Page 1

MDX-M690

MD Player section

Signal-to-noise ratio 90 dB

Frequency response 10 – 20,000 Hz

Wow and flutter Below measurable limit

Tuner section

FM

Tuning range 87.5 – 108.0 MHz

Aerial terminal External aerial connector

Intermediate frequency 10.7 MHz/450 kHz

Usable sensitivity 8 dBf

Selectivity 75 dB at 400 kHz

Signal-to-noise ratio 66 dB (stereo),

72 dB (mono)

Harmonic distortion at 1 kHz

0.6 % (stereo),

0.3 % (mono)

Separation 35 dB at 1 kHz

Frequency response 30 – 15,000 Hz

MW/LW

Tuning range MW: 531 – 1,602 kHz

LW: 153 – 279 kHz

Aerial terminal External aerial connector

Intermediate frequency 10.7 MHz/450 kHz

Sensitivity MW: 30 µV

LW: 40 µV

Power amplifier section

Outputs Speaker outputs

(sure seal connectors)

Speaker impedance 4 – 8 ohms

Maximum power output 52 W

× 4 (at 4 ohms)

General

Outputs Audio outp uts (front/re ar)

Subwoofer output (mono)

Power aerial relay control

lead

Power amplif ier co ntrol lead

Inputs Telephone ATT control lead

Illumination control lead

BUS control input

connector

BUS audio input connector

Remote controller input

connector

Aerial input connector

Loudness +8 dB at 100 Hz

+2 dB at 10 kHz

Power requirements 12 V DC car battery

(negative eart h )

Dimensions Approx. 178

× 50 × 182 mm

(w/h/d)

Mounting dimensions Approx. 182

× 53 × 160 mm

(w/h/d)

Mass Approx. 1.5 kg

Supplied accessories Parts for installation and

connections (1 set)

Front panel case (1)

Card remote commander

RM-X111

Tone controls Bass ±8 dB at 100 Hz

Treble ±8 dB at 10 kHz

Note

This unit cannot be connected to a digital preamplifier

or an equalizer.

Design and specifications are subject to change

without notice.

SERVICE MANUAL

Ver 1.0 2001.03

US and foreign patents licensed from Dolby Laboratories.

SPECIFICATIONS

AEP Model

UK Model

Model Name Using Similar Mechanism MDX-CA680

Base Mechanism Type MG-164MA-138

Optical Pick-up Name KMS-241C

9-870-294-11 Sony Corporation

2001C0500-1 Audio Entertainment Group

C 2001.3 General Engineering Dept.

FM/MW/LW MINI DISC PLAYER

Page 2

MDX-M690

TABLE OF CONTENTS

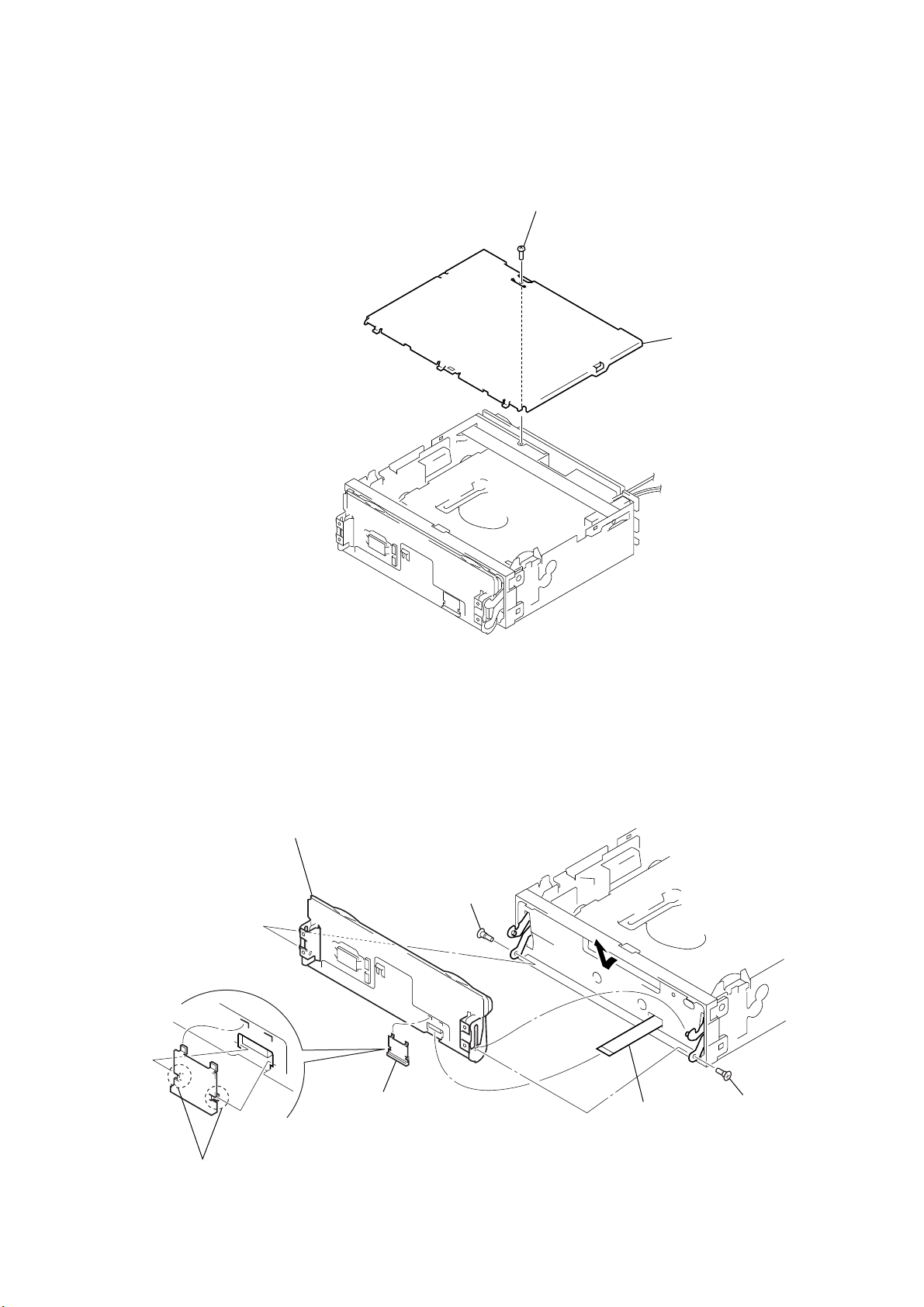

1. SERVICING NOTES............................................... 4

2. GENERAL

Location of Controls ....................................................... 5

3. DISASSEMBLY

3-1. Disassembly Flow ........................................................... 8

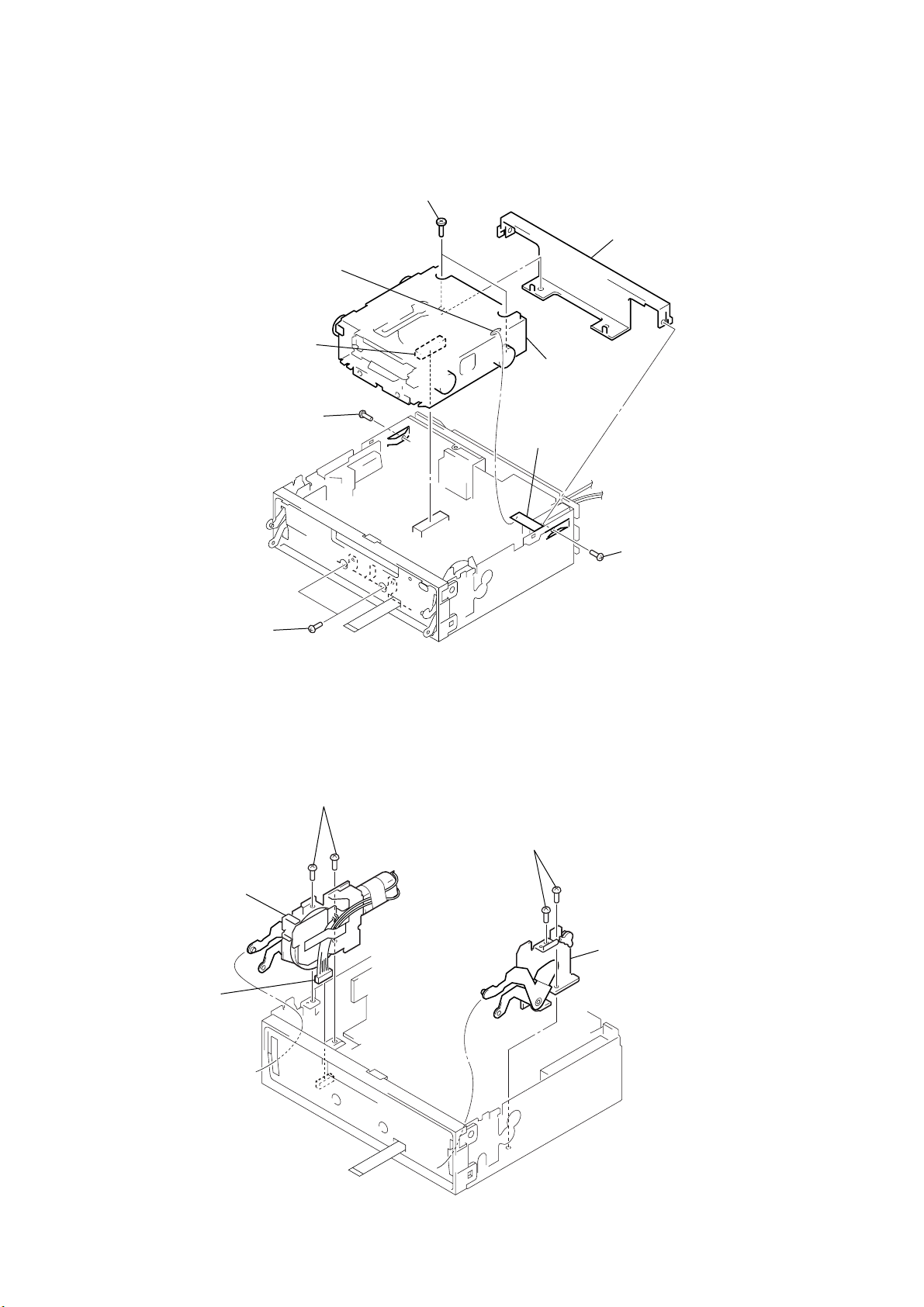

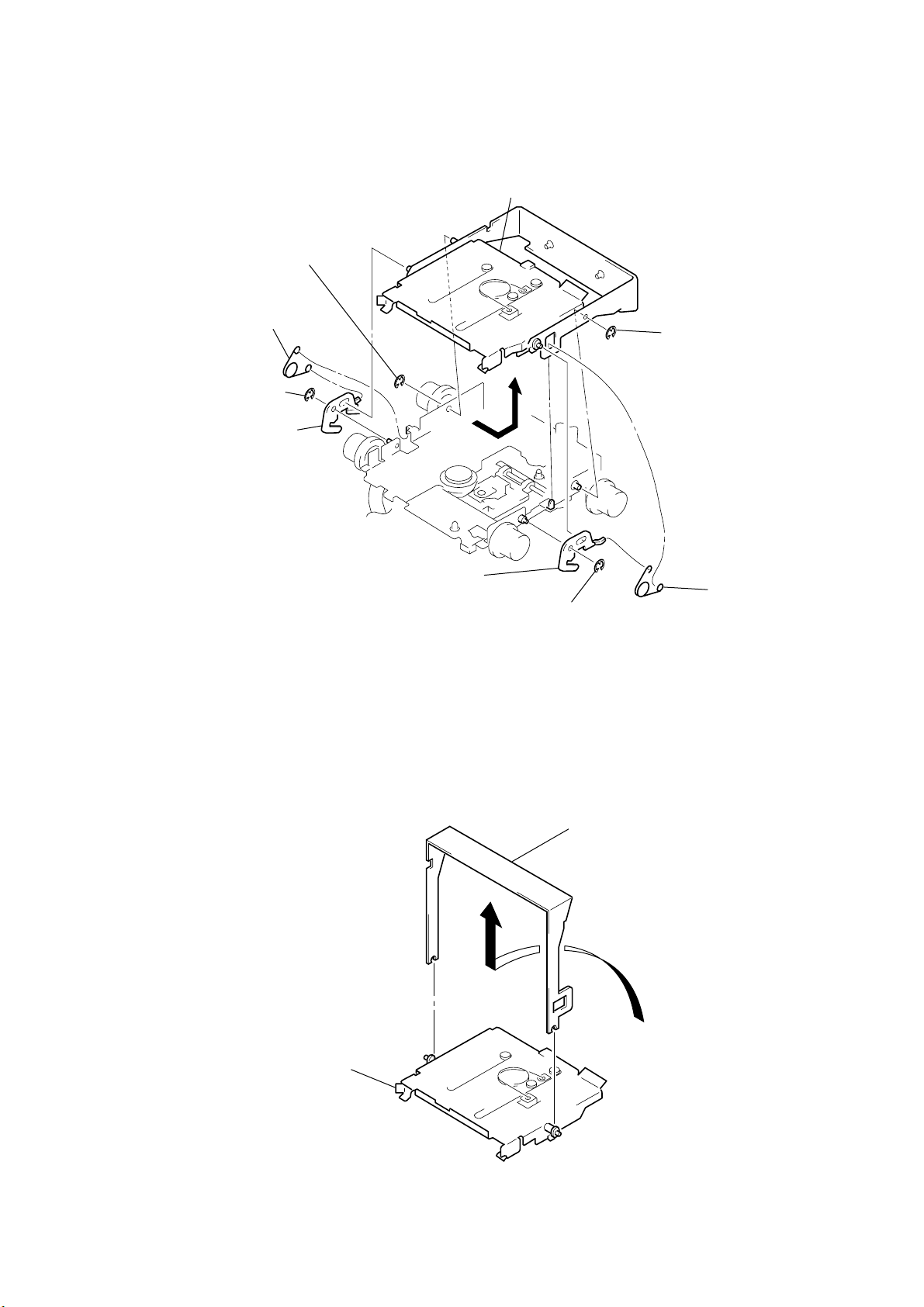

3-2. Cover ............................................................................... 9

3-3. Front Panel (Key) Assy ................................................... 9

3-4. Mechanism Deck (MG-164MA-138) ............................. 10

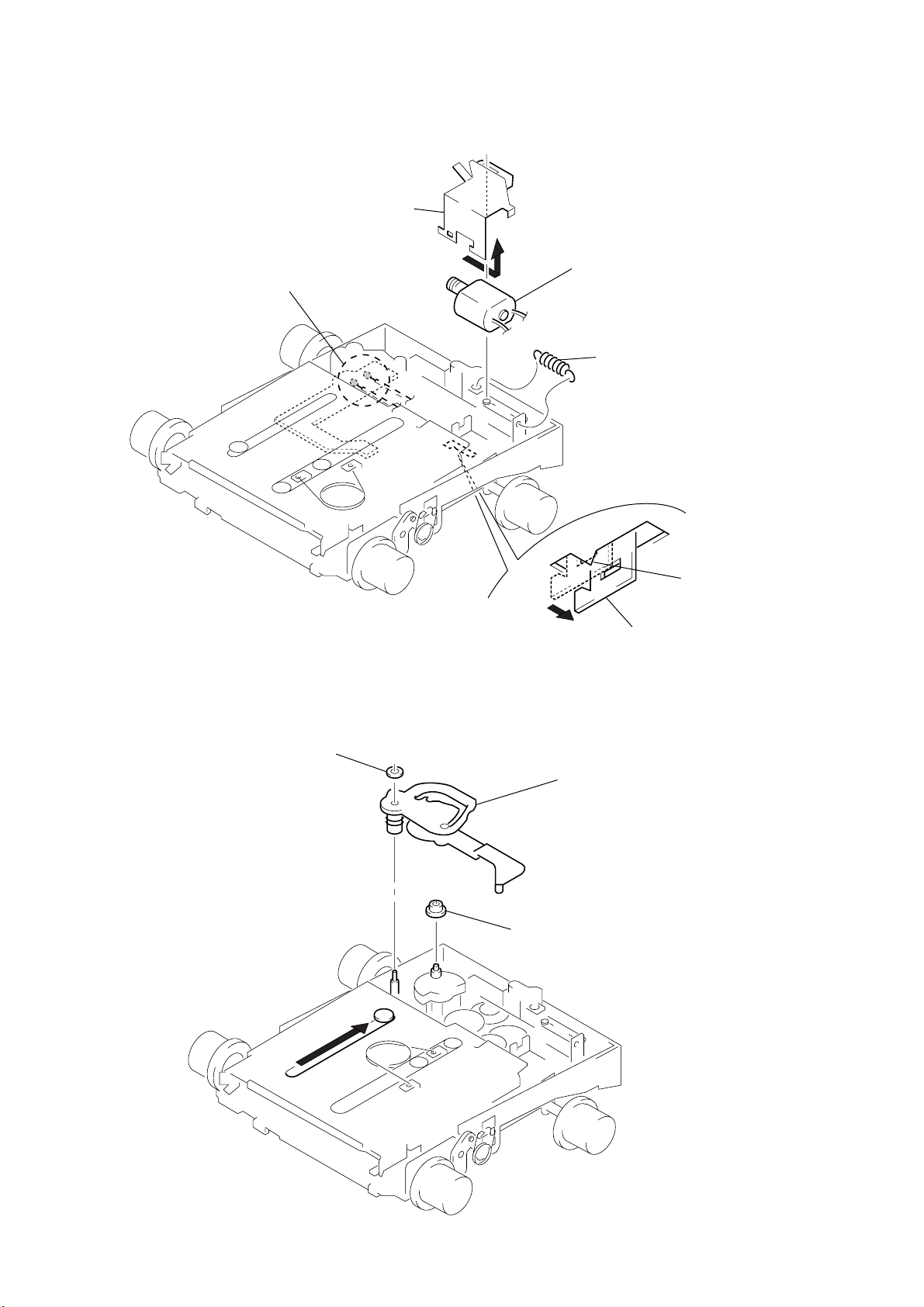

3-5. Motor Block Assy, Cam (R) Assy .................................. 10

3-6. Sub Panel Assy ................................................................ 11

