Page 1

RM-VZ950T

SERVICE MANUAL

Ver 1.0 2000. 08

SPECIFICATIONS

AEP Model

REMOTE COMMANDER

Page 2

TABLE OF CONTENTS

1. GENERAL

Getting Started ................................................................ 3

Location of Controls ....................................................... 4

Basic Operations ............................................................. 5

Advanced Features .......................................................... 13

Additional Information ................................................... 18

Appendix ......................................................................... 19

2. DISASSEMBLY

2-1. Case (Lower) ................................................................... 21

2-2. Remote Control Board.................................................... 21

2-3. Case, Inner....................................................................... 22

3. TEST MODE.............................................................. 23

4. DIAGRAMS

4-1. Block Diagram ................................................................ 27

4-2. Printed Wiring Boards..................................................... 29

4-3. Schematic Diagram......................................................... 31

4-4. IC Pin Function Description ........................................... 35

5. EXPLODED VIEW ................................................... 36

6. ELECTRICAL PARTS LIST ............................... 37

Notes on chip component replacement

• Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be damaged by heat.

– 2 –

Page 3

SECTION 1

GENERAL

This section is extracted from

instruction manual.

– 3 –

Page 4

– 4 –

Page 5

– 5 –

Page 6

– 6 –

Page 7

– 7 –

Page 8

– 8 –

Page 9

– 9 –

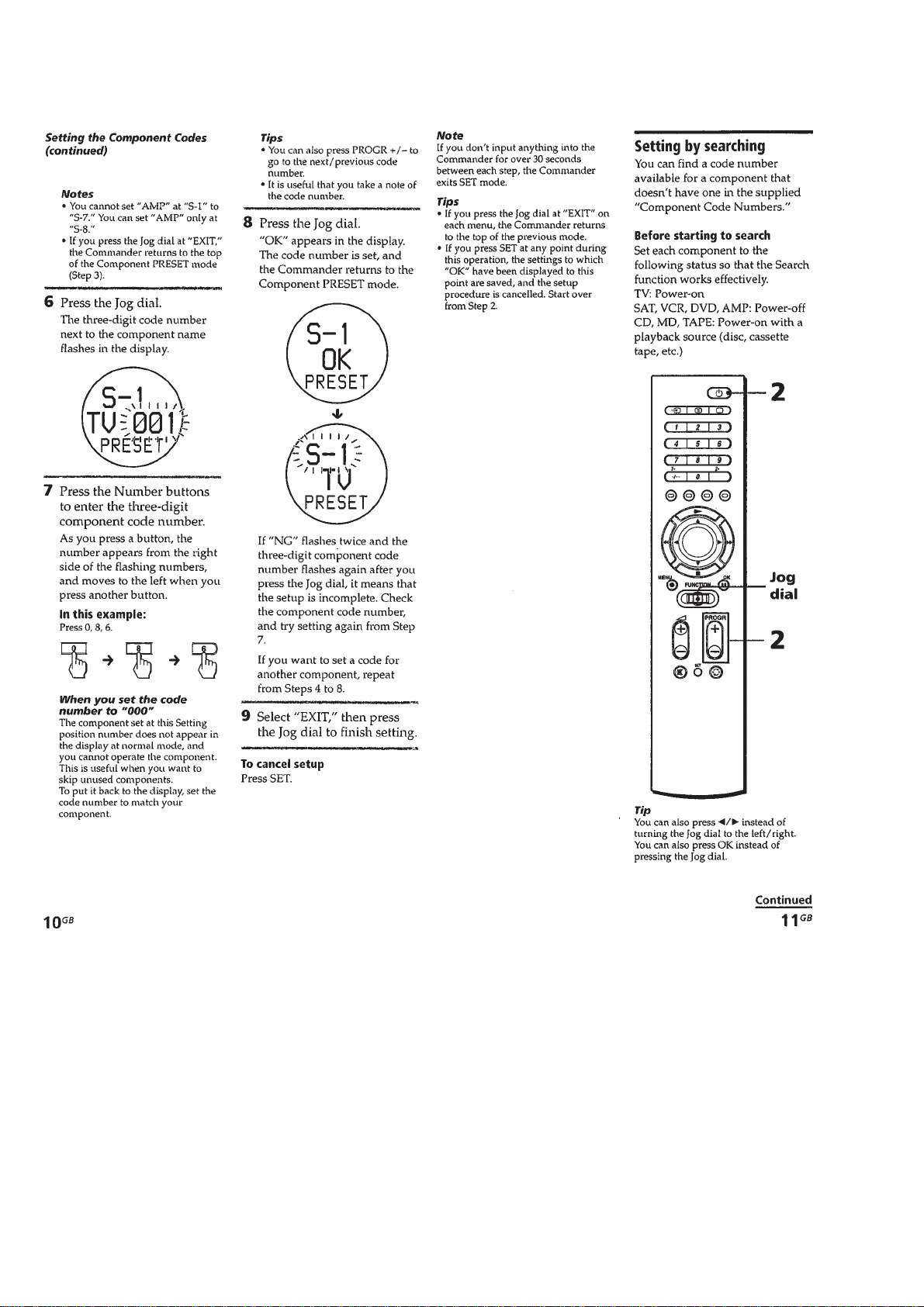

Page 10

– 10 –

Page 11

– 11 –

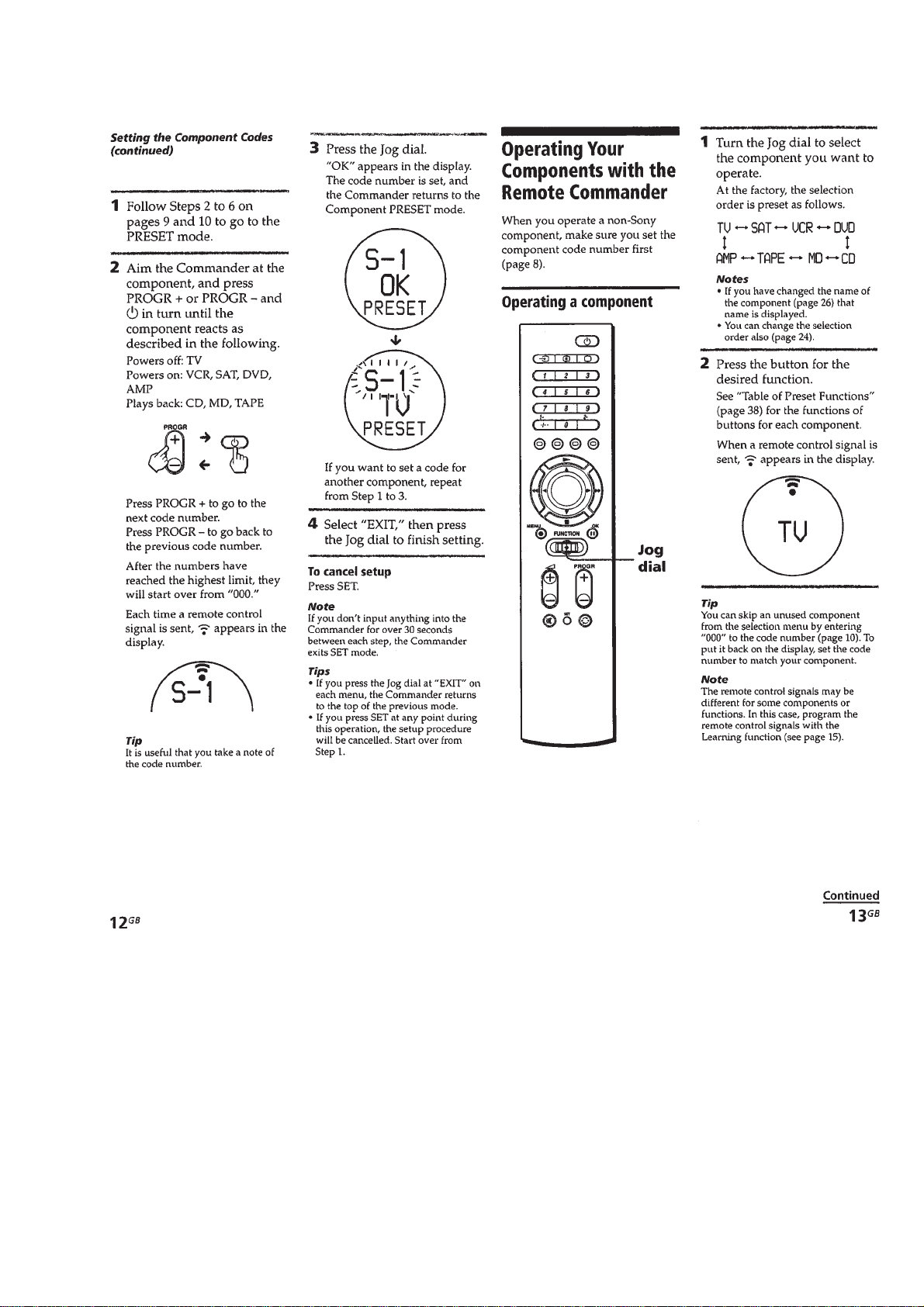

Page 12

– 12 –

Page 13

– 13 –

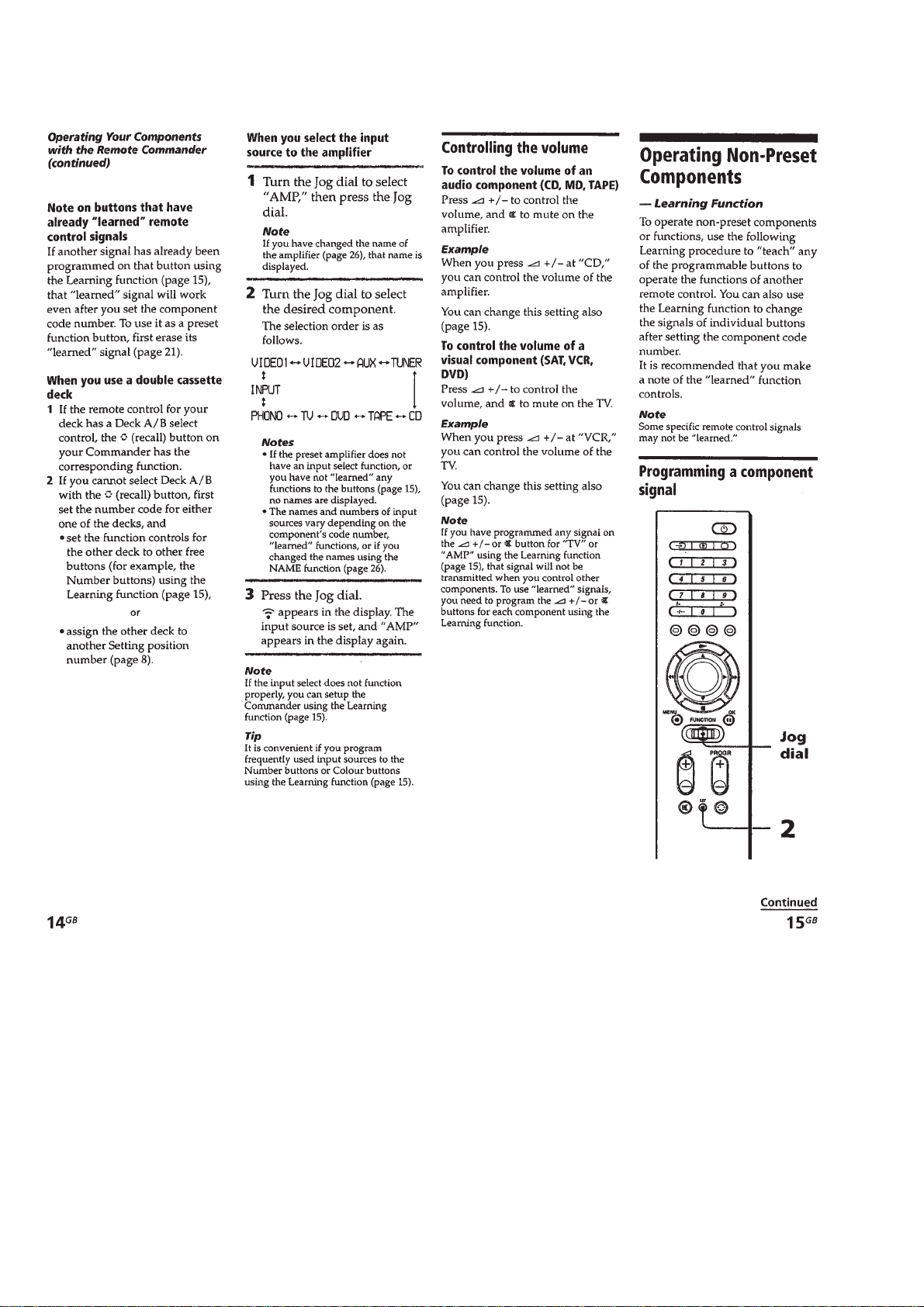

Page 14

– 14 –

Page 15

– 15 –

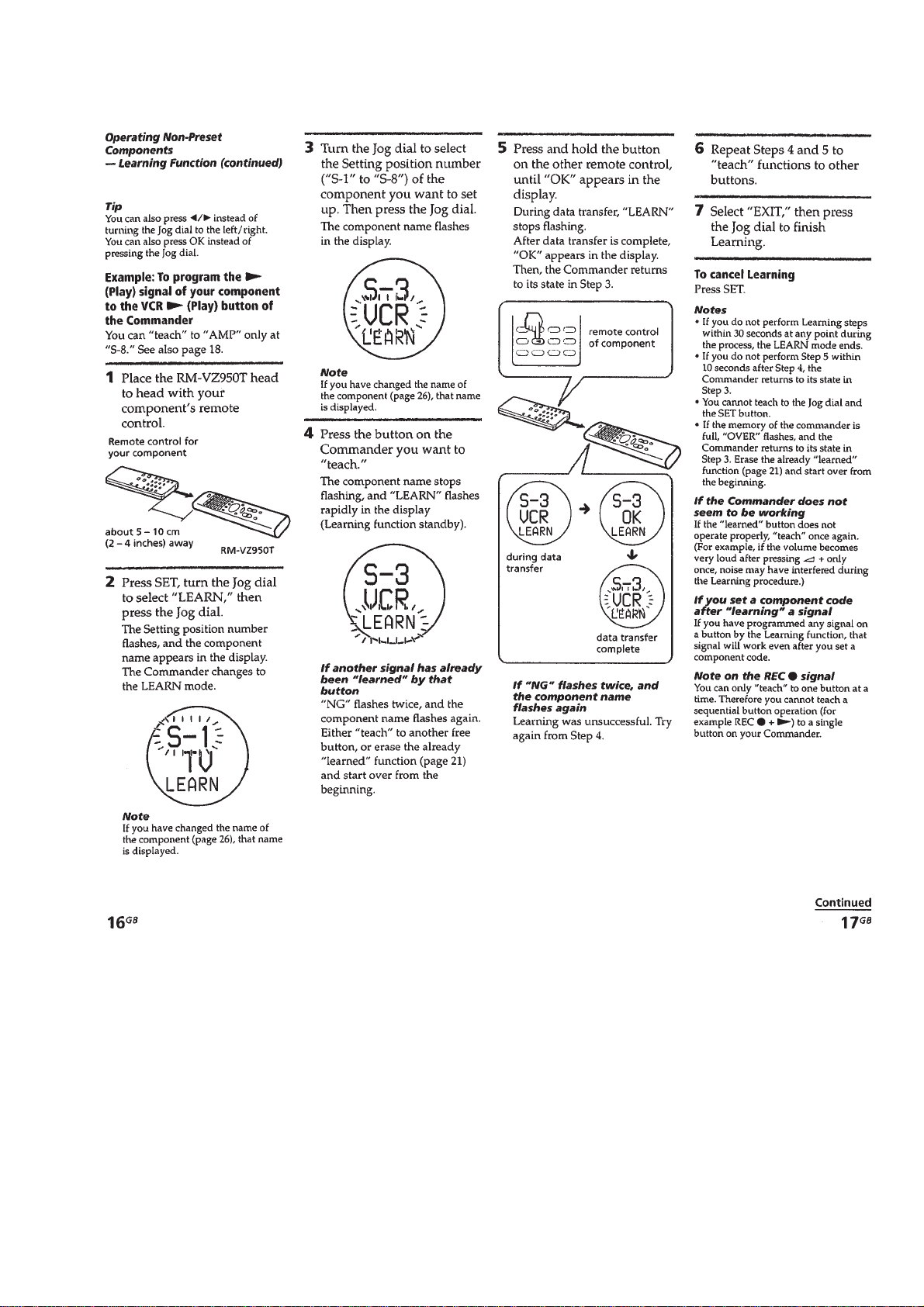

Page 16

– 16 –

Page 17

– 17 –

Page 18

– 18 –

Page 19

– 19 –

Page 20

– 20 –

Page 21

• This set can be disassemble in the order shown below.

