Sony SLV-SE100A1, SLV-SE100A2, SLV-SE100K, SLV-SE200G, SLV-SE200I Service Manual

...

SLV-SE100/SE200/SE250/SE300/

SE400/SE450/SX100/SX250

RMT-V257/V257A/V257B/V257C/V287

SERVICE MANUAL

AEP Model

SLV-SE100A1/A2/K,SE200V1/V2,

SE250B/D/P,SE300D1/D2,

SE400K,SE450B/D/K/P,

SX100K,SX250D

UK Model

SLV-SE200G/I,SE300G

East European Model

Russian Model

SLV-SE100K,SE400K,

SE450K,SX100K

(Except UK Model)

(UK Model only)

Photo : SL V -SE450D

RMT-V257B

Refer to the SERVICE MANUAL of VHS

MECHANICAL ADJUSTMENT

for

MECHANICAL ADJUSTMENTS. (9-921-647-11)

The abbreviations of SE100/SE200/SE250/SE300/SE400/SE450/SX100/SX250 contained in this service manual

are indicated when these models are common to all their corresponding models as given below.

Abbreviated models name

All models name

SLV-

SE100

SE100A1

SE100A2

SE100K

SE200

SE200G

SE200I

SE200V1

SE200V2

SE250

SE250B

SE250D

SE250P

SE300

SE300D1

SE300D2

SE300G

SE400

SE400K

SE450

SE450B

SE450D

SE450K

SE450P

SX100

SX100K

SX250

SX250D

SPECIFICATIONS

System

C

hannel coverage

SLV-SE100K,SE400K,SE450K,SX100K:

PAL (B/G, D/K)

VHF E2–E12, R1–R12

UHF E21–E69, R21–R69

CATV S1–S41, S01–S05

SLV-SE200G/I, SE300G:

PAL ( I)

VHF IA to IJ, SA10 to SA13 (SLV-SE200I only)

UHF B21 to B69

CATV S01 to S05, S1 to S20 (SLV-SE200I only)

HYPER S21 to S41 (SLV-SE200I only)

SLV-SE100A1/A2, SE200V1/V2, SE250D/P,

SE300D1/D2, SE450D/P, SX250D:

PAL ( B/G)

VHF E2 to E12

Canaux VHF italiens A to H

UHF E21 to E69

CATV S01 to S05, S1 to S20

HYPER S21 to S41

SLV-SE250B,SE450B:

SECAM (L):

VHF F2 to F10

UHF F21 to F69

CATV B to Q

HYPER S21 to S41

PAL (B/G):

VHF E2 to E12

Canaux VHF italiens A to H

UHF E21 to E69

CATV S01 to S05, S1 to S20

HYPER S21 to S41

RF output signal

UHF channels 21–69

Aerial out

75-ohm asymmetrical aerial socket

Tape speed

SP: PAL/MESECAM 23.39 mm/s

NTSC 33.35 mm/s

(SLV-SE250B,SE450B only)

SECAM 23,39 mm/s (recording/playback)

M

ESECAM 23,39 mm/s (playback only)

LP*: PAL/MESECAM 11.70 mm/s

(playback only, except: SLV-SE200G/I, SE300G)

(recording/playback: SLV-SE200G/I, SE300G)

NTSC 16.67 mm/s (playback only)

(SLV-SE450B only)

SECAM 11,70 mm/s (recording/playback)

M

ESECAM 11,70 mm/s (playback only)

EP*: NTSC 11.12 mm/s (playback only)

(SLV-SE200G/I, SE250D/P, SE300D1/D2/G,

Maximum recording/playback time

Fast-forward and rewind time

SE450B/D/P, SX250D)

10 hrs. in LP mode (with E300 tape)

Approx. 3 min. (with E180 tape)

S MECHANISM

— Continued on next page —

VIDEO CASSETTE RECORDER

Inputs and outputs

LINE-1 (TV)

i

21-pin

Video input: pin 20

Audio input: pins 2 and 6

Video output: pin 19

Audio output: pins 1 and 3

SLV-SE250B/D/P, SE450B/D/P, SX250D:

DECODER/

SLV-SE300D1/D2:

DECODER/

SLV-SE300D1/D2/G:

LINE-2 IN

SLV-SE300G:

LINE-3 IN

tLINE-2 IN

21-pin

Video input: pin 20

Audio input: pins 2 and 6

tLINE-3 IN

21-pin

Video input: pin 20

Audio input: pins 2 and 6

VIDEO IN, phono jack (1)

Input signal: 1 Vp-p, 75 ohms, unbalanced, sync

negative

AUDIO IN, phono jack (1)

Input level: 327 mVrms

Input impedance: more than 47 kilohms

21-pin

Video input: pin 20

Audio input: pins 2 and 6

General

Power requirements

220 – 240 V AC, 50 Hz

Power consumption

18 W

Operating temperature

5°C to 40°C

Storage temperature

–20°C to 60°C

Dimensions

prox. 355 × 96 × 285 mm (w/h/d)

Ap

(Approx. 14 × 3 /

including projecting parts and controls

Mass

Approx. 3.6 kg (Approx. 7 lb 15 oz.)

71

8

× 11 /4 inches)

Supplied accessories

Remote commander (1)

R6 (size AA) batteries (2)

Aerial cable (1)

Design and specifications are subject to change without

notice.

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY MARK 0 OR DOTTED LINE WITH

MARK 0 ON THE SCHEMATIC DIAGRAMS AND IN THE PARTS

LIST ARE CRITICAL TO SAFE OPERATION. REPLACE THESE

COMPONENTS WITH SONY PARTS WHOSE PART NUMBERS

APPEAR AS SHOWN IN THIS MANUAL OR IN SUPPLEMENTS

PUBLISHED BY SONY.

SAFETY CHECK-OUT

After correcting the original service problem, perform the following

safety checks before releasing the set to the customer.

1. Check the area of your repair for unsoldered or poorly-soldered

connections. Check the entire board surface for solder splashes

and bridges.

2. Check the interboard wiring to ensure that no wires are

"pinched" or contact high-wattage resistors.

3. Look for unauthorized replacement parts, particularly

transistors, that were installed during a previous repair . Point

them out to the customer and recommend their replacement.

4. Look for parts which, through functioning, show obvious signs

of deterioration. Point them out to the customer and

recommend their replacement.

5. Check the B+ voltage to see it is at the values specified.

6. Flexible Circuit Board Repairing

• Keep the temperature of the soldering iron around 270˚C

during repairing.

• Do not touch the soldering iron on the same conductor of the

circuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering

or unsoldering.

— 2 —

TABLE OF CONTENTS

SERVICE NOTE

1. ERROR CODE INDICATION···········································4

1 GENERAL

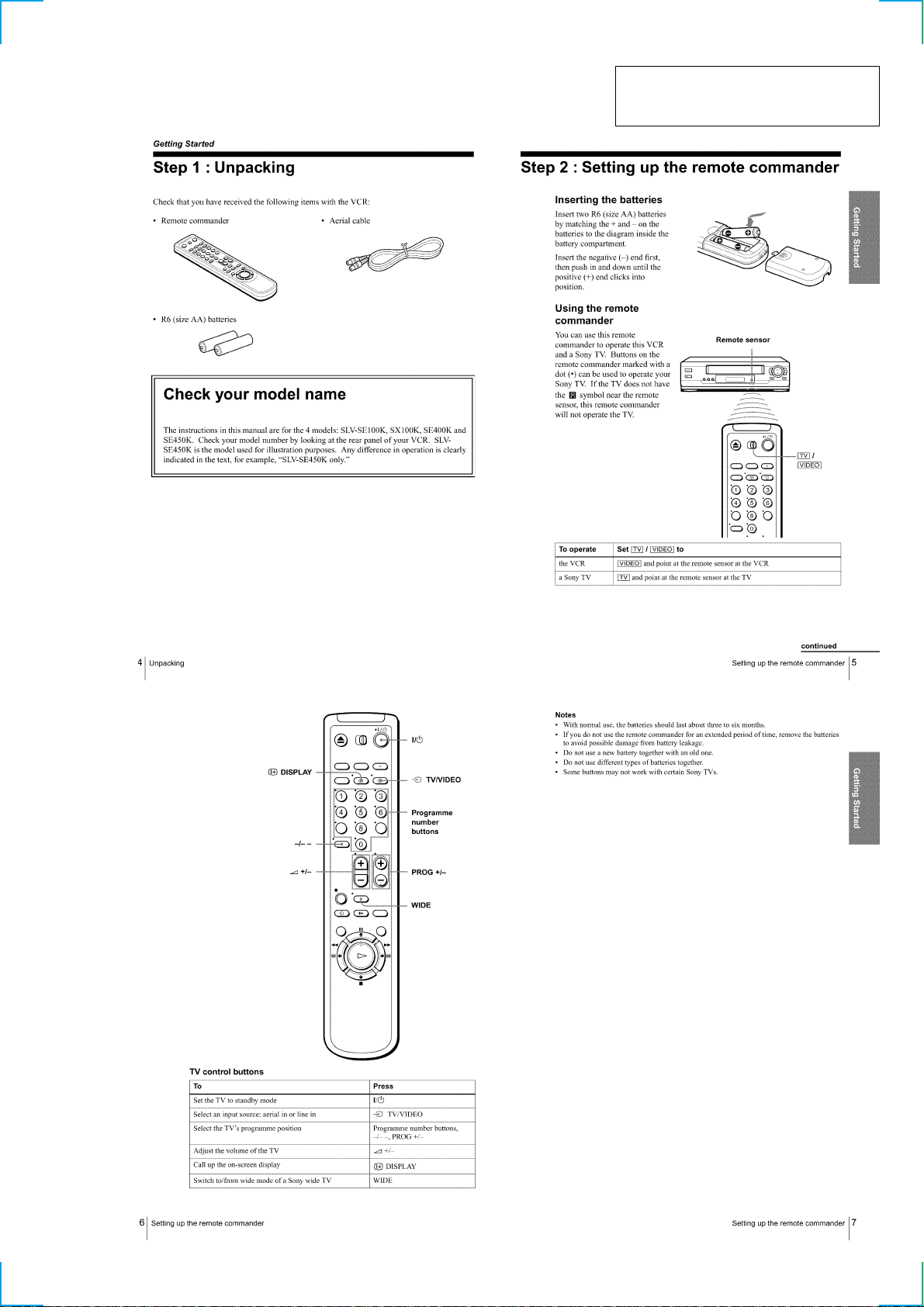

Getting Started···········································································1-1

Step 1 : Unpacking ································································1-1