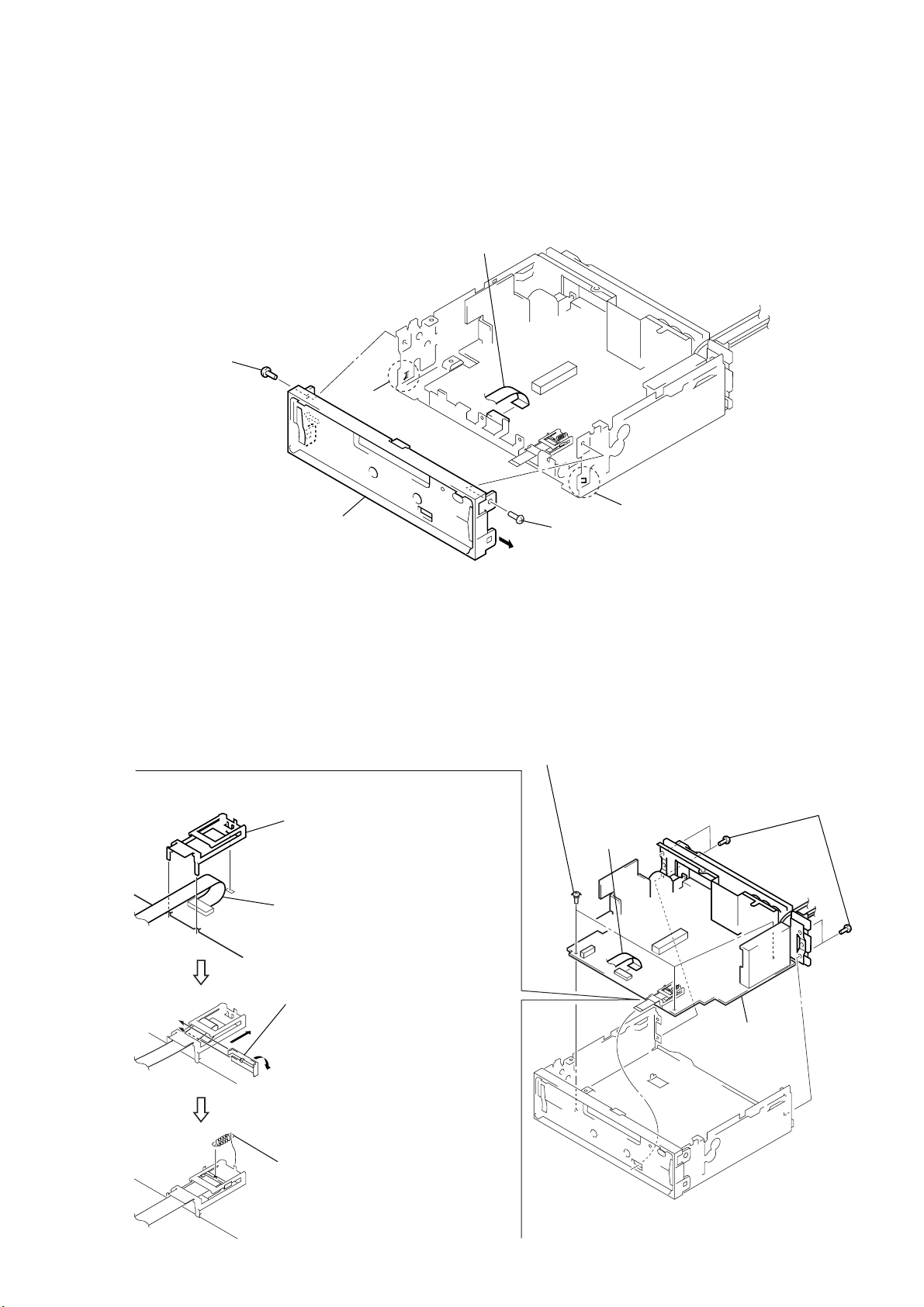

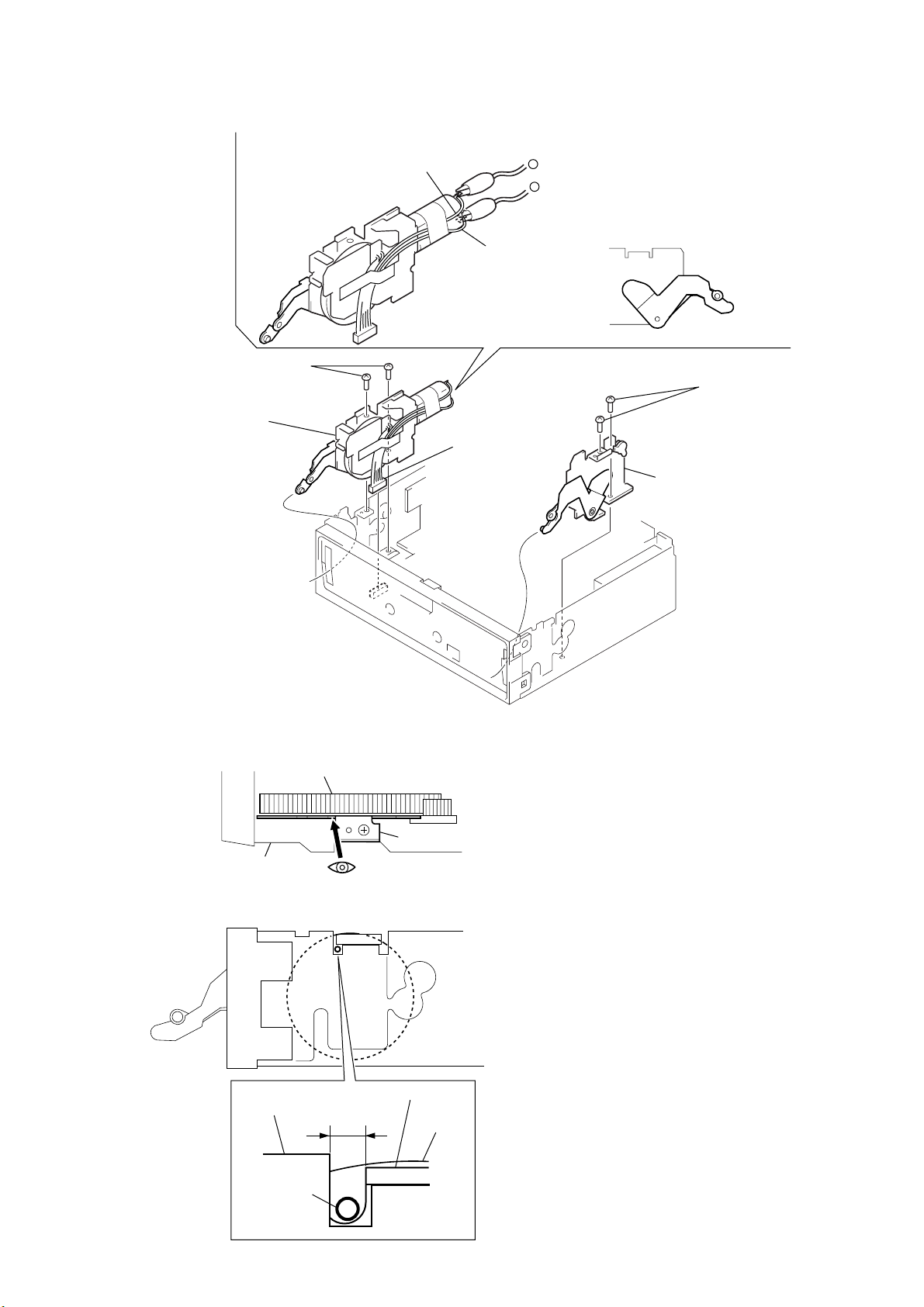

3-7. MAIN Board ................................................................... 11

3-8. Heat Sink ......................................................................... 12

3-9. SERVO Board ................................................................. 12

3-10. MD Cover Assy............................................................... 13

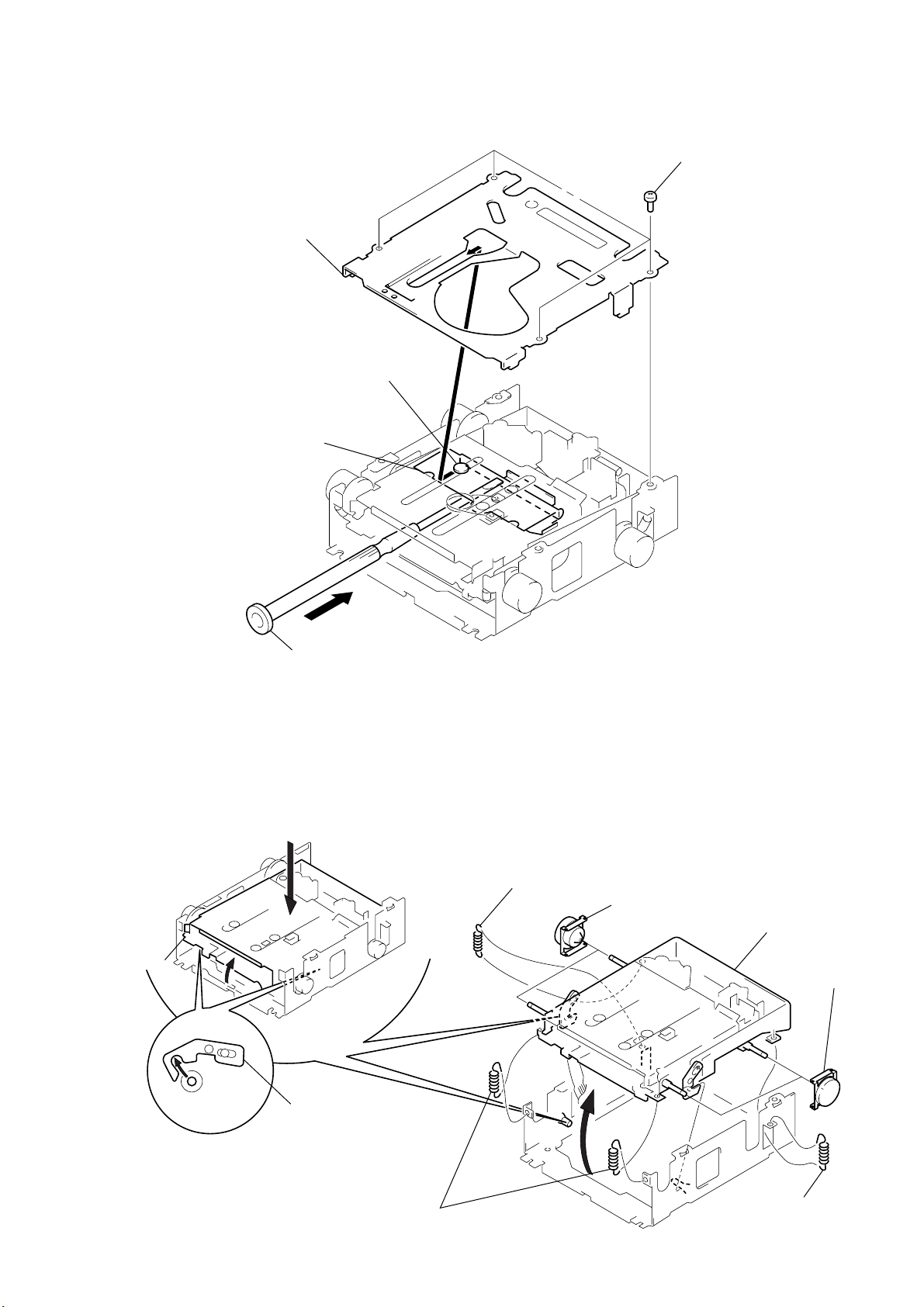

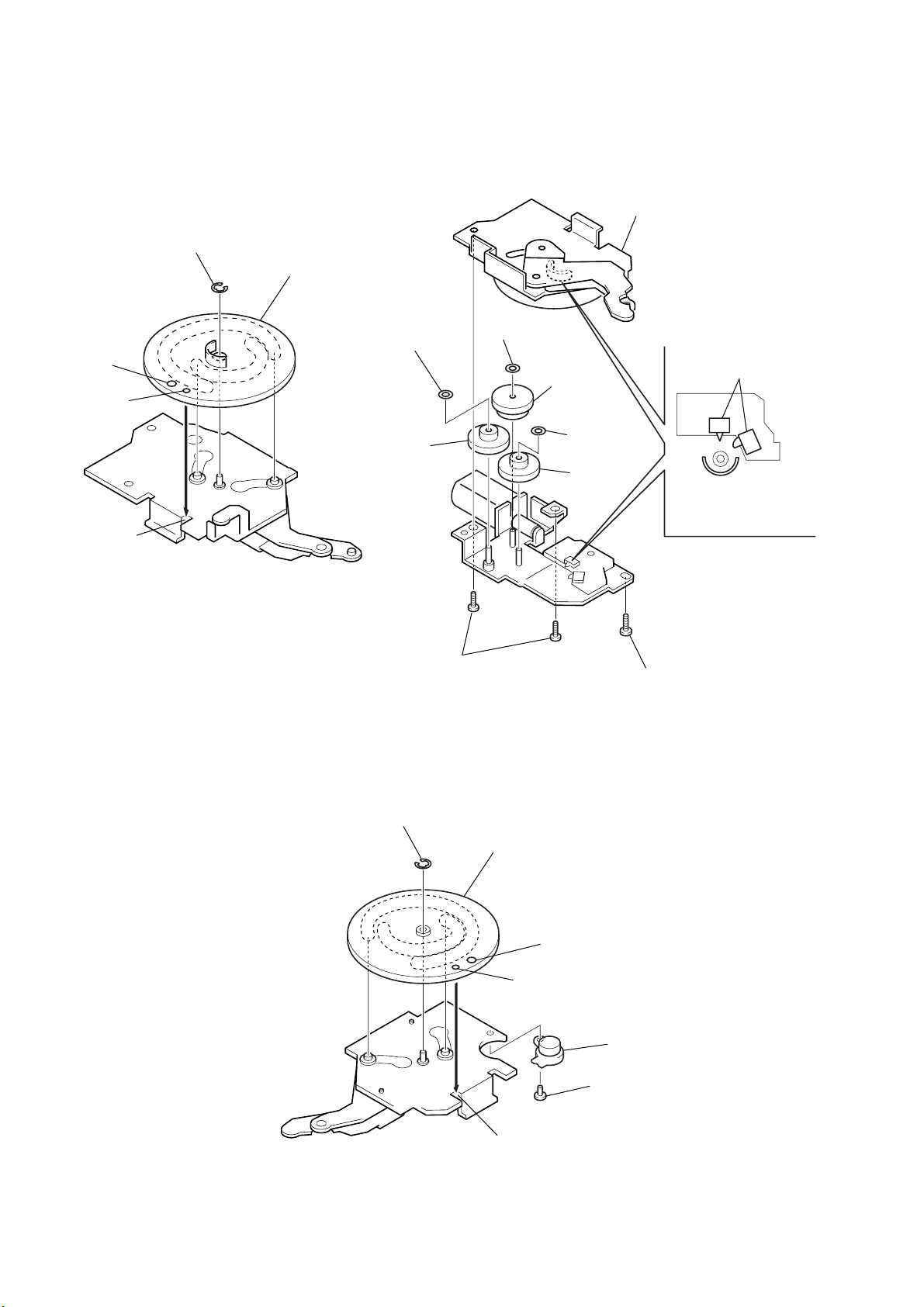

3-11. Float Block ...................................................................... 13

3-12. Lo Motor Assy (Loading) (M903).................................. 14

3-13. Lever (LE23) Assy .......................................................... 14

3-14. Holder Assy ..................................................................... 15

3-15. Chucking Arm Assy ........................................................ 15

