Sony PLM-S700E Service Manual

PLM-S700E

SERVICE MANUAL

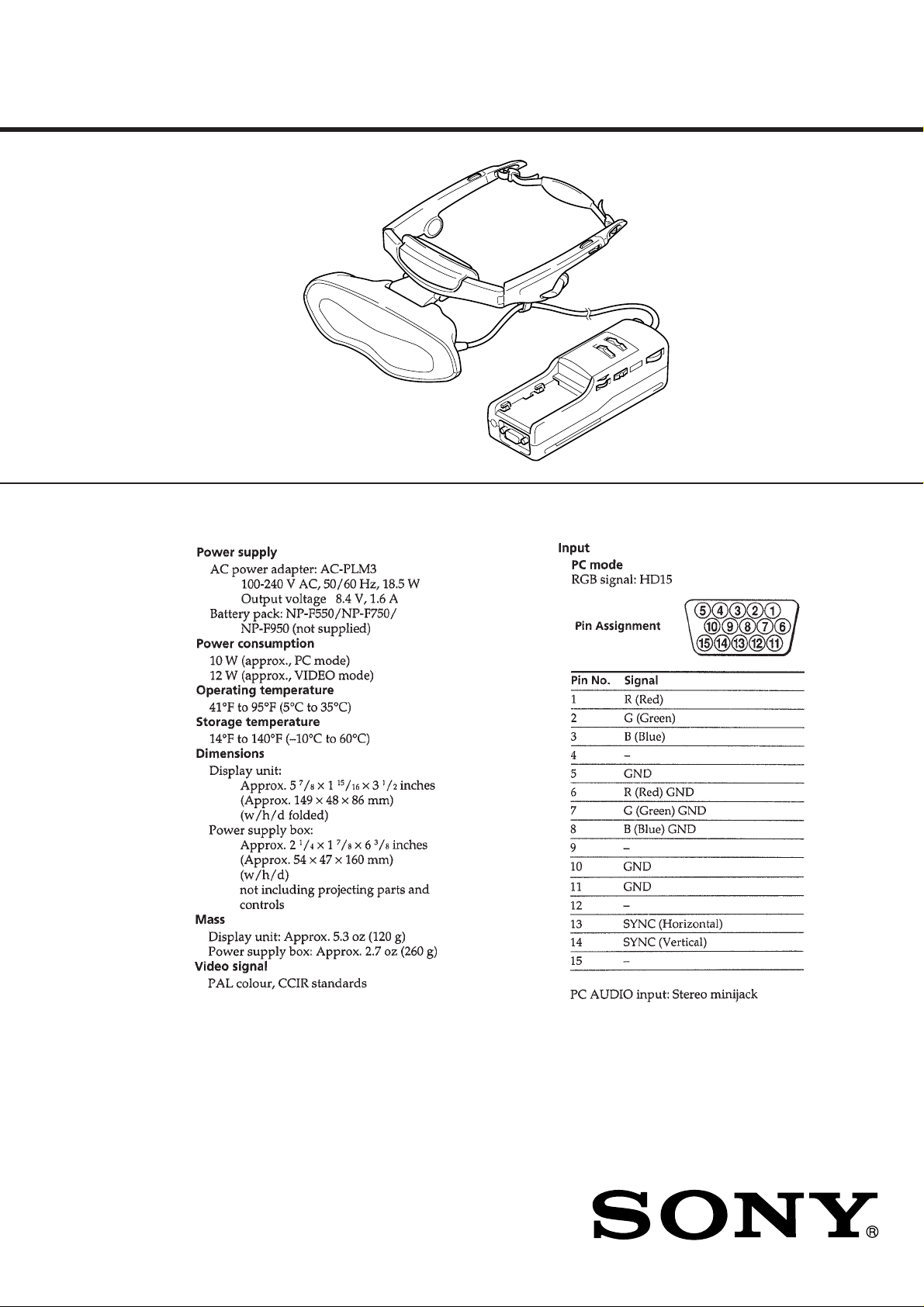

SPECIFICATIONS

AEP Model

9-928-115-31

– Continued on next page –

GLASSTRON

Notes on chip component replacement

• Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be damaged by heat.

Flexible Circuit Board Repairing

• Keep the temperature of the soldering iron around 270 ˚C during repairing.

• Do not touch the soldering iron on the same conductor of the

circuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering

or unsoldering.

