Sony RM-B750 Service Manual

REMOTE CONTROL UNIT

RM-B750

MAINTENANCE MANUAL

1st Edition (Revised 1)

Serial No. 100001 and Higher

! WARNING

This manual is intended for qualified service personnel only.

To reduce the risk of electric shock, fire or injury, do not perform any servicing other than that

contained in the operating instructions unless you are qualified to do so. Refer all servicing to

qualified service personnel.

! WARNUNG

Die Anleitung ist nur für qualifiziertes Fachpersonal bestimmt.

Alle Wartungsarbeiten dürfen nur von qualifiziertem Fachpersonal ausgeführt werden. Um die

Gefahr eines elektrischen Schlages, Feuergefahr und Verletzungen zu vermeiden, sind bei

Wartungsarbeiten strikt die Angaben in der Anleitung zu befolgen. Andere als die angegeben

Wartungsarbeiten dürfen nur von Personen ausgeführt werden, die eine spezielle Befähigung

dazu besitzen.

! AVERTISSEMENT

Ce manual est destiné uniquement aux personnes compétentes en charge de l’entretien. Afin

de réduire les risques de décharge électrique, d’incendie ou de blessure n’effectuer que les

réparations indiquées dans le mode d’emploi à moins d’être qualifié pour en effectuer d’autres.

Pour toute réparation faire appel à une personne compétente uniquement.

RM-B750

CAUTION

ADVARSEL

Danger of explosion if battery is incorrectly replaced.

Replace only with the same or equivalent type

recommended by the manufacturer.

Dispose of used batteries according to the

manufacturer’s instructions.

Vorsicht!

Explosionsgefahr bei unsachgemäßem Austausch

der Batterie.

Ersatz nur durch denselben oder einen vom

Hersteller empfohlenen ähnlichen Typ. Entsorgung

gebrauchter Batterien nach Angaben des

Herstellers.

ATTENTION

Il y a danger d’explosion s’il y a remplacement

incorrect de la batterie.

Remplacer uniquement avec une batterie du même

type ou d’un type équivalent recommandé par le

constructeur.

Mettre au rebut les batteries usagées conformément

aux instructions du fabricant.

Lithiumbatteri - Eksplosjonsfare.

Ved utskifting benyttes kun batteri som

anbefalt av apparatfabrikanten.

Brukt batteri returneres

apparatleverandøren.

VARNING

Explosionsfara vid felaktigt batteribyte.

Använd samma batterityp eller en likvärdig typ

som rekommenderas av apparattillverkaren.

Kassera använt batteri enligt gällande

föreskrifter.

VAROITUS

Paristo voi räjähtää jos se on virheellisesti

asennettu.

Vaihda paristo ainoastaan laitevalmistajan

suosittelemaan tyyppiin.

Hävitä käytetty paristo valmistajan ohjeiden

mukaisesti.

RM-B750

ADVARSEL!

Lithiumbatteri-Eksplosionsfare ved fejlagtig

håndtering.

Udskiftning må kun ske med batteri

af samme fabrikat og type.

Levér det brugte batteri tilbage til leverandøren.

1 (P)

For the customers in the Netherlands

Voor de klanten in Nederland

Hoe u de batterijen moet verwijderen, leest u in de tekst

van deze handleiding.

Gooi de batterij niet weg maar lever deze in als klein

chemisch afval (KCA).

Für Kunden in Deutschland

Entsorgungshinweis: Bitte werfen Sie nur entladene

Batterien in die Sammelboxen beim Handel oder den

Kommunen. Entladen sind Batterien in der Regel dann,

wenn das Gerät abschaltet und signalisiert “Batterie

leer” oder nach längerer Gebrauchsdauer der Batterien

“nicht mehr einwandfrei funktioniert”. Um

sicherzugehen, kleben Sie die Batteriepole z.B. mit

einem Klebestreifen ab oder geben Sie die Batterien

einzeln in einen Plastikbeutel.

2 (P)

RM-B750

Table of Contents

Manual Structure

Purpose of this manual ........................................................................................ 3 (E)

Relative manuals ................................................................................................. 3 (E)

Contents ............................................................................................................... 4 (E)

1. Service Overview

1-1. Connector Input/Output Signals ............................................................1-1 (E)

1-2. Connection Connector/Cable ................................................................ 1-1 (E)

1-3. Opening the RM-B750 ..........................................................................1-1 (E)

1-4. Board Layouts ....................................................................................... 1-2 (E)

1-5. Functions of Internal Switches .............................................................. 1-2 (E)

1-6. Flexible Card Wire ................................................................................1-3 (E)

1-6-1. Disconnecting/Connecting the Flexible Card Wire ............. 1-3 (E)

1-6-2. Shaping the Flexible Card Wire ...........................................1-4 (E)

1-7. Replacing the LCD Unit........................................................................ 1-5 (E)

1-8. Replacing the Touch Panel and Backlight ............................................ 1-7 (E)

1-9. Installing the IRIS Knob Assembly and WHITE Knob Assembly ....... 1-8 (E)

1-9-1. Installing the IRIS Knob Assembly ..................................... 1-8 (E)

1-9-2. Installing the WHITE Knob Assembly ................................ 1-9 (E)

1-10. Note on Service .....................................................................................1-9 (E)

1-10-1. Information of the Software Version ................................... 1-9 (E)

1-10-2. Description on Backup Battery ............................................ 1-9 (E)

1-10-3. Writing and Rewriting the PLD Internal Data ................... 1-10 (E)

1-10-4. Note on Replacing the FRAM ............................................ 1-11 (E)

1-10-5. Checking the Software Version ......................................... 1-11 (E)

1-10-6. Updating the Software ........................................................ 1-11 (E)

1-10-7. Touch Panel Calibration ..................................................... 1-12 (E)

1-10-8. Diagnosis ............................................................................1-13 (E)

1-10-9. Circuit Protective Elements ................................................ 1-14 (E)

1-10-10. Unleaded Solder .................................................................1-14 (E)

1-11. Recommended Replacement Parts ......................................................1-15 (E)

RM-B750

2. Electrical Alignment

2-1. Preparation ............................................................................................ 2-1 (E)

2-2. Adjusting the Video Level .................................................................... 2-2 (E)

1 (E)

3. Spare Parts

3-1. Notes on Repair Parts .................................................................................. 3-1

3-2. Exploded Views .......................................................................................... 3-2

3-3. Electrical Parts List ..................................................................................... 3-6

4. Semiconductor Pin Assignments

5. Block Diagram

Overall .................................................................................................................... 5-1

6. Schematic Diagrams

MPU-124 ................................................................................................................ 6-2

VA-211 ................................................................................................................... 6-8

VR-277 ................................................................................................................. 6-10

LED-385 ............................................................................................................... 6-13

LED-389 ............................................................................................................... 6-14

CN-2278 ............................................................................................................... 6-15

CN-2308 ............................................................................................................... 6-15

Frame Wiring........................................................................................................ 6-15

2 (E)

7. Board Layouts

MPU-124 ................................................................................................................ 7-2

VA-211 ................................................................................................................... 7-4

VR-277 ................................................................................................................... 7-5

CN-2278 ................................................................................................................. 7-6

CN-2308 ................................................................................................................. 7-6

LED-385 ................................................................................................................. 7-6

LED-389 ................................................................................................................. 7-6

RM-B750

Purpose of this manual

Relative manuals

Manual Structure

This manual is the maintenance manual for Remote Control Unit RM-B750.

This manual is intended for use by the trained system enginneers and sevice enginneers, and describes information (service overview, parts lists, schematic diagram

and board layout) on the premise of component level service.

Besides this maintenance manual the following manuals are available for this unit.

..

. Operation Manual (Supplied with this unit)

..

This manual is necessary for application and operation of this unit.

Part number: 3-620-577-XX

..

. System Manual (Available on request)

..

This manual is necessary for connection and operation of this unit and other

peripheral equipment.

If this manual is required, please contact your local Sony Sales Office/Service

Center.

..

. “Semiconductor Pin Assignments” CD-ROM (Available on request)

..

This “Semiconductor Pin Assignments” CD-ROM allows you to search for

semiconductors used in B&P Company equipment.

Semiconductors that cannot be searched for on this CD-ROM are listed in the

maintenance manual for the corresponding unit. The maintenance manual contains

a complete list of all semiconductors and their ID Nos., and thus should be used

together with the CD-ROM.

Part number: 9-968-546-XX

RM-B750

3 (E)

Contents

The following are summaries of the each section for understanding the manual.

Section 1 Service Overview

Describes information about connector input/output signals, function of internal

switches board locations, replacement of part and notes on services.

Section 2 Electrical Alignment

Describe video level adjustment procedure.

Section 3 Spare Parts

Describes parts list, exploded views and frame list used in the unit.

Section 4 Semiconductor Pin Assignments

Contains information on semiconductors used for the unit.

It includes a complete list of the semiconductors and their ID Nos. for retrieving

information on “Semiconductor Pin Assignments” CD-ROM, which is available

separately.

Please refer to this section together with the “Semiconductor Pin Assignments”

CD-ROM.

Information on the semiconductors not contained in the CD-ROM at the time of

issue of this manual, if any, is given in this section as well.

Section 5 Block Diagram

Describe overall block diagram.

Section 6 Schematic Diagrams

Describes schematic diagrams for every circuit board and frame wiring.

Section 7 Board Layouts

Describes board layouts for every circuit board.

4 (E)

RM-B750

Section 1

Service Overview

1-1. Connector Input/Output Signals

MONITOR

(BNC Type)

SDTV (NTSC/PAL) : VBS output (1.0 V p-p, 75 Z)

HDTV : Y signal output (1.0 V p-p, 75 Z)

* : This signal is output all the time.

CAMERA

(8P, FEMALE)

No. Signal Specification

1 TX (+) RM SERIAL DATA

2 TX (_)

3 RX (+) CAMERA SERIAL DATA

4 RX (_)

5 VIDEO (GND) GND for VIDEO

6 POWER (+) IN RM POWER

7 POWER (_) IN GND for POWER

8 VIDEO (X) OUT VBS 1.0 V p-p, Zo = 75 Z

C CHASSIS GND CHASSIS GND

*

1

2

7

8

6

3

4

5

(External View)