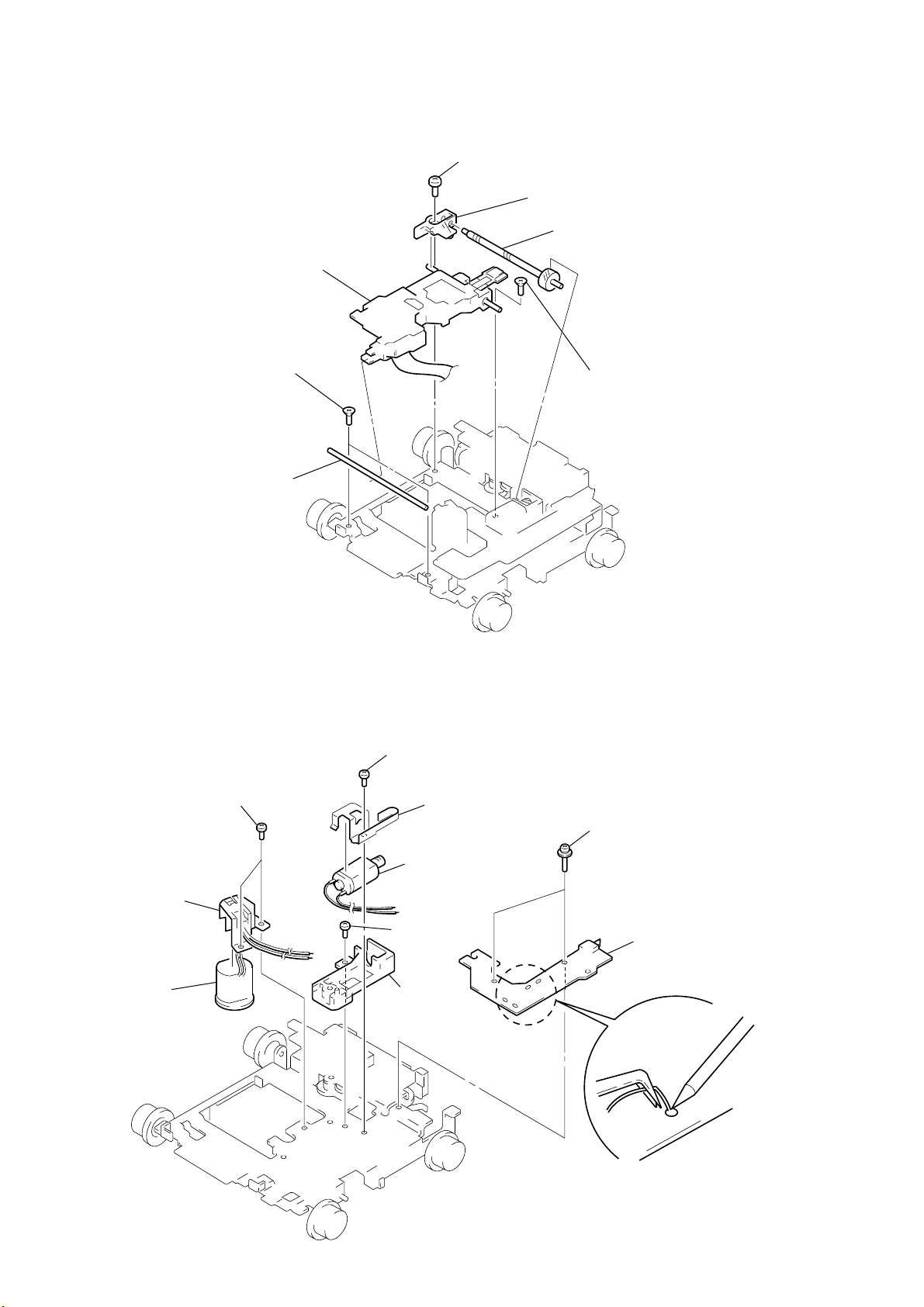

3-16. Optical Pick-up (KMS-241C) ......................................... 16

3-17. SL Motor Assy (Sled) (M902),

SP Motor Assy (Spindle) (M901)................................... 16

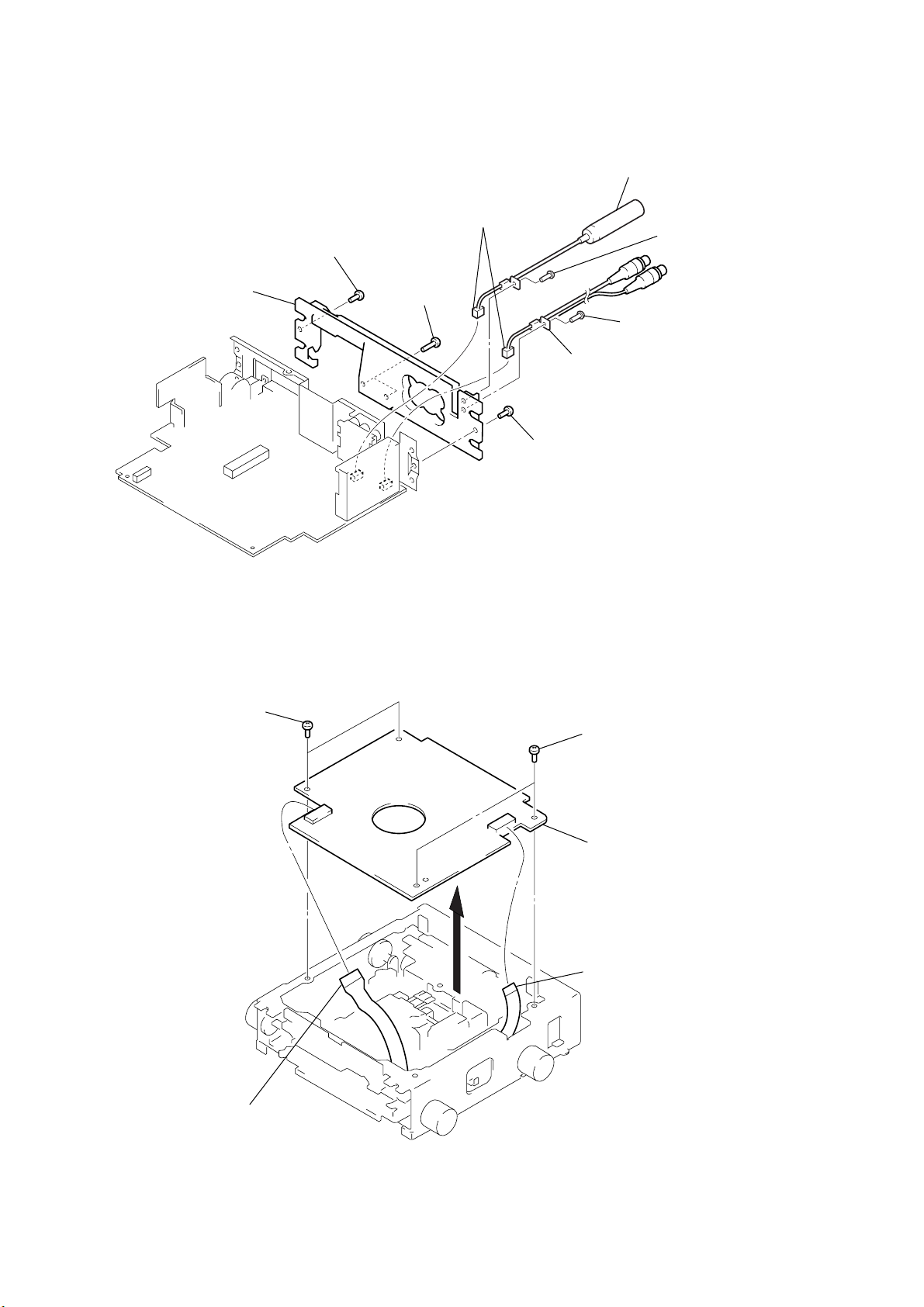

4. ASSEMBLY

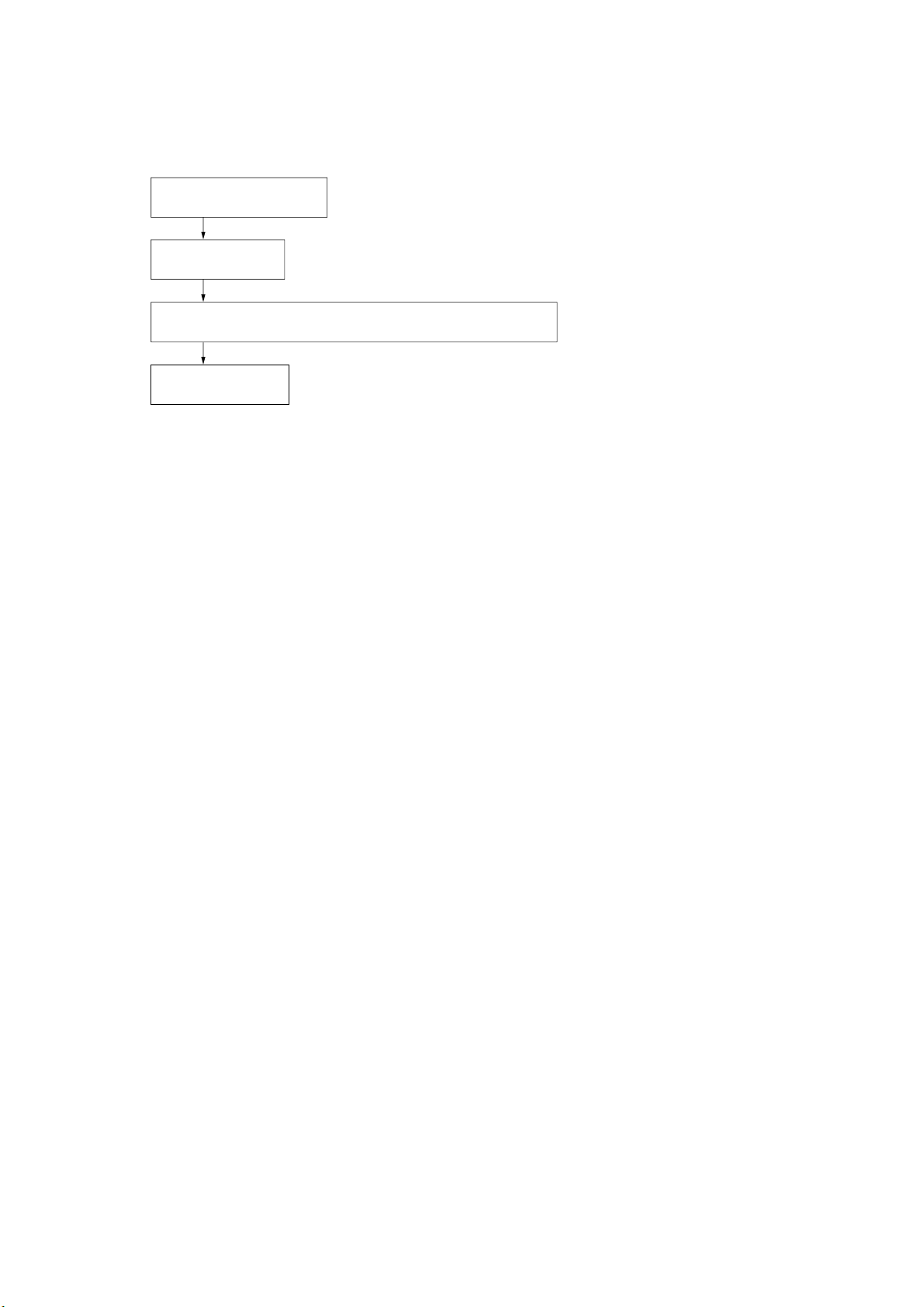

4-1. Assembly Flow................................................................ 17

4-2. Motor Block Assy ........................................................... 18

4-3. Cam (R) Assy .................................................................. 18

4-4. Adjusting Phase of Motor Block Assy,

Cam (R) Assy .................................................................. 19

4-5. Phase Check .................................................................... 19

