Page 1

Owner’s Guide 0300199-01 Rev . B

C

ONTROL

C

OUNTER

Catalog Number: 1756sc-CTR8

L

OGIX

M

ODULE

™

Page 2

Page 3

Important Notes

1. Please read all the information in this owner’s guide before installing

the product.

2. The information in this owner's guide applies to hardware version A

and firmware version 2.0 or later.

3. This guide assumes that the reader has a full working knowledge of the

relevant processor.

Notice

The products and services described in this owner's guide are useful in a

wide variety of applications. Therefore, the user and others responsible

for applying the products and services described herein are responsible

for determining their acceptability for each application. While efforts

have been made to provide accurate information within this owner's

guide, Spectrum Controls assumes no responsibility for the accuracy,

completeness, or usefulness of the information herein.

Under no circumstances will Spectrum Controls be responsible or liable

for any damages or losses, including indirect or consequential damages

or losses, arising out of either the use of any information within this

owner's guide or the use of any product or service referenced herein.

No patent liability is assumed by Spectrum Controls with respect to the

use of any of the information, products, circuits, programming, or

services referenced herein.

The information in this owner's guide is subject to change without notice.

Limited Warranty

Spectrum Controls warrants that its products are free from defects in

material and workmanship under normal use and service, as described in

Spectrum Controls literature covering this product, for a period of 1 year.

The obligations of Spectrum Controls under this warranty are limited to

replacing or repairing, at its option, at its factory or facility, any product

which shall, in the applicable period after shipment, be returned to the

Spectrum Controls facility, transportation charges prepaid, and which

after examination is determined, to the satisfaction of Spectrum Controls,

to be thus defective.

This warranty shall not apply to any such equipment which shall have

been repaired or altered except by Spectrum Controls or which shall

have been subject to misuse, neglect, or accident. In no case shall the

liability of Spectrum Controls exceed the purchase price. The

aforementioned provisions do not extend the original warranty period of

any product which has either been repaired or replaced by Spectrum

Controls.

Page 4

Page 5

Who Should Use

This Guide

Preface

Read this preface to familiarize yourself with the rest of the owner’s

guide. This preface covers:

• who should use this guide

• what this guide covers

• related Allen-Bradley documents

• terms & abbreviations you should know

Use this guide if you design, install, program, or maintain a control system

that uses Allen-Bradley ControlLogix Controllers.

Y ou should have a basic understanding of ControlLogix products. Y ou

should also understand electronic process control and the ladder program

instructions required to generate the electronic signals that control your

application. If you do not, contact your local Allen-Bradley representative

for the proper training before using these products.

What This Guide

Covers

Related AllenBradley Documents

This guide covers the 1756sc-CTR8 counter/flow module. It contains the

information you need to install, wire, use, and maintain these modules. It

also provides diagnostic and troubleshooting help should the need arise.

T able A lists several Allen-Bradley documents that may help you as you

use these products.

Table A. Related Allen-Bradley documents

Allen-Bradley Doc. No. Title Publication Number

1756-P A72, ControlLogix Power Supply Installation

-PB72 Instructions 1756-5.1

1756-A4, ControlLogix Chassis Installation Instructions 1756-5.2

-A7, -A10,

-A13, -A17

Page 6

vi ControlLogix™ Counter Module

1756 Series ControlLogix Module Installation Instructions

(Each module has separate document for installation) 1756-5.5,

1756-L1, Logix5550 Controller User Manual 1756-6.5.12

-L1M1, -L1M2

1756-DHRIO ControlLogix Data Highway Plus

Communication Interface Module User Manual 1756-6.5.2

1756-ENET ControlLogix Ethernet Communication Interface

Module User Manual 1756-6.5.1

T o obtain a copy of any of the Allen-Bradley documents listed, contact

your local Allen-Bradley office or distributor .

Terms &

Abbreviations You

Should Know

Y ou should understand the following terms and abbreviations before using

this guide.

-5.42

A/C - Refers to alternating current. This is a sine wave signal that is

typically associated with magentic pickup flowmeters.

Attenuation – The reduction in magnitude of a signal as it passes through

a system. The opposite of gain.

Channel – Refers to one of eight, small-signal analog input interfaces to

the module’s terminal block. Each channel is configured for connection to

a input device, and has its own configuration and status words.

Chassis – See rack.

Common mode rejection ratio (CMRR) - The ratio of a device’s

differential voltage gain to common mode voltage gain. Expressed in dB,

CMRR is a comparative measure of a device’s ability to reject

interference caused by a voltage common to its terminal relative to

ground.

Common mode voltage – The voltage difference between the negative

terminal and analog common during normal differential operation.

Cut-off frequency - The frequency at which the input signal is attenuated

3 dB by the digital filter. Frequency components of the input signal that

are below the cut-off frequency are passed with under 3 dB of attenuation

for low-pass filters.

Page 7

Preface vii

DC - Direct Current - This is typically associated with a DC squarewave pulse signal from a flowmeter.

dB (decibel) – A logarithmic measure of the ratio of two signal levels.

Digital filter - A low-pass mathmatic single order filter applied to the

signal. The digital filter provides high-frequency noise rejection.

Effective resolution – The number of bits in the channel data word that

do not vary due to noise.

Local System - A control system with I/O chassis within several feet of

the processor.

LSB (least significant bit) – The bit that represents the smallest value

within a string of bits.

Normal mode rejection (differential mode rejection) – A logarithmic

measure, in dB, of a device’ s ability to reject noise signals between or

among circuit signal conductors, but not between the equipment grounding

conductor or signal reference structure and the signal conductors.

Module update time – See channel update time.

Remote system - A control system where the chassis can be located

several thousand feet from the processor chassis. Chassis communication

is via the 1756-DHRIO and 1756-ENET Adapter.

Resolution – The smallest detectable change in a measurement, typically

expressed in engineering units (e.g. 0.15 °C).

Sampling time - The time required by the mocule to sample an input

channel.

Step response time – The time required for the module to reach 95% of

its expected, final value, given a full-scale step change in the output data

word.

Tags - Identifiers for configuration, data, and status information found

withing the module. T ags allow the user to modify specific module

attributes and view data and status.

Update time – The time for the module to sample and convert a channel

input signal and make the resulting value available to the ControlLogix

processor.

Page 8

viii ControlLogix™ Counter Module

Page 9

Table of Contents

T able of Contents ix

Preface v

Chapter 1

Module Overview

Chapter 2

Installing Your

Module

Chapter 3

Operation in the

System

Who Should Use This Guide ...................................................................................v

What This Guide Covers.......................................................................................... v

Related Allen-Bradley Documents ........................................................................... v

T able A. Related Allen-Bradley documents ............................................................. v

Terms & Abbreviations You Should Know............................................................. vi

General Description .................................................................................................. 1

Table 1.1 Hardware Features .................................................................................... 2

System Overview...................................................................................................... 2

Cables ....................................................................................................................... 3

Installing And Wiring Your Module ........................................................................ 1

Electrostatic Damage ................................................................................................ 1

Power Requirements................................................................................................. 2

Module Installation and Removal ............................................................................ 2

Wiring Your Module ................................................................................................6

Wiring Single-ended Inputs ..................................................................................... 7

Wiring Bi-Directional or Quadrature Inputs ............................................................ 8

Operation Within the

ControlLogix System .............................................................................................. 17

Ownership and Connections .................................................................................. 17

Using RSNetW orx and RSLogix 5000..................................................................... 17

Direct Connections ................................................................................................. 18

Module Operation .................................................................................................. 18

Modules in a Local Chassis ................................................................................... 18

Requested Packet Interval (RPI) ............................................................................ 19

Modules in a Remote Chassis................................................................................ 19

Listen-Only Mode .................................................................................................. 20

Multiple Owners of Input Modules ....................................................................... 20

Configuration Changes in an Input Module with Multiple Owners...................... 21

Chapter 4

Programming Your

Module

Module Installation ................................................................................................ 23

Adding Your Module to a Project .......................................................................... 23

Page 10

x ControlLogix™ Counter Module

Chapter 5

Configuring module

attributes:

Configuration, Data,

and Status Tags ...................................................................................................... 31

Send Configuration Data to the Module ................................................................ 31

Configuration Tags................................................................................................. 32

Channel Specific Settings ....................................................................................... 32

Output Tags ............................................................................................................ 37

Input Tags .............................................................................................................. 37

Chapter 6

Programming

Examples

Initial Programming................................................................................................. 39

Figure 5.1 Sample Ladder Logic ............................................................................. 40

Using the gate storage mode ................................................................................. 42

Installation Recommendations ............................................................................... 44

Meter Proving ......................................................................................................... 45

Chapter 7

Troubleshooting

Using Module Indicators to Troubleshoot............................................................ 45

Using RSLogix 5000 to Troubleshoot Your Module.............................................. 46

Module Configuration Errors ................................................................................. 47

Chapter 8

Maintaining Your

Module

Appendix A

Module

Specifications

Appendix B

Programming Your

Module

Preventive Maintenance ........................................................................................ 49

Safety Considerations ............................................................................................ 49

Electrical Specifications.......................................................................................... 53

Environmental Specifications ................................................................................. 54

Input Specifications ............................................................................................... 54

Accuracy ................................................................................................................ 54

Module Installation ................................................................................................ 57

Adding Your Module to a Project .......................................................................... 57

Declaration of Conformity ...................................................................................... 64

Page 11

Chapter 1

Module Overview

This chapter describes the counter module and explains how the

ControlLogix controller reads analog input data from the module. Read

this chapter to familiarize yourself further with your counter module. This

chapter covers:

• general description and hardware features

• an overview of system and module operation

General Description

This module is designed exclusively for use in the Allen-Bradley

ControlLogix 1756 I/O rack systems. The module reads AC and DC

pulse information from external sensors and stores it in its image table for

retrieval by all ControlLogix processors.

Following is a list of features available on the CTR8 module that allow

their use in a wide variety of applications.

· Removal and insertion under power (RIUP) - a system feature that

allows you to remove and insert modules while chassis power is applied

· Producer/consumer communications - an intelligent data exchange

between modules and other system devices in which each module

produces data without having been polled

· System timestamp of data - 64 bit system clock places a timestamp on

the transfer of data between the module and its owner controller within

the local chassis

· IEEE 32 bit floating point format

· On-Board Features, such as custom User Scaling, Analog and Digital

Filtering, and Under/Over Detection

· Class I/Division 2, UL, CUL, CE, and FM Agency Certification

Page 12

2 ControlLogix™ Counter Module

Input Types

The 1756-CTR supports both AC and DC input signal types. The module

input type is configured on a channel pair basis. Each pair must be

configured for the same input type.

Hardware Features

The module fits into any single slot for I/O modules in a ControlLogix

modular system. The module has a unique generic profile which may be

configured using your RSLogix 5000 programming software.

The module utilizes one removable terminal block, that provides

connections for the eight input channels. The module is configured

through RSLogix 5000 software, defining input type, counter control and

signal filtering.

Table 1.1 Hardware Features

System Overview

Hardware Function

OK LED Displays communication and fault status of the module

SYS LED Displays a fault condition

Side Label (Nameplate) Provides module information

Removable T erminal Block Provides electrical connection to input devices

Door Label Permits easy terminal identification

Self Locking T abs Secure module in chassis slot

Terminal Block Switch Locks the R TB to the module.

Diagnostic LEDs

The module contains diagnostic LEDs that help you identify the source of

problems that may occur during power-up or during normal operation.

Power-up and diagnostics are explained in Chapter 7, Testing Your

Module.

The module communicates with the ControlLogix processor and receives

+5 Vdc and +24 Vdc power from the system power supply through the

parallel backplane interface. You may install as many counter modules in

the system as the power supply can support.

Channels (0 through 7) can receive AC or DC input signals. Input types

must be configured in channel pairs. Each channel reports both count data

and rate data in independent registers. Extended status information is also

available for each channel.

Page 13

Chapter 1: Module Overview 3

System Operation

At power-up, the module checks internal circuits, memory , and basic

functions. During this time the SYS LED remains on. If the module does

not find any faults, it turns off the SYS LED.

After completing power-up checks, the module wait for a connection to an

owner controller then valid channel configuration data from your ladder

logic program. After channel configuration data is transferred, and one or

more channels are enabled, the module continuously converts the inputs to

floating point data for use in your ladder program.

Each time the module reads an input channel, the module tests that data

for a fault, i.e. signal mismatch, or out of range condition. If it detects an

error condition, the module sets a unique bit in the status tags.

Module Operation

The module’s input circuitry consists of eight single-ended inputs, routed

into an FPGA. The FPGA reads the input signals and converts them to

counter and rate and then presents them in floating point values.. The

input circuitry also supports gate inputs allowing you to disable and control

counter operation.

ables

C

Cable length should be kept to a minimum. Use the lowest capacitance

shielded cable available. We recommend that you use Belden #9501 (or

equivalent).

Table 1.2 Cable Specifications

Description Belden #9501

When used? AC/DC inputs.

Conductors 2, #24 A WG tinned copper (7x32)

Shield Beldfoil aluminum polyester shield w/ copper drain wire. .

