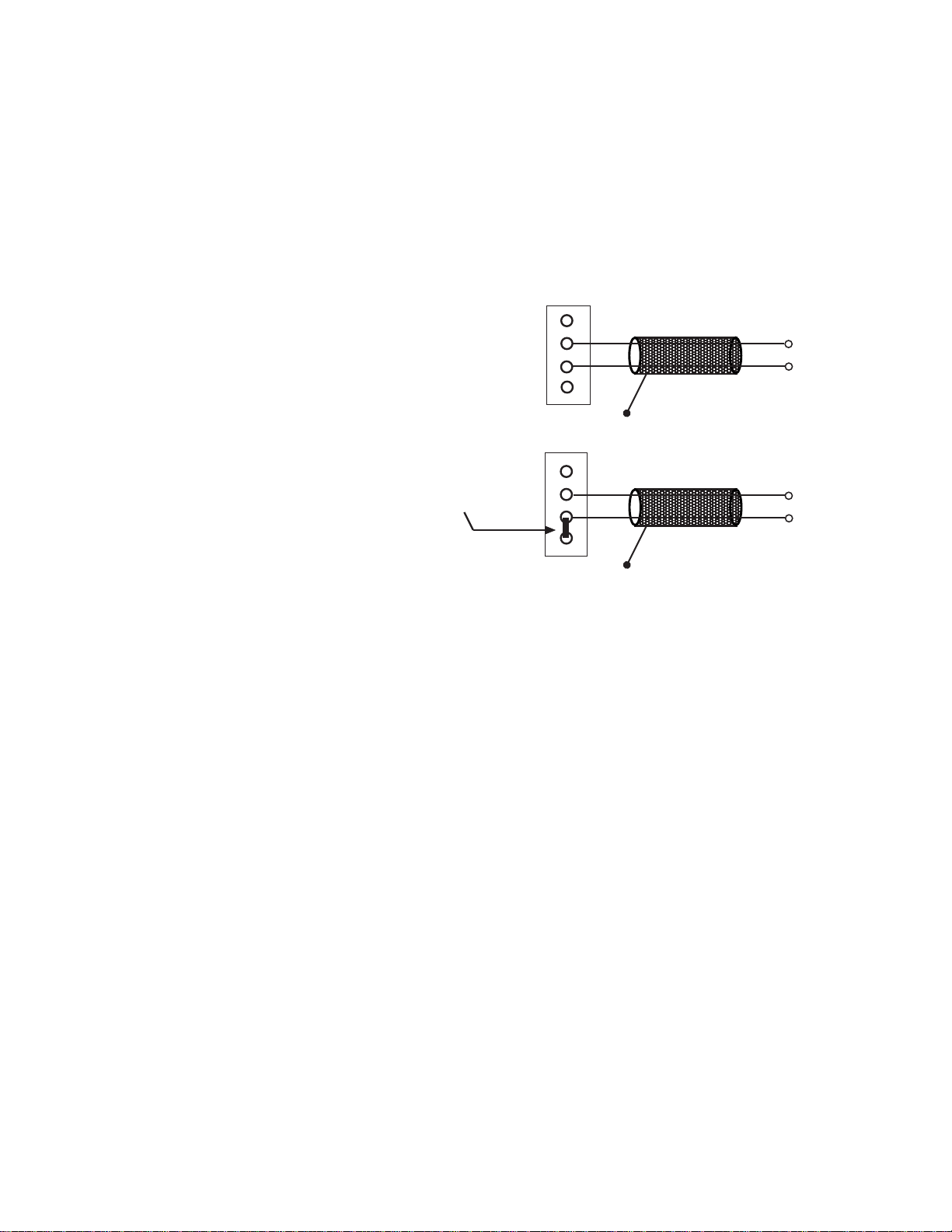

Figure 2.1. Module insertion into a rack

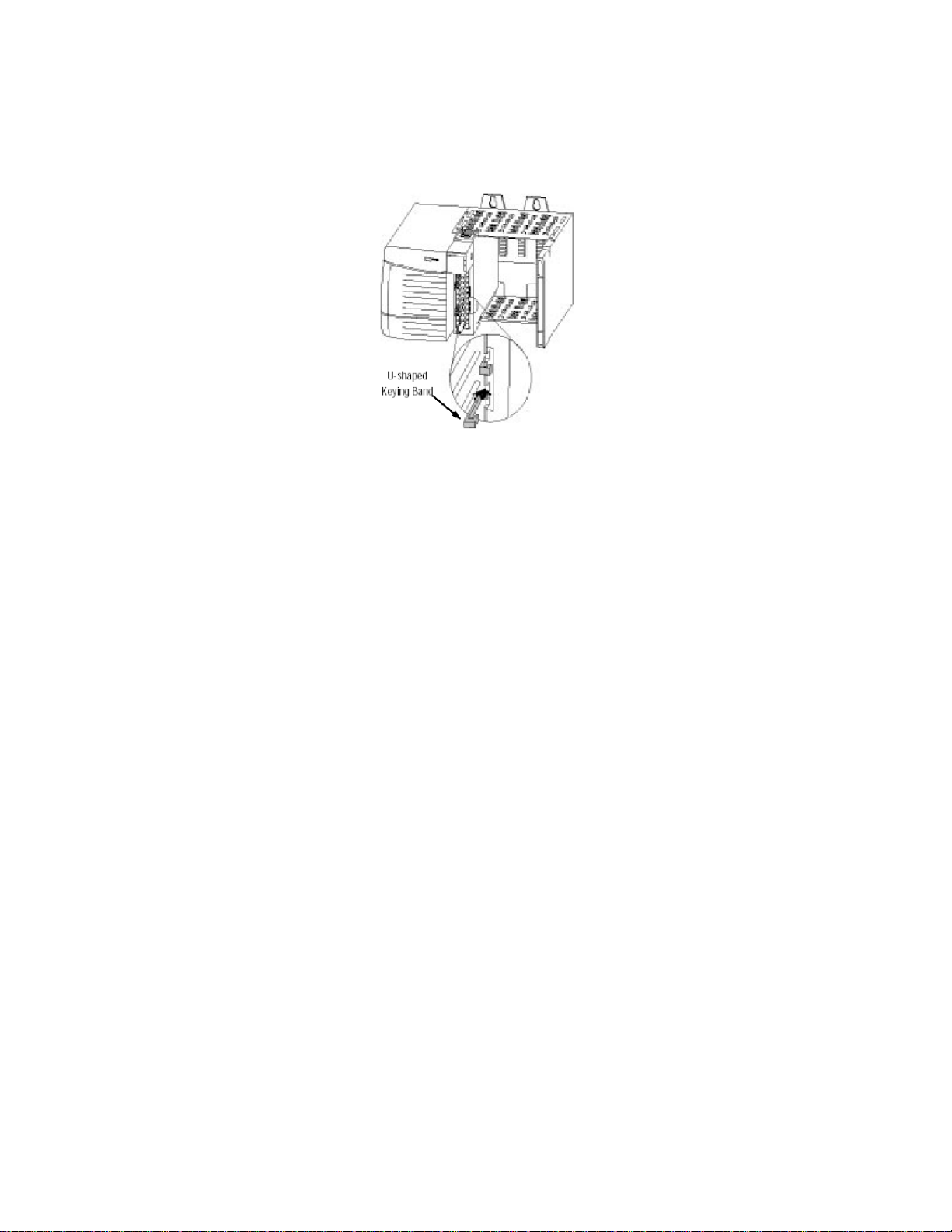

2. Key the R TB in positions that correspond to unkeyed module positions.

Insert the wedge-shaped tab on the RTB with the rounded edge first.

Push the tab onto the R TB until it stops.

Keying the Removable Terminal Block

Key the RTB to prevent inadvertently connecting the incorrect RTB to

your module.

When the RTB mounts onto the module, keying positions will match up.

For example, if you place a U-shaped keying band in position #4 on the

module, you cannot place a wedge-shaped tab in #4 on the R TB or your

RTB will not mount on the module.

W e recommend that you use a unique keying pattern for each slot in the

chassis.

1. Insert the U-shaped band with the longer side near the terminals. Push

the band onto the module until it snaps into place.

Page 26

14 ControlLogix™ Universal Analog Input Module

Figure 2.2. Terminal block diagram with keying

Wiring Your Module

Follow these guidelines to wire your input signal cables:

• Power, input, and output (I/O) wiring must be in accordance with Class

I, Division 2 wiring methods [Article 501-4(b) of the National Electrical

Code, NFP A 70] and in accordance with the authority having

jurisdiction.

• Peripheral equipment must be suitable for the location in which it is

used.

• Route the field wiring away from any other wiring and as far as

possible from sources of electrical noise, such as motors, transformers,

contactors, and ac devices. As a general rule, allow at least 6 in.

