Sony XR-CA630X Service manual

XR-CA630X

SERVICE MANUAL

Ver 1.0 2002.01

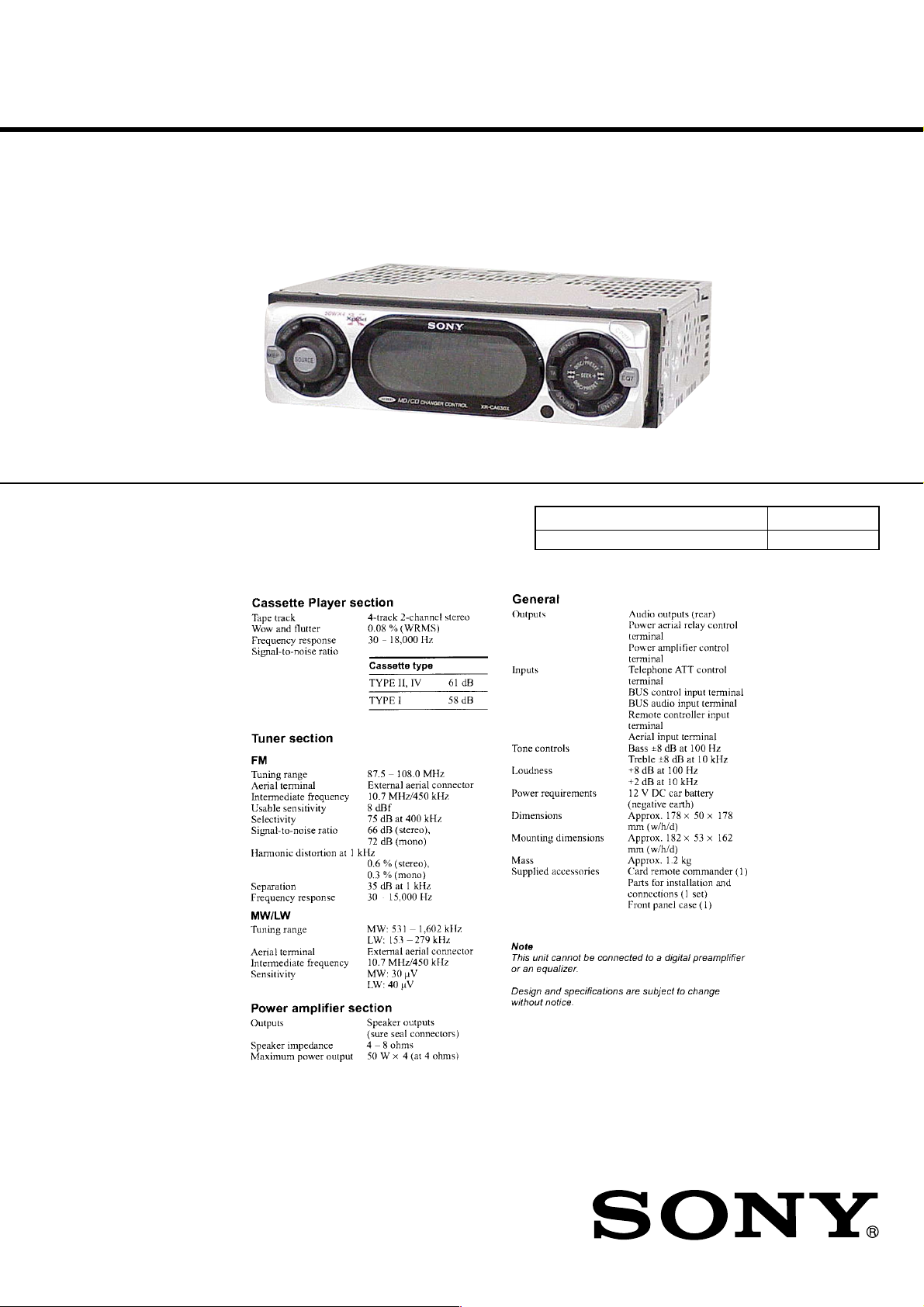

SPECIFICATIONS

AEP Model

UK Model

Model Name Using Similar Mechanism NEW

T ape Transport Mechanism Type MG-25M-136

9-873-471-01 Sony Corporation

2002A0500-1 e Vehicle Company

C 2002.1 Published by Sony Engineering Corporation

FM/MW/LW CASSETTE CAR STEREO

XR-CA630X

TABLE OF CONTENTS

1. GENERAL

Location of Controls ....................................................... 3

2. DISASSEMBLY

2-1. Disassembly Flow ........................................................... 7

2-2. Mechanism Deck (MG-25M-136) .................................. 7

2-3. MAIN Board ................................................................... 8

2-4. Heat Sink (ISO2P) .......................................................... 8

3. ASSEMBLY

3-1. Assembly Flow................................................................ 9

3-2. Housing ........................................................................... 10

3-3. Arm (Suction) ................................................................. 10

3-4. Lever (LDG-A)/(LDG-B) ............................................... 11

3-5. Gear (LDG-FT) ............................................................... 11

3-6. Guide (C)......................................................................... 12

3-7. Mounting Position of Capstan/Reel Motor (M901) ....... 12

4. MECHANICAL ADJUSTMENTS....................... 13

5. ELECTRICAL ADJUSTMENTS

Tape Deck Section .......................................................... 13

Tuner Section .................................................................. 13

6. DIAGRAMS

6-1. Note for Printed Wiring Boards and

Schematic Diagrams ....................................................... 14

6-2. Printed Wiring Board – MAIN Board – ......................... 15

6-3. Schematic Diagram – MAIN Board (1/3) – ................... 16

6-4. Schematic Diagram – MAIN Board (2/3) – ................... 17

6-5. Schematic Diagram – MAIN Board (3/3) – ................... 18

6-6. Printed Wiring Board – SUB Board – ............................ 19

6-7. Schematic Diagram – SUB Board – ............................... 19

6-8. Printed Wiring Board – KEY Board –............................ 20

6-9. Schematic Diagram – KEY Board – .............................. 21

6-10. IC Pin Function Description ........................................... 24

Notes on chip component replacement

• Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be damaged by heat.