TABLE OF CONTENTS

1. GENERAL

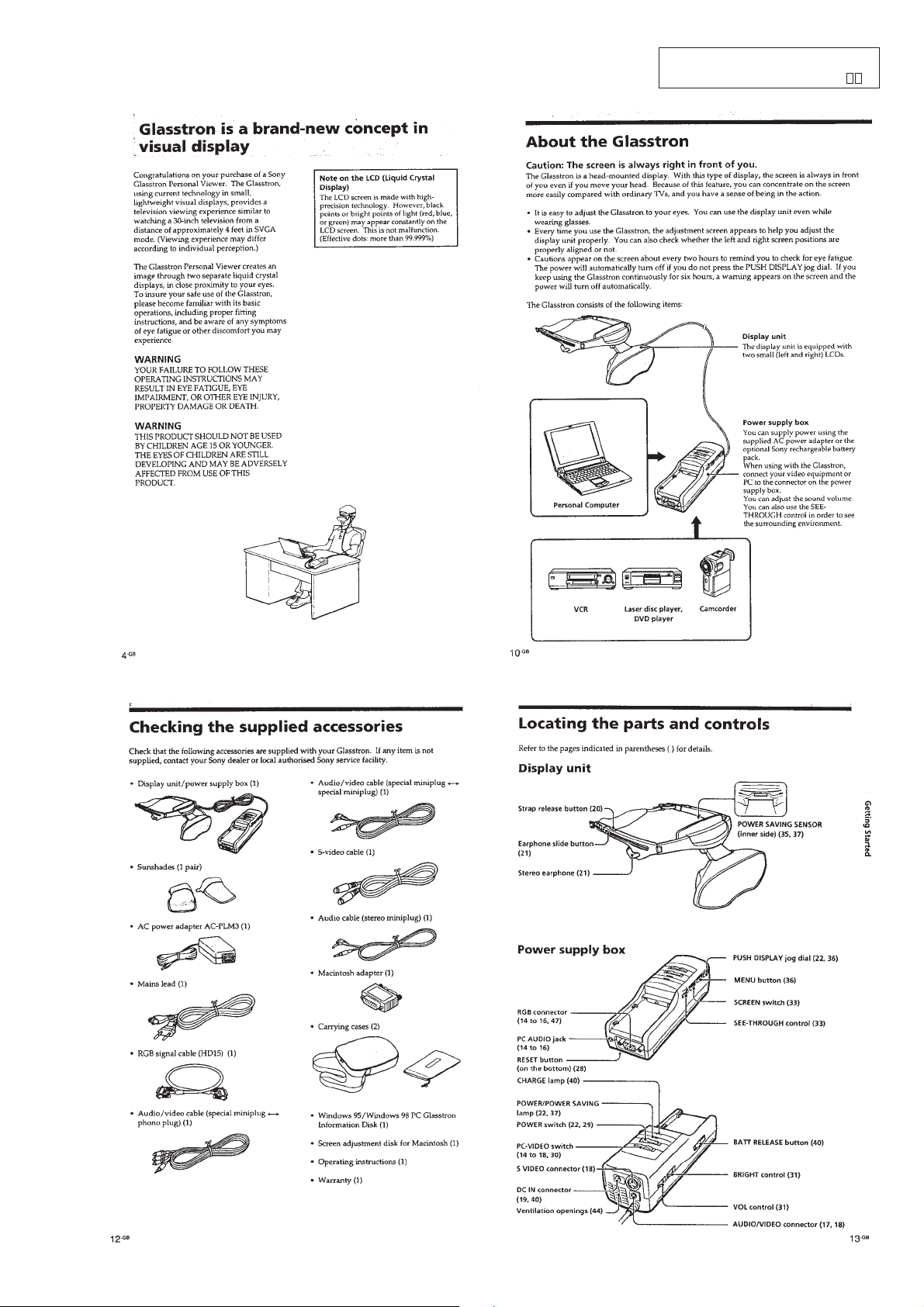

Glasstron is a brand-new concept in visual display .... 1-1

About the Glasstron ..................................................... 1-1

Checking the supplied accessories .............................. 1-1

Locating the parts and controls ................................... 1-1

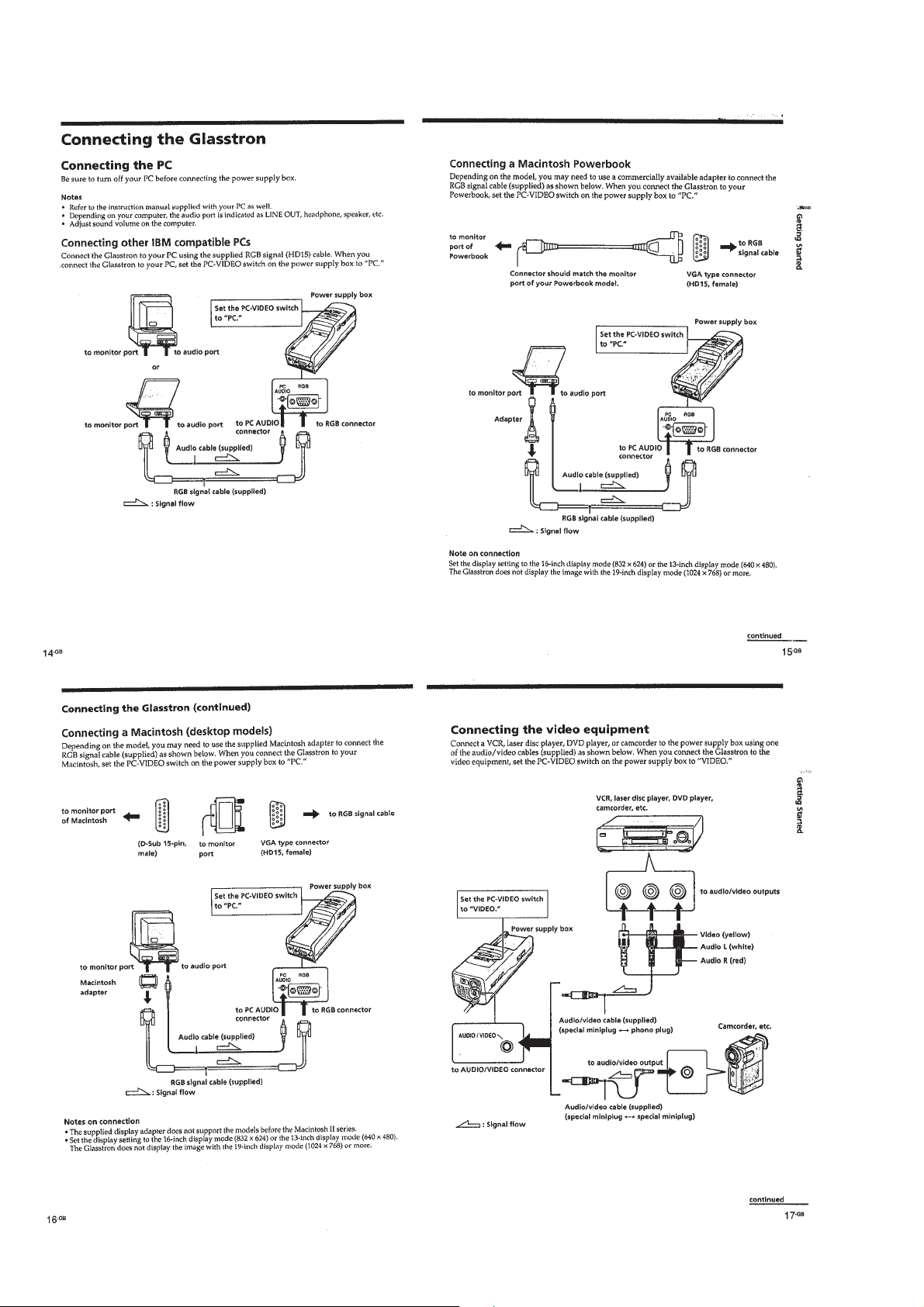

Connecting the Glasstron............................................. 1-2

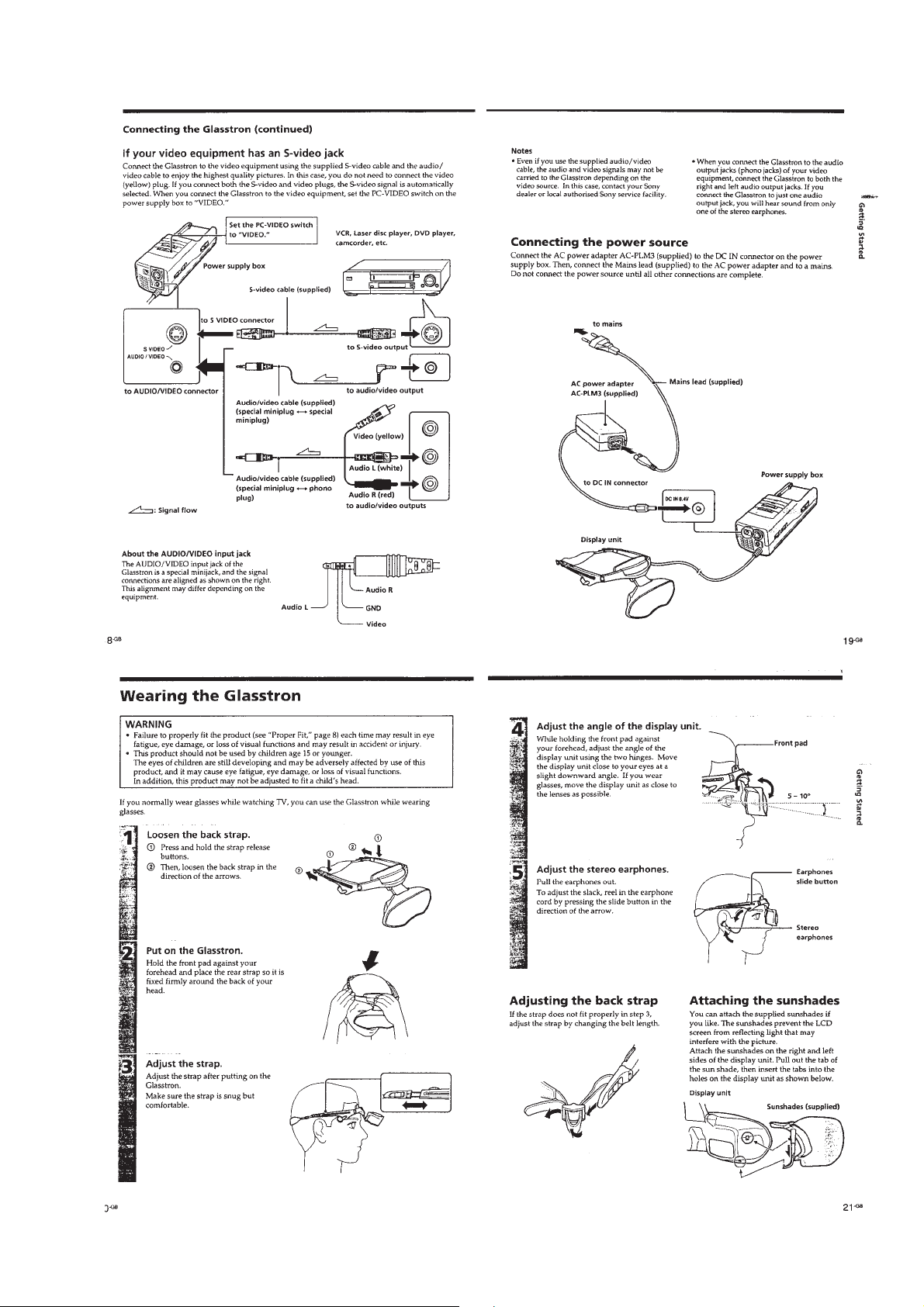

Wearing the Glasstron .................................................. 1-3

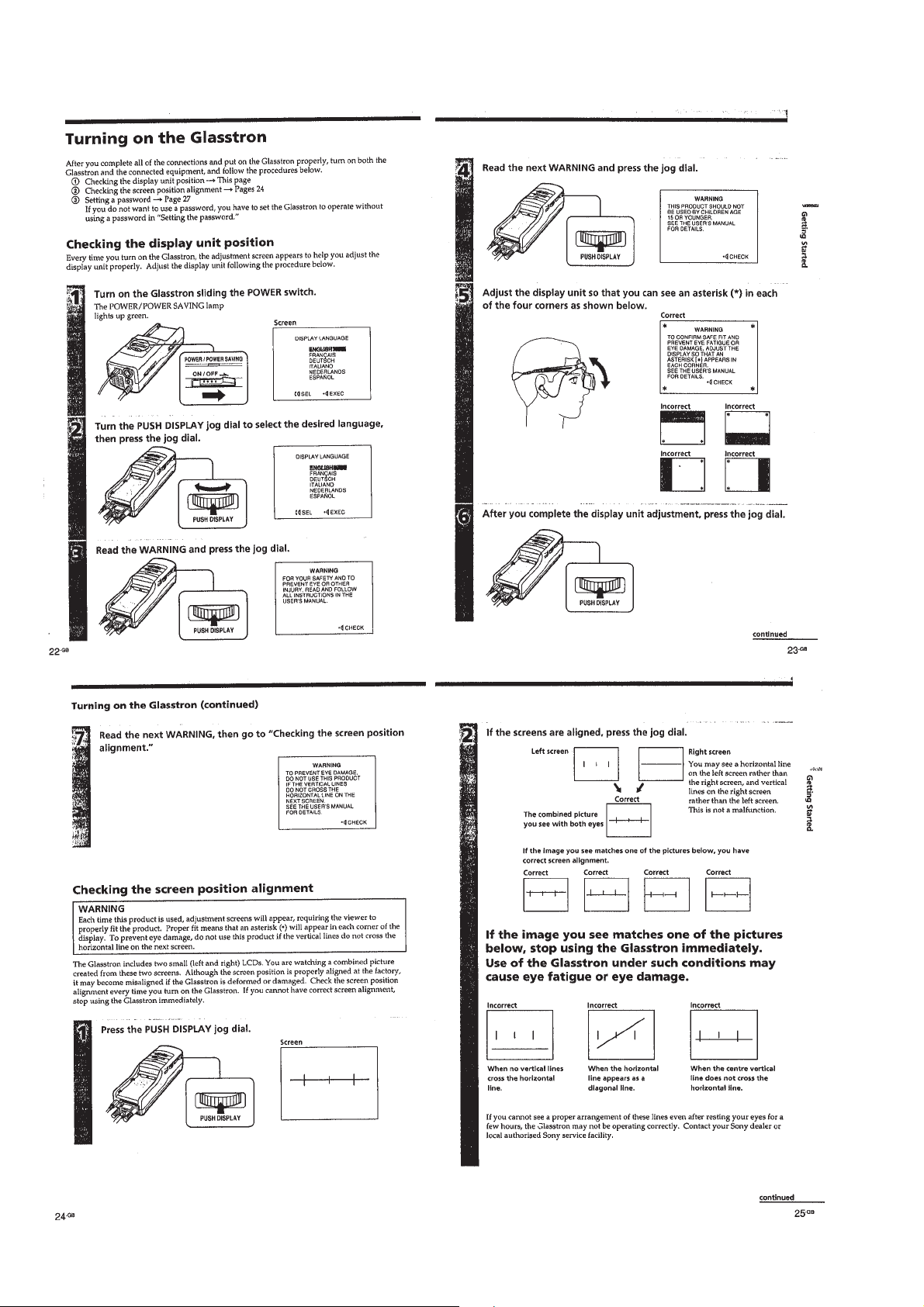

Turning on the Glasstron ............................................. 1-4

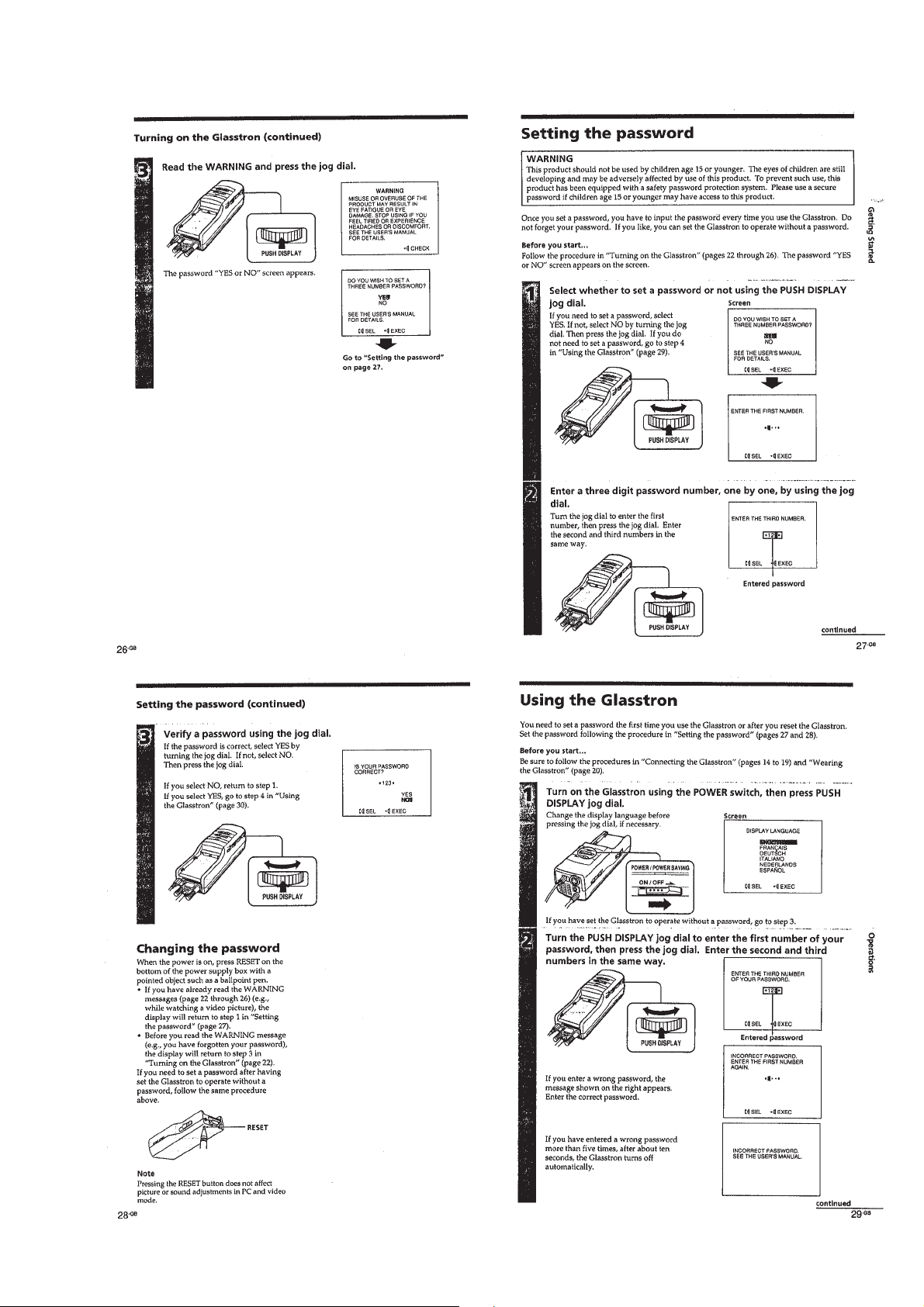

Setting the password .................................................... 1-5

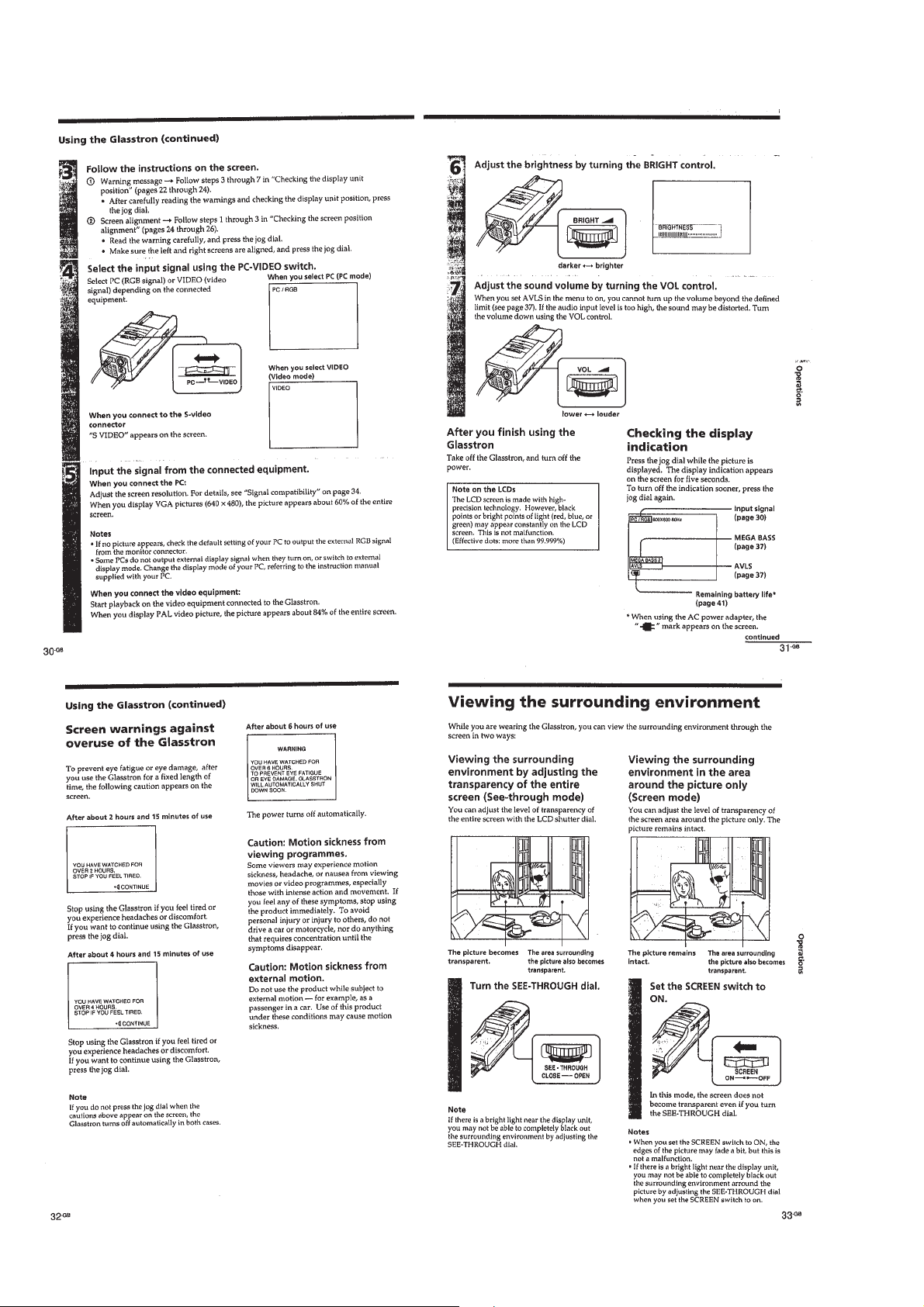

Using the Glasstron...................................................... 1-5

Viewing the surrounding environment ........................ 1-6

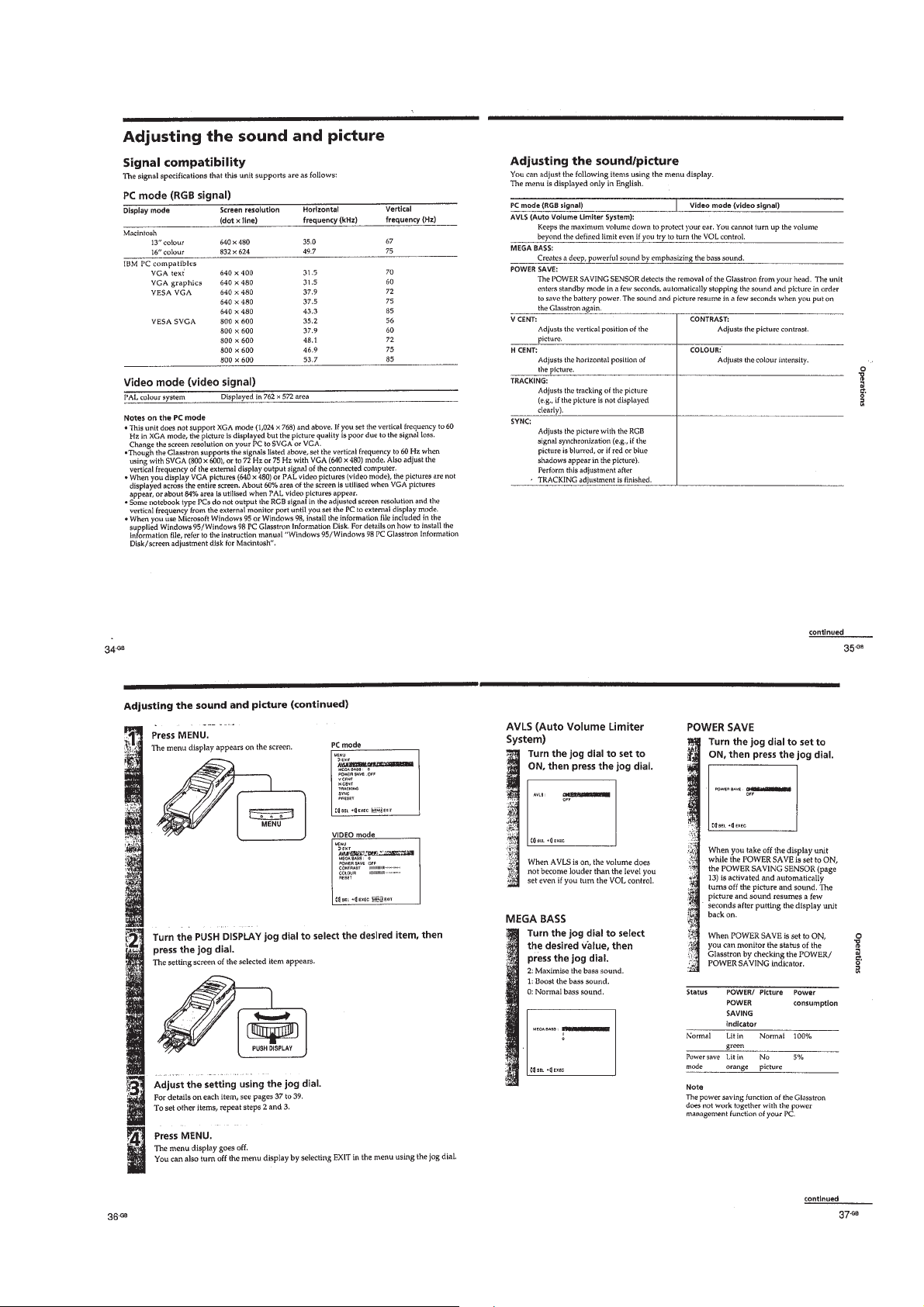

Adjusting the sound and picture .................................. 1-7

Using the optional battery pack................................... 1-8

2. DISASSEMBLY ...................................................... 2-1

3. ELECTRICAL ADJUSTMENTS...................... 3-1

4. DIAGRAMS

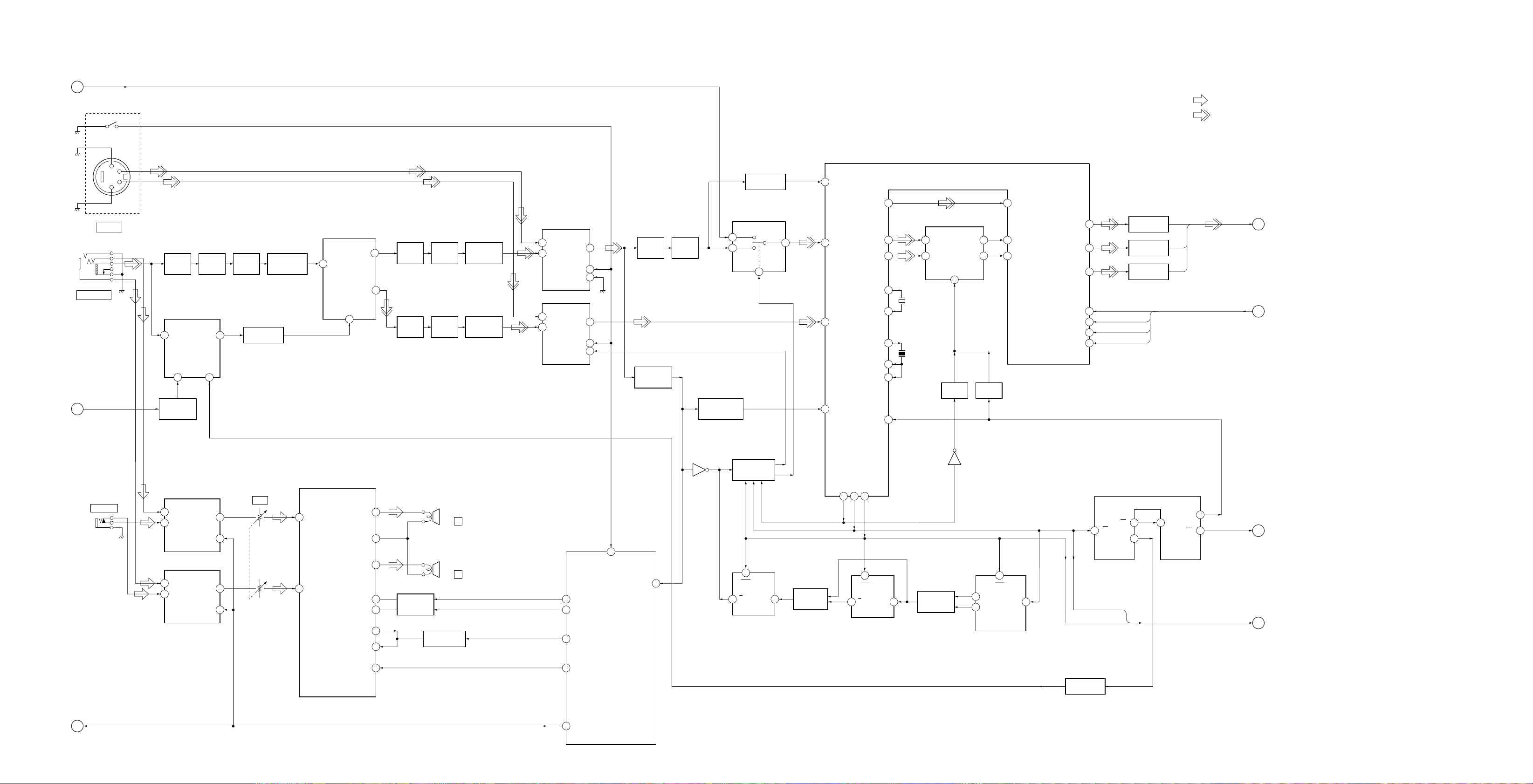

4-1. Block Diagram – AUDIO/VIDEO Section – ............. 4-1

4-2. Block Diagram

– A/D, D/A, OSD, SYNC Section –............................ 4-5

4-3. Block Diagram

– GAMMA CONTROL/LCD DRIVE Section – ........ 4-7

4-4. Block Diagram

– MODE CONTROL/SENSOR/LCS Section – ......... 4-9

4-5. Block Diagram – POWER SUPPLY Section –.......... 4-11

4-6. Notes for Printed Wiring Board and

Schematic Diagram...................................................... 4-14

4-7. Printed Wiring Board – JK-136 Board –.................... 4-15

4-8. Schematic Diagram – JK-136 Board –........................ 4-16

4-9. Schematic Diagram – YC-148 Board (1/3) – .............. 4-17

4-10. Schematic Diagram – YC-148 Board (2/3) –.............. 4-19

4-11. Schematic Diagram – YC-148 Board (3/3) –.............. 4-24

4-12. Printed Wiring Board – YC-148 Board – ................... 4-27

4-13. Printed Wiring Board – MA-324 Board –.................. 4-31

4-14. Schematic Diagram – MA-324 Board (1/7) –............. 4-35

4-15. Schematic Diagram – MA-324 Board (2/7) –............. 4-39

4-16. Schematic Diagram – MA-324 Board (3/7) –............. 4-43

4-17. Schematic Diagram – MA-324 Board (4/7) –............. 4-46

4-18. Schematic Diagram – MA-324 Board (5/7) –............. 4-49

4-19. Schematic Diagram – MA-324 Board (6/7) –............. 4-53

4-20. Schematic Diagram – MA-324 Board (7/7) –............. 4-55

4-21. Printed Wiring Board – LC-61 Board – ..................... 4-57

4-22. Schematic Diagram – LC-61 Board – ......................... 4-59

4-23. Printed Wiring Board – SW-306 Board –................... 4-62

4-24. Schematic Diagram – SW-306 Board – ...................... 4-65

4-25. Printed Wiring Board – DD-107 Board –................... 4-67

4-26. Schematic Diagram – DD-107 Board – ...................... 4-69

4-27. IC Pin Function Description ........................................ 4-88

5. EXPLODED VIEWS............................................. 5-1

6. ELECTRICAL PARTS LIST ............................ 6-1

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY MARK ! OR DOTTED

LINE WITH MARK ! ON THE SCHEMATIC DIAGRAMS

AND IN THE PARTS LIST ARE CRITICAL TO SAFE

OPERATION. REPLACE THESE COMPONENTS WITH

SONY PARTS WHOSE PART NUMBERS APPEAR AS

SHOWN IN THIS MANU AL OR IN SUPPLEMENTS PUBLISHED BY SONY.

– 2 –

SECTION 1

GENERAL

This section is extracted from instruction manual (3-862-932- ).

