Page 1

Owner’sGuide 0300181-05 Rev .G

™

SLC 5 00

F

LOWMETER INPUT

Catalog Numbers

1746sc-CTR4

1746sc-CTR8

50 KHZ C

M

OUNTER

ODULE

/

Page 2

Page 3

Important Notes

1. Please read all the information in this owner’s guide before installing

the product.

2. The information in this owner's guide applies to hardware and

firmware version 1.0 or later.

3. This guide assumes that the reader has a full working knowledge of

the relevant processor.

Notice

The products and services described in this owner's guide are useful in a

wide variety of applications. Therefore, the user and others responsible

for applying the products and services described herein are responsible

for determining their acceptability for each application. While efforts

have been made to provide accurate information within this owner's

guide, Spectrum Controls assumes no responsibility for the accuracy,

completeness, or usefulness of the information herein.

Under no circumstances will Spectrum Controls be responsible or liable

for any damages or losses, including indirect or consequential damages

or losses, arising out of either the use of any information within this

owner's guide or the use of any product or service referenced herein.

No patent liability is assumed by Spectrum Controls with respect to the

use of any of the information, products, circuits, programming, or

services referenced herein.

The information in this owner's guide is subject to change without notice.

Limited Warranty

Spectrum Controls warrants that its products are free from defects in

material and workmanship under normal use and service, as described in

Spectrum Controls literature covering this product, for a period of 1 year.

The obligations of Spectrum Controls under this warranty are limited to

replacing or repairing, at its option, at its factory or facility, any product

which shall, in the applicable period after shipment, be returned to the

Spectrum Controls facility, transportation charges prepaid, and which

after examination is determined, to the satisfaction of Spectrum Controls,

to be thus defective.

This warranty shall not apply to any such equipment which shall have

been repaired or altered except by Spectrum Controls or which shall

have been subject to misuse, neglect, or accident. In no case shall the

liability of Spectrum Controls exceed the purchase price. The

aforementioned provisions do not extend the original warranty period of

any product which has either been repaired or replaced by Spectrum

Controls.

Page 4

Page 5

Contents

Overview And Specifications......................................................... 7

General Features And Benefits.......................................................................................................... 7

Detailed Specifications ....................................................................................................................... 9

Table 1.1. Electrical specifications—module .................................................................................................. 9

Table 1.2. Physical specifications ...................................................................................................................10

Table 1.3. Environmental specifications ........................................................................................................10

Installing And W iring Your Module............................................. 1 1

Avoiding Electrostatic Damage........................................................................................................ 12

Determining Power Requirements..................................................................................................12

Table 2.1. Backplane current consumed........................................................................................................ 13

Selecting a Rack Slot ........................................................................................................................ 13

Setting your Jumpers ....................................................................................................................... 13

Inserting Your Module Into The Rack ........................................................................................... 14

Wiring Your Module ........................................................................................................................ 15

Terminal Block Wiring ...................................................................................................................................17

Labeling And Re-Installing The Terminal Block

(if it is removed) .......................................................................................................................... 18

Things To Consider Before Using

Your Module ............................................................................. 19

Module ID Code................................................................................................................................ 19

Table 3.1 Module ID codes ..............................................................................................................................19

Module Addressing........................................................................................................................... 20

Figure 3.1.......................................................................................................................................................... 20

Operating Modes .............................................................................................................................. 22

Table 3.2 Module operating modes ............................................................................................................... 22

Input Configurations........................................................................................................................ 22

Gate Modes........................................................................................................................................ 24

Channel Turn-On,

Turn-Off, and

Reconfiguration Times ............................................................................................................... 24

Response to Slot Disabling............................................................................................................... 24

Channel Configuration, Data,

and Status.................................................................................. 27

Configuring Each Input Channel ................................................................................................... 27

Output Register - Scale and Limit Data Values............................................................................. 34

Input Registers - Channel Data...................................................................................................... 37

Page 6

Check each output

channel’s

configuration and status............................................................................................................. 39

Programming / Application Examples ......................................... 43

Sample Counter Configuration

Simple Linear Counter

(10,000 Limit):............................................................................................................................. 43

Ring Counter Sample ....................................................................................................................... 44

Sample Configuration

Simple Ring Counter

w/ Flags (20k Limit): .................................................................................................................. 45

Using Preset Values

with Extended Mode................................................................................................................... 46

Using Scaling with

Count and Rate Outputs:........................................................................................................... 46

Application:

Meter Proving ............................................................................................................................. 47

Application Note:

Factor Data Errors ..................................................................................................................... 48

Testing Your Module .................................................................... 51

Inspecting Your Module................................................................................................................... 51

Disconnecting Prime Movers ........................................................................................................... 52

Powering Up...................................................................................................................................... 52

Interpreting The LED Indicators.................................................................................................... 53

Figure 6.1. LED block ..................................................................................................................................... 53

Operation........................................................................................................................................... 53

Table 6.1 Channel Status LED Blink Codes.................................................................................................53

Codes.................................................................................................................................................. 54

No Signal............................................................................................................................................ 54

Troubleshooting ................................................................................................................................ 55

Figure 6.2. Problem resolution flowchar t ..................................................................................................... 55

Maintaining Your Module

And Ensuring Safety................................................................. 57

Preventive Maintenance ................................................................................................................... 57

Safety Considerations....................................................................................................................... 57

Declaration of Conformity............................................................................................................... 59

Page 7

Chapter 1

Overview And Specifications

The 1746sc-CTR4 and the 1746sc-CTR8 are 4 and 8 channel Counter/

Flow Meter modules. The modules are suitable for general purpose

counter and flow meter applications that require a large number of input

channels and high accuracy. The module supports both AC and DC input

signal types. The counter functions include programmable control of the

counter including start, stop, reset, preset control and user defined flags.

The input levels for the counter mode are 5, 12, and 24 volts DC. The

Flow Meter mode is compatible with variable reluctance AC input. This

differential AC input will count AC zero crossing signals from 50 mV to

75 V peak.

Read this chapter to familiarize yourself with your counter module. This

chapter covers:

General Features And

Benefits

• General features and benefits

• Detailed specifications

• 8 Input Channels or 4 Channels of Quadrature Encoders

• 4 External Counter enable inputs

• Input voltage ranges: AC (50mv–75V peak), 5 Vdc, 12 Vdc, 24 Vdc

• Input uency: AC 50 KHz Max, DC 50 KHz Max

• Maximum count value: ±32 K or ±8 M

• Programmable Scaling, K, M, R Factor

• Channel update time of 4 msec/channel

• Rate output mode (Integrer and Floating Point)

• Counter logic level state

• Programmable Counter functions: start/stop/reset/present

• Programmable counter Alarm flags and zero flags

• 3 Selectable filters: 15 KHz, 30 KHz, 50 KHz

• Channel to back Plane isolation of 1000 Vdc

Page 8

8 SLC 500™ 50 KHz Counter / Flowmeter Input Module

Increased Accuracy and Reliability

The counter module offers ±1 count accuracy and ±1% or better

frequency measurement accuracy. Programmable functions allow the

user to define counter ranges and flags to accommodate process-specific

requirements. Full speed counter operation of over 50kHz is possible.

Reduced System Costs

High Channel density allows for lower resource usage. Eight channels

consume the resources associated with a standard two channel module.

State-of-the-Art Performance

These modules incorporate state of the art Programmable Gate Array

technology that allows high circuit density and functionality. The

module uses proprietary Allen-Bradley technology, so they operate and

perform like the latest Allen-Bradley products. They also provide high

resolution, user-programmable range settings, continuous temperature

compensation (no field calibration), software configuration,

programmable output limits, and programmable safe states in case of a

fault.

Detailed Specifications

Table 1.1. Electrical specifications—module

SpecificationSpecification

Specification Description

SpecificationSpecification

Configuration 4/8 Channel of differential counter inputs 2/4 Channels of

quadrature encoding 2/4 Input enable Control lines

Input Modes DC counter, AC flow meter,

Voltage Range AC 0-30VP 5VDC 12VDC 24VDC

VIL -50mV 1V 3V 5

VIH +50mV 3.5V 9V 13

Vmax (CE) ±75V ±75V ±75V ±75V

Vmax (UL) ±100V ±100V ±100V ±100V

Current Range 5mA Max @ 120V

Input Impedance Rin > 10 MOhm when within -10V to +12V range

Rin = 25kOhm when outside of -10V to +12V range

Cin 100pF Input Filter Off

Cin 1000pF Input Filter On

Counter Speed DC Inputs 0 Hz to 50kHz

AC Inputs 0 Hz to 50kHz

Input Frequency DC Inputs 1 Hz to 50kHz

AC Inputs 1 Hz to 50kHz

Counter Enable Input VI L 1.0V max

VI H 3.5V min

Page 9

Chapter 1: Overview And Specifications 9

Vmax 75 V

Input impedance 25K ohms

Input Filter

Digital Filter 50kHz (Default)

Digital Filter 30kHz

Analog Filter 15kHz

Min Pulse Time

DC mode 8us

External Enable/Disable Enable and Disable setup time = 20us

Channel Update Tim e

Counter Output Scaling OFF ON

Rate Output

Rate Instantaneous Mode 4.0 5.6 (msec per channel)

Rate Average Mode 1.0 1.0 (sec per channel)

Accuracy

Count mode ± 1 Count

Rate (Instant) ± 1% @ 50KHz, .001% @ 1Hz

Rate (Average) ± 1Hz

4.0 5.6 (msec per channel)

Maximum Count Value

Low Range -32,768 to +32,767

High Range -8,388,608 to +8,388,607

Fault detection Over & under range status bits, for all modes.

Page 10

10 SLC 500™ 50 KHz Counter / Flowmeter Input Module

Data Format

Counter mode Max Binary Value: -8,388,608 to +8,388,607

Rate mode Max Binary Value: -32,768 to +32,767

Isolation

Channel to Rack 1000 VDC Continuous Optical & magnetic

Channel to Channel 0VDC

Input Protection Max input voltage ±100VDC, 150VAC peak

Max input current ± 5mA@100Vp

Power Requirements

Internal rack +5v 175mA 225mA

Internal rack +24V 75mA 125mA

T able 1.2. Physical specifications

LED Indicators

Module Status The Module Status LED indicates the status of the power up

self test. The LED is on when the module is ready. Any self

test error is indicated with a blink code.

Channel Status CTR4 - 4 Green LEDs

CTR8 - 8 Green LEDs

The 8 Channel LED’s indicates that a channel is enabled.

T erminal Block 24 pin removable connector

Wire Size One 12 AWG to 28 AWG wires

CTR4 CTR8

Torque .5nm, 4.5 lb.in.

T able 1.3. Environmental specifications

T emperature / Humidity Ranges

Operating Temperature 0-60degC (32-140F)

Storage Temperature -40 to +85degC (-40 to + 185F)

Humidity Temperature 5% to 95% non-condensing

Certifications UL508 CUL& Class 1, Div II, (CSA equiv .)

FCC Part 15 class A CE Compliance to EN

61010-1 and EN 61131-2, EN50081-2, EN50082-2.