Flexible Circuit Board Repairing

• Keep the temperature of the soldering iron around 270 ˚C during repairing.

• Do not touch the soldering iron on the same conductor of the

circuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering

or unsoldering.

7. EXPLODED VIEWS

7-1. Chassis Section ............................................................... 27

7-2. Front Panel Section ......................................................... 28

7-3. MAIN Board Section ...................................................... 29

7-4. Mechanism Deck Section (MG-25M-136)..................... 30

8. ELECTRICAL PARTS LIST ............................... 31

2

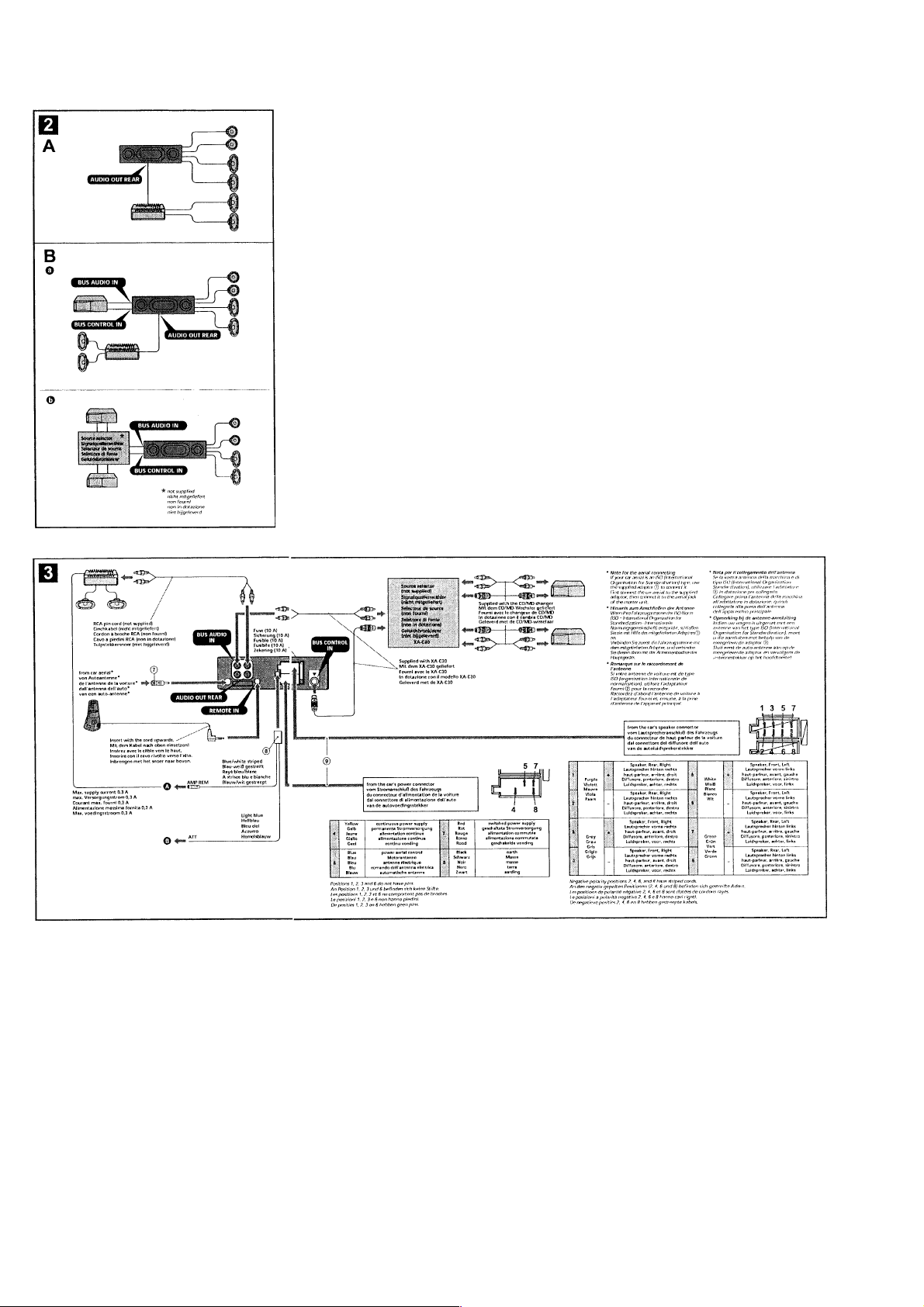

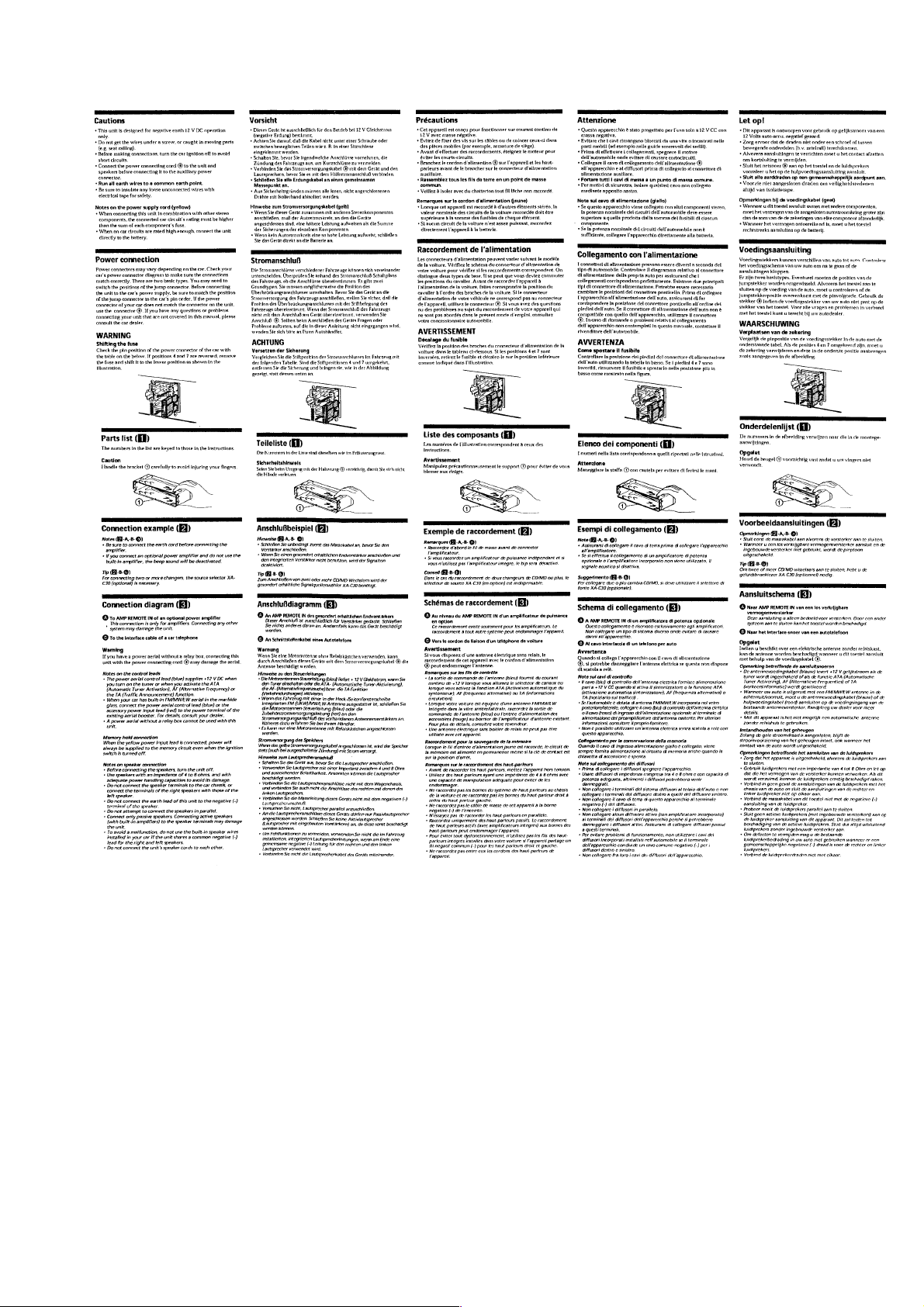

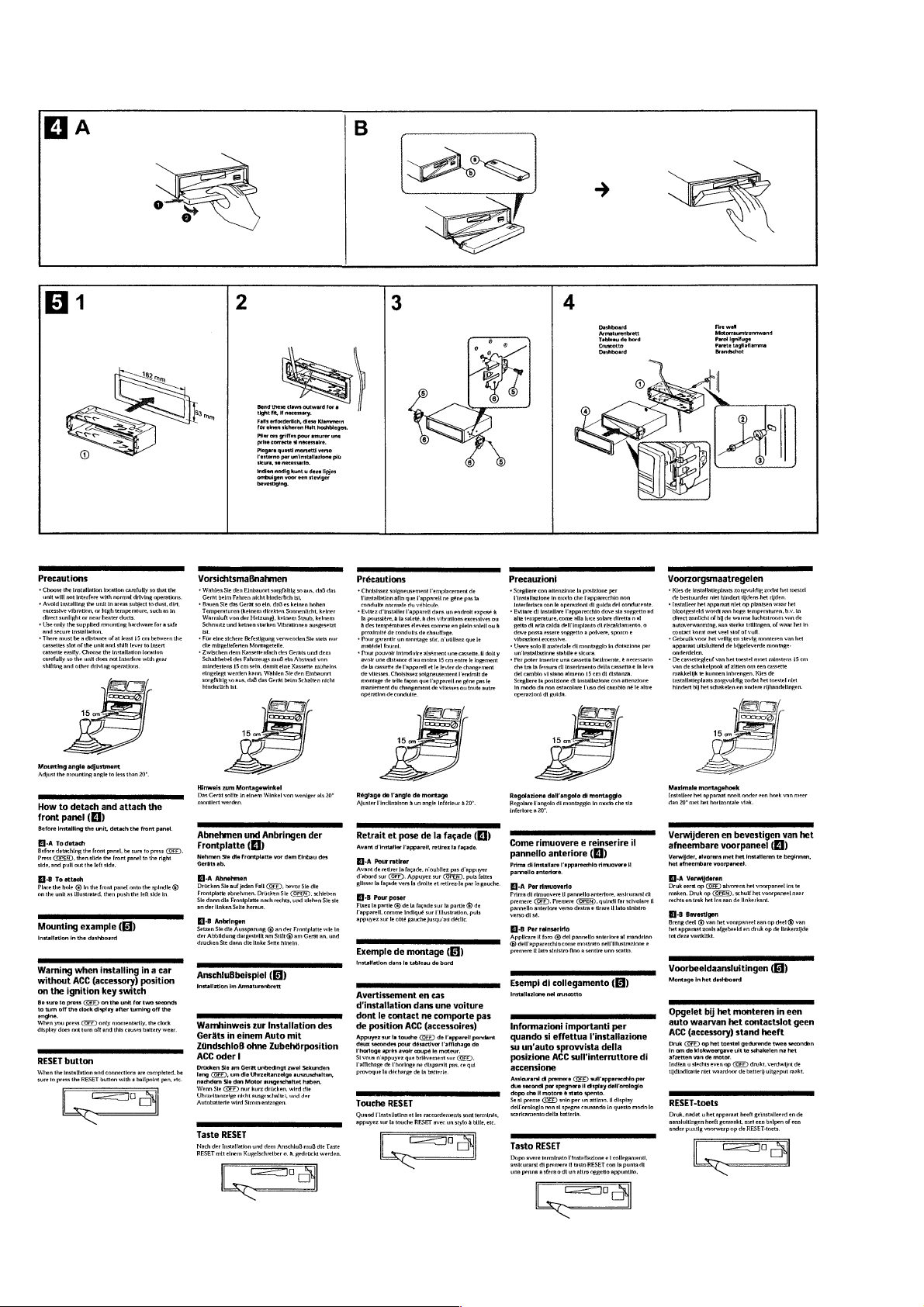

SECTION 1

GENERAL

XR-CA630X

This section is extracted from

instruction manual.

3

XR-CA630X

4

XR-CA630X

5

XR-CA630X

6

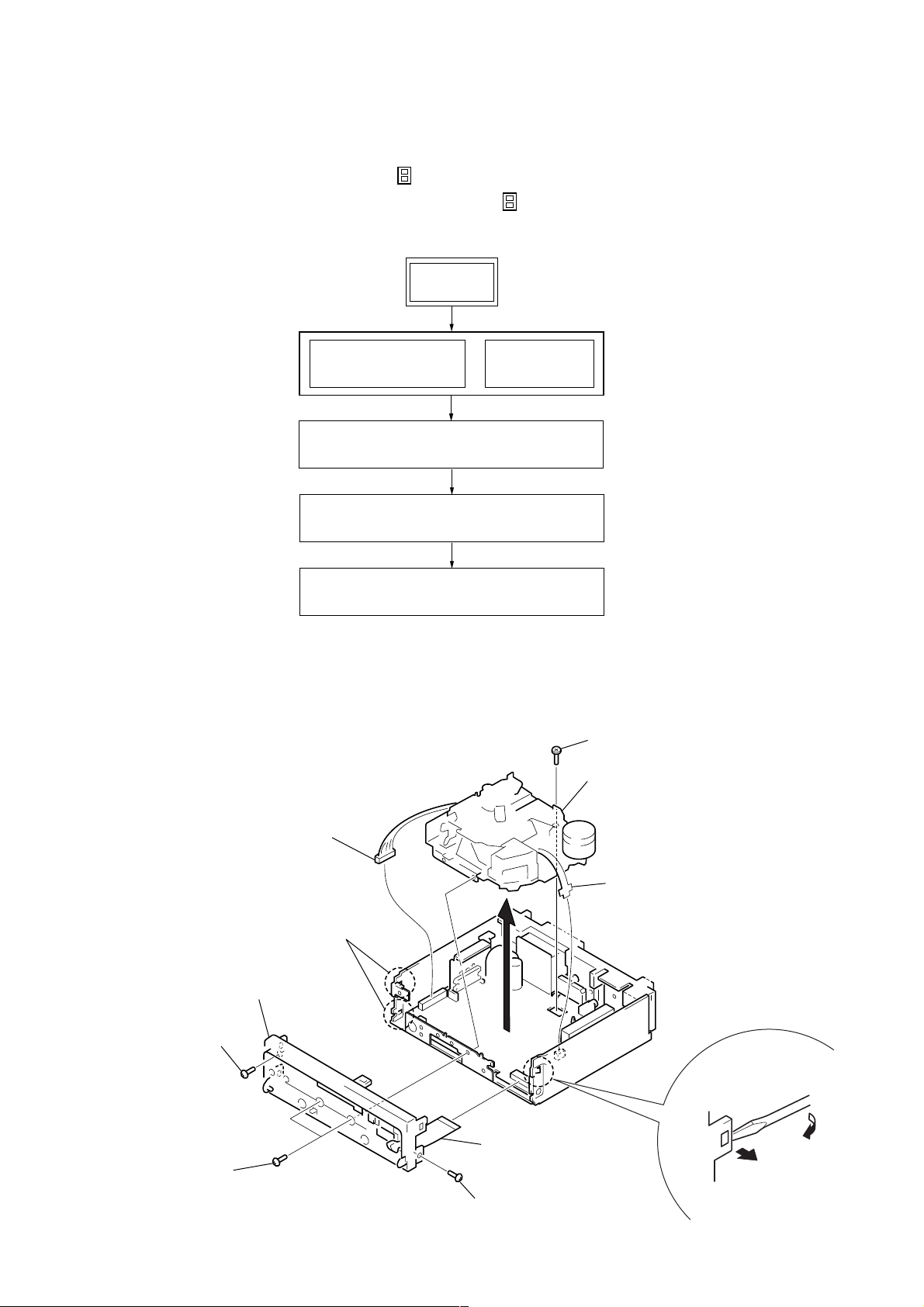

• This set can be disassembled in the order shown below.

2-1. DISASSEMBLY FLOW

Note 1: The process described in can be performed in any order.

Note 2: Without completing the process described in , the next process can not be performed.

Note 3: Illustration of disassembly is omitted.

XR-CA630X

SECTION 2

DISASSEMBLY

SET

FRONT PANEL SECTION

(Note 3)

2-2. MECHANISM DECK (MG-25M-136)

(Page 7)

2-3. MAIN BOARD

(Page 8)

2-4. HEAT SINK (ISO2P)

(Page 8)

Note: Follow the disassembly procedure in the numerical order given.