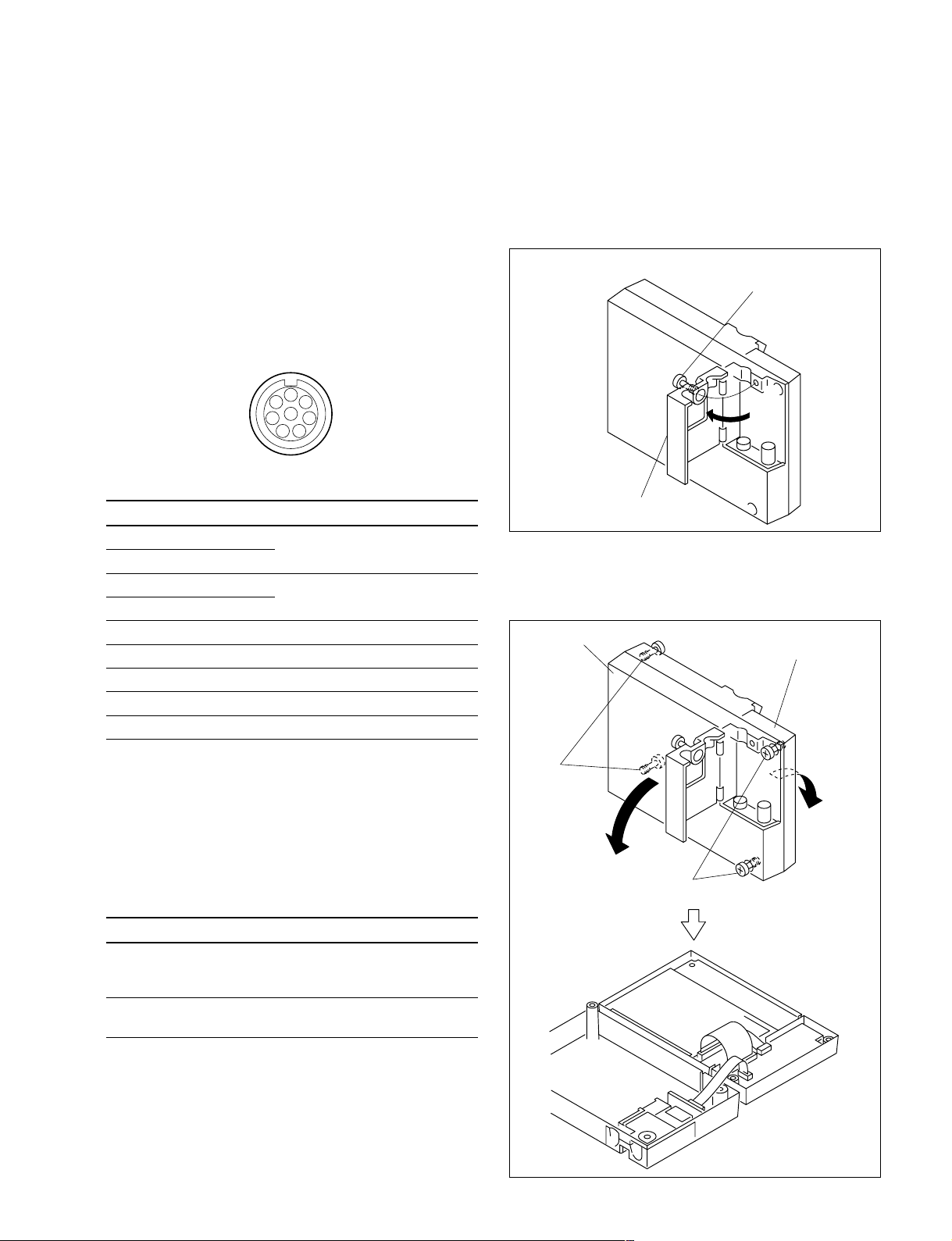

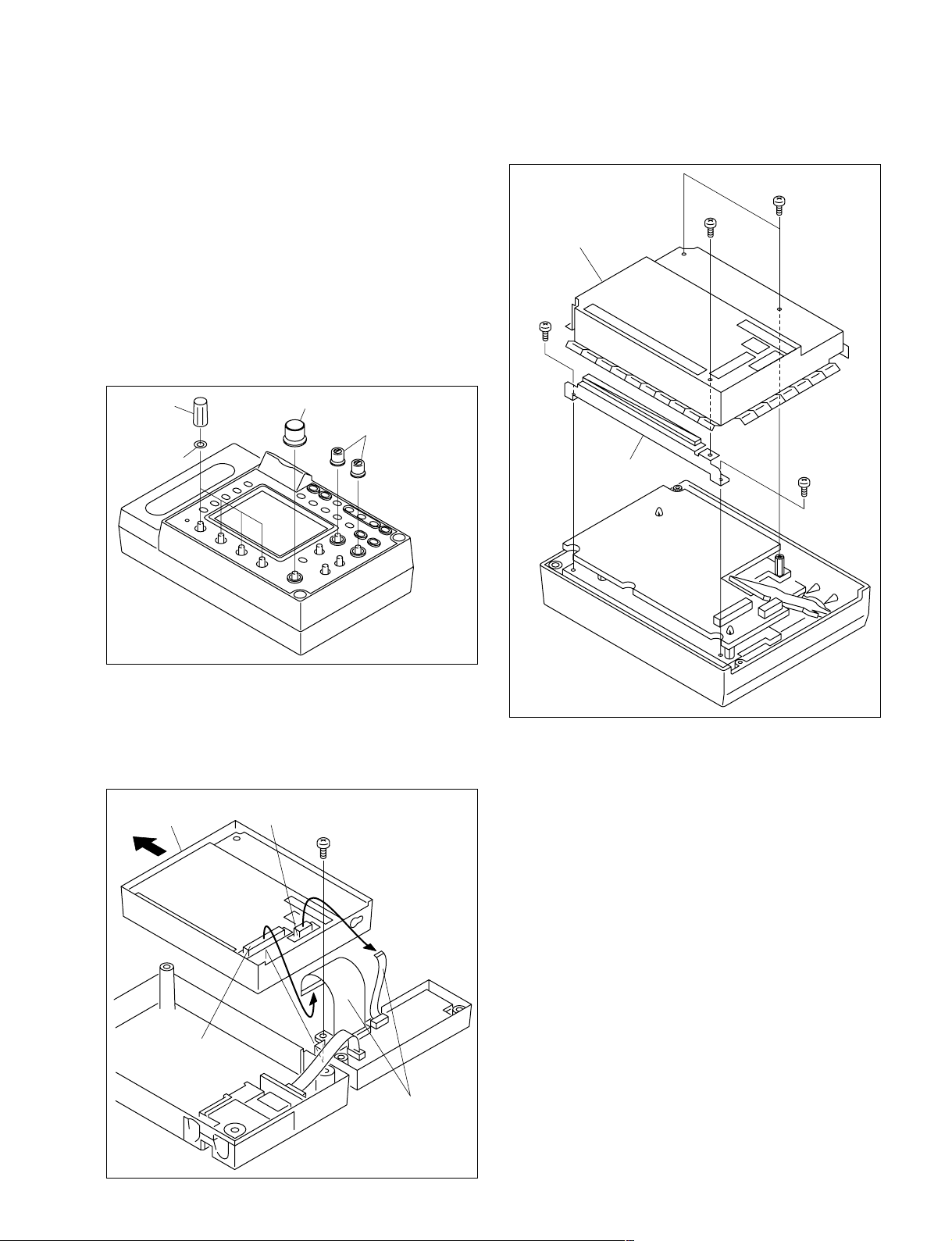

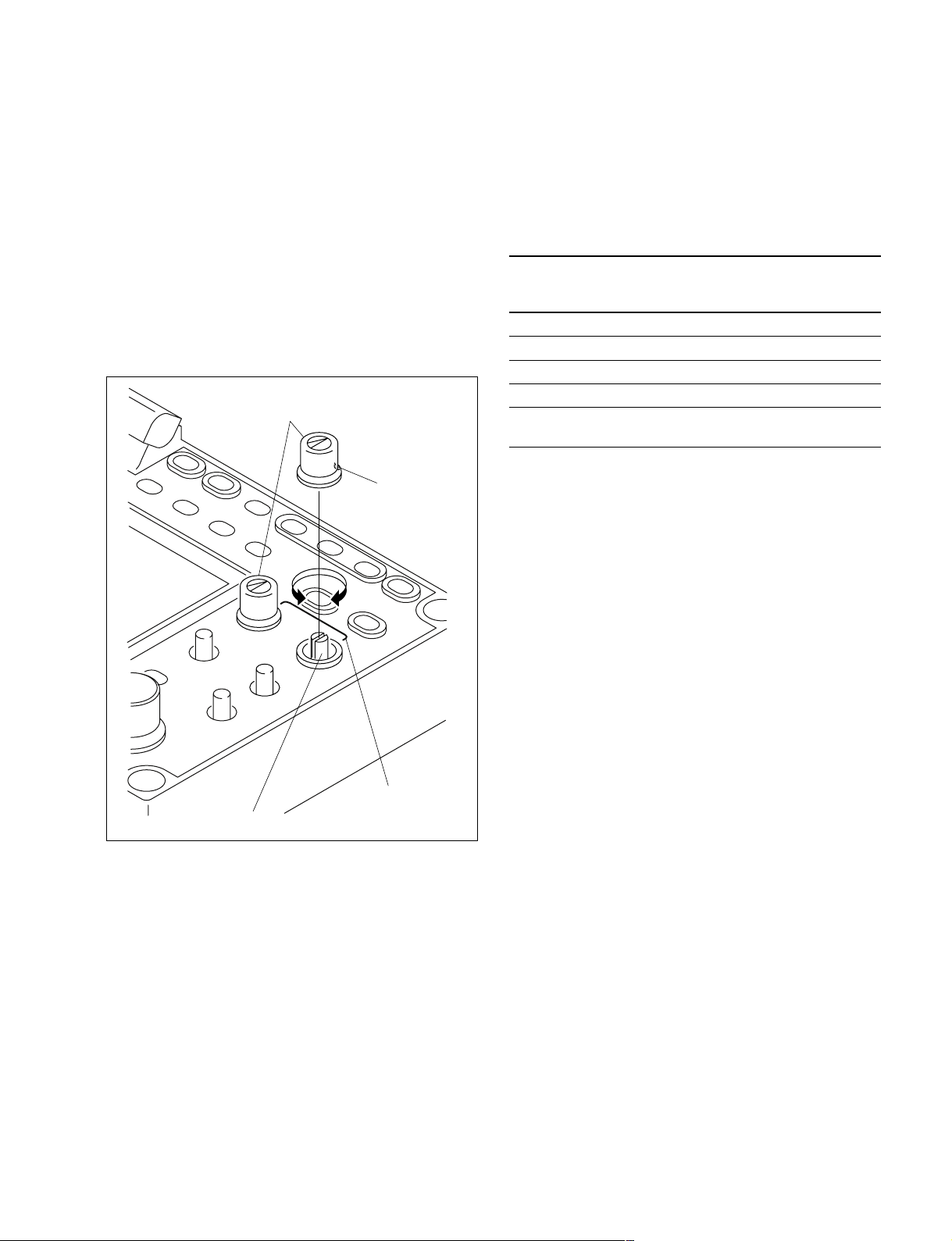

1-3. Opening the RM-B750

1. Loosen the screw (with drop-safe) and open the RM

connector cover in the direction of the arrow.

Screw

(with drop-safe)

RM connector cover

2. Loosen the four screws (with drop-safe) and open the

operation panel assembly and the bottom cover in the

direction of the arrow respectively.

Bottom cover

Operation panel assembly

1-2. Connection Connector/Cable

Connection made with the connector panels during installation or service, should be made with the connectors/

complete cable assemblies specified in the following list,

or equivalent parts.

Connector function Connection connector/Cable

CAMERA 1-706-848-11 PLUG, 8P MALE or

(8P, FEMALE) 1-783-372-11 Connection cord

(10 m) (supplied)

MONITOR 1-569-370-12 PLUG, BNC

(BNC)

RM-B750

Screws

(with drop-safe)

Screws

(with drop-safe)

1-1 (E)

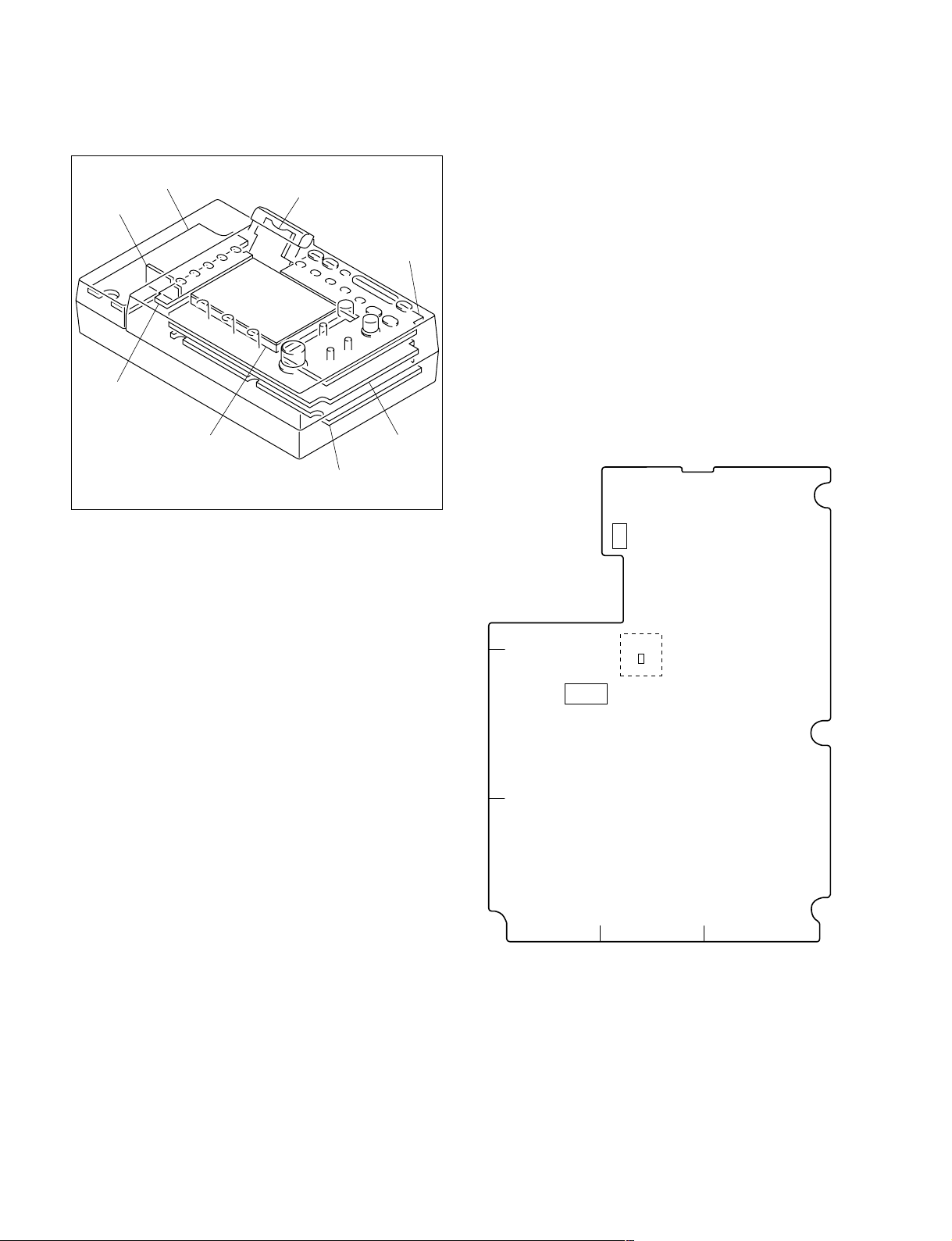

1-4. Board Layouts

1-5. Functions of Internal Switches

1-4. Board Layouts

VA-211 board

CN-2308 board

LED-389 board

LCD unit

CN-2278 board

MPU-124 board

LED-385 board

VR-277 board

1-5. Functions of Internal Switches

MPU-124 Board

. S201

This switch is not used.