Page 11

Chapter 2

Installing And Wiring Your Module

Read this chapter to install and wire your module. This chapter covers:

• avoiding electrostatic damage

• determining power requirements

• selecting a rack slot

• inserting your module into the rack

• wiring your module

Important - For UL and CUL compliance, power and input/output (I/O)

wiring must be in accordance with Class I, Division 2, wiring methods

[Article 501-4 (b) of the National Electrical Code , NFPA 70] and in

accordance with the authority having jurisdiction. Also, you must

observe the warnings shown below. Failure to observe these warnings

can cause personal injury.

WARNING

EXPLOSION HAZARD

Substitution of components may impair suitability for

!

Class I, Division 2;

When in hazardous locations, turn off power before replacing or

wiring modules;

Do not disconnect equipment unless power has been switched

off or the area is known to be non-hazardous.

Page 12

12 ControlLogix™ Counter Module

The following documents contain information that may help you as you

install and wire your module:

• National Electrical Code, published by the National Fire Protection

Association of Boston, MA

• IEEE Standard 518-1977, Guide for the Installation of Electrical

Equipment to Minimize Electrical Noise Inputs to Controllers fr o m

External Sources

• IEEE Standard 142-1982, Recommended Practices for Grounding of

Industrial and Commercial Power Systems

• Noise Reduction T echniques in Electronic Systems, by Henry W. Ott;

published by Wiley-Interscience of New York in 1976

Avoiding Electrostatic

Damage

Guard against electrostatic damage by observing the following

precautions:

CAUTION

!

ELECTROSTATICALLY SENSITIVE COMPONENTS

• Before handling the module, touch a grounded object to

rid yourself of electrostatic charge.

• When handling the module, wear an approved wrist strap

grounding device.

• Handle the module from the front, away from the

backplane connector. Do not touch backplane

connector pins.

• Keep the module in its static-shield container when not

in use or during shipment.

Failure to observe these precautions can degrade the module’s

performance or cause permanent damage.

Page 13

Determining Power

Requirements

Chapter 2: Installing And Wiring Y our Module 13

The backplane of the system can provide both 5 Vdc and 24 Vdc power .

The following table shows the maximum current consumed by your module

when using these power sources:

Table 2.1. Backplane current consumed

Catalog Number 5 Vdc 24 Vdc

1756sc-CTR8 230 mA 75 mA

Use T able 2.1 to calculate the total load on the system power supply . For

more information, see the Allen-Bradley system Installation and

Operation Manual.

Selecting a Rack Slot

Two factors determine where you should install your module in the rack:

ambient temperature and electrical noise. When selecting a slot for your

module, try to position your module:

• in a rack close to the bottom of the enclosure (where the air is cooler)

• away from modules that generate significant heat, such as 32-point

input/output modules

• in a slot away from ac or high-voltage dc modules, hard contact

switches, relays, and ac motor drives

• away from the rack power supply (if using a modular system)

Remember that in a modular system, the processor always occupies the

first slot of the rack.

Page 14

14 ControlLogix™ Counter Module

!

When inserting your module into the rack, you do not need to remove the

supplied 36-position terminal block from the module. If, however, you do

remove the terminal block, use the write-on label to identify your

module’s location.

CAUTION

POSSIBLE EQUIPMENT OPERATION

Before installing or removing your module, always disconnect

power from the SLC 500 system and from any other source to

the module (in other words, don’t “hot swap” your module), and

disconnect any devices wired to the module.

Failure to observe this precaution can cause unintended

equipment operation and damage.

To remove the terminal block, unscrew the two retaining screws at the

top and bottom of the terminal block, and using a screwdriver or needlenose pliers, carefully pry the terminal block loose.

T o insert your module into the rack, follow these steps:

1. Align the circuit board of your module with the card guides at the top

and bottom of the chassis.

Page 15

Chapter 2: Installing And Wiring Y our Module 15

2. Slide your module into the chassis until both top and bottom retaining

clips are secure. Apply firm even pressure on your module to attach it

to its backplane connector. Never force your module into the slot.

Cover all unused slots with the Card Slot Filler, Allen-Bradley part

number 1746-N2.

To remove your module, press the retaining clips at the top and bottom

of your module and slide it out.

Wiring Your Module

To wire the terminal block, you need:

• a small, flat-blade screwdriver

• Belden 8761 (shielded, twisted pair) cable or equivalent

CAUTION

!

Before wiring the terminal block, take some time to plan your system:

• Ensure that the SLC 500 system is installed in a NEMA-rated enclosure

and that the SLC 500 system is properly grounded.

• Route the field wiring away from any other wiring and as far as possible

from sources of electrical noise, such as motors, transformers,

contactors, and ac devices. As a general rule, allow at lease 6 in.

(about 15.2 cm) of separation for every 120 Vac of power.

POSSIBLE EQUIPMENT OPERATION

Before wiring your module, always disconnect power from the

SLC 500 system and from any other source to the module.

Failure to observe this precaution can cause unintended

equipment operation and damage.

• Routing the field wiring in grounded conduit can reduce electrical

noise further.

• If the field wiring must cross ac or power cables, ensure that they

cross at right angles.

To wire your module, follow these steps:

1. Determine the length of cable you need to connect a channel to its field

device. Remember to include additional cable to route the drain wire and

Page 16

16 ControlLogix™ Counter Module

foil shield to their ground points. Connect only one end of the shield to

the module.

2. At each end of the cable, strip some casing to expose the individual

wires.

3. Trim the exposed signal wires to 2 in. lengths. Strip about 3/16 in.

(about 5 mm) of insulation away to expose the end of each wire.

4. At one end of the cable, twist the drain wire and foil shield together,

bend them away from the cable, and apply shrink wrap.

5. At the other end of the cable, cut the drain wire and foil shield back to

the cable and apply shrink wrap.

Foil Shield and Drain Wire

Insulation

Clear Wire

Black Wire

6. Connect the wires to the terminal block and field device as shown in

the following figures and table. The recommended maximum torque is

4.5 in-lb (0.565 Nm) for all terminal screws.

Page 17

Chapter 2: Installing And Wiring Y our Module 17

T o guard against electrostatic damage and improve chassis grounding,

connect one of the shield pins on the terminal block of your module to

the chassis itself.

7. Repeat steps 1 through 6 for each channel on your module.

A system may malfunction due to a change in its operating environment.

After installing and wiring your module, check system operation. See the

Allen-Bradley system Installation and Operation Manual for more

information.

Terminal Block Wiring

Note: Channels 4-7 are only available on the 1746sc-CTR8 module.

Note: A pull up resistor may be necessary for open collector inputs. Refer

to Chapter 6 for additional information.

Page 18

18 ControlLogix™ Counter Module

Labeling And ReInstalling The

Terminal Block

(if it is removed)

The supplied label is mounted on the module door. This label helps

ensure that the terminal block is wired correctly for the module.

Once you have wired your module and properly labeled install the

terminal block on your module:

1. Align the terminal block with the receptacle.

2. Insert the terminal block and press firmly at the top and bottom until it

is properly seated.

3. Screw in the two retaining screws on the top and bottom of the

terminal block.

Page 19

Chapter 3

Things To Consider Before Using

Your Module

This chapter explains how the module and the SLC processor

communicate through the processor’s I/O image tables. It also describes

the module’s input filter characteristics. Topics discussed include:

• module ID code

• module addressing

• operating modes

• input configurations

• gate modes

• channel turn on / turn off / reconfiguration timing

Module ID Code

• response to slot disabling

Before using your module, you must configure the slot your module is in

by entering the module’s ID code in APS or RS Logix. Enter your

module’s ID code, select “other” from the list of modules on the APS or

RS Logix system I/O configuration display and enter your module’s ID

code at the prompt.

The module ID code for your input module is:

Table 3.1 Module ID codes

Catalog Number Module ID code

1746sc-CTR4 10200

1746sc-CTR8 10401

Page 20

20 SLC 500™ 50 KHz Counter / Flowmeter Input Module

Module Addressing

SLC 5/02-05

Data Files

Output Image

Input Image

SLC 5/02-05

Data Files

Output Image

Input Image

Slot e

Slot e

Slot e

Slot e

CTR-8

Output

Scan

Input

Scan

CTR-4

Output

Scan

Input

Scan

The CTR-8 module uses 32 input and 32 output registers, and the CTR-4

module uses 16 input and 16 output registers. Both modules use Class

III mode operation and cannot be used with Class I operation. The

following memory map shows you how the SLC processor’s output and

input tables are defined for the module. The SLC 5/01 processor does

not support Class III operation and is not compatible with this module.

This module is not suitable for use in remote rack applications with ASB

modules due to the input / output word size.