(about 15.2 cm) of separation for every 120 V of power.

• Routing the field wiring in a grounded conduit can reduce electrical

noise further.

• If the field wiring must cross ac or power cables, ensure that they cross

at right angles.

• T o limit the pickup of electrical noise, keep thermocouple, R TD,

millivolt, and milliamp signal wires as far from power and load lines as

possible.

• For improved immunity to electrical noise, use Belden 8761 (shielded,

twisted pair) or equivalent wire for millivolt sensors; or use shielded,

twisted pair thermocouple extension lead wire specified by the

thermocouple or RTD manufacturer. Using the incorrect type of

thermocouple extension wire or not following the correct polarity may

cause invalid readings.

• Ground the shield drain wire at only one end of the cable. The

preferred location is at the shield connections at the ControlLogix

chassis. (Refer to IEEE Std. 518, Section 6.4.2.7 or contact your sensor

manufacturer for additional details.)

Page 27

Preparing and

Wiring the Cables

Chapter 2: Installing And Wiring Y our Module 15

• Keep all unshielded wires as short as possible.

• T o limit overall cable impedance, keep input cables as short as possible.

Locate your I/O chassis as near the RTD or thermocouple sensors as

your application will permit.

• Tighten screw terminals with care. Excessive tightening can strip a

screw . The RTB terminations can accommodate 2.1…0.25 mm2

(14…22 AWG) shielded wire and a torque of 0.5 N•m (4.4 lb•in.).

• Follow system grounding and wiring guidelines found in your

ControlLogix Installation and Operation Manual.