Factory-setting: OFF

. S205 (BUZZER ON/OFF)

This switch selects whether the buzzer sounds (ON) or

not (OFF) when the CALL signal is input.

Factory-setting: ON

*1: S205 is not used on the MPU-124 board with suffix -21 and higher.

. S206 (CCU-PW ON/OFF)

This switch turns on/off the power to the front panel.

Factory-setting: ON

*1

C

S206

*1

S205

S201

B

A

12 3

MPU-124 board (A side)

1-2 (E)

RM-B750

Contact surface

Type B

Type C

Type D

Contact surface

Connector

Connector

Recessed portion

Recessed portion

Isolation surface (blue)

Connector

Recessed portion

Portion A

Portion A

Connector

Type A

Flexible card wire

Narrow

Contacting surface

Slot

Wide

Portion A

Portion A

Portion A

Portion A

Portion A

Portion A

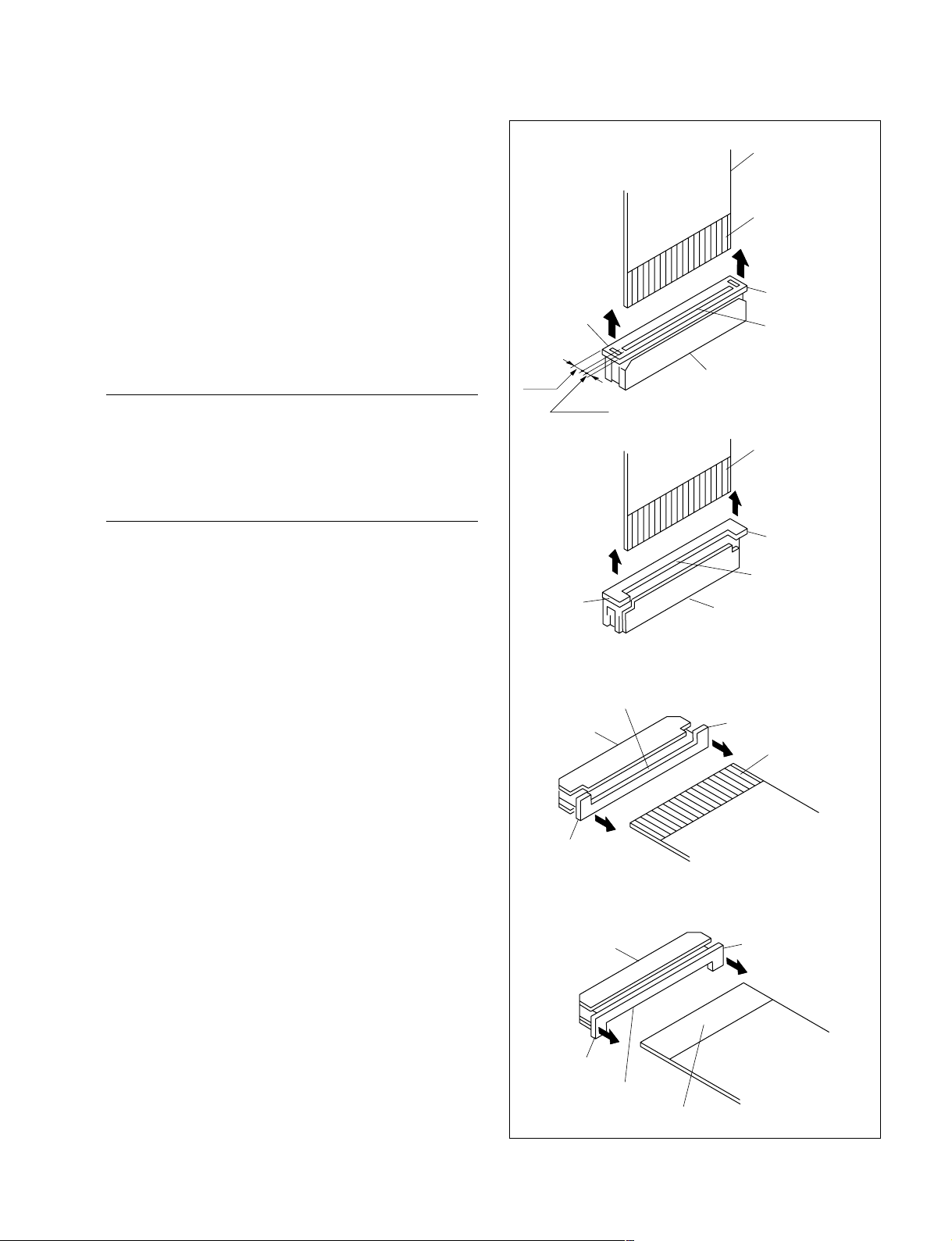

1-6. Flexible Card Wire

1-6-1. Disconnecting/Connecting the

Flexible Card Wire

Life of flexile card wire will be significantly shortened if it

is folded. Be very careful not to fold the flexible card wire.

The five types of different shape connectors are used in

this unit. (Type A to type E)

Because the direction of the flexible card wire is different

depending on the shape of the connector, be careful when

connecting the flexible card wire.

1-6. Flexible Card Wire

Disconnecting (Type A to D)

1. Turn off the power.

2. Slide the portion A in the direction of the arrow to

unlock and pull out the flexible card wire.

Connecting (Type A to D)

m

. Do not insert the flexible card wire sideways.

. Confirm that there is no stain or dust on the contact

surface of the flexible card wire.

1. Slide the portion A in the direction of the arrow and

securely insert the flexible card wire into the deep end

of the connector.

2. Return the portion A to its original position and lock

the connector.

n

When connecting the flexible card wire, check the connector shape, and great care should be taken for the direction

of the contact surface or isolation surface (blue).

(Refer to illustration of the type A to type D.)

RM-B750

1-3 (E)

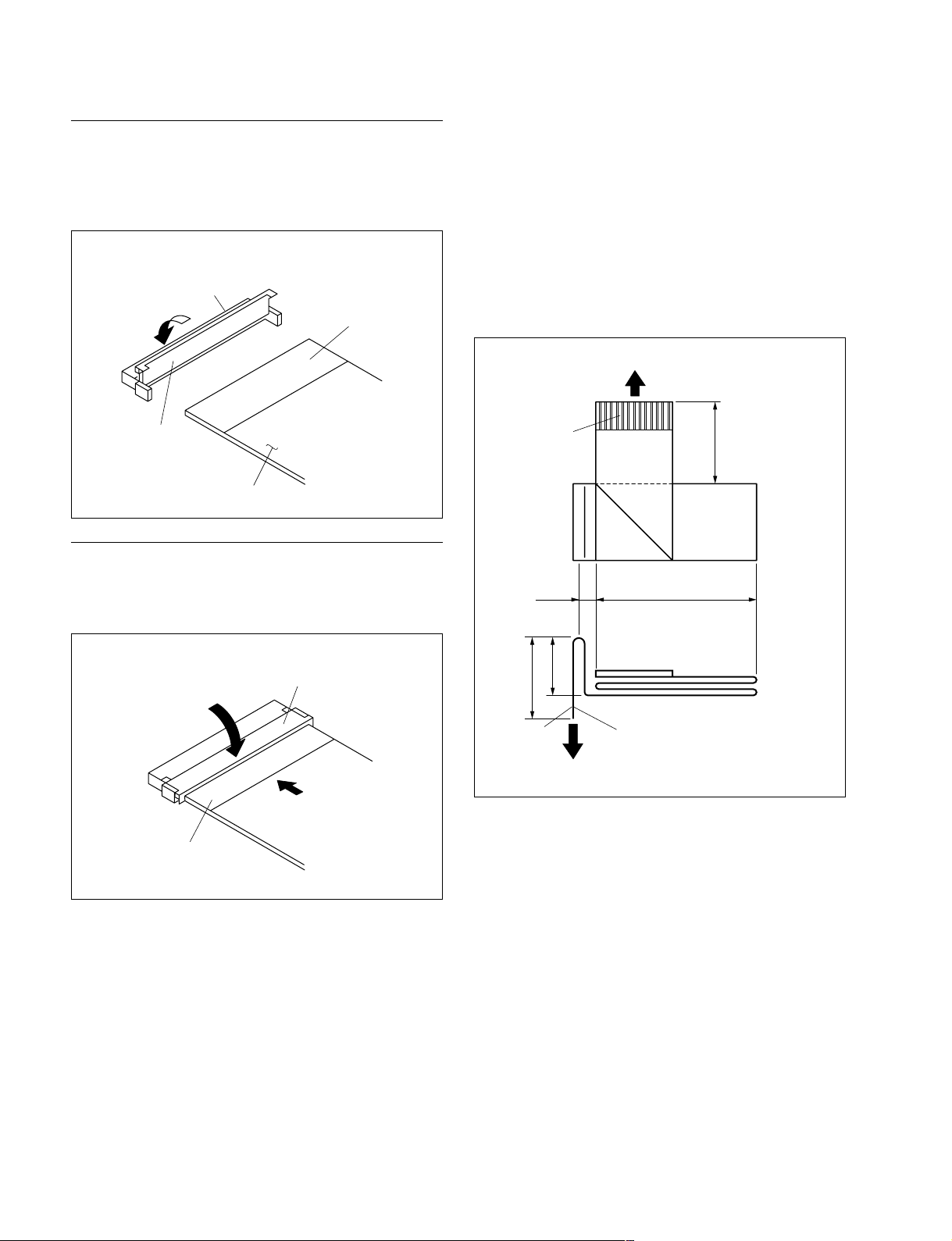

1-6. Flexible Card Wire

Disconnecting (Type E)

1. Turn off the power.

2. Open the portion A in the direction of the arrow and

pull out the flexible card wire.

Type E

Connector

Portion A

Flexible card wire

Isolation surface

(blue)

Connecting (Type E)

1-6-2. Shaping the Flexible Card Wire

When a new flexible card wire reaches as a service part,

carefully fold it referring to the illustration before installation into connector.

n

Never re-stretch the flexible card wire that has been folded

once, to the original shape.

Between CN-2278 board CN2 5 VR-277 board CN2

VR-277 board (CN2) side

Contacting

surface

11 mm

View from

the top

Insert the flexible card wire with the isolation surface

(blue) facing up and close the portion A.

Type E

Portion A

Isolation surface

(blue)

3 mm

7 mm

11 mm

Contacting

surface

CN-2278 board (CN2) side

Insulated surface (blue)

About 28 mm

View from

the side

1-4 (E)

RM-B750

1-7. Replacing the LCD Unit

1-7. Replacing the LCD Unit

n

Life of flexible card wire will be significantly shortened if it

is folded. Be very careful not to fold the flexible card wire.

