Page 1

16-Channel Universal Analog Input Module

(Catalog No. 140 AUI 040 00sc)

Installation Instructions

Document No. 0300180-02 Rev. B

Page 2

16-Channel Universal Analog Input Module

PREFACE

+ Note: Power, input and output (I/O) wiring must be in accordance with Class 1, Division 2 wiring methods

[Article 501-4 (b) of the National Electrical Code, NFPA 70] and in accordance with the authority having

jurisdiction.”

+ Note: Peripheral equipment must be suitable for the location in which it is used.

WARNING

ELECTROSTATICALLY SENSITIVE COMPONENTS

EXPLOSION HAZARD

Substitution of components may impair suitability for Class 1, Division 2.

WARNING

EXPLOSION HAZARD

Do not disconnect equipment unless power has been switched off or the area is known to be non

hazardous.

WARNING

This equipment is suitable for use in Class 1, Division 2, Groups A, B, C, and D or non-hazardous

locations only.

WARNING

EXPLOSION HAZARD

When in hazardous locations, turn off power before replacing or wiring modules.

Page 3

Quantum Series 140 AUI 040 00sc

Page 4

16-Channel Universal Analog Input Module

Contents

Chapter 1 - OVERVIEW 7

1.1 .................................................................................................................Inputs 8

1.2 ..................................................................................................................LEDs 9

1.3 ......................................................................................... Related Publications 9

Chapter 2 - MODULE SETUP FOR MODSOFT 11

2.1 ......................................................................................... General Information 11

2.2 ...................................................................... Installation of new run time files 11

2.3 ........................General information on data register usage and terminology: 12

2.4 ............................................................................. Zoom Sc reen Configuration 12

2.5 ...............................................................................4X Register Configuration 15

Chapter 3 - MODULE SETUP FOR CONCEPT 17

3.1 ......................................................................................... General Information 17

3.2 ...................................................................... Installation of new run time files 17

3.3 ........................General information on data register usage and terminology: 17

3.4 ............................................................. Concept I/O Map Module Parameters: 18

3.5 ................................................................. Spectrum I/O Configuration Utility 22

3.6 ............................................................................. SCIOCFG.EXE Installation: 22

Chapter 4 - MODULE CONFIGURA TION AND STA TUS 25

4.2 ..................................................... Module status information (Register 3x+8) 26

4.3 ............................................. Channel Status (Registers 3x+ 0 through 3x+7) 28

Chapter 5 - INST ALLATION 31

5.1 ..................................................................................................... Field Wiring 33

5.2 .............................................................................................. RTD Field wiring 33

5.3 ....................................................................... CJC Thermocouple Installation 34

Chapter 6 - APPLICATION NOTES 37

6.1 .................................................................................. General Application Tips 37

6.2 ....................................... Demultiplexing Channel Data - Autosequence Mode 37

6.3 ................... Using ladder to move data to a block of 16 consecutive registers 37

6.4 .........................................................................................Channel Update Rate 39

6.5 ...........................System Resolution and Accuracy - V oltage /Curr ent Modes 40

Chapter 7 - TROUBLESHOOTING 43

7.1 ......................................................................................... General Information 43

Chapter 8 - SPECIFICA TIONS 47

1.1 ...................................................................................Electrical Specifications 47

1.1A Table - Thermocouple Accuracy................................................................48

1.2 .......................................................................................System Specifications 50

1.3 ........................................................................... Environmental Specifications 50

Page 5

Quantum Series 140 AUI 040 00sc

Page 6

16-Channel Universal Analog Input Module

Chapter 1

OVERVIEW

The 140 AUI 040 00sc is a universal analog input module with 16 channels of input.

The module will accept voltage, current, resistance, thermocouple and RTD inputs. The voltage, current,

resistance and thermocouple inputs are divided into four groups of four inputs each. RTD inputs are divided

into 4 groups of 2 inputs each. Any combination of inputs may be used so long as they are configured on a

group basis. Each input has 12.5V of isolation from the other inputs. All inputs have 1000V DC isolation

channel-to-backplane.

This module has been designed for projects that include large quantities of analog and temperature inputs.

Process control and data acquisition applications for industries such as utilities, waste water, oil and gas, food

and beverage, and building automation are ideally suited for this module.

Input channels include over voltage circuit protection, over and under range detection and active notch

filtering. The modulde has open circuit detection for thermocouple inputs and both open and short circuit

detection for R TD inputs. The voltage mode of the module handles eight different voltage ranges and the

current mode handles three current ranges. Eight types of thermocouple inputs are supported. Sixteen types

of R TD inputs and four resistance input ranges are supported. You can configure the module to provide data in

one of four data formats. Set up of the module is very simple through the use of configuration and status

registers using Concept, Modsoft or Taylor programming software.

7

Page 7

Quantum Series 140 AUI 040 00sc

1.1 Inputs

The 16 Channels are separated into four groups of four. Each group can be configured for a different voltage,

current range, resistance, thermocouple and RTD range. The ranges available are as follows:

Current Ranges

• 4 to 20 mA, 0 to 20 mA, ±20mA

Voltage Ranges:

• ±0.05VDC, ±0.5VDC, ±2.0VDC, ±5VDC, ±10VDC, 0-10VDC, 0-5VDC, 1-5VDC

Resistance Ranges

• 150, 490, 980, 3000 ohm

Thermocouple Types

• Type J, K , T, E, R, S, B, N

RTD Types

• 100, 200, 500 and 1KΩ Pt Alpha 385,

100, 200, 500, and 1KΩ Pt Alpha 392,

100, 200, 500, and 1KΩ Nickel,

10Ω Copper 426,

120Ω Nickel 672, 604Ω Nickel/Iron 518.

The module can provide data to the PLC in the following formats:

• 12 bit (0 to 4095)

• signed 15 bit (-32768 to +32767)

• unsigned 16 bit (0 to 65535)

• DVM (0 to 10000)

Input Resistance 10MΩ nominal (V oltage)

250Ω nominal (Current)

8

Page 8

16-Channel Universal Analog Input Module

1.2 LEDs

The module has a front LED panel that includes 19 LEDs:

Ready LED - 1 Green LED indicates module’s self test has passed and is ready to communicate.

Active LED - 1 Green LED indicates BUS communication is established between the module and the rack.

Fault LED -1 Red LED indicates a module self test error, or fatal H/W error. A blink code will indicate the

type of self test error. Count the number of blinks before a pause to determine the error code in the table

below.

Blink # Fault

1 ROM CRC Error

2 EEPROM Error

3 RAM Error

4 Autocal Error

5 Watchdog T imer Error

6 CPU Error

7 DPM Error

Channel LED - 16 Green LEDs indicates the channel is enabled and a valid input signal level is present.

The LED is off if the channel is disabled. A blinking LED indicates that the channel has exceeded a range

limit.

1.3 Related Publications

• Modicon Modsoft Programmer User Manual. 890 USE 115 00

• Modicon TSX Quantum Automation Series Hardware Reference Guide. 840 USE 100 00

• IEEE Std 518- 1977, Guide for the Installation of Electrical Noise Inputs to Controllers from External Sources

• IEEE Std 142- 1982, Recommended Practice for Grounding of Industrial and Commercial Power Systems

• Noise Reduction T echniques in Electronic Systems, by Henry W. Ott; published by Wiley-Interscience of New York in

1976

9

Page 9

Quantum Series 140 AUI 040 00sc

10

Page 10

16-Channel Universal Analog Input Module

Chapter 2

MODULE SETUP FOR MODSOFT

2.1 General Information

Six steps must be performed in order to fully configure the Quantum system in preparation for using the AUI

040 00sc:

Step 1: Modsoft programming software must be updated so that the

140 AUI 040 00sc is recognized in the software (see Section 2.2).

Step 2: Select the appropriate slot location using the Modsoft I/O map. Choose the first 3x and 4x level registers to be

used in the system for the module’ s data, configuration and status information (see Section 2.3).

Step 3: Zoom screens for the module must be set to match application requirements (see Section 2.4).

Step 4: The 4x configuration register must be set to meet application requirements (see Section 4.1).

Step 5: Module status information is available to you. The various options must be understood and chosen to meet

your application requirements (see Section 4.2 and Section 4.3).

Step 6: Ladder rungs must be written to demultiplex the incoming 8 data registers to 16 user selected data registers (see

Section 6.3).

2.2 Installation of new run time files

If you are using the Modsoft programming software version 2.4 or 2.5, it is necessary to update the following

runtime files in order for Modsoft to recognize your module. Versions prior to 2.4 are not supported. Version

2.6 and newer already include these updates.

LMSFDT .SYS Zoom screens

GCNFTCOP .SYS I/O Map module definitions

QUANTUM.SYS Quantum help screens

This may be accomplished by first identifying the pathname where you have installed your Modsoft programming software and the drive letter of the floppy drive from which you intend to install. A typical pathname

assuming installation of the C: drive is as follows:

C:\MODSOFT

The new runtime files required to use all versions of this module are supplied on the 3.5 inch MSDOS formatted floppy disk titled:

“Quantum Runtime Files,” Spectrum Controls, Inc Part Number: 20500121-02

T o install these files, operate your PC in MSDOS mode, perform the following command:

C:>\COPY A:*.SYS C:\MODSOFT\RUNTIME

+ Note: This assumes you are installing from drive A: and that you have previously installed Modsoft in the

directory C:\MODSOFT. If not, you must make the appropriate substitutions.

11

Page 11

Quantum Series 140 AUI 040 00sc

2.3 General information on data register usage and terminology:

A total of nine 3x level and one 4x level registers are used by the 140 AUI 040 00sc. After you have completed the runtime file installation, you can go to the I/O Map screen and choose the 140 AUI 040 00sc by

selecting the desired slot, pressing <Shift + ?> which will display the modules available for configuration into

that slot. For module specific help, press <ALT + H>. After selecting the module, you must set the first 3x

and 4x level registers to be used. This will then automatically capture nine consecutive 3x level and one 4x

level register for use by the module. The architecture for this 16-channel module is as follows:

4x Configuration Word

3x + 0 Input Data Channel 1/9

3x + 1 Input Data Channel 2/10

3x + 2 Input Data Channel 3/11

3x + 3 Input Data Channel 4/12

3x + 4 Input Data Channel 5/13

3x + 5 Input Data Channel 6/14

3x + 6 Input Data Channel 7/15

3x + 7 Input Data Channel 8/16

The AUI 040 00sc multiplexes 16 channels of data into eight groups of two channels. Each group can be

selected through the 4x Configuration Word or can automatically sequence through all four groups of channels.