1-1

1-2

1-3

1-4

1-5

1-6

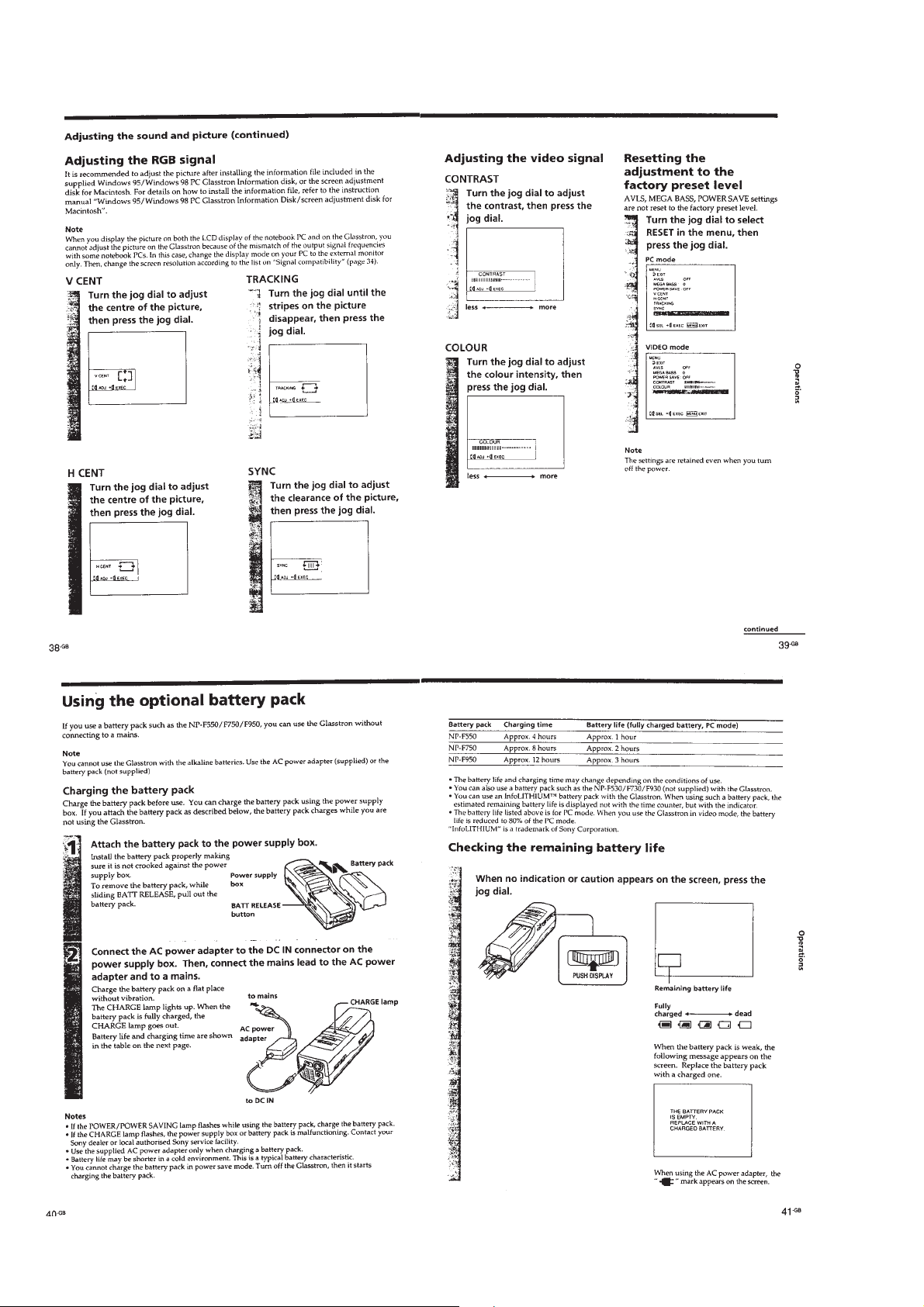

1-7

1-8

1-8 E

SECTION 2

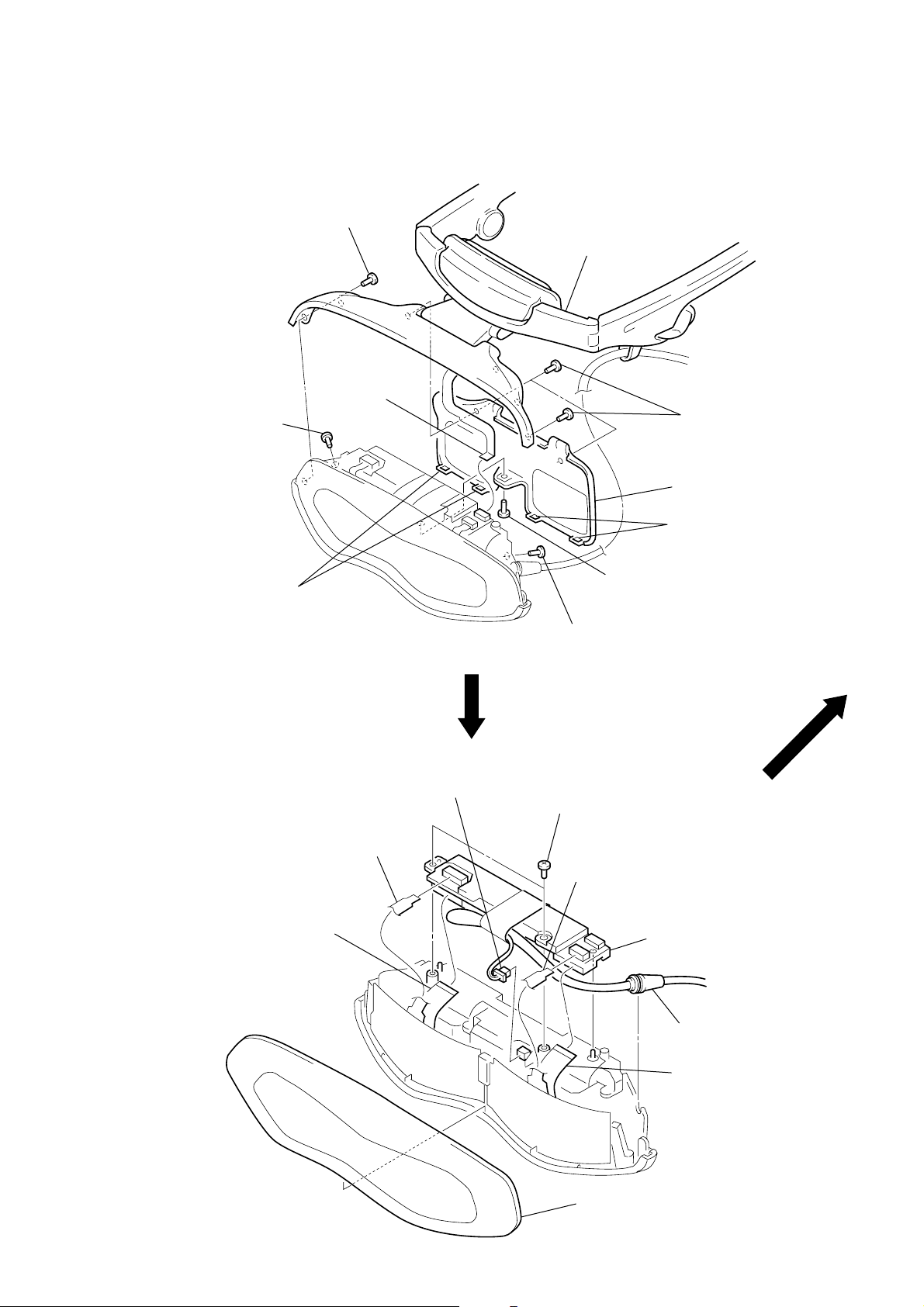

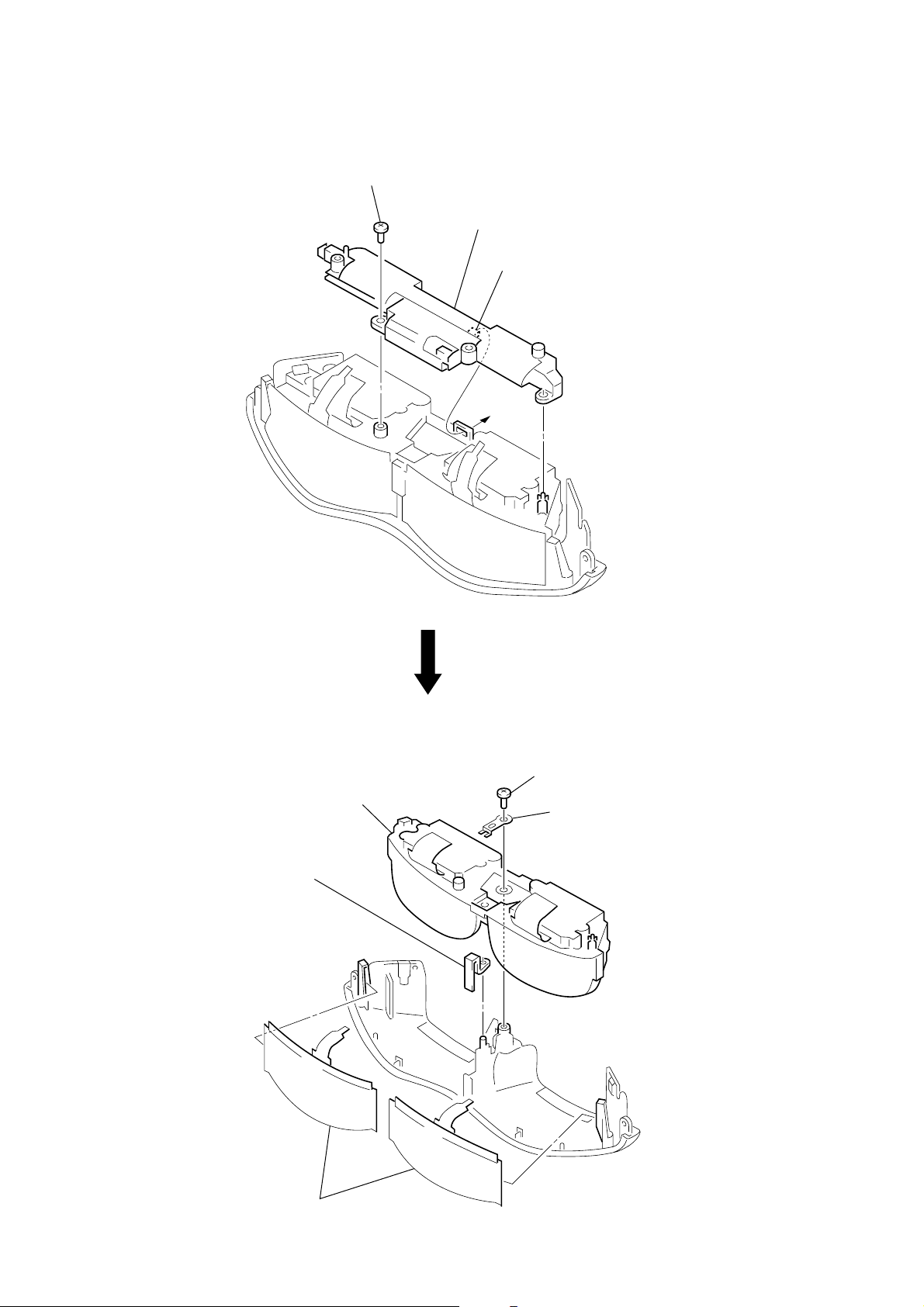

DISASSEMBLY

Note: Follow the disassembly procedure in the numerical order given.

LOADING BLOCK ASSY

1

screw

(M1.4

×

3.0)

6

FP661 flexible

board (CN803)

1

screw

(M1.4

×

3.0)

2

loading block assy

1

three screws

(M1.4

×

5

rear cabinet assy

3.0)

LC-61 BOARD

4

two claws

7

3

flexible board

(CN802)

flexible board

(CN805)

2

connector

(back light unit)

1

4

two screws

(M1.7 × 5)

3

3

screw

(M1.4

screw

(M1.4

×

3.0)

flexible board

(CN801)

6

4

two claws

×

3.0)

LC-61 board

2-1

1

front panel

5

connection cable

7

flexible board

(CN804)

BACK LIGHT UNIT

1

screw

(M1.7 × 5)

3

back light unit

2

claw

OPTICS BLOCK ASSY, FILM (PANEL) LIQUID CRYSTAL

3

optics block assy

4

shutter holder (C)

1

screw

(P1.7 × 4.0)

2

lens fixed plate

5

two film (panel) liquid crystals (C)

2-2 E

2-2

SECTION 3

White (100%)

approx.

0.3 V

approx.

0.7 V

approx.

0.3 V

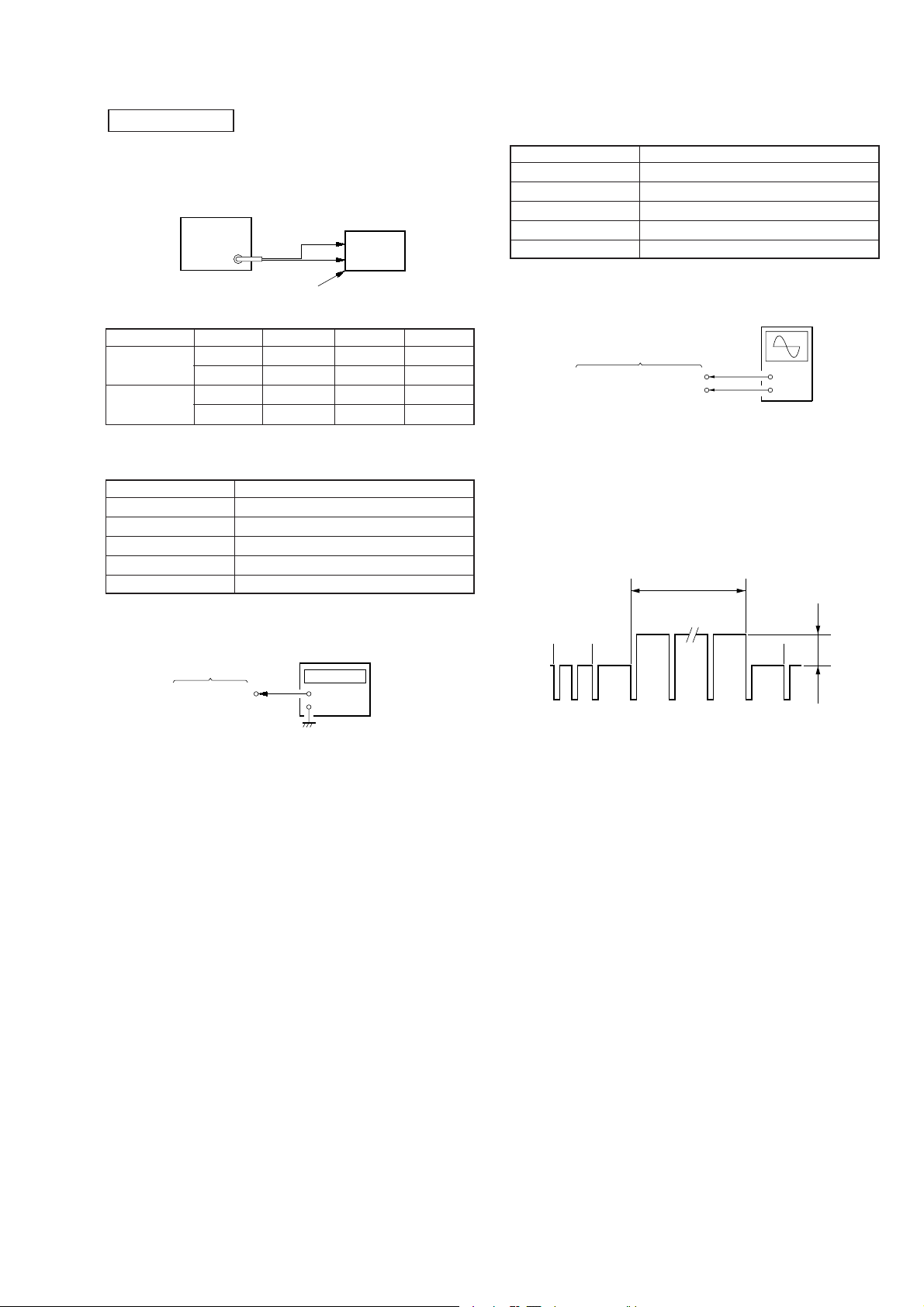

• When color bar signals are entered

Red

Burst signal (flat)

Horizontal sync signal

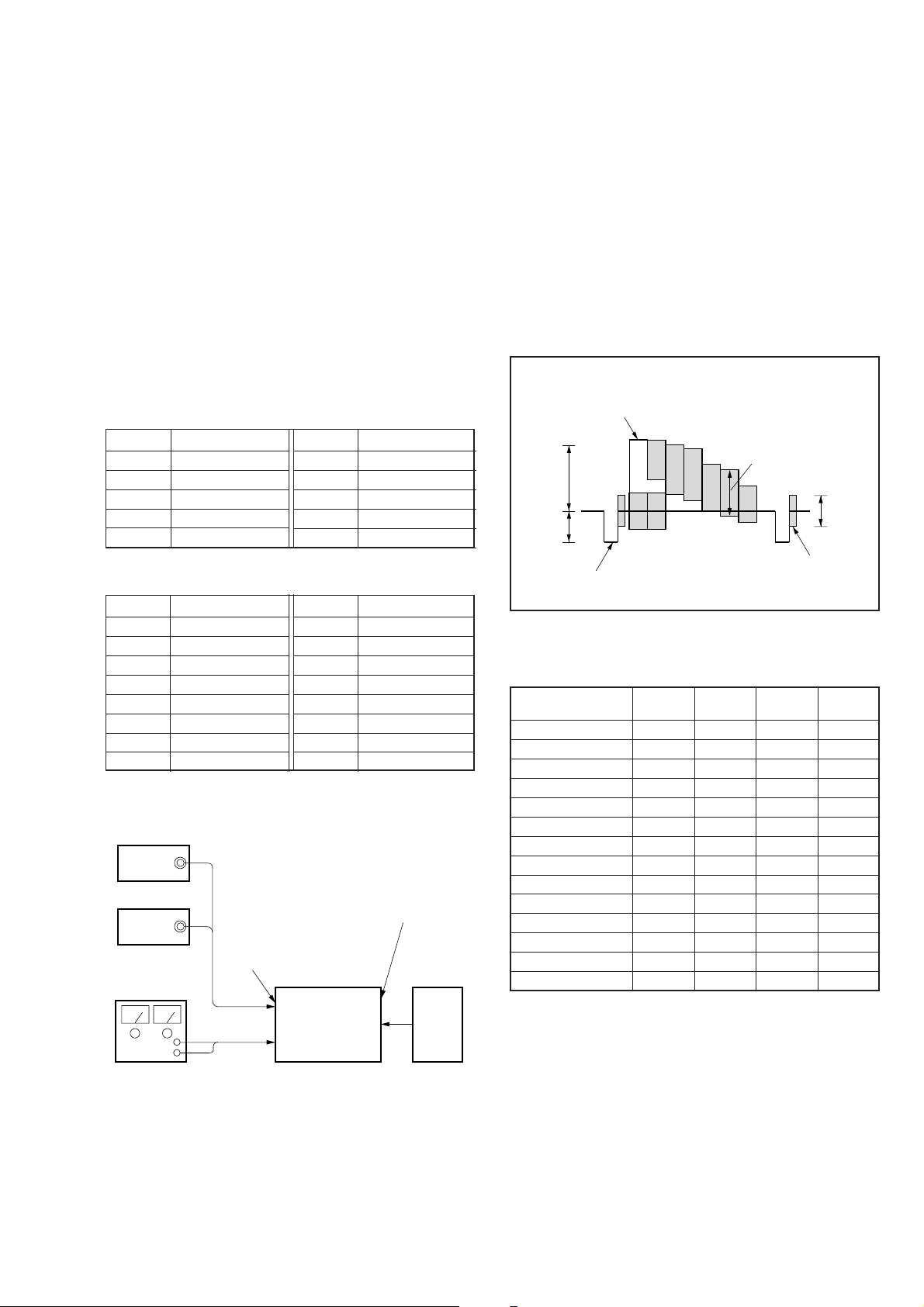

ELECTRICAL ADJUSTMENTS

Precautions on adjustment:

1. Perform the adjustment in the given order.

2. Power supply voltage: DC 8.4 V

3. Equipment required

Electrical adjustment requires the following measuring equipment.

