Sony SLV-778-HF Service manual

SLV-777HF/778HF/788HF

RMT-V231B/V232B

SERVICE MANUAL

G

Photo : SLV-788HF

j

• Refer to the SERVICE MANUAL of VHS MECHANICAL

ADJUSTMENT

(9-921-647-11)

for MECHANICAL ADJUSTMENTS.

SPECIFICATIONS

US Model

Canadian Model

SLV-777HF/778HF/788HF

PX Model

SLV-777HF

S MECHANISM

MICROFILM

VIDEO CASSETTE RECORDER

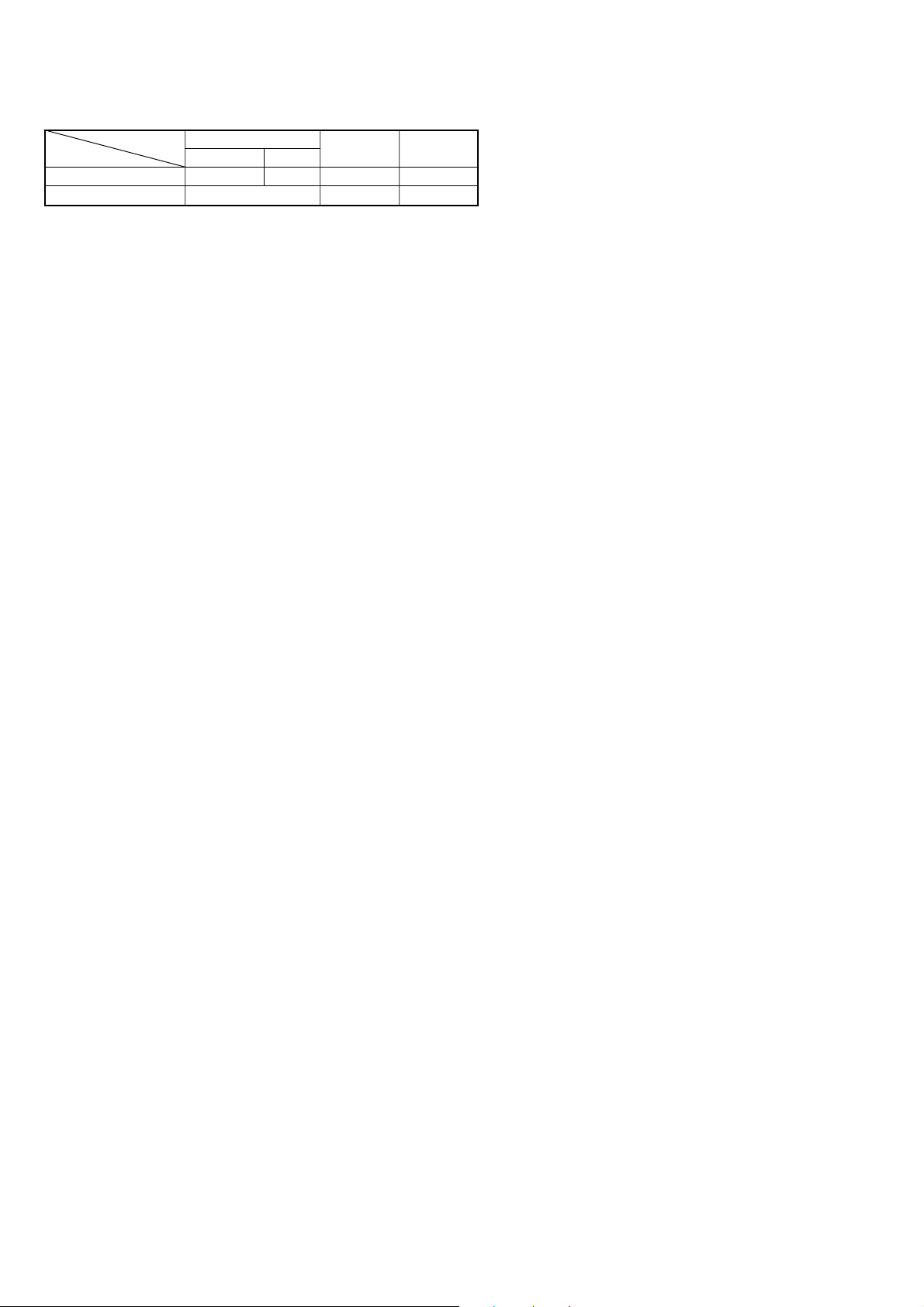

DIFFERENT SPECIFICATIONS

MODEL

SPECIFICATIONS

BODY COLOR

REMOTE COMMANDER

SLV-777HF

US, Canadian PX

TITAN BLACK

RMT-V231B

SLV-778HF

BLACK

RMT-V231B

SLV-788HF

BLACK

RMT-V232B

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY MARK ! OR DO TTED LINE WITH

MARK ! ON THE SCHEMATIC DIAGRAMS AND IN THE PARTS

LIST ARE CRITICAL TO SAFE OPERATION. REPLACE THESE

COMPONENTS WITH SONY PARTS WHOSE PART NUMBERS

APPEAR AS SHOWN IN THIS MANUAL OR IN SUPPLEMENTS

PUBLISHED BY SONY.

