Page 1

May 2017

GL6X2N

Hands-On training

Page 2

a - Keypad/LCD-Display

b - Handle

c - Rotor

d - Roll Cage

e - Axes Alignment Marks

f - Sighting Guides/Scope Mounts

g - Battery door

h - Rubber Cover/Recharge Jack

i - 5/8” x 11 Tripod Mounts

j - Rubber Feet

k -Turnable Legs

l - Plus and Minus Battery

Diagrams

GL612N/622N Components

a

b

c

e

d

f

i

g

h

j

k

i

l

Page 3

Powering the GL612N/GL622N

1 – GL is shipped with a rechargeable NiMH

battery pack (Q104667).

2 – The charger (Q104781) can be used as a

power supply when used Indoors

3 – The rechargeable battery pack can be

charged inside as well as outside of the

unit

4 – Alkaline batteries can be used as a backup

5 – An optional external power cable

(Q104802) is available too

6 – Plus and minus symbols indicate

how to put the alkalines into the

battery compartment

Page 4

Powering the RC602N

1. Open the battery door using a coin or similar pry

device to release the battery door tab on the RC602N.

RC602N will be shipped with alkaline batteries

Rechargeable batteries can be used optional but need

to be charged externally

2. Insert two AA batteries noting the plus (+) and minus (-)

diagrams inside the battery housing.

3. Close the battery door. Push down until it “clicks”

into the locked position.

Page 5

Battery status laser Battery Status Remote Control

Mask selection Radio Connectivity

Rotation speed HI alert

Standard Display

Button 1: MENU

Button 2: Grade Entering Mode

Button 3: Manual mode

Button 4: Rotation/Scan

Button 5, 8: up/down arrow buttons

Button 6, 7: left/right arrow buttons

Button 9: ON/OFF button

1 second to turn on the unit;

2 seconds to turn off the unit.

Leveling/Standby – LED (green/red)

Page 6

Depending on the setup (horizontal) and if a grade value has been

dialed in, the unit starts the temperature/reference check while the

thermometer symbol is flashing.

Don’t start a menu function before the reference check has been

finished.

When the temperature/reference check has been finished, the standard

display appears and the bubble symbols flash until self-leveling has

been completed.

If the self-leveling can’t be finished based on the selected sensitivity, an

error message appears

Turning On/Off the Laser

Page 7

X-Y- grade entering: Digit Select mode (Default)

button 2: Grade Entering Mode.

button 1 quick set to 0%

button 2 change the sign of the grade value

Press and release button 5 or 8 (down or up) to move the cursor to the X- or Y-axis.

Pressing and releasing button 6 or 7 (right or left) moves the cursor to the right/left.

Use button 1 or 2 (Plus or Minus) to set the desired digit.

button 3 return to the standard display

The laser will self-level to the required grade position after confirming the grade change with button 4.

Note: The bubble symbols at the laser’s LCD will flash until the laser has been self-leveled to the requested

grade position.

Standard Features

Page 8

X-Y-grade entering

Step and Go mode

Quickly press and release button 2 starts the grade entering mode.

Both grade values will be shown.

Press/release button 1 grade reverse Y

Press/release button 2 grade reverse X

Press/release button 3 return to the standard display.

Quickly press and release button 4 to confirm the selected grade

value and return to the standard display

Press and hold button 6 or 7 (left/right) to change X- axis grade value

after the comma; press and hold buttons 6 + 7 simultaneously starts X-axis quick change mode

where the grade value in front of the comma will be set to 0% and then starts changing in 1%

increments.

Press and hold button 5 or 8 (up/down) for changing Y -axis grade value; press and hold buttons 5 +

8 simultaneously starts Y - axis quick change mode where the grade value in front of the comma will

be set to 0% and then starts changing in 1% increments

Note: When the grade value for either axis reaches its highest amount, the grade value switches to the

lowest value for that axis. For example, the value switches from +25% to -25%.

The laser will self-level to the required grade position after confirming the grade change with button 4.

Note: The bubble symbols at the laser’s LCD will flash until the laser has been

self-leveled to the requested grade position.

Standard Display

Standard Features

Page 9

Using the Rotation mode

Repeatedly pressing the button 4 toggles through 300, 600, 750 rpm regardless if the unit is in automatic or

manual mode.