(1) Oscilloscope: 2 phenomena, band 30 MHz or more, with de-

lay mode (use 10 : 1 probe unless otherwise specified)

(2) Pattern generator

(3) Regulated power supply × 2

(4) Digital voltmeter

(5) Frequency counter

(6) Connector for adjustment

4. Measurement points for adjustment are located at CN1003 on

the YC-148 board and at CN206 on the MA-324 board. The

pin No. and signal name of CN1003 and CN206 are listed below.

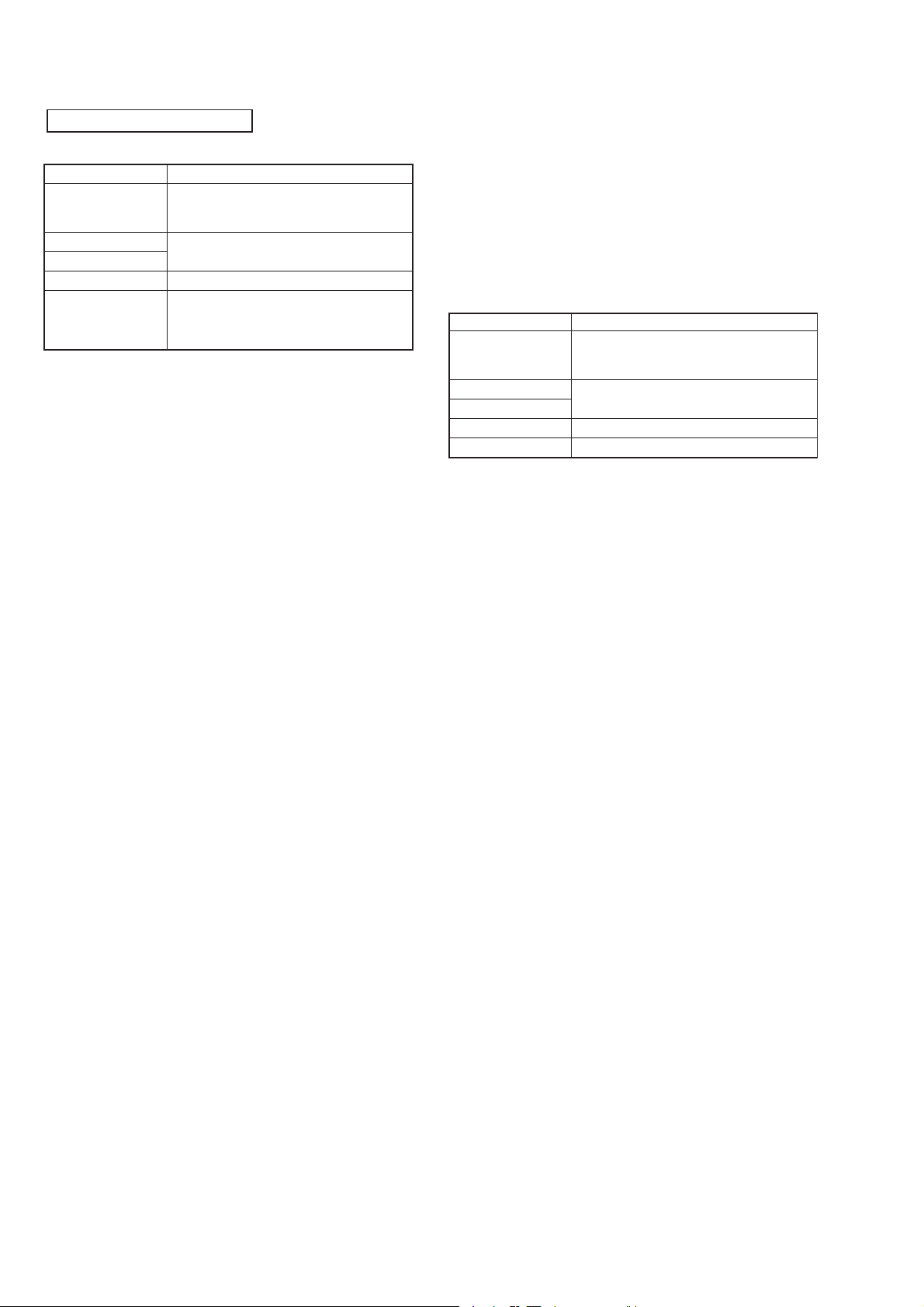

• YC-148 Board, CN1003

Pin No. Signal Name

1 GND

2 GND

3 GND

4 4FSC

5 GND

Pin No. Signal Name

6 GND

7 Y OUT

8 VIDEO G

9 N.C

10 GND

5. Setting up Input Signals

(1) Video Signal

In adjusting this set, video signals obtained from the pattern

generator are used, and therefore these video output signals

must satisfy the specification. Connect the oscilloscope to the

VIDEO IN terminal, and confirm that the sync signal amplitude of video signals is approximately 0.3 V, the amplitude of

video part is approximately 0.7 V, burst signal amplitude is

approximately 0.3 V and flat, and the level ratio of burst signal to “red” signal is 0.30 : 0.66.

Where “chroma signal, and color bar signal with burst signal

turned off” is specified in the text, enter chroma signal and

color bar signal of which burst signal is turned off to the VIDEO

IN terminal as video input signals for adjustment.

• MA-324 Board, CN206

Pin No. Signal Name

1 SIG R 1

2A

3 SIG G 1

4 POWER SW

5 SIG B 1

6 ENTER

7 INT H

8 VIDEO/XPC IN

Pin No. Signal Name

9 GND

10 GND

11 B

12 COM R

13 C

14 COM L

15 SIG CEN

16 P SIG B

Preparation:

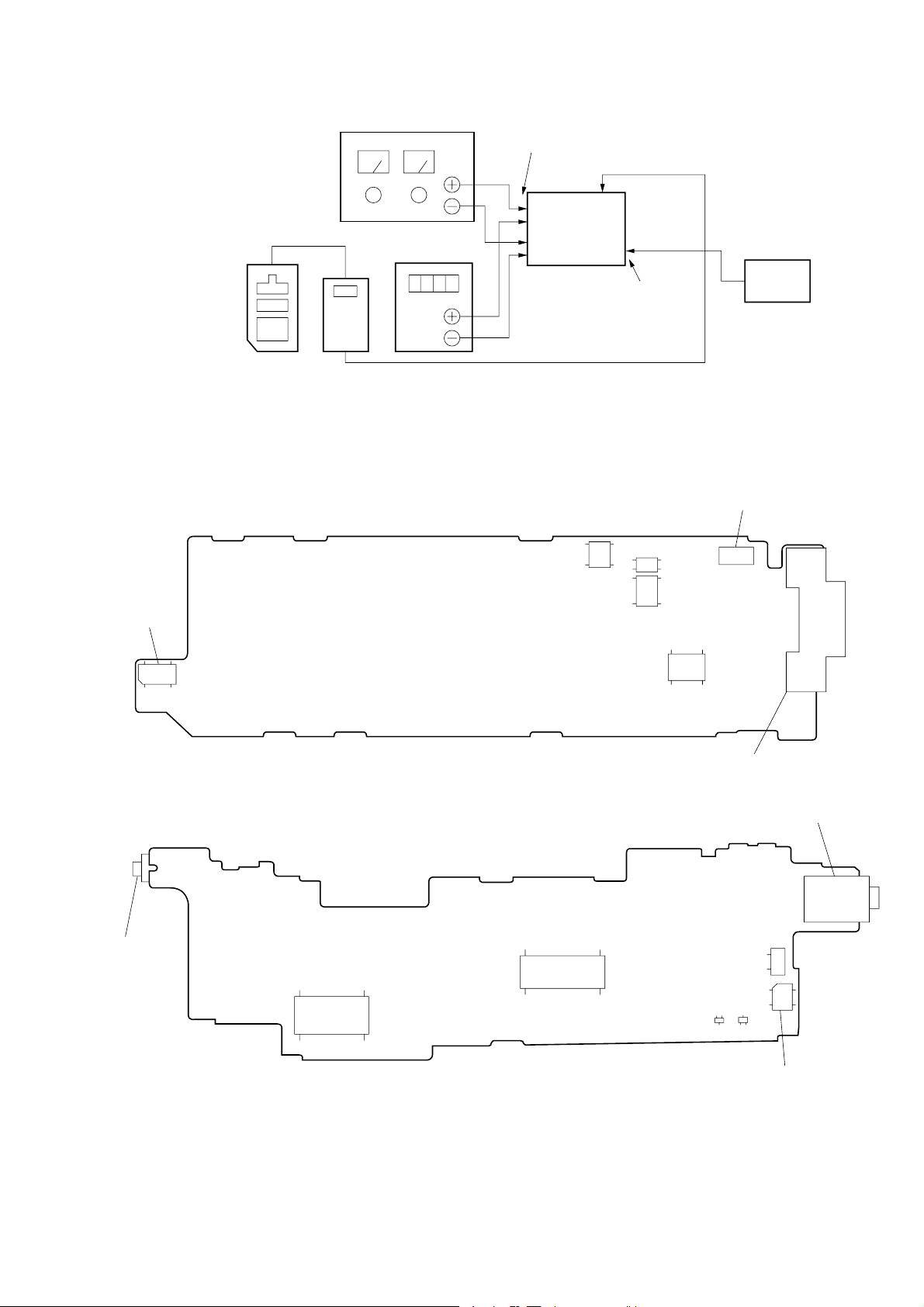

Connect electrical blocks as shown below.

VIDEO

SG

AUDIO

SG

DC 8.4V

AUDIO/VIDEO terminal

YC-148 board

(J1002)

DD-107 board

(J701)

suitable

Set PC

RGB terminal

MA-324 board

(J101)

Fig. 3-1. Pattern generator's color bar signals

(2) PC Signal (RGB signal)

Signal mode

PC98 24.82 56.41 640 400

VGA-TEXT 31.47 70.08 640 362

VGA-GRAP 31.47 59.94 640 480

VGA72 37.86 72.82 640 480

VGA75 37.50 74.99 640 480

MAC13’ 35.00 66.67 640 480

VGA85 43.27 85.01 640 480

SVGA56 35.16 56.26 800 600

SVGA60 37.88 60.32 800 600

SVGA72 48.08 72.19 800 600

SVGA75 46.88 75.01 800 600

SVGA85 53.68 85.07 800 600

MAC16’ 49.73 74.55 832 624

XGA60 48.36 59.99 1024 768

H V HDISP VDISP

(kHz) (Hz) (dots) (dots)

3-1

[Preparation for Adjustment]

1. Service Jigs

(1) Adjusting remote commander (RM-95-modified)

Note 1: J-6082-053-B

(2) Extension cable (for remote commander plug converter)

J-6082-291-A

Note 1: The page will not be changed over, unless the microprocessor in

the adjusting remote commander is a new one (UPD7503-G-C56-

12). In such a case, replace with new microprocessor (8-759148-35).

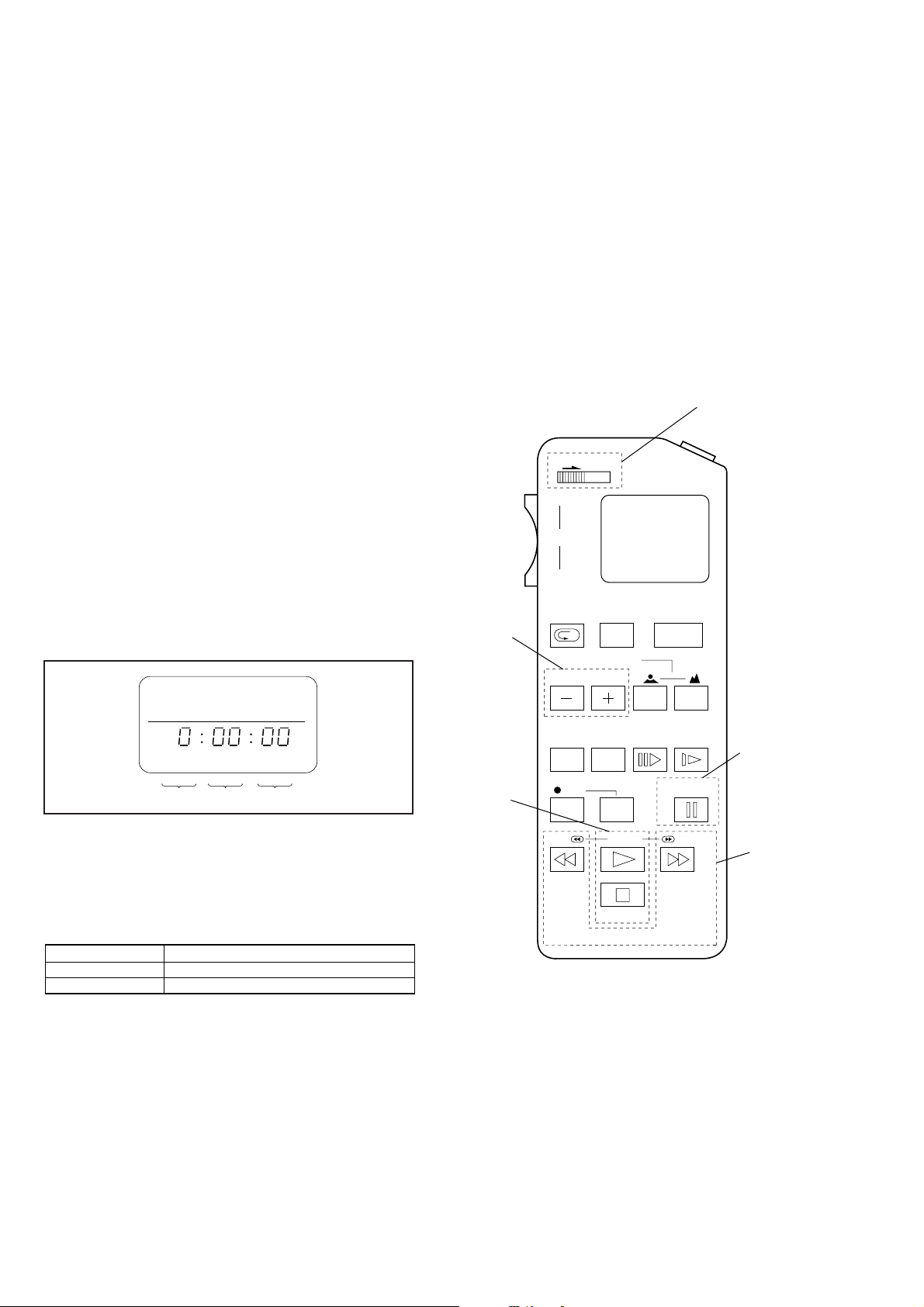

2. Adjusting Remote Commander

For the adjustment, the adjustment data saved in the nonvolatile memory (EEPROM) must be rewritten, and for this purpose the adjusting remote commander is used.

The adjusting remote commander makes two-way communication with the product using a remote control signal line

(LANC). The adjusting remote commander transmits pages,

addresses, and data up/down commands to the product. The

product transmits pages, addresses, and data to the adjusting

remote commander.

3. How to Use Adjusting Remote Commander

(1) Connect the adjusting remote commander to the CN501 on

MA-324 board via extension cable (J-6082-291A).

At this time, set the switch of extension cable to OFF

(

(OPEN) position.

Set the [PC] or [VIDEO] mode and turn ON the power on

the set.

(2) Set the HOLD switch on the adjusting remote commander to

the HOLD (SERVICE) position.

If connection is normal, the LCD display on the adjusting

remote commander will be as shown in Fig.3-2.

(4) Select page: 0, address: FF, and set 01 data. Thus, the data

input to page: E or F is enabled.

(5) After the adjustment finished, select page: 0, address: FF, and

set 00 data. Thus, the data change on page E or F is disabled.

(6) After all adjustments finished, turn OFF the main power sup-

ply (8.4 V) once.

4. Precaution on Use of Adjusting Remote Commander

Misoperation of the adjusting remote commander could erase

correct data. T o prev ent this, it is recommended to make a note

of data from page E or F before adjustment, and also to make

a note of new adjustment data each time the adjustment of one

item is finished.

Adjusting Remote Commander RM-95 (J-6082-053-B)

NORMAL/SERVICE

mode selection

)

Page change

HOLD

WIDE

ZOOM

TELE

REC

REVIEW

AUTO/MAN

EDIT SEARCH

FOCUS

START/

STOP

POWER

Page Data Address

Fig. 3-2

(3) Operate the adjusting remote commander as follows:

• Page change

Press the EDIT SEARCH + button to increase the page.

Press the EDIT SEARCH – button to decrease the page.

There are 16 pages from 0 to F.

Hexadecimal numbers

LCD display

Decimal conversion

0123456789ABCDEF

23456789A b c d E F

10

2 3 4 5 6 7 8 9 10 11 12 13 14 15

10

• Address change

Press the FF ()) button to increase the address.

Press the REW (0) button to decrease the address.

There are 256 addresses from 00 to FF.

• Data change (data setting)

Press the PLAY (() button to increase the data.

Press the STOP (p) button to decrease the data.

There are 256 data from 00 to FF.

• Adjustment data writing

The PAUSE button must be pressed to write adjustment

data (E or F pages) to the nonvolatile memory (EEPR OM).

(Unless the PAUSE is pressed, new data are not saved in

the nonvolatile memory.)