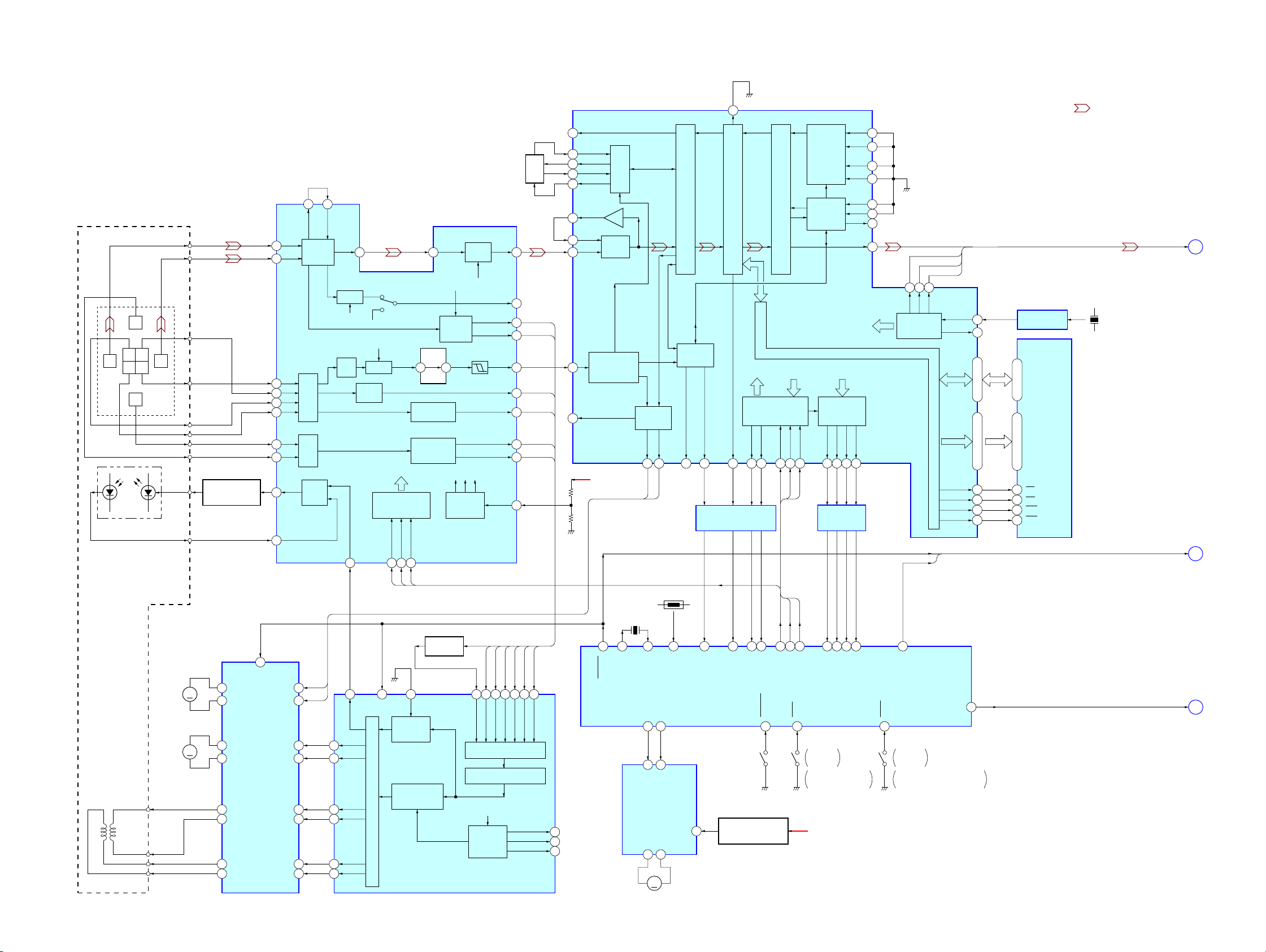

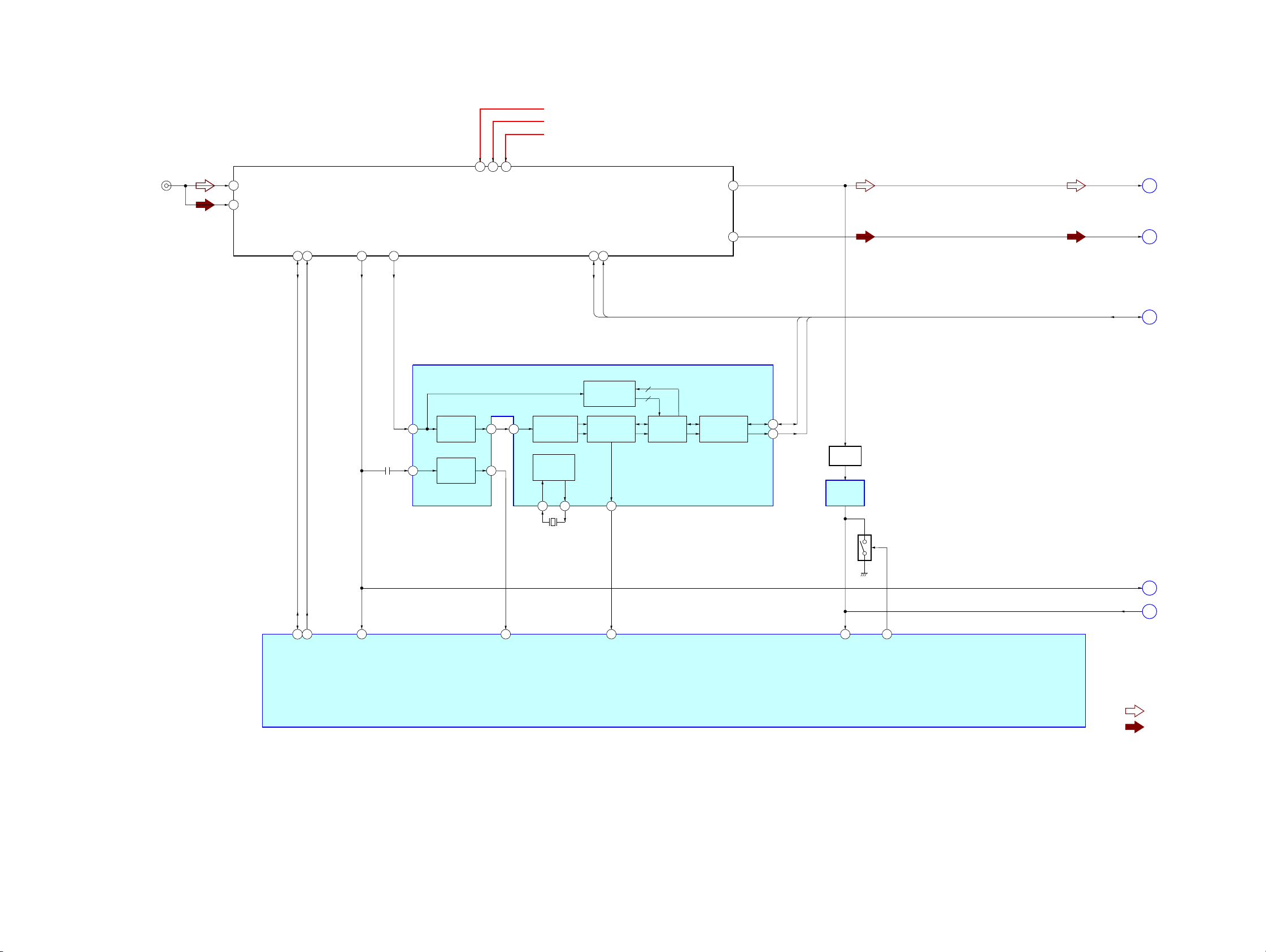

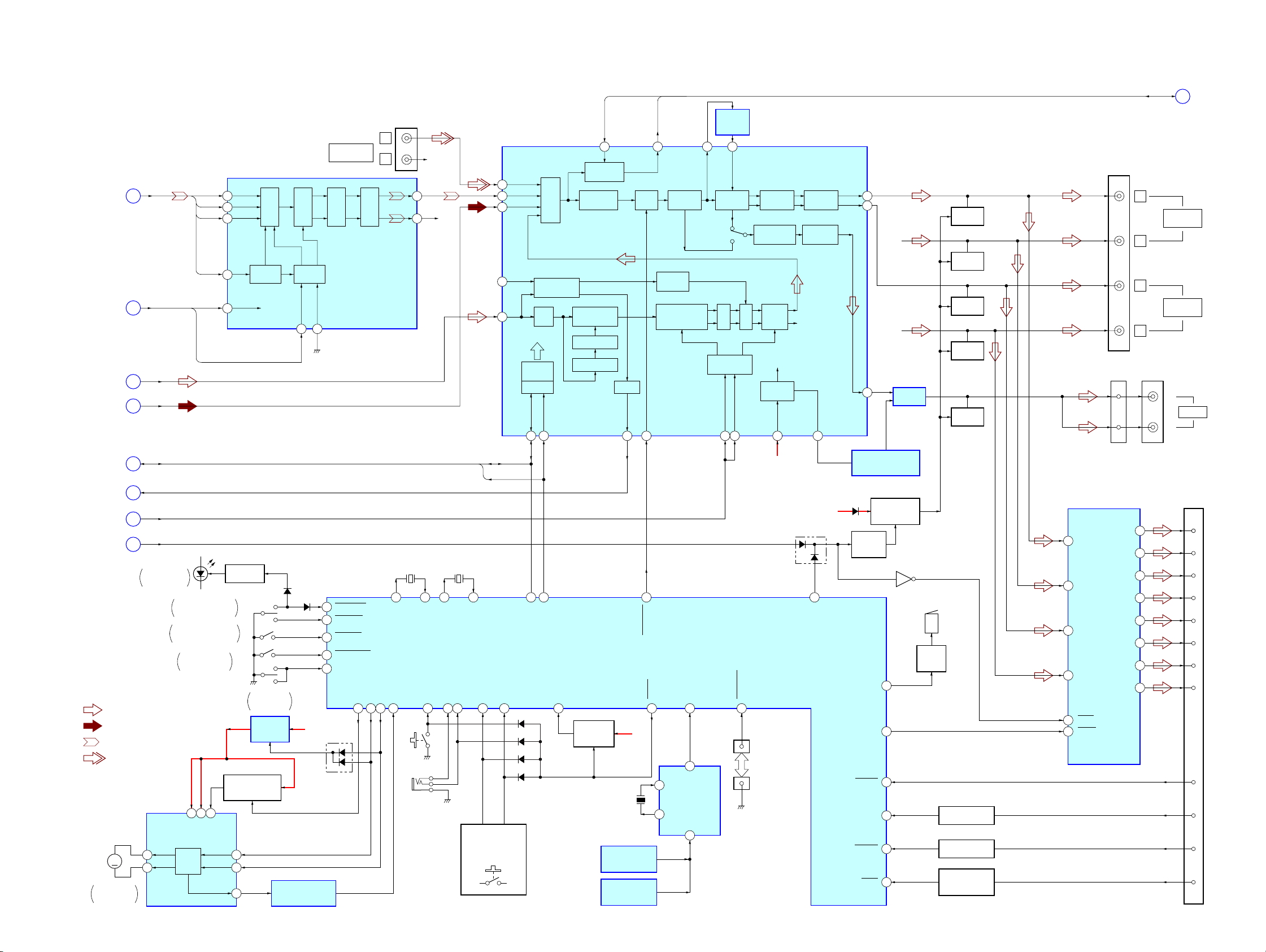

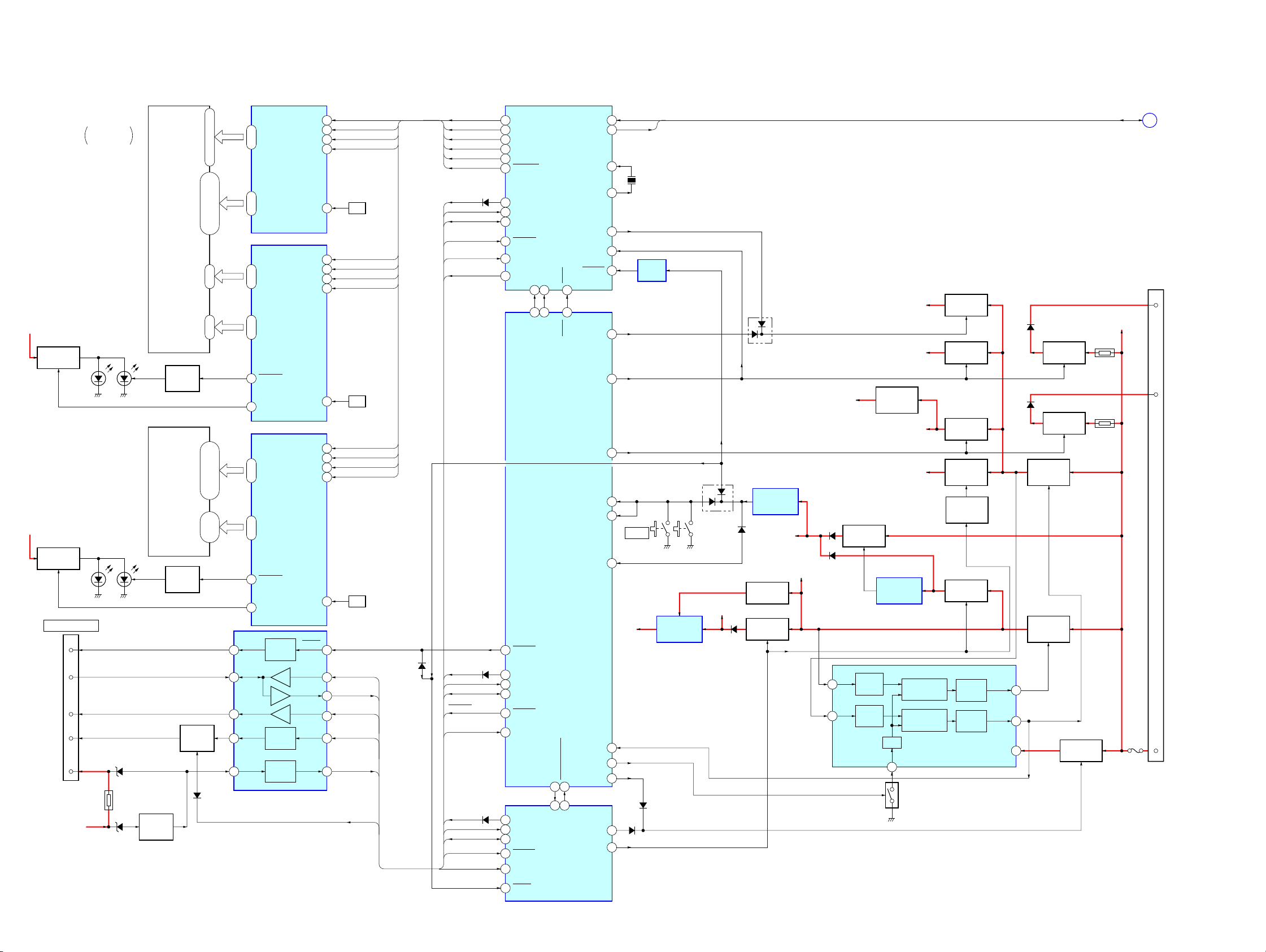

6. DIAGRAMS

6-1. Block Diagram – SERVO Section – ............................... 21

6-2. Block Diagram – TUNER Section – .............................. 22

6-3. Block Diagram – MAIN Section – ................................. 23

6-4. Block Diagram – DISPLAY/BUS CONTROL/

POWER SUPPLY Section – ........................................... 24

6-5. Note for Printed Wiring Boards and

Schematic Diagrams ....................................................... 25

6-6. Printed Wiring Boards – SERVO Section – ................... 27

6-7. Schematic Diagram – SERVO Section (1/2) –............... 28

6-8. Schematic Diagram – SERVO Section (2/2) –............... 29

6-9. Printed Wiring Board – MAIN Section (1/2) – .............. 30

6-10. Printed Wiring Boards – MAIN Section (2/2) – ............ 31

6-11. Schematic Diagram – MAIN Section (1/4) – ................. 32

6-12. Schematic Diagram – MAIN Section (2/4) – ................. 33

6-13. Schematic Diagram – MAIN Section (3/4) – ................. 34

6-14. Schematic Diagram – MAIN Section (4/4) – ................. 35

6-15. Printed Wiring Board – SUB MD Board –..................... 36

6-16. Schematic Diagram – SUB MD Board – ....................... 37

6-17. Printed Wiring Board – KEY Board –............................ 38

6-18. Schematic Diagram – KEY Board – .............................. 39

6-19. Printed Wiring Board – DISPLAY Board – ................... 40

6-20. Schematic Diagram – DISPLAY Board – ...................... 41

6-21. IC Pin Function Description ........................................... 49

7. EXPLODED VIEWS

7-1. Sub Panel Section............................................................ 61

7-2. Front Panel (DSPL) Section ........................................... 62

7-3. Front Panel (KEY) Section ............................................. 63

7-4. MAIN Board Section ...................................................... 64

7-5. Mechanism Deck Section-1 (MG-164MA-138) ............ 65

7-6. Mechanism Deck Section-2 (MG-164MA-138) ............ 66

5. ELECTRICAL ADJUSTMENTS

Test Mode........................................................................ 20

MD Section ..................................................................... 20

Tuner Section .................................................................. 20

8. ELECTRICAL PARTS LIST ............................... 67

2

Page 3

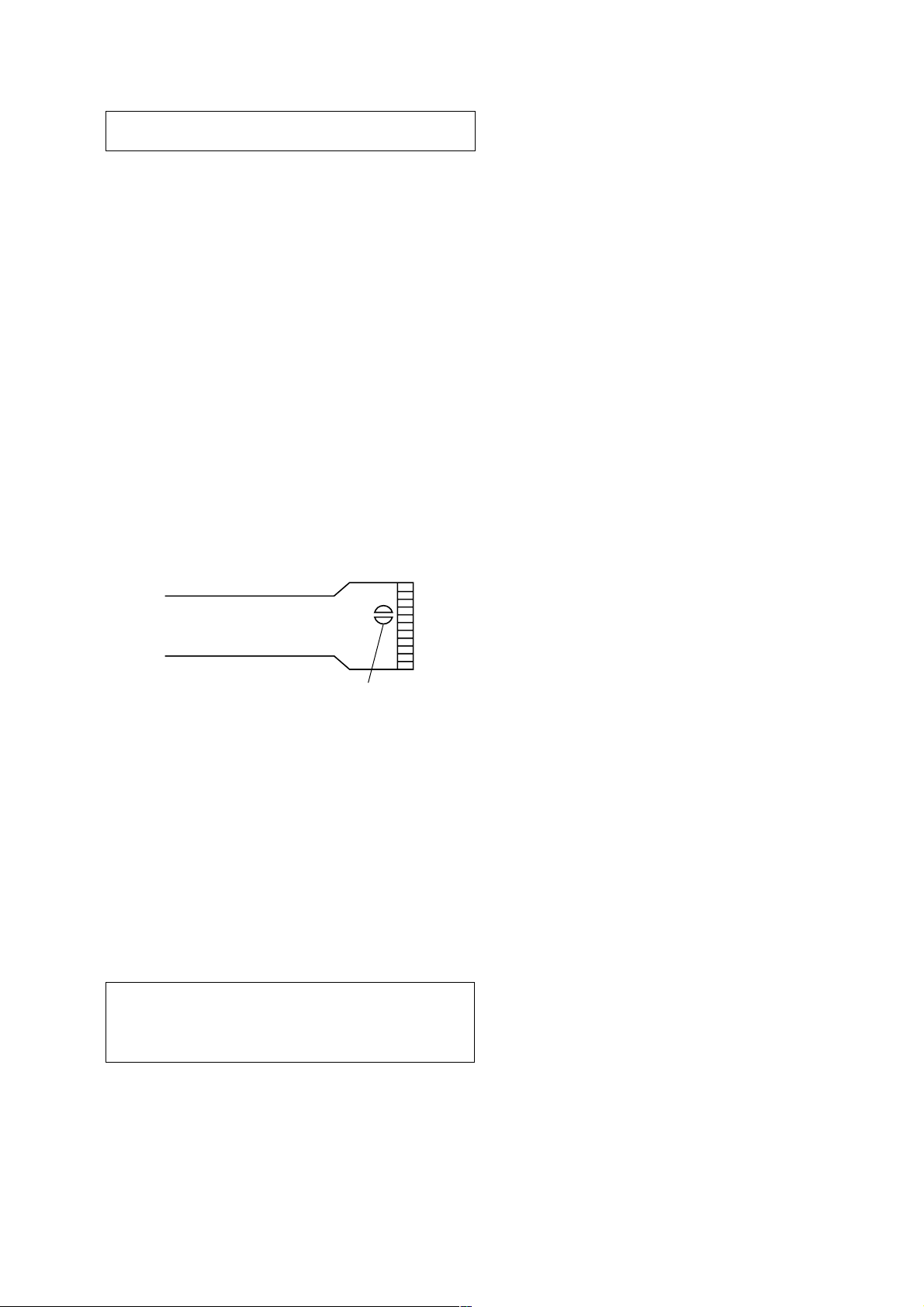

NOTES ON HANDLING THE OPTICAL PICK-UP

p

BLOCK OR BASE UNIT

The laser diode in the optical pick-up block may suffer electrostatic break-down because of the potential difference generated

by the charged electrostatic load, etc. on clothing and the human

body.

During repair, pay attention to electrostatic break-down and also

use the procedure in the printed matter which is included in the

repair parts.

The flexible board is easily damaged and should be handled with

care.

NOTES ON LASER DIODE EMISSION CHECK

Never look into the laser diode emission from right avove when

checking it for adustment. It is feared that you will lose your sight.

NOTES ON HANDLING THE OPTICAL PICK-UP BLOCK

(KMS-241C).

The laser diode in the optical pick-up block may suffer electrostatic break-down easily. When handling it, perform soldering

bridge to the laser-tap on the flexible board. Also perform measures against electrostatic break-down sufficiently before the operation. The flexible board is easily damaged and should be

handled with care.

MDX-M690

laser-ta

OPTICAL PICK-UP FLEXIBLE BOARD

Notes on chip component replacement

• Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be dam-

aged by heat.

Flexible Circuit Board Repairing

• Keep the temperature of the soldering iron around 270 ˚C during repairing.

• Do not touch the soldering iron on the same conductor of the

circuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering

or unsoldering.

CAUTION

Use of controls or adjustments or performance of procedures

other than those specified herein may result in hazardous radiation exposure.

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY MARK 0 OR DOTTED

LINE WITH MARK 0 ON THE SCHEMATIC DIAGRAMS

AND IN THE PARTS LIST ARE CRITICAL TO SAFE

OPERATION. REPLACE THESE COMPONENTS WITH

SONY PARTS WHOSE PART NUMBERS APPEAR AS

SHOWN IN THIS MANU AL OR IN SUPPLEMENTS PUBLISHED BY SONY.

3

Page 4

MDX-M690

m

SECTION 1

SERVICING NOTES

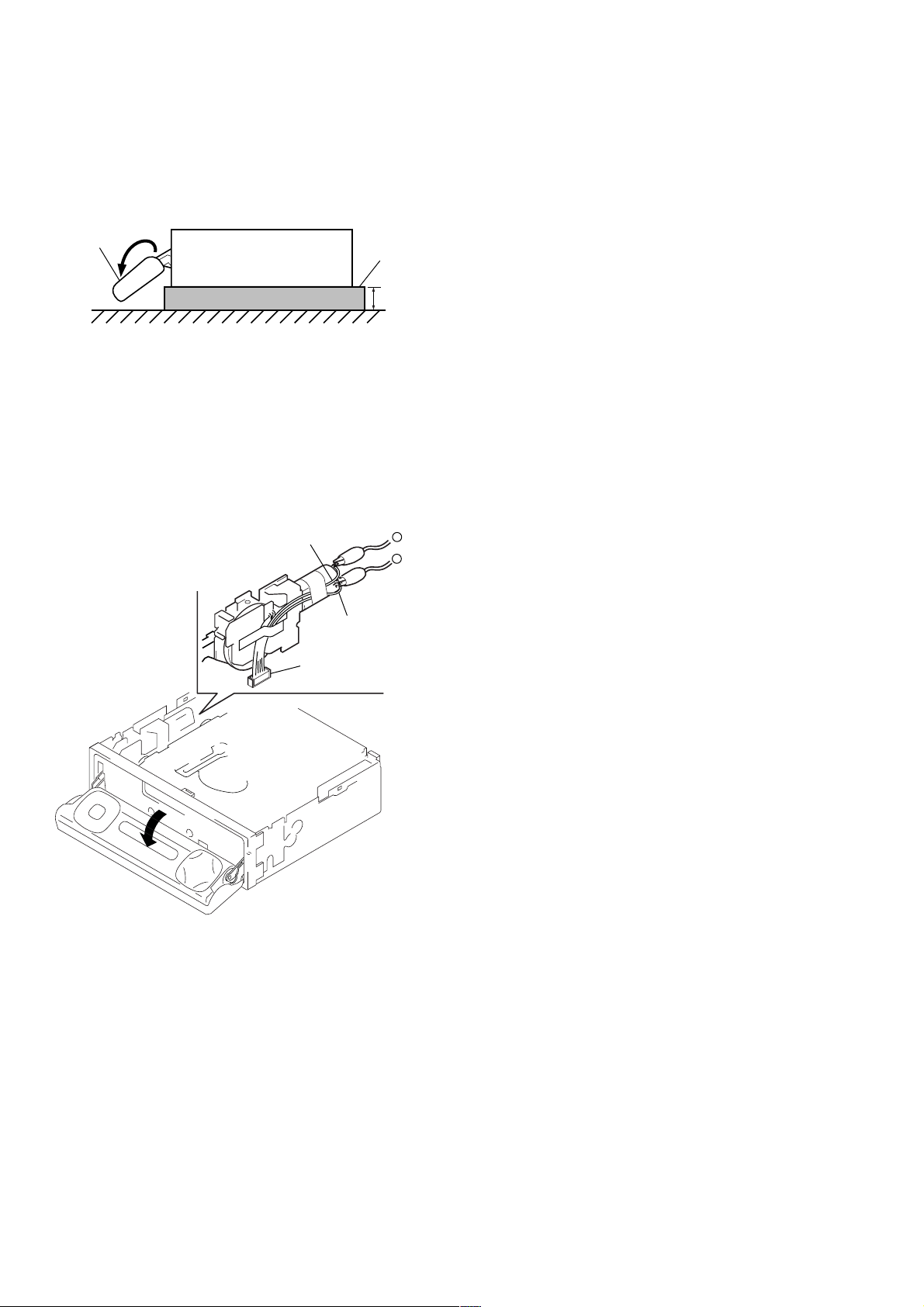

PRECAUTION ON OPEN/CLOSE FRONT PANEL

The front panel opens to the bottom of main unit.

In performing the repair, place the main unit on the base having

the height exceeding 1 cm.

front panel

MDX-M690

( SIDE VIEW)

Open the front panel by supplying the power through the following steps:

1. Disconnect the motor connector (CN602) from main board.

2. Supply the power to the motor.

Voltage : 9 V

Yellow wiring: MOTOR –

Black wiring : MOTOR +

yellow wiring

base

1c

–

+

DETACHING THE DISPLAY PANEL IN THE TEST MODE

In the normal mode, after pressing the [OPEN] key for two seconds to set the front panel in detaching position and detaching the

display panel is complete, the front panel closes automatically.

But in the test mode, the front panel opens automatically. (ref er to

page 20 for test mode)

black wiring

connector

(CN602)