Step 2 : Setting up the remote commander ····························1-1

Step 3 : Connecting the VCR·················································1-2

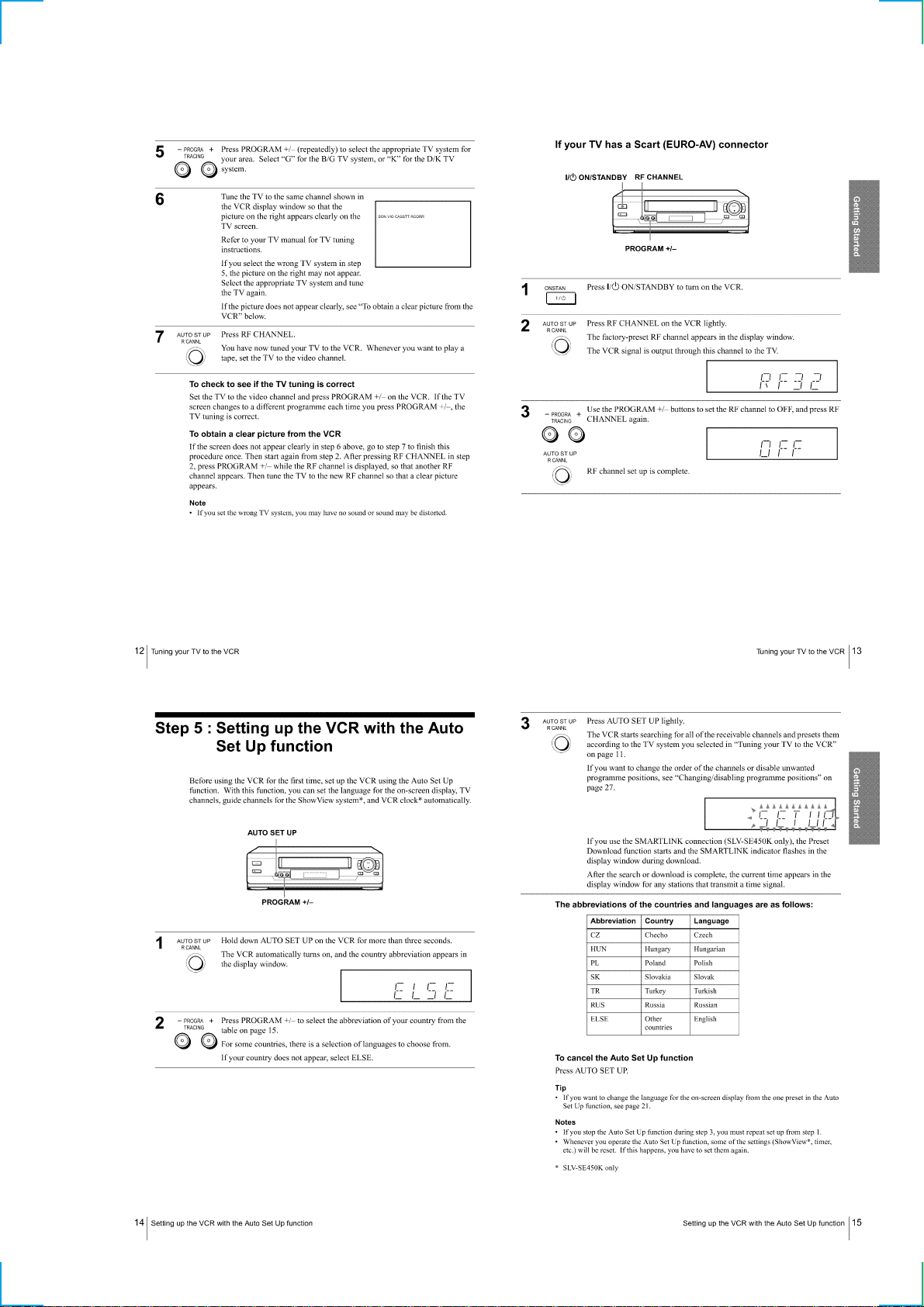

Step 4 : Tuning your TV to the VCR ·····································1-2

Step 5 : Setting up the VCR with the Auto Set Up function··1-3

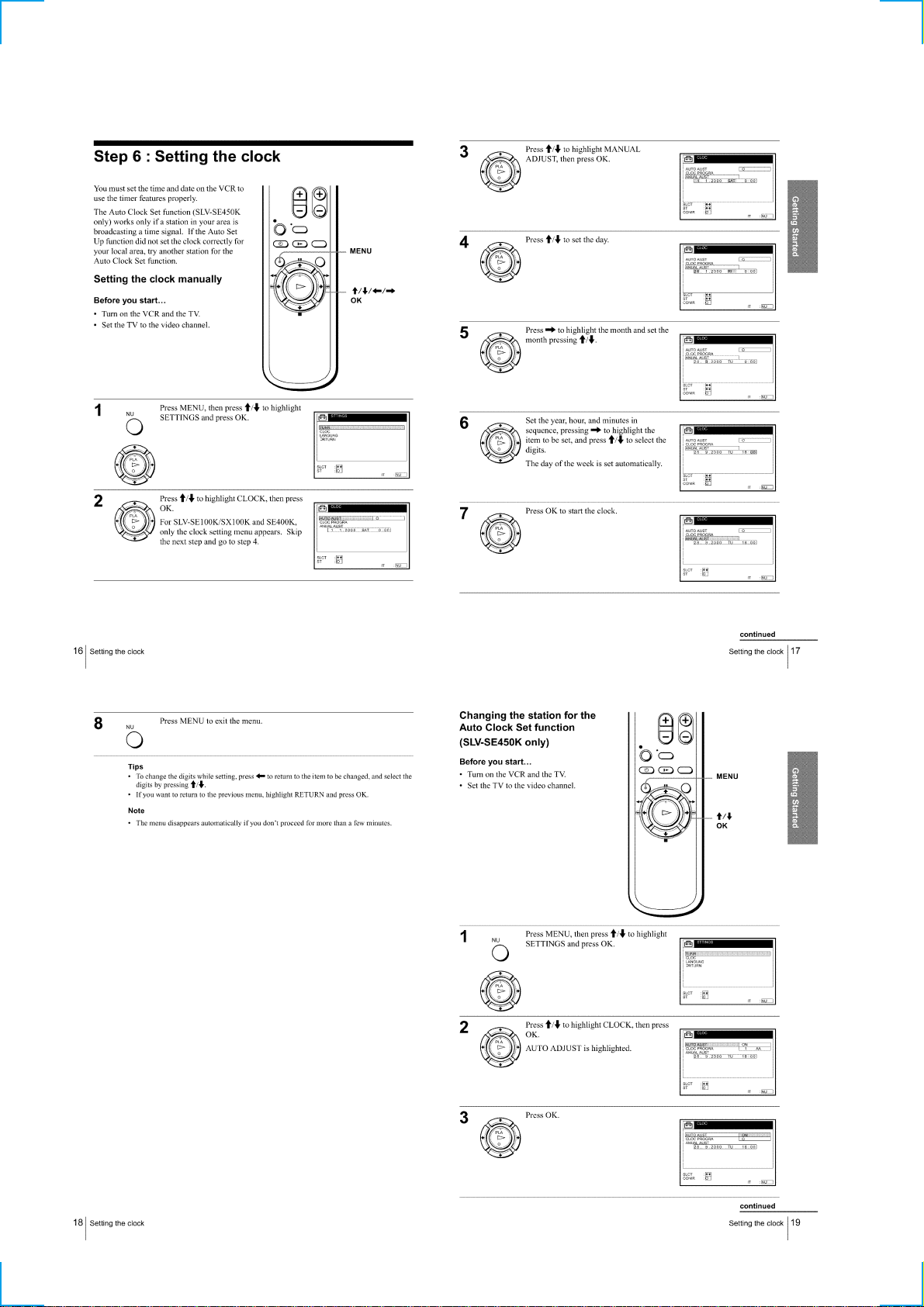

Step 6 : Setting the clock ·······················································1-4

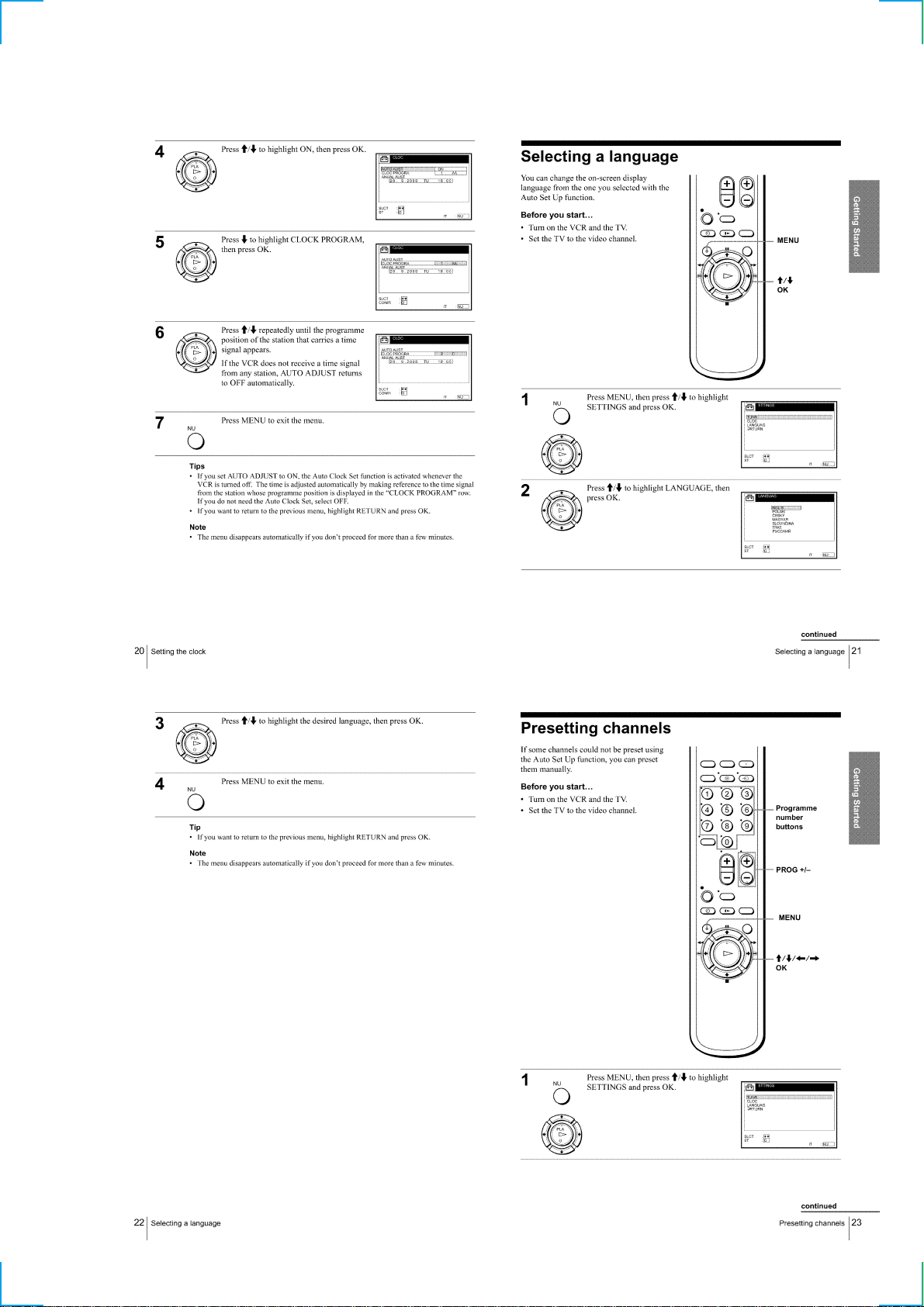

Selecting a language ······························································ 1-5