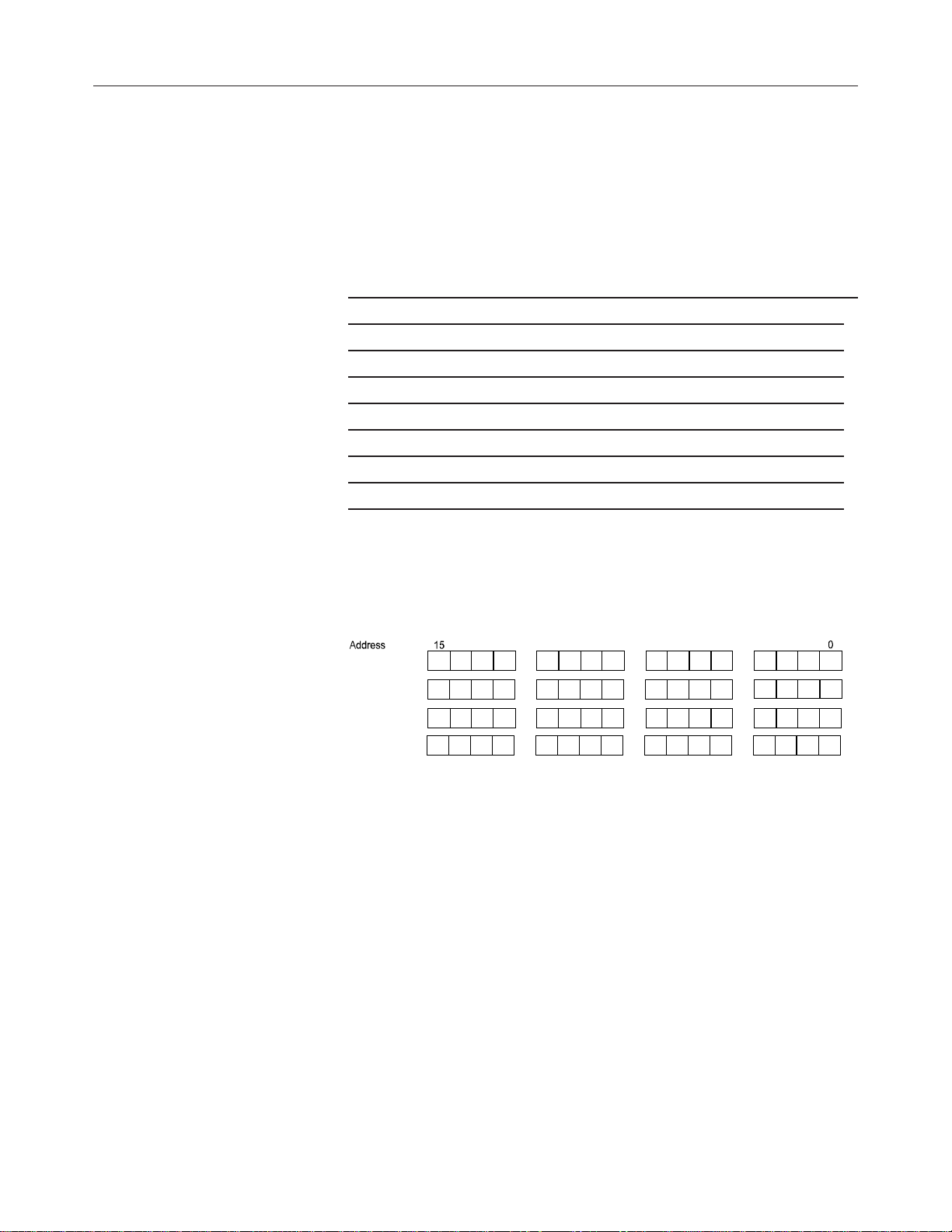

Figure 3.1Image table

Bit 0 Address

Word 0 O:e.0

Word 1 O:e.1

Word 2 O:e.2

Word 3 O:e.3

Word 28 O:e.28

Word 29 O:e.29

Word 30 O:e.30

Word 31 O:e.31

Word 0 I:e.0

Word 1 I:e.1

Word 2 I:e.2

Word 3 I:e.3

Word 28 I:e.28

Word 29 I:e.29

Word 30 I:e.30

Word 31 I:e.31

Bit 0 Address

Bit 0 Address

Word 0 O:e.0

Word 1 O:e.1

Word 2 O:e.2

Word 3 O:e.3

Word 12 O:e.12

Word 13 O:e.13

Word 14 O:e.14

Word 15 O:e.15

Word 0 I:e.0

Word 1 I:e.1

Word 2 I:e.2

Word 3 I:e.3

Word 12 I:e.12

Word 13 I:e.13

Word 14 I:e.14

Word 15 I:e.15

Bit 0 Address

Counter

Module

Image Table

Output Image

32 Words

Input Image

32 Words

Counter

Module

Image Table

Output Image

16 Words

Input Image

16 Words

Bit 15

Channel 0 Configuration Word

Channel 0 Preset / M Factor

Channel 0 Limit / K Factor

Channel 0 Rate Lim / R Factor

Channel 7 Configuration Word

Channel 7 Preset / M Factor

Channel 7 Limit / K Factor

Channel 7 Rate Lim / R Factor

Channel 0 Output Low (MSW)

Channel 0 Output High (LSW)

Channel 0 Frequency

Channel 0 Status Word

Channel 7 Output Low (MSW)

Channel 7 Output High (LSW)

Channel 7 Frequency

Channel 7 Status Word

Bit 15

Bit 15

Channel 0 Configuration Word

Channel 0 Preset / M Factor

Channel 0 Limit / K Factor

Channel 0 Rate Lim / R Factor

Channel 3 Configuration Word

Channel 3 Preset / M Factor

Channel 3 Limit / K Factor

Channel 3 Rate Lim / R Factor

Channel 0 Output Low (MSW)

Channel 0 Output High (LSW)

Channel 0 Frequency

Channel 0 Status Word

Channel 3 Output Low (MSW)

Channel 3 Output High (LSW)

Channel 3 Frequency

Channel 3 Status Word

Bit 15

Page 21

Chapter 3: Things T o Consider Before Using Y our Module 21

O:4.2

File type

Slot

Word

Element

Delimiter

Word

Delimiter

Output Image - Configuration Words

Thirty-two (CTR-8) or sixteen (CTR-4) words of the SLC processor’s

output image table are reserved for the module. For the CTR8, output

image words 0-31 are used to configure input channels 0-7. For the

CTR4, output image words 0-15 are used to configure input channels 0-4.

Each output image word configures a single channel, sets the preset, limit

and scale factors and can be referred to as a configuration word. Each

word has a unique address based on the slot number assigned to the

module.

Example Address - If you want to configure channel 2 on the module

located in slot 4 in the SLC chassis, your address would be O:4.4.

Chapter 4, Channel Configuration, Data, and Status, gives you detailed

bit information about the data content of the configuration word.

Input Image - Data Words and Status Words

Count data, Rate data, and status are given in four input words for each

channel.

Chapter 4, Channel Configuration, Data, and Status, gives you detailed

bit information about the content of the data word and the status word.

Page 22

22 SLC 500™ 50 KHz Counter / Flowmeter Input Module

Operating Modes

Input Configurations

The module’s operating mode determines the number of available counters

and which inputs are attached to them. There are two operating modes

and their input assignments are summarized in the table below .

Table 3.2 Module operating modes

Operational Mode CTR8 (CTR4) Input Channel Configuration

Single Ended Input 8 (4) Channels – One per input

Single Ended Up/Down 4 (2) Channels - One Input / One Direction Discrete

Quadrature Input 4 (2) Channels - T wo per input.

Input configurations determine how the 8 inputs cause the counter to

increment or decrement. The four available configurations are:

• Uni-Directional (up)

• Bi-Directional (up and down using two channels)

• X1 Quadrature Encoder

• X4 Quadrature Encoder

See the “Summary of A vailable Counter Configurations” for the input

configurations available for the counters, based on operating mode.

Uni-Directional

With this configuration, the input increments in an upward direction. All

8 channels may be configured in the unidirectional mode. Every clock

pulse will increment the counter on the rising edge. Note: The direction

of the counter may be inverted by setting the Count Direction bit described

in the Configuration chapter .

Bi-Directional

The bidirectional counter requires 2 input channels. In this mode one

nd

channel is used as the counter input and the 2

channel is used to

determine the count direction. The counter will increment when the

Direction Channel value is 0, and will decrement when the Counter

Direction Channel value is 1.

X1 Quadrature Encoder

The quadrature mode requires 2 input channels. When a quadrature

encoder is attached to an input channel pair, A and B, the count direction

is determined by the phase angle between inputs A and B. If A leads B,

the counter increments. If B leads A, the counter decrements. (The

counter changes value only on one edge of input 1.) The counter

increments once per quadrature cycle.

Page 23

Chapter 3: Things T o Consider Before Using Y our Module 23

Note: The X1 Quadrature mode provides additional Anti-Jitter

circuitry. This distinguishes between a valid quadrature sequence

and an invalid sequence due to electrical noise or jitter. Jitter can

occur if a quadrature encoder stops rotating right at an input sensor

trip point. This can cause additional unwanted clock pulses. The X1

quadrature mode can detect invalid transitions and filter these out.

X4 Quadrature Encoder

Like the X1 quadrature encoder, the count direction is determined by the

phase angle between inputs A and B. If A leads B, the counter

increments. If B leads A, the counter decrements. However, the counter

changes value on the rising and falling edges of inputs A and B. The

counter increments four times per quadrature cycle.

Note: In the X4 Quadrature mode, invalid signals are not detected. A

broken input wire, jitter or noise on the input can cause additional

counts to be registered. The modules response to four possible error

conditions are listed below:

A

B

Input A is active while input B is stuck high: Module will count down on input A transitions.

Input A is active while input B is stuck low: Module will count down on input A transitions.

Input A is stuck high while input B active: Module will count down on input B transitions.

Input A is stuck low while input B is active: Module will count up on input B transitions.

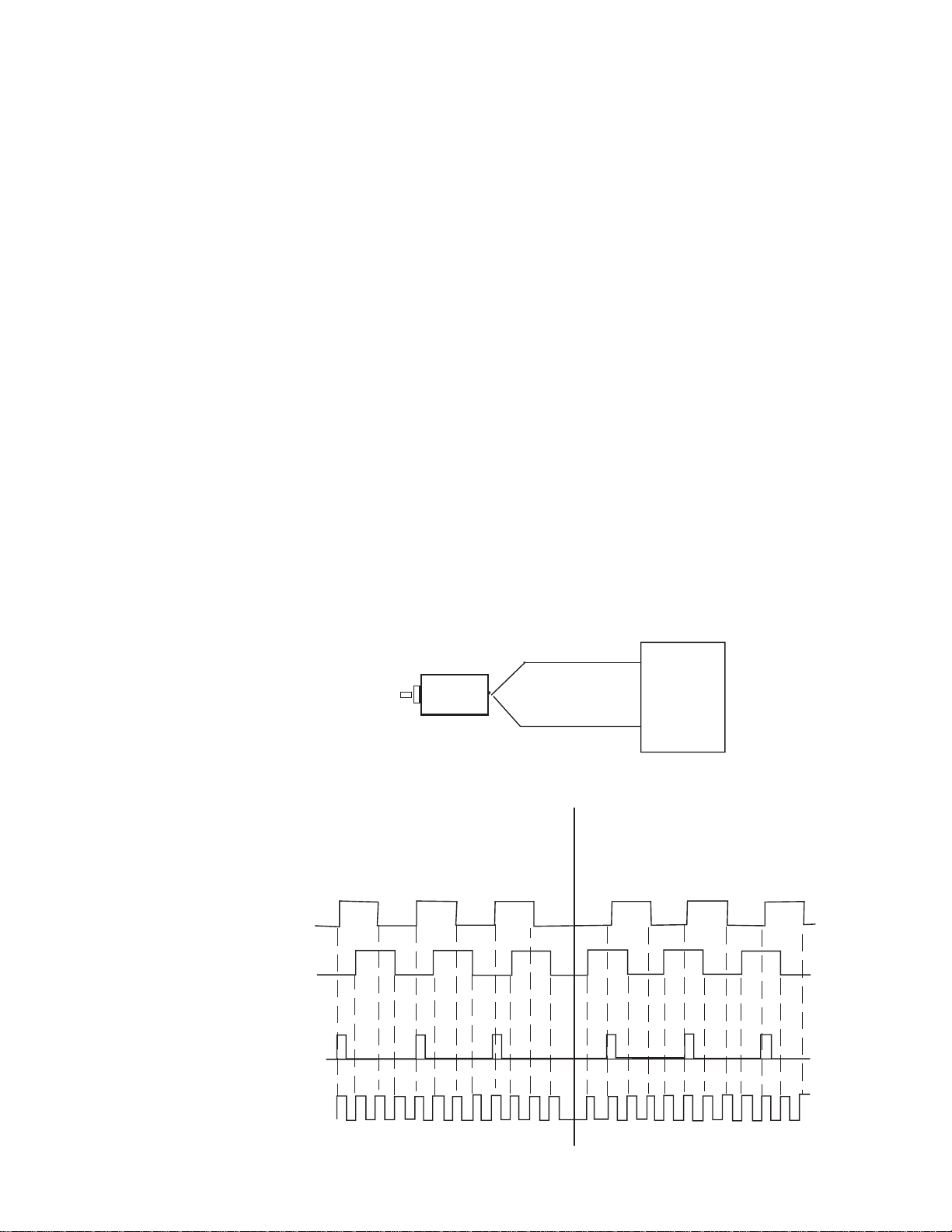

A

Input A

B

Quadrature

Input B

Encoder

Forward Rotation Reverse Rotation

x1 Count

x4 Count

1

2

3

1 2 3 4 5 6 7 8 9 10 11 12

2

10

11 10 9 8 7 6 5 4 3 2 1 0

Page 24

24 SLC 500™ 50 KHz Counter / Flowmeter Input Module

Gate Modes

Channel Turn-On,

Turn-Off, and

Reconfiguration Times

There are two methods to gate (start/stop) your counter, hardware and

software. The counter’s gate/preset mode determines what, if any, gating

is applied to the counter and what, if any , conditions will preset the counter

to the preset value.