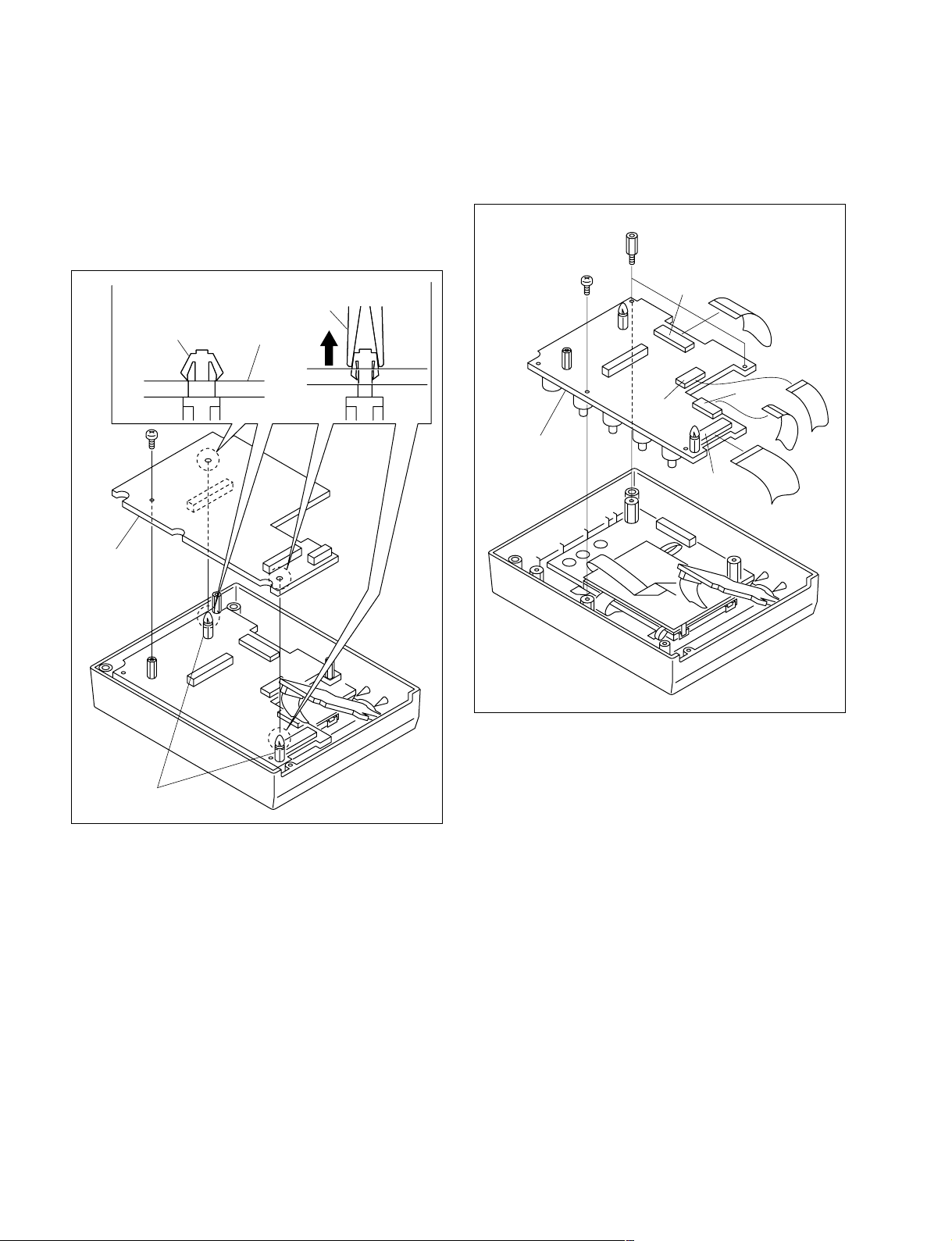

1. Remove the four RE knobs.

n

Poly-washer is installed under the RE knob. Be careful

not to lose the poly-washer.

2. Remove the IRIS knob assembly.

3. Remove the WHITE knob assembly.

RE knob

Washer

IRIS control assembly

WHITE knob assemblies

7. Remove the three screws and the RM shield assembly.

8. Remove the two screws and the PWB (BKP) stopper.

B2.6 x 5

B2.6 x 5

RM shield assembly

B2.6 x 5

PWB

(BKP) stopper

B2.6 x 5

4. Open the RM-B750. (Refer to Section 1-3.)

5. Remove the connectors (CN104, CN201) from the

MPU-124 board.

6. Remove the screws and the operation panel assembly

in the direction of the arrow.

Operation

panel assembly

MPU-124 board

(CN104)

MPU-124 board

(CN201)

B3 x 5

Flexible card wires

RM-B750

1-5 (E)

1-7. Replacing the LCD Unit

9. Remove the screw.

10. Hold the two PWB holders using a long nose pliers as

shown in Fig. and remove the MPU-124 board by

holding it up.

n

Be careful not to damage the printed foil pattern of the

MPU-124 board with the tip of a long nose plier.

Fig.1

PWB holder

B2.6 x 5

MPU-124

board

Long nose pliers

MPU-124 board

11. Disconnect the connectors (CN2, CN3, CN4, CN6)

from the VR-277 board.

12. Remove the two screws and hexagonal supports, and

remove the VR-277 board.

Hexagon supports

B2.6 x 5

CN3

CN6

VR-277 board

CN2

CN4

1-6 (E)

PWB holders

RM-B750

1-8. Replacing the Touch Panel and Backlight

1-7. Replacing the LCD Unit

13. Remove the two screws and the CN-2278 board.

14. Remove the screws (B2.6 x 5 : 3 pcs, PS2.6 x 5 : 1

pc) and the LCD unit.

15. Install the new LCD unit by reversing the steps of

removal.

n

The new LCD unit is supplied with the protection

sheet attached to the touch panel. Peel off the protection sheet before installation.

LCD unit

B2.6 x 5

PS2.6 x 5

CN-2278 board

B2.6 x 5

1-8. Replacing the Touch Panel and

Backlight

1. Remove the LCD unit. (Refer to Section 1-7.)

2. Disconnect the connectors (CN2, CN3, CN5, CN6)

from the LCD unit board.

n

Life of flexible card wire will be significantly shortened if it is folded. Be very careful not to fold the

flexible card wire.

CN6

CN3

CN2

CN5

LCD unit board

Protection

sheet

Touch panel of LCD unit

16. Install the four RE knobs, the IRIS control knob

assembly and the two WHITE knob assemblies.

n

When installing the IRIS control knob assembly and

the WHITE knob assemblies, refer to Section 1-9.

RM-B750

1-7 (E)

1-8. Replacing the Touch Panel and Backlight

1-9. Installing the IRIS Knob Assembly and WHITE Knob Assembly

3. Remove the four screws, the touch panel and the

backlight.

4. Install the new touch panel or the new backlight in the

LCD unit board.

n

The new touch panel is supplied with the protection

sheet attached. Peel off the protection sheet before

installation.

Precision

P1.7 x 2.5

LCD unit board

Precision

P1.7 x 2.5

Precision

P1.7 x 2.5

Back light

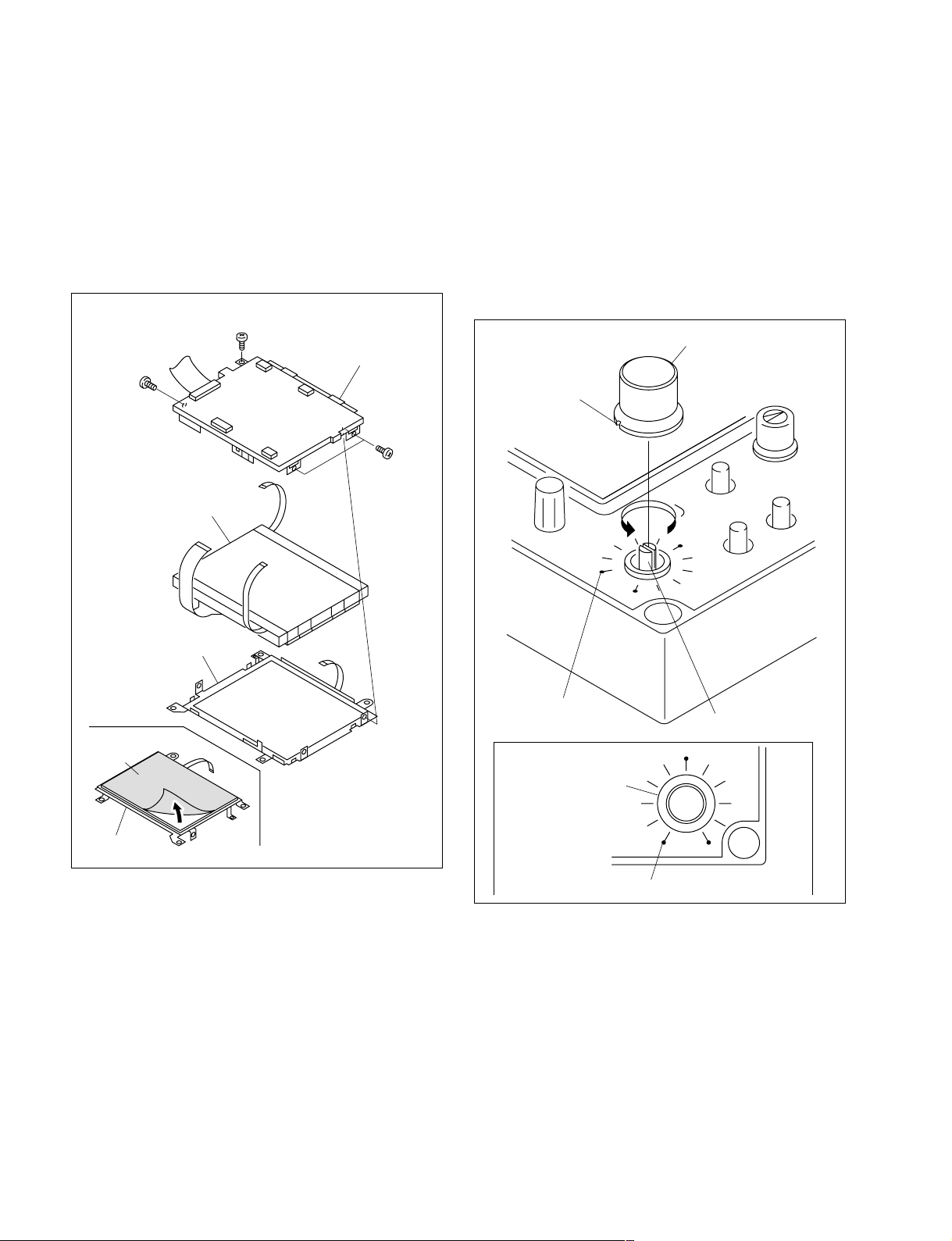

1-9. Installing the IRIS Knob Assembly

and WHITE Knob Assembly

1-9-1. Installing the IRIS Knob Assembly

1. Rotate the shaft of the IRIS knob fully in the direction

of the arrow.

2. To install the IRIS control knob assembly, align the

white mark of the IRIS control knob assembly with the

mark (shown in Fig. 1) on the operation panel.

IRIS control knob assembly

White mark

Touch panel

Protection

sheet

Touch panel

5. When installing the LCD unit in the RM-B750, reverse

the steps in Section 1-7.

Mark on the operation

panel

Fig. 1

IRIS knob assembly

Mark on the operation panel

Shaft of IRIS control knob

1-8 (E)

RM-B750

1-9. Installing the IRIS Knob Assembly and WHITE Knob Assembly

1-10. Note on Service

1-9-2. Installing the WHITE Knob Assembly

n

The two WHITE knob assemblies can be replace in the

same way.

1. Rotate the shaft of the WHITE knob fully and stop

rotation at the position that generates the clicking

sound.

2. Install the WHITE knob assembly while aligning the

white mark of it with the corresponding mark of the

operation panel.

WHITE knob assemblies

White mark

1-10. Note on Service

1-10-1. Information of the Software Version

There are the following Camcorder models to which this

unit can be connected:

Model Software File writing to

HDW-700/700A series Ver.1.00 or later No

HDW-F900 series Ver.1.00 or later Yes

HDW-750/730 series Ver.1.50 or later No

MSW-900 series Ver.1.60 or later No

DVW-707/709WS/ Ver.1.19 or later No

790WS series

No* : Data writing to the memory stick in the camera is possible.

1-10-2. Description on Backup Battery

w

The lithium battery is a critical part to safe operation.

Replace the component with Sony part whose part number

is listed in the manual published by Sony.

If the component is replaced by any part other than the

specified ones, this may cause a fire or electric shock.

Memory Stick

in this unit

*

*

Shaft of the WHITE knob

Mark on the

operation panel

c

When replacing the lithium battery, ensure that the battery

is installed with + and _ poles connected to the correct

terminals. An incorrect connection may cause an explosion

or leakage of fluid as a result, physical damage in the

surrounding materials may be caused.

A lithium battery on the MPU-124 board is used to back up

the date data to be stored in the memory stick. Reset the

date data using he RM configuration menu is the Maintenance

menu (Refer to the operation manual “Initial Settings”.)

after replacing the MPU-124 board or the dead battery.

Replacement part : BT1 (MPU-124 board)

DescriptiWon : CR-2032 (Lithium battery)

Parts number : ! 1-528-174-31

Recommended replacement period : Every 7 years

m

. When replacing the MPU-124 board, it is recommended

to replace the battery at the same time.

. Resetting the date data is required also when the battery

is removed from the battery holder.

RM-B750

1-9 (E)

1-10. Note on Service

1-10-3. Writing and Rewriting the PLD

Internal Data

This unit uses the PLD (Programmable Logic Device) that

supports the e-Production (EPR) system to write and

rewrite the internal data.