3x + 0 Input Data Channel 1/9 Group 2 Chn 5-8

3x + 1 Input Data Channel 2/10

3x + 2 Input Data Channel 3/11 Group 3 Chn 9-12

3x + 3 Input Data Channel 4/12 Group 4 Chn 13-16

3x + 4 Input Data Channel 5/13

3x + 5 Input Data Channel 6/14

3x + 6 Input Data Channel 7/15

3x + 7 Input Data Channel 8/16

Group 1 Chn 1-4

2.4 Zoom Screen Configuration

For Zoom Screen operation, please refer to Modicon’s Modsoft Programmer User Manual.

! Note: T o enter zoom screens from the I/O map menu, highlight the module entry and press the keys <AL T - Z>.

Most of the module setup will be done through the Modsoft zoom screens. The zoom screen setup establishes

the following parameters:

• Input Type

• Input Range

• Filter Frequency Selection

• Input Data Format

• Operational Mode

12

Page 12

16-Channel Universal Analog Input Module

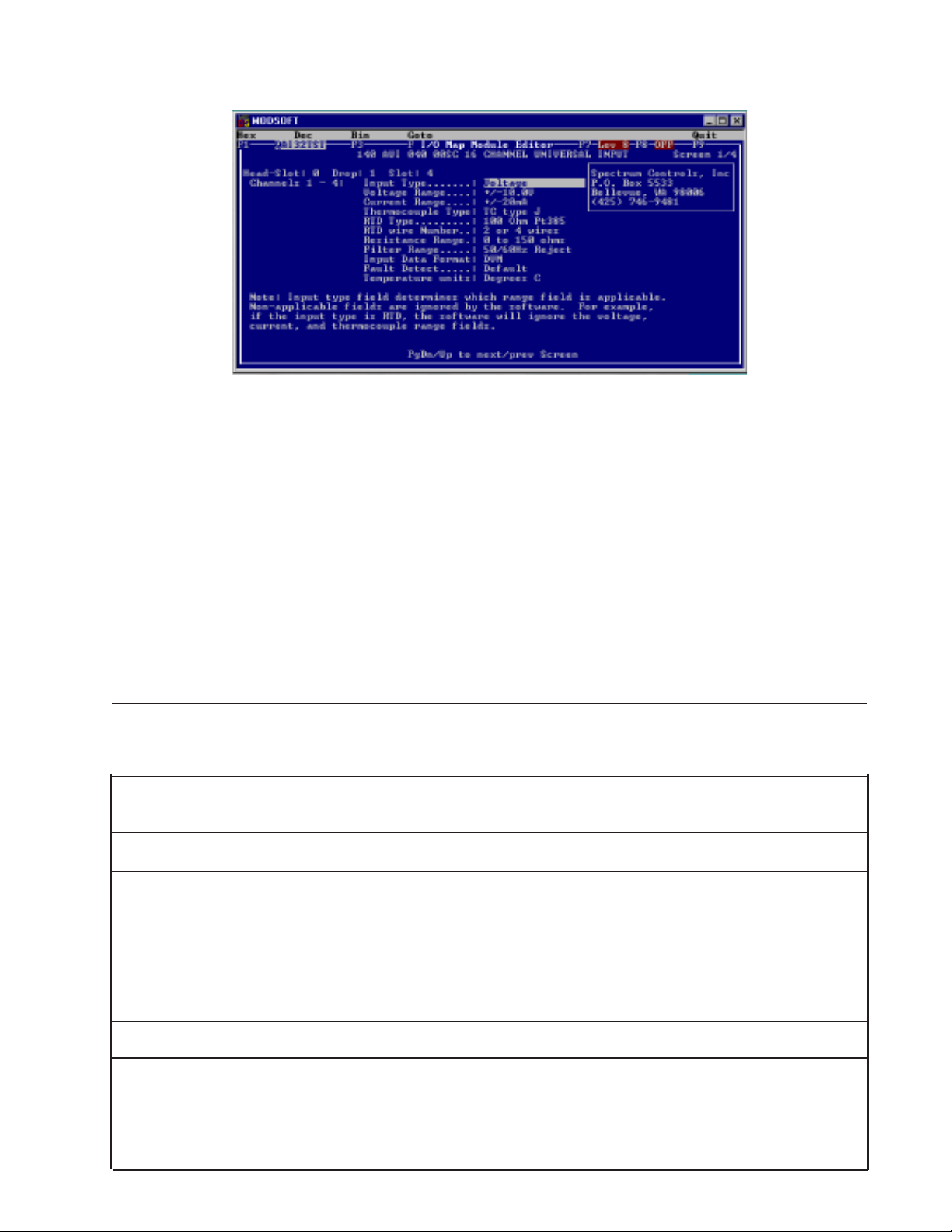

Figure 2.1

Input T ype:

You have 5 input types to select from, one of the following input types may be selected for each of the four

groups of four channels:

Type: Voltage [default]

Current

Thermocouple

RTD

Resistance

Input Range:

Depending on the type of input selected , one of the following input ranges may be selected for each of the

four groups of four channels:

Type: Voltage

Bipolar Ranges (vdc) -0.05 to +0.05 -0.50 to +0.50 -2.0 to +2.0 -5.0 to +5.0 -10.0 to +10.0

Unipolar Ranges (vdc) 0 to +5.0 +1.0 to +5.0 0 to +10.0

Type: Current

Ranges (mA) -20.0 to +20.0 0 to +20.0 4.0 to 20.0

Type: Thermocouple T ype J, K, T , E, R, S, B, N

Type: RTD

Pt 385 RTD 100ohm RTD 200ohm RTD 500ohm RTD 1000ohm

Pt 392 RTD 100ohm RTD 200ohm RTD 500ohm RTD 1000ohm

Cu 426 RTD 10ohm

Ni 618 RTD 100ohm RTD 200ohm RTD 500ohm RTD 1000ohm

Ni 672 RTD 120ohm

Ni/Fe 518 RTD 604ohm

Type: RTD Cfg. 2/4 Wire 3 Wire

Type: Resistance 150ohm 490ohm 980ohm 3000ohm

13

Page 13

Quantum Series 140 AUI 040 00sc

Filter Frequency Selection:

The Analog-to-Digital Conversion performs a filter function on the input signal. One of the following filter

frequencies may be selected for each of the four groups of eight channels:

Rejection Type Filter Freq. Zoom Screen Name

50/60Hz Rejection 13.65Hz 3dB [default] Reject 50/60Hz

High Noise Rejection 7.80 3dB Reject 28Hz

Mid Range 209.6Hz 3dB Reject 800Hz

High Speed 1676.8Hz 3dB Reject 6.4kHz

Input data format:

One of the following data formats may be selected for each of the four groups of four channels:

Format: Digital V oltmeter [default]

12-bit Unsigned Format

16-bit Signed Format

16-bit Unsigned Format

! Note: The module’s format selection must be compatible with the register format selected in Modsoft.

Fault Detection:

One of the following detection formats may be selected for each of the four groups of four channels:

Format: Default [Max on over-range, min on under-range]

Max on Fault

Min on Fault

0 on Fault

T emperature Units:

One of the following unit formats may be selected for each of the four groups of four channels:

Format: Degrees Celsius [default]

Degrees Fahrenheit

Calibration rate:

The Quantum module performs an on board system calibration at power up. The system calibration corrects

for temperature drift of the Analog to Digital Convertor (ADC) and related circuitry. System calibration can

be performed periodically based on the calibration rate selected below. This can affect the update time for

the module. For installations where the ambient temperature surrounding the I/O rack can change relatively

quickly, the user might consider going to a more frequent calibration selection in order to improve the accuracy

of the reading being taken. The autocalibration schedule rate may be selected from the following:

Once at power up only [default]

Every 1 min

Every 10 min

Every 30 min

14

Page 14

16-Channel Universal Analog Input Module

Selecting an autocalibration schedule rate is an exercise in tradeoffs. Performing autocalibration more frequently may result in greater accuracy due to variations caused by environmental factors such as temperature.

This accuracy has a cost in the burden imposed by performing the calibration. The calibration time is a

function of the filter frequency . Calibration times are listed below. The system cannot update the channel

data while performing calibration. In addition, if multiple filter frequencies are selected, calibrations for each

frequency and the execution time is cumulative. The worst case calibration time is when all filter frequencies

are enabled (7.8, 13.6, 50/60 and 1677 Hz). The time is then the total for all four times listed below. Also,

note that the channel enables have no effect on the auto calibration feature. If a filter frequency is enabled via

the zoom screens, then the autocalibration is performed for the frequency.

Filter Freq. 16 Ch. Update Rate

7.8 Hz - 3db 1992 msec

13.6 Hz - 3bd 1168 msec

209.6 Hz - 3db 132 msec

1677 Hz - 3db 80 msec

2.5 4X Register Configuration

Refer to Chapter 4 for 4x register setting information.

15

Page 15

Quantum Series 140 AUI 040 00sc

16

Page 16

16-Channel Universal Analog Input Module

Chapter 3

MODULE SETUP FOR CONCEPT

3.1 General Information

Six steps must be performed in order to fully configure the Quantum system in preparation for using the AUI

040 00sc:

Step 1: Concept programming software (V ersion 2.1 or newer) must be updated so that the 140 AUI 040 00sc is recognized in the software (see Section 3.2).

Step 2: Select the appropriate slot location using the Concept I/O map editor . Choose the first 3x and 4x level registers to

be used in the system for the module’ s data, configuration and status information (see Section 3.3).

Step 3: Parameters for the module must be set to match application requirements (see Section 3.4).

Step 4: The 4x configuration register must be set to meet application requirements (see Section 4.1).