External Hardware Gate Lines:

There are four external inputs, one for each pair of input channels, that

may be used to start and stop the counter. Each external gate is pulled

low internal to the module. A low input allows each pair of counter

channels to operate. The count enable line is compatible with 5, 12, and

24 VDC inputs. If pulled high with one of these inputs the pair of

counter channels are disabled.

Note: The module’s Channel LED’s only indicate the state of the counters

start/stop bit. They do not indicate that state of the external hardware

gate.

Counter Start / Stop Bit

This bit allows the counter to continue to count up or down from its

present value. Starting, or enabling this bit wil not override the external

counter input.

The time required for the module to recognize a new configuration for a

channel is one module update time.

Response to Slot

Disabling

Turn-off time requires up to one module update time.

Reconfiguration time is the same as turn-on time.

By writing to the status file in the modular SLC processor, you can

disable any chassis slot. Refer to your SLC programming manual for the

slot disable/enable procedure.

CAUTION

!

POSSIBLE EQUIPMENT OPERATION

Always understand the implications of disabling a module

before using the slot disable feature.

Failure to observe this precaution can cause unintended

equipment operation.

Page 25

Chapter 3: Things T o Consider Before Using Y our Module 25

Input Response

When a counter slot is disabled, the counter module continues to update

its input image table. However, the SLC processor does not read input

from a module that is disabled. Therefore, when the processor disables

the counter module slot, the module inputs appearing in the processor

table is not read. When the processor re-enables the module slot, the

current state of the module inputs are read by the processor during the

subsequent scan.

Output response

The SLC processor may change the counter module output data

(configuration) as it appears in the processor output image. However,

this data is not transferred to the counter module. The outputs are held in

their last state. When the slot is re-enabled, the data in the processor

image is transferred to the counter module.

Page 26

26 SLC 500™ 50 KHz Counter / Flowmeter Input Module

Page 27

Channel Configuration, Data,

and Status

Read this chapter to:

• configure each input channel

• set user-defined scale limits

• monitor each input channel

• check each output channel’s configuration and status

Chapter 4

Configuring Each Input

Channel

The Data Register format uses Class 3 operation. Class 3 mode allows

the module to use 32 input words and 32 output words of data, as listed

below. After installing your module, you must configure each channel

by setting bit values in each configuration word. Output words 0 through

31 of the output image file (addresses O:e.0 – O:e.31) configure channels

0-7 respectively and (addresses O:e.0 - O:e.15) for channels 0 - 3 of the

CTR4.

Page 28

28 SLC 500™ 50 KHz Counter / Flowmeter Module

Figure 4.1 - Configuration W ord

Address

O:e.3

O:e.13

O:e.16

O:e.19

15

Channel 0 Configuration WordO:e.0

Channel 0 Preset / M FactorO:e.1

Channel 0 Limit / K FactorO:e.2

Channel 0 Rate Limit / R Factor

Channel 1 Configuration WordO:e.4

Channel 1 Preset / M FactorO:e.5

Channel 1 Limit / K FactorO:e.6

Channel 1 Rate Limit / R FactorO:e.7

Channel 2 Configuration WordO:e.8

Channel 2 Preset / M FactorO:e.9

Channel 2 Limit / K FactorO:e.10

Channel 2 Rate Limit / R FactorO:e.11

Channel 3 Configuration WordO:e.12

Channel 3 Preset / M Factor

Channel 3 Limit / K FactorO:e.14

Channel 3 Rate Limit / R FactorO:e.15

Channel 4 Configuration Word

Channel 4 Preset / M FactorO:e.17

Channel 4 Limit / K FactorO:e.18

Channel 4 Rate Limit / R Factor

0

CTR4

CTR8

Channel 5 Configuration WordO:e.20

Channel 5 Preset / M FactorO:e.21

Channel 5 Limit / K FactorO:e.22

Channel 5 Rate Limit / R FactorO:e.23

Channel 6 Configuration WordO:e.24

Channel 6 Preset / M FactorO:e.25

Channel 6 Limit / K FactorO:e.26

Channel 6 Rate Limit / R FactorO:e.27

Channel 7 Configuration WordO:e.28

Channel 7 Preset / M FactorO:e.29

Channel 7 Limit / K FactorO:e.30

Channel 7 Rate Limit / R FactorO:e31

Page 29

Chapter 4: Channel Configuration, Data, and Status 29

Figure 4.2 - Configuration W ord Settings

Address

15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

Channel 0 Configuration WordO:e.x

Filter

0 =Normal

1 = Program

0 = Neg

1 = Preset

0 = Zero

1 = Preset

Directrion

Roll over to

Roll under to

Scale / Limit Mode

0 = Normal

1 = Inverted

0=Standard

1=Extended

0 = 50kHz

1 = 30kHz

Count Size

Stop in Limit

0 = Off

1 = On

0 = Off

1 = On

Stop on Zero

00 = UniDirect

01 = BiDirect

10 = Quad x1

11 = Quad x4

00 = AC

01 = 5 V

10 = 12V

11 = 24V

Count Mode

Input Range

Counter Start/Stop: (Configuration Bit 0)

This bit allows the counter to continue to count up or down from its

present value.

Note: Starting or enabling the counter with this bit will not override the

external counter enable input. The external input enable and the counter

start bit must both be enabled for the counter to continue counting. If

either the counter stop bit or the external input enable line are disabled

the counter will hold it’s last value and stop counting.

Rate Mode

Reset Flags

0 = Normal

1 = Reset

0 = Instant

1 = Average

Preset

Counter Enable

0 = Start

1 = Stop

0 = Off

1 = On

Counter Preset: (Configuration Bit 1)

When this bit is set, the value in counter preset word is loaded into the

counter. The counter preset can be used to set the counter to an initial

starting value. The bit should be set for at least 2 I/O scans. The bit can

be held on until the data in the counter data is verified to be equal to the

preset value. The counter will hold the preset value until the counter

preset bit is turned off. At this time normal counter functions will resume.

Note: A Counter Reset function is achieved by using the Counter

Preset, when the preset value is set to zero.

Refer to the Preset and Limit Data Value Configuration section for more

information about loading your preset value.

Page 30

30 SLC 500™ 50 KHz Counter / Flowmeter Module

Reset Flags: (Configuration Bit 2)

The reset flags command is performed when this bit is set. Reset flags

affects the counter zero, counter limit and counter maximum flags

(Status word bits 8, 6, and 5 respectively .) These particular flags remain

high, regardless of the counter behavior, until a reset is performed. This

allows adequate time to read the flags after an event has occured.

If user Counter Limit is set to 0 (0 indicates undefined), these flags will

remain high until reset:

Count is equal to zero or counter decremented down through zero flag

(Status word bit 8).

Count up or down through the maximum count flag

(Status word bit 5).

If a Counter Limit is never set (Status word bit 6) the flags will not

annunciate.

If user Counter Limit is set to a non-zero value ( User defined limit), these

flags are will remain high until reset:

Count is equal to zero or counter decremented down through zero flag

(Status word bit 8).

Count up or down through the limit flag (Status word bit 6).

And these flags do not remain high:

Maximum count flag (Status word bit 5) is set if count value is

exactly equal to 32,767 (16 bit) or 8,388,607 (24 bit). Otherwise it is

clear.

Rate Mode: (Configuration Bit 3)

Refer to Appendix A for Floating Point Rate Mode

Rate - Average:

When the rate mode bit is set to a “1” the rate detection circuit is in

“Rate Average” mode. The rate average mode counts the number of

input transitions over a 1 second interval and calculates the input rate

averaged over the 1 second interval. The rate average mode is slow, in

that it reports updated rates at once per second. However this mode is

accurate to ± 1 count over the full range of measurement.

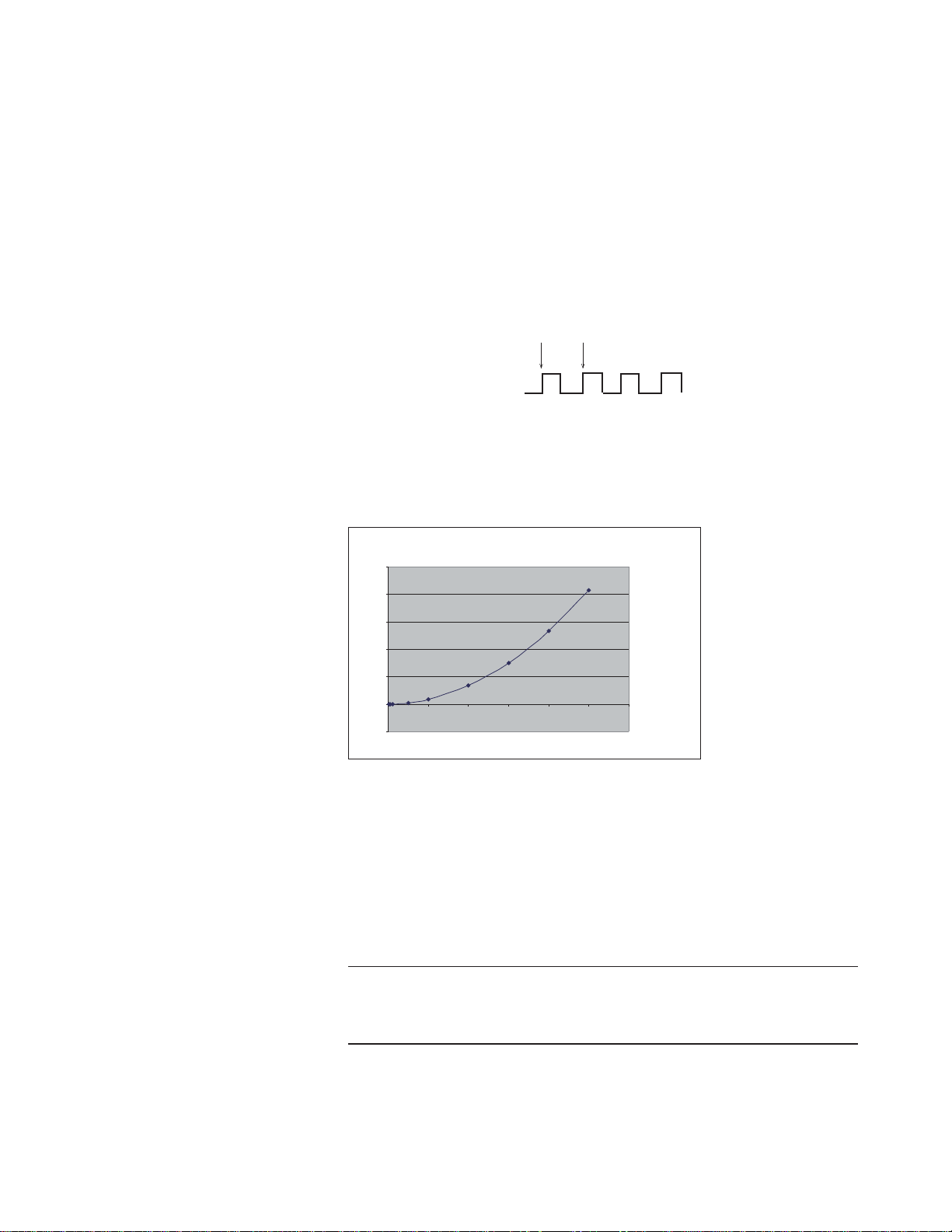

Figure 4.4 - One Second Rate Average

One Second Average of Periods

Page 31

Chapter 4: Channel Configuration, Data, and Status 31

One Period

Rate - Instant:

When this bit is reset to “0” the rate detection circuit operates in “Instant”

mode. Instant measurements are fast, in that they calculate a rate based

on one cycle. However the accuracy of the measurement degrades as

the input clock rate goes up to 50KHz, and any jitter within one cycle will

be measured.