r

d

SECTION 2

DISASSEMBLY

Set

Note: Follow the disassembly procedure in the numerical order given.

2-1. CASE (LOWER)

Case (Lower) Remote Control Board Case, Inne

2

two hexagon socket bolts

×

5)

(2.6

4

three claws

4

three claws

1

Remote the

battery case lid

in the direction

of arrow

A

3

A

.

two screws

(P2

×

6)

2-2. REMOTE CONTROL BOARD

1

filter

5

A

case (lower)

2

Rotate two brackets

to remove.

4

Remove the remote control boar

in the direction of arrow A.

4

two claws

3

– 21 –

wire

Page 22

2-3. CASE, INNER

4

thirty-one

switches

2

two screws

(P2 × 4)

3

jog board

1

key, rubber

Note on mounting the switches

1. Mount each switch, meeting its bosses

with respective guides.

2. Mount each switch to original position,

as its shape is different each other.

NOTE ON MOUNTING THE RUBBER FOOT

1

Pull the knob

of rubber foot.

5

cover, LCD

6

escutcheon, jog

2

7

Pull out the inner case.

After mounting, cut off

the knob of rubber foot.

– 22 –

Page 23

SECTION 3

TEST MODE

[GENERAL]

The test mode of this set consists of six test items including BATT

test, LCD test, KEY test, LEARN test, MEMORY test, and

MEMORY ERASE test and further each test item comprises several check items.

[Setting/Releasing Test Mode]

Setting the test mode:

Push the [SET] key while pushing the [MENU ] key. The “B ATT

TEST” will be displayed, when the test mode is set.

Releasing the test mode:

If the specified key is not pushed for more than 60 seconds while

the set is waiting for key input for the test item selection, or if the

test item “EXIT TEST” is selected.

[Test Item Selection]

1. Operation key

In the test mode, operate the jog dial and [SET] key.

2. Operating method

(1) Progress operation

Pushing the jog, progress the check items in order.

(2) Next test operation

• Clicking the left jog button at the check item selection causes

the “NEXT TEST” to be displayed for confirmation. (“NEXT

TEST” is displayed on LCD with “NEXT” blinking)

• Pushing the jog with the “NEXT TEST” on LCD causes the

next test item of current test to be displayed for selection.

• Clicking the right jog button with the “NEXT TEST” on LCD