Step 5: Module status information is available to you. The various options must be understood and chosen to meet

your application requirements (see Section 4.2 and Section 4.3).

Step 6: Ladder rungs must be written to demultiplex the incoming 8 data registers to 16 user selected data registers (see

Section 6.3).

3.2 Installation of new run time files

The 140 AUI 040 00sc is manufactured by Spectrum Controls, Inc. Follow the Concept installation procedure for

outsourced modules. This requires the install disk provided with your module, which includes the following files

(assuming drive A:):

A:\CONCEPT\SPECTRUM.MDC - SpectrumI/O for Quantum Module Definition file.

A:\CONCEPT\SPECTRUM.HLP - Spectrum I/O for Quantum Help file.

To update the Concept database with a new Spectrum I/O module:

1. Insert the install disk into drive A:

2. Start the Concept Modconnect Tool (Modconf.exe).

3. Open the installation file “SPECTRUM.MDC”

4. Select the module to add or press the “Add All” button

5. Save the changes before exiting the Modconnect tool.

This will update the Concept database permanently unless you later undo the changes using the Modconnect

Tool, or perform a new Concept software install.

3.3 General information on data register usage and terminology:

A total of nine 3x level and one 4x level registers are used by the 140 AUI 040 00sc. After you have completed adding the modules to the Concept database using the Modconnect tool, you can add a module to a drop

by using the Concept Configurator as follows:

1. Open an existing or create a new project.

2. Select the Configurator from the project pulldown menu.

3. Select Configure then select the I/O map menu.

4. On the I/O map menu, press the EDIT button for the appropriate drop.

5. Push the button in the module select column for the appropriate slot.

6. Select the desired module from the list of available modules.

7. Enter the starting 3x register address (InRef). Nine registers are automatically allocated.

8. Enter the starting 4x register address (OutRef). One register is allocated.

9. Press the parameters button. (Refer to the SC Config Utility - Section 3.5)

10. Verify register values are correct for the desired behavior.

17

Page 17

Quantum Series 140 AUI 040 00sc

The register data formats are discussed in the following section.

4x Configuration Word

3x + 0 Input Data Channel 1/9

3x + 1 Input Data Channel 2/10

3x + 2 Input Data Channel 3/11

3x + 3 Input Data Channel 4/12

3x + 4 Input Data Channel 5/13

3x + 5 Input Data Channel 6/14

3x + 6 Input Data Channel 7/15

3x + 7 Input Data Channel 8/16

The AUI 040 00sc multiplexes 16 channels of data into four groups of four channels. Each group can be

selected through the 4x Configuration Word or can automatically sequence through all four groups of channels.

Group 1 Chn 1-4

3x + 0 Input Data Channel 1/9 Group 2 Chn 5-8

3x + 1 Input Data Channel 2/10

3x + 2 Input Data Channel 3/11 Group 3 Chn 9-12

3x + 3 Input Data Channel 4/12 Group 4 Chn 13-16

3x + 4 Input Data Channel 5/13

3x + 5 Input Data Channel 6/14

3x + 6 Input Data Channel 7/15

3x + 7 Input Data Channel 8/16

3.4 Concept I/O Map Module Parameters:

Concept programming software does not implement zoom screens for ModConnect partner modules and

allows only direct editing of the I/O configuration parameters using 16 bit hex values. Spectrum Controls has

provided a software utility to simplify the configuration process. Refer to Section 3.5 for details.

From the Concept main screen, highlight the “configure” pull-down menu and choose “I/O Map.” In the I/O

Map screen insert the number for the correct “drop” and choose “edit.” Select the Spectrum Controls catalog

number that you wish to use from the list presented. When the screen appears, representing the Spectrum

module you have selected, highlight the parameters button. You must insert Hex values for registers #1, 2 and

3 to fully configure the module. The format that will instruct you on how to create the I/O map parameters is

listed below. For each of the parameters listed we have provided a detailed explanation in Chapter 2. Please

refer to detailed functional descriptions in the MODSOFT zoom screen discussions (Section 2.4). You must

go through each of the options below to establish the correct pattern for each of these three registers. Once

you have the bit pattern, then you can convert each to a four-digit Hex value that is used in the parameters

screen.

Configuration Register 1

Group 1 Group 2 Group 3 Group 4

Ch. 1-4 Ch. 5-8 Ch. 9-12 Ch. 13-16

Zoom +10 Zoom +12 Zoom +14 Zoom +16

18

Page 18

16-Channel Universal Analog Input Module

1 2 3 4 5 6 7 8 910111213141516

Input Type

Voltage Range

Current Range

Thermocouple Type

RTD Type

RTD Wire #

Bit Selection Pattern: Input Type for Group 1, 2, 3, 4 - Zoom Register 1,3,5,7

Bit 14 Bit 15 Bit 16 Description

0 0 0 Voltage (Default)

0 0 1 Current

0 1 0 Thermocouple

011RTD

1 0 0 Resistance

1 0 1 CJC

1 1 0 Not valid

1 1 1 Not valid

Bit Selection Pattern: Volt age Range for Group 1, 2, 3, 4 - Zoom Register 1,3,5,7

Bit 11 Bit 12 Bit 13 Description

0 0 0 -0.05 to +0.05vDC

0 0 1 -0.50 to +0.50vDC

0 1 0 -2.00 to +2.00vDC

0 1 1 -5.00 to +5.00vDC

1 0 0 -10.0 to +10.0vDC *(default)

1 0 1 0 to +5.0vDC

1 1 0 1 to +5.0vDC

1 1 1 0 to +10.0vDC

Bit Selection Pattern: Current Range for Group 1, 2, 3, 4 - Zoom Register 1,3,5,7

Bit 9 Bit 10 Description

0 0 -20 to +20mA

0 1 0 to +20mA

1 0 4 to +20mA

1 1 N/A

Bit Selection Pattern: Thermocouple Type for Group 1, 2, 3, 4 - Zoom Register 1,3,5,7

Bit 6 Bit 7 Bit 8 Description

0 0 0 Thermocouple type J

0 0 1 Thermocouple type K

0 1 0 Thermocouple type T

0 1 1 Thermocouple type E

1 0 0 Thermocouple type R

1 0 1 Thermocouple type S

1 1 0 Thermocouple type B

1 1 1 Thermocouple type N

19

Page 19

Quantum Series 140 AUI 040 00sc

Bit Selection Pattern: Volt age Range for Group 1, 2, 3, 4 - Zoom Register 1,3,5,7

Bit 2 Bit 3 Bit 4 Bit 5 Description

0000RTD 100 ohm Pt 385

0001RTD 200 ohm Pt 385

0010RTD 500 ohm Pt 385

0011RTD 1000 ohm Pt 385

0100RTD 100 ohm Pt 392

0101RTD 200 ohm Pt 392

0110RTD 500 ohm Pt 392

0111RTD 1000 ohm Pt 392

1000RTD 10 ohm Cu 426

1001RTD 100 ohm Ni 618

1010RTD 200 ohm Ni 618

1011RTD 500 ohm Ni 618

1100RTD 1000 ohm Ni 618

1101RTD 120 ohm Ni 672

1110RTD 604 ohm Ni/Fe 518

1 1 1 1 Not used

Bit Selection Pattern: R TD / Resistance Wires for Group 1, 2, 3, 4 - Zoom Register 1,3,5,7

Bit 1 Description

0 2 or 4 Wire

1 3 W ire

Configuration Register 2

Group 1 Group 2 Group 3 Group 4

Ch. 1-4 Ch. 5-8 Ch. 9-12 Ch. 13-16

Zoom +11 Zoom +15 Zoom +17 Zoom +16

1 2 3 4 5 6 7 8 910111213141516

Resistance Range

Filter Frequency

Input Data Format

Fault Detection

Temperature Units

Not Used

Bit Selection Pattern: Input Resistance Range for Group 1, 2, 3, 4 - Zoom Register 2,4,6,8

Bit 15 Bit 16 Description

0 0 150ohm (Default)

0 1 490ohm

1 0 980ohm

1 1 3000ohm

Bit Selection Pattern: Input Filter Frequency for Group 1, 2, 3, 4 - Zoom Register 2,4,6,8

Bit 13 Bit 14 Description

0 0 50/60Hz Rejection 13.65Hz 3db (Default)

0 1 High Noise Rejection 7.8Hz 3db

1 0 Mid Range Noise Rejection 209.6Hz 3db

1 1 High Speed 1676.8Hz 3db

20

Page 20

16-Channel Universal Analog Input Module

Bit Selection Pattern: Input Data Format for Group 1, 2, 3, 4 - Zoom Register 2,4,6,8

Bit 11 Bit 12 Description

0 0 16 bit unsigned integer

0 1 DVM (Default)

1 0 12 bit unsigned integer

1 1 15 bit signed integer

Bit Selection Pattern: Fault Detect for Group 1, 2, 3, 4 - Zoom Register 2,4,6,8

Bit 9 Bit 10 Description

0 0 Disabled

0 1 Max. on Fault (Default)

1 0 Mi.n. on Fault

1 1 0 on Fault

Bit Selection Pattern: T emperature Units for Group 1, 2, 3, 4 - Zoom Register 2,4,6,8

Bit 8 Description

0 Degrees Celcius (Default)

1 Degrees Farenheight

Once you have established the correct bit pattern for each of these three registers, you can convert each to a

four digit Hex value that is used in the parameters screen. A Hex conversion table follows:

0000=0

0001=1

0010=2

0011=3

0100=4

0101=5

0110=6

0111=7

1000=8

1001=9

1010=A

1011=B

1100=C

1101=D

1110=E

1111=F

21

Page 21

Quantum Series 140 AUI 040 00sc

3.5 Spectrum I/O Configuration Utility

“SCIOCFG.EXE” is a utility provided on the install disk under the typical pathname

“A:\CONCEPT\SCIOCFG.EXE”. “SCIOCFG.EXE” is intended to help users configure Spectrum I/O when

using Concept. This tool is intended to make the configuration of I/O modules supplied by Spectrum Controls

easy to accomplish when using Concept.