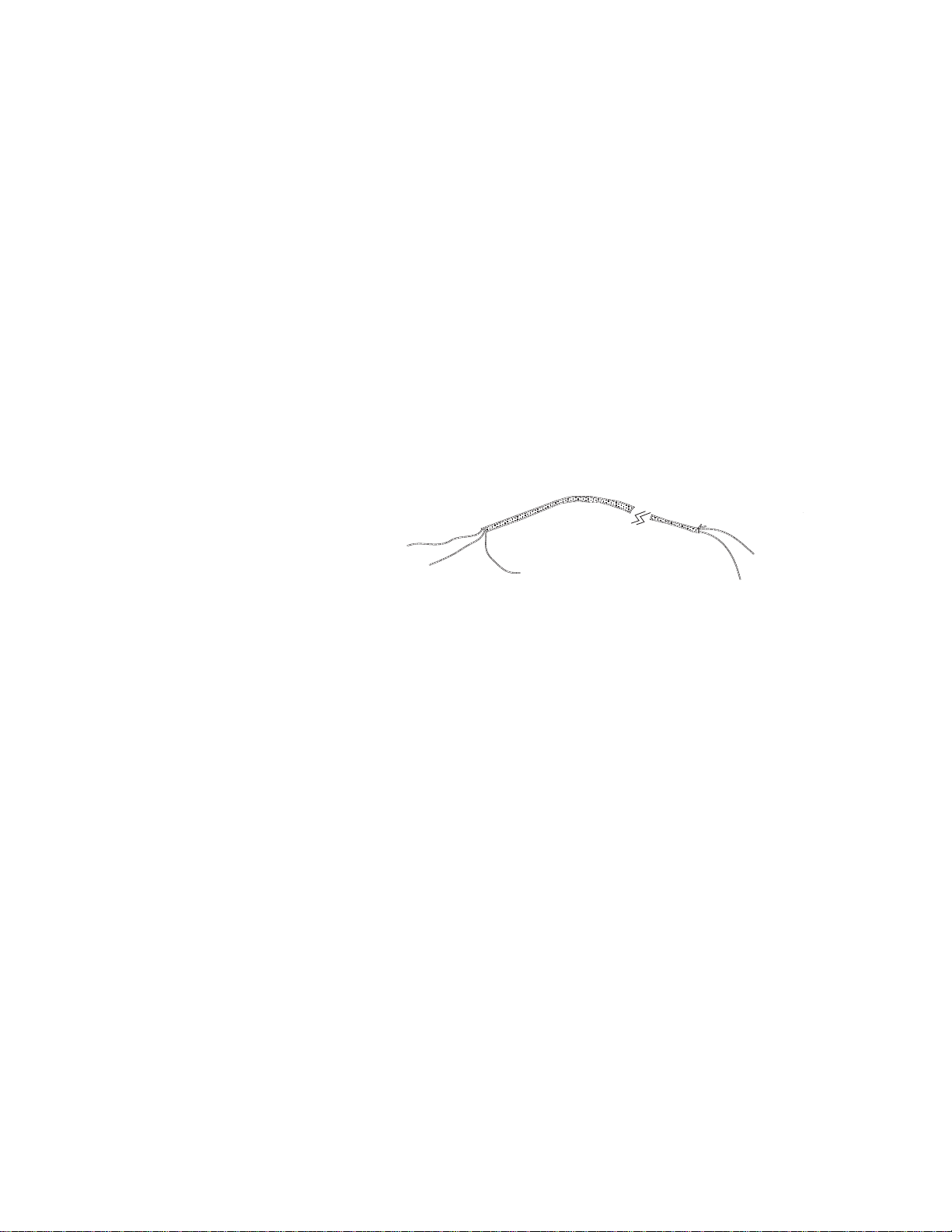

T o prepare and connect cable leads and drain wires, follow these steps:

Signal Wires

Cable

Drain Wire

(At the module-end of the cable, extract

the drain wire but remove the foil shield.)

(Remove foil shield and drain wire

from sensor-end of the cable.)

Signal Wires

1. At each end of the cable, strip some casing to expose individual wires.

2. Trim signal wires to 5-inch lengths beyond the cable casing. Strip about

3/16 inch (4.76 mm) of insulation to expose the ends of the wires.

3. At the module-end of the cables (see figure above):

- extract the drain wire and signal wires

- remove the foil shield

- bundle the input cables with a cable strap

4. Connect pairs of drain wires together, Channels 0 and 1, Channels 2

and 3, Channels 4 and 5, Channels 6 and 7. Keep drain wires as short

as possible.

5. Connect the drain wires to the grounding lug on the PLC chassis.

6. Connect the signal wires of each channel to the terminal block.

Important: Only after verifying that your connections are correct for

each channel, trim the lengths to keep them short. Avoid cutting leads

too short.

7. At the source-end of cables from mV devices:

- remove the drain wire and foil shield

- apply shrink wrap as an option

Page 28

16 ControlLogix™ Universal Analog Input Module

- connect to mV devices keeping the leads short

Important: If noise persists, try grounding the opposite end of the cable,

instead (Ground one end only.)

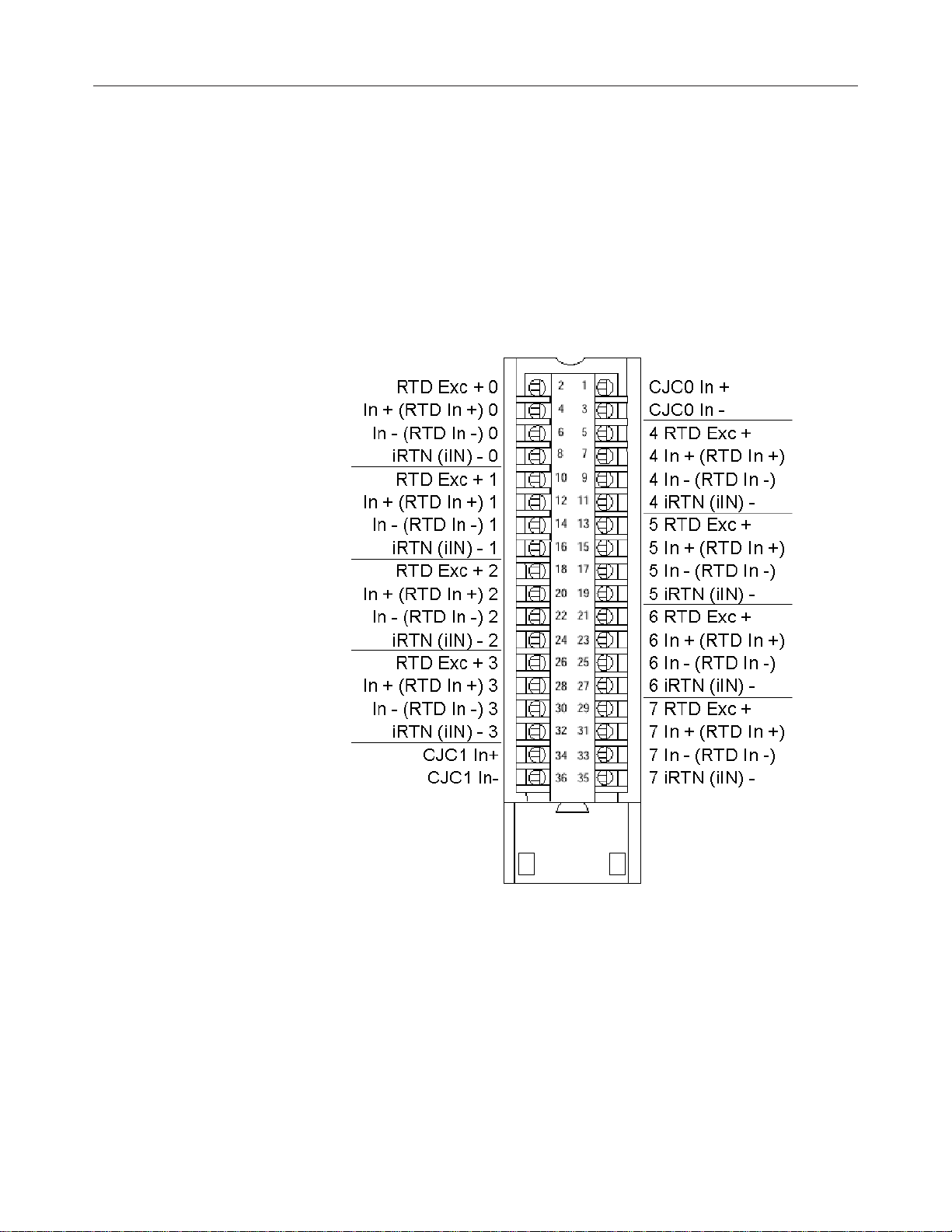

Terminal Block

Layout

The following figure shows the general terminal block layout. The input

signal type will determine which pins are used.