4

Page 5

SECTION 2

5

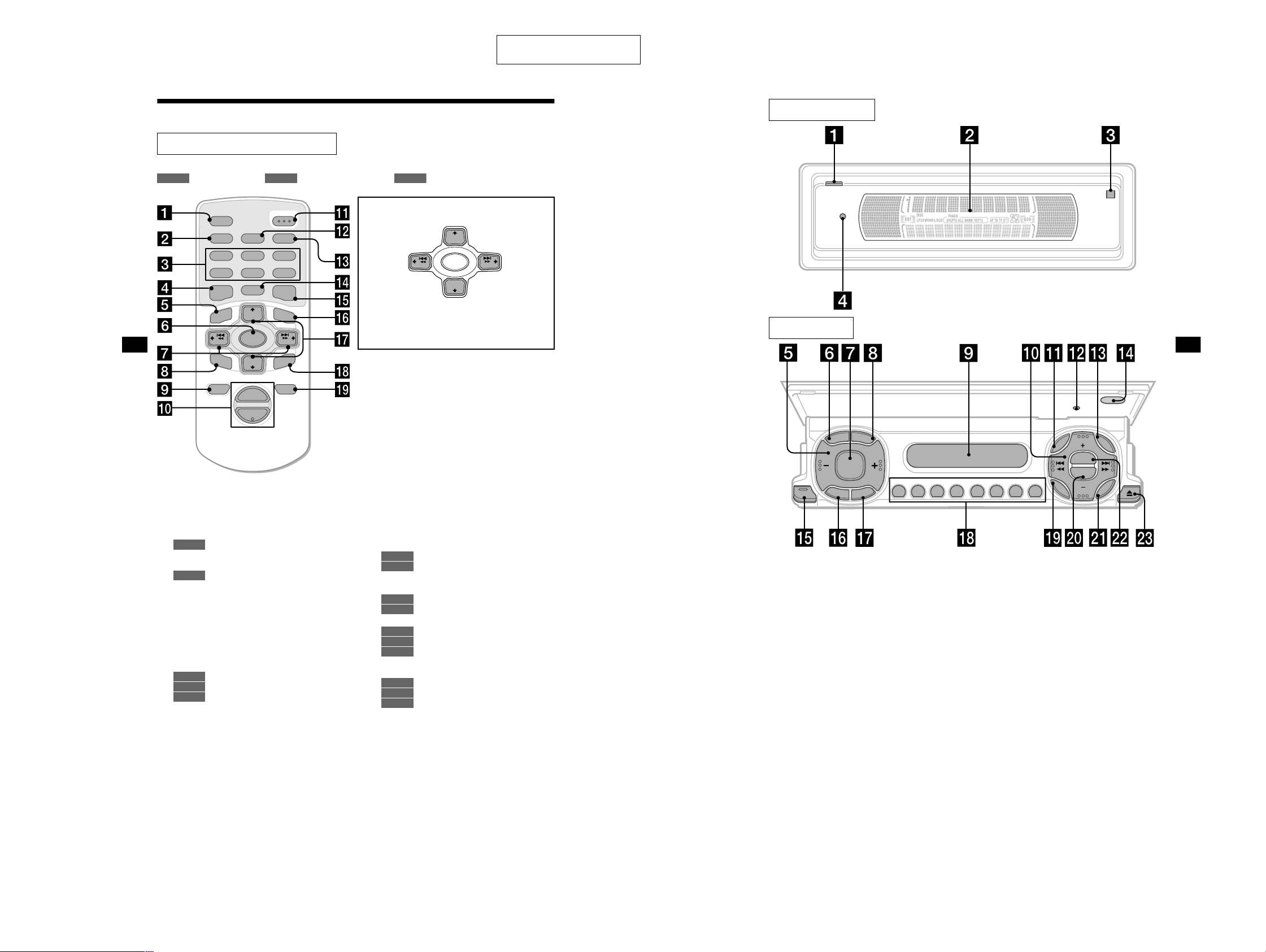

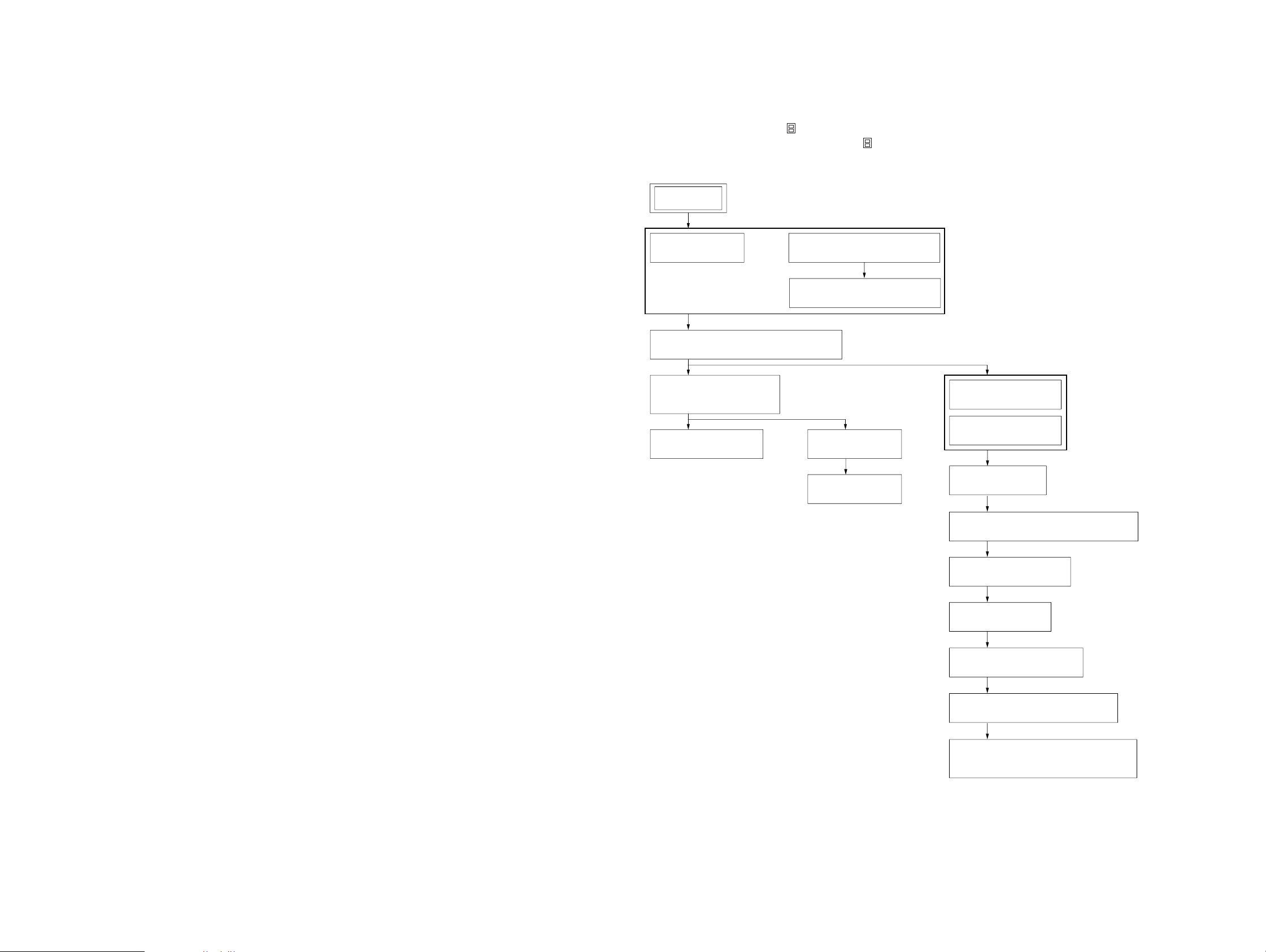

The corresponding buttons of the unit

control the same functions as those on

the card remote commander.

a OPEN button 9, 11, 37

b Main display window

c qf Receptor for the card remote

commander

d qs Reset button 9

e Volume adjust buttons

f SCRL (scroll) button

g SOURCE button

h DSPL/PTY (display mode change/

programme type) button

i Sub display window

j DISC +/– (cursor up/down) buttons

SEEK –/+ (cursor left/right) buttons

k MENU button

m LIST button

o

CLOSE (front panel close) button

9, 11

p OFF (Stop/Power off) button*

q MODE button

r Number buttons

s SOUND button

t EQ7 button

u ENTER button

v DSO button

w Z (eject) button 11

Main display panel

Operation side

CLOSE

O

F

F

M

O

D

E

SOURCE

ENTER

SOUND

M

E

N

U

LIST

DISC

RESET

DISC

DSO

REP SHUF

EQ7

AF TA

123456

S

C

R

L

D

S

P

L

P

T

Y

GENERAL

Location of controls

Card remote commander RM-X111

Refer to the pages listed for details.

: During Playback : During radio reception : During menu mode

CD/MD

RADIO MENU

MDX-M690

This section is extracted from

instruction manual.

AF

2

5

MODE

+

DISC

SOURCE

–

DISC

+

VOL

OPEN/CLOSE

LIST

SEEK

ENTER

ATTOFF

SCRL

PTY

DSPL

REP SHUF

1

4

EQ7 DSO

MENU

–

SEEK

SOUND

–

a SCRL (scroll) button 12

b DSPL/PTY (display mode change/

programme type) button 12, 13, 17,

20, 25, 35

c Number buttons

CD/MD

(1) REP 12

(2) SHUF 12

RADIO

15, 16, 18, 19, 22, 24

d EQ7 button 26

e MENU button 10, 13, 14, 15, 19, 21,

23, 25, 26, 27, 28, 30, 31, 33, 34, 35

f SOURCE (Power on/Radio/CD/MD)

button 10, 11, 13, 15, 16, 19, 22, 26,

27, 29, 30, 31, 33, 35

g </, SEEK +/– buttons 10, 28, 29, 30,

31

11

CD/MD

16, 18, 22

RADIO

10, 13, 14, 15, 21, 23, 25, 26,

MENU

27, 28, 30, 31, 33, 34, 35

h SOUND button 28, 29, 30, 31

4

M (DISC)

(+): to select upwards

< (SEEK)

TA

3

6

+

(–): to select

leftwards/

.

In menu mode, the currently selectable button (s) of

these four are indicated with a “ v” in the display.

Note

If the unit is turned off by pressing (OFF) for 2

seconds, the unit cannot be operated with the card

remote commander unless (SOURCE) on the unit is

pressed, or a disc is inserted to activate the unit first.

Tip

Refer to “Replacing the lithium battery” for details on

how to replace the batter ies (page 36).

SEEK

(–): to select downwards

–

m (DISC)

+

DISC

SOURCE

–

DISC

+

SEEK

, (SEEK)

(+): to select

rightwards/

>

i OFF (Stop/Power off) button 11, 35

j VOL +/– buttons 19

k OPEN/CLOSE button 11, 37

l AF button 18, 19

m TA butto n 19

n MODE button

CD/MD

11, 13

RADIO

15, 16, 19, 22

o DSO button 27

p LIST button

CD/MD

RADIO

13, 14

17, 24

q M/m DISC +/– buttons

26, 27, 28, 30, 31, 33, 34, 35

r ENTER button

16, 17, 20, 22, 23, 24, 25

RADIO

10, 13, 14, 15, 19, 21, 23, 25,

MENU

CD/MD

14

RADIO

17, 20, 23, 24, 25

MENU

10, 13, 14, 15, 19, 21, 23, 25,

11, 14

CD/MD

26, 27, 30, 31, 33, 34, 35

s ATT button 33

55

Page 6

MDX-M690

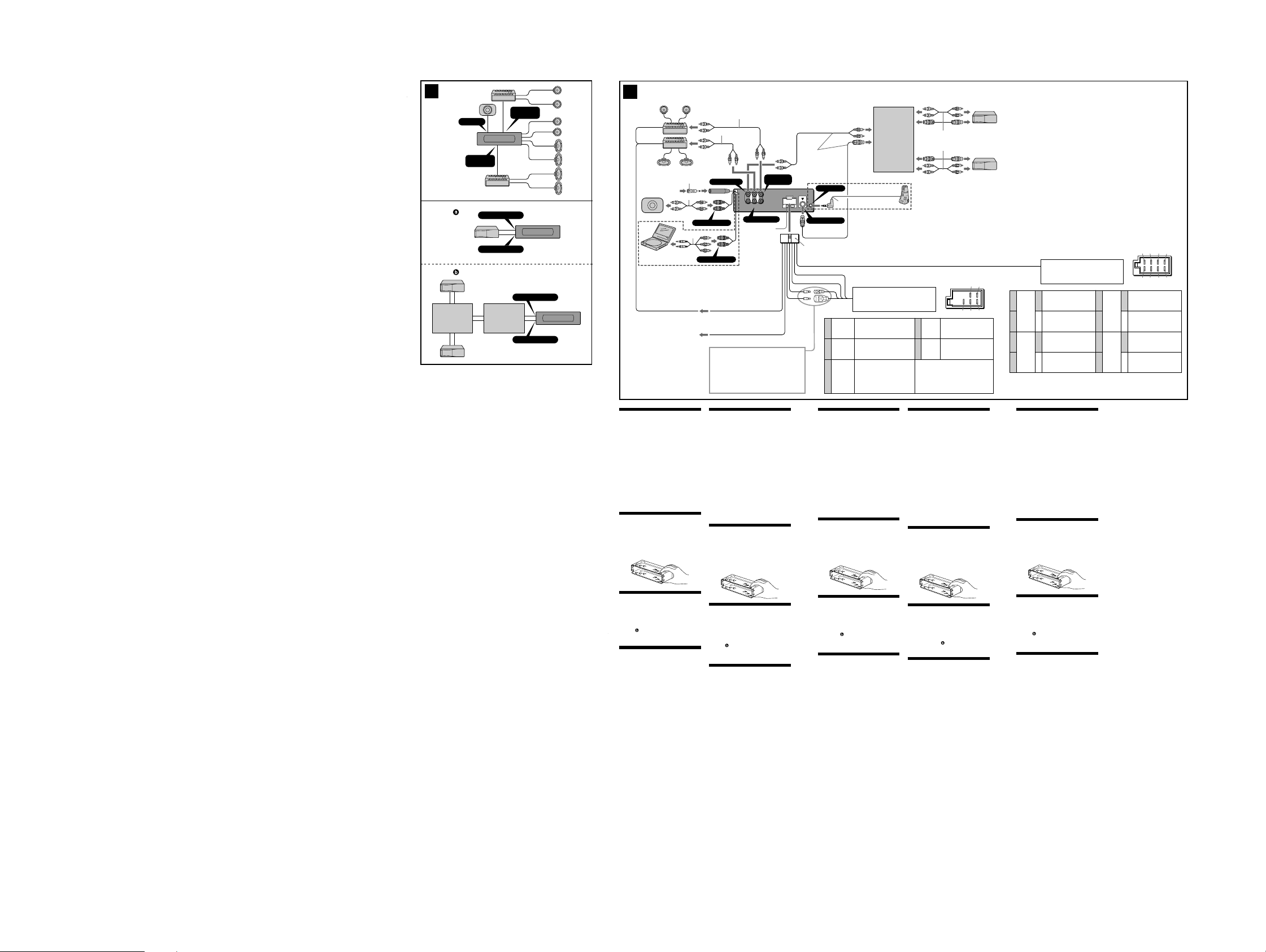

2 A

B

Source selector*

Signalquellenwähler*

Sélecteur de source*

Selettore di fonte*

Geluidsbronkiezer*

SUB OUT

AUDIO OUT

REAR

BUS AUDIO IN

BUS CONTROL IN

DAB tuner unit*

Syntoniseur DAB*

DAB-Tunereinheit*

DAB tuner*

Sintonizzatore DAB*

XT-100DAB

AUDIO OUT

FRONT

BUS AUDIO IN

BUS CONTROL IN

* not supplied

nicht mitgeliefert

non fournis

non in dotazione

niet bijgeleverd

3

from car aerial

von Autoantenne

de l’antenne de la voiture

dall’antenna dell’auto

van een auto-antenne

4

*

3

*

Max. supply current 0.3 A

max. Versorgungsstrom 0,3 A

Courant max. fourni 0,3 A

Alimentazione massima fornita 0,3 A

Max. voedingsstroom 0,3 A

*1Note for the aerial connecting

If your car aerial is an ISO (International Organisation for

Standardisation) type, use the supplied adaptor 6 to

connect it. First connect the car aerial to the supplied

adaptor, then connect it to the aerial jack of the master

unit.

2

*

RCA pin cord (not supplied)

3

*

CDX-M770 only

2

*

2

*

Supplied with XA-C30

Mit dem XA-C30 geliefert

Fourni avec le XA-C30

In dotazione con il modello

XA-C30

1

*

1

*

1

*

1

*

6

1

*

2

*

SUB OUT (MONO)

5

*

BUS AUDIO IN

L

R

AUDIO OUT

AUDIO OUT

BUS

FRONT

REAR

AUDIO

AUDIO OUT REAR

Fuse (10 A)

Sicherung (10 A)

Fusible (10 A)

Fusibile (10 A)

Zekering (10 A)

AUDIO OUT

FRONT

Geleverd met de XA-C30

REMOTE IN

BUS CONTROL IN

8

*

Source selector (not

supplied)

Signalquellenwähler

(nicht mitgeliefert)

Sélecteur de source

(non fourni)

Selettore di fonte

(non in dotazione)

Geluidsbronkiezer

(niet bijgeleverd)

XA-C30

Supplied with the CD/MD changer

Mit dem CD/MD-Wechsler geliefert

Fourni avec le changeur de CD/MD

In dotazione con il cambia CD/MD

Geleverd met de CD/MD-wisselaar

7

*

8

6

AUX-IN (AUDIO)

*

Blue/white striped

Blau-weiß gestreift

A

AMP REM

B

ATT

Rayé bleu/blanc

A strisce blu e bianche

Blauw/wit gestreept

Light blue

Hellblau

Bleu ciel

Azzurro

Hemelsblauw

See “Power Connection diagram” on the reverse side for

details.

Näheres dazu finden Sie im “Stromanschlußdiagramm”.

Blättern Sie dazu bitte um.

Schéma de connexion d’alimentation

Voir le “

pour plus de détails.

Per ulteriori informazioni, vedere “Diagramma dei

collegamenti di alimentazione” che si trova sul retro.

Zie “Voedingsaansluitschema” op de achterkant voor

meer details.

” au verso

4

5

Orange/White

Orange-weiß

Rayé orange/

6

Yellow

Gelb

Jaune

Giallo

Geel

Blue

Blau

Bleu

Blu

Blauw

gestreift

blanc

Arancione/

bianco

Oranje/wit

from the car’s power connector

vom Stromanschluß des Fahrzeugs

du connecteur d’alimentation de la voiture

dal connettore di alimentazione dell’auto

van de autovoedingsstekker

continuous power supply

permanente Stromversorgung

alimentation continue

alimentazione continua

continu voeding

power aerial control

Motorantenne

antenne électrique

comando dell’antenna elettrica

automatische antenne

switched illumination power supply

geschaltete

Beleuchtungsstromversorgung

alimentation de l’éclairage

commuté

alimentazione a illuminazione

commutata

geschakelde verlichting

stroomvoorziening

Red

Rot

7

Rouge

Rosso

Rood

Black

Schwarz

8

Noir

Nero

Zwart

Positions 1, 2 and 3 do not have pins.

An Position 1, 2 und 3 befinden sich keine Stifte.

Les positions 1, 2 et 3 ne comportent pas de

broches.

Le posizioni 1, 2 e 3 non hanno piedini.

De posities 1, 2 en 3 hebben geen pins.

57

4

68

switched power supply

geschaltete Stromversorgung

alimentation commutée

alimentazione commutata

geschakelde voeding

earth

Masse

masse

terra

aarding

4

*

Auxiliary equipment such as portable DVD player DVP-FX1

(not supplied)

5

*

supplied with the auxialiry equipment

6

*

Be sure to match the colour-coded code for audio to the

appropriate jacks from the unit.

7

*

CDX-M670,MDX-M690 only

8

*

Insert with the cord upwards

1

*

Hinweis zum Anschließen der Antenne

Wenn Ihre Fahrzeugantenne der ISO-Norm (ISO =

International Organization for Standardization Internationale Normungsgemeinschaft) entspricht,

schließen Sie sie mit Hilfe des mitgelieferten Adapters 6

an. Verbinden Sie zuerst die Fahrzeugantenne mit dem

mitgelieferten Adapter, und verbinden Sie diesen dann mit

der Antennenbuchse des Hauptgeräts.

2

*

Cinchkabel (nicht mitgeliefert)

3

*

nur CDX-M770

4

*

Zusätzliche Geräte wie z. B. der tragbare DVD-Player DVPFX1

5

*

mit den Zusatzgeräten mitgeliefert

6

*

Achten Sie darauf, das farbcodierte Audiokabel mit den

richtigen Buchsen am Gerät zu verbinden.

7

*

nur CDX-M670 und MDX-M690

8

Mit dem kabel nach oben einsetzen!

*

1

*

Remarque sur le raccordement de l’antenne

Si votre antenne de voiture est de type ISO (organisation

internationale de normalisation), utilisez l’adaptateur

fourni 6 pour la raccorder. Raccordez d’abord l’antenne de

voiture à l’adaptateur fourni et, ensuite, à la prise

d’antenne de l’appareil principal.

2

*

Cordon à broche RCA (non fourni)

3

*

CDX-M770 uniquement

4

Equipement auxiliaire en option tel que le lecteur portable

*

DVD DVP-FX1

5

*

fourni avec l’équipement auxiliaire

6

*

Veillez à faire correspondre le code couleur audio aux

fiches de l’appareil.

7

*

CDX-M670,MDX-M690 uniquement

8

*

Insérez avec le câble vers le haut

1

2

3

4

Negative polarity positions 2, 4, 6, and 8 have striped cords.

An den negativ gepolten Positionen (2, 4, 6 und 8) befinden sich gestreifte Adern.