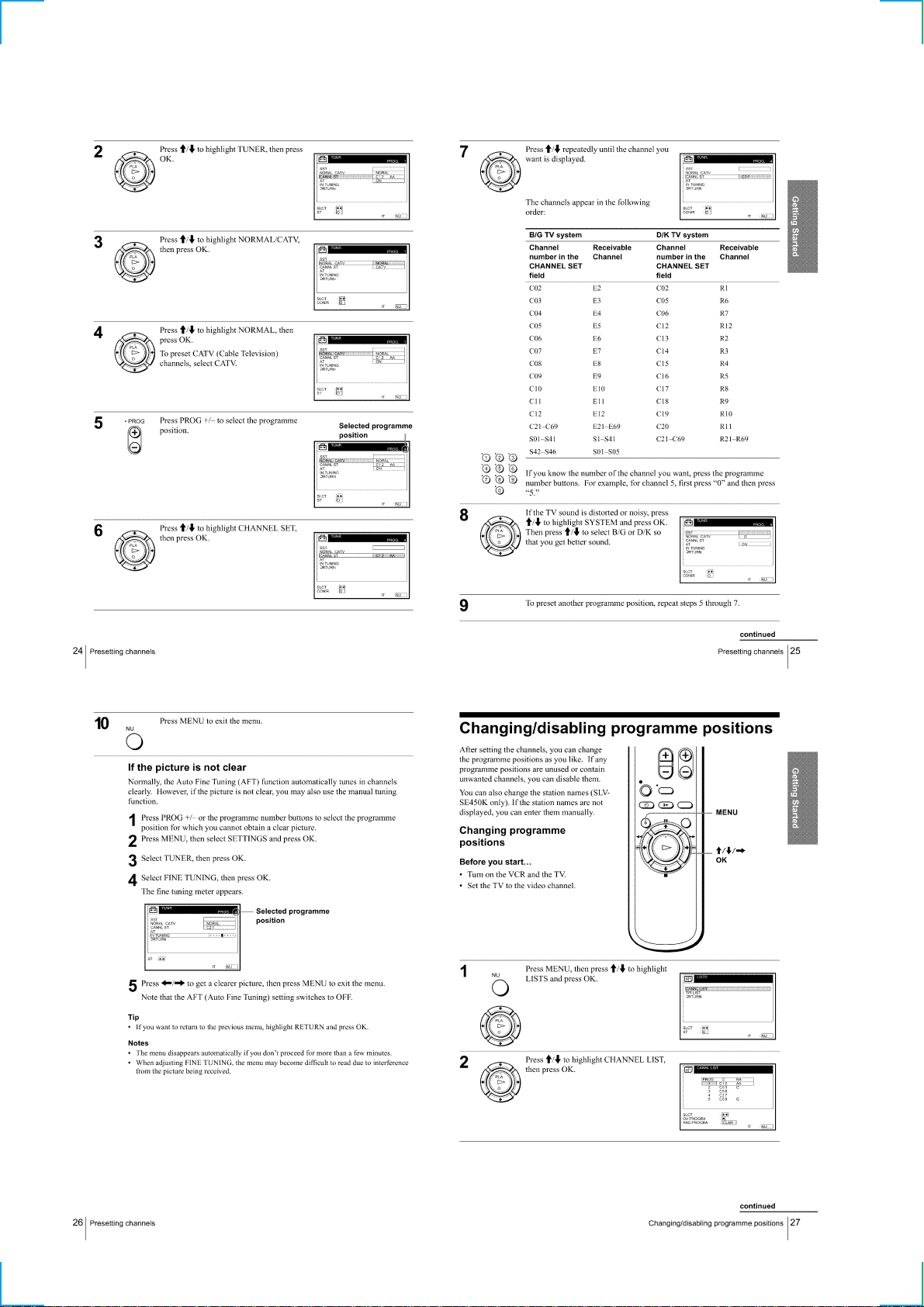

Presetting channels ································································1-5

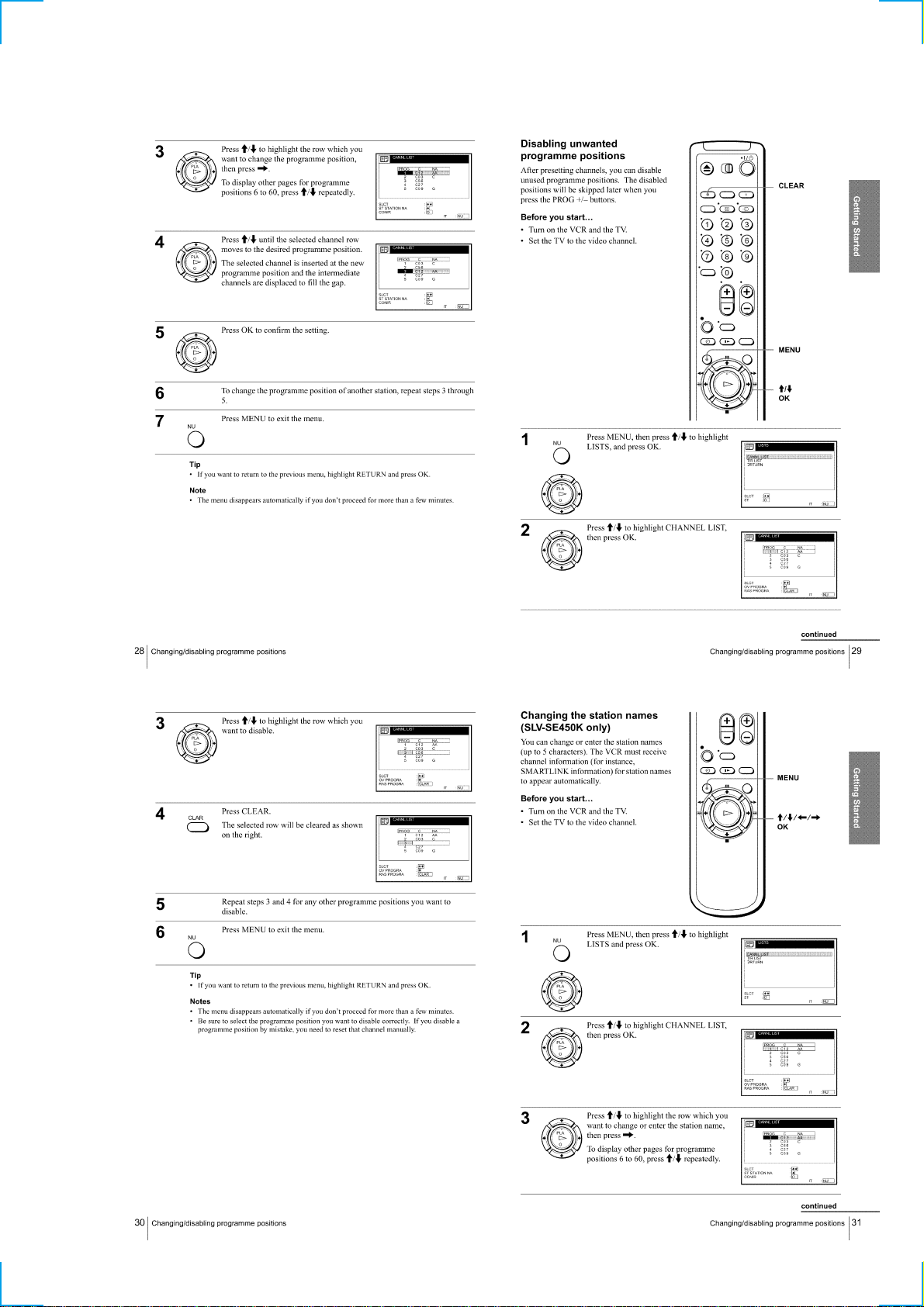

Changing/disabling programme positions ·····························1-6

Basic Operations········································································1-8

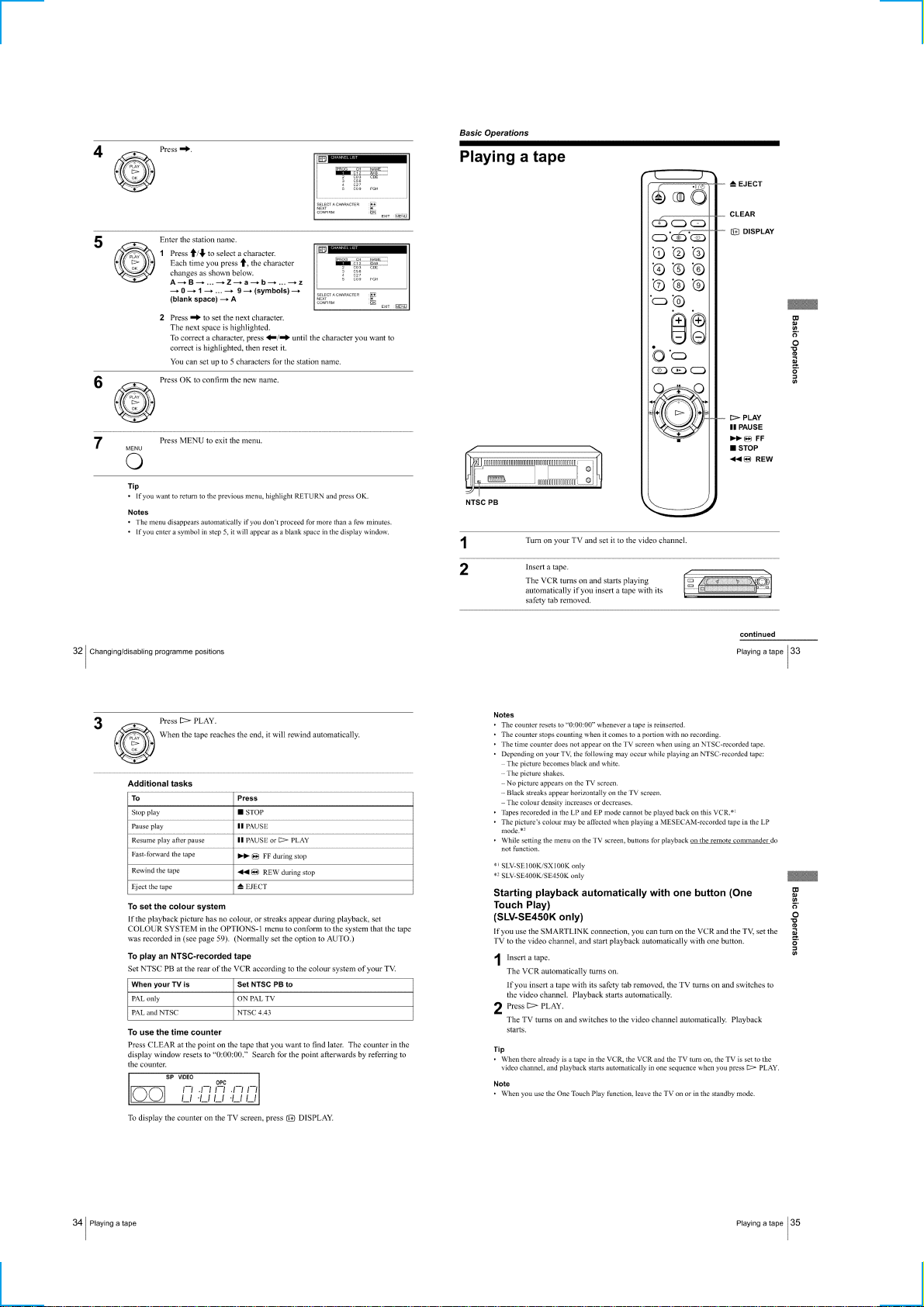

Playing a tape·········································································1-8