Page 29

Wiring Voltage/

Current Inputs the

IF8u Module

Chapter 2: Installing And Wiring Y our Module 17

V oltage inputs use the terminal block pins labelled IN+ and INCurrent inputs use the terminal block pins labelled IN+ and IN-

Voltage Inputs

EXC+

IN+

INiRTN

CABLE SHIELD

Current Inputs

Voltage +

Voltage -

ADD

JUMPER

EXC+

IN+

INiRTN

Current +

Current -

CABLE SHIELD

Page 30

18 ControlLogix™ Universal Analog Input Module

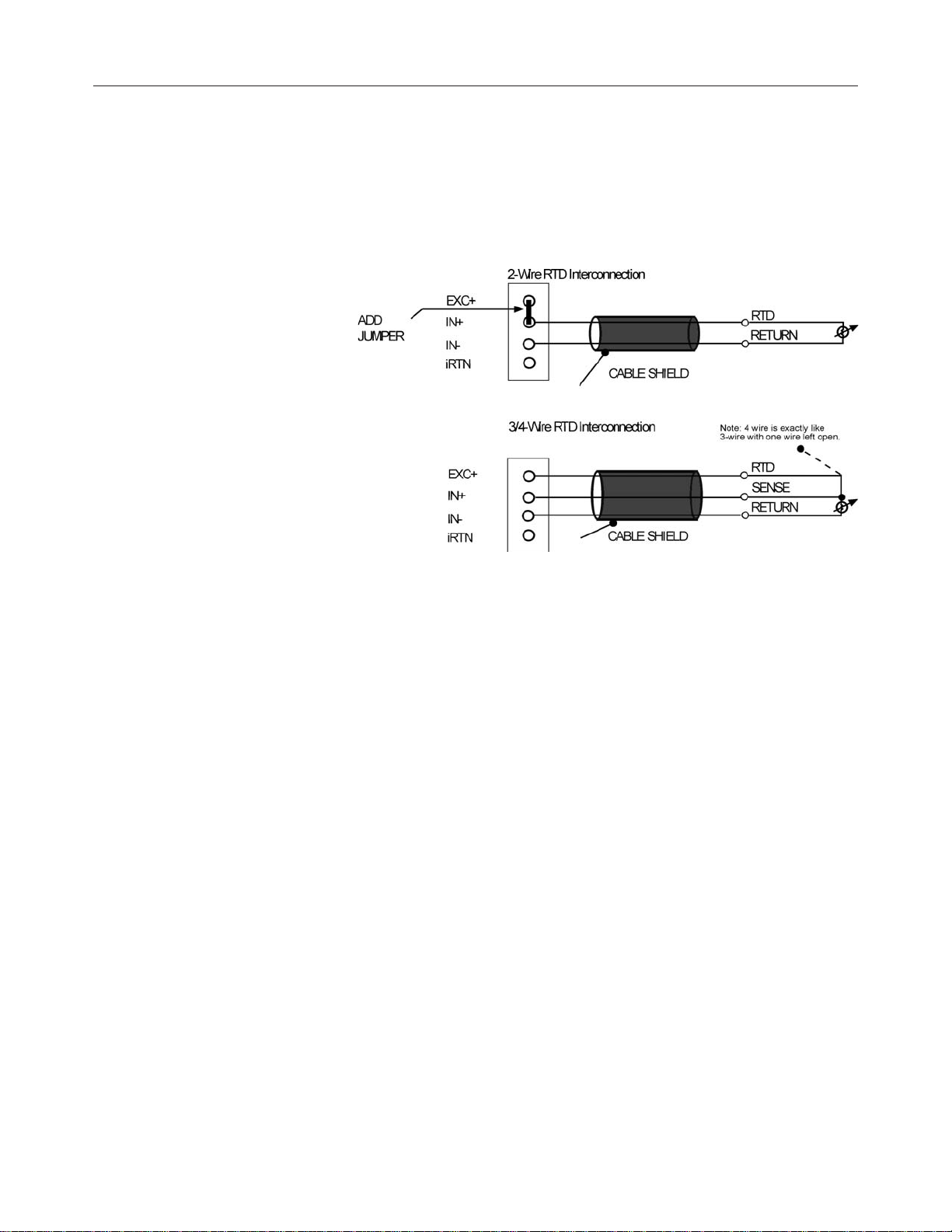

Wiring RTD or

Resistance Sensors

to the IF8u Module

The IF8u module supports two, three, and four wire RTDs or resistance

inputs connected individually to the module as shown in the figure below.

These are:

* 2-wire R TDs, which are composed of 2 RTD lead wires (EXC+ and

IN- with a jumper between EXC+ and IN+)

* 3-wire R TDs, which are composed of a 2 Signal and 1 RTD return lead

wires (EXC+ and IN+ with a the return RTD lead to IN-)

* 4-wire R TDs, which are composed of 2 Signal and 2 RTD return lead

wires (EXC+ and IN+ with a the return RTD lead to IN-) The fourth

lead is not used so wiring is identical to 3 wires RTDs.

* 2- wire Resistance, which is composed of 2 leads (EXC+ and IN- with

a jumper between EXC+ and IN+)

* 3- wire Resistance, which is composed of 3 leads (EXC+ IN+ and

IN-) and the resistance lies between IN+ and IN-

In any RTD sensing system, it is important that the lead and sense wire

resistances are matched as much as possible. The lead lengths, and their

resulting impedances, must be matched and kept small to eliminate the

introduction of connectivity errors. The 3/4-wire R TDs are the most

accurate, with 2-wire R TDs being the most inaccurate. In 2-wire the lead

resistance adds error to the resulting degree reading. With a 1.008mA

current source, 1Ω of lead resistance adds 1.008µV, or 2.82°C error, with

the 100Ω 385 alpha type. T o gain an understanding of how lead

resistance affects RTD readings, the µV/C for each RTD type is listed

below.