ATTENTION AU COMPOSANT AYANT RAPPORT

À LA SÉCURITÉ!

LES COMPOSANTS IDENTIFÉS P AR UNE MARQ UE ! SUR LES

DIAGRAMMES SCHÉMA TIQUES ET LA LISTE DES PIÈCES SONT

CRITIQUES POUR LA SÉCURITÉ DE FONCTIONNEMENT. NE

REMPLACER CES COMPOSANTS QUE PAR DES PIÈSES SONY

DONT LES NUMÉROS SONT DONNÉS DANS CE MANUEL OU

DANS LES SUPPÉMENTS PUBLIÉS PAR SONY.

— 2 —

SAFETY CHECK-OUT

After correcting the original service problem, perform the following

safety checks before releasing the set to the customer.

1. Check the area of your repair for unsoldered or poorly-soldered

connections. Check the entire board surface for solder splashes

and bridges.

2. Check the interboard wiring to ensure that no wires are

"pinched" or contact high-wattage resistors.

3. Look for unauthorized replacement parts, particularly

transistors, that were installed during a previous repair . Point

them out to the customer and recommend their replacement.

4. Look for parts which, though functioning, show obvious signs

of deterioration. Point them out to the customer and

recommend their replacement.

5. Check the line cord for cracks and abrasion.

Recommend the replacement of any such line cord to the

customer.

6. Check the B+ voltage to see it is at the values specified.

7. Check the antenna terminals, metal trim, "metallized" knobs,

screws, and all other exposed metal parts for AC leakage.

Check leakage as described below.