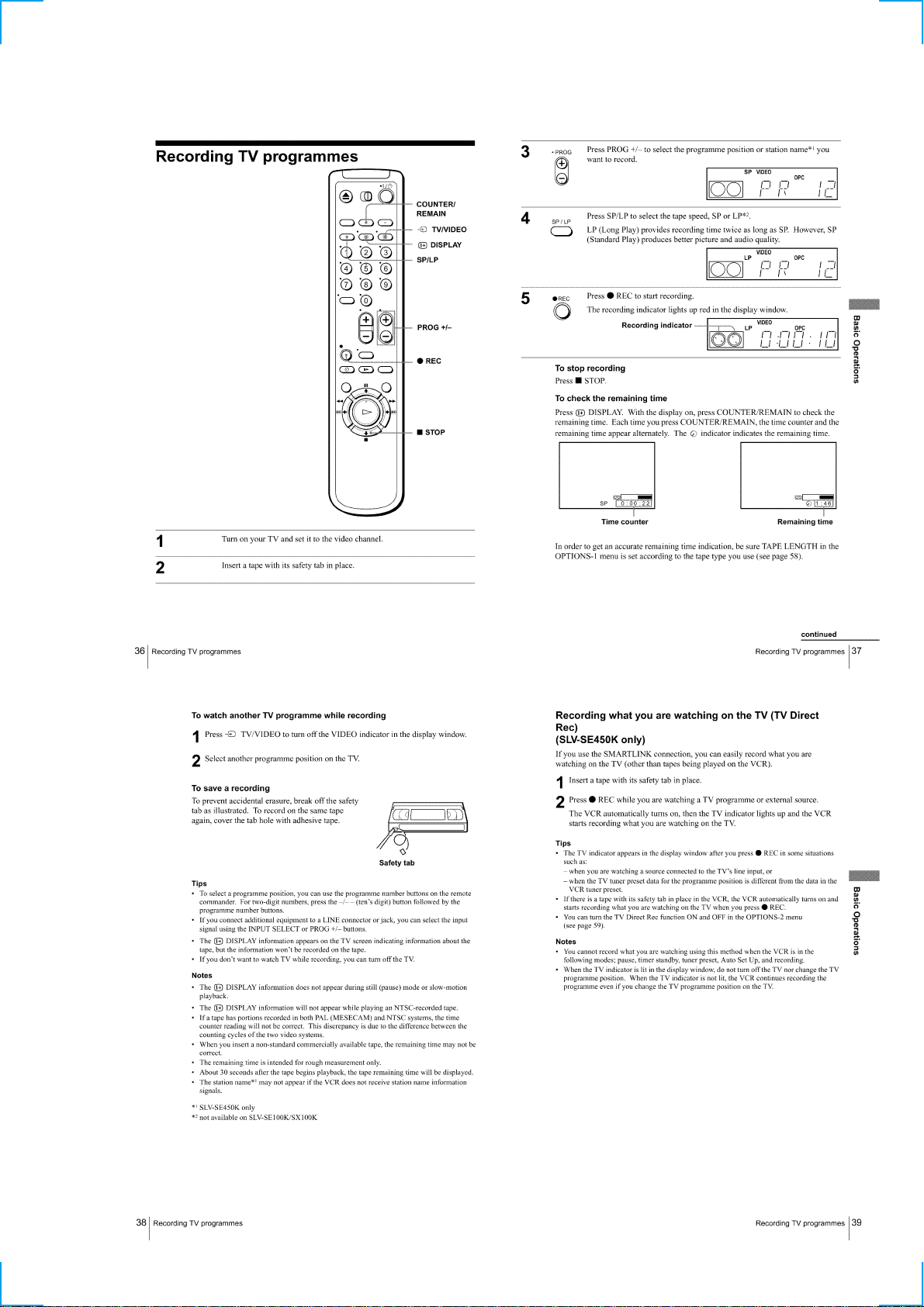

Recording TV programmes ···················································1-9

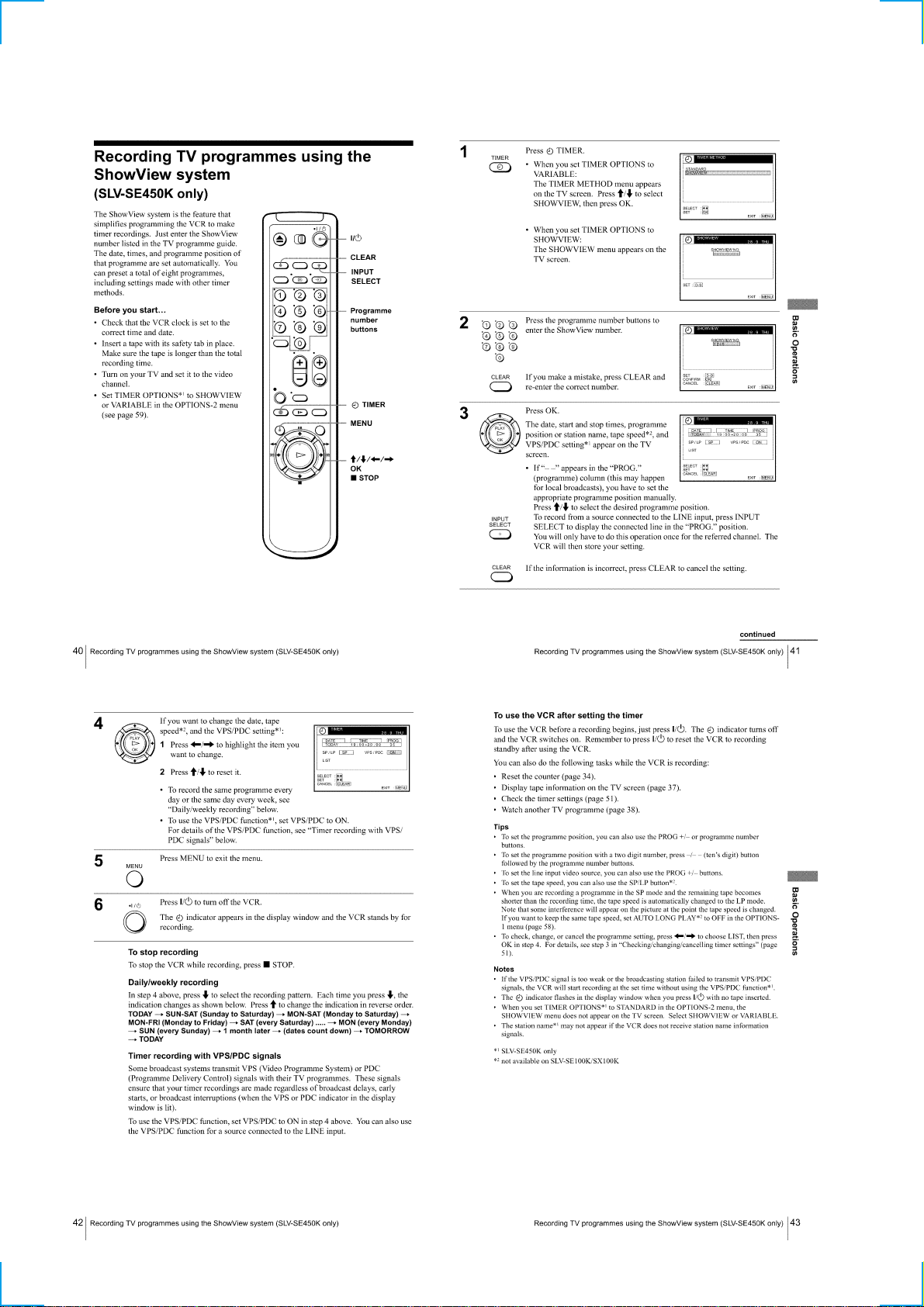

Recording TV programmes using the ShowView system ···1-10

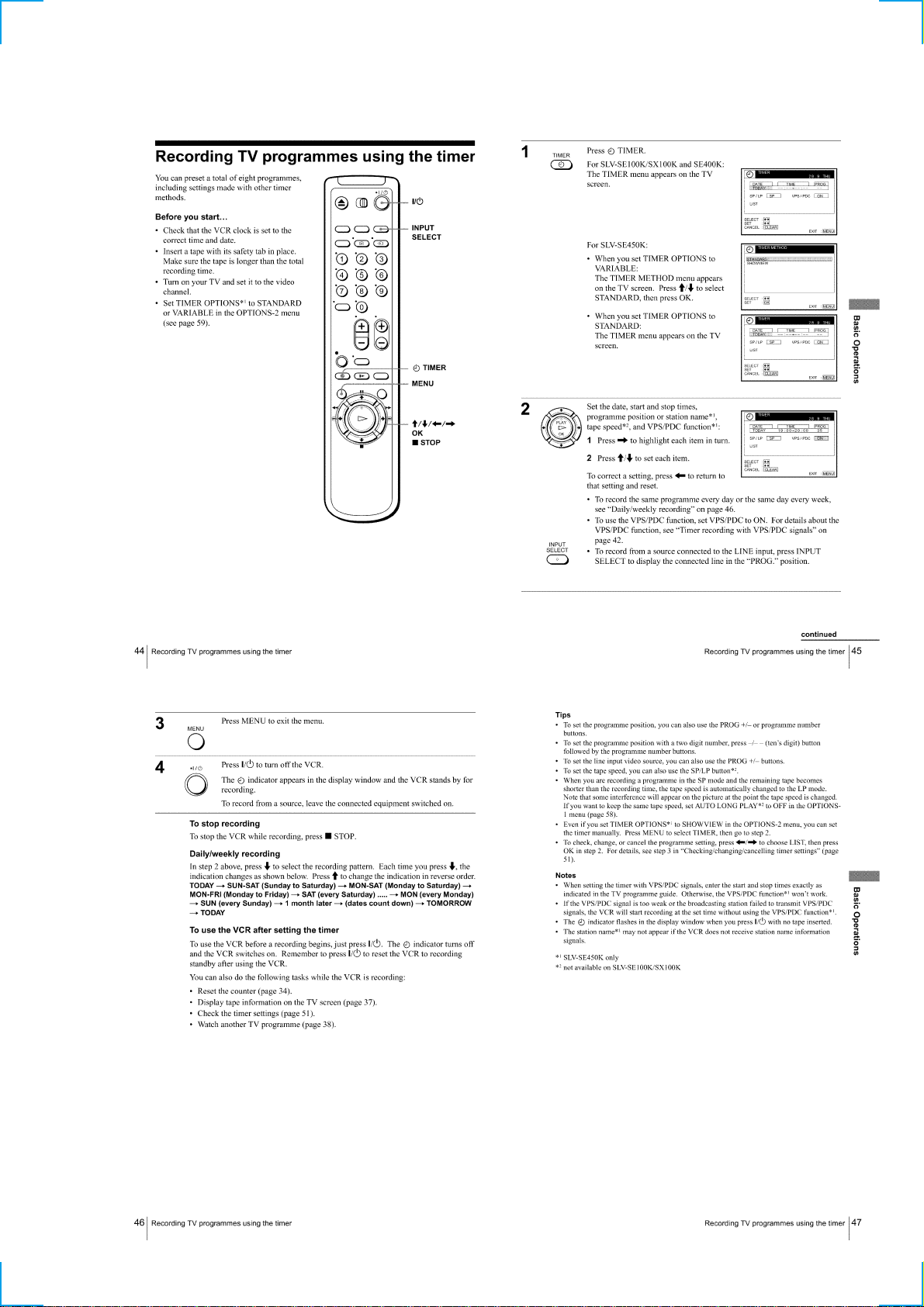

Recording TV programmes using the timer ························1-11

Additional Operations ·····························································1-12