Version 2.1 of the Concept programming software introduced the tool for importing ModConnect module

definition files into the Concept database. This allows Concept users to configure ModConnect I/O such as

the 140 AUI 040 00sc. However, Concept V2.1 does not provide a means for ModConnect I/O developers to

design their own I/O configuration menus. Instead, Concept provides a generic interface where the user must

enter configuration parameters in hexadecimal values. The Spectrum I/O modules are designed to be feature

rich with an efficient use of registers. This requires the user to be intimately aware of the initialization parameters structure in order to perform simple I/O configuration changes. Simply stated, users can calculate the

correct hexadecimal values for the configuration parameters but it is a tedious task, SCIOCFG is designed to

relieve the user of this burden.

SCIOCFG presents the user with user friendly selection lists using standard Windows interfaces. SCIOCFG

also automatically constrains all parameters to legal values during the data entry process.

SCIOCFG may be run in one of two modes, stand alone mode, or synchronous mode. In the stand alone

mode, the user configures the data for a given module as desired. SCIOCFG then presents the parameters in

hexadecimal values so the user may then manually transfer this data to Concept at a later time.

In the synchronous mode, SCIOCFG runs in the background waiting for the user to select the generic I/O

parameters configuration menu for any one of the modules supported. When this occurs, SCIOCFG reads the

data from the Concept generic I/O parameter configuration menu, and activates the appropriate I/O parameter

configuration menu. When the user clicks on the SCIOCFG OK button, the new data is sent back to Concept.

3.6 SCIOCFG.EXE Installation:

SCIOCFG.EXE is a 32-bit W indows program requiring Windows 95 or newer. Installation of SCIOCFG.EXE

is simple. Copy the SCIOCFG.EXE file from the installation disk to the desired directory . Then you may add

a shortcut to the windows desktop or add the program to the windows taskbar using standard windows

techniques.

e.g. From a DOS window:

C:\>MD C:\SCIOCFG

C:\> COPY A:\CONCEPT\SCIOCFG.EXE C:\SCIOCFG

To add a shortcut:

1. Place the mouse cursor on an open area of the windows desktop.

2 . Click the right mouse button.

3 . Select the “New” option.

4. Select the “Shortcut” option.

5. Enter the full install pathname. E.G. C:\SCIOCFG\SCIOCFG.EXE

+ Note :The user may optionally configure SCIOCFG to always run in either the stand alone mode or the

synchronous mode. T o do this, place a space in one of the following strings immediately after the full

pathname:

NO_SYNC

SYNC_WITH_CONCEPT

E.G. C:\SCIOCFG\SCIOCFG.EXE SYNC_WITH_CONCEPT

22

Page 22

16-Channel Universal Analog Input Module

6 . Name as desired.

7. Activate the “Finish” button.

T o add to Windows Programs Selections or a Folder:

1. Click and hold the left mouse button on the taskbar start button.

2. Select “Settings, “Taskbar” and release the mouse button.

3 . Select the “Start Menu Programs” tab index.

4. Press the Add button.

5 . Choose an existing folder (perhaps the Concept programming folder) or create a new folder to hold SCIOCFG.EXE.

6 . Add SCIOCFG.EXE as described for adding shortcuts step 5.

SCIOCFG EXE is ready to run.

The SCIOCFG.EXE should be running as a background task, whenever Concept software is being used to

change the configuration registers of the 140 AUI 040 00sc series of modules. Start SCIOCFG.EXE by

double clicking on the SCIOCFG.EXE icon, then start Concept software.

Figure 3.1 SC Config Utility Screen

23

Page 23

Quantum Series 140 AUI 040 00sc

24

Page 24

16-Channel Universal Analog Input Module

Chapter 4

MODULE CONFIGURA TION AND ST ATUS

The 140 AUI 040 00sc uses a total of nine 3x level and one 4x level registers. After Modsoft (Section 2.3)

or Concept (Section 3.3) software is installed, additional configuration and status registers are set as follows:

4.1 Configuration word format (Register 4x)

1 2 3 4 5 6 7 8 910111213141516

Channel 1/2 Disable

Channel 3/4 Disable

Channel 5/6 Disable

Channel 7/8 Disable

Channel 9/10 Disable

Channel 11/12 Disable

Channel 13/14 Disable

Channel 15/16 Disable

Bank Select

Sequence Mode

Data Mode

Calibration Rate

Lead Measurement

4x Lead Resistance Measurement: Bits 1-2

This applies only when the module interfaces 3 wire RTDs. These two bits determine how frequently the

module will measure the RTD lead wire resistance. It is unlikely lead resistance will change much over time.

Reading the lead resistance effectively doubles the update time for RTD measurements

Bit 1 Bit 2 Mode

0 0 Equal to calibration rate

0 1 On power up only

1 0 Every 3-wire RTD reading

1 1 Not Allowed

4x Calibration Mode: Bits 3-4

These two bits are used to select a desired calibration interval.

Bit 3 Bit 4 Mode

0 0 On power up only

0 1 Every Minute

1 0 Every 10 Minutes

1 1 Every 30 Minutes

4x Data Input Mode: Bits 5-6

The module continuously outputs a group of eight registers worth of data. The data for a given group can be

paged between two modes. These are the standard channel input data and channel status data.

Bit 5 Bit 6 Input Modes

0 0 Input Data

0 1 Status Data 1

1 0 Not Used

1 1 Status Data 2

25

Page 25

Quantum Series 140 AUI 040 00sc

4x Autosequence Disable: Bit 7

When in Auto Sequence Mode, the module ignores the channel bank select in the 4X-configuration word, and

instead sequences through both banks automatically . The values in the eight data registers belong to the bank

identified in the status word bank ID (3X+8 bit 1). The user must set aside 16 registers as a permanent image

of the channel data. During run time, the ladder need only determine the current bank for the eight data

registers (3x+0 through xx+7) in order to determine where the data should be copied into the 16-channel

register image.

When in Manual Sequence Mode (Bit 7 = 0) the module reads only the eight channels identified by the Bank

Select Bits.

When autosequence is disabled, the user must manually increment the group select in the configuration word

and the module sends back only the data requested.

Sample ladder logic for both techniques is provided in section 6.3.

4x Bank Select: Bit 8

Bit 8 is used to select the desired Bank of channels. Bank 0 is defined as the first eight input channels. I.e.

configuration groups 1 and 2. And bank 1 is defined as the second 8 input channels. I.e. configuration groups

3 and 4. The bank select bit is used for individual bank selection when the Manual Sequence mode is used.

4x Group Channel Disable: Bits 9-16

These bits are used to enable or disable channel pairs. A “0” enables the group, a “1” disables the group.

Disabling groups of channels improves system response time.

Bit 16: Channels 1-2

Bit 15: Channels 3-4

Bit 14: Channels 5-6

Bit 13: Channels 7-8

Bit 12: Channels 9-10

Bit 11: Channels 11-12

Bit 10: Channels 13-14

Bit 9: Channels 15-16

4.2 Module status information (Register 3x+8)

The information provided in this register is generic information about this module. Bits 1-8 and 10 provide

error status information. Bits 13-16 indicate what information is present in the current inputs registers.

1 2 3 4 5 6 7 8 910111213141516

Range Error

Configuration Error

Broken Input

CJC Error

CPU Error

Watchdog Error

RAM Failure

Bank Select Echo

Sequence Mode Error

Data Mode Echo

ROM Failure

EEPROM Failure

Not Used

26

Page 26

16-Channel Universal Analog Input Module

3x+8 Not Used: Bits 1, 2

3x+8 EEPROM Error: Bit 3

An onboard re-writeable memory error has occured. Contact your technical support representative.

3x+8 ROM Failure: Bit 4

A read only memory error has occured. Contact your technical support representative.

3x+8 Data Mode Echo: Bits 6,5

The Module continuously outputs a bank of eight registers worth of data. The data for a given bank can be

paged between 2 modes. These are the standard channel input data and channel status data.

3x+8 Sequence Mode Echo: Bits 7

When in Auto Sequence Mode, the module ignores the channel bank select in the 4X-configuration word, and

instead sequences through both banks automatically . The values in the eight data registers belong to the bank

identified in the status word bank ID (3X+8 bit 1). The user must set aside 16 registers as a permanent image

of the channel data. During run time, the ladder need only determine the current bank for the eight data

registers (3x+0 through xx+7) in order to determine where the data should be copied into the 16-channel

register image.

When in Manual Sequence Mode the module reads only the eight channels identified by the Bank Select Bits.

3x+8 Bank Select Echo: Bits 8

This bit is used to show the selected bank channels. This will indicate individual bank selection when the Auto

Sequence mode in not used. The bank select is used for multiplexing out the Modules input data and status

data. The channel Status Mode disables the normal data input mode and reports the status on the selected

bank of 8 channels. The channel status bits echo back the selected input range data format and error status.

3x+8 RAM Failure: Bits 9

A random access memory error has occured. Contact your technical support representative.

3x+8 Watchdog Error: Bits 10

A watchdog timeout error occured. Contact your technical support representative.

3x+8 CPU Error: Bits 11

A central processing unit error has occured. Contact your technical support representative.

3x+8 CJC Error: Bits 12

A cold junction compensation error has occured. Check your onboard CJC sensor connections. These are

found on the terminal block.

3x+8 Broken Input Mode: Bits 13

Check your input connections for continuity .

3x+8 Configuration Error: Bit 14

An illegal configuration was attempted. When this occurs configuration will not be accepted by the module

and this flag will be set. By using 4x register bits 1 and 2 to set the module to “status” individual channels

flags can be checked to determine which channel or group is incorrect.

3x+8 Out of Range Error: Bits 15-16

These two bits indicate that an over or under range condition exists on at least one channel within the group.

Bits 1-2 correspond to two groups of eight channels each. When an Out of Range Flag is set, the Channel

Status mode (see Section 4.3) can be enabled to report which channel is out of range.

+ Note: An over range error indicates that a channel input is a value greater than or equal to the maximum for the range selected for

that channel group. An under range error indicates that a channel input is a value less than or equal to the minimum for the selected

range.