Data change

COUNTER

RESET DISPLAY FRAME SLOW

PAUSE

FF

RM-95

REW

REC

PB

STOP

Fig. 3-3

Data writing

Address

change

3-2

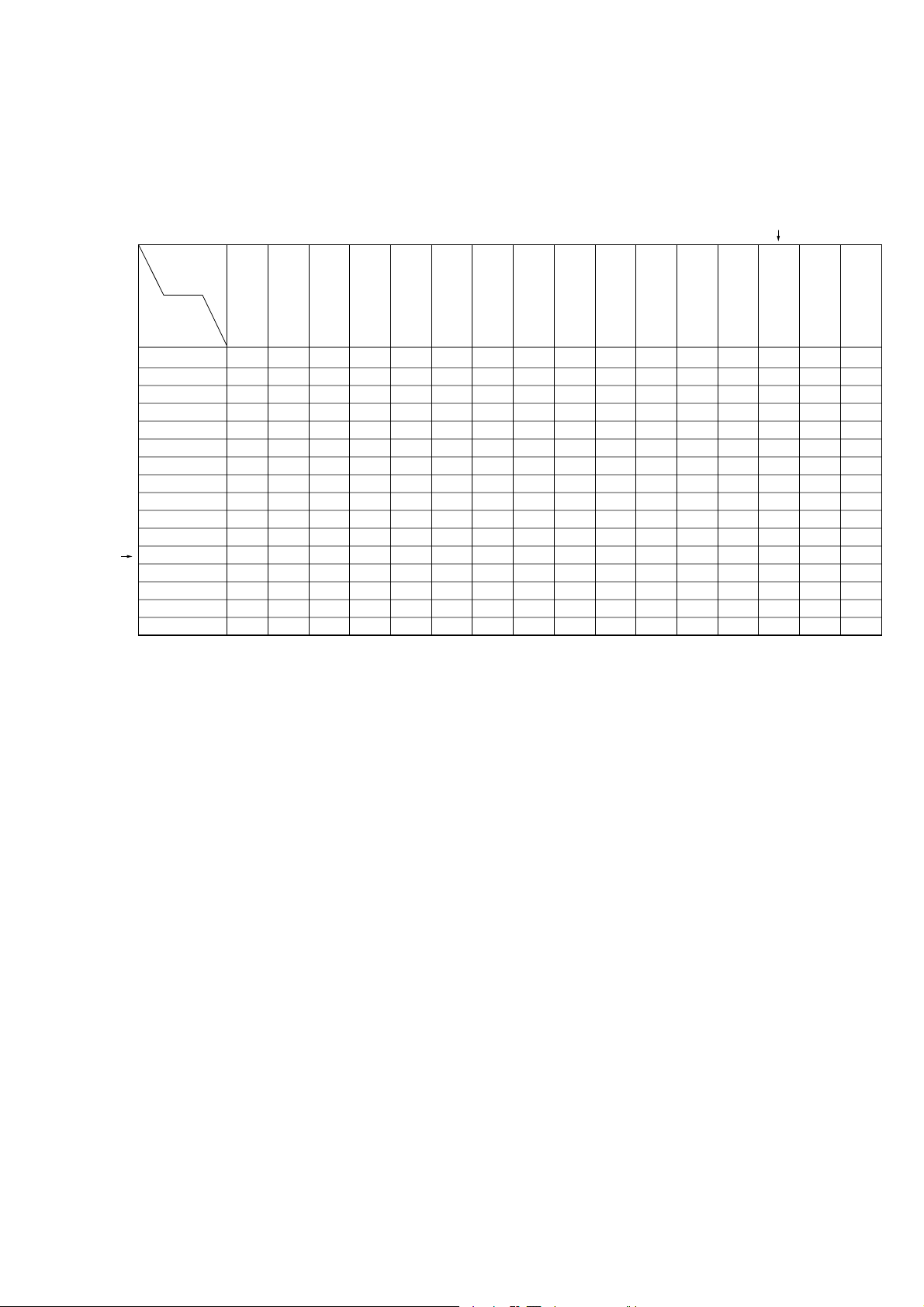

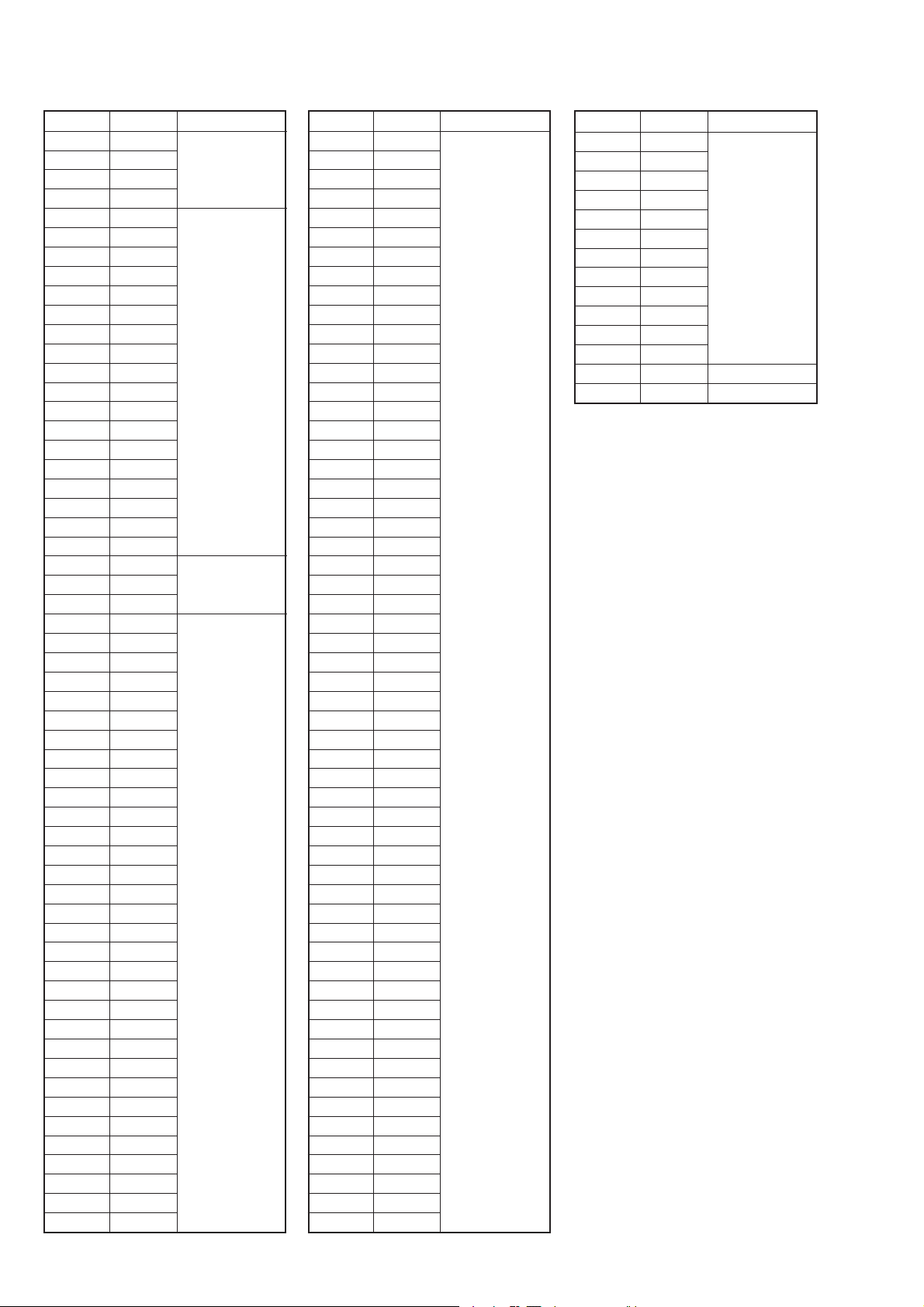

5. Data Processing

Certain adjustment items require the microprocessor data to be read out or the displayed data (hexadecimal numbers) on jigs or

adjusting remote commander to be calculated to get adjustment data. In such a case, convert hexadecimal numbers into decimal

numbers once, then make calculation, and convert its result into he xadecimal n umber as adjustment data. Table 1 shows hexadecimal

– decimal number conversion.

Hexadecimal – Decimal number conversion.

Lower digit

of hex.

0123456789

Higher digit

of hex.

00

123456789

1

1

2

3

4

5

6

7

8

9

A (A)

B (b)

C (c)

D (d)

E (E)

F (F)

16 17 18 19 20 21 22 23 24 25

32 33 34 35 36 37 38 39 40 41

48 49 50 51 52 53 54 55 56 57

64 65 66 67 68 69 70 71 72 73

80 81 82 83 84 85 86 87 88 89

96 97 98 99 100 101 102 103 104 105

112 113 114 115 116 117 118 119 120 121

128 129 130 131 132 133 134 135 136 137

144 145 146 147 148 149 150 151 152 153

160 161 162 163 164 165 166 167 168 169

176 177 178 179 180 181 182 183 184 185

192 193 194 195 196 197 198 199 200 201

208 209 210 211 212 213 214 215 216 217

224 225 226 227 228 229 230 231 232 233

240 241 242 243 244 245 246 247 248 249

Tab le 1.

2

A

(A) B(b) C(c) D(d) E(E) F(F)

10

26

42

58

74

90

106

122

138

154

170

186

202

218

234

250

11

27

43

59

75

91

107

123

139

155

171

187

203

219

235

251

12

13 14 15

28

29 30 31

44

45 46 47

60

61 62 63

76

77 78 79

92

93 94 95

108

109 110 111

124

125 126 127

140

141 142 143

156

157 158 159

172

173 174 175

188

189 190 191

204

205 206 207

220

221 222 223

236

237 238 239

252

253 254 255

Note: Data in ( ) are displayed on jig or adjusting remote commander.

Example:If display on jig or adjusting remote commander is BD (bd)

As higher digit of hex. number is B (b) and lower digit is D (d), the intersection “189” of 1 and 2 in Table 1 is the target decimal number.

3-3

6. Power ON Procedure for Adjustment

(1) Connect an extension cable to the adjusting remote commander.

(2) Set the [PC] or [VIDEO] mode on the set.

(3) After making sure that the HOLD switch on the adjusting remote commander is not turned on (not at left (NOR) position), supply 8.4

Vdc to the DC IN (J701).

(With the HOLD switch at HOLD position, the initial operation of the set does not finish, disabling the POWER switch function.)

(4) Turn ON the POWER switch on the set. Confirm that a green LED lights up.

(5) Set the HOLD switch on the adjusting remote commander to the HOLD (right (ADJ)) position.

7. Adjustment Finishing Procedure

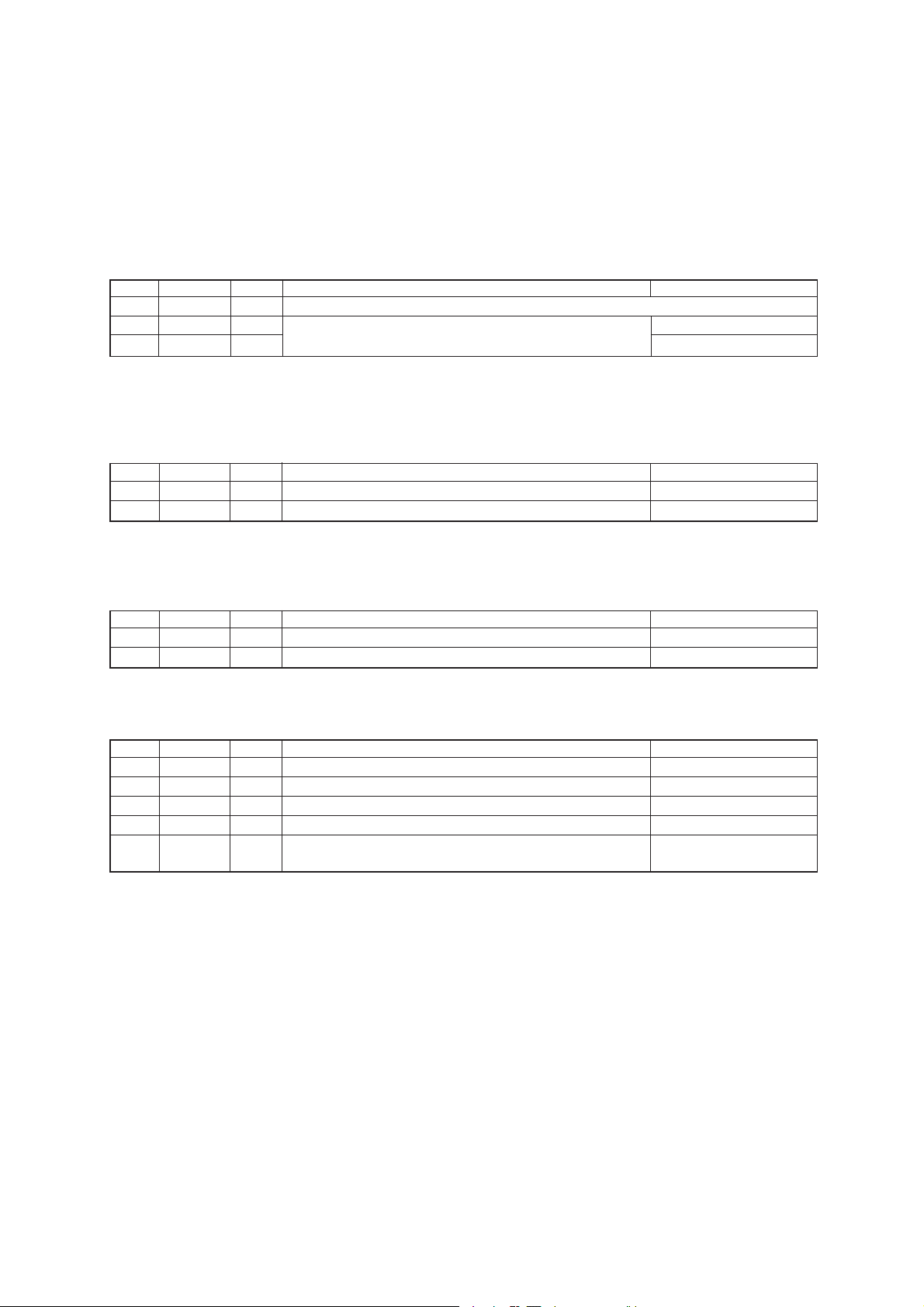

Order Page Address Data Description Remarks

1. E or F Check if adjusted data are written correctly to the given page and address.

2. 2 FF 00

3. 0 FF 00 Page E or F: Write protect

4. Set HOLD switch on adj. remote commander to NOR position.

Set data 00 to given page and address.

Page 2: Reset

8. Password Reset (for operation check of the set)

(1) Turn the PO WER switc h on, then press the “Pass word Reset” a t the bottom of Po wer Bo x to reset the passwor d set by the customer.

(2) Operating the jog dial, select “No” on the Password Set screen to set “disuse of password”.

Or,

Order Page Address Data Description Remarks

1. 0 01 01 Set data 01 to given page and address. Page E or F: Cancel protect

2. E or F 04 FF Set data FF to given page and address and press PAUSE. Set disuse of password

Final: After all adjustments and operation check finished, turn the POWER switch on, press the "Password Reset" at the bottom of Power Box, and

turn the POWER switch off.

9. EXT. VIDEO AUDIO mode: Turn the POWER switch on, and press and operate the jog dial from the initial screen.

Or,

Order Page Address Data Description Remarks

1. 2 00 01 Set data 01 to given page and address.

2. 2 2B 00 Set data 00 to given page and address.

10. Picture and tone quality standard setting: Press the MENU button and set the BRIGHT control.

Or,

Set data 01 to page:0, address:01 to cancel the protect on page F.

Order Page Address Data Description Remarks

F 7B 3F Set data 3F to given page and address, and press PAUSE. Ope. – Brightness: Center

F 53 40 Set data 40 to given page and address, and press PAUSE. Ope. – Contrast: Center

F 50 3F Set data 3F to given page and address, and press PAUSE. Ope. – Hue: Center

F 51 3F Set data 3F to given page and address, and press PAUSE. Ope. – Density: Center

F 8C 02 Set data 02 to given page and address, and press PAUSE.

Ope.– Bass boost: 0,

VOL. limit: OFF

Volume (Display unit) – Maximum

3-4

[Preset Data Writing]

Connection:

(1) Connect the adjusting remote commander to the CN501 on MA-324 board, and set the [VIDEO] mode (S904).

Data Writing Procedure

(1) Set data: 01 to page: 0, address: 01.

(2) Enter the data given in the table below.

Note: To write the data to the EEPROM, press the PAUSE button on the adjusting remote commander each time the data is set.

(3) After writing all data, set data: 00 to page: 0, address: FF.

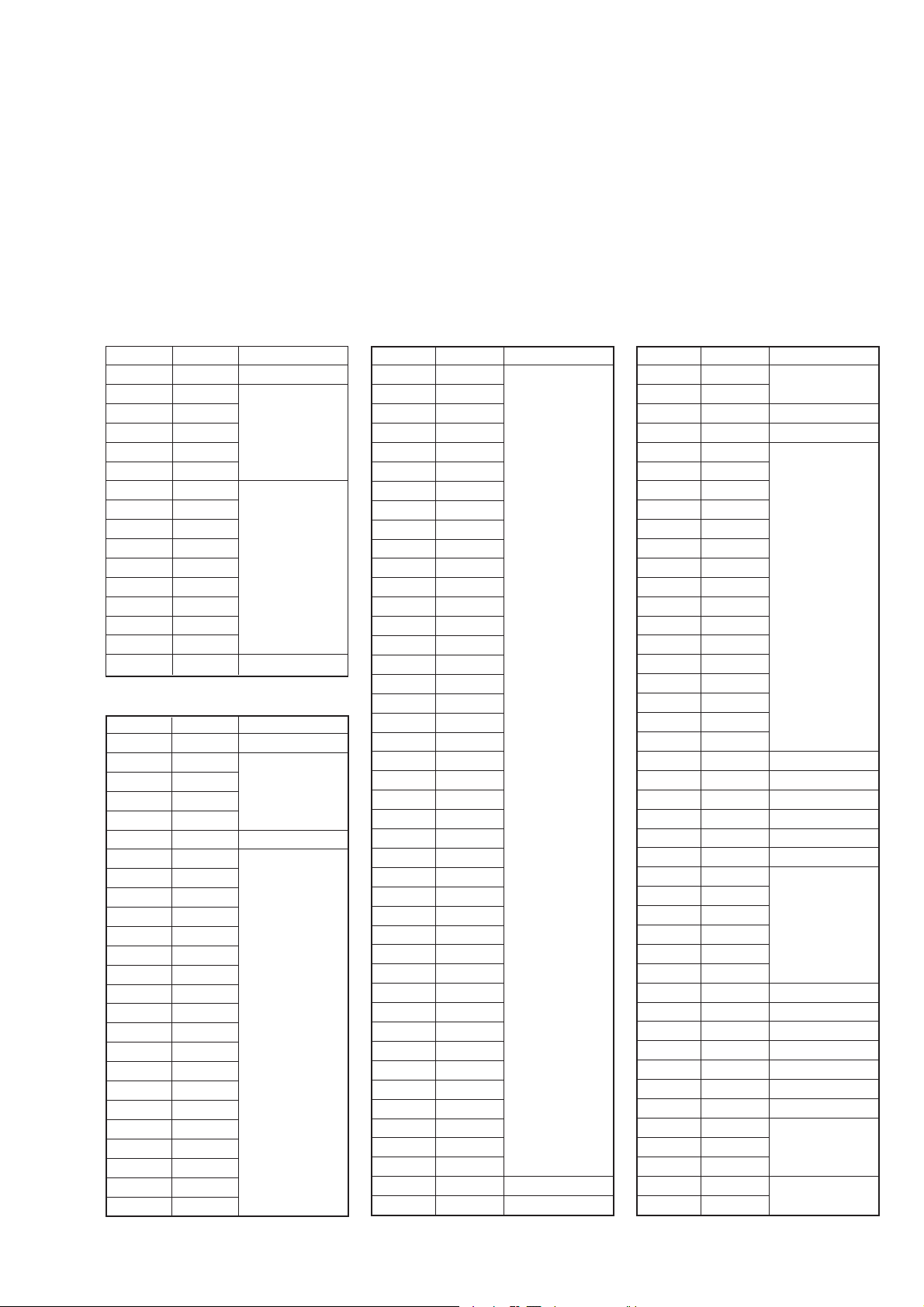

E or F Page Adjustment Address and Initial Value

Make setting and adjustment only when IC502 (EEPROM) was replaced.