causes the set to return to the check item before the “NEXT

TEST” display.

• Clicking the left jog button with the “NEXT TEST” on LCD is

ignored.

(3) Skip operation

• Clicking the right jog button while the set is waiting for key

input causes the “SKIP” to be displayed for confirmation.

(“SKIP” is blinking on the LCD)

• Pushing the jog with the “SKIP” on LCD allows the set to pro-

ceed to the next check item of current item.

• Clicking the right jog button with the “SKIP” on LCD causes

the set to return to the check item before the “SKIP” display.

• Clicking the left jog button with the “SKIP” on LCD is ignored.

The skip operation at the last check item for each item causes

the next test item to be displayed for selection.

z

3. Test item selection display list

• Test items

(1) BATT test selection display: “BATT TEST” is displayed (with

“BATT” blinking)

(2) LCD test selection display: “LCD TEST” is displayed (with

“LCD” blinking)

(3) KEY test selection display: “KEY TEST” is displayed (with

“KEY” blinking)

(4) LEARN test selection display: “LEARN TEST” is displayed

(with “LEARN” blinking)

(5) MEMOR Y test selection display: “MEMORY TEST” is dis-

played (with “MEMORY” blinking)

(6) MEMOR Y ERASE test selection display: “DEL MEMOR Y”

is displayed (with “DEL” blinking)

(7) EXIT test selection display: “EXIT TEST” is displayed (with

“EXIT” blinking)

• (1) is displayed immediately after the test mode is set.

Each time the right jog button is clicked, the display varies in

order of (1) → (2) → (3) → (4) → (5) → (6) → (7) → (1) → and

so on. Also, the display v aries in the re v er se direction when the

left jog button is clicked.

• Pushing the jog at any display causes the displayed test mode to

be activated.

• The test item selection screen will appear, if any test item finished, or the test mode was released in the next test. At this

time, the LCD will display the next test item of currently selected test item. However, any test item can be selected there

through the jog operation.

[Test Mode Items]

1. BATT test

(1) Battery voltage check:

Whether the battery voltage is below or over 2.5 V is checked.