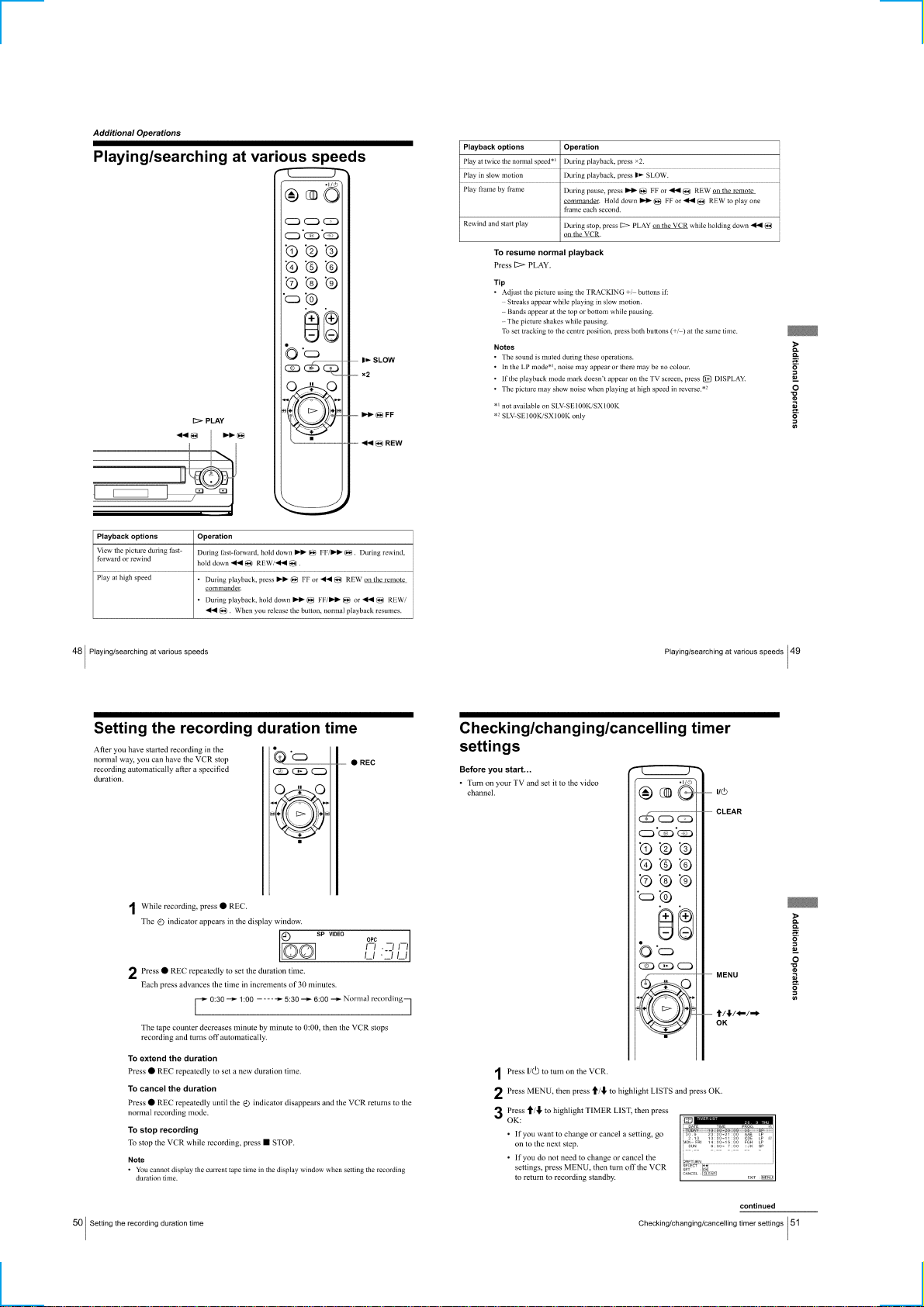

Playing/searching at various speeds ····································1-12

Setting the recording duration time ·····································1-12

Checking/changing/cancelling timer settings ······················1-12

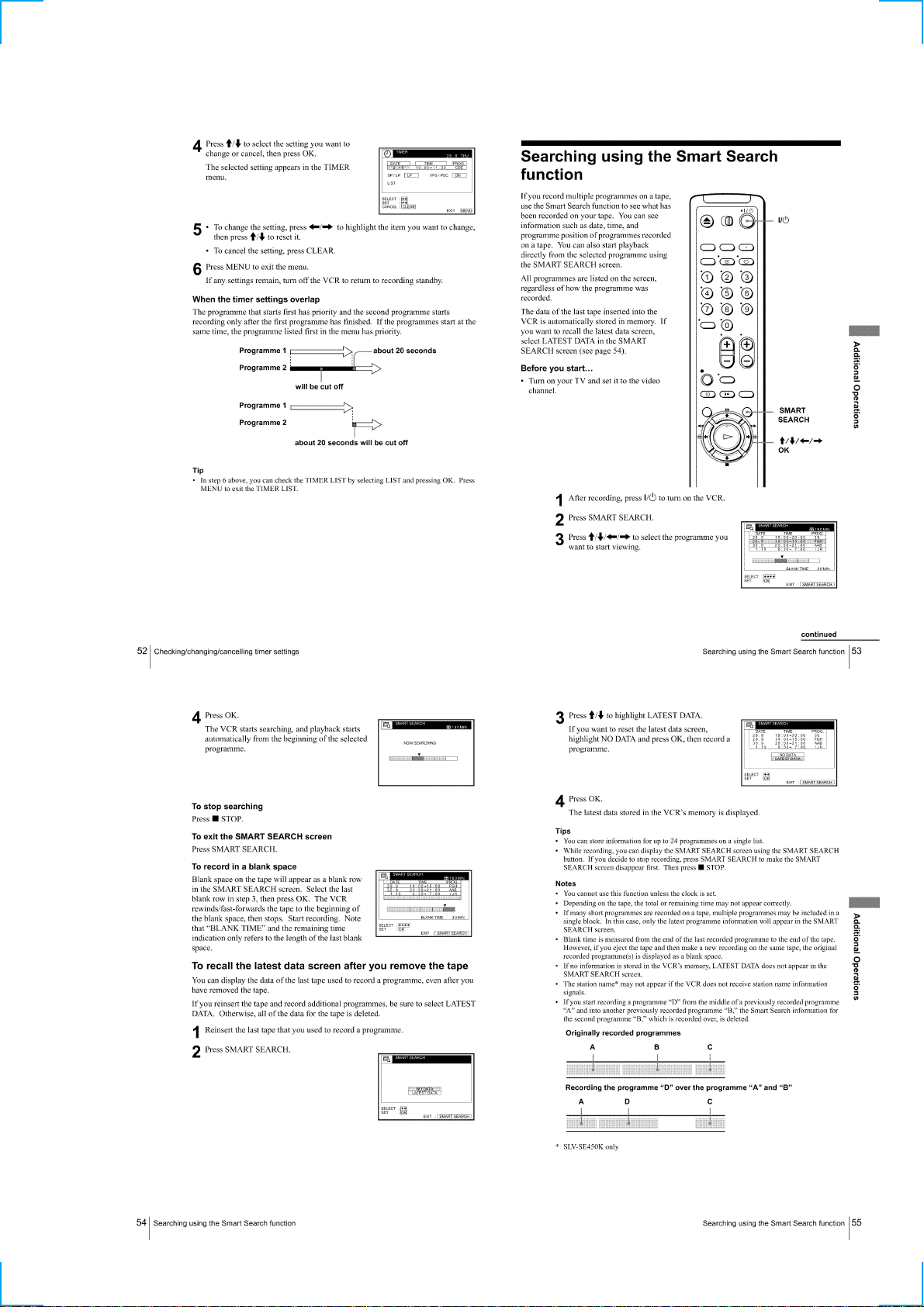

Searching using the Smart Search function ·························1-13

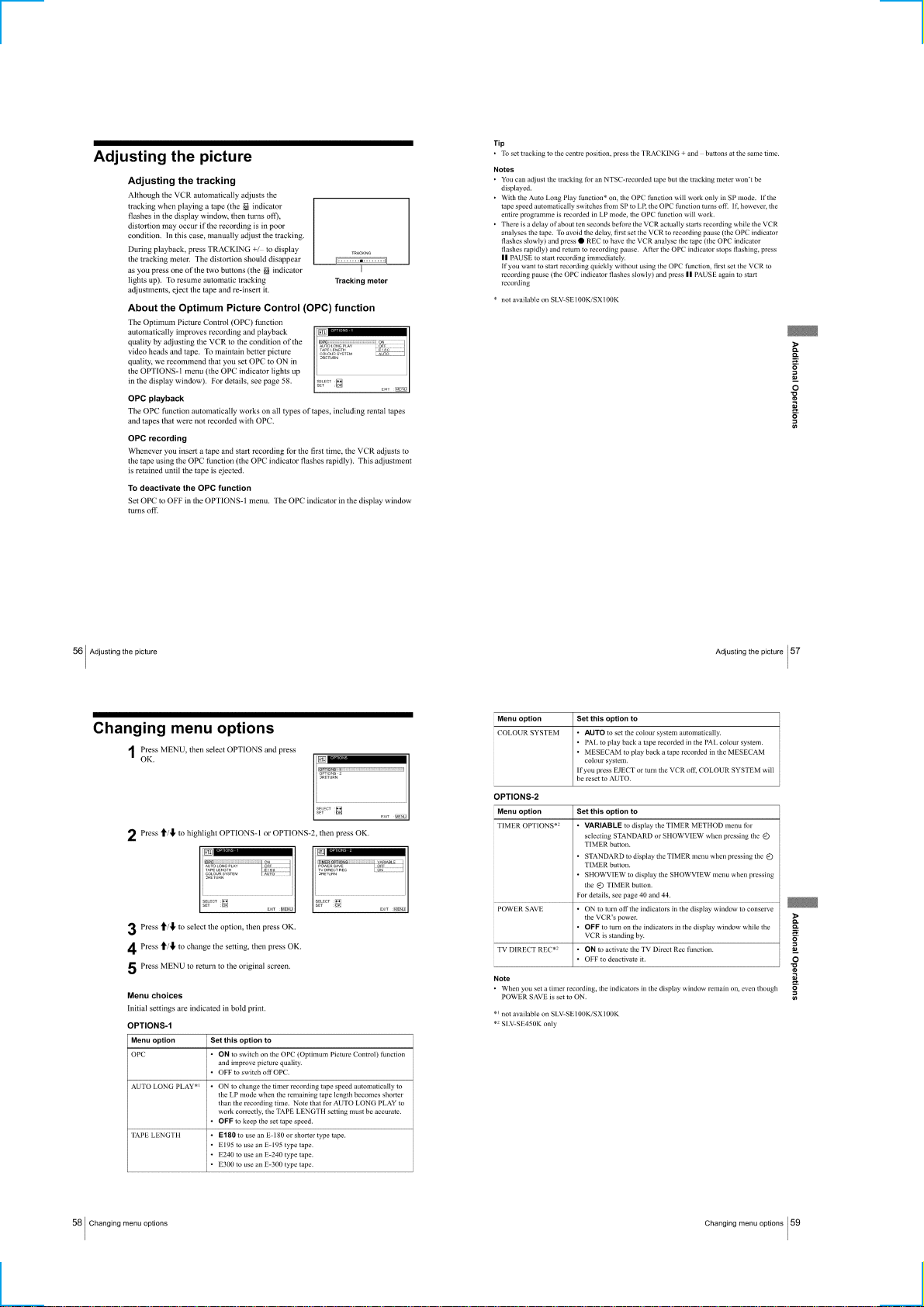

Adjusting the picture ···························································1-14

Changing menu options ·······················································1-14

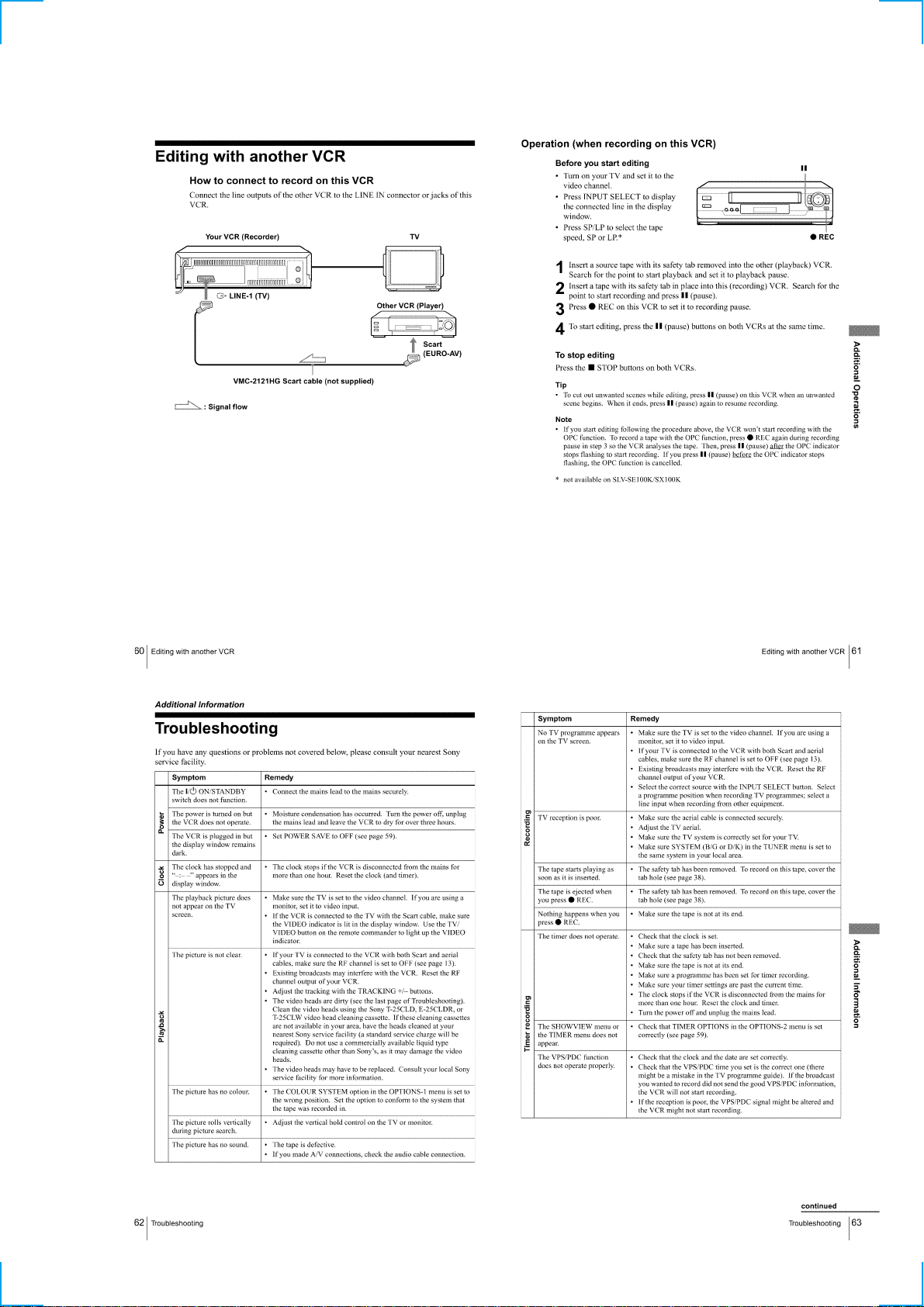

Editing with another VCR ··················································· 1-15