Les positions de polarité négative 2, 4, 6 et 8 sont dotées de cordons rayés.

Le posizioni a polarità negativa 2, 4, 6 e 8 hanno cavi rigati.

De negatieve posities 2, 4, 6 en 8 hebben gestreepte kabels.

from the car’s speaker connector

vom Lautsprecheranschluß des Fahrzeugs

du connecteur de haut-parleur de la voiture

dal connettore del diffusore dell’auto

van de autoluidsprekerstekker

Lautsprecher hinten rechts

haut-parleur, arrière, droit

+

Diffusore, posteriore, destro

Purple

Luidspreker, achter, rechts

Violett

Mauve

Viola

Lautsprecher hinten rechts

Paars

haut-parleur, arrière, droit

–

Diffusore, posteriore, destro

Luidspreker, achter, rechts

Lautsprecher vorne rechts

haut-parleur, avant, droit

+

Diffusore, anteriore, destro

Grey

Luidspreker, voor, rechts

Grau

Gris

Grigio

Lautsprecher vorne rechts

Grijs

haut-parleur, avant, droit

–

Diffusore, anteriore, destro

Luidspreker, voor, rechts

Speaker, Rear, Right

Speaker, Rear, Right

Speaker, Front, Right

Speaker, Front, Right

*1Nota per il collegamento dell’antenna

Se la vostra antenna della macchina è di tipo ISO

(International Organization Standardization), utilizzare

l’adattatore 6 in dotazione per collegarla. Collegare prima

l’antenna della macchina all’adattatore in dotazione,

quindi collegarla alla presa dell’antenna dell’apparecchio

principale.

2

*

Cavo a piedini RCA (non in dotazione)

3

*

solo CDX-M770

4

Apparecchio opzionale ausiliario quale il lettore DVD

*

portatile DVP-FX1

5

*

in dotazione con l’apparecchio ausiliario

6

*

Assicurarsi che i cavi differenziati in base al colore per l’audio

corrispondano alle prese appropriate dell’apparecchio.

*7solo CDX-M670,MDX-M690

8

*

Inserire con il cavo rivolto verso l’alto

1

*

Opmerking bij de antenne-aansluiting

Indien uw wagen is uitgerust met een antenne van het

type ISO (International Organisation for Standardization),

moet u die aansluiten met behulp van de meegeleverde

adaptor 6. Sluit eerst de auto-antenne aan op de

meegeleverde adaptor en vervolgens de antennestekker op

het hoofdtoestel.

2

*

Tulpstekkersnoer (niet bijgeleverd)

3

*

alleen CDX-M770

4

*

Los verkrijgbare apparatuur zoals de draagbare DVDspeler DVP-FX1

5

*

meegeleverd met de los verkrijgbare apparatuur

6

*

Zorg ervoor dat de kleurcode voor audio overeenkomt met

de betreffende aansluitingen op het toestel.

7

*

alleen CDX-M670, MDX-M690

8

*

Inbrengen met het snoer naar boven

13 57

24 68

Speaker, Front, Left

White

Weiß

Blanc

Bianco

Green

Verde

Groen

Wit

Grün

Vert

Lautsprecher vorne links

haut-parleur, avant, gauche

+

Diffusore, anteriore, sinistro

Luidspreker, voor, links

Speaker, Front, Left

Lautsprecher vorne links

haut-parleur, avant, gauche

–

Diffusore, anteriore, sinistro

Luidspreker, voor, links

Speaker, Rear, Left

Lautsprecher hinten links

haut-parleur, arrière, gauche

+

Diffusore, posteriore, sinistro

Luidspreker, achter, links

Speaker, Rear, Left

Lautsprecher hinten links

haut-parleur, arrière, gauche

–

Diffusore, posteriore, sinistro

Luidspreker, achter, links

5

6

7

8

Cautions

•This unit is designed for negative earth 12 V DC

operation only.

•Do not get the wires under a screw, or caught in

moving parts (e.g. seat railing).

•Before making connections, turn the car ignition

off to avoid short circuits.

•Connect the power connecting cord 8 to the unit

and speakers before connecting it to the auxiliary

power connector.

•Run all earth wires to a common earth point.

•Be sure to insulate any loose unconnected wires

with electrical tape for safety.

Notes on the power supply cord (yellow)

•When connecting this unit in combination with

other stereo components, the connected car

circuit’s rating must be higher than the sum of

each component’s fuse.

•When no car circuits are rated high enough,

connect the unit directly to the battery.

Parts list (1)

The numbers in the list are keyed to those in the

instructions.

For the use of release key qs, see the supplied

operating instructions.

Caution

Handle the bracket 1 carefully to avoid injuring

your fingers.

Connection example (2)

Notes (2-A)

• Be sure to connect the earth cord before

connecting the amplifier.

• If you connect an optional power amplifier and do

not use the built-in amplifier, the beep sound will

be deactivated.

Tip (2-B-

)

For connecting two or more CD/MD changers, the

source selector XA-C30 (optional) is necessary.

Connection diagram (3)

A

To AMP REMOTE IN of an optional power

amplifier

This connection is only for amplifiers. Connecting

any other system may damage the unit.

B

To the interface cable of a car telephone

Warning

If you have a power aerial without a relay box,

connecting this unit with the supplied power

connecting cord 8 may damage the aerial.

Notes on the control leads

• The power aerial control lead (blue) supplies +12 V

DC when you turn on the tuner or when you

activate the AF (Alternative Frequency), TA (Traffic

Announcement) function.

• When your car has built-in FM/MW/LW aerial in

the rear/side glass, connect the power aerial

control lead (blue) or the accessory power input

lead (red) to the power terminal of the existing

aerial booster. For details, consult your dealer.

• A power aerial without a relay box cannot be used

with this unit.

Memory hold connection

When the yellow power input lead is connected,

power will always be supplied to the memory circuit

even when the ignition switch is turned off.

Notes on speaker connection

• Before connecting the speakers, turn the unit off.

• Use speakers with an impedance of 4 to 8 ohms,

and with adequate power handling capacities to

avoid its damage.

• Do not connect the speaker terminals to the car

chassis, or connect the terminals of the right

speakers with those of the left speaker.

• Do not connect the earth lead of this unit to the

negative (–) terminal of the speaker.

• Do not attempt to connect the speakers in parallel.

• Connect only passive speakers. Connecting active

speakers (with built-in amplifiers) to the speaker

terminals may damage the unit.

• To avoid a malfunction, do not use the built-in

speaker wires installed in your car if the unit shares

a common negative (–) lead for the right and left

speakers.

• Do not connect the unit’s speaker cords to each

other.

Vorsicht

•Dieses Gerät ist ausschließlich für den Betrieb bei 12

V Gleichstrom (negative Erdung) bestimmt.

•Achten Sie darauf, daß die Kabel nicht unter einer

Schraube oder zwischen beweglichen Teilen wie z.

B. in einer Sitzschiene eingeklemmt werden.

•Schalten Sie, bevor Sie irgendwelche Anschlüsse

vornehmen, die Zündung des Fahrzeugs aus, um

Kurzschlüsse zu vermeiden.

•Verbinden Sie das Stromversorgungskabel 8 mit

dem Gerät und den Lautsprechern, bevor Sie es mit

dem Hilfsstromanschluß verbinden.

•Schließen Sie alle Erdungskabel an einen

gemeinsamen Massepunkt an.

•Aus Sicherheitsgründen müssen alle losen, nicht

angeschlossenen Drähte mit Isolierband abisoliert

werden.

Hinweise zum Stromversorgungskabel (gelb)

•Wenn Sie dieses Gerät zusammen mit anderen

Stereokomponenten anschließen, muß der

Autostromkreis, an den die Geräte angeschlossen

sind, eine höhere Leistung aufweisen als die Summe

der Sicherungen der einzelnen Komponenten.

•Wenn kein Autostromkreis eine so hohe Leistung

aufweist, schließen Sie das Gerät direkt an die

Batterie an.

Teileliste (1)

Die Nummern in der Liste sind dieselben wie im

Erläuterungstext.

Wie Sie den Löseschlüssel qs verwenden, schlagen

Sie bitte in der mitgelieferten Bedienungsanleitung

nach.

Vorsicht

Seien Sie beim Umgang mit der Halterung 1

vorsichtig, damit Sie sich nicht die Hände verletzen.

Anschlu§beispiel (2)

Hinweise (2-A)

• Schließen Sie unbedingt zuerst das Massekabel an,

bevor Sie den Verstärker anschließen.

• Wenn Sie einen gesondert erhältlichen

Endverstärker anschließen und den integrierten

Verstärker nicht benutzen, wird der Signalton

deaktiviert.

Tip (2-B- )

Zum Anschließen von zwei oder mehr CD/MDWechslern wird der gesondert erhältliche

Signalquellenwähler XA-C30 benötigt.

Anschlu§diagramm (3)

A

An AMP REMOTE IN des gesondert erhältlichen

Endverstärkers

Dieser Anschluß ist ausschließlich für Verstärker

gedacht. Schließen Sie nichts anderes daran an.

Andernfalls kann das Gerät beschädigt werden.

B

An Schnittstellenkabel eines Autotelefons

Warnung

Wenn Sie eine Motorantenne ohne Relaiskästchen

verwenden, kann durch Anschließen dieses Geräts

mit dem mitgelieferten Stromversorgungskabel 8

die Antenne beschädigt werden.

Hinweise zu den Steuerleitungen

• Die Motorantennen-Steuerleitung (blau) liefert

+ 12 V Gleichstrom, wenn Sie den Tuner einschalten

oder die AF- (Alternativfrequenzsuche) oder die TAFunktion (Verkehrsdurchsagen) aktivieren.

• Wenn das Fahrzeug mit einer in der Heck-/

Seitenfensterscheibe integrierten FM (UKW)/MW/

LW-Antenne ausgestattet ist, schließen Sie die

Motorantennen-Steuerleitung (blau) oder die

Zubehörstromversorgungsleitung (rot) an den

Stromversorgungsanschluß des vorhandenen

Antennenverstärkers an. Näheres dazu erfahren Sie

bei Ihrem Händler.

• Es kann nur eine Motorantenne mit Relaiskästchen

angeschlossen werden.

Stromversorgung des Speichers

Wenn das gelbe Stromversorgungskabel

angeschlossen ist, wird der Speicher stets (auch bei

ausgeschalteter Zündung) mit Strom versorgt.

Hinweise zum Lautsprecheranschluß

• Schalten Sie das Gerät aus, bevor Sie die

Lautsprecher anschließen.

• Verwenden Sie Lautsprecher mit einer Impedanz

zwischen 4 und 8 Ohm und ausreichender

Belastbarkeit. Ansonsten können die Lautsprecher

beschädigt werden.

• Verbinden Sie die Lautsprecheranschlüsse nicht mit

dem Wagenchassis, und verbinden Sie auch nicht die

Anschlüsse des rechten mit denen des linken

Lautsprechers.

• Verbinden Sie die Masseleitung dieses Geräts nicht

mit dem negativen (–) Lautsprecheranschluß.

• Versuchen Sie nicht, Lautsprecher parallel

anzuschließen.

• An die Lautsprecheranschlüsse dieses Geräts dürfen

nur Passivlautsprecher angeschlossen werden.

Schließen Sie keine Aktivlautsprecher (Lautsprecher

mit eingebauten Verstärkern) an, da diese sonst

beschädigt werden können.

• Um Fehlfunktionen zu vermeiden, verwenden Sie

nicht die im Fahrzeug installierten, integrierten

Lautsprecherleitungen, wenn am Ende eine

gemeinsame negative (–) Leitung für den rechten

und den linken Lautsprecher verwendet wird.

• Verbinden Sie nicht die Lautsprecherkabel des

Geräts miteinander.

Prcautions

•Cet appareil est conçu pour fonctionner sur

courant continu de 12 V avec masse négative.

•Evitez de fixer des vis sur les câbles ou de coincer

ceux-ci dans des pièces mobiles (par exemple,

armature de siège).

•Avant d’effectuer des raccordements, éteignez le

moteur pour éviter les courts-circuits.

•Branchez le cordon d’alimention 8 sur l’appareil

et les haut-parleurs avant de le brancher sur le

connecteur d’alimentation auxiliaire.

•Rassemblez tous les fils de terre en un point de

masse commun.

•Veillez à isoler avec du chatterton tout fil lâche

non raccordé.

Remarques sur le cordon d’alimentation (jaune)

•Lorsque cet appareil est raccordé à d’autres

éléments stéréo, la valeur nominale des circuits de

la voiture raccordée doit être supérieure à la

somme des fusibles de chaque élément.

•Si aucun circuit de la voiture n’est assez puissant,

raccordez directement l’appareil à la batterie.

Liste des composants (1)

Les numéros de l’illustration correspondent à ceux

des instructions.

Pour l’utilisation de la clé de déblocage qs,

reportez-vous au mode d’emploi.

Attention

Manipulez précautionneusement le support 1

pour éviter de vous blesser aux doigts.

Exemple de raccordement (2)

Remarques (2-A)

• Raccordez d’abord le fil de masse avant de

raccorder l’amplificateur.

• Si vous raccordez un amplificateur de puissance

indépendant et que vous n’utilisez pas

l’amplificateur intégré, le bip sonore est désactivé.

Conseil (2-B-

)

Dans le cas du raccordement de deux changeurs de

CD/MD ou plus, le sélecteur de source XA-C30 (en

option) est indispensable.

Schma de raccordement (3)

A

Au niveau du AMP REMOTE IN d’un

amplificateur de puissance facultatif

Ce raccordement existe seulement pour les

amplificateurs. Le raccordement à tout autre

système peut endommager l’appareil.

B

Vers le cordon de liaison d’un téléphone de

voiture

Avertissement

Si vous disposez d’une antenne électrique sans

boîtier de relais, le branchement de cet appareil au

moyen du cordon d’alimentation fourni 8 risque

d’endommager l’antenne.

Remarques sur les fils de contrôle

• Le fil de commande (bleu) de l’antenne électrique

assure une alimentation de +12 V CC lorsque vous

mettez le syntoniseur sous tension ou lorsque vous

activez la fonction AF (fréquence secondaire) ou

TA (informations routières).

• Lorsque votre voiture est équipée d’une antenne

FM/MW/LW intégrée dans la vitre arrière/latérale,

raccordez la sortie de commande de l’antenne

(bleu) ou l’entrée d’alimentation des accessoires

(rouge) au bornier de l’amplificateur d’antenne

existant. Pour plus de détails, consultez votre

revendeur.

• Une antenne électrique sans boitier de relais ne

peut pas être utilisée avec cet appareil.

Raccordement pour la conservation de la mémoire

Lorsque le fil d’entrée d’alimentation jaune est

raccordé, le circuit de la mémoire est alimenté en

permanence même si la clé de contact est sur la

position d’arrêt.

Remarques sur le raccordement des haut-parleurs

• Avant de raccorder les haut-parleurs, mettez

l’appareil hors tension.

• Utilisez des haut-parleurs ayant une impédance de

4 à 8 ohms avec une capacité de manipulation

adéquate pour éviter de les endommager.

• Ne raccordez pas les bornes du système de hautparleurs au châssis de la voiture et ne raccordez

pas les bornes du haut-parleur droit à celles du

haut-parleur gauche.

• Ne raccordez pas le câble de masse de cet appareil

à la borne négative (–) de l’enceinte.

• N’essayez pas de raccorder les haut-parleurs en

parallèle.

• Raccordez uniquement des haut-parleurs passifs.

Le raccordement de haut-parleurs actifs (avec

amplificateurs intégrés) aux bornes des hautparleurs peut endommager l’appareil.

• Pour éviter tout dysfonctionnement, n’utilisez pas

les fils des haut-parleurs intégrés installés dans

votre voiture si l’appareil partage un fil négatif

commun (–) pour les haut-parleurs droit et gauche.

• Ne raccordez pas entre eux les cordons des hautparleurs de l’appareil.

Attenzione

•Questo apparecchio è stato progettato per l’uso solo

a 12 V CC con massa negativa.

•Evitare che i cavi rimangano bloccati da una vite o

incastrati nelle parti mobili (ad esempio nelle guide

scorrevoli dei sedili).

•Prima di effettuare i collegamenti, spegnere il

motore dell’automobile onde evitare di causare

cortocircuiti.

•Collegare il cavo di collegamento dell’alimentazione

8 all’apparecchio e ai diffusori prima di collegarlo

al connettore di alimentazione ausiliare.

•Portare tutti i cavi di massa a un punto di massa

comune.

•Per sicurezza, assicurarsi di isolare qualsiasi cavo

non collegato mediante apposito nastro.

Note sul cavo di alimentazione (giallo)

•Se questo apparecchio viene collegato con altri

componenti stereo, la potenza nominale dei circuiti

dell’automobile deve essere superiore a quella

prodotta dalla somma dei fusibili di ciascun

componente.

•Se la potenza nominale dei circuiti dell’automobile

non è sufficiente, collegare l’apparecchio

direttamente alla batteria.

Elenco dei componenti (1)

I numeri nella lista corrispondono a quelli riportati

nelle istruzioni.

Per informazioni sull’utilizzo del tasto di rilascio

qs, vedere le istruzioni per l’uso in dotazione.

Attenzione

Maneggiare la staffa 1 con cautela per evitare di

ferirsi le mani.

Esempi di collegamento (2)

Note (2-A)

• Assicurarsi di collegare il cavo di terra prima di

collegare l’apparecchio all’amplificatore.

• Se si collega un amplificatore di potenza opzionale

e non si utilizza l’amplificatore incorporato, il

segnale acustico verrà disattivato.

Suggerimento (2-B-

Per collegare due o più cambia CD/MD, si deve

utilizzare il selettore di fonte XA-C30 (opzionale).

Schema di collegamento (3)

A

B

Avvertenza

Quando si collega l’apparecchio con il cavo di

alimentazione in dotazione 8, si potrebbe

danneggiare l’antenna elettrica se questa non ha la

scatola di relè.

Note sui cavi di controllo

• Il cavo di controllo dell’antenna elettrica (blu)

fornisce corrente continua +12 V CC quando si

accende il sintonizzatore o quando si attiva la

funzione AF (frequenza alternativa) o TA

(notiziario sul traffico).

• Se l’automobile è dotata di antenna FM/MW/LW

incorporata nel vetro posteriore/laterale, collegare il

cavo (blu) di controllo dell’antenna elettrica o il cavo

(rosso) di ingresso dell’alimentazione opzionale al

terminale di alimentazione del preamplificatore

dell’antenna esistente. Per ulteriori informazioni,

consultare il proprio fornitore.

• Non è possibile usare un’antenna elettrica senza

scatola a relè con questo apparecchio.

Collegamento per la conservazione della memoria

Quando il cavo di ingresso alimentazione giallo è

collegato, viene sempre fornita alimentazione al

circuito di memoria anche quando la chiavetta a

accensione è spenta.

Note sul collegamento dei diffusori

• Prima di collegare i diffusori spegnere

l’apparecchio.

• Usare diffusori di impedenza compresa tra 4 e 8

ohm e con capacità di potenza adeguata,

altrimenti i diffusori potrebbero venir danneggiati.