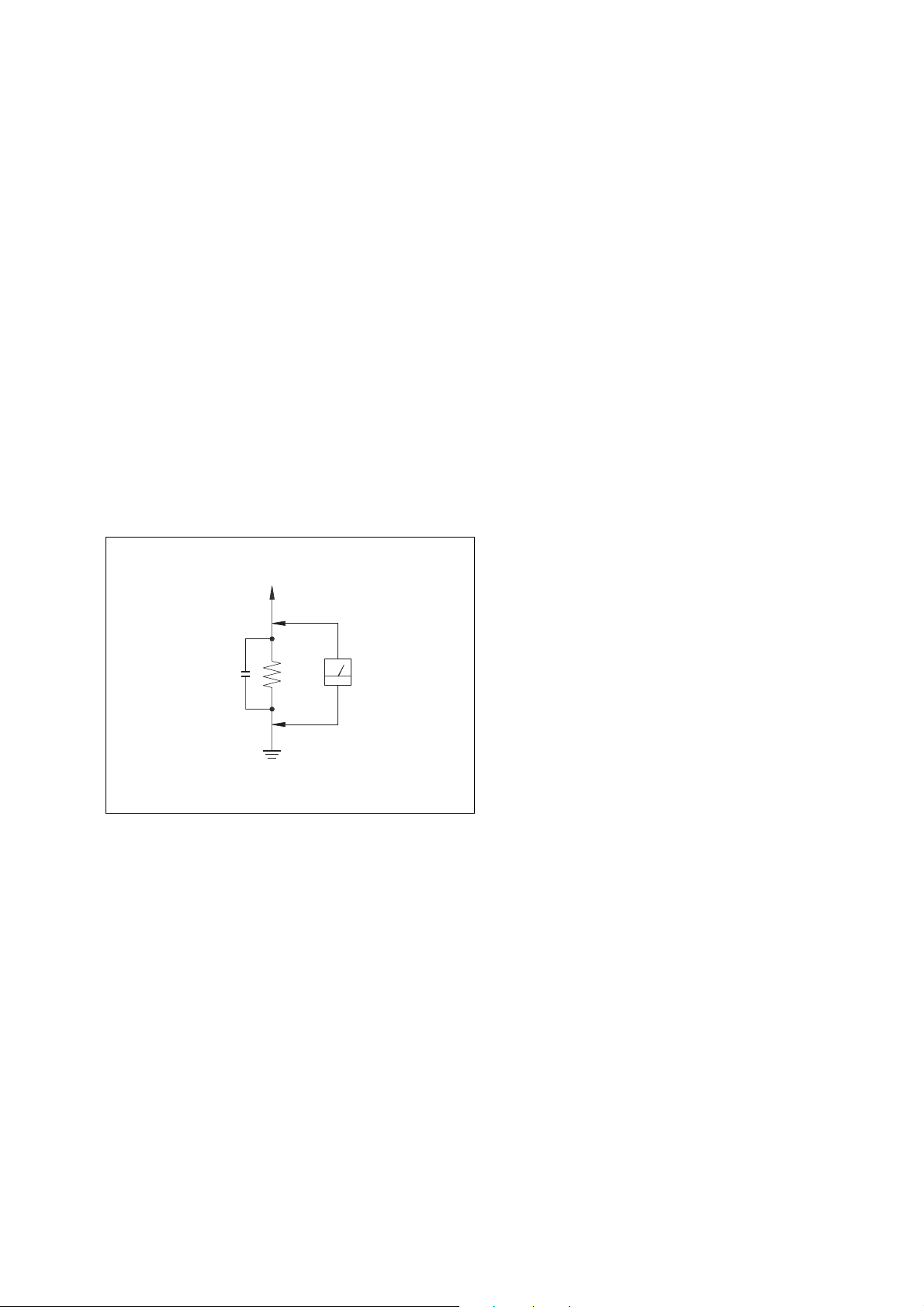

T o Exposed Metal

Parts on Set

AC

0.15

µ

F

1.5 k

Ω

Voltmeter

(0.75 V)

LEAKAGE TEST

The AC leakage from any exposed metal part to earth ground and

from all exposed metal parts to any exposed metal part having a

return to chassis, must not exceed 0.5mA (500 microampers).

Leakage current can be measured by any one of three methods.

1. A commercial leakage tester, such as the Simpson 229 or RCA

TW-540A. F ollow the manufacturers' instructions to use these

instruments.

2. A battery-operated A C milliammeter. The Data Precision 245

digital multimeter is suitable for this job.

3. Measuring the voltage drop across a resistor by means of a

VOM or battery-operated AC v oltmeter . The "limit" indication

is 0.75V, so analog meters must have an accurate lo w v oltage

scale. The Simpson 250 and Sanwa SH-63Trd are examples

of a passive VOM that is suitable. Nearly all battery operated

digital multimeters that have a 2V A C range are suitable. (See

Fig. A)

Earth Ground

Fig. A. Using an A C v oltmeter to check A C leakage.