Page 31

Chapter 2: Installing And Wiring Y our Module 19

RTD Type Current Source V/°C

100Ω Pt 385 1.008mA 357µV/°C

200Ω Pt 38 5 1.008mA 714µV/°C

500Ω Pt 385 2 52 µA 447µV/°C

1000Ω Pt 385 25 2µA 893µV/°C

100Ω Pt 3916 1.008mA 377µV/°C

200Ω Pt 3916 1.008mA 754µV/°C

500Ω Pt 3916 25 2µA 472µV/°C

1000Ω Pt 3916 25 2 µA 941µV/°C

120Ω Ni 61 8 1.008mA 694µV/°C

200Ω Ni 618 1.008mA 1389µV/

500Ω Ni 618 25 2µA 867µV/°C

1000Ω Ni 618 25 2µA 1733µV/°C

10Ω Cu 426 25 2µA 9.7µV/°C

120Ω Ni 67 2 1.008mA 929µV/°C

°

C

The accuracies specified for the IF8u R TDs do not include errors due to

lead resistance imbalances.

Important: To ensure temperature or resistance value accuracy, the

resistance difference of the cable lead wires must be equal to or less than

0.01 ohms.

Important: Keep total lead resistance as small as possible and less than

25 ohms.

There are several ways to insure that the lead values match as closely as

possible. They are as follows:

* Use quality cable that has a small tolerance impedance rating.

* Use a heavy gauge lead wire which has less resistance per foot.

Page 32

Wiring

Thermocouples to

the IF8u Module

One end of thermocouple to IN+

Other end of thermocouple to IN-

Thermocouple Inputs

EXC+

IN+

INiRTN

CJC Sensors

CJC+

CJC-

CABLE SHIELD

White (With Potted Sensor)

White (No Sensor)

TC +

TC -

For cold junction compensation be sure the two supplied thermistors are

connected. One should be connected between CJC0-IN+ and CJC0-INand the other should be connected between CJC1-IN+ and CJC1-IN-.

Also be sure configuration tag “.CJDisable” is set to zero to perform cold

junction compensation for thermocouple inputs

Cold Junction Compensation (CJC)

CAUTION

!

POSSIBLE EQUIPMENT OPERATION

Both CJCs are critical to ensure accur ate thermocouple input

readings at each channel.

Failure to observe this precaution can cause unintended

equipment operation and damage.

Page 33

Page 34

22 ControlLogix™ Universal Analog Input Module

Page 35

Ownership andOwnership and

Ownership and

Ownership andOwnership and

ConnectionsConnections

Connections

ConnectionsConnections

Chapter 3: Operation within the System 23

Operation Within the

ControlLogix System

This chapter describes how the 1756sc-IF8u analog module works within

the ControlLogix system. This chapter covers:

• Ownership and connections to the module

• Direct connections

• Listen only mode

• Configuration changes with multiple owners.

Every I/O module in the ControlLogix system must be owned by a

Logix5550 Controller to be useful. This owner-controller stores

configuration data for every module that it owns and can be local or

remote in regard to the I/O module’s position. The owner sends the I/O

module configuration data to define the module’ s behavior and begin

operation within the control system. Each ControlLogix I/O module must

continuously maintain communication with its owner to operate normally.

Using RSNetWorx

and RSLogix 5000

T ypically , each module in the system will have only 1 owner . Input

modules can have more than 1 owner . Output modules, however , are

limited to a single owner.

The I/O configuration portion of RSLogix5000 generates the

configuration data for each I/O module in the control system, whether

the module is located in a local or remote chassis. A remote chassis, also

known as networked, contains the I/O module but not the module’s

owner controller . Configuration data is transferred to the controller during

the program download and subsequently transferred to the appropriate I/

O modules. I/O modules in the same chassis as the controller are ready

to run as soon as the configuration data has been downloaded. You must

run RSNetW orx to enable I/O modules in the networked chassis.

Running RSNetW orx transfers configuration data to networked modules

and establishes a Network Update Time (NUT) for ControlNet that is

compliant with the desired communications options specified for each

module during configuration. If you are not using I/O modules in a

networked chassis, running RSNetW orx is not necessary. However,

anytime a controller references an I/O module in a networked chassis,

RSNetW orx must be run to configure ControlNet. Follow these general

guidelines when configuring I/O modules:

1. Configure all I/O modules for a given controller using RSLogix 5000

and download that information to the controller .

Page 36

24 ControlLogix™ Universal Analog Input Module

2. If the I/O configuration data references a module in a remote chassis,

run RSNetWorx.

Important: RSNetWorx must be run whenever a new module is added

to a networked chassis. When a module is permanently removed from a

remote chassis, we recommend that RSNetWorx be run to optimize the

allocation of network bandwidth.

DirectDirect

Direct

DirectDirect

ConnectionsConnections

Connections

ConnectionsConnections

A direct connection is a real-time data transfer link between the

controller and the device that occupies the slot that the configuration data

references. When module configuration data is downloaded to an ownercontroller, the controller attempts to establish a direct connection to each

of the modules referenced by the data.

If a controller has configuration data referencing a slot in the control

system, the controller periodically checks for the presence of a device

there. When a device’ s presence is detected, the controller automatically

sends the configuration data. If the data is appropriate to the module

found in the slot, a connection is made and operation begins. If the

configuration data is not appropriate, the data is rejected and an error

message displays in the software. In this case, the configuration data can

be inappropriate for any of a number of reasons.

ModuleModule

Module

ModuleModule

OperationOperation

Operation

OperationOperation

Modules in a Local

Chassis

The controller maintains and monitors its connection with a module. Any

break in the connection, such as removal of the module from the chassis

while under power, causes the controller to set fault status bits in the data

area associated with the module. The RSLogix 5000 software may

monitor this data area to announce the modules’ failures.

In traditional I/O systems, controllers poll input modules to obtain their

input status. Analog input modules in the ControlLogix system are not

polled by a controller once a connection is established. The modules

multicast their data periodically . Multicast frequency depends on the

options chosen during configuration and where in the control system that

input module physically resides. An input module’ s communication, or

multicasting, behavior varies depending upon whether it operates in the

local chassis or in a remote chassis. The following sections detail the

differences in data transfers between these set-ups.

When a module resides in the same chassis as the owner controller, the

following two configuration parameters will affect how and when the

input module multicasts data:

· Real T ime Sample (R TS) configured via Real T ime Sample tag.

