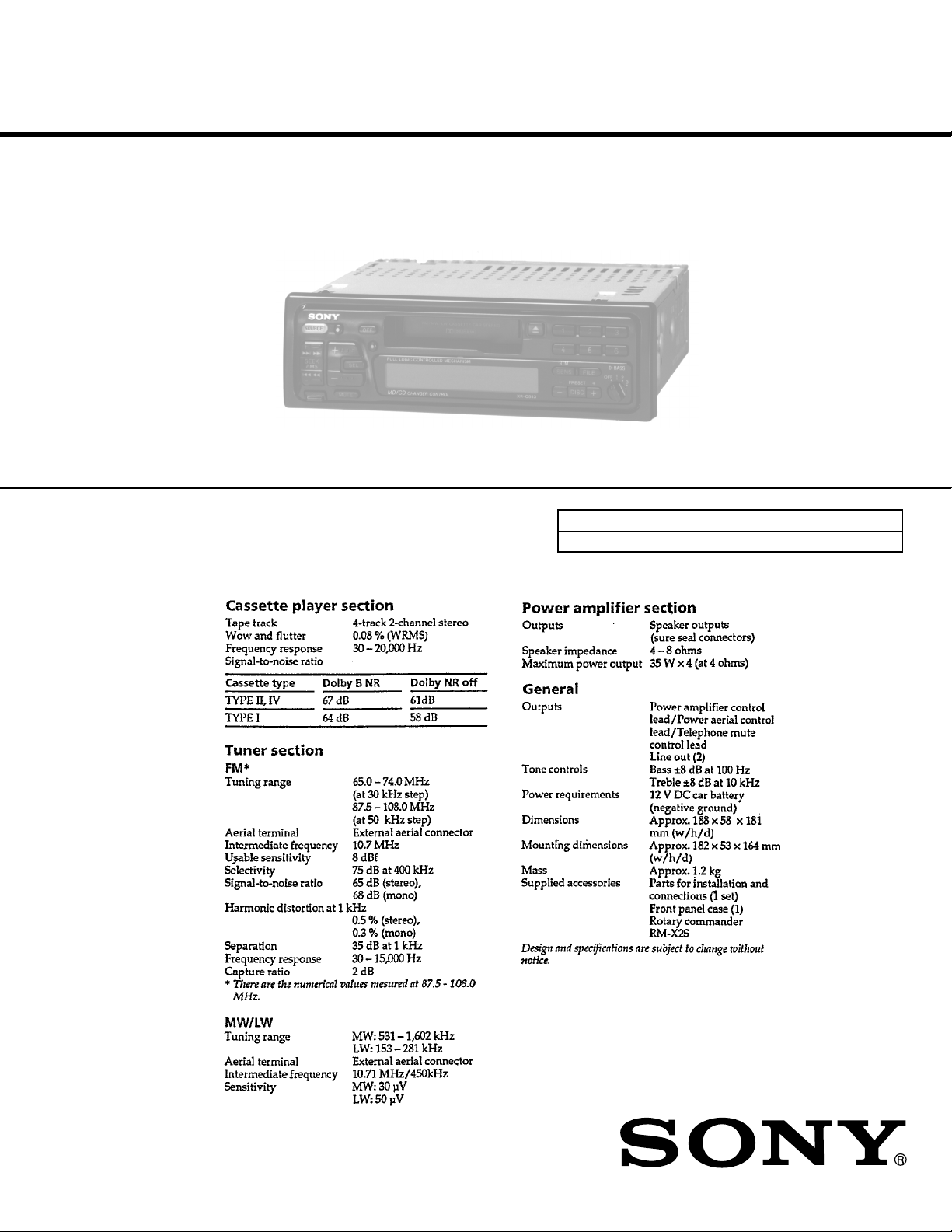

Sony XR-C553SP Service manual

XR-C553SP

SERVICE MANUAL

Ver 1.1 2001.08

For RM-X2S (Remote Commander),

please reter to RM-X2S/X3S Service

Manual (9-960-039-∏) previously issued.

East European Model

Dolby noise reduction manufactured under license

from Dolby Laboratories Licensing Corporation.

“DOLBY” and the double-D symbol a are trademarks

of Dolby Laboratories Licensing Corporation.