Manual mode

Pressing and releasing button 3 at the Standard Display activates/deactivates the manual mode

regardless if set up horizontal or vertical.

Manual mode is indicated by horizontal lines next to the axes symbols. An additional bubble helps to adjust

the laser on the cross axis when set up vertical.

In Manual mode (horizontal), the Y-axis can be sloped by pressing the Up-(5) and Down-(8)- Arrow

buttons on the laser‘s keypad or the remote control. Additionally, the X-axis can be sloped by pressing

the Left-(6) and Right-(7) Arrow-buttons on the laser or remote control.

In vertical mode, the up and down arrow buttons adjust the Z-axis slope, and the left and right arrow

buttons align the laser beam to the right/left side.

To resume automatic self-leveling mode, press the manual button 3 again.

Standard Features

Page 10

Menu Functions (Radio controlled)

Press and release button 1 at the Standard Display to enter the MENU.

The menu offers always only the features which can be selected depending on the setup (horizontal or vertical).

The selected icon will be highlighted. A down arrow at the the right site indicates that the user can scroll down

through the menu using the button 8 (down arrow).

Note: As soon as the menu has been opened, button 2 (question mark) can be used to open a help text which

explains the selected function more in detail.

After going to the next menu row, a up/down arrow at the the right site indicates that the user can scroll

up/down through the menu rows (4 different screens) using the buttons 5/8 (up/down arrows).

Pressing and releasing button 3 changes the unit always back to the standard or previous display.

Press and release the buttons 6/7 until the desired icon at the selected menu row is highlighted.

Press and release button 4 to open the submenu OR start the selected function.

Menu functions when set up horizontal (GL622N)

Menu functions when set up vertical

Special MENU Features

PlaneLok

Grade

Match

Axis Align Mask Mode Standby

Reference

Check

Settings Info Service

PlaneLok Mask Mode Standby Line Scan Settings Info Service

Page 11

The PlaneLok mode can be activated in horizontal and vertical automatic and

manual mode. In PlaneLok mode when set up horizontal, the beam will be

locked to a fixed elevation point (up to 150 m (490 ft) located on one

axis at each side of the laser. For keeping vertical alignments fixed to a

direction point, PlaneLok can be used in both directions on the X-axis.

1. Set up the laser over the reference point.

2. Attach the HL760 receiver to a grade rod. Place the receiver at the second point and adjust it to the

On-grade position. The receiver should be permanently mounted at this location and at the desired

elevation.

3. Use the sighting guides on the top of the laser to align the laser to the receiver. Turn the laser on the

tripod until it is roughly aligned to the receiver’s position (the alignment range on both axes is +/-40).

4. Press and release the MENU button at the Standard Display and select PlaneLok.

5a. When set up horizontally, press and release button 4 to open the PlaneLok submenu; select the

desired PlaneLok axis then press button 4 to start PlaneLok.

Note: The laser starts to search for the receiver. A flashing Receiver and

Lock symbol appears at the selected axis and becomes solid when

PlaneLok has been completed.

Horizontal setup

Vertical setup

Automatic PlaneLok mode

(X only GL622N)

Page 12

5b. When set up vertically, press and release button 4 to open the PlaneLok submenu; select the

desired PlaneLok axis then press button 4 to start PlaneLok.

(Y only with GL622N)

Note: When used in vertical mode, the receiver has to be placed with the photocell on the bottom side.

The HL760 display shows a flashing –PL– during the time the laser is searching and adjusting the beam to the

on-grade position.

When PlaneLok is complete, –PL– stops flashing at the HL760 display.

Note: The laser continues to servo to the receiver’s signals.

6. Exiting of PlaneLok can be done by pressing button 3 (ESC).

Note: If the setup will be disturbed for a minute (beam will be blocked),

an Alert comes up. After deleting the error message with button 4 PlaneLok needs to be started again.

It’s recommended to use the batter board adapter M402 for setting up the GL6X2N and the 105516 vertical

adapter for setting up the HL760.

Automatic PlaneLok mode

Page 13

Steep Slope using PlaneLok

Set up the GL6X2N at the bottom part of the steep slope

area using the slope bracket (M401 laser tilting base).

Check the laser beam elevation and place the receiver at the

desired hub.

