Page 1

SURVEY PRO

for Recon & Nomad

Reference Manual

© 2008 Tripod Data Systems, Inc.

All Rights Reserved

Page 2

IMPORTANT: BY OPENING THE SEALED MEDIA PACKAGE, YOU ARE AGREEING TO BE BOUND BY THE TERMS AND CONDITIONS OF

THE LICENSE AGREEMENT AND LIMITATIONS OF LIABILITY ("Agreement"). THIS AGREEMENT CONSTITUTES THE COMPLETE

AGREEMENT BETWEEN YOU AND TRIPOD DATA SYSTEMS, INC. ("Licensor"). CAREFULLY READ THE AGREEMENT AND IF YOU DO

NOT AGREE WITH THE TERMS, RETURN THE UNOPENED MEDIA PACKAGE AND THE ACCOMPANYING ITEMS (including written

materials and binders or other containers) TO THE PLACE WHERE YOU OBTAINED THEM FOR A FULL REFUND.

LICENSE. LICENSOR grants to you a limited, non-exclusive license to (i) install and operate the copy of the computer program contained in this

package ("Program") on a single computer (one central processing unit and associated monitor and keyboard) and (ii) make one archival copy of the

Program for use with the same computer. LICENSOR retains all rights to the Program not expressly granted in this Agreement.

OWNERSHIP OF PROGRAMS AND COPIES. This license is not a sale of the original Program or any copies. LICENSOR retains the ownership of

the Program and all subsequent copies of the Program made by you, regardless of the form in which the copies may exist. The Program and

accompanying manuals ("Documentation") are copyrighted works of authorship and contain valuable trade secrets and confidential information

proprietary to LICENSOR. You agree to exercise reasonable efforts to protect LICENSOR'S proprietary interest in the Program and Documentation

and maintain them in strict confidence.

USER RESTRICTIONS. You may physically transfer some Programs from one computer to another provided that the Program is operated only on

one computer. Other Programs will operate only with the computer that has the same security code and cannot be physically transferre d to another

computer. You may not electronically transfer the Program or operate it in a time-sharing or service bureau operation. You agree not to translate,

modify, adapt, disassemble, de-compile, or reverse engineer the Program, or create derivative works based on the Program or Documentation or any

portions thereof.

TRANSFER. The Program is provided for use in your internal commercial business operations and must remain at all times upon a single computer

owned or leased by you. You may not rent, lease, sublicense, sell, assign, pledge, transfer or otherwise dispos e of the Program or Documentati on, on

a temporary or permanent basis, without the prior written consent of LICENSOR.

TERMINATION. This License is effective until terminated. This License will terminate automatically without notice from LICENSOR if you fail to

comply with any provision of this License. Upon termination you must cease all use of the Program and Documentation and return them, and any

copies thereof, to LICENSOR.

GENERAL. This License shall be governed by and construed in accordance with the laws of the State of Oregon, United States of America.

LICENSOR grants solely to you a limited warranty that (i) the media on which the Program is distributed shall be substantially free from material

defects for a period of NINETY (90) DAYS, and (ii) the Program will perform substantially in accordance with the material descriptions in the

Documentation for a period of NINETY (90) DAYS. These warranties commence on the day you first obtain the Program and extend only to you, the

original customer. These limited warranties give you specific legal rights, and you may have other rights, which vary from state to state.

Except as specified above, LICENSOR MAKES NO WARRANTIES OR REPRESENTATIONS, EXPRESS OR IMPLIED, REGARDING THE

PROGRAM, MEDIA OR DOCUMENTATION AND HEREBY EXPRESSLY DISCLAIMS THE WARRANTIES OF MERCHANTABILITY AND

FITNESS FOR A PARTICULAR PURPOSE. LICENSOR does not warrant the Program will meet your requirements or that its operations will be

uninterrupted or error-free.

If the media, Program or Documentation are not as warranted above, LICENSOR will, at its option, repair or replace the nonconforming item at no

cost to you, or refund your money, provided you return the item, with proof of the date you obtained it, to LICENSOR within TEN (10) DAYS after

the expiration of the applicable warranty period. If LICENSOR determines that the particular item has been damaged by accident, abuse, misuse or

misapplication, has been modified without the written permission of LICENSOR, or if any LICENSOR label or serial number has been removed or

defaced, the limited warranties set forth above do not apply and you accept full responsibility for the product.

The warranties and remedies set forth above are exclusive and in lieu of all others, oral or written, express or implied. Statements or

representations which add to, extend or modify these warranties are unauthorized by LICENSOR and should not be relied upon by you.

LICENSOR or anyone involved in the creation or delivery of the Program or Documentation to you shall have no liability to you or any third party

for special, incidental, or consequential damages (including, but not limited to, loss of profits or savings, downtime, damage to or replacement of

equipment and property, or recovery or replacement of programs or data) arising from claims based in warranty, contract, tort (including

negligence), strict liability, or otherwise even if LICENSOR has been advised of the possibili ty of such claim or damage. LICENSOR'S liability for

direct damages shall not exceed the actual amount paid for this copy of the Program.

Some states do not allow the exclusion or limitation of implied warranties or liability for incidental or consequential damages, so the above

limitations or exclusions may not apply to you.

If the Program is acquired for use by or on behalf of a unit or agency of the United States Government, the Program and Documentation are provided

with "Restricted Rights". Use, duplication, or disclosure by the Government is subject to restrictions as set forth in subparagraph (c)(1)(ii) of the

Rights in Technical Data and Computer Software clause at DFARS 252.227-7013, and to all other regulations, restrictions and limitations applicable

to Government use of Commercial Software. Contractor/manufacturer is Tripod Data Systems, Inc., PO Box 947, Corvallis, Oregon, 97339, United

States of America.

Should you have questions concerning the License Agreement or the Limited Warranties and Limitation of Liability, please contact in writing:

Tripod Data Systems, Inc., PO Box 947, Corvallis, Oregon, 97339, United States of America.

The TDS triangles logo, the TDS icons and Survey Pro are trademarks of Tripod Data Systems, Inc. Windows CE, ActiveSync, the Windows logo and

Pocket PC are trademarks or registered trademarks of Microsoft Corporation in the United States and/or other countries. Bluetooth and the

Bluetooth symbol are registered trademarks of Bluetooth SIG Inc. USA. CompactFlash is a registered trademark of SanDisk Corp. All other names

mentioned are trademarks, registered trademarks or service marks of their respective companies. This software is based in part on the work of the

Independent JPEG Group.

TRIPOD DATA SYSTEMS SOFTWARE LICENSE AGREEMENT

LIMITED WARRANTIES AND LIMITATION OF LIABILITY

U.S. GOVERNMENT RESTRICTED RIGHTS

TRADEMARKS

900-0033-XXQ 052008

ii

Page 3

Table of Contents

Reference

Welcome..................................................................................................1

Main Menu.............................................................................................3

File Menu................................................................................................7

Open / New .............................................................................. 8

New Job...................................................................................... 9

Save As.....................................................................................15

Import....................................................................................... 16

Export....................................................................................... 22

Import Control Points............................................................ 26

Backup / Restore Job ............................................................. 26

Transfer.................................................................................... 31

Register Modules.................................................................... 32

About Survey Pro................................................................... 33

Exit............................................................................................ 33

Job Menu..............................................................................................35

Settings..................................................................................... 36

Edit Points................................................................................ 60

Edit Polylines........................................................................... 65

Edit Alignments......................................................................69

Auto Linework........................................................................77

View Raw Data File................................................................81

View DTM................................................................................84

Manage Layers........................................................................91

Job Information....................................................................... 92

Calculator................................................................................. 93

Manage Pictures...................................................................... 95

Take Picture.............................................................................96

Job Menu – GPS..................................................................................99

Settings................................................................................... 100

Job Menu – Basic GPS......................................................................115

Settings................................................................................... 116

iii

Page 4

Survey Menu...................................................................................... 123

Backsight Setup..................................................................... 124

Traverse / Sideshot.............................................................. 130

Repetition Shots.................................................................... 136

Multiple Sideshots................................................................138

Radial Sideshots.................................................................... 139

Distance Offset...................................................................... 140

Horizontal Angle Offset ...................................................... 141

Vertical Angle Offset............................................................ 142

Auto Collect........................................................................... 143

Corner & 2 Lines................................................................... 145

Corner & Angle..................................................................... 146

Corner & Offset..................................................................... 147

Corner & Plane...................................................................... 148

Surface Scan........................................................................... 149

Video Scan .............................................................................152

Shoot From Two Ends.......................................................... 156

Record Mode......................................................................... 157

Resection................................................................................ 158

Remote Elevation.................................................................. 161

Check Point............................................................................ 162

Solar Observation .................................................................163

Remote Control.....................................................................168

Survey Menu – GPS..........................................................................177

GPS Status.............................................................................. 178

Start GPS Survey................................................................... 184

Data Collection...................................................................... 197

Control Points........................................................................202

Post Processing...................................................................... 205

End GPS Survey.................................................................... 209

Base Setup..............................................................................210

Rover Setup ........................................................................... 211

Projection ...............................................................................211

Remote Elevation.................................................................. 234

Import GPS Control.............................................................. 235

Receiver Information............................................................ 240

iv

Page 5

Adjust with Projection.........................................................241

Projection Calculator............................................................246

File Management ..................................................................249

Survey Menu – Basic GPS...............................................................251

GPS Status.............................................................................. 252

Start GPS Survey................................................................... 252

Data Collection...................................................................... 259

Control Points........................................................................261

Post Processing...................................................................... 262

Projection ...............................................................................262

Receiver Information............................................................ 263

File Management ..................................................................263

Leveling Menu...................................................................................265

Select/Create Loop............................................................... 266

2 Peg Test............................................................................... 274

Adjustment............................................................................ 276

Leveling Remote Control..................................................... 278

Stakeout Menu ..................................................................................279

Stake Points............................................................................280

Stake List of Points Screen................................................... 285

Stake to Line..........................................................................287

Offset Staking........................................................................ 291

Slope Staking.........................................................................298

Point Slope Staking............................................................... 305

Stake Line and Offset........................................................... 309

Stake Curve and Offset........................................................ 312

Stake Spiral and Offset......................................................... 316

Show Station.......................................................................... 320

Store Offset Points................................................................322

Stake DTM............................................................................. 325

Station Staking ...................................................................... 330

Define a Location..................................................................334

Where is Next Point.............................................................. 336

Stakeout Menu – GPS and Basic GPS...........................................339

Stake Points............................................................................340

Stake to Line..........................................................................342

v

Page 6

Slope Staking.........................................................................345

Line and Offset...................................................................... 347

Curve and Offset................................................................... 348

Spiral and Offset................................................................... 348

Show Station and Offset ......................................................348

Store Offset Points................................................................350

Stake DTM............................................................................. 350

Where is Next Point.............................................................. 352

Inverse Menu.....................................................................................353

Inverse Point to Point........................................................... 354

Inverse Point to Line ............................................................ 355

Inverse Point to Polyline...................................................... 356

Inverse Point to Multiple Points......................................... 358

Inverse Point to Location / Point.......................................359

Cogo Menu.........................................................................................361

Point in Direction.................................................................. 362

Intersection............................................................................363

Offset Line.............................................................................. 365

Offset Points..........................................................................366

Station Offset......................................................................... 367

Corner Angle.........................................................................368

Compute Area.......................................................................369

Triangle Solutions................................................................. 370

Map Check............................................................................. 371

Predetermined Area.............................................................374

HD/VD to SD/ZA ............................................................... 376

SD/ZA to HD/VD ............................................................... 377

AU Conversion ..................................................................... 378

Average Points...................................................................... 379

Curve Menu........................................................................................381

Curve Solution......................................................................382

Known PI and Tangents......................................................384

Three Point Curve................................................................. 385

Compute Radius Point......................................................... 387

Line Tangent to Circles........................................................ 389

Curve Layout......................................................................... 389

vi

Page 7

Curve Layout......................................................................... 390

Traverse on Curve................................................................ 394

Parabolic Curve..................................................................... 396

Parabolic Layout................................................................... 398

Straight Grade....................................................................... 400

Spiral....................................................................................... 401

Spiral Layout......................................................................... 402

Traverse on Spiral................................................................. 403

Roads Menu.......................................................................................405

Add/Edit Templates............................................................406

Edit Alignments.................................................................... 409

Add/Edit Roads ................................................................... 409

Road Stakeout ....................................................................... 421

Road Slope Staking............................................................... 427

Road Station and Offset.......................................................430

Station Equation.................................................................... 433

Adjust Menu......................................................................................435

Scale........................................................................................ 436

Translate.................................................................................437

Rotate...................................................................................... 438

Traverse Adjust..................................................................... 439

Miscellaneous Screens.....................................................................445

Past Results............................................................................ 446

Create Points.......................................................................... 447

Edit Description List............................................................. 448

Trimble Slant HR -> HR ...................................................... 449

Convert Slant HI to HI.........................................................449

Quick Pick Editor.................................................................. 450

Select Point(s)........................................................................ 451

Map View............................................................................... 452

Map Display Options...........................................................454

Manage Basemaps................................................................ 455

Edit Basemaps....................................................................... 456

Smart Targets ........................................................................ 457

vii

Page 8

Appendix A

Transverse Mercator Zones.................................................A-1

Lambert Zones ......................................................................A-2

viii

Page 9

Welcome

Congratulations on your decision to purchase a Tripod Dat a Systems

product. TDS is serious about providing the best possible products to

our customers and know that you are serious about your tools. We are

proud to welcome you to the TDS family.

The TDS Survey Pro team is continually improving and updating

Survey Pro. Please take a few minutes to register your copy so that

you will be eligible for upgrades. You can do this either by completing

and returning the product registration card or by visiting our Web

site (www.tdsway.com).