If the part listed below needs to be replaced or to be

upgraded, contact your Sony Sales Office/Service Center.

n

The part number of PLD (or ROM for PLD) in which data

is not written yet, is shown in “Section 3. Spare Parts”.

Therefore, if part replacement is required, write the data by

the following procedure.

In the case of the PLD type that runs on the program stored

in external ROM, data needs not to be written only by

replacing the part if the specific PLD only is defective.

e-Production system has the advantages shown

below.

. To write/rewrite the PLD internal data:

1. The standard fixture (cable) can be used.

2. The standard software (PLD Download Tool) can be

used.

. The PLD internal data is controlled in the Sony Database

Server under the name Project file (E_xxx_xxx_xx_xx).

. The printed circuit board is equipped with the standard

connector (EPR connector) to write the PLD internal

data. The indication “EPR” is shown on the printed

circuit board.

Data write procedure

Data write procedure in the PLD (or ROM for PLD) is

outlined below.

For details of data write procedure, refer to “Download

Tool Operating Instruction for Device Programming”

which is available in the same site where the PLD Download Tool software is available.

1. Prepare the Project file.

n

Download the Project file from the Sony Database

Server.

2. Turn off the power of this unit. Connect the PC

parallel port to the EPR connector of the target board

using the PLD download fixture (cable).

3. Turn on the power of this unit.

Start the Download Tool software and read the Project

file.

4. Program the PLD (or ROM for PLD) with the Download Tool software.

5. Upon completion of programming, check that error

message is not displayed. Turn off the power of this

unit and back on.

Corresponding PLD

PLD EPR connector Project file No.

(Ref No./board name) (Ref No./board name)

IC106/MPU-124 CN101/ MPU-124 E_000_000_31_xx

Equipment required

. PLD download fixture

(Sony part number: J-7120-140-A)

The cable connected PC to this unit.

. PC

A PC having parallel port.

A PC in which the PLD Download Tool software is

already installed.

For the applicable OS and the operating environment,

refer to “Download Tool Operating Instruction for

Device Programming”.

1-10 (E)

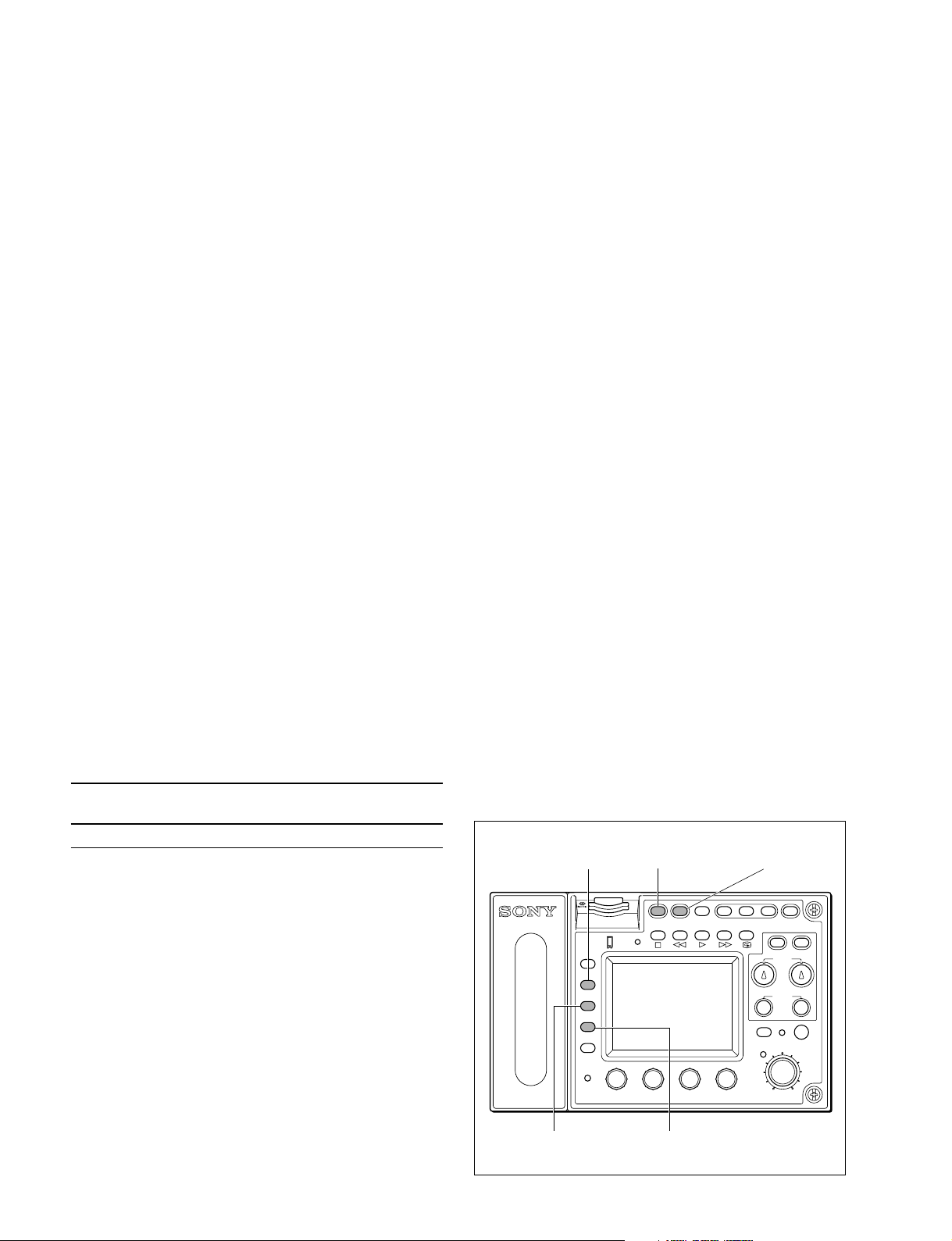

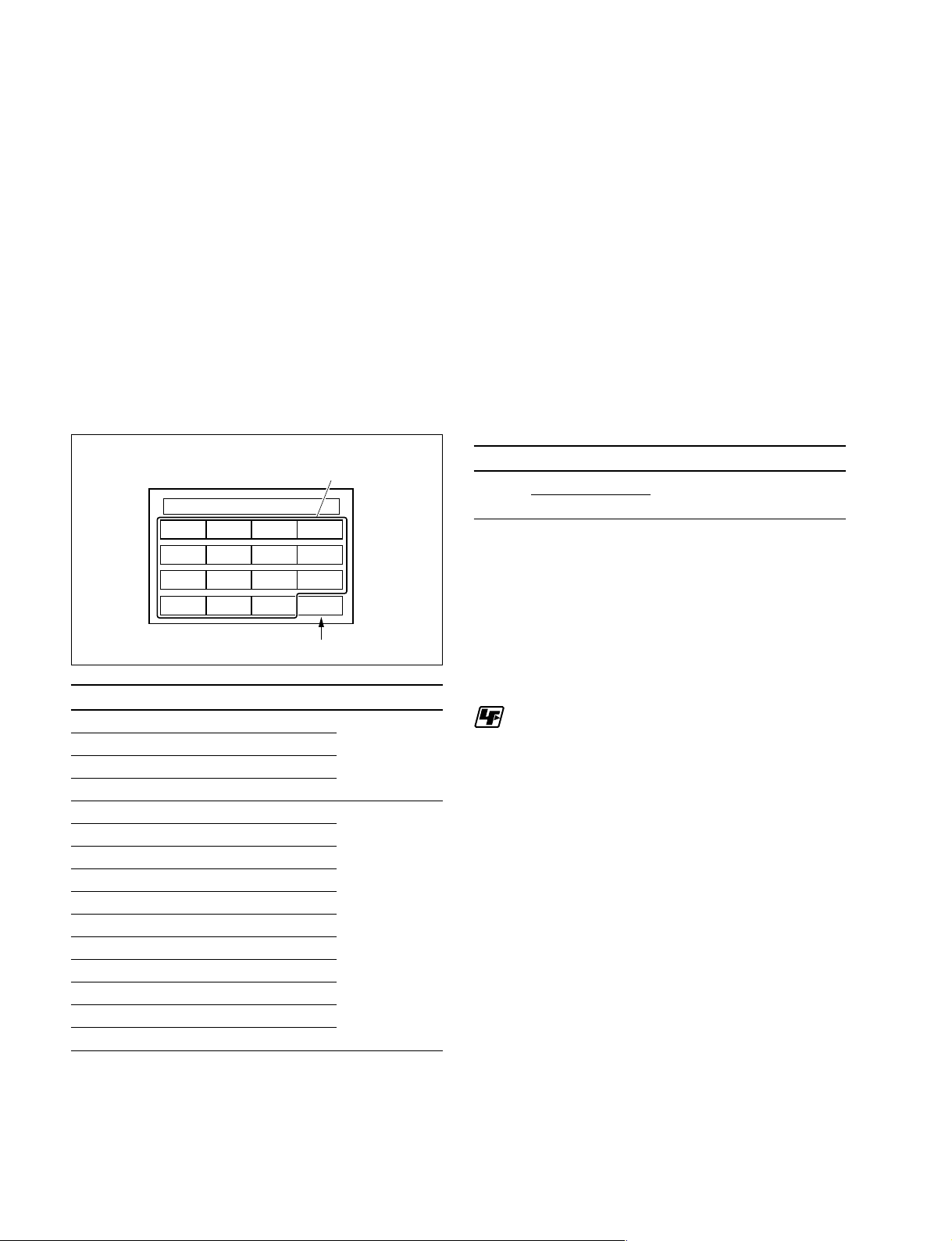

FUNCTION button

MEMORY

MONITOR

FUNCTION

VF DISP

MAINTENANCE

VF MENU

SCENE

CANCEL

PAI NT

ENTER

ALARM

MENU SELECT BRIGHT CONTRAST

MAINTENANCE button

PANEL ACTIVE

button

PAN EL

STANDARD TEST BARS CLOSE

ACTIVE

STICK

SCENE button

STANDARD button

VTR

START/STOP

AWB

WHITE

BLACK

IRIS/MB

AUTO

MASTER

ACTIVE

IRIS

BLACK

EXT

IRIS

REMOTE CONTROL UNIT RM-B750

ABB

RM-B750

1-10. Note on Service

1-10-4. Note on Replacing the FRAM

Initialize the FRAM (IC10, IC11) on the MPU-124 board

as described below after replacing them.

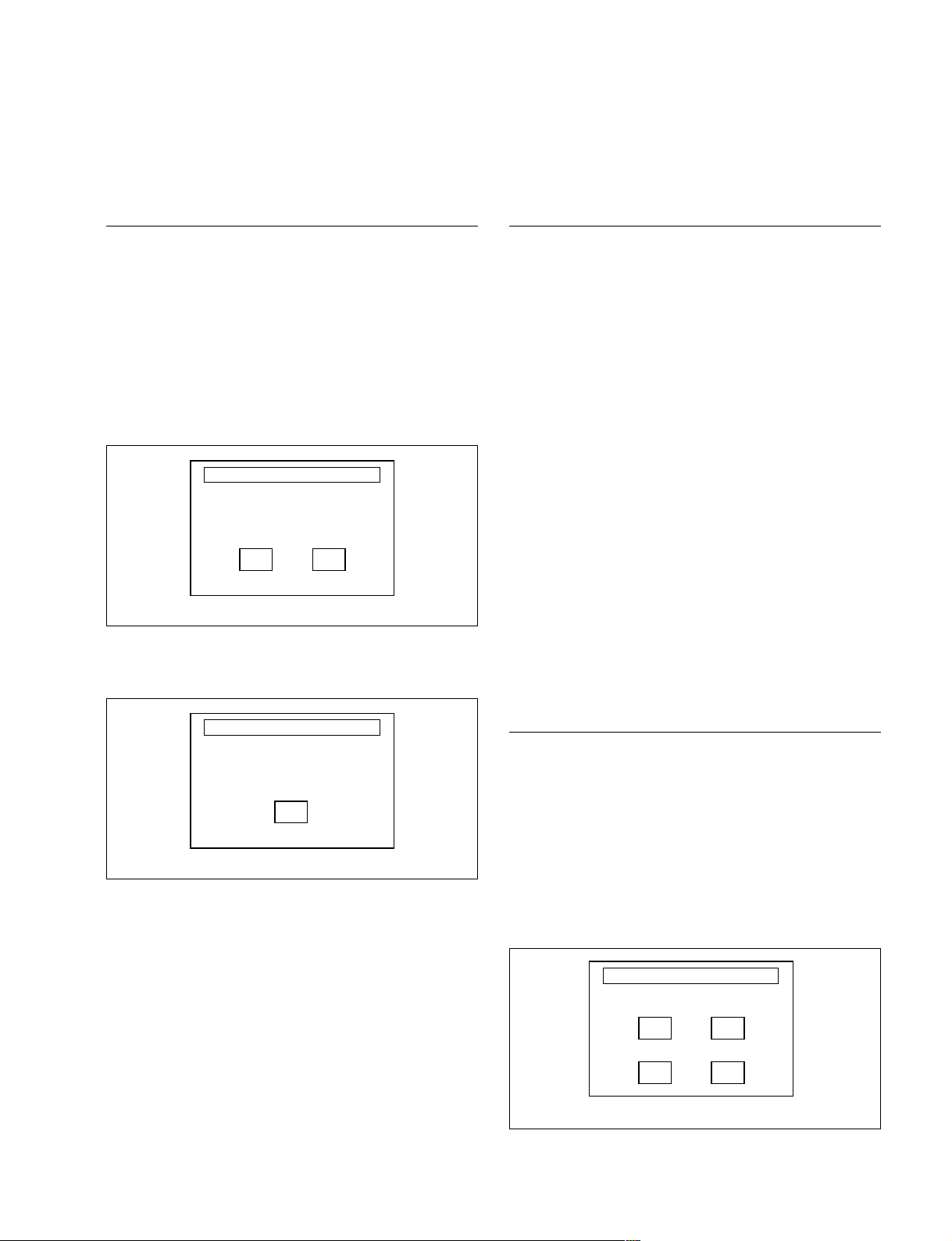

Procedures

1. Press and light the PANEL ACTIVE button.

2. Press the PANEL ACTIVE, STANDARD and FUNCTION buttons simultaneously.

The Diag Mode 2 menu appears.

