Page 1

User’s Manual Pub. 0300266-02 Rev. B

Page 2

ii Point IO™ 4 Channel Universal Analog Input Module

User’s Manual Pub. 0300266-02 Rev. B

Important Notes

1. Please read all the information in this owner’s guide before installing the

product.

2. The information in this owner's guide applies to hardware Series A and

firmware version 1.00 or later.

3. This guide assumes that the reader has a full working knowledge of the

relevant processor.

Notice

The products and services described in this owner's guide are useful in a wide

variety of applications. Therefore, the user and others responsible for applying

the products and services described herein are responsible for determining their

acceptability for each application. While efforts have been made to provide

accurate information within this owner's guide, Spectrum Controls, Inc. assumes

no responsibility for the accuracy, completeness, or usefulness of the information

herein.

Under no circumstances will Spectrum Controls, Inc. be responsible or liable for

any damages or losses, including indirect or consequential damages or losses,

arising out of either the use of any information within this owner's guide or the

use of any product or service referenced herein.

No patent liability is assumed by Spectrum Controls, Inc. with respect to the use

of any of the information, products, circuits, programming, or services referenced

herein.

The information in this owner's guide is subject to change without notice.

Limited Warranty

Spectrum Controls, Inc. warrants that its products are free from defects in

material and workmanship under normal use and service, as described in

Spectrum Controls, Inc. literature covering this product, for a period of 1 year.

The obligations of Spectrum Controls, Inc. under this warranty are limited to

replacing or repairing, at its option, at its factory or facility, any product which

shall, in the applicable period after shipment, be returned to the Spectrum

Controls, Inc. facility, transportation charges prepaid, and which after

examination is determined, to the satisfaction of Spectrum Controls, Inc., to be

thus defective.

This warranty shall not apply to any such equipment which shall have been

repaired or altered except by Spectrum Controls, Inc. or which shall have been

subject to misuse, neglect, or accident. In no case shall the liability of Spectrum

Controls, Inc. exceed the purchase price. The aforementioned provisions do not

extend the original warranty period of any product which has either been repaired

or replaced by Spectrum Controls, Inc.

Page 3

Point IO™ 4 Channel Universal Analog Input Module iii

Table of Contents

IMPORTANT NOTES ............................................................................................................................................ II

LIMITED WARRANTY .......................................................................................................................................... II

CHAPTER 1 MODULE OVERVIEW ..................................................................................................................... 1-1

SECTION 1.1 GENERAL DESCRIPTION .............................................................................................................................. 1-1

SECTION 1.2 INPUT TYPES ............................................................................................................................................ 1-2

SECTION 1.3 DATA FORMATS ....................................................................................................................................... 1-2

SECTION 1.4 FILTER FREQUENCIES ................................................................................................................................ 1-3

SECTION 1.5 HARDWARE FEATURES .............................................................................................................................. 1-3

1.5.1 LED Indicators ........................................................................................................................................... 1-5

SECTION 1.6 SYSTEM OVERVIEW ................................................................................................................................... 1-6

1.6.1 Module Power-up ..................................................................................................................................... 1-6

1.6.2 Module Operation ..................................................................................................................................... 1-6

CHAPTER 2 INSTALLATION AND WIRING .......................................................................................................... 2-1

SECTION 2.1 COMPLIANCE TO EUROPEAN UNION DIRECTIVES ............................................................................................. 2-1

2.1.1 EMC Directive ............................................................................................................................................ 2-1

2.1.2 Low Voltage Directive ............................................................................................................................... 2-1

SECTION 2.2 POWER REQUIREMENTS ............................................................................................................................ 2-2

SECTION 2.3 GENERAL CONSIDERATIONS ........................................................................................................................ 2-2

2.3.1 Hazardous Location Considerations .......................................................................................................... 2-2

2.3.1 Prevent Electrostatic Discharge ................................................................................................................ 2-3

2.3.2 Remove Power .......................................................................................................................................... 2-3

2.3.3 Selecting a Location .................................................................................................................................. 2-3

SECTION 2.4 MOUNTING ............................................................................................................................................. 2-4

2.4.1 Before You Begin ....................................................................................................................................... 2-4

2.4.2 Install Mounting Base ............................................................................................................................... 2-5

2.4.3 Install the I/O Module ............................................................................................................................... 2-5

2.4.4 Install the Removable Terminal Block (RTB) ............................................................................................. 2-6

2.4.5 Remove a Mounting Base ......................................................................................................................... 2-6

2.4.6 Install a 1734-TOPS Base .......................................................................................................................... 2-7

2.4.7 Remove a 1734-TOPS Base ....................................................................................................................... 2-7

SECTION 2.5 FIELD WIRING CONNECTIONS ...................................................................................................................... 2-7

2.5.1 Wiring Diagram ........................................................................................................................................ 2-9

2.5.2 System Wiring Configurations ................................................................................................................ 2-10

CHAPTER 3 CONFIGURING THE 1734SC-IF4U USING RSLOGIX 5000 ................................................................... 3-1

SECTION 3.1 INTRODUCTION ........................................................................................................................................ 3-1

SECTION 3.2 ABOUT COMMUNICATIONS......................................................................................................................... 3-1

SECTION 3.3 USE GENERIC PROFILE ............................................................................................................................... 3-2

3.3.1 Add a Local Ethernet Bridge Module ........................................................................................................ 3-3

3.3.2 Add a Remote Ethernet Point IO Adapter ................................................................................................. 3-5

3.3.3 Add the Generic Point IO Module ............................................................................................................. 3-7

SECTION 3.4 USE ADD-ON-PROFILE .............................................................................................................................. 3-8

3.4.1 Installing the Add-On Profile ..................................................................................................................... 3-8

3.4.2 Adding the IF4U Module to Your Logix Project ......................................................................................... 3-9

SECTION 3.5 MODULE CONFIGURATION....................................................................................................................... 3-10

3.5.1 Channel Configuration Details ................................................................................................................ 3-12

3.5.2 RTD Accuracy .......................................................................................................................................... 3-13

SECTION 3.6 READ INPUT DATA ................................................................................................................................. 3-16

3.6.1 Input Assembly Status Bit Definitions ..................................................................................................... 3-17

SECTION 3.7 GETTING TECHNICAL ASSISTANCE .............................................................................................................. 3-18

SECTION 3.8 DECLARATION OF CONFORMITY ................................................................................................................ 3-18

User’s Manual Pub. 0300266-02 Rev. B

Page 4

iv Point IO™ 4 Channel Universal Analog Input Module

APPENDIX A MODULE SPECIFICATIONS ............................................................................................................... 1

INDEX ............................................................................................................................................................. I-1

User’s Manual Pub. 0300266-02 Rev. B

Page 5

Point IO™ 4 Channel Universal Analog Input Module v

User’s Manual Pub. 0300266-02 Rev. B

Preface

Read this preface to familiarize yourself with the rest of the manual. This preface

covers the following topics:

• Who should use this manual

• How to use this manual

• Related documentation

• Rockwell Automation Technical Support

• Documentation

• Conventions used in this manual

Who Should

Use This Manual

Use this manual if you are responsible for designing, installing, programming, or

troubleshooting control systems that use Allen-Bradley I/O and/or compatible

controllers, such as CompactLogix and ControlLogix.

How to Use

This Manual

As much as possible, we organized this manual to explain, in a task-by-task

manner, how to install, configure, program, operate, and troubleshoot a control

system using the 1734sc-IF4U.

Related

Documentation

The table below provides a listing of publications that contain important

information about Allen-Bradley PLC systems.

For

Refer to this Document

Allen-Bradley

Pub. No.

A description and overview of the

1734 and 1734D series POINT I/O

modules and compatible control

platforms. Also includes an

overview of how to specify a

POINT I/O system.

POINT I/O Selection

Guide

1734-SG001

Information about how to install

the 1734-EP24DC, Series B

POINT I/O 24 VDC Expansion

Power Supply.

Expansion Power

Supply Installation

Instructions

1734-IN058

Information about how to install

1734-TB and -TBS POINT I/O

Wiring Base Assemblies

Wiring Base Assembly

Installation Instructions

1734-IN511

Information about how to install

1734-TB3 and -TB3S POINT I/O

Wiring Base Assemblies.

Wiring Base Assembly

Installation Instructions

1734-IN013

Page 6

vi Point IO™ 4 Channel Universal Analog Input Module

User’s Manual Pub. 0300266-02 Rev. B

Technical

Support

For technical support, please contact your local Rockwell Automation

TechConnect Office for all Spectrum products. Contact numbers are as follows:

• USA (1) 440-646-6900

• United Kingdom (44) 01908 635230

• Australia 1800-809-929

• Mexico 001-888-365-8677

• Brazil (55) 11 3618 8800

• Europe +49 211 41553 63

or send an email to

support@spectrumcontrols.com

Documentation

If you would like a manual, you can download a free electronic version from the

Internet at www.spectrumcontrols.com

Conventions

Used in This

Manual

The following conventions are used throughout this manual:

• Bulleted lists (like this one) provide information not procedural steps.

• Lists provide sequential steps or hierarchical information.

• Italic type is used for emphasis.

• Bold type identifies headings and sub-headings:

WARNING

Identifies information about practices or circumstances that can lead to

personal injury or death, property damage, or economic loss. These

messages help you to identify a hazard, avoid a hazard, and recognize the

consequences.

ATTENTION

Actions ou situations risquant d’entraîner des blessures pouvant être

mortelles, des dégâts matériels ou des pertes financières. Les messages «

Attention » vous aident à identifier un danger, à éviter ce danger et en

discerner les conséquences.

NOTE

Identifies information that is critical for successful application and

understanding of the product.

Page 7

User’s Manual Pub. 0300266-02 Rev. B

Chapter 1

Module Overview

The 1734sc-IF4U module has four analog input channels that support current,

voltage, RTD, resistance, and thermocouple input types. This chapter includes

information about:

• General description

• Input types

• Data formats

• Filter frequencies

• Hardware features

• System overview and module operation

Section 1.1

General

Description

The IF4U module digitally converts and stores analog data for each configured

input. Each input channel can be independently configured for input type, data

format, and filter frequency.

Page 8

1-2 Chapter 1: Module Overview

User’s Manual Pub. 0300266-02 Rev. B

Section 1.2

Input Types

The IF4U module supports the following input types.