SPECIFICATIONS

Model Name Using Similar Mechanism NEW

T ape Transport Mechanism T ype

MG-52A-135

FM/MW/LW CASSETTE CAR STEREO

9-925-531-12 Sony Corporation

2001H0500-1 e Vehicle Company

C 2001.8 Shinagawa Tec Service Manual Production Group

TABLE OF CONTENTS

SERVICING NOTES

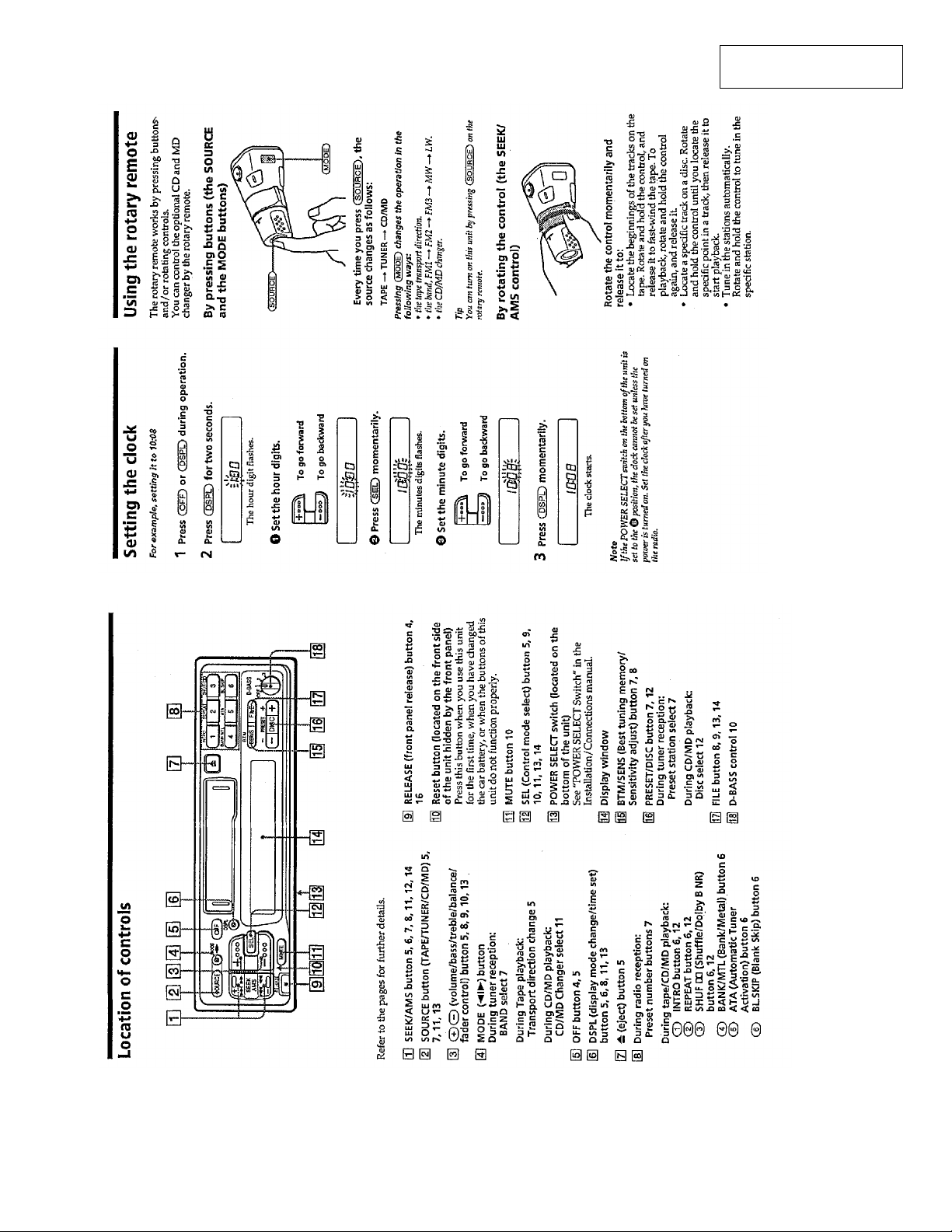

1. GENERAL

Location of Controls .......................................................... 3

Setting the Clock ............................................................... 3

Using the Rotary Remote .................................................. 3

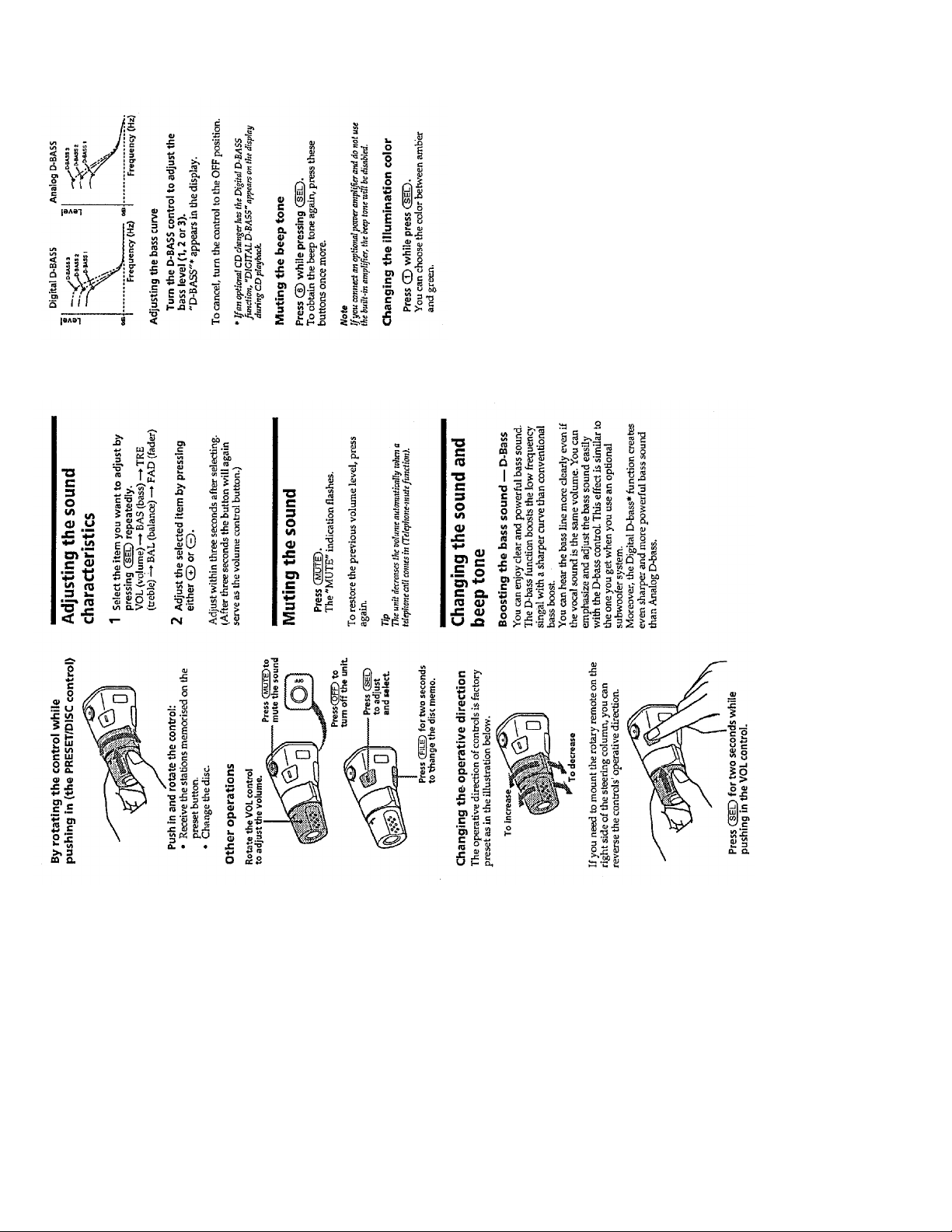

Adjusting the Sound Characteristics ................................. 4

Muting the Sound .............................................................. 4