Insulation PVC

Jacket Chrome PVC

Agency NEC Type CM

Approval

Temperature 80°C

Rating

Page 14

4 ControlLogix™ Counter Module

Page 15

Electrostatic

Damage

Installing And Wiring Y our Module

Read this chapter to install and wire your module. This chapter covers:

• avoiding electrostatic damage

• determining power requirements

• installing the module

• wiring signal cables to the module’s terminal block

Electrostatic discharge can damage semiconductor devices inside this

module if you touch backplane connector pins. Guard against

electrostatic damage by observing the following precautions:

CAUTION

Power

Requirements

ELECTROSTATICALLY SENSITIVE COMPONENTS

• Before handling the module, touch a grounded

object to rid yourself of electrostatic charge.

• When handling the module, wear an approved wrist strap

grounding device.

• Handle the module from the front, away from the

backplane connector. Do not touch backplane connector pins.

• Keep the module in its static-shield container when not in use or

during shipment.

Failure to observe these precautions can degrade the module’s

performance or cause permanent damage.

The module receives its power through the ControlLogix chassis

backplane from the fixed or modular +5 VDC and +24 VDC chassis

power supply . The maximum current drawn by the module is shown in

the table below .

Table 2.1. Maximum current drawn by the module

5VDC Amps 24VDC Amps

0.230 0.075

Page 16

Using your module in the ControlLogix System

Place your module in any slot of a ControlLogix modular, or modular

expansion chassis.

An analog I/O module translates an analog signal into, or from, a

corresponding digital representation which controllers can easily operate

on for control purposes.

A ControlLogix I/O module mounts in a ControlLogix chassis and uses a

Removable T erminal Block (R TB) to connect all field-side wiring.

Before you install and use your module you should have already:

· installed and grounded a 1756 chassis and power supply.

· ordered and received an RTB for your application.

Important: RTBs are not included with your module purchase.

Specify Allen Bradley Part Number:

1756-TBCH - 36 position screw terminals

1756-TBS6H - 36 position press terminals

Module Installation

and Removal

When installing the module in a chassis, it is not necessary to remove the

terminal blocks from the module. However, if the terminal blocks are

removed, use the write-on label located on the side of the terminal blocks

to identify the module location and type.

Preventing Electrostatic Discharge

This module is sensitive to electrostatic discharge.

ATTENTION: Electrostatic discharge can damage integrated

circuits or semiconductors if you touch backplane connector pins.

Follow these guidelines when you handle the module:

· Touch a grounded object to discharge static potential

· Wear an approved wrist-strap grounding device

· Do not touch the backplane connector or connector pins

· Do not touch circuit components inside the module

· If available, use a static-safe work station

· When not in use, keep the module in its static-shield box

Page 17

Removal and Insertion Under Power

These modules are designed to be installed or removed while chassis

power is applied.

ATTENTION: When you insert or remove a module while backplane

power is applied, an electrical arc may occur. An electrical arc can

cause personal injury or property damage by:

· sending an erroneous signal to your system’s field devices

causing unintended machine motion or loss of process control.

· causing an explosion in a hazardous environment.

Repeated electrical arcing causes excessive wear to contacts on

both the module and its mating connectors. Worn contacts may

create electrical resistance that can affect module operation.

Compliance to European Union Directives

If this product bears the CE marking, it is approved for installation within

the European Union and EEA regions. It has been designed and tested to

meet the following directives.

EMC Directive

This product is tested to meet Council Directive 89/336/EEC

Electromagnetic Compatibility (EMC) and the following standards, in

whole or in part, documented in a technical construction file:

EN 61010-1 and EN 61131-2, EN61000-6-2:2001, EN61000-6-4:2001

EN61010-1:2001

This product is intended for use in an industrial environment.

Low Voltage Directive

This product is tested to meet Council Directive 73/23/EEC Low Voltage,

by applying the safety requirements of EN 61131-2 Programmable

Controllers, Part 2 - Equipment Requirements and T ests.

For specific information required by , EN61131-2:1994 + A11:1996 +

A12:2000, see the appropriate sections in this publication, as well as the

following Allen-Bradley publications:

· Industrial Automation Wiring and Grounding Guidelines For Noise

Immunity, publication 1770-4.1

· Automation Systems Catalog, publication B1 1 1

Page 18

This equipment is classified as open equipment and must be installed

(mounted) in an enclosure during operation as a means of providing

safety protection.

CAUTION

POSSIBLE EQUIPMENT OPERATION

ATTENTION: The module is designed to support Removal and

Insertion Under Power (RIUP). However, when you remove or

insert an RTB with field-side power applied, unintended machine

motion or loss of process control can occur. Exercise extreme

caution when using this feature.

ATTENTION: Counter input isolated secondary circuits must be

energy limited and limited to not source more than 5.8 amp into

either the Counter inputs or the Gate inputs in the event of a

component failure

WARNING

The 1756sc-CTR8 module is to be used only with the Allen-Bradley

1756 ControlLogix System.

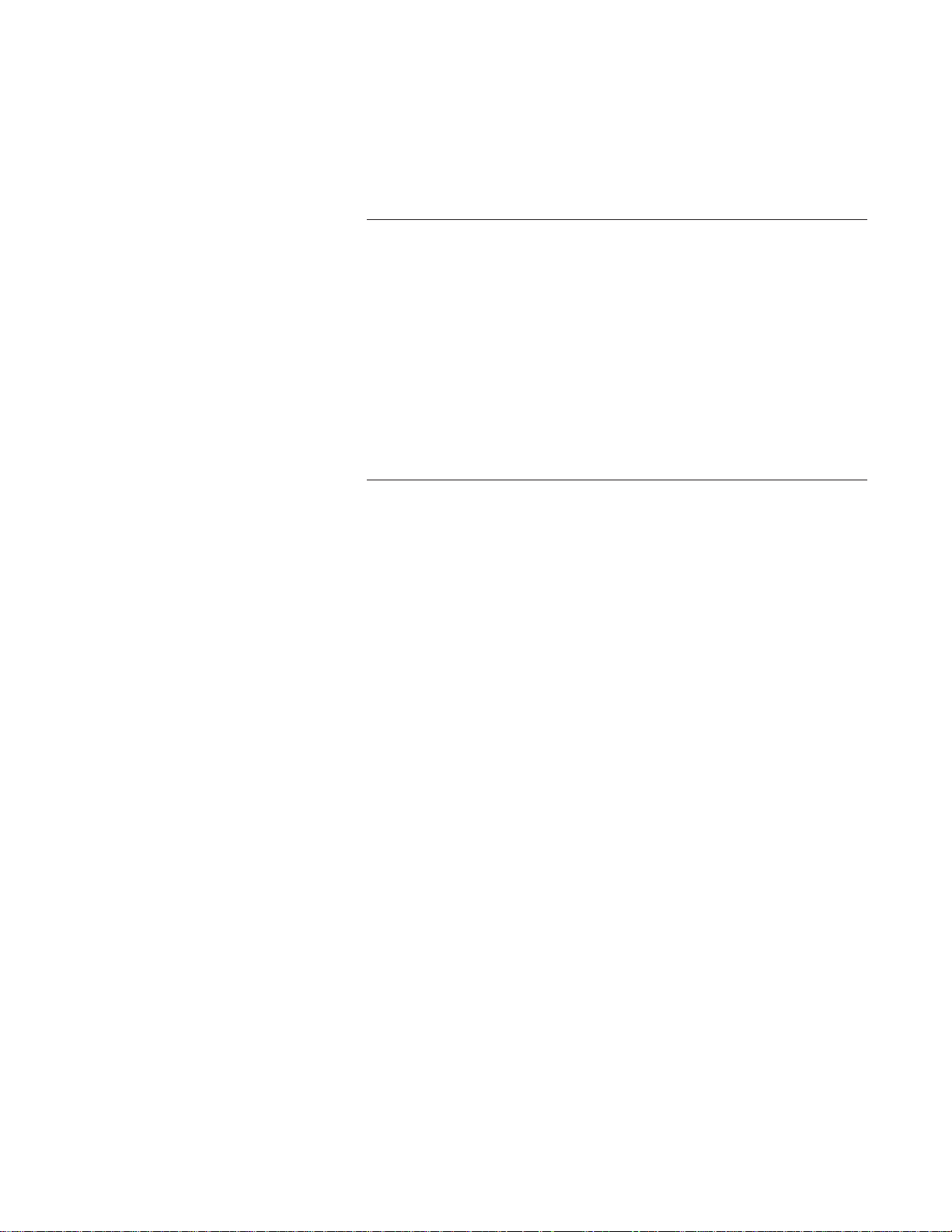

T o insert your module into the rack, follow these steps:

1. Align the circuit board of your module with the card guides at the top

and bottom of the chassis.

Figure 2.1. Module insertion into a rack

Page 19

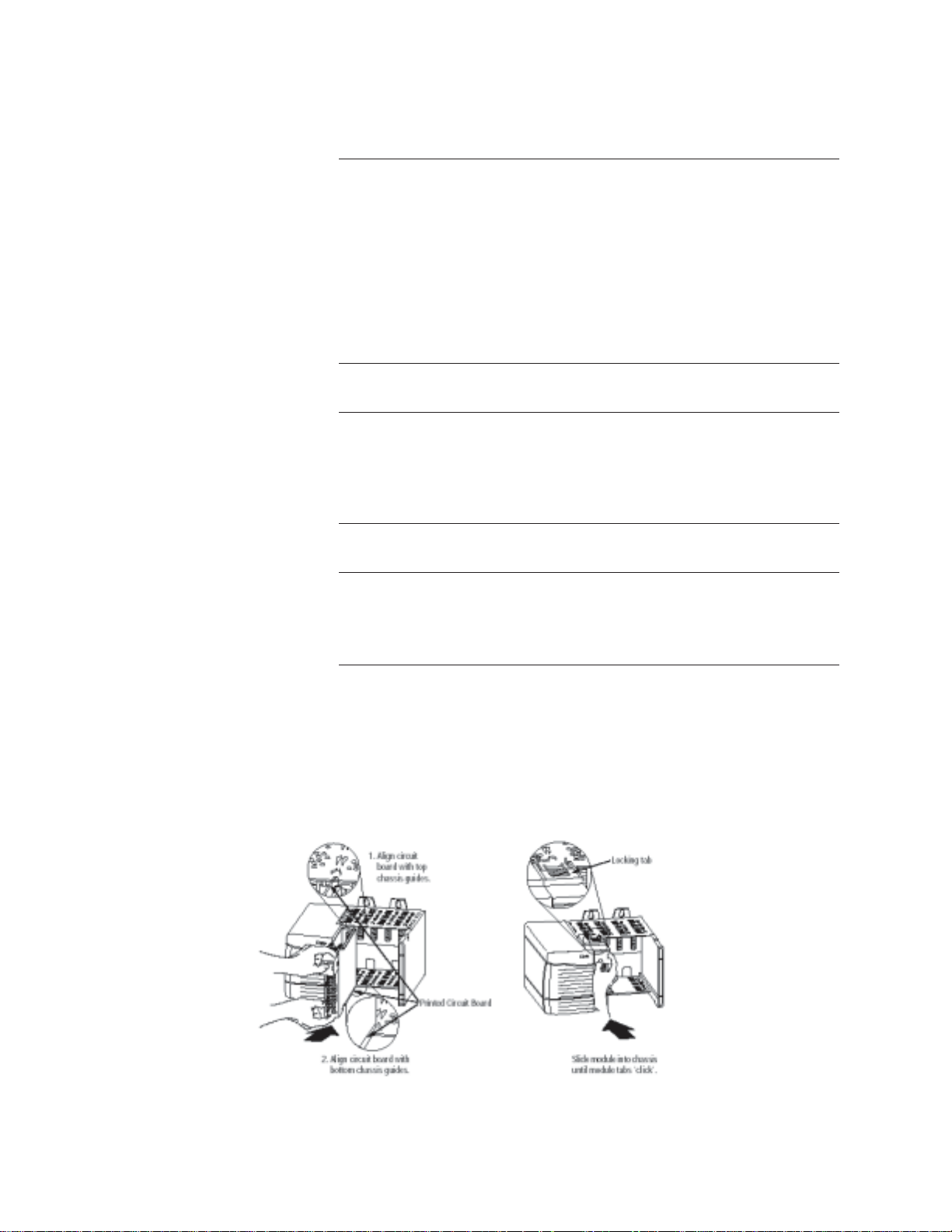

2. Key the R TB in positions that correspond to unkeyed module

positions. Insert the wedge-shaped tab on the R TB with the rounded

edge first. Push the tab onto the R TB until it stops.

Keying the Removable Terminal Block

Key the RTB to prevent inadvertently connecting the incorrect RTB to

your module.

When the RTB mounts onto the module, keying positions will match up.

For example, if you place a U-shaped keying band in position #4 on the

module, you cannot place a wedge-shaped tab in #4 on the R TB or your

RTB will not mount on the module.

W e recommend that you use a unique keying pattern for each slot in the

chassis.

1. Insert the U-shaped band with the longer side near the terminals. Push

the band onto the module until it snaps into place.

Figure 2.2. Terminal block diagram with keying

Wiring Your Module

Follow these guidelines to wire your input signal cables:

• Power, input, and output (I/O) wiring must be in accordance with

Class 1, Division 2 wiring methods [Article 501-4(b) of the National

Electrical Code, NFP A 70] and in accordance with the authority having

jurisdiction.

• Peripheral equipment must be suitable for the location in which it is

used.

• Route the field wiring away from any other wiring and as far as

possible from sources of electrical noise, such as motors, transformers,

contactors, and ac devices. As a general rule, allow at least 6 in. (about

15.2 cm) of separation for every 120 V of power.