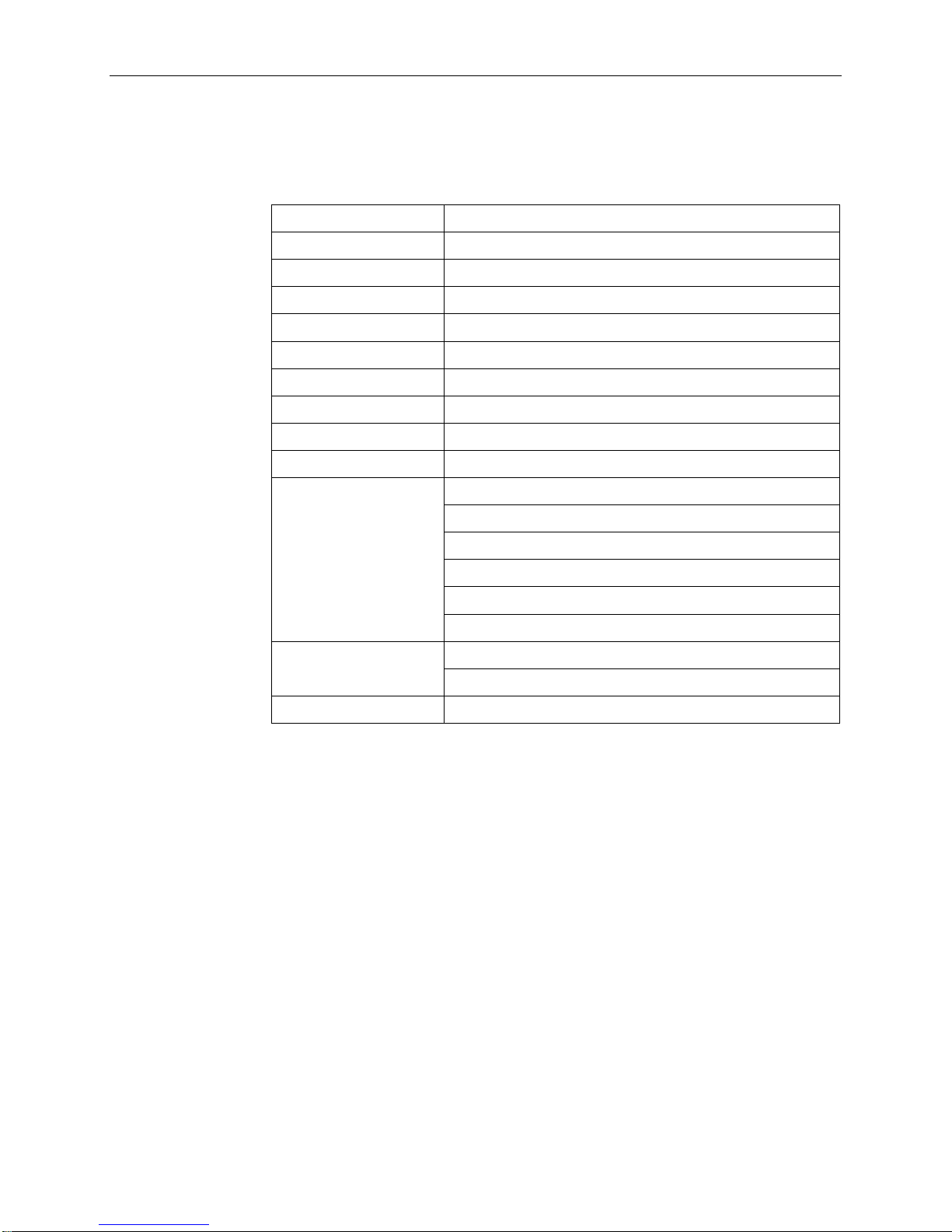

Table 1-1. Input Types

Input Type

Range

E Type Thermocouple

-270 to 1000 ˚C (-454 to 1832 ˚F)

J Type Thermocouple

-210 to 1200 ˚C (-346 to 2192 ˚F)

K Type Thermocouple

-270 to 1370 ˚C (-454 to 2498 ˚F)

T Type Thermocouple

-270 to 400 ˚C (-270 to 752 ˚F)

100 Ω Pt α 0.385

-200 to 850 ˚C (-328 to 1562 ˚F)

1000 Ω Pt α 0.385

-200 to 850 ˚C (-328 to 1562 ˚F)

100 Ω Pt α 0.3916

-200 to 630 ˚C (-328 to 1166 ˚F)

1000 Ω Pt α 0.3916

-200 to 630 ˚C (-328 to 1166 ˚F)

Resistance

0 to 3000 Ω

Voltage

±50 mV

±100 mV

±1 V

0 to 5 V

1 to 5 V

±10 V (IF4U)

Current

4 to 20 mA

0 to 20 mA

CJC

-25 ˚C to 85 ˚C

Section 1.3

Data Formats

For each channel, the data can be configured for:

• Engineering Units ×1

• Engineering Units ×10

• Scaled-for-PID

• Raw/proportional counts

Page 9

Chapter 1: Module Overview 1-3

User’s Manual Pub. 0300266-02 Rev. B

Section 1.4

Filter

Frequencies

The module uses a notch filter to provide noise rejection for each input channel.

The filter for each channel is programmable allowing you to select from 4

different filter options:

• 4.17 Hz

• 16.7 Hz

• 62 Hz

• 470 Hz

Section 1.5

Hardware

Features

Channels are wired as differential inputs.

Module configuration is done via the controller’s programming software. The

module configuration is stored in the memory of the controller. Refer to your

controller’s user manual for more information. The illustration below shows the

module’s hardware features.

Figure 1-1.

Page 10

1-4 Chapter 1: Module Overview

User’s Manual Pub. 0300266-02 Rev. B

Figure 1-2.

Page 11

Chapter 1: Module Overview 1-5

User’s Manual Pub. 0300266-02 Rev. B

1.5.1 LED Indicators

The 1734 analog HART module uses several LEDs to show operational status.

The status LEDs are defined below:

Table 1-2. LED Status Indicators

Indicator

State

Description

Module

Status

Off

No power applied to device.

Solid Green

Device operating normally.

Flashing Green

Device needs commissioning due to configuration missing,

incomplete, or incorrect.

NOTE: The module always sets default values for invalid

configurations. Therefore, this status will not be shown.

Flashing Red

Not used with this module.

Solid Red

Recoverable fault.

ADC communications fault, or backplane communications error.

Flashing Red/Green

Device is in self-test mode.

This is only used during factory test and power-up.

Channel

Status

Off

Channel disabled. Will remain off after power-up until connection

established. Analog processing will not take place if no connection is

made.

Solid Green

Normal (channel scanning inputs).

Flashing Green

Calibration mode.

Solid Red

Major channel fault.

ADC communications fault.

Analog values will remain at current state until fault has recovered.

Flashing Red

Channel at end of range.

Flashing Red/Green

Displayed during power-up.

Network

Status

Off

Device not powered/Not online.

Solid Green

Device operational AND online AND connected.

Flashing Green

Device operational AND online but not connected.

OR

Device online AND device needs commissioning.

Flashing Red

Minor fault AND/OR connection timeout AND/OR no network

power.

Solid Red

Critical fault OR critical link failure.

Page 12

1-6 Chapter 1: Module Overview

User’s Manual Pub. 0300266-02 Rev. B

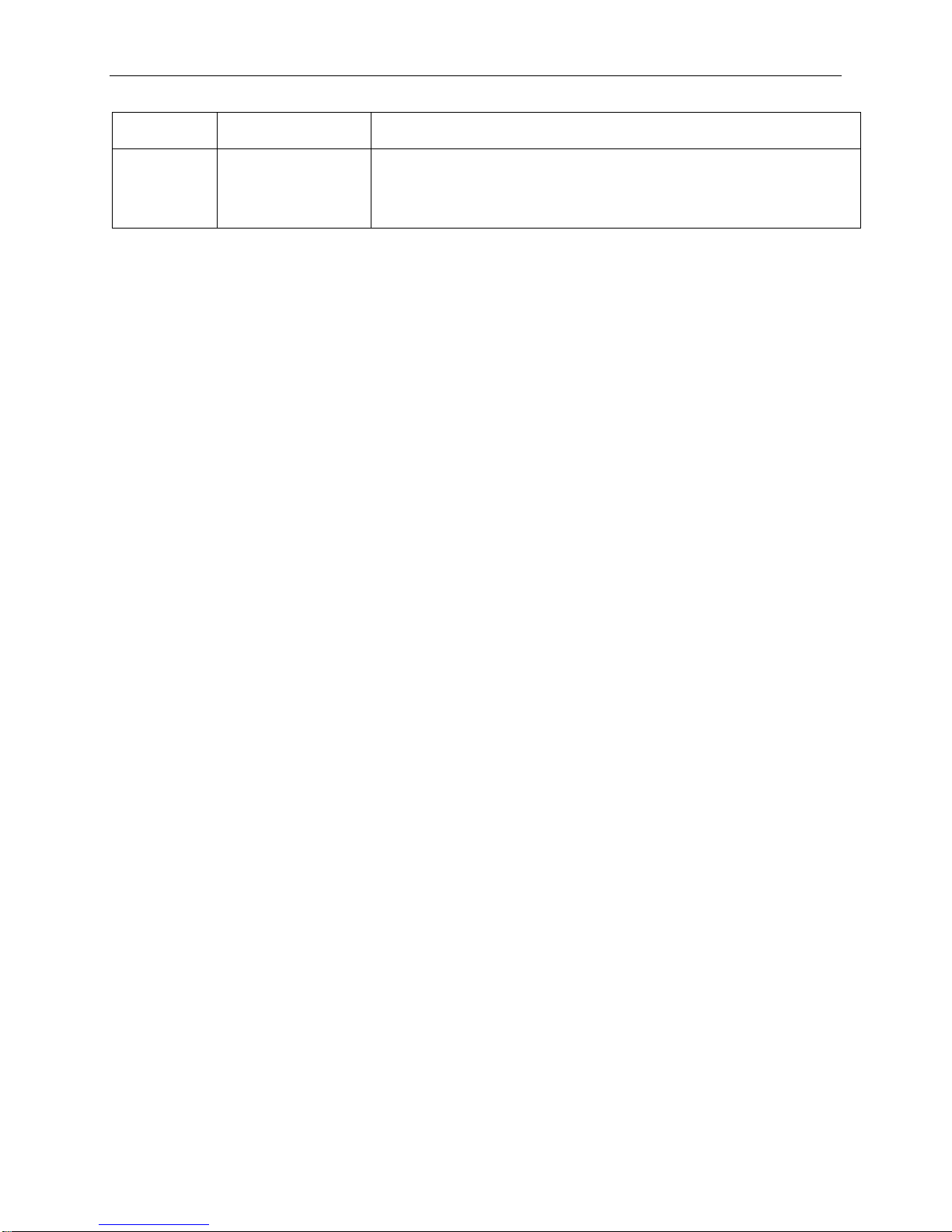

Indicator

State

Description

Flashing Red/Green

Communication faulted and received an identify comm fault request long protocol.

Also displayed during power-up.

Section 1.6

System

Overview

The module communicates to the controller via a 1734 Control Net, Device Net,

or Ethernet adapter. The module receives 5 and 24 VDC power through the bus

interface.

1.6.1 Module Power-up

At power-up, the module performs a check of its internal circuits, memory, and

basic functions. If no faults are found during power-up diagnostics, the module

status LED is turned on.

After power-up checks are complete, the module waits for valid channel

configuration data. If an invalid configuration is detected, the module will

generate a PLC fault. Once a channel is properly configured and enabled, it

continuously converts the input data to a value within the range selected for that

channel.

1.6.2 Module Operation

The 1734sc-IF4U module provides four, independent, analog input channels.

Each channel includes four selectable filter settings, and can be configured for

voltage, thermocouple, current, resistance or RTD input types.