2-2. MECHANISM DECK (MG-25M-136)

COVER

(Note 3)

7

screw (PTT2.6 × 6)

8

mechanism deck (MG-25M-136)

4

1

screw (PTT2.6 × 6)

1

two screws

(PTT2.6 × 6)

sub panel assy

6

connector

(CN351)

2

two claws

3

flat flexible (14core) cable

(CN701)

1

screw (PTT2.6 × 6)

5

flexible board

(CN301)

2

claw

7

XR-CA630X

)

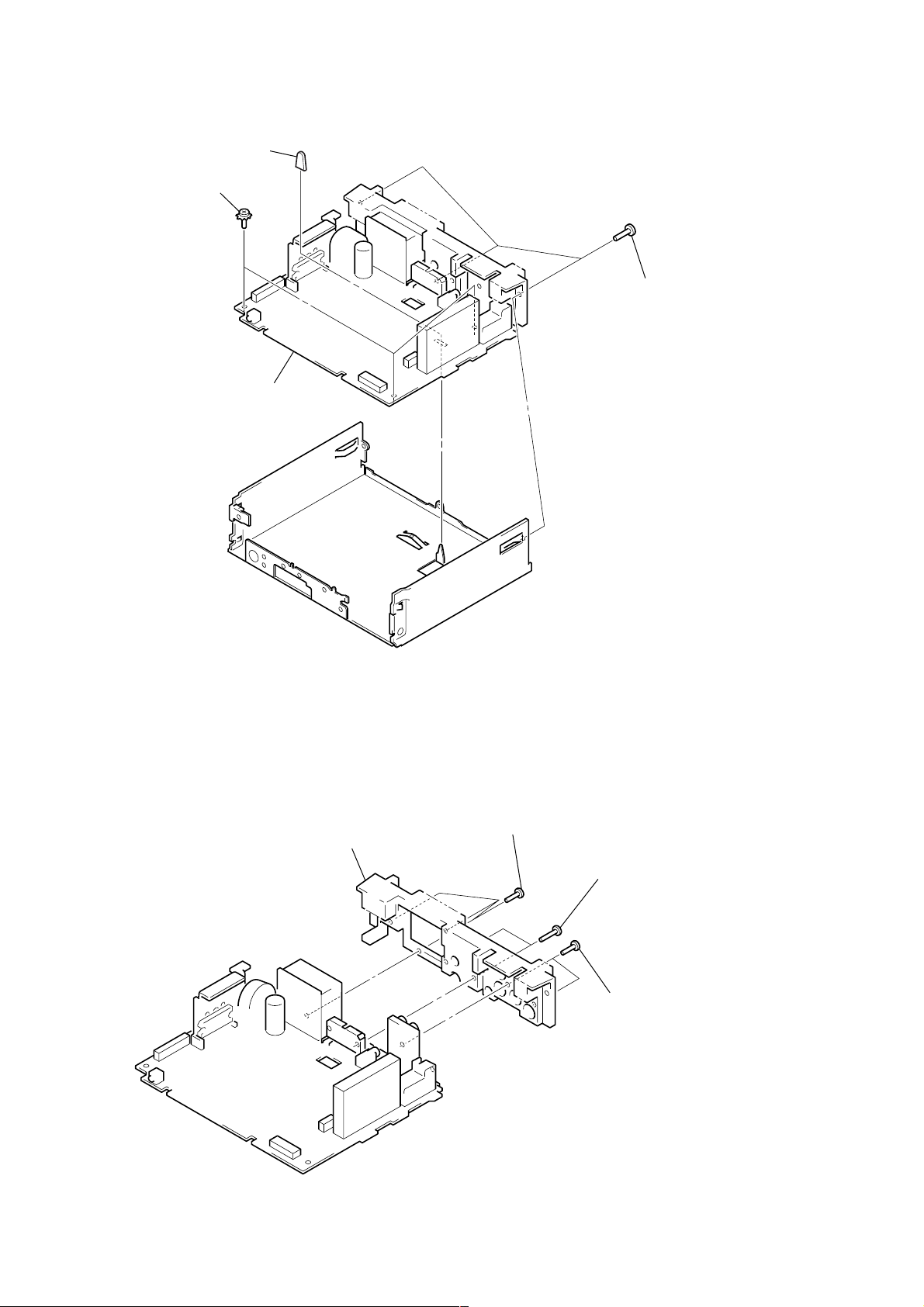

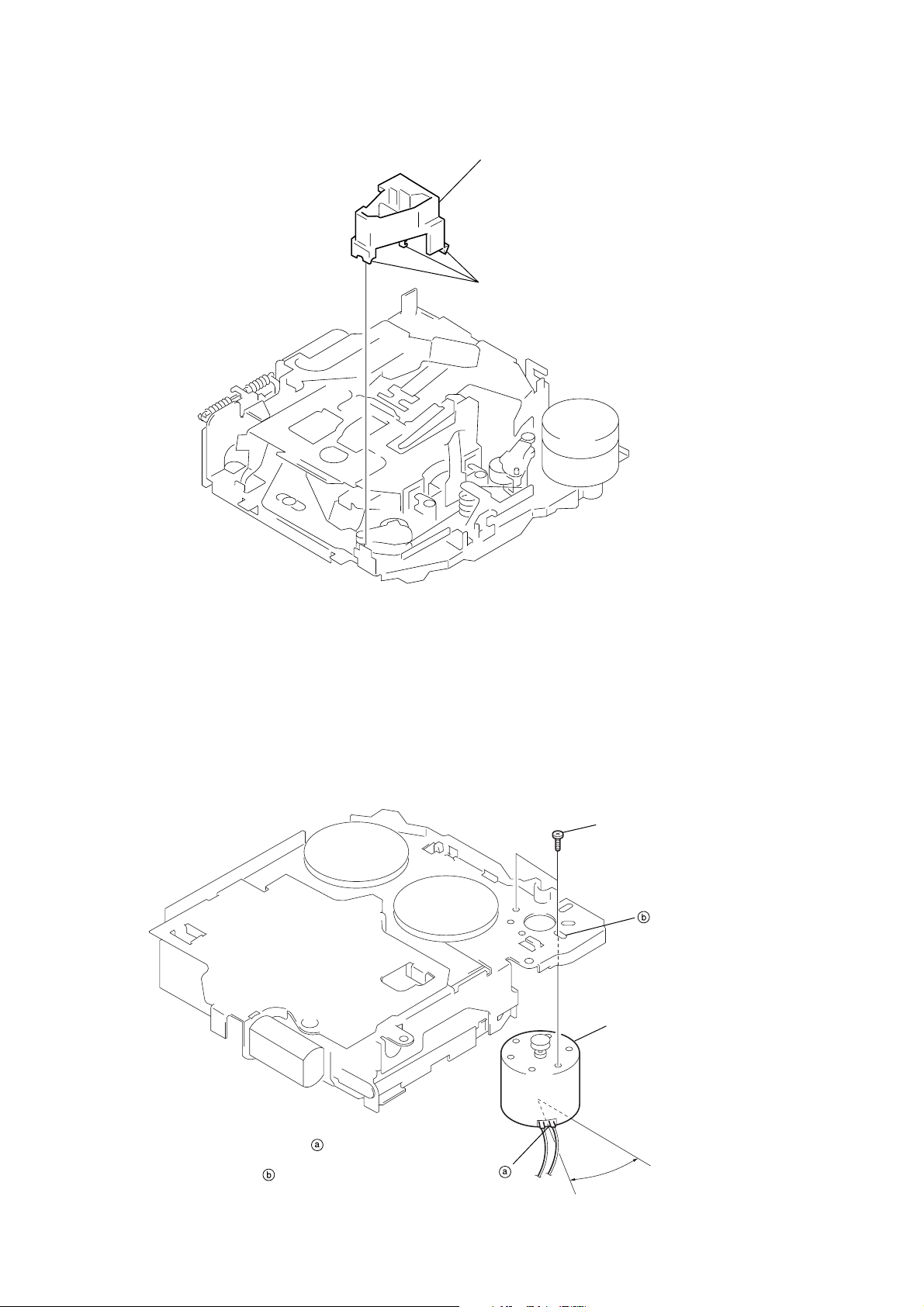

2-3. MAIN BOARD

3

2

three ground point screws

(PTT2.6

×

6)

rubber cap (25)

4

main board

1

three screws

(PTT2.6

×

8)

2-4. HEAT SINK (ISO2P)

3

heat sink (ISO2P)

1

three screws

(PTT2.6

×

8)

2

two screws

(PTT2.6

1

×

12)