R-1

Page 10

Page 11

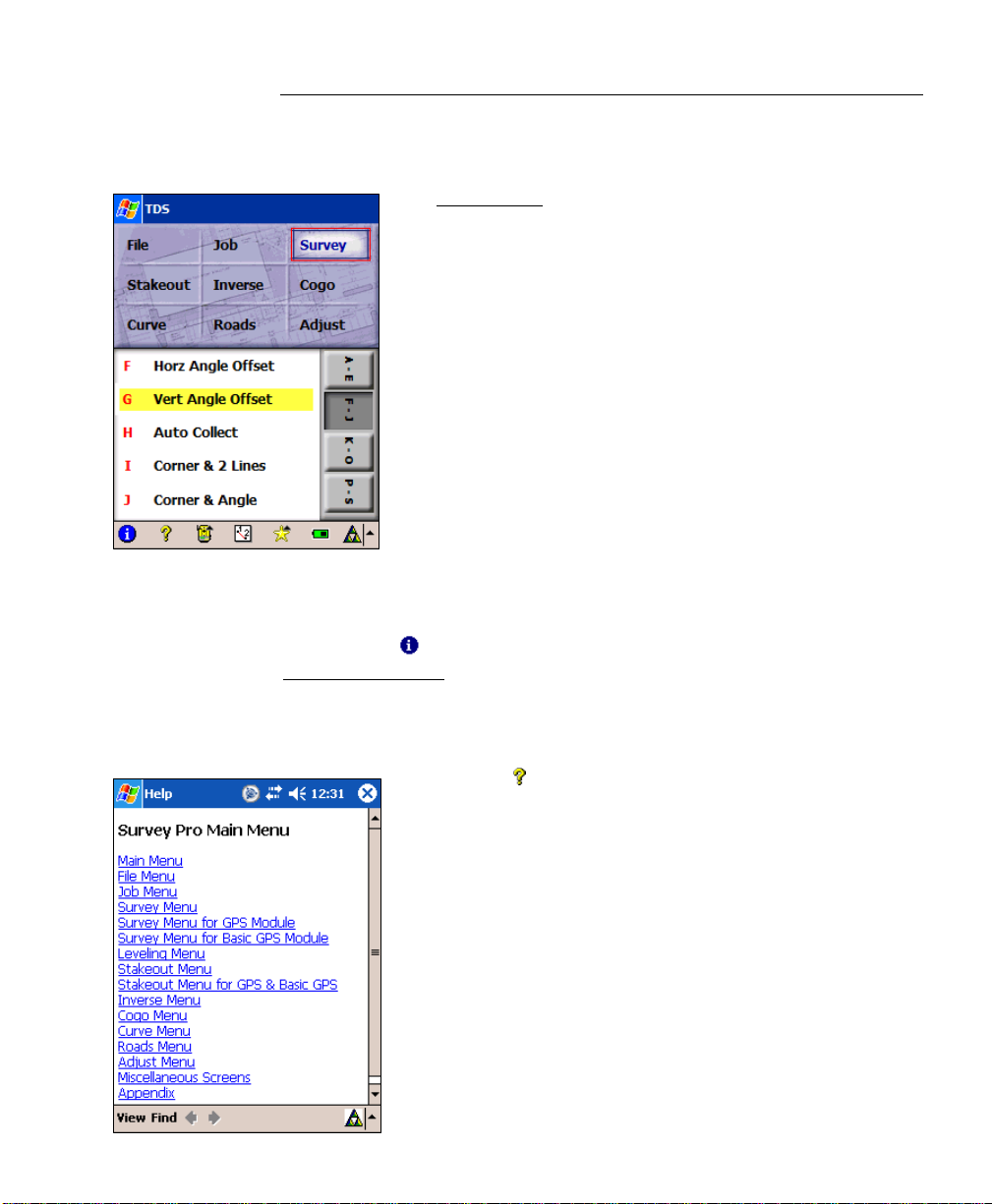

Main Menu

The Main Menu is the starting point where all the other

Survey Pro screens described in this manual are

accessed.

The area at the bottom of the screen is called the

command bar. The small buttons in the command bar

are used as follows:

About Survey Pro

Tapping the icon or selecting File | About Survey Pro opens the

About Survey Pro

screen. See Page R-33.

Online Help

Tapping the button opens the online help, which allows

you to access information similar to the information you

would find in the reference manual for each screen.

R-3

Page 12

Survey Pro Reference Manual

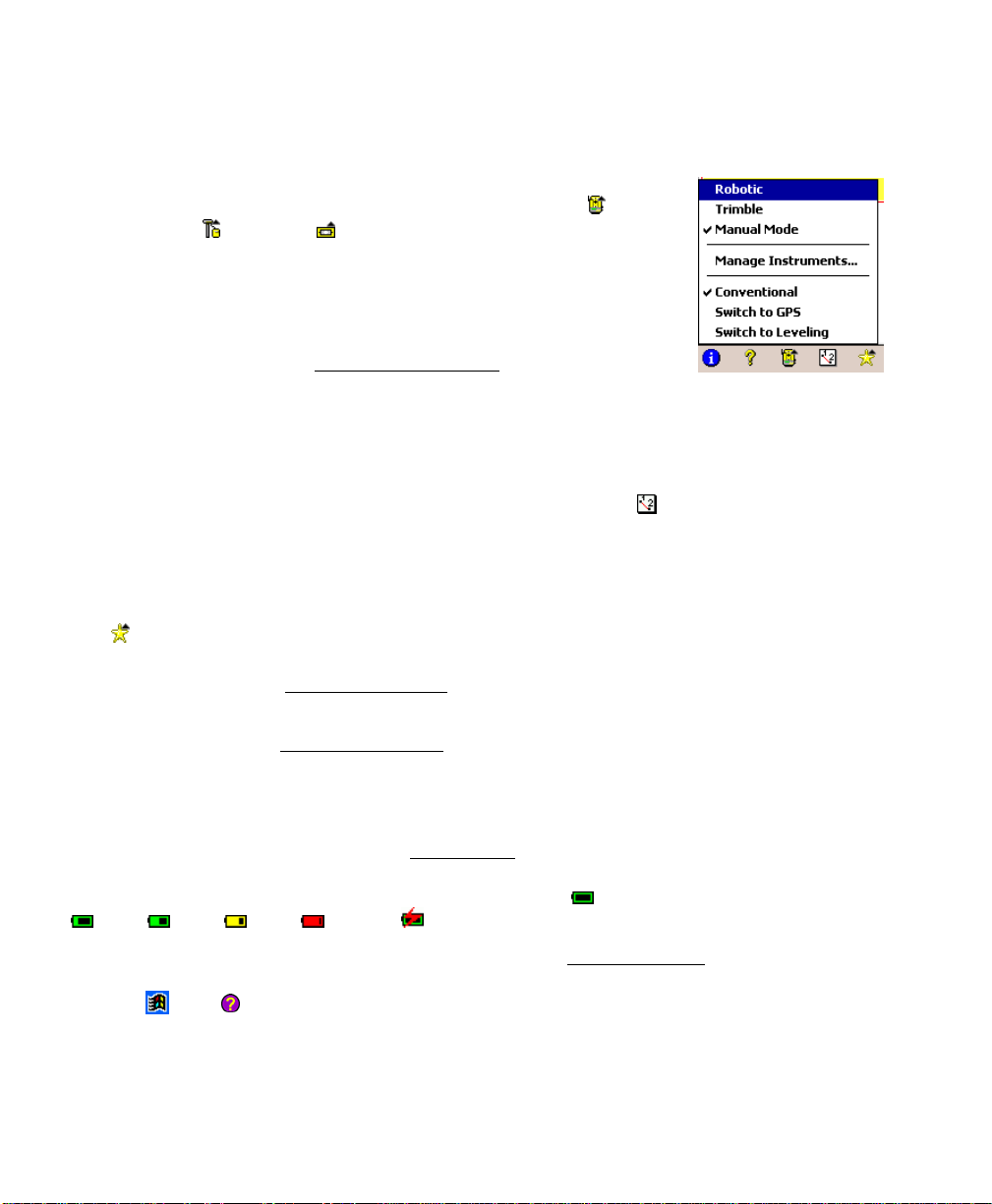

Surveying Mode

The instrument icon indicates which collection mode the software

is running in. There are three possible surveying modes:

Conventional,

open a list of options to do any of the following:

• Switch to another instrument mode.

• Select a different instrument profile.

GPS, and Leveling. Tapping this icon will

• Quickly access the Instrument Settings

screen (Page R-36).

Map View

A map view of the current job can be displayed by tapping the

button. See Page R-455.

Quick Pick

The (Quick Pick) button is used to quickly access any of a variety of

commonly-used Survey Pro routines. The l ist of routines available is

customizable using the Quick Pick Editor

The User’s Manual also contains more information on using the

Quick Pick button and Quick Pick Editor

(Page R-450).

.

Battery Level

The battery icon at the bottom of the Main Menu displays the

condition of the Survey Pro’s rechargeable battery. The icon has five

variations depending on the level of charge remaining:

75%, 50%, 25%, 5% and charging.

100%,

Tapping the battery icon is a shortcut to the Microsoft Power Settings

screen. You can get more information while viewing this screen by

tapping

R-4

then

.

Page 13

Main Menu

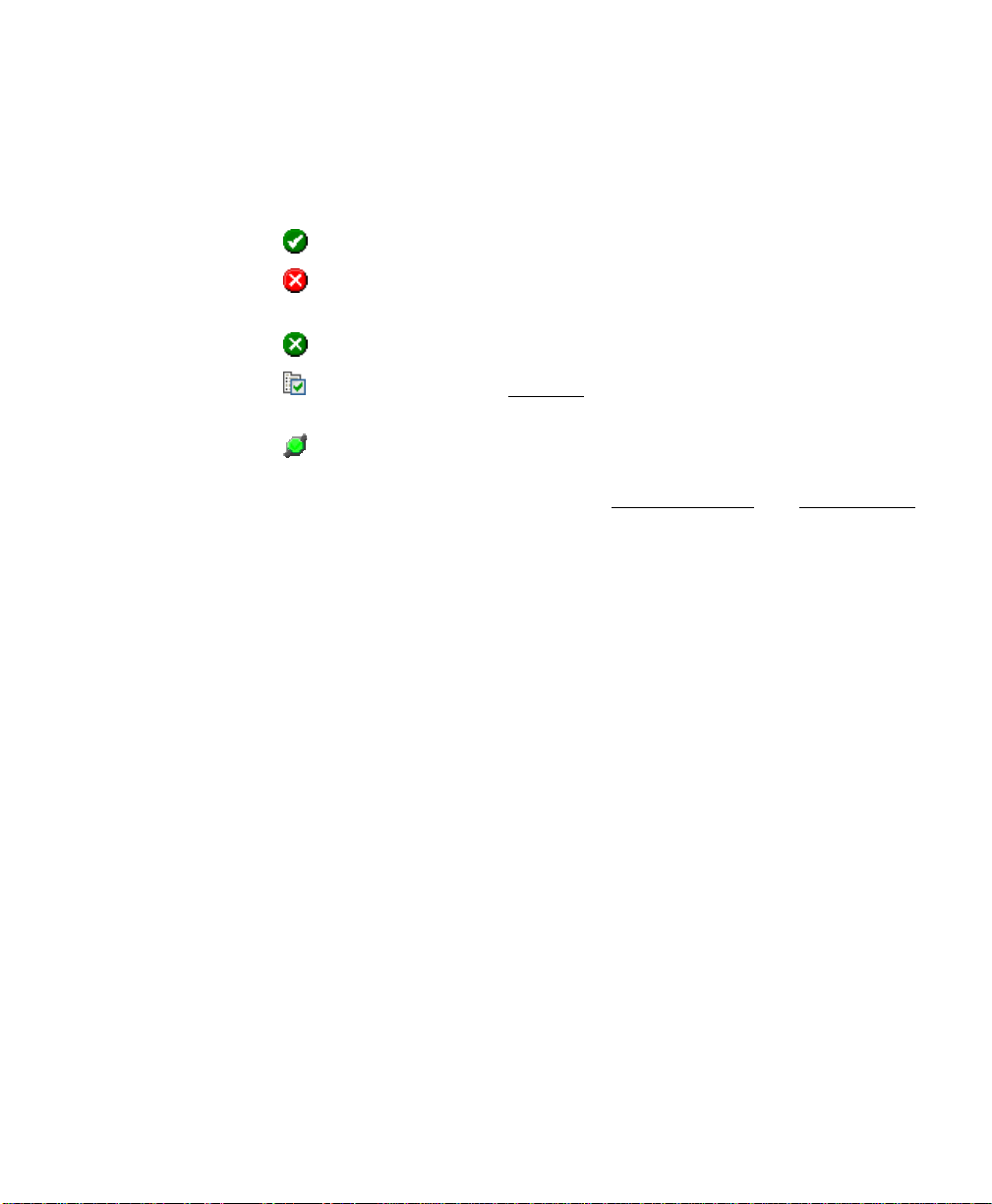

Other Command Bar Buttons

There are additional command bar buttons availab le i n scre ens other

than the Main Menu. Each is described below.

(OK): Performs the desired action then closes the current screen.

(Cancel - Red X): Closes the current screen without performing the

action intended by the screen.

(Close - Green X): Closes the current screen.

(Settings): Opens the Settings screen (Page R-36) associated with

the current screen.

(GPS Status): This is used to view the current status and access

the settings for a GPS receiver when using the GeoL ock feature (Page

R-168). It is only available from the Remot e Control

screens when using a Trimble or Geodimeter robotic total station.

and Remote Shot

R-5

Page 14

Page 15

File Menu

The File Menu contains routines to transfer files between the data

collector and another device.