The 1734sc-IF4U module uses a 20-bit Sigma-Delta ADC (Analog-to-Digital

Converter) to achieve 18-bit resolution. (This may be limited to 16-bits resolution

by backplane communication.) Inputs to the ADC are first multiplexed through

analog switches, and then buffered by a precision, low offset and drift,

programmable gain amplifier. The ADC also provides the programmable current

source used in resistive measurements.

The 1734sc-IF4U plug-in module communicates over its isolated CAN Bus

interface through the module backplane. The 1734 network adapter then

communicates to the PLC controller.

Page 13

Chapter 1: Module Overview 1-7

User’s Manual Pub. 0300266-02 Rev. B

See the block diagram below:

+24VDC

+3.3VDC ±2%

-15VDC ±3VDC

GND

Isolated

CAN Bus

CAN

Bus

and

+5VDC

ADC

SPI Interface

Voltage / Current (4-chs)

RTD / Resistance (2/4-chs)

Thermocouple (3-chs)

GND

Analog_1

Analog_0

I

s

o

l

a

t

i

o

n

Point Bus

LEDs

Processor

Isolation

Barrier

Controls and Status

Controls

Notes:

1) I/O’s are ESD protected

CJC (1-ch)

Analog_2

Protection,

Filtering,

Analog

Switch

Matrix,

PGA

+15VDC ±3VDC

Current Srcs

PGA_Interrupt

Low

Input-Power

Interrupt

and

System_Reset

SPI Interface

Power Supplies

And

Power Monitor

Isolation

Barrier

CLK

System

Clock

Generator

Page 14

1-8 Chapter 1: Module Overview

User’s Manual Pub. 0300266-02 Rev. B

Page 15

User’s Manual Pub. 0300266-02 Rev. B

Chapter 2

Installation and Wiring

This chapter will cover:

• Compliance to European union directives

• Power requirements

• General considerations

• Mounting

• Field wiring connections

Section 2.1

Compliance to

European

Union Directives

This product is approved for installation within the European Union and EEA

regions. It has been designed and tested to meet the following directives.

2.1.1 EMC Directive

The 1734sc-IF4U module is tested to meet Council Directive 89/336/EEC

Electromagnetic Compatibility (EMC) and the following standards, in whole or

in part, documented in a technical construction file:

• IEC 61000-6-4:2007 Electromagnetic compatibility (EMC)–Part 6-4:

Generic standards–Emission standard for industrial environments.

• IEC 61000-6-2:2005 Electromagnetic compatibility (EMC)–Part 6-2:

Generic standards–Immunity for industrial environments.

This product is intended for use in an industrial environment.

2.1.2 Low Voltage Directive

This product is tested to meet Council Directive 73/23/EEC Low Voltage, by

applying the safety requirements of EN 61131-2 Programmable Controllers, Part

2–Equipment Requirements and Tests. For specific information required by

EN61131-2, see the appropriate sections in this publication, as well as the

following Allen-Bradley publications:

• Industrial Automation, Wiring and Grounding Guidelines for Noise

Immunity, publication 1770-4.1

• Automation Systems Catalog, publication B113

Page 16

2-2 Chapter 2: Installation and Wiring

User’s Manual Pub. 0300266-02 Rev. B

Section 2.2

Power

Requirements

The module receives power through the bus interface from the +5 VDC/+24

VDC system power supply. The maximum current drawn by the module is

shown in the table below:

5 VDC

24 VDC

15 mA (maximum)

20 mA (maximum)

Section 2.3

General

Considerations

1734 I/O is suitable for use in an industrial environment when installed in

accordance with these instructions. Specifically, this equipment is intended for

use in clean, dry environments Pollution degree 21 and to circuits not exceeding

Over Voltage Category II2(IEC 60664-1)3.

2.3.1 Hazardous Location Considerations

This equipment is suitable for use in Class I, Division 2, Groups A, B, C, D or

non-hazardous locations only. The following WARNING statement applies to

use in hazardous locations.

WARNING

EXPLOSION HAZARD

• Substitution of components may impair suitability for Class I,

Division 2.

• Do not replace components or disconnect equipment unless power

has been switched off or the area is known to be non-hazardous.

Touch a grounded object to discharge static potential.

• Do not connect or disconnect components unless power has been

switched off or the area is known to be non-hazardous.

• This product must be installed in an IP54 rated enclosure.

• All wiring must comply with N.E.C. article 501-4(b).

1

Pollution Degree 2 is an environment where, normally, only non-conductive pollution occurs except that

occasionally a temporary conductivity caused by condensation shall be expected.

2

Over Voltage Category II is the load level section of the electrical distribution system. At this level,

transient voltages are controlled, and do not exceed the impulse voltage capability of the product’s

insulation.

3

Pollution Degree 2 and Over Voltage Category II are International Electrotechnical Commission (IEC)

designations.

Page 17

Chapter 2: Installation and Wiring 2-3

User’s Manual Pub. 0300266-02 Rev. B

2.3.1 Prevent Electrostatic Discharge

WARNING

Electrostatic discharge can damage integrated circuits or semiconductors if

you touch analog I/O module bus connector pins or the terminal block on

the input module. Follow these guidelines when you handle the module:

• Touch a grounded object to discharge static potential.

• Wear an approved wrist-strap grounding device.

• Do not touch connectors or pins on component boards.

• Do not touch circuit components inside the module.

• If available, use a static-safe work station.

• When not in use, keep the module in its static-shield box.

2.3.2 Remove Power

WARNING

Remove power before removing or inserting this module. When you

remove, or insert, a module with power applied, an electrical arc may

occur. An electrical arc can cause personal injury or property damage by:

• Sending an erroneous signal to your system’s field devices,

causing unintended machine motion.

• Causing an explosion in a hazardous environment.

• Electric arcing causes excessive wear to contacts on both the

module and its mating connector, and may lead to premature

failure.

2.3.3 Selecting a Location

Reducing Noise

Most applications require installation in an industrial enclosure to reduce the

effects of electrical interference. Analog inputs are highly susceptible to

electrical noise. Electrical noise coupled to the analog inputs will reduce the

performance (accuracy) of the module. Group your modules to minimize adverse

effects from radiated electrical noise and heat. Consider the following conditions

when selecting a location for the analog module. Position the module:

• Away from sources of electrical noise such as hard-contact switches,

relays, and AC motor drives.

• Away from modules which generate significant radiated heat. Refer to

the module’s heat dissipation specification.

In addition, route shielded, twisted-pair, analog input wiring away from any high

voltage I/O wiring.

Page 18

2-4 Chapter 2: Installation and Wiring

User’s Manual Pub. 0300266-02 Rev. B

Section 2.4

Mounting

2.4.1 Before You Begin

Note that this series C product can be used with the following:

• ControlNet and EtherNet/IP adapters ONLY, using RSLogix 5000

software, version 11 or later.

See the figures to familiarize yourself with major parts of the module, noting that

the wiring base assembly is one of the following:

• 1734-TB or 1734-TBS POINT I/O two-piece terminal base, which

includes the 1734-RTB removable terminal block and 1734-MB

mounting base.

• 1734-TOP or 1734-TOPS POINT I/O one-piece terminal base.

Page 19

Chapter 2: Installation and Wiring 2-5

User’s Manual Pub. 0300266-02 Rev. B

2.4.2 Install Mounting Base

WARNING

During panel or DIN rail mounting of all devices, be sure that all debris

(metal chips, wire strands, etc.) is kept from falling into the module.

Debris that falls into the module could cause damage when power is

applied to the module.

To install the mounting base on the DIN rail, proceed as follows:

1. Position the mounting base vertically above the installed units (adapter,

power supply or existing module.

2. Slide the mounting base down allowing the interlocking side pieces to

engage the adjacent module or adapter.

3. Press firmly to seat the mounting base on the DIN rail. The mounting

base will snap into place.

4. To remove the mounting base from the DIN rail, remove the module, and

use a small bladed screwdriver to rotate the base locking screw to a

vertical position. This releases the locking mechanism. Then lift straight

up to remove.

2.4.3 Install the I/O Module

The module can be installed before, or after base installation. Make sure that the

mounting base is correctly keyed before installing the module into the mounting

base. In addition, make sure the mounting base locking screw is positioned

horizontal referenced to the base:

Page 20

2-6 Chapter 2: Installation and Wiring

User’s Manual Pub. 0300266-02 Rev. B

1. Using a bladed screwdriver, rotate the key switch on the mounting base

clockwise until the number required for the type of module being

installed aligns with the notch in the base.

2. Make certain the DIN rail locking screw is in the horizontal position.

(You cannot insert the module if the locking mechanism is unlocked.)

3. Insert the module straight down into the mounting base and press to

secure. The module will lock into place.

2.4.4 Install the Removable Terminal Block (RTB)

A removable terminal block is supplied with your wiring base assembly. To

remove the terminal block, pull up on the RTB handle. This allows the mounting

base to be removed and replaced as necessary without removing any of the

wiring. To reinsert the removable terminal block:

1. Insert the end opposite the handle into the base unit. This end has a

curved section that engages with the wiring base.

2. Rotate the terminal block into the wiring base until it locks itself in place.

3. If an I/O module is installed, snap the RTB handle into place on the

module.

2.4.5 Remove a Mounting Base

To remove a mounting base, you must remove any installed module, and the

module installed in the base to the right. Remove the removable terminal block

(if wired):

1. Unlatch the RTB handle on the I/O module.

2. Pull on the RTB handle to remove the removable terminal block.

3. Press on the module lock on the top of the module.

4. Pull on the I/O module to remove from the base.

5. Repeat steps 1, 2, 3, and 4 for the module to the right.

Page 21

Chapter 2: Installation and Wiring 2-7

User’s Manual Pub. 0300266-02 Rev. B

6. Use a small-bladed screwdriver to rotate the orange base locking screw

to a vertical position.

This releases the locking mechanism.

7. Lift straight up to remove.

2.4.6 Install a 1734-TOPS Base

1. Position the base vertically above the installed units, such as an adapter,

power supply, or existing module.

2. Slide the base down, allowing the interlocking side pieces to engage the

adjacent installed unit.

3. Press firmly to seat the base on the DIN rail until the base snaps into

place.

4. Verify that the DIN-rail locking screw is in a horizontal, locked position

before inserting an I/O module.

2.4.7 Remove a 1734-TOPS Base

To remove a wiring base from the DIN rail, you must remove the module

installed to the right of the base:

1. Squeeze the module locking mechanism of the module to the right of the

base, pulling up to remove the module.

2. Turn the orange locking screw to a vertical position to unlock the base

from the DIN rail.

3. Slide the base up to release it from its mating units.

Section 2.5

Field Wiring

Connections

Consider the following when wiring your system:

General

• Power and input wiring must be in accordance with Class 1, Division 2

wiring methods, Article 501-4(b) of the National Electric Code, NFPA

70, and in accordance with the authority having jurisdiction.

• Use Belden™ 8761, or equivalent, shielded wire.

• To ensure optimum accuracy, limit overall cable impedance by keeping a

cable as short as possible. Locate the module as close to input devices as

the application permits.

• Digital and analog power must be supplied by an Isolated Secondary

Limited Energy Low Voltage source.