“BATT CHECK LOW” is displayed if the battery voltage is below

2.5 V, or “BATT CHECK GOOD” is displayed if over 2.5 V The

battery voltage is checked at 0.5 second interval until the jog is

pushed, and LCD display is updated. Proceed to (2) if the jog is

pushed

(2) DC/DC stop check:

DC/DC is stopped whichever the battery voltage is below or over

2.5 V The set waits f or either key input or jog operation. When

either the key or jog is operated, DC/DC starts, and after LCD

initial setting, the BATT test is conducted, and then the “LCD

TEST” is displayed for selection.

(4) Others

If no key is pushed for more than 60 seconds while the set is waiting for the check item selection of current test item, the next test

item is displayed.

– 23 –

Page 24

2. LCD test

h

LCD display: Explanatory notes

Second

digit

First

digit

First line

Second line

Third

digit

Fourth

digit

Fifth

digit

Sixt

digit

(10) Sixth digit character, vertical one-column dots horizontal

scanning check:

The display of the fifth digit is cleared, and the similar to (5) check

is made to the 2, 3 line characters on the sixth digit. Proceed to

(11) if the jog is pushed.

(11) Backlight blinking check:

The backlight turns on for 0.5 sec when “BACK LIGHT ON” is

displayed, and it turns off for 0.5 sec when “BACK LIGHT OFF”

is displayed. This is repeated until the jog is pushed. When the jog

is pushed, the backlight turns off, the LCD test finishes, and the

“KEY TEST” is displayed for selection.

Third line

(1) Transmission mark blinking check:

Only the “

” is displayed for 0.5 sec and hidden for 0.5 sec

repeatedly. Proceed to (2) if the jog is pushed.

(2) First line, horizontal one-r ow dots vertical scanning check:

The transmission mark is cleared, and horizontal one-row dots of

2 to 5 digit characters on the first line are displayed from the top

row to the bottom row, every 0.3 sec for each row . This is repeated

until the jog is pushed. Proceed to (3) if the jog is pushed.

(3) Second line, horizontal one-row dots vertical scanning check:

The display of the first line is cleared, and the similar to (2) check

is made to the 1 to 6 digit characters on the second line. Proceed to

(4) if the jog is pushed.

(4) Third line, horizontal one-row dots vertical scanning check:

The display of the second line is cleared, and the similar to (2)

check is made to the 1 to 6 digit characters on the third line. Proceed to (5) if the jog is pushed.

(5) First digit character, vertical one-column dots horizontal

scanning check:

The display of the third line is cleared, and horizontal one-column

dots of 2, 3 digit characters on the first digit are displayed from

the left to the right, every 0.3 sec for each column. This is repeated

until the jog is pushed. Proceed to (6) if the jog is pushed.

(6) Second digit character, vertical one-column dots horizontal

scanning check:

The display of the first digit is cleared, and the similar to (5) check

is made to the 1 to 3 line characters on the second digit. Proceed to

(7) if the jog is pushed.

3. KEY test

When a key other than that specified on the LCD was pushed, or

when multiple keys were pushed, “KEY CHECK NG??” is displayed for one second, and then the LCD returns to the screen

displayed last.

1 key check:

(1)

The set waits for the input of 1 key when “push POWER key”

is displayed. When 1 key is pushed, the initially preset TV

POWER key data code is outputted from the REM (output of 3

frames), and the set proceeds to (2).

(2) t key check:

The set waits for the input of t key when “push INPUT key” is

displayed. When the t key is pushed, the set proceeds to (3).

(3) / key check:

The set waits for the input of / key when “push TEXT key” is

displayed. When the / key is pushed, the set proceeds to (4).

a key check:

(4)

The set waits for the input of a key when “push TV key” is

displayed. When the a key is pushed, the set proceeds to (5).

(5) [1] key check:

The set waits for the input of [1] key when “push 1 key” is displayed. When the [1] key is pushed, the set proceeds to (6).

(6) [2] key check:

The set waits for the input of [2] key when “push 2 key” is displayed. When the [2] key is pushed, the set proceeds to (7).

(7) [3] key check:

The set waits for the input of [3] key when “push 3 key” is displayed. When the [3] key is pushed, the set proceeds to (8).

(7) Third digit character, vertical one-column dots horizontal

scanning check:

The display of the second digit is cleared, and the similar to (5)

check is made to the 1 to 3 line characters on the third digit. Proceed to (8) if the jog is pushed.

(8) Fourth digit character, vertical one-column dots horizontal

scanning check:

The display of the third digit is cleared, and the similar to (5) check

is made to the 1 to 3 line characters on the fourth digit. Proceed to

(9) if the jog is pushed.

(9) Fifth digit character, vertical one-column dots horizontal

scanning check:

The display of the fourth digit is cleared, and the similar to (5)

check is made to the 1 to 3 line characters on the fifth digit. Proceed to (10) if the jog is pushed.

(8) [4] key check:

The set waits for the input of [4] key when “push 4 key” is displayed. When the [4] key is pushed, the set proceeds to (9).

(9) [5] key check:

The set waits for the input of [5] key when “push 5 key” is displayed. When the [5] key is pushed, the set proceeds to (10).

(10) [6] key check:

The set waits for the input of [6] key when “push 6 key” is displayed. When the [6] key is pushed, the set proceeds to (11).

(11) [7] key check:

The set waits for the input of [7] key when “push 7 key” is displayed. When the [7] key is pushed, the set proceeds to (12).

(12) [8] key check:

The set waits for the input of [8] key when “push 8 key” is displayed. When the [8] key is pushed, the set proceeds to (13).

– 24 –

Page 25

(13) [9] key check:

The set waits for the input of [9] key when “push 9 key” is displayed. When the [9] key is pushed, the set proceeds to (14).

(14) [1- -/--] key check:

The set waits for the input of [1- -/--] key when “push -/— ke y” is

displayed. When the [1- -/--] key is pushed, the set proceeds to

(15).

(15) [0] key check:

The set waits for the input of [0] key when “push 0 key” is displayed. When the [0] key is pushed, the set proceeds to (16).

(16) [2-] key check:

The set waits for the input of [2-] key when “push 2- key” is displayed. When the [2-] key is pushed, the set proceeds to (17).

x

(17) [ $RED%] key check:

The set waits for the input of [ $RED%] key when “push RED key”

is displayed. When the [ $RED%] key is pushed, the set proceeds

x

x

to (18).

x

(18) [ $GREEN%] key check:

The set waits for the input of [ $GREEN%] key when “push GREEN

key” is displayed. When the [ $GREEN%] key is pushed, the set

x

x

proceeds to (19).

x

(19) [ $YELLOW%] key check:

The set waits for the input of [ $YELLOW%] key when “push

YELLOW key” is displayed. When the [ $YELLOW%] key is

x

x

pushed, the set proceeds to (20).

x

[ $BLUE%] key check:

(20)

The set waits for the input of [ $BLUE%] k ey when “push BLUE

key” is displayed. When the [ $BLUE%] key is pushed, the set

x

x

proceeds to (21).

(21) N v key check:

The set waits for the input of N v key when “push UP key” is

displayed. When the N v key is pushed , the set proceeds to (22).

(22) m b key check:

The set waits for the input of m b key when “push ← key” is

displayed. When the m b key is pushed, the set proceeds to

(23).