Changing the Sound and Beep Tone .................................. 4

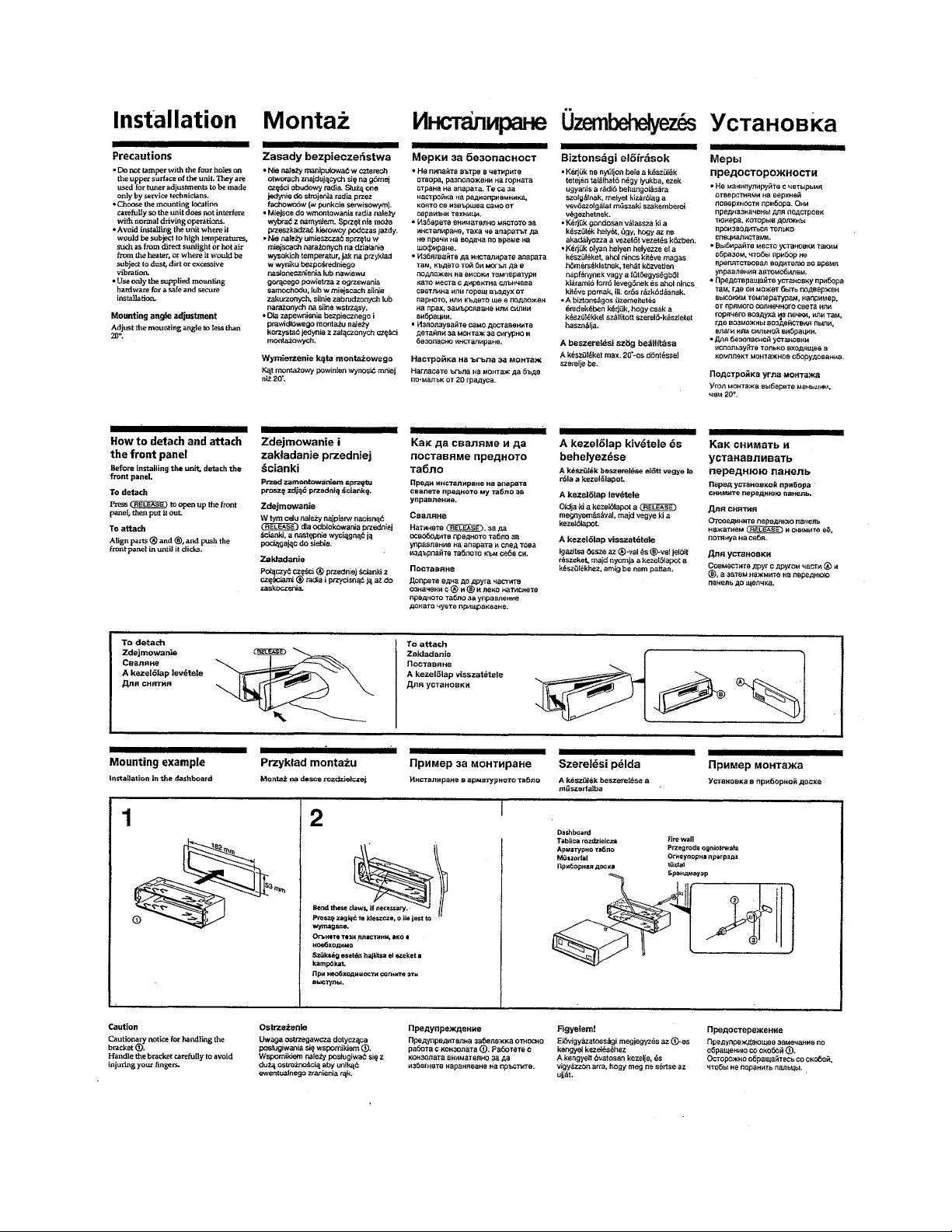

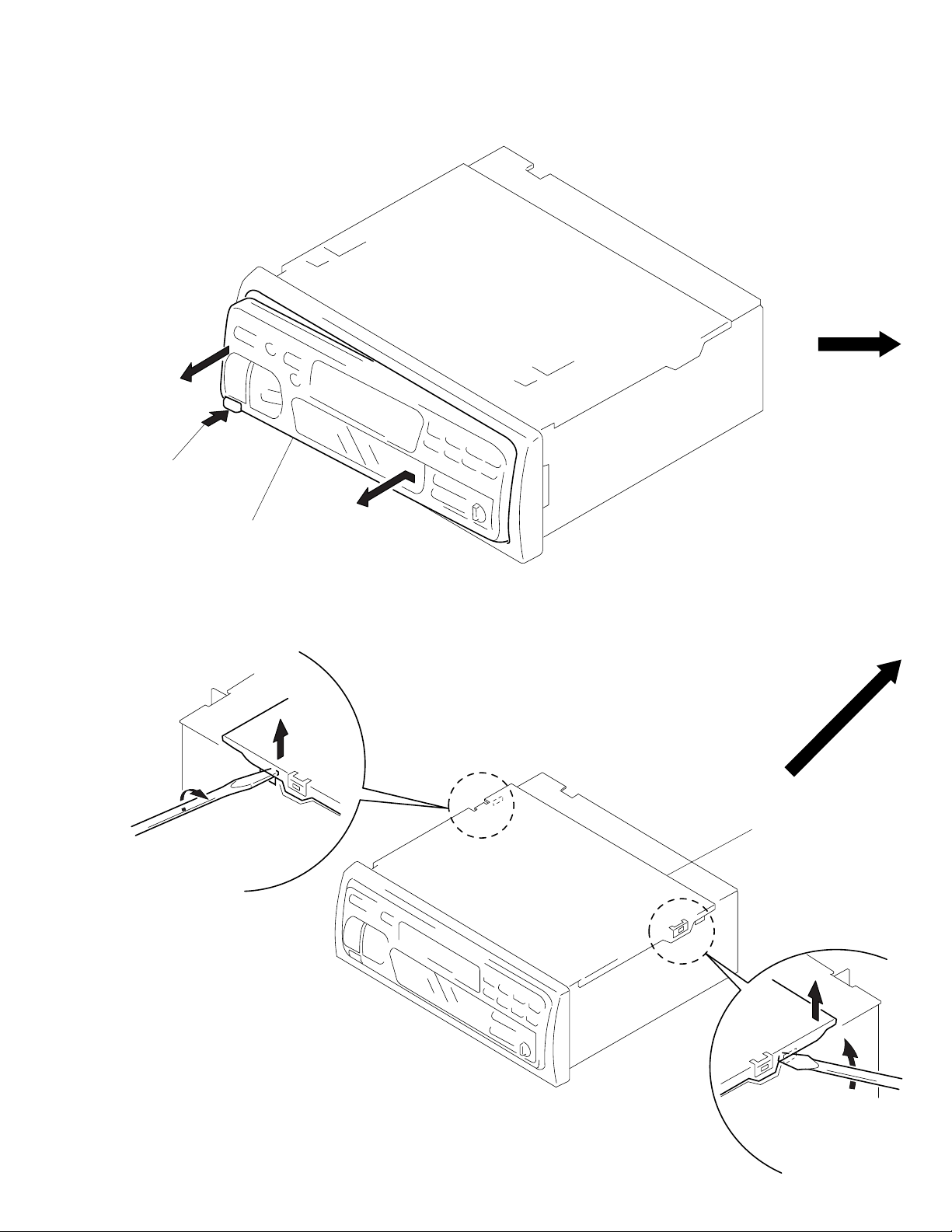

Installation ......................................................................... 5