Page 22

2-8 Chapter 2: Installation and Wiring

User’s Manual Pub. 0300266-02 Rev. B

Grounding

WARNING

USE SUPPLY WIRES SUITABLE FOR 20 °C ABOVE

SURROUNDING AMBIENT TEMPERATURE.

WARNING

UTILISER DES FILS D’ALIMENTATION QUI CONVIENNENT A

UNE TEMPERATURE DE 20 °C AU-DESSUS DE LA

TEMPERATURE AMBIANTE.

• This product is intended to be mounted to a well-grounded mounting

surface such as a metal panel. Additional grounding connections from

the module’s mounting tabs or DIN rail (if used) are not required unless

the mounting surface cannot be grounded.

• Under normal conditions, the drain wire (shield) should be connected to

the metal mounting panel (earth ground). Keep shield connection to earth

ground as short as possible.

• Ground the shield drain wire at one end only. The typical location is as

follows:

- For grounded thermocouples or millivolt sensors, this is at the

sensor end.

- For insulated/ungrounded thermocouples, this is at the module

end. Contact your sensor manufacturer for additional details.

• Refer to Industrial Automation Wiring and Grounding Guidelines, Allen-

Bradley publication 1770-4.1, for additional information.

Noise Prevention

• Route field wiring away from any other wiring and as far as possible

from sources of electrical noise, such as motors, transformers, contactors,

and AC devices. As a general rule, allow at least 15.2 cm (6 in.) of

separation for every 120 V of power.

• Routing field wiring in a grounded conduit can reduce electrical noise.

• If field wiring must cross AC or power cables, ensure that they cross at

right angles.

• If noise persists for a device, try grounding the opposite end of the cable

shield or ground both ends of the shield.

Page 23

Chapter 2: Installation and Wiring 2-9

User’s Manual Pub. 0300266-02 Rev. B

2.5.1 Wiring Diagram

Refer to the following wiring diagrams for field wiring connections.

Table 2-1. Terminal Block Pinout

RTB Pin#

Usage

Usage

RTB

Pin#

0

Ch 0+ (Input 0)

Ch 2+ (Input 1)

1 2 Ch 0- (Input 2)

Ch 2- (Input 3)

3 4 Ch 1+ (Input 4)

Ch 3+ (Input 5)

5 6 Ch 1- (Input 6)

Ch 3- (Input 7)

7

Figure 2-1. Voltage, Current, and Thermocouple

NOTE

The CJC sensor shown in the diagram above can only be installed across

terminals 0 and 2.

Figure 2-2. Three-, and Four-Wire RTD

When measuring a 3-wire RTD, you must make an electrical short at the

terminal block as shown below (see external jumper connection above):

RTD

Drive

RTN

Sense+

Short the following terminals for Sense-

RTD1

0 2 4

2 to 6

RTD2

1 3 5

3 to 7

0

Ch 0+

2

Ch 0-

4

Ch 1+

6

Ch 1-

1

Ch 2+

3

Ch 2-

5

Ch 3+

7

Ch 3-

CJC Sensor

- +

+ -

24 V PWR

Supply

2-wire

XMTR

Thermocouple

Input

4 to 20 mA

Input

Voltage

Input

White

Connector

Blue

Connector

0

Ch 0+

2

Ch 0-

4

Ch 1+

6

Ch 1-

1

Ch 2+

3

Ch 2-

5

Ch 3+

7

Ch 3-

3-wire RTD

External

Jumper

4-wire RTD

Page 24

2-10 Chapter 2: Installation and Wiring

User’s Manual Pub. 0300266-02 Rev. B

Figure 2-3. 2-Wire RTD and Resistance

NOTE

The IF4U supports several input types, and can be configured for one of

the following input combinations:

• 4-Channels Voltage + mV + Current

• 3-Channels Thermocouple

• 2-Channels 3/4-Wire RTD

• 4-Channels 2-Wire RTD/Resistance

• Or a combination of two or more input types listed above (for

example, 1 Channel of Thermocouple and 1 Channel of 3/4-wire

RTD).

2.5.2 System Wiring Configurations

The following table and configuration drawings show you the different wiring

configurations supported by connections to the terminal block. The 3-wire RTD

configurations require you to install an external jumper:

Table 2-2. System Configuration

Configuration

Voltage or

Current (V/I)

Thermocouple

(TC)

RTD/Resistance

(3 and 4-wire)

CJC(s)

1 0 0 2 0 2 2 0 1 0 3 0 1 1 1 4 2 1 0 1 5 1 2 0 1 6 0

34 0 1 7

45 0 0

0

4

Optional configuration

5

Optional configuration

0

Ch 0+

2

Ch 0-

4

Ch 1+

6

Ch 1-

1

Ch 2+

3

Ch 2-

5

Ch 3+

7

Ch 3-

2-wire RTD

or

Resistance

2-wire RTD

or

Resistance

2-wire RTD

or

Resistance

2-wire RTD

or

Resistance

Page 25

Chapter 2: Installation and Wiring 2-11

User’s Manual Pub. 0300266-02 Rev. B

Figure 2-4. System Configuration 1 (4-Wire)

RTD 1 RTD 2

Drive 0

Rtn 0

Sense 0+

Sense 0-

0 1

2 3

4 5

6 7

Drive 2

Rtn 2

Sense 2+

Sense 2-

Terminal Block

Ch 0

Ch 1

Ch 2

Ch 3

#

Terminal Number

Figure 2-5. System Configuration 2 (3-Wire)

RTD 1 RTD 2

Drive 0

Rtn 0

Sense 0+

Sense 0-

0 1

2 3

4 5

6 7

Drive 2

Rtn 2

Sense 2+

Sense 2-

Terminal Block

External jumpers

installed by User

Ch 0

Ch 1

Ch 2

Ch 3

#

Terminal Number

Page 26

2-12 Chapter 2: Installation and Wiring

User’s Manual Pub. 0300266-02 Rev. B

Figure 2-6. System Configuration 3 (3-Wire and 4-Wire are Interchangeable)

RTD 1 RTD 2

Drive 0

Rtn 0

Sense 0+

Sense 0-

0 1

2 3

4 5

6 7

Drive 2

Rtn 2

Sense 2+

Sense 2-

Terminal Block

External jumper

installed by User

Ch 0

Ch 1

Ch 2

Ch 3

#

Terminal Number

Figure 2-7. System Configuration 4 (3-Wire and 4-Wire are Interchangeable)

RTD 1 RTD 2

Drive 0

Rtn 0

Sense 0+

Sense 0-

0 1

2 3

4 5

6 7

Drive 2

Rtn 2

Sense 2+

Sense 2-

Terminal Block

External jumper

installed by User

Ch 0

Ch 1

Ch 2

Ch 3

#

Terminal Number

Page 27

Chapter 2: Installation and Wiring 2-13

User’s Manual Pub. 0300266-02 Rev. B

Figure 2-8. System Configuration 5 (4-Wire RTD with Current or Voltage)

RTD 1 V / I

V / I

Drive 0

Rtn 0

Drive 2

Rtn 2

Drive 3

Rtn 3

Sense 0+

Sense 0-

Terminal Block

0 1

2 3

4 5

6 7

Ch 0

Ch 1

Ch 2

Ch 3

#

Terminal Number

Figure 2-9. System Configuration 6 (3-Wire RTD with Current or Voltage)

RTD 1 V / I

V / I

Drive 0

Rtn 0

Drive 2

Rtn 2

Drive 3

Rtn 3

Sense 0+

Terminal Block

0 1

2 3

4 5

6 7

Sense 0-

External jumper

installed by User

Ch 0

Ch 1

Ch 2

Ch 3

#

Terminal Number

Page 28

2-14 Chapter 2: Installation and Wiring

User’s Manual Pub. 0300266-02 Rev. B

Figure 2-10. System Configuration 7 (4-Wire RTD with Thermocouple)

RTD 2

Drive 2

Rtn 2

Sense 2+

Sense 2-

CJC

TC

Drive 0

Rtn 0

Drive 1

Rtn 1

Terminal Block

0 1

2 3

4 5

6 7

Ch 0

Ch 1

Ch 2

Ch 3

#

Terminal Number

Figure 2-11. System Configuration 8 (3-Wire RTD with Thermocouple)

RTD 2

Drive 2

Rtn 2

Sense 2+

Sense 2-

CJC

TC

Drive 0

Rtn 0

Drive 1

Rtn 1

Terminal Block

0 1

2 3

4 5

6 7

External jumper

installed by User

Ch 0

Ch 1

Ch 2

Ch 3

#

Terminal Number

Page 29

Chapter 2: Installation and Wiring 2-15

User’s Manual Pub. 0300266-02 Rev. B

Figure 2-12. System Configuration 9 Thermocouple with Voltage or Current

V / I

V / I

CJC

TC

Terminal Block

0 1

2 3

4 5

6 7

Ch 0

Ch 1

Ch 2

Ch 3

Drive 0

Rtn 0

Drive 1

Rtn 1

Drive 2

Rtn 2

Drive 3

Rtn 3

#

Terminal Number

Figure 2-13. System Configuration 10 Thermocouple with Voltage or

Current

V / I

TC

CJC

TC

Terminal Block

0 1

2 3

4 5

6 7

Ch 0

Ch 1

Ch 2

Ch 3

Drive 0

Rtn 0

Drive 1

Rtn 1

Drive 2

Rtn 2

Drive 3

Rtn 3

#

Terminal Number

Page 30

2-16 Chapter 2: Installation and Wiring

User’s Manual Pub. 0300266-02 Rev. B

Figure 2-14. System Configuration 11 All Thermocouples

TC

TC

CJC

TC

Terminal Block

0 1

2 3

4 5

6 7

Ch 0

Ch 1

Ch 2

Ch 3

Drive 0

Rtn 0

Drive 1

Rtn 1

Drive 2

Rtn 2

Drive 3

Rtn 3

#

Terminal Number

Figure 2-15. System Configuration 12 All Current or Voltage

V / I

V / I

V / I

V / I

Terminal Block

0 1

2 3

4 5

6 7

Ch 0

Ch 1

Ch 2

Ch 3

Drive 0

Rtn 0

Drive 1

Rtn 1

Drive 2

Rtn 2

Drive 3

Rtn 3

#

Terminal Number

Page 31

User’s Manual Pub. 0300266-02 Rev. B

Chapter 3

Configuring the 1734sc-IF4U

Using RSLogix 5000

This chapter covers the following subjects:

• Introduction

• About Communications

• Using Generic Profile

• Using Add-On Profile (AOP)

• Module Configuration

• Reading Input Data

• Getting Technical Assistance

• Declaration of Conformity

Section 3.1

Introduction

This chapter will describe how to configure the IF4U module using RSLogix

5000 programming software.