3. Press the SCENE button. FRAM initialized display

appears.

4. Press [Start] or the SCENE button. Initializing will

start.

FRAM initialized

push SCENE to start

Start Cancel

1-10-5. Checking the Software Version

For checking the software version, follow the procedure

described below.

Procedures

1. Press and light the PANEL ACTIVE button.

2. Press and light the MAINTENANCE button.

The maintenance menu appears.

3. Press [RM|Config] in the maintenance menu. The

display will be switched to the RM Configuration

menu.

4. Press [Security] of the RM configuration menu to

select the Security screen.

5. Press [Engineer] and set the engineer mode. Then

press [Exit] to return to the RM configuration menu.

6. Press [Information] in the RM Configuration menu

and check the software version.

1-10-6. Updating the Software

LCD

5. On completing initializing, the message “FRAM

initialized” appears.

FRAM initialized

FRAM initialized

push SCENE

Exit

LCD

6. Press [Exit] or the SCENE button to leave the menu.

The program can be updated using a memory stick. When

updating is necessary, follow the procedure described

below.

n

Save an updated program in a memory stick in advance.

Procedures

1. Insert the memory stick in which an updated program

is already saved.

2. Press and light the PANEL ACTIVE button.

3. Press the PANEL ACTIVE, STANDARD and FUNCTION buttons simultaneously.

The Diag Mode 2 menu appears.

4. Press [Ver|Up] in the Diag Mode 2 menu. The display

will be switched to the Firmware Update display.

Diag Mode 2

Main BL ON

TP Ver Up

RM-B750

LCD

LCD

Date

Time

1-11 (E)

1-10. Note on Service

5. Press [Main|Update]. Updating will start.

Firmware Update

LCD

Boot

Update

Main

Update

6. On completing updating, the message “COMPLET-

ED” appears.

<FIRMWARE UPDATE 1/2>

ERASING

PROGRAMMING

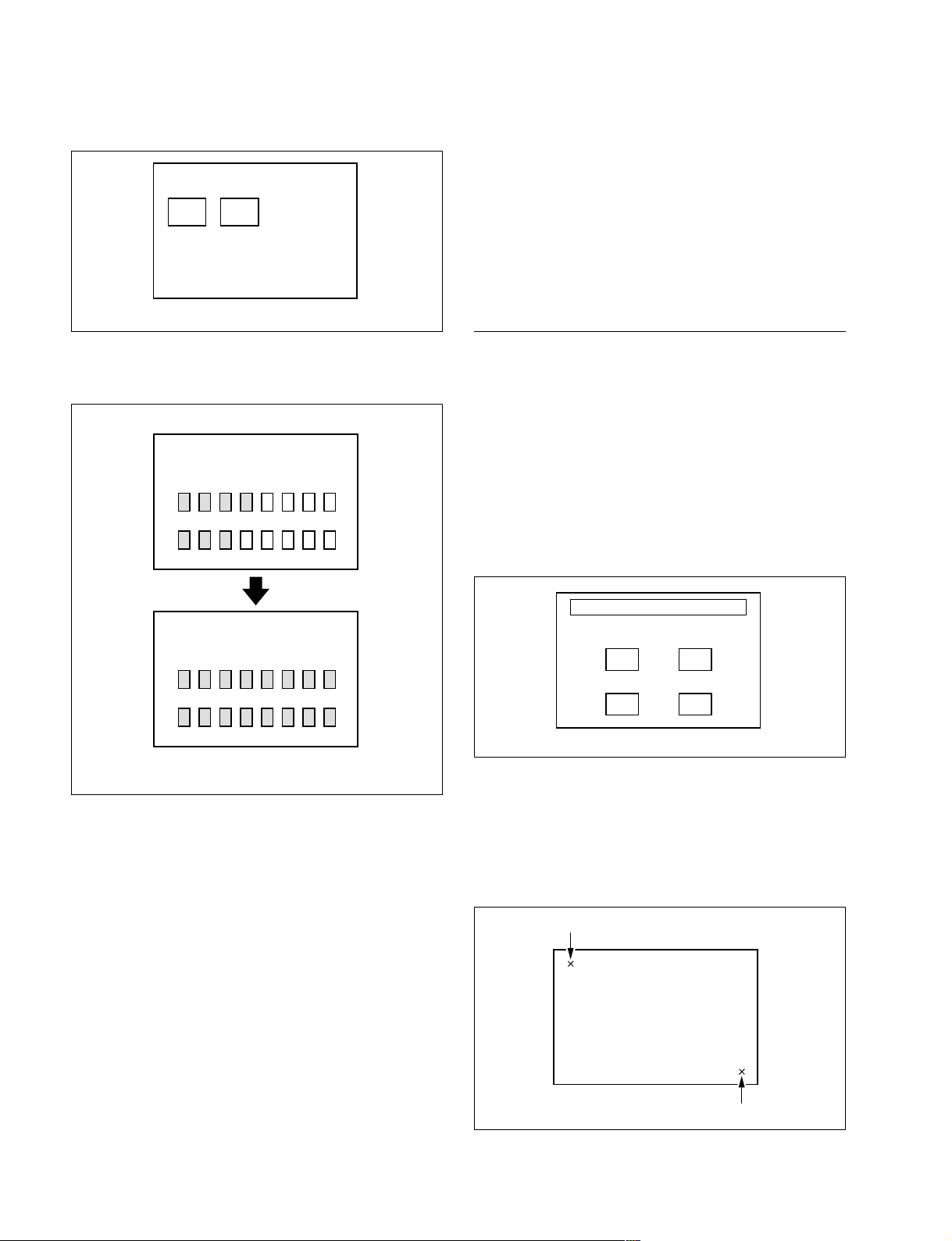

1-10-7. Touch Panel Calibration

If the display is not put into the appropriate mode, or is not

switched to the appropriate screen when pressing the

parameter on the LCD, calibrate the touch panel as described below.

Tool: Stylus pen (commercially available) or

the stick with thin tip which does not damage the

touch panel.

Procedures

1. Press and light the PANEL ACTIVE button.

2. Press the PANEL ACTIVE, STANDARD and FUNCTION buttons simultaneously.

The Diag Mode 2 menu appears.

3. Press [TP] in the Diag Mode 2 menu.

The display will be switched to the Touch Panel

Calibration display.

(If the display is not switched, press the PAINT

button.)

<FIRMWARE UPDATE 2/2>

COMPLETED

ERASING

PROGRAMMING

LCD

7. Finish updating in either way described below.

. While pressing the PANEL ACTIVE button, press

the STANDARD button within one second to exit

the menu.

. Turn the power of the power supply unit to off, and

then turn on.

Diag Mode 2

Main BL ON

TP Ver Up

LCD

LCD

Date

Time

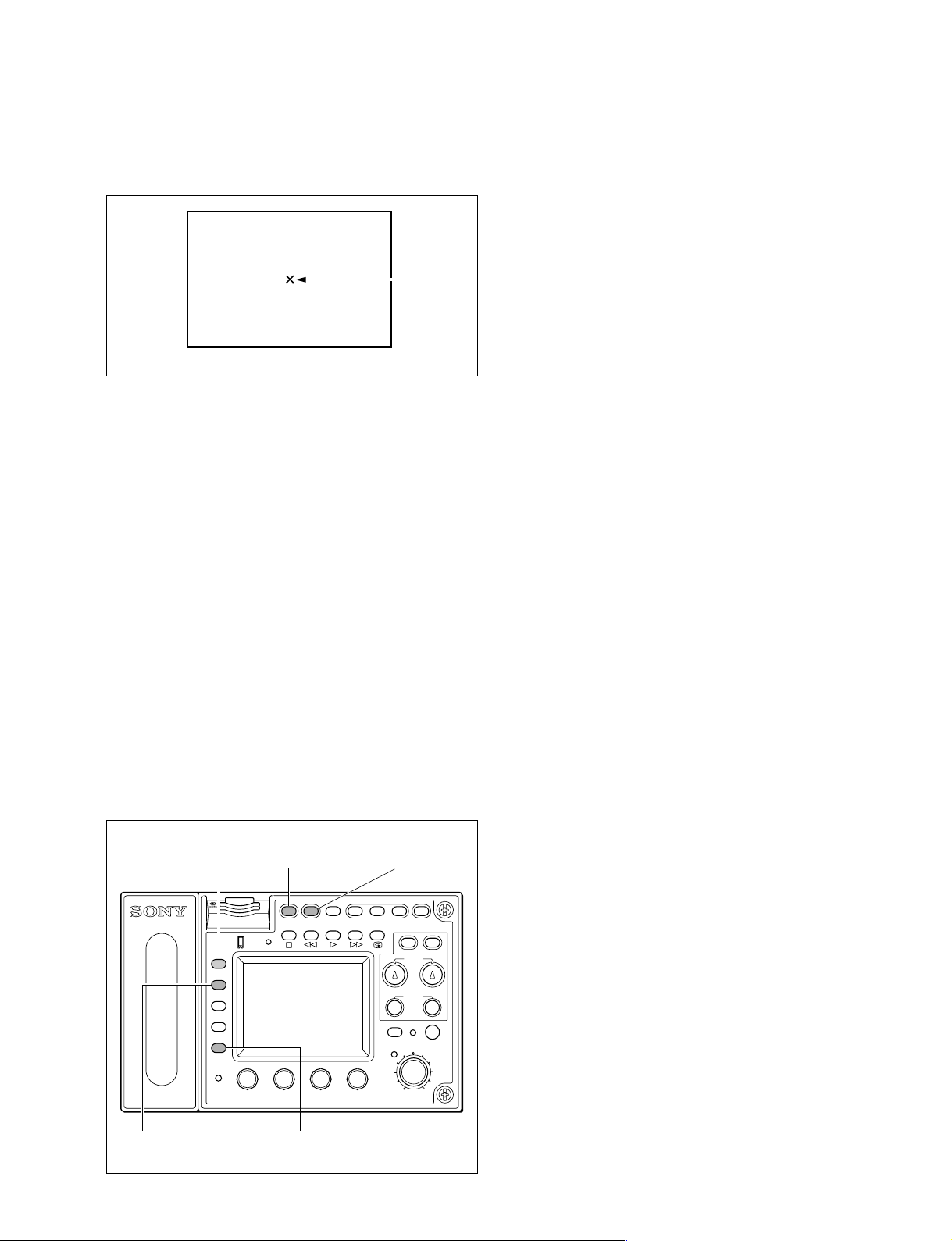

4. Touch the center of x mark (Portion A) at the left top

on the LCD first, and touch the center of x mark

(Portion B) at the bottom right on the LCD using the

stylus pen.

The display will be switched to the Calibration Check

display.

Portion A

Touch Panel Calibration

1-12 (E)

LCD

Portion B

RM-B750

1-10. Note on Service

5. Touch the center of the x mark (Portion C) at the

center on the Calibration Check display using the

stylus pen.

Calibration Check

Portion C

LCD

6. On completing calibration properly, the message

“Calibration Complete” appears.

7. When the calibration is failed, the message “Retry”

appears and return to the Diag Mode 2 menu after few

seconds.