A: Open / New

B: Save As

C: Import

D: Export

E: Control File

F: Backup / Restore Job

G: Transfer

H: Register Modules

I: About Survey Pro

J: Exit

R-7

Page 16

Survey Pro Reference Manual

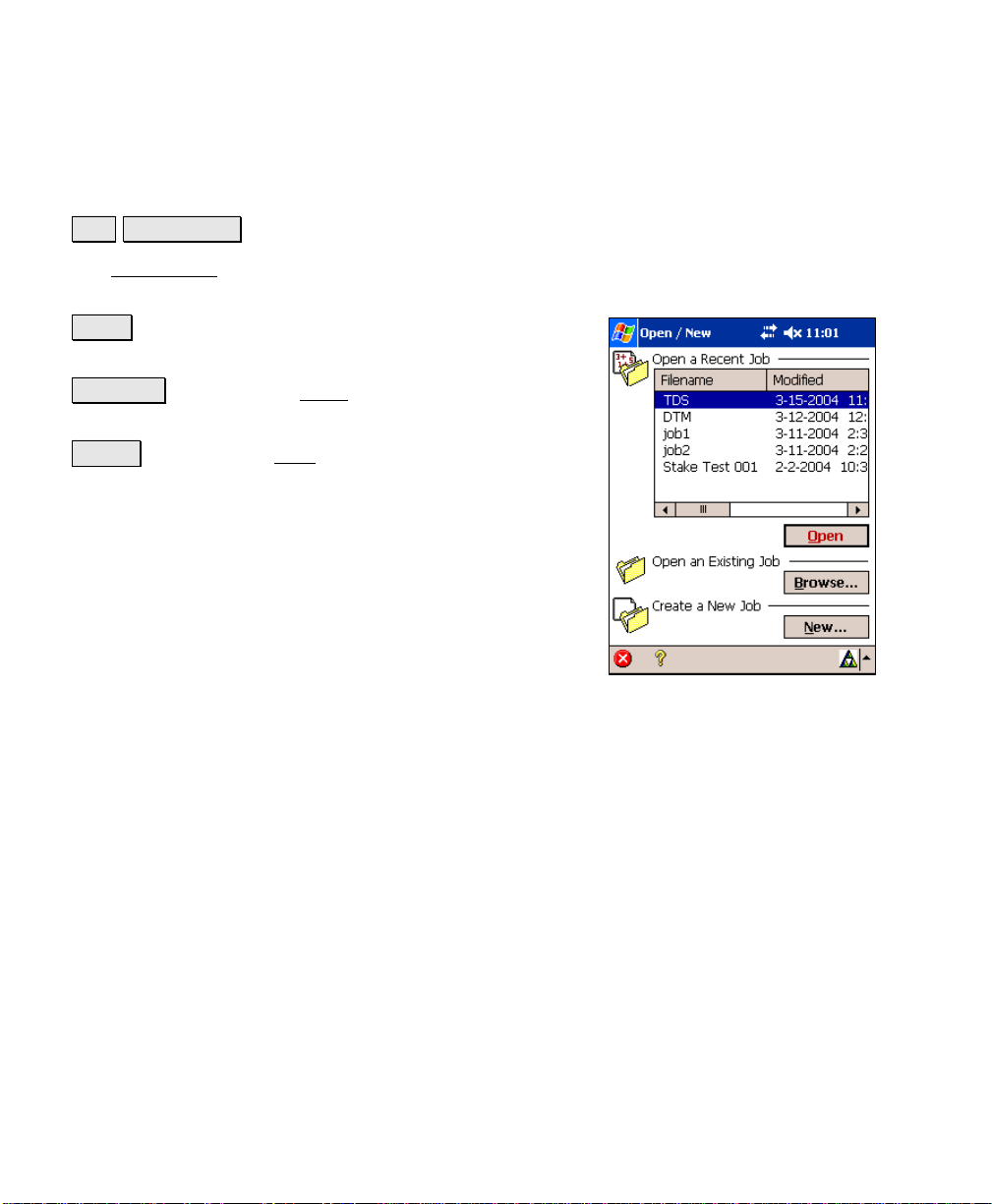

Open / New

File Open / New.

The Open / New screen is used to open a recent job or create a new

one. This screen also appears when Survey Pro is first started.

Open : opens the job selected in the Open a Recent Job

list.

Browse… : will open the Open screen (Page R-14) where

an existing job to open can be selected.

New… : will open the New screen (Page R-9) where a

new job can be created.

R-8

Page 17

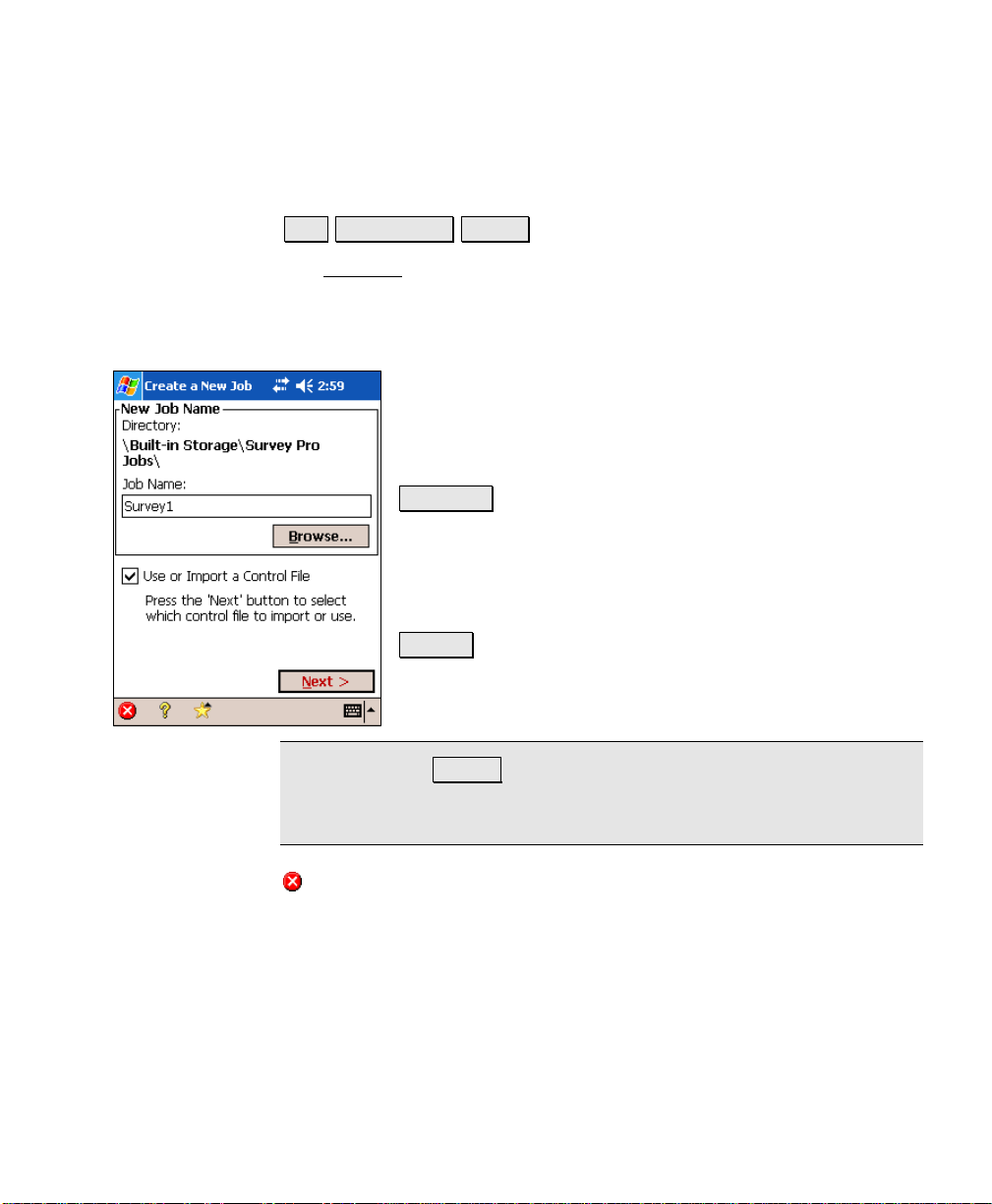

New Job

File Open / New New….

The New Job wizard is used to create a new job.

Create a New Job 1

Directory: displays the directory where the current job

will be stored.

Job Name: is where the name of the new job is entered.

The default name is the current date.

Browse… : allows you to select a different directory

where to store the new job.

Use or Import a Control File: When checked, you can

select an external control file or import the points from a

different job as control points.

Next > : opens the next screen. The screen that opens

depends on if a control file will be used.

File Menu

Note: Pressing Next> may result in a warning if you have chosen a

folder in the data collector’s RAM instead of a location on an external

CF card. See Page 58 for more information.

(Cancel): cancels the creation of a new job and brings you back to

the main menu.

R-9

Page 18

Survey Pro Reference Manual

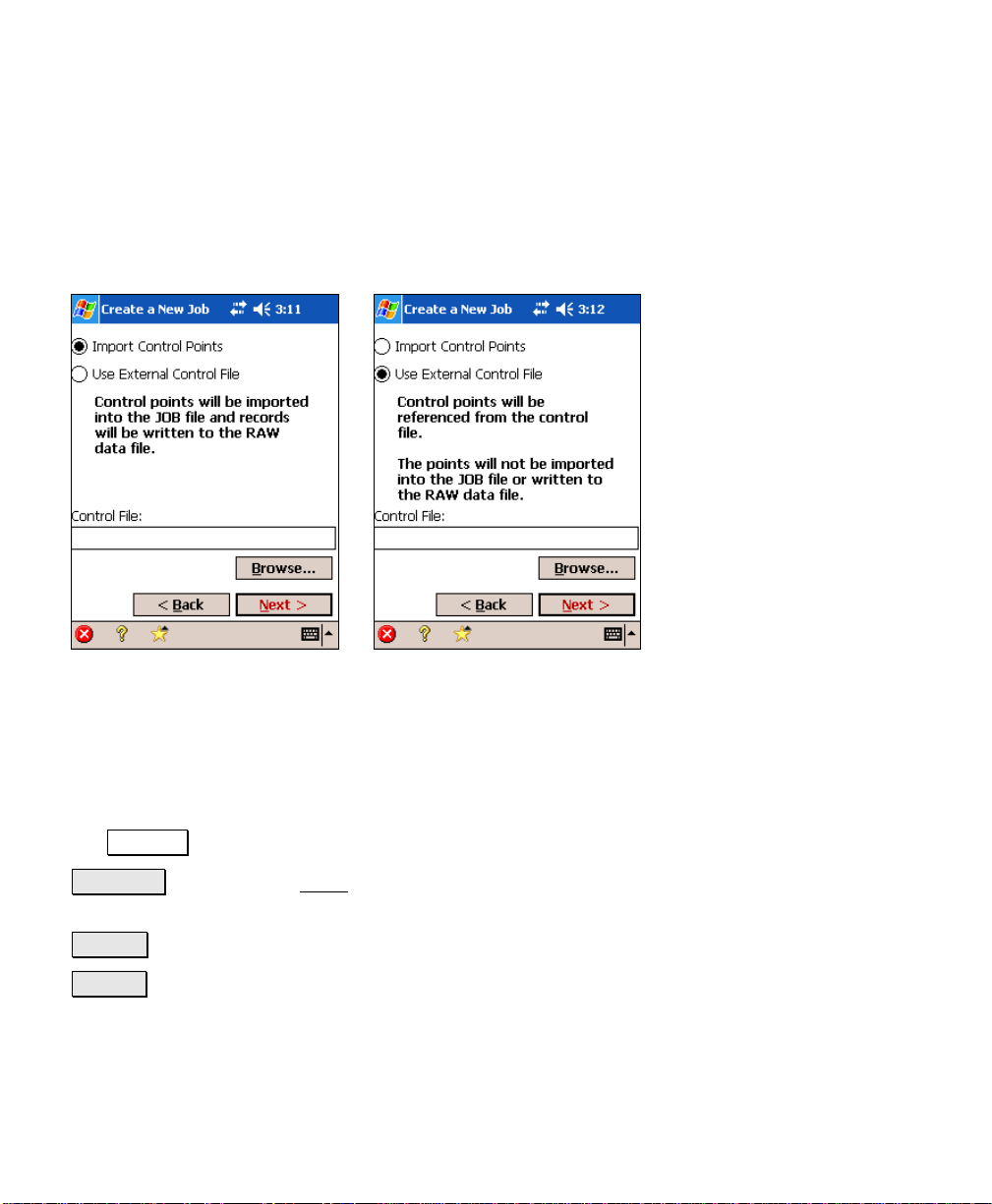

Create a New Job 2 – (Imported or External Control File)

This screen will only open next when a control file will be used or

imported.

Import Control Points: When selected, the points in the control file

will be imported into the new job.

Use External Control File: When selected, the control points in the

control file will be accessible from the new job, but will not be

imported.

Control File: displays the path and control file name selected with

the Browse… button.

Browse… : will open the Open screen (Page R-14) where an existing

job can be selected as a control file.

< Back : returns you to the previous screen.

Next > : opens the next screen.

R-10

Page 19

File Menu

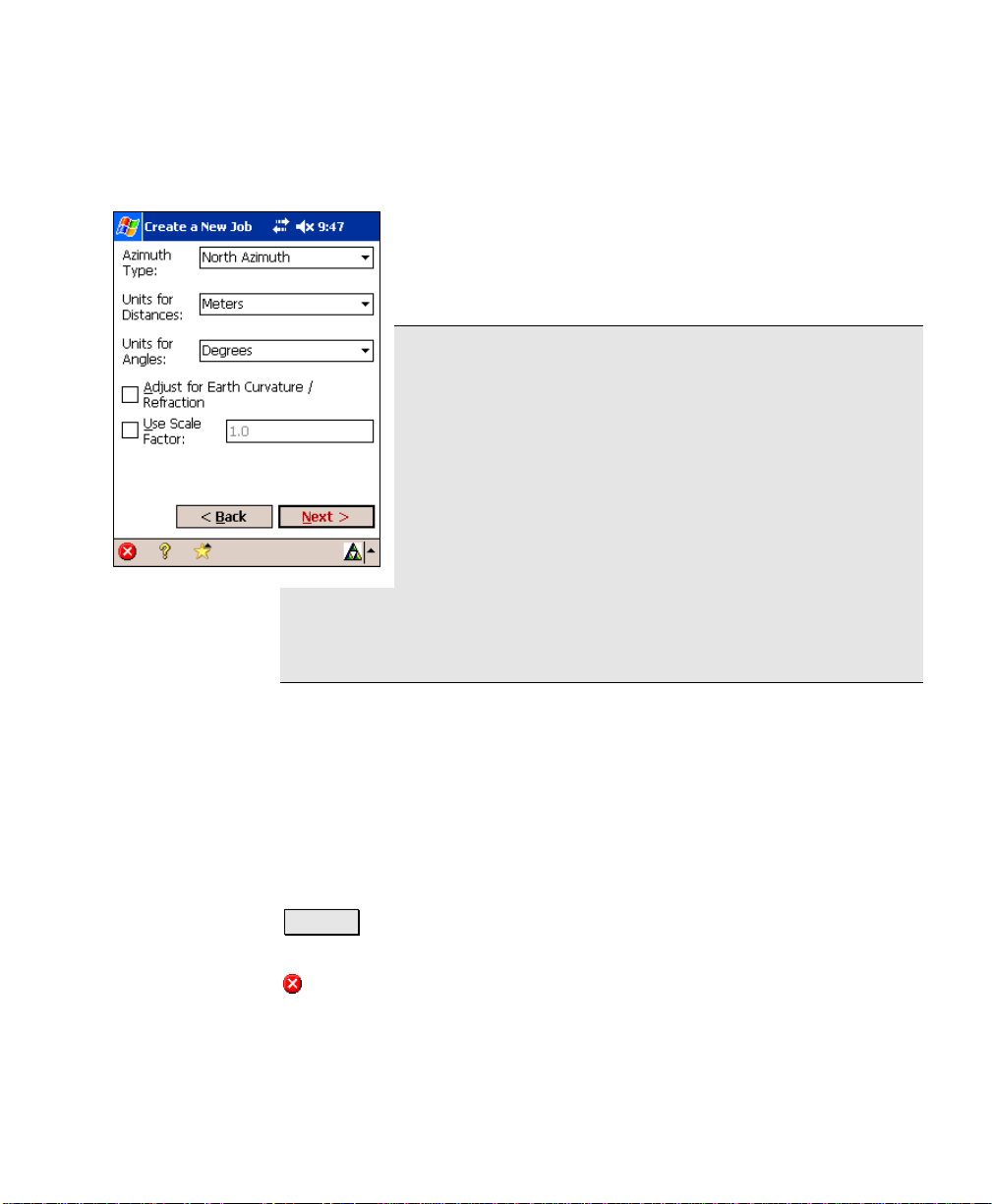

Create a New Job 3

Azimuth Type: specifies if you are surveying with a

North Azimuth or South Azimuth.