E Page:

Address Data Remarks

00 01 Fixed value

01 EB

02 DC

03 DA

04 8C

05 DE

06 DC

07 05

08 08

09 07

0A B8 Fixed value

0B 0B

0C 60

0D 54

0E 40

0F – FF – Not used

Charge adj.

F Page:

Address Data Remarks

00 – 0F – Not used

10 00

11 01

12 00

13 FF

14 01 Video adj.

15 03

16 FF

17 00

18 00

19 FF

1A FF

1B FF

1C FF Fixed value

1D FF

1E FF

1F FF

20 00

21 03

22 DE

23 86

24 12

25 1F

26 00

27 00

Fixed value

Address Data Remarks

28 01

29 03

2A 02

2B 05

2C 1D

2D FC

2E 1F

2F 18

30 04

31 40

32 10

33 06

34 47

35 03

36 00

37 00

38 00

39 24

3A 24

3B 24

3C 4C

3D 4C Fixed value

3E 4C

3F 3F

40 3F

41 3F

42 9C

43 9C

44 9C

45 00

46 00

47 00

48 40

49 40

4A 40

4B C1

4C C0

4D C0

4E 41

4F 00

50 40

51 3F

52 7A Video adj.

53 3F Fixed value

Address Data Remarks

54 5B

55 80

56 87 H-Sync adj.

57 80 Loading adj.

58 00

59 00

5A 00

5B 00

5C 80

5D 80

5E 80

5F AE

60 AE

61 AE

62 03

63 03

64 03

65 2F

66 2F

67 2F

68 65 R Gain adj.

69 65 G Gain adj.

6A 65 B Gain adj.

6B 94 R Bias adj.

6C 94 G Bias adj.

6D 94 B Bias adj.

6E 80

6F 80

70 80

71 80

72 80

73 80

74 9A SigCen adj.

75 35 V COM R adj.

76 35 V COM L adj.

77 00 Fixed value

78 3E Sid Lvl adj.

79 6A Prg Lvl adj.

7A 60 Blk Lim adj.

7B 1F

7C 00 Fixed value

7D FF

7E 5B

7F 63

Video adj.

Fixed value

Fixed value

Battery down adj.

3-5

Address Data Remarks

80 73

81 7B

82 80

83 01

84 49

85 FF

86 00

87 00

88 00

89 00

8A 00

8B 00

8C 02

8D 00

8E 00

8F 00

90 80

91 41

92 00

93 00

94 80

95 41

96 5D

97 29 Video adj.

98 4F

99 FF

9A 80

9B FF

9C 01

9D FF

9E FF

9F FF

A0 81

A1 38

A2 20

A3 3A

A4 1C

A5 40

A6 45

A7 42

A8 45 Fixed value

A9 42

AA A5

AB 44

AC A5

AD 44

AE C0

AF 46

B0 A1

B1 4F

B2 D8

B3 52

B4 11

B5 55

B6 26

B7 58

B8 22

Battery down adj.

Fixed value

Address Data Remarks

B9 48

BA 5B

BB 4A

BC 17

BD 21

BE A8

BF 22

C0 CB

C1 1A

C2 CF

C3 1B

C4 0C

C5 26

C6 22

C7 28

C8 99

C9 1E

CA EE

CB 1F

CC E1

CD 1C

CE 10

CF 1E

D0 B2

D1 25

D2 BE

D3 27 Fixed value

D4 D9

D5 1D

D6 1E

D7 1F

D8 1D

D9 2D

DA 14

DB 30

DC 68

DD 1A

DE 68

DF 1A

E0 B4

E1 28

E2 19

E3 2B

E4 1D

E5 2D

E6 14

E7 30

E8 AD

E9 25

EA B8

EB 27

EC AD

ED 1D

EE EE

EF 1E

F0 84

F1 28

Address Data Remarks

F2 E3

F3 2A

F4 B6

F5 38

F6 78

F7 3D

F8 CC

F9 1A

FA 03

FB 00

FC 00

FD 00

FE 00 Charge adj.

FF FF Fixed value

Fixed value

3-6

VIDEO BLOCK

r

To adjust the video block, connect a pattern generator as shown

below. As video input signals for adjustment, enter video output

signals (color bar signals), unless otherwise specified.

Pattern Generator

Set

[Video Mute Level Adjustment]

Condition:

Input signal All black (IRE 0%) signal (No set up)

Measurement point YC-148 board CN1003 pin 7

Measuring equipment Oscilloscope

Adjustment page F

Adjustment address 52

Specification value 0 ± 0.03 Vp-p

VIDEO IN jack (J1002)

Preparation:

Page Address Data

Sub-Color

Switch the PAL F 14 01

Signal mode (NTSC) (F) (14) (00)

PAL F 54 5B

(NTSC) (F) (54) (80)

[4fsc FreeRun Adjustment]

Condition:

Input signal No signal

Measurement point YC-148 board CN1003 pin 4

Measuring equipment Frequency Counter

Adjustment page F

Adjustment address 55

Specification value 17.73450 MHz ± 20 Hz (PAL)

Connection:

Frequency Counte

YC-148 Board

CN1003 pin

(4FSC)

4\

+

–

Connection:

YC-148 Board

7

CN1003 pin

CN1003 pin

Adjustment Procedure:

(1) Connect a oscilloscope to the CN1003 pin 7 on the YC-148

(YOUT)

1

(GND)

Oscilloscope

(DC range)

+

–

board.

(2) Set (or confirm) data: 01 to page 0, address 01. (Cancel F

page protect)

(3) On page F, address: 52, change data with the PLAY and STOP

buttons and press the PAUSE button to write data so that the

A level of wafeform on the oscilloscope satisf ies the specification value.

24H11H

9H 10H 25H

A

Adjustment and Adjustment Parts: YC-148 board (see page 3-15)

Adjustment Procedure:

(1) Connect a frequency counter to the CN1003 pin 4 on the

YC-148 board.

(2) Set (or confirm) data: 01 to page: 0, address: 01.

(Cancel F page protect)

(3) On page: F, address: 55, change data with the PLAY and

STOP buttons and press the PAUSE button to write data so

that the frequency counter reading satisfies the specification

value.

Adjustment and Adjustment Parts: YC-148 board (see page 3-15)

3-7

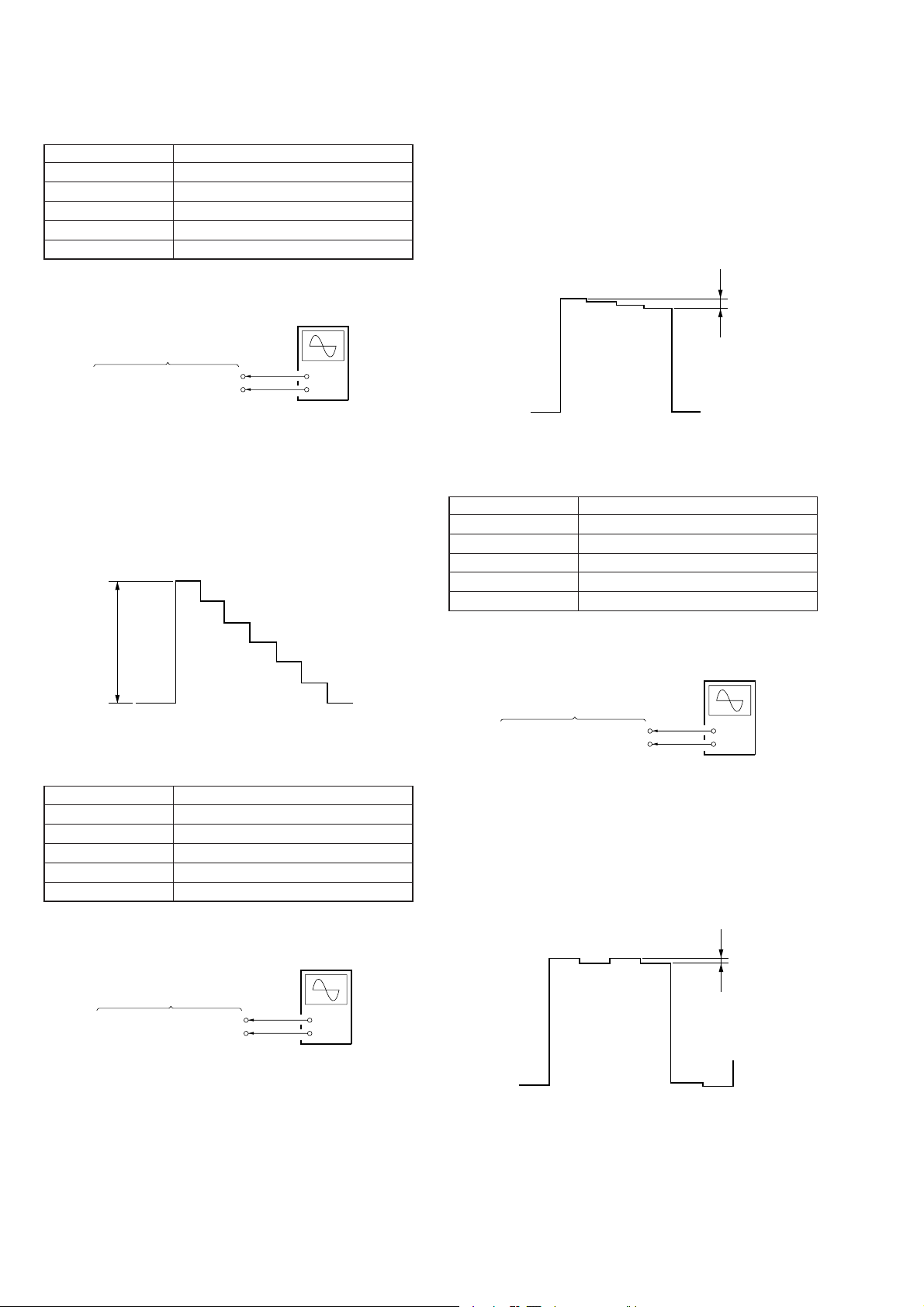

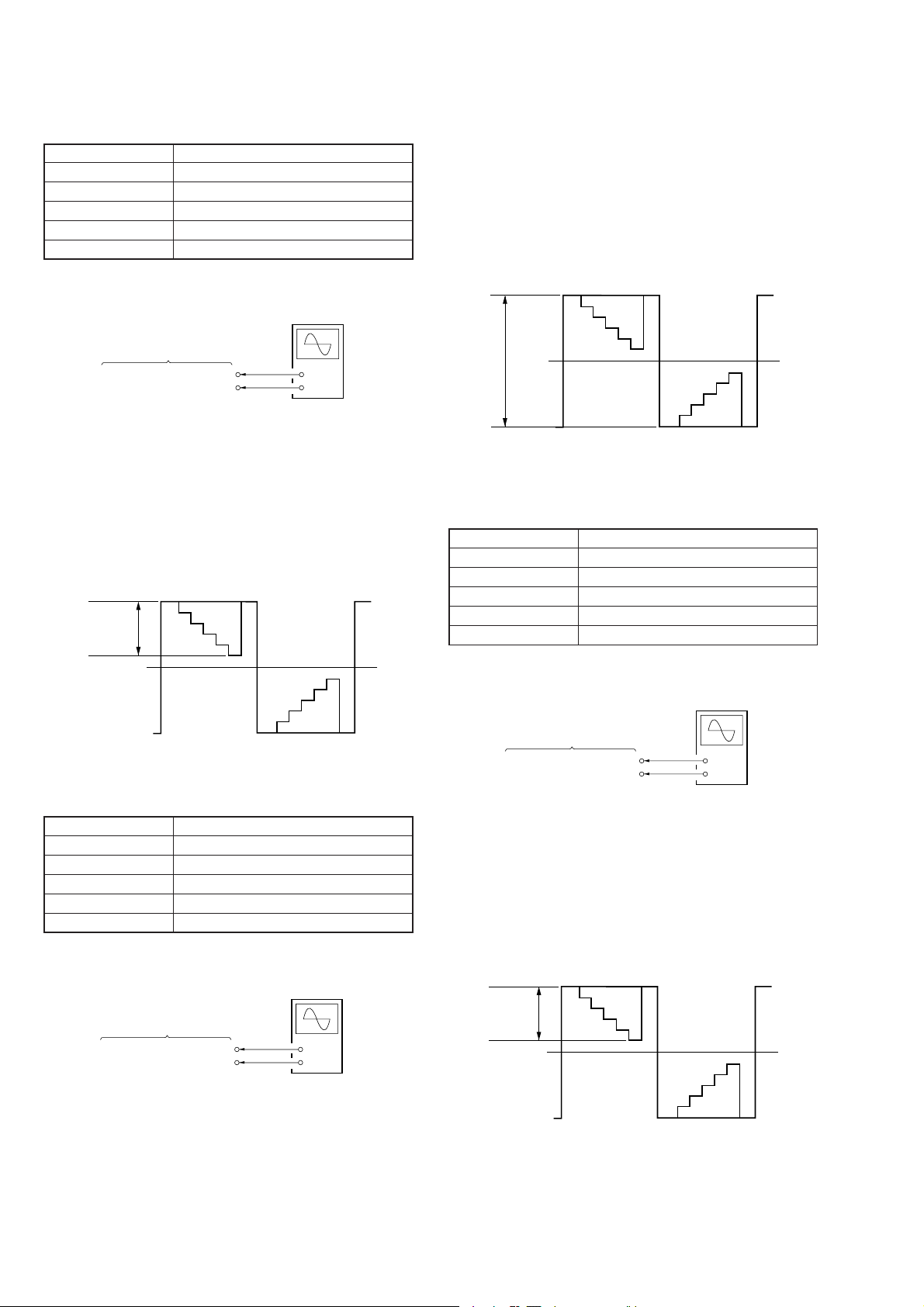

[Video Contrast Adjustment]

Condition:

Input signal 10 step signal (Whie: 100 IRE level)

Measurement point YC-148 board CN1003 pin 8

Measuring equipment Oscilloscope

Adjustment page F

Adjustment address 96

Specification value 0.7 ± 0.02 Vp-p

Adjustment Procedure:

(1) Connect a oscilloscope to the CN1003 pin 8 on the YC-148

board.

(2) Set (or confirm) data: 01 to page 0, address 01. (Cancel F

page protect)

(3) On page F, address: 98, change data with the PLAY and STOP

buttons and press the PAUSE button to write data so that the

C level of wafeform on the oscilloscope satisfies the specification value.

Connection:

YC-148 Board

8

CN1003 pin

CN1003 pin

Adjustment Procedure:

(1) Connect a oscilloscope to the CN1003 pin 8 on the YC-148

(VIDEO G)

1

(GND)

Oscilloscope

(DC range)

+

–

board.

(2) Set (or confirm) data: 01 to page 0, address 01. (Cancel F

page protect)

(3) On page F, address: 96, change data with the PLAY and STOP

buttons and press the PAUSE button to write data so that the

B level of wafeform on the oscilloscope satisfies the specification value.

B

Adjustment and Adjustment Par ts: YC-148 board (see page 3-15)

[Color Adjustment]

Condition:

Input signal Color bar signal

Measurement point YC-148 board CN1003 pin 8

Measuring equipment Oscilloscope

Adjustment page F

Adjustment address 98

Specification value 0 ± 0.02 Vp-p

Connection:

Oscilloscope

(DC range)

C

Adjustment and Adjustment Parts: YC-148 board (see page 3-15)

[Hue Adjustment]

Condition:

Input signal Color bar signal

Measurement point YC-148 board CN1003 pin 8

Measuring equipment Oscilloscope

Adjustment page F

Adjustment address 97

Specification value 0 ± 0.02 Vp-p

Connection:

Oscilloscope

(DC range)

YC-148 Board

8

CN1003 pin

CN1003 pin

Adjustment Procedure:

(1) Connect a oscilloscope to the CN1003 pin 8 on the YC-148

(VIDEO G)

1

(GND)

+

–

board.

(2) Set (or confirm) data: 01 to page 0, address 01. (Cancel F

page protect)

(3) On page F, address: 97, change data with the PLAY and STOP

buttons and press the PAUSE button to write data so that the

D level of wafeform on the oscilloscope satisfies the specification value.