Perform the steps 3 to 5 again.

8. Press the PANEL ACTIVE and STANDARD buttons

simultaneously to leave the menu.

1-10-8. Diagnosis

The unit is provided with the diagnosis function which can

be used for the self-diagnosis of the knobs on the control

panel by performing the following procedure.

1. Press and light the PANEL ACTIVE button.

2. Press the PANEL ACTIVE, STANDARD and MONITOR buttons simultaneously to the diagnosis mode.

3. For the diagnosis items, perform the operation or the

checking as shown below.

Buttons

Turn off the lit button, and the next button will be lit. Then

turn off the lit button. Repeat this operation in order from

the all buttons.

Indicator, Access lamp

(EXT, MEMORY STICK, ALARM, IRIS/MB ACTIVE)

EXT : LED is flashing from amber.

MEMORY STICK, ALARM :

green → red → amber → off, and

back to green.

IRIS/MB ACTIVE : LED is flashing from green.

FUNCTION button

RM-B750

MONITOR

button

MEMORY

STICK

MONITOR

FUNCTION

VF DISP

MAINTENANCE

VF MENU

SCENE

CANCEL

PAI NT

ENTER

ALARM

MENU SELECT BRIGHT CONTRAST

PANEL ACTIVE

button

PAN EL

STANDARD TEST BARS CLOSE

ACTIVE

PAINT button

STANDARD button

VTR

START/STOP

AWB

WHITE

BLACK

IRIS/MB

AUTO

MASTER

ACTIVE

IRIS

BLACK

EXT

IRIS

REMOTE CONTROL UNIT RM-B750

ABB

1-13 (E)

1-10. Note on Service

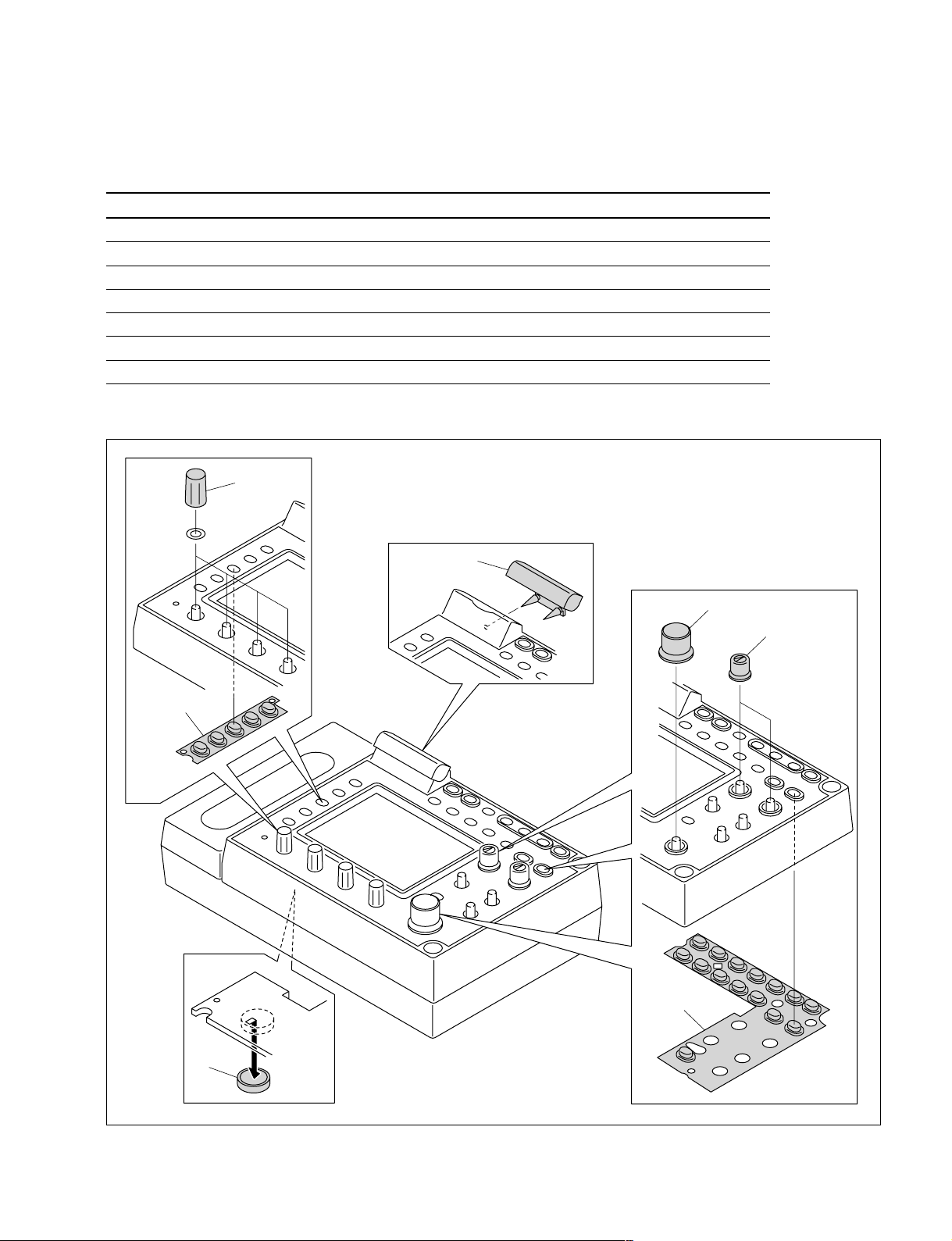

Controls, Rotary Encoder

Turn the controls from 01 to 15 in the following table in

order, and check that the followings are satisfied using

Diag Mode 1.

. When turning the control knob, the appropriate VR No.

of this control knob is displayed at the bottom right on

the LCD. Also the adjustment value is displayed in the

appropriate box on the LCD.

(The display position of the VR No is assigned in order

of VR No. 01 and 02 from the upper left on the LCD.)

.

The variable range of the adjustment value which is

displayed by turning the control knob is coincide with the

value of the adjustable range column in the following table.

**

* When turning the WHITE-R control knob (VR No. 5)

**

Adjustment value

Diag Mode 1

0

1-10-9. Circuit Protective Elements

The positive characteristic thermistor (for power supply)

functions as a circuit protective element on the VR-277

board (B side) of the unit shown below. The thermistor

increases the internal resistance and limits the current

flowing to the circuits when an overcurrent flows or when

the ambient temperature increases and the element reaches

the specified temperature.If the elements operates,turn off

the main power and inspect the RM-B750 internal

circuit.After removing the cause of the equipment abnormality and the temperature of the element decreases,turn

on the power again and operare the unit correctly.It takes

about 1 minute for the elements to cool down after the

main power is turned off.

Borad Ref.No. Address Protective circuit/equipment

VR-277 THP203 C-2 Circuit inside the board

THP205 B-2

1-10-10. Unleaded Solder

5

LCD

VR No.

VR No. Adjustment controls Adjustable range

01 Rotary encoder 1

02 Rotary encoder 2

03 Rotary encoder 3

04 Rotary encoder 4

05 WHITE-R _90 (or less) to

06 _ +90 (or more)

07 WHITE-B

08 _

09 BLACK-R

10 _

11 BLACK-B

12 MASTER BLACK control

13 IRIS control

14 _

15 _

*1: The rotary encoder 1 is the left most of the control knob.

*1

*1

*1

*1

_99 to +99

Boards requiring use of unleaded solder are printed with a

lead free mark (LF) indicating the solder contains no lead.

(Caution: Some printed circuit boards may not come

printed with the lead free mark due to their particular size.)

: LEAD FREE MARK

m

. Be sure to use the unleaded solder for the printed circuit

board printed with the lead free mark.

. The unleaded solder melts at a temperature about 40 dC

higher than the ordinary solder, therefore, it is recommended to use the soldering iron having a temperature

regulator.

. The ordinary soldering iron can be used but the iron tip

has to be applied to the solder joint for a slightly longer

time. The printed pattern (copper foil) may peel away if

the heated tip is applied for too long, so be careful.

4. Press the PANEL ACTIVE and STANDARD buttons

simultaneously to leave the menu.

1-14 (E)

RM-B750

1-11. Recommended Replacement Parts

1-11. Recommended Replacement Parts

The list below shows the recommended replacement parts. Replace them as needed.

No. Part name Sony part number Remarks

1 KNOB, RE 3-635-891-0X Rubber part

2 RUBBER KEY B 3-620-281-0X Rubber part

3 MS LID 3-620-276-0X Rubber part

4 KNOB ASSY,VOLUME CONTROL X-3651-342-X Rubber part

5 WHITE KNOB ASSY X-3608-461-X Rubber part

6 RUBBER KEY A 3-620-280-0X Rubber part

7 BATTERY, LITHIUM CR2032 1-528-174-1X Replace it every 7 years.

*1 : Check that parts are not deformed or deteriorated periodically. Replace them as needed.

*2 : Refer to Section 1-10-1.

1

*1

*1

*1

*1

*1

*1

2

3

4

5

6

RM-B750

7

1-15 (E)

Section 2

Electrical Alignment

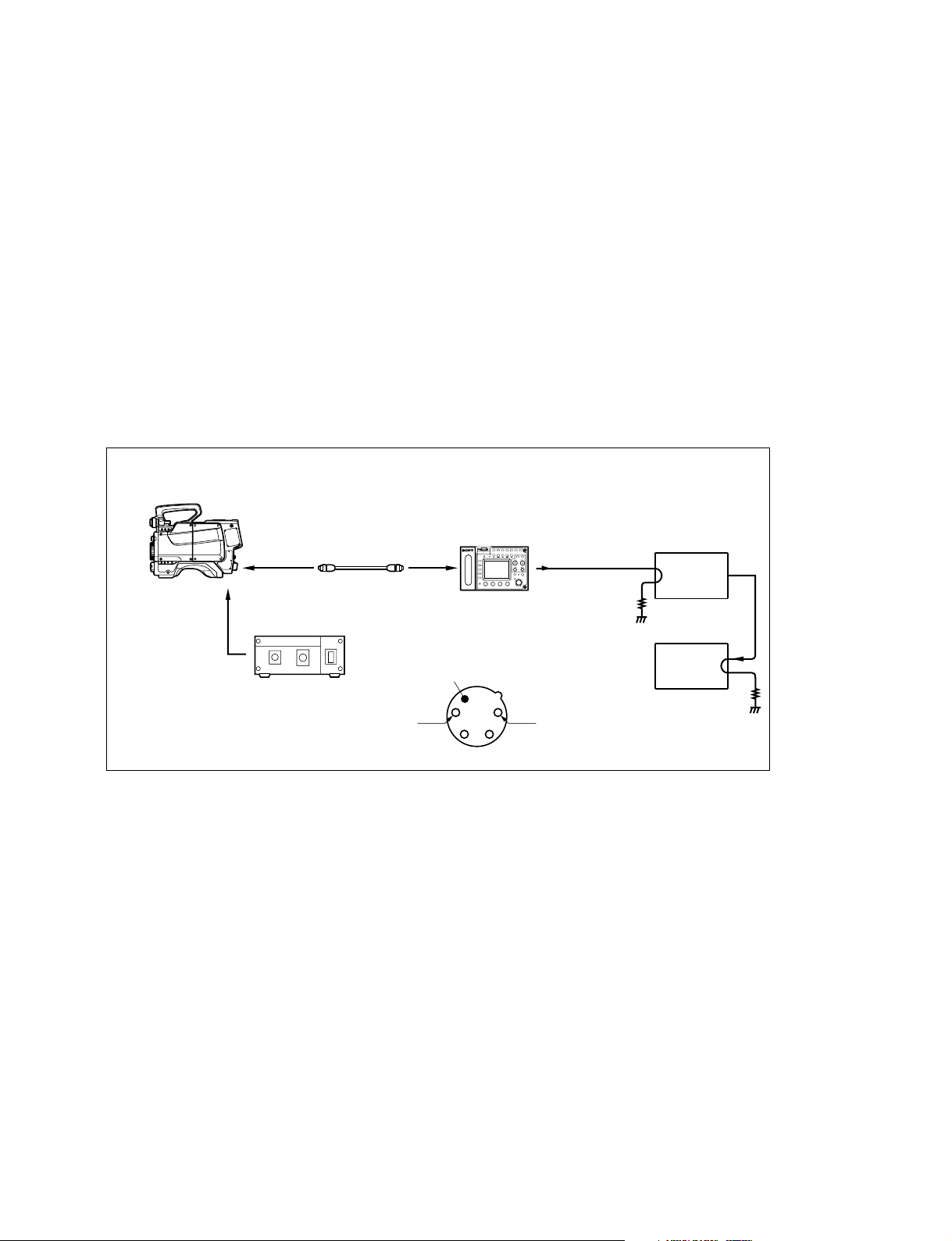

2-1. Preparation

Measuring Equipment

. Waveform monitor/Vectorscope Tektronix 1780R (for NTSC)/1781R (for PAL) or equivalent

. Color monitor

Peripheral Equipment

. BVP-E10 + CA-530/570/950, or

HDC-950/930

(The video output should be present at the remote connector.)