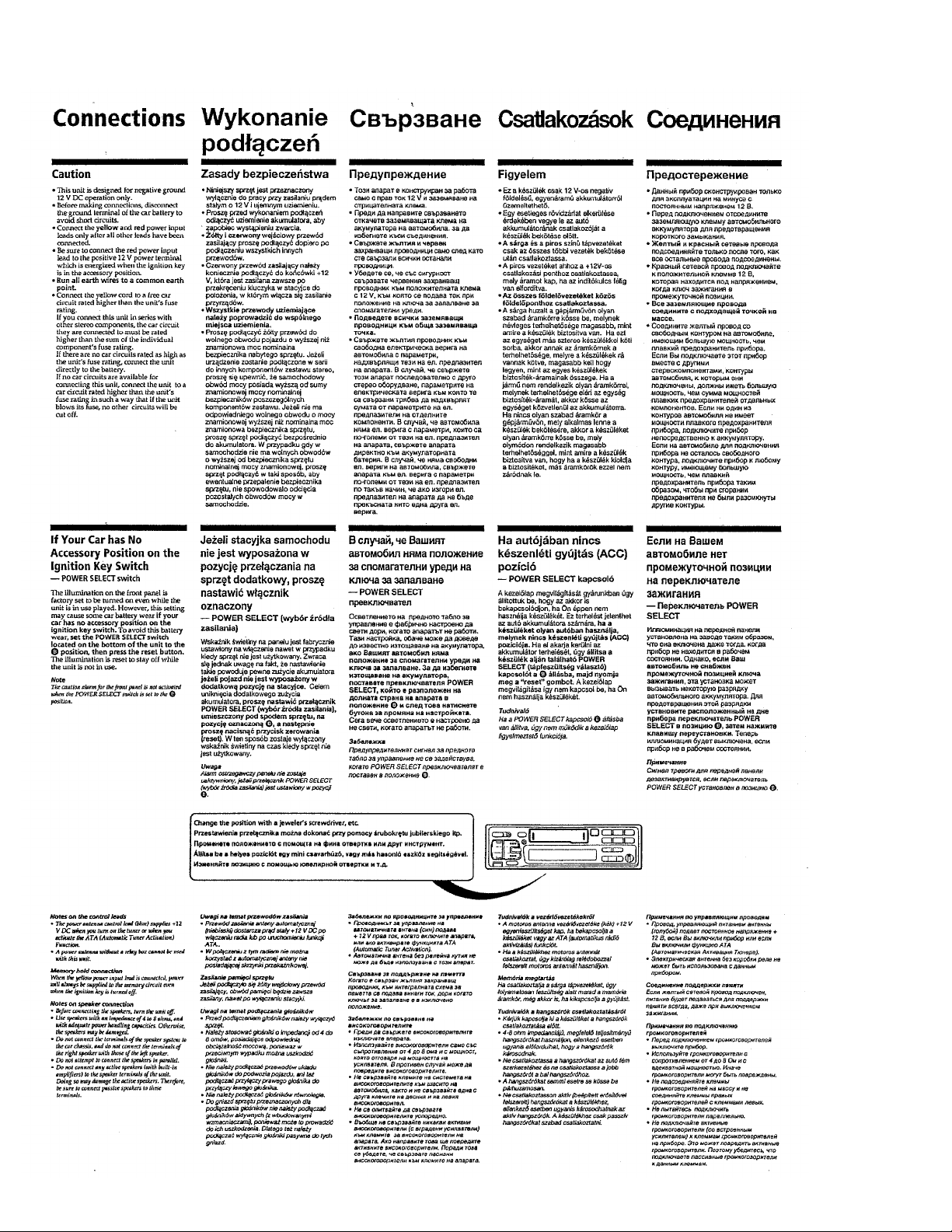

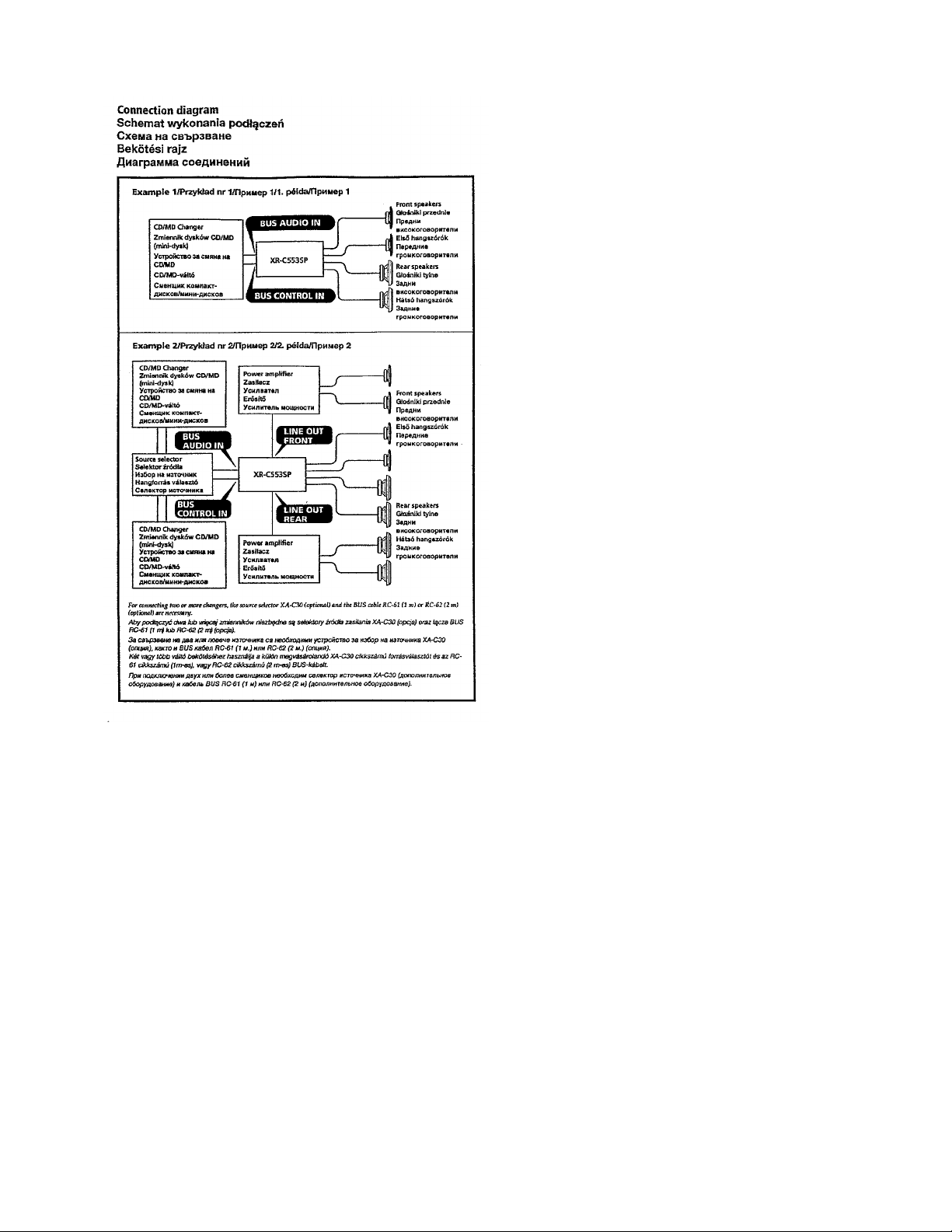

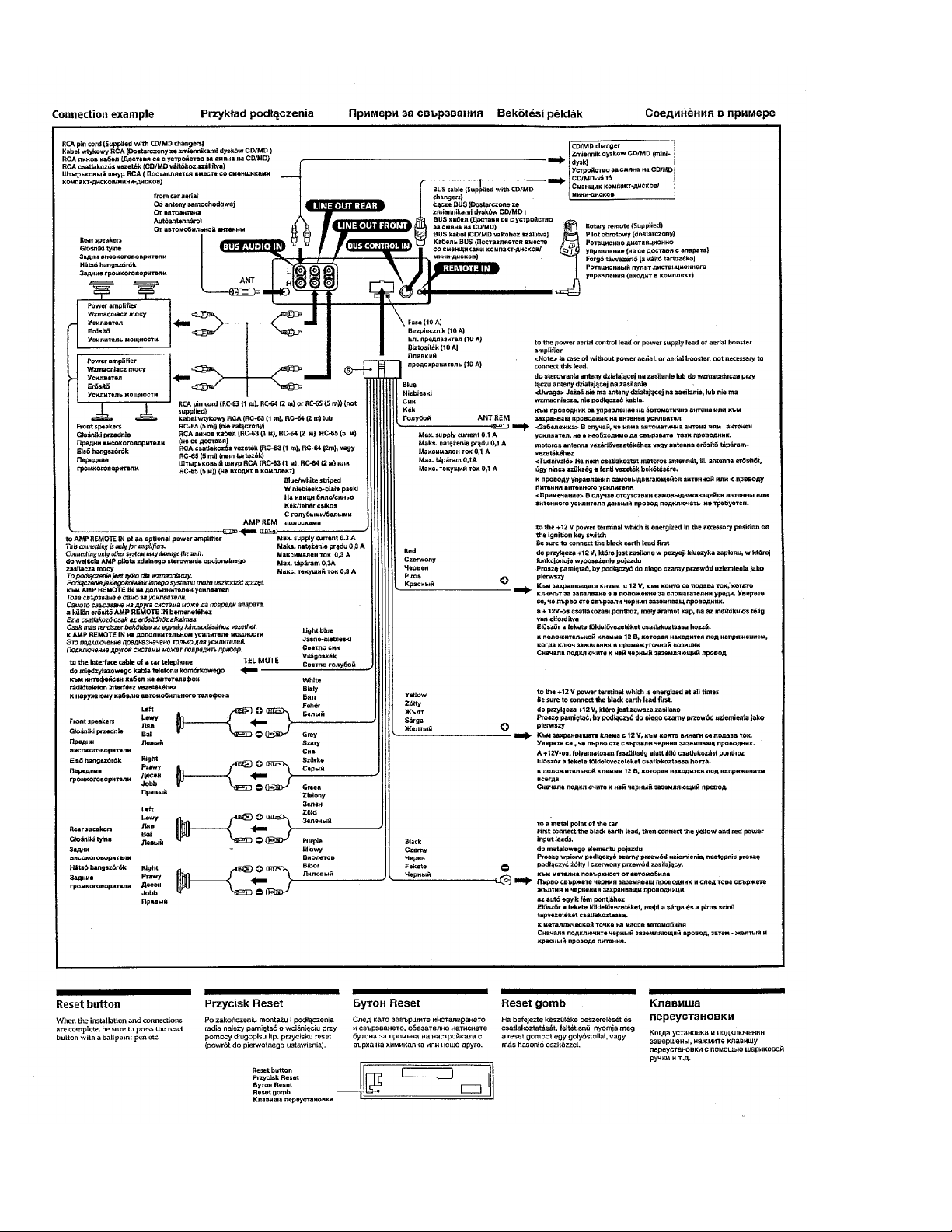

Connections ....................................................................... 6

2. DISASSEMBLY............................................................ 9

3. ASSEMBLY OF MECHANISM DECK............... 11

4. MECHANICAL ADJUSTMENTS ......................... 17

5. ELECTRICAL ADJUSTMENTS

Test Mode .......................................................................... 17

Tape Deck Section ............................................................. 17

Tuner Section..................................................................... 18

6. DIAGRAMS

6-1. IC Pin Function Description.............................................. 22

6-2. Block Diagram (1/2).......................................................... 25

6-3. Block Diagram (2/2).......................................................... 27

6-4. Printed Wiring Boards –Main Section– ............................ 29

6-5. Schematic Diagram –Main Section– ................................ 33

6-6. Printed Wiring Board –Display Section– ......................... 37

6-7. Schematic Diagram –Display Section– ............................ 39

Flexible Circuit Board Repairing

• Keep the temperature of the soldering iron around 270 ˚C during

repairing.

• Do not touch the soldering iron on the same conductor of the

circuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering or

unsoldering .

Notes on chip component replacement

• Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be dam-

aged by heat.

7. EXPLODED VIEWS .................................................. 44

8. ELECTRICAL PARTS LIST .................................. 48

– 2 –

SECTION 1

GENERAL

This section is extracted

from instruction manual.