Figure 4.3 - One Period Rate Measurement

The accuracy while operating in the average mode is ±1 count. When

using the Instant mode the accuracy is ±1% at 50kHz and improves to

±0.002% at 100Hz. The graph below shows the rate accuracy in Hertz vs.

Frequency.

Frequency Error

Frequency Error

250

200

150

100

Error

Error in Hz

50

Error

0

0 10,000 20,000 30,000 40,000 50,000 60,000

-50

Instant Rate Mode Error

Frequency

Frequency

Input Rate

Input Range: (Configuration Bits 4-5)

This group of 2 bits selects one of 4 input ranges. Each range is selected

for a given system voltage level. Each range has its own counter trip

level. Refer to the Specifications section of this manual for input limit

information.

Table 4.2 Input Range Selection Bits (O:e.4-O:e.5)

Mode Bit Setting Range

AC 00 50 mV to 30 VAC

DC 01 0 to 5 VDC

D C 10 0 to 12 VDC

D C 11 0 to 24 VDC

Note: The input range must configured in channel pairs to operate

properly. Pairs are channels 0-1, 2-3, 4-5, 6-7.

Note: You should allow at least 1 scan time for input range

information to be updated at the PLC.

Page 32

32 SLC 500™ 50 KHz Counter / Flowmeter Module

Count Mode: (Configuration Bits 6-7)

The Count Mode bit selects 1 of 4 types of counter operation.

The Unidirectional counter mode is configured as an Up or Down

counter. The module will support 8 unidirectional input channels. Every

clock pulse increments the counter .

Note: The direction of the count can be inverted by the COUNT

DIRECTION bit (see bit 12).

The Bidirectional counter requires 2 channels inputs. In this mode one

nd

channel is used as the counter input and the 2

channel is used to

determine the count direction. The counter will increment when the

Direction input channel is a 1, and will decrement the counter when the

Direction input channel is a 0. Even channels, 0,2,4,6 are inputs. Odd

channels, 1,2,5,7 control direction. Both channels within a pair must be

configured for bidirectional mode. Bidirectional encoding will report the

same count value on each channel’s output.

When the counter is set to Quadrature mode channels will be configured

into quadrature encoding pairs. Both channels within a pair must be

configured for quadrature mode. Quadrature encoding will report the

same quadrature count value on each channel’s output. Quadrature mode

allows for the channels to count up or down depending on the quadrature

encoding direction. The COUNT DIRECTION bit can invert the

direction of the quadrature encoding. The QUAD X1 mode clocks the

counter once every quadrature cycle. The QUAD X4 mode clocks the

counter 4 times every quadrature cycle, once for every edge transition on

both input lines.

Table 4.3 Count Mode Settings

ModeMode

Mode

ModeMode

ChannelsChannels

Channels

ChannelsChannels

BitsBits

Bits

BitsBits

FunctionFunction

Function

FunctionFunction

UniDirectional 8 00 Unidirectional Up/Down counter

BiDirectional 4 01 Bidirectional Up/Down counter

Quad X1 4 1 0 Quadrature Mode 1 count/cycle

Quad X4 4 11 Quadrature Mode 4 counts/cycle

Stop on Zero: (Configuration Bit 8)

This bit, when set, will hold the counter output at zero. When the

counter counts down to zero the counter will either count through zero or

hold its output at zero counts, until the Zero flag is cleared. When cleared

the counter will continue to count.

Note: The stop on zero function only applies to counts decrementing

down through zero.

Page 33

Chapter 4: Channel Configuration, Data, and Status 33

Stop on Limit: (Configuration Bit 9)

This bit, when set, will hold the counter output at its limit value. When the

counter counts to the limit value it will either rollover to zero, or hold its

output at the limit value, until the Limit Flag is cleared. When released the

counter will continue to count. If the user defined limit register is equal to

zero, the limit is internally set to 32,767 (Normal Mode) or 8,388,607

(Extended Mode).

Filter Frequency: (Configuration Bit 10)

This bit selects the cutoff frequency that the input channel will allow.

When the bit is set to 1 the filter will be set to limit input noise to 30kHz.

This selection should be used for Counter or Flow Meter applications

running at speeds less than 30kHz. When this bit is set to 0 the channel

will run at full speed and filter noise above 50kHz.

A 15kHz hardware filter is also available by using the onboard jumper

settings. To activate the filter for Channels 0-3 remove the shunt on the

JP2 jumper. To activate the filter for Channels 4-7 (CTR8 only) remove

the shunt on JP3.

Count Size: (Configuration Bit 11)

This bit determines the maximum counter value. When set to 0 the

channel counter will count up to ±32K (1 word of data). When the

maximum value of 32,767 is reached, the Maximum Count flag is set,

and rollover will occur at this point. When the count size is extended to

±8,388,607 by setting this bit to 1, the Counters Maximum flag is

extended to ±8M and data output is formed using two words. The

counter Preset and Limit values are also extended to ±8M. This means

that the resolution of the Preset and Limit values are set in blocks of 256

counts (8bits) beacause only one word is available for each limit. This

allows the preset and limit values to cover the whole ±8M bit range.

-32K-8M +8M

Extended Normal

0

+32K

Normal Extended

Count Direction: (Configuration Bit 12)

This bit inverts the current direction of the counter. When set to 0 this bit

has no effect on the direction. When toggled to 1 the count direction in

unidirectional mode is forced to count down. In bidirectional mode or

Quadrature mode the counter direction is reversed from it’s current

direction.

Counter Roll Over: (Configuration Bit 13)

When the counter exceeds the maximum count, the counter will roll over

the top. When the counter rolls over it can roll over to a starting value

of zero, or it can start at the user defined preset value. When this bit is

set to 0 the counter will roll over to zero. When set to 1 the counter will

roll over to the preset value. If the stop on limit flag is set the counter will

not roll over until the flag is released. When released the counter will roll

over to zero or its preset value.

Page 34

34 SLC 500™ 50 KHz Counter / Flowmeter Module

Counter Roll Under: (Configuration Bit 14)

When the counter rolls under zero it can continue to count down into

negative numbers, or it can start at the user defined preset value. When

this bit is set to 0 the counter will continue to count down through zero

into negative numbers. When set to 1 the counter will roll under to the

preset value. If the stop on zero flag is set the counter will not roll under

until the flag is released. When released the counter will roll under to its

maximum or preset value.

Program Scale Factors: (Configuration Bit 15)

Each channel has four words which configure the behavior of that

channel, the configuration word, the Preset / M factor word, the counter

Limit / K factor word, and the Rate Limit / R Factor word. Normally the

2nd, 3rd and 4th words are Preset, Counter Limit, and Rate Limit

respectively. However, when values are input into the scale factors and

bit 15 of the configuration word is set the module programs the scale

factors into non-volatile memory. When scale factors are programmed the

R and K/M Factor Flags are set in the status register.

Output Register - Scale

and Limit Data Values

When using the Counter Preset, Counter Limit, Rate Limit or K / M / R

Factors you must input the value that is appropriate for your application.

The values follow each channels configuration word and use the next

three configuration words. For example, Channel 0 has a configuration

word address of O:e.0, Preset address of O:e.1, a Counter Limit address

of O:e.2, and a Rate Limit address of O:e.3. Refer to the Input word

data diagram in the beginning of this chapter for channel specific address

information.

Figure 4.5 - Preset / Limit / Rate Limit Words

Address

O:e.z Rate Limit / R Factor

15

Counter Preset / M FactorO:e.x

Counter Limit / K FactorO:e.y

Counter Preset / M Factor:

The counter preset function is used in Normal operation mode. This input

data word is used in conjunction with the scale/limit mode bit. When this

bit is set, the value in the counter preset word is loaded into the counter.

The counter preset can be used to set the counter to an initial starting

value. The bit should be set for at least one I/O scan. The bit can be held

on until the data in the counter data is verified to be equal to the preset

value. The counter will hold the preset value until the counter preset bit

is turned off. At this time normal counter functions will resume. The

preset value is typically set less than the Counter limit value.

0

Page 35

Chapter 4: Channel Configuration, Data, and Status 35

Note: In extended count mode (counts up to +/- 8M) the preset will be

multiplied by 256 internally such that a user preset of 1000 will result

in a preset of 25600. This allows the preset value to cover the whole

+/- 8 million count range.

In program scale factor mode an M Factor is stored in the module’s nonvolatile memory . If an M Factor is defined (not zero) then the data value

output for the counter value will be COUNT x (M Factor/10,000). A

value of zero must be written to the M Factor to disable this feature.

Figure 4.7 - Limit / M Factor Word

Address

15

Counter Limit / M FactorO:e.y

0

Example:

An M Factor of 10,200 will increase the output count by 2%.

Output Count = Input Count * 10,200/10,000

Output Count = Input Count * 1.02

Note: When the count size is extended to ±8M using Configuration Bit

11, the Counters Maximum flag is extended to ±8M. The counter

Preset and Limit values are also extended to ±8M. This means that

the resolution of the Preset and Limit values are set in blocks of 256

counts (8bits). This allows the preset and limit values to cover the

whole ±8M bit range. Refer to the applications section of this

manual for more information about setting limit and scale values.

Counter Limit / K Factor:

The counter limit mode is used in Normal operation mode. This input data

word is used in conjunction with the Scale / Limit Mode enable bit. When

the counter limit bit is set, the counter limit flag will be active. When the

counter value is greater then or equal to the Limit value the Counter Limit

flag bit will be set. If the Stop On Limit bit is set the counter will not

exceed the counter limit.