Units for Distances: specifies if your distances will be

entered in International Feet, U.S. Feet, or Meters.

Note: You can enter a distance in any distance field in

units other than what is set for the job by appending the

distance value with the following characters:

y f or ft or ift International Feet

y usf or usft US Survey Feet

y i or in Inches

y m Meters

y cm Centimeters

y mm Millimeters

Once the cursor leaves that field, the distance will be converted

automatically. (A space between the value and the unit abbreviation

is optional.)

y c or ch Chains

Units for Angles: specifies if angles will be entered in Degrees or

Grads.

; Adjust for Earth Curvature / Refraction: When checked, the

elevations recorded from all shots will be adjusted to compensate for

earth curvature and refraction.

; User Scale Factor: When checked, all horizontal distances when

taking shots will be adjusted by the scale factor entered here.

Next > : opens the final screen, which can be one of two different

possible screens depending on if a control file is being imported.

(Cancel): cancels the creation of a new job and brings you back to

the main menu.

R-11

Page 20

Survey Pro Reference Manual

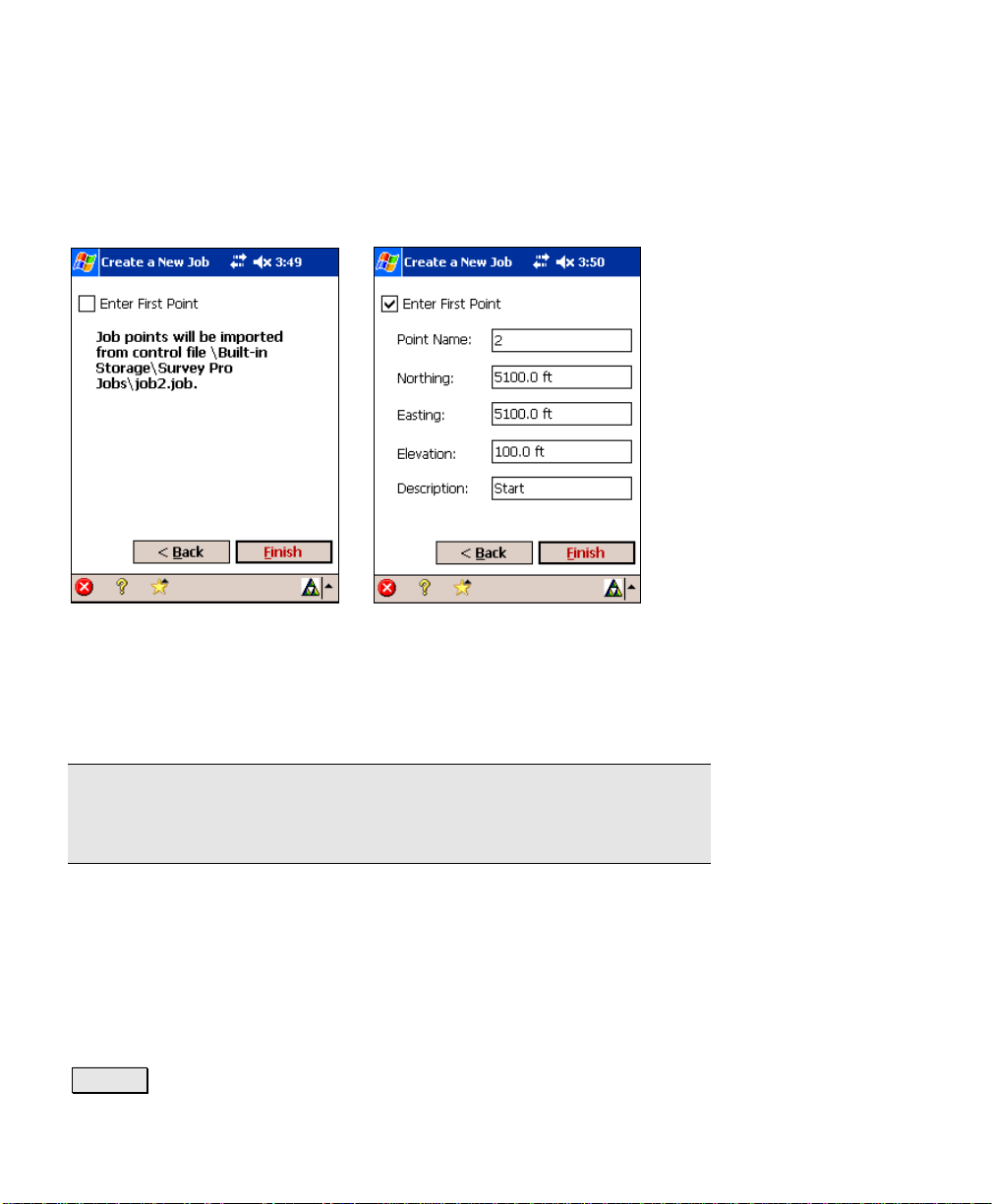

Create a New Job 4 – (Imported Control File)

This screen will only open when a control file is being im ported.

Screen when checkbox is

unchecked.

Enter First Point: When this box is checked, the additional fields will

appear allowing you to create a new point.

Note: Although all new jobs must have at least one point, creating a

new point when importing a control file is optional since points are

already being loaded into the job in the form of control points.

Point Name: is the name of the initial point.

Northing: is the Y-coordinate of the initial point.

Easting: is the X-coordinate of the initial point.

Elevation: is the elevation of the initial point.

Description: is the description of the initial point.

< Back : returns you to the previous screen.

R-12

Screen when checkbox is

checked.

Page 21

File Menu

Finish : stores a new job file and raw data file using the specified

information.

(Cancel): cancels the creation of a new job and brings you back to

the main menu.

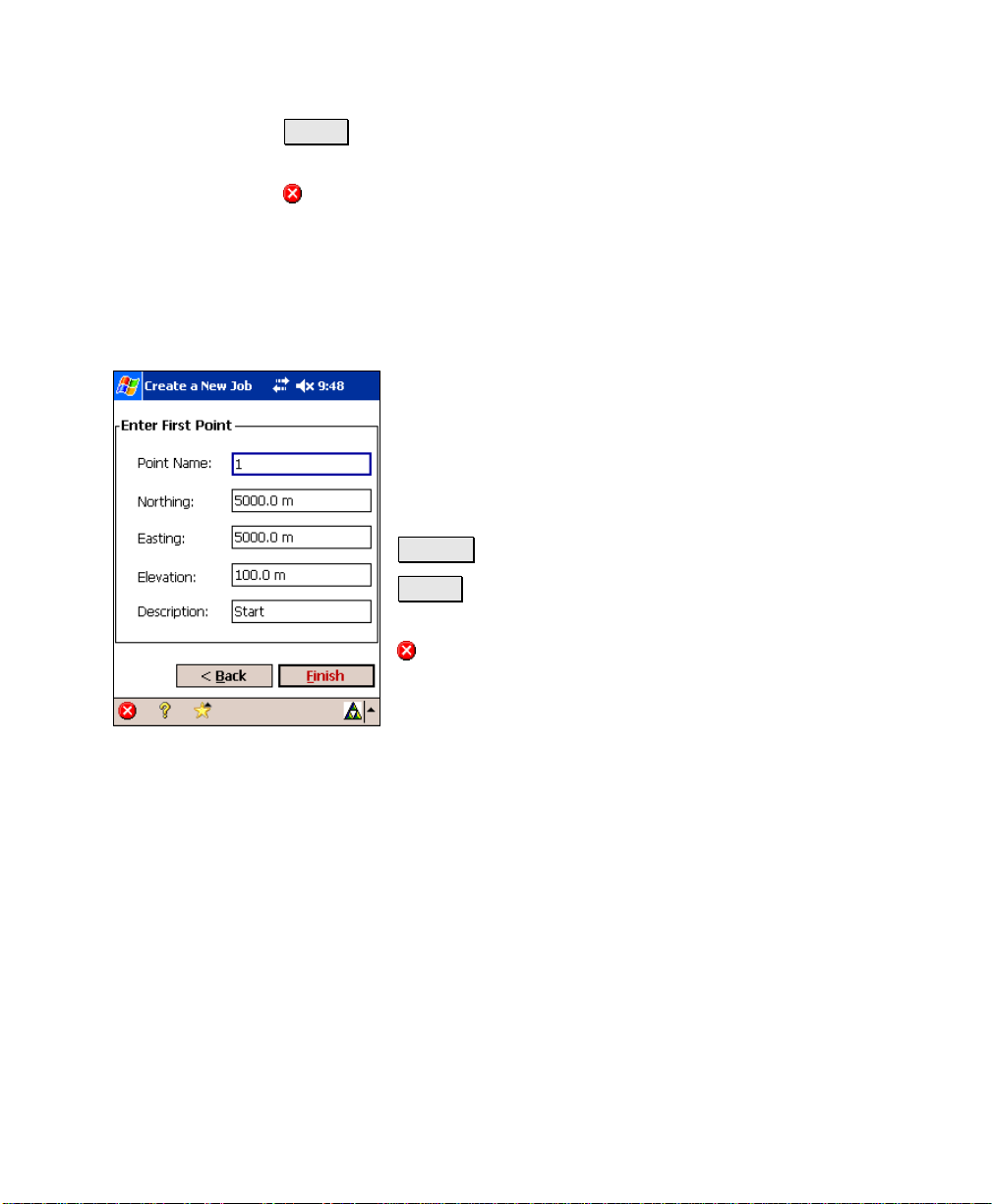

Create a New Job 5 – (External or No Control File)

Point Name: is the name of the initial point.

Northing: is the Y-coordinate of the initial point.

Easting: is the X-coordinate of the initial point.

Elevation: is the elevation of the initial point.

Description: is the description of the initial point.

< Back : returns you to the first screen.

Finish : stores a new job file and raw data file using the

specified information.

(Cancel): cancels the creation of a new job and brings

you back to the main menu.

R-13

Page 22

Survey Pro Reference Manual

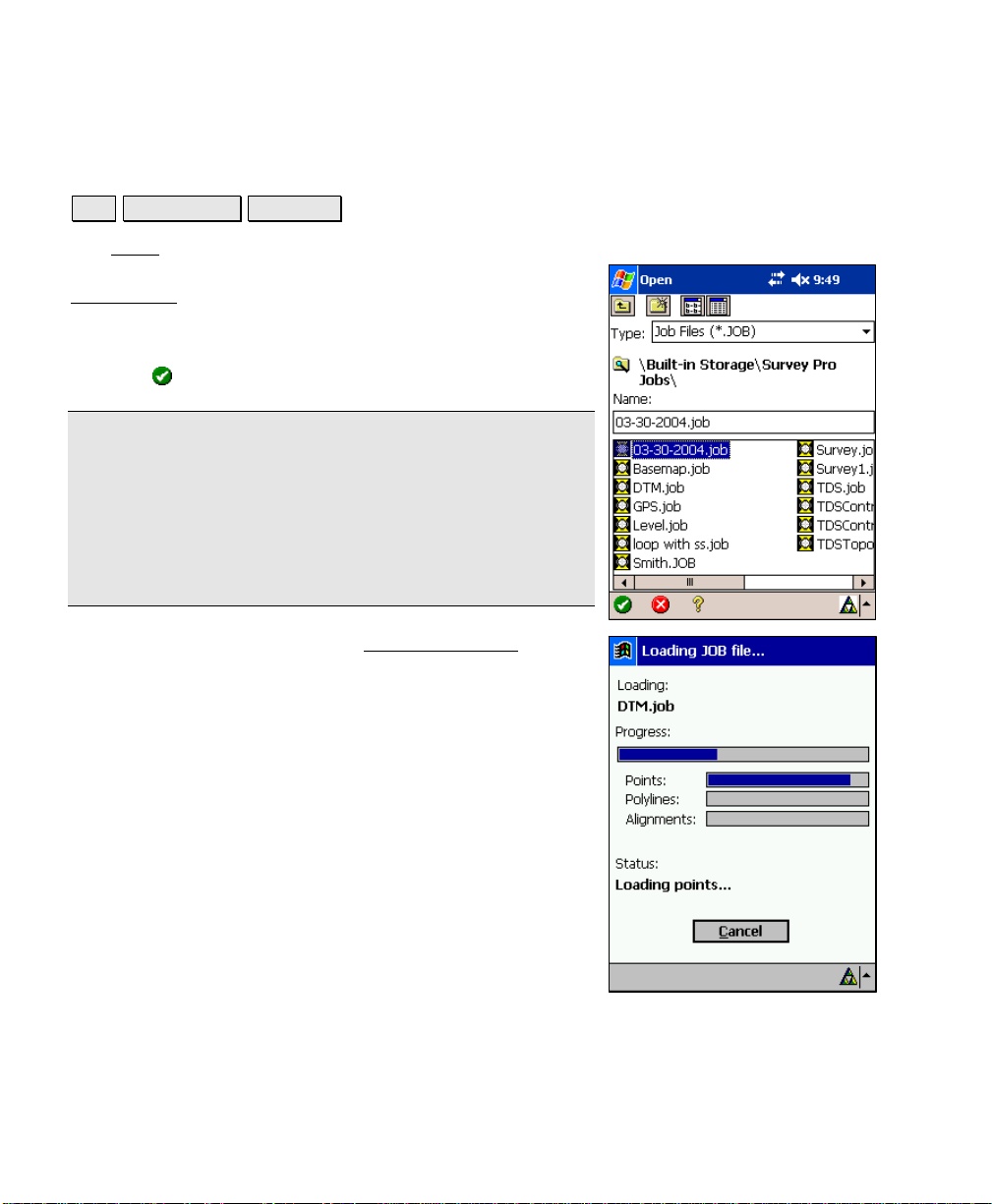

Open

File Open / New. Browse….