– 3 –

– 4 –

– 5 –

– 6 –

– 7 –

– 8 –

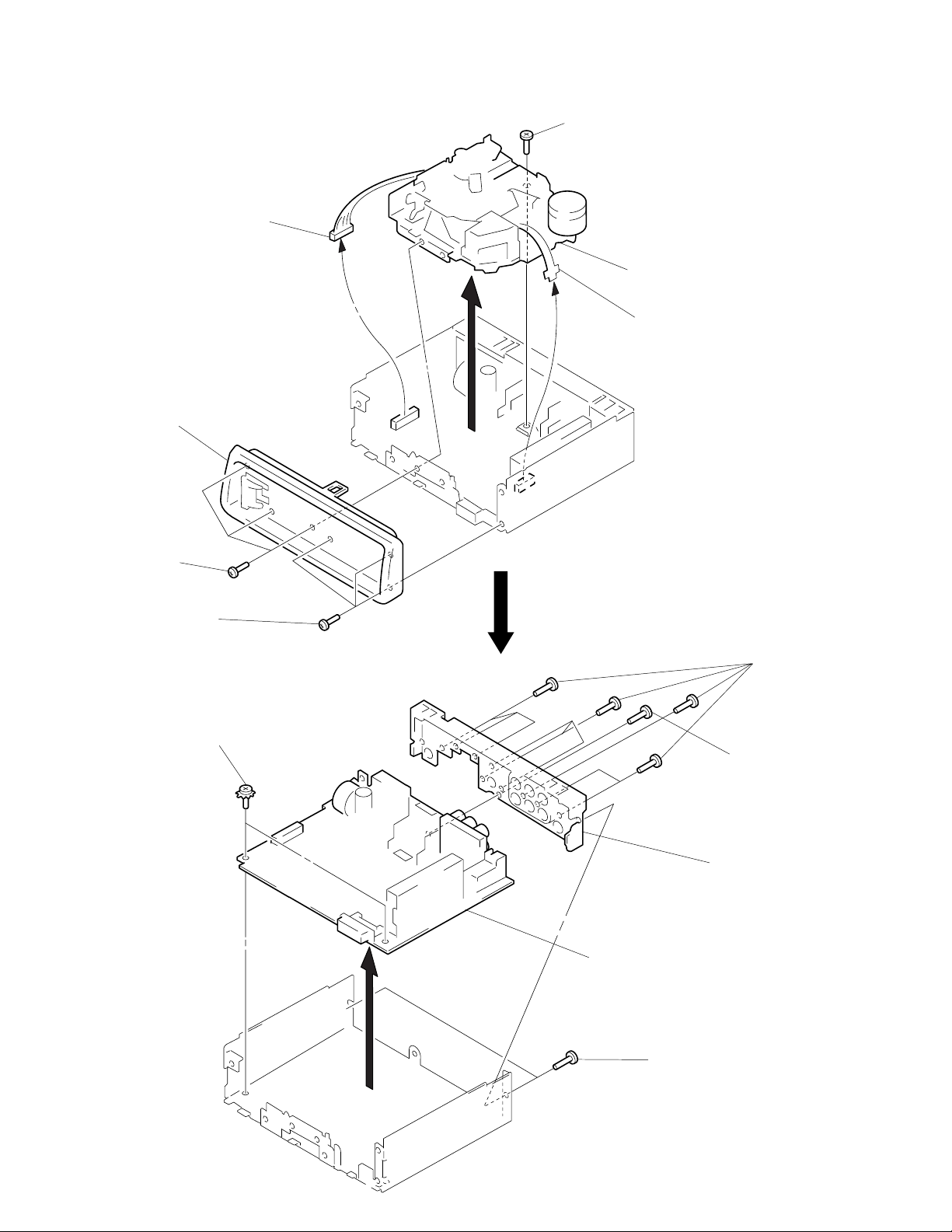

SECTION 2

DISASSEMBLY

Note: Follow the disassembly procedure in the numerical order given.

FRONT PANEL ASS’Y

1

Push the button

(release)

A

2

Remove the front panel ass’y

to the direction of the arrow A.

COVER ASS’Y

1

2

3

cover ass’y

2

1

– 9 –

SUB PANEL, MECHANISM DECK (MG-52A-135)

3

connector

(CN302)

2

sub panel

1

three screws

(PTT2.6 × 8)

5

screw

(PTT2.6 × 6)

6

mechanism deck

(MG-52A-135)

4

flexible flat cable

(CN301)

1

three screws

(PTT2.6 × 8)

MAIN BOARD, HEAT SINK

2

two ground point

screws

3

main board

1

two screws

(PTT2.6 × 8)

1

5

heat sink

4

nine screws

(PTT2.6 × 10)

screw

(PTT2.6 × 8)