Section 3.2

About

Communications

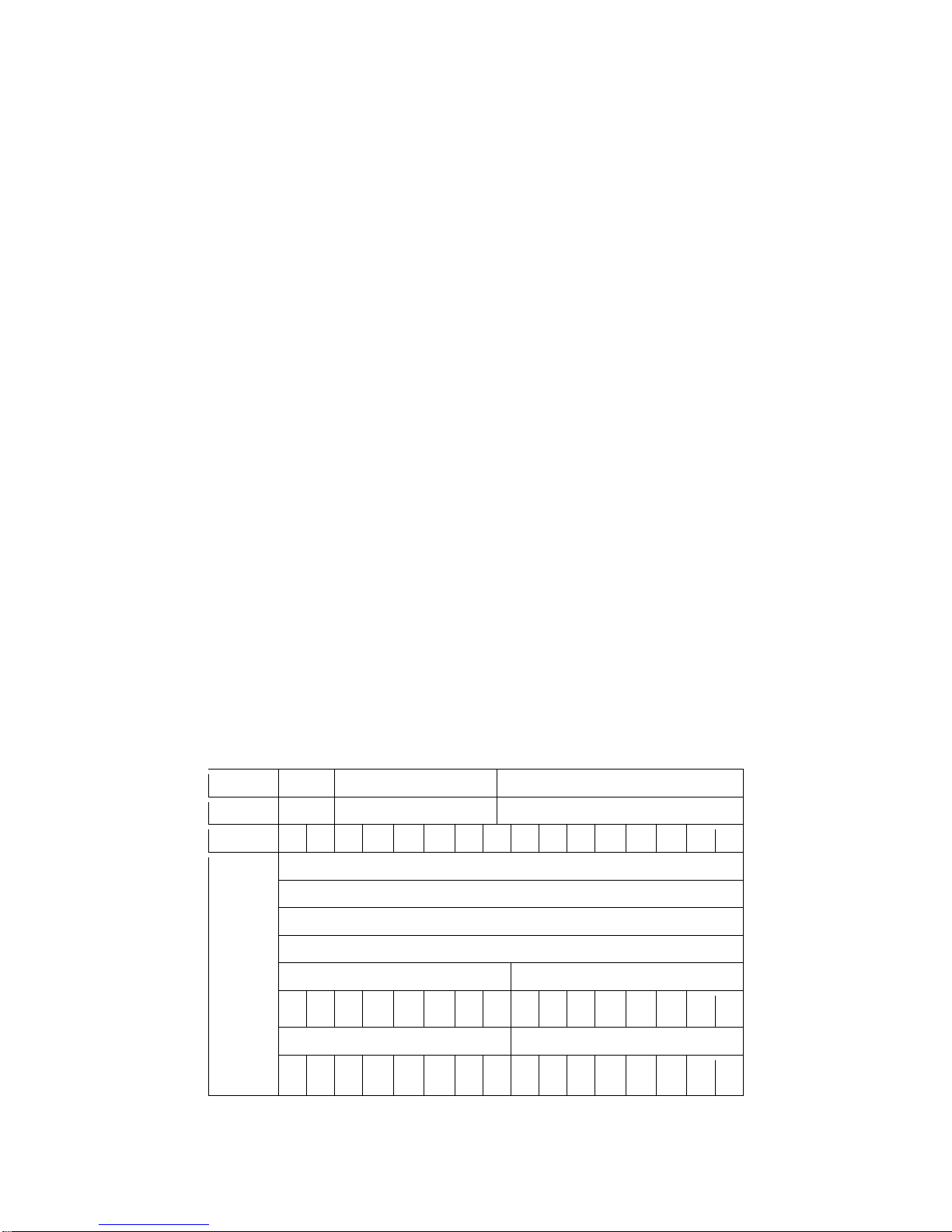

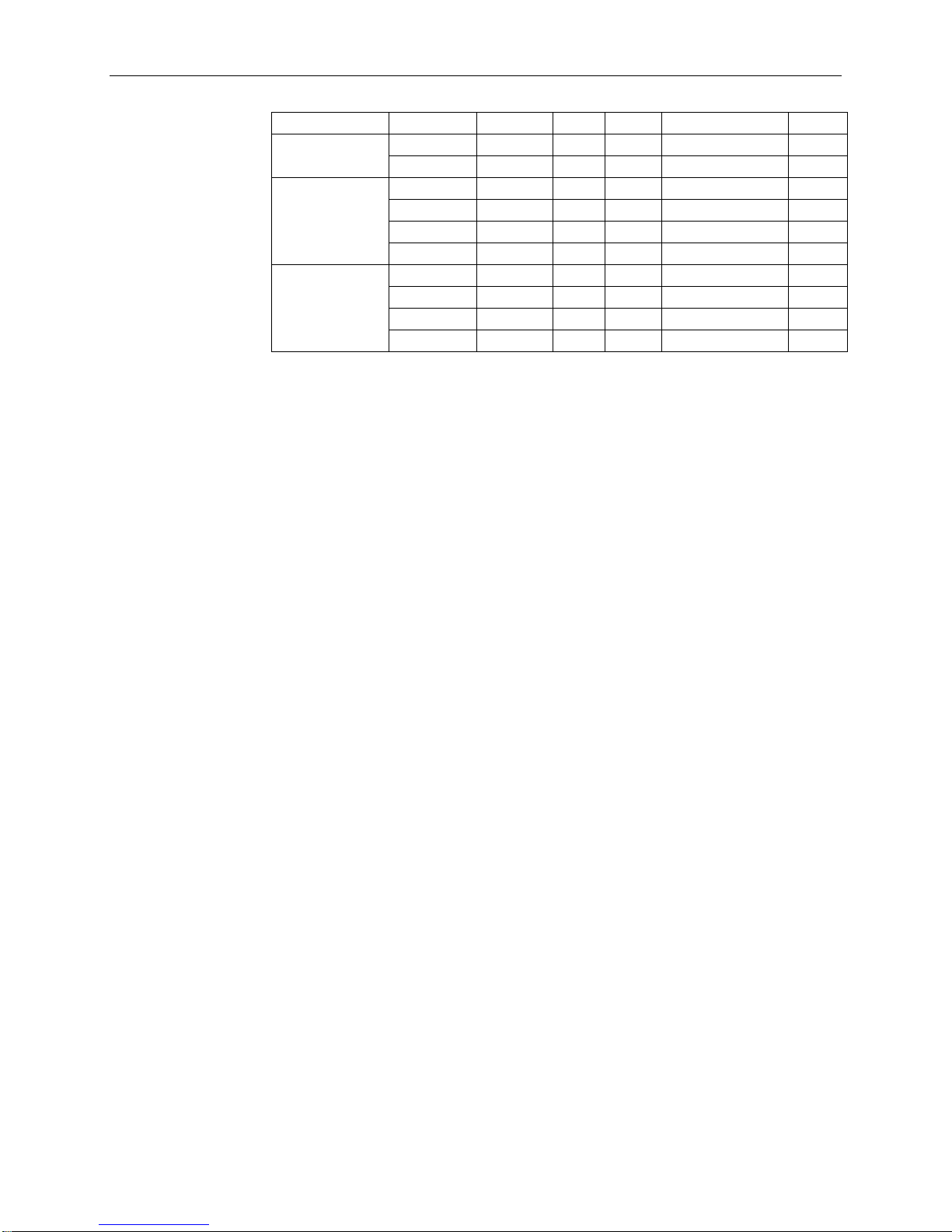

The module produces and consumes data as follows:

IF4U Produce/Consume Data

Instance:

Description:

Total Size:

100 Analog Only

16 Bytes RSL 5K (Dnet 12 bytes)

Bit

15

14

13

12

11

10

09

08

07

06

05

04

03

02

01

00

Analog

data

12 bytes

0×00 0×0B

Channel 0 Data - INT

Channel 1 Data - INT

Channel 2 Data - INT

Channel 3 Data - INT

Status Byte for Channel 1

Status Byte for Channel 0

n/a

n/a

n/a

OC

OR

UR

n/a

CF

n/a

n/a

n/a

OC

OR

UR

n/a

CF

Status Byte for Channel 3

Status Byte for Channel 2

n/a

n/a

n/a

OC

OR

UR

n/a

CF

n/a

n/a

n/a

OC

OR

UR

n/a

CF

Page 32

3-2 Chapter 3: Configuring the 1734sc-IF4U for RSLogix 5000

User’s Manual Pub. 0300266-02 Rev. B

WARNING

The IF4U module is not compatible with the 1734-ADN, ADN(X), and

PDN device net adapters, and the 1734-APB PROFIBUS adapter.

WARNING

The 1734sc-IF4U is not field upgradable.

WARNING

The ControlNet adapter (1734-ACNR) has a maximum data transmit limit

of 600 bytes. Therefore, the maximum number of 1734sc-IF4U modules

that can be installed behind a ControlNet adapter is 14. The maximum

number of modules that can be installed behind an EtherNet adapter

(1734-AENT) is 19.

Section 3.3

Use Generic

Profile

The generic point IO module profile can be used to represent the IF4U module

within RSLogix 5000. The generic profile should be used for RSLogix 5000

versions 14 and older. Before the generic profile can be added to the IO

configuration, the proper communication module needs to be added to the IO

configuration first. To add a communication module to RSLogix 5000:

1. Add the new local communication module to your project.

2. Configure the local module, including:

a. Naming the module.

b. Choosing a Communication Format.

c. Setting the Revision level.

d. Setting the module location as necessary such as the slot number

for a 1756-CNB module.

e. Choosing an Electronic Keying method.

3. Add the new remote module to your project, such as a 1734 Control Net

adapter or Ethernet Adapter (that is, 1734-ACNR or 1734-AENT,

respectively).

4. Configure the remote module similarly to the local module.

5. Download the configuration to the controller.

NOTE

If you are using Control Net, you must schedule the network using

RSNetworks for Control Net after adding the local and remote

communication modules.

Page 33

Chapter 3: Configuring the 1734sc-IF4U for RSLogix 5000 3-3

User’s Manual Pub. 0300266-02 Rev. B

NOTE

When you create a new RSLogix 5000 project with the CompactLogix

1769-L32C or L35CR controller, the Controller Organizer creates a

Control Net port in the local chassis. In this case, you do not need to add a

separate, local communication module.

NOTE

When you create a new RSLogix 5000 project with the CompactLogix

1769-L23E, 1769-L32E or L35E controller, The Controller Organizer

creates an Ethernet port in the local chassis. In this case, you do not need

to add a separate, local communication module.

3.3.1 Add a Local Ethernet Bridge Module

After you have started RSLogix 5000 software and created a controller project,

you can add Ethernet communication modules. A local Ethernet communication

module is a module that resides in the same chassis as the controller.

1. Select a New Module for the I/O Configuration.

2. Select the module type from the Select Module type pop-up.

Right-click on I/O

Configuration

Select New Module

Page 34

3-4 Chapter 3: Configuring the 1734sc-IF4U for RSLogix 5000

User’s Manual Pub. 0300266-02 Rev. B

The example below uses a 1756-ENBT module:

3. Configure the local Ethernet bridge module:

Click OK

Select the local Ethernet

bridge module

Name the module

Select the module’s slot number

Enter IP address of ENBT

Select the module’s revision

level

Select electronic keying level

Click OK

Page 35

Chapter 3: Configuring the 1734sc-IF4U for RSLogix 5000 3-5

User’s Manual Pub. 0300266-02 Rev. B

3.3.2 Add a Remote Ethernet Point IO Adapter

After you have added the local Ethernet communication module, you must add

remote Ethernet communication modules. A remote Ethernet module is a module

that resides in a separate chassis from the controller.