• Routing the field wiring in a grounded conduit can reduce electrical

noise further.

Page 20

• If the field wiring must cross ac or power cables, ensure that they

cross at right angles.

• To limit the pickup of electrical noise, keep signal wires as far from

power and load lines as possible.

• Ground the shield drain wire at only one end of the cable. The

preferred location is at the shield connections at the ControlLogix

chassis. (Refer to IEEE Std. 518, Section 6.4.2.7 or contact your sensor

manufacturer for additional details.)

• Tighten screw terminals with care. Excessive tightening can strip a

screw.

• Follow system grounding and wiring guidelines found in your

ControlLogix Installation and Operation Manual.

Preparing and Wiring the Cables

T o prepare and connect cable leads and drain wires, follow these steps:

Signal Wires

(At the module-end of the cable, extract

the drain wire but remove the foil shield.)

1. At each end of the cable, strip some casing to expose individual

wires.

2. Trim signal wires to 5-inch lengths beyond the cable casing. Strip

about 3/16 inch (4.76 mm) of insulation to expose the ends of the wires.

3. At the module-end of the cables (see figure above):

- extract the drain wire and signal wires

- remove the foil shield

- bundle the input cables with a cable strap

4. Connect pairs of drain wires together, Channels 0 and 1, Channels 2

and 3, Channels 4 and 5, Channels 6 and 7. Keep drain wires as short as

possible.

Drain Wire

Cable

(Remove foil shield and drain wire

from sensor-end of the cable.)

Signal Wires

5. Connect the drain wires to the grounding lug on the PLC chassis.

6. Connect the signal wires of each channel to the terminal block.

Important: Only after verifying that your connections are correct for

each channel, trim the lengths to keep them short. Avoid cutting leads

too short.

7. At the source-end of cables from devices:

- remove the drain wire and foil shield

- apply shrink wrap as an option

- connect to mV devices keeping the leads short

Page 21

Wiring Single-ended

0

3

Inputs

Important: If noise persists, try grounding the opposite end of the cable,

instead (Ground one end only.)

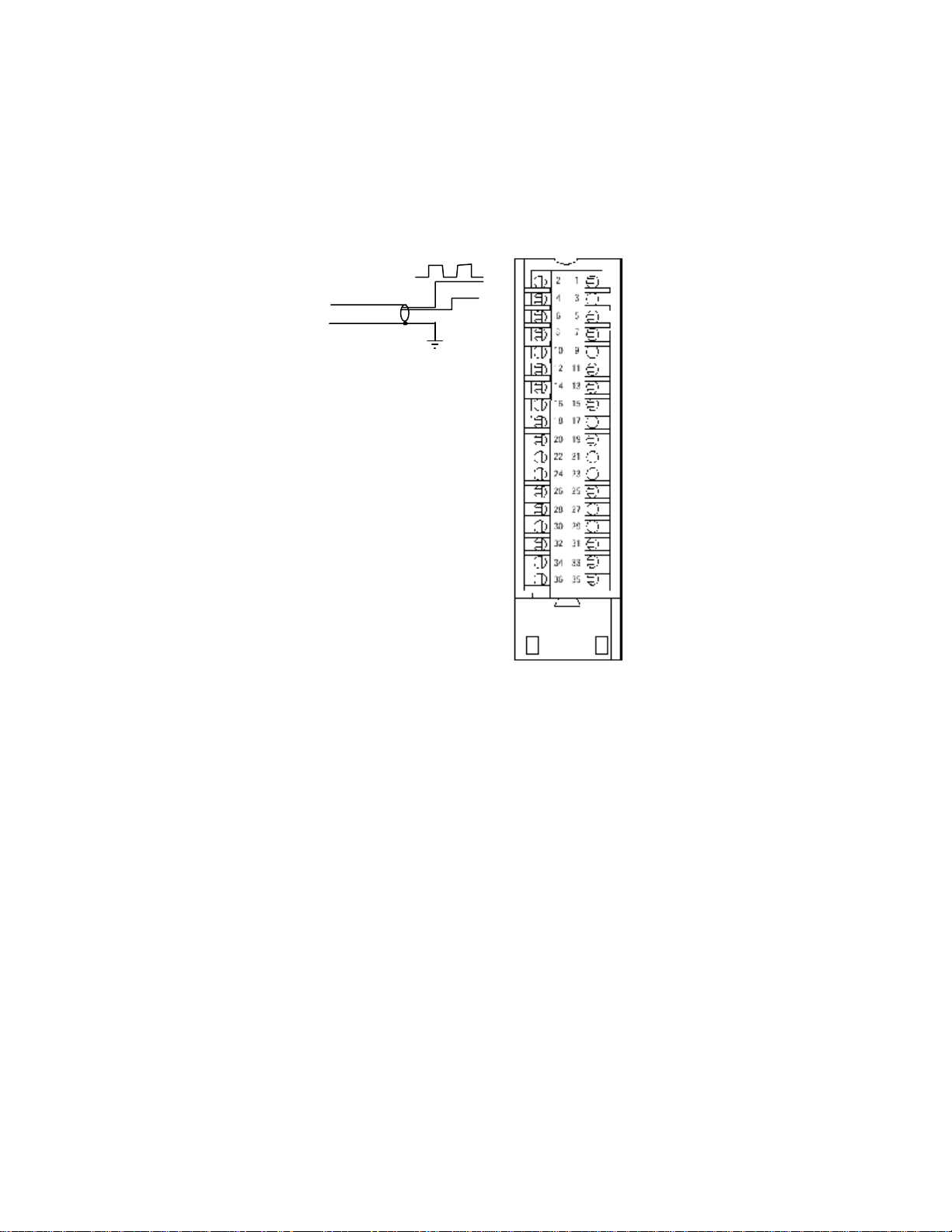

The following figure shows the general terminal block layout. A single-ended input uses a pair of

terminals, Hi(x) and Com. Gate lines are wired with their respective Gate(x) and Com terminals.

Single-ended Wiring

Unidirecti onal I nput

Chassis

Ground

Hi 4

Com

Gate 4

Com

Hi 5

Com

Gate 5

Com

Hi 6

Com

Gate 6

Com

Hi 7

Com

Gate 7

Com

N/C

N/C

Hi 0

Com

Gate

Com

Hi 1

Com

Gate 1

Com

Hi 2

Com

Gate 2

Com

Hi 3

Com

Gate

Com

N/C

N/C

Page 22

Wiring Bi-

g

Directional or

Quadrature Inputs

Input use channel pairs, for example Hi2(A), Com, Hi2(B), Com. There

is one gate input per channel pair.

Bi-directional/Quadrature Wirin

Bi-directional Input

Chassis

Ground

Quadrature Input

Chassis

Ground

A

Z

B

Hi 3 (A)

Com

Gate 3

Com

Hi 3 (B)

Com

N/C

Com

Hi 4 (A)

Com

Gate 4

Com

Hi 4 (B)

Com

N/C

N/C

N/C

N/C

Hi 0 (A)

Com

Gate 0

Com

Hi 0 (B)

Com

N/C

Com

Hi 1 (A)

Com

Gate 1

Com

Hi 1 (B)

Com

N/C

N/C

N/C

N/C

Page 23

Page 24

Ownership and

Connections

Chapter 3

Operation Within the

ControlLogix System

This chapter describes how the 1756sc-CTR8 analog module works

within the ControlLogix system. This chapter covers:

• Ownership and connections to the module

• Direct connections

• Listen only mode

• Configuration changes with multiple owners.

Every I/O module in the ControlLogix system must be owned by a

Logix5550 Controller to be useful. This owner-controller stores

configuration data for every module that it owns and can be local or

remote in regard to the I/O module’s position. The owner sends the I/O

module configuration data to define the module’ s behavior and begin

operation within the control system. Each ControlLogix I/O module must

continuously maintain communication with its owner to operate normally.

Using RSNetWorx

and RSLogix 5000

T ypically , each module in the system will have only 1 owner . Input

modules can have more than 1 owner . Output modules, however , are

limited to a single owner.

The I/O configuration portion of RSLogix5000 generates the

configuration data for each I/O module in the control system, whether

the module is located in a local or remote chassis. A remote chassis, also

known as networked, contains the I/O module but not the module’s

owner controller . Configuration data is transferred to the controller during

the program download and subsequently transferred to the appropriate I/

O modules. I/O modules in the same chassis as the controller are ready

to run as soon as the configuration data has been downloaded. You must

run RSNetW orx to enable I/O modules in the networked chassis.

Running RSNetW orx transfers configuration data to networked modules

and establishes a Network Update Time (NUT) for ControlNet that is

compliant with the desired communications options specified for each

module during configuration. If you are not using I/O modules in a

networked chassis, running RSNetW orx is not necessary. However,

anytime a controller references an I/O module in a networked chassis,

RSNetW orx must be run to configure ControlNet. Follow these general

guidelines when configuring I/O modules:

Page 25

DirectDirect

Direct

DirectDirect

ConnectionsConnections

Connections

ConnectionsConnections

Chapter 3: Operation within the System 15

1. Configure all I/O modules for a given controller using RSLogix 5000

and download that information to the controller .

2. If the I/O configuration data references a module in a remote chassis,

run RSNetWorx.

Important: RSNetWorx must be run whenever a new module is added

to a networked chassis. When a module is permanently removed from a

remote chassis, we recommend that RSNetWorx be run to optimize the

allocation of network bandwidth.

A direct connection is a real-time data transfer link between the

controller and the device that occupies the slot that the configuration data

references. When module configuration data is downloaded to an ownercontroller, the controller attempts to establish a direct connection to each

of the modules referenced by the data.

If a controller has configuration data referencing a slot in the control

system, the controller periodically checks for the presence of a device

there. When a device’ s presence is detected, the controller automatically

sends the configuration data. If the data is appropriate to the module

found in the slot, a connection is made and operation begins. If the

configuration data is not appropriate, the data is rejected and an error

message displays in the software. In this case, the configuration data can

be inappropriate for any of a number of reasons.

Module OperationModule Operation

Module Operation

Module OperationModule Operation

Modules in a Local

Chassis

The controller maintains and monitors its connection with a module. Any

break in the connection, such as removal of the module from the chassis

while under power, causes the controller to set fault status bits in the data

area associated with the module. The RSLogix 5000 software may

monitor this data area to announce the modules’ failures.

In traditional I/O systems, controllers poll input modules to obtain their

input status. Analog input modules in the ControlLogix system are not

polled by a controller once a connection is established. The modules

multicast their data periodically . Multicast frequency depends on the

options chosen during configuration and where in the control system that

input module physically resides. An input module’ s communication, or

multicasting, behavior varies depending upon whether it operates in the

local chassis or in a remote chassis. The following sections detail the

differences in data transfers between these set-ups.

When a module resides in the same chassis as the owner controller, the

following two configuration parameters will affect how and when the

input module multicasts data:

· Real Time Sample (RTS) configured via Real Time Sample tag.

· Requested Packet Interval (RPI) configured via I/O module properties.

Page 26

16 ControlLogix™ Counter Module

Requested Packet

Interval (RPI)

Real Time Sample (RTS)

This configurable parameter instructs the module to perform the

following operations:

1. scan all of its input channels and store the data into on-board memory

2. multicast the updated channel data (as well as other status data) to the

backplane of the local chassis

This configurable parameter also instructs the module to multicast its

channel and status data to the local chassis backplane.

The RPI instructs the module to multicast the current contents of its

on-board memory when the RPI expires, (i.e. the module does not

update its channels prior to the multicast).

Important: The RPI value is set during the initial module configuration

using RSLogix 5000.

Modules in a

Remote Chassis

It is important to note that the module will reset the RPI timer each time

an RTS is performed. This operation dictates how and when the owner

controller in the local chassis will receive updated channel data,

depending on the values given to these parameters. If the RTS value is

less than or equal to the RPI, each multicast of data from the module will

have updated channel information. In effect, the module is only

multicasting at the R TS rate.

If the R TS value is greater than the RPI, the module will multicast at

both the RTS rate and the RPI rate. Their respective values will dictate

how often the owner controller will receive data and how many

multicasts from the module contain updated channel data. Note: Even

though data may be transfered at the RPI rate, the data will be indentical

to the previous RTS data transfer.

If an input module resides in a networked chassis, the role of the RPI

and the module’s R TS behavior change slightly with respect to getting

data to the owner. The RPI and RTS intervals still define when the

module will multicast data within its own chassis (as described in the

previous section), but only the value of the RPI determines how often the

owner controller will receive it over the network.

When an RPI value is specified for an input module in a remote chassis,

in addition to instructing the module to multicast data within its own

chassis, the RPI also “reserves” a spot in the stream of data flowing

across the ControlNet network.

Page 27

Chapter 3: Operation within the System 17

The timing of this “reserved” spot may or may not coincide with the

exact value of the RPI, but the control system will guarantee that the

owner controller will receive data at least as often as the specified RPI.

The “reserved” spot on the network and the module’s RTS are

asynchronous to each other. This means there are Best and Worst Case

scenarios as to when the owner controller will receive updated channel

data from the module in a networked chassis.

Best Case RTS Scenario

In the Best Case scenario, the module performs an RTS multicast with

updated channel data just before the “reserved” network slot is made

available. In this case, the remotely located owner receives the data

almost immediately.