• Non collegare i terminali del sistema diffusori al

telaio dell’auto e non collegare i terminali del

diffusore destro a quelli del diffusore sinistro.

• Non collegare il cavo di terra di questo

apparecchio al terminale negativo (–) del diffusore.

• Non collegare i diffusori in parallelo.

• Non collegare alcun diffusore attivo (con

amplificatore incorporato) ai terminali dei diffusori

dell’apparecchio perché si potrebbero danneggiare

i diffusori attivi. Assicurarsi di collegare diffusori

passivi a questi terminali.

• Per evitare problemi di funzionamento, non

utilizzare i cavi dei diffusori incorporati installati

nell’automobile se il terminale dell’apparecchio

condivide un cavo comune negativo (–) per i

diffusori destro e sinistro.

• Non collegare fra loro i cavi dei diffusori

dell’apparecchio.

)

A AMP REMOTE IN di un amplificatore di

potenza opzionale

Questo collegamento è riservato esclusivamente

agli amplificatori. Non collegare un tipo di

sistema diverso onde evitare di causare danni

all’apparecchio.

Al cavo interfaccia di un telefono per auto

Let op!

•Dit apparaat is ontworpen voor gebruik op

gelijkstroom van een 12 Volts auto-accu, negatief

geaard.

•Zorg ervoor dat de draden niet onder een schroef of

tussen bewegende onderdelen (b.v. zetelrail)

terechtkomen.

•Alvorens aansluitingen te verrichten moet u het

contact afzetten om kortsluiting te vermijden.

•Sluit het netsnoer 8 aan op het toestel en de

luidsprekers vooraleer u het op de

hulpvoedingsaansluiting aansluit.

•Sluit alle aarddraden op een gemeenschappelijk

aardpunt aan.

•Voorzie niet aangesloten draden om

veiligheidsredenen altijd van isolatietape.

Opmerkingen bij de voedingskabel (geel)

•Wanneer u dit toestel aansluit samen met andere

componenten, moet het vermogen van de aangesloten

autostroomkring groter zijn dan de som van de

zekeringen van elke component afzonderlijk.

•Wanneer het vermogen ontoereikend is, moet u het

toestel rechtstreeks aansluiten op de batterij.

Onderdelenlijst ( 1)

De nummers in de afbeelding verwijzen naar die in

de montage-aanwijzingen.

Raadpleeg de meegeleverde gebruiksaanwijzing om

de speciale sleutel te bedienen qs.

Voorzichtig

Houd de beugel 1 voorzichtig vast zodat u uw

vingers niet verwondt.

Voorbeeldaansluitingen ( 2)

Opmerkingen (2-A)

• Sluit eerst de massakabel aan alvorens de

versterker aan te sluiten.

• Als u een los verkrijgbare vermogensversterker

aansluit en de ingebouwde versterker niet

gebruikt, is de pieptoon uitgeschakeld.

Tip (2-B-

)

Om twee of meer CD/MD-wisselaars aan te sluiten,

hebt u de geluidsbronkiezer XA-C30 (optioneel)

nodig.

Aansluitschema (3)

A

Naar AMP REMOTE IN van een los verkrijgbare

vermogensversterker

Deze aansluiting is alleen bedoeld voor

versterkers. Door een ander systeem aan te sluiten

kan het toestel worden beschadigd.

B

Naar het interface-snoer van een autotelefoon

Opgelet

Indien u een elektrische antenne heeft zonder

relaiskast, kan het aansluiten van deze eenheid met

het bijgeleverde netsnoer 8 de antenne beschadigen.

Opmerking betreffende de aansluitsnoeren

• De voedingskabel (blauw) van de elektrisch

bediende antenne levert +12V gelijkstroom

wanneer u de tuner aanschakelt of de functie AF

(Alternative Frequency) of TA (Traffic

Announcement) activeert.

• Wanneer uw auto is uitgerust met een FM/MW/

LW-antenne in de achterruit/voorruit, moet u de

antennevoedingskabel (blauw) of de

hulpvoedingskabel (rood) aansluiten op de

voedingsingang van de bestaande

antenneversterker. Raadpleeg uw dealer voor

meer details.

• Met dit apparaat is het niet mogelijk een

automatische antenne zonder relaishuis te

gebruiken.

Instandhouden van het geheugen

Zolang de gele stroomdraad is aangesloten, blijft de

stroomvoorziening van het geheugen intact, ook

wanneer het contact van de auto wordt

uitgeschakeld.

Opmerkingen betreffende het aansluiten van de

luidsprekers

• Zorg dat het apparaat is uitgeschakeld, alvorens de

luidsprekers aan te sluiten.

• Gebruik luidsprekers met een impedantie van 4 tot

8 Ohm en let op dat die het vermogen van de

versterker kunnen verwerken. Als dit wordt

verzuimd, kunnen de luidsprekers ernstig

beschadigd raken.

• Verbind in geen geval de aansluitingen van de

luidsprekers met het chassis van de auto en sluit de

aansluitingen van de rechter en linker luidspreker

niet op elkaar aan.

• Verbind de massakabel van dit toestel niet met de

negatieve (–) aansluiting van de luidspreker.

• Probeer nooit de luidsprekers parallel aan te

sluiten.

• Sluit geen actieve luidsprekers (met ingebouwde

versterkers) aan op de luidspreker-aansluiting van

dit apparaat. Dit zal leiden tot beschadiging van

de actieve luidsprekers. Sluit dus altijd uitsluitend

luidsprekers zonder ingebouwde versterker aan.

• Om defecten te vermijden mag u de bestaande

luidsprekerbedrading in uw auto niet gebruiken

wanneer er een gemeenschappelijke negatieve (–)

draad is voor de rechter en linker luidsprekers.

• Verbind de luidsprekerdraden niet met elkaar.

66

Page 7

MDX-M690

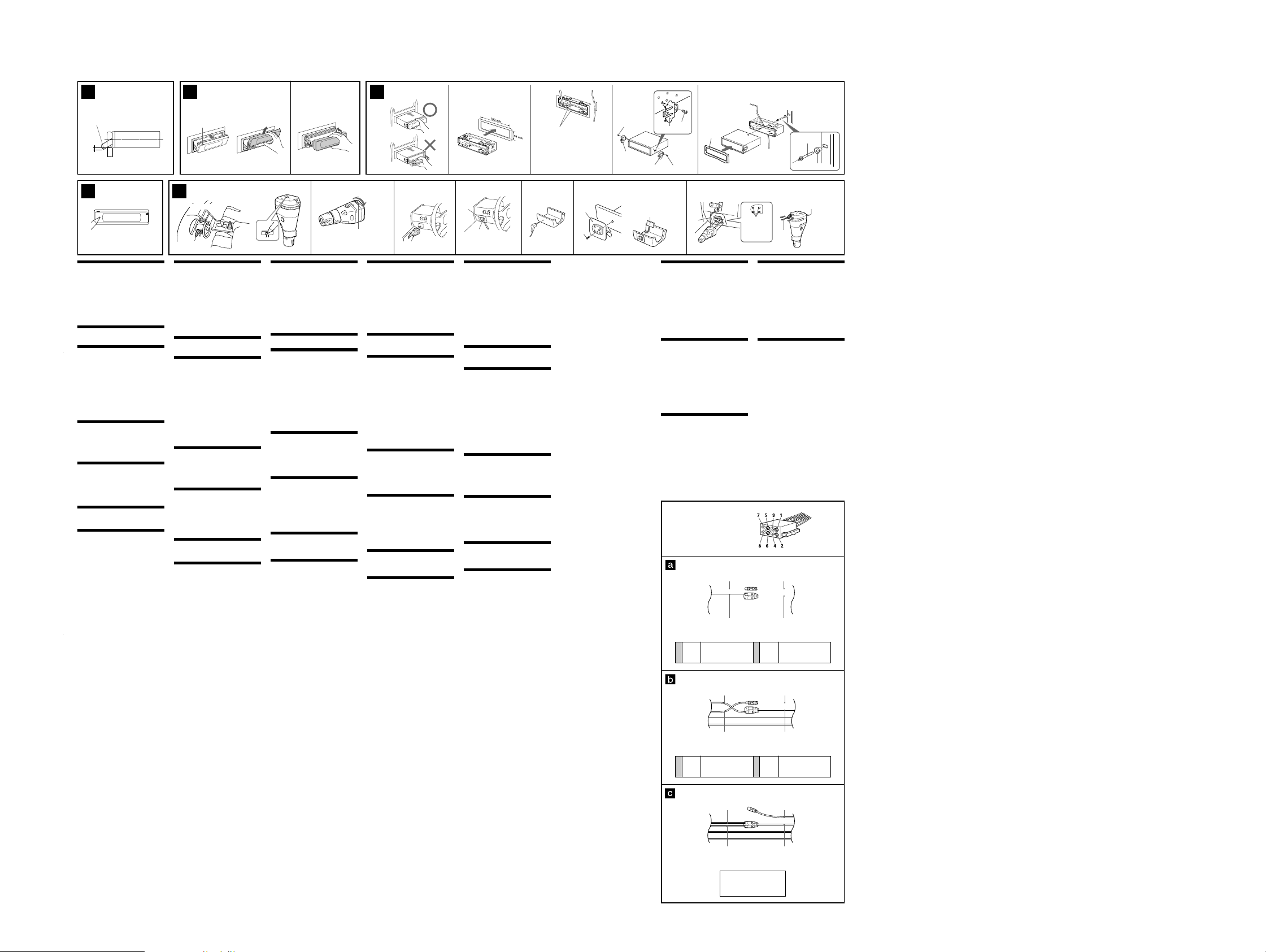

4

Extended portion of the front panel

Überstehender Teil der Frontplatte

Partie étendue de la façade

Parte sporgente del pannello anteriore

Verlengstuk van het frontpaneel

7 mm

20 mm

7

Precautions

•Choose the installation location carefully so that the unit

will not interfere with normal driving operations.

•Avoid installing the unit in areas subject to dust, dirt,

excessive vibration, or high temperature, such as in direct

sunlight or near heater ducts.

•Use only the supplied mounting hardware for a safe and

secure installation.

Mounting angle adjustment

(CDX-M770/M670)

Adjust the mounting angle to less than 60°.

(MDX-M690)

Adjust the mounting angle to less than 20°.

Extended portion of the front

panel (4)

How to detach and attach the

main display window ( 5)

Before installing the unit, detach the front panel.

5-A To detach

1 Press (OPEN) on the unit for 2 seconds.

CD/MD playback or radio reception stops, and the front

panel automatically tilts at an angle of 30°.

2 Detach the main display window as illustrated.

After the main display window detaching is complete,

the front panel closes automaticaly.

5-B To attach

Place the main display window on the front side of the unit

as illustrated, then lightly push the front panel into

position until it clicks.

Mounting example ( 6)

Installation in the dashboard

6-

Note

*

When installing this unit, be sure to close the front

panel of the unit.

If the front panel is opened while installing and given too

much force, it may cause a malfunction.

Warning when installing in a car

without ACC (accessory) position

on the ignition key switch

Be sure to press (OFF) on the unit for two seconds to

turn off the clock display after turning off the engine.

When you press (OFF) only momentarily, the clock

display does not turn off and this causes battery wear.

Reset button (7)

When the installation and connections are completed, be

sure to press the Reset button with a ballpoint pen, etc.

Installing the rotary commander

(RM-X5S) (8)

Notes

• Choose the mounting location carefully so that the rotary

commander will not interfere with operating the car.

• Do not install the rotary commander where it may

jeopardize the safety of the (front) passenger in anyway.

• When installing the rotary commander, be sure not to

damage the electrical cables etc. on the other side of the

mounting surface.

• Avoid installing the rotary commander where it may be

subject to high temperatures, such as from direct sunlight

or hot air from the heater etc.

• The Rev/Nor-select switch is located on the bottom of the

rotary commander. Select “Nor” to use the rotary

commander as the factory-set position. Select “Rev” when

you mount the rotary commander on the right side of the

steering column.

Tip

Rev/Nor cannot be selected on the side of master unit.

1 Press the buttons and rotate the controls to make

sure that your master unit reacts well.

You can change the direction of infrared rays by turning

the dial on the rotary commander.

Caution

Be sure that the place where you install the rotary

commander is within the range of receptor on the unit.

2 Choose the exact location for the rotary

commander to be mounted, then clean the

mounting surface.

Dirt or oil impair the adhesive strength of the doublesided adhesive tape.

3 Mark position for the supplied screw.

Use the screw holes on the mounting hardware 0 to

mark the positions.

If you cannot make the mounting hardware 0 fit easy,

cut the mounting hardware 0 to fit the steering wheel

column cover.

4 Remove the steering wheel column cover, and drill

2 mm diameter hole where you have marked.

5 Warm the mounting surface and the double-sided

adhesive tape on the mounting hardware 0 to the

temperature of 20 °C to 30 °C, and attach the

mounting hardware 0 onto the mounting surface

by applying even pressure. Then screw it down

with the supplied screw 9.

Attach a piece of heavy duty tape etc. on the other side

of the mounting surface to cover the protruding tips of

the screws so that they will not interfere with the

electrical cables etc. inside the steering wheel column.

6 After installing the steering wheel column cover,

attach the rotary commander to the mounting

hardware by aligning the four holes on the bottom

of the rotary commander to the four catches on the

mounting hardware and sliding the rotary

commander until it locks into place as illustrated.

Cautions

• Be sure to attach the supplied strap qa when installing the

rotary commander near the steering wheel.

• Be sure that the strap qa does not get caught on the car

controls (gear, shifter, etc.).

• Be sure to tighten the stopper of the strap qa after

hanging the strap qa on the indicator switch, etc.

Tip

There are two holes for the strap qa. You can use whichever

hole you prefer.

Note

If you are mounting the rotary commander to the steering

wheel column, make sure that the protruding tips of the

screws on the inner surface of the column do not in anyway

hinder or interfere with the movement of the rotating shaft,

operative parts of the switches or the electrical cables etc.

inside the column.

5 6AB 23

(OPEN)

*

c

Mounting example

Montagebeispiel

8 23 41

Exemple de montage

Vorsichtsma§nahmen

•Wählen Sie den Einbauort sorgfältig so aus, daß das

Gerät beim Fahren nicht hinderlich ist.

•Bauen Sie das Gerät so ein, daß es keinen hohen

Temperaturen (keinem direkten Sonnenlicht, keiner

Warmluft von der Heizung), keinem Staub, keinem

Schmutz und keinen starken Vibrationen ausgesetzt ist.

•Für eine sichere Befestigung verwenden Sie stets nur die

mitgelieferten Montageteile.

Hinweis zum Montagewinkel

(CDX-M770/M670)

Das Gerät sollte in einem Winkel von weniger als 60°

montiert werden.

(MDX-M690)

Das Gerät sollte in einem Winkel von weniger als 20°

montiert werden.

berstehender Teil der

Frontplatte ( 4)

Abnehmen und Anbringen des

Haupt-Displays (5)

Nehmen Sie die Frontplatte vor dem Einbau des

Geräts ab.

5-A Abnehmen

1Drücken Sie 2 Sekunden lang (OPEN) am Gerät.

Die CD/MD-Wiedergabe bzw. der Radioempfang

stoppt, und die Frontplatte wird automatisch in einem

Winkel von 30 Grad geneigt.

2 Nehmen Sie das Haupt-Display wie in der

Abbildung dargestellt ab.

Wenn das Haupt-Display abgenommen ist, schließt sich

die Frontplatte automatisch.

5-B Anbringen

Setzen Sie das Haupt-Display wie in der Abbildung

dargestellt an die Vorderseite des Geräts an, und drücken

Sie die Frontplatte dann leicht in die richtige Position, bis

sie mit einem Klicken einrastet.

Montagebeispiel ( 6)

Installation im Armaturenbrett

6-

Hinweis

*

Achten Sie beim Einbau des Geräts darauf, die

Frontplatte geschlossen zu halten.

Wenn sich die Frontplatte beim Einbau öffnet und Sie zu

stark darauf drücken, kann es zu einer Fehlfunktion kommen.

Warnhinweis zur Installation des

Gerts in einem Auto mit Zndschlo§

ohne Zubehrposition ACC oder I

Drücken Sie am Gerät unbedingt zwei Sekunden lang

(OFF), um die Uhrzeitanzeige auszuschalten,

nachdem Sie den Motor ausgeschaltet haben.

Wenn Sie (OFF) nur kurz drücken, wird die

Uhrzeitanzeige nicht ausgeschaltet, und der Autobatterie

wird Strom entzogen.

Rcksetztaste (7)

Nach der Installation und dem Anschluß muß die

rücksetztaste mit einem Kugelschreiber o. ä. gedrückt werden.

Installieren des Joystick

(RM-X5S) (8)

Hinweise

• Wählen Sie den Montageort sorgfältig aus, so daß der

Joystick beim Fahren nicht im Wege ist.

• Montieren Sie den Joystick nicht an einer Stelle, an der er

eine Gefahr für den Beifahrer auf dem Vordersitz

darstellen könnte.

• Achten Sie bei der Montage des Joystick darauf, die

Elektrokabel an der anderen Seite der Montagefläche

nicht zu beschädigen.

• Montieren Sie den Joystick nicht an einer Stelle, an der er

hohen Temperaturen, zum Beispiel direktem Sonnenlicht

oder der Warmluft aus der Wagenheizung, ausgesetzt ist.

• Der Wählschalter Rev/Nor befindet sich an der Unterseite

des Joysticks. Wählen Sie „Nor“, wenn die werkseitig

voreingestellte Drehrichtung der Regler beibehalten

werden soll. Wählen Sie „Rev“, wenn Sie den Joystick auf

der rechten Seite der Lenksäule anbringen.

Tip

Rev/Nor kann nicht mit dem Hauptgerät ausgewählt werden.

1Drücken Sie die Tasten, drehen Sie die Regler, und

vergewissern Sie sich, daß das Hauptgerät

entsprechend reagiert.

Sie können die Richtung der Infrarotstrahlen ändern,

indem Sie den Regler am Joystick drehen.

Vorsicht

Vergewissern Sie sich, daß der Montageort des Joysticks

innerhalb der Reichweite des Empfängers am Gerät ist.

2Wählen Sie die Stelle aus, an der Sie den Joystick

montieren wollen, und reinigen Sie dann die

Montagefläche.

Staub oder Fettspuren beeinträchtigen die Haftung des

doppelseitigen Klebebandes.

3 Markieren Sie die Stelle zum Anbringen der

mitgelieferten Schraube.

Verwenden Sie dazu die Bohrung im Montageteil 0.

Wenn das Montageteil 0 nicht auf die Abdeckung der

Lenkradsäule paßt, schneiden Sie es bitte zurecht.

4 Nehmen Sie die Abdeckung der Lenkradsäule ab,

und bohren Sie an der Stelle, die Sie gerade

markiert haben, ein Loch von 2 mm Durchmesser.

5Erwärmen Sie die Montagestelle und das

doppelseitige Klebeband am Montageteil 0 auf

eine Temperatur von 20 bis 30 °C, und drücken Sie

dann das Montageteil 0 mit gleichmäßigem Druck

auf die Montagestelle. Befestigen Sie es dann mit

der mitgelieferten Schraube 9.