(23) M B key check:

The set waits for the input of M B key when “push → key” is

displayed. When the M B key is pushed, the set proceeds to

(24).

(24) x V key check:

The set waits for the input of x V key when “push DOWN key”

is displayed. When the x V key is pushed, the set proceeds to

(25).

(25) [MENU ] key check:

The set waits for the input of [MENU ] key when “push MENU

key” is displayed. When the [MENU ] key is pushed, the set

z

z

z

proceeds to (26).

(26) [OK ] key check:

The set waits for the input of [OK ] key when “push OK key” is

displayed. When the [OK ] key is pushed, the set proceeds to

X

X

X

(27).

2

(27)

[ +] key check:

The set waits for the input of [ +] key when “push VOL + key”

is displayed. When the [ +] key is pushed, the set proceeds to

2

2

(28).

2

(28) [ --] key check:

The set waits for the input of [ --] key when “push VOL - key”

is displayed. When the [ --] key is pushed, the set proceeds to

2

2

(29).

(29) % key check:

The set waits for the input of % key when “push MUTE key” is

displayed. When the % key is pushed, the set proceeds to (30).

(30) [PROGR +] key check:

The set waits for the input of [PROGR +] key when “push CH +

key” is displayed. When the [PROGR +] key is pushed, the set

proceeds to (31).

(31) [PROGR --] key check:

The set waits for the input of [PROGR --] key when “push CH -

key” is displayed. When the [PROGR --] key is pushed, the set

proceeds to (32).

(32)

key check:

The set waits for the input of key when “push RECALL key” is

displayed. When the

key is pushed, the set proceeds to (33).

(33) Jog right check:

The set waits for the jog right turn when “turn RIGHT JOG” is

displayed. When the jog is turned to the right, the set proceeds to

(34). (In this item, “SKIP” is disabled)

(34) Jog left check:

The set waits for the jog left turn when “turn LEFT JOG” is displayed. When the jog is turned to the left, the Key test f inishes and

the “LEARN TEST” is displayed for selection. (In this item,

“NEXT TEST” is disabled)

4. LEARN test

The learn function is tested. Infrared data are sent from other remote commander to the photodetector for the learn function to

test if the learn function operates normally, and the learned data

are outputted through infrared when the jog is pushed. Check if

the learning data are identical to the infrared output data using an

external device. (For the test, use the exclusi v e checker in the f actory, and the product in the field)

(1) Infrared input check:

The set waits for the input of infrared data (PDT) when “input

LEARN” is displayed on the LCD. If infrared data input is abnormal, “NG input LEARN” is displayed on the LCD. “input

LEARN”is again displayed when the jog is pushed. If infrared

data input is normal, “GOOD input LEARN” is displayed on the

LCD. The set proceeds to (2) when the jog is pushed.

(2) Learned data output check:

The learned data are outputted by the amount of 3 frames from the

REM. Then, the Learn test finished, and the set proceeds to the

MEMORY test.

– 25 –

Page 26

5. MEMORY test

• For the EEPROM, the memory occupation display, writing error history display, error test, and data erasing are carried out.

• For the writing error history display, whether the data writing

error occurred since the EEPROM was erased last is displayed.

• For the error test, the data are written to all areas, and then

whether all data are correct is checked and the result is displayed.

• After the error test finished, the data in all areas of EEPROM

are erased and all settings are initialized.

(1) EEPROM memory occupation display

How many percents of all memory areas are occupied with the

learned data is displayed in steps of 10%. When no data is stored,

0% is displayed, or otherwise, the unit place is rounded up. The

set proceeds to (2) when the jog is pushed.

(2) EEPROM writing error history display

In actual, each time the writing error occurred in the EEPROM,

the error flag turns on. “MISSED MEMORY” is displayed on the

LCD if the error flag is present, or “NO MISSED MEMORY” is

displayed if not present. The set proceeds to (3) when the jog is

pushed.

(3) EEPROM error test

(a) Memory writing confirmation display

“WRITE MEMORY” and “push SETkey MEMORY”

are alternately displayed on the LCD every second. T he

set proceeds to (b) if the SET key is pushed.

(b) Memory data writing (-1)

The lower 8-bit values of the memory addresses are

written to all areas.

If an error occurred during data writing, the set goes to

(g) with the error flag turned on, or if no error occurs,

the set proceeds to (c).

(g) Memory check result display

“TEST GOOD MEMORY” is displa yed on the LCD if

the error flag is not present, or “TEST ERROR

MEMORY” is displayed if the error flag is present. Push

the jog, and the MEMORY test finishes and the

“MEMORY ERASE” is displayed f or selection.

6. MEMORY ERASE

(1) Memory erasing

(a) Memory erasing confirmation display

“DELETE MEMORY” and “push SETk e y MEMORY”

are alternately displayed on the LCD every second. The

set proceeds to (b) if the SET key is pushed.

(b) All bytes in the EEPROM are erased to return all set-

tings to initial state.

During this operation if an error occurred, the set goes

to (c) with the error flag turned on, or if no error occurs,

the set proceeds to (c) with the error flag not turned on.

For the LCD display of (a) and (b), see below.

DEL

MEMORY

(c) Memory erasing result display

“DEL GOOD MEMORY” is displayed on the LCD if

the error flag is not present, or “DEL NG MEMORY” is

displayed if the error flag is present. Push the jog, and

the MEMORY ERASE test finishes and the test items

are displayed for selection.

DEL

MEMORY

(c) Memory data check (-1)

All bytes are read for checking.

If an error occurred during data check, the set goes to

(g) with the error flag turned on, or if no error occurs,

the set proceeds to (d).

(d) Memory data writing (-2)

The inverted lo wer 8-bit values of the memory addresses

are written to all areas.

If an error occurred during data writing, the set goes to

(g) with the error flag turned on, or if no error occurs,

the set proceeds to (e).

(e) Memory data check (-2)

All bytes are read for checking. If an error occurred during data check, the set goes to (g) with the error flag

turned on, or if no error occurs, the set proceeds to (f).

(f) Memory erasing

All bytes are erased to return all settings to initial state.

If an error occurred, the set goes to (g) with the error

flag turned on, or if no error occurs, the set proceeds to

(g).

For the LCD display of (b) to (f), see below.