Worst Case RTS Scenario

In the W orst Case scenario, the module performs an RTS multicast just

after the “reserved” network slot has passed. In this case, the ownercontroller will not receive data until the next scheduled network slot.

Listen-Only Mode

Because it is the RPI and NOT the RTS which dictates when the

module’s data will be sent over the network, we recommend the RPI

value be set LESS THAN OR EQUAL TO the RTS to make sure that

updated channel data is received by the owner controller with each

receipt of data.

Any controller in the system can listen to the data from any I/O module

(e.g. input data or “echoed” output data) even if the controller does not

own the module (i.e. it does not have to hold the module’ s configuration

data to listen to the module).

The “listen only” mode is set during the I/O configuration process.

Choosing a ‘Listen-Only’ mode option allows the controller and module

to establish communications without the controller sending any

configuration data. In this instance, another controller owns the module

being listened to.

Important:Controllers using the Listen-Only mode continue to receive

data multicast from the I/O module as long as a connection between an

owner and I/O module is maintained. If the connection between all

owners and the module is broken, the module stops multicasting data and

connections to all ‘Listening controllers’ are also broken.

Multiple Owners of

Input Modules

Because ‘Listening controllers’ lose their connections to modules when

communications with the owner stop, the ControlLogix system will allow

you to define more than one owner for input modules.

Page 28

18 ControlLogix™ Counter Module

Important: Only input modules can have multiple owners. If multiple

owners are connected to the same input module, they must maintain

identical configuration for that module.

In the example below, Controller A and Controller B have both been

configured to be the owner of the input module.

When the controllers begin downloading configuration data, both try to

establish a connection with the input module. Whichever controller’s data

arrives first establishes a connection. When the second controller’s data

arrives, the module compares it to its current configuration data (the data

received and accepted from the first controller).

If the configuration data sent by the second controller matches the

configuration data sent by the first controller the connection is also

accepted. If any parameter of the second configuration data is different

from the first, the module rejects the connection and the user is informed

by an error in the software.

The advantage of multiple owners over a ‘Listen-only’ connection is that

now either of the controllers can lose the connection to the module and

the module will continue to operate and multicast data to the system

because of the connection maintained by the other owner controller.

Configuration

Changes in an

Input Module with

Multiple Owners

Note: The previous discussion of multiple owners assues the

configuration tag “.configrevnumber” is set to 1. Operation differs is the

tag is set to 0. Refer to Chapter 5 for descriptions of this tag’s settings.

Y ou must be careful when changing an input module’ s configuration data

in a multiple owner scenario. When the configuration data is changed in

one of the owners, for example, Controller A, and sent to the module,

that configuration data is accepted as the new configuration for the

module. Controller B will continue to listen, unaware that any changes

have been made in the module’ s behavior .

Important: When changing configuration for a module with multiple

owners, we recommend the connection be inhibited. T o prevent other

owners from receiving potentially erroneous data, as described above,

the following steps must be followed when changing a module’ s

configuration in a multiple owner scenario when online:

1. For each owner controller, inhibit the controller’s connection to the

module in the software on the I/O Module Connection tab.

2. Make the appropriate configuration data changes in the software.

Page 29

Chapter 3: Operation within the System 19

Page 30

Chapter 4

Programming Your Module

This chapter explains how to program your module in the ControlLogix

system. It also describes how the module’ s input configuration are

incorporated into your ladder logic program. T opics discussed include:

• importing the module’s configuration profile

• reviewing accessing and altering configuration options.

• configuring the modules input type and filter settings

• configuring alarms and limits

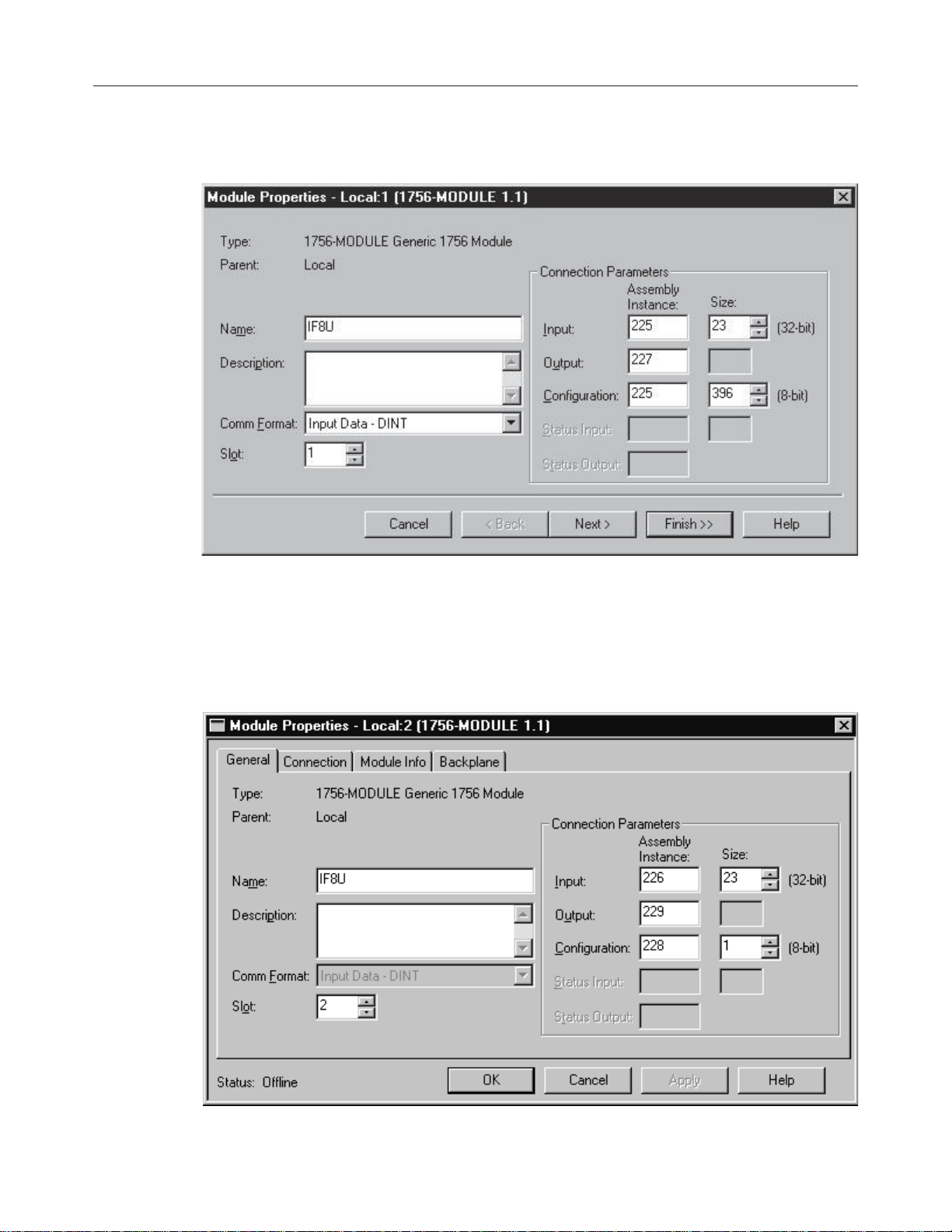

Module Installation

Adding Your Module

to a Project

Incorporating your module into the system is similar to adding any type of

I/O module. You will use your RSLogix 5000 programming software. The

module is not currently in the pick list of this software so you will drag and

drop sample information from a sample program. This allows you to

import the configuration database into your project and set the attributes of

each tag. These settings control features such as the modules input type,

channel input range, data format, filter frequency, etc.

Y ou will need to download the sample project from our website and then

import this into your project. Then you may access the controller tags to

configure the module once this process is complete.

The module has a unique set of tag definitions which are used to configure

specific features. Chapter 5, Channel Configuration, Data, and Status,

gives you detailed information about the data content of the configuration.

These values are set using your programming software and ladder logic.

Before you can use these feature you must first include the module into the

project.

Page 31

Chapter 4: Programming Y our Module 21

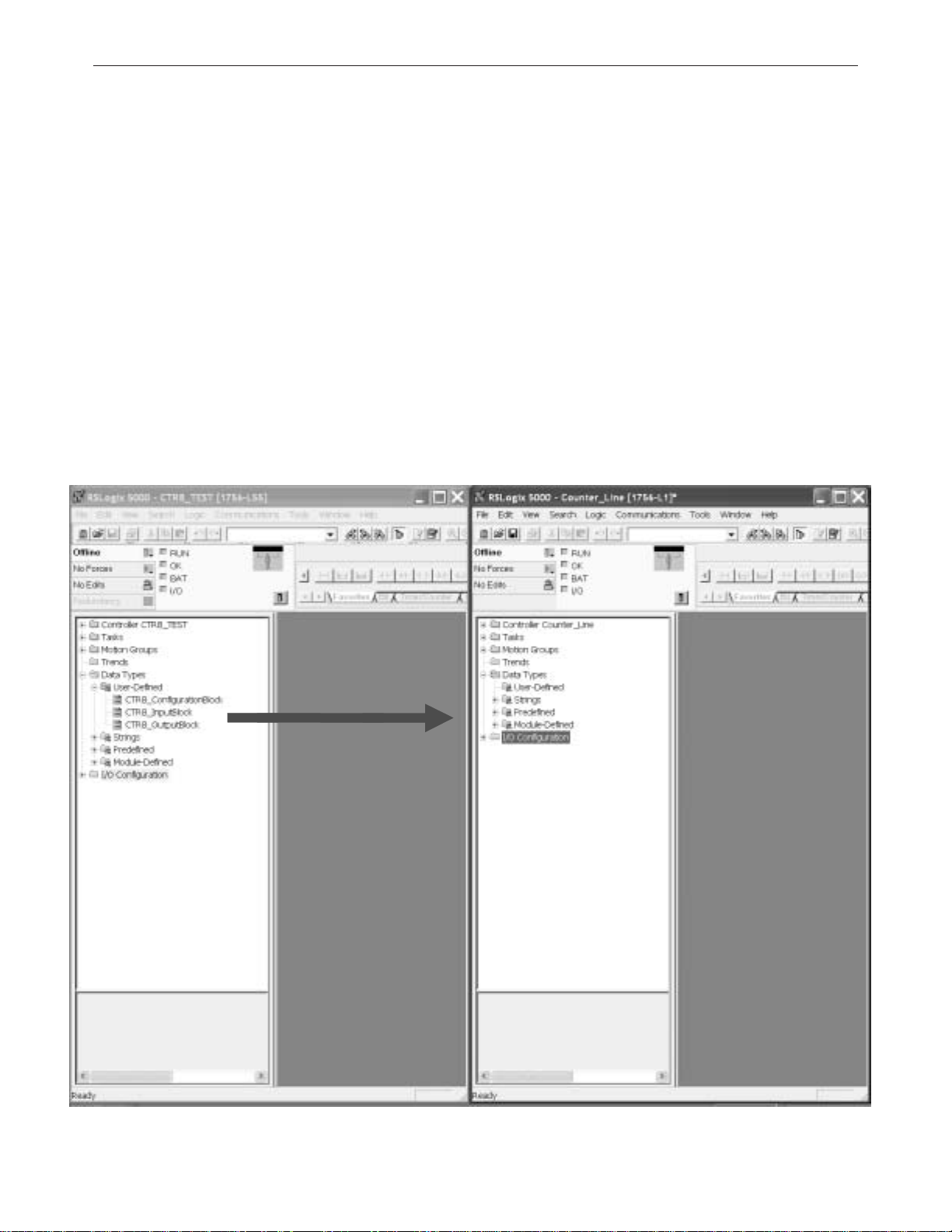

Step 1-

your project. Drag and drop the CTR8 module into the I/O configuration

section of your project.

1. Open the sample project.

2. Open your new project.

3. Click once on the CTR8 in the sample project.

4. Drag and drop it into the I/O Configuration section of your project.

See Appendix D for the I/O module property details.

Open the sample project with the CTR8 information. Open

Page 32

22 ControlLogix™ Counter Module

Step 2-

sample project into your project.

There are three CTR8 user defined data types that need to be moved.

ConfigurationBlock

InputBlock

OutputBlock

1. Click on the data type

2. Drag it into your new project.

3. Continue to drag and drop the data types until all four have been moved.

Note: These can only be moved one at a time.