– 10 –

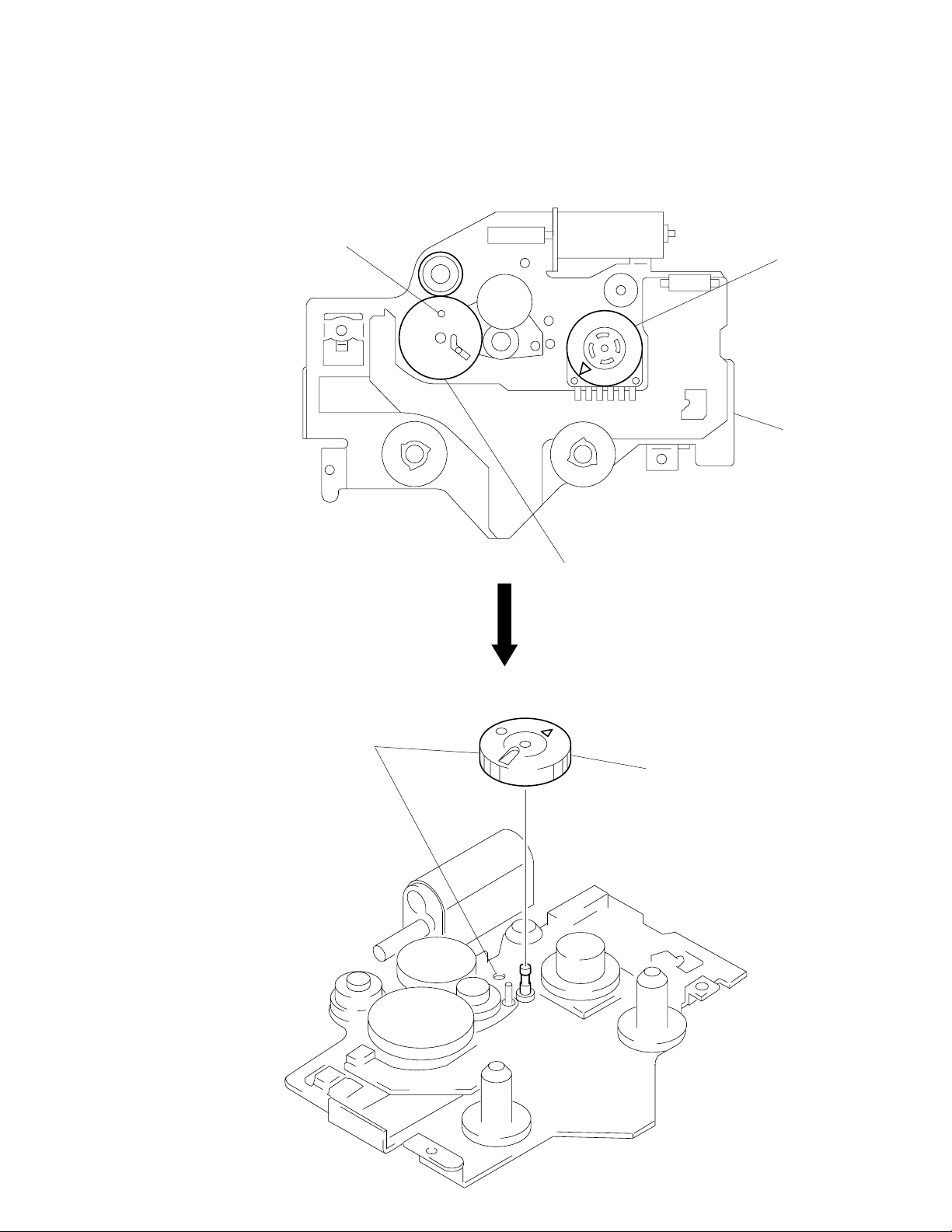

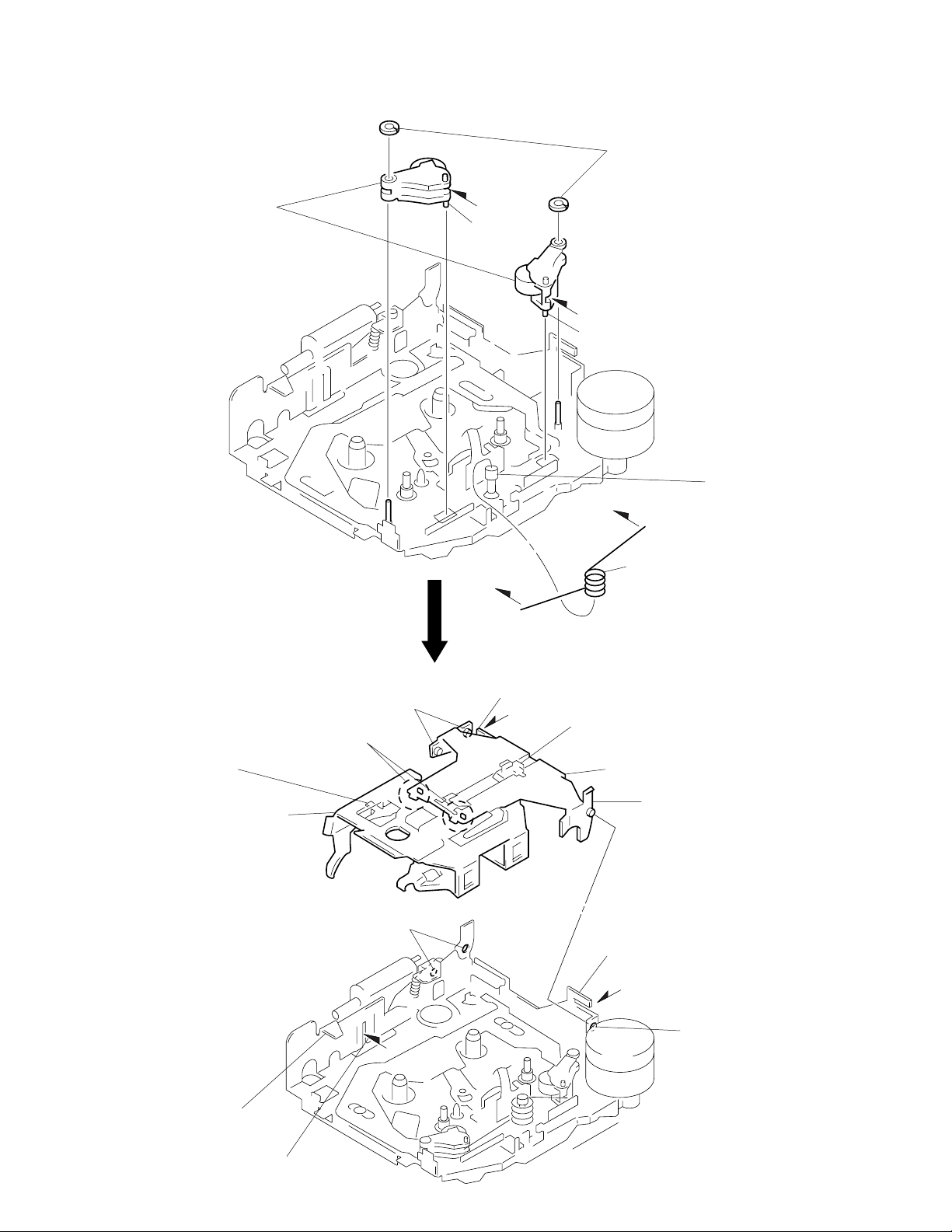

SECTION 3

ASSEMBLY OF MECHANISM DECK

Note: Follow the assembly procedure in the numerical order given.

ALIGNMENT OF FRONT SWITCH

hole

1

Align ¢ mark on the rotary switch

the position shown in the figure.

chassis (S) ass’y

GEAR (LDGE)

1

Align hole as shown in the figure.

2

Align hole in the gear (LDG-D) with the

position shown in the figure.

2

Install the gear (LDG-E).