The Open screen is used to open any existing job and is required to

open a job that is not listed in the Recent Job list in the

Open / New

A list of all the jobs in the current directory is displayed.

Simply tap on the job name that you want to open and

then tap

Note: TDS CR5 files can be opened just like any Survey

Pro JOB file. When a CR5 file is opened, it is

automatically converted and stored to a JOB file with

the same name. If a matching RW5 raw data file exists,

it too will be converted and saved to a Survey Pro RAW

file with a note inserted indicating that the conversion

took place.

When a job is being opened, the Loading JOB file screen

will open briefly and display the status of the loading

process.

screen.

.

R-14

Page 23

File Menu

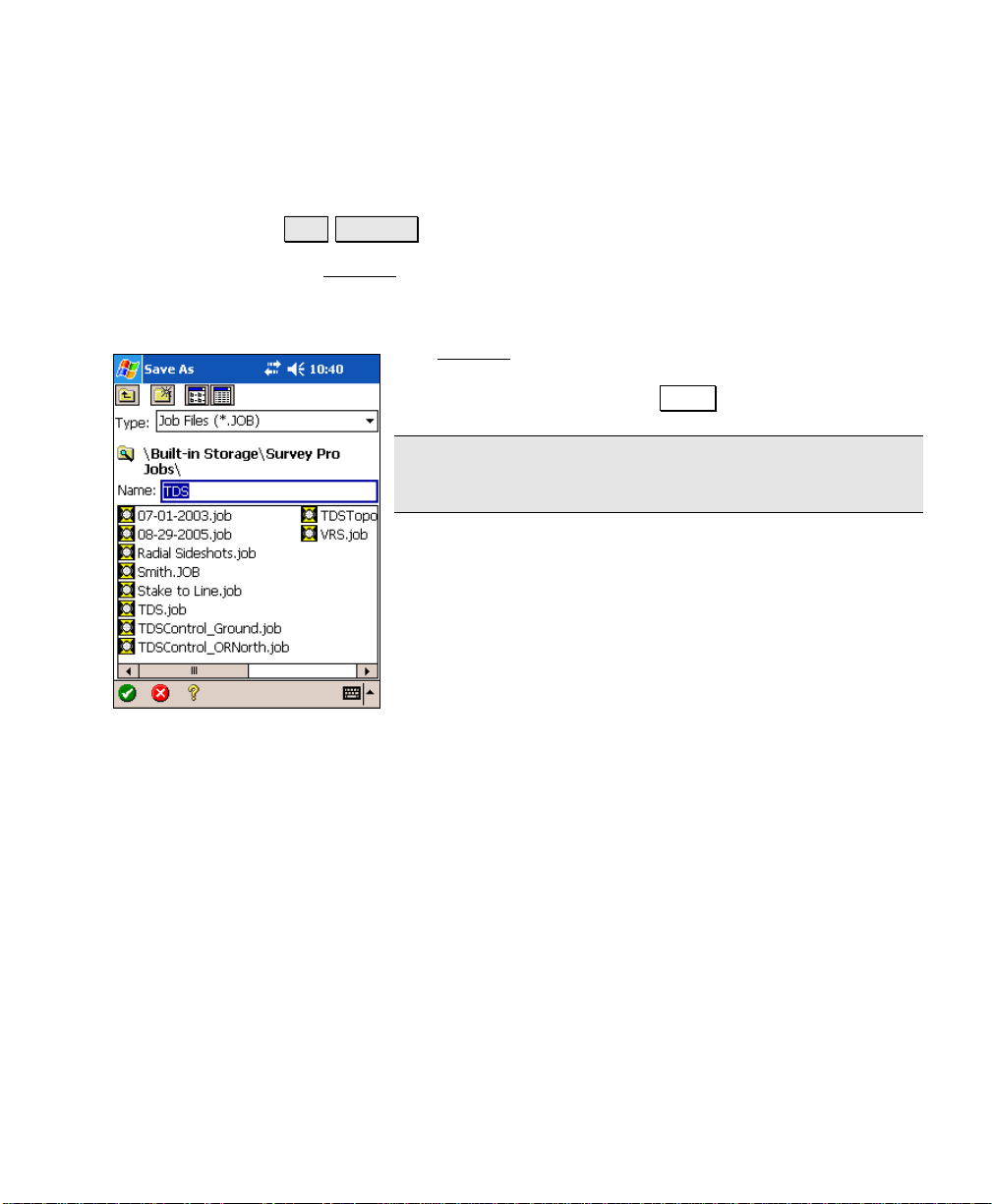

Save As

File Save As.

The Save As screen allows you to save a copy of the current job under

a new name. The copy that is created will then become th e current

job.

The Save As

operating system. Simply enter a new name for the

current job and then tap the Save button.

Note: It is not necessary to include the .JOB extension

since it will automatically be added for you.

dialog box is identical to that found in the

R-15

Page 24

Survey Pro Reference Manual

Import

File Import.

The Import screen is used to add the points from another source into

the current job or import the data from a LandXML file to the current

job.

Warning: Coordinate values can change when they are imported!

Importing coordinates from any source other than a JOB file requires

that the distance units used in the source file be specified. It is not

necessary to specify the distance units when importing coordinates

from a JOB file since those units are written within the file.

If importing coordinates where the distance un its in the source file

are different than the distance units for the current job, the im ported

coordinates will be converted to the current job’s distance units when

they are imported. This is normally the desired result, but it can

cause a problem if any distance units were set incorrectly. This

situation can most commonly occur when working with International

Feet and US Survey Feet where the conversion from one to the other

is not always obvious.

Usually the difference between International Feet and US Survey

Feet is negligible (2 parts per million), but when dealing with State

Plane or UTM mapping plane coordinates, which are often very large

in magnitude, the difference can be substantial if the coordinates are

converted from one format to the other.

If importing coordinates from a source, such as an HP 48, where you

are not sure if the units are in International Feet or US Surve y F eet

into a job that is set to International Feet or US Survey Feet, you will

usually just want to import them without any conversion being

performed. To do this, be sure to select the same distance units for

the source file as those set for the current job.

R-16

Page 25

File Menu

Coordinates from a variety of file typ es can be im ported into the

current job. The first Import

types listed below. The next screen that opens depends on the

selection made here.

• Job Files (*.JOB): import coordinates from another

Job file.

• Coordinate Files (*.CR5): import coordinates from

a TDS CR5 coordinate file.

• GPS Files (*.GPS): import coordinates from a TDS

GPS coordinate file.

• Text Files (*.TXT): text files can contain coordinates

in several different possible formats. The Import

ASCII Wizard is used to define the format of the text

file being imported.

• Text Files (*.CSV): this is a simplified text file

import routine where the source file is comma

delimited and has a *.CSV extension.

• LandXML Files (*.xml): imports points, alignments, polylines,

and parcels from a LandXML file.

screen is used to select from the file

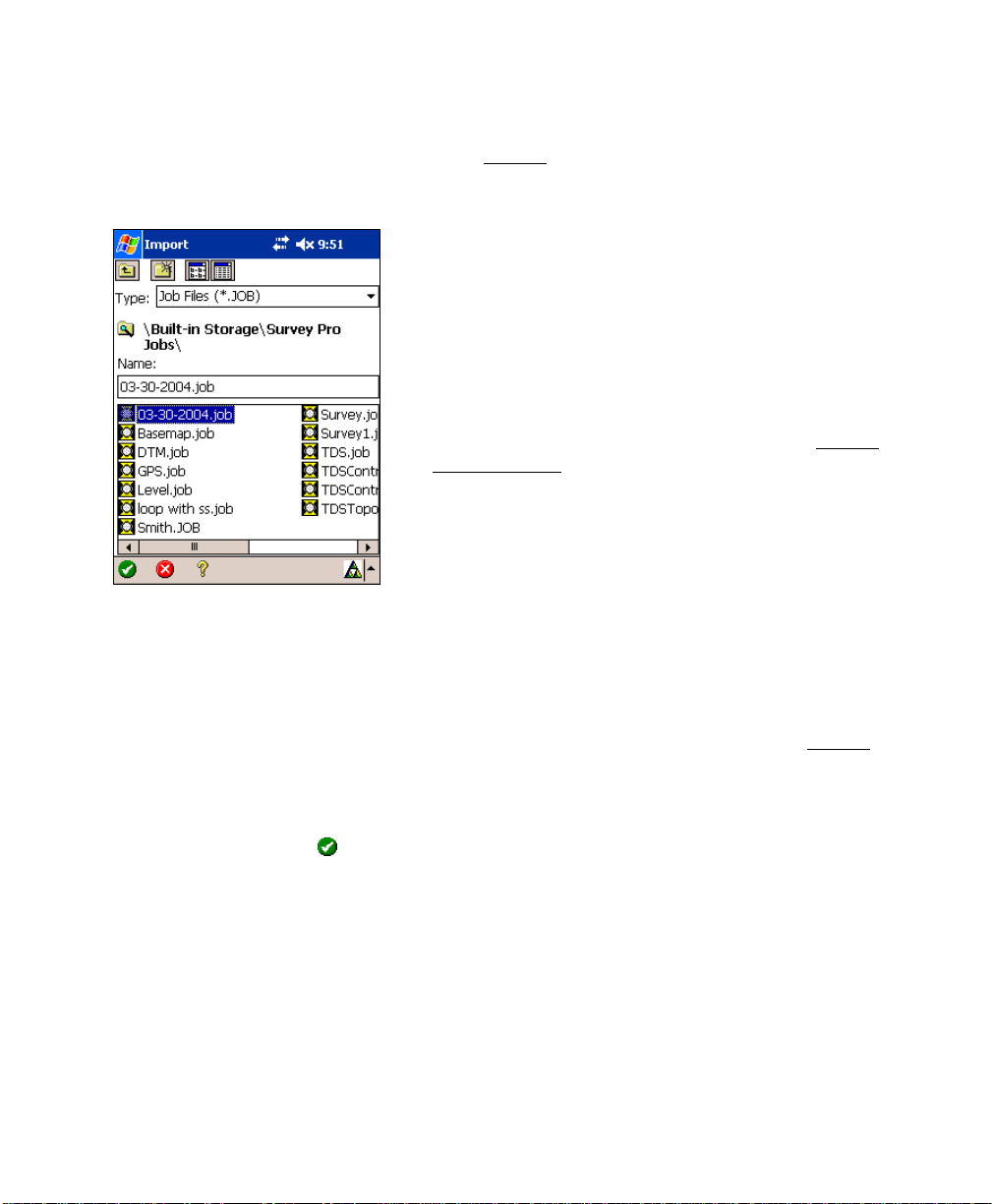

Import *.JOB Coordinates

When importing coordinates from anot her *.JOB file, the Import

screen is used, described above.

A list of all the jobs available in the current directory is displayed.

Simply tap on the job name that you want to import and then tap

button. The points in the selected job will be added to the

the

points in the current job.

R-17

Page 26

Survey Pro Reference Manual

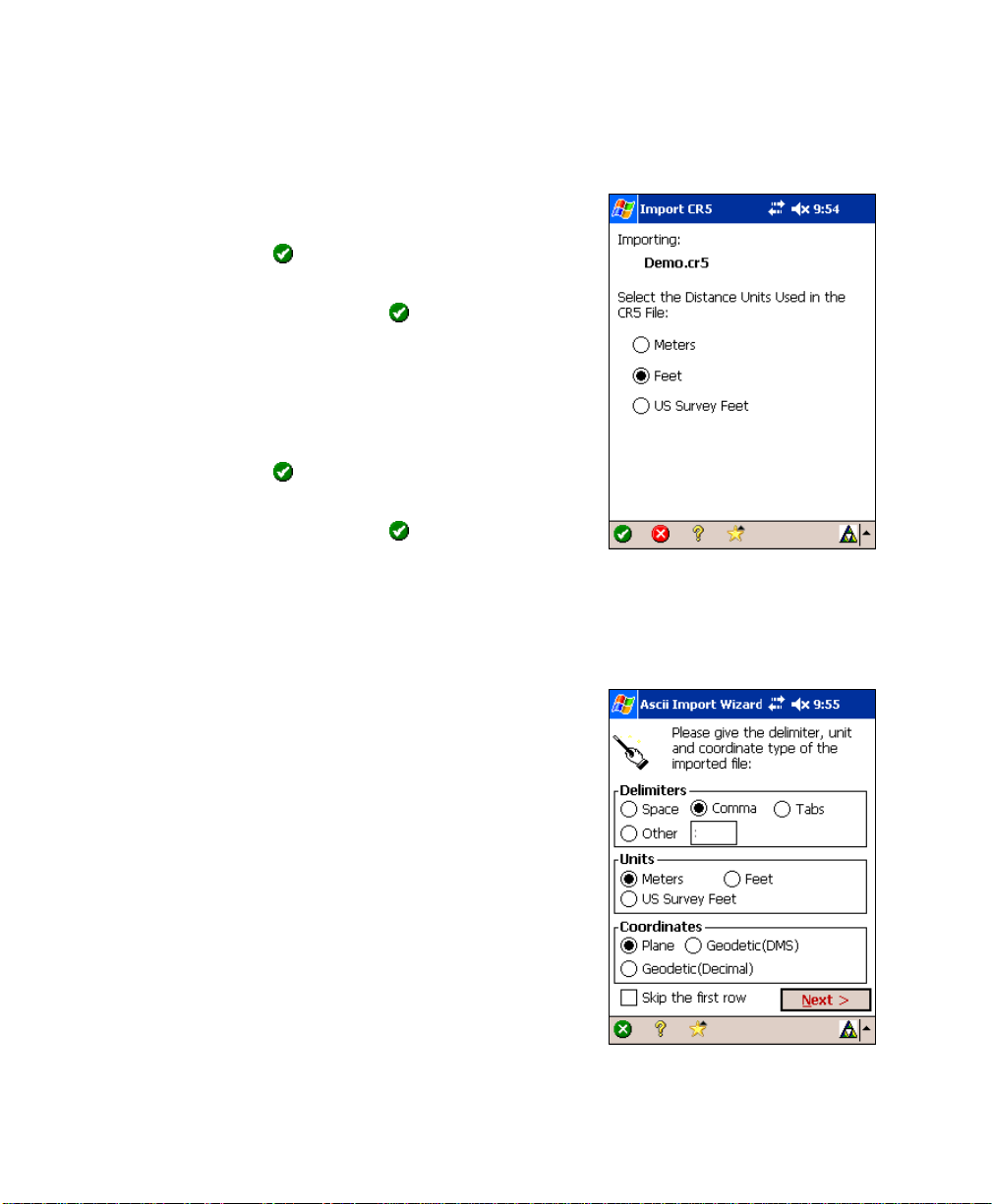

Import *.CR5 Coordinates

When importing a CR5 file, you will first be prompted to

select the layer where you want the new data stored.