Drag and drop the CTR8 user-defined data types from the

Page 33

Chapter 4: Programming Y our Module 23

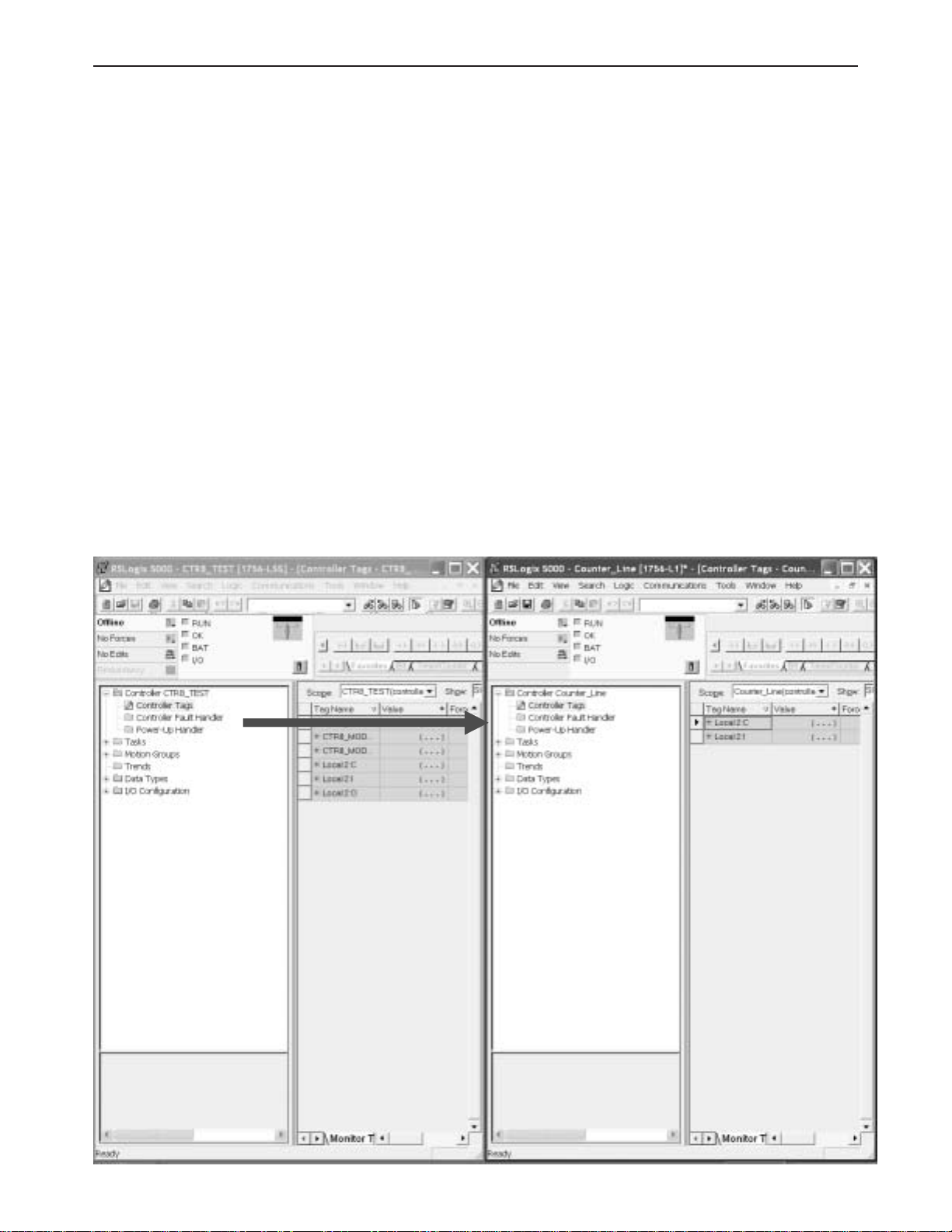

Step 3-

sample project into your project.

1. Right click on the Controller T ags item of the sample project and select

edit.

2. Right click on the Controller T ags item of your project and select edit.

3. Scroll down to the Controller tags of the sample project and select all the

tags by highlighting them.

4. Drag and drop these tags into your project.

Note: CTR8_Config and CTR8_Input contain the configuration, data and

status tags for the CTR8 module. The other tags are used for performing

various functions to your module via ladder logic.

Note: Be sure all tags are displayed before moving them. Select Display All

from the Edit drop down window .

Note: The “Local:3:I” and “Local:3:C” tags are not copied.

Drag and drop the controller configuration tags from the

Page 34

24 ControlLogix™ Counter Module

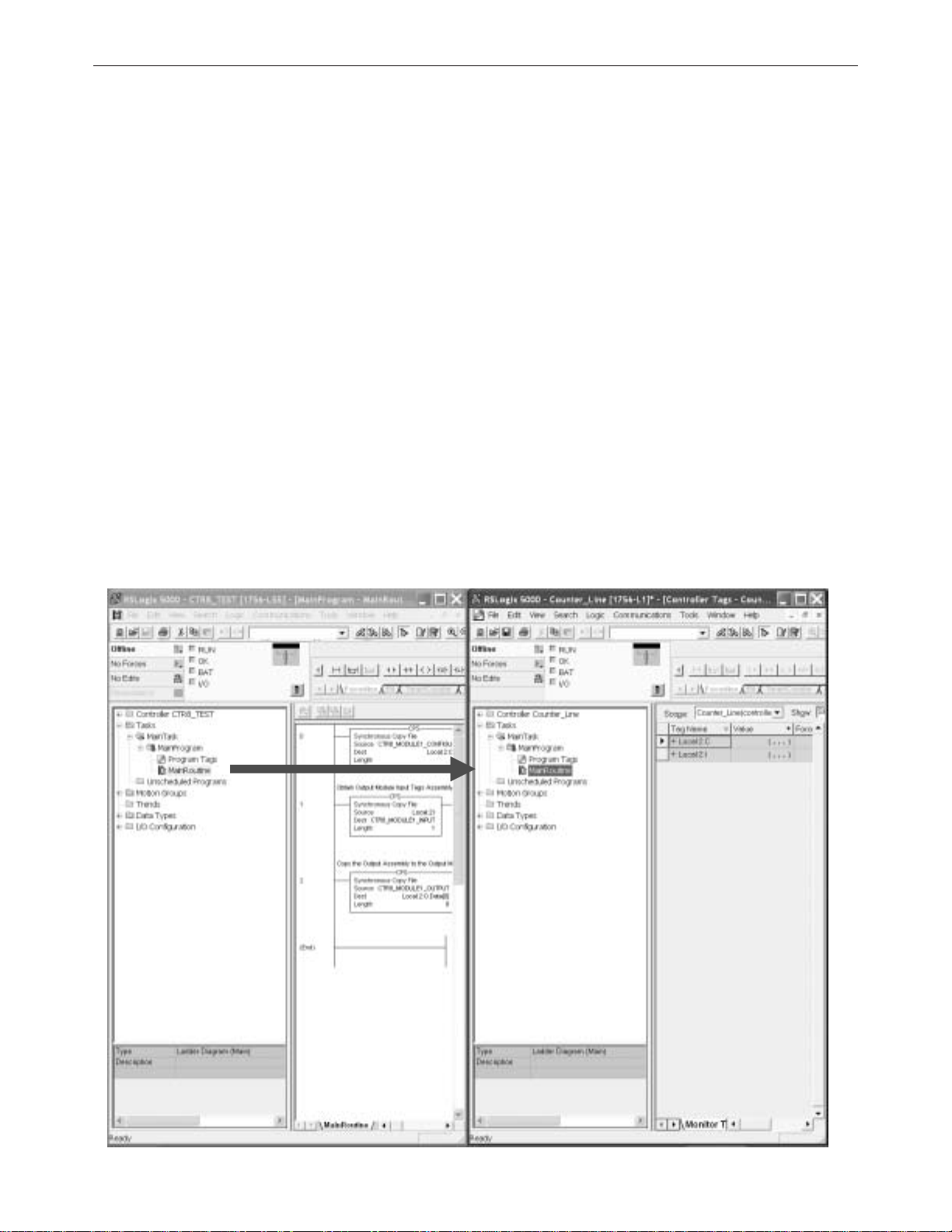

Step 4-

1. In your project, right mouse click on the MainRoutine item and select

“New Routine...” CTR8 was entered in the example above.

2. Double click on the MainRoutine item in the sample project and then

double click on the added new routine in your project to display their

corresponding ladder logic.

3. Left mouse inside the MainProgram ladder logic in the sample project

and press crtl-A to select all the rungs.

4. Drag and drop these rungs over and add them to the new routine’s ladder

logic. Note: You will need to delete the one blank “solid bar” rung either at

the top or bottom of the routine which was left over from the newly created

routine.

5. Now add a JSR ladder instruction in your MainRountine which calls this

routine.

Note: RSLogix 5000 will verify the ladder logic sample. You may receive

errors regarding invalid tags. Y ou will need to change the slot addressing in

the logic to coordinate with the location of the CTR8.

This completes the installation of module in the system

Create a new ladder logic routine in your project.

Page 35

Configuring module

attributes:

Configuration Tags

Chapter 4: Programming Y our Module 25

The module has settings that are global and channel specific. These are

accessed via the controller tags. Specific information regarding these tag

settings may be found in Chapter 5.

Channel Specific Tags

These settings control channel specific behavior such as input type, range,

filter frequency, units, and alarms. Specific information regarding these

tags may be found in Chapter 5.

Page 36

26 ControlLogix™ Counter Module

Data Tags

These tags represent the process data values in their final form.

Status Tags

These tags report module status such as alarm conditions, faults, and

errors.

Page 37

Chapter 4: Programming Y our Module 27

Page 38

28 ControlLogix™ Counter Module

Configuration, Data,

and Status Tags

Read this chapter to:

• send configuration data to the module

• configure global module properties

• configure each input channel

• check each input channel’s data

• check module and individual channel status

This chapter outlines the detailed settings for the 1756sc-CTR8. These

settings determine the modules input types, filter frequencies, scan rates,

and various attributes. Detailed descriptions of these settings are available

in the T ag Definition section of this chapter .

Chapter 5

Send Configuration

Data to the Module

Note: The following format is used to describe tags

Tag Name Range Data Type

After changing the configuration tags in this chapter you must then send

them to the module. T o do this you may perform any of these operations:

1. Inhibit then un-inhibit the module via the module properties dialog,

Connection T ab

2. Reset the module via the modules properties dialog. Module Info tab.

3. Reset the module via ladder logic. See the “DoReset” rung in the

sample ladder project.

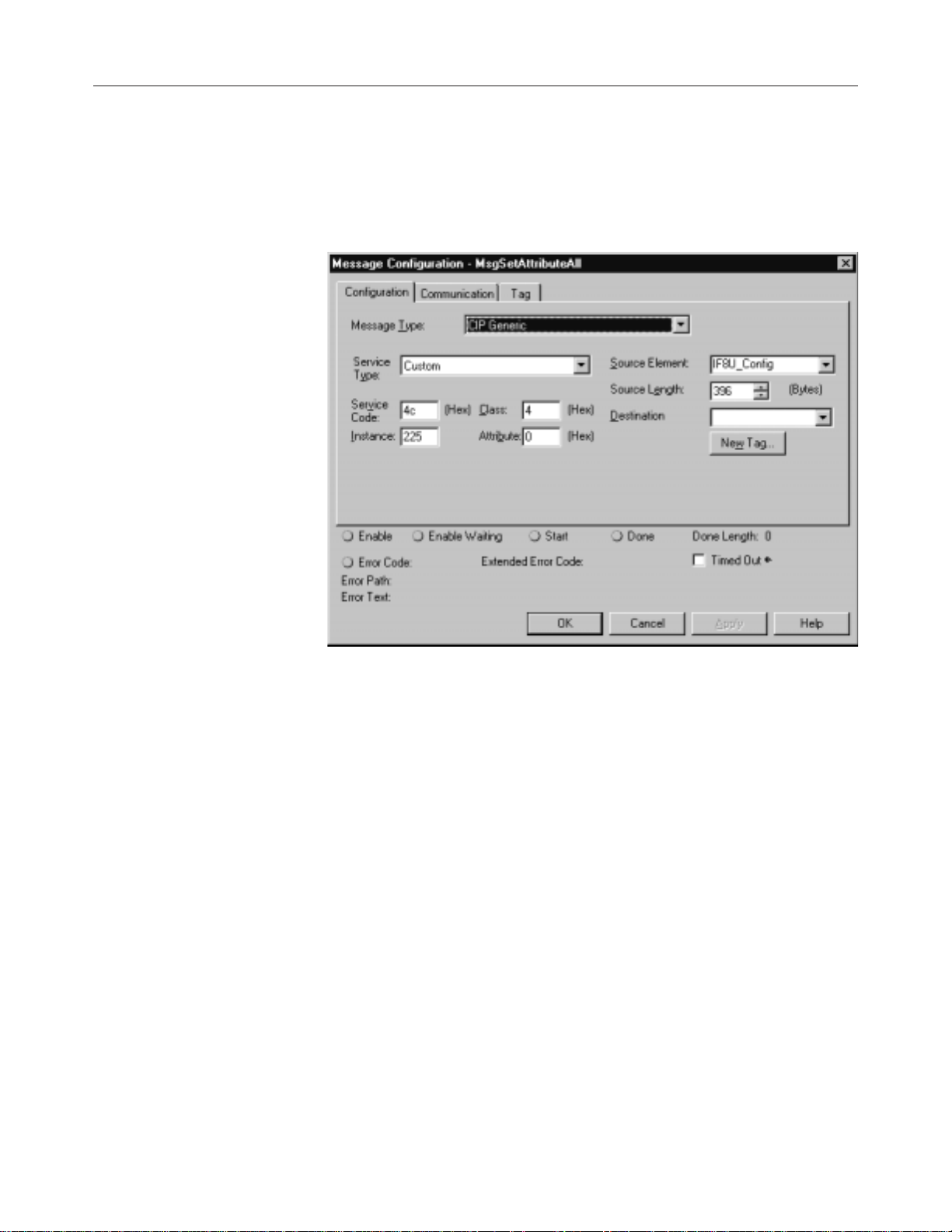

4. Perform a “Set Attribute All” or Module Reconfigure message

instruction via ladder logic. Refer to your sample program for information

about the “DoSetAttrAll” command.

Note: If an invalid configuration is sent to the module a connection error

will occur. See chapter 7 for a list of error codes.