– 11 –

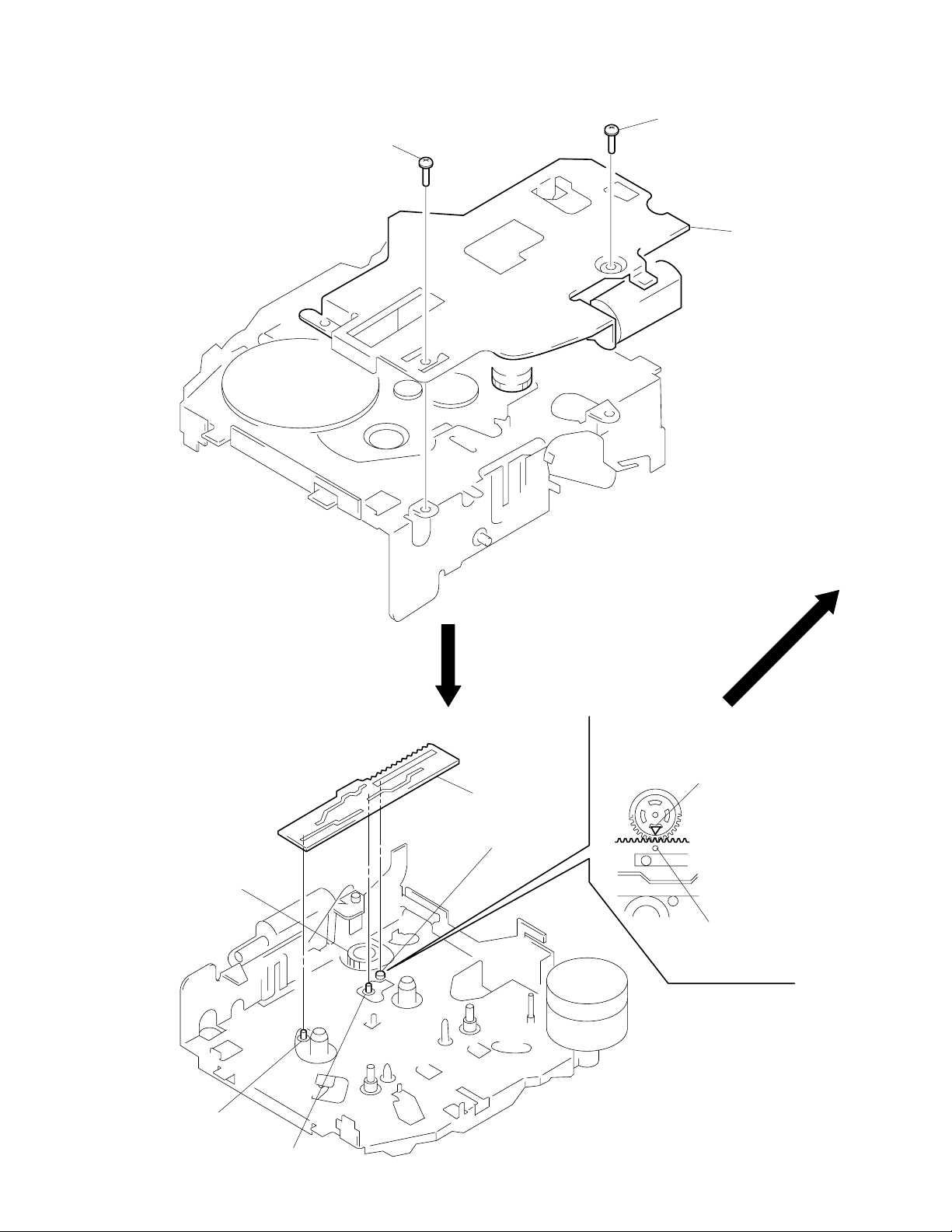

CHASSIS (S) ASS’Y

2

screw (PS2 × 4)

2

screw (PS2 × 4)

1

chassis (S) ass’y

LEVER (MODE)

1. Align ¢ mark on the rotary switch with

hole in the lever (mode).

2. Fit on positions A, B and C and install

the lever (mode).

rotary switch

A

lever (mode)

C

¢

mark on rotary switch

hole in lever (mode)

B

– 12 –

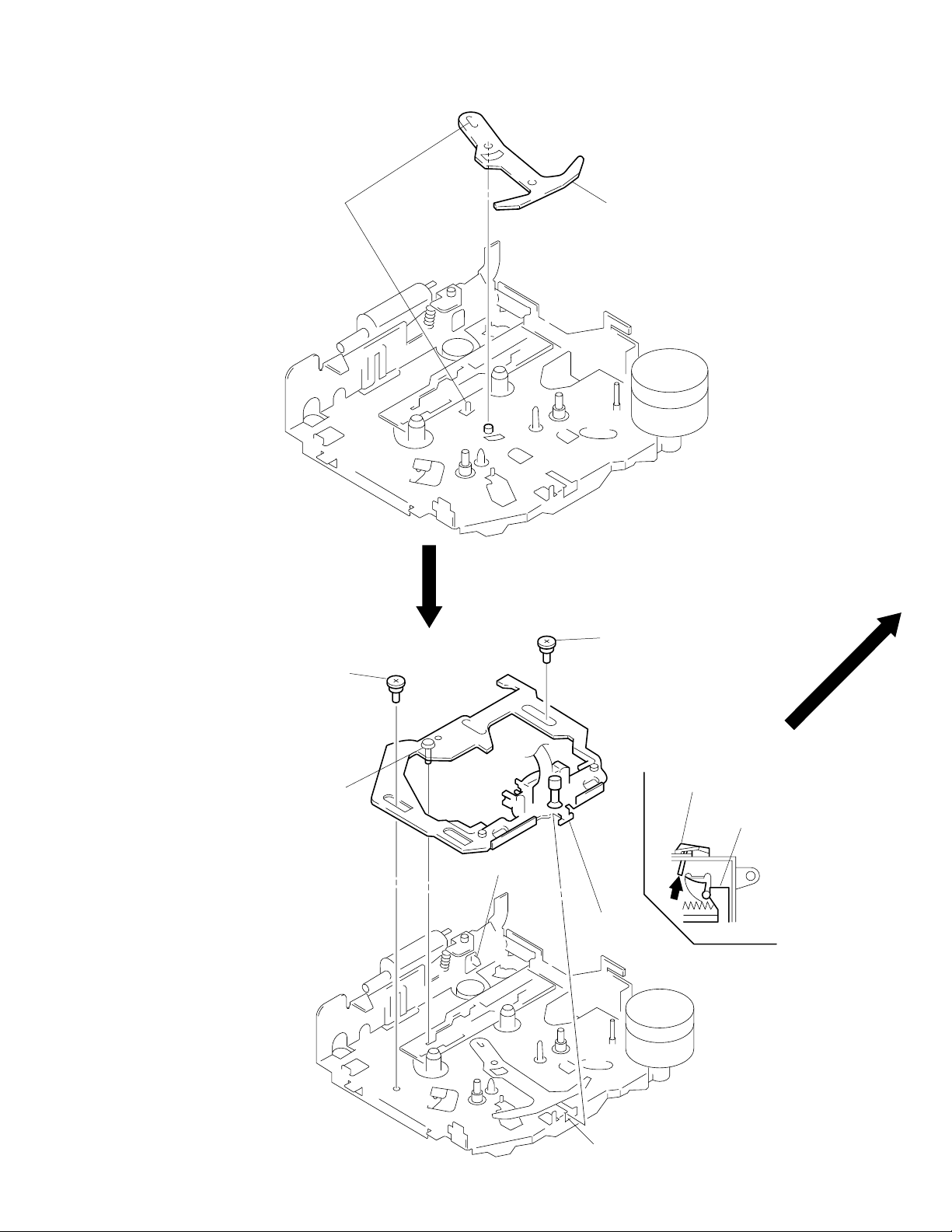

LEVER (PINCH SELECTION)

1

Align.

2

lever (pich selection)

HEAD PLATE ASS’Y

5

2

Fit shaft in groove.

step screw (HP)

ATS lever

5

1

Fit in groove.

step screw (HP)

3

Press the ATS lever.

4

Position the head plate sub

ass’y as shown in the figure.

– 13 –

groove

LEVER (PINCH) ASS’Y

2

two polyethylene washers

1

Fit shaft of the lever (Pinch) ass’y

in hole on the chassis (M) ass’y and

install the lever (pinch) ass’y.

B

shaft

B

C

shaft

shaft

A

C

3

Install the spring (pinch press) to shaft A.

Set the ends of spring to B and C.

HOUSING

4

Fit claws on B part.

3

2

Install the hanger on to

two claws of the housing.

Put the housing

under A part.

5

Fit projections on C part.

C

part

7

Holder the hanger by bending the claw.

1

Install the catch to the hanger.

hanger

6

Fit projections on D part.

8

Holder the hanger by

bending the claw.

D

part

A

part

B

part

– 14 –

Loading...

Loading...