NOTE

If you plan to use the 1734 Control Net adapter, you will need to install

the 1734sc-IF4U EDS file before scheduling the network. The latest EDS

files can be found at (www.spectrumcontrols.com).

1. Select a New Module for the I/O Configuration:

Right-click on the local

communication module

Select New Module

Page 36

3-6 Chapter 3: Configuring the 1734sc-IF4U for RSLogix 5000

User’s Manual Pub. 0300266-02 Rev. B

2. Select the module type from the Select Module type pop-up:

3. Configure the remote Ethernet communication module:

Select the remote Ethernet

communication module.

Click OK

Name the module

Select the Comm. Format

Enter IP address of ENBT

Select the chassis size

Select electronic keying level

Click OK

Select the module revision

level

Page 37

Chapter 3: Configuring the 1734sc-IF4U for RSLogix 5000 3-7

User’s Manual Pub. 0300266-02 Rev. B

3.3.3 Add the Generic Point IO Module

After adding the remote Ethernet communication module, the 1734 Generic

Module must be added. The following steps must be followed to add the 1734

Generic IO Module:

1. Select a New Module for the I/O Configuration:

2. Select the module type from the Select Module type pop-up:

Right-click on the

remote communication

Select New Module

Select Generic

Module

Click OK

Page 38

3-8 Chapter 3: Configuring the 1734sc-IF4U for RSLogix 5000

User’s Manual Pub. 0300266-02 Rev. B

3. Configure the Generic 1734 Module (that is, 1734sc-IF4U):

Section 3.4

Use

Add-On-Profile

For RSLogix 5000 version 15 and greater, an Add-On module profile is available

for download at (www.spectrumcontrols.com). The Add-On profile allows the

user to add the IF4U module to the RSLogix 5000 module pick list. The profile

provides configuration and information screens to the user to simplify

installation. Follow the procedure below to install and use the Add-On profile.

3.4.1 Installing the Add-On Profile

1. Download the zipped file from the Spectrum Controls website and unzip

the file (www.spectrumcontrols.com).

2. Open the created folder and double-click on the MPSetup.exe file.

3. Follow the online prompts.

Name the module

Enter Input Data – SINT

for Comm. Format

Enter module slot #

Enter the input assembly

instance and size

Enter the output

assembly (always 190)

Enter the configuration

assembly instance and

size

Click OK

Page 39

Chapter 3: Configuring the 1734sc-IF4U for RSLogix 5000 3-9

User’s Manual Pub. 0300266-02 Rev. B

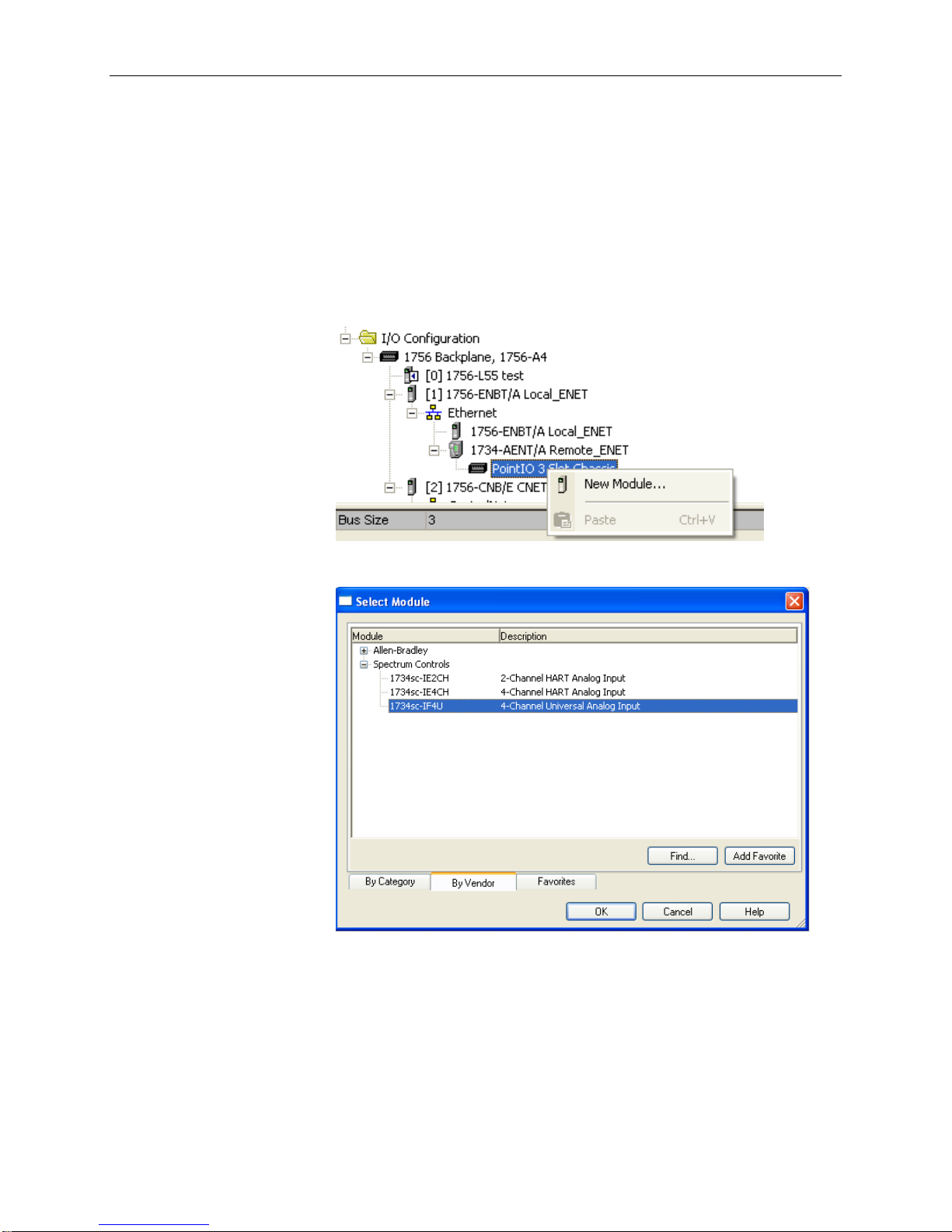

3.4.2 Adding the IF4U Module to Your Logix Project

Once the profiles are installed, you can access them through RSLogix 5000 via

the I/O Configuration. Follow the procedure below to add a module:

1. Before you can add the 1734sc-IF4U to your RSLogix 5000 project, you

must first add a local communication module and a remote

communication adapter. Complete sections 3.3.1 and the relevant listed

steps above, before proceeding to step 2 below.

2. In the I/O Configuration, right mouse click on the Point IO backplane

under the remote communication adapter that you added in step 1 above

and select New Module.

3. When the dialog screen opens, select the By Vendor tab and expand the

Spectrum Controls folder:

4. Highlight the module and press the OK button.

Page 40

3-10 Chapter 3: Configuring the 1734sc-IF4U for RSLogix 5000

User’s Manual Pub. 0300266-02 Rev. B

5. Give the module a unique name:

6. Enter an RPI Rate:

7. Configure the rest of the module using the Module Configuration tab.

Section 3.5

Module

Configuration

The IF4U can be configured using the AOP or by using the 1734 generic module

profile. The configuration tags for the IF4U are located under the controller tags.

The following examples describe the tag structure allocated by the Generic

Module profile and the AOP.

Name the module

Set the RPI rate

Page 41

Chapter 3: Configuring the 1734sc-IF4U for RSLogix 5000 3-11

User’s Manual Pub. 0300266-02 Rev. B

Generic Module Profile:

[Name of remote communication module]:e:x.Data[0 to 198]

e = IF4U slot number

x = Image Type (i.e. C, I, or O)

AOP (Add-On-Profile):

[Name of remote communication module]:e:x

e = IF4U slot number

x = Image Type (i.e. C, I, or O)

NOTE

The AOP will provide a predefined tag structure for the configuration. See

example below.

Figure 3-1. AOP Config. Tags

Table 3-1. IF4U Configuration Assembly

Instance:

225 (0×E1)

Size:

12 bytes RSL 5K (DNET 8 bytes)

OFFSET

FIELD

TYPE

BYTES

0×00

Channel 0 Configuration

(See Channel Configuration Details below)

INT

2

0×02

Channel 1 Configuration (Same as above)

INT

2

0×04

Channel 2 Configuration (Same as above)

INT

2

0×06

Channel 3 Configuration (Same as above)

INT

2

Page 42

3-12 Chapter 3: Configuring the 1734sc-IF4U for RSLogix 5000

User’s Manual Pub. 0300266-02 Rev. B

3.5.1 Channel Configuration Details

To Select

Make these bit settings

15

14

13

12

11

10

09

08

07

06

05

04

03

02

01

00

Channel Enable

Enable (Default)

0

Disable

1

Filter Frequency

(Ignored if Display CJC)

17 Hz (Default)

0 0 4 Hz 0 1

62 Hz 1 0

470 Hz

1 1

CJC Disable

Enable (Default)

0

Disable

1

Open Circuit

(Ignored if Display CJC)

Upscale (Default)

0 0 Downscale

0 1 Zero 1 0

N/A 1 1

Input Type

-10 to 10 V Default

0 0 0 0 0

0 to 10 V

0 0 0 0 1 1 to 5 V

0 0 0 1 0 0 to 5 V

0 0 0 1 1

±1 V 0 0 1 0 0

±100 mV

0 0 1 0 1 ±50 mV

0 0 1 1 0 4 to 20 mA

0 0 1 1 1 0 to 20 mA

0 1 0 0 0 Type J TC

0 1 0 0 1

Type K TC

0 1 0 1 0

Type T TC

0 1 0 1 1 Type E TC

0 1 1 0 0 100 Pt 385

0 1 1 0 1 1000 Pt 385

0 1 1 1 0 100 Pt 3916

0 1 1 1 1

1000 Pt 3916

1 0 0 0 0

3000 ohm

1 0 0 0 1 CJC 1 0 0 1 0

Data Format

Eng. Units ×1 (Default)

0 0 Eng. Units ×10

0 1 Raw/Proportional Data

1 0

Scaled for PID

1 1

2/3/4 Wire RTD

(Only valid for RTD/R

ranges)

3 Wire w/ Comp (Default)

0 0 4 Wire

0 1 2 Wire

1 0

Temperature Scale

(Only valid for

temperature ranges)

Degrees C (Default)

0

Degrees F

1

Page 43

Chapter 3: Configuring the 1734sc-IF4U for RSLogix 5000 3-13

User’s Manual Pub. 0300266-02 Rev. B

Channel Disable (Bit 0)

Enable (Default) = 0, Disable = 1. If the channel is disabled, all other fields are

ignored.

Filter Frequency (Bits 1 and 2)

The filter selection affects how the module attenuates the input signal at the

specified frequency. It also affects the update time of the input data which is

reflected in the minimum conversion time for each channel. Lower filter

frequencies are recommended for RTD and Thermocouple modes. The total

update time for the module can be calculated using the table below. Default

setting is 17 Hz.