TTES

TTES

MEMORY

MEMORY

– 26 –

Page 27

4-1. BLOCK DIAGRAM

RM-VZ950T

SECTION 4

DIAGRAMS

D1

REMOTE CONTROL

SIGNAL RECEIVER

BUFFER,

WAVEFORM

SHAPING

IC4

SW1

FUNCTION

D3, 4

REMOTE CONTROL

SIGNAL TRANSMITTER

CHARACTOR

GENERATOR

CIRCUIT

CURSOR BLINK

CONTROL CIRCUIT

DISPLAY

DATA RAM

TIMING

GENERATOR

PARALLEL/

SERIAL

CONVERTER

CIRCUIT

V5

30 32 37

SHIFT

REGISTER

& LATCH

CIRCUIT

SHIFT

REGISTER

CIRCUIT

V5OUT

BOOSTER

CIRCUIT

SEGMENT

DRIVER

COMMON

DRIVER

S1 – S15,

S21 – S25, S41 – S50

C1 – C7,

C9 – C15, C17 – C23

CMK1

VCI

1 – 8, 59 – 73,

79 – 83, 99, 100

11 – 17,

19 – 25, 51 – 57

26

LCD1

LIQUID

CRYSTAL

DISPLAY

43 – 50

40

41

42

LED DRIVE

Q1

DB0 – DB7

RS

R/W

E

RESET

BUFFER

RESET

CIRCUIT

BUSY

FLAG

IN/OUT

DATA

REGISTER

LIQUID CRYSTAL

DISPLAY DRIVER

IC2

ADDRESS

COUNTER

INSTRUCTION

REGISTER

& DECODER

44

61

PDT

27

PCNT

63

JDT1

64

JDT2

65

JDT3

58

JST

REM

DB0 – DB7

76 – 80, 1 – 3

8

RS

9

RW

10

E

6 39

LRST

Ref No.

S11

S12

S13

S14

S15

S16

S17

S21

S22

S23

S25

S26

S27

S31

S32

S33

S34

PANEL DESIGNATION

1

3

9

x (BLUE)

M B

PROGR –

a

6

2 –

OK X

PROGR +

SET

/

2

8

x (YELLOW)

Ref No.

S35

S41

S42

S43

S44

S45

S46

S52

S53

S55

S56

S57

S62

S63

S64

S65

KEY MATRIX

S11 – 17, S21 – 23,

S25 – 27, S31 – 35,

S41 – 46, S52, S53,

S55 – 57, S62 – 65

PANEL DESIGNATION

N v

t

5

0

x (GREEN)

x V

2 +

4

1 – -/-MENU z

2 –

%

1

7

x (RED)

m b

19 – 2552 – 57

KDT1 – KDT7KST1 – KST7

SYSTEM

CONTROLLER

IC1

X2

69

–5V

REGULATOR

IC8

SDA

16 5

18

SCL

36 – 39

BL1 – BL4

5

LPOW

60

RESET

31

CE

66

VDET

X1

70

SDA

6

SCL

EEPROM

IC3

D5 – 8

(LCD BACK LIGHT)

SYSTEM CONTROLLER (IC1),

EEPROM (IC3), LED B+

LCD B+

LIQUID CRYSTAL DISPLAY

DRIVER (IC2) B+

B+ SWITCH

Q2

RESET SIGNAL

GENERATOR

IC7

DC/DC

CONVERTER

IC5

VOLTAGE

DETECT

IC6

LCD B+

DRY BATTERY

SIZE “AA”

(IEC DESIGNATION R6)

2PCS. 3V

05

X1

5MHz

– 27 – – 28 –

Page 28

RM-VZ950T

(

)

V

4-2. PRINTED WIRING BOARDS

123 4 5 6 7 8 9 10 11 12 13 14

D5-8

• Semiconductor Location

Ref. No. Location

D1 F-2

D2 F-11

D3 G-1

D4 F-1

D5 C-8

D6 C-7

D7 C-8

D8 C-7

IC1 F-4

Ref. No. Location

IC2 G-8

IC3 F-3

IC4 G-3

IC5 F-12

IC6 G-4

IC7 G-4

IC8 E-9

Q1 E-2

Q2 E-6

Note on Printed Wiring Boards:

• Y : parts extracted from the conductor side.

z

•

•

: Through hole.

f

: internal component.

• : Pattern from the side which enables seeing.

• : Carbon pattern.

(The other layers' patterns are not indicated.)

Caution:

Pattern face side: Parts on the pattern face side seen from

(Conductor Side) the pattern face are indicated.

Parts face side: Parts on the par ts face side seen from

(Component Side) the parts face are indicated.

DRY BATTERY

SIZE “AA”

IEC DESIGNATION R6

2PCS. 3

– 29 –

– 30 –

Page 29

4-3. SCHEMATIC DIAGRAM • See page 33 for Waveforms. • See page 34 for IC Block Diagrams.

RM-VZ950T

Note on Schematic Diagram:

• All capacitors are in µF unless otherwise noted. pF: µµF

50 WV or less are not indicated except for electrolytics

and tantalums.

• All resistors are in Ω and 1/

specified.

4

W or less unless otherwise

– 31 – – 32 –

,

WAVEFORM

SHAPING

f

•

: internal component.

• C : panel designation.

• U : B+ Line.

• V : B– Line.

• Power voltage is dc 3 V and fed with regulated dc power

supply from battery terminal.

• Voltages and waveforms are dc with respect to ground

under no-signal conditions.

• Voltages are taken with a VOM (Input impedance 10 MΩ).

Voltage variations may be noted due to normal production tolerances.

• Waveforms are taken with a oscilloscope.

Voltage variations may be noted due to normal production tolerances.

• Circled numbers refer to waveforms.

Page 30

• Waveforms

2

098765432

098765432

098

– REMOTE CONTROL Board –

1 IC1 yl (X2)

1V/DIV, 50 ns/DIV

200 ns

2 IC5 4 (LX)

1V/DIV, 5 µs/DIV

3.9 Vp-p

4.6 Vp-p

11.4

µ

s

– 33 –

Page 31

• IC Block Diagrams

8

IC2 NJU6424FG1-T

1

SEG43

SEG44

2

SEG45

3

SEG46

4

SEG47

5

SEG48

6

SEG49

7

SEG50

8

9

COMMK2

10

COM24

11

COM23

COM22

12

COM21

13

COM20

14

COM19

15

COM18

16

COM17

17

COM8

18

COM7

19

COM6

20

COM5

21

COM4

22

COM3

23

COM2

24

COM1

25

SEGMENT

SIGNAL

DRIVER

COMMON

SIGNAL

DRIVER

BIAS

CIRCUIT

SEG42SEG41

SEG40SEG39SEG38SEG37SEG36SEG35SEG34SEG33SEG32SEG31

100 99 98 97 96 95 94 93 92 91 90 89 88 87 86 85 84 83 82 81 80 79 78 77 76

50BIT

SHIFT

REGISTER

50BIT

LATCH

CIRCUIT

26BIT

SHIFT

REGISTER

TIMING

GENERATOR

CIRCUIT

CR OSCILLATOR

CIRCUIT

PARALLEL/SERIAL

CONVERTER

CIRCUIT

CURSOR

BLINK

CONTROL

CIRCUIT

ADDRESS

COUNTER

SEG30SEG29SEG28SEG27SEG26SEG25SEG24SEG23SEG22SEG21

CHARACTOR

GENERATOR

BOOSTER

CIRCUIT

9600BIT

DISPLAY DATA RAM

CHARACTOR

GENERATOR

30 X 8BITS

INSTRUCTION

DECODER

32 X 5BIT

RESET

CIRCUIT

INSTRUCTION

REGISTER

SEG20SEG19SEG1

DATA

REGISTER

IN/OUT BUFFER

BUSY

FLAG

75

SEG17

74

SEG16

73

SEG15

72

SEG14

71

SEG13

70

SEG12

69

SEG11

SEG10

68

SEG9

67

SEG8

66

SEG7

65

SEG6

64

SEG5

63

SEG4

62

SEG3

61

SEG2

60

SEG1

59

58

COM16

57

COM15

56

COM14

COM13

55

COM12

54

COM11

53

COM10

52

COM9

51

26

27

OMMK1

IC5 XC6372C361PR-T

SLOW

START

REFERENCE

VDD

VOLTAGE

CHIP

ENABLE

COMPARATOR

–

+

VOUT

1

NC

2

CE

3

BIAS

PHASE

28

OSC2

LIMITER

PWM/PFM

CONTROL

OSC 100kHz

29

30 31 3833 3432 35 36 37

V5

OSC1

VLX

VSS

BUFFER

V5OUT

39 40 41 42 43 44 45 46 47 48 49 50

C2–

C2+

VCI

C1–

C1+

VDD

RESET

VSS

5

LX

4

E

RS

R/W

DB0

DB1

DB2

DB3

DB4

DB5

DB6

DB7

– 34 –

Page 32

4-4. IC PIN FUNCTION DESCRIPTION

• MAIN BOARD IC1 µPD780058GK-A04-9EU (SYSTEM CONTROLLER)