. AC adaptor AC-550/550CE, or DC variable power supply

Connection

COLOR VIDEO CAMERA

CAMERA ADAPTOR

BVP-E10 series

CA-570/530 series

REMOTE

*

DC IN

AC ADAPTOR

AC-550/550CE

or DC variable

power supply

REMOTE CABLE

(supplied with

RM-B750,10 m)

*

Micro switch

_

PANEL

STANDARD TEST BARS CLOSE

VTR

ACTIVE

START/STOP

MEMORY

STICK

ABB

AWB

WHITE

MONITOR

FUNCTION

BLACK

VF DISP

MAINTENANCE

VF MENU

SCENE

IRIS/MB

CANCEL

AUTO

MASTER

ACTIVE

IRIS

BLACK

PAINT

EXT

ENTER

IRIS

ALARM

MENU SELECT

REMOTE CONTROL UNIT RM-B750

REMOTE

CONTROL UNIT

RM-B750

14

23

MONITOR

+

Waveform monitor/

Vector scope

A-ch

75 Z

Color monitor

75

PIX

Z

If using a DC variable power supply to drive power, connect the positive (+) side of the power supply to

pin 4 of the DC IN connector on the camera adaptor, and negative (_) side to pin 1.

n

When the power is supplied via the DC IN connector, be sure to press the micro switch on the DC IN

connector, that turns on the power. It is recommended to use an XLR plug when driving power via the

DC IN connector.

Initial settings

. PANEL ACTIVE button/Operation panel : ON (lit)

. Test signal select button/Operation panel : BARS

. CABLE COMP SELECT

*1 : To select the cable length, use the menu of this unit. For details, refer to the operation manual supplied with the unit.

RM-B750

*1

: 10 m

2-1 (E)

2-2. Adjusting the Video Level

2-2. Adjusting the Video Level

Notes

. All measuring equipment shall be calibrated.

. Also the alignment for the camera, camera adaptor and OHB shall be completed.

. About ten-minute warm-up time is allowed before beginning adjustment.

. The waveforms differ according to the specifications (TV standard and encoded level) of a camera

connected to the unit during adjustment.

In this manual, every waveform corresponding to the specifications is given.

Adjustment Procedure

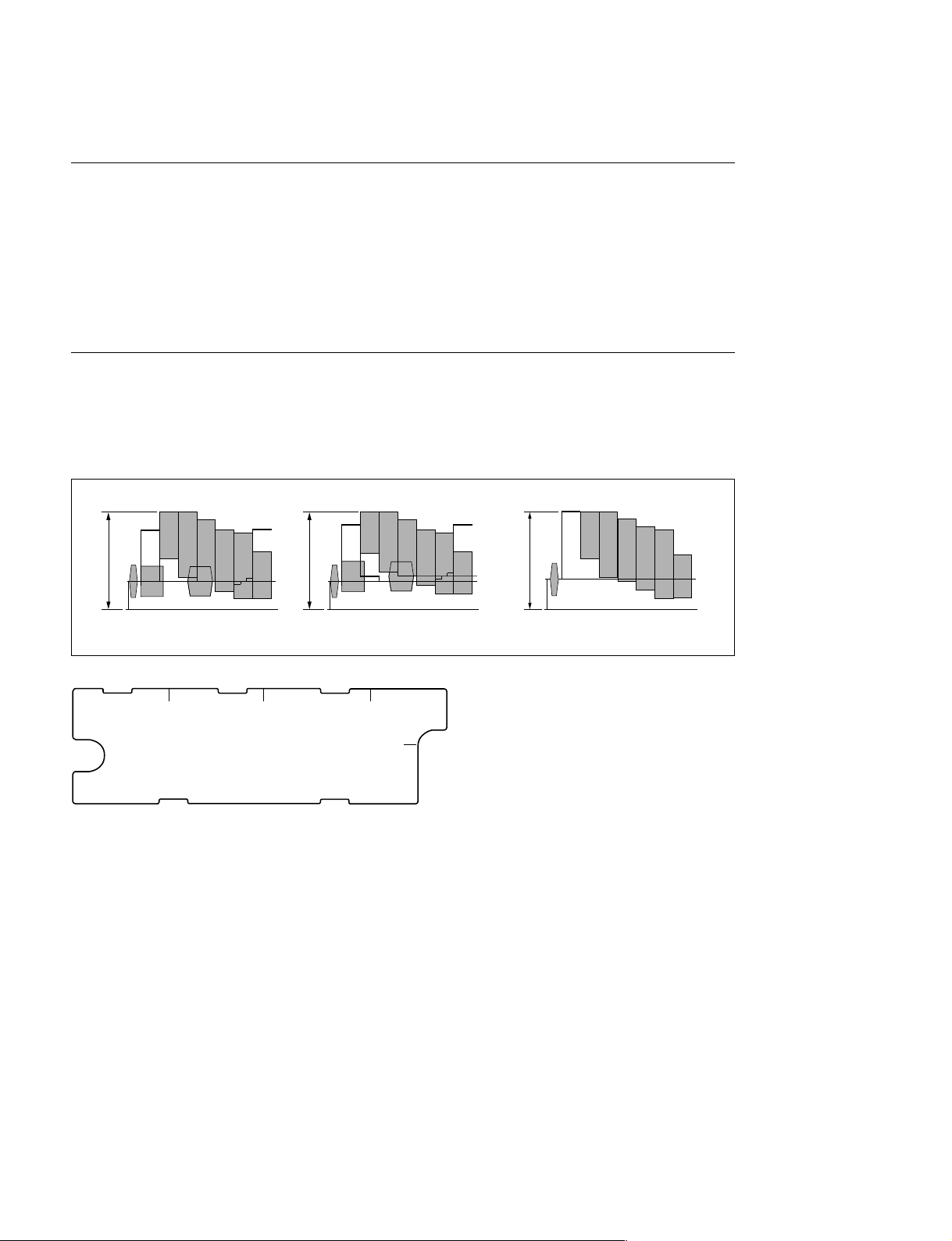

Test Point : MONITOR connector

Adjustment Point : 1RV1/VA-211 board

Specification : A = 1.00 ±0.05 Vp-p (terminated with 75 Z)

(140 ± 7 IRE)

A

(NTSC Setup 0 %)

AB CD

RV1

1

A

(NTSC Setup 7.5 %)

1

2

VA-211 board (A side)

A

(PAL)

2-2 (E)

RM-B750

Section 3

Spare Parts

3-1. Notes on Repair Parts

1. Safety Related Components Warning

w

Components marked ! are critical to safe operation.

Therefore, specified parts should be used in the case of

replacement.

2. Standardization of Parts

Some repair parts supplied by Sony differ from those

used for the unit. These are because of parts commonality and improvement.

Parts list has the present standardized repair parts.

3. Stock of Parts

Parts marked with “o” at SP (Supply Code) column of

the spare parts list may not be stocked. Therefore, the

delivery date will be delayed.

4. Harness

Harnesses with no part number are not registered as

spare parts.

In need of repair, get components shown in the list and

repair using them.

3-1.

RM-B750

3-1

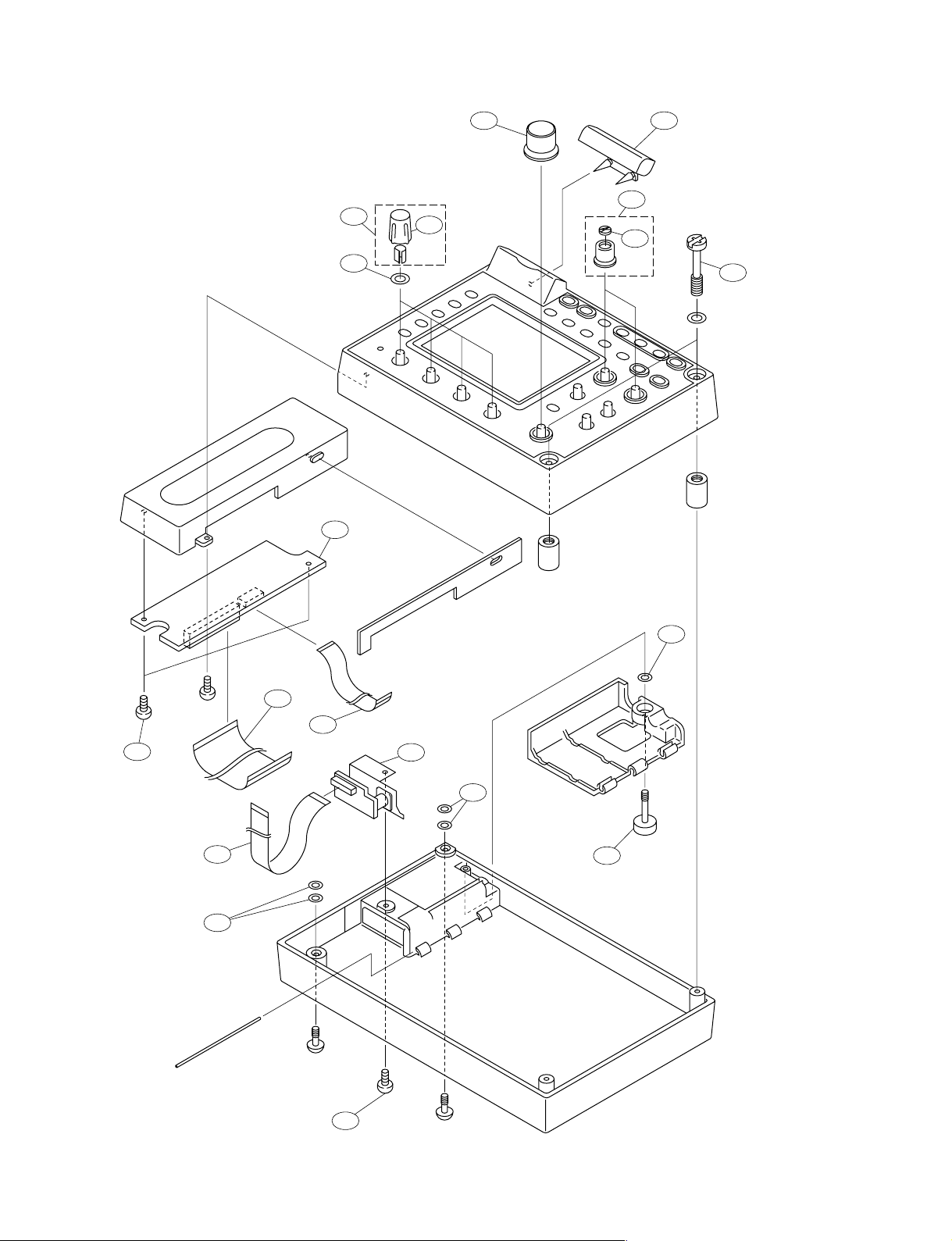

Knob and Board Block

3-2. Exploded Views

84

3

14

12

9

15

13

WASHER,PLASTIC

(4 x 0.5)

1

10

B3 x 5

7

5

10

6

16

2

10

11

3-2

B4 x 6

7

B4 x 6

RM-B750

No. Part No. SP Description

1 A-8345-286-A s MOUNTED CIRCUIT BOARD, VA-211

2 A-8345-288-A s MOUNTED CIRCUIT BOARD, CN-2308

3 X-3608-461-1 s WHITE KNOB ASSY

4 X-3651-342-0 s KNOB ASSY,VOLUME CONTROL

5 1-574-144-11 s WIRE, FLAT TYPE (12 CORE)

6 1-775-422-11 s WIRE,FLAT TYPE(30CORE)

7 3-364-941-01 s SCREW (+B) (2.6X5),NYLOK

8 3-620-276-02 s MS LID

9 3-635-891-02 s KNOB,RE

10 3-687-116-01 o WASHER(4),STOPPER (PLA)

11 3-697-760-11 s SCREW,COIN

12 3-701-444-21 s WASHER PLASTIC 6.2X0.5)

13 3-729-091-01 s SCREW (M4X17.5) (STEEL)

14 A-8279-951-A s KNOB ASSY,RE

15 2-141-015-41 s PLATE,COLOR

16 1-769-629-11 s WIRE,FLAT TYPE (12P)

7-623-925-01 s WASHER,PLASTIC (4X0.5)

7-682-546-04 s SCREW +B3X5

7-682-560-09 s SCREW +B4X6

Knob and Board Block

RM-B750

3-3

Loading...

Loading...