— 3 —

TABLE OF CONTENTS

SERVICE NOTE

1. ERROR CODE INDICATION··········································· 6

2. HOW TO REPLACE A ROTARY UPPER DRUM

(777HF, 778HF MODEL) ·················································· 7

2-1. HOW TO REMOVE A ROTARY UPPER DRUM ············ 7

2-2. HOW TO ATTACH A NEW ROTARY

UPPER DRUM··································································· 7

1. GENERAL

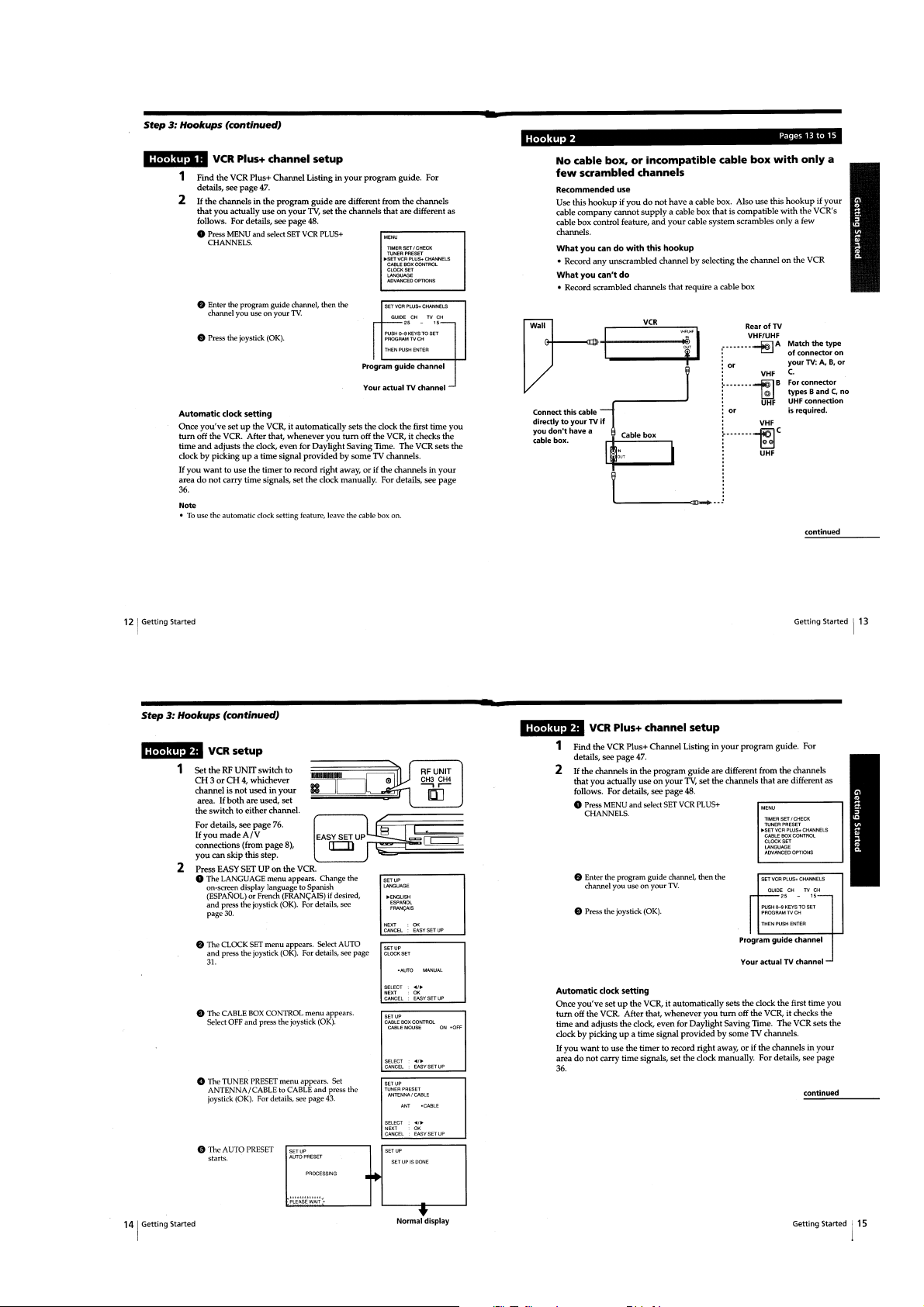

Getting Started

Unpacking··············································································1-1

Setting up the remote commander ·········································1-1

Hookups ·················································································1-1

Selecting a language ······························································1-7

Setting the clock ····································································1-7

Setting up cable box control ··················································1-9

Presetting channels ······························································1-10

Setting up VCR Plus+··························································1-11

Basic Operations

Playing a tape·······································································1-12

Recording TV programs ······················································1-13

Recording TV programs using VCR Plus+ ·························1-14

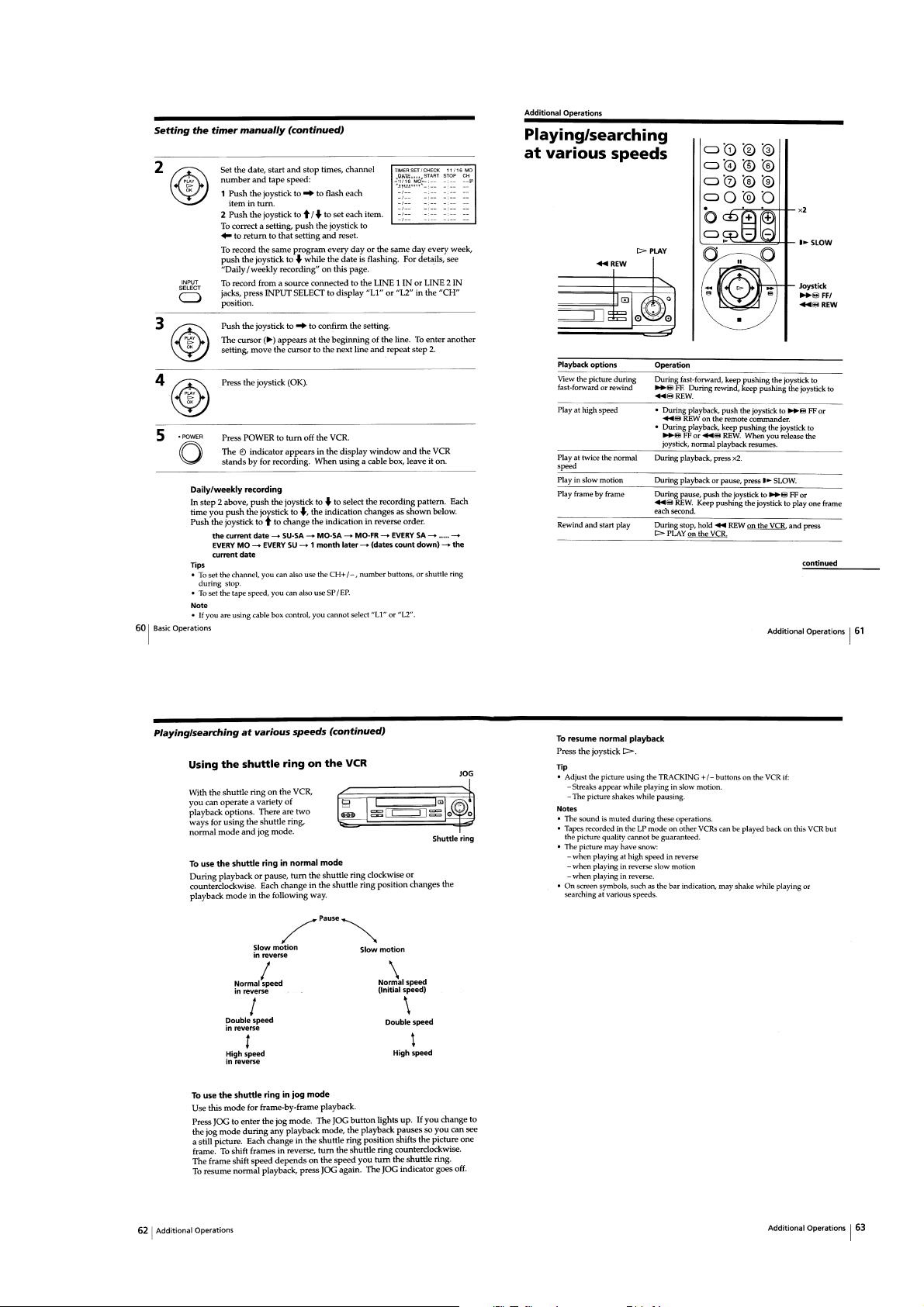

Setting the timer manually···················································1-14