two screws

(PTT2.6

×

8

8

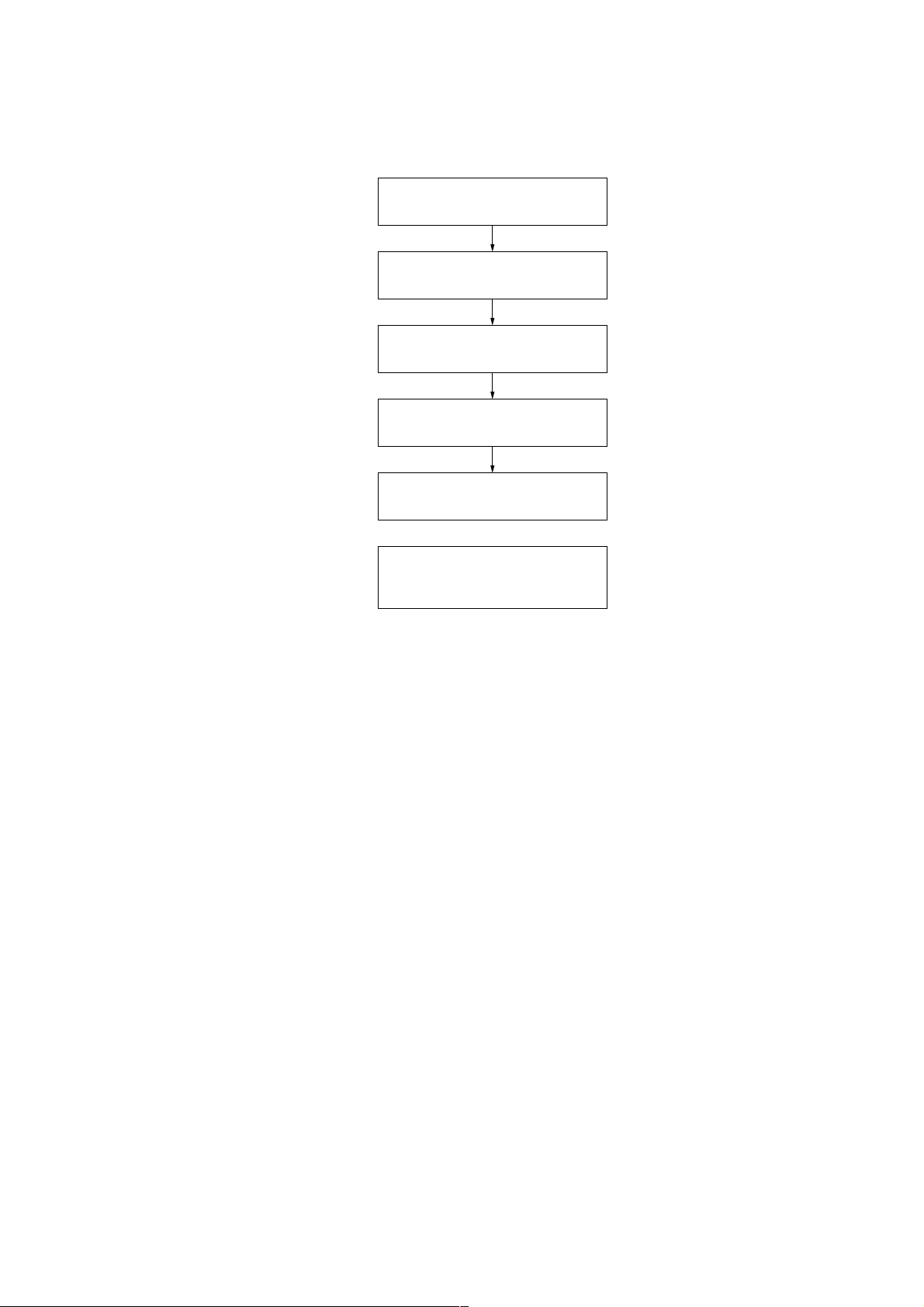

• This set can be assembled in the order shown below.

3-1. ASSEMBLY FLOW

XR-CA630X

SECTION 3

ASSEMBLY

3-2. HOUSING

(Page 10)

3-3. ARM (SUCTION)

(Page 10)

3-4. LEVER (LDG-A)/(LDG-B)

(Page 11)

3-5. GEAR (LDG-FT)

(Page 11)

3-6. GUIDE (C)

(Page 12)

3-7. MOUNTING POSITION OF

CAPSTAN/REEL MOTOR (M901)

(Page 12)

9

XR-CA630X

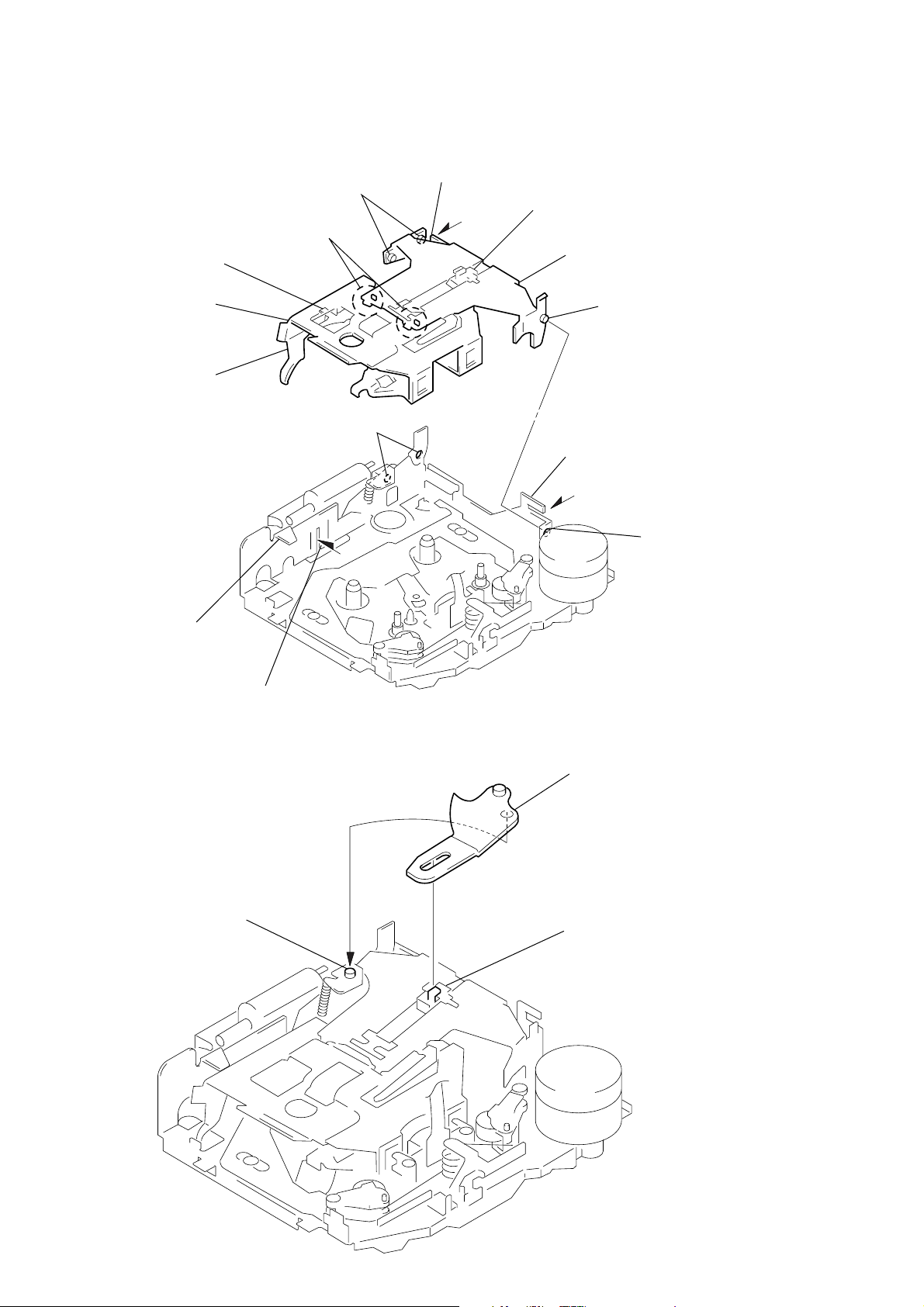

Note: Follow the assembly procedure in the numerical order given.