Select a layer and tap

In the next screen, select the distance units that the

coordinates were stored in and tap .

to continue.

Import *.GPS Coordinates

When importing a GPS file, you will first be prompted to

select the layer where you want the new data stored.

Select a layer and tap

In the next screen, select the distance units that the

coordinates were stored in and tap .

When importing coordinates from both a TDS CR5 and GPS file from

the same job, the GPS coordinate will be linked to the coordinates in

the CR5 file. For more information on this, refer to the GPS User’s

Guide.

to continue.

Import *.TXT Coordinates

Since the coordinates in an ASCII *.TXT file can be

stored in a variety of formats, two screens are used to

define the format of the file that is being imported once a

layer is selected. The source *.TXT file can contain

either plane coordinates or geodetic coordinates.

Delimiters: is the character that separates each column

of text in the ASCII file.

Units: are the units that the distances in the file were

stored in.

Coordinates: is used to specify if the coordinat es are

plane coordinates, geodetic coordinates in degreesminutes-seconds format, or geodetic coordinates in

decimal format.

R-18

Page 27

File Menu

; Skip the first row: should be checked if the first line in the ASCII

file contains non-coordinate information, such as a heading.

Next > : opens the second screen.

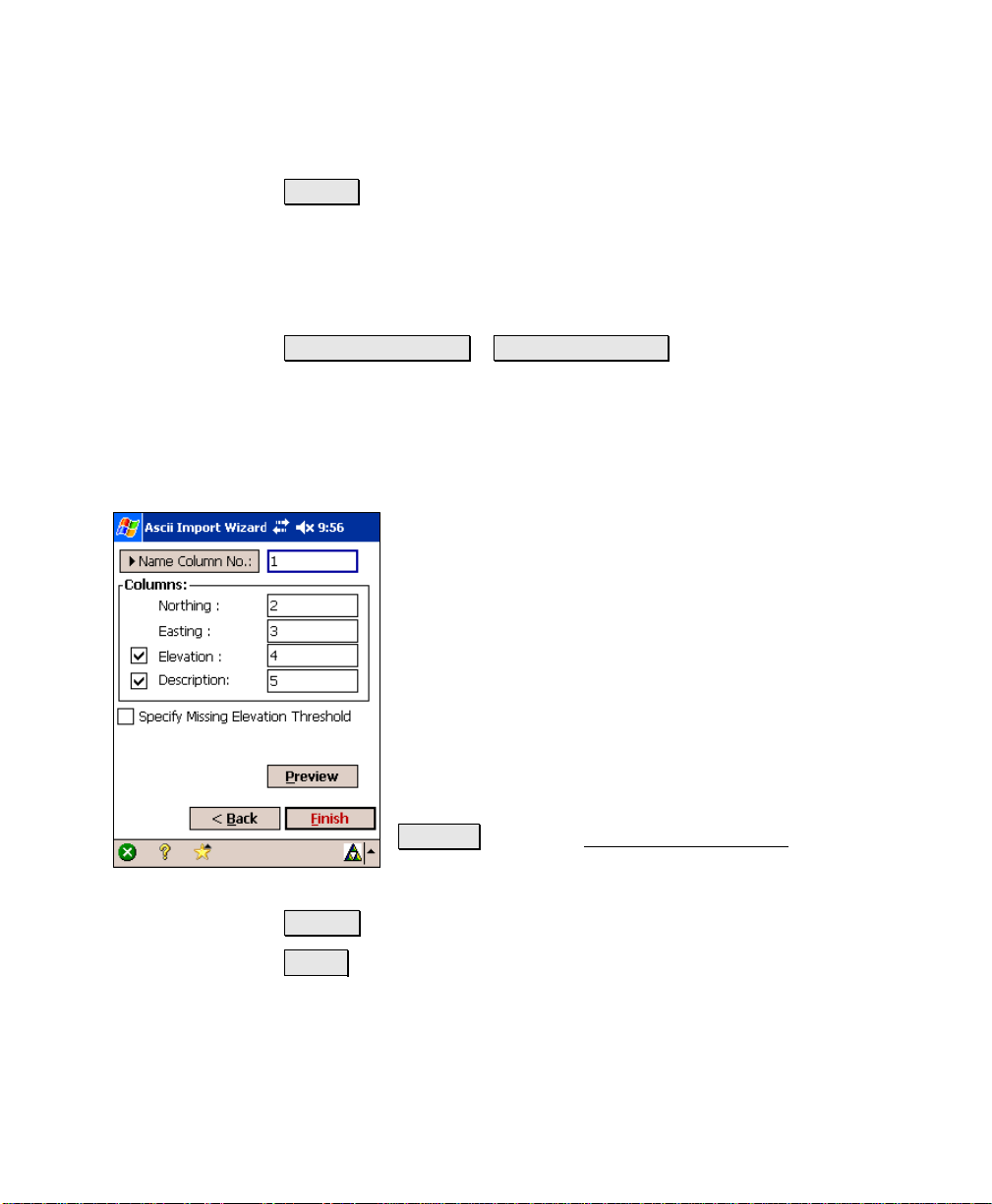

Import *.TXT Coordinates – Screen Two

Name Column No. / Start Point Name : When the first option is

selected here, the column number used for the name field in the

*.TXT file is specified here. When the second opti on is selected, it is

assumed that the *.TXT file does not contain point names and will

assign the first point the name specified here and increment to the

next available point name for the remaining points.

Columns: is where the column number for each specified

coordinate exists in the source *.TXT file. The

coordinates types displayed here can either be for plane

coordinates or geodetic coordinates depending on the

selections made in the previous screen. If a coordinate

has a checkbox, which is unchecked, it is assumed that

the source *.TXT file does not contain columns for that

type of coordinate.

; Specify Missing Elevation Threshold: if the source

file was created from coordinates with no elevations, but

the file contains an elevation column with values, such

as 0, check this box and indicate the value in the field

that will appear to the right.

Preview : opens the ASCII Import Preview window

containing all the point data that will be imported. This

is useful to check for errors before actually importing new data.

< Back : returns to the previous screen.

Finish : imports the new point data into the current project.

R-19

Page 28

Survey Pro Reference Manual

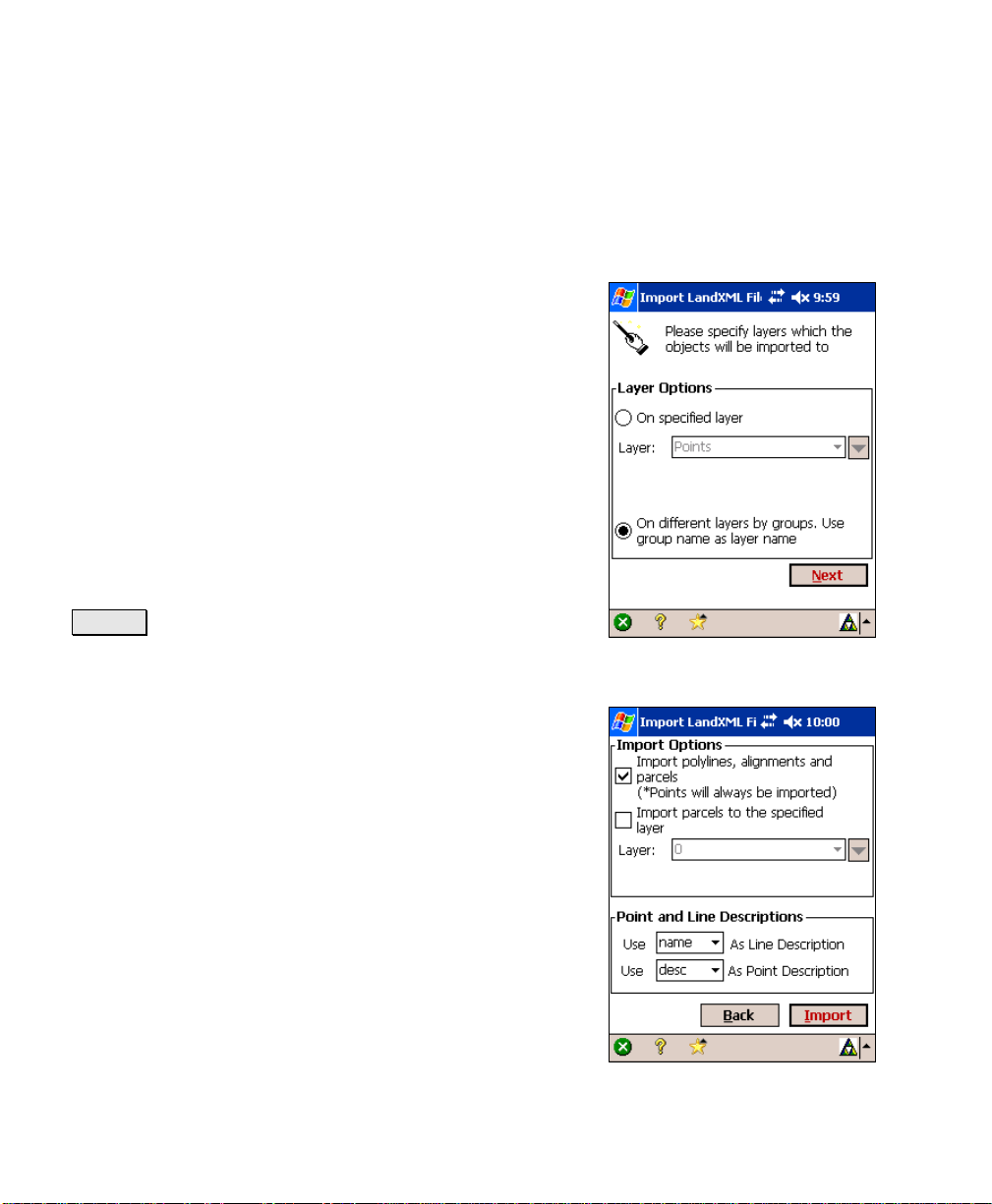

Import LandXML Coordinates

Points, alignments, polylines, and parcels can be imported from a

LandXML file.

The way the LandXML data is imported depends on how the data is

stored in the source file and how the settings are

configured in the two screens described below.

Consult the User’s Manual for more information on the

conditions that affect how the data is imported.

On specified layer: will import all the data on the

specified layer.

On different layers by groups: will import points,

alignments, and parcels to layers named by the group

name for the data in the source file. If the group name is

an invalid layer name (e.g., it is empty or contains

invalid characters), the data will be stored to the active

layer.

Next > : opens the second configuration screen.

Import polylines, alignments and parcels: When this is checked,

polylines, alignments and parcels will be imported, as well as the

points. When unchecked, only the points will be

imported.

Import parcels to the specified layer: When this is

checked, imported parcels will be stored to the sel ected

layer. If unchecked, parcels will be stored to the layer

specified in the previous screen.

For more information on how parcels are imported,

consult the User’s Manual.

Point and Line Descriptions: You can select what

information to use as the description for imported lines

and points in the corresponding two fields.

Lines can either be assigned the name or description

from the source file and points can either be assigned the

description or code from the source file.

R-20

Page 29

File Menu

Back : returns to the previous screen.

Import : imports the specified data into the current project. A

results screen will open listing the details of the imported data.

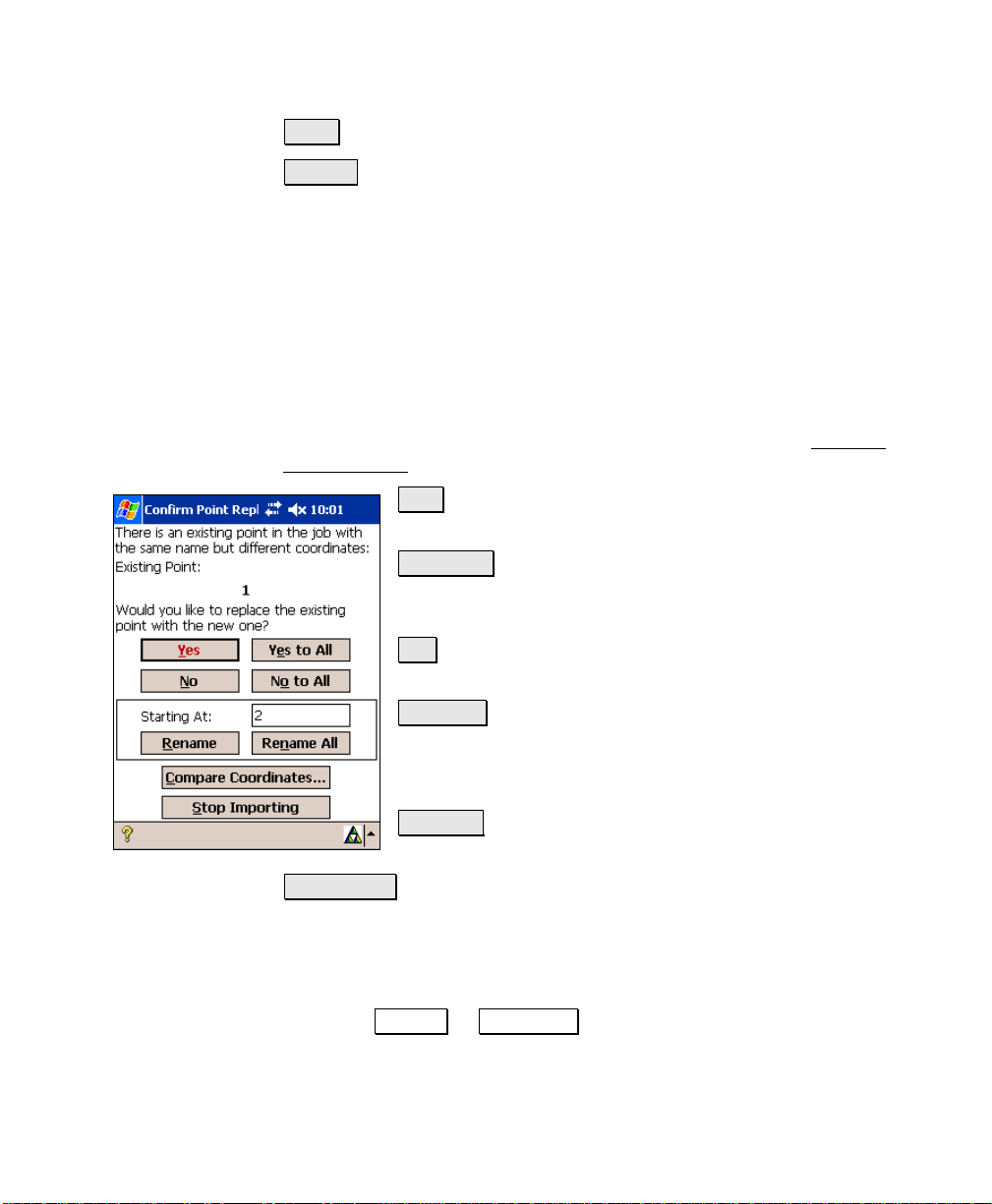

Confirm Point Replace

If a point being imported has the same name and the same

coordinates as a point that is already in the current job, it is ignored

and a message will be displayed after the remaining points ar e

imported to indicate this.