· Requested Packet Interval (RPI) configured via I/O module properties.

Real Time Sample (RTS)

Page 37

Requested Packet

Interval (RPI)

Chapter 3: Operation within the System 25

This configurable parameter instructs the module to perform the

following operations:

1. scan all of its input channels and store the data into on-board memory

2. multicast the updated channel data (as well as other status data) to the

backplane of the local chassis

This configurable parameter also instructs the module to multicast its

channel and status data to the local chassis backplane.

The RPI instructs the module to multicast the current contents of its

on-board memory when the RPI expires, (i.e. the module does not

update its channels prior to the multicast).

Important: The RPI value is set during the initial module configuration

using RSLogix 5000.

It is important to note that the module will reset the RPI timer each time

an RTS is performed. This operation dictates how and when the owner

controller in the local chassis will receive updated channel data,

depending on the values given to these parameters. If the RTS value is

less than or equal to the RPI, each multicast of data from the module will

have updated channel information. In effect, the module is only

multicasting at the R TS rate.

Modules in a

Remote Chassis

If the R TS value is greater than the RPI, the module will multicast at

both the RTS rate and the RPI rate. Their respective values will dictate

how often the owner controller will receive data and how many

multicasts from the module contain updated channel data. Note: Even

though data may be transfered at the RPI rate, the data will be indentical

to the previous R TS data transfer.

If an input module resides in a networked chassis, the role of the RPI

and the module’s R TS behavior change slightly with respect to getting

data to the owner. The RPI and RTS intervals still define when the

module will multicast data within its own chassis (as described in the

previous section), but only the value of the RPI determines how often the

owner controller will receive it over the network.

When an RPI value is specified for an input module in a remote chassis,

in addition to instructing the module to multicast data within its own

chassis, the RPI also “reserves” a spot in the stream of data flowing

across the ControlNet network.

The timing of this “reserved” spot may or may not coincide with the

exact value of the RPI, but the control system will guarantee that the

owner controller will receive data at least as often as the specified RPI.

Page 38

26 ControlLogix™ Universal Analog Input Module

The “reserved” spot on the network and the module’s RTS are

asynchronous to each other. This means there are Best and Worst Case

scenarios as to when the owner controller will receive updated channel

data from the module in a networked chassis.

Best Case RTS Scenario

In the Best Case scenario, the module performs an RTS multicast with

updated channel data just before the “reserved” network slot is made

available. In this case, the remotely located owner receives the data

almost immediately.

Worst Case RTS Scenario

In the W orst Case scenario, the module performs an RTS multicast just

after the “reserved” network slot has passed. In this case, the ownercontroller will not receive data until the next scheduled network slot.

Because it is the RPI and NOT the RTS which dictates when the

module’s data will be sent over the network, we recommend the RPI

value be set LESS THAN OR EQUAL TO the RTS to make sure that

updated channel data is received by the owner controller with each

receipt of data.

Listen-Only Mode

Multiple Owners of

Input Modules

Any controller in the system can listen to the data from any I/O module

(e.g. input data or “echoed” output data) even if the controller does not

own the module (i.e. it does not have to hold the module’ s configuration

data to listen to the module).

The “listen only” mode is set during the I/O configuration process.

Choosing a ‘Listen-Only’ mode option allows the controller and module

to establish communications without the controller sending any

configuration data. In this instance, another controller owns the module

being listened to.

Important:Controllers using the Listen-Only mode continue to receive

data multicast from the I/O module as long as a connection between an

owner and I/O module is maintained. If the connection between all

owners and the module is broken, the module stops multicasting data and

connections to all ‘Listening controllers’ are also broken.

Because ‘Listening controllers’ lose their connections to modules when

communications with the owner stop, the ControlLogix system will allow

you to define more than one owner for input modules.

Important: Only input modules can have multiple owners. If multiple

owners are connected to the same input module, they must maintain

identical configuration for that module.

In the example below, Controller A and Controller B have both been

configured to be the owner of the input module.

Page 39

Chapter 3: Operation within the System 27

When the controllers begin downloading configuration data, both try to

establish a connection with the input module. Whichever controller’s data

arrives first establishes a connection. When the second controller’s data

arrives, the module compares it to its current configuration data (the data

received and accepted from the first controller).

If the configuration data sent by the second controller matches the

configuration data sent by the first controller the connection is also

accepted. If any parameter of the second configuration data is different

from the first, the module rejects the connection and the user is informed

by an error in the software.

The advantage of multiple owners over a ‘Listen-only’ connection is that

now either of the controllers can lose the connection to the module and

the module will continue to operate and multicast data to the system

because of the connection maintained by the other owner controller.

Note: The previous discussion of multiple owners assues the

configuration tag “.configrevnumber” is set to 1. Operation differs is the

tag is set to 0. Refer to Chapter 5 for descriptions of this tag’s settings.

Configuration

Changes in an

Input Module with

Multiple Owners

Y ou must be careful when changing an input module’ s configuration data

in a multiple owner scenario. When the configuration data is changed in

one of the owners, for example, Controller A, and sent to the module,

that configuration data is accepted as the new configuration for the

module. Controller B will continue to listen, unaware that any changes

have been made in the module’ s behavior .

Important: When changing configuration for a module with multiple

owners, we recommend the connection be inhibited. T o prevent other

owners from receiving potentially erroneous data, as described above,

the following steps must be followed when changing a module’ s

configuration in a multiple owner scenario when online:

1. For each owner controller, inhibit the controller’s connection to the

module in the software on the I/O Module Connection tab.

2. Make the appropriate configuration data changes in the software.

3. Repeat steps 1 and 2 for all owner controllers, making the exact

same changes in all controllers.

4. Uncheck the Inhibit box in each owner’s configuration to reconnect

each module.

Page 40

28 ControlLogix™ Universal Analog Input Module

Page 41

Chapter 4

Programming Y our Module

This chapter explains how to program your module in the ControlLogix

system. It also describes how the module’s input configuration are

incorporated into your ladder logic program. T opics discussed include:

• importing the module’s configuration profile

• reviewing accessing and altering configuration options.

• configuring the modules input type and filter settings

• configuring alarms and limits

Module Installation

Adding Your Module

to a Project

T o incorporate the module into the system, you must use the RSLogix

5000 programming software. If you’re using RSLogix 5000 version 15 or

greater, an AOP (Add-On-Profile) is available and can be downloaded

from our website at (http://www .spectrumcontrols.com/downloads.htm).