27

Page 27

Quantum Series 140 AUI 040 00sc

4.3 Channel Status (Registers 3x+ 0 through 3x+7)

(Registers 3x+ 0 through 3x+7) Status Mode 1:

1 2 3 4 5 6 7 8 910111213141516

3x+0 . . . 7 RTD Wire Number Echo: Bit 1

3x+0 . . . 7 RTD T ype Echo: Bits 2-5

3x+0 . . . 7 Thermocouple Range Echo: Bits 6-8

3x+0 . . . 7 Current Range Echo: Bits 9-10

3x+0 . . . 7 V oltage Range Echo: Bit s 1 1-13

3x+0 . . . 7 Input T ype Echo: Bits 14-16

Input Type Echo

Voltage Range Echo

Current Range Echo

Thermocouple Range Echo

RTD Type Echo

RTD Wire Number Echo

(Registers 3x+ 0 through 3x+7) Status Mode 2:

1 2 3 4 5 6 7 8 910111213141516

Resistance Range Echo

Filter Echo

Format Echo

Fault Detect Echo

Temperature Units Echo

Calibration Error

Configuration Error

Over Range

Under Range

Broken Input

CJC Error

Bank Number

3x+0 . . . 7 Bank Number: Bit 1

3x+0 . . . 7 CJC Error Echo: Bit 2

3x+0 . . . 7 Broken Input Echo: Bit 3

3x+0 . . . 7 Under Range Flag: Bit 4

This is a nonfatal under range flag. The bit is set to “1” when an input value is read within one count of the

minimum range value. When the input value is within normal limits the flag is automatically reset to “0.”

28

Page 28

16-Channel Universal Analog Input Module

3x+0 . . . 7 Over Range Flag: Bit 5

This is a nonfatal over range flag. The bit is set to “1” when an input value is read within one count of the

maximum range value. When the input value is within normal limits the flag is automatically reset to “0.”

3x+0 . . . 7 Configuration Error Flag: Bit 6

The calibration error flag is a fatal error. When the flag is set to “1” there is a configuration mismatch.

Configuration errors include any illegal configuration, such the selection of an unsupported format or filter

option, or configurations that must be the same for all channels within a group of channels.

3x+0 . . . 7 Calibration Error Flag: Bit 7

The calibration error flag is a fatal error. When the flag is set to “1” the ADC cannot calibrate within specifications.

3x+0 . . . 7 Temperature Units Echo: Bit 8

3x+0 . . . 7 Fault Detect Echo: Bits 9-10

3x+0 . . . 7 Format Echo: Bit 11-12

3x+0 . . . 7 Filter Echo: Bit 13-14

3x+0 . . . 7 Resistance Range Echo: Bit 15-16

RTD Fault Detection

The module can detect both RTD open circuits and shorts. This works as follows:

· Open positive excitation. The S/W will read positive full scale. This will be flagged as a bad input.

Reading will default to the full-scale value for the range selected. Note that S/W can detect an overrange which is not an open input.

· Open negative excitation. Reading will be 0. This will cause the reading to be flagged as a bad input.

V alue read will be negative full scale for the range selected.

· Open high signal. The module switches in the reference voltage prior to reading the RTD voltage. This

charges the filter capacitor downstream of the input multiplexer . If the input is open, This capacitance

will charge the filter capacitor upstream of the multiplexer input. This will cause the reading to eventually go to positive full scale and will be flagged as a bad input as it is when ther is an open positive

excitation. Note that this capacitive charging process may take several updates. This method is not

designed to instantly flag an open wire, but to ensure it will eventually “float” high enough to be an

obvious fault. Because of input range limitations, this method does not apply to the 3000 ohm resistance range or the 1000 ohm RTD ranges.

· Open low signal. If this wire opens, it will cause the input voltage read to float. If the input voltage

drifts too high or too low, a fault will be detected. Unlike the open hi signal, there is no technique

implemented to detect this type of fault.

29

Page 29

Chapter 5

INST ALLATION

16-Channel Universal Analog Input Module

+ Note: When field wiring the I/O modules, the maximum wire size that should be used is 1-14 AWG or 2-16 AWG; the

minimum size is 20 AWG.

+ Note: The field wiring terminal block (Modicon # 140 XTS 002 00) or the 140 CFA040 00 40 pin Cablefast

Terminal block must be ordered separately. (The terminal block includes the removable door label.)

+ Note: Power, input and output (I/O) wiring must be in accordance with Class 1, Division 2 wiring methods [Article

501-4 (b) of the National Electrical Code, NFPA 70] and in accordance with the authority having jurisdiction.”

+ Note: Peripheral equipment must be suitable for the location in which it is used.

31

Page 30

Quantum Series 140 AUI 040 00sc

WARNING

ELECTROSTATICALLY SENSITIVE COMPONENTS

EXPLOSION HAZARD

Substitution of components may impair suitability for Class 1, Division 2.

WARNING

EXPLOSION HAZARD

Do not disconnect equipment unless power has been switched off or the area is known to be non hazardous.

WARNING

This equipment is suitable for use in Class 1, Division 2, Groups A, B, C, and D or non-hazardous locations

only.

WARNING

EXPLOSION HAZARD

When in hazardous locations, turn off power before replacing or wiring modules.

Before installing the module, you should:

• Configure all of the appropriate zoom screen, configuration and other necessary set up according to Chapters 2 and 3.

• Field wire the module’s terminal block for your application.

For field wiring, use shielded, twisted-pair cable (such as Belden 9418 for voltage and current applications),

and ground each cable’s shield wire at one end only. At the opposite end of each cable, tape the exposed

shield wire to insulate it from electrical contact. A good shield wire ground is a rack assembly mounting bolt

or stud.

32

Page 31

16-Channel Universal Analog Input Module

5.1 Field Wiring

+ Note: In the process of wiring the modules, route all signal wires as far as possible from potential sources

of electrical noise, such as motors, transformers, etc., (especially ac devices). As a general rule, allow 15.2

cm (6 in) of separation for every 120V of power. Signal wires must never share the same conduit with ac

wiring. Also, when you must route signal wires past ac wiring, do so at right angles.

Figure 5.1 - Field Wiring - Voltage, Current, Thermocouple Inputs

Group Signal Name Pin # Signal Name Group

CJC 1 HI ( + ) 21 1 IN HI ( + ) 1

CJC 1 LO ( - ) 43 1 IN LO ( - ) 1

1 2 IN HI ( + ) 65 3 IN HI ( + ) 1

1 2 IN LO ( - ) 87 3 IN LO ( - ) 1

1 4 IN HI ( + ) 10 9 5 IN HI ( + ) 2

1 4 IN LO ( - ) 12 11 5 IN LO ( - ) 2

2 6 IN HI ( + ) 14 13 7 IN HI ( + ) 2

2 6 IN LO ( - ) 16 15 7 IN LO ( - ) 2

2 8 IN HI ( + ) 18 17 SHIELD 1

2 8 IN LO ( - ) 20 19 SHIELD 2

SHIELD 3 22 21 9 IN HI ( + ) 3

SHIELD 4 24 23 9 IN LO ( - ) 3

3 10 IN HI ( + ) 26 25 11 IN HI ( + ) 3

3 10 IN LO ( - ) 28 27 11 IN LO ( - ) 3

3 12 IN HI ( + ) 30 29 13 IN HI ( + ) 4

3 12 IN LO ( - ) 32 31 13 IN LO ( - ) 4

4 14 IN HI ( + ) 34 33 15 IN HI ( + ) 4

4 14 IN LO ( - ) 36 35 15 IN LO ( - ) 4

4 16 IN HI ( + ) 38 37 CJC 2 HI ( + )

4 16 IN LO ( - ) 40 39 CJC 2 LO ( - )

5.2 RTD Field wiring

RTDs may be wired using 2/4 wire or 3 wire configurations.

Figure 5.2 - Field Wiring - RTD Inputs

Group RTD Signal Pin # RTD SIGNAL Group

21EXCIT 1 Hi 1

43EXCIT 1 Lo 1

1 RTD 1 IN ( + ) 65EXCIT 2 Hi 1

1 RTD 1 IN ( - ) 87EXCIT 2 Lo 1

1 RTD 2 IN ( + )10 9 EXCIT 3 Hi 2

1 RTD 2 IN ( - ) 12 11 EXCIT 3 Lo 2

2 RTD 3 IN ( + )14 13 EXCIT 4 Hi 2

2 RTD 3 IN ( - ) 16 15 EXCIT 4 Lo 2

2 RTD 4 IN ( + )18 17

2 RTD 4 IN ( - ) 20 19

22 21 EXCIT 5 Hi 3

24 23 EXCIT 5 Lo 3

3 RTD 5 IN ( + )26 25 EXCIT 6 Hi 3

3 RTD 5 IN ( - ) 28 27 EXCIT 6 Lo 3

3 RTD 6 IN ( + )30 29 EXCIT 7 Hi 4

3 RTD 6 IN ( - ) 32 31 EXCIT 7 Lo 4

4 RTD 7 IN ( + )34 33 EXCIT 8 Hi 4

4 RTD 7 IN ( - ) 36 35 EXCIT 8 Lo 4

4 RTD 8 IN ( + )38 37

4 RTD 8 IN ( - ) 40 39

33

Page 32

Quantum Series 140 AUI 040 00sc

5.3 CJC Thermocouple Installation

When using thermocouples it is necessary to install the supplied Cold Junction Compensation thermocouples to

meet temperature accuracy specification. There are two CJC sensors, on located on the top of the terminal

block, the second located at the bottom of the terminal block. The CJC sensors are premounted on a small

circuit board to ease installation. To install the sensors unscrew terminal pairs 2/4 and 37/39 and slide the CJC

sensors under the screws. Tighten the screws to no more than 10 lbs. in. of torque.

Group Signal Name Pin # Signal Name Group

Insert CJC

#1 here.