If an imported point is encountered with the same name, but with

different coordinates as a point in the current project, the Confirm

Point Replace screen will open.

Yes : will replace the point in the current job with the

point being imported.

Yes to All : will replace the point in the current job with

the point being imported and perform the same action for

any remaining duplicate points.

No : will not import the duplicate point, keeping the

coordinates for the existing point unchanged.

No to All : will not import the duplicate point, keeping

the coordinates for the existing point unchanged and

perform the same action for any remaining duplicate

points.

Rename : will store the new point in the current job

under the name specified in the Starting At field.

Rename All : will store the new point in the current job under the

name specified in the Starting At field and perform the same action for

any remaining duplicate points, storing them with the next available

point name.

Start At: is the point name assigned to the imported point when

using the Rename or Rename All functions.

R-21

Page 30

Survey Pro Reference Manual

Compare Coordinates… : will open a dialog box showing the

coordinates for the duplicate points to assist in making a decision of

how to handle the new point.

Stop Importing : will not import the current duplicate point and will

stop importing any remaining points. All previous points wi ll still be

imported into the current job.

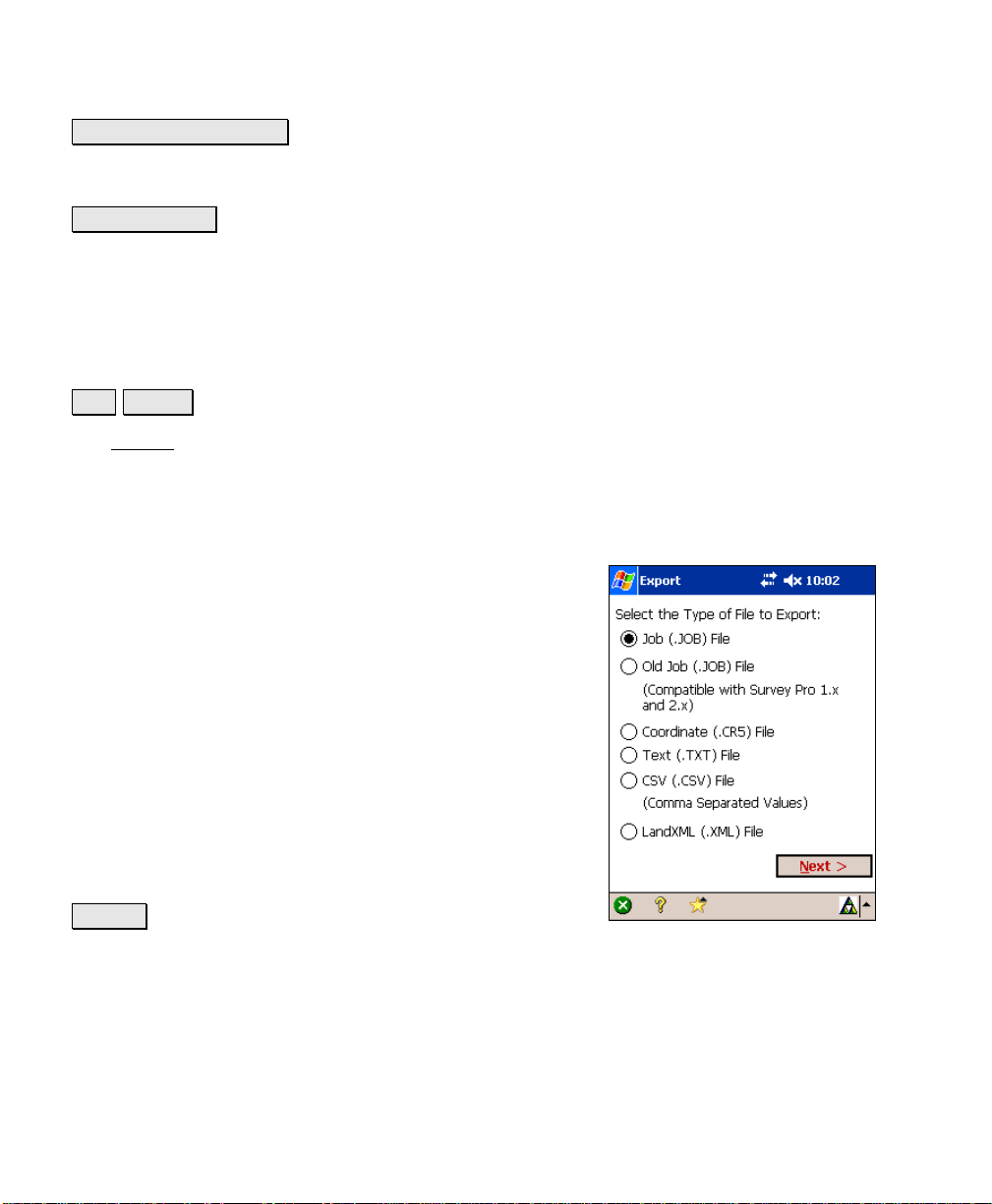

Export

File Export.

The Export screen allows you to export selected points from the

current job to a new job or to a coordinate file in another format. You

can also export all the objects in the current job to a LandXML file.

This first screen is used to specify the type of file that you want to

export data to.

Job (.JOB) File: When selected, the points are exported

to a TDS JOB file.

Old Job (.JOB) File: When selected, the points are

exported to a TDS JOB file that is compatible with

versions of Survey Pro for Windows CE earlier than 3.0.

Coordinate (.CR5) File: When selected, the points are

exported to a TDS CR5 coordinate file format.

Text (.TXT) File: When selected, the points are exported

to an ASCII text file.

CSV (.CSV) File: When selected, the points are exported

to an ASCII text file that is comma delimited and the file

is automatically given a *.CSV extension.

Next > : opens the next screen, which is determined by

the selected file type.

R-22

Page 31

File Menu

Export – Screen Two

The second Export screen will open for any file type that was selected

in the previous screen except LandXML. This screen is used to select

the points from the current project that you want to export to the

selected file type. (Exporting to a LandXML file is described later.)

To/From… : allows you to specify a range of points to

export.

Tap Points… : allows you to select the points to export by

tapping them from a map view.

: The power button provides additional point selection

options, which include selecting all control points, all

non-control points and selection by description.

< Back : returns to the previous screen.

Next > : opens the next screen, which is determined by

the selected file type.

Export *.JOB Coordinates

When exporting to another *.JOB file, the Save As screen is opened

where the file name and location is entered f or the new *.JOB file.

Export Old *.JOB Coordinates

This option functions exactly as the Export *.JOB rout ine, described

above, only the resulting file is written to be compatible with the

Survey Pro Version 2.x format, and earlier.

R-23

Page 32

Survey Pro Reference Manual

Export *.CR5 Coordinates

The Export CR5 dialog box will open when exporting

coordinates to a TDS CR5 coordinate file.

CR5 File Options: specifies if the resulting file should be

Sequential or Non-Sequential. (The HP 48 data collector

can only use sequential coordinate files .)

< Back : returns to the previous screen.

Export : exports the selected coordinates to the new CR5

file.

Export *.TXT Coordinates

Since the coordinates in an ASCII *.TXT file can be

stored in a variety of formats, two screens are used to

define the format of the resulting file.

Delimiters: is the character that separates each column

of text in the ASCII file.

Coordinates: is used to select if the resulting

coordinates should be plane coordinates, geod etic

coordinates in degrees-minutes-seconds format, or

geodetic coordinates in decimal format.

Units: are the distance units that will be written to the

resulting TXT file. These units are automatically set to

the same units that are set for the current job.

; Headers in the first row: When checked, a heading

describing each column is inserted in the first row. For

example, the following header could be insert ed:

Name,Northing,Easting,Elevation,Description

< Back : returns to the previous screen.

Next > : opens the second screen.

R-24

Page 33

File Menu

Export *.TXT Coordinates – Screen Two

Select the desired order and format for the resulting TXT

file from the list of options.

Finish : exports the selected points to the TXT file.

Export *.CSV Coordinates

This routine is identical to the Export *.TXT Coordinates

routine, described above with the exception that th e

formatting for the exported file is automatically set to

comma delimited and the extension for the file name will

be *.CSV.

Export LandXML (.XML) File

Unlike the other export routines, which only export

points, the LandXML export routine allows you to export

points along with polylines and alignments.

Export polylines and alignments: will export the points

in the current project as well as any polylines and

alignments. If this is unchecked, only the points will be

exported.

Export polylines on the specified layer as parcels:

will export the polylines on the selected layer as parcels.

(Polylines on other layers will still be exported, only not

as parcels.)

Export point description as: allows you to select to

export the point descriptions as LandXML descriptions

or codes.

R-25

Page 34

Survey Pro Reference Manual

Import Control Points

File Import Control.

The Import Control screen is used to manage a control

file for the current job.

Import… : opens the Open screen (Page R-14) where an

existing job can be selected as a control file. The control

points will then be imported into the current job and

stored to the CONTROL layer.

External Control File: displays the path and file for the

current external control file (if one is used).

Clear : clears the current external control file.

Browse… : opens the Open screen (Page R-14) where an

existing job can be selected as an external control file. (If

any point names in the external control file are also used

in the current job, the control file cannot be used.)

Backup / Restore Job

File Backup / Restore.

The Backup / Restore wizard consists of a series of

screens that are used to backup or restore all the files

associated with the current job.

The routine also gives you the option of st oring a

snapshot of a customized map view to the archive. This

can then be used to visually identify an archive.

Any number of backups can be created for a particular

job. All the existing backups for the current job are

listed in the main Backup / Restore

other information including the date the backup was

created, the number of files stored in the archive and if

the archive includes a snapshot. Archives that include a

snapshot are shown with a

R-26

screen, along with

icon, while those without a

Page 35

File Menu

snapshot have a

icon. A new (empty) archive has a icon.

All of the backups for a particular job are physically stored to a single

compressed file located in the \Jobs directory on the data collector.

This file will have the same filename as the curren t j ob, only the

*.Backup extension is appended to the name. For example, the

backups for a job with a filename of Smith.Job will be stored in a file

called Smith.Job.Backup.

New Archive… : opens the New Archive screen where a

name is entered for the new backup archive being

created. Once created, an empty archive will be listed in

the main Backup / Restore

screen, which can then be

selected to backup the current job.

Delete Archive… : opens a prompt asking if you are sure.

If you select Yes at the prompt, the archive selected from

the main Backup / Restore

screen will be deleted.

Properties… : opens the Archive Properties screen.

Backup: When selected, tapping Next> will begin the

backup routine where the data for the current job will be

stored to the selected archive.

Restore: When selected, tapping Next> will begin the

restore routine where the data from the selected archive will be

restored, overwriting the current job.

Next> : accesses the next screen.

R-27

Page 36

Survey Pro Reference Manual

Backup / Restore - Archive Properties

File Backup / Restore Properties….

The Archive Properties screen lists the files stored

within the selected archive along with other information.

The file sizes listed in this screen are in bytes. Since all

backup archives are compressed, the file sizes displayed

represent the compressed files, or the amount of space

actually being used by the file(s) on the data collector.

View Snapshot… : will display the snapshot from the

selected archive if one was included when the archive

was originally created.

R-28

Page 37

File Menu

Backup / Restore – Backup

When performing a backup, all the files associat ed with the current

job are listed and will be included in the archive.

; Create Snapshot: When checked, the next screen will

prompt you to create a snapshot of the current job’s map

view, which will then be included in the archive.

< Back : returns to the previous screen.

Backup : accesses the next screen.

Backup / Restore - Create a Snapshot

The Create a Snapshot screen is a map view that is used

to configure the map as desired and the resulting image

will be saved in the archive as a snapshot along with the

job files.

(OK): will create the archive along with a snapshot of

the map as it is configured on the screen.

(Cancel): will create the backup archive without a

snapshot.

R-29

Page 38

Survey Pro Reference Manual

Backup/Restore – Restore

When restoring the job files from an archive, the

archived files will replace the existing files of the current

job.

Warning: If you do not want to lose any new data that

was collected after the archive being restored was

created, you should first backup the current job to a new

archive before restoring an older archive.

< Back : will return to the previous screen.

Restore : will restore the backed up job from the

selected archive. The current job is then deleted and

replaced by the backup job.

R-30

Page 39

File Menu

Transfer

File Transfer.

The Transfer screen allows you to transfer files between the data

collector and another device running TDS software.

Connecting to: specifies which device you are

communicating with from the following options:

• HP48: if you are connecting to a Hewlett Packard

HP48 calculator.

• Husky: if you are connecting to a Husky FS-ser ies

data collector.

• Ranger / TSCe / ACU / Pocket PC: if you are

connecting to any of the devices listed.

• Windows PC: if you are connecting to a personal

computer that is running Windows CE Services.

• Geodimeter 600: if you are connecting to a

Geodimeter 600-series total station running TDS

onboard software.

COM Port: specifies which COM port you are using on the l ocal

machine.

Baud Rate: specifies the communications speed. The baud rate must

match in both units for successful communications.

Parity: specifies the parity. The parity must match in both units.

When in doubt, select None here. All transfers are controlled from

the PC when in this special mode.

Enter Server Mode : places the data collector in server mode where all

file transfers are controlled from a PC running either TDS Survey

Link or TDS ForeSight. Tapping Cancel will disconnect server mode.

Send File… : will open the Open dialog box where the file that you

want to send can be selected. Once selected, the file is sent from the

data collector to the specified device. A progress bar will be displayed

R-31

Page 40

Survey Pro Reference Manual

that indicates how much of the file has been transferred. Tapping

Cancel will stop the file transfer.

Note: The Send routine should be initiated shortly after issuing the

receive command on the other device.

Receive File… : allows you to receive a file from another device. This

should be tapped prior to issuing the Send command on the other

device. Tapping Cancel will stop the file transfer.