Note: When operating in standard count mode, if the K Factor x

Count Limit is > 32767 a configuration error will occur.

Note: In extended counter mode the limit will be multiplied by 256

internally such that a user limit of 1000 will result in a limit of

256,000.

In program scale factor mode a K factor is stored in the module’ s nonvolatile memory . If a K Factor is defined (not zero) then the data value

output for the counter is the counter value divided by the K Factor. A

value of zero must be written to the K Factor to disable this feature.

Figure 4.6 - Preset / K Factor Word

Address

15

Counter Preset / K FactorO:e.x

0

Page 36

36 SLC 500™ 50 KHz Counter / Flowmeter Module

Rate Limit / R Factor:

The rate limit function is used in the Normal operation mode. The Rate

Limit represents a target maximum value for rate. When the rate value is

greater then or equal to the rate limit value the Rate Limit flag bit will be

set.

In program scale factor mode an R Factor is stored in the module’s nonvolatile memory. If an R Factor is defined (not zero) then the data value

output for the counter value will be Rate / R Factor. A zero value must

be written to the R Factor to disable this feature.

Figure 4.8 - Rate Limit / R Factor Word

Address

15

Rate Limit / R FactorO:e.z

Refer to the applications section of the manual for limit and scale

examples.

Floating Point Rate Mode is activated by setting the Rate Factor to -1.

See Applendix A for information about the floating point mode.

0

Page 37

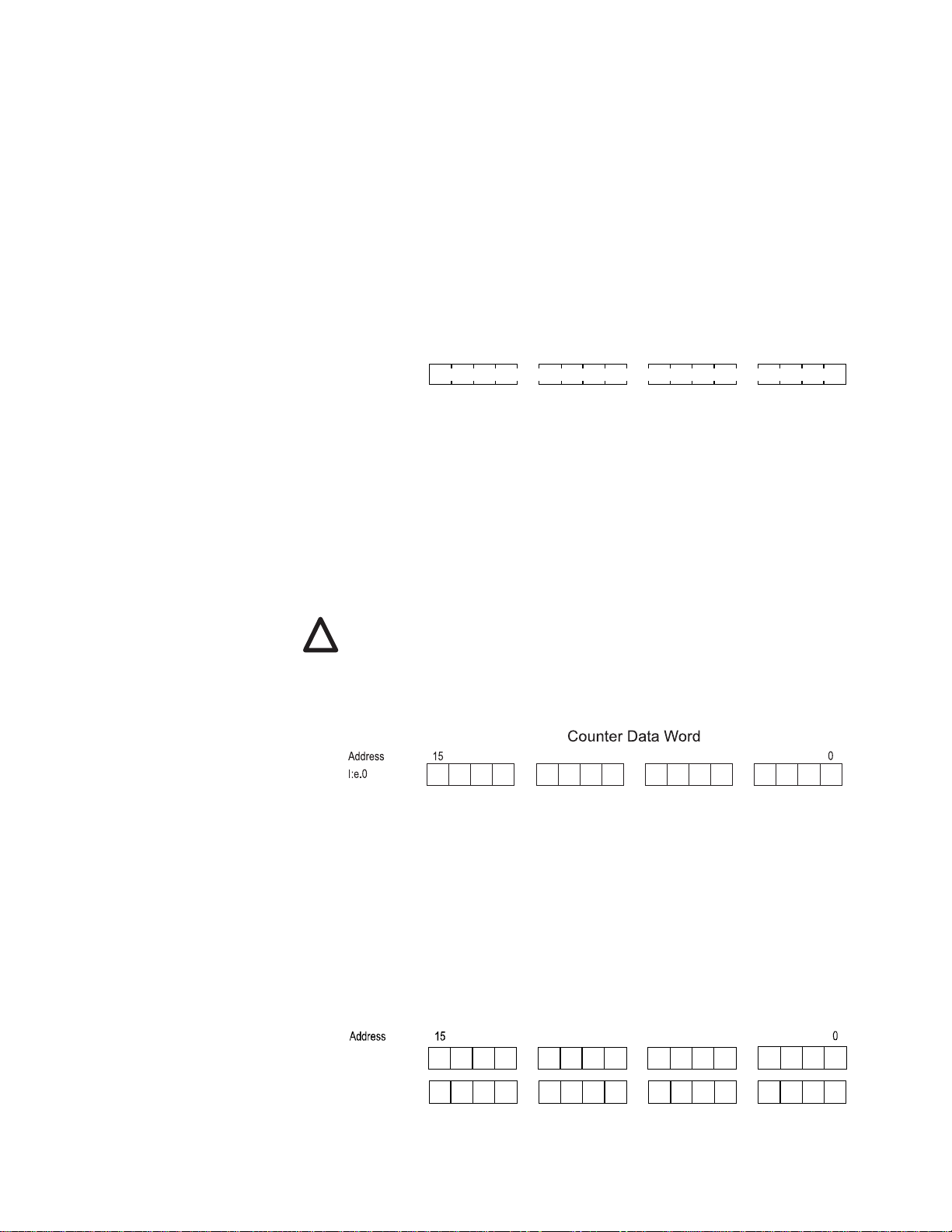

Input Registers Channel Data

Chapter 4: Channel Configuration, Data, and Status 37

The channel data consists of 4 words, the lower counter data value, the

upper counter data value, the rate data value and the channel status data.

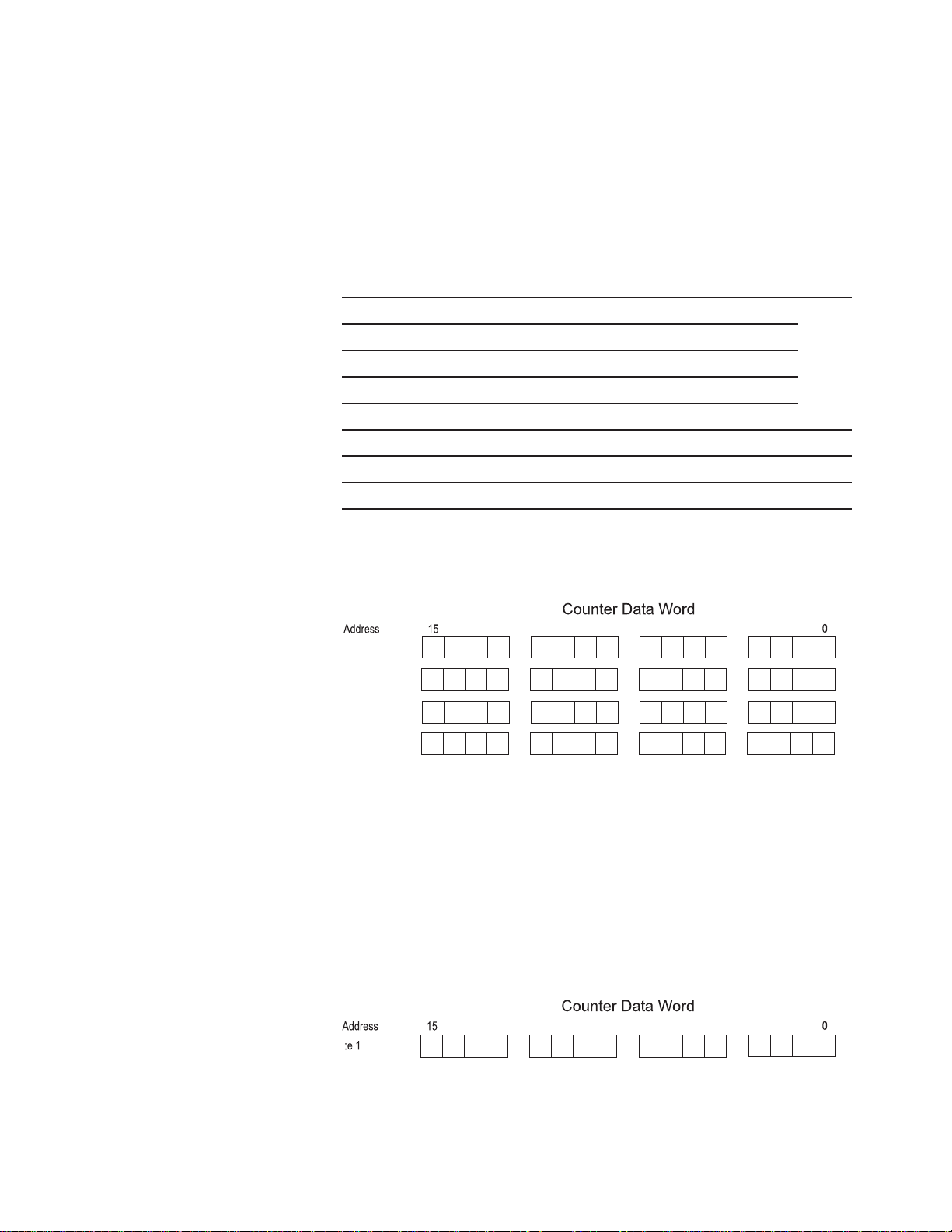

Table 4.4 - Data Word Addresses

CTR8 CTR4 Scale/Limit Value

I:e.0 to I:e.3 I:e.0 to I:e.3 0 Channel MSW, LSW , Rate Data, Status Reg

I:e.4 to I:e.7 I:e.4 to I:e.7 1 Channel MSW, LSW , Rate Data, Status Reg

I:e.8 to I:e.11 I:e.8 to I:e.11 2 Channel MSW , LSW, Rate Data, S tatus Reg

I:e.12 to I:e.15 I:e.12 to I:e.15 3 Channel MSW , LSW, Rate Data, S tatus Reg

I:e.16 to I:e.19 (n/a) 4 Channel MSW, LSW , Rate Data, St atus Reg

I:e.20 to I:e.23 (n/a) 5 Channel MSW, LSW , Rate Data, St atus Reg

I:e.24 to I:e.27 (n/a) 6 Channel MSW, LSW , Rate Data, St atus Reg

I:e.28 to I:e.31 (n/a) 7 Channel MSW, LSW , Rate Data, St atus Reg

Figure 4.9 - Data Words

8

9

I:e.w

I:e.x

I:e.y

I:e.z

Counter MSW

Counter LSW

Rate Output

Status Output

Counter Output Register, High word:

This output data register contains the upper word of the counters

accumulator. This register is a 16 bit word in binary 2’s complement

format. When operating in the extended count mode, ±8M counts, the

high word is equal to the counter value/1,000 and the low word is the

remainder. For example, a count of 40,123 would result in a high word

equal to 40, and the low word equal to 123. The high word = 40 and the

low word = 123.

Figure 4.11 -Counter High Word

8

9

Counter Input High

This register is always zero when operating the the standard (32k) count

mode.

Page 38

38 SLC 500™ 50 KHz Counter / Flowmeter Module

Counter Output Register, Low word:

This output data register contains the lower word of the counter

accumulator. This register is a signed16 bit word in binary 2’ s complement

format and will allow count values up to ±32K. This word is used in

conjunction with the counter’s upper output word when in the extended

count mode. Bit 15 represents the sign for each word. When the counter

is operating in the extended mode, the low and high words are used

together to form a composite number that extends the counter to ±8M.