Additional Operations

Playing/searching at various speeds ····································1-15

Searching for a selected point on the tape ···························1-16

Skip-searching automatically···············································1-16

Recording TV programs using the quick timer ···················1-16

Checking/changing/cancelling timer settings ······················1-17

Recording stereo and bilingual programs ····························1-17

Adjusting the picture ···························································1-18

Changing menu options ·······················································1-18

Editing with another VCR ···················································1-18

Additional Information

General setup information ···················································1-19

Index to parts and controls···················································1-19

2. DISASSEMBLY

2-1. UPPER CASE,

FRONT PANEL BLOCK ASSEMBLY ·························· 2-1

2-2. FR-138 BOARD, DM-80 BOARD ·································2-1

2-3. REAR PANEL ·································································2-1

2-4. POWER BLOCK, MA-327 BOARD (WITH S

MECHANISM DECK) ···················································2-2

2-5. S MECHANISM DECK ················································· 2-2

2-6. INTERNAL VIEWS························································2-3

2-7. CIRCUIT BOARDS LOCATION···································2-4

3. BLOCK DIAGRAMS

3-1. OVERALL BLOCK DIAGRAM····································3-1

3-2. VIDEO BLOCK DIAGRAM ··········································3-3

3-3. SERVO/SYSTEM CONTROL BLOCK DIAGRAM ····· 3-5

3-4. AUDIO BLOCK DIAGRAM ··········································3-7

3-5. MODE CONTROL BLOCK DIAGRAM ·······················3-9

3-6. TUNER BLOCK DIAGRAM ·······································3-11

3-7. POWER SUPPLY BLOCK DIAGRAM ·······················3-13

4. PRINTED WIRING BOARDS AND

SCHEMATIC DIAGRAMS

4-1. FRAME SCHEMATIC DIAGRAM································4-1

4-2. PRINTED WIRING BOARDS AND

SCHEMATIC DIAGRAMS ············································ 4-3

• MA-327 (REC/PB AMP, VIDEO, SERVO/SYSTEM

CONTROL, AUDIO, TUNER)

PRINTED WIRING BOARD ·························4-3

• MA-327 (REC/PB AMP)

SCHEMATIC DIAGRAM ······························4-5

• MA-327 (VIDEO, NORMAL AUDIO)

SCHEMATIC DIAGRAM ······························4-8

• MA-327 (SERVO/SYSTEM CONTROL)

SCHEMATIC DIAGRAM ····························4-11

• MA-327 (ON SCREEN DISPLAY)

SCHEMATIC DIAGRAM···························· 4-15

• MA-327 (AFM AUDIO)

SCHEMATIC DIAGRAM···························· 4-17

• MA-327 (TUNER)

SCHEMATIC DIAGRAM···························· 4-19

• MA-327 (POWER SUPPLY, AV BUS)

SCHEMATIC DIAGRAM···························· 4-21

• FR-138 (MODE CONTROL)

PRINTED WIRING BOARD ·······················4-23

• FR-138 (MODE CONTROL)

SCHEMATIC DIAGRAM ····························4-25

• DM-80 (OPERATION SWITCHES)

PRINTED WIRING BOARD AND

SCHEMATIC DIAGRAM ····························4-27

• JK-162 (LINE-2 IN)

PRINTED WIRING BOARD AND

SCHEMATIC DIAGRAM ····························4-28

• POWER BLOCK SR801 (SWITCHING REGULATOR)

PRINTED WIRING BOARD AND

SCHEMATIC DIAGRAM ····························4-29

• POWER BLOCK SR709 (SWITCHING REGULATOR)