CJC 1 HI ( + ) 21 1 IN HI ( + ) 1

CJC 1 LO ( - ) 43 1 IN LO ( - ) 1

1 2 IN HI ( + ) 65 3 IN HI ( + ) 1

1 2 IN LO ( - ) 87 3 IN LO ( - ) 1

1 4 IN HI ( + ) 10 9 5 IN HI ( + ) 2

1 4 IN LO ( - ) 12 11 5 IN LO ( - ) 2

2 6 IN HI ( + ) 14 13 7 IN HI ( + ) 2

2 6 IN LO ( - ) 16 15 7 IN LO ( - ) 2

2 8 IN HI ( + ) 18 17 SHIELD 1

2 8 IN LO ( - ) 20 19 SHIELD 2

SHIELD 3 22 21 9 IN HI ( + ) 3

SHIELD 4 24 23 9 IN LO ( - ) 3

3 10 IN HI ( + ) 26 25 11 IN HI ( + ) 3

3 10 IN LO ( - ) 28 27 11 IN LO ( - ) 3

3 12 IN HI ( + ) 30 29 13 IN HI ( + ) 4

3 12 IN LO ( - ) 32 31 13 IN LO ( - ) 4

4 14 IN HI ( + ) 34 33 15 IN HI ( + ) 4

4 14 IN LO ( - ) 36 35 15 IN LO ( - ) 4

4 16 IN HI ( + ) 38 37 CJC 2 HI ( + )

4 16 IN LO ( - ) 40 39 CJC 2 LO ( - )

Insert CJC

#2 here.

34

Page 33

16-Channel Universal Analog Input Module

35

Page 34

Quantum Series 140 AUI 040 00sc

36

Page 35

16-Channel Universal Analog Input Module

Chapter 6

APPLICA TION NOTES

6. 1 General Application Tips

The following is a list of do’ s and don’ts that should be observed in your applications.

• Select the appropriate 140 AUI 040 00sc from the I/O map selection screen.

• Configure the module using your programming software, make appropriate use of Configuration and Status registers as

outlined in Chapters 2 through 4.

• Ensure correct units of measure are selected for data type.

• Use the lowest filter frequency setting possible for your application, this ensures the most stable and accurate

readings.

• Configure the 4x Register.

• Check that the Green Ready LED is lit when the module is powered up and has completed its self test.

• Check that the Green Active LED is lit when data is being transferred to the Quantum CPU.

6.2 Demultiplexing Channel Data - Autosequence Mode

The autosequence mode of operation is intended to simplify the demultiplexing of channel data from the eight

input registers into storage for the 16 channels. The autosequence mode is enabled under the following conditions:

• Input Mode = Data Mode (Configuration W ord Bits 5 & 6 = 0)

In the autosequence mode, the group select bits in the configuration word are ignored. Instead, the module

samples channel data in groups of eight (8), presents the data to the PLC and then scans the next group

automatically. The ladder logic then reads the status word to determine which data is being presented and

copies the data to the appropriate storage locations for those channels.

The module update rate is determined by the number of channels enabled and the filter frequencies selected.

For example, if all 16 channels are enabled and the filter frequency for all groups is 50/60 Hz, then the cycle

time for a full set of 16 channels is 16 x 73 msec or 1.168 seconds.

It takes two ladder logic scans of the eight registers to see all 16 channels. These two scans must be completed at least twice as fast as the module update time to ensure no data is missed. In the example above the

ladder scan time would need to run at 1.168 sec/8 or 146 msec or faster to ensure no data is missed.

Refer to Section 6.4 Channel Update Rate for channel update times.

6. 3 Using ladder to move data to a block of 16 consecutive registers

The following ladder logic shows how to move data from the 8 multiplexed input words to a block of 16 output

words starting at location 400101 with the autosequence mode disabled. This example file for use only with

Modsoft programming software can be formed on the install disk shipped with your module. The file is under

the A:\Programs subdirectory. To install:

1. Insert the install disk into drive A:

2. Copy A:\Programs\QAI32_AC.* C:\Modsoft\Programs

3. Select File QAI32_AC under Modsoft to run.

37

Page 36

Quantum Series 140 AUI 040 00sc

The I/O map is as follows: (Manual Mode)

Rack Slot Module Input Ref Output Ref Description

1 03 AUI 040 00 3000001-3000009 4000001-400001 AUI04000 AN IN 16CH

30009 30009 30009 30001

NCBT NCBT NCBT 400101

#5 #6 #8

BLKM

#8

30009 30009 30009 30001

NCBT NCBT NOBT 400109

#5 #6 #8

BLKM

#8

38

Page 37

16-Channel Universal Analog Input Module

The following ladder logic shows how to move data from the 8 multiplexed input words to a block of 32 output

words starting at location 400101 using the autosequence mode. This example file for use only with Modsoft

programming software can be formed on the install disk shipped with your module. The file is under the

A:\Programs subdirectory . T o install:

1. Insert the install disk into drive A:

2. Copy A:\Ladder\Q16 Universal\LAD_MM_AC.* C:\Modsoft\Programs

3. Select File LAD_MM_AC under Modsoft to run. The I/O map is as follows:

Rack Slot Module Input Ref Output Ref Description

1 03 AUI 040 00 3000001-3000009 4000001-400001 AUI04000 AN IN 16CH

30009 30009 30009 30001

NCBT NCBT NCBT 400101

#5 #6 #8

BLKM

#8

400001

SBIT

#8

30009 30009 30009 30001

NCBT NCBT NOBT 400109

#5 #6 #8

BLKM

#8

400001

RBIT

#8

6.4 Channel Update Rate

The module’s channel update rate is determined by the filter frequency selection. A lower filter frequency

takes longer to update each channel. The following table shows the single channel update rate and 16 channel

update rate for each filter frequency.

1 channel 16 channel

Filter Update Time Update time

7.8 Hz 124 ms 1990 ms

13.65 Hz 73 ms 1168 ms

209.6 Hz 7.6 ms 122 ms

1667 Hz 4.7 ms 76 ms

39

Page 38

Quantum Series 140 AUI 040 00sc

+ Note: Channel update time is the time required for the module to acquire an input sign and update the

module’s data registers. The scan rate of the Quantum system will vary with application ladder and system

configuration.

+ When using RTDs add 3ms per channel. For 3-wire DTR configurations double the update time of wire

resistance is measured every cycle.

+ When using thermocouples the CJC calibration time will increase scan times by 150ms and channel update

times by 1ms.

+ Note: Periodic system calibration will also effect channel update times for one scan cycle.

6.5 System Resolution and Accuracy - Voltage /Current Modes

The system resolution listed below is the smallest input signal change that the ADC can detect. The resolution

level is affected by the filter frequency selected.

The resolution levels for the voltage mode and current mode apply to the full scale input ranges.

System accuracy is the total error between an actual input signal level and the module output data value.

System accuracy is effected by external wiring, signal noise, filter frequency , calibration, temperature, and

output data formats. The table below lists that system accuracy verses temperature.

T e mp V oltage Mode Current Mode

25°C Typical ±0.03% ± 6 mV ±0.05% ±10µA

60°C Max ±0.05% ±10mV ±0.10% ± 20µA

+ Note: Accuracy calculations are based on the full scale current and voltage input range. These are 0 to 20

mA and ±10V respectively.

6. 6 Range and Data Format Selection

Each of the module’s input ranges can be viewed in one of the four data in formats below. The table shows

the minimum and maximum values are equal to the under range and over range trip points.