Change the GL into manual mode and tilt the unit to the

approx. steep slope position until the receiver on top starts to

catch the beam.

Page 14

10/16/2017 14

Steep Slope using PlaneLok

Select PlaneLok at the menu and start automatic PlaneLok by pressing button 4.

The transmitter starts searching for the receiver HL760 and locks the beam at the on-grade

position.

Page 15

The Grade Match mode can be activated in horizontal automatic mode.

In Grade Match mode, the laser can be used to measure the existing grade value between two known

elevation points (up to 150 m (490 ft) located on one axis at each side of the laser

1. Set up the laser over the reference point.

2. Attach the HL760 receiver to a grade rod. Check the laser’s elevation next to

the laser then position the receiver at the second point WITHOUT changing the

receiver’s elevation on the rod.

3. Use the sighting guides on the top of the laser to align the laser to the receiver.

Turn the laser on the tripod until it is roughly aligned to the receiver’s position

(the alignment range on both axes is +/-40°).

4. Press and release the MENU button at the Standard Display and select Grade Match.

5. Select the desired Grade Match axis then press button 4 to start Grade Match.

Note: The laser starts to search for the receiver. A flashingReceiver an angle symbol

appears at the selected axis and disappears when Grade Match has been completed.

While the laser is searching and adjusting the beam to the on-grade position,

the HL760 display shows a flashing –GM–. When Grade Match has been completed,

the HL760 goes back to the standard elevation display. The remote control as well as the laser

will display the final measured grade value.

Note: If Grade match can’t be completed by checking the limits, the laser comes with an

Error message (Grade Match has Failed) which can be deleted with button 4 (OK).

Automatic Grade Match mode

(X only GL622N)

Page 16

Automatic Axis Alignment mode adjusts automatically the direction

the grade axis is pointing to the receiver’s location by an electronically

simulation of rotating the unit on its base to match the hub.

Using Axis Alignment, the laser axes can be aligned to one

direction hub (up to 150 m (490 ft) located on one axis at each

side of the laser.

1. Set up the laser over the reference point.

2. Place the grade rod with the attached HL760 receiver at the desired direction hub.

3. Use the sighting guides on the top of the laser to align the laser to the receiver.

Turn the laser on the tripod until it is roughly aligned to the receiver’s position.

(the alignment range on both axes is +/-40°).

4. Press and release the MENU button at the Standard Display and select Axis Align.

5. Adjust the receiver into the beam before starting the automatic Axis Alignment to reduce the

time needed for finishing the alignment.

5. Select the desired axis then press button 4 to start Axis Align.

Note: The laser starts to search for the receiver while -AA- is flashing at the HL760 LCD.

Note: A flashing Alignment symbol appears at the selected axis, becomes

solid when Axis Alignment has been completed and then disappers while

the flashing bubbles come back. A short line on top of Y and X

confirms an Axis Alignment has been completed.

Automatic Axis Alignment mode (only GL622N)

Page 17

Mask mode

Select the Mask icon and press and release button 4 to open the Mask setting menu.

Depending on which side or corner the beam should be turned off, the required sector can

be selected.

Press and release the buttons 5 to 8 for moving a short flashing line around the mask

mode symbol.

For selecting the sector where the bar is flashing, press and release button 1 (SET).

After setting the first sector, button 1 changes to show CLR which offeres the capability

of deleting the selected mask sector again. Use button 5 to 8 to move the flashing bar

to other required areas and repeat the setting process.

When all areas have been set, press button 4 to store the mask sector selection until the

unit will be turned off.

Note: The unit always powers up with the mask mode deactivated (default).

Activating/Deactivating Standby mode

Press and release the MENU button at the Standard Display and select Standby.

Pressing and releasing button 4 activates the Standby mode.

The self-leveling will be stopped and the beam will be turned off while the HI alert

is still active.

The display shows the standby symbol and the Level/Standby LED flashes red every 5

seconds. To deactivate Standby mode and restore full operation of the laser, press

and release button 4.

Mask Mode / Standby mode

Page 18

Temp Reference Check / Settings

Start Reference Check

When working during temperature changes and over long distances the product requires

a frequent reference check to maintain accuracy. The transmitter will do reference check

on a regular basis. When carrying out work where accuracy is paramount it is advised to

manually prompt a reference check.