D

YC-148 Board

CN1003 pin

CN1003 pin

8

(VIDEO G)

1

(GND)

+

–

Adjustment and Adjustment Parts: YC-148 board (see page 3-15)

3-8

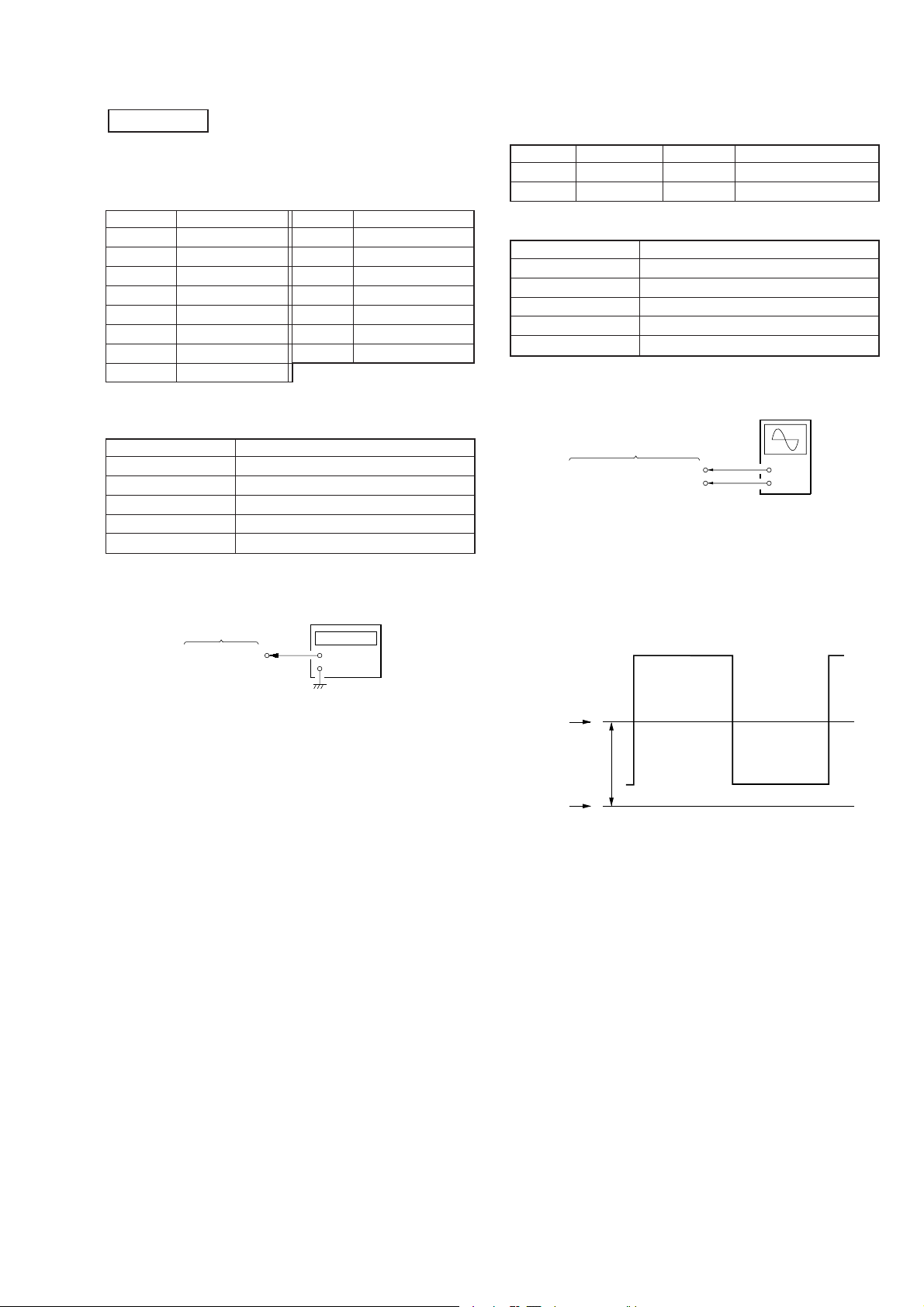

PC BLOCK

r

E

Signal

Center

GND

• To adjust the PC block, set the PC mode on the set.

• For the PC block adjustment, input a PC RGB signals. (J101 on

the MA-324 board) The pin No. and signal name of J101 is

listed below.

Pin No. Signal Name Pin No. Signal Name

1 Red 9 Sync GND

2 Green 10 GND

3 Blue 11 GND

4–12–

5 GND 13 H-Sync

6 RGB GND 14 V-Sync

7 RGB GND 15 –

8 RGB GND

[H-Sync Frequency Adjustment]

Condition:

Input signal No signal

Measurement point MA-324 board CN206 pin 7

Measuring equipment Frequency Counter

Adjustment page F

Adjustment address 56

Specification value 38 ± 1 kHz

Connection:

Frequency Counte

MA-324 Board

CN206 pin

(INT H)

7\

+

–

[Signal Center Level Adjustment]

Preparation:

Page Address Data Remarks

F 7B 1F BRIGHT (Center)

F 11 03 BRIGHT (Fixed)

Condition:

Input signal SVGA60 Hz: All Black

Measurement point MA-324 board CN206 pin 3

Measuring equipment Oscilloscope

Adjustment page F

Adjustment address 74

Specification value 7.0 ± 0.1 V

Connection:

MA-324 Board

3

CN206 pin

CN206 pin

Adjustment Procedure:

(1) Connect a frequency counter to the CN206 pin 3 on the

(SIG G 1)

9

(GND)

Oscilloscope

(DC range)

+

–

MA-324 board.

(2) Set (or confirm) data: 01 to page: 0, address: 01.

(Cancel F page protect)

(3) On page: F, address: 74, change data with the PLAY and

STOP buttons and press the PAUSE button to write data so

that the E level of waveform on the oscilloscope.

Adjustment Procedure:

(1) Connect a frequency counter to the CN206 pin 7 on the

MA-324 board.

(2) Set (or confirm) data: 01 to page: 0, address: 01.

(Cancel F page protect)

(3) On page: F, address: 56, change data with the PLAY and

STOP buttons and press the PAUSE button to write data so

that the frequency counter reading satisfies the specification

value.

Adjustment and Adjustment Parts: MA-324 board (see page 3-15)

Adjustment and Adjustment Parts: MA-324 board (see page 3-15)

3-9

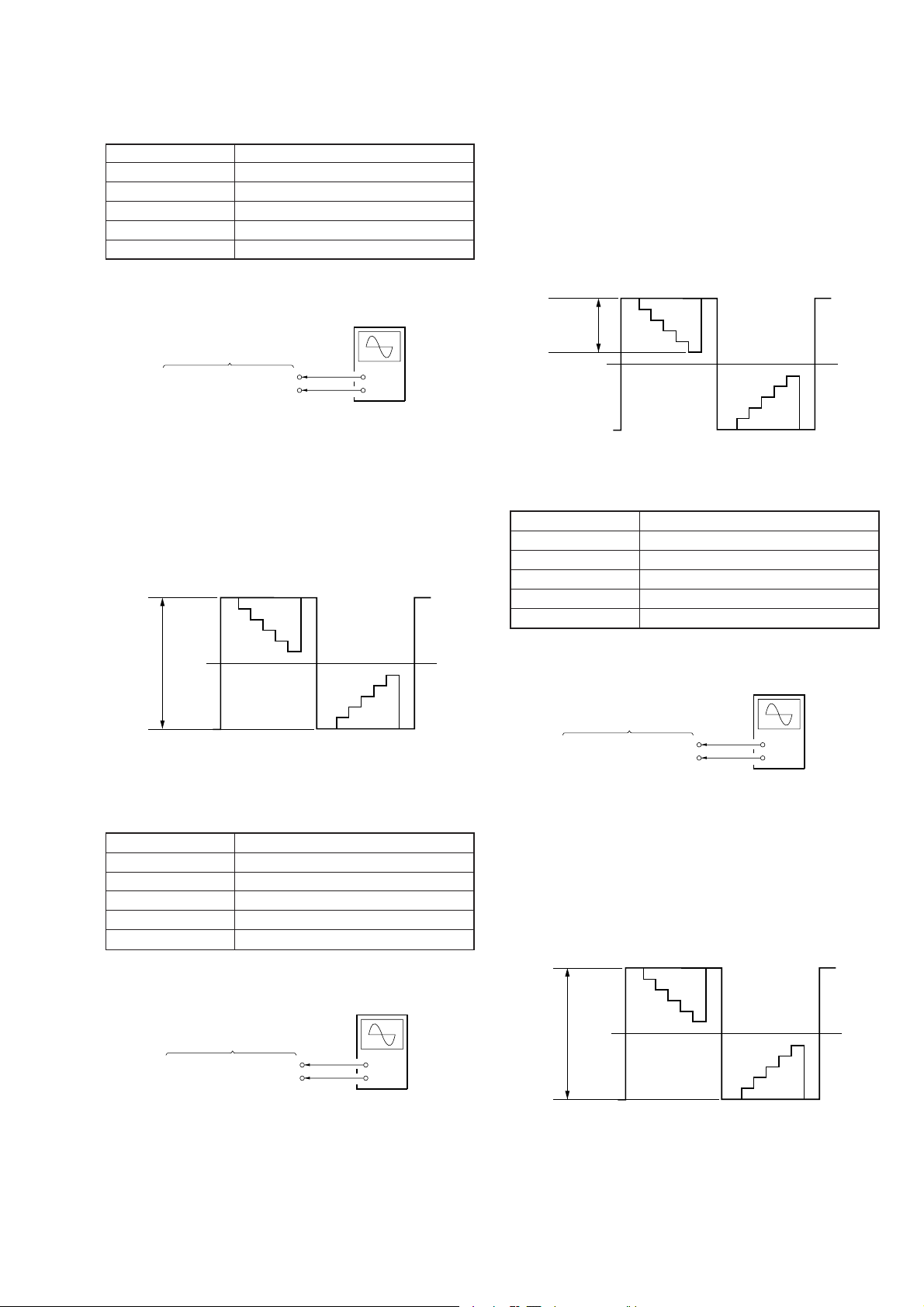

[R Gain Adjustment]

Condition:

Input signal SVGA 60 Hz: RGB 0.7 Vp-p, 16 Step

Measurement point MA-324 board CN206 pin 1

Measuring equipment Oscilloscope

Adjustment page F

Adjustment address 68

Specification value 2.7 ± 0.1 Vp-p

Connection:

Oscilloscope

(DC range)

Adjustment Procedure:

(1) Connect an oscilloscope to the CN206 pin 1 on the MA-

324 board.

(2) Set (or confirm) data: 01 to page: 0, address: 01.

(Cancel F page protect)

(3) On page: F, address: 6B, change data with the PLAY and

STOP buttons and press the PAUSE button to write data so

that the G level of waveform on the oscilloscope satisfies

the specification value.

Black

Level

MA-324 Board

1

CN206 pin

CN206 pin

Adjustment Procedure:

(1) Connect an oscilloscope to the CN206 pin 1 on the MA-

(SIG R 1)

9

(GND)

+

–

324 board.

(2) Set (or confirm) data: 01 to page: 0, address: 01.

(Cancel F page protect)

(3) On page: F, address: 68, change data with the PLAY and

STOP buttons and press the PAUSE button to write data so

that F level of waveform on the oscilloscope satisfies the

specification value.

Black

Level

F

White

Level

Adjustment and Adjustment Parts: MA-324 boar d (see page 3-15)

[R Bias Adjustment]

Condition:

Input signal SVGA 60 Hz: RGB 0.7 Vp-p, 16 Step

Measurement point MA: 324 board CN206 pin 1

Measuring equipment Oscilloscope

Adjustment page F

Adjustment address 6B

Specification value 8.4 ± 0.1 Vp-p

Connection:

Oscilloscope

(DC range)

MA-324 Board

CN206 pin

CN206 pin

1

(SIG R 1)

9

(GND)

+

–

G

Black

Level

Adjustment and Adjustment Parts: MA-324 board (see pag e 3-15)

[G Gain Adjustment]

Condition:

Input signal SVGA 60 Hz: RGB 0.7 Vp-p, 16 Step

Measurement point MA-324 board CN206 pin 3

Measuring equipment Oscilloscope

Adjustment page F

Adjustment address 69

Specification value 2.7 ± 0.1 Vp-p

Connection:

Oscilloscope

(DC range)

MA-324 Board

3

CN206 pin

CN206 pin

Adjustment Procedure:

(1) Connect an oscilloscope to the CN206 pin 3 on the MA-

(SIG G 1)

9

(GND)

+

–

324 board.

(2) Set (or confirm) data: 01 to page: 0, address: 01.

(Cancel F page protect)

(3) On page: F, address: 69, change data with the PLAY and

STOP buttons and press the PAUSE button to write data so

that H level of waveform on the oscilloscope satisfies the

specification value.

Black

Level

H

White

Level

Adjustment and Adjustment Parts: MA-324 board (see pag e 3-15)

3-10

[G Bias Adjustment]

Condition:

Input signal SVGA 60 Hz: RGB 0.7 Vp-p, 16 Step

Measurement point MA-324 board CN206 pin 3

Measuring equipment Oscilloscope

Adjustment page F

Adjustment address 6C

Specification value 8.4 ± 0.1 Vp-p

Adjustment Procedure:

(1) Connect an oscilloscope to the CN206 pin 5 on the MA-

324 board.

(2) Set (or confirm) data: 01 to page: 0, address: 01.

(Cancel F page protect)

(3) On page: F, address: 6A, change data with the PLAY and

STOP buttons and press the PAUSE button to write data so

that the J level of waveform on the oscilloscope satisfies

the specification value.

Connection:

Oscilloscope

(DC range)

MA-324 Board

3

CN206 pin

CN206 pin

Adjustment Procedure:

(1) Connect an oscilloscope to the CN206 pin 3 on the MA-

(SIG G 1)

9

(GND)

+

–

324 board.

(2) Set (or confirm) data: 01 to page: 0, address: 01.

(Cancel F page protect)

(3) On page: F, address: 6C, change data with the PLAY and

STOP buttons and press the PAUSE button to write data so

that the I level of waveform on the oscilloscope satisfies

the specification value.

Black

Level

I

Black

Level

Adjustment and Adjustment Parts: MA-324 board (see page 3-15)

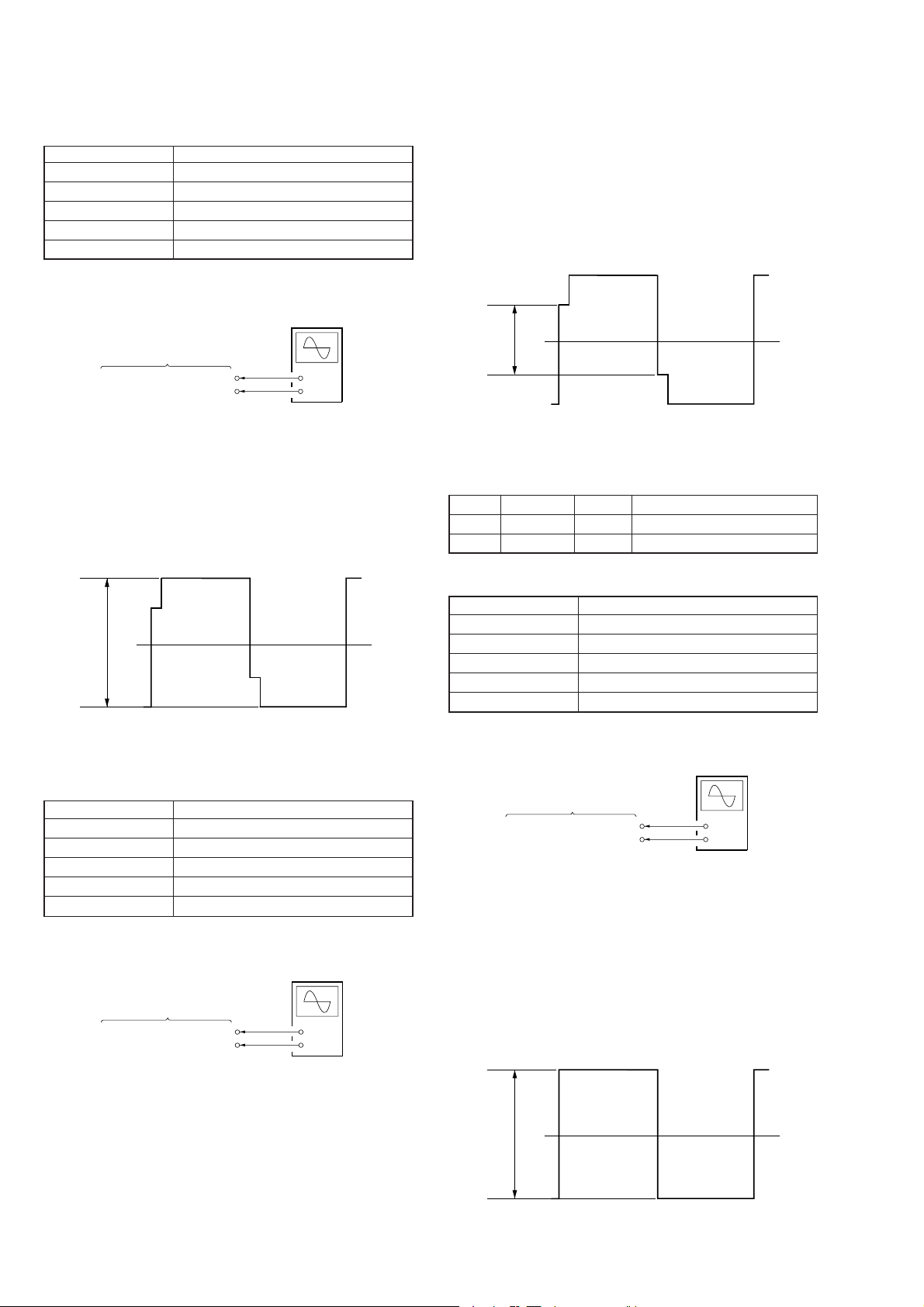

[B Gain Adjustment]

Condition:

Input signal SVGA 60 Hz: RGB 0.7 Vp-p, 16 Step

Measurement point MA-324 board CN206 pin 5

Measuring equipment Oscilloscope

Adjustment page F

Adjustment address 6A

Specification value 2.7 ± 0.1 Vp-p

Connection:

Oscilloscope

(DC range)

Black

Level

J

White

Level

Adjustment and Adjustment Parts: MA-324 board (see page 3-15)

[B Bias Adjustment]

Condition:

Input signal SVGA 60 Hz: RGB 0.7 Vp-p, 16 Step

Measurement point MA-324 board CN206 pin 5

Measuring equipment Oscilloscope

Adjustment page F

Adjustment address 6D

Specification value 8.4 ± 0.1 Vp-p

Connection:

Oscilloscope

(DC range)

MA-324 Board

5

CN206 pin

CN206 pin

Adjustment Procedure:

(1) Connect an oscilloscope to the CN206 pin 5 on the MA-

(SIG B 1)

9

(GND)

+

–

324 board.

(2) Set (or confirm) data: 01 to page: 0, address: 01.

(Cancel F page protect)

(3) On page: F, address: 6D, change data with the PLAY and

STOP buttons and press the PAUSE button to write data so

that the K level of waveform on the oscilloscope satisfies

the specification value.

Black

Level

MA-324 Board

CN206 pin

CN206 pin

5

(SIG B 1)

9

(GND)

K

+

–

Black

Level

Adjustment and Adjustment Parts: MA-324 board (see page 3-15)

3-11

[SID Level Adjustment]

Condition:

Input signal SVGA 60 Hz: RGB 0.7 Vp-p, 16 Step

Measurement point MA-324 board CN206 pin !§

Measuring equipment Oscilloscope

Adjustment page F

Adjustment address 78

Specification value 9.1 ± 0.1 Vp-p

Adjustment Procedure:

(1) Connect an oscilloscope to the CN206 pin !§ on the MA-

324 board.

(2) Set (or confirm) data: 01 to page: 0, address: 01.

(Cancel F page protect)

(3) On page: F, address: 79, change data with the PLAY and

STOP buttons and press the PAUSE button to write data so

that the M level of waveform on the oscilloscope satisfies

the specification value.

Connection:

Oscilloscope

(DC range)

MA-324 Board

CN206 pin

CN206 pin

!§

(P SIG B)

9

(GND)

+

–

Adjustment Procedure:

(1) Connect an oscilloscope to the CN206 pin !§ on the MA-

324 board.

(2) Set (or confirm) data: 01 to page: 0, address: 01.