3-2. HOUSING

5 Fit projection on C part.

2 Install the hanger onto

two claws of the housing.

4 Fit claw on B part.

7 Hold the hanger by bending the claw.

1 Install the catch to the hanger.

hanger

3 Put the housing

under A part.

housing

A part

6 Fit projection on D part.

C part

8 Hold the hanger by

bending the claw.

D part

B part

3-3. ARM (SUCTION)

2 Move the arm (suction) in the arrow

direction and fit on projection.

projection

1 Fit the arm (suction) on the shaft.

10

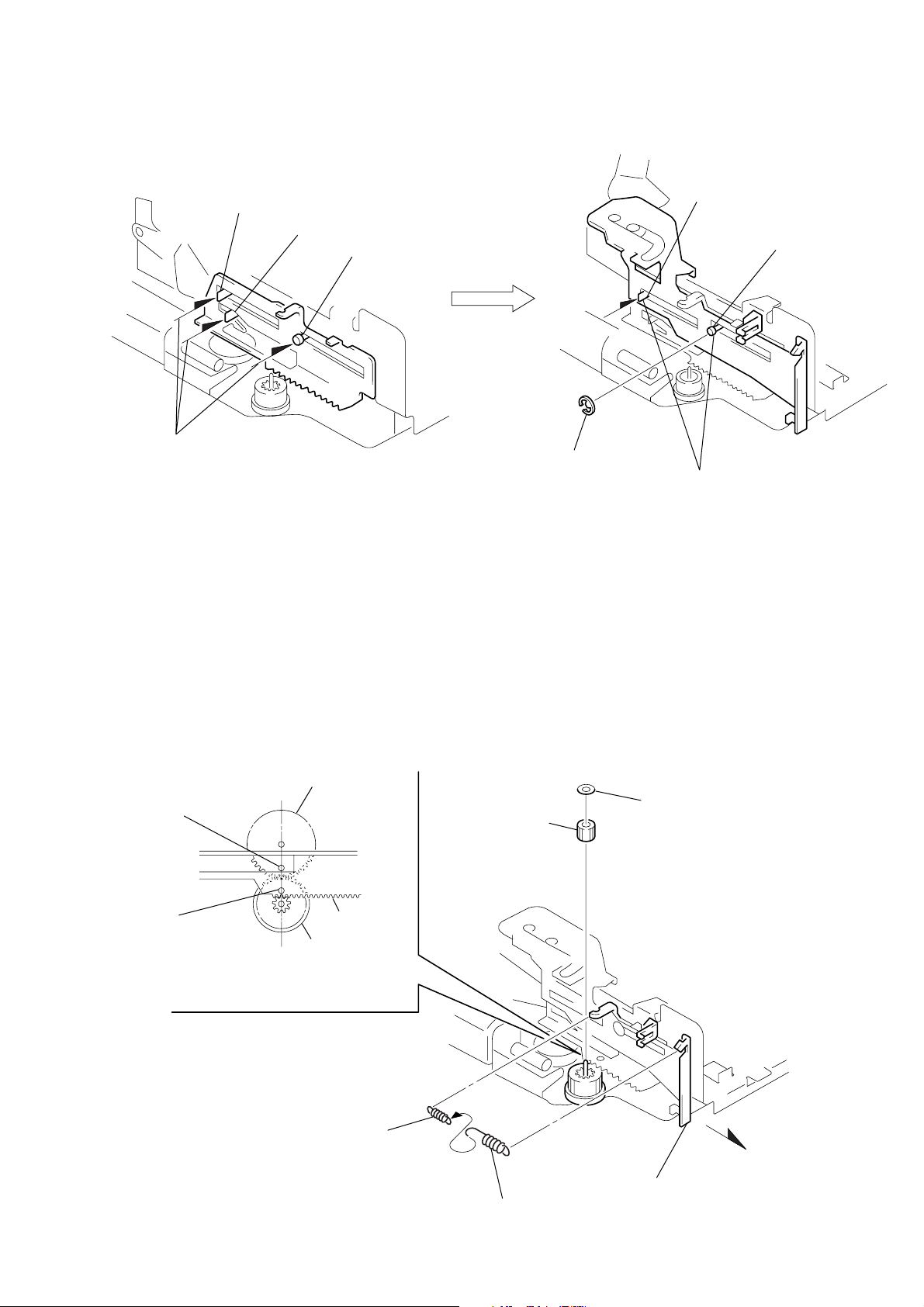

3-4. LEVER (LDG-A) / (LDG-B)

)

XR-CA630X

shaft A

1 Fit the lever (LDG-A) on

shafts A – C and install it.

shaft B

shaft C

shaft A

shaft B

3 type-E stop ring 2.0

2 Fit the lever (LDG-B) on

shafts A and B and

install it.

3-5. GEAR (LDG-FT)

hole

hole

4 Align hole in the gear (LDG-D)

with hole the lever (LDG-A).

2 tension spring (LD-2)

gear (LDG-D)

6 polyethylene washer

5 gear (LDG-FT)

lever (LDG-A)

gear (LDG-FB)

1

2 tension spring (LD-1)

3 Move the lever (LDG-B

in the arrow direction.

11

XR-CA630X

s

3-6. GUIDE (C)

2 guide (C)

1 three claws

3-7. MOUNTING POSITION OF CAPSTAN/REEL MOTOR (M901)

Note: Mount the motor so that the

angle between of the

motor and the hole for the

screw becomes 30

shown in this figure.

°

as

two precision screw

(P2 × 2)

capstan/reel motor

(M901)

30˚

12

Loading...

Loading...