The AOP allows you to add the IF8U to the RSLogix 5000 pick list and

contains custom configuration screens for the module. If you do plan to

use the AOP, you can skip the remainder of this chapter.

For those that plan to use RSLogix 5000 version 14 or older, the generic

module profile must be used to add the IF8U to a new or existing project.

An RSLogix 5000 sample project utilizing the generic module profile is

available for download on our website at (www .spectrumcontrols.com/

downloads.htm). The ladder sample contains user defined input and

configuration tags used to configure and read analog data from the IF8U

module. The configuration tags control features such as the modules input

type, channel input range, data format, filter frequency, etc.

The module has a unique set of tag definitions which are used to configure

specific features. Chapter 5, Channel Configuration, Data, and Status,

gives you detailed information about the data content of the configuration.

These values are set using your programming software and ladder logic.

Before you can use these feature you must first include the module into

the project.

Page 42

30 ControlLogix™ Universal Analog Input Module

1.

Open the sample project with the IF8u information. Open your

project. Drag and drop the IF8u module into the I/O configuration section

of your project.

1. Open the sample project.

2. Open your new project.

3. Click once on the IF8u in the sample project.

4. Drag and drop it into the I/O Configuration section of your project.

See Appendix D for the I/O module property details.

Page 43

Chapter 4: Programming Y our Module 31

2.

Drag and drop the IF8u user-defined data types from the sample

project into your project.

There are four IF8u user defined data types that need to be moved.

ChannelConfig

ChannelStatus

IF8u_Config_Template

IF8u_Input_Template

1. Click on the data type

2. Drag it into your new project.

3. Continue to drag and drop the data types until all four have been moved.

Note: These can only be moved one at a time.

Page 44

32 ControlLogix™ Universal Analog Input Module

3.

Drag and drop the controller configuration tags from the sample

project into your project.

1. Right click on the Controller T ags item of the sample project and select

edit.

2. Right click on the Controller T ags item of your project and select edit.

3. Scroll down to the Controller tags of the sample project and select all

the tags by highlighting them.

4. Drag and drop these tags into your project.

Note: IF8u_Config and IF8u_Input contain the configuration, data and

status tags for the IF8u module. The other tags are used for performing

various functions to your module via ladder logic.

Note: Be sure all tags are displayed before moving them. Select Display

All from the Edit drop down window.

Note: The “Local:3:I” and “Local:3:C” tags are not copied.

Page 45

Chapter 4: Programming Y our Module 33

4.

Create a new ladder logic routine in your project.

1. In your project, right mouse click on the MainRoutine item and select

“New Routine...” IF8u was entered in the example above.

2. Double click on the MainRoutine item in the sample project and then

double click on the added new routine in your project to display their

corresponding ladder logic.

3. Left mouse inside the MainProgram ladder logic in the sample project

and press crtl-A to select all the rungs.

4. Drag and drop these rungs over and add them to the new routine’s

ladder logic. Note: Y ou will need to delete the one blank “solid bar” rung

either at the top or bottom of the routine which was left over from the

newly created routine.

5. Now add a JSR ladder instruction in your MainRountine which calls this

routine.

Note: RSLogix 5000 will verify the ladder logic sample. You may receive

errors regarding invalid tags. You will need to change the slot addressing

in the logic to coordinate with the location of the IF8u.

This completes the installation of module in the system

Page 46

34 ControlLogix™ Universal Analog Input Module

Configuring module

attributes:

Configuration Tags

The module has settings that are global and channel specific. These are

accessed via the controller tags. Specific information regarding these tag

settings may be found in Chapter 5.

Global module tags

These settings are used globally by the module. They control features

such as the module autocalibration modes, and various other attributes.

Page 47

Chapter 4: Programming Y our Module 35

Channel Specific Tags

These settings control channel specific behavior such as input type, range,

filter frequency , units, and alarms. Specific information regarding these

tags may be found in Chapter 5.

Data Tags

These tags represent the process data values in their final form.

Page 48

36 ControlLogix™ Universal Analog Input Module

Status Tags

These tags report module status such as alarm conditions, faults, and

errors.

Page 49

Chapter 5: Channel Configuration, Data, and Status 37

Chapter 5

Choosing a Wiring Method The 1756-IF16 and 1756-IF8 modules support the following three wiring

Configuration, Data,

and Status Tags

Read this chapter to:

• send configuration data to the module

• configure global module properties

• configure each input channel

• check each input channel’s data

• check module and individual channel status

This chapter outlines the detailed settings for the 1756sc-IF8u. These

settings determine the modules input types, filter frequencies, scan rates,

and various attributes. Detailed descriptions of these settings are available

in the Tag Definition section of this chapter.

Send Configuration

Data to the Module

Note: An AOP (Add-On_Profile) is availabe for the 1756sc-IF8U and can

be downloaded from our website at (http://www.spectrumcontrols.com/

downloads.htm).

Note: The following format is used to describe tags

Tag Name Range Data Type

After changing the configuration tags in this chapter you must then send

them to the module. To do this you may perform any of these operations:

1. Inhibit then un-inhibit the module via the module properties dialog,

Connection Tab

2. Reset the module via the modules properties dialog. Module Info tab.

3. Reset the module via ladder logic. See the “DoReset” rung in the

sample ladder project.

4. Perform a “Set Attribute All” or Module Reconfigure message

instruction via ladder logic. Refer to your sample program for information

about the “DoSetAttrAll” command.

Page 50

38 ControlLogix

™

Universal Analog Input Module

Note: If an invalid configuration is sent to the module a connection error

will occur. See chapter 7 for a list of error codes.

Configuration Tags

Global Module

Settings

The following Global Module Settings and Channel Specific Settings

sections allow custom configuration of the module. These tags can be

found within the IF8u_config controller tag.

The following tag settings are module related:

Configuration ManagementConfiguration Management

Configuration Management

Configuration ManagementConfiguration Management

.ConfigRevNumber 0, 1 BOOL

0: The module will always accept this configuration if valid. This value

must be used for on-the-fly configuration changes.

1: In multiple owner systems if there is already a connection to the module

then this configuration must match the one of the current connection in

order for this controller to connect to the module.Channel On/Off

Note: The Module Reconfigure message instruction sets this parameter to

zero.