Pin No. Pin Name I/O Description

1 to 3 DB5 to DB7 I/O

4 AVSS —

5 LPOW O

6 LRST O

7 AVREF1 I

8RSO

9RWO

10 E O

11 to 15 P20 to P24 —

16 SDA I/O

17 P26 —

18 SCL O

19 to 25 KDT1 to KDT7 I

26 P47 —

27 PCNT O

28 IPOW O

29, 30 P52, P53 —

31 CE O

32 P55 —

33 VSS1 —

34, 35 P56, P57 —

36 to 39 BL1 to BL4 —

40 to 43 P64 to P67 —

44 REM O

45 to 51 P31 to P37 —

52 to 57 KST1 to KST6 O

58 JST O

59 P127 —

60 RESET I

61 PDT I

62 P01 —

63 JDT1 I

64 JDT2 I

65 JDT3 I

66 VDET I

67 VSS0 —

68 VDD1 —

69 X2 O

70 X1 I

71 IC —

72 XT2 O

73 XT1 I

74 VDD0 —

75 AVREF0 I

76 to 80 DB0 to DB4 I/O

Two-way data bus with the liquid crystal display driver (IC2)

Ground terminal (for A/D converter)

Power on/off control signal output for the liquid crystal display driver (IC2) “L”: power on

Reset signal output to the liquid crystal display driver (IC2) “L”: reset

Reference voltage input terminal (for A/D converter)

Register selection signal output to the liquid crystal display driver (IC2)

Data read/write selection signal output to the liquid crystal display driver (IC2)

“L”: data write, “H”: data read

Data enable signal output to the liquid crystal display driver (IC2)

Not used (open)

Two-way data bus with the EEPROM (IC3)

Not used (open)

Serial data transfer clock signal output to the EEPROM (IC2)

Key data input from the key matrix “L” input when key pressing

Not used (open)

Learning control signal output to the TC4069 (IC4)

Not used (open)

Not used (open)

Power on/off control signal output supply to the DC/DC converter (IC5) “H”: power on

Not used (open)

Ground terminal

Not used (open)

LED drive signal output of the liquid crystal display back light (D5 to D8) “L”: LED on

Not used (open)

LED drive signal output of the remote control signal transmitter (D3, D4) “H”: LED on

Not used (open)

Key scan output to the key matrix “L” output when key waiting

Jog scan output to the rotary encoder (SW1)

Not used (open)

System reset signal input from the reset signal generator (IC7) “L”: reset

For several hundreds msec. after the power supply rises, “L” is input, then it changes to “H”

Learning data input from the TC4069 (IC4)

Not used (open)

Jog dial pulse input of the rotary encoder (SW1) (A phase input)

Jog dial pulse input of the rotary encoder (SW1) (B phase input)

Push switch input of the rotary encoder (SW1)

Voltage detection signal input terminal

Ground terminal

Power supply terminal (+3.6V)

Main system clock output terminal (5 MHz)

Main system clock input terminal (5 MHz)

Internal connection terminal (connected to ground)

Sub system clock output terminal Not used (open)

Sub system clock input terminal Not used (open)

Power supply terminal (+3.6V)

Reference voltage input terminal (for A/D converter)

Two-way data bus with the liquid crystal display driver (IC2)

– 35 –

Page 33

SECTION 5

EXPLODED VIEW

NOTE:

• -XX and -X mean standardized parts, so they

may have some difference from the original

one.

• Color Indication of Appearance Parts

Example:

KNOB, BALANCE (WHITE) . . . (RED)

↑↑

Parts Color Cabinet's Color

9

8

7

not

supplied

5

5

• Items marked “*” are not stocked since they

are seldom required for routine service. Some

delay should be anticipated when ordering

these items.

• The mechanical parts with no reference number in the exploded views are not supplied.

• Accessories and packing materials are given

in the last of the electrical parts list.

10

not

supplied

6

11

12

#3

21

13

not

supplied

4

#2

3

#1

2

1

Ref. No. Part No. Description Remark

1 3-220-687-01 FOOT, RUBBER

2 3-220-680-01 LID, BATTERY CASE

3 3-220-683-01 CASE (LOWER)

4 3-220-686-01 TERMINAL (C), BATTERY

* 5 3-220-677-01 EDGE, SIDE

6 3-220-679-01 BUTTON (B)

7 3-220-681-01 CASE (TOP)

* 8 3-220-672-01 ESCUTCHEON, JOG

9 3-220-691-01 PANEL, LCD

10 3-220-692-01 COVER, LCD

19

1

not

supplied

LCD1

14

20

15

18

16

17

Ref. No. Part No. Description Remark

14 3-220-689-01 TERMINAL, ZEBRA

* 15 1-679-852-11 REMOTE CONTROL BOARD

16 9-885-008-54 WIRE

17 3-220-684-01 TERMINAL (A), BATTERY

18 3-220-685-01 TERMINAL (B), BATTERY

19 3-220-676-01 FILTER

* 20 3-220-674-01 DOOM, POLY

21 3-220-678-01 BUTTON (A)

LCD1 9-885-008-47 DISPLAY PANEL, LIQUID CRYSTAL

#1 7-685-104-14 SCREW +P 2X6 TYPE2 NON-SLIT

* 11 3-220-682-01 CASE, INNER

12 A-4541-208-A JOG BOARD, COMPLETE

* 13 3-220-675-01 KEY, RUBBER

#2 7-621-996-05 BOLT, HEXAGON SOCKET 2.6X5

#3 7-685-102-19 SCREW +P 2X4 NON-SLIT TYPE 2

– 36 –

Page 34

SECTION 6

ELECTRICAL PARTS LIST

JOG

REMOTE CONTROL

NOTE:

• Due to standardization, replacements in the

parts list may be different from the parts specified in the diagrams or the components used

on the set.

• -XX and -X mean standardized parts, so they

may have some difference from the original

one.

• RESISTORS

All resistors are in ohms.

METAL: Metal-film resistor.

METAL OXIDE: Metal oxide-film resistor.