Table 3-2. Channel Conversion Time

ADC Filter Name

(Update Frequency)

Conversion

Time

Step Response/Module update

Rate6

470 Hz

37 ms

= Sum of conversion times for each

enabled channel

62 Hz

65 ms

17 Hz

153 ms

4 Hz

512 ms

Example:

Channels 0/1 are configured for 3-wire RTD and 4 Hz filter:

Channel 2 is configured for 17 Hz voltage.

Channel 3 is configured for 62 Hz current.

The RTD channel pair has a conversion time of 1024 ms (512*2).

The module scan time will be 1024+153+62 = 1239 ms

3.5.2 RTD Accuracy

The RTD Algorithms used have a curve-fit accuracy that is generally within two

to three decimal places of a degree C across the span of measured resistance

ranges. This conversion accuracy has little effect on the final result. RTD

conversion is therefore heavily dependent on its ability to accurately measure

resistance.

CJC Disable (Bit 3)

When this bit is set, no CJC compensation is applied to the channel if it is

configured as a thermocouple. Default setting is enabled.

Open Circuit Response (Bits 4 and 5)

The open circuit response defines the state of the channel data when an open-

6

The module update time is purely the sum of the conversion times for each enabled channel except

when a channel is configured for a 3-wire RTD. For each channel configured for a 3-wire RTD, double

the conversion time.

Page 44

3-14 Chapter 3: Configuring the 1734sc-IF4U for RSLogix 5000

User’s Manual Pub. 0300266-02 Rev. B

circuit or short-circuit condition is detected. Default setting is upscale.

Response Option

Definition

Upscale

Sets the input data value to full-scale value. The full-scale

value is determined by the selected input type and data

format.

Downscale

Sets the input data value to minimum-scale value. The

minimum-scale value is determined by the selected input

type and data format.

Zero

Sets the input data value to zero (0).

Input Type (Bits 6 through 10)

These bits specify the input type for each channel. If channel 0 or 2 is configured

for multi-wire RTD, the configuration for the adjacent odd channel (1, 3) is

ignored. It is recommended to configure both channels identically (0 and 1, 2,

and 3) when using multi-wire RTD. This reduces confusion in the setup. A zero

will be reported for the adjacent odd channel in multi-wire RTD. The ±10 V

range is the default input type for each IF4U channel.

Data Format (Bits 11 and 12)

Data Format dictates how the data is presented. Engineering Units ×1 is the

default.

Table 3-3. Data Formats

Input Range

Input Value

Condition

EU ×1

EU ×10

Raw Prop

PID

E Type TC

1000.00 °C

High Limit

10000

1000

32767

16383

1000.00 °C

High Range

10000

1000

32767

16383

-270.00 °C

Low Range

-2700

-270

-32768

0

-270.00 °C

Low Limit

-2700

-270

-32768

0

J Type TC

1200.00 °C

High Limit

12000

1200

32767

16383

1200.00 °C

High Range

12000

1200

32767

16383

-210.00 °C

Low Range

-2100

-210

-32768

0

-210.00 °C

Low Limit

-2100

-210

-32768

0

K Type TC

1370.00 °C

High Limit

13700

1370

32767

16383

1370.00 °C

High Range

13700

1370

32767

16383

-270.00 °C

Low Range

-2700

-270

-32768

0

-270.00 °C

Low Limit

-2700

-270

-32768

0

T Type TC

400.00 °C

High Limit

4000

400

32767

16383

400.00 °C

High Range

4000

400

32767

16383

-270.00 °C

Low Range

-2700

-270

-32768

0

-270.00 °C

Low Limit

-2700

-270

-32768

0

RTD

100 Ohm Pt 0.385

850.00 °C

High Limit

8500

850

32767

16383

850.00 °C

High Range

8500

850

32767

16383

-200.00 °C

Low Range

-2000

-200

-32768

0

-200.00 °C

Low Limit

-2000

-200

-32768

0

RTD

1000 Ohm Pt 0.385

850.00 °C

High Limit

8500

850

32767

16383

850.00 °C

High Range

8500

850

32767

16383

Page 45

Chapter 3: Configuring the 1734sc-IF4U for RSLogix 5000 3-15

User’s Manual Pub. 0300266-02 Rev. B

Input Range

Input Value

Condition

EU ×1

EU ×10

Raw Prop

PID

-200.00 °C

Low Range

-2000

-200

-32768

0

-200.00 °C

Low Limit

-2000

-200

-32768

0

RTD

100 Ohm Pt 0.392

630.00 °C

High Limit

6300

630

32767

16383

630.00 °C

High Range

6300

630

32767

16383

-200.00 °C

Low Range

-2000

-200

-32768

0

-200.00 °C

Low Limit

-2000

-200

-32768

0

RTD

1000 Ohm Pt 0.392

630.00 °C

High Limit

6300

630

32767

16383

630.00 °C

High Range

6300

630

32767

16383

-200.00 °C

Low Range

-2000

-200

-32768

0

-200.00 °C

Low Limit

-2000

-200

-32768

0

Resistance

0..3000 Ohms

3000.00 ohms

High Limit

30000

3000

32767

16383

3000.00 ohms

High Range

30000

3000

32767

16383

0.00 ohms

Low Range

0 0 -32768

0

0.00 ohms

Low Limit

0 0 -32768

0

±50 mV

52.50 mV

High Limit

5250

525

Clipped

16793

50.00 mV

High Range

5000

500

32767

16383

-50.00 mV

Low Range

-5000

-500

-32768

0

-52.50 mV

Low Limit

-5250

-525

Clipped

-410

±100 mV

105.00 mV

High Limit

10500

1050

Clipped

16793

100.00 mV

High Range

10000

1000

32767

16383

-100.00 mV

Low Range

-10000

-1000

-32768

0

-105.00 mV

Low Limit

-10500

-1050

Clipped

-410

0..5 V

5.25 VDC

High Limit

5250

525

Clipped

17202

5.00 VDC

High Range

5000

500

32767

16383

0.00 VDC

Low Range

0 0 -32768

0

0.00 VDC

Low Limit

0 0 -32768

0

10..5 V

5.25 VDC

High Limit

5250

525

Clipped

17407

5.00 VDC

High Range

5000

500

32767

16383

1.00 VDC

Low Range

1000

100

-32768

0

0.50 VDC

Low Limit

500

50

Clipped

-2048

±10 V

(IF4U only)

10.50 V dc

High Limit

10500

1050

Clipped

16793

10.00 V dc

High Range

10000

1000

32767

16383

-10.00 V dc

Low Range

-10000

-1000

-32768

0

-10.50 V dc

Low Limit

-10500

-1050

Clipped

-410

0..10 V

(IF4U only)

10.50 V dc

High Limit

10500

1050

Clipped

17202

10.00 V dc

High Range

10000

1000

32767

16383

0.00 V dc

Low Range

0 0 -32768

0

0.00 V dc

Low Limit

0 0 -32768

0

0.00 VDC

0 0 -32768

0

0

±1 V

1.05 VDC

High Limit

10500

1050

Clipped

16793

1.00 VDC

High Range

10000

1000

32767

16383

-1.00 VDC

Low Range

-10000

-1000

-32768

0

-1.05 VDC

Low Limit

-10500

-1050

Clipped

-410

4..20 mA

21.00 mA

High Limit

21000

2100

Clipped

17407

20.00 mA

High Range

20000

2000

32767

16383

Page 46

3-16 Chapter 3: Configuring the 1734sc-IF4U for RSLogix 5000

User’s Manual Pub. 0300266-02 Rev. B

Input Range

Input Value

Condition

EU ×1

EU ×10

Raw Prop

PID

4.00 mA

Low Range

4000

400

-32768

0

3.00 mA

Low Limit

3000

300

Clipped

-1024

0..20 mA

21.00 mA

High Limit

21000

2100

Clipped

17202

20.00 mA

High Range

20000

2000

32767

16383

0.00 mA

Low Range

0 0 -32768

0

0.00 mA

Low Limit

0 0 -32768

0

CJC

85.00 °C

High Limit

8500

850

Clipped

16383

85.00 °C

High Range

8500

850

32767

16383

-25.00 °C

Low Range

-2500

-250

-32768

0

-25.00 °C

Low Limit

-2500

-250

Clipped

0

2/3/4 Wire RTD (Bits 13 and 14)

These bits are used for RTD and Resistance modes only. They are used to specify

2-, 3-, or 4-wire RTD modes. This setting is ignored for non-resistance/RTD

input types. Default setting is 3-wire.

Temperature Scale (Bit 15)

Set to 1 to display degrees Fahrenheit. Otherwise 0 displays temperature in

degrees Celsius (default). This field is ignored for non-temperature ranges.

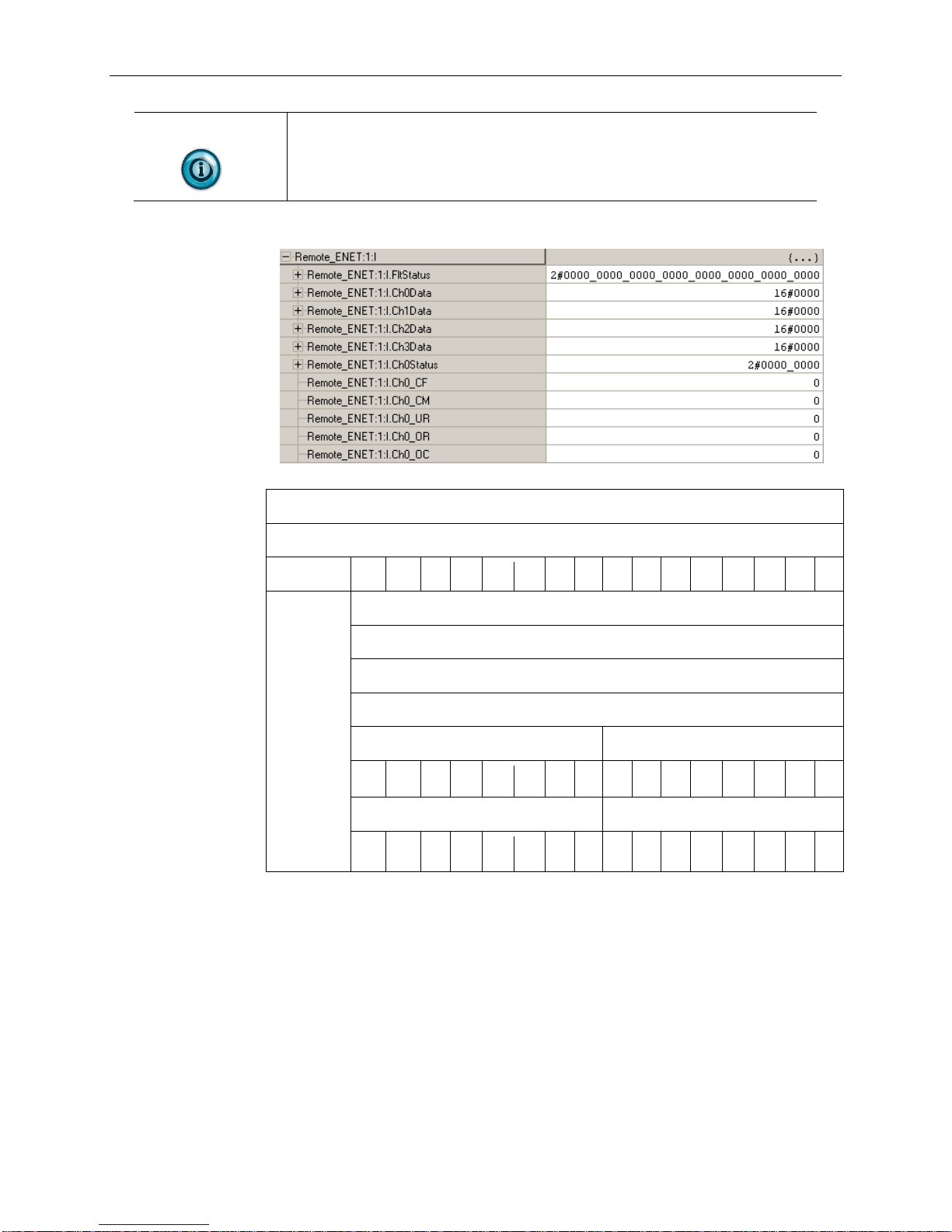

Section 3.6

Read Input

Data

The input data file contains module status information and analog input data for

each of the input channels. Analog input data is read for each channel, converted

to a scaled digital value, and stored in the input tags. The input tags for the IF4U

are located under the controller tags. The following examples describe the tag

structure allocated by the Generic Module profile and the AOP.