Bringen Sie ein Stück sehr festes Klebeband o. ä. an der

Gegenseite der Montagefläche an, um die vorstehenden

Spitzen der Schrauben abzudecken, damit diese nicht

die Elektrokabel in der Lenkradsäule beschädigen

können.

6 Bringen Sie nun die Abdeckung der Lenkradsäule

wieder an, und befestigen Sie dann den Joystick

auf dem Montageteil, indem Sie die vier

Aussparungen an der Unterseite des Joysticks an

den vier Haken auf dem Montageteil ausrichten

und den Joystick daraufschieben, bis er einrastet,

wie auf der Abbildung zu sehen.

Vorsicht

• Achten Sie darauf, den mitgelieferten Riemen qa

anzubringen, wenn Sie den Joystick in der Nähe des

Lenkrades installieren.

• Achten Sie darauf, daß sich der Riemen qa nicht an

Bedienelementen des Fahrzeugs verfängt (Schalthebel,

Handbremse usw.).

• Achten Sie darauf, den Stopper des Riemens qa

anzuziehen, nachdem Sie den Riemen qa an den

Blinkerhebel o. ä. gehängt haben.

Tip

Für den Riemen qa sind zwei Aussparungen vorhanden. Sie

können sie nach Belieben auswählen.

Hinweis

Wenn Sie den Joystick an der Lenkradsäule montieren,

achten Sie darauf, daß die vorstehenden Spitzen der

Schrauben an der Innenfläche der Lenkradsäule die

Bewegung der Lenkwelle, die Funktionsteile der Schalter

bzw. die Elektrokabel innerhalb der Lenkradsäule in keiner

Weise behindern.

Esempio di montaggio

Montagevoorbeeld

Rev Nor

Infrared rays dial

Regler für Infrarotstrahlen

Molette de réglage des rayons IR

Manopola raggi infrarossi

Knop infraroodstralen

Prcautions

•Choisissez soigneusement l’emplacement de l’installation

afin que l’appareil ne gêne pas la conduite normale du

véhicule.

•Evitez d’installer l’appareil dans un endroit exposé à la

poussière, à la saleté, à des vibrations excessives ou à des

températures élevées comme en plein soleil ou à

proximité de conduits de chauffage.

•Pour garantir un montage sûr, n’utilisez que le matériel

fourni.

Rglage de langle de montage

(CDX-M770/M670)

Ajustez l’inclinaison à un angle inférieur à 60°.

(MDX-M690)

Ajustez l’inclinaison à un angle inférieur à 20°.

Partie tendue de la faade (4)

Comment retirer et fixer lcran

mobile (5)

Avant d’installer l’appareil, retirez la façade.

5-A Pour retirer

1

Appuyez sur la touche (OPEN) de l’appareil pendant

2 secondes.

la lecture du CD/MD ou la radio s’arrête et la façade

s’incline automatiquement suivant un angle de 30 degrés.

2 Retirez l’écran mobile de la façon indiquée dans

l’illustration.

Lorsque vous avez entièrement retiré l’écran mobile, la

façade se referme automatiquement.

5-B Pour poser

Placez l’écran mobile devant l’appareil ainsi qu’il est indiqué

dans l’illustration, puis exercez une légère pression sur la

façade jusqu’à ce qu’il s’encliquette.

Exemple de montage (6)

Installation dans le tableau de bord

6-

Remarque

*

Pendant l’installation de l’appareil, vérifiez que le

panneau avant de cet appareil est fermé.

Si le panneau avant est ouvert pendant l’installation et s’il

subit une force trop importante, un dysfonctionnement

risque de se produire.

Avertissement en cas dinstallation

dans une voiture dont le contact ne

comporte pas de position ACC

(accessoires)

Appuyez sur la touche (OFF) de l’appareil pendant

deux secondes pour désactiver l’affichage de

l’horloge après avoir coupé le moteur.

Si vous n’appuyez que brièvement sur (OFF), l’affichage

de l’horloge ne disparaît pas, ce qui provoque la décharge

de la batterie.

Touche de rinitialisation ( 7)

Quand l’installation et les raccordements sont terminés,

appuyez sur la touche de rèinitialisation avec un stylo à

bille, etc.

Installation du satellite de

commande (RM-X5S) (8)

Remarques

• Choisissez soigneusement l’endroit de montage afin que le

satellite de commande n’interfère pas avec les commandes

de la voiture.

• N’installez pas le satellite de commande dans un endroit

qui risque de compromettre la sécurité du passager avant

de quelque façon que ce soit.

• Lors de l’installation du satellite de commande, veillez à

ne pas endommager les câbles électriques, etc., situés de

l’autre côté de la surface de montage.

• Evitez d’installer le satellite de commande là où il risque

d’être soumis à des températures élevées comme sous le

rayonnement direct du soleil ou à côté d’une conduite de

chauffage, etc.

• Le commutateur de sélection Rev/Nor est situé dans la

partie inférieure du satellite de commande.

Sélectionnez “Nor” pour utiliser le satellite de commande

dans la position définie par défaut.

Sélectionnez “Rev” si vous montez le satellite de

commande du côté droit de la colonne de direction.

Conseil

Il est impossible de sélectionner Rev/Nor sur le côté de

l’appareil principal.

1 Appuyez sur les boutons et tournez les commandes

pour vérifier que l'appareil principal réagit

correctement.

Vous pouvez changer le sens des rayons IR en tournant

la molette située sur le satellite de commande.

Précaution

Assurez-vous que l’endroit où vous installez le satellite de

commande est à portée du récepteur de l’appareil.

2 Choisissez la position de montage exacte du

satellite de commande et nettoyez la surface de

montage.

Les souillures et l’huile altèrent le pouvoir adhérent de

l’adhésif double face.

3 Marquez la position pour la vis fournie.

Utilisez l’orifice de vissage du support de montage 0

pour marquer les positions.

Si vous ne parvenez pas à ajuster aisément le support de

montage 0, découpez-le afin qu'il s'adapte à la colonne

de direction.

4Déposez la garniture de la colonne de direction et

percez un trou de 2 mm de diamètre aux endroits

que vous avez marqués.

5 Chauffez la surface de montage et l’adhésif double

face sur le support de montage 0 à une

température comprise entre 20 °C et 30 °C et fixez

le support de montage sur la surface de montage

0 en exerçant une pression uniforme. Vissez

ensuite la vis 9 fournie.

Collez de la bande adhésive résistante, etc., de l’autre

côté de la surface de montage de manière à couvrir

l’extrémité saillante des vis de telle sorte qu’elle ne

puissent entrer en contact direct avec les câbles

électriques, etc., à l’intérieur de la colonne de direction.

6 Après avoir remonté le couvercle de la colonne de

direction, fixez le satellite de commande sur le

support de montage en alignant les quatre orifices

pratiqués à la base du satellite sur les quatre ergots

du support de montage et faites coulisser le

satellite de commande jusqu’à ce qu’il s’encliquette

dans sa position définitive comme illustré.

Précautions

• Lors de l’installation du satellite de commande près du

volant, veillez à bien fixer la courroie qa fournie.

• Assurez-vous que la courroie qa ne soit pas prise dans les

commandes du véhicule (levier de vitesses, etc.).

• Assurez-vous de bien serrer la vis de sécurité de la courroie

qa après avoir accroché celle-ci au levier de changement

de direction, etc.

Conseil

Il existe deux orifices réservés à la courroie qa. Vous pouvez

utiliser indifféremment l’un ou l’autre.

Remarque

Si vous montez le satellite de commande sur la colonne de

direction, assurez-vous que l’extrémité saillante des vis à

l’intérieur de la colonne de direction n’entrave en aucune

façon le mouvement de l’axe, des organes de commande, des

commutateurs ou des câbles électriques, etc., à l’intérieur de

la colonne de direction.

Precauzioni

•Scegliere con attenzione la posizione per l’installazione in

modo che l’apparecchio non interferisca con le operazioni

di guida del conducente.

•Evitare di installare l’apparecchio dove sia soggetto ad

alte temperature, come alla luce solare diretta o al getto di

aria calda dell’impianto di riscaldamento, o dove possa

essere soggetto a polvere, sporco e vibrazioni eccessive.

•Usare solo il materiale di montaggio in dotazione per

un’installazione stabile e sicura.

Regolazione dellangolo di montaggio

(CDX-M770/M670)

Regolare l’angolo di montaggio in modo che sia inferiore a 60°.

(MDX-M690)

Regolare l’angolo di montaggio in modo che sia inferiore a 20°.

parte sporgente del pannello

anteriore ( 4)

Come rimuovere e applicare la

finestra del display principale ( 5)

Prima di installare l’apparecchio rimuovere il pannello

anteriore.

5-A Per rimuoverlo

1 Premere (OPEN) sull’apparecchio per 2 secondi.

la riproduzione di CD/MD o la ricezione radio si

arresta, quindi il pannello anteriore si inclina

automaticamente di 30 gradi.

2 Rimuovere la finestra del display principale, come

illustrato.

Una volta completata la rimozione della finestra del

display principale, il pannello anteriore si chiude

automaticamente.

5-B Per reinserirlo

Posizionare la finestra del display principale sul lato

anteriore dell’apparecchio come illustrato, quindi spingere

il pannello anteriore evitando di esercitare eccessiva

pressione fino a quando non scatta in posizione.

Esempio di montaggio (6)

Installazione nel cruscotto

6-

Nota

*

Durante l’installazione dell’apparecchio, assicurarsi

di chiudere il relativo pannello anteriore.

Se durante l’installazione il pannello anteriore è aperto e

viene esercitata eccessiva forza, è possibile che si

verifichino problemi di funzionamento.

Informazioni importanti per quando

si effettua linstallazione su unauto

sprovvista della posizione ACC

sullinterruttore di accensione

Assicurarsi di premere (OFF) sull’apparecchio per due

secondi per spegnere il display dell’orologio dopo che

il motore è stato spento.

Se si preme (OFF) solo per un attimo, il display

dell’orologio non si spegne causando in questo modo lo

scaricamento della batteria.

Tasto di azzeramento (7)

Dopo avere terminato l’installazione e i collegamenti,

assicurarsi di premere il tasto di azzeramento con la punta

di una penna a sfera, ecc.

Installazione del telecomando a

rotazione (RM-X5S) (8)

Note

• Scegliere attentamente la posizione di montaggio in modo

che il telecomando a rotazione non interferisca con la guida.

• Non installare il telecomando a rotazione in posizione tale

da poter compromettere in alcun modo la sicurezza del

passeggero.

• Al momento di installare il telecomando a rotazione

assicurarsi di non danneggiare i cavi elettrici ecc. nella parte

posteriore della superficie di montaggio.

• Non installare il telecomando a rotazione in posizione

soggetta ad alte temperature, ad esempio esposto alla luce

solare diretta o al calore proveniente dall’impianto di

riscaldamento della vettura.

• L’interruttore di selezione Rev/Nor è situato nella parte

inferiore del telecomando a rotazione.

Selezionare “Nor” per utilizzare il telecomando a rotazione

con le impostazioni di fabbrica. Selezionare “Rev” quando il

telecomando a rotazione viene montato sul lato destro del

piantone di guida.

Suggerimento

Non è possibile selezionare Rev/Nor dall’unità principale.

1

Premere i tasti e ruotare i comandi per verificare che

l'apparecchio principale funzioni correttamente.

È possibile cambiare la direzione dei raggi infrarossi

ruotando la manopola sul telecomando a rotazione.

Attenzion

Assicurarsi che il luogo in cui viene installato il telecomando

a rotazione sia all’interno della gamma del ricettore

dell’unità principale.

2 Scegliere la posizione esatta di montaggio del

telecomando a rotazione, quindi pulire la superficie

di montaggio.

La sporcizia o l’unto possono pregiudicare la tenuta del

nastro biadesivo.

3 Segnare la posizione di montaggio per la vite in

dotazione.

Usare il foro per la vite sulla staffa di montaggio 0 per

segnare la posizione.

Se non è possibile installare la staffa di montaggio 0

facilmente; tagliare la staffa di montaggio 0 per

adattarla alla copertura del piantone di guida.

4 Rimuovere il coperchio della colonna del volante e

praticare un foro di 2 mm di diametro nella

posizione contrassegnata.

5 Riscaldare la superficie di montaggio e il nastro

biadesivo sulla staffa di montaggio 0 ad una

temperatura compresa tra 20 °C e 30 °C. Applicare

la staffa di montaggio 0 sulla superficie di

montaggio esercitando una pressione omogenea,

quindi fissarla avvitando la vite 9 in dotazione.

Applicare una striscia di nastro adesivo pesante sull’altro

lato della superficie di montaggio in modo da coprire la

punta sporgente delle viti perché queste non interferiscano

con i cavi elettrici all’interno della colonna del volante.

6 Dopo aver rimontato il coperchio della colonna del

volante, montare il telecomando allineando i

quattro fori sul fondo del comando ai quattro fermi

sulla staffa di montaggio e facendo scorrere il

telecomando fino a che non si blocca in posizione,

come illustrato in figura.

Attenzione

• Assicurarsi di inserire il cordino qa in dotazione quando si

installa il telecomando a rotazione vicino al volante.

• Assicurarsi che il cordino qa non rimanga incastrato tra i

comandi dell’automobile (cambio, pedali, ecc.).

• Assicurarsi di stringere il fermo del cordino qa dopo aver

applicato il cordino qa all’interruttore dell’indicatore e così

via.

Suggerimento

Esistono due fori per il cordino qa.

Utilizzare indifferentemente uno dei due.

Nota

Se il telecomando viene montato sulla colonna del volante,

assicurarsi che le punte sporgenti delle viti sulla superficie

interna della colonna non pregiudichino o interferiscano in

alcun modo con il movimento dell’albero, con i componenti

degli interruttori o con i cavi elettrici etc. all’interno della

colonna.

1

1

0

Mark

Markierung

Marques

Contrassegno di montaggio

Merkteken

Voorzorgsmaatregelen

•Kies de installatieplaats zorgvuldig zodat het toestel de

bestuurder niet hindert tijdens het rijden.

•Installeer het apparaat niet op plaatsen waar het

blootgesteld wordt aan hoge temperaturen, b.v. in direct

zonlicht of bij de warme luchtstroom van de

autoverwarming, aan sterke trillingen, of waar het in

contact komt met veel stof of vuil.

•Gebruik voor het veilig en stevig monteren van het

apparaat uitsluitend de bijgeleverde montageonderdelen.

Maximale montagehoek

(CDX-M770/M670)

Installeer het apparaat nooit onder een hoek van meer

dan 60° met het horizontale vlak.

(MDX-M690)

Installeer het apparaat nooit onder een hoek van meer

dan 20° met het horizontale vlak.

Verlengstuk van het frontpaneel

(4)

Het hoofddisplay losmaken en

bevestigen (5)

Verwijder, alvorens met het installeren te beginnen,

het afneembare voorpaneel.

5-A Verwijderen

1 Hou (OPEN) op het toestel 2 seconden ingedrukt.

CD/MD-weergave of radio-ontvangst stopt en het

frontpaneel kantelt automatisch in een hoek van 30

graden.

2 Maak het hoofddisplay los zoals de afbeelding laat

zien.

Nadat het hoofddisplay volledig is losgemaakt, sluit het

frontpaneel automatisch.

5-B Bevestigen

Plaats het hoofddisplay vooraan op het toestel zoals de

afbeelding laat zien en druk het vervolgens lichtjes op zijn

plaats tot het vastklikt.

Montagevoorbeeld ( 6)

Montage in het dashboard

6-

Opmerking

*

Bij het installeren van het toestel dient het

frontpaneel te zijn gesloten.

Als het frontpaneel tijdens het installeren open is, kan het

worden geforceerd wat tot een defect kan leiden.

Opgelet bij het monteren in een auto

waarvan het contactslot geen ACC

(accessory) stand heeft

Druk (OFF) op het toestel gedurende twee seconden

in om de klokweergave uit te schakelen na het

afzetten van de motor.

Indien u slechts even op (OFF) drukt, verdwijnt de

tijdindicatie niet waardoor de batterij uitgeput raakt.

Terustelknop (7)

Druk, nadat u het apparaat heeft geïnstalleerd en de

aansluitingen heeft gemaakt, met een balpen of een ander

puntig voorwerp op de terustelknop.

Installatie van de

bedieningssatelliet (RM-X5S) (8)

Opmerkingen

• Ga zorgvuldig te werk bij het kiezen van een geschikte

montagepositie zodat de bedieningssatelliet u nooit

hindert bij het rijden.

• Installeer de bedieningssatelliet nooit op een plaats waar

hij de veiligheid van de (voor)passagier in gevaar kan

brengen.

• Bij het installeren van de bedieningssatelliet moet u erop

letten dat u de elektrische bedrading en dergelijke aan de

andere kant van het montagevlak niet beschadigt.

• Installeer de bedieningssatelliet niet op plaatsen waar hij

blootstaat aan hoge temperaturen, bijvoorbeeld door

rechtstreekse zonnestraling of warme lucht afkomstig van

de verwarming, enz.

• De Rev/Nor-keuzeschakelaar bevindt zich onderaan op de

bedieningssatelliet.

Kies “Nor” om de bedieningssatelliet te gebruiken met de

fabrieksinstelling.

Kies “Rev” wanneer u de bedieningssatelliet rechts op de

stuurkolom monteert.

Tip

Rev/Nor kan niet worden geselecteerd op het

hoofdtoestel.

1 Druk op de toetsen en draai aan de regelaars om

zeker te zijn dat uw master unit goed functioneert.

U kunt de richting van de infraroodstralen wijzigen

door aan de knop op de bedieningssatelliet te draaien.

Let op!

Zorg ervoor dat u de bedieningssatelliet installeert

binnen het ontvangstbereik van het toestel.

2 Kies de exacte installatieplaats voor de

bedieningssatelliet en maak vervolgens het

montagevlak schoon.

Vuil of vet tasten het kleefvermogen van het

dubbelzijdige plakband aan.

3 Markeer een bevestigingspunt voor de

meegeleverde schroef.

Markeer de posities aan de hand van de schroefgaten

in het bevestigingselement 0.

Als het bevestigingselement 0 niet goed past, moet u

het overtollige gedeelte afsnijden zodat het wel in de

stuurkolombekleding past.

4 Verwijder de stuurkolombekleding en boor een gat

van 2 mm op de gemarkeerde posities.

5 Warm het bevestigingsvlak en de dubbelzijdige

kleefband op het bevestigingselement 0 op tot

een temperatuur van 20 à 30 °C en plaats de steun

op het bevestigingsvlak door gelijkmatig aan te

drukken. Schroef hem vervolgens vast met de

meegeleverde schroef 9.

Breng een stuk tape of iets dergelijks aan op de andere

kant van het bevestigingsvlak om te voorkomen dat de

uitstekende schroefpunten in contact komen met de

elektrische bedrading en dergelijke binnenin de

stuurkolom.

6 Plaats de stuurkolombekleding terug en bevestig

de bedieningssatelliet op het montage-accessoire

door de vier gaten onderaan de bedieningssatelliet

te laten samenvallen met de vier