Page 39

Chapter 5: Channel Configuration, Data, and Status 29

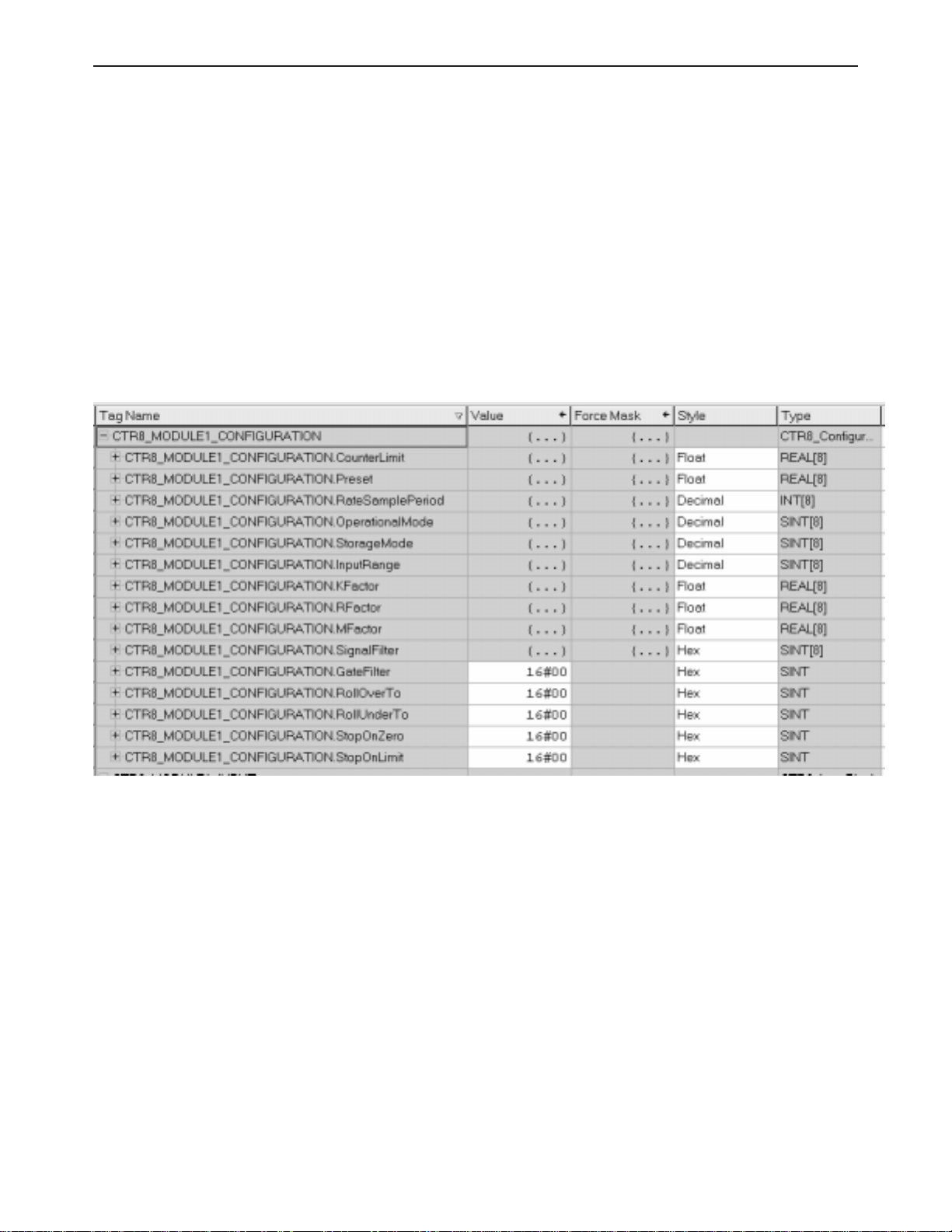

Configuration Tags

Channel Specific

Settings

The following Global Module Settings and Channel Specific Settings

sections allow custom configuration of the module. These tags can be

found within the CTR8_config controller tags.

[x] designates the channel number

(C) designates the value may be changed during module operation

CountLimit[x] 0 - 16777215 FLOAT (C)

Designates the channel rollover value. The maximum value is 1677215

when scaling is off. When scaling is applied the maximum value is

1677215/K*M.

Preset[x] 0 - 16777215 FLOAT (C)

Designates the channel preset value. Module begins counting at this value.

IMPORTANT: This value cannot be greater than the rollover value. The

maximum value is 1677215 when scaling is off. When scaling is applied the

maximum value is 1677215/K*M.

RateSamplePeriod[x] 0-2000 INT

When using period/rate mode, set this value as a multiple of 10ms between

0 and 2000. This becomes the integration time over which rate data is

averaged.

OperationalMode[x] 0,1 INT

Designates channel operational mode.

0 = unidirectional counter mode (Up)

1 = bidirectional counter mode (Up / Down)

2 = encoder X1 mode

3 = encoder X4 mode

Note: Channels must be configured in pairs. (0,1) (2,3) (3,4) (4,5) (5,6) (6,7)

Input configurations determine how the 8 inputs cause the counter to

increment or decrement. The four available configurations are:

• Uni-Directional (up)

• Bi-Directional (up and down using two channels)

• X1 Quadrature Encoder

• X4 Quadrature Encoder

Page 40

30 ControlLogix™ Counter Module

Uni-Directional

With this configuration, the input increments in an upward direction. All 8

channels may be configured in the unidirectional mode. Every clock pulse

will increment the counter on the rising edge. Note: The direction of the

counter may be inverted by setting the Count Direction bit described in the

Configuration chapter.

Bi-Directional

The bidirectional counter requires 2 input channels. In this mode one

channel is used as the counter input and the 2

determine the count direction. The counter will increment when the

Direction Channel value is 0, and will decrement when the Counter

Direction Channel value is 1.

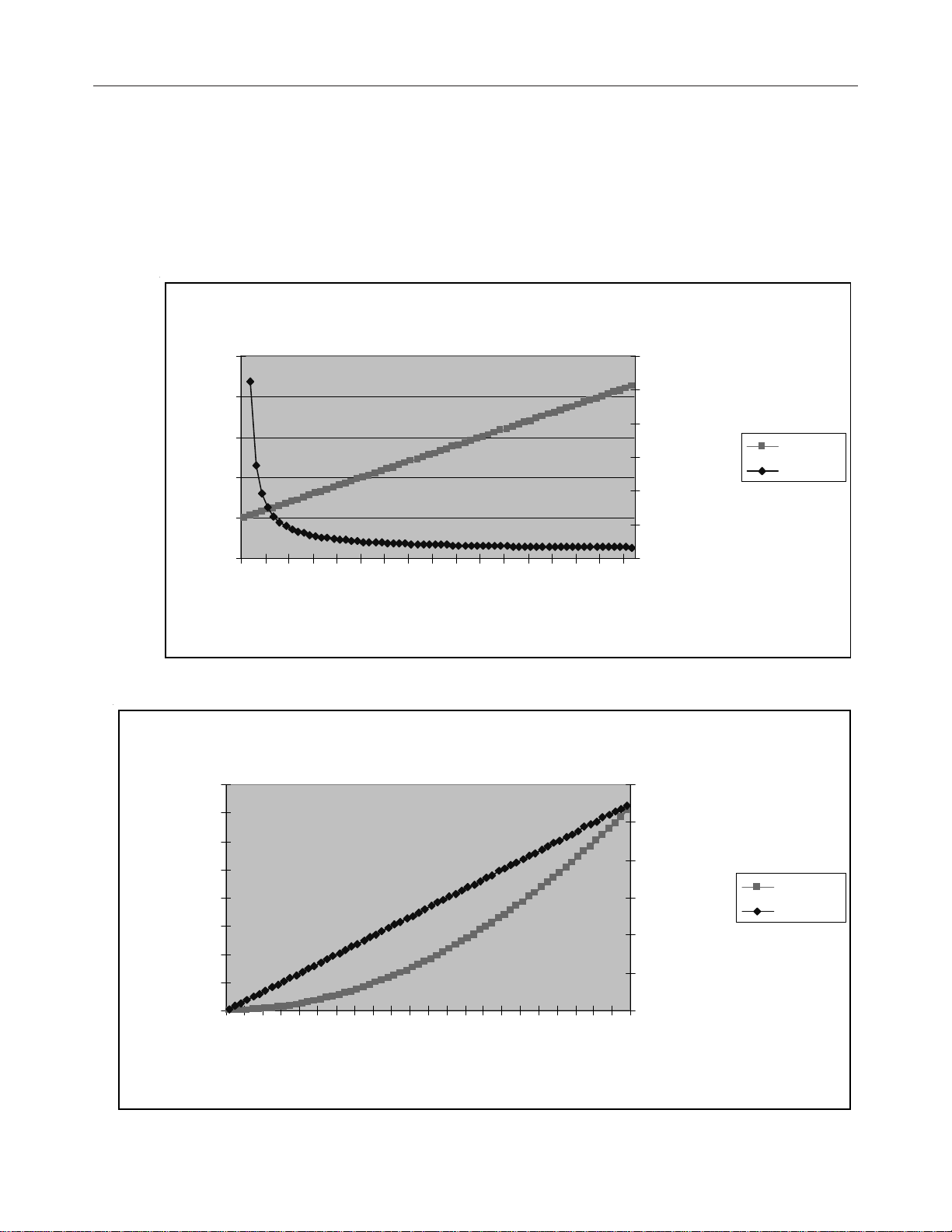

X1 Quadrature Encoder

The quadrature mode requires 2 input channels. When a quadrature

encoder is attached to an input channel pair, A and B, the count direction is

determined by the phase angle between inputs A and B. If A leads B, the

counter increments. If B leads A, the counter decrements. (The counter

changes value only on one edge of input 1.) The counter increments once

per quadrature cycle.

nd

channel is used to

Note: The Quadrature mode provides additional Anti-Jitter circuitry.

This distinguishes between a valid quadrature sequence and an

invalid sequence due to electrical noise or jitter. Jitter can occur if a

quadrature encoder stops rotating right at an input sensor trip point.

This can cause additional unwanted clock pulses. Quadrature mode

can detect invalid transitions and filter these out.

X4 Quadrature Encoder

Like the X1 quadrature encoder, the count direction is determined by the

phase angle between inputs A and B. If A leads B, the counter increments.

If B leads A, the counter decrements. However, the counter changes

value on the rising and falling edges of inputs A and B. The counter

increments four times per quadrature cycle.

Page 41

Chapter 5: Channel Configuration, Data, and Status 31

A

Input A

A

B

x1 Count

x4 Count

B

Quadrature

Input B

Encoder

Forward Rotation Reverse Rotation

1

2

3

1 2 3 4 5 6 7 8 9 10 11 12

2

10

11 10 9 8 7 6 5 4 3 2 1 0

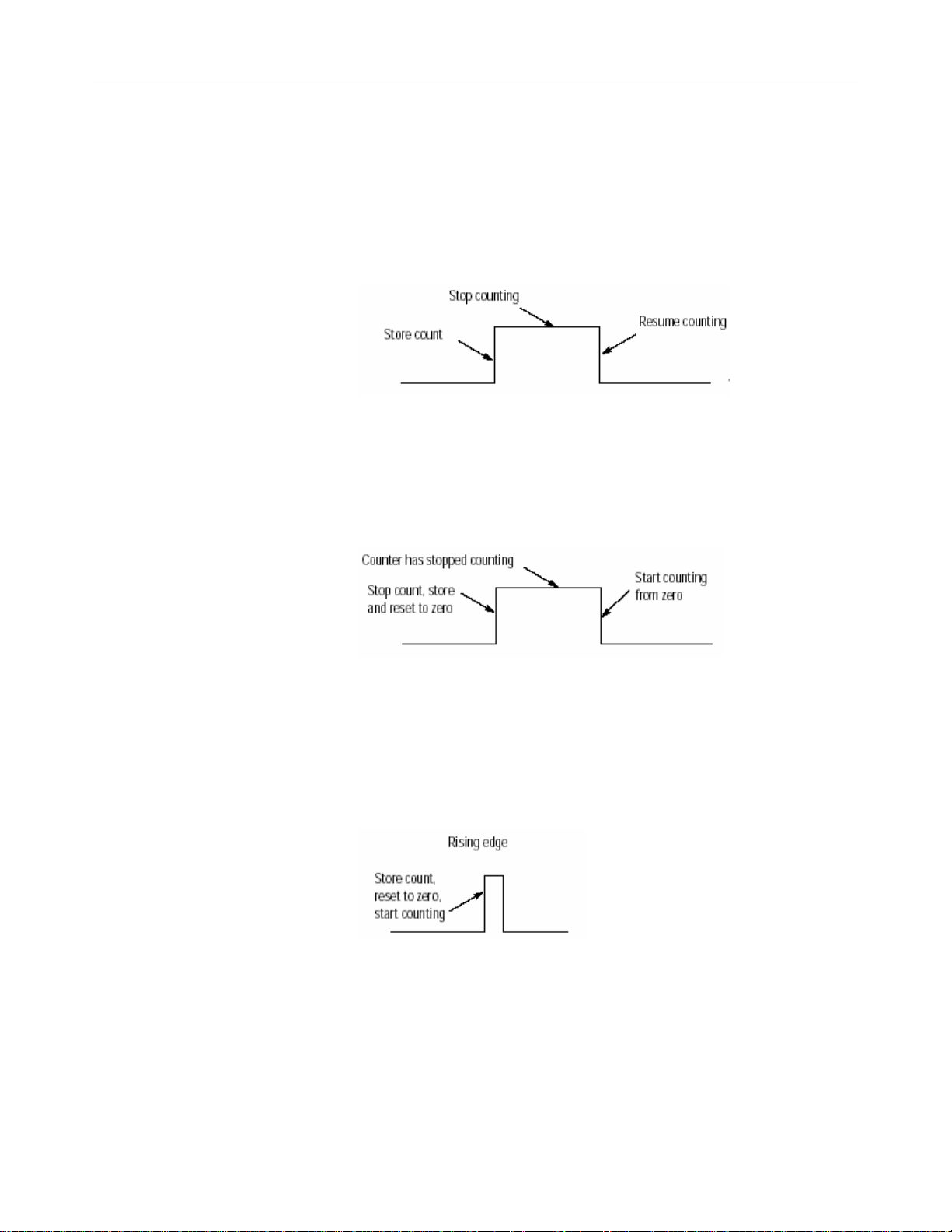

StorageMode[x] 0 - 4 INT (C)

This mode determines how the gate behavior effects counter behavior .