Press and release the MENU button at the Standard display and select Reference Check.

Button 4 starts the reference check considering the current temperature inside the

housing. While the procedure the rotation will be stopped.

Note: A grade value has to be entered before the unit starts the reference check.

Setting Menu

Press and release the MENU button at the Standard Display and select Settings.

Press and release button 4 to open the Setting Menu; select the desired function then

press button 4 to open the selected submenu function OR start the selected function.

Please see the Setting Menu details at the end of the user guide.

Page 19

Info

Press and release the MENU button at the Standard Display and select Info.

Buttons 6/7 can be used to toggle between GL, RC and Runtime

Press and release button 4 to confirm the selection.

The GL/RC information (software version, ID, etc.) or the runtime of the GL will be displayed.

Additional detailed RC information is available using the RC602N menu :

Info

Page 20

Press and release the MENU button at the Standard Display and select Service.

Buttons 6/7 can be used to toggle between Calibration Y and Calibration X OR

Calibration Z when set up vertically.

Press and release button 4 to confirm the selection.

The calibration at the selected axis starts the field calibration procedure.

The RC602N Service menu offers one additional feature:

RF Connectivity

Press and release button 4 to get a status of the current Radio connectivity.

Service

Page 21

Line Scan

Line Scan centers the rotor horizontally and can be used to align the plumb beam to a desired horizontal

position.

Press and release the MENU button 1 at the Standard Display and select Line Scan.

Pressing and releasing button 4 activates the Line Scan mode while the rotor checks the limits

of the X- axis and stops at the center position.

Pressing button 3 (ESC) stops the movement and changes the unit into manual mode.

Corrections up and down can be done using button 5/8; for left/right corrections use button 6/7.

Press and release the manual button 3 to change the unit back to full automatic mode.

Special Features - Vertical Setup

Page 22

Press and release the MENU button 1 at the Standard Display and select Settings.

Press and release button 4 to open the Setting Menu; select the desired function,

then press button 4 to open the selected submenu function OR start the selected function.

The Setting Menu offers the following functions:

Pairing Grade Entry Grade Display Sensitivity HI-alert User Name

Password Password RF-Channel Language Position Info

Set On/Off

Pairing

1. When in Settings, press and release button 4 at the GL612N/622N to open the Pairing menu.

The display shows the currently paired units (up to two receivers and two remote controls).

2. If already 2 remote controls have been paired, one of them has to

be deleted using button 1 (CLR).

3. Turn on the RC602N and select the Pairing menu and press button 4.

The GL612N/622N pairs now automatically with the new remote control.

Pairing the transmitter with a new remote control

The chain symbol at button 1 indicates the remote has not been paired before which

means no radio connectivity is given.

Pressing the pairing button 1 will initiate a pairing request.

The transmitter has to be in pairing mode as shown above.

Note: Make sure that pairing mode is selected only at one transmitter which is within the

radio range of the remote during a pairing request. Otherwise pairing procedure can

be confused.

Setting Menu

Page 23

Pairing the transmitter with receiver (HL760)

To pair the transmitter and the receiver select Settings and press and release button 4

to open the Pairing menu. The display shows the currently paired units (up to 2 receivers).

If already 2 receivers have been paired, one or both of them have to be deleted using

button 1 (CLR).

Next, turn on the receiver then press and hold the Deadband (A) and the Audio (B)

buttons for two seconds. After two seconds the display shows MENU first, then RDIO.

Press and release the Units (C) button – display shows the current radio mode.

If not already set to LS, press Units button (C) and then press Deadband or Audio button

until LS is displayed. Press Units button (C) again to enter selection.

Press and release the Audio button (B) – display shows PAIR.

Press the Units button again – the display shows PAIR and a rotating bar. After completing PAIR, OK will be

displayed.

The GL612N/GL622N pairs now automatically with the new receiver.

Press and release the HL760 Power button two times to exit the menu.

A laser symbol is lit to confirm the receiver works in GL mode.

A

C B

Setting Menu

Page 24

Grade Entry

Select the Grade Entry icon and press and release button 4 to open the Grade Entry menu.

Buttons 6/7 can be used to toggle between Step and Go and Digit Select.

Press and release button 4 to confirm the selection.