Additional Information ····························································1-15

Troubleshooting ···································································1-15

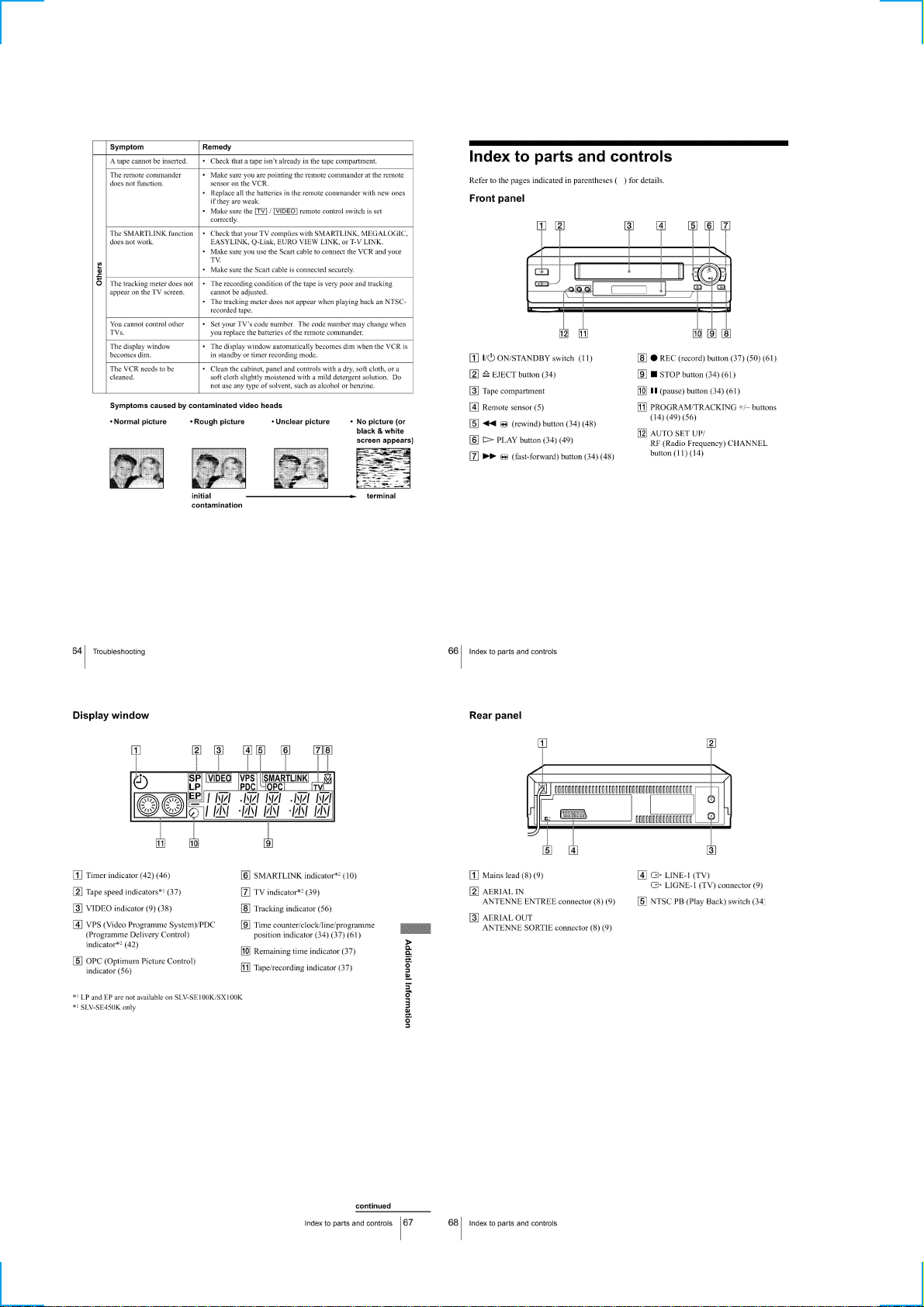

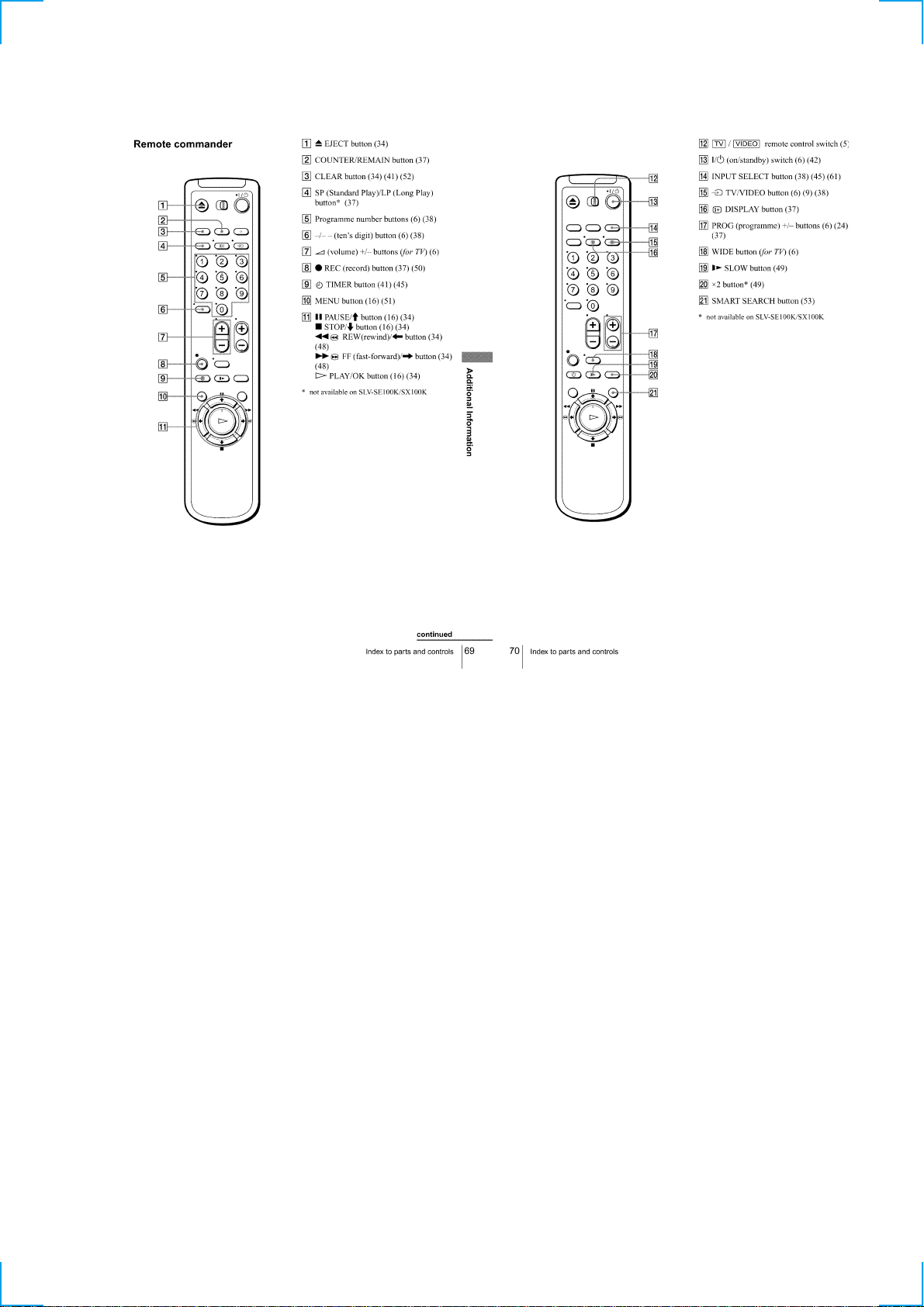

Index to parts and controls··················································· 1-16

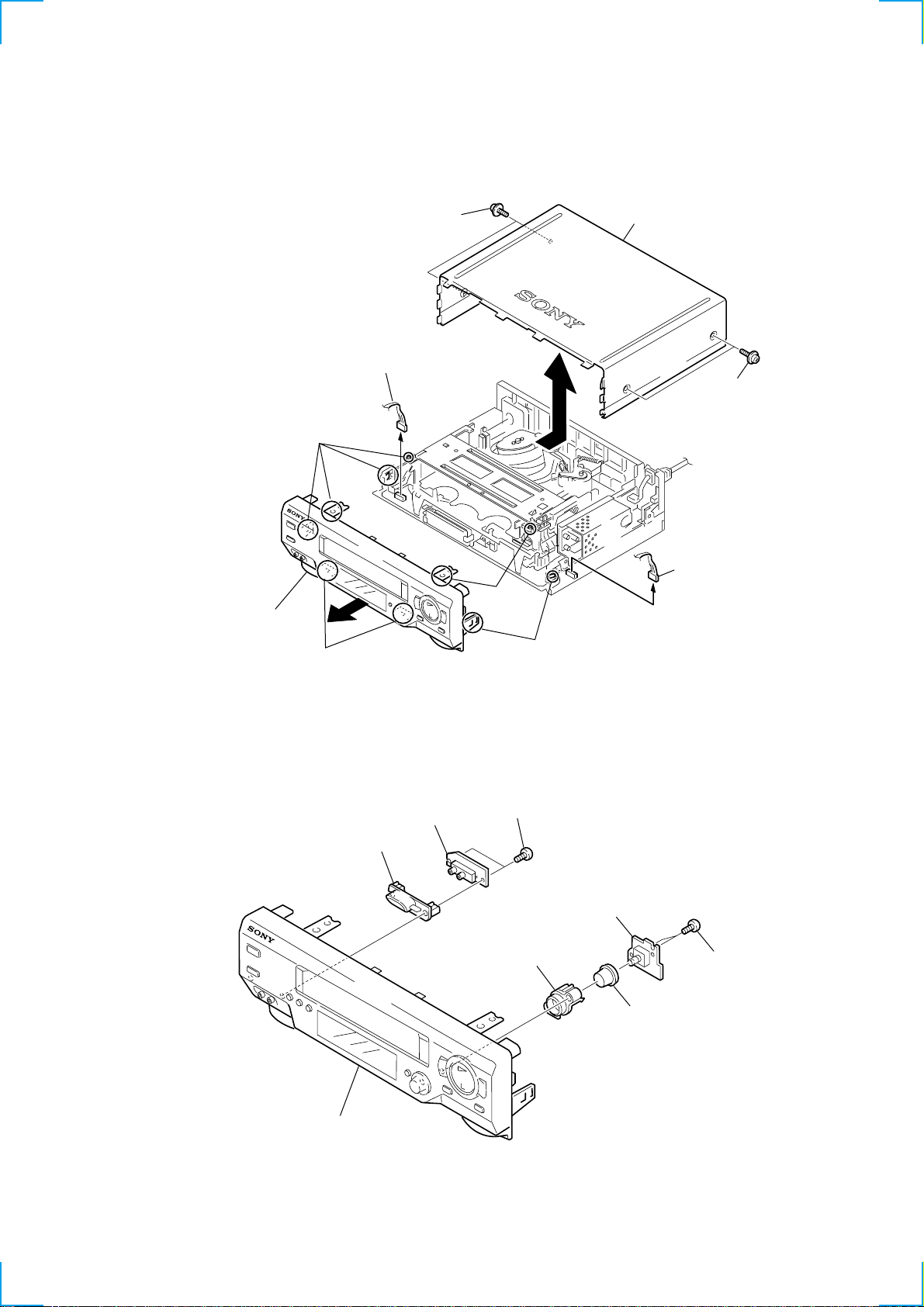

2 DISASSEMBLY

2-1. CASE, FRONT PANEL BLOCK ASSEMBLY··············2-1

2-2. KK-22 BOARD (SE300, SE450B/D/P),

JK-179 BOARD (SE300) ················································2-1

2-3. REAR PANEL ·································································2-2

2-4. POWER BLOCK, MA-372 BOARD······························ 2-2

2-5. MECHANISM DECK·····················································2-3

2-6. INTERNAL VIEWS························································2-4

2-7. CIRCUIT BOARDS LOCATION···································2-5

3 BLOCK DIAGRAMS

3-1. OVERALL BLOCK DIAGRAM ····································3-1

3-2. VIDEO BLOCK DIAGRAM ··········································3-3

3-3. SERVO/SYSTEM CONTROL BLOCK DIAGRAM ·····3-5

3-4. AUDIO BLOCK DIAGRAM ··········································3-7

3-5. POWER BLOCK DIAGRAM·········································3-9

4 PRINTED WIRING BOARDS AND

SCHEMATIC DIAGRAMS

4-1. FRAME SCHEMATIC DIAGRAM································4-3

4-2. PRINTED WIRING BOARDS AND

SCHEMATIC DIAGRAMS ············································4-5

• MA-372 (VIDEO, AUDIO, SERVO/SYSTEM

CONTROL, TUNER, POWER SUPPLY)