F: nonflammable

Ref. No. Part No. Description Remark Ref. No. Part No. Description Remark

A-4541-208-A JOG BOARD, COMPLETE

********************

< CONNECTOR >

CN2 9-885-008-53 CONNECTOR 5P

< JOG ENCODER >

SW1 1-473-406-11 ENCODER, ED JOG (FUNCTION)

**************************************************************

* 1-679-852-11 REMOTE CONTROL BOARD

**********************

3-220-684-01 TERMINAL (A), BATTERY

3-220-685-01 TERMINAL (B), BATTERY

3-220-689-01 TERMIAL, ZEBRA

< CAPACITOR >

C1 1-126-607-21 ELECT CHIP 47uF 20% 4V

C2 1-126-204-21 ELECT CHIP 47uF 20% 16V

C3 1-128-008-21 ELECT CHIP 3.3uF 20% 35V

C4 1-128-008-21 ELECT CHIP 3.3uF 20% 35V

C5 1-128-008-21 ELECT CHIP 3.3uF 20% 35V

C6 1-128-008-21 ELECT CHIP 3.3uF 20% 35V

C7 1-164-230-11 CERAMIC CHIP 220PF 5% 50V

C8 1-162-967-11 CERAMIC CHIP 0.0033uF 10% 50V

C9 1-164-361-11 CERAMIC CHIP 0.047uF 16V

C10 1-164-361-11 CERAMIC CHIP 0.047uF 16V

C11 1-164-361-11 CERAMIC CHIP 0.047uF 16V

C12 1-164-361-11 CERAMIC CHIP 0.047uF 16V

C13 1-164-361-11 CERAMIC CHIP 0.047uF 16V

C14 1-164-361-11 CERAMIC CHIP 0.047uF 16V

C15 1-164-361-11 CERAMIC CHIP 0.047uF 16V

C16 1-164-361-11 CERAMIC CHIP 0.047uF 16V

< CONNECTOR >

• Items marked “*” are not stocked since they

are seldom required for routine service.

Some delay should be anticipated when ordering these items.

• SEMICONDUCTORS

In each case, u: µ, for example:

uA. . : µA. . uPA. . : µPA. .

uPB. . : µPB. . uPC. . : µPC. .

uPD. . : µPD. .

• CAPACITORS

uF: µF

• COILS

uH: µH

D4 8-719-053-06 LED SLR-932A-7

D5 8-719-058-69 LED LNJ308G8JRA (LCD BACK LIGHT)

D6 8-719-058-69 LED LNJ308G8JRA (LCD BACK LIGHT)

D7 8-719-058-69 LED LNJ308G8JRA (LCD BACK LIGHT)

D8 8-719-058-69 LED LNJ308G8JRA (LCD BACK LIGHT)

< IC >

IC1 8-759-699-74 IC uPD780058GK-A04-9EU

IC2 9-885-008-48 IC NJU6424FG1-T

IC3 9-885-008-49 IC HN58X24256FPI-T

IC4 8-759-530-29 IC TC4069UBFT (EL, N)

IC5 9-885-008-50 IC XC6372C361PR-T

IC6 8-759-479-03 IC S-80825ANNP-EDN-T2

IC7 8-759-665-49 IC S-80818ANNP-EDF-T2

IC8 9-885-008-51 IC XC62KN5002MR-T

< COIL >

L1 1-412-032-11 INDUCTOR CHIP 100uH

< TRANSISTOR >

Q1 8-729-047-62 TRANSISTOR 2SC3440-T12-1F

Q2 9-885-008-52 TRANSISTOR 2SA1603A-T

< RESISTOR >

R1 1-218-867-11 METAL CHIP 6.8K 5% 1/16W

R2 1-216-833-11 METAL CHIP 10K 5% 1/16W

R3 1-216-833-11 METAL CHIP 10K 5% 1/16W

R4 1-216-861-11 METAL CHIP 2.2M 5% 1/16W

R5 1-218-726-11 METAL CHIP 27K 5% 1/16W

R6 1-216-840-11 METAL CHIP 39K 5% 1/16W

R7 1-216-818-11 METAL CHIP 560 5% 1/16W

R8 1-216-846-11 METAL CHIP 120K 5% 1/16W

R9 1-216-833-11 METAL CHIP 10K 5% 1/16W

R10 1-216-833-11 METAL CHIP 10K 5% 1/16W

When indicating parts by reference

number, please include the board.

(REMOTE CONTROL SIGNAL TRANSMITTER)

CN1 9-885-008-53 CONNECTOR 5P

< DIODE >

D1 9-885-008-55 DIODE TPS705 (HATA)

(REMOTE CONTROL SIGNAL RECEIVER)

D2 8-719-076-88 DIODE MA2Z720001S0

D3 1-807-851-11 LED SLR-931A

(REMOTE CONTROL SIGNAL TRANSMITTER)

R11 1-216-857-11 METAL CHIP 1M 5% 1/16W

R12 1-216-857-11 METAL CHIP 1M 5% 1/16W

R13 1-216-845-11 METAL CHIP 100K 5% 1/16W

R14 1-216-845-11 METAL CHIP 100K 5% 1/16W

R15 1-216-857-11 METAL CHIP 1M 5% 1/16W

R16 1-216-839-11 METAL CHIP 33K 5% 1/16W

R17 1-216-845-11 METAL CHIP 100K 5% 1/16W

R18 1-216-845-11 METAL CHIP 100K 5% 1/16W

– 37 –

Page 35

RM-VZ950T

REMOTE CONTROL

Ref. No. Part No. Description Remark

R19 1-216-845-11 METAL CHIP 100K 5% 1/16W

R20 1-216-845-11 METAL CHIP 100K 5% 1/16W

R21 1-216-134-91 METAL CHIP 2.2 5% 1/8W

R22 1-216-134-91 METAL CHIP 2.2 5% 1/8W

R23 1-216-811-11 METAL CHIP 150 5% 1/16W

R24 1-216-810-11 METAL CHIP 120 5% 1/16W

R25 1-216-810-11 METAL CHIP 120 5% 1/16W

R26 1-216-810-21 METAL CHIP 120 5% 1/16W

R27 1-216-810-11 METAL CHIP 120 5% 1/16W

< VIBRATOR >

X1 1-767-452-11 VIBRATOR, CERAMIC (5MHz)

**************************************************************

MISCELLANEOUS

***************

16 9-885-008-54 WIRE

LCD1 9-885-008-47 DISPLAY PANEL, LIQUID CRYSTAL

**************************************************************

ACCESSORIES & PACKING MATERIALS

********************************

3-223-637-11 MANUAL, INSTRUCTION (ENGLISH, GERMAN)

3-223-637-21 MANUAL, INSTRUCTION (FRENCH, ITALIAN)

3-223-637-31 MANUAL, INSTRUCTION (DUTCH, SWEDISH)

3-223-637-41 MANUAL, INSTRUCTION

(SPANISH, PORTUGUESE)

3-223-638-11 MANUAL, INSTRUCTION (for PRESET)

(ENGLISH, FRENCH, GERMAN, SPANISH,

DUTCH, SWEDISH, ITALIAN, PORTUGUESE)

Ref. No. Part No. Description Remark

9-927-994-11

Sony Corporation

Audio Entertainment Group

– 38 –

Printed in Japan C 2000. 8

2000H0538-1

Published by General Engineering Dept.

Loading...

Loading...