Grade Display

Select the Grade Display icon and press and release button 4 to open the Grade Display menu.

The desired Grade Display Mode (Percent/ Permille/Degree) can be selected using the buttons 6/7.

Press and release button 4 to

confirm the selected display mode.

Sensitivity Selection

Select the Sensitivity icon and press and release button 4 to open the Sensitivity menu.

The desired Sensitivity: Low, Mid (Default) and High) can be selected using the buttons 6/7.

Press and release button 4 to

confirm the selected Sensitivity.

Setting Menu

Page 25

HI-alert Selection

Select the HI icon and press and release button 4 to open the HI-Alert menu.

The desired HI-alert: 5 min.(Default), 30 seconds and HI-Off) can be selected using the buttons 6/7.

Press and release button 4

to confirm the selected HI-alert.

Depending on the HI settings, the green leveling LED flashes after 5 minutes or 30 seconds every 4 seconds

to confirm the HI alert is active. If HI alert is turned Off, the green LED stays on solid after self-leveling has

been completed.

User Name

Select the User name icon and press and release button 4 to open the User name menu (Cursor flashes).

One row for typing names in big font (15) and one row in small font (18)

for letters or numbers are available.

Button 5 and 8 can be used to toggle between both rows.

Changing the characters can be done using the buttons 1 and 2.

Press and release button 4 to confirm the selected user name.

The display falls back to the main menu.

Any time the unit will be powered up, the User info will be displayed for couple seconds.