Range Signed 16 bit* Unsigned 16 bit Unsigned 12 bit DV M

Min Max Min M ax Min Max Min Max

+/-0.05V -32,767 32,767 0 65,535 0 4,095 -5,000 5,000

+/-0.5V -32,767 32,767 0 65,535 0 4,095 -5,000 5,000

+/-2.0V -32,767 32,767 0 65,535 0 4,095 -2,000 2,000

+/-5.0V -32,767 32,767 0 65,535 0 4,095 -5,000 5,000

+/-10.0V -32,767 32,767 0 65,535 0 4,095 -10,000 10,000

0..5V -32,767 32,767 0 65,535 0 4,095 0 5,000

1..5V -32,767 32,767 0 65,535 0 4,095 1,000 5,000

0..10V -32,767 32,767 0 65,535 0 4,095 0 10,000

+/-20mA -32,767 32,767 0 65,535 0 4,095 -2,000 2,000

0..20mA -32,767 32,767 0 65,535 0 4,095 0 2,000

4..20mA -32,767 32,767 0 65,535 0 4,095 400 2,000

Resistance 150 ohm 2/4 wire -32,767 32,767 0 65,535 0 4,095 0 1,500

Resistance 150 ohm 3 wire -32,767 32,767 0 65,535 0 4,095 0 1,500

Resistance 500 ohm 2/4 wire -32,767 32,767 0 65,535 0 4,095 0 5,000

Resistance 500 ohm 3 wire -32,767 32,767 0 65,535 0 4,095 0 5,000

Resistance 1000 ohm 2/4 wire -32,767 32,767 0 65,535 0 4,095 0 10,000

Resistance 1000 ohm 3 wire -32,767 32,767 0 65,535 0 4,095 0 10,000

Resistance 3000 ohm 2/4 wire -32,767 32,767 0 65,535 0 4,095 0 30,000

Resistance 3000 ohm 3 wire -32,767 32,767 0 65,535 0 4,095 0 30,000

40

Page 39

16-Channel Universal Analog Input Module

Range Signed 16 bit** Unsigned 16 bit Unsigned 12 bit DVM deg C DVM deg F

Min Max Min M ax Min Max Min Max Min Max

RTD Pt 385 -32,767 32,767 0 65,535 0 4,095 -2,000 8,500 3,280 15,620

RTD Pt 385 -32,767 32,767 0 65,535 0 4,095 -2,000 8,500 3,280 15,620

RTD Pt 385 -32,767 32,767 0 65,535 0 4,095 -2,000 8,500 3,280 15,620

RTD Pt 385 -32,767 32,767 0 65,535 0 4,095 -2,000 8,500 3,280 15,620

RTD Pt 3916 -32,767 32,767 0 65,535 0 4,095 -2,000 6,600 3,280 11,660

RTD Pt 3916 -32,767 32,767 0 65,535 0 4,095 -2,000 6,600 3,280 11,660

RTD Pt 3916 -32,767 32,767 0 65,535 0 4,095 -2,000 6,600 3,280 11,660

RTD Pt 3916 -32,767 32,767 0 65,535 0 4,095 -2,000 6,600 3,280 11,660

RTD Nickel 618 -32,767 32,767 0 65,535 0 4,095 -600 2,500 -760 3,560

RTD Nickel 618 -32,767 32,767 0 65,535 0 4,095 -600 2,500 -760 3,560

RTD Nickel 618 -32,767 32,767 0 65,535 0 4,095 -600 2,500 -760 3,560

RTD Nickel 618 -32,767 32,767 0 65,535 0 4,095 -600 2,500 -760 3,560

R TD Copper 426 -32,767 32,767 0 65,535 0 4,095 1,000 2,600 1,480 5,000

RTD Nickel 672 -32,767 32,767 0 65,535 0 4,095 -800 2,600 1,120 5,000

R TD Nickel/Iron 518 -32,767 32,767 0 65,535 0 4,095 1,000 2,000 1,480 3,920

Thermocouple type J -32,767 32,767 0 65,535 0 4,095 -2,100 7,600 -3,460 14,000

Thermocouple type K -32,767 32,767 0 65,535 0 4,095 -2,700 13,700 -4,540 24,980

Thermocouple type T -32,767 32,767 0 65,535 0 4,095 -2,700 4,000 -4,540 7,520

Thermocouple type E -32,767 32,767 0 65,535 0 4,095 -2,700 10,000 -4,540 18,320

Thermocouple type R -32,767 32,767 0 65,535 0 4,095 0 17,680 320 32,140

Thermocouple type S -32,767 32,767 0 65,535 0 4,095 0 17,680 320 32,140

Thermocouple type B -32,767 32,767 0 65,535 0 4,095 3,000 18,200 5,720 32,667*

Thermocouple type N -32,767 32,767 0 65,535 0 4,095 0 13,000 320 23,720

* Thermocouple Type B readings are clipped at 32,767 counts fo rthe DVM and degF scales. Readings above 32,767 are

flagged as an over-range error .

** Same as 15bit + sign.

6.7 RTD and Thermocouple inputs.

Thermocouples convert temperature to very small voltages. The Quantum Universal module’ s specifications

for thermocouple inputs assume the 50/60 Hz filter setting or the low speed (7.8 Hz 3dB, 28Hz stop freq) filter

is being used. These two filter settings are recommended for thermocouple inputs. Using the two faster filter

settings will provide a faster update rate, but with noise and accuracy degradation.

RTDs are resistance temperature detectors. RTDs convert temperature to resistance levels which the

quantum universal measures. In some cases the resistance change per degree is very small. The accuracy

specifications assume the 50/60 Hz filter or the low speed filter (7.8Hz 3db) is being used. These two filter

settings are recommended for RTD inputs.

Recommended filter settings for R TD and thermocouple inputs are listed below.

Filter J, K, T, E, N S, B, N RTD

Thermocouple inputs Thermocouple inputs Inputs

Reject 50/60Hz Recommended Recommended Recommended

Reject 28Hz Recommended Recommended Recommended

Reject 800 Hz Some accuracy Not recommended Minimal

degradation accuracy degradation

Reject 6400Hz Do not use Do not use Not recommended

41

Page 40

Quantum Series 140 AUI 040 00sc

Thermocouples and R TDs are linearized per the following standards:

Thermocouple: per NIST , ITS-90

R TD:

Pt 385: IEC751-1983

Pt 392: JISC1604-1989

Ni 618: DIN 43760

Ni 672: MINCO Application Aid #18, Date 5/90 Type Ni

Cu 426: SAMA RC21-4-1966

Ni/Fe 518: MINCO Application Aid #18, Date 5/90 T ype Ni-Fe

RTDs use a switched current source to measure resistance. The settling time for this source has been set so

that R TD inputs will operate properly with a cable length of up to 1000 feet.

Thermocouple inputs require cold junction compensation to acquire accurate data. Thermistors perform cold

junction compensation by measuring the temperature of the terminal block where the thermocouple wire

connects to the terminals. The two CJC headers measure this temperature at the top and bottom of the

terminal block and software interpolates the temperature for all points inbetween. As a simple rule of thumb,

the less temperature difference between the top and the bottom of ther terminal block, the more accurate the

cold junction compensation will be. To achieve the best results it is recommended the module be kept away

from any significant source of heat The CJC headers have been designed for easy installation into the

Quantum universal terminal block as shown in section 5.3. However these thermistors can be installed to a

remote location to provide remote CJC compensation if necessary .

T o meet specified accuracy the module should be mounted vertically and the terminal block door should be

closed.

42

Page 41

16-Channel Universal Analog Input Module

Chapter 7

TROUBLESHOOTING

7.1 General Information

Review of the Module Setup Procedures in Section 2.1 is recommended prior to following the troubleshooting

steps below to help isolate the problem. The troubleshooting guide lists a variety of possible problems. Step

through each item on the list and verify whether or not the module is working. If a particular step is not

working, follow the corrective action listed.

STEP 1: Check module power and self test.

VERIFY: The controller module’s READY and RUN LED’s are on.

CORRECTIVE ACTION:

• Insure that the rack’s power supply is connected properly and its PWR OK LED is on.

• Place the controller in run mode by using the Modsoft Start Command.

• If the rack’s power will not come up, or the system will not go into run mode, refer to the Quantum Automation Series

Hardware Reference Guide for more information.

STEP 2: Check module power and self test.

VERIFY: The module’s green READY LED is on. This indicates that the module has power and has

completed it functional self test.

CORRECTIVE ACTION:

• Check rack power, and reinstall the module in the rack.

STEP 3: Check the module’s fault LED.

VERIFY: The module’s red FAULT LED is off. This LED indicates a module hardware error.

CORRECTIVE ACTION:

• The module has a fatal hardware error. Contact your local distributor or Spectrum Controls Customer Satisfaction

Group listed at the back of this manual.

The module has a front LED panel that includes 19 LEDs:

Ready LED 1 Green LED indicates module’s self test has passed and is ready to communicate.

Active LED 1 Green LED indicates BUS communication is established between the module the rack.

43

Page 42

Quantum Series 140 AUI 040 00sc

Fault LED 1 Red LED indicates a module self test error, or fatal H/W error. A blink code will be defined that will

indicate the type of self test error. Count the number of blinks before a pause to determine the error code in

the table below .

Fault LED Blink Code

Blink # Fault

1 ROM CRC Error

2 EEPROM Error

3 RAM Error

4 Autocal Error

5 Watchdog Timer Error

6 CPU Error

7 DPM Error

Channel LED 32 Green LEDs indicates the channel is enabled and a valid input signal level is present. The LED is off if the

channel is disabled. A blinking LED indicates that the channel has exceeded a range limit.

STEP 4: Check the module’s communication status.

VERIFY: The module’s green ACTIVE LED is on. This indicates that the module is communicating properly

with the rack.

CORRECTIVE ACTION:

• Set the rack into run mode.

• Reinstall the module in the rack.

STEP 5: Check the module’s health status.

VERIFY: The module is reported as healthy in the Modsoft I/O map Screen. Check to make sure that the

module description, slot location, and register assignments are correct. Also, verify that the module is recognized and reported as healthy. If an asterisk is present before the module’s name, then the module is not

recognized by the rack.

CORRECTIVE ACTION:

• Reinstall the module in the rack.

• Reselect the module in the I/O Map using the <Shift + ?> key. If the module is not listed, install the Modsoft Runtime

files included with your module.

STEP 6: Check the module’s register operation.

VERIFY: The 4X configuration word and the 3X+8 Status word are setup properly. As a quick check,

disable all ladder programming and set the 4X register to 0000 Hex and verify that the 3X+8 Status register

cycles through the values 0000, 0001, 0010, and 0011 Hex.

44

Page 43

16-Channel Universal Analog Input Module

CORRECTIVE ACTION:

• Check steps 1 through 6 above and then call Spectrum Controls Customer Satisfaction at (425) 746-9481.

45

Page 44

Quantum Series 140 AUI 040 00sc

46

Page 45

16-Channel Universal Analog Input Module

Chapter 8

SPECIFICATIONS

1.1 Electrical Specifications

· Number of Channels 16 differential V , I, TC multiplexed inputs or 8 RTD inputs

· Configuration 4 groups of 4 inputs. All configuration occurs via software.

· Input Ranges Thermocouple types: J,K,T ,E,R,S,B,N

V oltage: ±50mV , ±100mV , ±0.5V, ±2.0V , 0 to 5V ,

1 to 5V , 0 to 10V, ±10.0V

Current: 0 to 20 mA, 4 to 20 mA, ±20mA

R T D : 100 Ohm Pt 385 Alpha

200 Ohm Pt 385 Alpha

500 Ohm Pt 385 Alpha

1000 Ohm Pt 385 Alpha

100 Ohm Pt 392 Alpha

200 Ohm Pt 392 Alpha

500 Ohm Pt 392 Alpha

1000 Ohm Pt 392 Alpha

100 Ohm Nickel 618 Alpha

200 OhmNickel 618 Alpha

500 Ohm Nickel 618 Alpha

1K Ohm Nickel 618 Alpha

10 Ohm Copper 426 Alpha

120 Ohm Nickel 618 Alpha

120 Ohm Nickel 672 Alpha

604 Ohm Nickel/Iron 518 Alpha

2, 3, and 4 wire connection supported.

Resistance: 150, 500, 1000, and 3000 Ohm

· Cold Junction Compensation T wo terminal block CJCs

· Input Linearization Thermocouple: per NIST , ITS-90

R TD:

Pt 385: IEC751-1983

Pt 392: JISC1604-1989

Ni 618: DIN 43760

Ni 672: MINCO Application Aid #18, Date 5/90 Type Ni

Cu 426: SAMA RC21-4-1966

Ni/Fe 518: MINCO Application Aid #18, Date 5/90 T ype Ni-Fe

V oltage or Current: Not Applicable

· RTD excitation: 2.5mA/0.3mA

· RTD wire length 1000 foot maximum w/settling time of 1msec TBV.

· CJC: Two IC sensors located at terminal block.