Generic Module Profile:

[Name of remote communication module]:e:x.Data[0 to 198]

e = IF4U slot number

x = Image Type (that is, C, I, or O)

AOP (Add-On-Profile):

[Name of remote communication module]:e:x

e = IF4U slot number

x = Image Type (i.e. C, I, or O)

Page 47

Chapter 3: Configuring the 1734sc-IF4U for RSLogix 5000 3-17

User’s Manual Pub. 0300266-02 Rev. B

NOTE

The AOP will provide a predefined tag structure for the configuration. See

example below.

Figure 3-2. AOP Input Tags

Table 3-4. IF4U Input Assembly

Instance:

Description:

Total Size:

100 Analog Only

16 Bytes RSL 5K (Dnet 12 bytes)

Bit

15

14

13

12

11

10

09

08

07

06

05

04

03

02

01

00

Analog data

12 bytes

0×00-0×0B

Channel 0 Data - INT

Channel 1 Data - INT

Channel 2 Data - INT

Channel 3 Data - INT

Status Byte for Channel 1

Status Byte for Channel 0

n/a

n/a

n/a

OC

OR

UR

n/a

CF

n/a

n/a

n/a

OC

OR

UR

n/a

CF

Status Byte for Channel 3

Status Byte for Channel 2

n/a

n/a

n/a

OC

OR

UR

n/a

CF

n/a

n/a

n/a

OC

OR

UR

n/a

CF

3.6.1 Input Assembly Status Bit Definitions

Under Range and Over Range trip points are determined by the Low Range and

High Range values in the Table 3-3. Data Formats.

The CF bit is set when any of the other status bits are set.

CF = Channel Fault status; 0 = no error, 1 = fault

UR = Underrange; 0 = no error, 1 = fault

OR = Overrange; 0 = no error, 1 = fault

OC = Open Circuit: 0 = no error, 1 = fault (not valid for all ranges)

n/a = Always 0.

Page 48

3-18 Chapter 3: Configuring the 1734sc-IF4U for RSLogix 5000

User’s Manual Pub. 0300266-02 Rev. B

Section 3.7

Getting Technical

Assistance

Note that your module contains electrostatic components that are susceptible to

damage from electrostatic discharge (ESD). An electrostatic charge can

accumulate on the surface of ordinary wrapping or cushioning material. In the

unlikely event that the module should need to be returned to Spectrum

Controls Inc., please ensure that the unit is enclosed in approved ESD

packaging (such as static-shielding/metallized bag or black conductive

container). Spectrum Controls, Inc. reserves the right to void the warranty on

any unit that is improperly packaged for shipment.

RMA (Return Merchandise Authorization) form required for all product returns.

For further information or assistance, please contact your local distributor, or call

the Spectrum Controls Technical Support at:

For Rockwell Automation Compatible I/O Products:

USA (1) 440-646-6900

United Kingdom (44) 01908 635230

Australia 1800-809-929

Mexico 001-888-365-8677

Brazil (55) 11 3618 8800

Europe +49 211 41553 630

Section 3.8

Declaration of

Conformity

Available upon request

Page 49

User’s Manual Pub. 0300266-02 Rev. B

Appendix A

Module Specifications

General Specifications

Parameter

Specification

Module location

1734-TBxx

PointBus current

15 mA

Power dissipation

0.6 W maximum at 28.8 VDC

Thermal dissipation

2.0 BTU/hr maximum at 28.8 VDC

Isolation Voltage

50 V (continuous), Basic Insulation Type from Controller

to Field (Field Inputs are not isolated from Field Power)

Channel-to-Channel,

Low Level, Nongalvanic Isolation

10 VDC measured between the IN- leads (5 VDC if using

±10 V range). Maximum voltage between any two pins

must be limited to 24 VDC. The allowed voltage on any

Input pin from Field Ground is ±11 V.

External DC power

Supply Voltage

Voltage Range

Supply Current

24 VDC nominal

10..28.8 VDC

20 mA at 24 VDC

Dimensions (H × W

× D), approx.

56 × 12 × 75.5 mm (2.21 × 0.47 × 2.97 in.)

Key switch position

3

Enclosure type rating

None (open-style)

Wire size

Determined by installed terminal block

Wiring category

2–on signal ports

Wire type

Shielded

Terminal base screw

torque

Determined by installed terminal block

Weight, approx.

35 g (1.235 oz.)

Page 50

A-2 Appendix A: Module Specifications

User’s Manual Pub. 0300266-02 Rev. B

Input Specifications

Input

Specification

Inputs per module

System Configuration 1: 2 each 4-/3-/2-wire RTDs/Resistors

System Configuration 2: 2 each V/I, 1 each 4-/3-/2-wire RTD/Resistor

System Configuration 3: 1 each TC, 1 each 4-/3-/2-wire RTD/Resistor, 1

each CJC

System Configuration 4: 2 each V/I, 1 each TC, 1 each CJC

System Configuration 5: 1 each V/I, 2 each TC, 1 each CJC

System Configuration 6: 3 each TC, 1 each CJC

System Configuration 7: 4 each V/I

Resolution

18 Bits

ADC Type

Sigma Delta

CMRR

>96 dB Typical with 4 Hz and 17 Hz filters

NMRR

4 Hz Filter 74 dB minimum at 50 and 60 Hz

17 Hz Filter 65 dB minimum at 50 and 60 Hz

62 Hz Filter First notch at 31 Hz, typically 30 dB

470 Hz Filter First notch at 237 Hz, typically 35 dB

Input ranges

0-20 mA, 4-20 mA, ±50 mV, ±100 mV, 0-5 V, 1-5 V, 0-10 V, ±10 V,

types J, K, T, E thermocouple, 100 Ω and 1000 Ω PT385 and PT3916,

3000 Ω resistance.

pH sensor ±1 V

Input Impedance Tolerances

Current Impedance: 253.0 ±4.5% ohms

Voltage Impedance: ±5.5% ohms

IF4U: 5.0 Mohms at 10 Vin, 650 Kohms at 1 Vin

Cable/Lead Resistance

(applies to 3 and 4-wire RTD &

resistance measurements)

2 Ohms maximum (equivalent to 300 ft., 18 AWG) to guarantee

published accuracy.

Data Format

Signed integer

Maximum overload

Fault protected to 24 VDC

Calibration

Factory calibrated, user calibration not supported

Indicators

1 green/red module status LED

1 green/red network status LED

4 green/red input status LEDs

1 green/red module status LED

1 green/red network status LED

2 green/red input status LEDs

Page 51

Appendix A: Module Specifications A-3

User’s Manual Pub. 0300266-02 Rev. B

Input

Specification

Thermocouple Inputs

Linearization per ITS-90, The limits do not include the cold junction

compensation or thermocouple sensor errors.

System accuracy at 25 °C (Using 4 Hz and 17 Hz filters)

Type J: ±0.6 °C maximum

Type T (-190 °C to 400 °C): ±1 °C maximum

Type T (-270 °C to -190 °C): ±7 °C maximum

Type K (-200 °C to 1370 °C): ±1 °C maximum

Type K (-270 °C to -200 °C): ±10 °C maximum

Type E (-200 °C to 1000 °C): ±0.6 °C maximum

Type E (-270 °C to -200 °C): ±5 °C maximum

System accuracy at 0 °C to +55 °C (Using 4 Hz and 17 Hz filters)

Type J ±1.2 °C maximum

Type T (-190 °C to 400 °C): ±2 °C maximum

Type T (-270 °C to -190 °C): ±14.0 °C maximum

Type K (-200 °C to 1370 °C): ±2 °C maximum

Type K (-270 °C to -200 °C): ±20 °C maximum

Type E (-200 °C to 1000 °C): ±1.2 °C maximum

Type E (-270 °C to -200 °C): ±10 °C maximum

CJC profile accuracy

±3 ºC maximum

CJC Sensor resolution

±0.4 ºC maximum for 0 to 60 ºC

CJC Sensor accuracy

±1 ºC maximum

Voltage Inputs

System accuracy at 25 ºC (Using 4 Hz and 17 Hz filters)

±20 µV maximum for ±50 mV inputs

±20 µV maximum for ±100 mV inputs

±3 mV maximum for the pH Sensor (±1.0 V range)

±3 mV maximum for 0-5 V inputs

±3 mV maximum for 1-5 V inputs

±10 mV maximum for 0-10 V inputs

±10 mV maximum for ±10 V inputs

System accuracy at 0 °C to +55 °C (Using 4 Hz and 17 Hz filters)

±40 µV maximum for ±50 mV inputs

±40 µV maximum for ±100 mV inputs

±6 mV maximum for the pH Sensor (±1.0 V range)

±6 mV maximum for 0-5 V inputs

±6 mV maximum for 1-5 V inputs

±20 mV maximum for 0-10 V inputs

±20 mV maximum for ±10 V inputs

Page 52

A-4 Appendix A: Module Specifications

User’s Manual Pub. 0300266-02 Rev. B

Input

Specification

Current Inputs

System accuracy at 25 ºC (Using 4 Hz and 17 Hz filters)

±20 µA maximum for 0-20 mA inputs

±20 µA maximum for 4-20 mA inputs

System accuracy at 0 °C to 55 ºC (Using 4 Hz and 17 Hz filters)

±50 µA maximum for 0-20 mA inputs

±50 µA maximum for 4-20 mA inputs

IF4U

RTD Inputs

System accuracy at 25 ºC (Using 4 Hz and 17 Hz filters)

±0.5 ºC for 1000 Ω Platinum 385 and 3916

±0.8 ºC for 100 Ω Platinum 385 and 3916