Setting Menu

Page 26

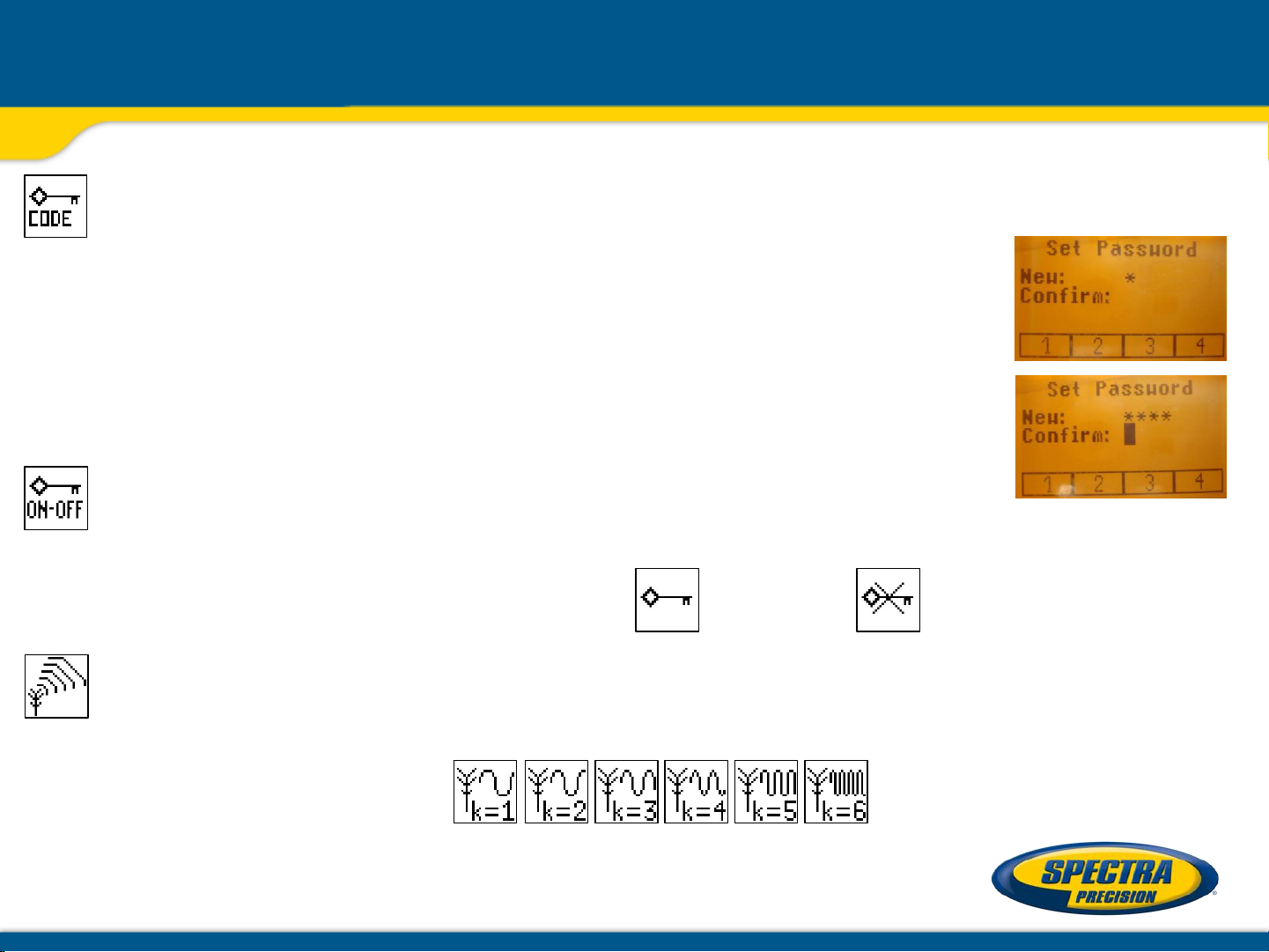

Set Password

Select the Set Password icon and press and release button 4 to open the Password menu.

Use button 1 to 8 to type in a password containing of 4 digits and repeat the password

at the second row.

Press and release button 4 to store the selected password; unit falls back to the

standard menu.

After powering up the unit, the standard display comes up if the correct password will

be entered, otherwise the unit turns off automatically.

Password On/Off

Select the Set Password ON-Off icon and press and release button 4 to open the Password menu.

Buttons 6/7 can be used to toggle between Password On and Password Off if a Password has been

entered before.

Press and release button 4 to confirm the selection.

Radio (RF) Channel

Select the RF Channel icon and press and release button 4 to open the Radio Channel menu.

The desired RF Channel: 1 to 6 can be selected using the buttons 6/7.

Press and release button 4 to

confirm the selected RF Channel.

Note: After changing the RF channel, the RC and HL needs to be paired again.

Setting Menu

Page 27

Select Language

Select the Language icon and press and release button 4 to open the Language menu.

Use button 5 to 8 to select the required local language (EN, DE, IT, FR, ES, PT, NL, DA, NO, SV, FI, PL, TR,

CZ).

Press and release button 4 to store the selected Language; unit falls back to the standard menu.

Position Info

when working with high grade values the product requires the position info to maintain accuracy and avoid

errors caused by different gravity. The user has the chance to provide the position info of the job site to

the product. This is the degree of latitude as well as the altitude.

Chose Settings and navigate to the sub menu position info. Press button 4 to activate the submenu. With

buttons 1 and 2 the different values can be increased/decreased. Also ‚+‘ or ‚-‘ for the latitude can be

changed with buttons 1 and 2. With buttones 5, 6, 7 and 8 the cursor position can be changed.

Restore to default: scroll down to ‚Default position‘. Press button 1 (Set); the unit will change to default

values; press button 4 to confirm the change.

Setting Menu

Page 28

Any error message can be deleted with a short press of button 4 (OK).

The table shows the related description and possible solutions.

The next service center should be contacted if a different error message as shown at the table will be displayed.

Error Messages

Error

codes

Description

Solution

21

Temporary EEprom problem

Repeat pairing and re

-enter the customer settings

120

HI alert

- Unit Heigt changed

Check laser beam elevation

130

Mechanical Limit during Axis Alignment or Grade

Match

Re

-align the closer to the alignment point; check if existing

slope is above +/

-25%

131

Rake Angle Limit

Pre

-tilt the unit closer to the alignment point

140

Laser beam blocked

Make sure there are no obstacles between the transmitter

and the

HL750

141

Time Out

- Alignment could not be completed in the

allowed time

Check radio operating range/ connection; check stable laser

setup

150

No receiver

- Receiver not available for single axis

automatic function

Make sure the receiver is on and paired

152

No receiver

- The laser searched for the receiver but

could not find it

Check the operating range for auto function and restart the

auto alignment

153

Lost Receiver

- The laser searched and found the

receiver but then lost it

Check the operating range for auto function and restart the

auto alignment

160

X or Y level

sensor defect

Contact service center

Loading...

Loading...