· Fault detection: Over and under-range

At Full Scale for +/-10V

Open thermocouple

Open RTD

47

Page 46

Quantum Series 140 AUI 040 00sc

· Filter Frequencies 7.8, 13.65, 209.6, 1676 3dB

· Resolution 24 bit Sigma Delta ADC

· Data Formats DVM (both °C and °F), 16 bit unsigned, 12 bit unsigned, 16 bit signed

· Conversion Type Sigma Delta ADC

· Analog Input Conversion Rate

Input Channel Update Time (V, I, TC, RTD 4wire) estimated

Filter 1 Channel 16 Channels

7.8 Hz 124ms 1992ms

13.65 Hz 73ms 1168ms

209.6 Hz 7.6ms 122ms

1.677kHz 4.7ms 76ms

+ Note: Channel update time is the time required for the module to acquire an input sign and update the module’s data

registers. The scan rate of the Quantum system will vary with application ladder and system configuration.

+ When using RTDs add 3ms per channel. For 3-wire DTR configurations double the update time of wire resistance is

measured every cycle.

+ When using thermocouples the CJC calibration time will increase scan times by 150ms and channel update times by 1ms.

+ Note: Periodic system calibration will also effect channel update times for one scan cycle.

· Normal Mode Rejection 64.5 dB, 50 Hz, 60 Hz with 50/60 Hz rejection filter selection

88dB with high noise rejection setting.

· Common Mode Rejection 96dB 50 Hz, 60 Hz with 50/60 Hz filter selected.

120dB with high noise rejection setting.

· Input Resistance > 10M Ohm V oltage/Thermocouple/R TD

=250 Ohm Current

1.1A Table - Thermocouple Accuracy

Table 1.1A shows Thermocouple Accuracy at Selected Temperatures in degrees Celsius below and illustrates how accuracy

of thermocouple input changes over the temperature range. This is caused by a non-linear slope the thermocouples exhibit

which is “steep” (10s of microvolts per degree) at high temperatures and “flat” (microvolts per degree) at low temperatures.

Thus the accuracy tends to be very good at high temperatures and remains fairly good until about –100 degrees C (depending

on thermcouple type) where it becomes worse. The accuracy table below assumes that the module is mounted in a vertical

orientation and the terminal block door is closed.

Thermocouple Accuracy at Selected Temperatures in degr ees Celsius

TC Type Temp Typ Max Temp Typ Max Temp Typ Max Temp Typ Max Temp Typ Max

J -210 2.5 4.5 -200 2.5 4.1 -100 1.1 2.1 275 0.9 1.7 760 0.8 1.7

K -270 17 24 -200 2 4.8 -100 1.2 2.5 550 1 2.0 1370 1.1 3.0

T -270 13.5 2 0 -200 5.8 10 -100 1.6 2.8 65 0.9 1.7 400 0.7 1.4

E -270 13 18.5 -200 5.5 10 -100 1.2 2.2 365 0.8 1.4 1000 1 1.9

R0 2.3 5.6 885 1 2.7 1768 1.1 3.3

S03.5 5.6 885 1.7 3.0 1768 1.8 3.5

B 300 3.9 10.8 600 2.2 5.6 1060 1.5 3.2 1820 1.4 3.1

N0 0.9 2.1 650 0.8 1.8 1300 1.1 2.3

48

Page 47

16-Channel Universal Analog Input Module

1.1B Table - Thermocouple Accuracy

Table 2 Thermocouple Accuracy per temperature range below shows the accuracy of thermocouple inputs over a range of temperatures.

T able 2 Thermocouple Accuracy per temperature range

Range 1 (deg C) Range 2 (deg C) Range 3 (deg C) typ/max CJC accuracy

TC Range Spec Range Spec Range Spec

J -100 to +760 1.1 -200 to -100 2.5 typ 0.7 deg C

K -100 to 1370 1.2 -200 to -100 2 -270 to -200 19 typ 0.7 deg C

T -100 to 400 1. 6 -200 to -100 5.8 -270 to -200 15.5 typ 0.7 deg C

E -100 to 1000 1.2 -200 to -100 5.5 -270 to -200 14.5 typ 0.7 deg C

R 0 to 1768 2.3 typ 0.7 deg C

S 0 to 1768 3. 5 typ 0.7 deg C

B 600 to 1820 2.2 300 to 600 2.2 typ 10 deg C

N 0 to 1300 0.9 typ 0.7 deg C

J -100 to +760 2.1 -210 to -100 4.8 max 1.25 deg C

K -100 to 1370 3.0 -200 to -100 4.8 -270 to -200 24 max 1.25 deg C

T -100 to 400 2 .8 -200 to -100 10 -270 to -200 20 max 1.25 deg C

E -100 to 1000 2.2 -200 to -100 10 -270 to -200 18.5 max 1.25 deg C

R 0 to 1768 5.6 max 1.25 deg C

S 0 to 1768 5. 6 max 1.25 deg C

B 600 to 1820 4.6 300 to 600 10.8 max 40 deg C

N 0 to 1300 2.3 max 1.25 deg C

1.1B Table - RTD Accuracy

R TD T y pe Resistance (Ω) Range (deg C) Range (deg F) T ypical Max

Acc. (deg C) Error (deg C)

RTD 385 Alpha 10 0 -200 to +850 -328 to +1562 0.5 1. 6

RTD 385 Alpha 20 0 -200 to +850 -328 to +1382 0.5 1. 6

RTD 385 Alpha 50 0 -200 to +850 -328 to +1562 0.5 1. 6

RTD 385 Alpha 1000 -200 to +850 -328 to +1562 0 .5 1. 6

RTD 3916 Alpha 10 0 -200 to +630 -328 to +1166 0 .4 1. 3

RTD 3916 Alpha 20 0 -200 to +630 -328 to +1166 0 .4 1. 3

RTD 3916 Alpha 50 0 -200 to +630 -328 to +1166 0 .4 1. 3

RTD 3916 Alpha 1000 -200 to +630 -328 to +1166 0.4 1. 3

RTD Nickel 618 100 -60 to +180 -76 to +356 0.2 0. 6

RTD Nickel 618 200 -60 to +180 -76 to +356 0.2 0. 6

RTD Nickel 618 500 -60 to +180 -76 to +356 0.2 0. 6

RTD Nickel 618 1000 -60 to +180 -76 to +356 0. 2 0.6

RTD Copper 426 10 -100 to +260 -148 to +500 0.3 0.9

RTD Nickel 672 120 -80 to +260 -112 to +500 0. 2 0.6

RTD Nickel/Iron 518/604 -100 to +200 -148 to +392 0.2 0. 6

49

Page 48

Quantum Series 140 AUI 040 00sc

1.1C Table - Resistance Accuracy

Resistance Range (Ω) Accuracy (Ω) Max Error(Ω)

15 0 0 to 150 0.1 0. 2

45 0 0 to 500 0.2 0. 7

95 0 0 to 1000 0.5 1. 4

3000 0 to 3000 1.5 4.4

1.1D Table - Voltage & Current Accuracy

Voltage/Current

Range Accuracy (%FS)

Typ (25C) Max (temp)

+/-50mV 0.025 0.05

+/- 0.5V 0.025 0.05

+/-2V 0.025 0.05

+/- 5V 0.025 0.05

10V 0.05 0.10

0 to 20mA 0.10 0.20

4 to 20mA 0.10 0.20

+/-20mA 0.05 0.10

· CJC Accuracy <±1 .3 °C

· Calibration Modules will be factory-calibrated, then stored in EEPROM.

Software controlled auto-calibration will occur periodically.

· Maximum Overvoltage +/-20 VDC continuous +/-14VDC CJC Inputs

· Maximum Overcurrent 28 mA continuous

· Isolation Voltage 1000VDC terminal block to backplane

+/-12.5VDC channel to channel

· Backplane Current draw 550mA @ 5VDC

· Thermal Dissipation 2 W

· External DC Power Required No

1.2 System Specifications

Specification Description

Data Registers:

Output (4X) 1 Configuration Registers

Input (3X) 9 registers; 8 input registers, 1 status register

Zoom 4 configuration registers

LED Indicators A standard 16 channel LED array will be used

1 Green LED Ready. Module has passed self-test and is ready to communicate.

1 Red LED Fault: Indicates module self-test error or fatal HW error.

16 Green LED Input point status.

Terminal Block Standard 40 pin Quantum connector #43502767

Wire Size 1-14A WG , or 2-16A WG wires

Interface Quantum standard ASIC and dual-port SRAM BIU

Compatibility

Hardware All Modicon Quantum Racks and all current MPUs

50

Page 49

16-Channel Universal Analog Input Module

Software Modsoft V2.X, Concept Vx.x

Compatibility with zoom screen configuration menu.

Dimensions Single Quantum Slot,

Standard Enclosure, plastic, T erminal Block and LED array .

Weight 1lbs (452g) max.

1.3 Environmental Specifications

Environmental tests are run in accordance with the standards specified or in accordance to IPA2000/3000 or equal compliance.

T est Description Standard Class/Limit

Mechanical

V ibration of Unpackaged Products IE C 68-2-6 5g @ 10-500Hz per

Shock of Unpackaged Products Operating

Non Operating 30g peak acceleration, 11(+/-1)ms pulse width

50g peak acceleration, 11(+/-1)ms

T emperature / Humidity

Operating T emperature 0 to 60 C (32 to 131F) minimum

Storage T emperature -40 to 85 C

Humidity-Temperature IEC 68-2-3 0 to 95% RH non condensing @ 60 degree C

Altitude 2000 Meters fully operational

Electrical

Electrostatic Discharge IEC 801-2

Surge Transient Susceptibility

Radiated EMI Susceptibility IEC 801-3

Dielectric Withstand

Conducted EMI Susceptibility

Conducted Emissions CISPR 11 Class A

Electrical Fast Transient IEC 801-4

Radiated Emissions CISPR 11 Class A

Surge Impulse IEC 801-5

Conducted Immunity IEC 801-6

Fast Surge Immunity EN61000-4-5

V oltage Dropouts:

(V ariation & Dips) EN61000-4-11

Reference: SA IAP 2000 Mechanical Environmental Specifications #043 500021 Rev: 1.02

51

Page 50

Quantum Series 140 AUI 040 00sc

52

Page 51

16-Channel Universal Analog Input Module

Notice

The products and services described in this publication are useful in a wide variety of applications. Therefore,