The low word represents counts up to 1000 and the high word represents

counts that carry over 1000. (When the counter is configured in Extended

mode.)

Actual count = (Value of the high word x 1000) + (V alue of the low word).

Figure 4.10 -Counter Low W ord

8

9

Counter Input Low

Rate Output Register word:

Refer to Appendix A for floating point rate mode.

This output data register contains the rate value while operating in rate

mode. This register is a 16 bit word in binary 2’ s complement format and

represents the input value. Note that if the R Factor is present the output

date value is represented as the Rate / R Factor. Rates greater than

32kHz must use a R factor otherwise overflow will occur. If the R factor

is set to 2 and your input rate is 50kHz, the data output word will read

25,000.

Figure 4.12 -Counter Rate Word

8

9

Rate Input Value

Page 39

Check each input

channel’s

configuration and status

Chapter 4: Channel Configuration, Data, and Status 39

Output Channel Status Flags

Figure 4.13 Counter Output - Channel Status Flags

Address

0 = OK

1 = Error

0= OK

1= Error

15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

Channel 0 Status WordI:e.3

Channel 1 Status WordI:e.7

Channel 2 Status WordI:e.11

Channel 3 Status WordI:e.15

Channel 4 Status WordI:e.19

Channel 5 Status WordI:e.23

Channel 6 Status WordI:e.27

Channel 7 Status WordI:e.31

Rate Max

Rate Limit

0 = Zero

1 = Set

0 = Zero

1 = Set

System Error

K or M Factor

Configuration Error

Rate Limit / R Factor

0 = Reset

1 = Set

0 = Reset

1 = Set

0 = Reset

1 = Set

Rate Zero

0 = Reset

1 = Set

Count Zero

0 = Reset

1 = Set

Count Max

Count Size

Count Limit

Count Preset

0 = Standard

1 = Extended

0 = Reset

1 = Set

0 = Reset

1 = Set

Direction Invert

Counter Enable

Count Direction

0 = Start

Counter Input State

1 = Stop

0 = Low

1 = High

0 = Up

1 = Down

0 = Normal

1 = Invert

Page 40

40 SLC 500™ 50 KHz Counter / Flowmeter Module

Counter Start/Stop Echo: (Status Bit 0)

This bit echo’s the setting of the Counter Enable bit set in the channels

control register. The counter enable bit allows the counter to continue to

count up or down from its present value.

Counter Input State: (Status Bit 1)

This bit shows the current value of the input state. The state of the input

will be sampled at the end of the current update cycle. For rapidly

changing counter inputs the state of this bit could be either high or low

depending on the exact time of measurement. The purpose for this bit is

to provide slow counter feedback and single count diagnosis. This bit can

also be used as a general purpose digital input line back to the PLC.

Counter Direction State: (Status Bit 2)

This bit shows the current direction of the counter. The state of the

counter direction will be sampled at the end of the current update cycle.

For rapidly changing counter inputs the state of this bit could be either

high or low depending on the exact time of measurement. The purpose

for this indicator is to provide quadrature detection feedback to aid in

system diagnosis.

Count Direction Invert Bit echo: (Status Bit 3)

This bit echo’s the state of the Count Direction bit set in the channel

configuration register. The count direction status echo’s the state of the

invert bit. It does not determine if the count is going up or down.

Count Size Selection echo (Status Bit 4)

This bit echo’s the state of the maximum counter value selected in the

configuration register. When zero the channel counter is in standard

mode and will count up to ±32K (1 word of data). When set to 1 the is

in the extended mode and will have a maximum value of 8M which is

formed using the MSW and LSW data words..

Counter Max Flag: (Status Bit 5)

The flag is set when the maximum count, based on Normal or Extended

mode, is reached. Refer to the Reset Flags, Configuration Bit 2, in the

configuration word section of this chapter for a description of this flag’s

operation.

Counter Limit Flag: (Status Bit 6)

The flag is set when the user defined count limit is reached. Refer to the

the configuration word section of this chapter for a description of this

flag’s operation.

Counter Preset Echo: (Status Bit 7)

The flag is echos the state of the preset bit on the configuration register.

Page 41

Chapter 4: Channel Configuration, Data, and Status 41

Counter Zero Flag: (Status Bit 8)

The flag is set when the counter counts down through zero. Refer to the

configuration word section of this chapter for a description of this flag’s

operation.

Max Rate Flag: (Configuration Bit 9)

The max rate flag is set when the input rate exceeds its maximum range

of 32,767kHz. This flag indicates that the input counter rate is over the

valid range of the module and that the value indicated in the rate data

register may not be correct. This flag will stay on until the input rate

falls below the rate limit. If a Rate R Factor of 2 or more is used the

Max Rate Flag will be set at an input frequency of 50kHz

Rate Limit Flag: (Configuration Bit 10)

When the rate value is greater than or equal to the Rate Limit value the

Rate Limit flag bit will be set. This flag will stay on until the input rate

falls below the rate limit.

Rate Zero Flag: (Configuration Bit 11)

The rate zero flag is set when the input rate is zero. This flag can be

used to flag an input fault condition. The rate zero flag is set when no

input is detected for 2 seconds.

K Factor / M Factor Set Flag: (Configuration Bit 12)

This bit indicates that a non zero K or M factor value has been written to

the module’s non-volatile memory. This value will be use to scale the

input counter data. When a K or M factor is set all count data will be

scaled by the K or M factor data.

R Factor Set Flag: (Configuration Bit 13)

This bit indicates that a non zero R factor value has been written to the

module’s non-volatile memory . This R factor value is used to scale the

rate data or enable the floating point rate mode.

Configuration Error Flag: (Configuration Bit 14)

This flag is set when the channel configuration word is set to an illegal

state. An example would be if one channel was configured for

quadrature detection and its quadrature pair was not. In this case both

channels would have their configuration flags set until the configuration

word was corrected. All counter data will be set to zero when an illegal

configuration occurs.

System Error Flag: (Configuration Bit 15)

This flag is set when the module detects a system error. System Errors

are reported when the module can’t complete its power up self test or

detects some other on line error, like a watchdog time out.

Page 42

42 SLC 500™ 50 KHz Counter / Flowmeter Module

Page 43

Sample Counter

Configuration

Simple Linear

Counter

(10,000 Limit):

Chapter 5

Programming / Application Examples

Learning to configure your counter to meet your application requirements

will require knowledge of counter configuration, ladder logic programming

and data management. Read this chapter to familiarize yourself with how

to use the advanced features of your module for:

This configuration for Channel 0 of the counter module will allow the user

to count from zero to a maximum value of 10,000 counts.

10,000

-32K-8M -8M

0

+32K

T o facilitate this you must input a Limit of 10,000 counts. This cycle will

continue, without stopping , with these configuration settings.

Channel 0 - Output Register Configuration (O:e.0)

Output Register Configuration

Config. Bit Description Bit Setting Description

*15 Normal 0 Normal Mode

14 Roll Under 0 Roll to Neg. #s

13 Roll Over 1 Roll to Preset

12 Direction 0 (Default) No Inversion

1 1 Count Size 0 (Default) ±32K Std.

10 Freq. Filter 0 (Default) 50kHz

9 Stop on Limit 0 (Default) No Stop

8 Stop on Zero 0 (Default) No Stop

6/ 7 Count Mode 00 (Default) Unidirectional

4/ 5 Input Range 00 (Default) 50mV-30VAC

3 Rate. Mode 0 (Default) Instant Mode

2 Reset Flags 0 (Default) Of f

1 Counter Preset 0 (Default) Off

No scale factors or associated flags are used. The input range is based on

your input signal type. The filter on the input rate defaulted to 50kHz.

Configuration W ord

O:e.2 Counter Limit 10,000

W e have set the limit to 10,000.

Page 44

44 SLC 500™ 50 KHz Counter / Flowmeter Module

0 Count 10,000

Roll Over

Note: If we change Configuration Bit 9 to 1 the counter will reach the

limit and then hold its value until the Limit Flag is cleared. Then it

will roll to 0, and continue counting to 10,000. Each time the limit is

reached the flag must be reset before proceeding.

Note: If we toggle Configuration Bit 12 the counter counts in a

downward direction. It will start at 0 and count to -32,768. It will

then Roll Under to +32,767. If Configuration Bit 14 is set the

counter will Roll Under to this Preset Value.

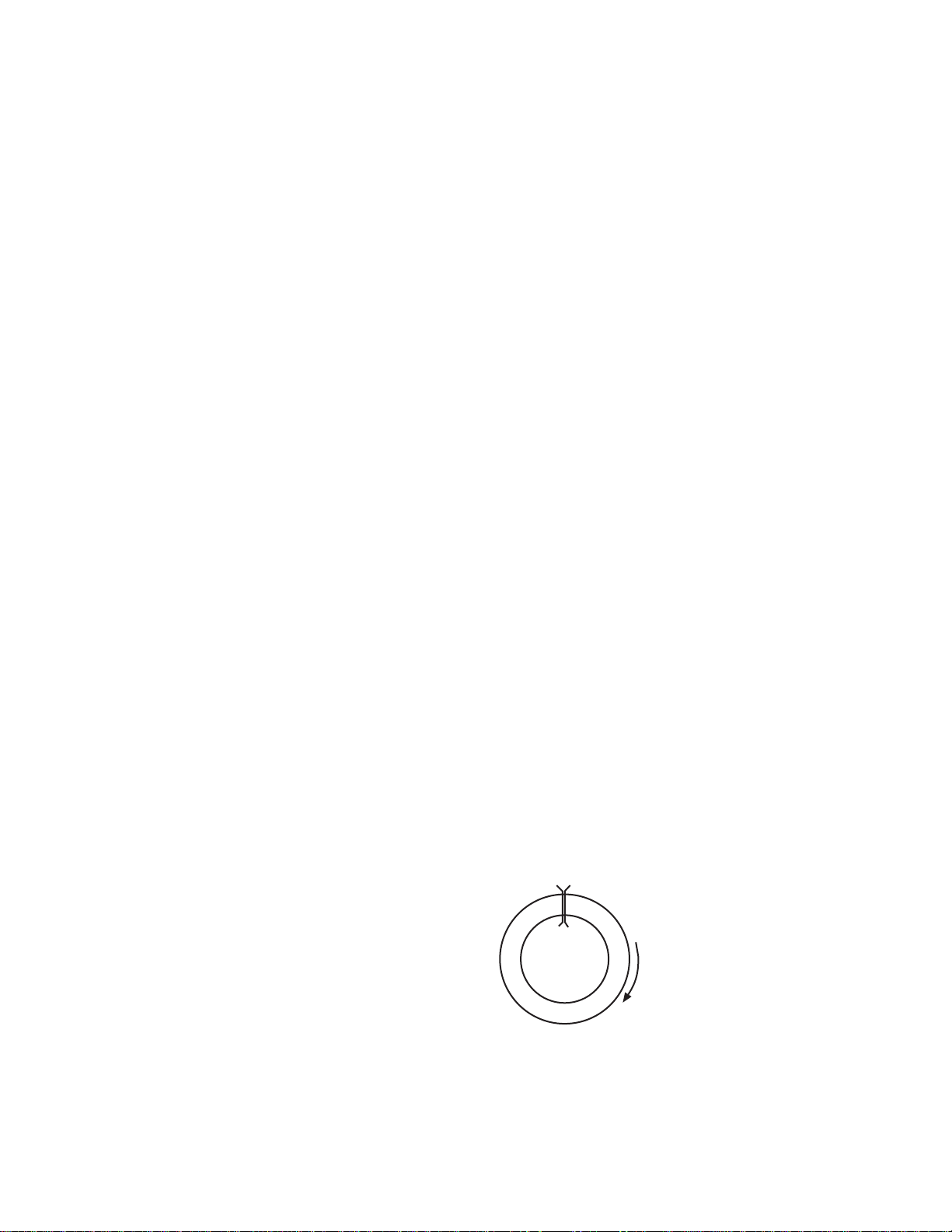

Ring Counter

Sample

The figure below demonstrates a ring counter operation. In a ring counter

operation, the count value changes between zero and maximum. If, when

counting up, the counter reaches the maximum value, it rolls over to zero.