0 = no store mode

1 = store and continue mode

2 = store, wait, and resume mode

3 = store and reset, wait, and start mode

4 = store and reset, and start mode

The behaviors are characterized as follow:

StorageMode = 0 - No gate activity stored

StorageMode = 1 - Read, Store count, and continue counting

Page 42

32 ControlLogix™ Counter Module

StorageMode = 2 - Store/Wait/Resume

StorageMode = 3 - Store-Reset/Wait/Start

StorageMode = 4 - Store-Reset/Start

InputRange[x] 0, 1 INT

This setting determines the threshold were the counter will begin to trigger.

Select the range that is best suited to your sensor’s range.

0= AC 50mVpp threshold

1= AC 200mVpp threshold

2= 5V

3= 12V/24V

KFactor[x] 0 - 1x10

32

FLOAT (C)

The K scale factor is used for counter scaling. This allows users to scale

the counter output into more useful units, like gallons per minute. When a

non-zero Scale Factor value is set the scale calculation is always

performed. A value of zero must be written to the Scale Factor to disable

this feature. This counter value is divided by the K factor. K factors are

positive numbers.

RFactor[x] 0 - 1x10

32

FLOAT (C)

In Program Mode the data value in this register is used for scaling. The

M scale factor is used for meter calibration. When a non-zero Scale

Factor value is set the scale calculation is always performed. A value of

zero must be written to the Scale Factor to disable this feature.

Page 43

Chapter 5: Channel Configuration, Data, and Status 33

The M factor value expressed as a floating point number. This value is

multiplied by the counter actual count value, and gives the M factor a

range of +- TBD (Prior counter modules we produced have been +/-

3.2765). Most M factors will be within +- 5% of 1.0000.

MFactor[x] 0 - 1x10

32

FLOAT (C)

The R scale factor can be used for scaling of the output frequency. The

output frequency is divided by the R scale value. The frequency value is

divided by the R factor. R factors must be positive numbers. A negative

value will cause a configuration error.

SignalFilter[x] 0-3 INT

Designates whether channel 0 uses the analog filter

0 = do not use analog or digital filter

1 = use digital filter (25kHz)

2 = use both digital (25kHz) and analog (12kHz) filters

3= use digital (25kHz), analog (12kHz), and debounce filter (30Hz)

NOTE: The digital and analog filters are separate entities which are

combined into the same tag on this module. The debounce filter

debounces the input for 35 to 40msec after the input transitions.

GateFilter[x] 0,1 INT

0 = No filter

1 = Debounce filter.

The debounce filter debounces the input for 35 to 40msec after the input

transitions.

RollOverTo[x] 0,1 BOOL (C)

Designates which value channel 0 will roll-over to:

0 = zero

1 = preset

RollUnderTo[x] 0,1 BOOL (C)

Designates which value channel 0 will roll-under to:

0 = normal (max value)

1 = preset

Stoponzero[x] 0,1 BOOL (C)

Designates what channel 0 will do when it counts down to 0.

0 = roll-under

1 = stop at zero

Stoponlimit[x] 0,1 BOOL (C)

Designates what channel 0 will do when it counts up to the count_limit.

0 = rollover

1 = stop at the limit

Page 44

34 ControlLogix™ Counter Module

Output Tags

Disable[x] 0 , 1 BOOL

Enable the counter for channel [x].

0=enable

1=disable

ResetCounter[x] 0,1 BOOL

Resets counter 0 and begins counting.

0 = do not reset

1 = reset

LoadPreset[x] 0 . 1 BOOL

Loads preset count value into counter [x] and begins counting.

0 = no action

1 = load preset

ResetFlags[x] 0 ,1 BOOL

Reset all flags.

0=not Reset

1=Reset

CounterInvert[x] 0,1 BOOL

Invert current direction of counter.

0=Standard

1=Inverted

Input Tags

ResetNewStoredFlag[x] 0,1 BOOL

Reset new stored data flag.

0=not Reset

1=Reset

ResetNewRateFlag[x] 0,1 BOOL

Reset rate data flag.

0=not Reset

1=Reset

The following data tags are preceeded by the tag name

CTR8_Input.ChannelData[x] where x is the channel number 0-7.

CommStatus 0,65535 DINT

Displays module connection status.

0 = module is connected

65535 = module is not connected

Count[x] 0-16777215 FLOAT

Displays the channel count value.

Page 45

Chapter 5: Channel Configuration, Data, and Status 35

StoredValue[x] 0-16777215 FLOAT

Displays the value of the stored stored counts register. The maximum

value is 1677215 when scaling is off. When scaling is applied the

maximum value is 1677215/K*M.

Rate[x] 0 - 65,000 REAL

Current rate value.

EnableEcho[x] 0, 1 BOOL

Software enable for the channel. This is an echo of the output tag.

0=Enable

1=Disable

WasReset[x] 0 ,1 BOOL

Displays whether the channel counter was reset.

0 = Counter was not reset

1 = Counter was reset

WasPreset[x] 0 ,1 BOOL

Displays whether the preset value for the channel counter was loaded.

0 = Preset value was not loaded

1 = Preset value was loaded

NewStoredData 0, 1 BOOL

0 = Data not stored

1 = Data Stored

NewRateData 0,1 BOOL

0 = Data is Old

1 = Data is New

GateState[x] 0,1 BOOL

Displays the channel Z state.

0 = Gate is Not Active

1 = Gate is Active

CounterInputState[x] 0,1 BOOL

This echos the state of the input. Note that this is also impacted by the

gate and/or enable line.

CountDirection[x] 0,1 BOOL

0 = Counting up

1 = Counting down

CTRLimit[x] 0,1 BOOL

This flag is latched when counts are equal to the user defined limit.

0 = Not set

1 = Set

CTRZero[x] 0,1 BOOL

0 = Not set

1 = Set

Page 46

36 ControlLogix™ Counter Module

CST DINT

Coordinated System Time. This is the time that the processor reads data

from the FPGA. It is not the actual time that the count occurred. There

will only be one CST tag for the entire module.

Page 47

Chapter 5: Channel Configuration, Data, and Status 37

Page 48

38 ControlLogix™ Counter Module

Programming Examples

Earlier chapters explained how the tag configuration defines the way the

module operates. This chapter shows some basic programming which

controls the operation of the module. It also provides you with segments

of ladder logic specific to unique situations that might apply to your

programming requirements.

Chapter 6

Initial Programming

Figure 6.1 illustrates some basic ladder logic commands which will allow

you to:

• program the initial configuration into the module

• copy data to user defined tags

• reset the module

• make on-the-fly configuration changes

• unlatch alarms

Additional ladder logic and configuration samples may also be found on

our web site: www.spectrumcontrols.com.

Page 49

Chapter 6: Ladder Program Examples 39

Figure 5.1 Sample Ladder Logic

Rung 0 - This rung copies the configuration data (CTR8_Config) into the

module’s configuration image memory . This rung is required.

Rung 1 - This rung copies the input data received from the module’s input

memory into the CTR8_Input tag for monitoring and ladder usaged. this

rung is required.

Rung 2 - This is an optional example rung indicating how to reset the

module via ladder logic.

Rung 3 - This is an optional example rung indicating how to send on-thefly configuration data to the module. This is useful if you would like to

change channel alarm or scaling tags without causing interuption in

channel updates. Changing other tags will cause a 2.5 second delay in

channel updates but the connection will not be interupted.

Page 50

40 ControlLogix™ Counter Module

Y ou may use either the SetAttributeAll to accomplish this.

Set Attribute All message:

Page 51

Using the gate

storage mode

Chapter 6: Ladder Program Examples 41

The gate storage mode allows you to configure the external gate to react

in several ways. The StorageMode[x] tag has 5 valid configurations:

StorageMode[x]

This mode determines how the gate behavior effects counter behavior .

0 = no store mode

1 = store and continue mode

2 = store, wait, and resume mode

3 = store and reset, wait, and start mode

4 = store and reset, and start mode

StorageMode = 1 - Read, Store count, and continue counting

This mode could be used in a cutting operation to determine the length of

the cut material. When the gate is triggered the current count value is

stored and the counter continues to count. The length of the material

would then be determined by subtracting the correct count value from the

stored value.

The gate behavior

Page 52

42 ControlLogix™ Counter Module

StorageMode = 2 - Store/Wait/Resume

This mode may be used in a situation were accumulated count is

important but the process may stop. For instance, if you are running filling

line and want to know the daily production a flowmeter will measure the

total quantity even through start/stop cycles.

StorageMode = 3 - Store-Reset/Wait/Start

This mode could be used in a bottle filling line when you want to control

the precise amount being dispensed. The fill occurs, the enable is

triggered and the bottle moves. The next bottle comes into place and the

fill starts at zero.

StorageMode = 4 - Store-Reset/Start

This mode could be used for a meter proving line when there are two

trigger points, a start and a stop. A pulse trigger caused by a ball crossing

a proximity switch zeros the counter and starts the accumulation. When

the ball reaches the end of the run another pulse occurs stopping and

storing the accumulated value.

Page 53

Installation

Recommendations

Chapter 6: Ladder Program Examples 43

High Impedance Inputs

If the input device is an open collector type if may be necessary to use a

pull up or pull down resistor in order to achieve the proper threshold

crossover point. W e recommend stating is a 1kohm resistor and typing it

between the input path and ground to pull down or the input path an a +12/

24V source for pull up.

Filter Frequency Settings

Use of digital filters will insure best possible performance.

Recommendations are as follows:

Maximum Signal Input Filter

65kHz No Filtering

25kHz 25kHz Digital Filter

12kHz 25kHz and 12kHz Filters

Debounce Filter

The debounce filter is best used when the gate input is connected to low

frequency input devices such as relays or proximity switches. These

devices do not typically have any on-board debounce circuitry .

Page 54

44 ControlLogix™ Counter Module

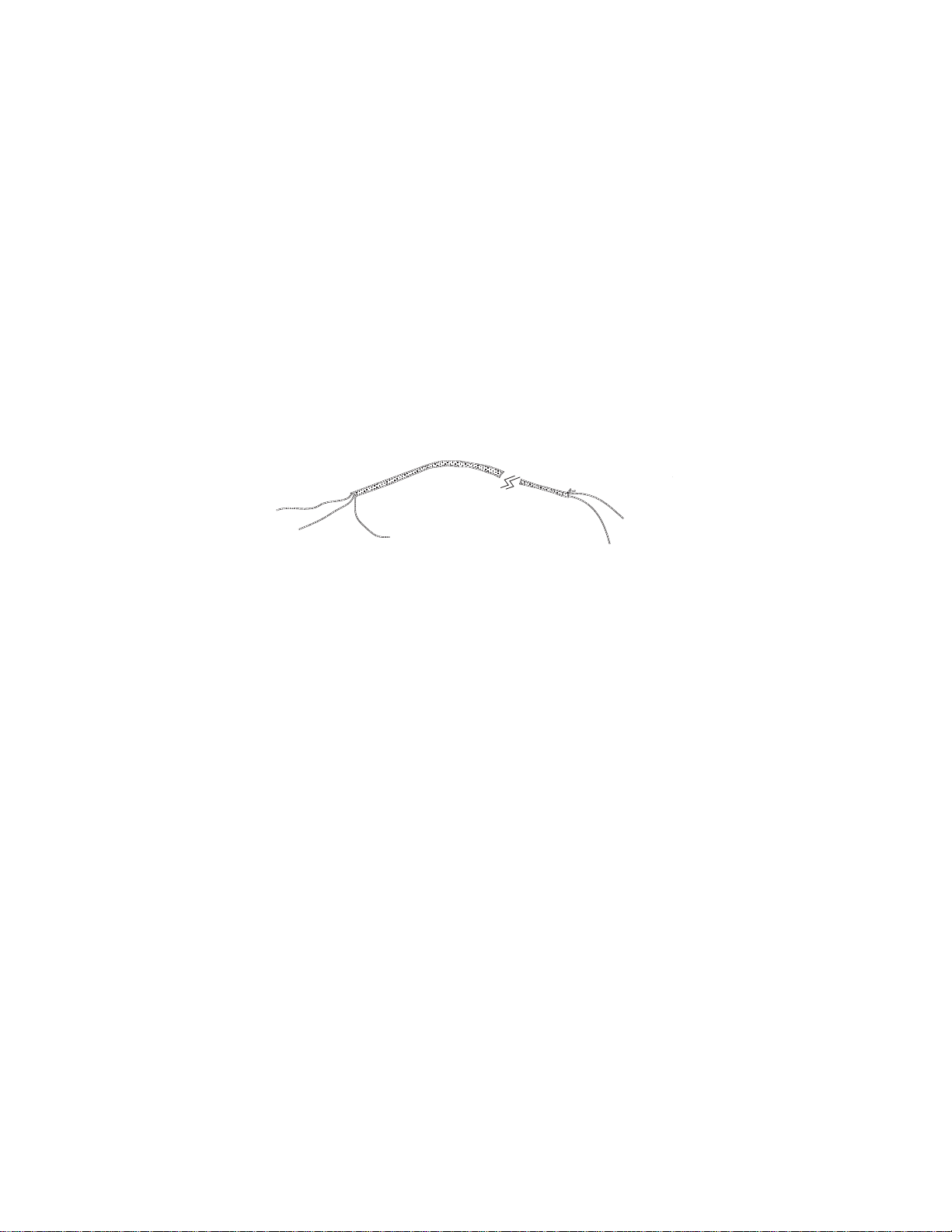

Meter Proving

The 1756sc-CTR8 module provides a feature that allows the user to

perform meter proving functions. A typical meter proving application

would include two detector sensors that are located a fixed distance from

each other within a section of pipe used specifically for meter proving.