Register Modules

File Register Modules.

The Register Modules screen is used to upgrade the Survey Pro

software. Refer to the User’s Manual for more information on

registering additional modules.

If no modules have been registered, Survey Pro will run

in Demo Mode. When running in Demo Mode, users are

able to test and use every routine availabl e in the

software. Although, Demo Mode limits all jobs to no

more than 25 points. If a job exists on the data collector

that contains more than 25 points, it cannot be opened

while running in Demo Mode.

Registered: Indicates that the corresponding module

has been added.

R-32

Page 41

Enter Registration Code : Opens the Register screen,

shown here, where the registration number for a

particular module can be entered.

About Survey Pro

File About Survey Pro.

The About screen displays the version of the Surve y P r o

CE software.

File Menu

Hardware Information : is a shortcut to the Windows

System Information screen.

Exit

File Exit.

This will close the Survey Pro software and return you to

the operating system installed on your data collect or.

R-33

Page 42

Page 43

Job Menu

A: Settings

B: Edit Points

C: Edit Polylines

D: Edit Alignments

E: Auto Linework

F: View Raw Data File

G: View DTM

H: Manage Layers

I: Job Information

J: Calculator

K: Manage Pictures

L: Take Picture

R-35

Page 44

Survey Pro Reference Manual

Settings

Job Settings.

See Page R-100 if running in RTK GPS mode.

The Settings

where each individual screen accesses different types of settings.

screen actually consists of several separate screens

Instrument Settings

Job Settings Instrument Settings.

The Instrument Settings screen is actually the first of

multiple screens used to identify and configure the

instrument(s) you are using with Survey Pro. The

correct settings must be configured for successful

communications between the data collector and the

instrument.

The upper portion of the first Instrument Settings

lists the names of all the instrument profiles on the data

collector. The other columns list the COM Port, Brand,

and Model of the instrument defined in each profile.

Manual Mode: is a special profile that cannot be deleted.

When activated, all surveying is performed without

being connected to an instrument and all shot data must

be entered manually.

screen

Note: When running in leveling mode, the Instrument Settings… can

be selected for Manual Mode to open the Level Method screen

described on Page R-40.

Instrument Settings : opens the next Instrument Settings screen

where the settings in the selected instrument profile can be modified.

R-36

Page 45

Job Menu

Note: When editing an existing instrument profile, you cannot modify

the instrument brand or model.

Create New Instrument : opens the next Instrument Settings screen

where you can configure the settings for a new instrument and create

a new instrument profile.

Activate : activates the selected instrument profile.

GeoLock : opens the GeoLock Settings screen (Page R-176).

Delete : deletes the selected instrument profile.

Import : imports an instrument profile from an instrument profile

file that was previously loaded on the data collect o r.

Export : saves the selected instrument profile to a file, which can

then be transferred to another data collector and then imported.

Warning: Performing a hard reset on the data collector will result in

all the user-created instrument profiles to be deleted. It is

recommended that all instrument profiles be exported to files so in

the event of a hard reset they can be recovered using the Import

routine.

R-37

Page 46

Survey Pro Reference Manual

Instrument Settings – Screen Two

The second Instrument Settings screen opens whenever a new

instrument profile is being created, or when an existing profile is

being edited.

The options available on this screen will vary slightly depending on

the total station model selected.

Name: is the name of the instrument profile being

created or changed. This is the name that appears in the

list on the first Instrument Settings

Brand: is where you specify the manufacturer of the

instrument that you are using from a dropdown list.

Model: is where you specify the model of the instrum ent

that you are using from a dropdown list.

Serial Port: is the serial port on the data collector used

for communications with the total station. (Bluetooth can

also be selected for wireless communication b etween the

data collector and a compatible total station.)

Baud Rate: is the speed at which communication occurs

with the total station. This must match the baud rate

configured within the total station.

screen.

Parity: is the parity used for communication with the instrument.

This must match the parity setting configured within the total

station.

PIN: (applicable only when using a supported total station) is the

Personal Identification Number that was entered in the total station.

These numbers must match for successful communications.

Bluetooth… : (applicable only when using Bluetooth with a supported

total station) accesses the Bluetooth configuration screen that comes

with the Bluetooth driver software where you can quickly check or

change the virtual COM port and favorites.

Note: See the User’s Manual for more information on configuring

Bluetooth with a supported total station.

R-38

Page 47

Job Menu

Defaults : will set the Serial Port, Baud Rate and Parity to their default

values based on the selected total station.

Instrument Settings… : accesses the settings that are specific for the

selected total station.

Send to Instrument : (applicable only to specific total stations) will

send the selected instrument settings to the total station. This is

particularly useful with robotic total stations after the total sta tion

has been reset.

NOTICE:

The settings that are available after tapping the

Instrument Settings… button in non-leveling mode directly control

the settings that are built into the selected total station. Since total

station manufactures release new models every year, TDS cannot

maintain the necessary set up documentation for every existing

model and the models that are not yet available. The set up

procedure for your particular total station is better handled by t h e

total station manufacturer, or your instrument’s dealer.

If you have specific questions on the set up of your total stati on y ou

should refer to the documentation that was included with your total

station. The numbers listed below are provided for your convenience:

Trimble: 800-538-7800

Zeiss: 800-538-7800

Geodimeter: 800-538-7800

Leica: 800-327-4773

Nikon: 516-547-8500

Pentax: 800-729-1419

Topcon: 800-223-1130

R-39

Page 48

Survey Pro Reference Manual

Level Method

Job Settings Instrument (select Manual Mode) Instrument Settings…

The Level Method screen is used to select the leveling method you

want to use while using Manual Mode while running in leveling mode.

This will affect the type of data you are prompted for when taking

shots.

Three Wire: Prompts for shot data will require upper,

center, and lower wire readings.

Single Wire: Prompts for shot data will require center

wire readings only.

Electronic: Prompts for shot data will require a vertical

and horizontal distance.

Trigonometric: Prompts for shot data will require a

zenith angle and horizontal distance.

R-40

Page 49

Job Menu

Units Settings

Job Settings Units.

The Units Settings card defines the units that are used within the

software, sent from the total station, entered from the keypad an d

displayed on the screen.

Units for Distances: defines the units used for length as Meters,

International Feet, or US Survey Feet.

Note: You can enter a distance in any distance field in

units other than what is set for the job by appending the

distance value with the following characters:

y f or ft or ift International Feet

y usf or usft US Survey Feet

y i or in Inches

y m Meters

y cm Centimeters

y mm Millimeters

y c or ch Chains

Once the cursor leaves that field, the distance w il l be

converted automatically. (A space between the value and

the unit abbreviation is optional.)

Warning: When creating a new job, it is important that the Units for

Distances field be set to the correct units. This allows you to

seamlessly switch between different units in mid-job.

Problems can arise if these units are inadvertently set to the incorrect

units when entering new data. For example, assume a new job was

created by hand-entering a list of coordinates where the job was set to

International Feet and the coordinates being entered were in US

Survey Feet. Now assume you created another new job and correctly

set it to US Survey Feet. If you then imported the hand-entered points

from the other job, they would be converted to different units when no

conversion should have taken place. Depending on the magnitude of

R-41

Page 50

Survey Pro Reference Manual

the imported coordinates, the error after the conversion could be

significant.

Units for Angles: defines the units used for angles as Degrees or

Grads (gons).

Display Directions as: will display directions as a Bearing or Azimuth.

Azimuth type: defines if you are using a North Azimuth or a South

Azimuth.

Coord. Order: allows you to customize the labeling and or der for

coordinates used throughout the software. You can select any of the

following formats:

• N, E, Elev. (Northing, Easting, Elevation)

• X, Y, Z

• E, N, Elev. (Easting, Northing Elevation)

• Y, X, Z

Format Settings

Job Settings Format.

The Format Settings card defines the number of places

beyond the decimal point that are displayed for various

values in all screens, and how stations are defined. (All

internal calculations are performed using full precision.)

Northings / Eastings: will allow you to display from

zero to six places passed the decimal point for northing

and easting values.

Elevations: allows you to display from zero to six places

passed the decimal point for elevations.

Sq feet / meters: allows you to display from zero to four

places passed the decimal point for square feet or square

meter values.

Acres / Hectares: allows you to display from zero to

four places passed the decimal point for acre or hectare

values.

R-42

Page 51

Job Menu

Distances: allows you to display from zero to six places passed the

decimal point for distances.

Angles: allows you to include from zero to four fractional seconds

with angle values.

Stations: allows you to display stations in any of the following

formats:

• 12+34.123: displays stations where the number to the left of

the + advances after traveling 100 feet or meters.

• 1+234.123: displays stations where the number to the left of

the + advances after traveling 1,000 feet or meters.

• 1,234.123: displays standard distances rather than stations.

Files Settings

Job Settings Files.

The Files Settings card allows you to select a feature code file.

Feature Code File: displays the selected feature code file

to use with the current job. See the User’s Manual for

more information on feature codes.

Browse : Opens a dialog to select a feature code file to

use with the current job. Tap the filename and then tap

Open .

Clear : closes the currently selected file so that it is no

longer associated with the current job.

R-43

Page 52

Survey Pro Reference Manual

Descriptions Settings

Job Settings Descriptions., or (from any Description field),

Description Settings…

The Descriptions Settings

files and configure how descriptions are handled.

Use Description Code File: Mark this item to use a

description file that contains codes and click the

associated Browse button to navigate to and select the

file. Description code files contain one code/description

pair per line where the code and description are

separated by a space or a tab. (The code cannot contain

spaces.)

Use Description List File: Mark this item to use a

description file containing a list of descriptions without

codes – one description per line and click the associated

Browse button to navigate to and select the file.

Load Description List from Job File: Marking this item

results in descriptions used in the current job, as well as

any new descriptions entered, to be included in the

description list.

Add New Descriptions to Description List: Marking this item

results in only new descriptions entered since marking this box to be

included in the description list. (If the preceding box is marked, new

descriptions are added whether or not this item is marked.)

Show Description List Automatically: Marking this item results

in a drop-down list of descriptions being displayed as soon as text

is entered into a Description field. If unmarked, the list can be

displayed by selecting Show Description List using the

button associated with a Description field. Double-clicking a

description in the list will replace the entered text with the selected

description.

card allows you to select description code

power

R-44

Page 53

Job Menu

Surveying Settings

Job Settings Surveying.

The Surveying Settings card allows you to select various options that

affect how data collection is performed.

; Prompt for Description: When checked, a prompt for

a description will appear before any new point is stored

from only the routines under the Survey

123).

Note: Descriptions can be no longer than 16 characters.

; Prompt for Height of Rod: When checked, a prompt

for the rod height will appear before any new point is

stored.

; Prompt for Layer: When checked, a prompt to select

a layer will appear before any new point is stored from

only the routines under the Survey

menu (Page R-

menu (Page R-123).

; Prompt for Attributes: When checked, a prompt to

select feature information will appear before any new point is stored

from only the routines under the Survey

also requires that a feature file be selected from the Files Settings

card, described above.

; Prompt for Picture: if checked, a prompt will appear before

storing a point where you have the option of taking one or more

pictures associated with the current point. (Only available when

running on a Nomad with a digital camera.)

; Adjust for Earth Curvature / Refraction: when checked, the

elevations for new points are adjusted to compensate f or the

curvature of the earth and refraction.

; Detect Duplicate Shots: When checked, a prompt will appear

before attempting to store a second shot to the same location. This

helps to catch when robotic total stations have lost lock while

surveying. The distance tolerances set in the Repetition Settings

menu (Page R-123). This

R-45

Page 54

Survey Pro Reference Manual

screen are used in determining when two shots are at the same

location.

; Survey with True Azimuths: automates the process of adjusting

the circle on the total station when traversing so that you can survey

with azimuths rather than horizontal angles (see Page R-133).

Scale Factor: displa

factor, if one is configured.

Setup Scale… : access the Scale Settings screen where a mapping

plane scale factor can be configured in a variety of ways, or disabled.

ys the details on the current mapping plane scale

Scale Settings

Job Settings Surveying Setup Scale.

The Scale Settings screen is the starting point for setting up a

mapping grid scale factor. Once configured, you will return to the

Surveying Settings

scale settings.

Do not use a scale factor: This option will disable any

mapping plane scaling that is currently enabled.

Use a single combined scale factor: This uses a single

combined scale factor that is provided for you, or one can

be computed with the Calculate Scale

Use a grid factor with sea level correction: This

option uses a mapping plane scale factor that is adj u sted

for elevation changes.

Use automatic map plane grid factor with sea level

correction: This option uses a combined scale factor that

is adjusted for elevation changes.

screen where you must then tap to save the

wizard.

Use map plane ground coordinates: When checked,

you can configure the job to use map plane ground

coordinates.

Combined Factor: is where you enter a combined scale factor if

already known, otherwise it is the combined scale factor computed

from the Calculate Scale

R-46

wizard.

Page 55

Job Menu

Grid Factor: is where you enter a map plane scale factor if alrea dy

known, otherwise it is the scale factor computed from the Calculate

Scale wizard.

Calculate Scale : This opens the Calculate Scale wizard (Page R-47),

which is used to calculate a combined scale factor or map plane scale

factor.

Setup Map Ground Coordinates : This will first check that a map

projection is selected and if not, prompt you t o sel ect one. Next, it

opens a wizard where after providing an origin point and ground

system offset coordinates, the entire job northing/easting database

will be updated with the ground coordinate system transformation.

Change Map Zone : Opens the Select Coordinate System wizard

where you can choose a mapping plane zone or localized site from the

coordinate system database file as described on Page R-224. You can

eate a new zone and datum with user-specified parameters.

also cr

Calculate Scale

Job Settings Surveying Setup Scale Calculate Scale.

The Calculate Scale wizard is available when Use a single combined

scale factor or Use a grid factor with sea level correction is selected in

the Scale Settings

factor. If a map zone is not currently selected, you will

first be required to set one up before continuing (Page

224).

Projection: displays th

zone.

Select Point: is where you specify a reference point.

Calc Scale > : opens Screen Two if Use a single combined

scale factor was selected. If Use a grid factor with sea

level correction was selected, you will return to the Scale

Settings screen and the computed grid factor will be

entered for you.

screen and is used to compute a scale

e details about the current map

R-47

Page 56

Survey Pro Reference Manual

Screen Two

Ellipsoid Height: The height of the ground above the

ellipsoid surface.

< Back : returns to the previous screen.

Solve > : opens Screen Three.

Screen Three

Mapping Plane Scale Factor: displays the scale factor

that will correct for the effects of map projection

distortion.