PRINTED WIRING BOARD AND

SCHEMATIC DIAGRAM ····························4-31

5. INTERF ACE,

IC PIN FUNCTION DESCRIPTION

5-1. SYSTEM CONTROL —

MECHANISM BLOCK INTERFACE

(MA-327 BOARD IC160)···············································5-1

5-2. SYSTEM CONTROL —

SERVO PERIPHERAL CIRCUIT INTERFACE

(MA-327 BOARD IC160)···············································5-1

5-3. SYSTEM CONTROL — SYSTEM CONTROL

PERIPHERAL CIRCUIT INTERF ACE

(MA-327 BOARD IC160)···············································5-2

5-4. SYSTEM CONTROL AND RF MODULATOR—

INPUT SELECTION BLOCK INTERFACE

(MA-327 BOARD IC160)···············································5-2

5-5. SYSTEM CONTROL —

VIDEO/RP BLOCK INTERFACE

(MA-327 BOARD IC160)···············································5-2

5-6. SYSTEM CONTROL —

AUDIO BLOCK INTERFACE

(MA-327 BOARD IC160)···············································5-2

5-7. SERVO/SYSTEM CONTROL MICROPROCESSOR

(MA-327 BOARD IC160)···············································5-3

6. ADJUSTMENTS

6-1 MECHANICAL ADJUSTMENTS ·································6-1

6-2. ELECTRICAL ADJUSTMENTS ···································6-1

2-1. PREPARATION BEFORE ADJUSTMENT ···················6-1

2-1-1.Equipment Required ························································6-1

2-1-2.Equipment Connection ····················································6-1

2-1-3.Input Signal Check ··························································6-1

2-1-4.Alignment Tape ·······························································6-1

2-1-5.Input/Output Levels and Impedance ·······························6-2

2-1-6.Adjustment Sequence ······················································ 6-2

2-2. POWER SUPPLY CHECK ············································· 6-2

2-2-1.Output Voltage Check (MA-327 Board) ·························6-2

2-3. SERVO SYSTEM CHECK ·············································6-3

2-3-1.RF Switching Position/

AF Switching Position Adjustments (MA-327 Board) ···6-3

— 4 —

2-4. VIDEO SYSTEM CHECKS ···········································6-4

2-4-1.X’tal OSC Check (MA-327 Board)·································6-4

2-4-2.SYNC AGC Check (MA-327 Board)······························6-4

2-4-3.Recording Y Level Check (MA-327 Board) ···················6-4

2-4-4.Recording Chroma Level Check(MA-327 Board) ··········6-5

2-4-5.Playback Level Check (MA-327 Board) ·························6-5

2-5. AUDIO SYSTEM ADJUSTMENT·································6-5

2-5-1.ACE Head Adjustment ····················································6-5

2-5-2.E-E Output Level Check ················································· 6-5