(Cancel F page protect)

(3) On page: F, address: 78, change data with the PLAY and

STOP buttons and press the PAUSE button to write data so

that the L level of waveform on the oscilloscope satisfies

the specification value.

L

M

Adjustment and Adjustment Parts: MA-324 board (see pag e 3-15)

[Black Limitte Adjustment]

Preparation:

Page Address Data Remarks

F 11 01 Cancel protect of BRIGHT

F 7B 10 Change the BRIGHT level

Condition:

Input signal SVGA 60 Hz: RGB ALL Black

Measurement point MA-324 board CN206 pin 3

Measuring equipment Oscilloscope

Adjustment page F

Adjustment address 7A

Specification value 8.7 ± 0.1 Vp-p

Adjustment and Adjustment Parts: MA-324 boar d (see page 3-15)

[PRG Level Adjustment]

Condition:

Input signal SVGA 60 Hz: RGB 0.7 Vp-p, 16 Step

Measurement point MA-324 board CN206 pin !§

Measuring equipment Oscilloscope

Adjustment page F

Adjustment address 79

Specification value 6.8 ± 0.1 Vp-p

Connection:

Oscilloscope

(DC range)

MA-324 Board

CN206 pin

CN206 pin

!§

(P SIG B)

9

(GND)

+

–

Connection:

MA-324 Board

3

CN206 pin

CN206 pin

Adjustment Procedure:

(1) Connect an oscilloscope to the CN206 pin 3 on the MA-

(SIG G 1)

9

(GND)

Oscilloscope

(DC range)

+

–

324 board.

(2) Set (or confirm) data: 01 to page: 0, address: 01.

(Cancel F page protect)

(3) On page: F, address: 7A, change data with the PLAY and

STOP buttons and press the PAUSE button to write data so

that the N level of waveform on the oscilloscope satisfies

the specification value.

(4) Set data: 1F to page F, address: 7B.

Black

Level

N

Black

Level

Adjustment and Adjustment Parts: MA-324 board (see pag e 3-15)

3-12

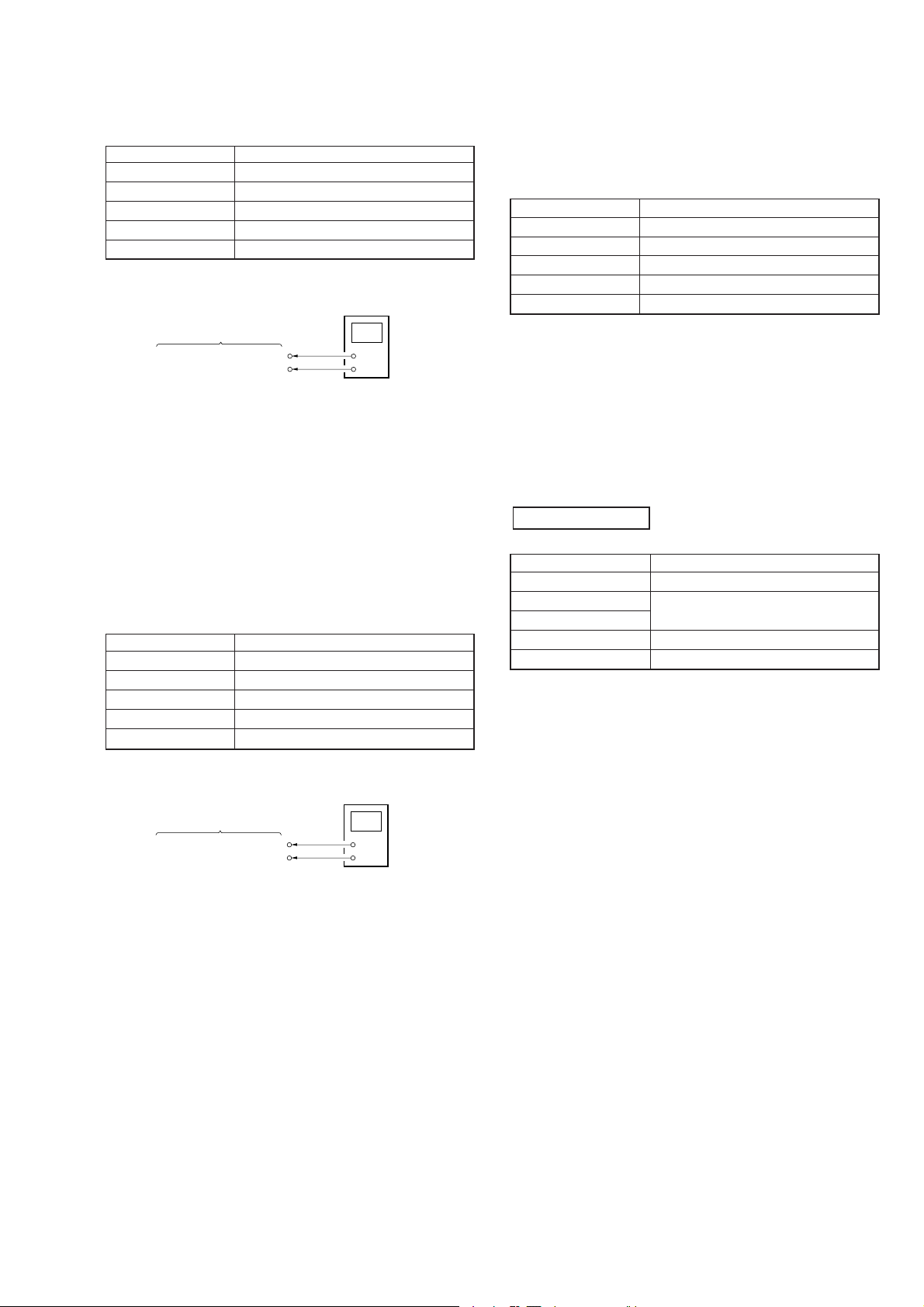

[VCOM R Adjustment]

Condition:

Input signal SVGA 60 Hz: RGB 0.7 Vp-p, 16 Step

Measurement point MA-324 board CN206 pin !™

Measuring equipment Degital voltmeter

Adjustment page F

Adjustment address 75

Specification value 6.64 ± 0.02 V

Connection:

Digital Voltmeter

MA-324 Board

CN206 pin

CN206 pin

!™

(COM R)

9

(GND)

+

–

Adjustment Procedure:

(1) Connect a digital voltmeter to the CN206 pin !™ on the MA-

324 board.

(2) Set (or confirm) data: 01 to page: 0, address: 01.

(Cancel F page protect)

(3) On page: F, address: 75, change data with the PLAY and

STOP buttons and press the PAUSE button to write data so

that the digital voltmeter reading satisfies the specification

value.

Adjustment and Adjustment Parts: MA-324 board (see page 3-15)

[VCOM L Adjustment]

Condition:

Input signal SVGA 60 Hz: RGB 0.7 Vp-p, 16 Step

Measurement point MA-324 board CN206 pin !¢

Measuring equipment Digital voltmeter

Adjustment page F

Adjustment address 76

Specification value 6.64 ± 0.02 V

Connection:

Digital Voltmeter

MA-324 Board

CN206 pin

CN206 pin

!¢

(COM L)

9

(GND)

+

–

Adjustment Procedure:

(1) Connect a digital voltmeter to the CN206 pin !¢ on the MA-

324 board.

(2) Set (or confirm) data: 01 to page: 0, address: 01.

(Cancel F page protect)

(3) On page: F, address: 76, change data with the PLAY and

STOP buttons and press the PAUSE button to write data so

that the digital voltmeter reading satisfies the specification

value.

[White Balance Adjustment]

Preparation:

Set data: 1F to page: F, address: 7B.

Condition:

Input signal SVGA 60 Hz: White (50%)

Measurement point LCD R screen

Measuring equipment Video camera

Adjustment page F

Adjustment address 6B, 6D

Specification value With no color

Adjustment Procedure:

(1) LCD R screen on video camera.

(2) Set (or confirm) data: 01 to page: 0, address: 01.

(Cancel F page protect)

(3) Page: F, address: 6B, 6D

Change data at these two addresses with the PLA Y and ST OP

buttons and press the PAUSE button to write data so that the

F page data of looking into the finder.

Adjust it so that the finest white can be seen.

POWER SAVING

[Power Saving Sensor Adjustment]

Mode PC

Signal No signal

Measurement point

Measurement equipment

Adjustment page F

Adjustment address 57

Adjustment Procedure:

(1) Place the specified board 6.5 cm away from sensor.

(2) Set data: 08 to page: F, address 8C.

(3) Find the value when the highest bit of the data on page: 3,

address: 12 changes to “H” with raising the data on page: F,

address: 57 from the initial value data: 40h by 08h.

(4) Set data: 00 to page: 0, address: FF.

(5) Set data: 02 to page: F, address: 8C.

Note: It is necessary to input data: 03 to page: 0, address: FF before read-

ing the data in page: 03. Also without input the data: 00 to page: 0,

address: FF, you cannot input any data to page: F after the data in

page: 3 is read.

Displayed data on adj. remote commander

Adjustment and Adjustment Parts: MA-324 board (see page 3-15)

3-13

POWER SUPPLY BLOCK

[Change Adjustment]

Mode PC

Signal PC AUDIO IN: No signal

Measurement point

Measuring equipment

Adjustment page E, F

Adjustment address 0B, 0C, 0D, 0E (E page)

Connection:

Referring to Fig. 3-4 (see page 3-15), connect the following equipment.

(1) Connect the regulated power supply and a digital voltmeter

to DC IN terminal.

(2) Connect the adjusting remote commander to the CN501 on

MA-324 board.

(3) Connect a PC to the RGB and PC ADUIO IN terminals.

Menu Setting:

(Picture and tone quality standard setting) (see page 3-4)

Adjustment Procedure:

(1) Adjust the output voltage of regulated power supply so that

DC IN terminal voltage (DD-107 board J701) is 8.85 ± 0.01

Vdc.

(2) Turn ON the POWER switch on the set.

(3) Set data: 03 to page: 0, address: FF.

(4) Set data: 0A to page: 2, address: 01.

(5) Read data (XXh) on page: 3, address: 74.

(6) Set data: 00 to page: 0, address: FF.

(7) Set data: 01 to page: 0, address: 01. (Cancel E and F page

protect)

(8) Using the following formulas (calculation of hexadecimal

numbers), calculate the adjustment data and enter them to

respective adjustment addresses.

(Refer to 5. Data Processing on page 3-3)

Page: E Address: 00 E00 = 01

Page: E Address: 01 E01 = XXh

Page: F Address: FE FFE = XXh – 39h

(9) Set data: 00 to page: 0, address: 01.

(10) Connect the regulated power supply and a digital voltmeter

to the battery terminal.

(Keep connecting the regulated power supply to DC IN terminal)

(11) Adjust the output voltage of regulated power supply so that

the battery terminal voltage is 8.35 ± 0.01 Vdc.

(12) Set data: 03 to page: 0, address: FF.

(13) Set data: 0A to page: 2, address: 01.

(14) Read data (YYh) on page: 3, address: 75.

(15) Set data: 00 to page: 0, address: FF.

(16) Set data: 01 to page: 0, address: 01.

(17) Using the following formulas (calculation of hexadecimal

numbers), calculate the adjustment data and enter them to

respective adjustment addresses.

(Refer to 5. Data Processing on page 3-3)

Page: E Address: 02 E02 = YYh

Page: E Address: 03 E03 = YYh – 02h

Page: E Address: 04 E04 = YYh – 55h

Page: E Address: 05 E05 = YYh + 02h

Page: E Address: 06 E06 = DC

Page: E Address: 07 E07 = 05

RGB IN: No signal

VOLUME: Minimum

Displayed data on adj. remote commander

00, 01, 02, 03, 04, 05, 06, 07, 08, 09, 0A,

FE (F page)

Page: E Address: 08 E08 = 08

Page: E Address: 09 E09 = 07

Page: E Address: 0A E0A = B8

Page: E Address: 0B E0B = 0B

Page: E Address: 0C E0C = 60

Page: E Address: 0D E0D = 54

Page: E Address: 0E E0E = 40

(18) Set data: 00 to page: 0, address: 01.

Note: After setting each data, be sure to press the PAUSE button on the

adjusting remote commander.

[Battery Down Adjustment]

Mode PC

Signal PC AUDIO IN: No signal

Measurement point

Measuring equipment

Adjustment page F

Adjustment address 7E, 7F, 80, 81, 82, 83

RGB IN: No signal

VOLUME: Minimum

Displayed data on adj. remote commander

Connection:

Referring to Fig. 3-4 (see page 3-15), connect the following equipment.

(1) Connect the regulated power supply and a digital voltmeter

to the battery terminal.

(2) Connect the adjusting remote commander to the CN501 on

MA-324 board.

(3) Connect a pattern generator to the RGB and PC AUDIO IN

terminal.

Menu Setting:

(Picture and tone quality standard setting) (see page 3-4)

Adjustment Procedure:

(1) Adjust the output voltage of regulated power supply so that

the battery terminal voltage is 6.0 ± 0.01 Vdc.

(2) Turn ON the POWER switch on the set.

(3) Set data: 03 to page: 0, address: FF.

(4) Set data: 0A to page: 2, address: 01.

(5) Read data (ZZh) on page: 3, address: 7D.

(6) Set data: 00 to page: 0, address: FF.

(7) Set data: 01 to page: 0, address: 01. (Cancel F page protect)

(8) Using the following formulas (calculation of hexadecimal

numbers), calculate the adjustment data and enter them to

respective adjustment addresses.

(Refer to 5. Data Processing on page 3-3)

Page: F Address: 7E F7E = ZZh

Page: F Address: 7F F7F = ZZh + 0Ah

Page: F Address: 80 F80 = ZZh + 0Dh

Page: F Address: 81 F81 = ZZh + 10h

Page: F Address: 82 F82 = ZZh + 16h

Page: F Address: 83 F83 = 01

(9) Set data: 00 to page: 0, address: 01.

Note: After setting each data, be sure to press the PAUSE button on the

adjusting remote commander.

3-14

Regulated power supply

Battery

terminal

MA-324 board

(CN501)

Adjusting

Remote

Commander

Extension cable

(J-6082-291-A)

Adjustment and Adjustment Parts:

[MA-324 Board] (Side A)

CN206

For check

connector

Digital

Voltmeter

Fig. 3-4

Set

IC508

MA-324 board

(J101)

YC-148 board

(J1001)

IC502

IC507

PC

CN501

Connect adjusting

remote commander

[YC-148 Board] (Side A)

J1001

AUDIO IN jack

IC1106

IC1001

IC443

Q1001

J101

RGB JACK

J1002

AUDIO/VIDEO jack

CN1004

Q1002

CN1003

For check connector

3-15

3-15 E

SECTION 4

DIAGRAMS

4-1. BLOCK DIAGRAM – AUDIO/VIDEO Section

APC CONT

A

(Page 4-10)

(ON: PLUG IN)

1

Y

3

C

4

2

J1401

S VIDEO

AUDIO/VIDEO

B

(Page 4-10)

J1002

4FSC CONT

VIDEO

BUFFER

Q1003

SYNC GENERATOR

VIDEO

6

17.734475MHz

CLOCK

X1001

4

IC1003

XTAL

CLAMP

D1002,

Q1004

4FSC

7

L.P.F.

FL1001

5

BGATE

Q1005 – 1009

SYNC BUFFER

Q1019 – 1021

VIDEO AMP

Y/C SEPARATOR

IC1002

VIN

18

29

YOUT

COUT

CLK IN

PLM-S700E

• SIGNAL PATH

: AUDIO

: VIDEO

12

13

14

27

29

3

1

2

22

VIDEO RGB DECODER

IC1001

R-Y IN

16

B-Y IN

14

SAND

X1003

4.433619MHz

X1002

500kHz

BUFFER

Q1025

R-Y

B-Y

5

SAMPLE & HOLD

IC1004

11

12

BUFFER

Q1026

Y IN

16

R

G

B

SUB COLOR, CONTRAST,

CONTRAST

COLOR

HUE

VIDEO AMP

Q1033 – 1035

VIDEO AMP

Q1030 – 1032

VIDEO AMP

Q1027 – 1029

R

23

R-Y IN

18

B-Y IN

19

SUB COLOR

CONT

COLOR

HUE

24

G

25

B

SUB COLOR

37

38

20

21

R, G, B

COLOR, HUE

D

(Page 4-5)

E

(Page 4-10)

SYNC BUFFER

Q1024

IC1009, 1010

VIDEO SELECT SWITCH &

VIDEO AMP

IC1010

IN1

5

7

VIDEO

BUFFER

Q1014

VIDEO

BUFFER

Q1010

L.P.F.

FL1003

L.P.F.

FL1002

VIDEO AMP

Q1015 – 1017

VIDEO AMP

Q1011 – 1013

1

3

1

3

IN2

IN2

IN1

IC1009

OUT

SW1

SW2

OUT

SW1

SW2

7

2

4

7

2

4

CLAMP

Q1022

SYNC DETECT

D1001,

Q1001, 1002

VIDEO

BUFFER

Q1018

TIME CONSTANT

APC CONTROL SWITCH

7

6

SWITCH

Q1023

IC1011

1

5

SYNC Y

39

Y

Y

36

C

34

H AFC

4

R-Y

B-Y

FSC OUT

PAL FSC

32FHVCO OUT

32FHVCO IN1

32FHVCO IN2

CLP

C

(Page 4-5)

05

J1001

AUDIO IN

PC/XV AU CONT

IC1301, 1302

LINE SELECT SWITCH &

LINE AMP

IC1302

1

IN1

3

IN2

IN1

1

3

IN2

OUT

SEL

IC1301

OUT

SEL

Q1036

HEADPHONE AMP

IN1

IN2

IC151

OUT1

VREF

OUT2

BB SW

MIX OUT

AVC IN

MUTE SW

4

3

2

LP

9

DBB SWITCH

8

5

6

11

Q153, 154

HP401

(HEADPHONE)

HP402

(HEADPHONE)

AVLS SWITCH

Q156

L

63

R

DBB MID ON

49

DBB NORM ON

50

XAVLS ON

48

AU MUTE

90

PC/XV AU CONT

19

XS DET

SYNC DET

SYSTEM CONTROLLER

IC501 (1/5)

XVIDEO

83

RV1301

VOL

7

2

7

2

13

14

GATE SWITCH

IC1013, 1015,

IC1020

6

CLR

Q

LATCH

IC1012

CK

3 1

SWITCHING

IC1019

BLKHDVD

9 10 11

6

CLR

3 1

Q

LATCH

IC1016

CK

SWITCHING

IC1017

IC1006

MULTIVIBRATOR

IC1005

2Q

7

1Q

1B

5

1Q

6

1

CLR

14

QA

11

QD

COUNTER

IC1014

2

CK

VIDEO H SYNC

VIDEO V SYNC

EDGE DETECT

IC1007, 1008

2A

12

10

9

2Q

VIDEO H SYNC, VIDEO V SYNC

BF

F

(Page 4-5)

G

(Page 4-5)

4-1

4-2

4-3

Loading...

Loading...