PRINTED WIRING BOARD ·························4-5

• MA-372 (1/10)(REC/PB HEAD AMP)

SCHEMA)TIC DIAGRAM ····························4-7

• MA-372 (2/10)(SECAM PROCESSOR)

SCHEMATIC DIAGRAM ······························4-9

• MA-372 (3/10)(VPD/PDC)

SCHEMATIC DIAGRAM ····························4-11

• MA-372 (4/10)(Y/C, AUDIO PROCESSOR)

SCHEMATIC DIAGRAM ····························4-13

• MA-372 (5/10)(SERVO/SYSTEM CONTROL)

SCHEMATIC DIAGRAM ····························4-15

• MA-372 (6/10)(USER CONTROL)

SCHEMATIC DIAGRAM ····························4-17

• MA-372 (7/10)(INPUT/OUTPUT)

SCHEMATIC DIAGRAM ····························4-19

• MA-372 (8/10)(C+ SWITCH)

SCHEMATIC DIAGRAM ····························4-21

• MA-372 (9/10)(TUNER)

SCHEMATIC DIAGRAM ····························4-23

• MA-372 (10/10)(POWER SUPPLY)

SCHEMATIC DIAGRAM ····························4-25

• JK-179 (LINE-2 IN)

PRINTED WIRING BOARD AND

SCHEMATIC DIAGRAM ····························4-27

• KK-22 (DIAL TIMER)

PRINTED WIRING BOARD AND

SCHEMATIC DIAGRAM ····························4-27

• POWER SUPPLY BLOCK

PRINTED WIRING BOARD ·······················4-28

• POWER SUPPLY BLOCK

SCHEMATIC DIAGRAM ····························4-29

5 INTERFACE, IC PIN FUNCTION

DESCRIPTION

5-1. SYSTEM CONTROL — VIDEO/RP BLOCK

INTERFACE (MA-372 BOARD IC162) ························5-1

5-2. SYSTEM CONTROL — SERVO PERIPHERAL

CIRCUIT INTERFACE (MA-372 BOARD IC162) ·······5-1

5-3. SYSTEM CONTROL — MECHANISM BLOCK

INTERFACE (MA-372 BOARD IC162) ························5-2

5-4. SYSTEM CONTROL — SYSTEM CONTROL

PERIPHERAL CIRCUIT INTERFACE

(MA-372 BOARD IC162)···············································5-2

5-5. SYSTEM CONTROL — AUDIO BLOCK INTERFACE

(MA-372 BOARD IC162)···············································5-2

5-6. SERVO/SYSTEM CONTROL MICROPROCESSOR

PIN FUNCTIONS (MA-372 BOARD IC162)················5-3

5-7. MODE CONTROL PIN FUNCTIONS

(MA-372 BOARD IC420)···············································5-5

6 ADJUSTMENTS

6-1. MECHANICAL ADJUSTMENTS ·································6-1

6-2. ELECTRICAL ADJUSTMENTS ···································6-1

2-1. PREPARATION BEFORE ADJUSTMENT···················6-1

2-1-1.Equipment Required ························································6-1

2-1-2.Equipment Connection ····················································6-1

2-1-3.Set-up of Adjustment······················································· 6-1

2-1-4.Alignment Tape ·······························································6-1

2-1-5.Input/Output Levels and Impedance ·······························6-2

2-1-6.Adjustment Sequence ······················································6-2

2-2. POWER SUPPLY CHECK ·············································6-2

2-2-1.Output Voltage Check (MA-372 Board) ·························6-2

2-3. SERVO SYSTEM CHECK ·············································6-3

2-3-1.RF Switching Position Adjustment (MA-372 Board) ·····6-3

2-4. AUDIO SYSTEM ADJUSTMENT·································6-3

2-4-1.Normal Audio System Adjustment ··································6-3

2-4-2.ACE Head Adjustment ····················································6-3

2-4-3.E-E Output Level Check ·················································6-3

2-4-4.Frequency Response Check·············································6-3

2-5. ADJUSTING PARTS LOCATION DIAGRAM ·············6-4

7 REPAIR PARTS LIST

7-1. EXPLODED VIEWS ······················································7-1

7-1-1.FRONT PANEL AND UPPER CASE SECTION ··········7-1

7-1-2.CHASSIS SECTION·······················································7-2

7-1-3.MECHANISM DECK SECTION-1 ·······························7-3

7-1-4.MECHANISM DECK SECTION-2 ·······························7-4

7-1-5.MECHANISM DECK SECTION-3 ·······························7-5

7-2. ELECTRICAL PARTS LIST ··········································7-6

— 3 —

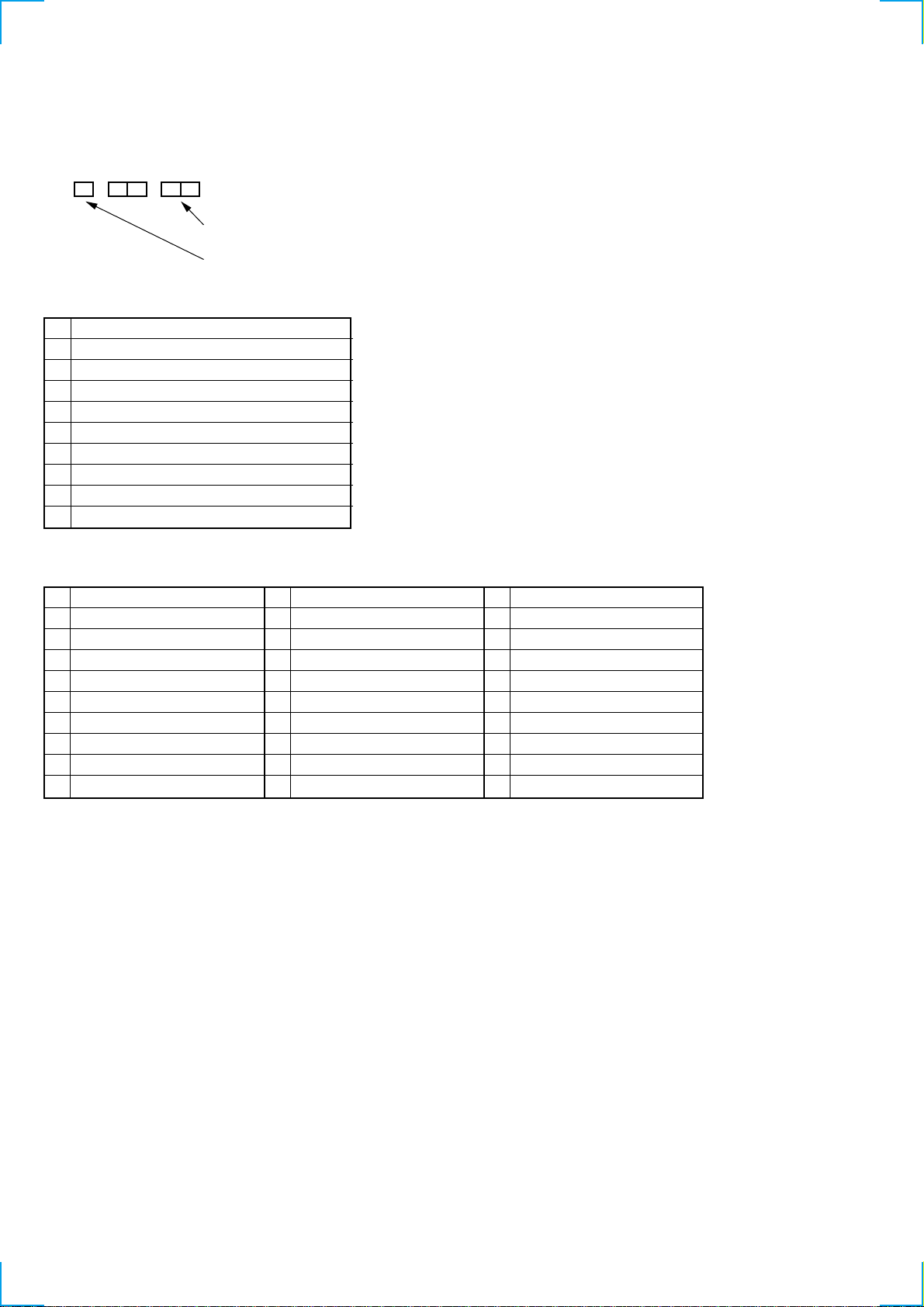

SERVICE NOTE

1. ERROR CODE INDICATION

• Error codes are indicated using the lower 5 digits in the fluorescent display tube.

“At this time, Colon “:” between character is not indicated.”

Mode code indication when the error has occurred.

Error code

ERROR CODE

0 No error

1 Cam encoder error Loading direction

2 Cam encoder error Unloading direction

3 T reel error

4 S reel error

5 Capstan error

6 Drum error

7 Error on initializing

8 Cassette loading error

9 Reserve

MODE CODE

0 Power-on eject 10 FWD x1 20 REW play

1 Power-on initial 11 FWD x2 21 Cas. loading

2 Power-off eject 12 CUE 22 Tape loading

3 Power-off stop 13 PB-pause 23 Power-off loading

4 FF 14 RVS-pause 24 Mecha. error (Power on)

5 REW 15 RVS x1 25 Power-on eject initial

6 REC 16 RVS x2 26 Power-off eject initial

7 REC- pause 17 REV 27 APC REC

8 Power-on stop 18 Power-off initial 28 Cas. loading

9 PB 19 Mecha. error (Power off) (No auto PB check)

— 4 —

SLV-SE100/SE200/SE250/SE300/SE400/SE450/SX100/SX250

SECTION 1

GENERAL

This section is extracted from instruction

manual. (SLV-SE100K/SX100K/SE400K/

SE450K model)(3-868-344-11)