2-5-3.Overall Output Level and Distortion Factor Check·········6-6

2-5-4.Overall Noise Level Check··············································6-6

2-6. TUNER SYSTEM ADJUSTMENT································6-6

2-6-1.Separation Adjustment (MA-327 Board) ························6-6

2-7. ADJUSTING PARTS LOCATION DIAGRAM·············6-8

7. REPAIR PARTS LIST

7-1. EXPLODED VIEWS ······················································7-1

7-1-1.FRONT PANEL ASSEMBLY AND UPPER CASE

SECTION ········································································7-1

7-1-2.CHASSIS SECTION·······················································7-2

7-1-3.MECHANISM DECK-1 ················································· 7-3

7-1-4.MECHANISM DECK-2 ················································· 7-4

7-1-5.MECHANISM DECK-3 ················································· 7-5

7-2. ELECTRICAL P ARTS LIST ··········································7-6

— 5 —

SLV-777HF/778HF/788HF

SERVICE NOTE

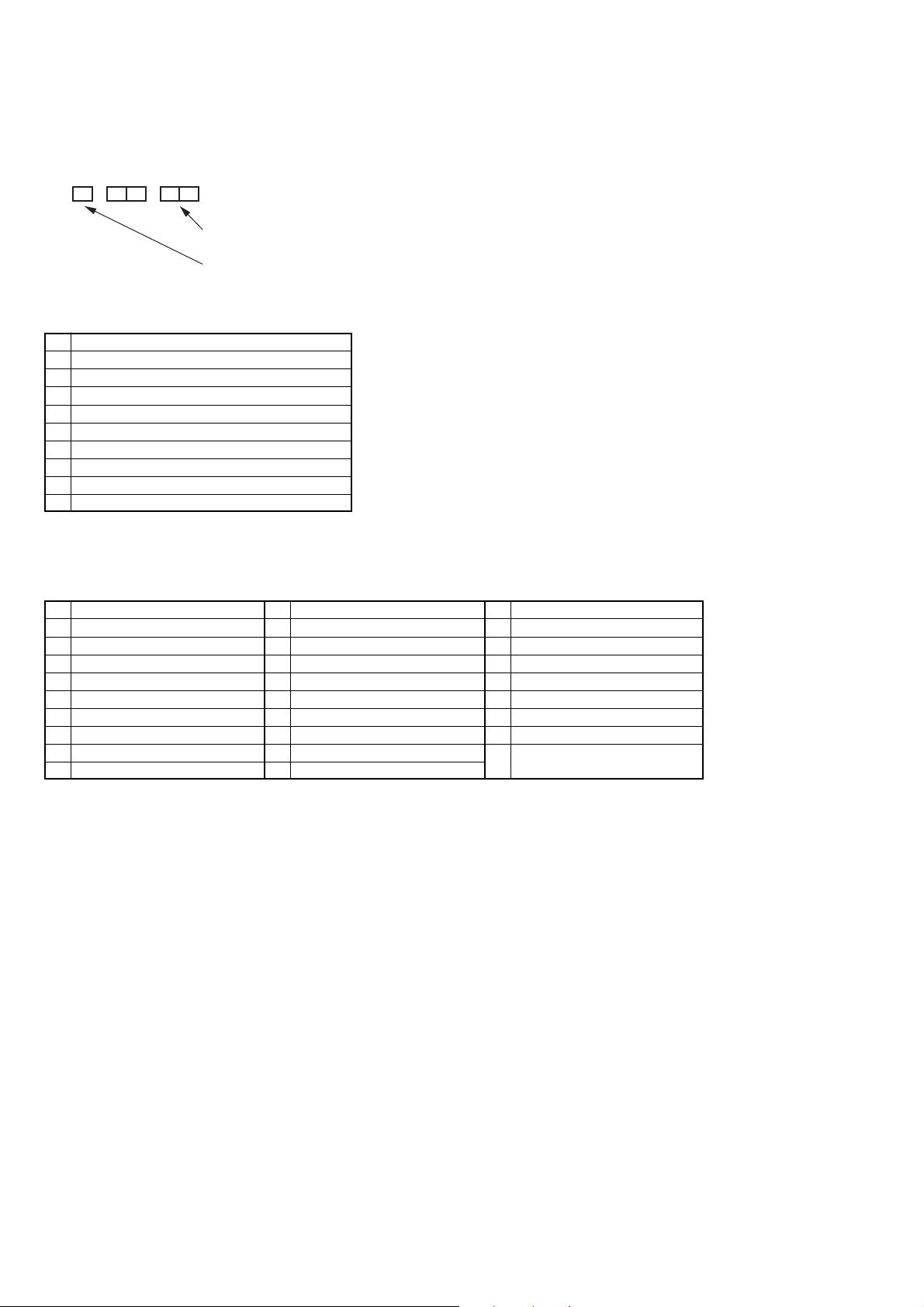

1. ERROR CODE INDICATION

• Error codes are indicated using the lower 5 digits in the fluorescent display tube.

“At this time, Colon “:” between character is not indicated.”

Mode code indication when the error has occurred.