Temperature Measurement:

.RemoteTermination 0, 1 BOOL

Not Used.

.CJDisable 0, 1 BOOL

0: The cold junction compensation terminal block thermistors will be read.

Thermocouple input values will be compensated based on the thermistor

readings.

1: The cold junction compensation thermal block thermistors will not be

read. Thermocouple input values will be compensated with the default 25

degC value plus CJCOffset.

Note: 2 thermistors have been provided with the module to be installed on

your terminal block if cold junction compensation is to be used.

.TempMode 0, 1 BOOL

0: Temperatures for thermocouples, RTDs and the cold junction

thermistors will be displayed in degrees Celsius.

Page 51

Chapter 5: Channel Configuration, Data, and Status 39

1: Temperatures for thermocouples, RTDs and the cold junction

thermistors will be displayed in degrees Fahrenheit.

.CJOffset -25 to +65 degC REAL

-45 to + 117 degF

A temperature offset added to the cold junction compensation temperature

values. This is interpreted as degrees C if the .TempMode = 0 and

degrees F if the .TempMode = 1.

Module Sampling Time

The universal module update time is defined as the time required for the

module to sample and convert the input signals of all enabled input

channels and make the resulting data values available to the processor.

The sample time is influenced by the input type, filter frequency, CJC

acquisition (if enabled) and autocal configuration settings. For example,

when thermocouples are selected, it is necessary to perform a cold

junction compensation, (CJC), measurement to obtain best possible

accuracy. This CJC measurement occurs in a systematic fashion and

adds approximately 26ms to the update time. The following tables

illustrate the components used to calculate typical channel update times.

Overhead:

5 ms - This must be included in all calculations and represents backplane

communication and other service routines within the module.

Filter Frequency:

The channel filter frequency will impact timing. The following table shows

associated time adders based on frequency selection.

Filter Additional Time

10Hz 125 ms per channel

50/60Hz 26 ms per channel

100Hz 18 ms per channel

250Hz 10 ms per channel

1kHz 6 ms per channel

Page 52

40 ControlLogix

™

Universal Analog Input Module

Input Type:

Each input type has a specific settling time. Select each channel input

type and add the time value.

Time (ms) Type Tag: .RangeType

0 All voltage, current, and thermocouple types

3 100_Pt_385 8

3 100_Pt_392 12

3 120_Ni_618 16

3 120_Ni_672 20

3 10_Cu_426 21

3 604_NiFe_518 22

3 0_250_Ohm 23

3 0_500_Ohm 24

4 200_Pt_385 9

4 500_Pt_385 10

4 200_Pt_392 13

4 500_Pt_392 14

4 200_Ni_618 17

4 500_Ni_618 18

4 0_1000_Ohm 25

4 0_2000_Ohm 26

8 1000_Pt_385 11

8 1000_Pt_392 15

8 1000_Ni_618 19

8 0_3000_Ohm 27

8 0_4000_Ohm 28

Example 1:

4 channels with 200 Ohm PT 385 RTD (Input Type 9) at 100Hz filter =

18ms + 4ms = 22ms * 4 channels = 88ms

2 channels of voltage at 1khz = 2 * 6ms = 12ms

2 thermocouples at 250Hz = 2 * 10ms = 20ms

Total = 5ms (overhead) + 26ms (CJC) + 88ms + 12ms + 20ms = 151ms

(Actual measured = 158ms)

Example 2:

8 channels, 0-4000 ohm (type 28) at 250Hz = 10ms + 8ms = 18ms * 8 =

144ms + 5ms = 149ms. (Actual measured = 117ms)

Note: This is approximation only. The time changes because the software

does not need to spend time setting up the ADC for another filter

frequency if it is the same as the previous channel. The same applys for

the the gain settings, etc. Example 2 illustrates there is a significant

savings because the filter frequency and input type are the same.

Note: If the autocalibration is enabled the module sampling time will

increase by as much as 500ms when autocalibration is being performed.

Page 53

Chapter 5: Channel Configuration, Data, and Status 41

.RealTimeSample 10-30,000 ms INT

The time in milliseconds that updated input data is to be sent from the

module to the controller. If this value is smaller than the minimum update

time to scan all input channels, then the actual rate will be greater than this

value. In this case you may determine what the actual sample time is by

subtracting two successive values of the .RollingTimeStamp input tag.

Real Time Sampling (RTS) and Requested Packet

Interval (RPI)

This RealTimeSample tag instructs the module to scan its input channels

and obtain all available data. After the channels are scanned, the module

multicasts that data. This feature is used on a module-wide basis.

During module configuration, you specify a Real Time Sampling (RTS)

period via the .RealTimeSample tag and a Requested Packet Interval

(RPI) period. Both of these features instruct the module to multicast data,

but only the RTS feature instructs the module to scan its channels before

multicasting.

You may access the RPI in the Module Properties menu.

Page 54

42 ControlLogix

™

Universal Analog Input Module

Automatic Calibration:

Autocalibration is an automated input path calibration. This insures best

possible accuracy under varying application conditions. Autocalibration

may be turned on or off. When autocalibration is active you may also set

the interval at which the calibration occurs.

.DisableCyclicAutocal 0, 1 BOOL

0: Module auto-calibration is performed on power up, reset, and

reconfiguration as well as according to the .CyclicAutocalPeriod.

1: Module auto-calibration is only performed on module power-up, reset,

and reconfiguration.

Note: Changing the following tags via the set attribute all or module

reconfiguration message will not cause the auto-calibration to be

performed upon acceptance of the configuration.

.Alarm Enable .ProcessAlarmLatch .RateAlarmLatch

.TenOhmOffset .DigitalFilter .RateAlarmLimit

.LowSignal .HighSignal .LowEngineering

.HighEngineering .LAlarmLimit .HighAlarmLimit

.LLAlarmLimit .HHAlarmLimit .AlarmDeadband

.CyclicAutocalPeriod 0-3 INT

Perform module auto-calibration:

0: Only on powerup and reset.

1: Every 1 minute.

2: Every 10 minutes.

3: Every 30 minutes.

Note: Options 1 through 3 are not valid if cyclic autocal is disabled.

Page 55

Channel Specific

Settings

Chapter 5: Channel Configuration, Data, and Status 43