1-1

1-2

1-3

1-4

1-5

1-6

1-7

1-8

1-9

1-10

1-11

1-12

1-13

1-14

1-15

1-16

1-17

MEMO

1-18E

SLV-SE100/SE200/SE250/SE300/SE400/SE450/SX100/SX250

SECTION 2

DISASSEMBLY

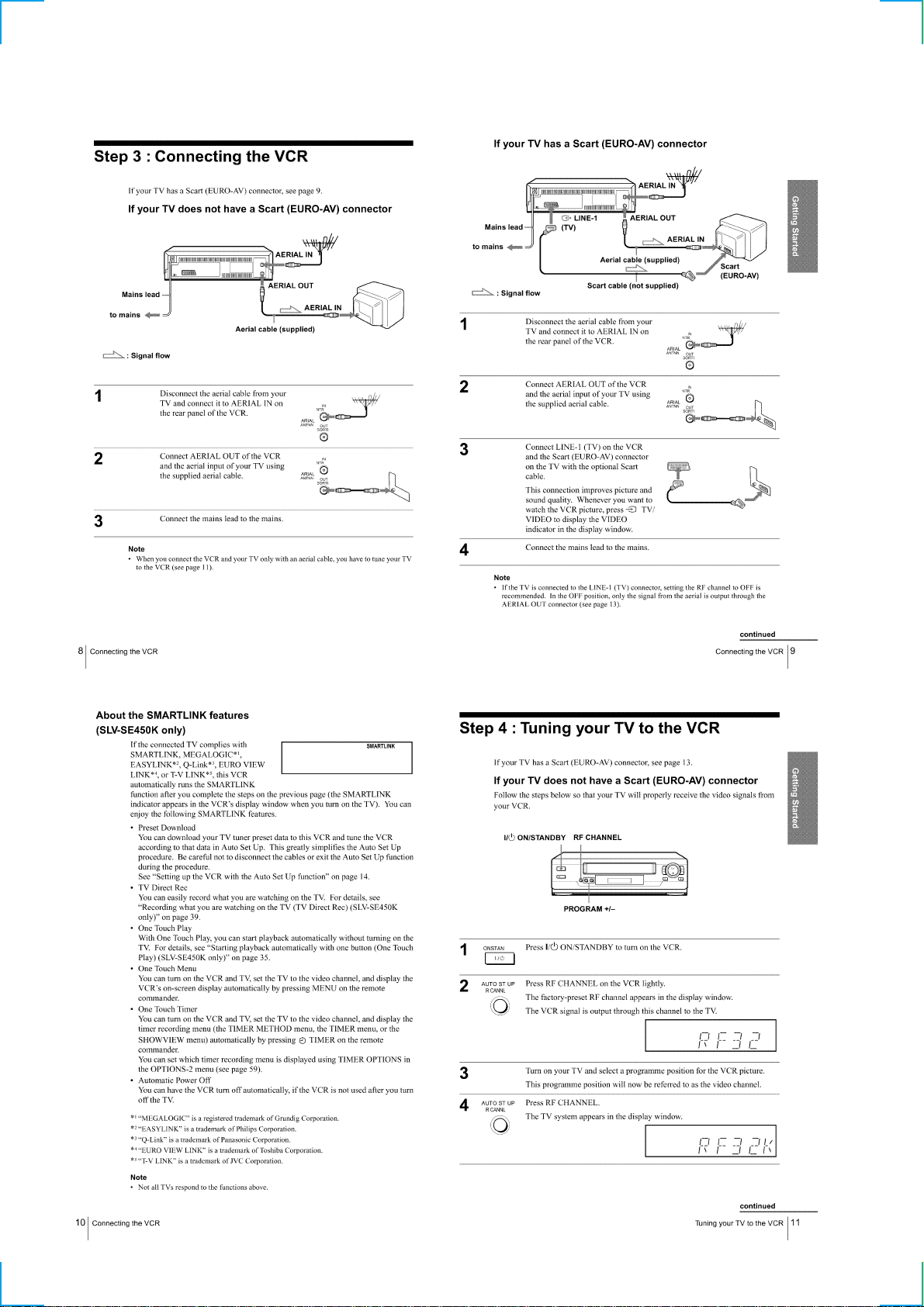

NOTE: Follow the disassembly procedure in the numerical order given.

2-1. CASE, FRONT PANEL BLOCK ASSEMBLY

6 Panel block assembly

(Engaged by the hook.)

Hooks

Hooks

1 T apping screw

4 Connector

3 Upper case

2 Tapping screw

5 Connector

Hooks

Hooks

2-2. KK-22 BOARD (SE300, SE450B/D/P), JK-179 BOARD (SE300)

5 T wo screws

6 JK-179 board

7 Pin jack cover

Front panel assembly

(B2.6 × 8)

2 KK-22 board

4 Dial timer escutcheon

3 Dial timer knob

1 Two screws

(B2.6 × 8)

2-1

2-3. REAR PANEL

r

2 Rear panel

(Engaged by the hook.)

Hooks

Hooks

Hooks

1 POWER code stoppe

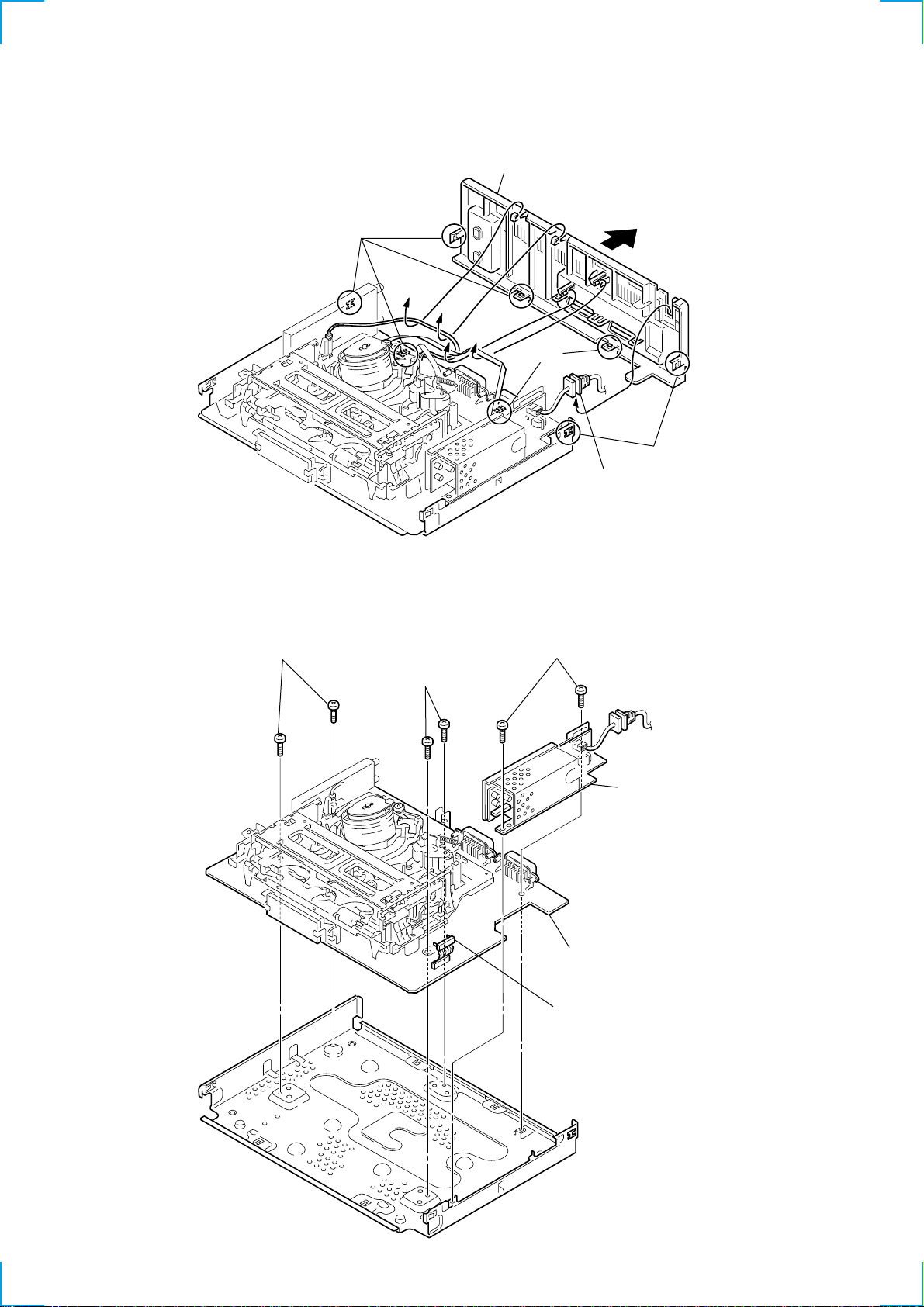

2-4. POWER BLOCK, MA-372 BOARD

4 T wo screws

(Sumitite (B3) +BV)

5 T wo screws

(Sumitite (B3) +BV)

2 T wo screws

3 Power block

6 MA-372 board with

mechanism deck

1 One connector

2-2

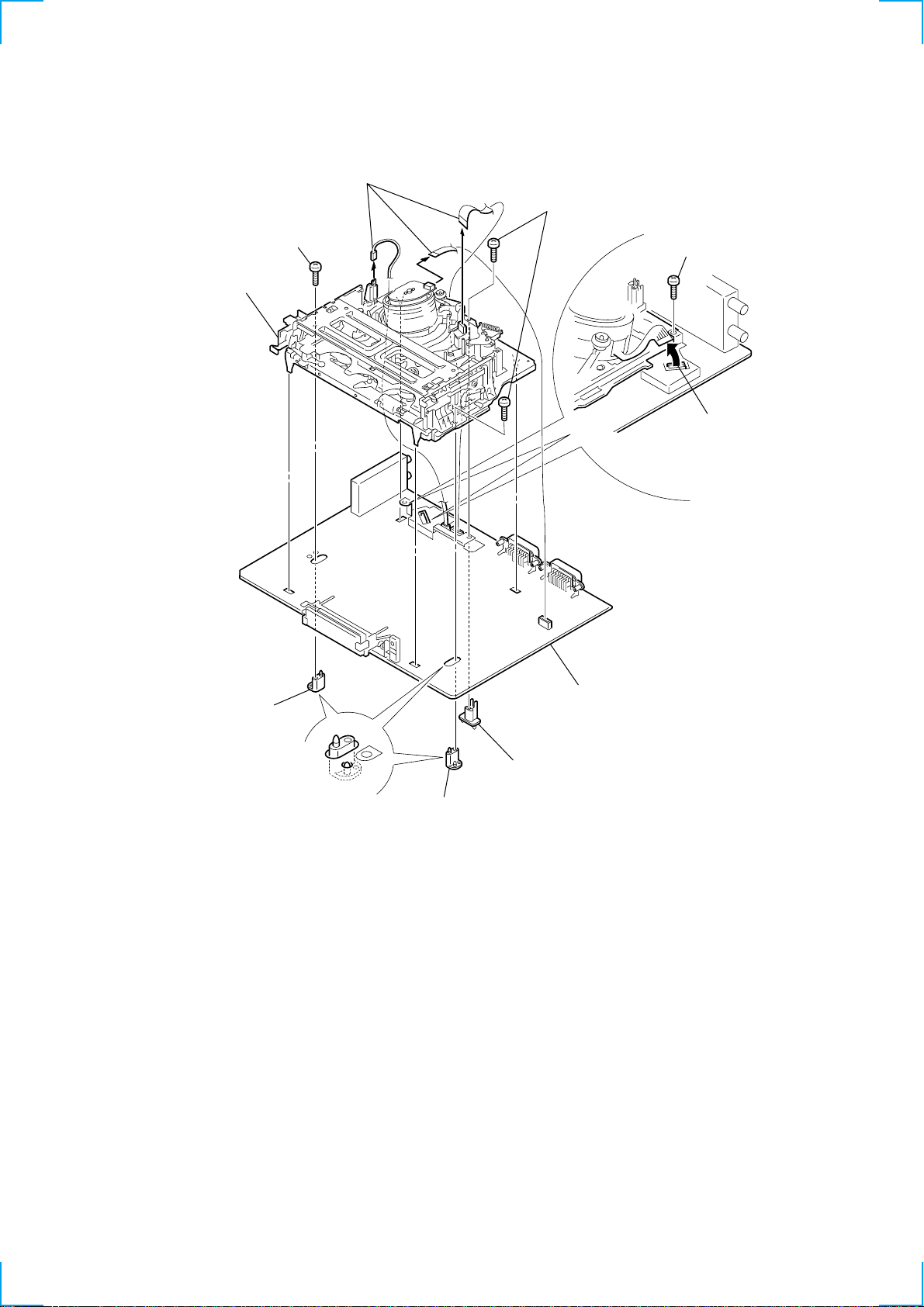

2-5. MECHANISM DECK

4 Screw

(BVTP 3 × 12)

0 Mechanism deck

3 Three connectors

6 T wo screws

(BVTP 3 × 12)

2 Screw

(BVTP 3 × 12)

1 Flexible board

5 MD base (R)

9 MA-372 board

8 MD base (M)

7 MD base (R)

2-3

Loading...

Loading...