Error code

ERROR CODE

0 No error

1 Cam encoder error Loading direction

2 Cam encoder error Unloading direction

3 T reel error

4 S reel error

5 Capstan error

6 Drum error

7 Error on initializing

8 Cassette loading error

9 Reserve

MODE CODE

0 P ower-on eject 10 FWD x1 20 REW play

1 P ower-on initial 11 FWD x2 21 Cas. loading

2 Power-off eject 12 CUE 22 Tape loading

3 Power-off stop 13 PB-pause 23 Power-off loading

4 FF 14 RVS-pause 24 Mecha. error (Power on)

5 REW 15 RVS x1 25 Power-on eject initial

6 REC 16 RVS x2 26 Power-off eject initial

7 REC- pause 17 REV 27 APC REC

8 P ower-on stop 18 Power-off initial 28 Cas. loading

9 PB 19 Mecha. error (Power off) (No auto PB check)

— 6 —

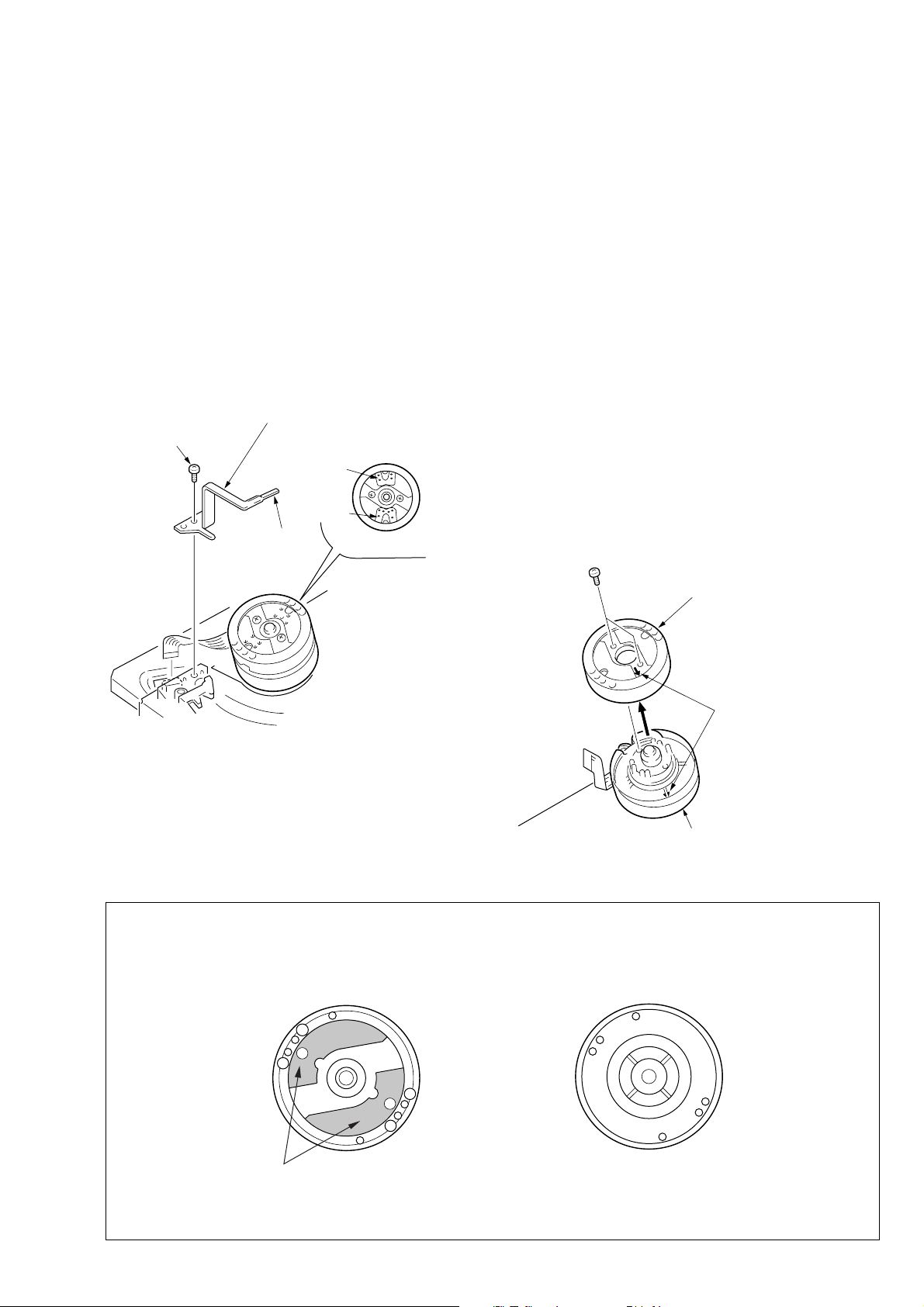

2. HOW TO REPLACE A ROTARY

3

PSW3 × 8

Upper drum assembly

DZR-45-R (8-848-576-02)

(777HF, 778HF)

Align the two arrow marks.

A

Lower drum assembly

DZL-51B/J-RP (8-848-666-11)

(777HF, 778HF)

There is no printed circuit board.

DRUM ASSEMBLY

DZH-94A/Z-RP

(8-839-044-02)

—T op View—

UPPER DRUM

(777HF, 778HFMODEL)

See below for note.

2-1. HOW TO REMOVE A ROTARY UPPER DRUM

1) Remove screw 1 (+P3 × 8) and remove the ground shaft

assembly 2. (Refer to Fig. 4.)

2) Remove soldering which is marked by arrow and remove the

rotary upper drum board completely.

3) Remove two screws 3 (PSW3 × 8) and remove the rotary

upper drum in the direction of A. (Refer to Fig. 5.)

If removal is difficult, remove it while rotating it slowly.

Note: If removal is difficult, check again if soldering is removed

completely.

2

Ground shaft assembly

1

Screw (+P3 × 8)

Soldering

Soldering

4

Plate

spring

Drum when viewed

from the top

2-2. HOW TO ATTACH A NEW ROTARY UPPER

DRUM

1) Pay attention so that finger print or like must not be put when

inserting a new upper drum into lower drum.

2) Align mark of the rotary upper drum board with the mark of

the rotary transformer board so that the screw hole on the upper

drum and that on the lower drum are aligned. (Refer to Fig. 5.)

3) If attaching is difficult, attach a upper drum while rotating it

slowly.

Note: Pay attention not to damage the video heads.

Confirm that the upper drum is inserted completely.

4) Tighten the two screws 3 (PSW3 × 8). (Refer to Fig. 5.)

5) Fix the earth shaft 2 by tightening the screw 1 (+P3 × 8) so

that protrusion at the tip of the earth shaft contacts the center

of the drum shaft.

Note: When attaching the ground shaft assembly 2, never give

force to the plate spring 4.

NOTE : There are two types of drum assemb ly built in models e xcept SLV-788HF (DZH-94A/Z-RP only).

[Discrimination]

Fig. 4

Fig. 5

UPPER DRUM ASSEMBLY

DZR-45-R (777HF, 778HF)

(8-848-576-02)

—T op View—

There are two printed circuit boards

on the top.

Note: It cannot be divided to two parts, the

upper and the lower drum assemblies.

— 7 —

SECTION 1

GENERAL

SLV-777HF/778HF/788HF

This section is extracted from the

SLV-788HF instruction manual.

1-1

1-2

1-3

1-4

1-5

1-6

1-7

1-8

1-9

1-10

1-11

1-12

1-13

1-14

1-15

1-16

Loading...

Loading...