The operation does not disrupt the in situ flowmeter’s operation.

Detector #1

Displacer

Detector #2

Utilizing the external gate enable to start and stop count functions enables

the user to count pulses as fast as 65kHz to an accuracy of 1 count.

Here is an example wave form representing the start and stop transitions

on the external gate enable, and the associated pulses that the module

would accumulate: [Storage mode 3, store, reset, wait, start]

External Channel Enable

Flow Meter Input

1 2 3 4 NA

Given the above wave form, the module will begin counting the first

positive going input pulse after the external enable input goes low . The

module will accumulate 4 counts in the channel count register and stop

when the external enable input goes high.

Page 55

Chapter 6: Ladder Program Examples 45

Page 56

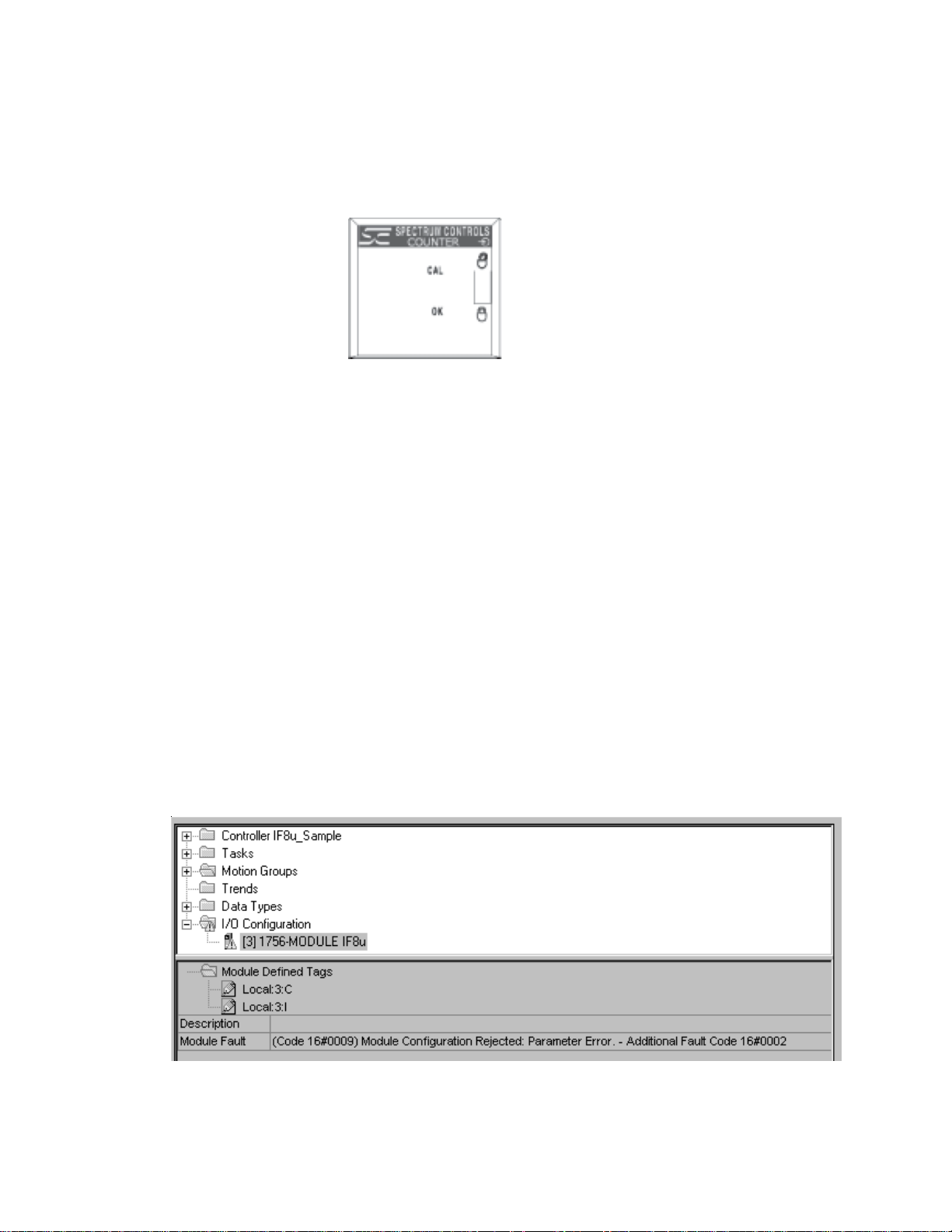

Using Module

Indicators to

Troubleshoot

Chapter 7

T roubleshooting

The count module has indicators which provide indication of module

status. ControlLogix modules use the following:

LED This display: Means Take this action:

O K Steady Green Light The inputs are being multicast No ne

O K Flashing Green Light The module has passed internal None

diagnostics but is not currently

performing connected communication

O K Flashing Red Light Previously establisched communication Check controller

has timed out and chassis communications

O K Steady Red Light It is likely the module should be replaced See below

Under fault conditions the CTR8 will communicate a particular error via a

LED blink code. A description of the fault conditions and LED blink codes

is listed below ...

OK LED SYS LED Fault Status

RE D 1 Blink EEPROM seed completed.

RE D 2 Blinks– EEPROM seed failed.

RE D 3 Blinks EEPROM CRC failed.

RE D 4 Blinks Invalid serial number .

RE D 5 Blinks Boot code CRC failed.

RE D 6 Blinks App CRC failed.

RE D 7 Blinks– FPGA configuration fail.

RE D 8 Blinks– FPGA scan fail.

RE D 9 Blinks Not Applicable

RE D 10 Blinks XA W atchdog timeout.

In most instances you may try resetting the module to clear the fault. If you are not successful, contact technical

support as the module may require repair.

Note: In RSLogix5000 the Fault Status can be seen in the “Module Info”

tab of the module’s properties dialog.

Page 57

Using RSLogix 5000

to Troubleshoot

Your Module

Chapter 7: Testing Y our Module 47

The following LED display is used with ControlLogix analog input

modules:

In addition to the LED display on the module, RSLogix 5000 will alert you

to fault conditions. You will be alerted in one of three ways:

· W arning signal on the main screen next to the module-This occurs when

the connection to the module is broken

· Fault message in a screen’s status line · Notification in the Tag Editor General module faults are also reported in the T ag Editor . Diagnostic faults

are only reported in the T ag Editor

· Status on the Module Info Page

The screens below display fault notification in RSLogix 5000.

Page 58

48 ControlLogix™ Counter Module

Module

Configuration Errors

Fault information on the properties screen.

Determining Fault Type

When you are monitoring a module’s properties dialog in RSLogix 5000

and receive a fault message, the module fault area lists the type of fault.

The “Additional Fault Code” value details the configuration error if the

“(16#0009) module configuration rejected: Parameter Error” was

received.

Global Err ors

16#0F04 - .ConfigurationRevError

If the .ConfigurationRevNumber tag is 1 and a second owner

attempts to connect with a different configuration, this error

will occur. You must adjust the second owners configuration

to match the first.

16#0F05 - .ConfiguratinRevNumber Error

An invalid value has been entered into this tag.

Page 59

Chapter 7: Testing Y our Module 49

Channel Specific Err ors

Note: n = channel number (0-7)

0x010(n) Preset is defined larger than rollover limit for channel (n).

0x0200 Input Range mismatch for channel pair 0 and 1.

0x0202 Input Range mismatch for channel pair 2 and 3.

0x0204 Input Range mismatch for channel pair 4 and 5.

0x0206 Input Range mismatch for channel pair 5 and 7.

0x030(n) Invalid operational mode for channel (n).

0x040(n) Invalid storage mode for channel (n).

0x050(n) Invalid input range for channel (n).

0x060(n) Invalid signal filter for channel (n).

0x070(n) RateSamplePeriod out of range for channel (n).

0x0800 Operational mode mismatch for channel pair 0 and 1.

0x0802 Operational mode mismatch for channel pair 2 and 3.

0x0804 Operational mode mismatch for channel pair 4 and 5.

0x0806 Operational mode mismatch for channel pair 6 and 7.

0x090(n) Preset too high for channel (n).

0x0A0(n) Count limit too high for channel (n).

0x0B0(n) RateSamplePeriod not divisible by 10 for channel (n).

Note: If there are multiple errors in the configuration tags only one will be

displayed at a time. Once the displayed error has been corrected, the

additional errors will be displayed upon reconnection to the module. Each

error must be resolved before a running connection will be allowed.

Page 60

50 ControlLogix™ Counter Module

Maintaining Y our Module

And Ensuring Safety

Read this chapter to familiarize yourself with:

• preventive maintenance

• safety considerations

The National Fire Protection Association (NFPA) recommends

maintenance procedures for electrical equipment. Refer to article 70B of

the NFPA for general safety-related work practices.

Preventive

Maintenance

The printed circuit boards of your module must be protected from dirt, oil,

moisture, and other airborne contaminants. T o protect these boards, install

the ControlLogix system in an enclosure suitable for its operating

environment. Keep the interior of the enclosure clean, and whenever

possible, keep the enclosure door closed.

Chapter 8

Safety

Considerations

Also, regularly inspect the terminal connections for tightness. Loose

connections may cause a malfunctioning of the SLC system or damage to

the components.

WARNING

!

Safety is always the most important consideration. Actively think about the

safety of yourself and others, as well as the condition of your equipment.

The following are some things to consider:

Indicator Lights – When the module status LED on your module is

illuminated, your module is receiving power.

POSSIBLE LOOSE CONNECTIONS

Before inspecting connections, always ensure that

incoming power is OFF.

Failure to observe this precaution can cause personal injury and equipment

damage.

Activating Devices When Troubleshooting – Never reach into a

machine to activate a device; the machine may move unexpectedly. Use a

wooden stick.

Page 61

Chapter 8: Maintaining Y our Module And Ensuring Safety 51

Standing Clear Of Machinery – When troubleshooting a problem with

any ControlLogix system, have all personnel remain clear of machinery .

The problem may be intermittent, and the machine may move

unexpectedly. Have someone ready to operate an emergency stop switch.

CAUTION

!

Safety Circuits – Circuits installed on machinery for safety reasons (like

over-travel limit switches, stop push-buttons, and interlocks) should always

be hard-wired to the master control relay . These circuits should also be

wired in series so that when any one circuit opens, the master control

relay is de-energized, thereby removing power . Never modify these

circuits to defeat their function. Serious injury or equipment damage may

result.

!

POSSIBLE EQUIPMENT OPERATION

Never reach into a machine to actuate a switch.

Also, remove all electrical power at the main power

disconnect switches before checking electrical

connections or inputs/outputs causing machine

motion.

Failure to observe these precautions can cause personal injury or equipment

damage.

WARNING

EXPLOSION HAZARD

SUBSTITUTION OF COMPONENTS MA Y IMP AIR

SUITABILITY FOR CLASSI DIVISION2.

WARNING

!

EXPLOSION HAZARD

DO NOT DISCONNECT EQUIPMENT UNLESS POWER

HAS BEEN SWITCHED OFF OR THE AREA IS KNOWN

TO BE NON-HAZARDOUS

NONO

TE:TE:

NO

TE: THIS EQUIPMENT IS SUITABLE FOR USE IN

NONO

TE:TE:

CLASS

NON-HAZARDOUS LOCA TIONS ONL Y.

II

I, DIVISION 2, GROUPS A, B, C, AND D OR

II

Page 62

52 ControlLogix™ Counter Module

WARNING

EXPLOSION HAZARD

!

!

WHEN IN HAZARDOUS LOCATIONS, TURN OFF

POWER BEFORE REPLACING OR WIRING MODULES.

WARNING

THIS DEVICE IS INTENDED TO ONL Y BE USED WITH

!

THE ALLEN-BRADLEY CONTROLLOGIX 1756 I/O

SYSTEM.

Page 63

Chapter 8: Maintaining Y our Module And Ensuring Safety 53

Page 64

Electrical

Specifications

Appendix A

Module Specifications