If, when counting down, the counter reaches zero, it rolls under to the

maximum value.

Maximum Value Zero

Count Down

Ring Counter

Rollover

Count Up

Page 45

Sample

Configuration

Simple Ring Counter

w/ Flags (20k Limit):

Chapter 5: Ladder Program Examples 45

This configuration for the counter module will allow the user to count from

a minimum value of 0 to a limit value of 20,000 counts Each time a

revolution has occurred the counter limit flag will be set. Your ladder

program may use this flag to increment an accumulator, thus counting

revolutions. The flag must be reset before another complete revolution

occurs otherwise the accumulator can not be incremented.

Channel 0 Output Register Configuration (O:e.0)

Config. Bit Description Bit Setting Description

*15 Normal 0 Normal Mode

14 Roll Under 1 Preset

13 Roll Over 1 Roll to Zero

12 Direction 0 (Default) No Inversion

1 1 Count Size 0 (Default) ±32K

10 Freq. Filter 0 (Default) 50kHz

9 Stop on Limit 0 No Stop

8 Stop on Zero 0 (Default) N/A

6/ 7 Count Mode 00 (Default) Uni-Directional

4/ 5 Input Range 00 (Default) 50mV-30VAC

3 Rate Mode 0 (Default) Instant

2 Reset Flags 0 (Default) Toggle each Rev.

1 Counter Preset 0 (Default) Off

Output Word - O:e.1 Counter Preset= 20,000

Output W ord - O:e.2 Counter Limit = 20,000

A ring counter is configured by setting the preset and limit values to the

same count and setting the roll over to zero and roll under to preset bits.

Zero must always be the starting point and the maximum value must

always be positive.

20K Ring Counter

020,000

Rollover

Flag Set

on Each

Revolution

Count Up

Page 46

46 SLC 500™ 50 KHz Counter / Flowmeter Module

The above figure illustrates counting in a clockwise direction.

Using Preset Values

with Extended Mode

The Counter Preset and Counter Limit functions are affected by the

Count Size Configuration Bit 11. The default counter range is ±32K but

may be extended to ±8M.

Using Scaling with

Count and Rate

Outputs:

-32K-8M +8M

Extended Normal

0

+32K

Normal Extended

When operating in the extended range, ±8M, all Counter Preset and

Counter Limit are multiplied by 256. The resolution of the Preset and

Limit values in the standard mode is one count. The resolution in the

extended mode is 256 counts.

Count Size ±32K ±8M Description

Preset V alue 1000 256,000 = 1000 x 256

Limit Value 10 0 2560 = 100 x 256

Count Output:

Counter output scaling is applied using the K & M scale factors. When a

scale factor is applied to the counter the Counter Output Register = (Raw

Count * (M factor /10000) * 1/ K Factor). When a scale factor is being

used the Preset and Limit flags are also scaled.

Rate Output:

Rate output scaling is applied using the R scale factors. When a scale

factor is applied to the module the Rate Output Register = Incoming

frequency / R Factor. When a scale factor is being used the Rate Limit

flag is also scaled.

Example:

As an example if a rate factor of R = 2 is programmed into the module.

The Rate Limit value is set to 10KHz

In this example the Rate Limit Flag would be set when the input

≥

frequency is

20KHz.

Rate Limit Flag = Input Frequency * R factor

Page 47

Application:

Meter Proving

Chapter 5: Ladder Program Examples 47

Rate Limit Flag = 10,000Hz * 2 = 20,000Hz

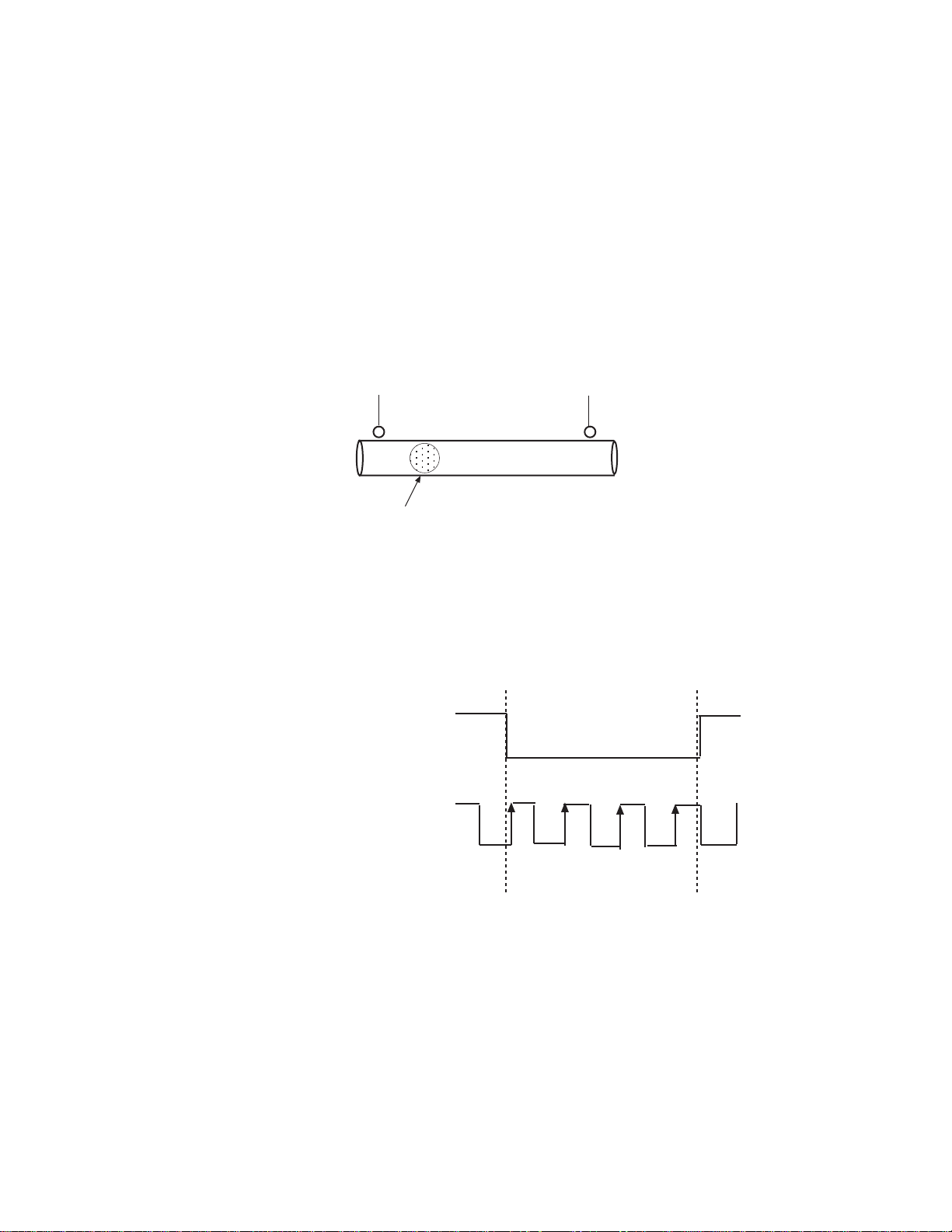

The 1746sc-CTR4/8 module provides a feature that allows the user to

perform meter proving functions. A typical meter proving application

would include two detector sensors that are located a fixed distance from

each other within a section of pipe used specifically for meter proving.

The operation does not disrupt the in situ flowmeter’s operation.

Detector #1

Displacer

Detector #2

Utilizing the external gate enable to start and stop count functions enables

the user to count pulses as fast as 20 microseconds to an accuracy of 1

count.

Here is an example wave form representing the start and stop transitions

on the external gate enable, and the associated pulses that the module

would accumulate:

External Channel Enable

Flow Meter Input

1 2 3 4 NA

Given the above wave form, the module will begin counting the first

positive going input pulse after the external enable input goes low . The

module will accumulate 4 counts in the channel count register and stop

when the external enable input goes high.

Page 48

48 SLC 500™ 50 KHz Counter / Flowmeter Module

The external enable line accommodates 5 Vdc, 12 Vdc and 24 Vdc signals

and is pulled low internally.

Vdc, 24 Vdc and up to 75 Vac inputs.

Application Note:

Factor Data Errors

The 1746sc-CTR4/8 module provides a feature that allows the user to load

M, K and Rate factor values into module memory without consuming

additional control registers. In order to accommodate this feature into the

design, three of the four registers assigned to each channel of the module

are multiplexed with the Counter Preset, Limit and Rate limit values.

If factored data values are inadvertently loaded into the module without

user knowledge of this occurring, the module can appear to be non

functional.

Follow these steps to identify if factored data values have been loaded and

if so, how to clear those values to return the module to default operation.

Use Channel Status registers to identify the presence of Factored

Data values

The counter input accommodates 5 Vdc, 12

Use Bits 12 and 13 in the channel status registers to verify if factored data

is present. If either or both of the bits are set to a one the module has

factor data values loaded.

Here are the address for the channel status registers:

Channel Register

0 I:e.3 (Where e indicates slot where module is installed)

1 I:e.7

2 I:e.11

3 I:e.15

CTR8 only:

4 I:e.19

5 I:e.23

6 I:e.27

7 I:e.31

Clear loaded factor data

Page 49

Chapter 5: Ladder Program Examples 49

In order to clear the factored data 0 must be loaded into the Preset / K

Factor, Limit / M Factor and Limit / R Factor registers. After entering 0

into these registers bit 15 of the module Configuration register

must be toggled from 0 to 1 and then back to 0.

There are 4 registers assigned for each Channels output configuration

word. The first register assigned is the channel configuration register .

The next 3 registers are the Preset / K Factor, Limit / M Factor and Limit

/ R Factor registers respectively.

Refer to Page 24 for detailed information regarding the output